Page 1

Operator’s Manual

PH-15, PH-20, PFH-15 and PFH-20

Coulter Command System

Manufacturing, Inc.

P.O. Box 5060 ● Salina, Kansas 67402-5060

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious- follow without exception. Your life and the lives of

others depend on it!

© Copyright 2000 Printed

5/31/2001

12611

Cover illustration may show optional equipment not supplied with standard unit.

148-384M

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . .1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Description of Unit. . . . . . . . . . . . . . . . . . . .4

Using This Manual. . . . . . . . . . . . . . . . . . . .4

Definitions . . . . . . . . . . . . . . . . . . . . . . .4

Owner Assistance . . . . . . . . . . . . . . . . . . . .4

Section 1 Assembly and Setup. . . . . . . . . . . .5

Prestart Checklist . . . . . . . . . . . . . . . . . . . .5

Depth Sensing Wheel . . . . . . . . . . . . . . . . .5

Sensor Box . . . . . . . . . . . . . . . . . . . . . .6

Gauge Wheel Lift Cylinder . . . . . . . . . .7

Speed Sensor . . . . . . . . . . . . . . . . . . . .7

Lift Switch . . . . . . . . . . . . . . . . . . . . . . .8

Wiring Harness . . . . . . . . . . . . . . . . . . .8

Tongue Cylinder . . . . . . . . . . . . . . . . . .9

Hydraulic Control Valve. . . . . . . . . . . .10

Hydraulic Connections . . . . . . . . . . . .11

Control Box . . . . . . . . . . . . . . . . . . . . .12

Sensor Box Adjustments. . . . . . . . . . . . . .13

Section 2 Operating Instructions . . . . . . . . .14

Load Sensing Hydraulics . . . . . . . . . . . . . 14

Hydraulic Hook-Up & Function. . . . . . . . . 14

Operation of Electronic Controls. . . . . . . . 15

Field Adjustments. . . . . . . . . . . . . . . . . . . 16

Lift Switch. . . . . . . . . . . . . . . . . . . . . . 16

Speed Sensor . . . . . . . . . . . . . . . . . . 17

Hydraulic Valve . . . . . . . . . . . . . . . . . 17

Section 3 Troubleshooting. . . . . . . . . . . . . . 18

System Schematics . . . . . . . . . . . . . . . . . 20

Hydraulic Schematic . . . . . . . . . . . . . 20

Electrical Schematic. . . . . . . . . . . . . . 21

Section 4 Maintenance & Lubrication. . . . . 22

Maintenance. . . . . . . . . . . . . . . . . . . . . . . 22

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . 22

Depth Sensing Arm Wheel Pivot . . . . . . . 22

Axle Bearings . . . . . . . . . . . . . . . . . . . . . . 22

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Torque Values Chart. . . . . . . . . . . . . . . . . 23

© Copyright 2000 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication,and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains, Seed-Lok

All other brands and product names are trademarks or registered trademarks of their respective holders.

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

Great Plains Manufacturing, Incorporated T r ademarks

Printed in the United States of America.

Page 3

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

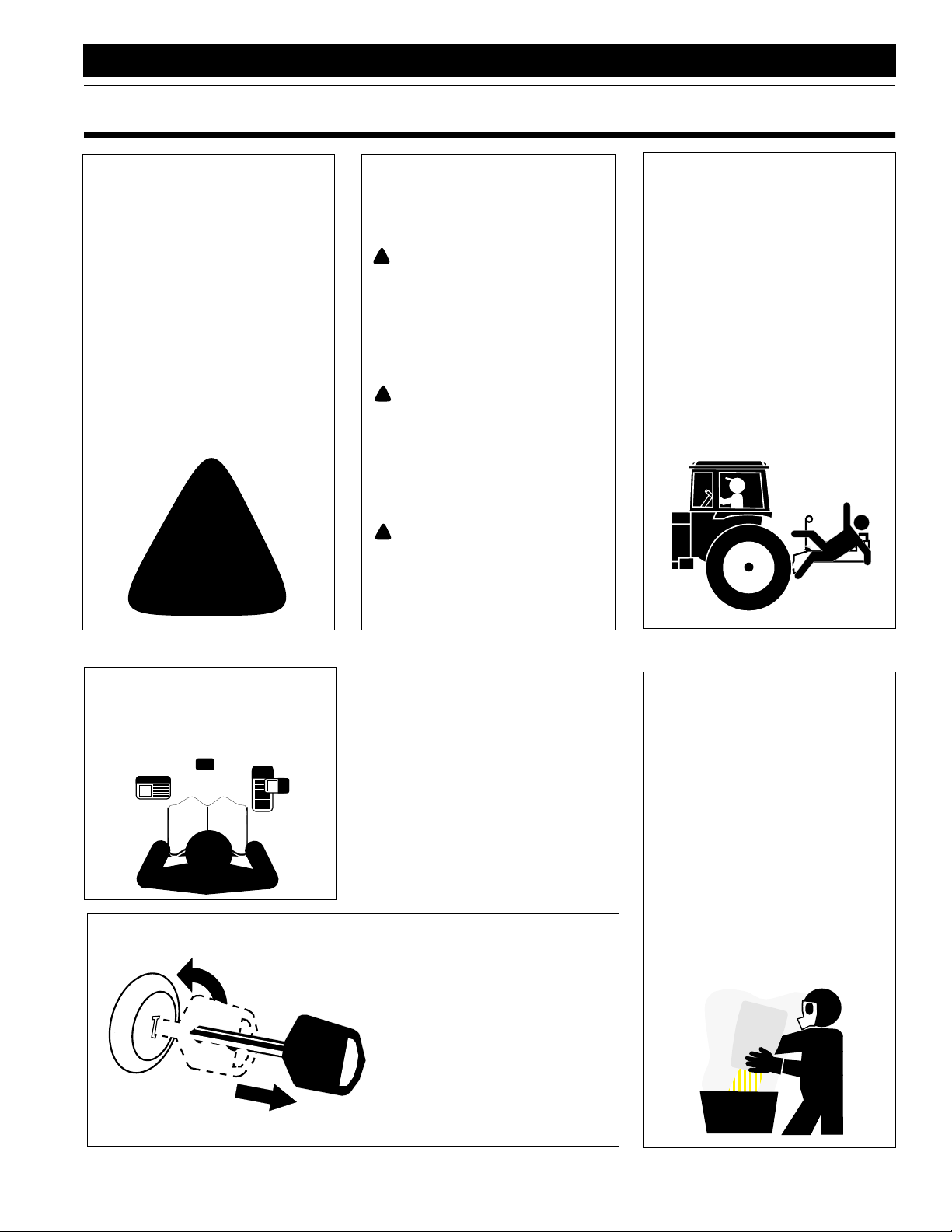

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to

personal safety involved and extra

safety precaution must be taken.

When you see this symbol, be alert

and carefully read the message that

follows it. In addition to design and

configuration of equipment, hazard

control and accident prevention are

dependent upon the awareness,concern, prudence and proper training of

personnel involved in the operation,

transport, maintenance and storage

of equipment.

!

Be Aware of Signal Words

Signal words designate a degree or

level of hazard seriousness. The signal words are:

!

DANGER

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for functional purposes, cannot be guarded.

!

WARNING

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

!

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Keep Riders

Off Machinery

Riders obstruct the operator’s view.

Riders could be struck by foreign

objects or thrown from machine.

▲ Never allow riders on implement.

▲ Never allow children to operate

equipment.

For Your Protection

▲ Thoroughly read and understand

Safety Decals, page 4. Read all

instructions noted on decals.

OFF

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine,

and remove key.

▲ Detach and store implement in an

area where children normally do

not play. Secure implement with

blocks and supports.

Handle

Chemicals Properly

Agricultural chemicals can be dangerous. Improper use can seriously

injure persons, animals, plants, soil

and property.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Follow instructions on container

label.

▲ Avoid inhaling smoke from any

type of chemical fire.

▲ Store or dispose of unused chem-

icals as specified by chemical

manufacturer.

6/21/2004

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

1

Page 4

Important Safety Information

Great Plains Mfg., Inc.

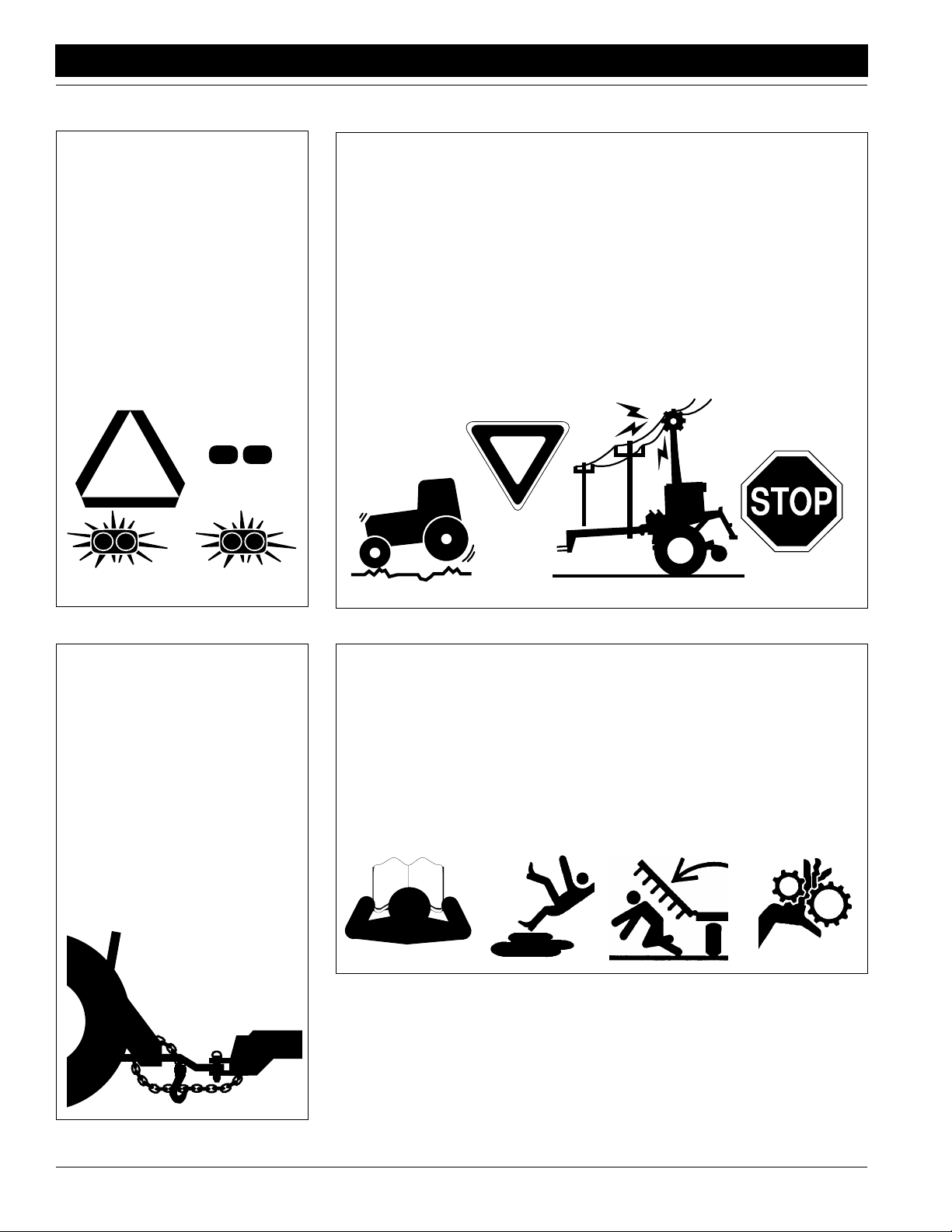

Use Safety

Lights and Devices

Slow-moving tractors, self-propelled

equipment and towed implements

can create a hazard when driven on

public roads. They are difficult to see,

especially at night.

▲ Use flashing warning lights and

turn signals whenever driving on

public roads.

▲ Use lights and devices provided

with implement.

Transport

Machinery Safely

Maximum transport speed for implement is 20 mph. Some rough terrains

require a slower speed. Sudden

braking can cause a towed load to

swerve and upset.

▲ Do not exceed 20 mph. Never

travel at a speed which does not

allow adequate control of steering

and stopping. Reduce speed if

towed load is not equipped with

brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that,

when fully loaded, weighs more

than 1.5 times the weight of towing vehicle.

Use A Safety Chain

▲ Use a safety chain to help con-

trol drawn machinery should it

separate from tractor drawbar.

▲ Use a chain with a strength rat-

ing equal to or greater than the

gross weight of towed machinery.

▲ Attach chain to tractor drawbar

support or other specified

anchor location. Allow only

enough slack in chain to permit

turning.

▲ Replace chain if any links or end

fittings are broken, stretched or

damaged.

▲ Do not use safety

chain for towing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment. Refer to this manual

for additional information.

▲ Work in a clean, dry area.

▲ Lower implement to ground, put

tractor in park, turn off engine,

and remove key before performing

maintenance.

▲ Allow implement to cool completely.

▲ Inspect all parts. Make sure parts

are in good condition and installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before operation.

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

2

Page 5

Great Plains Mfg., Inc.

Important Safety Information

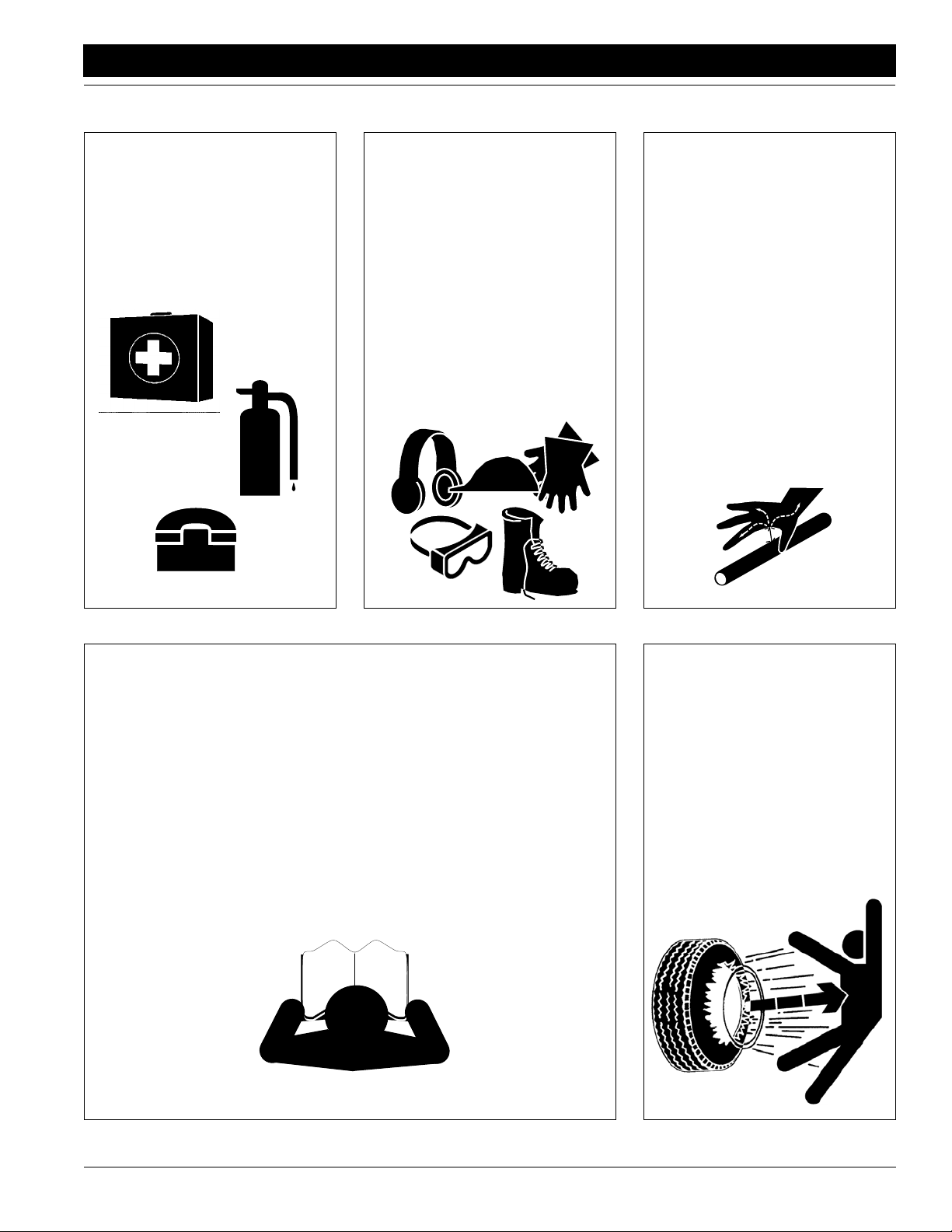

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extin-

guisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to

loud noise can cause hearing

impairment or hearing loss, wear

suitable hearing protection such

as earmuffs or earplugs.

▲ Because operating equipment

safely requires your full attention,

avoid wearing radio headphones

while operating machinery.

Avoid High

Pressure Fluids Hazard

Escaping fluid under pressure can

penetrate skin, causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or card-

board, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a doc-

tor immediately. Any fluid injected

into the skin must be surgically

removed within a few hours or

gangrene may result.

Safety at All Times

Thoroughly read and understand this

manual before operating implement.

Refer to Safety Decals, page 4. Read

all instructions noted on decals.

▲ Be familiar with all implement

functions.

▲ Operate implement from driver’s

seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Do not dismount a moving tractor.

Dismounting a moving tractor could

cause serious injury or death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet and clothing

away from power-driven parts.

▲ Wear snug-fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of working area.

▲ Do not turn tractor too tight, caus-

ing implement to ride up on

wheels.

Tire Safety

Tire changing can be dangerous and

should be performed by trained personnel using correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side–not in front of or over tire

assembly. Use a safety cage if

available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for weight

involved.

6/21/2004

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

3

Page 6

Introduction

Introduction

Great Plains Mfg., Inc.

Great Plains welcomes you to its growing family of new

product owners. This implement has been designed with

care and built by skilled workersusing quality materials.

Proper setup, maintenance and safe operating practices

will help you get years of satisfactory use from the machine.

Description of Unit

The Precision Hitch Coulter CommandSystem couplesa

microprocessor with electro-hydraulicsto provide a stateof-the-art system for maintaining coulter depthregardless

of the terrain or soil type. It also provides coulter depth adjustment from the tractor cab.

The Coulter Command System contains a depth sensing

wheel, an electronic control box, a speed sensor, a depth

sensorbox,a lift controlswitch,a wiring harness, atop link

and a hydrauliccontrol valve. It uses the tongue cylinder

from your Precision Hitch.

This manual applies to the following:

• 148-382A Precision Hitch Coulter Command,

Non Fertilizer

• 148-383A Precision Hitch Coulter Command, For

Fertilizer

Referto the Precision Hitchoperator’s manualfor detailed

informationonsafelyoperating,adjusting, troubleshooting

and maintaining the Precision Hitch. Refer to the parts

manual for Coulter Command part identification.

• 148-365M PH-15, PH-20, PFH-15 and PFH-20

Operator’s Manual

• 148-365P PH-15, PH-20, PFH-15 and PFH-20

Parts Manual

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer.They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’sparts were specially designed and should

only be replaced with Great Plains parts. Always use the

serial and model number when ordering parts from your

Great Plains dealer.

Your Great Plains dealer wants youto be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealershipservice manager.Make sure they are aware of anyproblems so

they can assist you.

2. If you are still unsatisfied, seek out the owner or general manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustments, troubleshooting and maintenance.

Readthis manualand followthe recommendationsto help

ensure safe and efficient operation.

Theinformation in this manual iscurrent at printing. Some

parts maychange to assure top performance.

Definitions

The following terms are used throughout this manual.

Right-handand left-hand as used in thismanual are deter-

mined by facing the direction the machinewill travel while

in use unless otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct oper ation,

read and follow the directions provided before continuing.

NOTE: Useful information related to the preceding topic.

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

4

Page 7

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

Section 1 Assembly and Setup

Prestart Checklist

Check

All major frame components

Fasteners and pins that were shipped with the Coulter Command System.

NOTE: All hardware from the factory has been installed in the

location where it will be used. If a part or fastener is temporarily

removed for assembly reasons, remember where it goes.Keep

the parts separated.

Have a minimum of 2 people at hand while assembling the

Coulter Command System.

Have a forklift or loader along with chains and safety stands

ready for the assembly task.

If you are unsure where a fastener is used, refer to the Parts

Manual to identify it.

Depth Sensing Wheel

If your Precision Hitch is equipped with liquid fertilizer

(PFH), the fertilizer drive wheel doubles as the coulter

depth sensing wheel and will require additional sensor assembly and adjustment.

If you do not have the liquid fertilizer option (PFH), the

coulter command will contain a coulter depth sensing

wheel which is subassembled and preadjusted.

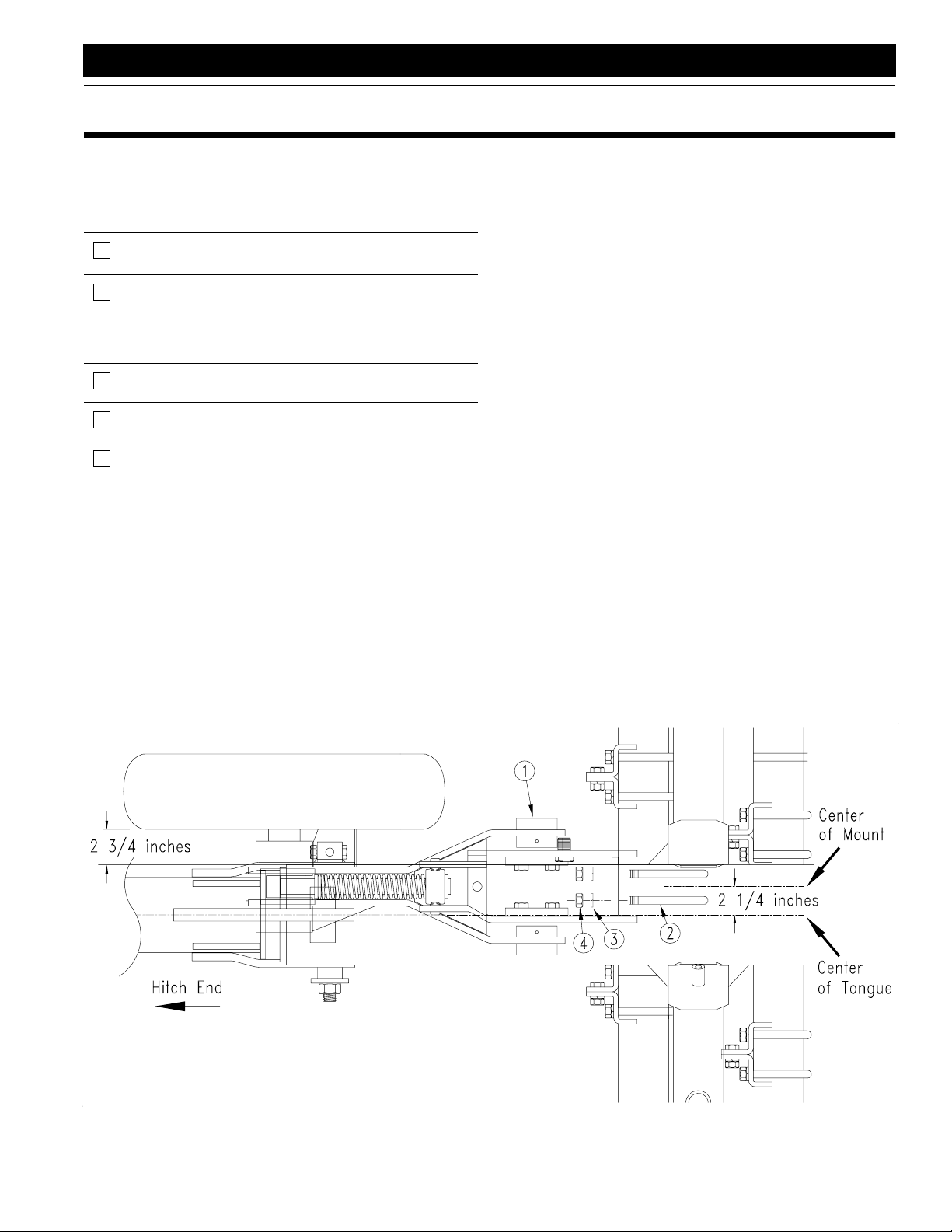

See Figure 1-1.

Installthe coulter depthsensing wheel assembly(1) to the

front 4” x 4” coulter tool bar tube with the two 5/8 x 6 inch

u-bolts (2), lock washers (3) and nuts (4).

Position the center of the coulter depth sensing wheel

mount bracket2 1/4 inches to the rightof the centerof the

Precision Hitch beam. This will leave about 2 3/4 inch

clearancebetweenthe inside ofthe depthsensing tireand

the edge of the hitch center beam.

6/21/2004

Figure 1-1

Depth Sensing Wheel

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

18439

5

Page 8

Section 1 Assembly and Setup

Great Plains Mfg., Inc.

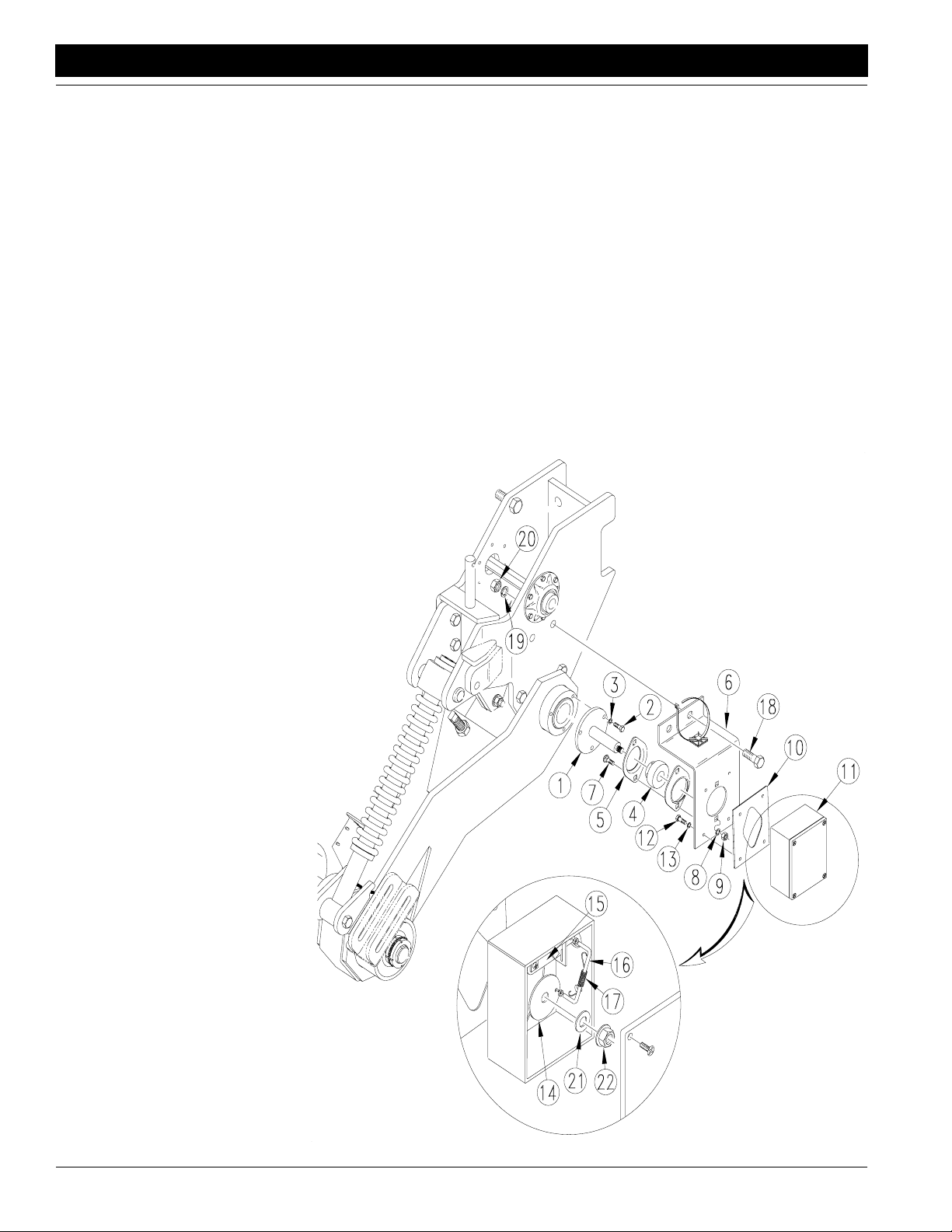

Sensor Box

Ifthe sensor boxisnot preassembledto the depthsensing

wheel, refer to Figure 1-2 and the following instructions.

1. Assemble sensor spindle (1) to left end of fertilizer

drivewheel rockshaftwith three1/4 x3/4 inch bolts(2)

and lock washers(3).

2. Bolt the bearing (4) betweentwo flangettes (5) andto

theback side of thesensor mount plate (6) with5/16 x

3/4 inch carriage bolts (7), lock washers (8) and nuts

(9). Do not tighten nuts at this time.

NOTE: Position the heads of the bolts against the

flangettes with lock washers and nuts pointing outward.

Locking collar on bearing should point away from the sensor mount plate and toward the coulter depth sensing

wheel.

3. Place rubber gasket (10) between sensor box (11)

and the sensor mount plate (6). Screw sensor box to

sensor mount plate with #10 x 7/16 inch pan head

screws (12) and star lock washers(13).

4. Remove cover from sensor box and inspect the internal linkages.The circular disk (14) should be linked to

the flat bar (15) with a formed round bar link (16).

Make sure the round bar link is in place and secured

witha spring clip extensionspring(17) that is connected between the circular disk and the flat bar through

the small holes.

5. Slide bearing and sensor mount plate subassembly

oversensorspindle(1), andbolt sensormountplate to

drive wheel mount bracket with 1/2 x 1 1/2 inch bolts

(18), lock washers(19) and nuts (20).

6. Place circular disk (13) over threaded end of sensor

spindle (1) and install a 3/8 inch washer (21) and

flange nut (22). Do not tighten flange nut at this time.

7. With the circular disk inplace, slide the sensormount

plate subassembly in or out until the vertical flat bar

link (15) and the circular disk are aligned.

8. Tighten two set screws on the bearing (4) to hold the

subassembly in place.

9. Tighten the flangette bolts (7) being careful not to

damage the internal linkages.

10. Set sensor box cover and cover screws aside and

continue with speed sensor assembly.

Figure 1-2

Sensor Box

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

6

18427

Page 9

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

Gauge Wheel Lift Cylinder

Refer to Figure 1-3.

1. Install the base end of the lift cylinder (1) to gauge

wheel mount bracket with a 1/2 x 1 3/4 inch clevis pin

(2) anda 1/8 x 3/4 inch cotter pin (3) provided with the

cylinder.

NOTE: The ports on the cylinder should point away from

the depth sensing gauge wheel.

2. Place the rod end of the lift cylinder between the slotted lugs on the gauge wheel arm. Place a flat washer

(4) on the outside of each slotted lug on the gauge

wheel arm. Pin in place with a 1 1/2 x 2 3/4 inch clevis

pin (5) and a 1/8 x 3/4 inch cotter pin (3).

Speed Sensor

Refer to Figure 1-4.

1. Removethetire and rimfrom the depthsensing wheel

andbolt thespeed sensorplate (1)between thewheel

and rim.

2. Screw the speed sensor (2) to the sensor mounting

bracket at bottom of the gauge wheel with #6 x 1/2

inch pan head screws (3), lock washers (4) and flat

washers (5).

3. Position sensor to just touch the speed sensor plate

(1) and tighten screws.

4. Route co-axial cable (6) from sensor, across gauge

wheel arms, and up the side opposite the tire.

5. Screwtheend fittinginto the co-axconnector ontop of

the sensor box(7).

6. Slide co-axial cable into notches at the bottom of

gauge wheel arms and fastento the side of gauge

wheel arm with the cabletie mounts (8) and cable ties

(9). Make sure the cable does not rub anything as

depth sensing wheel moves up and down.

Figure 1-3

Gauge Wheel Lift Cylinder

18428

6/21/2004

Figure 1-4

Gauge Wheel Lift Cylinder

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

18429

7

Page 10

Section 1 Assembly and Setup

Great Plains Mfg., Inc.

Lift Switch

Refer to Figure 1-5.

1. Bolt the plunger activated lift switch(1) to the switch

mount located nextto the left transport lift cylinder at

rear of the Precision Hitch transport frame with two

#10 x 3/4 inch pan head screws (2), flat washers (3),

lockwashers(4) andnuts (5).Do not tightenscrews at

this time.

2. Fastenrockshaftswitch cam (6)to transport rockshaft

just below the lift switch. Position the cam so it contacts the lift switch when hitch is raised and moves

awayfrom the lift switch when hitch is lowered. Position the worm gear screwon the cam mounting band

to the bottom of the rockshaft so it does not interfere

with the lift switch.

3. Adjust lift switch in the slotted holes so the plunger

movesin about1/8 inch when the camactivates itand

tighten the#10 screws. Do not bottom out the plunger

on the lift switch.

4. Rotate the cam assembly so it hits the plunger when

the hitch is raised just enough to begin to pick the

openers off the ground.

Wiring Harness

Refer to Figure 1-5.

1. Route the wiring harness (7) through 8 x 8 inch hitch

tube and to the lift switch at the rear of the machine.

Plug into the lift switch and support the cable with cable tie mounts (8) and cableties (9) or strapthe cable

to the hydraulichoses.

2. Plug the 4-pin connectorof the wiring harness tosensor box on the depth sensing wheel and support the

cable with cablemounts and ties.

3. Route the 9-pin connector through the spring hose

loop and to the tractor hitch. This will plug into the 9pin female connector from the control box extension

cable.

4. Plugthe otherthree short leadsinto theleads fromthe

solenoids on the hydraulic control valves (10 and 11)

after they are installed.

Figure 1-5

Lift Switch and Wiring Harness

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

8

18430

Page 11

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

Tongue Cylinder

Refer to Figure 1-6.

1. Removestroke pointer gauge (1) at the rod end of the

tongue cylinder. Retorque cylinder tie rod bolts to 95

ft-lbs.

2. Remove stroke pointer (2) at cylinder rod clevis.

3. Turn tonguecylinder withrodend pointingforwardand

down and with ports turned up. Use clevis pin (3),flat

washer (4) and cotter pin (5)to replacestroke pointer

pin at what is now the base end of the cylinder.

4. Connect rod end to tongue with clevis pin (6) and hair

pin cotter (7).

5. Remove elbow fitting (8) at base end of tongue cylinder and screw the 1/16inch orifice plate (9) into base

end port. Screw orifice plate in far enough so it does

not interfere with elbow fitting.

6. Replace fitting.

IMPORTANT: Failureto install the orifice platewill not allow Coulter Command to operate correctly.

6/21/2004

Figure 1-6

Tongue Cylinder

18432

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

9

Page 12

Section 1 Assembly and Setup

Hydraulic Control Valve

Refer to Figure 1-7.

1. Bolt the electronic depth control valve (1) to the top of

thevalvemount bracket(2)with 5/16x 4 inchbolts (3),

lock washers (4) and hex nuts (5). Position valve so

solenoids set abovethe middle of the top surface of

valve mount.

2. Bolt the lift circuit manifold (6) to the side of the valve

mount bracket with 5/16 x 4 inch bolts (7), lock washers (4) and hex nuts (5). Position valveso the four

ports pointawayfromvalvemountandsolenoid points

up.

3. Attach the valve mount to the Precision Hitch with 1/2

x 5 1/2 inch bolt (8), lock washer (9) and hex nut (10).

Assemble the bolt through the pivot tube (11) located

behind the tongue cylinder. Position valve mount so

dual solenoids facetoward rear of machine.

Great Plains Mfg., Inc.

Figure 1-7

Hydraulic Control Valve

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

10

19361

Page 13

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

Hydraulic Connections

Refer to Figure 1-8.

1. On the top valve assemblethe 3/4elbows (1) to valve

ports marked“P” and “T”and the3/4 straight adapters

(2) to valve ports marked “A” and “B”.

2. Onthe lower valveassemblethe 3/4 straightadapters

(2) to valveports marked “V1” and “V2” and the 3/4 elbows (1) to valve ports marked “C3” and “C4”.

3. Assemble the 9/16 elbows (3) to valve ports marked

“C1” and “C2” of the lower valve.

4. Assemble the remaining two 9/16 elbows (3) to the

ports on the side of the gauge wheel lift cylinder (4).

5. Removehoses(5)from tonguecylinder andassemble

them to the elbows at parts “P” and “T” on the top

valve.

6. Connect the 20inch long hose (6) between port “B”of

the top valve and the tongue cylinder base end fitting.

7. Connect the 30inch long hose (7) between port “A”of

the top valve and the tongue cylinder rod end fitting.

8. Remove hoses (8) from the front side of the relief

valve(9) which is mounted on the tongue tube andassemble them to the elbows at ports “C3” and “C4” on

the lower valve.

NOTE: The hose coming from the base end of the transport lift cylinders connects to port “C3”. The hose coming

from the rod end of the transport lift cylindersconnects to

port “C4”.

9. Connect a 36 inch long hose (10) to port “C1” of the

lower valve and the elbow on the base end of the

gauge wheel lift cylinder.

10. Connect a 36 inch long hose (10) to port “C2” of the

lowervalveand the elbow onthe rod end of thegauge

wheel lift cylinder.

11. Removethe plug from the top of the lowervalveat the

port labeled “M4” and replace it with the relief cartridge (11). Torque the cartridge to 30 ft-lbs.

12. Removethe reliefvalve andmount (9) which ismounted to the tongue tube by removing the 3/8 inch u-bolt.

Discard the relief valve and its mount.

13. Route the three wiring harness leads, mentioned on

page 8, step 4, under the valve mount.

14. Plug lead “A” into solenoid “A”.

15. Plug lead “B” into solenoid “B”.

16. Plug lead “S1” into solenoid “S1”.

6/21/2004

Figure 1-8

Hydraulic Connections

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

19360

11

Page 14

Section 1 Assembly and Setup

Control Box

1. Mount the control box, Figure 1-9, at a convenient locationin the tractorcab. Connectthe 12’ extensioncable to the 9-pin connector on the back of the control

box and route the cable back toward the tractor drawbar area making sure it willnot get kinkedor pinched.

2. Connect the power cord to a good uninterrupted 12

voltpowersourceonthe tractor.Connecting directlyto

the battery is recommended. Plug the cord into the

lead with the 2-Pin connector on the back of the control box. The polarity of the power supply is very important to prevent circuit damage. The white wire of

the power cord must be connected to the "+" positive

battery terminal andthe black wire to the "-" negative

battery terminal.

Great Plains Mfg., Inc.

Figure 1-9

Control Box

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

12

12575

Page 15

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

Sensor Box Adjustments

Refer to Figure 1-10.

Coulter commanddepth sensing wheel assemblies which

are preassembled at the factory are preadjusted and

should not require further adjustment. If the sensor box at

the depth sensing wheel has been field installed, or if its

linkage gets out of adjustment, it must be adjusted using

one of the following two procedures:

1. The best and most accuratemeans of adjusting the

linkage inside the sensor box makes use of a voltmeter which reads 0-12 voltsDC. The Control Box in the

tractormust be properly connected to a powersource

and the POWERswitch must be ON. The TONGUE

HYDRAULICS switch should be in the MANUAL

mode. The wiring harness must be connected to the

control box and the sensor box.The depth sensing

wheel should be off the ground with the arm rotated

down as far as its spring-loaded down-pressure link

will allow.Remove the cover from the sensorbox and

inspect the internal linkage for proper assembly as

shown in Figure 1-10.

With the depth sensing wheel in the max down position,the voltagepotential betweenthe lead containing

theWHITEWIRE andthe groundlead (BLACKWIRE)

in the gauge wheel sensor box(#1) should be 5 volts

DC plus or minus 1/4 volt. To adjust the gauge wheel

sensor boxlinkage, loosen the 3/8 inchhex flange nut

(#2) on the sensor spindle androtate the circulardisk

(#3) until the voltage potential between the lead containingtheWHITE WIREand theground lead(BLACK

WIRE) (#1) is 5 voltsDC plus orminus 1/4 volt.Rotating the circular disk counterclockwise increases voltage potential, androtating the circular disk clockwise

decreases the voltage potential.

2. The second means of adjusting the linkage inside the

sensor box involves measuring from the inside edge

ofthe box to theleft pivot of the formedround-bar link.

Thedepth sensingwheelshould beoff theground and

rotated down as far as its spring-loaded down-pressure link will allow. Removethe cover from the sensor

boxand inspect the internal linkage forproper assembly as shownin Figure 1-10.

With the depth sensing wheel in the max down position,the pivot betweenthe vertical flat-bar linkand the

formed round-bar link should be 15/16 inch from the

front inside edge of the sensor box.

Withthe sensor boxlinkage properly assembled,loosen the 3/8 inch hex flange nut on the sensor spindle

and rotate the circular disk until thepivot between the

vertical flat-bar link and the formed round-bar link is

15/16inch +or -1/16 inchfrom the frontinside edgeof

the box. Be careful not to rotate the circular disk as

you retighten the nut. Replace the sensor box cover.

Once the voltagepotential reads 5 volts DC, + or - 1/4

volt,tighten the 3/8 inch flange nut. Be careful not to rotatethe circulardisk asyou tightenthe nut.Replace the

sensor box cover.

Some models of the sensor box have a mark on the

vertical flat-bar link which should line up with a mark

on the link’s slotted mount plate at the correct preset

voltage. With the depth sensing wheel in the max

downposition, themarksshould line upat a voltageof

5 volts DC + or - 1/4 volt. Aligning the marks is more

accuratethan relying on the 15/16 inchmeasurement.

6/21/2004

Figure 1-10

Sensor Box Adjustments

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

12619

13

Page 16

Section 2 Operating Instructions

Section 2 Operating Instructions

Great Plains Mfg., Inc.

The Coulter Command couples a microprocessor with

electro-hydraulics to provide a state-of-the-art system for

maintaining coulter depth regardless of the terrain or soil

type. It also provides coulter depth adjustment from the

tractor cab.A manual feature allows manual control of the

front hydraulic tongue cylinder for hitching, unhitching, or

making adjustments. To understand the Coulter Command system, one must be familiar with the functions of

the Hydraulics and the Electronic controls.

Load Sensing Hydraulics

To operateCoulter Command, some tractors with loadsensing or constant-flow hydraulics require a bypass

valve,Great Plains part number 810-400C.Contact your

Great Plains dealer to order the bypass valve.

NOTE: Failure to install a bypass valve on load-sensingtractors maycause major tractordamage. Consult

yourtractor dealer to verifyif the bypassvalve isneeded.

After installing the bypass valve, set valve as follows:

1. Close bypass valve for no oil flow by turning knob (1)

on valve clockwise. See Figure 2-1.

17987

Figure 2-1

Bypass Valve

2. Adjust flow-control valve for tractor to a maximum of

10 gpm. If you do not have a flowmeter, hook a standard 8-inch stroke,4-inch bore cylinder to the circuit.

At 10 gpm, the cylinder willtake about 2.6 secondsto

extend.

3. Engage tractor hydraulics for Coulter Command.

4. Using a pressure gauge, turn knob on bypass valve

counterclockwise until pressure gauges reads 1800

psi. Lock bypassvalve at this setting.

Hydraulic Hook-Up & Function

Tractors with closed-center hydraulic systems and

variable displacement hydraulic pumps.

(If you are not familiar with your tractor's hydraulics, consult your tractordealer.)

Fortractorswith closed-center hydraulicsorpressure/flow

compensated hydraulicswhich arepowered by a variable

displacement hydraulic pump, turn the knurled control

knob on the left side of the hydraulicvalve completely

clockwiseand lockit in placewith the circularlock disk.Do

notapply anytorqueto thecontrol knobafterit bottomsout

or valve damage mayoccur. Be sure the lockdisk is

snuggedtopreventthecontrol knobfrom vibratingloosein

field operation.

Thetongue cylinder hydraulic circuitconsists of the hoses

from ports "P" and "T". Once the hydraulic valveis set for

CLOSED CENTER operation, the Coulter Command

tongue cylinder circuit requires live hydraulic power supplied to the port labeled "P". This is accomplished by

pushing FORWARD on the tractor remote hydraulic lever

and LOCKING IT OPEN in this position.

• OnJohn Deeretractors equippedwith SOUND-GUARD

R Body you must use the LEVER LOCK CLIP John

Deere Part No. R52667 to lock the lever in the forward

position.See your tractor dealerfor purchase and installation of this clip.

• OnJohn Deere 7000Series tractors, rotatevalve detent

selector to MOTOR POSITION to lock the lever in the

forward position.

• On Case-IH Magnum tractors use the circuit designed

for HYDRAULIC MOTOR CONTROL andlock the lever

forward in the detent position. The detent pressure will

probably have to be turned up to its maximum setting.

DO NOT tie the hydraulic lever on past the detent positionwith a strap. This couldshift the spool beyondits designed operating position and cause system damage.

See your tractor dealer for hydraulic system details.

• On other model tractors use the circuitdesigned for HY-

DRAULIC MOTOR CONTROL and lock the lever forward in the detent position. The detent pressure will

probably have to be turned upto its maximum setting or

some other mechanical detent holder will have to be

used to hold the lever forward. See your tractor dealer

for the proper means of providing constant pressure/

flow to the tongue cylinder circuit.

The Coulter Command hydraulic circuit requires a flow

rateof8 to12 gallons perminuteforefficient operation.On

high flow rate tractors, the flow control on the tractor remote may have to be turned down so as not to exceed 12

gallons per minute.Flow rateshigher than 12 gallons per

minute will not damage the valve, but may cause poor

Coulter Command performance.

The remote tractorhydraulic leverwill haveto be locked in

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

14

Page 17

Great Plains Mfg., Inc.

Section 2 Operating Instructions

positionto supply oil to the "P"port of thehydraulic control

valve,regardless of whether youwant to control the

tongue hydraulic cylinder manually or automatically.

ThePrecisionHitch transport hydrauliccircuitcontains the

hoses from the ports marked "V1" and "V2". This circuit

mustbe connected to oneof the remaining circuitsfor raisingand lowering thetransport system.This circuit mustreceive hydraulic pressure for raising the machine even

while the hydraulic tongue circuit is "locked in" for continuous use. If the machine will not raise when the hydraulic

tongue circuit is "locked in," consult your tractor dealer.

You may need to run the transport hydraulic circuit on a

"priority circuit" and the hydraulictongue circuit on an alternateremote ifthe tractorhydraulicsallowslivehydraulic

power to other remotes. If the "priority circuit" is the only

circuit suitablefor HYDRAULICMOTORCONTROL, then

run the transport hydraulic circuit on the "priority circuit"

andrun thehydraulictongue circuiton analternate remote

with the Coulter Command valve in the OPEN CENTER

MODE.

Tractors with open center hydraulic systems or fixed

displacement hydraulic pumps.

(If you are not familiar with your tractor's hydraulics, consult your tractordealer.)

Fortractorswith open-center hydraulicsoron tractorswith

fixed displacement hydraulic pumps turn the knurled control knob on the left side of the hydraulicvalve completely

counterclockwise and lock it in place with thecircular lock

disk. Be sure the lock disk is snugged to prevent the control knob from vibrating loose in field operation.

ThePrecisionHitch transport hydrauliccircuitcontains the

hoses from the ports marked "V1" and "V2". This circuit

must be connected to tractor's "priority circuit" to supply

hydraulic pressure for raising the machine even while the

hydraulic tongue circuit is "locked in" for continuous use.

The "No.1" hydraulic circuit on most open-center tractors

is the priority circuit.

Thetongue cylinder hydraulic circuitconsists of the hoses

fromports "P" and "T".Connect "P" and "T" toa circuit otherthan the "priority circuit". Once the hydraulicvalveis set

for OPEN CENTER operation, the Coulter Command

tongue cylinder circuit requires live hydraulic power suppliedto the port labeled "P".This is accomplishedby pushing FORWARD on the tractor remote hydraulic lever and

LOCKINGIT OPEN in this position. The remote tractorhydraulic leverwill have tobe lockedin position tosupply oil

to the "P" port of the hydraulic control valve,regardless of

whether you want to control the tongue hydraulic cylinder

manually or automatically.

The Coulter Command tongue hydraulic circuit requires a

flow rate of 8 to 12 gallons per minute for efficient operation. On high flowrate tractors, turn down the flowrate on

the tractor remote,if possible, so as not to exceed 12 gallons per minute. Flow rates higher than 12 gallons per

minute will increase the heat generated by the Coulter

Command circuit when it circulates this high flow of oil.

When operating the Coulter Command tongue hydraulic

circuit in the OPEN CENTER mode, use poppet style

quick couplers on the hoses connecting to the tractor.

These quick couplers allow better flow throughsome tractor remotes and may produce less heat when circulating

continuous hydraulic flow through them. Parker Hannifin

offersthe poppet style Pioneer quick coupler in their 8010

Series couplers. Fortractors with Pioneer quickcouplers

use Pioneer 8010-4P poppet style male couplers when

operating in the OPEN CENTER mode. See Figure 2-2.

Poppet Style Ball Style

Figure 2-2

Quick Couplers

16316

Operation of Electronic Controls

1. Connect power cord to an uninterrupted, 12-voltpower source on tractor. Connecting directly to battery is

recommended. Plug cord into lead with two-pin connector on back of control box. The polarity ofthe power supply is veryimportant to prevent circuit damage.

The white wireof the power cord must be connected

to the "+" positive battery terminal and the black wire

to the "-" negative battery terminal.

2. Connect the control box cable to the back of the control boxand route it out of the tractor. Connect it to the

hitch wiring harness.

3. With the remote tractor hydraulic lever locked in positionto supply oil to the "P" port of the hydrauliccontrol

valve,turn the power switch on.

a. For manual tongue hydrauliccylinder operation,

simply movethe UP-DOWN switch the desired direction. Moving the switch to the UP position extends the tongue cylinder,and movingthe switch

to the DOWNposition retracts the tongue cylinder. If UP retracts the cylinder, then your remote

hydraulicleveris notsupplying oilto the"P" port of

the hydraulic control valve, or the wires going to

the solenoids are reversed. By moving the UPDOWN switch, the AUTO-MANUAL switch automatically switches to the MANUAL mode. If you

want to manually hold the tongue hydraulic cylinder in the position set by the automatic controls

without moving it, just switch the AUTO-MANUAL

switch to MANUAL.

b. Forautomatic coulter depthcontrol, simply switch

the AUTO-MANUAL switch to AUTO and dial in

the desired coulter depth you wish to maintain

withthecoulter depthcontrol knob.(The markings

onthe knob settings are forreference only and do

not represent a depth measurement.)

6/21/2004

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

15

Page 18

Section 2 Operating Instructions

!

WARNING

Make sure all people, animals, and objects are clear of the

coulter tool bar before switching the tongue hydraulics to the

AUTO mode.

Turning the coulter depth switch clockwise makes the

coulters run shallower, and turning the coulter depth

switchcounterclockwise makesthe coulters run deeper.If

the Precision Hitch is not moving or is on a hard surface,

turning the coulter depthswitch maynot cause the tongue

cylinderto retracttothe desiredposition. Thecoulters may

notpenetrate to thedesired depth untilthe Precision Hitch

is moving. A pulsing ofthe valve maybe the onlyreaction

when adjusting the COULTER DEPTH knob on a stationary machine.The coulter depth setting can always be

changed "on-the-go" if you desire.

With the AUTO-MANUAL switch in the AUTO mode, the

coulters will always maintain a consistent depth regardless of terrain, soil type or speed. When lifting and turning

in the field, the tongue cylinder will remain in its last automatically set mid stroke position. When the machine is

lowered, the coulters will automatically return to their preset depth.

Great Plains Mfg., Inc.

Lift Switch Field Adjustments

Figure 2-3

12681

Field Adjustments

Lift Switch

Referto Figure 2-3.The switchat the rear of the Precision

Hitch determines the point in the lift cycle at which the automatic feature of the Coulter Command will be interrupted andthe depth sensing gauge wheel will be lifted off the

groundfor turning around. Since thePrecision Hitch transport tires can belowered during operation to provideflotation for the drill or planter in soft soil conditions, coulter

command should not be interrupted, and the depth sensing gauge wheel should not be lifted until after the transport tiresare loweredto the pointwhere theyare nolonger

usedfor system flotation. Thisis usually the point in the lift

cycle when the drill or planter openers are just being lifted

out of the ground.

Acam fastenedto the rockshaftactivates a plungerswitch

which causes the automatic feature of the Coulter Command to be interrupted and the depth sensing gauge

wheel to be lifted off the ground forturning the Precision

Hitch around in the field.

1. To properly adjustthe liftswitch timing, loosen andro-

tate the cam assembly so it hits the plunger roller of

the lift switchwhen the Precision Hitch is raised just

enoughto begin to pickthe openersout of the ground.

BE CAREFUL NOTTO "BOTTOM OUT" THE LIFT

SWITCH PLUNGER when the plunger roller climbs

the surfaceof the cam. Tighten the cam onto the rockshaft.

2. To adjust the lift switch position loosen the two #10

screws and slide it up or down in the slotted switch

mount holes so the plunger moves in only about

1/8 inch when the cam activates it. DO NOT "BOTTOM OUT" THE LIFT SWITCH PLUNGER.

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

16

Page 19

Great Plains Mfg., Inc.

Section 2 Operating Instructions

!

WARNING

Shut the tractor off and put all hydraulic valve levers in neutral

position before attempting to work on or crawl under the machine. Do not crawl under a raised machine without the transport locks securely in place. Sudden hydraulic activation or

failure could cause serious injury or death.

Aproperly adjusted liftswitch allows theautomatic coulter

depth feature to be interrupted early in the lift cycle. This

providesthe fastest liftcycle times when turning around in

thefield. Operating the liftswitch early in thelift cycle, also

provides the maximum amount oftime forthe depth sensing gauge wheel cylinder to completely extendas the machine is lowered back to field position. It is important that

thedepth sensing gaugewheel cylinder alwaysbefully extendedwhen thePrecision Hitch isin fieldposition to allow

the depth sensing gauge wheel to float through its full

range of motion.

Speed Sensor

The Coulter Command depth control system automatically

compensates for changes in ground speed. A speed sensor and speed sensor plate mounted behind the coulter

depth sensing wheel monitors the ground speed so the

Coulter Command can adjust forit. This sensor should be

in close proximity to the speed sensor plate. In general, it

should never need adjustment. If the sensor does get

moved, it should be adjusted against the speed sensor

plate until itjust touches the plate in the closest part of the

rotation. A bent speed sensor plate should be straightenedor replacedimmediately.Toadjust the speedsensor,

loosenthe two #6screws on thesensor and slide it toward

thespeed sensor plate.Rotate thedepth sensingwheel to

theposition where the speed sensor plate isclosest to the

sensor mount, and retighten the sensor mount screws

where the sensor just touches the speed sensor plate.

Hydraulic Valve

All adjustable valve cartridges on the hydraulic valve

blocks are preset at the manufacturer and should not be

tampered with. Tampering with a cartridge valvecould result severe frame damage to the Precision Hitch.

The only required adjustment is on the upper hydraulic

control valve.This valve contains a rotary knob for setting

the Coulter Command to be used with either OPEN CENTERED or CLOSED CENTERED tractor hydraulics.

Check the ownersmanual of your tractor to determine

what type of hydraulic system youhave.

Referto “HydraulicHook-Up & Function”on page 14of

this manual for setting the hydraulic control valve for your

style of tractor.

6/21/2004

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

17

Page 20

Section 3 Troubleshooting

Section 3 Troubleshooting

Problem Possible Cause Solution

Great Plains Mfg., Inc.

Coulters move up when the

down switch is operated and

down when the up switch is

operated.

Automatic Coulter depth control stops adjusting coulter

depth

T urningthe COUL TERDEPTH

knob does not set coulters

deep enough.

Not supplying oil to the "P" port of the

hydraulic valve.

Solenoids wired backward or hoses from

port "A" and port "B" reversed at the

hydraulic valve.

TONGUE HYDRAULICS switch bumped to

MANUAL mode.

Tractor remote hydrauliclever not locked for

constant oil supply to valve.

System variables out of adjustment Turn power switch OFF and back on again

If the tongue cylinder runs completely

retracted, the tractor drawbar is to high.

If in extremely hard conditions with the

machine standing the tongue cylinder

pulses but does not retract.

If the COULTER DEPTH knob is turned to

"A" and the tongue cylinder will not completely retract when moving through the

field then the internal sensor box linkage is

not set correctly.

Reverse the remote hydraulic lever in the

tractor.

Unplug solenoids and swap wire leads to

them.

Flip TONGUE HYDRAULICSswitchback to

AUTO mode

Lock Tractor remote hydraulic lever with

rubber tarp strap or other means.

so system variables can reset. Then flipthe

AUTO-MANUAL switch to AUTO and

resume operation.

Use a straight drawbar or one which

sweeps down.

This is perfectly normal. The cylinder will

not penetrate the coulters on a stationary

machine in hard conditions. Pull forward

and check coulter depth on a moving

machine.

Adjust the sensor box internal linkage. See

"Sensor Box Adjustments" on page 13.

The hydraulic valve constantly pulses when you are

stopped to refill or adjust

something.

T urningthe COUL TERDEPTH

switch to "E" does not allow

the coulters to run shallow

enough.

Depth sensing gauge wheel

notlifting offthe ground when

Precision Hitch is raised.

If the sensor box linkage is properly

adjusted and tongue cylinder constantly

pulses while moving through the field but

the front tongue cylinder will not retract, you

do not have enough system weight.

Hard soil conditions are hindering coulter

penetration while stopped.

The internal sensor box linkage is not set

correctly.

Coulter Command power is OFF or 12 volt

power has been interrupted.

The lift switch has become disconnected or

the lift switch cam on the rockshaft is not

properly adjusted.

Add fertilizer or water to liquid tanks. Add

tool bar weight brackets to coulter tool bars.

Flip TONGUE HYDRAULICS switch to

MANUAL mode while you are stopped or

turn coulter command power OFF. Pulsing

does not hurt the valve, but can be annoying.

Adjust the sensor box internal linkage. See

"Sensor Box Adjustments" on page 13.

Coulter Command must be connected and

the power must be ON for the depth sensing gauge wheel to raise when the Precision Hitch is raised. The depth sensing

gauge wheel should raise with the transport

lift circuit with Coulter Command in either

the AUTO or MANUAL mode is long as the

power is ON.

Adjust the lift switch cam. See "Lift Switch"

under Section 2 "Operating Instructions"

on Page 16.Check cable connections on lift

switch leads.

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

18

Page 21

Great Plains Mfg., Inc.

Section 3 Troubleshooting

Problem Possible Cause Solution

Coulter depth erratic or will

not adjust when you turn the

"DEPTH CONTROL" dial.

T ransportliftcylinderswill not

lift the Precision Hitch for

transport.

Moisture present in the master control

box.

Hydraulic flow rates of more than 12

gallons per minute to the hydrauliccontrol valve when operating in the

CLOSED-CENTER mode.

Inconsistent 12-volt power supply.

OPEN-CENTER tractors with multiple

sets of hydraulicoutlets use the #1 circuitforpriority flowwhich slowsdownor

cuts off flow to the other circuits. This

problem will occur if Coulter Command

ports "P"and"T" arepluggedinto the#1

circuit.

The master control box in the tractor

mustbe kept dry.Moisture on the circuit

board or in the control terminals will

cause false readings.

Turn downthe flow rateon thetractor remotewhich isproviding oilto thetongue

hydraulic circuit.

Connect the power cord directly to the

battery. The Coulter Command electrical circuit must have a good uninterrupted power supply. Fluctuations in

the power supply will cause inconsistent electrical readings.

Connect transport lift circuit ports "V1" and

"V2" to the #1 hydraulic circuit on OPENCENTER tractors. Ports "P" and "T" of the

Coulter Command hydraulics should connect to another circuit other than the #1 circuit on OPEN-CENTER tractors.

System generating excess

heat when operating in the

OPEN CENTER MODE.

On CLOSED-CENTER tractors the

CoulterCommandshouldbeconnected

to a circuit capableof HYDRAULIC MOTORCONTROL for supplying constant

pressure/flowto remote locations. If the

machine will not raisewhen thehydraulic tongue circuit is "locked in," consult

yourtractordealer.You mayneed to run

the transport hydraulic circuit on a "priority circuit" and the hydraulic tongue

circuit on an alternate remote if the tractor hydraulics allows livehydraulic

power to other remotes.

The OPEN CENTER - CLOSED CENTER control knob is not turned

completely counterclockwise.

Ball style quick couplers may produce

more heat when circulating continuous

hydraulic flow through them.

On CLOSED-CENTER tractors, if the

"priority circuit" is the only circuit suitable for HYDRAULIC MOTOR

CONTROL or supplying constant pressure/flow to remote locations, then run

the transport hydraulic circuit on the

"priority circuit" and run the hydraulic

tongue circuit on an alternate remote

with the Coulter Command valve in the

OPENCENTER MODE. See "Tractors

with open center hydraulic systems

or fixed displacement hydraulic

pumps," page 15.

Turn the knurled control knob onthe left

side of the hydraulic valve completely

counterclockwise and lockit in place

with the circular lock disk.

Use poppet style male quick couplers.

Fortractors withPioneer quickcouplers

usePioneer 8010-4P poppetstyle male

couplers when operating in the OPEN

CENTER mode. See Figure 2-2, page

15.

6/21/2004

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

19

Page 22

Section 3 Troubleshooting

Problem Possible Cause Solution

Great Plains Mfg., Inc.

Depth sensing gauge wheel

not lowering to the ground

when Precision Hitch is lowered, or depth sensing gauge

wheel cylinder not fully

extending when the machine

is lowered.

T ransportliftcylinderswill not

retract completely . (Transport

tires will not lift off the

ground.)

The lift switch cam on the rockshaft is not

properly adjusted.

Relief valve "M3" is set too low. Turn valve adjustment screw on top of valve

Relief valve "M4" is set too low. Turn valve adjustment screw on top of valve

Adjust the lift switch cam. See "Lift Switch"

under Section 2 "Operating Instructions"

on Page 16.

"M3" one eighth turn clockwise. Valve "M3"

is preset to relieve at 600 psi. Turning the

adjustment screw one eighth turn clockwise

increases the relief setting by approximately 75 psi.

!

CAUTION

Any attempt to set valve "M3" above 1200

psi could result in system malfunction. Setting the valve "M3" above 750 psi will slow

down the lift cycle time.

"M4" one eighth turn clockwise. Valve "M4"

is preset to relieve at 900 psi. Turning the

adjustment screw one eighth turn clockwise

increases the relief setting by approximately 75 psi.

!

CAUTION

Any attempt to set valve "M4" above 1200

psi could result in transport frame or transport rockshaft damage.

System Schematics

If problems occur in the hydraulicor electric systems,

refer to the schematics belowand on page 21 tohelp

locate the problem.

Hydraulic Schematic

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

20

16313

Page 23

Great Plains Mfg., Inc.

Section 3 Troubleshooting

Electrical Schematic

6/21/2004

16314

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

21

Page 24

Section 4 Maintenance & Lubrication

Section 4 Maintenance & Lubrication

Maintenance

The Coulter Command is relatively maintenance free.

The switches, sensors, and linkages should not need

any routine adjustment unless they are moved or

damaged.

Lubrication

Lubrication Symbols

50

Great Plains Mfg., Inc.

As

Required

Lubrication is required every 50 hours of operation.

10

12405

Use a multipurpose spray club. Use as required.

Do not over lubricate.

Seasonally

Lubrication is requiredLubrication is required every 10 hours of operation.

12

Depth Sensing Arm Wheel Pivot

Located on the depth sensing wheel Pivot Arm (2 Total)

Type of Lubrication: Multi-Purpose Lithium Base Grease

Quantity: Until grease begins to emerge

2-3Years

Axle Bearings

Repack

Type of Lubrication: Wheel Bearing Grease

12408

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004

22

Quantity: Full Pack

Page 25

Great Plains Mfg., Inc.

Appendix

Appendix

Torque V alues Chart for Common Bolt Sizes

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8436597

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 8

Bolt Size

(Metric)

4

N · m ft-lb N · m ft-lb N · m ft-lb

1

in-tpi = nominal thread diameter in inches-threads per inch

4

mm x pitch = nominal thread diameter in millimeters x thread pitch

Bolt Head Identification

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

2

N· m = newton-meters

3

ft-lb= foot pounds

6/21/2004

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

23

Page 26

Great Plains Manufacturing, Inc.

Corporate Office: PO. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...