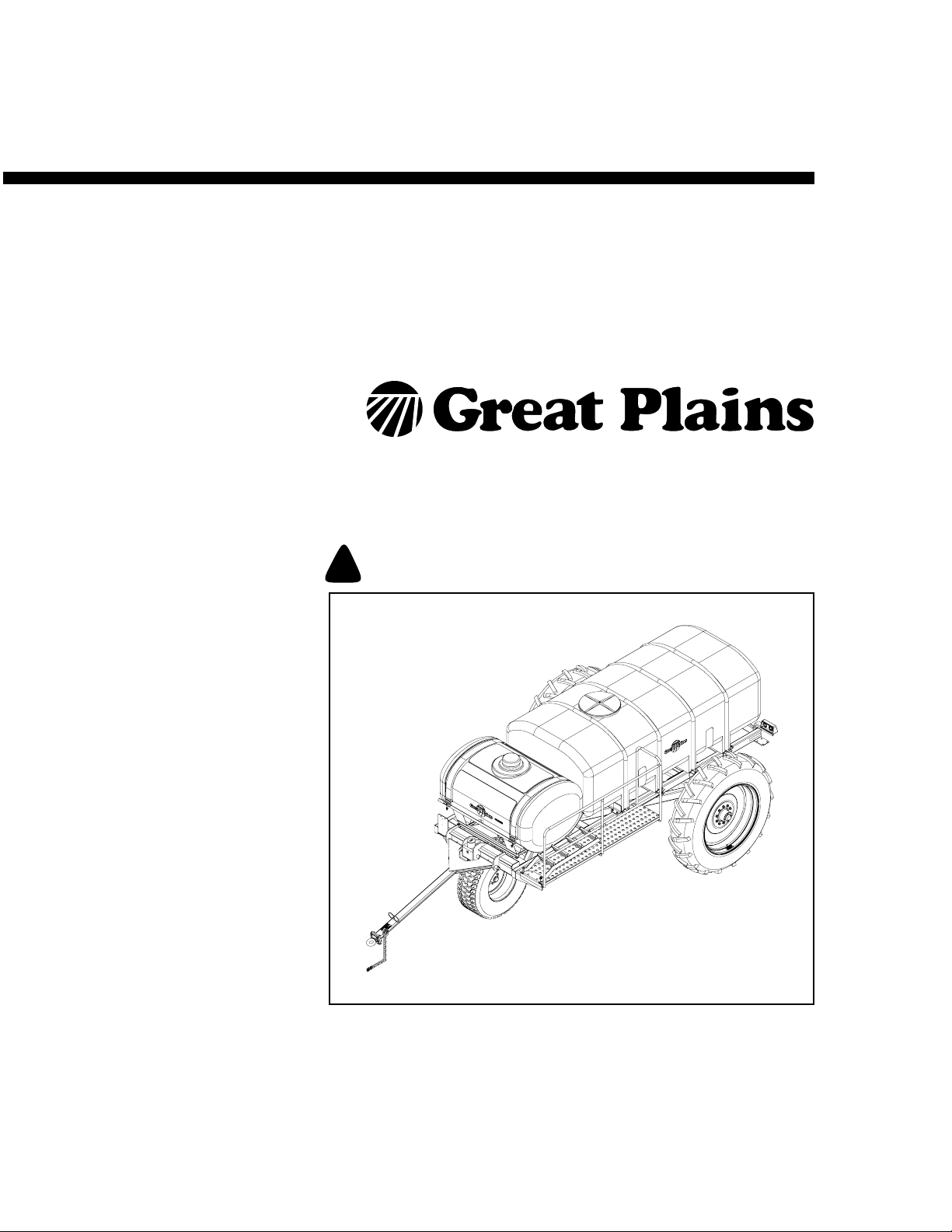

Page 1

Operator’s Manual

PFC1600 and PFC2000

Planter Fertilizer Carts

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

26015

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 2007 Printed 03/28/2007 407-158M

Page 2

Table of Contents

Important Safety Information.................................... 1

Safety Decals........................................................... 6

Introduction................................................................9

Document Family................................................. 9

Description of Unit.................................................... 9

Intended Usage.................................................... 9

Using This Manual................................................... 9

Definitions............................................................ 9

Owner Assistance.................................................. 10

Preparation and Setup ............................................ 11

Pre-Setup Checklist............................................... 11

Planter Preparation................................................ 11

Hitching Cart to Planter.......................................... 12

Plan The Hitch ................................................... 12

If using Bulk Boxes......................................... 12

If Using Bulk Hoppers .................................... 12

Hitching With Empty Tank.................................. 13

Hitching With Loaded Tank................................13

Electrical and Monitor Connections ................... 14

Monitor Setup................................................. 14

Making Electrical Connections....................... 14

Make Fertilizer Connections .................................. 15

Cart Connection Overview................................. 15

Planter Connection Overview ............................ 15

Making Fertilizer Connections............................ 16

Bleeding Gauge Line ............................................. 17

Operating Instructions............................................ 18

Pre-Start Checklist................................................. 18

Tank Inspection...................................................... 18

Transporting the Cart............................................. 19

Loading Fertilizer ................................................... 20

Loading 1600 Gallon Tank.................................21

Loading 400 Gallon Tank...................................22

Field Pumping........................................................ 23

PFC2000 Pumping From 1600 Only..................24

PFC2000 Point Row Pumping from 1600...... 24

PFC1600 Pumping............................................. 25

PFC1600 Point Row Pumping from 1600...... 25

Pumping From 400 only.....................................26

Pumping 400 (Only) With Planter Pumps ...... 26

Point Row Pumping with Planter Pumps........ 27

Pumping 400 With Cart Pump ....................... 27

Point Row Pumping from 400 via Cart........... 28

Pumping From Both Tanks................................ 29

Point Row Pumping From 1600

in Both Mode.................................................. 29

Point Row Pumping From 400

in Both Mode.................................................. 29

Field Set-Up Checklist........................................... 30

Field Operation...................................................... 30

Planting.............................................................. 31

Electric Clutch Operation................................... 31

Electric Clutch Lock-Up.................................. 32

Parking and Storage.............................................. 33

Stopping/Standing ............................................. 33

Short-Term Parking ........................................... 33

Extended Parking .............................................. 34

Drain Bulk Material......................................... 34

Drain Lines..................................................... 34

Seasonal Storage.................................................. 36

Adjustments............................................................. 37

Pump Setting Determination.................................. 37

Liquid Fertilizer Strainers....................................... 38

Pump Strainer.................................................... 38

Quick-Fill Strainer.............................................. 38

Troubleshooting ...................................................... 39

General Troubleshooting....................................... 39

Maintenance and Lubrication................................. 41

Maintenance.......................................................... 41

Fertilizer Plumbing Maintenance ........................... 42

Tank Cleaning.................................................... 42

Strainer Maintenance......................................... 42

Lubrication............................................................. 43

Appendix.................................................................. 46

Specifications and Capacities................................ 46

Tire Inflation Chart................................................. 46

Torque Values Chart.............................................. 47

PFC2000 Plumbing................................................ 48

PFC1600 Plumbing................................................ 49

Planter Assembly Installation................................. 50

Warranty................................................................ 54

© Copyright 2007 All rights Reserved

Great PlainsManufacturing, Inc.pro videsthis publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this

product at the time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

03/28/2007 401-406M

Great Plains Manufacturing, Incorporated Tr ademarks

Printed in the United States of America.

Page 3

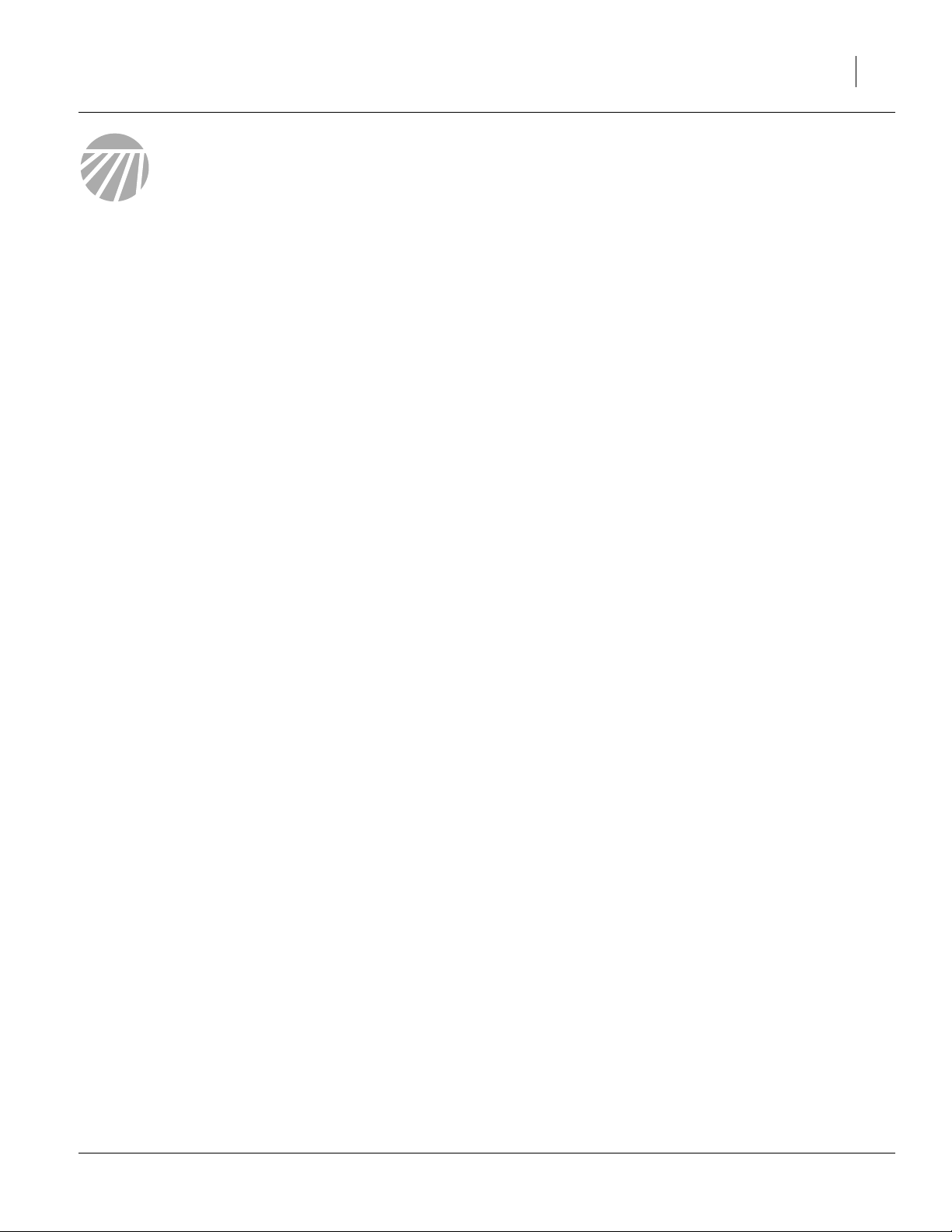

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident preventionare

dependent upon the awareness, concern, prudence

and proper training of personnel involved in the operation, transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury. This signal word is limited to the most extreme

situations, typically for machine components that, for

functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert

against unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

!

DANGER

!

WARNING

!

CAUTION

!

1

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 6, thor-

oughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during opera-

tion.

03/28/2007 407-158M

Page 4

2

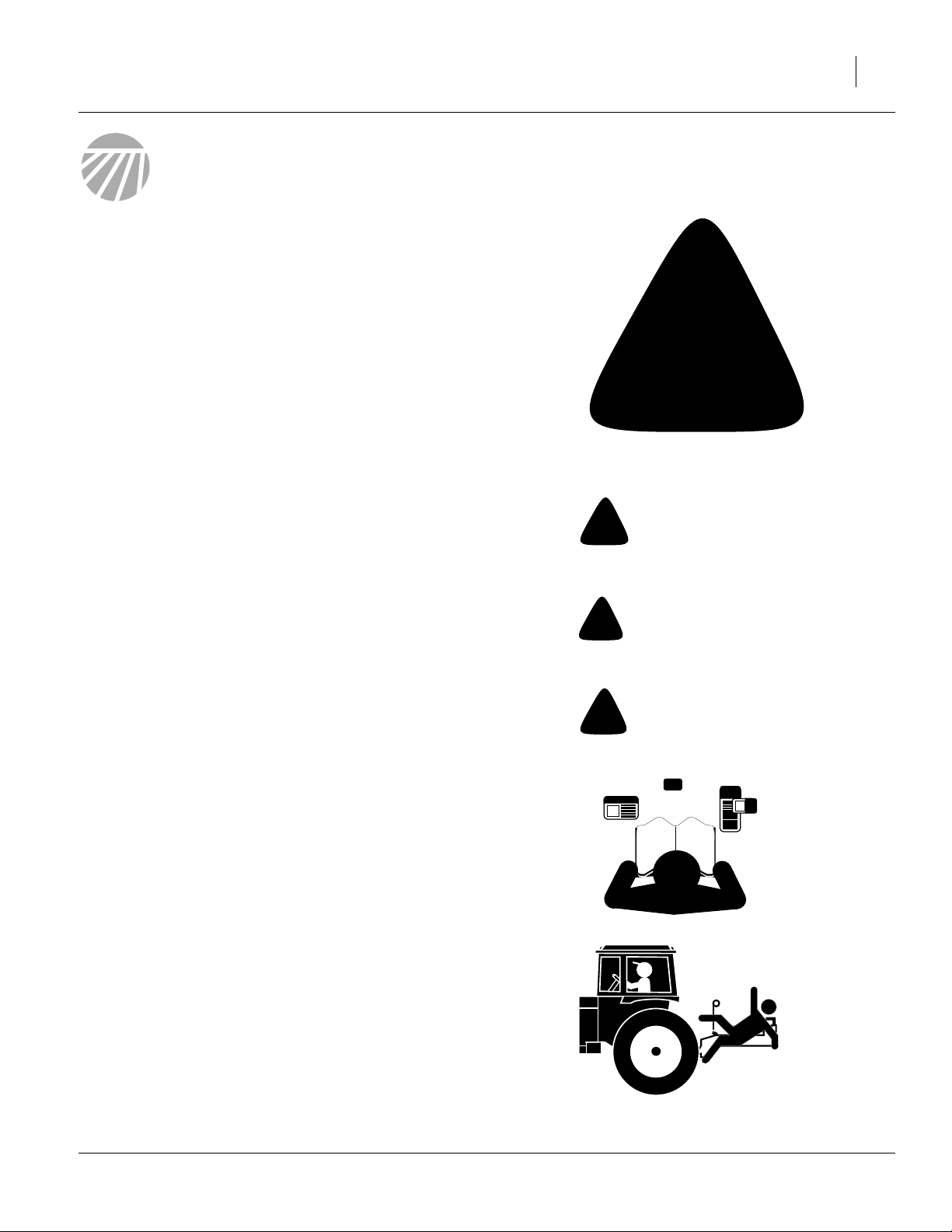

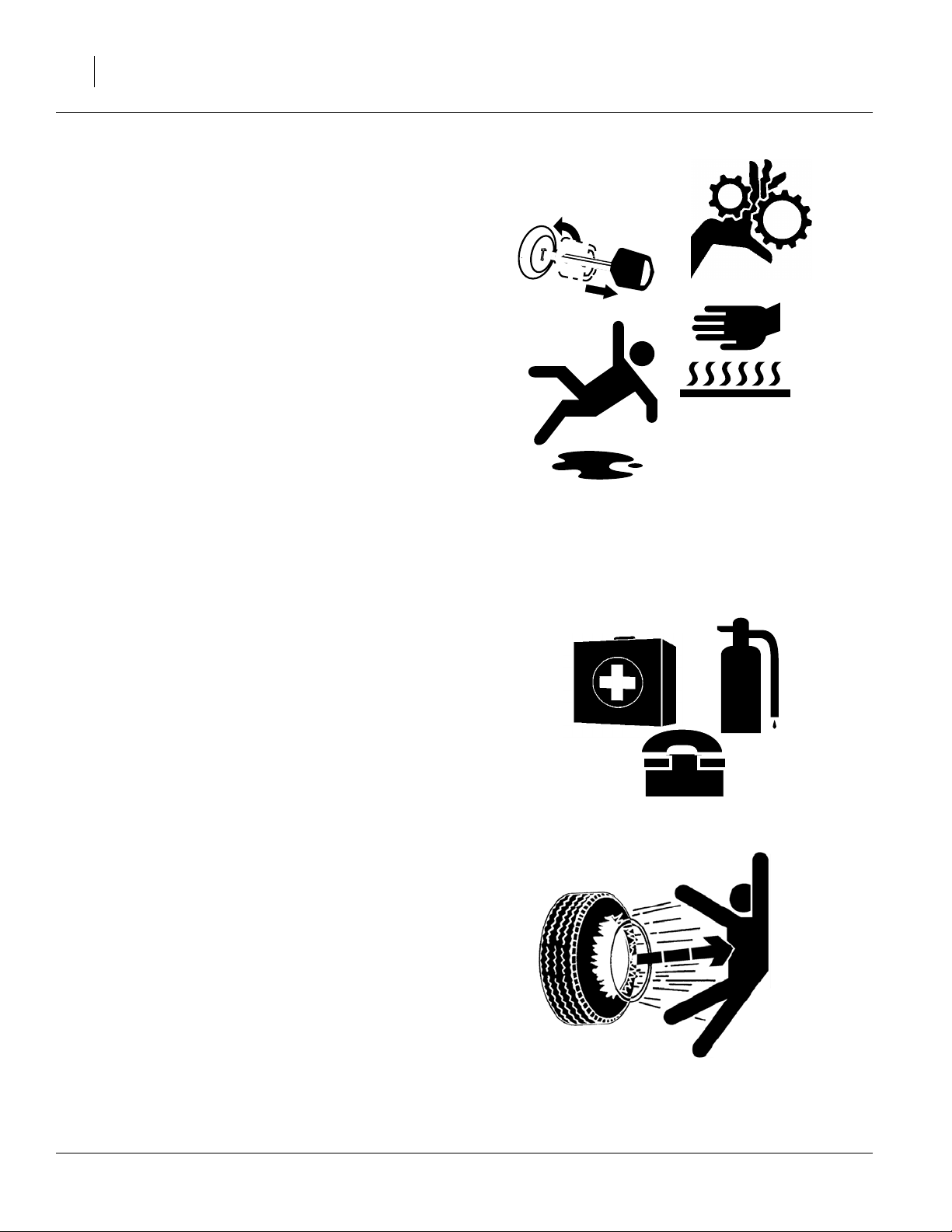

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper

use can seriously injure persons, animals, plants, soil

and property.

▲ Read and follow chemical manufacturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Avoid inhaling smoke from any type of chemical fire.

▲ Never add chemical concentrates to an empty tank.

Start with tank half full of water.

▲ Rinse out tank tanks and discard rinse water on last field

treated.

▲ Never drain, rinse or wash tank or its plumbing within

100 feet of a freshwater source, nor at a car wash.

▲ Store or dispose of unused chemicals as specified by

chemical manufacturer.

▲ Dispose of empty chemical containers properly. Laws

generally require power rinsing or rinsing three times,

followed by perforation of the container to prevent reuse.

Wear Protective Equipment

▲ Wear protective clothing and equipment specified by

chemical manufacturer.

▲ Wear clothing and equipment appropriate for the job.

Avoid loose-fitting clothing.

▲ Routine tank valve operation requires operator presence

under the cart. Wear a chemical-resistant hard hat.

▲ Because prolonged exposure to loud noise can cause

hearing impairment or hearing loss, wear suitable hearing protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

▲ Make sure your respiration cartridges are suitable for the

chemicals, and not expired or clogged.

▲ Waterproof unlined gloves are essential for any workers

handling tank cart controls or hoses. Neoprene is recommended.

▲ Chemical jackets, gowns or aprons are essential for

workers loading chemicals or working beneath the cart.

▲ All workers need waterproof boots or foot coverings, to

avoid contact with both spilled and applied chemicals.

407-158M 03/28/2007

Page 5

3

Shutdown and Storage

▲ Drain and safely store or dispose of residual liquids.

▲ Flush tank(s) and lines with water. Winterize if freezing

weather is possible before next use.

▲ Secure cart using blocks at wheels.

▲ Detach and store cart in an area where children normally

do not play.

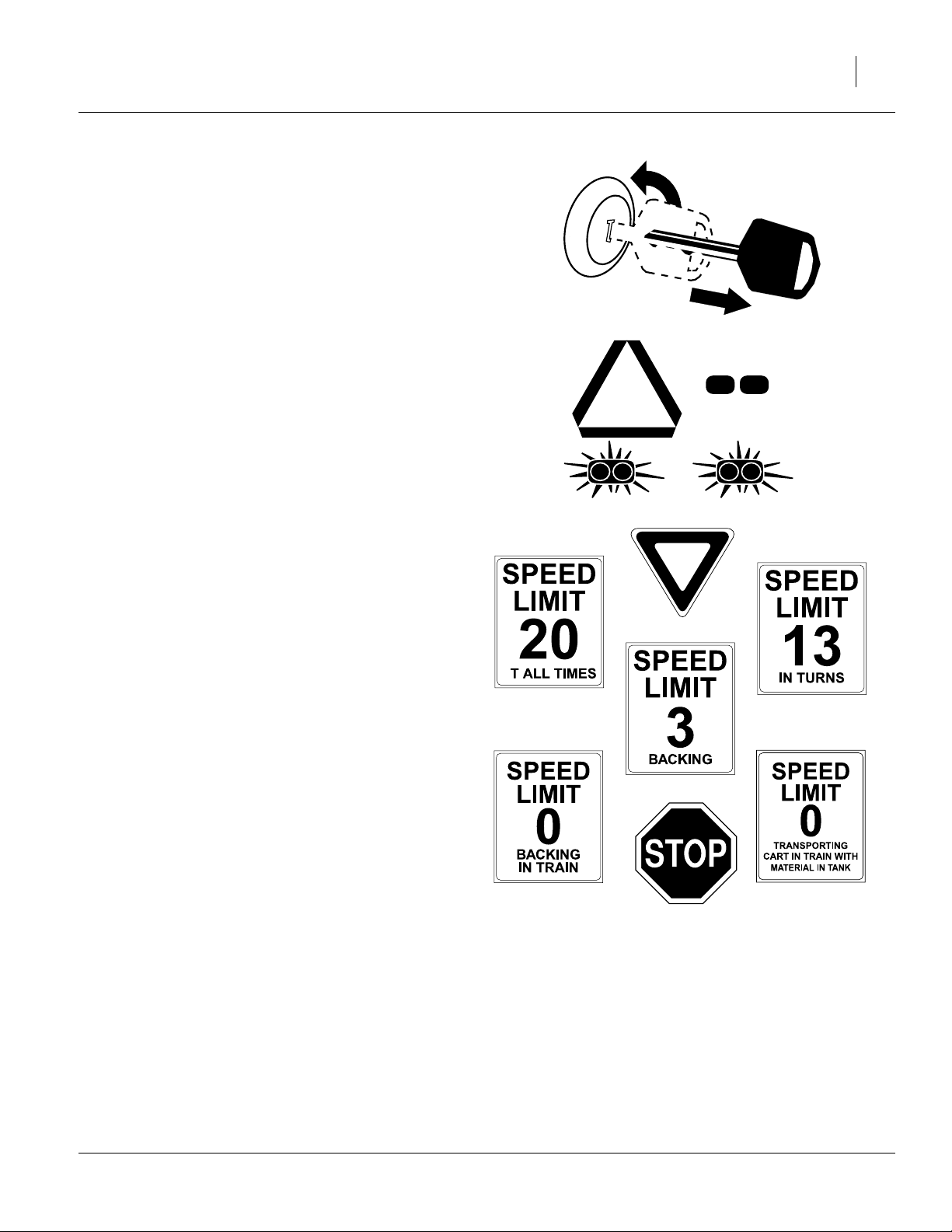

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create a hazard when driven on public roads. They are

difficult to see, especially at night.

▲ Use flashing warning lights and turn signals whenever

driving on public roads.

Use lights and devices provided with implement

Transport Machinery Safely

Maximum transport speed for implement is 20 mph, 13

mph in turns. Some rough terrains require a slower

speed. Sudden braking can cause a towed load to

swerve and upset.

▲ Use the safety chain provided with the cart.

OFF

▲ Never transport the cart in train with the planter unless

the tanks are completely empty.

▲ Do not exceed 20 mph. Never travel at a speed which

does not allow adequate control of steering and stopping.

Reduce speed if towed load is not equipped with brakes.

▲ Do not attempt to back up with cart attached to planter.

Castering of the planter’s rear wheels, and the cart’s lead

wheel, make precise directional control difficult.

▲ Comply with state and local laws.

▲ Do not tow an implement train that, when fully loaded,

weighs more than 1.5 times the weight of towing vehicle.

▲ Carry reflectors or flags to mark cart in case of break-

down on the road.

▲ Keep clear of overhead power lines and other obstruc-

tions when transporting. Refer to transport dimensions

under “Specifications and Capacities” on page 46.

A

03/28/2007 407-158M

Page 6

4

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Put tractor in park, turn off engine, and remove key

before performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow cart pump to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on cart.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

OFF

▲ Remove all tools and unused parts from cart before oper-

ation.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor,ambulance, hospital

and fire department near phone.

Tire Safety

Tire changing can be dangerous and should be performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension

hose long enough for you to stand to one side–not in front

of or over tire assembly. Use a safety cage if available.

911

▲ When removing and installing wheels, use wheel-han-

dling equipment adequate for weight involved.

407-158M 03/28/2007

Page 7

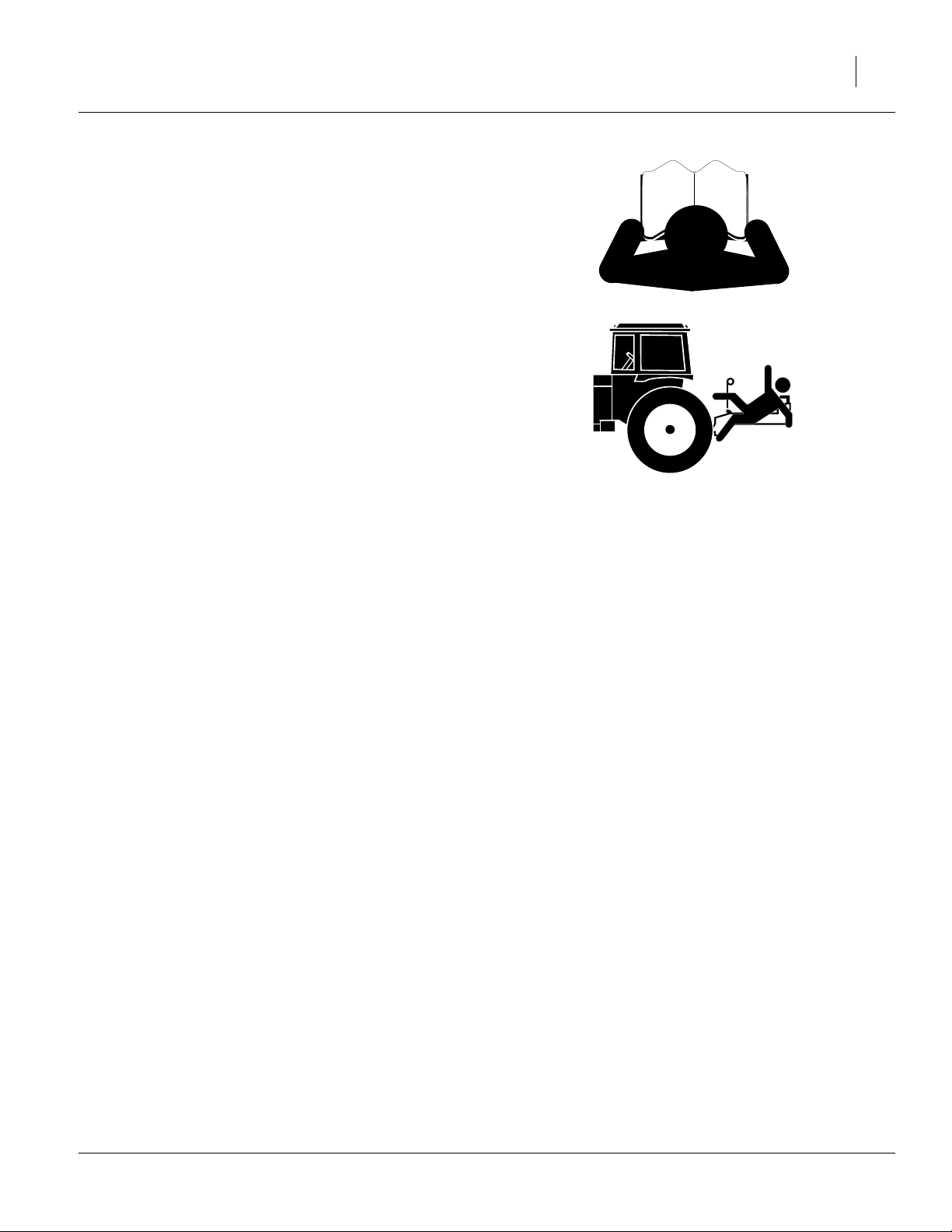

Safety At All Times

Thoroughly read and understand the instructions in

this manual before operation. Read all instructions

noted on the safety decals.

▲ Be familiar with all cart functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave cart unattended with tractor engine run-

ning.

▲ Do not dismount a moving tractor. Dismounting a mov-

ing tractor could cause serious injury or death.

▲ Do not stand between the tractor and cart or planter and

cart during hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

5

▲ Watch out for wires, trees, etc., when folding and raising

cart. Make sure all persons are clear of working area.

03/28/2007 407-158M

Page 8

6

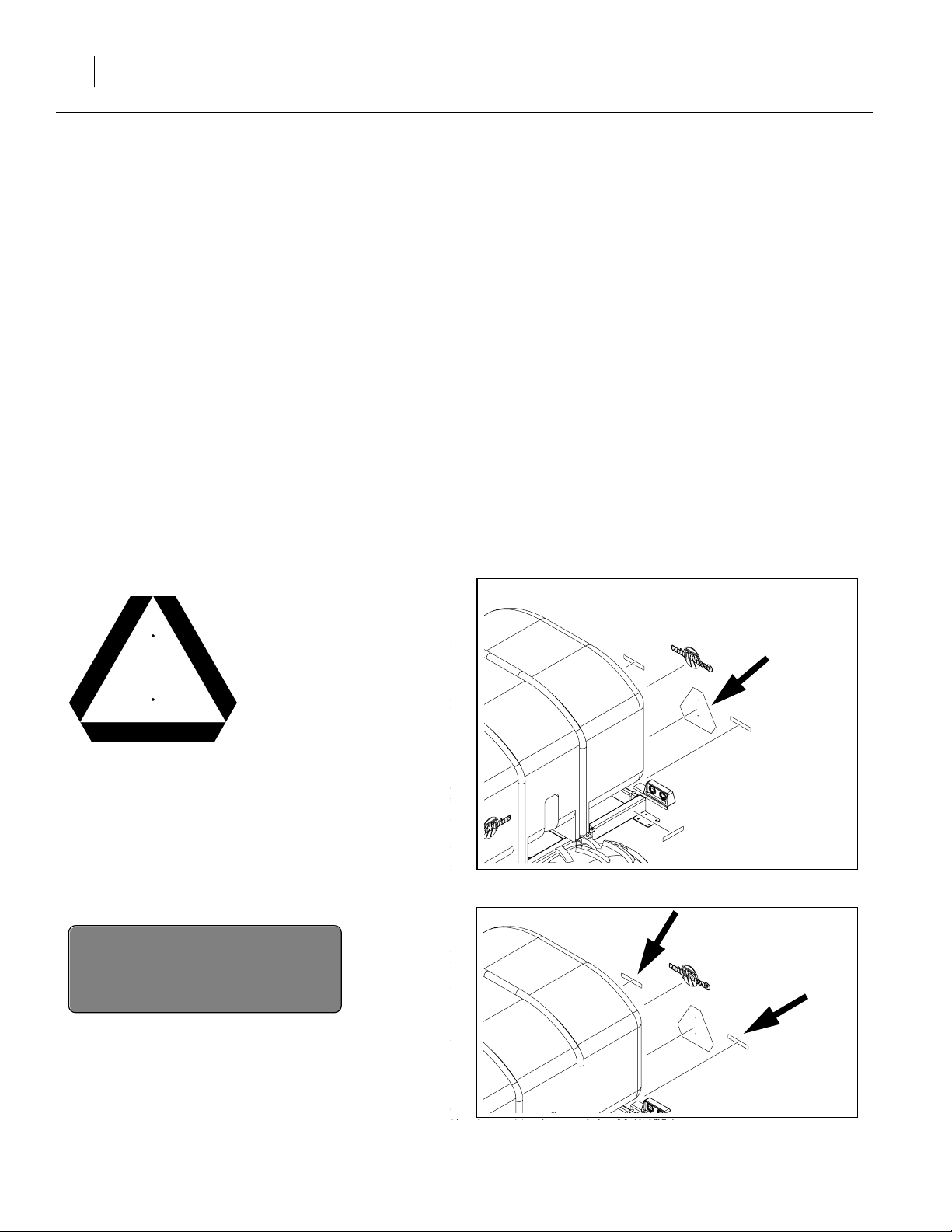

Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new

decals from your Great Plains dealer. Refer to this section for proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

818-055C

Slow Moving Vehicle Reflector

On the back of the cart, frame center;

1 total

838-266C

26016

Red Reflectors

On the main frame back, each side;

two total

26016

407-158M 03/28/2007

Page 9

838-255C

Amber Reflectors

On the main frame sides, front and back,

on the main frame front, each side;

six total.

7

26016

26016

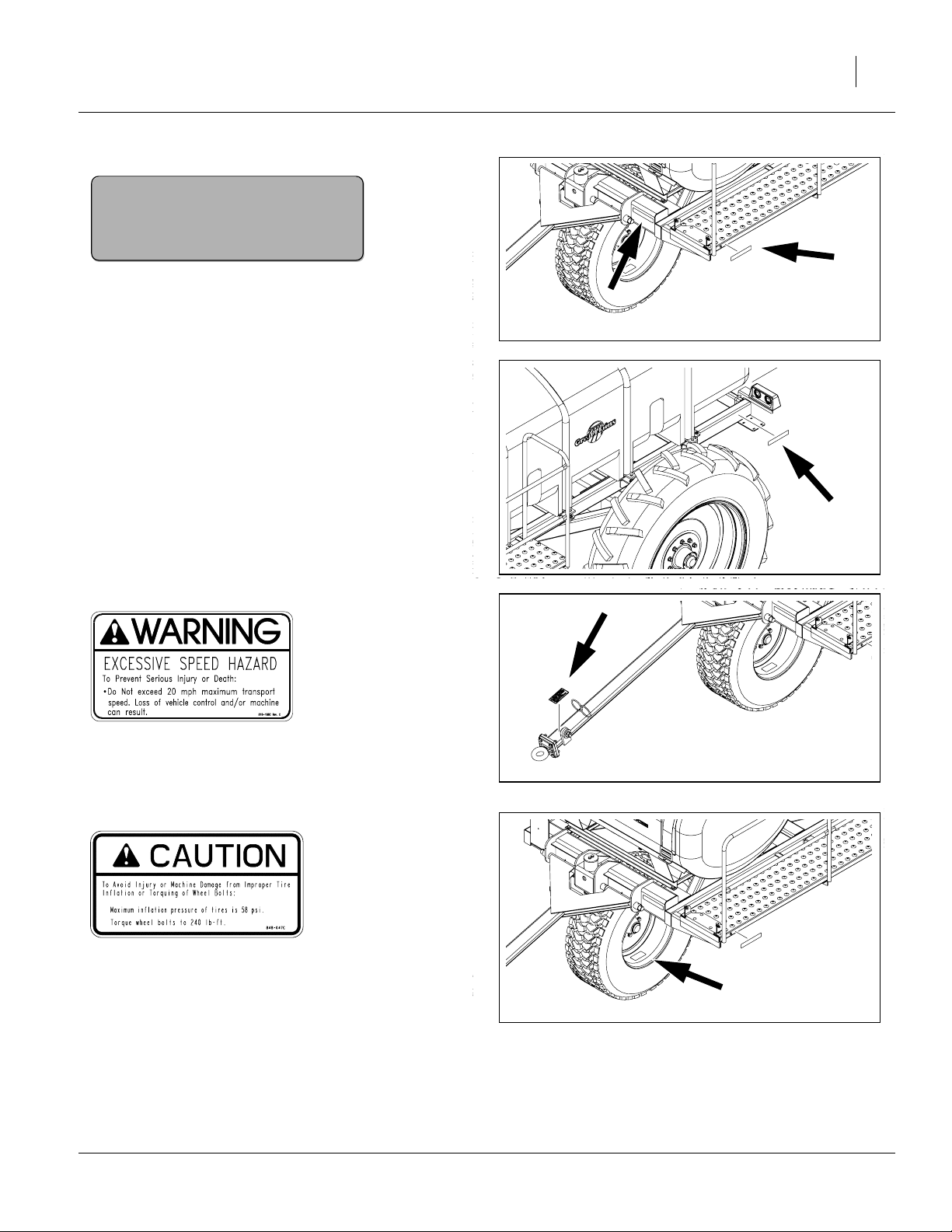

818-188C

Warning: Transport Speed

On tongue, one total

848-047C

Caution: Tire Pressure & Torque

Inside rim of front caster wheel;

one total

26016

26016

03/28/2007 407-158M

Page 10

8

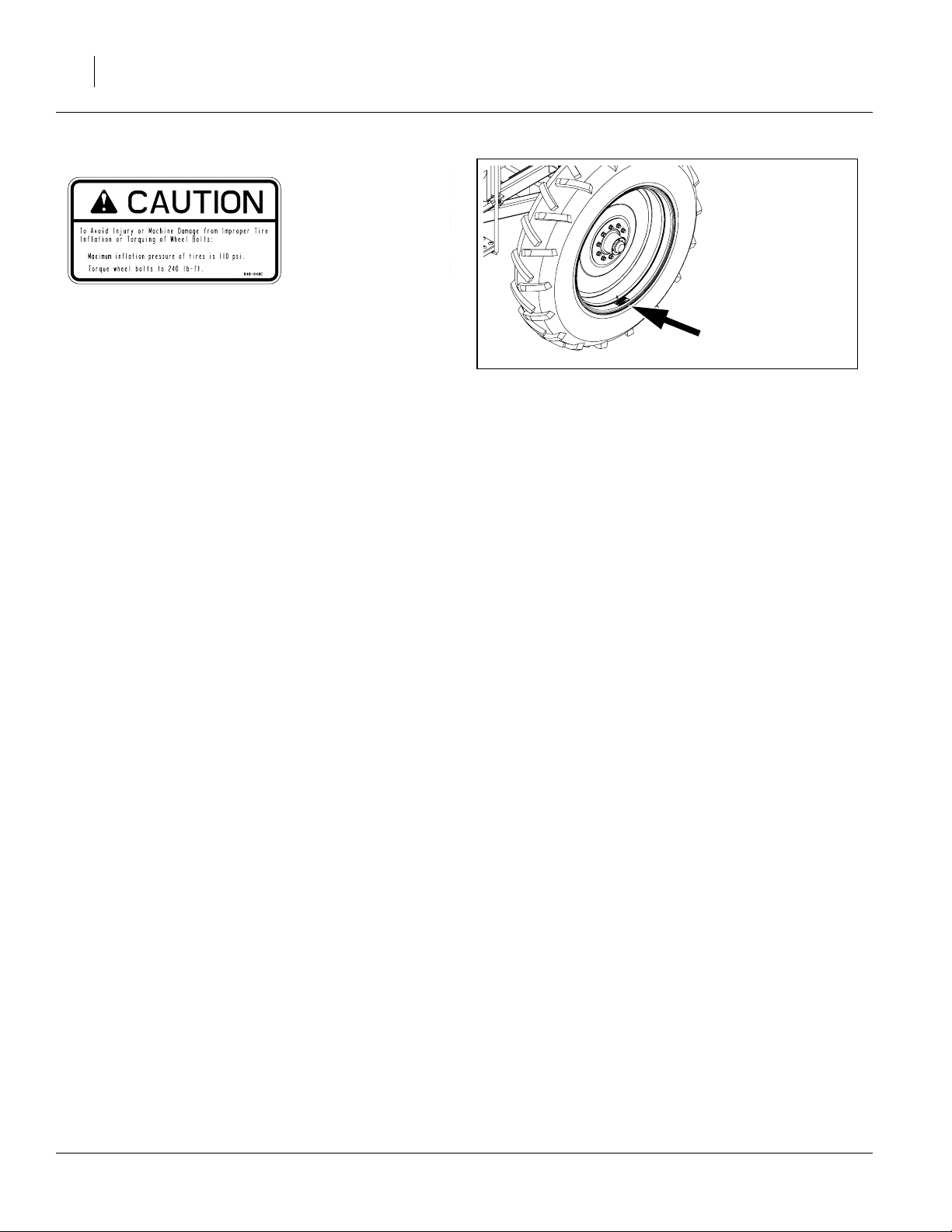

848-048C

Caution: Tire Pressure & Torque

Inside rim of main wheels;

two total

26016

407-158M 03/28/2007

Page 11

Introduction

Introduction 9

Great Plains welcomes you to its growing family of new

product owners. Your PFC1600 or PFC2000 Planter

Fertilizer Cart has been designed with care and built by

skilled workers using quality materials. Proper setup,

maintenance, and safe operating practices will help you

get years of satisfactory use from the machine.

Document Family

407-158M Owner’s Manual (this document)

407-158P Parts

(Note1) Pump Instruction/Parts Manual

(Note2) Planter Operator’s Manual

(Note1) DICKEY-john Seed Monitor Manual

1 Pump and seed monitor manuals supplied by their

respective manufacturers, and not separately orderable

from Great Plains.

2. There may be more than one Great Plains Planter that

supports these tank carts. The planter manual may

include important tank setup and operating information.

Description of Unit

The PFC1600/2000 Cart is a pull-type implement for

supplying liquid fertilizer to specific supporting models

of Great Plains planters. At time of publication, the following planter models accepted PFC1600/2000 Carts:

YP2425 60ft Yield-Pro Planter

Use with any planter requires:

• Trailing pintle hook hitch

• 3-inlet “Hi-Rate” fertilizer manifold

• On-planter fertilizerpump if single-inlet “Starter” manifold is also installed

If your planter does not havethese prerequisite systems

and features, it may be possible to add them. Consult

your Great Plains dealer.

Intended Usage

Use the PFC1600/2000 Cart to apply liquid fertilizer to

production-agriculture crops only.

Do not use the cart to store, transport or apply herbicides or insecticides, nor to store or transport water for

potable uses.

Do not modify the cart for use with planters or attachments other than Great Plains products specified for

use with the PFC1600/2000 Cart.

Using This Manual

This manual will familiarize you with safety, assembly,

operation, adjustments, troubleshooting, and maintenance. Read this manual and follow the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

Right-hand and left-hand as used in this manual are

determined by facing the direction the machine will

travel while in use unless otherwise stated.

IMPORTANT !

A crucial point of information related to the preceding

topic. Read and follow the directions to remain saf e,

avoid serious damage to equipment and ensure

desired field results.

Note: Useful information related to the preceding topic.

03/28/2007 407-158M

Page 12

10

Owner Assistance

If you need customer service or repair parts,contact a

Great Plains dealer. They have trained personnel,

repair parts and equipment specially designed for

Great Plains products.

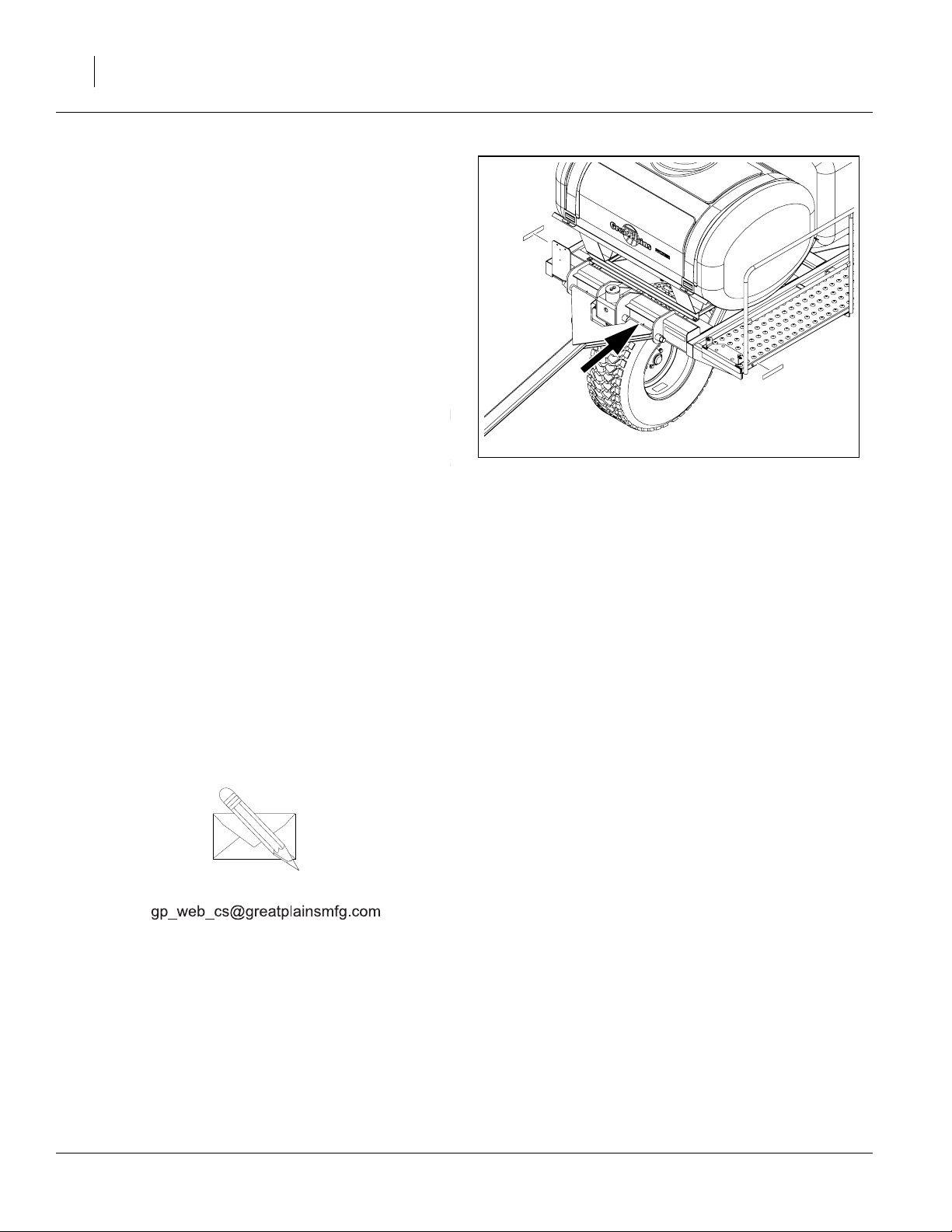

Refer to Figure 1

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts.

Always use the serial and model number when ordering parts from your Great Plains dealer. The serialnumber plate is located on the left end of the seed cart

tool bar, as shown.

Record your PFC1600/2000 Cart model and serial

number here for quick reference:

Model Number:__________________________

Serial Number: __________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part

of this manual or are not satisfied with the service

received, please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems so they can assist you.

Figure 1

Serial Number Plate

26016

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

785-823-3276

407-158M 03/28/2007

Page 13

Preparation and Setup

This section helps you prepare your tractor and

PFC1600/2000 Cart for use, and covers tasks that

need to be done only once per hitch, seasonally, or

when the tractor/cart configuration changes.

Before using the PFC1600/2000 Cart in the field, you

must hitch the cartto a compatible planter.Periodically

thereafter, maintenance is required.

Pre-Setup Checklist

1. Read and understand “Important Safety Information” on page 1.

2. Check that all working parts are moving freely,

bolts are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and lubricated. See “Lubrication” on page 43.

4. Check that all safety decals and reflectors are correctly located and legible. Replace if damaged.

See “Safety Decals” on page 6.

5. Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Tire Inflation

Chart” on page 46.

Preparation and Setup 11

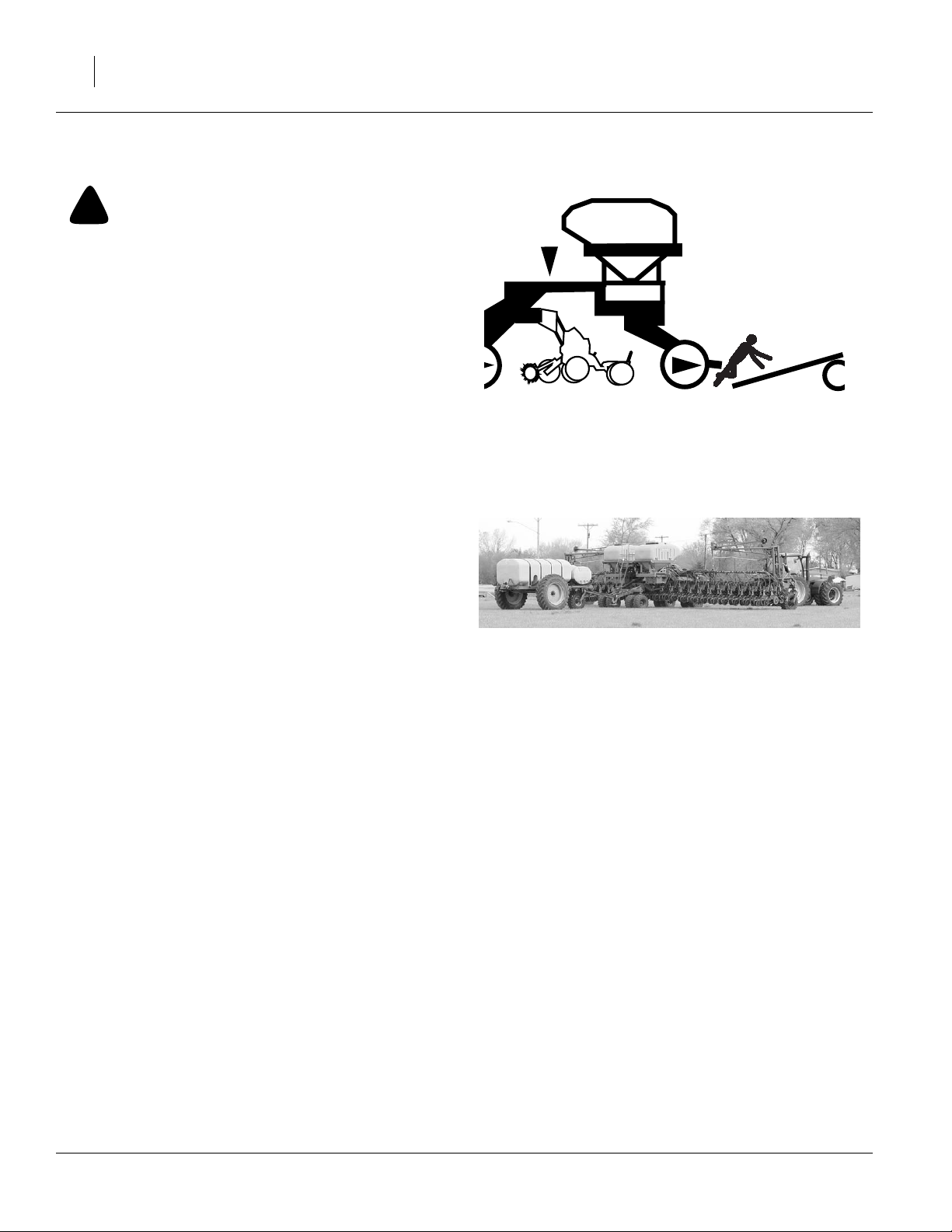

Planter Preparation

The PFC1600/2000 Cartsare designed to be towed, in

train, behind the Great Plains YP2425 planter. The

planter must be ordered with, or upgraded to include:

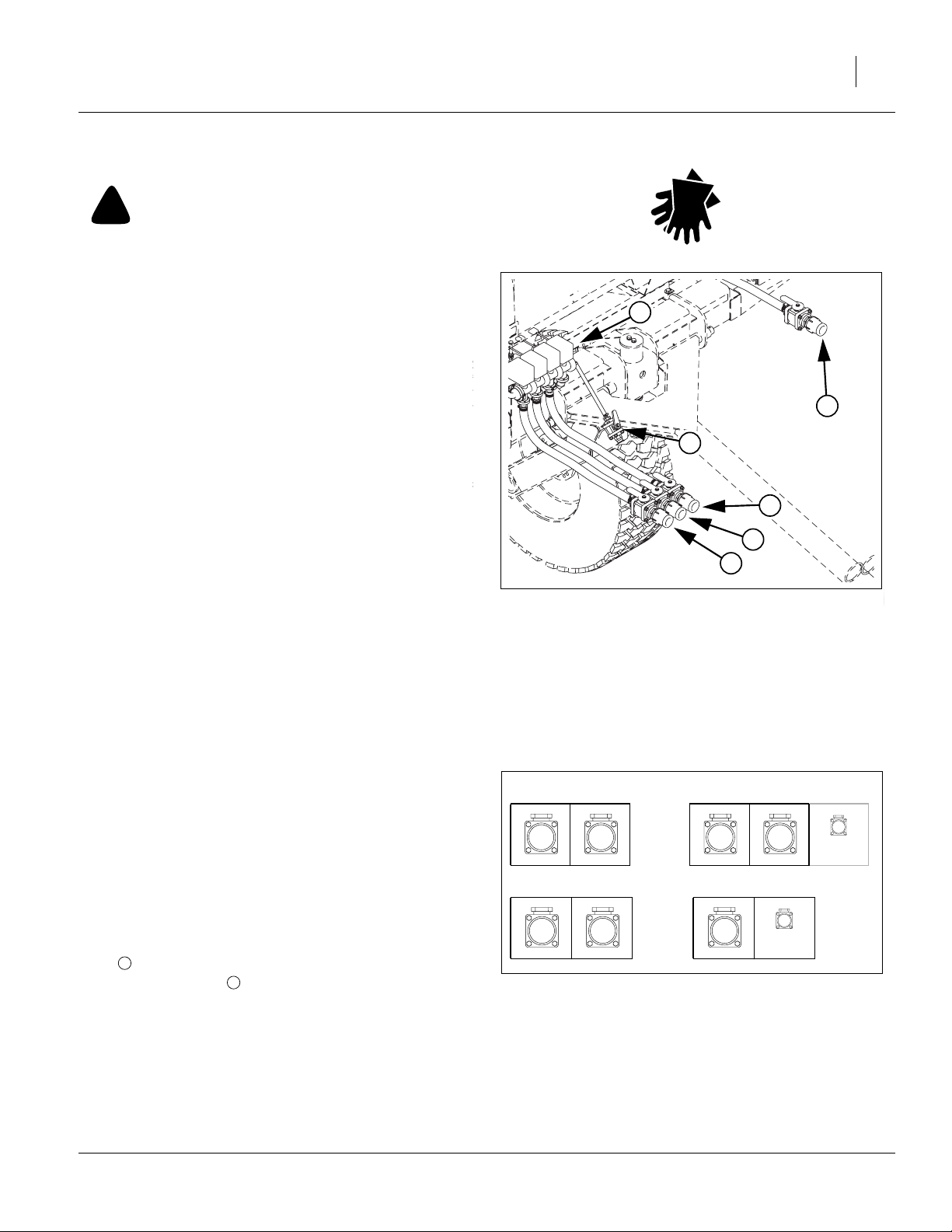

• rear pintle hitch ( in Figure 2), and

• the “Hi-Rate” fertilizer manifold, which includes 3

inlet ports at the back of the planter ( in Figure 2)

and if the PFC2000 tank, intended for dual materials:

• “Starter” manifold system (single inlet), and

• ground drive fertilizer pumps

If the PFC1600/2000 Cart was purchased on the same

order with the YP2425, two cart-supporting cable

assemblies ( in Figure 2) and one pressure gauge

3

line ( in Figure 2) will have been installed on the

planter at the factory. These assemblies extend the

lighting and CANbus circuits to the rear pintle hitch on

the planter, and extend pressure status to the planter.

If the PFC1600/2000 Cart was ordered separately,

these assemblies are supplied in a carton with the

cart, and must be installed on the planter prior to first

cart use. See “Planter Assembly Installation” on

page 50.

1

2

4

2

4

1

Figure 2

YP2425 Cart Hitch & Inlets

2

3

26035

03/28/2007 407-158M

Page 14

12

Hitching Cart to Planter

!

DANGER

Exercise extreme care in hitching.

▲ The rear wheels and rear hitch of the YP2425 planter

move during planter raise/lower operations.

▲ If planter movements are required, it will be difficult for

the tractor operator to see the tank cart hitch and anyone

near it.

▲ If the planter is moved, both tractor operator and hitch

observer must be within sight of each other for prearranged hand signals, or must be in continuous electronic communication.

▲ Hitch only on level ground. The tank cart has no brakes.

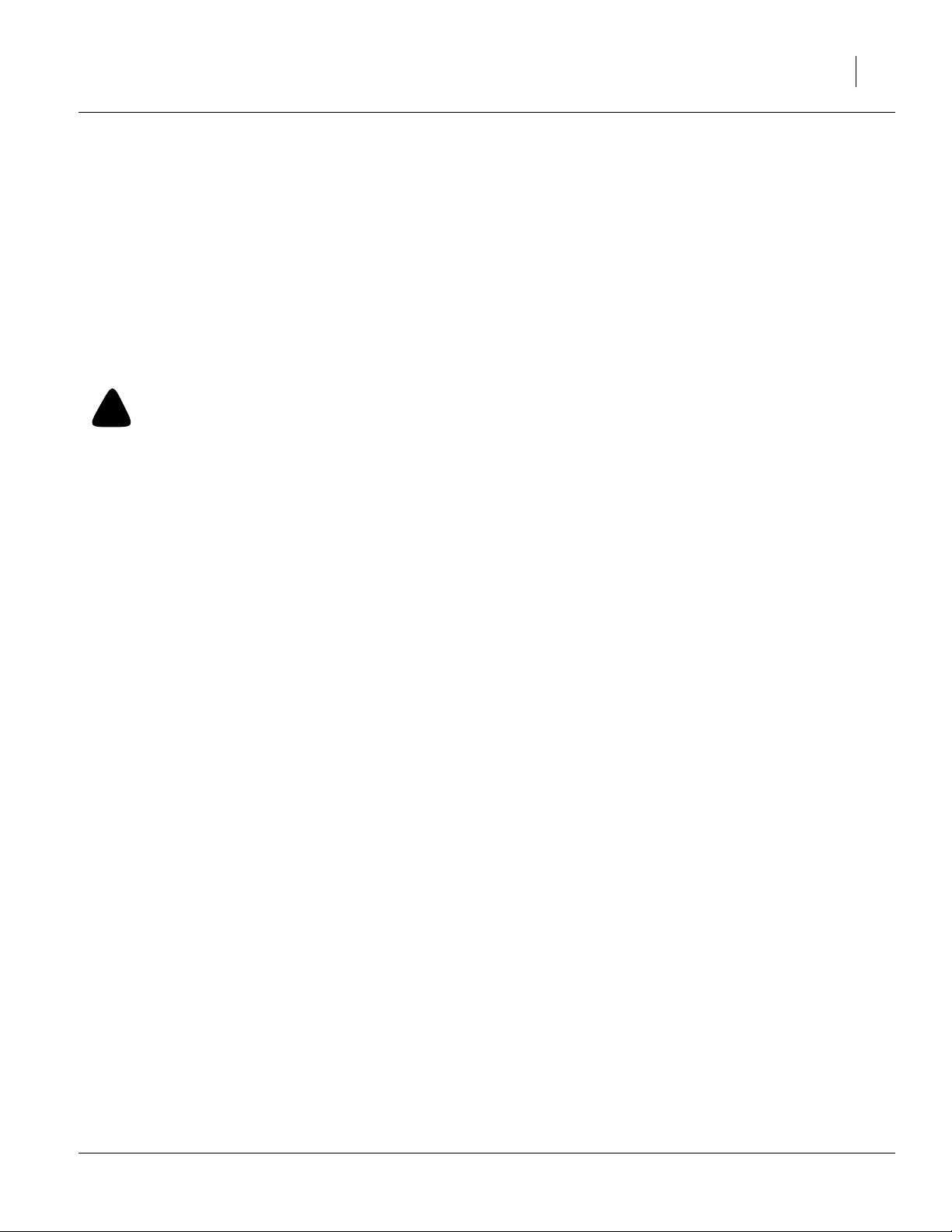

Plan The Hitch

There are some situations to avoid in preparing the

planter/tank for the field:

• Spot the planter so that only forward moves are

required after hitching the cart.Itis difficult to control

reverse steering of the train.

• When the cart is loaded with fertilizer, it generally

cannot be moved by hand safely. If extra power

equipment is not available, plan to hitch the tank

cart by hand-moving the cart when empty.

• When the cart is hitched to the planter, it prevents

fork-lift access to the back of the planter for loading

seed in bulk boxes. The planter can be side-loaded

(when folded), but only if the fork lift is rated for the

long reach required.

• If seed is pre-loaded before planter highway movement, steering and braking hazards increase (as

well as wear on wheel bearings). If fertilizer is also

loaded before highway movement, you will exceed

the control ability of any tractor.

Load fertilizer in the field. If this is not possible, tow the

pre-loaded cart to the field by itself, and not in train

with the planter.

Figure 3

Tank Cart in Train

26049

If using Bulk Boxes

1. Move empty planter and tank cart to field.

2. Load boxed seed on planter.

3. Hitch empty tank cart to planter.

4. Load fertilizer.

407-158M 03/28/2007

If Using Bulk Hoppers

1. Move empty planter and tank cart to field.

2. Install seed hoppers.

3. Load seed with auger.

4. Hitch empty tank cart to planter.

5. Load fertilizer.

Page 15

Hitching With Empty Tank

1. Position planter for forward-only movement after

hitching. Set parking brake on tractor and shut off

tractor. Planter may be raised or lowered.

2. Have two people move the cart to engage the

tongue loop with the pintle hitch.

3. Secure the safety chain around the rear hitch

weldment frame.

4. Remove wheel chocks.

Hitching With Loaded Tank

!

DANGER

Only do this for immediate field operations, and not transport. The planter plus a loaded tank cart is not safe to move

any distance on public roads, even if the tractor is rated for

80,000 pounds.

1. Raise and fold the planter, so that the hitch

observer does not need to stand beyond the

unfolded wing ends. Position planter for forwardonly movement after hitching.

Preparation and Setup 13

2. Picka spot for the hitch point, about six feet behind

the planter’s rear hitch. Place a small object at the

spot.

3. Using another towing implement pull the cart

toward the hitching point at an angle, from the

rear, and to the side of the planter. Stop when the

tongue loop is over the hitching point.

4. Disconnect the cart, lower the tongue loop to the

ground, and swing it back away from the planter.

5. Have the hitch observer stand clear of the planter

and signal to the tractor operator to back the

planter up slowly.

6. Signal stop when the pintle hitch is over the hitching spot.

7. Set the parking brake on the tractor and shut it off.

8. Engage the tongue loop with the pintle hitch.

9. Secure the safety chain around the hitch weldment

frame.

10. Remove wheel chocks.

03/28/2007 407-158M

Page 16

14

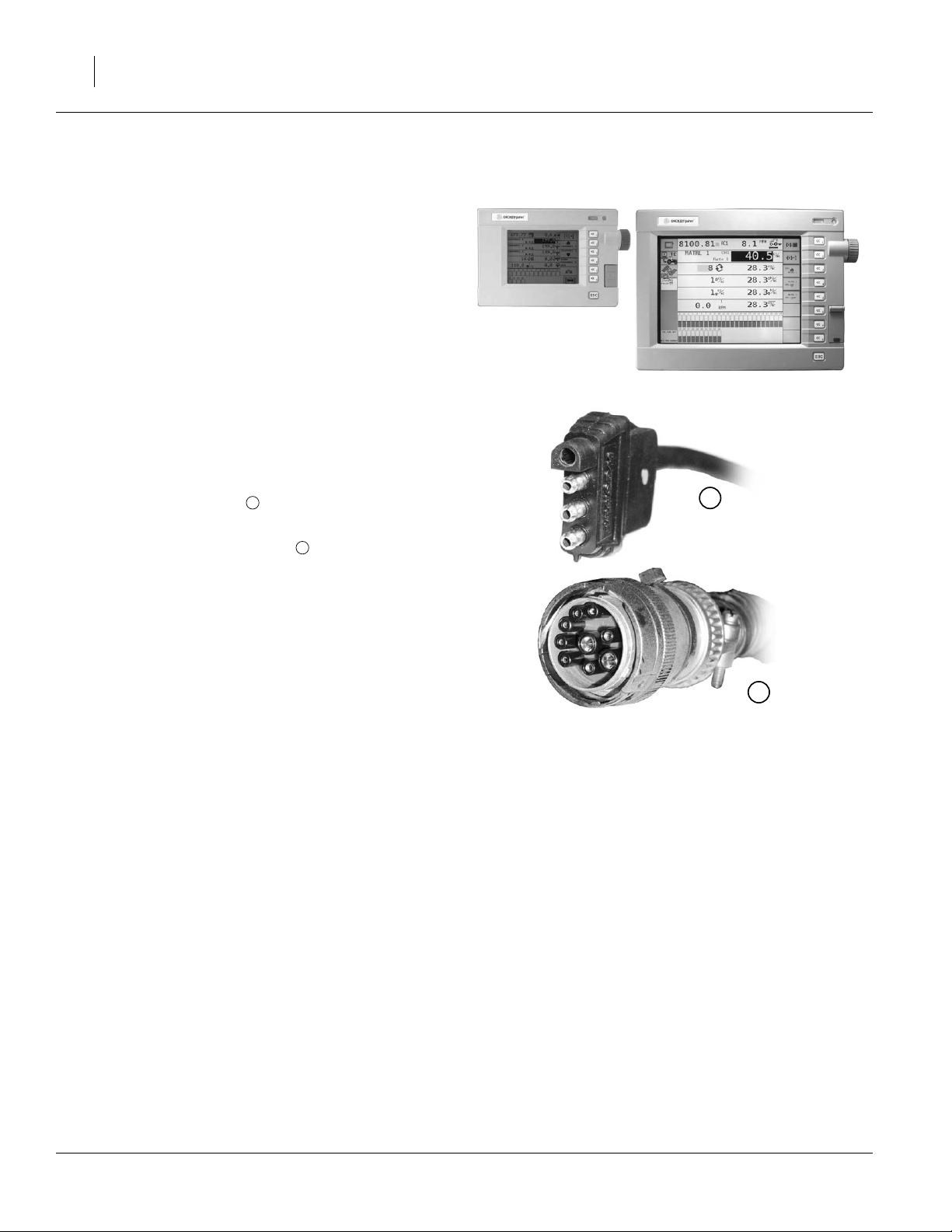

Electrical and Monitor Connections

Monitor Setup

Before using the cart for the first time, it is necessary

to configure the planter seed monitor to correctly process cart signals and correctly control the clutch and

manifold valves.

For the 3-inlet Hi-Rate” manifold, this configuration

includes telling the monitor which row number range is

served by each inlet. If your manifold system has one

drop line per row unit, Clutch Switch Coverage table in

the planter Operator’s Manual shows the row unit numbers for Left/Center/Right.

Making Electrical Connections

Refer to Figure 4

Make sure tractor is shut down with accessory power

off before making connections.

11. Mate the lighting plug to the outlet connector on

the planter.

1

25421

1

12. Mate the pump control cable to the DICKEY-

2

john outlet on the planter.

13. Secure cables so they do not get caught in pintle

hitch. Failure to do so could cause cables to be

crushed, requiring cable replacement, and possible electrical damage to systems.

Figure 4

Connector Identification

2

26144

25237

407-158M 03/28/2007

Page 17

Make Fertilizer Connections

!

CAUTION

Always wear chemical gloves and other protective apparel

and equipment specified for the materials to be applied.

Material hose connections depend on your planter

configuration, cart model, and intended application.

Refer to Figure 5 and to Figure 23 and Figure24 on pages

48 and 49.

Cart Connection Overview

1. Manifold port 1, 2in CAM

This hose supplies the “Hi-Rate” manifold section

on the left side of the planter.

2. Manifold port 2, 2in CAM

This hose supplies the “Hi-Rate” manifold section

in the center section of the planter.

3. Manifold port 3, 2in CAM

This hose supplies the “Hi-Rate” manifold section

on the right side of the planter.

4. Manifold port 4, no hose

By-pass to 1600 gallon tank. Opened by seed

monitor whenever any of ports 1, 2 or 3 are closed.

5. Gauge line,

Supplies pressure gauge on planter

6. 400 Gallon Tank line, 2in CAM

Present only on model PFC2000, supplies single

line to ground drive pumps of “Starter” system on

planter.

3

⁄

in CAM

4

Preparation and Setup 15

4

5

1

2

3

Figure 5

PFC2000 Hose Connections

6

26145

Planter Connection Overview

L. Left Side, 2in CAM receptacle

Hi-rate inlet for planter left wing.

C. Center, 2in CAM receptacle

Hi-rate inlet for planter center section.

R. Right Side, 2in CAM receptacle

Hi-rate inlet for planter right wing.

S. Starter, 2in CAM receptacle

Inlet for entire starterfertilizer manifold. Present as

S

only if starter manifold installed; otherwise

gauge line inlet is mounted at this position.

G. Gauge Line,

Gauge (only) line for tank cartpump.Supplied with

tank cart. May be factory-installed. Tied to other

hoses if no bracket position available.

03/28/2007 407-158M

G

3

⁄

in CAM receptacle

4

Planter has both Starter & Hi-rate Systems

L

Planter has only Hi-rate System

L

C

C

YP2425 Fertilizer Inlets

R

R

Figure 6

S

G

G

26146

Page 18

16

Making Fertilizer Connections

PFC2000 Cart, YP2425 Planter with Starter and Hi-rate Manifolds, & Ground Drive Pumps

Cart Hose

Planter Inlet

1

L

2

C

3

R

5

G

PFC1600 Cart, YP2425 Planter with Hi-rate Manifold only

Cart Hose N/A

Planter Inlet

1

L

2

C

3

R

5

G

26147

26146

1. Wear chemical gloves and protective apparel.

2. Close all shut-off valves on hoses and inlets.

3. Clean any debris from outlets and inlets.

4. Make hose connections as shown in the table

above.

5. Secure any unused hoses as shown in Figure 7.

Fold them back and secure them to the cart

tongue so that the outlet valves point slightly

downward(topreventcollecting the dust thrown up

during normal planter operation).

6. Do not re-open connection valves until ready to

plant, and cart’s pump selector valve has been set

to desired tank.

6

S

Figure 7

26148

Secure Extra Hoses

407-158M 03/28/2007

Page 19

Bleeding Gauge Line

Refer to Figure 8

When operating the tank for the first time air must be

bled from the hose of “Hi-Rate” fertilizer gauge line .

Releasing air from this line makes the gauge reading

more reliable.

1. Open the bleed valve at the magnetic gauge on

the planter wing.

2. Plant and fertilizeuntil fluid is observed exiting the

dump line .

3. Stop planting, close the bleed valve, and resume

planting.

3

2

1

Preparation and Setup 17

2

1

3

Figure 8

Gauge Bleed Valve

26149

03/28/2007 407-158M

Page 20

18

Operating Instructions

This section covers general operating procedures.

Experience, machine familiarity, and the following

information will lead to efficient operation and good

working habits. Always operate farm machinery with

safety in mind.

Pre-Start Checklist

Perform the following steps before transporting the

PFC1600/2000 Cart to the field.

❑ Carefully read “Important Safety Information”on

page 1.

❑ Review the application instructions and Material

Safety Data Sheet (MSDS) for the fertilizer(s).

❑ Review the plumbing location/control diagram for

your tank cart.

❑ Lubricate cartas indicated under “Lubrication”on

page 43.

❑ Check all tires for proper inflation. See “Tire Infla-

tion Chart” on page 46.

❑ Check all bolts, pins, and fasteners. Torque as

shown in “Torque Values Chart” on page 47.

❑ Check cart for worn or damaged parts. Repair or

replace parts before going to the field.

❑ Check tank hoops and straps to be sure they are

tight and tanks are secure.

❑ Check fertilizer hoses, fittings, and valves for

leaks. Repair or replace before going to the field.

❑ Always inspect the tanks before use.

MSDS

Tank Inspection

1. Wear a respirator suitable for the material presently in or previously dispensed from the tank(s).

2. Swing the ladder down from its storage position on

the walkboard.

3. Remove the lid on each tank and inspect for:

- residual fertilizer incompatible with next use

- contaminants

- debris that might clog filters

- trapped animals lost tools, etc.

If it is necessary to flush a tank, or remove debris

too large to flush, see “Tank Cleaning” on

page 42.

4. Re-secure each lid and stow the ladder.

407-158M 03/28/2007

Inspection Access Ladder

Figure 9

26150

Page 21

Transporting the Cart

If heading to the field, before departing, ensure that

fertilizer rate has been determined, or that the necessary data is with you.

Empty, the cart adds 5,900 pounds. If towing in train

with the YP2425 planter, make sure that this does not

exceed the braking capability of the tractor.

If towing in train, plan the move so that no reverse

moves will be required. Direction in reverse cannot be

reliably controlled for distances more than a few feet.

!

DANGER

Never transport the cart, in train, if there is any liquid in the

tanks. Full, the cart weighs nearly 30,000 pounds and

makes the train uncontrollable on roads regardless of tractor capability.

1. Hitch.

Make both electrical and hose connections. See

“Hitching Cart to Planter” on page 12.

Operating Instructions 19

A

2. Set CFM “Fert.Pump” switch off.

3. Always have lights on for highway operation.

4. Comply with all federal, state and local safety laws

when traveling on public roads.

5. Travel with caution.

6. Keep train length in mind when clearing intersections. The YP2425 plus PFC1600/2000 Cart add

nearly 75 feet to the length of your tractor.

!

CAUTION

Do not exceed 20 mph when driving straight.

!

CAUTION

Do not exceed 13 mph in turns.

!

CAUTION

Do not exceed 3 mph in reverse when towing separately.

!

CAUTION

Avoid all reverse moves when towing in train.

03/28/2007 407-158M

Page 22

20

Loading Fertilizer

!

CAUTION

Always wear recommended protective apparel and equipment specified for the materials to be applied.

IMPORTANT !

Use only liquid fertilizer.

This cart is not designed for dry fertilizer mixes.

The PFC1600/2000 Carts are designed to be loaded

using the 2in CAM quick-fill inlet at the left rear of the

cart. If for any reason you cannot use that inlet, you

can also load material via the ladder, walkboard and

top hatches Hatches are threaded and unscrew.

Note: The fitting at ofFigure 10 and Figure 12 is a fil-

ter,and not analternate threaded inlet. Donotremove it during filling.

Have seed loaded in planter, and cart hitched and connected to planter before loading fertilizer.

Determine how to monitor tank fill level. If the day is

bright, or loading at night with a bright light available, it

is possible to see the fluid levelthrough the semi-translucent tank walls. Otherwise, it is necessaryto have an

observer monitor through the tank hatch.

Note: Is it not possible to use the cart pump to load ma-

terial,asitonly pumps when thecart is inmotion.

If the fertilizer source has no pump, the YP2425

planter has auxiliary hydraulic power at the rear

hitch, which may be used to operate a hydraulic

pump.

Be familiar with the location of plumbing valves on the

tank cart. Common task require setting as many as

three valves. See pages 48 and 49.

7

407-158M 03/28/2007

Page 23

Loading 1600 Gallon Tank

Refer to Figure 10

Operating Instructions 21

1. Close quick-fill shutoff valve :

Handle pointing back: no flow at inlet

Handle pointing left: inlet open

2. If cart is model PFC2000, set selector valve to

1600 gallon tank:

Handle forward: quick-fill to 400 gallon tank

Handle down: no flow from quick-fill inlet

Handle back: quick-fill to 1600 gallon tank

Note: This valve is not present (or needed) on tank

model PFC 1600.

Refer to Figure 10 and Figure 11

1. Set the inlet valve of the 1600 gallon tank to the

fill position:

Handle left: tank inlet open to quick-fill

Handle back: no flow to or from tank

Handle right: tank inlet open to cart pump

2. Remove cap at inlet .

3. Connect supply hose to 2in CAM inlet .

4. If monitoring fill level at hatch, swing down walkboard ladder and position observer (in suitable

protective apparel).

8

5 6

3

4

6

6

7

4

3

5

Figure 10

Quick Fill for 1600

26151

8

5. Open quick-fill shutoff valve . Also open any

valve(s) on the supply hose(s).

6. Using an external pump (usually on the fertilizer

supply tank), pump fertilizer to desired level in

tank.

7. Shut off pump when tank is at desired level.

8. Close shut-off valve .

9. Close valve(s) on supply hose(s) and disconnect

fertilizer source.

10. If cart is model PFC2000, set selector valve off.

11. Set the discharge valve of the 1600 gallon tank

to closed (back) or to pump (right), depending on

the next planned task.

3

3

4

8

Figure 11

1600 Gallon Tank Inlet

26165

03/28/2007 407-158M

Page 24

22

Loading 400 Gallon Tank

(Model PFC2000 only)

Refer to Figure 12

1. Close quick-fill shutoff valve :

3

Handle pointing back: no flow at inlet

Handle pointing left: inlet open

2. Set selector valve to 400 gallon tank:

4

Handle forward: quick-fill to 400 gallon tank

Handle down: no flow from quick-fill inlet

Handle back: quick-fill to 1600 gallon tank

Refer to Figure 12 and Figure 13

1. Close the outlet valve of the 400 gallon tank:

2

Handle forward: outlet supplies planter

Handle down: outlet closed / no flow from tank

Handle back: outlet supplies cart pump

2. Set the inlet valve of the 400 gallon tank to the

1

fill position:

Handle down: no flow at tank inlet

Handle forward: tank inlet open to quick-fill

3. Remove cap at inlet .

4. Connect supply hose to 2in CAM quick-fill inlet .

5 6

6

5. If monitoring fill level at hatch, swing down walkboard ladder and position observer (in suitable

protective apparel).

6

7

4

3

5

Figure 12

Quick Fill for 400

26151

6. Open quick-fill shutoff valve . Also open any

3

valve(s) on the supply hose(s).

7. Using an external pump (usually on the fertilizer

supply tank), pump fertilizer to desired level in

tank.

8. Shut off pump when tank is at desired level.

9. Close shut-off valve .

3

10. Close valve(s) on supply hose(s) and disconnect

fertilizer source.

11. Set selector valve off.

12. Set the 400 gallon tank inlet valve to closed

4

1

(handle down).

13. Set the 400 gallon tank outlet valve to planter

2

(forward) or pump (back) depending on next

planned task.

2

Figure 13

400 Gallon Tank Inlet

1

26153

407-158M 03/28/2007

Page 25

Field Pumping

Regardless of the tank(s) and manifolds to be used,

perform the following:

1. Make all pre-use maintenance and safety checks.

2. Determine and make the cart pump dial setting (if

cart pump to be used). See “Pump Setting Deter-

mination” on page 37.

3. Hitch the cart to the planter; make and check all

electrical and plumbing connections.

Refer to Figure 23 on page 48 or Figure 24 on page 49.

4. Load fertilizer in the tank(s) to be used; shut off

and cap the quick-fill inlet . PFC2000 only: Set

quick-fill selector valve to OFF.

5. Configure the seed monitor to apply fertilizer, but

have the “Fert.Pump” switch OFF for the moment.

6. Open the (four or five) hose valves on both sides

(planter/cart) of the connections at the planter rear

hitch.

10

11

Operating Instructions 23

25421

26033

03/28/2007 407-158M

Page 26

24

PFC2000 Pumping From 1600 Only

Configuration:

PFC2000 Tank Cart

YP2425 with 3-inlet “Hi-Rate” Manifold

all 3 inlets and section booms in use on planter

Refer to Figure 23 on page 48

1. Set 400 gallon inlet and outlet valves to

13 14

OFF.

2. Set valve at 1600 gallon tank discharge to feed

12

pump.

3. Set pump inlet selector valve to 1600 tank.

15

4. Set CFM “Fert.Pump” switch to ON and begin

planting.

The ground drive pump on the cart will pump fertilizer

to all three planter manifold sections when planter is

lowered and cart is in motion, unless commanded off

by the seed monitor or CFM “Fert.Pump” switch.

PFC2000 Point Row Pumping from 1600

If it is necessary to disable fertilizerapplication for one

or two planter sections, such as for point rows, use the

Clutch Folding Module switches.When you disable the

clutches for any seed meters, the monitor also closes

the manifold valve for that planter section. This provides automatic fertilizer control for point rows.

Whenever one or two of the cart manifold valves (#1,

2, 3) are closed, the bypass valve (#4) is open. This

prevents over-pressure in the planter manifolds. The

bypass line is connected to the cart pump inlet

16

when pumping from the 1600 gallon tank.The bypass

is also connected to the tank discharge line.

407-158M 03/28/2007

Page 27

PFC1600 Pumping

Configuration:

YP2425 with 3-inlet “Hi-Rate” Manifold

PFC1600 Tank Cart

Refer to Figure 24 on page 49

Operating Instructions 25

1. Set valve at 1600 gallon tank discharge to feed

12

pump.

2. Set CFM “Fert.Pump” switch to ON and begin

planting.

The ground drive pump on the cart will pump fertilizer

to all three planter manifold sections when planter is

lowered and cart is in motion, unless commanded off

by the seed monitor or CFM “Fert.Pump” switch.

PFC1600 Point Row Pumping from 1600

If it is necessary to disable fertilizerapplication for one

or two planter sections, such as for point rows, use the

Clutch Folding Module switches.When you disable the

clutches for any seed meters, the monitor also closes

the manifold valve for that planter section. This provides automatic fertilizer control for point rows.

Whenever one or two of the cart manifold valves (#1,

2, 3) are closed, the bypass valve (#4) is open. This

prevents over-pressure in the planter manifolds. The

bypass line is connected to the cart pump inlet at

16

all times when pumping from the 1600 gallon tank

12

(valve set to pump). The bypass is also connected

to the tank discharge line.

03/28/2007 407-158M

Page 28

26

Pumping From 400 only

In the normal mode, the 400 gallon tank is pumped by

the ground-drive pumps on the planter, and is pumped

to the single-inlet “Starter” manifold system.

In a reserve-tank or small-application scenario, the

400 gallon tank may be pumped by the cart. It will

pump to the “Hi-rate” 3-inlet manifold system.

Is it not possible to pump to the same planter manifold

from both tanks simultaneously. The pump inlet selector valve is open to only one tank at a time, and there

is no tank cross-feed line.

Pumping 400 (Only) With Planter Pumps

Configuration:

PFC2000 Tank Cart

YP2425 with single-inlet “Starter” Manifold

Tank hose line #6 is connected to planter “Starter”

inlet.

Refer to Figure 23 on page 48

1. Set 1600 gallon discharge valve to OFF

12

(unless applying two materials, in which case see

page 29).

2. Set 400 gallon inlet valve OFF

3. Set pump inlet selector valve OFF

4. Set 400 gallon outlet valve at to feed hose line

13

15

14

#6

5. Set CFM “Fert.Pump” switch OFF and begin planting.

IMPORTANT !

Steps must be taken to prevent the cart’s ground

drive clutch from engaging. If you fail to at least set

the CFM switch OFF, the cart pump may run against

closed valves, collapse or burst hoses/lines, run dry

and itself be damaged.

Alternatives to the “Fert.Pump” switch include setting

seed monitor “Hi-Rate” material liquid channels OFF.

(leave the Starter channel ON), setting 1600 gallon

tank quantity to zero, or disconnecting monitor cable

to cart.

The ground drive pumps on the planter will pump fertilizer to the entire planter “Starter” manifold when

planter is lowered and cart is in motion.

407-158M 03/28/2007

Page 29

Point Row Pumping with Planter Pumps

The planter ground drive pumps operate whenever the

planter is lowered and moving. The CFM “Fert.Pump”

switch has no effect on these pumps. There are also

no shutoff valves in the lines.

You can disable either half of the “Starter” system by

removing a chain or sprocket. This may not be practical on frequent point row turns.

Pumping 400 With Cart Pump

Although optimized for two-material application

through the single-inlet “Starter” manifold on the

planter, the 400 gallon tank can also be used to feed

the 3-inlet “Hi-Rate” manifold.

This might be done using the 400 gallon tank as a

reserve, or because the task requires less than 400

gallons.

Configuration:

PFC2000 Tank Cart

YP2425 with 3-inlet “Hi-Rate” Manifold

Note: Do not use cart pump to supply the single-inlet

“Starter” manifold.

This is the “reserve” or small job situation, using the

small tank to supply the “Hi-Rate” boom. If you are

relying on quantity-remaining/low-alerts on the seed

monitor, be sure to enter the correct initial tank quantity.

Refer to Figure 23 on page 48

Operating Instructions 27

1. If the planter has a “Starter” manifold, with wingmounted ground-drive pumps, disable those

pumps. Tie up the wheel arms or remove chains.

2. Set 1600 gallon discharge valve to OFF.

3. Set 400 gallon inlet valve OFF.

13

4. Set 400 gallon outlet valve at to feed pump.

5. Set pump inlet selector valve to 400 tank.

12

14

15

6. Set CFM “Fert.Pump” switch to ON and begin

planting.

The ground drive pump on the cart will pump fertilizer

to all three planter manifold sections when planter is

lowered and cart is in motion, unless commanded off

by the seed monitor or CFM “Fert.Pump” switch.

03/28/2007 407-158M

Page 30

28

Point Row Pumping from 400 via Cart

!

CAUTION

It must be acceptable for modest quantities of the material

in the 400 gallon tank to be bypassed into the 1600 gallon

tank. If this is not the case, do not disable, or let the seed

monitor disable, any of feed lines 1, 2 or 3.

If it is necessary to disable fertilizerapplication for one

or two planter sections, such as for point rows, use the

Clutch Folding Module switches.When you disable the

clutches for any seed meters, the monitor also closes

the manifold valve for that planter section. This provides automatic fertilizer control for point rows.

Note: Also use the following valve settings to ensure

bypass protection for the cart pump.

1. Set 1600 gallon discharge valve to pump.

2. Set 400 gallon inlet valve OFF.

3. Set 400 gallon outlet valve at to feed pump.

4. Set pump inlet selector valve to 400 tank.

5. Set CFM “Fert.Pump” switch to ON and begin

planting.

Whenever one or two of the cart manifold valves (#1,

2, 3) are closed, the bypass valve (#4) is open. This

prevents over-pressure in the planter manifolds.

Excess material is pumped into the 1600 gallon tank.

If the 400 gallon tank is emptied before the task is

complete, switch back to 1600 gallon mode and use

the bypassed material.

13

12

14

15

407-158M 03/28/2007

Page 31

Pumping From Both Tanks

Configuration:

PFC2000 Tank Cart

YP2425 with 3-inlet “Hi-Rate” Manifold and

single-inlet “Starter” manifold.

This situation presumes that twodifferentmaterials are

being applied at the same time. The 3-inlet “Hi-rate”

boom is pumped by the cart pump. The single-inlet

“Starter” boom is pumped by the planter’sground drive

pumps.

Refer to Figure 23 on page 48

Operating Instructions 29

1. Set 400 gallon tank inlet valve to OFF.

2. Set 400 gallon tank outlet valve to hose line #6

13

14

(forward hose).

3. Set1600 gallon tank discharge valve to feed

12

pump.

4. Set pump inlet selector valve to 1600 tank.

15

5. Set CFM “Fert.Pump” switch to ON and begin

planting.

The ground drive pump on the cart pumps fertilizer to

all three “Hi-Rate” planter manifold sections when

planter is lowered and cart is in motion, unless commanded off by the seed monitor, CFM point row clutch

switches or CFM “Fert.Pump” switch.

Point Row Pumping From 1600

in Both Mode

If it is necessary to disable fertilizerapplication for one

or two planter sections, such as for point rows, use the

Clutch Folding Module switches.When you disable the

clutches for any seed meters, the monitor also closes

the manifold valve for that planter section. This provides automatic fertilizer control for point rows.

Whenever one or two of the cart manifold valves (#1,

2, 3) are closed, the bypass valve (#4) is open. This

prevents over-pressure in the pump line. The bypass

line (16) is connected to the cart pump inlet when

pumping from the 1600 gallon tank.The bypass is also

connected to the tank discharge line.

Point Row Pumping From 400

in Both Mode

The planter ground drive pumps operate whenever the

planter is lowered and moving. The CFM “Fert.Pump”

switch has no effect on these pumps. There are also

no shutoff valves in the lines.

You can disable either half of the “Starter” system by

removing a chain or sprocket.

03/28/2007 407-158M

Page 32

30

Field Set-Up Checklist

Use the following tables to develop a final checklist for

your tractor/cart configuration. Additional or fewer steps

may be necessary depending on tractor features, cart

options and planting accessories.

Table 1: Mechanical

Pintle hitch closed on tongue loop 13

Chain secured to planter hitch 13

Tank hoops and straps tight. Tanks

secure.

Parking chocks removed from wheels Walkboard ladder stowed 18

Table 2: Electrical

Verify electrical hookups solid 14

Power up seed monitor and observe

any diagnostic messages

Running/braking/turning lamps all work-

ing

*. Refer to monitor manual.

Table 3: Plumbing

Hose circuits to be used, secured to

correct planter inlets

Unused hoses secured on tongue and

protected from dust/debris

Closed: Quick-fill shut-off valve 21, 22

Open: Outlet/discharge valve on tank to

be used

PFC2000: pump selector valve set to

tank to be used

Open: valve(s) on hose lines to planter 23

Open: valve(s) on planter inlet(s) 23

Fertilizer rate setting computed and set

on pump

Check for leaks at all fittings and con-

nections, and under tanks generally

Page

Page

Page

16

16

23

23

Table 4: Fertilizer

Check for correct orifice plates

Check unused rows correctly closed off -

-

*

-

Check all row unit lines are connected,

free of kinks, and discharge tube/nozzles are clear

*. Check Seed Rate manual.

Gauge Wheel Cart Drive

Check gauge wheel inflation and tread

condition

Check all chains for lubrication and

proper slack

Check clutch operation 31

Page

*

-

Page

46

43

Field Operation

Because tank cart operation is largely automatic, few

steps need to added to planter operations. Tank operations during planter motion are covered in the YP2425

Operator’s Manual.

-

-

407-158M 03/28/2007

Page 33

Planting

When all checklist items are complete, tank operation

during a planting pass normally is automatic and

requires no operator intervention to control pumps.

Lowering and raising the planter automatically

engages and disengages the ground drive pumps on

the planter.

Lowering and raising the planter operates a height

switch on the planter that signals the seed monitor to

engage and disengage the pump clutch on the cart.

All pumps stop when planter motion stops.

The cart pump (only) may be disengaged under the

control of the seed monitor, either by CFM switches,or

commanding channels off.

See “Field Pumping” on page 23 for details on using

various tank configurations.

Planting at speeds recommended for the seed also

results in reliable pumping rates.

When reloading seed, check fertilizer consumption

against anticipated use to that point.

Operating Instructions 31

Figure 14

Planting

26154

Electric Clutch Operation

The PFC1600/2000 Cart has a clutch in the pump

drive system. In normal operation, the planter’s seed

monitor system controls the clutch. When the planter is

lowered for planting, the clutch is engaged.

Refer to Figure 15

The “Fert.Pump” switch on the cab Clutch Folding

Module (CFM) can independently disable the cart

clutch.

Note: This does not shut off any wing-mounted ground

drivepumps (whichhavenoclutches).Todisable

one or both ground drive pumps, remove a

sprocket or tie-up the drive wheel arm. Do not

merely close valves.

In the normal (up) position, the clutch is controlled by

the seed monitor. The LED above the switch is on only

when the switch is up AND the seed monitor has

engaged the pump clutch.

In the off (down) position, the clutch is off at all times.

There is no standard provision to force the clutch on

when the seed monitor would have it off. There is a

mechanical lock-up capability at the clutch housing,

described in the following section.

1

1

Figure 15

CFM: Clutch Switch

26119

03/28/2007 407-158M

Page 34

32

Electric Clutch Lock-Up

Refer to Figure 16 and Figure 17

During system flushing/winterizing, or in case of electric clutch failure, the electric clutch can be mechanically engaged. If metric bolts required cannot be

located, borrow three from storage locations near the

clutches on the YP2425 planter.

2

3

1. Align the cutouts with the holes .

2. Insert M8-1.25×14mm long metric bolts .

If you observehalf the hole obstructed by a metal disc

4

, you are not at a cutout.

If the entire hole is obstructed by a metal disc , you

are not at a cutout.

When at a cutout, the bolt will screw in with minimal

resistance until the bolt head reaches the clutch face.

Note: Use only 14mm length bolts. Longer bolts will

damagethe clutch. Shorter bolts maynot effecta

lock-up.

Clutch lock-up for field operations introduces risks of

spill and/or equipment damage. With the clutch

locked-up, perform:

no highway movements,

no reverse movements,

no movements with planter hitched but seed

monitor off (valves will close),

no movements unhitched from the planter

unless gauge line is open, and

no empty-tank (dry pump) movements.

In lock-up, the pump will be operating whenever the

main cart wheels are turning.

1 2

3

4

IMPORTANT !

2

Figure 16

Electric Clutch Lockup

4

1

Figure 17

Clutch Plate Nearly at Cutout

22906

2

26168

407-158M 03/28/2007

Page 35

Parking and Storage

Residual fertilizer in the cart represents a corrosion

and freezing risk to planter components. The pump is

further at riskfrom exposure to air if run dry,or drained

and not properly prepared for storage (even for just a

few days).

This section repeats some cautions and steps from the

pump manual supplied with the cart. This is not a substitute for that material. Read and follow the instructions in the pump manual.

IMPORTANT !

Failure to properly care for your pump and other cart

components can lead to serious equipment damage

in a relatively short span of time.

Stopping/Standing

If suspending operation, but leaving the cart hitched to

the planter, no specific items require attention.

Operating Instructions 33

Short-Term Parking

If parking the cart, for less than 24 hours, unhitched

from the planter:

1. Choose a location with level firm ground. Do not

unhitch on a slope.

2. Close valves on both sides of the hose connections. There may be fertilizerunder pressure in the

lines, particularly the gauge line.

3. Wear chemical gloves and face protection. Disconnect the hoses, and tie them off the ground at the

cart.

4. Disconnect the electrical connections.

5. Tighten tanks lids.

6. Remove the cart’s safety chain from the planter

and open the pintle hitch.

7. Pull the tongue to the side and lower it to the

ground.

03/28/2007 407-158M

Page 36

34

Extended Parking

When parking for more than 24 hours, residual fertilizer must be flushed from the pump, otherwise salts in

the fertilizer will corrode the pump. In general, this

means that residual fertilizer in the tank(s) first needs

to be recovered or drained.

Operating the pump without the planter requires clutch

lockup. See “Electric Clutch Lock-Up” on page 32.

The cart may be towed for this pumping, or the right

wheel may be raised on a stable jack-stand, and the

right wheel turned by hand.

8. First perform step 1 through step 7 of “Short-Term

Parking” on page 33, but position the cart at a

location where residual fertilizer may be safely

recovered or drained from the tanks and lines.

Drain Bulk Material

If a modest or substantial quantity of fertilizer remains

in either tank, drain it via quick-fill inlet.

9. Connect a hose to the inlet, or place a large container there. Make sure the inlet shut-off valve is

closed.

10. Open the shut-off valve at the inlet to the tank to

be drained.

11. On the PFC2000, set the fill selector valve to the

tank to be drained.

12. Slowly open the quick-fill inlet shut-off valve, and

drain until flow ceases.

13. On the PFC2000, repeat for the other tank.

Drain Lines

Evenafter tank drain-back, severalgallons of materials

are likely to be present in the hoses, and trapped

between valves in the various circuits. A low bucket is

needed for thorough gravity draining of hose lines.

14. Loosen the flange clamp at the outlet of each manifold valve (#1, 2 & 3), to admit air.

15. Place the bucket or collection pan under each forward hose. Slowly open the connector valve to

fully open and drain the line. If any part of the hose

line is lower than the connector, lift the hose moving from back to front, to drain the line. Close the

valve. Repeat for each 2in hose.

16. Repeat step 15 for the 3/4in gauge line. This will

not fully drain this line, as it is open through the

manifold and back to the pump. It will be further

flushed with the pump.

407-158M 03/28/2007

Page 37

17. Set the collection pan or bucket on a raised platform/stool just below the drain line at each tank

inlet. Loosen the flange clamp on the drain cap,

and drain the lines at that area. Operate adjacent

valves to drain any fluid in nearby lines.

18. Set the collection pan or bucket on a raised platform/stool just below manifold valve #4 (the recirculation line). Remove the flange clamp

connecting the recirculation line to the manifold,

and drain the line. Operate valves at the 1600 gallon tank discharge line to introduce air and further

drain that line.

19. Close all valves and re-tighten the flange clamps

at the drains. Fill the tanks with several gallons of

clean water. Using waste water containers, repeat

step 9 through step 18.

20. Hitch the cart to a tractor, and lock-up the cart’s

electric clutch. See “Electric Clutch Lock-Up” on

page 32. Adjust the cart pump to setting 10.

21. Close all valves. Refill the tanks with about twice

as much water as for the previous flushing.

22. Fully open the hose valve on the gauge line. This

line is open through the manifold back to the

pump.

Operating Instructions 35

23. On the PFC2000, set the pump selector valve for

the 1600 gallon tank.

24. At the 1600 gallon tank, set the discharge selector

valve to the pump line.

25. Pull the cart with the tug until most (but not all) of

the water has been pumped from the tank.

26. On PFC2000, set the pump selector valve for the

400 gallon tank. At the 400 gallon tank, set the

outlet selector valve to the pump line.

27. Pull the cart with the tug until most (but not all) of

the water has been pumped from the tank.

28. Remove the bolts from the clutch.

03/28/2007 407-158M

Page 38

36

Seasonal Storage

Do not leave water, even clean water, in the pump for

extended periods. Do not leave water in the lines if

freezing is possible prior to next tank use. Replace the

water with RV antifreeze.

29. Perform step 8 through step 20.

30. Perform step 21 through step 28, substituting RV

antifreeze for water in this second flushing.

Note: If freezing is imminent, and performing an anti-

freeze flush is not possible in time, remove the

pump from the cart and store it in a warm location. Use two people. The pump is heavy.

31. Consider loosening the flange clamps at the tank

drains and leaving them that way in storage. be

sure to tag them for tightening at next use. By leaving the clamps loose, any fluid collecting in the

tank will drain off rather than become a freezing,

contamination or safety hazard.

Fluid build-up can occur from condensation, or

from rain if a tank lid is left askew.

32. Clean cart of mud, dirt, excess oil and grease.

33. Park cart in an area where children do not play.

Chock wheels. Tighten tank lids.

407-158M 03/28/2007

Page 39

Adjustments

The PFC1600/2000 Cart itself has two adjustments:

1. The setting on the pump ( in Figure 18). This

setting controls the stroke length of the piston, and

the flow rate through the valve.

2. Strainer mesh screen sizes.

There are several adjustments on the planter that

affect fertilizer application:

• orifice selection

• ground drive pump sprockets

• relief valve setting

The planter adjustments are described in the planter’s

Seed Rate charts and Operator’s Manual.

1

Adjustments 37

1

Figure 18

Cart Ground Drive Pump

26155

Pump Setting Determination

1. Using the application recommendations for the fertilizer, and knowledge of local conditions, choose

the desired material application rate in gallons per

acre.

Refer to Figure 19

2. On the pump slide chart , set the top sliding

scale to the Loaded Radius and Sprocket Ratio

values shown in the table at right.

3. Note the Maximum Ground Speed.

4. On the bottom scale, set the Swath Width at the

line through diamond indicator below Ground

Speed.

5. On the lower NGP-7055 scale, find the desired

gallons per acre.

6. Above the gallons per acre rate, read the Pump

Setting.

The pump setting dial scale is in arbitrary units. The

setting controls volume per pump revolution. The slide

chart is required because the relationship is not linear.

The slide chart is not specific to the PFC1600/2000

Cart. The information at right is needed to use the

chart.

Note: The pump slide chart does not anticipate the ac-

tual 172/18 ratio and 33.6in loaded radius of the

PFC1600/2000 Cart. The sprocket pairing and

loaded radius values shown at right have been

mutually adjusted to within scale range so that

the chart calculates correct results.

1

1

4

3

6

5

Figure 19

Cart Pump Slide Chart

For Slide Chart Scale Use Value

SPROCKET RATIO 5/1

LOADED RADIUS 14

SWATH WIDTH

YP2425-2430 (24 row 30in) 720in

YP2425-3620 (36 row 20in) 720in

YP2425-4715 (47 row 15in) 705in

YP2425-48TR (48 row 30in) 720in

26156

2

03/28/2007 407-158M

Page 40

38

Liquid Fertilizer Strainers

The PFC1600/2000 Cart system includes two strainers; one at the quick-fill inlet, and one at the pump outlet.

You need to check that the pump screen is an appropriate size for the orifice plates you plan to use.

Pump Strainer

Refer to Figure 20

The pump strainer was delivered with an 80 mesh

screen . Other screen sizes are availablefrom Banjo

Corporation.

1

!

DANGER

Wear protective gloves when changing screens.

If changing screen sizes, keep in mind the following:

• Generally, select a mesh screen the same or slightly

smaller than the orifice size.

• A substantially smaller mesh (e.g. 100) will reduce

manifold orifice plates plugging so often, but the

strainer screen will have to be cleaned more often.

• A much larger mesh (e.g. 50 or 30) will pass more

material but should only be considered when using

large manifold orifice plates.

• A plugged or partially plugged screen will result in a

reduced application rate. It may also result in backpressure at the pump, and possible seal damage.

• Mesh sizes: (Smallest) 100, 80, 50, 30 (Largest)

Quick-Fill Strainer

Refer to Figure 21

The inlet strainer was delivered with a 12 mesh screen

2

. In general, it is not necessary to replace the screen

with a different size. If the screen becomes clogged

and cannot be cleaned, replace it with another 12

mesh.

Figure 20

Pump Strainer

1

18418

2

!

DANGER

Wear protective gloves when changing screens.

If changing screen sizes, keep in mind the following:

• Using a substantially smaller mesh may slow tank

filling.

• Using a larger mesh increases the risk of clogging

the pump strainer.

407-158M 03/28/2007

Figure 21

Quick-Fill Strainer

21808

Page 41

Troubleshooting

General Troubleshooting

Problem Cause Solution

No Flow

(Pump Lines 1, 2 or 3)

and Gauge Reads zero

Closed Valve(s)

Disconnected control cable or seed

monitor not configured

“Fert.Pump” switch off Turn switch on (up).

Seed monitor not configured to deliver

fertilizer.

Tank empty Refill tank

Failed electric clutch

Tank contents have gelled, coagulated

or frozen

Failed/stuck manifold valve Repair or replace valve.

Broken drive chain Repair or replace chain

Failed pump See pump manual

Troubleshooting 39

Check planter inlet, cart hose outlet,

tank discharge/outlet, pump inlet selector (PFC2000 only)

Check control cable. Use seed monitor

menus to confirm that cart clutch and

manifold valves are detected and configured.

Review menus.

If planting cannot wait for repairs, lockup clutch until it can be repaired or

replaced.

If warming does not improve flow, drain

tank(s) and refill.

No Flow

(400 Gallon line 6)

No Pressure Reading

or Erratic Reading

(Pump Line)

Closed valve(s)

Tank empty Refill tank

Tank contents have gelled, coagulated

or frozen

Closed valve(s)

Gauge is correct Review “No Flow” troubleshooting items

Air in line can cause erratic reading.

Failed gauge Replace gauge

Tank contents have gelled, coagulated

or frozen

Check planter gauge line inlet, cart hose

outlet, and tank outlet selector

If warming does not improve flow, drain

tank(s) and refill.

Check planter gauge line inlet, cart hose

outlet

Loosen fitting at gauge and plant until

fertilizer emerges there.

If warming does not improve flow, drain

tank(s) and refill.

03/28/2007 407-158M

Page 42

40

Problem Cause Solution

Flow Too Low

(Pump Lines 1, 2 or 3)

Incorrect pump setting

Tire under-inflated Check tire pressure.

Clogged strainer Close valves. Inspect and flush strainer.

Orifice size too small

Valve not fully open

Ground drive wheel slipping

Bypass line #4 open when it should not

be (if hoses 1, 2 & 3 are in active use,

bypass #4 should be closed).

Tank contents have gelled, coagulated

or frozen

Pump wearing See pump manual.

System leaks result in insufficient flow to

row units

Review desired application rate, and rerun calculation with slide chart.

Reviewrecommended size in Seed Rate

manual.

Check same valves as for “No Flow”.

Open valve.

If tires are correctly inflated, wait for

improved field conditions. If that is not

an option, and slippage is constant,

adjust pump setting to compensate.

Repair or replace valve.

If warming does not improve flow, drain

tank(s) and refill.

Inspect tank and hose paths to row

units. Tighten or repair any leaks.

Flow Too High

(Pump Lines 1, 2 or 3)

Flow Too Low

(400 gal Line 6)

Flow Too High

(400 gal Line 6)

Incorrect pump setting

Orifice size too large

Incorrect ground drive setting on planter

Orifice size too small

Relief valve set too low. Material is flow-

ing, but out dump line.

Valve not fully open

Tank contents have gelled, coagulated

or frozen

Incorrect ground drive setting on planter

Orifice size too large

Review desired application rate, and rerun calculation with slide chart.

Reviewrecommended size in Seed Rate

manual.

Review recommended sprockets in

Seed Rate manual.

Reviewrecommended size in Seed Rate

manual.

Re-adjust relief valve. See planter seed

rate manual.

Check same valves as for “No Flow”.

Open valve.

If warming does not improve flow, drain

tank(s) and refill.

Review recommended sprockets in

Seed Rate manual.

Reviewrecommended size in Seed Rate

manual.

407-158M 03/28/2007

Page 43

Maintenance and Lubrication

Maintenance

Proper servicing and maintenance is the key to long

implement life. With careful and systematic inspection,

you can avoid costly maintenance, downtime, and

repair.

!

CAUTION

The line from the pump outlet, through the pump strainer,

manifold through gauge line #5 to gauge on the planter may

be pressurized even when not pumping. Open any connections on this line slowly to avoid spraying.

Always turn off and remove the tractor key before making any adjustments or performing any maintenance

when hitched.

1. After using your cart for several hours, check all

bolts to be sure they are tight.

Maintenance and Lubrication 41

OFF

2. Remove excess slack from chain. Clean and use

chain lube on all roller chains as needed.

3. Maintain proper air pressure in cart tires.

4. Clean cart on a regular basis. Regular and thorough cleaning will lengthen equipment life and

reduce maintenance and repair.

5. Lubricate areas listed under “Lubrication” on

page 93.

6. Replace any worn, damaged, or illegible safety

labels by obtaining new labels from your Great

Plains dealer.

03/28/2007 407-158M

Page 44

42

Fertilizer Plumbing Maintenance

Depending on the time before next use, and the

weather possible during that period, follow the steps

beginning at “Parking and Storage” on page 33.

Tank Cleaning

1. Wearprotectiveapparel, including footwear,as the

ground under the cart will get damp.

2. Perform the steps at “Parking and Storage” on

page 33.

3. Remove the drain caps from all tanks.

4. On the 1600 gallon tank, set the tank discharge

valve to select the pump side.

5. Open the tank lids and rinse the inside of each

tank with a strong stream of water from a hose.

6. Re-attach the drain caps, but leave them loose to

permit drainage of residual moisture, and any that

may collect. Tag the caps for tightening at next

tank use.

7. Add a fewcups of anti-freeze to each tank. Most of

it will drain out, but what remains will protect any

hoses or fittings that did not otherwise drain.

8. Secure the tank lids.

Strainer Maintenance

!

WARNING

Some chemicals will cause serious burns, lung damage, and

death. Avoid contact with skin or eyes. Wear proper protective equipment as requiredby chemical manufacturer. Avoid

prolonged breathing of chemical fumes. Wear respirator as

required by chemical manufacturer. Seek medical assistance

immediately if accident occurs. Know what to do in case of

an accident.

Refer to Figure 22

There are two strainers, of different types, on the cart.

Once is at the quick-fill inlet, and the other at the pump

outlet.

1. Shut off valves on both sides of strainer.