Great Plains PD8070 User Manual

Great Plains Mfg., Inc.

Update Kit

PD8070 Planters

Used with:

• Model year 2006 and earlier PD8070 planters

General Information

These instructions explain how to install the Update Kit.

This upgrade includes several components that improve

the precision and reliability of seed delivery:

• Ground drive rate sensor

• Enhanced seed tube

• Solid row unit chain idlers

These instructions apply to:

Option Package Part Number

PD8070 UPDATE KIT 402-234A

Installation Instructions 1

Before You Start

Each kit converts one planter.

For each kit, inventory the contents per the “Parts Lists”

on page 9.

Review the instructions, to make sure the steps are

understood and what tools are expected.

Have the following items at hand:

• the tractor with the DICKEY-john seed monitor for this

planter

• 401-266M Operator’s Manual for PD8070

• 401-266P Parts Manual for PD8070

• basic hand tools, including drill and drill bits.

• sheet metal cutting tool

If necessary, move the planter to a dry well-lighted location suitable for disassembly.

1. Raise the planter and install lift cylinder locks

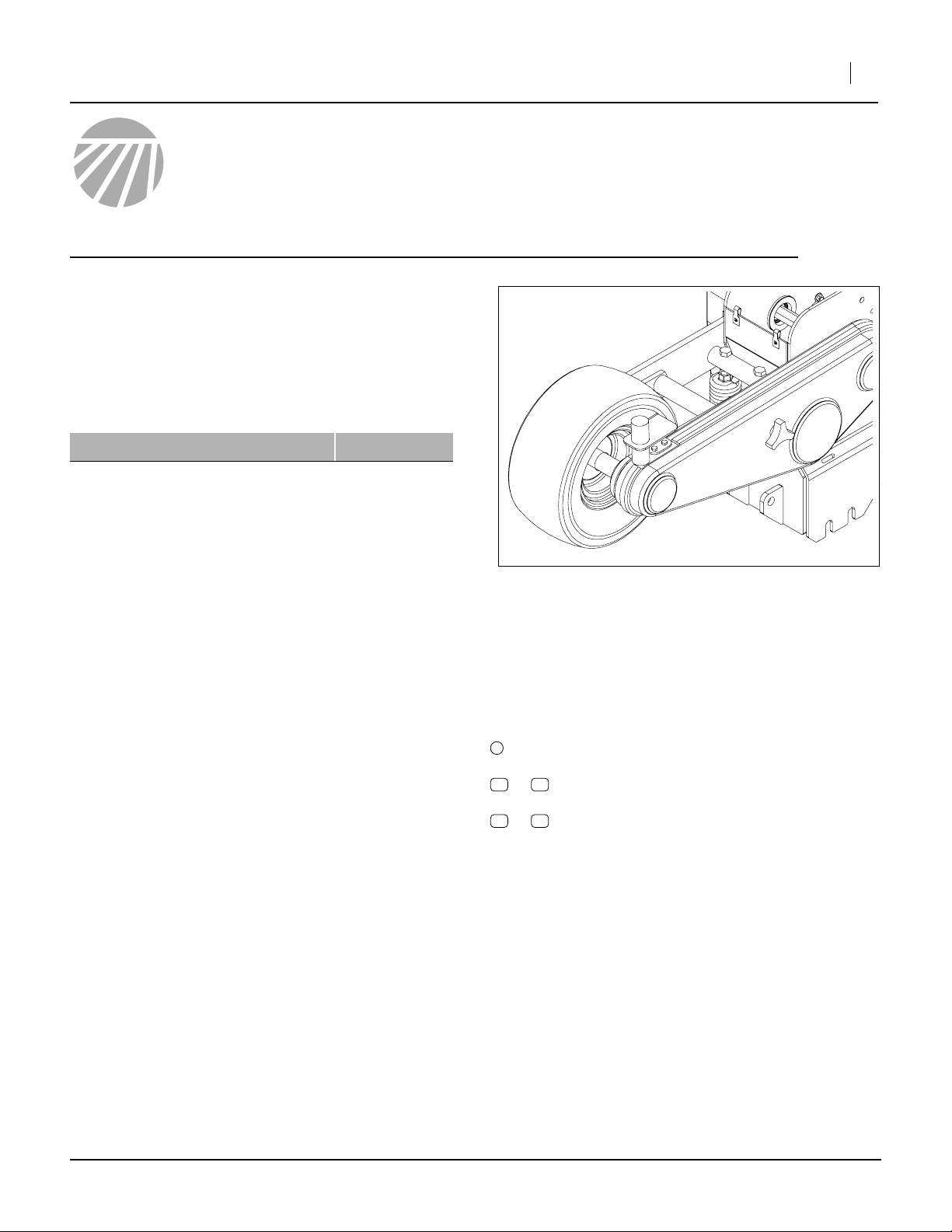

Figure 1

Sensor Installed, Cover On

“Left” and “Right” are facing in the direction of machine

travel.

1

callouts identify components in the currently

referenced Figure or Figures

11 23

to callouts reference new parts from the list on

page 9

51 63

to callouts reference existing parts from the list on

page 9.

26000

2. Power off the seed monitor.

3. Remove the seed hoppers with seed meters.

Secure the tractor.

Notations and Conventions

©Copyright 2007 Printed 02/02/2007 402-231M

2 Update Kit

Ground Drive Sensor Installation

Remove Components from Work Area

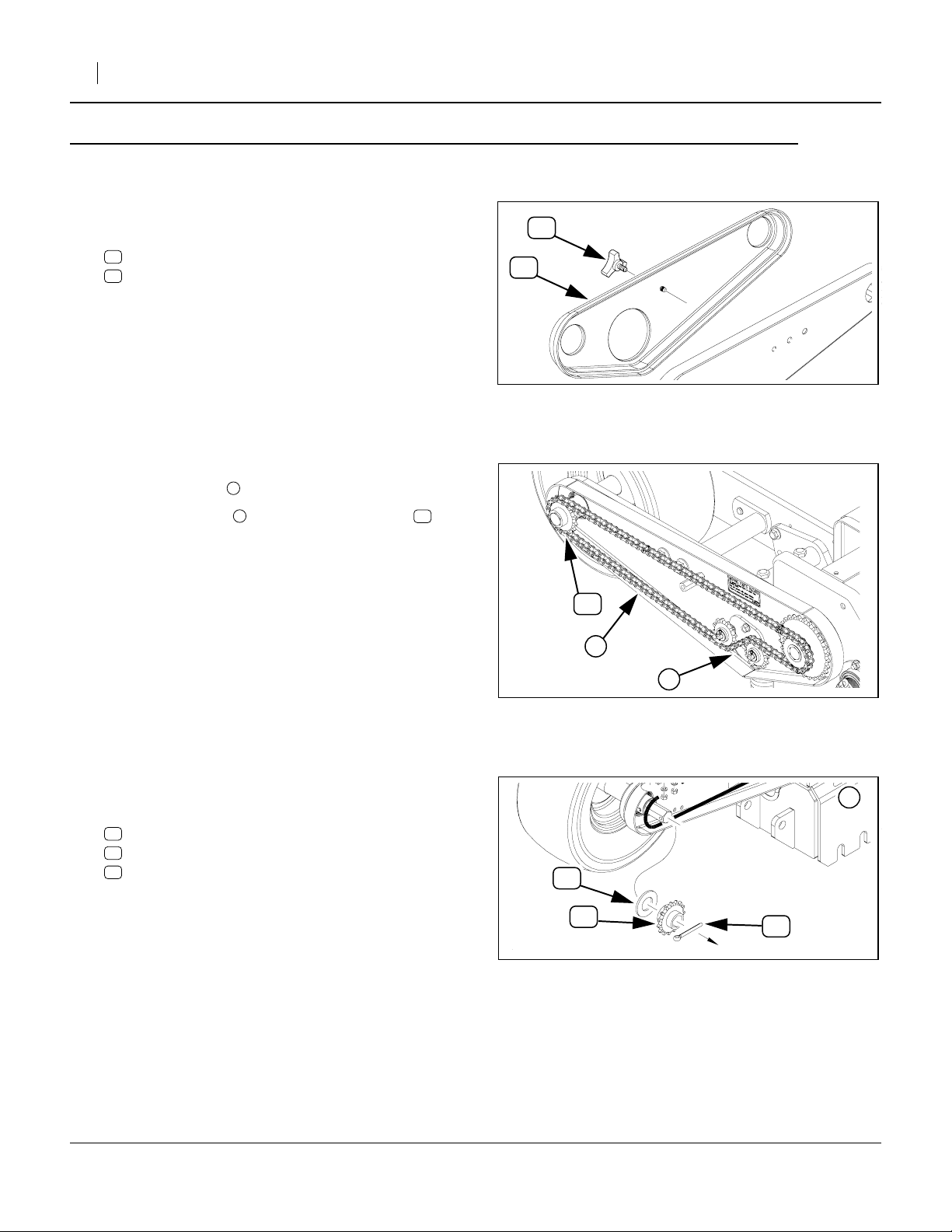

Refer to Figure 2

4. On the left hand contact drive, gain access to the

area to be updated by, removing and saving the:

60

KNOB, TRANS. SHIELD

62

LH CONTACT DRIVE CHAIN COVER

Great Plains Mfg., Inc.

60

62

Refer to Figure 3

5. Loosen the idlers .

6. Remove the chain from the drive sprocket

and let it hang toward the idlers.

Refer to Figure 4

7. At the contact wheel shaft, remove and save one

each of these existing parts:

58

PIN COTTER 1/4 X 2 PLT

59

SPKT 40C15 X 7/8 HEX BORE

57

WASHER FLAT SAE 1

1

259

Figure 2

Remove Cover

59

2

1

Figure 3

Dismount Sprocket & Washer

57

26002

16863

1

59

Figure 4

Dismount Sprocket & Washer

402-231M 02/02/2007

58

25493

Great Plains Mfg., Inc.

Mark for Sensor Hole

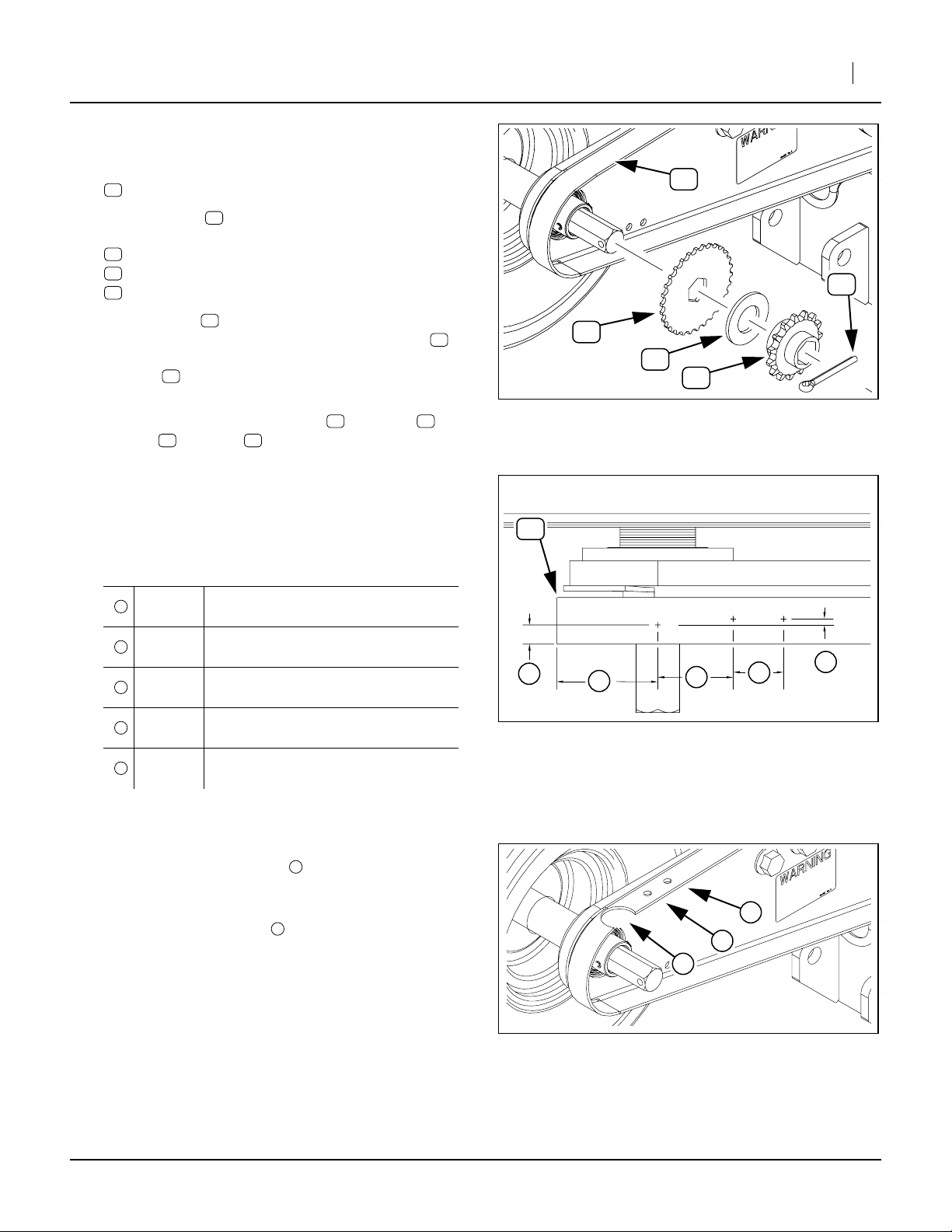

Refer to Figure 5 and Figure 6

8. Select one new:

12

402-262D DISC, MAG PICKUP

Installation Instructions 3

+

51

9. Place the disc on the shaft, and temporarily reinstall:

58

PIN COTTER 1/4 X 2 PLT

59

SPKT 40C15 X 7/8 HEX BORE

57

WASHER FLAT SAE 1

10. Slide the disc in and out on the shaft, and

determine the average position. Mark the shield

directly above the average top center position of

the disc . Compare the result to the predicted

measurements in the table at step 12.

11. Remove and save the cotter pin , sprocket ,

washer and disc .

57 12

12

12

62

12

58 59

Mark for Sensor Mount Holes

Refer to Figure 6

12. Mark for two additional holes forward and slightly to

the left of the sensor hole, as depicted in Figure 6.

Hole Placement

1

2

3

4

5

9.5mm

0.375in

51mm

2.0in

38.1mm

1.5in

25.4mm

1.0in

3.2mm

0.125in

Sensor hole to edge of shield

(approximate)

Sensor hole to end of shield

(approximate)

Sensor hole to rear mount hole

Mount hole to mount hole

Sensor/Mount centerline offset

51

1

12

57

59

Figure 5

Mark Sensor Hole

2

Mark Sensor Mount Holes

3

Figure 6

58

26003

4

5

26001

Drill Holes for Sensor Mount

Refer to Figure 7

13. Drill or cut the sensor hole to a diameter

between 32mm and 35mm. File off any sharp

edges.

1

2

14. Drill the mounting holes to diameters between

6.7mm and 7.1mm.

2

2

1

Figure 7

Cut Holes

02/02/2007 402-231M

26004

Loading...

Loading...