Page 1

ENGLISH

P18028E

JANUARY 2012

OPERATORS MANUAL

& PARTS LIST

DTX 300 / 350

Page 2

ENG If you require a copy of this document in your native language

pleasecontactyourdealerorSimbaGreatPlains.

DAN Hvisduharbrugforeteksemplarafdettedokumentpåditsprog,

bedesdukontaktedinforhandlerellerSimbaGreatPlains.

CZE Požadujete-li kopii tohoto dokumentu ve svém rodném jazyce,

obraťte se prosím na svéhoprodejcenebo na společnost Simba

GreatPlains.

HUN Haszeretnéeztaleírástmagyarulismegkapni,kérjük,értesítsea

forgalmazójátvagyaSimbaGreatPlains-t.

FRA Pourobtenirunexemplaireduprésentdocumentdanslalanguede

votrechoix,veuillezcontacter votre représentantouSimbaGreat

Plains.

LIT JeiprireiktųšiodokumentokopijosJūsųgimtąjakalba,kreipkitėsį

savoplatintojąarbaį„SimbaGreatPlains“.

BUL Аковиенеобходимокопиенатозидокументнародниявиезик,

моля да се обърнетекъм вашия дилър или към Simba Great

Plains.

RUM Dacă aveţi nevoie de o copie a acestui document în limba

dumneavoastră natală vă rugăm să vă contactaţi dealerul sau

SimbaGreatPlains.

RUS Чтобы получить копию данного документа на вашем родном

языке, обратитесь к своему дилеру или в компанию «Simba

GreatPlains»

GER WennSieeinExemplardiesesDokumentsinIhrer Muttersprache

brauchen,dannwendenSiesichbitteanIhrenHändleroderandie

SimbaGreatPlains.

Page 3

Declaration of Conformity

DECLARATION OF CONFORMITY

Simba International Limited hereby declare that the Simba DTX, as dened by the Serial Number attached

to the Machine Chassis, conforms with the following Directives and Regulations, and has been certied

accordingly.

EC Machinery Directive 2006/42/EC.

The Supply of Machinery (Safety) Regulations 2008.

The Provision and Use of Work Equipment Regulations 1998.

Specically related harmonised standards are:

EN ISO 12100-1: 2003 (Safety of Machinery).

EN ISO 12100-2: 2003 (Safety of Machinery).

EN ISO 4254-1: 2009 (Agricultural machinery - Safety - General Requirements).

THE MANUFACTURER:

Simba International Limited

Woodbridge Road

SLEAFORD

Lincolnshire

NG34 7EW

England

Telephone (+44) (0)1529 304654.

CERTIFIED ON BEHALF OF SIMBA INTERNATIONAL LIMITED:

Colin Adams

Managing Director

3DTX

Operating Instructions

Page 4

Introduction

WARRANTY

TERMS AND CONDITIONS

In this warranty Simba International Ltd., is referred to as “the Company”.

1. Subject to the provisions of this warranty the Company warrants each new machine sold by it to

be sold free from any defect in material or workmanship for a period of 12 months from date of

installation with the end-user.

Some specic items have additional warranty over and above the standard 12 months. Details of

these can be obtained upon request directly from the distributor or Simba International Ltd.

2. If the machine or part thereof supplied by the Company is not in accordance with the warranty

given in clause 1 the Company will at its option:

(a) make good the machine or part thereof at the Company’s expense, or

(b) make an allowance to the purchaser against the purchase price of the machine or part

thereof, or

(c) accept the return of the machine and at the buyers option either:

I) repay or allow the buyer the invoice price of the machine or part thereof, or

II) replace the machine or part thereof as is reasonably practical.

3. This warranty shall not oblige the Company to make any payment in respect of loss of prot or

other consequential loss or contingent liability of the Purchaser alleged to arise from any defect

in the machine or impose any liability on the Company other than that contained in clause 2.

4. Any claim under this warranty must be notied to the Company in writing specifying the matters

complained of within 14 days from the date of repair.

5. Any claim under this warranty must be made by the original purchaser of the machine and is not

assignable to any third party.

6. If the purchaser hires out the machine to any third party the warranty shall apply only to matters

notied to the Company in writing within 90 days of the date of delivery and clause 1 shall be read

as if the period of 90 days were substituted for the period of 12 months.

7. The warranty will cease to apply if:

(a) any parts not made, supplied or approved in writing by the Company are tted to the machine or

(b) any repair is carried out to the machine other than by or with the express written approval of the

Company or

(c) any alterations not expressly authorized by the Company in writing are made to the machine or

(d) the machine is damaged by accident or

(e) the machine is abused or overloaded or used for a purpose or load beyond its design capabilities,

or used in conjunction with a tractor whose power output capability exceeds the stated implement

power requirement by more than 40%. For the purpose of these terms and conditions, “stated

implement power requirement” refers to wheeled tractors unless specically stated. These power

requirements should be reduced by 20% when used in conjunction with tracked tractors.

(f) the machine is operated as part of a ‘cultivation train’ where more than one implement is being

towed, without the express written approval of Simba International Ltd.

(g) any maintenance is not carried out in accordance with the service schedules in the operator’s

manual.

(h) the Installation and Warranty Registration Certicate is not received by Simba International Ltd.,

Service Dept., Woodbridge Road, Sleaford, Lincolnshire, England, NG34 7EW, within 7 days of

installing a new machine.

DTX

4

Operating Instructions

Page 5

Machine Identication

Machine Identication

Enter the relevant data in the following list upon acceptance of the machine:

Serial Number

Type of Machine

Machine Width

Year of Construction

Delivery Date

First Operation

Accessories

Operating Instructions/Spare Parts List: January 2012

Dealer Address:

Name: _________________________________

Street: _________________________________

Place: _________________________________

Tel.: _________________________________

Dealer’s Customer No.: ______________________

Simba Great Plains Address:

Simba Great Plains

Woodbridge Road Ind. Est.

Sleaford

Lincolnshire

NG34 7EW

Tel.: +44 (0) 1529 304654

Fax: +44 (0) 1529 413468

E-Mail: simba.international@simba.co.uk

Customer No.: _________________________

Operating Instructions

5DTX

Page 6

Contents

Contents

Machine Identication .............................................................................................................5

Introduction ..............................................................................................8

Foreword ..........................................................................................................................8

Warranty Guidelines .........................................................................................................8

1. Safety Data .......................................................................................9

1.1 Safety Symbols .......................................................................................................9

1.2 Use for the Intended Purpose .............................................................................. 11

1.3 Operational Safety ................................................................................................11

1.4 No Liability for Consequential Damage................................................................. 11

1.5 Road Trafc Safety ...............................................................................................12

1.6 Accident Prevention ..............................................................................................12

1.6.1 Hitching-up the machine .......................................................................................12

1.6.2 Changing Equipment ............................................................................................12

1.6.3 During Operation...................................................................................................13

1.7 Servicing & Maintenance ......................................................................................13

2. Transportation and Installation .....................................................15

2.1 Delivery .................................................................................................................15

2.2 Transportation .......................................................................................................15

2.3 Installation .............................................................................................................15

2.4 Hitching Up / Preparing for Transport ...................................................................16

2.5 When driving on the road ......................................................................................16

2.6 Parking the machine .............................................................................................16

3. Technical Data ................................................................................17

4. Adjustment/Operation .....................................................................18

4.1 Description ............................................................................................................18

4.2 3 Point Linkage .....................................................................................................20

4.3 Tines .....................................................................................................................20

4.3.1 Pro-Lift Wings .......................................................................................................20

4.4 Disc Units ..............................................................................................................21

4.5 DD Lite Roller........................................................................................................21

4.6 DD600 Roller ........................................................................................................21

4.7 Work Settings ........................................................................................................22

4.8 General Rules When Setting the DTX ..................................................................22

4.9 Starting Settings....................................................................................................23

4.10 Adjusting Depth.....................................................................................................23

4.11 TurboJet ................................................................................................................24

4.12 Work Instructions ..................................................................................................24

4.13 Parking the machine .............................................................................................24

4.14 Checks ..................................................................................................................24

DTX

6

Operating Instructions

Page 7

Contents

5. Servicing and Maintenance ............................................................25

5.1 Servicing ...............................................................................................................25

5.2 Cleaning ................................................................................................................25

5.3 Disc Hub Maintenance .........................................................................................25

5.3.1 Tightening Disc Hubs ............................................................................................25

5.3.2 Bearing Seals........................................................................................................26

5.4 DD Lite Roll ...........................................................................................................26

5.5 DD600 Roll............................................................................................................26

5.6 Preparation for Storage.........................................................................................26

5.7 Tines .....................................................................................................................27

5.8 Operator Support ..................................................................................................27

5.9 Maintenance Intervals ...........................................................................................27

5.10 Maintenance Overview .........................................................................................28

5.11 Lubricating the Machine ........................................................................................29

5.12 Handling of Lubricants ..........................................................................................29

5.13 Lubricants .............................................................................................................30

6. Faults and Remedies ......................................................................31

7. Parts & Assembly ...........................................................................33

Operating Instructions

7DTX

Page 8

Introduction

Introduction

Foreword

Make sure you have read and follow the

Operating Instructions carefully before

using the machine. By doing so, you will

avoid accidents, reduce repair costs and

downtime and increase the reliability and

service life of your machine. Pay attention

to the safety instructions!

SIMBA will not accept any responsibility

for any damage or malfunctions resulting

from failure to comply with the Operating

Instructions.

These Operating Instructions will assist

you in getting to know your machine and in

using it correctly for its intended purposes.

First, you are given general instructions in

handling the machine. This is followed by

sections on servicing, maintenance and

the action to be taken should a malfunction

occur.

We reserve the right to alter

illustrations as well as technical

data and weights contained in

these Operating Instructions for the

purpose of improving the machine.

Warranty Guidelines

The period of liability for material defects

(warranty) relating to our products is 12

months. In the case of written deviations

from the statutory provisions, these

agreements shall apply.

They shall become effective upon

installation of the machine with the end

customer. All wear parts are excluded from

the warranty.

All warranty claims must be submitted to

SIMBA via your dealer.

These operating instructions are to be read

and followed by all persons working on or

with the machine, e.g.:

• Operation (including preparation,

remedying of faults in the operating

sequence and servicing).

• Maintenance (maintenance and

inspection)

• Transportation.

Together with the Operating Instructions,

you receive a Spare Parts List and a

Machine Registration form. Field service

technicians will instruct you in the operation

and servicing of your machine. Following

this, the Machine Registration form is to

be returned to your dealer. This conrms

your formal acceptance of the machine.

The warranty period begins on the date of

delivery.

DTX

8

Operating Instructions

Page 9

1. Safety Data

1.0 Safety Data

The following warnings and safety

instructions apply to all sections of these

Operating Instructions.

1.1 Safety Symbols on

the machine

Read and observe the

Operating Instructions

before using the machine!

Parts may y off during

operation. Keep a safe

distance away from the

machine!

Keep clear of the working

range of foldable machine

components!

Watch out for escaping

pressurised uids! Follow

the instructions in the

Operating Instructions!

Never reach into areas

where there is a danger of

being crushed by moving

parts!

No passengers are allowed

on the machine!

Never reach into any

revolving parts!

Operating Instructions

9DTX

Page 10

1. Safety Data

Refer to Operating

Instructions before

attempting maintenance.

Operating Instructions:

The Operating Instructions distinguish

between three different types of warning

and safety instructions. The following

graphic symbols are used:

Important!

Risk of injury!

Risk of fatal and serious injuries!

It is important that all the safety instructions

contained in these Operating Instructions

and all the warning signs on the machine

are read carefully.

Ensure that the warning signs are legible.

Replace any signs that are missing or

damaged.

These instructions must be followed in order

to prevent accidents. Inform other users of

the warnings and safety instructions.

Do not carry out any operations which may

affect safe use of the machine.

All references to left and right in this manual

are made from the rear of the machine,

facing the direction of travel (unless

otherwise stated).

DTX

10

Operating Instructions

Page 11

1. Safety Data

1.2 Use for the Intended

Purpose

The SIMBA DTX is built using the latest

technology and in accordance with the

relevant recognised safety regulations.

However, risks of injury for the operator or

third parties and impairment of the machine

or other tangible assets can arise during

use.

The machine is only to be operated when

in a technically perfect condition and for the

intended purpose, taking into consideration

safety and risks and following the

Operating Instructions. In particular, faults

that can impair safety are to be remedied

immediately.

Original parts and accessories from SIMBA

have been specially designed for this

machine. Spare parts and accessories not

supplied by us have not been tested or

authorised. Installation or use of non-original

SIMBA products may have a detrimental

effect on specic design features of the

machine and affect the safety of machine

operators and the machine itself. SIMBA

will accept no liability for damage resulting

from the use of non-original parts or

accessories.

1.3 Operational Safety

The machine is to be put in operation

only after instruction has been provided

by an employee of the authorised dealer

or an employee of SIMBA. The “Machine

Registration” form is to be completed and

returned to your dealer.

All protective and safety equipment, such

as removable protective equipment, must

be in place and functioning reliably before

the machine is put in use.

Check screws and bolts regularly

for tightness and retighten if

necessary.

In the event of malfunctions,

stop and secure the machine

immediately.

Ensure that any faults are

remedied immediately.

1.4 No Liability for

Consequential Damage

The DTX has been manufactured by SIMBA

with great care. However, problems may

still occur when it is used for the intended

purpose. These may include:

The SIMBA DTX is designed solely as a

cultivation implement. Use for any other

purpose, e.g., as a means of transport,

will be deemed to be improper use. SIMBA

will accept no liability for damage resulting

from improper use. The risk will be borne

solely by the operator.

Use of the DTX behind high power tractors

(in excess of 40% above the maximum

recommended) can lead to high loads

and stresses which can cause long term

structural damage to the chassis and

key components. Such overloading can

compromise safety and is to be avoided.

• Worn wearing parts.

• Damage caused by external factors.

• Incorrect driving speeds.

• Incorrect setting of the unit (incorrect

attachment, non-adherence to the Setting

instructions).

Therefore, it is crucial to

always check your machine

before and during operation for

correct operation and adequate

application accuracy.

Compensation claims for damage which

has not occurred to the machine is

excluded. This includes any consequential

damage resulting from incorrect operation.

11DTX

Operating Instructions

Page 12

1. Safety Data

1.5 Road Trafc Safety

When driving on public roads, tracks and

areas, it is important to observe the relevant

road trafc laws as well as the specic

regulations relating to this machine.

Pay attention to the permitted axle

loads, tyre carrying capacity, and

total weight in order to maintain

adequate braking and steerability.

Passengers on the machine are

strictly forbidden!

Check that lights / indicators (if

applicable) are working before

transporting the machine.

Max. road transport speed 16mph

(25km/h).

Beware of trapping hazards

when manipulating the parking

stands, steps or other moving

parts. Ensure any heavy

components are fully supported

when removing pins / bolts.

1.6.1 Hitching-up the

machine

There is a risk of injury when hitching/

unhitching the machine. Observe the

following:

• Secure the machine against rolling.

• Take special care when reversing the

tractor!

• There is a risk of being crushed between

the machine and the tractor!

• Park the machine on rm, level ground.

1.6 Accident Prevention

In addition to the Operating Instructions,

it is important to observe the accident

prevention regulations specied by

agricultural trade associations. It is the

Operator’s responsibility to ensure that all

other persons are excluded from the danger

zones surrounding or on the machine

during its operation.

It is the Owner’s responsibility to ensure:

• the Operator is trained and competent

to use the machine

• the tractor is suitable for the machine

• adequate Risk and COSHH assessments

have been undertaken regarding the

machine’s use. Specically, these

include issues concerning contact with

the soil, dust, crop residues, chemicals,

lubricants and other compounds during

operation or maintenance, and the

possibility of stones being ejected at

high speed during work.

&

tractor,

1.6.2 Changing

Equipment

• Secure the machine to prevent it from

accidentally rolling away!

• Use suitable supports to secure any

raised frame sections suspended above

you!

• Caution! Risk of injury due to projecting

parts!

Never climb on to rotating parts

such as the roll unit. These parts

may rotate causing you to slip and

suffer serious injury!

Removing components during

maintenance may affect the

stability of the machine. Ensure

it is fully supported in case of

unexpected weight shifts.

DTX

12

Operating Instructions

Page 13

1.7 Servicing &

Maintenance

Ensure that regular checks and inspections

are always carried out within the periods

required by law or specied in these

Operating Instructions.

When carrying out service and maintenance

work always:

• switch off the tractor engine and remove

the ignition key.

• wait until all the machine parts have

stopped moving.

• depressurise the hydraulic system.

Many hydraulic circuits contain lock or

overcentre valves which can retain pressure

in the lines even after depressurising the

tractor side of these circuits. If in doubt,

consult trained personnel (such as your

local Simba Dealer) to ensure such valves

are depressurised to the correct procedure

before removing or servicing any parts

connected downstream of these valves.

Check all hydraulic lines for leaks, loose

connections, chafe marks and damage.

Remedy any deciencies immediately!

Pay particular attention to hose renewal

intervals as outlined in the specic sections

which follow. ALL hydraulic hoses have a

safe maximum working life of 6 (SIX) years

from date of installation, provided they

remain in a safe condition. Hoses which

exceed 6 years of age should be replaced,

or inspected and certied by a suitably

qualied person to have an extended life

period which should be recorded.

1. Safety Data

Pay particular attention to those items which

require specialist service tools or training to

be carried out by qualied personnel. Do

not attempt to service these items yourself!

These include items retaining pressure

(e.g. accumulator circuits), or force (e.g.

spring tines), and DD axles of any type.

13DTX

Operating Instructions

Page 14

2. Transportation / Installation

DTX

14

Operating Instructions

Page 15

2. Transportation / Installation

2.0 Transportation

and Installation

Transportation and initial installation of the

machine are described in this chapter.

2.1 Delivery

The machine is normally delivered fully

assembled.

• The machine can be lifted off with a

crane or other suitable lifting equipment.

• The machine should be hitched to a

tractor and driven off a low-loader.

2.2 Transportation

The DTX can be transported on public

roads by hitching it up to a tractor or on a

low-loader.

• It is important to observe the permitted

dimensions and weights when

transporting the machine.

• If the machine is transported on a trailer

or a low-loader, it must be secured

using straps or other devices.

2.3 Installation

When carrying out installation and

maintenance work there is a higher risk of

injury. It is important that you familiarise

yourself with the machine and read the

Operating Instructions beforehand.

Operator instruction and initial installation of

the machine are carried out by our service

technicians or authorised distributors.

The machine must not be used in any way

beforehand! The machine can only be

released for operation after instructions

have been provided by our service

technicians or authorised distributors.

• If any modules or parts have been

removed for transportation, these shall

be mounted by our service technicians/

authorised dealers before the instruction

takes place.

• Check all important screw connections!

• Lubricate all nipples and joints!

• Check all hydraulic connections and

lines for damage.

• Before transporting the machine on

public roads, it must be adjusted

to its transportation position and

the stipulations relating to road

transportation fullled.

• The maximum permissible speed is

25km/h.

On machines tted with a

TurboJet seeder unit the hopper

should be emptied before road

transport.

Operating Instructions

15DTX

Page 16

2. Transportation / Installation

2.4 Hitching Up / Preparing

for Transport

When hitching-up the machine,

ensure that no-one is between

the tractor and the machine.

1. Connect the tractor to the machine

using the hydraulics to raise or lower

the the height of the tractor lower link

arms.

2. When the lower link arms are aligned

t the lower link pins and the lynch

pins.

3. Fit the tractor toplink between the

tractor and the machine.

4. Raise the machine using the tractor

link arms.

2.6 Parking the machine

In order to avoid damage as a result of

moisture, the machine should be parked, if

possible, indoors or under cover.

When manoeuvring the

machine, pay attention to your

surroundings. Ensure that

nobody is in the manoeuvring

area (watch for children!).

Park the machine on level and solid

ground.

Lower the machine onto the parking

stands / tines ensuring that it is stable.

Remove the toplink and lower the link

arms so that pins can be removed.

Switch off the tractor.

2.5 When driving on the

road

When driving on the road the machine must

be converted to the transportation position.

When driving on the road, raise

the machine completely to

prevent the working elements

dragging on the ground.

Ensure that the tractor rear lights

are visible from behind during

transport.

Fig. 2A: Parking Position

DTX

16

Operating Instructions

Fig. 2B: Parking Stand Stowage

Page 17

3. Technical Data

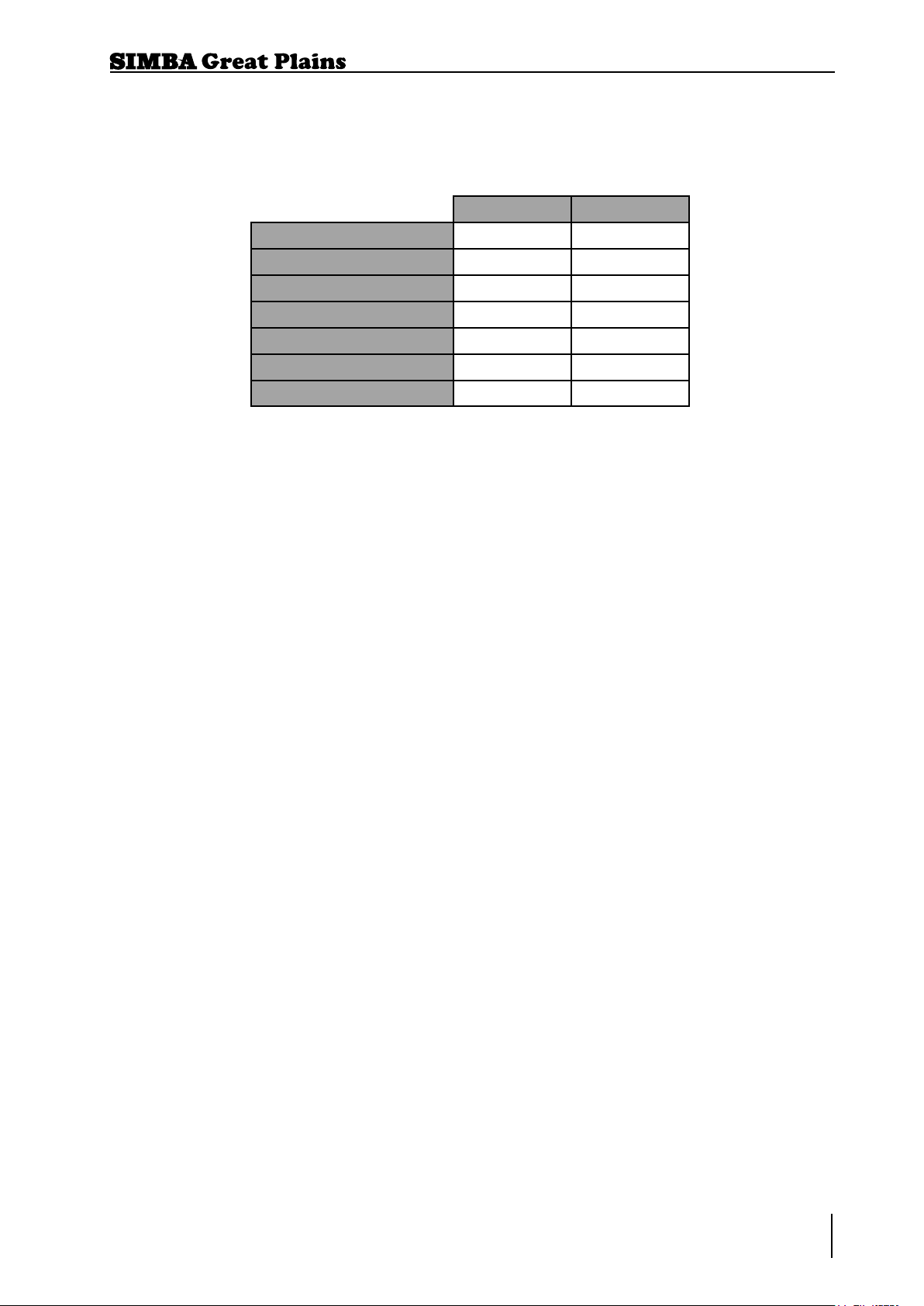

3.0 Technical Data

3.0m 3.5m

Working Width 3000mm 3500mm

Transport Width 3000mm 3500mm

Transport Height N/A N/A

Transport Length 3356mm 3356mm

Weight 2590kg 3260kg

Centre of Gravity* 1642mm 1620mm

Tractor Power Req.** 200-300Hp 200-400Hp

* Dimension from linkage in transport position.

** It is important to correctly match your implement to your tractor for optimum performance.

Operating Instructions

17DTX

Page 18

4. Adjustment / Operation

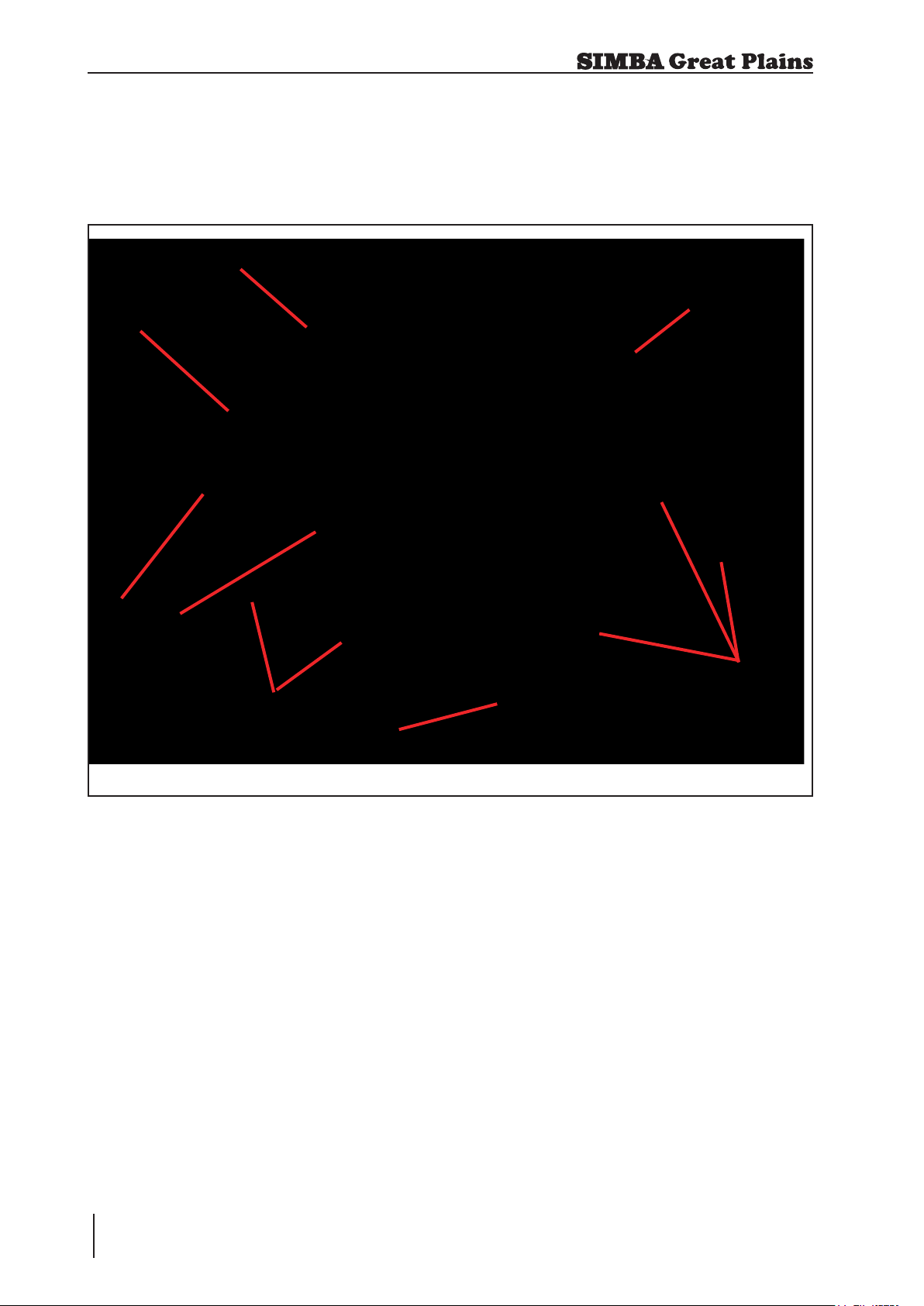

4.0 Adjustment/Operation

4.1 Description

7

6

4

5

4

3

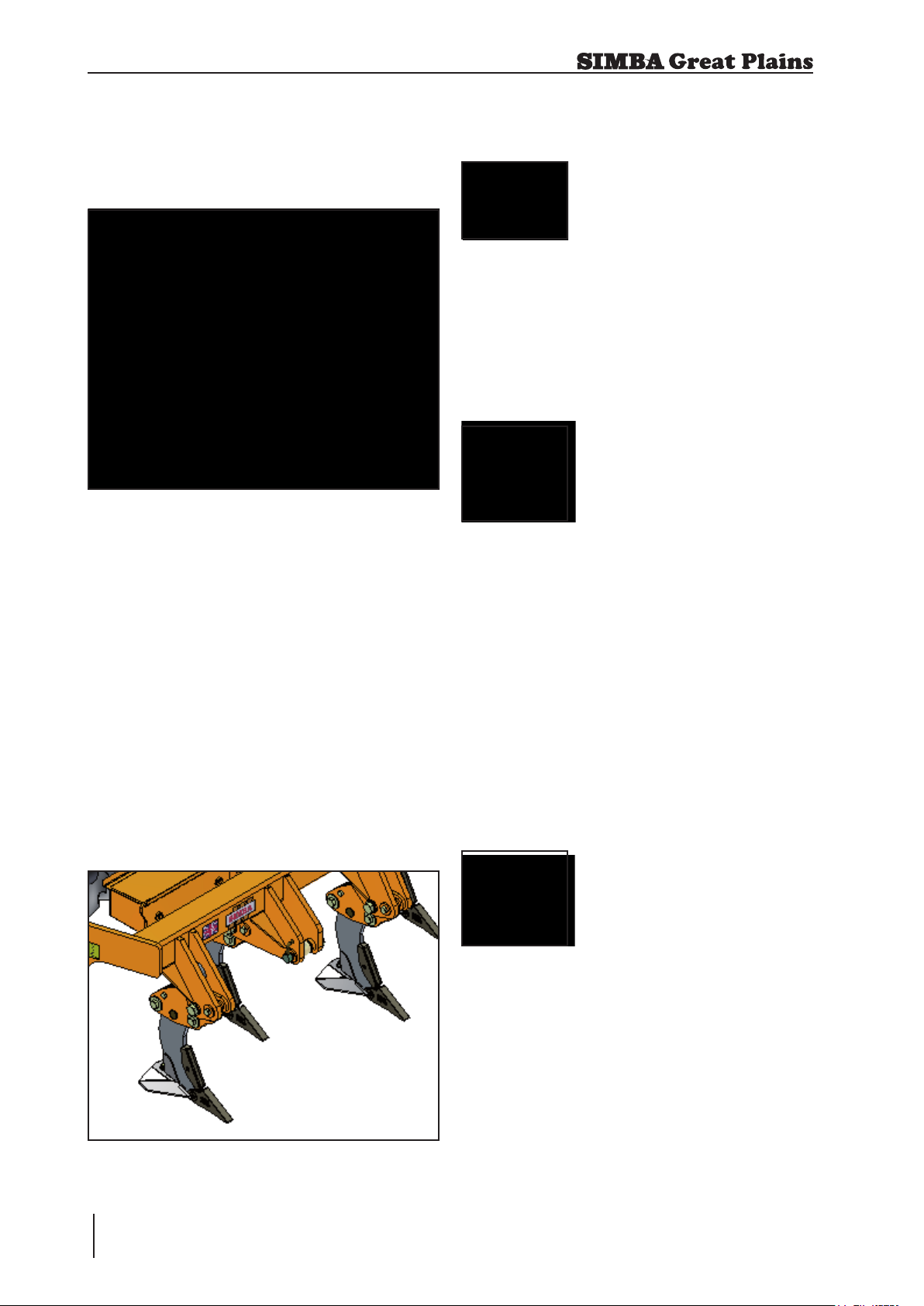

Fig. 4.01: Simba DTX 300

1. 3 Point Linkage

2. Pro-Lift Tines

3. Discs

4. Disc Angle Adjuster

5. Roll Depth Linkage

6. DD Lite Roll

7. DD Lite Scrapers

1

2

DTX

18

Operating Instructions

Page 19

The SIMBA DTX is an amalgamation of

time proven, successful Simba designed

components brought together to form this

important development. The DTX provides

a one pass mix with a ssured layer at disc

depth for through drainage and root access

to lower horizons. This enables rapid

drainage and access after rain, creating

a greater effective capacity for moisture

compared to ploughing for the same

effective total depth of cultivation.

In principle, the machine is a subsoiler

followed by an offset disc designed for

low draft, high speed operations. The

addition of a rear mounted roll enables

effective cultivation in one pass. The key

to the DTX’s success are the tines which

maintain shatter across the full width of

cultivation. This is followed by the discs

that cultivate the soil surface and minimise

and clod formation. Finally, the rear roll

consolidates the surface, cracks any clods

and rms the soil prole after the rear discs

complete mixing to depth. This starts the

‘top down’ cultivation process, retaining

weathered tilth in the surface level for stale

seedbed purposes. The corrugated top

and shattered lower horizons are left fully

weatherproof to any conditions between

cultivation and drilling whilst retaining

moisture below the surface for rapid straw

breakdown and optimum establishment of

the next crop.

4. Adjustment / Operation

Operating Instructions

19DTX

Page 20

4. Adjustment / Operation

4.2 3 Point Linkage

The DTX 300 is tted with a standard

Category 3 linkage at the front of the

machine.

Fig. 4.02: 3 Point Linkage

4.3 Tines

The DTX is tted with either Pro-Lift or

LD (Low Disturbance) tines. The tines are

arranged in a staggered formation to give

lower draft requirements and the ability to

work progressively deeper. The tines are

spaced at 400mm. Each tine is shear bolt

protected. Tine depth is achieved by moving

the tines up and down in the adjustable

clamps.

Different wings are available to suit the soil

conditions and optimise the performance

of the machine.

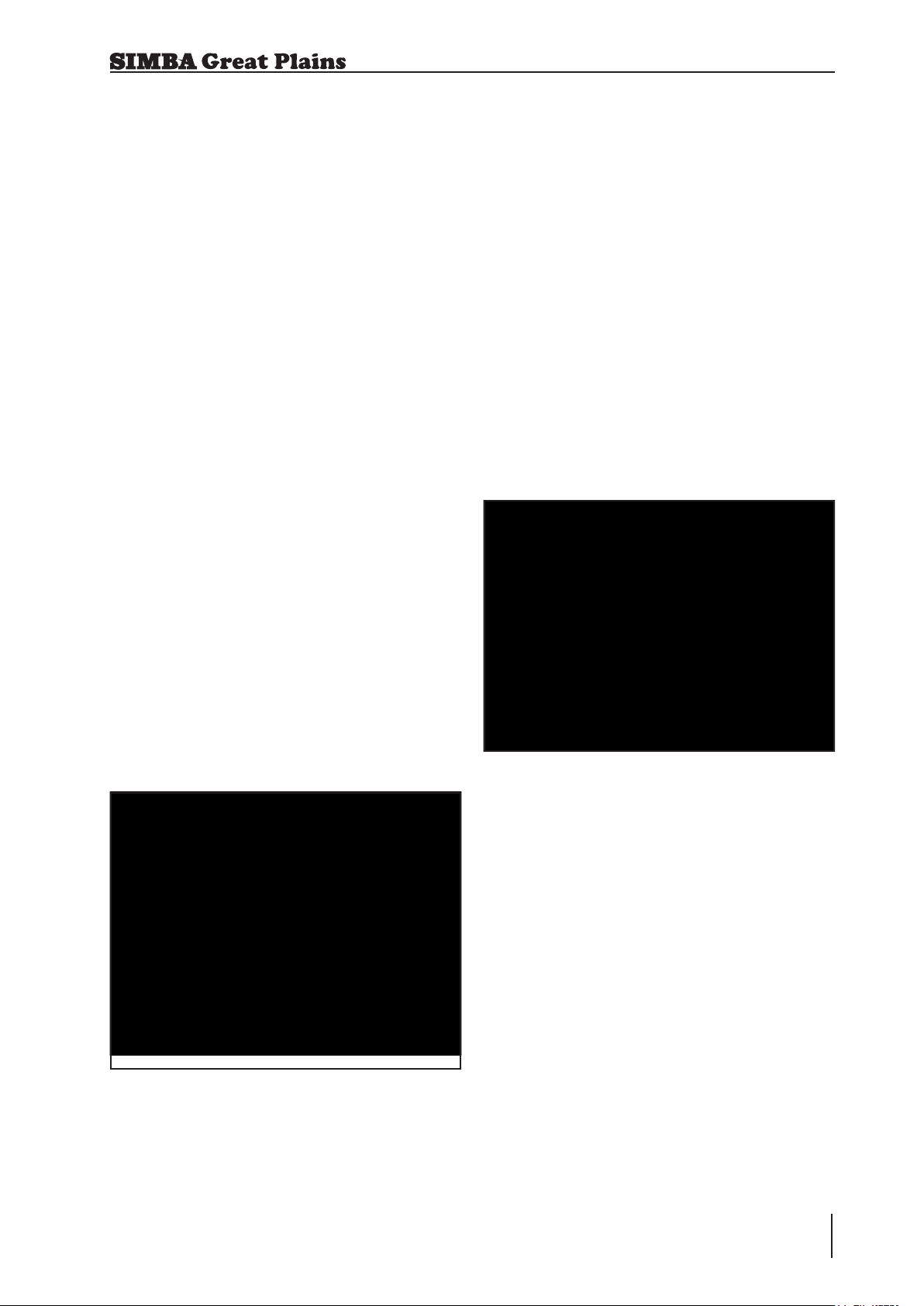

4.3.1 Pro-Lift Wings

Standard Wing

P09060

Maximum soil disturbance with

minimum draft requirement under

normal circumstances.

Wing angle reduces wear rates on

leg.

Extra Lift Wing

P10392

Increased lift height and rake angle

creates greater soil disturbance on

all soil types especially in moister

conditions.

Lower relative distance between

edge of wing and point reduces draft

requirement.

Has ability to work at lower depths

with no decrease in soil disturbance

or risk of smear.

Fig. 4.03: Pro-Lift Tines

DTX

20

Operating Instructions

Extra Wide Wing

P10411

Improved lateral shatter in moist/wet

soils, or non-cohesive soils.

Ideal for deep vegetable applications

under light/medium soils.

Page 21

4. Adjustment / Operation

4.4 Disc Units

The DTX features two rows of discs which

chop and mix the crop residue. A disc

spacing of 250mm ensures a ne tilth.

The discs tted to the DTX are 500mm in

diameter (20”) and 6mm thick. They are

manufactured from heat treated chrome

boron steel which ensures excellent wear

resistance and enhanced working life.

Each disc is mounted on a Pro-Active

sprung leaf linked to a track rod system.

Gang angles can be varied with ease and

accuracy using a graduated adjuster.

Adjustable angling of the discs (between

10°-25°) ensures penetration and stubble

mixing are achieved in one pass. Working

depth can be varied via the 3 point linkage

and the rear roll linkage.

4.5 DD Lite Roller

The DD Lite roller is made up of individual

Double Disc (patented) Ring segments.

The DD Lite roll is designed to consolidate

the soil whilst cutting and crushing any

clods.

Even in heavy, wet soils it can easily be

operated with minimal blockages occurring.

The rear DD Lite roller carries a proportion

of the machine’s weight to ensure

consolidation. It also regulates the depth

of the disc units. The corrugated surface

left by the roller is weatherproof both for

wet or dry situations.

A level, evenly cultivated nish is maintained

by adjusting the balance of soil throw

between the front and rear disc.

Sprung Pro-Active leaves offer protection

against damage as well as offering a

degree of contour following as they ex up

and down in work.

Fig. 4.05: DD Lite Roller

4.6 DD600 Roller

The standard DD600 roller is made up of

individual Double Disc (patented) Ring

segments.

The DD rings are designed to consolidate

the soil whilst cutting and crushing any clods.

Even in heavy, wet soils it can easily be

operated with minimal blockages occurring.

Fig. 4.04: Discs

The rear DD Lite roller carries a proportion

of the machine’s weight to ensure

consolidation. It also regulates the depth

of the disc units. The corrugated surface

left by the roller is weatherproof both for

wet or dry situations.

21DTX

Operating Instructions

Page 22

4. Adjustment / Operation

4.7 Work Settings

Optimum performance has been found to

be achieved when the DD roll rings have

worn away the painted nish leaving a

smooth shiny surface. When the DD rings

are new or rusty, soil may tend to pick up on

the surface and blockage may occur, this

will reduce when the rings are shiny again.

The DTX should be run with the chassis level

to slightly tail low. In practice it is possible

to use the DTX on ground conditions that

are unsuitable to achieve the desired

effect, and it is usually possible to operate

the DD roll without regular blockage under

such unsuitable conditions, assuming that

the roll assemblies are tight, the scrapers

correctly adjusted and rings smooth. As

such, especially under wet conditions, it is

advisable to check on the cultivation effect

of the DTX.

4.8 General Rules when

Setting the DTX

The lighter the land conditions the

less the disc angle required and the

forward speed can be increased.

The wetter the land conditions the less

the disc angle required and the forward

speed will need to be decreased.

Heavier land will require more of a disc

angle and a slower forward speed.

The more the trash the less the angle

on the discs and forward speed will

have to be decreased.

On ploughed land reduce the disc

angle to give a cutting/chopping

action.

The DTX should be lifted fully clear of the

ground for all headland turns. Turning with

the tines, disc units or roller on the ground

could lead to damage of these components.

In work, the tractor lower link arms

should be run in position control with draft

introduced if required.

In hard conditions increase the disc

angle to increase penetration.

DTX

22

Operating Instructions

Page 23

4. Adjustment / Operation

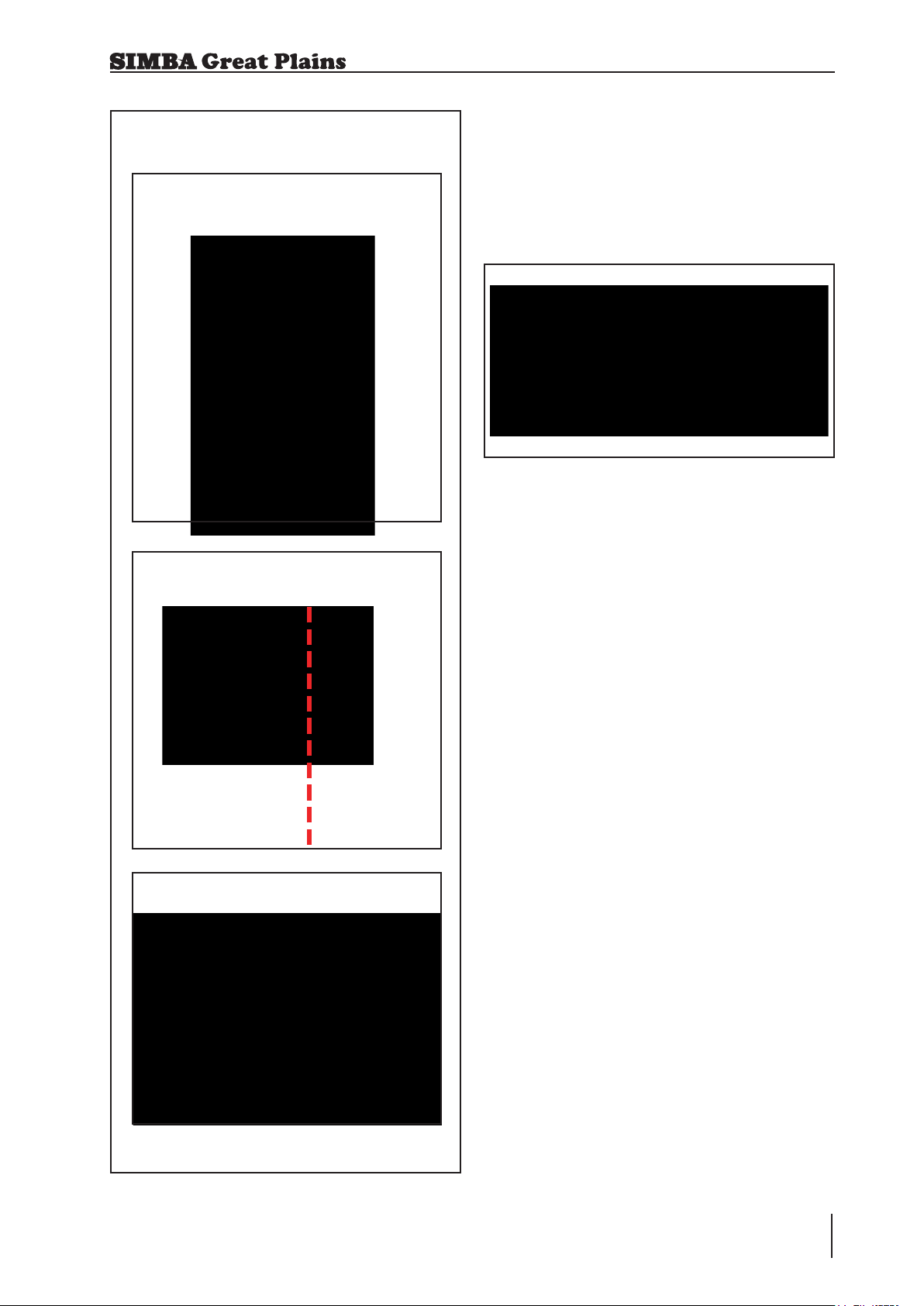

4.9 Starting Settings

Tine Depth

.

Disc Angle

4.10 Adjusting Depth

To change the working depth it is advisable

to lift the machine clear of the ground so

that the rear roll linkage becomes loose.

Move the position of the depth pins to

change the depth.

Fig. 4.06: Roll Linkage

When the depth has been altered, lower the

machine into work and check operation. If

the depth change has been signicant then

other setting could be affected. This could

be chassis pitch (front to rear) and disc

angle for the given depth.

Roll Depth

.

A small amount of cultivation, eg. a 20

metre run, should be carried out before

altering these settings to check whether

they are now suitable for the cultivation

effect required. These settings should be

addressed immediately to prevent too

much work being carried out.

SPRUNG LEAF

.

Operating Instructions

23DTX

Page 24

4. Adjustment / Operation

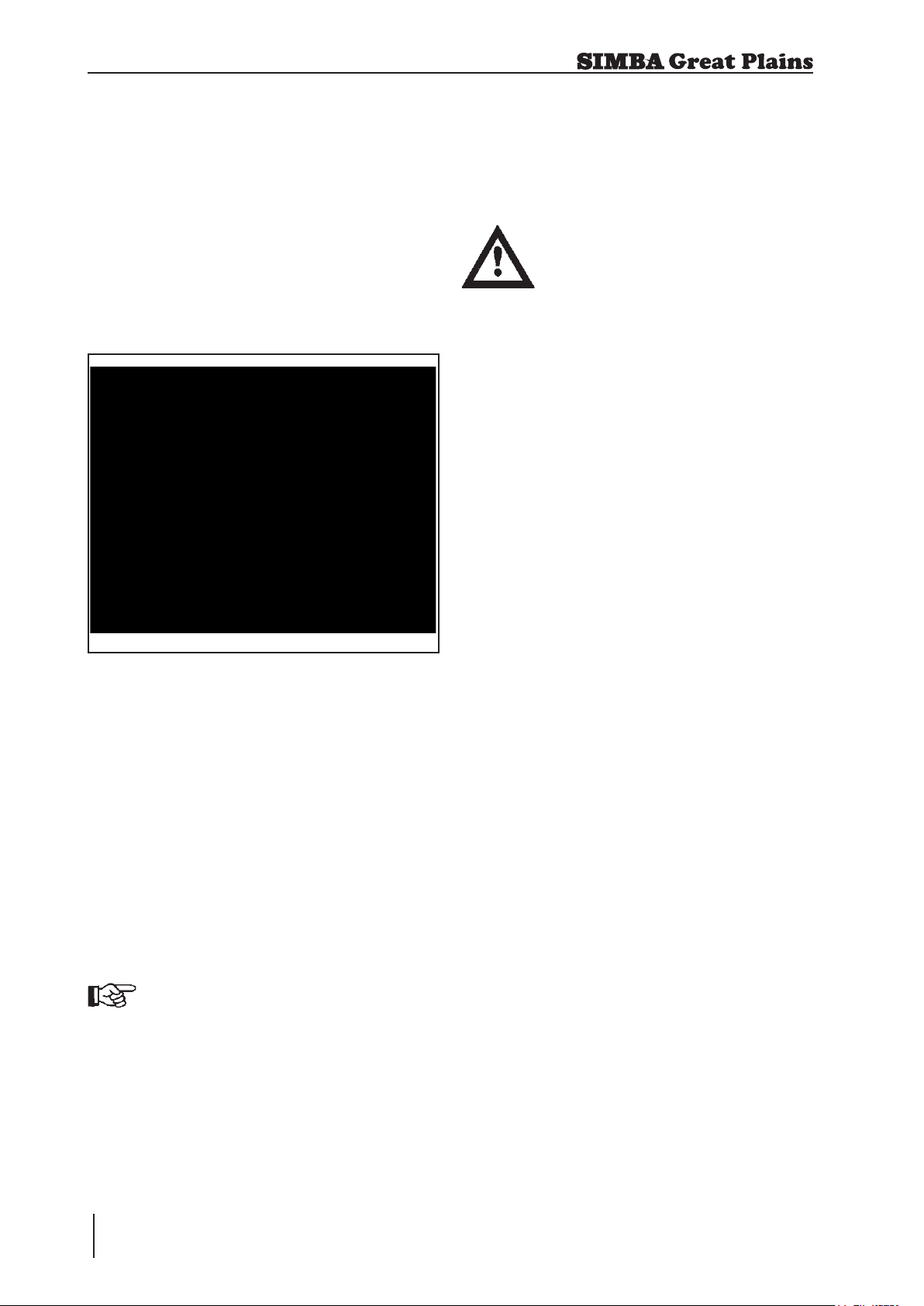

4.11 TurboJet

The SL can be tted with an optional

TurboJet Oil Seed Rape applicator. The

Turbo Jet is an air seeder unit which uses

two fans to deliver seed behind the rear roll

in work.

The TurboJet can be operated from the cab

of the tractor using an advanced computer

control module, the RDS Wizard System.

Fig. 4.07: DTX with TurboJet

4.13 Parking the machine

In order to avoid damage as a result of

moisture, the machine should be parked, if

possible, indoors or under cover.

When manoeuvring the

machine, pay attention to your

surroundings. Ensure that

nobody is in the manoeuvring

area (watch for children!).

Park the machine on level and solid

ground.

Lower the machine onto the parking

stands / tines ensuring that it is stable.

Remove the toplink and lower the link

arms so that pins can be removed.

Switch off the tractor.

4.14 Checks

The working quality depends on the

adjustments and checks made prior to and

during work, as well as on regular servicing

and maintenance of the machine.

4.12 Work Instructions

Driving speed

The DTX 300 can be driven at speeds of up

to 12 km/h.

This depends on the eld conditions (type

of soil, surface trash, etc.).

Drive more slowly if the conditions are

difcult or a rmer nish is required.

Turning:

Before turning, the machine should

be lifted out of work while driving.

Likewise, it should lowered back

into work once the turn has been

completed.

Before beginning work it is therefore

important to carry out any necessary

servicing and to lubricate the machine as

required.

Checks prior to, and during

work:

Is the machine correctly hitched up

and the coupling device locked?

Is the machine in a level operating

position and the working depth set

correctly?

Working Elements

Are the discs and other cultivation

tools in a serviceable condition?

Are the scrapers still operable, so that

the rolls do not jam?

DTX

24

Operating Instructions

Page 25

5. Servicing and Maintenance

5.0 Servicing and

Maintenance

Follow the safety instructions for

servicing and maintenance.

5.1 Servicing

Your machine has been designed and

constructed for maximum performance,

operational efciency and operator

friendliness under a wide variety of

operating conditions.

Prior to delivery, your machine has

been checked at the factory and by your

authorised dealer to ensure that you

receive a machine in optimum condition.

To ensure trouble-free operation,

it is important that servicing and

maintenance work is performed at

the recommended intervals.

Regularly examine hub caps,

seals, shear and pivot bolts and

all tracking bolts for tightness

and effectiveness twice weekly

or every 50 working hours

(whichever is more frequent).

5.3.1 Tightening Disc Hubs

1 Ensure that the bearing seal is in the

correct orientation when replacing /

assembling components.

2 Ensure that the stub axle is free from

dirt and the nut and outer bearing can

easily slide on it.

3 Tighten the crown nut with a hand

spanner (a torque wrench is not

req uired) while turning th e hub

clockwise until the bearing drags

slightly (you feel the hub turning

heavily). Some resistance will be due

to friction from the seal.

5.2 Cleaning

In order to ensure that the machine is

always in operating condition and to

achieve optimum performance, perform

the cleaning and servicing work at regular

intervals.

Avoid cleaning the roll / disc bearings with

a high- pressure hose or a direct water jet.

The housing, screwed connections and

ball bearings are not watertight.

5.3 Disc Hub Maintenance

Grease every disc hub until

grease shows from the seals

according to the lubricating

intervals outlined on page 28.

Check disc hubs regularly for

tightness.

4 Turn back the crown nut to the next

locking position. Even if the tightening

of the nut has reached an exact xing

position, turn it back.

5 Insert the retaining pin.

6 Try to shake/rock the outer edge of the

hub/spindle: play of 0.1 / 0.2mm will

not reduce the bearings’ life and, in

addition, prevents overheating. If the

adjustment is correct the hub should

turn freely with the only friction being

from the seal.

Å

Å

Å

Å

Fig. 5.01: Checking Disc Bearing Adjustment

Operating Instructions

25DTX

Page 26

5. Servicing and Maintenance

5.4.1 Bearing Seals

It is important when replacing the labyrinth

type bearing seals in disc hubs that the

seal is tted the right way round. The

chamfered lip side should be at the outside

of the bearing housing, nearest the disc

arm (see Fig. 5.02). This chamfered lip

prevents dirt ingress into the housing and

also allows grease to be ushed though

when greasing.

Chamfered Seal

ITEM PART NO DESCRIPTION

1 --- DISC ARM

2 P12900 NIPPLE - GREASE M8

3 P14593 HUB CASTING

4 P14594 HUB CAP

5 P12908 SPRING PIN

6 P12907 NUT CASTLE M27x1.5

7 SEAL 64x45x9.5

8 P12415 BEARING 32008 40x68x19

9 BEARING 32206 30x62x21

Fig. 5.02: Correct Seal Orientation

5.4 DD Lite Roll

The spacers and rings on the DD Lite Roll

are held under tension by the end plates at

the outer ends of the roll tube.

Specialist equipment is required

for the disassembly of DD Lite

rollers. Please consult your

dealer under any circumstances

that require disassembly of these

rollers.

Maintenance of these rollers is limited

to yearly/end of season greasing of the

bearings and regular inspection to ensure

the assemblies are tight, and scrapers are

correctly set.

The scraper is intended to clear

dirt from blocking between

adjacent DD rings. If adjustment

to the scrapers is required ensure

that the scraper cannot contact the

spacer even under load. Regularly

inspect the spacers for signs of

wear and adjust any scrapers to

ensure no contact can be made.

5.5 Double Disc Axles

The axles on this roller are tensioned by the

main axle through the centre of the rings

and bearings.

Specialist equipment is required

for the disassembly of Double

Disc axles. Please consult your

dealer under any circumstances

that require disassembly of these

axles.

Maintenance of these rollers is limited to

daily greasing of the bearings to ush out

dirt, and regular inspection to ensure the

assemblies are tight, and scrapers are

correctly set. The axles can be tightened

provided the bearing pillar ‘U’ bolts are

loosened to avoid preloading the bearings

as they move sideways to each other.

Ensure the bearing pillars are re- tightened

to the mainframe after this.

5.6 Preparation for

Storage

If you need to store the machine for a longer

period, observe the following points:

• Park the machine undercover if possible.

• Protect the roll / discs against rust. If you

need to spray the implements with oil, use

light, biologically degradable oils, e.g. rape

oil.

DTX

26

Operating Instructions

Page 27

5. Servicing and Maintenance

Cover any rubber sections before

using oil sprays. These sections

must not be oiled. Remove

any traces of oil with a suitable

cleaning agent.

5.7 Tines

When performing maintenance

work on tines extreme care

should be taken. Wear goggles

and gloves at at all times when

maintaining tines.

Safely support unfolded machine

in raised position using taps

and stands before attempting

maintenance work on tines.

Do not attempt to assist tting

tine points with a steel headed

hammer, this can lead to

splintering of the metal due to its

hardness, which can cause injury.

If tine tting requires assistance,

a copper/hide or plastic mallet

should be used.

5.8 Operator Support

If you have a problem, please contact your

dealer. They will endeavour to solve any

problems which may occur and provide you

with support at all times.

5.9 Maintenance

Intervals

Apart from daily maintenance, the

maintenance intervals are based on the

number of operating hours and time data.

Keep a record of your operating hours to

ensure that the specied maintenance

intervals are adhered to as closely as

possible.

Never use a machine that is due for

maintenance. Ensure that all deciencies

found during regular checks are remedied

immediately.

Avoid sharp-edged and pointed

parts (disc blades, etc.) when

working on the machine.

Place the machine on suitable

supports when working

underneath! Do not work under a

machine which is not supported!

On a new machine tighten all nuts and bolts

after 5 hours work and again after 15 hours.

This also applies to parts that have been

moved or replaced. After the initial 15 hours

of work a once a week check should be

sufcient depending on daily work rates.

In order to enable your dealer to deal with

problems as quickly as possible, it helps

if you can provide them with the following

data. Always state the:

• Customer Number

• Name and Address

• Machine Model

• Serial Number of Machine

• Date of Purchase and Operating Hours

• Type of Problem

27DTX

Operating Instructions

Page 28

5. Servicing and Maintenance

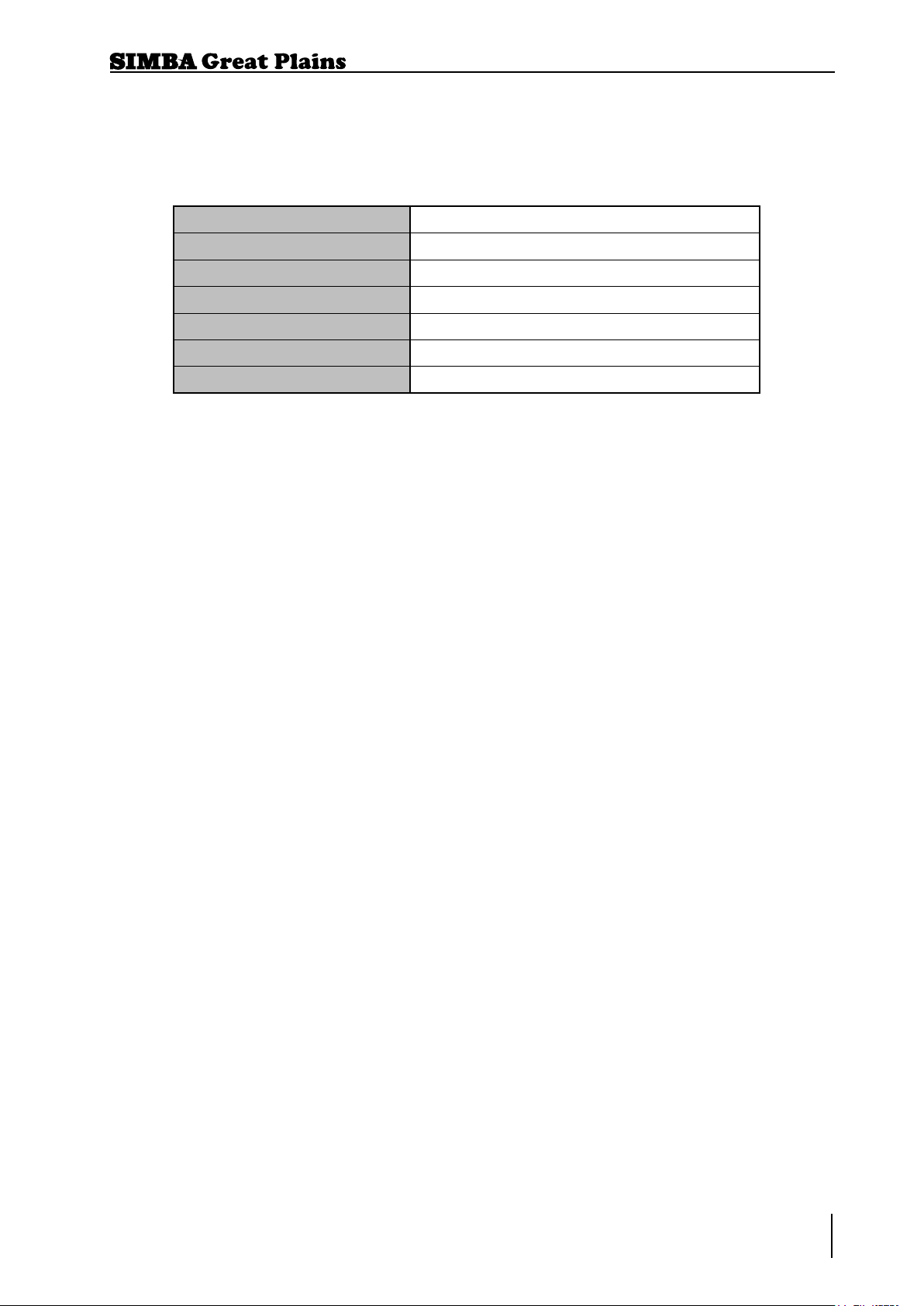

5.10 Maintenance Overview

Key

Inspect

L

Grease

Settings

10 Hours

Scrapers

10 Hours

DD Lite Roll

Bearings

200 Hours

One pump only!

L

L

Disc Angle

Adjusters

200 Hours

DD600 Roll

Bearings

Parking

Stands

Linkage

Before Each Use

Tines

Before Each Use

Disc Hubs

200 Hours

See section 5.11 on page 31

L

L

DTX

28

Operating Instructions

10 Hours

Before Each Use

L

Page 29

5. Servicing and Maintenance

5.11 Lubricating the

Machine

Please read the section entitled “Using

Lubricants” carefully before lubricating the

machine.

The machine must be lubricated regularly in

order for it to remain serviceable. Regular

lubrication also contributes towards

extending the service life of your machine.

The recommended lubricating intervals are

specied in “Inspection” and “Maintenance

Intervals”.

After it has been washed using a highpressure hose or steam cleaned, the

machine should always be lubricated using

a grease gun.

5.12 Handling of

Lubricants

Please ensure that you read the following

instructions as well as the relevant

information. This also applies to any of your

employees who handle lubricants.

Hygiene

Lubricants do not present a health hazard

provided they are used for their specied

purpose.

In the case of prolonged skin contact,

lubricants - especially low-viscosity oils

- may remove the natural layer of fat

contained in the skin, resulting in dryness

and possible irritation .

It is important to take extreme care when

handling waste oil as it may contain other

irritants.

Vapours given off by cleaning agents and

oils are also a potential health hazard.

You should therefore not carry any oily

cloths around. Change soiled work clothing

as soon as possible.

Always exercise extreme care and observe

the recommended hygiene rules when

handling mineral oil products. Details of

these handling regulations can be found

in information provided by the health

authorities.

Storage and Handling

• Always store lubricants where they cannot

be accessed by children.

• Never store lubricants in open or

unlabelled containers.

Fresh Oil

• Apart from taking the usual care and

observing hygiene rules, there is no need

to take any special precautions when

handling fresh oil.

Waste Oil

• Waste oil can contain harmful contaminants

which may cause skin cancer, allergies and

other illnesses.

Attention!

Oil is a toxic substance. Should you swallow

any oil, do not try to vomit. Contact a doctor

immediately.

Protect your hands with barrier cream or

wear gloves to avoid contact with the skin.

Wash off any traces of oil thoroughly with

soap and hot water.

• Wash your skin thoroughly with soap and

water.

• Use special cleaning agents to clean any

dirt off your hands.

• Never wash oil residue from your skin with

petrol, diesel fuel or parafn.

• Avoid skin contact with any oily clothing.

• Do not keep any oily rags in your pockets.

• Wash soiled clothing before wearing it

again.

• Ensure that any oily footwear is disposed

of in the proper manner.

Operating Instructions

29DTX

Page 30

5. Servicing and Maintenance

Measures in case of injury

through oil

Eyes:

Should any oil be splashed into your eyes,

rinse with water for 15 minutes. If the eye is

still irritated, contact a doctor immediately

If oil is swallowed

If oil is swallowed, it is important not to induce

vomiting. Contact a doctor immediately.

Skin irritation caused by oil

In case of prolonged skin contact, wash off

the oil with soap and water.

Oil Spills

Use either sand or a suitable granular

absorbent to soak up any spilt oil. Dispose

of the oil-contaminated absorbent in the

proper manner.

Oil Fires

Never use water to extinguish an oil re.

The oil will oat on the water causing the

re to spread.

Burning oil-lubricant must be extinguished

using a carbon dioxide powder or foam

extinguisher. Always wear respiratory

equipment when dealing with res of this

type.

5.13 Lubricants

Simba strongly recommend the use of

Lithium Complex EP2 Grease in the disc

hubs of your DTX. This grease is a Lithium

Complex soap dispersed in a mineral

oil and is interpreted by IARC as being

non-carcinogenic. Grease cartridges are

available from Simba (P12710). Using this

grease in combination with the labyrinth type

seal it is permissible to lengthen the greasing

interval on the disc hubs to 200 hours. If

using a standard agricultural grease the disc

hubs should be lubricated every 50 hours.

Advantages of Lithium Complex EP2

Grease

Excellent mechanical stability.

Excellent load carrying properties.

Wide temperature range.

Excellent oxidation stability.

Excellent water resistance.

Compatibility with other greases.

All other lubricating points on the machine

can be lubricated with multigrade lubricating

grease as specied in DIN 51825 KP/2K -

40.

Waste Oil Disposal

Oil-contaminated waste and used oil must

be disposed of in accordance with current

legislation.

Waste oil must be collected and disposed

of in accordance with local regulations.

Never pour used oil into unsealed sewage

systems or drains or onto the ground.

DTX

30

Operating Instructions

Page 31

6. Faults and Remedies

6. Faults and Remedies

DTX Troubleshooting

Fault Possible Cause Remedy

Machine ‘bouncing’ in work. Disc angle too great. Reduce disc angle.

Speed too fast. Reduce speed (<12kmh).

DD Lite Roll blocks

regularly.

Scrapers incorrectly

adjusted

Conditions may not be

ideal for using machine.

Inadequate consolidation. Not enough weight on rear

roll.

Not enough cultivated soil

depth.

Speed too fast. Reduce speed (<12kmh).

Surface nish is uneven

Not enough roll pressure Reduce draft control

and cloddy

Wings too aggressive Fit different wings, either

Running nose down Level frame

Adjust scrapers to clear dirt

from between DD Rings.

Wait for more favourable

conditions.

Increase chassis pitch

slightly via tractor toplink.

Increase working depth.

narrower wings or wings

with a shallower rake (see

page 20)

All ground not being moved

by tines

Working too shallow Increase tine depth

Working too shallow Increase tine depth

Wings not aggressive

Fit wider wings

enough

Operating Instructions

31DTX

Page 32

7. Parts and Assembly

DTX

32

Operating Instructions

Page 33

7. Parts & Assembly

Table of contents

DTX 300 Complete Machine Assembly ... 34

DTX 350 Complete Machine Assembly ... 36

DTX 300 Mainframe Assembly ................ 38

DTX 350 Mainframe Assembly ................ 40

Toolbox Assembly .................................... 42

Pro-Lift Tine Assembly (Retrot to 2009 Model)... 44

Pro-Lift Tine Assembly (2010 Model) .............. 46

LD Tine Assembly (2010 Model) ..................... 48

DTX 300 DD Lite Roll Assembly .............. 50

DTX 350 DD Lite Roll Assembly .............. 52

DD Lite Scraper Assembly....................... 54

DTX 300 Aqueel 2 Assembly ................... 56

DTX 300 DD600 Roll Assembly............... 58

DTX 350 DD600 Roll Assembly............... 60

DD600 Axle Assembly - 6 Rings .............. 62

DD600 Axle Assembly - 7 Rings .............. 64

DD600 Axle Assembly - 8 Rings .............. 66

DD600 Pillar Assembly ............................ 68

DTX 350 Front Light Assembly ................ 70

DTX 350 Rear Light Assembly ................ 72

Sticker Guide ........................................... 74

DTX 300 Sticker Layout........................... 76

DTX 350 Sticker Layout........................... 78

TurboJet Mounting Assembly ..................80

Distributor Head Assembly ...................... 82

Radar Mounting (Aqueel 2) ..................... 84

7. Parts and Assembly

Operating Instructions

33DTX

Page 34

7. Parts and Assembly

TITLE COMPANYMASS KgCOSTCATEGORYCOMMENTSQTYMATERIALDESCRIPTIONISSUEPART NOITEM 18.54 1 TOOL BOX ASSEMBLY AAS36031 0.05 P167151 DTX 300 - STICKER KIT LAYOUTEAS36252 48.05 5 DTX TINE POCKETBAS37783 1809.48 1 DTX300 MAIN FRAME ASSEMBLYCAS38214 703.86 1 DTX300 - ROLL ASSEMBLYAAS42135 0.29 B 1ABS PlasticMANUAL - DTX 2011AP180286

C

ISSUE

6

ASSEMBLY

AS3820

FROM SERIAL NO. TO SERIAL NO.

PART NO.

AGD

20/10/2008

DATE:-

DRAWN:-

© 2009

1

2

4

3

SIMBA

DTX

MACHINE:-

DTX

34

Operating Instructions

5

DESCRIPTION:-

DTX300 - FULL MACHINE ASSEMBLY

Page 35

7. Parts and Assembly

AS3820

ITEM PART NO DESCRIPTION QTY COMMENTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

AS3603 TOOL BOX ASSEMBLY 1

AS3625 DTX 300 - STICKER KIT LAYOUT 1

AS3778 DTX TINE POCKET 5

AS3821 DTX300 MAIN FRAME ASSEMBLY 1

AS4213 DTX300 - ROLL ASSEMBLY 1

P18028 MANUAL - DTX 2011 1

DTX300 - FULL MACHINE ASSEMBLY

Operating Instructions

35DTX

Page 36

7. Parts and Assembly

TITLE

COMPANYMASS KgCOSTCATEGORYCOMMENTSQTYMATERIALDESCRIPTIONISSUEPART NOITEM

48.04 6 DTX TINE POCKETBAS37781

2136.57 A 1 DTX 350 CHASSIS ASSEMBLYAAS42502

801.56 A 1 DTX350 ROLL ASSEMBLYAAS42513

0.03 AP184841 DTX350 STICKER KIT LAYOUTAAS42524

16.00 A 1 REAR LIGHT KIT ASSEMBLYAAS44935

15.11 A 1 REAR LIGHT KIT ASSEMBLYAAS44946

0.29 B 1ABS PlasticMANUAL - DTX 2011AP180287

AAS4249

ISSUE

6

7

ASSEMBLY

2

1

FROM SERIAL NO. TO SERIAL NO.

PART NO.

KSL

23/12/2010

DATE:-

DRAWN:-

© 2009

SIMBA

4

DTX 350

MACHINE:-

3

5

DESCRIPTION:-

DTX 350 TOP LEVEL ASSEMBLY

DTX

36

Operating Instructions

Page 37

7. Parts and Assembly

AS4249

ITEM PART NO DESCRIPTION QTY COMMENTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

AS3778 DTX TINE POCKET 6

AS4250 DTX 350 CHASSIS ASSEMBLY 1

AS4251 DTX350 ROLL ASSEMBLY 1

AS4252 DTX350 STICKER KIT LAYOUT 1

AS4493 REAR LIGHT KIT ASSEMBLY 1

AS4494 REAR LIGHT KIT ASSEMBLY 1

P18028 MANUAL - DTX 2011 1

DTX 350 TOP LEVEL ASSEMBLY

Operating Instructions

37DTX

Page 38

7. Parts and Assembly

A

7

43

2

15

C

ISSUE

51

17

18

16

23

24

49

20

19

47

4

8

17

48

40

ASSEMBLY

AS3821

TO SERIAL NO.

FROM SERIAL NO.

PART NO.

2

22

13

46

8

11

7

50

AGD

02/11/2009

DATE:-

DRAWN:-

© 2008

A

5

3

45

E

44

12

37

6

33

32

35

29

27

28

9

31

1

25

41

D

SIMBA

DTX

MACHINE:-

38

26

E

DTX

38

Operating Instructions

26

14

34

5

7

36

39

21

10

30

13

41

38

38

D

42

DESCRIPTION:-

DTX300 MAIN FRAME ASSEMBLY

Page 39

7. Parts and Assembly

Y

AS3821

ITEM PART NO DESCRIPTION QTY COMMENTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

P00040 BOLT M36x140 GR. 8.8 2

P00407 BOLT M20x80 GR. 8.8 4

P01071 PIN Ø25x130 4

P01287 BOLT M20x150 GR. 8.8 5

P01704 BOLT M16x50 GR8.8 2

P01901 BOLT M16x80 GR. 8.8 44

P02008 NUT LOCK M16 'TYPE T' 92

P02009 NUT LOCK M20 9

P02012 NUT LOCK M36 2

P02037 WASHER SPRING M12 110

P02318 BOLT M16x120 GR. 8.8 4

P02483 LYNCH PIN CAT 1 2

P02484 LYNCH PIN CAT 2 6

P02602 WASHER FLAT M16 154

P02603 WASHER FLAT M20 8

P02789 BOLT M8x20 GR. 8.8 2

P04423 LYNCH PIN CAT 3 3

P05122 SERIAL PLATE 1

P05400 WASHER FLAT M6 3

P05401 WASHER SPRING M6 3

P07229 NUT LOCK M12 FINE 1.5 66

P07545 PLASTIC END CAP 60x60 2

P08817 WASHER SPRING M8 2

P10293 BOLT M6x20 GR. 8.8 3

P11462 DISC BLADE Ø515x6 22

P11494 BOLT M16x55 GR. 8.8 42

P12620 TOP PLATE 22

P12621 SPACER Ø36xØ16.5x31mm 44

P12622 TRACK ARM 20

P12646 PIN Ø20x125 2

P12782 SPRUNG LEAF 20mm 22

P12783 LYNCH PIN CAT 0 22

P12810 NUT CASTLE M24 22

P12815 BOLT M24x185 STRUCTURAL GR 8.8 22

P12886 Ø24xØ16x13mm SPACER BUSH 22

P13174 BOLT M12x50 GR10.9 1.5P 66

P14027 PIN Ø25x118 HANDLED 2

P14600 DISC ARM UNIT RH 11

P14601 DISC ARM UNIT LH 11

P14754 BALL CAT 3 LOWER Ø37 2

P15438 ANGLE GUIDE 2

P15926 BOLT M12x20 GR8.8x1.25 110

P16354 HOOK TRACK ROD ARM 2

P16759 TRACK ROD-11 HOLE 2

P16764 PARKING STAND 2

P17076 ADJUSTER 350-600 2

P17286 CHASSIS-DTX300 1

P17308 SHEAR BOLT STOWAGE M20 1

P17815 MANUAL HOLDER - COMPLETE 1

P17892 PIN LOWER LINK CAT 3 2

P17893 PIN UPPER LINK CAT 3 1

DTX300 MAIN FRAME ASSEMBL

39DTX

Operating Instructions

Page 40

7. Parts and Assembly

TITLE

COMPANYMASS KgCOSTCATEGORYCOMMENTSQTY

MATERIAL

DESCRIPTIONISSUEPART NO

1.59

£3.37B 2Steel, High Strength

Low Alloy

BOLT M36x140 GR. 8.8AP000401

0.28£0.32B 4Steel, High Strength

Low Alloy

BOLT M20x80 GR. 8.8AP004072

0.56£1.07 4EN 8 / 080M40PIN Ø25x130AP010713

0.45£0.57B 5Steel, High Strength

Low Alloy

BOLT M20x150 GR. 8.8AP012874

C

42

32

31

26

5

13

AAS4250

5

32

31

B

27

13

33

6

23

46

19

18

40

27

26

25

5

13

25

28

34

30

6

6

33

6

24

35

ISSUE

20

ASSEMBLY

FROM SERIAL NO. TO SERIAL NO.

37

PART NO.

17

49

50

48

7

KSL

45

4

16

15

22

16

39

47

22/12/2010

DATE:-

DRAWN:-

© 2009

SIMBA

DTX 350

MACHINE:-

B

25

13

14

2

7

44

14

A

34

A

DTX

40

Operating Instructions

7

2

14

13

14

6

8

6

13

12

11

10

36

29

10

21

3

38

1

43

12

43

24

9

41

DESCRIPTION:-

DTX 350 CHASSIS ASSEMBLY

Page 41

7. Parts and Assembly

AS4250

ITEM PART NO DESCRIPTION QTY COMMENTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

P00040 BOLT M36x140 GR. 8.8 2

P00407 BOLT M20x80 GR. 8.8 4

P01071 PIN Ø25x130 4

P01287 BOLT M20x150 GR. 8.8 5

P01901 BOLT M16x80 GR. 8.8 52

P02008 NUT LOCK M16 'TYPE T' 108

P02009 NUT LOCK M20 9

P02012 NUT LOCK M36 2

P02037 WASHER SPRING M12 130

P02318 BOLT M16x120 GR. 8.8 4

P02483 LYNCH PIN CAT 1 2

P02484 LYNCH PIN CAT 2 6

P02602 WASHER FLAT M16 182

P02603 WASHER FLAT M20 8

P02789 BOLT M8x20 GR. 8.8 2

P04423 LYNCH PIN CAT 3 3

P05122 SERIAL PLATE 1

P05400 WASHER FLAT M6 3

P05401 WASHER SPRING M6 3

P07229 NUT LOCK M12 FINE 1.5 78

P07545 PLASTIC END CAP 60x60 2

P08817 WASHER SPRING M8 2

P10293 BOLT M6x20 GR. 8.8 3

P11462 DISC BLADE Ø515x6 26

P11494 BOLT M16x55 GR. 8.8 52

P12620 TOP PLATE 26

P12621 SPACER Ø36xØ16.5x31mm 52

P12622 TRACK ARM 24

P12646 PIN Ø20x125 2

P12782 SPRUNG LEAF 20mm 26

P12783 LYNCH PIN CAT 0 26

P12810 NUT CASTLE M24 26

P12815 BOLT M24x185 STRUCTURAL GR 8.8 26

P12886 Ø24xØ16x13mm SPACER BUSH 26

P13174 BOLT M12x50 GR10.9 1.5P 78

P14027 PIN Ø25x118 HANDLED 2

P14600 DISC ARM UNIT RH 13

P14601 DISC ARM UNIT LH 13

P14754 BALL CAT 3 LOWER Ø37 2

P15438 ANGLE GUIDE 2

P15926 BOLT M12x20 GR8.8x1.25 130

P16354 HOOK TRACK ROD ARM 2

P16764 PARKING STAND 2

P17076 ADJUSTER 350-600 2

P17308 SHEAR BOLT STOWAGE M20 1

P17815 MANUAL HOLDER - COMPLETE 1

P17892 PIN LOWER LINK CAT 3 2

P17893 PIN UPPER LINK CAT 3 1

P18095 CHASSIS - DTX 350 1

P18105 TRACK ROD-13 HOLE 2

DTX 350 CHASSIS ASSEMBLY

Operating Instructions

41DTX

Page 42

7. Parts and Assembly

DTX

42

Operating Instructions

Page 43

7. Parts and Assembly

AS3603

ITEM PART NO DESCRIPTION QTY COMMENTS

1

P00003 BOLT M12x40 GR. 8.8 2

2

P02007 NUT LOCK M12 2

3

P02483 LYNCH PIN CAT 1 1

4

P02601 WASHER FLAT M12 2

5

P09162 TOOLBOX LID 1

6

P10017 TOOLBOX BODY 1

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

TOOL BOX ASSEMBLY

Operating Instructions

43DTX

Page 44

7. Parts and Assembly

TITLE

COMPANYMASS KgCOSTCATEGORYCOMMENTSQTYM ATERIALDESCRIPTIONISSUEPART NOITEM

0.10

£0.10

B

1Ste el, High Strength

Low Alloy

BOLT M16x40 GR. 8.8

A

P000071

0.49£0.57B 2

Steel, High Strength

Low Alloy

BOLT M24x100 GR. 8.8

AP000172

0.70£0.87B 1Steel, High Strength

Low Alloy

BOLT M24x160 GR. 8.8AP000233

0.28£0.81B 1Steel, High Strength

BOLT M16x150 GR. 8.8AP013524

C

ISSUE

7

11

7

7

10

ASSEMBLY

AS4026

11

6

14

19

5

6

22

23

24

23

25

4

10

3

MACHINES (M24 & M16 BOLTS)

TO FIT 2010 TINE POCKETS TO 2009

PIVOT & SHEAR BUSHES REQUIRED

11

FROM SERIAL NO. TO SERIAL NO.

PART NO.

KSL

18/03/2010

DATE:-

DRAWN:-

© 2009

2

SIMBA

21

11

2

2010 DTX CHASSIS

20

17

16

2009 DTX CHASSIS

6

9

18

15

1

13

DTX

MACHINE:-

12

8

8

DTX

44

Operating Instructions

DESCRIPTION:-

DTX TINE POCKET FOR 2009 MACHINE

Page 45

7. Parts and Assembly

AS4026

ITEM PART NO DESCRIPTION QTY COMMENTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

P00007 BOLT M16x40 GR. 8.8 1

P00017 BOLT M24x100 GR. 8.8 2

P00023 BOLT M24x160 GR. 8.8 1

P01352 BOLT M16x150 GR. 8.8 1

P02007 NUT LOCK M12 1

P02008 NUT LOCK M16 'TYPE T' 3

P02010 NUT LOCK M24 3

P02481 ROLL PIN Ø16x40 2

P02602 WASHER FLAT M16 1

P02604 WASHER FLAT M24 Ø50 2

P02606 WASHER FLAT M24 Ø70 4

P09148 POINT - PROLIFT CrFe 1

P09161 PIN Ø45x72 1

P09166 LYNCH PIN CAT 2 LOCKING 1

P10392 WING - PROLIFT 250mm 1

P11181 WEAR SHROUD 1

P12018 WEARSHIN PROLIFT REVERSIBLE 1

P12787 BOLT M16x75 GR8.8 1

P12950 BOLT M12x35 SOCKET CAP 1

P16286 DTX TINE 400 W/DEPTH 1

P17284 TINE POCKET RH 1

P17289 TINE POCKET LH 1

P17292 TINE SUPPORT BUSH 2

P17543 SHEAR BOLT BUSH 1

P17544 PIVOT BOLT BUSH 1

DTX TINE POCKET FOR 2009 MACHINE

Operating Instructions

45DTX

Page 46

7. Parts and Assembly

8

9

13

12

16

6

24

8

12

7

21

5

25

27

4

26

27

13

3

12

B

ISSUE

ASSEMBLY

AS3778

TO SERIAL NO.

FROM SERIAL NO.

PART NO.

KSL

17/09/2009

DATE:-

DRAWN:-

© 2009

2

SIMBA

15

12

23

22

6

11

19

20

18

2

10

1

14

DTX

MACHINE:-

10

DTX

46

Operating Instructions

17

DESCRIPTION:-

DTX TINE POCKET

Page 47

7. Parts and Assembly

AS3778

ITEM PART NO DESCRIPTION QTY COMMENTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

P00007 BOLT M16x40 GR. 8.8 1

P00017 BOLT M24x100 GR. 8.8 2

P00036 BOLT M30x180 GR. 8.8 1

P01287 BOLT M20x150 GR. 8.8 1

P02007 NUT LOCK M12 1

P02008 NUT LOCK M16 'TYPE T' 2

P02009 NUT LOCK M20 1

P02010 NUT LOCK M24 2

P02011 NUT LOCK M30 1

P02481 ROLL PIN Ø16x40 2

P02602 WASHER FLAT M16 1

P02606 WASHER FLAT M24 Ø70 4

P02608 WASHER FLAT M30 2

P09148 POINT - PROLIFT CrFe 1

P09161 PIN Ø25x72 1

P09166 LYNCH PIN CAT 2 LOCKING 1

P10392 WING - PROLIFT 250mm 1

P11181 WEAR SHROUD 1

P12018 WEARSHIN PROLIFT REVERSIBLE 1

P12787 BOLT M16x75 GR8.8 1

P12950 BOLT M12x35 SOCKET CAP 1

P16286 DTX TINE 400 W/DEPTH 1

P17284 TINE POCKET RH 1

P17289 TINE POCKET LH 1

P17290 SHEAR BOLT BUSH 1

P17291 PIVOT BOLT BUSH 1

P17292 TINE SUPPORT BUSH 2

DTX TINE POCKET

Operating Instructions

47DTX

Page 48

7. Parts and Assembly

TITLE

COMPANYMASS KgCOSTCATEGORYCOMMENTSQTYMATERIALDESCRIPTIONISSUEPART NOI TEM

0.49

£0.57B 1Steel, High Strength

Low Alloy

BOLT M24x100 GR. 8.8AP000171

1.27

£1.17

B 1

Steel, High Strength

Low Alloy

BOLT M30x180 GR. 8.8

AP000362

0.17£0.16B 1Steel, High Strength

Low Alloy

BOLT M16x80 GR. 8.8AP019013

BAS4032

7

10

5

9

6

21

8

25

27

11

23

27

25

28

22

28

4

26

24

26

29

14

ISSUE

ASSEMBLY

FROM SERIAL NO. TO SERIAL NO.

PART NO.

EH

15/04/2010

DATE:-

DRAWN:-

© 2009

10

SIMBA

9

12

3

13

18

17

1

11

2

20

16

15

DTX

MACHINE:-

DTX

48

Operating Instructions

19

DESCRIPTION:-

DTX LD TINE POCKET ASSEMBLY

Page 49

7. Parts and Assembly

AS4032

ITEM PART NO DESCRIPTION QTY COMMENTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

P00017 BOLT M24x100 GR. 8.8 1

P00036 BOLT M30x180 GR. 8.8 1

P01901 BOLT M16x80 GR. 8.8 1

P02007 NUT LOCK M12 1

P02008 NUT LOCK M16 'TYPE T' 1

P02009 NUT LOCK M20 1

P02010 NUT LOCK M24 1

P02011 NUT LOCK M30 1

P02602 WASHER FLAT M16 2

P02606 WASHER FLAT M24 Ø70 2

P02608 WASHER FLAT M30 2

P05207 PIN Ø16x73 1

P05534 NUT LOCK M10 1

P10367 CAPSCREW M12x40 GR10.9 1

P11275 NUT TOOTHED M12 2

P12778 BOLT M10x45 GR8.8 1

P13812 WING - LD 1

P15055 TINE - LD SHORT 1

P15809 BOLT M12x40 CSK SQ 8.8 2

P15957 POINT EP 1