Page 1

From Serial Number 12724

P15126 11/07/07

Page 2

ST-Bar

2

Operating Instructions

Page 3

Declaration of Conformity

DECLARATION OF CONFORMITY

Simba International Limited hereby declare that the Product described in this Operators Manual, and defined

by the Serial Number Plate attached to the Chassis of the Machine (a part copy of which is detailed overleaf

and must be completed indicating the relevant machine details), conforms with the following Directives and

Regulations, and has been certified accordingly.

EC Machinery Directive 89/392/EEC, as amended by 91/3688/EEC, 93/44/EEC, and

93/688/EEC.

In order to fulfill the requirements of health and safety described in the EC Directive, the following standards

and technical specifications have been taken into account:

EN 292 - 1

EN 292 - 2

THE MANUFACTURER

Simba International Limited

Woodbridge Road

SLEAFORD

NG34 7EW

Lincolnshire

NG34 7EW

England.

Telephone 01529 304654.

CERTIFIED ON BEHALF OF SIMBA INTERNATIONAL LIMITED.

Rod Daffern

Chairman

Simba International Limited

Operating Instructions

3ST-Bar

Page 4

y

.

a

e

r

r

t

y

e

o

e

e

l

e

s

e

s

s

e

l

Warranty

WARRANTY

TERMS AND CONDITIONS

In this warranty Simba International Ltd., is referred to as “the Company”.

1. Subject to the provisions of this warranty the Company warrants each new machine sold b

it to be sold free from any defect in material or workmanship for a period of 12 months from

date of installation with the end-user.

Some specific items have additional warranty over and above the standard 12 months

Details of these can be obtained upon request directly from the distributor or Simb

International Ltd.

2. If the machine or part thereof supplied by the Company is not in accordance with th

warranty given in clause 1 the Company will at its option:

(a) make good the machine or part thereof at the Company’s expense, or

(b) make an allowance to the purchaser against the purchase price of the machine o

part thereof, or

(c) accept the return of the machine and at the buyers option either:

I) repay or allow the buyer the invoice price of the machine or part thereof, o

II) replace the machine or part thereof as is reasonably practical.

3. This warranty shall not oblige the Company to make any payment in respect of loss of profi

or other consequential loss or contingent liability of the Purchaser alleged to arise from an

defect in the machine or impose any liability on the Company other than that contained in

clause 2.

4. Any claim under this warranty must be notified to the Company in writing specifying th

matters complained of within 14 days from the date of repair.

5. Any claim under this warranty must be made by the original purchaser of the machine and

is not assignable to any third party.

6. If the purchaser hires out the machine to any third party the warranty shall apply only t

matters notified to the Company in writing within 90 days of the date of delivery and claus

1 shall be read as if the period of 90 days were substituted for the period of 12 months.

7. The warranty will cease to apply if:

(a) any parts not made, supplied or approved in writing by the Company are fitted to th

machine or

(b) any repair is carried out to the machine other than by or with the express written approva

of the Company or

(c) any alterations not expressly authorized by the Company in writing are made to th

machine or

(d) the machine is damaged by accident or

(e) the machine is abused or overloaded or used for a purpose or load beyond its design

capabilities, or used in conjunction with a tractor whose power output capability exceed

the stated implement power requirement by more than 40%. For the purpose of thes

terms and conditions, “stated implement power requirement” refers to wheeled tractor

unless specifically stated. These power requirements should be reduced by 20% when

used in conjunction with tracked tractors.

(f) the machine is operated as part of a ‘cultivation train’ where more than one implement i

being towed, without the express written approval of Simba International Ltd.

(g) any maintenance is not carried out in accordance with the service schedules in th

operator’s manual.

(h) the Installation and Warranty Registration Certificate is not received by Simba Internationa

Ltd., Service Dept., Woodbridge Road, Sleaford, Lincolnshire, England, NG34 7EW, within

7 days of installing a new machine.

ST-Bar

4

Operating Instructions

Page 5

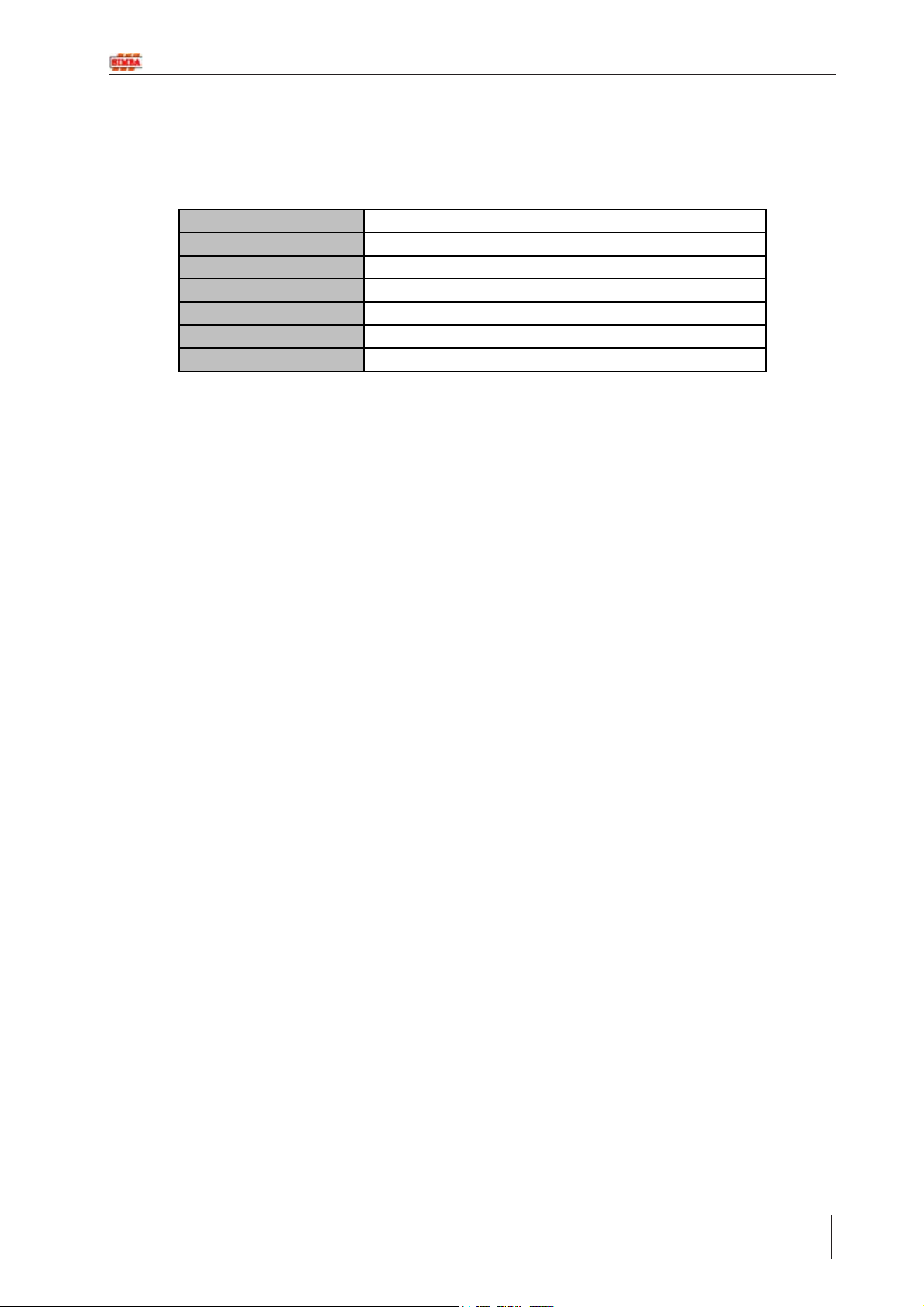

Machine Identification

Enter the relevant data in the following list upon

acceptance of the machine:

Serial Number

Parent Machine

Machine Width

Year of Construction

Delivery Date

First Operation

Accessories

Operating Instructions/Spare Parts List: July 2007

Machine Identification

Dealer Address: Name: ......................................................................

Street: ......................................................................

Place: ......................................................................

Tel.: ................................................................. ....

Dealer's Customer No.: ............................................................

SIMBA Address: SIMBA

Woodbridge Road Ind. Est.

Sleaford

Lincolnshire

NG34 7EW

Tel.: 01529 304654

Fax: 01529 413468

E-Mail: simba.international@simba.co.uk

SIMBA Customer No.: .................................................................

Operating Instructions

5ST-Bar

Page 6

ST-Bar

6

Operating Instructions

Page 7

Table of Contents

Contents

Machine Identification .......................................................................................................5

Introduction ............................................................................................. 8

Foreword ......................................................................................................................... 8

Warranty Guidelines ......................................................................................................... 8

1. Safety Data .......................................................................................... 9

1.2 Use for the Intended Purpose ..................................................................................... 9

1.3 Operational Safety ................................................................................................... 10

1.4 No Liability for Consequential Damage .................................................................... 10

1.5 Changing Equipment ................................................................................................ 10

1.6 During Operation ...................................................................................................... 10

1.7 Servicing & Maintenance .......................................................................................... 10

2. Transportation and Installation ........................................................ 11

2.1 Delivery ....................................................................................................................11

2.2 Transportation .......................................................................................................... 11

2.3 Installation ................................................................................................................ 11

2.4 Connecting the ST-Bar to the Mounted X-Press ........................................................ 11

3. Adjustment/Operation ....................................................................... 13

3.1 Description .............................................................................................................. 13

3.2 Work Instructions ...................................................................................................... 14

3.3 Checks..................................................................................................................... 14

3.4 Parking .................................................................................................................... 14

3.5 Adjustment ............................................................................................................... 14

4. Servicing and Maintenance .............................................................. 15

4.1 Servicing .................................................................................................................. 15

4.2 Cleaning .................................................................................................................. 15

4.3 Storage / Parking ..................................................................................................... 15

4.4 Operator Support ..................................................................................................... 15

4.5 Maintenance Intervals ............................................................................................... 15

4.6 Maintenance Overview ............................................................................................. 16

6. Parts and Assembly .......................................................................... 17

Operating Instructions

7ST-Bar

Page 8

Introduction

Introduction

Foreword

Make sure you have read and follow the

Operating Instructions carefully before using

the machine. By doing so, you will avoid

accidents, reduce repair costs and downtime

and increase the reliability and service life

of your machine. Pay attention to the safety

instructions!

SIMBA will not accept any responsibility for

any damage or malfunctions resulting from

failure to comply with the Operating

Instructions.

These Operating Instructions will assist you

in getting to know your component and in using

it correctly for its intended purposes. First, you

are given general instructions in handling the

component. This is followed by sections on

servicing, maintenance and the action to be

taken should a malfunction occur.

We reserve the right to alter

illustrations as well as technical data

and weights contained in these

Operating Instructions for the purpose

of improving the component.

Warranty Guidelines

1. The period of liability for material defects

(warranty) relating to our products is 12

months. In the case of written deviations

from the statutory provisions, these

agreements shall apply.

They shall become effective upon installation

of the machine with the end customer. All wear

parts are excluded from the warranty.

2. Warranty claims must be submitted to the

SIMBA Customer Service Department in

Sleaford via your dealer. It is only possible

to process claims which have been correctly

completed and submitted no later than 14

days after the date of repair.

These operating instructions are to be read

and followed by all persons working on or

with the component, e.g.:

• Operation (including preparation, remedying

of faults in the operating sequence and

servicing).

• Maintenance (maintenance and inspection)

• Transportation.

Together with the Operating Instructions, you

receive a Spare Parts List and a Machine

Registration form. Field service technicians

will instruct you in the operation and

servicing of your machine. Following this,

the Machine Registration form is to be

returned to SIMBA. This confirms your

formal acceptance of the machine. The

warranty period begins on the date of delivery.

3. In the case of deliveries made under the

warranty which are subject to the return of

the old parts, the old parts must be returned

to SIMBA within 28 days after the damage

occurred.

4. In the case of deliveries made under the

warranty which are not subject to the return

of the old parts, these parts must be kept for

the purpose of further decisions for a period

of 3 months after receipt of the warranty claim.

5. Warranty repairs to be carried out by

outside companies, or repairs which are

expected to take more than 10 working

hours, must be agreed upon in advance with

the Customer Service Department.

ST-Bar

8

Operating Instructions

Page 9

Safety Data

1. Safety Data

The following warnings and safety instructions

apply to all sections of these Operating

Instructions. All safety instructions for the

parent machine should be followed.

1.1 Operating Instructions:

The Operating Instructions distinguish

between three different types of warning and

safety instructions. The following graphic

symbols are used:

Important!

Risk of injury!

Risk of fatal and serious injuries!

It is important that all the safety instructions

contained in these Operating Instructions

and all the warning signs on the machine

are read carefully.

1.2 Use for the Intended

Purpose

The SIMBA ST-Bar is built using the latest

technology and in accordance with the relevant recognised safety regulations. However,

risks of injury for the operator or third parties

and impairment of the machine or other

tangible assets can arise during use.

The Toolbar unit is only to be operated when

in a technically perfect condition and for the

intended purpose, taking into consideration

safety and risks and following the Operating

Instructions. In particular, faults that can

impair safety are to be remedied

immediately.

Original parts and accessories from SIMBA

have been specially designed for this unit.

Spare parts and accessories not supplied by

us have not been tested or authorised.

Installation or use of non-original SIMBA

products may have a detrimental effect on

specific design features of the unit and affect

the safety of machine operators. SIMBA will

accept no liability for damage resulting from

the use of non-original parts or accessories.

Ensure that the warning signs are legible.

Replace any signs that are missing or

damaged.

These instructions must be followed in order

to prevent accidents. Inform other users of

the warnings and safety instructions.

Do not carry out any operations which may

affect safe use of the machine.

The SIMBA ST-Bar is designed solely as a

Toolbar unit. Use for any other purpose, e.g.,

as a means of transport, will be deemed to

be improper use. SIMBA will accept no

liability for damage resulting from improper

use. The risk will be borne solely by the

operator.

Operating Instructions

9ST-Bar

Page 10

Safety Data

1.3 Operational Safety

All protective and safety equipment, such as

removable protective equipment, must be in

place and functioning reliably before the

machine is put in use.

Check screws and bolts regularly for

tightness and retighten if necessary.

In the event of malfunctions, stop and

secure the machine immediately.

Ensure that any faults are remedied

immediately.

1.4 No Liability for

Consequential Damage

The ST-Bar has been manufactured by

SIMBA with great care. However, problems

may still occur when it is used for the intended

purpose. This may include:

1.5 Changing Equipment

• Use suitable supports to secure any raised

frame sections suspended above you!

• Caution! Risk of injury due to projecting parts!

1.6 During Operation

The person in charge must:

• provide the operator with a copy of the

Operating Instructions.

• ensure that the operator has read and

understood the instructions.

1.7 Servicing &

Maintenance

Ensure that regular checks and inspections

are always carried out within the periods

required by law or specified in these

Operating Instructions.

• Worn wearing parts.

• Damage caused by external factors.

• Incorrect driving speeds.

• Incorrect setting of the unit (incorrect

attachment, non-adherence to the Setting

instructions).

Therefore, it is crucial to always

check your Toolbar unit before and

during operation for correct

operation and adequate application

accuracy.

Compensation claims for damage which has

not occurred to the component is excluded.

This includes any consequential damage

resulting from incorrect operation.

Prior to performing maintenance and

servicing work, ensure that the machine is

positioned on solid, level ground and is secure

and stable.

Before cleaning the unit with water, steam jets

(high-pressure cleaning apparatus) or other

cleaning agents, cover all openings into

which, for reasons of safety or operation, no

water, steam or cleaning agents are to

penetrate.

When carrying out servicing and maintenance

work, retighten any loose screw connections.

ST-Bar

10

Operating Instructions

Page 11

Transportation & Installation

2. Transportation and

Installation

Transportation and initial installation of the

machine are described in this chapter.

2.1 Delivery

The Toolbar unit is normally delivered, fully

assembled, on a (low-bed) truck.

The machine can be lifted off with a crane,

fork-lift truck, or other suitable lifting

equipment.

When doing so, the weight, the centre of

gravity and the attachment points on the unit

are to be taken into account.

Depending on the lifting gear, attachment is

only to be at appropriate points on the frame.

2.2 Transportation

The ST-Bar unit must be lifted clear of the

ground for road transport.

2.3 Installation

When carrying out installation and

maintenance work there is a higher risk of

injury. It is important that you familiarise

yourself with the component and read the

Operating Instructions beforehand.

2.4 Connecting the ST-Bar

to the Mounted X-Press

1. Attach the parking stands to the X-Press

(see Fig. 3.03 on page 14 and Pages

26-30 for details).

2. The Mounted X-Press should be parked

on a firm, level surface using all four

parking stands.

3. Attach the ST-Bar to the tractor using

the link pins provided with the Mounted

X-Press.

4. Using pins, fit the balls to the X-Press

lower links (see Items 13 & 14 on Pages

18 & 20 and Items 15 & 16 on Page

22).

5. With the Toolbar attached to the tractor,

align the rear linkage of the Toolbar with

the linkage of the Mounted X-Press. The

rear parking stands and/or roll height of

the X-Press can be used to level the

machine enabling easier linkage.

Engage the balls in the hooks on the

Lower links of the X-Press.

6. Fit the Toplink Adjuster on the Toolbar

to the X-Press upper link.

Fig. 2.01: X-Press with ST-Bar

11ST-Bar

Operating Instructions

Page 12

Transportation / Installation

ST-Bar

12

Operating Instructions

Page 13

3. Adjustment/Operation

2

Adjustment / Operation

1

3

Fig. 3.01: ST-Bar

3.1 Description

1. Front 3 Point Linkage

2. Rear 3 Point Linkage Toplink Adjuster

3. Rear 3 Point Linkage Hooks

4. Terra-Grip Tines

The SIMBA ST-Bar is designed to be used in

conjunction with a 2.5m, 3m or 4m Mounted

X-Press. The Toolbar provides effective tine

cultivation ahead of the disc blades of the XPress.

Terra-Grip tines have a robust, basic

construction and are suitable for all soil types.

The spring-loaded auto-reset system with a

500kg trip force on each tine prevents damage

to the tines and tine brackets.

When the auto reset system is activated an

initial progressive phase holds the tine in the

4

ground in a steady position until the trip point

is reached. In the subsequent spring

compression phase the tine is raised gently

and rapidly to a maxmum height of 230mm.

The tines can be fitted with a selection of points

depending on application and have 6 depth

settings in 25mm increments.

The clip-on points are attached to the tine with

a quick release mechanism. A wedge

shaped bracket is bolted on to the tine and a

hammer is used to force the coulter on/off the

taper using the removal tool provided to

disengage the quick release system.

The quick release mechanism makes it

possible to change the points quickly and

easily without having to use any other tools.

The quick release system consists of a

wedge, plunger and a rubber spring.

Operating Instructions

13ST-Bar

Page 14

Adjustment / Operation

3.2 Work Instructions

Turning:

The ST-Bar (and Mounted X-Press)

should be lifted out of work while

turning.

3.3 Checks

The working quality depends on the

adjustments and checks made prior to and

during work, as well as on regular servicing

and maintenance of the component.

Before beginning work it is therefore

important to carry out any necessary servicing

required.

Working Elements

• Are the Terra-Grip Tines in good working

order?

3.4 Parking

When attached to the Mounted X-Press the

machine should be parked resting on the

parking stands and the Terra-Grip tines. With

the machine raised the rear parking stands

on the X-Press should be moved into the

parking position. The machine can now be

lowered onto the tines and stands (see Fig.

3.02 below).

Fig. 3.03: Parking Positions (Detached)

3.5 Adjustment

There are several ways to adjust the ST-Bar

in order to get the best results. See Fig. 3.04

below.

The main depth of the combined machines

(Toolbar & X-Press) is governed by the rear

roll of the X-Press. The tine depth is controlled

by adjusting the tine leg (C). However a

greater degree of tine settings can be

attained by utilising the linkage between the

Toolbar and the X-Press (A & B). For

instance, if the lower link (B) is placed in the

upper hole on the X-Press linkage it will create

a shallower working range for the tines.

Alternatively, placed in the lower hole on the

X-Press linkage, a deeper working range is

achieved. The toplink adjuster (A) can be

used to alter the pitch between the Toolbar

and X-Press if desired.

Fig. 3.02: Parking Position (Attached)

When detached, the ST-Bar should be parked

resting on its parking stands and the TerraGrip tines for stability and the X-Press can

be parked using its front and rear parking

stands (see Fig. 3.03).

ST-Bar

14

Operating Instructions

Fig. 3.04: Adjustment

Page 15

Servicing and Maintenance

4. Servicing and

Maintenance

Follow the safety instructions for

servicing and maintenance.

4.1 Servicing

Your ST-Bar unit has been designed and

constructed for maximum performance,

operational efficiency and operator

friendliness under a wide variety of operating

conditions.

Prior to delivery, your Toolbar unit has been

checked at the factory and by your authorised

dealer to ensure that you receive it in optimum

condition.

To ensure trouble-free operation, it is

important that servicing and maintenance

work is performed at the recommended

intervals.

When changing points on TerraGrip tines extreme care should be

taken. Wear goggles at all times

when changing tine points.

4.2 Cleaning

In order to ensure that the Toolbar is always

in operating condition and to achieve

optimum performance, perform the cleaning

and servicing work at regular intervals.

4.4 Operator Support

If you have a problem, please contact Your

dealer. They will endeavour to solve any

problems which may occur and provide you

with support at all times.

In order to enable your dealer to deal with

problems as quickly as possible, it helps if

you can provide them with the following data.

Always state the

• Customer Number

• Name and Address

• Machine Model

• Serial Number

• Date of Purchase and Operating Hours

• Type of Problem

4.5 Maintenance Intervals

Apart from daily maintenance, the

maintenance intervals are based on the

number of operating hours and time data.

Keep a record of your operating

hours to ensure that the specified

maintenance intervals are adhered

to as closely as possible.

Never use an ST-Bar unit that is due

for maintenance. Ensure that all

deficiencies found during regular

checks are remedied immediately.

4.3 Storage / Parking

In order to avoid damage as a result of

moisture, the machine should be parked, if

possible, indoors or under cover.

15ST-Bar

Operating Instructions

Page 16

Servicing and Maintenance

4.6 Maintenance Overview

ST Toolbar Maintenance Overview

After first operation Instructions

Check all screws / bolts Check they are firmly seated. Tighten /

Secure if necessary.

During operation

Terra-Grip Tines Check condition, mountings and smooth

operation. Replace worn parts

immediately.

Parking Stands Check condition, mountings and smooth

operation. Replace if necessary.

Interval

---

Daily

Daily

ST-Bar

16

Operating Instructions

Page 17

Parts & Assembly

6. Parts & Assembly

2.5m ST-Bar .................................................................................................................. 18

3m ST-Bar ..................................................................................................................... 20

4m ST-Bar ..................................................................................................................... 22

Terra-Grip Tines ............................................................................................................. 24

Parking Stands .............................................................................................................. 26

2.5m ST-Bar with 2.5m Mounted X-Press ....................................................................... 30

3m ST-Bar with 3m Mounted X-Press............................................................................. 31

4m ST-Bar with 4m Mounted X-Press............................................................................. 32

ST-Bar Lift and Tie-down Points ..................................................................................... 33

Operating Instructions

17ST-Bar

Page 18

Parts & Assembly

B

600

TINE CENTRES ALL

AS2747

CAR

27/09/2006

ST BAR

ST BAR 2.5M

ST-Bar

18

Operating Instructions

Page 19

Parts & Assembly

AS2747

ITEM PART NO DESCRIPTION QTY COMMENTS

AS2104 ST BAR TINE ASSEMBLY 4

1

P01054 PIN Ø25x140 1

2

P02484 LYNCH PIN CAT 2 6

3

P02485 R CLIP Ø6x120 3

4

P04959 TOPLINK CAT 2 9" 1

5

P05122 SERIAL PLATE 1

6

P05207 PIN Ø16x73 2

7

P07543 PLAST IC EN D CAP 40x40 2

8

P12725 POINT REMOVAL TOOL 1

9

P13013 MANUAL CASE Ø100 1

10

P13092 RIVET Ø3x10x Ø6 HEAD 4

11

P13775 PARKING STAND LEG 2

12

P14754 CAT 3 LOWER BALL 2

13

P14996 CAT 3 LOWER LINK PIN 2

14

P14999 LOWER BALL SPACER CAT 3 2

15

P15027 ST -BAR 2.5M 1

16

P15112 UPPER LINK PIN 1

17

P15118 CAT 3 LOWER LINK PIN - BUSHED 2

18

P15126 MANUAL - XPRESS TOOLBAR 2007 1

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

ST-BAR 2.5M

Operating Instructions

19ST-Bar

Page 20

Parts & Assembly

BAS2746

580

TINE CENTRES ALL

CAR

26/09/2006

ST BAR

ADJACENT TO HOOKS

ENSURE TINE RETAINING

CENTRE ON THE TINE

BOLTS ARE FITTED WITH

HEADS TOWARDS MACHINE

ST BAR 3.0M

ST-Bar

20

Operating Instructions

Page 21

Parts & Assembly

AS4746

ITEM PART NO DESCRIPTION QTY COMMENTS

AS2104 ST BAR TINE ASSEMBLY 5

1

P01054 PIN Ø25x140 1

2

P02484 LYNCH PIN CAT 2 6

3

P02485 R CLIP Ø6x120 3

4

P04959 TOPLINK CAT 2 9" 1

5

P05122 SERIAL PLATE 1

6

P05207 PIN Ø16x73 2

7

P07543 PLASTIC END CAP 40x40 2

8

P12725 POINT REMOVAL TOOL 1

9

P13013 MANUAL CASE Ø100 1

10

P13092 RIVET Ø3x10x Ø6 HEAD 4

11

P13775 PARKING STAND LEG 2

12

P14754 CAT 3 LOWER BALL 2

13

P14996 CAT 3 LOWER LINK PIN 2

14

P14999 LOWER BALL SPACER CAT 3 2

15

P15018 ST BAR 3.0M 1

16

P15112 UPPER LINK PIN 1

17

P15118 CAT 3 LOWER LINK PIN - BUSH ED 2

18

P15126 MANUAL - XPRESS TOOLBAR 2007 1

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

ST BAR 3.0M

Operating Instructions

21ST-Bar

Page 22

Parts & Assembly

TINE CENTRES ALL

565

B

AS2735

CAR

20/09/2006

ENSURE TINE RETAINING

BOLTS ARE FITTED WITH

ST BAR

ADJACENT TO HOOKS

CENTRES ON THE TINES

HEADS TOWARDS MACHINE

ST TOOLBAR 4.0M

ST-Bar

22

Operating Instructions

Page 23

Parts & Assembly

AS2735

ITEM PART NO DESCRIPTION QTY COMMENTS

AS2104 ST BAR TINE ASSEMBLY 7

1

P01054 PIN Ø25x140 1

2

P02484 LYNCH PIN CAT 2 6

3

P02485 R CLIP Ø6x120 3

4

P04959 TOPLINK CAT 2 9" 1

5

P05122 SERIAL PLATE 1

6

P05207 PIN Ø16x73 2

7

P07543 PLAST IC EN D CAP 40x40 2

8

P12725 POINT REMOVAL TOOL 1

9

P13013 MANUAL CASE Ø100 1

10

P13092 RIVET Ø3x10x Ø6 HEAD 4

11

P13775 PARKING STAND LEG 2

12

P14754 CAT 3 LOWER BALL 2

13

P14977 ST BAR 4.0M 1

14

P14996 CAT 3 LOWER LINK PIN 2

15

P14999 LOWER BALL SPACER CAT 3 2

16

P15112 UPPER LINK PIN 1

17

P15118 CAT 3 LOWER LINK PIN - BUSHED 2

18

P15126 MANUAL - XPRESS TOOLBAR 2007 1

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

ST T OOLBAR 4.0M

Operating Instructions

23ST-Bar

Page 24

Parts & Assembly

CAR

C

AS2104

06/05/2004

ST-Bar

24

Operating Instructions

ST BAR TINE ASSEMBLY

Page 25

Parts & Assembly

AS2104C ST BAR T INE ASSEMBLY

ITEM PART NO DESCRIPTION QTY COMMENTS

H00230085 BUSH Ø38xØ30x35 2

1

H00230086 BUSH Ø34xØ30x40 2

2

H00230087 BUSH Ø34xØ30x25 1

3

H00230098 BUSH Ø44xØ36x30 1

4

H00370060 ROLL PIN Ø10x50 2

5

H00370074 ROLL PIN Ø6x50 2

6

H34060801 TINE ARM LH 1

7

H34060803 TINE ARM R H 1

8

H34060806 CLAMP BASE 1

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

H34060807 PIN Ø30x178 1

H34060809 SPRING Ø84xØ19x372 1

H34060816 SPRING Ø50xØ10x273 1

H34060822 BUSH Ø40xØ34x105 1

H34060842 SPRING PIVOT 1

H34060844 SPRING T OP PLAT E 1

H34060845 SPRING T UBE 1

H34060846 BOLT M24x360 GR8.8 1

H34080847 WASHER Ø57xØ26x8 1

P00742 BOLT M20x120 GR. 8.8 2

P02008 NU T LOCK M16 3

P02485 R CLIP Ø6x120 1

P02602 WASHER FLAT M16 6

P02603 WASHER FLAT M20 4

P02649 BOLT M16x90 GR. 8.8 1

P03116 BOLT M20x90 GR. 8.8 2

P05207 PIN Ø16x73 1

P12711 WEDGE COMPLETE 1

P12911 TERRAGRIP CONVERTER 1

P13093 TINE - ST TYPE 1

P13135 POINT KNOCK ON 100mm 1

P14517 CLAMP PLATE 132x92/82 1

P14588 BOLT M16x75 GR10.9 2

P14913 BOLT 1/2" U NCx3" CSK SQ. 2

P14914 NU T LOCK 1/2" UNC 2

Operating Instructions

25ST-Bar

Page 26

Parts & Assembly

AAS2739

CAR

20/09/2006

X-PRESS

X-PRESS PARKING STAND

ST-Bar

26

Operating Instructions

Page 27

Parts & Assembly

AS2739

ITEM PART NO DESCRIPTION QTY COMMENTS

P01352 BOLT M16x150 GR. 8.8 2

1

P02008 NU T LOCK M16 2

2

P02485 R CLIP Ø6x120 1

3

P02602 WASHER FLAT M16 4

4

P05207 PIN Ø16x73 1

5

P07543 PLAST IC EN D CAP 40x40 1

6

P14998 PARKING STAND LEG 1

7

P15003 PARKING STAND BASE 1

8

P15004 RETAINING PLATE 1

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

X-PRESS PARKING STAND

Operating Instructions

27ST-Bar

Page 28

Parts & Assembly

AAS2740

PJG

20/09/2006

ST-Bar

28

Operating Instructions

3PL X-PRESS PARKIGN STAND - FRONT

Page 29

Parts & Assembly

AS2740

ITEM PART NO DESCRIPTION QTY COMMENTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

P14997 PARKING STAND LEG 1

P07543 PLASTIC END CAP 40x40 1

P05207 PIN Ø16x73 1

P02485 R CLIP Ø6x120 1

3PL X-PRESS PARKING STAND - FRONT

Operating Instructions

29ST-Bar

Page 30

Parts & Assembly

AAS2742

360.00210.00

ST BAR AND XPRESS ARE COMBINED,

PARK COMBINATION ON ST BAR PIONTS

AN REAR STANDS.

USE REAR STANDS (ITEM NO. 2 IN

STANDS ( ITEM NO. 3 ) WHEN

EXTENDED RANGE AND XPRESS FRONT

DETACHING AND ATACHING ST BAR.

CAR

30/10/2006

STANDS FITTED TO REAR OF XPRESS (

ITEM NO. 2C ) USED IN MID RANGE WHEN

ST-Bar

30

Operating Instructions

ST BAR STANDS ( ITEM NO. 1 ) USED WHEN ST BAR DETACHED,

PARK ST BAR ON STANDS AND POINTS.

GENERAL ASSEMBLY 2.5M

Page 31

Parts & Assembly

AAS2743

CAR

30/10/2006

360 360

XPRESS FRONT STANDS ( ITEM NO. 3 ) WHEN DETACHING

STANDS FITTED TO REAR OF XPRESS ( ITEM NO. 2 ) USED

PARK COMBINATION ON ST POINTS AND REAR STANDS

IN MID RANGE WHEN ST BAR AND XPRESS ARE COMBINED,

AND ATTACHING ST BAR.

USE REAR STANDS ( ITEM NO. 2 ) IN EXTENDED RANGE AND

ST BAR STANDS ( ITEM NO. 1 ) USED WHEN ST BAR DETACHED, PARK

ST BAR ON STANDS AND PIONTS.

Operating Instructions

GENERAL ASSEMBLY 3.0M

31ST-Bar

Page 32

Parts & Assembly

AAS2744

310 310

CAR

30/10/2006

STANDS FITTED TO REAR OF XPRESS ( ITEM NO. 2 ) USED IN MID

RANGE WHEN ST BAR AND XPRESS ARE COMBINED, PARK

XPRESS FRONT STANDS ( ITEM NO. 3 ) WHEN DETACHING

COMBINATION

ON ST BAR POINTS AND REAR STANDS.

AND ATTACHING ST BAR.

USE REAR STANDS ( ITEM NO. 2 ) IN EXTENDED RANGE AND

ST-Bar

32

Operating Instructions

ST BAR STANDS ( ITEM NO. 1 ) USED WHEN ST BAR DETACHED, PARK ST BAR

ON STANDS AND POINTS.

GENERAL ASSEMBLY 4.0M

Page 33

Parts & Assembly

TO TIE DOWN

USE LOWER LINKS

A

AS2749

CAR

20/09/2006

LIFTING POINT

ST BAR

SUPPORT TO TIE DOWN

USE HOLE THRO. HOOK

ST BAR LIFT AND TIE DOWN POINTS

Operating Instructions

33ST-Bar

Page 34

ST-Bar

34

Operating Instructions

Loading...

Loading...