P13929 19/12/05

Single Beam Toolbar

2

Operating Instructions

Declaration of Conformity

DECLARATION OF CONFORMITY

Simba International Limited hereby declare that the Product described in this Operators Manual, and defined

by the 5 digit Registration number stamped onto the inside of the roller, conforms with the following Directives

and Regulations, and has been certified accordingly.

EC Machinery Directive 89/392/EEC, as amended by 91/3688/EEC, 93/44/EEC, and

93/688/EEC.

In order to fulfill the requirements of health and safety described in the EC Directive, the following standards

and technical specifications have been taken into account:

EN 292 - 1

EN 292 - 2

THE MANUFACTURER

Simba International Limited

Woodbridge Road

SLEAFORD

NG34 7EW

Lincolnshire

NG34 7EW

England.

Telephone 01529 304654.

CERTIFIED ON BEHALF OF SIMBA INTERNATIONAL LIMITED.

Philip J. Wright. BSc (Hons) C Eng. MI Agr.E

Technical Director.

Operating Instructions

3Single Beam Toolbar

y

.

a

e

r

r

t

y

e

o

e

e

l

e

s

e

s

s

e

l

Warranty

WARRANTY

TERMS AND CONDITIONS

In this warranty Simba International Ltd., is referred to as “the Company”.

1. Subject to the provisions of this warranty the Company warrants each new machine sold b

it to be sold free from any defect in material or workmanship for a period of 12 months from

date of installation with the end-user.

Some specific items have additional warranty over and above the standard 12 months

Details of these can be obtained upon request directly from the distributor or Simb

International Ltd.

2. If the machine or part thereof supplied by the Company is not in accordance with th

warranty given in clause 1 the Company will at its option:

(a) make good the machine or part thereof at the Company’s expense, or

(b) make an allowance to the purchaser against the purchase price of the machine o

part thereof, or

(c) accept the return of the machine and at the buyers option either:

I) repay or allow the buyer the invoice price of the machine or part thereof, o

II) replace the machine or part thereof as is reasonably practical.

3. This warranty shall not oblige the Company to make any payment in respect of loss of profi

or other consequential loss or contingent liability of the Purchaser alleged to arise from an

defect in the machine or impose any liability on the Company other than that contained in

clause 2.

4. Any claim under this warranty must be notified to the Company in writing specifying th

matters complained of within 14 days from the date of repair.

5. Any claim under this warranty must be made by the original purchaser of the machine and

is not assignable to any third party.

6. If the purchaser hires out the machine to any third party the warranty shall apply only t

matters notified to the Company in writing within 90 days of the date of delivery and claus

1 shall be read as if the period of 90 days were substituted for the period of 12 months.

7. The warranty will cease to apply if:

(a) any parts not made, supplied or approved in writing by the Company are fitted to th

machine or

(b) any repair is carried out to the machine other than by or with the express written approva

of the Company or

(c) any alterations not expressly authorized by the Company in writing are made to th

machine or

(d) the machine is damaged by accident or

(e) the machine is abused or overloaded or used for a purpose or load beyond its design

capabilities, or used in conjunction with a tractor whose power output capability exceed

the stated implement power requirement by more than 40%. For the purpose of thes

terms and conditions, “stated implement power requirement” refers to wheeled tractor

unless specifically stated. These power requirements should be reduced by 20% when

used in conjunction with tracked tractors.

(f) the machine is operated as part of a ‘cultivation train’ where more than one implement i

being towed, without the express written approval of Simba International Ltd.

(g) any maintenance is not carried out in accordance with the service schedules in th

operator’s manual.

(h) the Installation and Warranty Registration Certificate is not received by Simba Internationa

Ltd., Service Dept., Woodbridge Road, Sleaford, Lincolnshire, England, NG34 7EW, within

7 days of installing a new machine.

Single Beam Toolbar

4

Operating Instructions

Machine Identification

Enter the relevant data in the following list upon

acceptance of the machine:

Serial Number

Type of Machine

Machine Width

Year of Construction

Delivery Date

First Operation

Accessories

Operating Instructions/Spare Parts List: December 2005

Machine Identification

Dealer Address: Name: ......................................................................

Street: ......................................................................

Place: ......................................................................

Tel.: ................................................................. ....

Dealer's Customer No.: ............................................................

SIMBA Address: SIMBA

Woodbridge Road Ind. Est.

Sleaford

Lincolnshire

NG34 7EW

Tel.: 01529 304654

Fax: 01529 413468

E-Mail: simba.international@simba.co.uk

SIMBA Customer No.: .................................................................

Operating Instructions

5Single Beam Toolbar

Single Beam Toolbar

6

Operating Instructions

Table of Contents

Contents

Machine Identification .......................................................................................................5

Introduction ............................................................................................. 8

Foreword ......................................................................................................................... 8

Warranty Guidelines ......................................................................................................... 8

1. Safety Data ...................................................................................... 9

1.2 Use for the Intended Purpose ................................................................................. 9

1.3 Operational Safety ................................................................................................ 10

1.4 No Liability for Consequential Damage ................................................................ 10

1.5 Changing Equipment ............................................................................................ 10

1.6 During Operation .................................................................................................. 10

1.7 Servicing & Maintenance ...................................................................................... 10

2. Transportation and Installation.................................................... 11

2.1 Delivery ................................................................................................................ 11

2.2 Transportation ...................................................................................................... 11

2.3 Installation ............................................................................................................ 11

2.4 Hitching-up the machine ....................................................................................... 11

3. Adjustment/Operation ................................................................... 12

3.1 Description........................................................................................................... 12

3.2 Pro-Lift tines .........................................................................................................13

3.2.1 Pro-Lift Wings ...................................................................................................... 13

3.3 Furrower Tines ..................................................................................................... 14

3.4 Marker Arms......................................................................................................... 14

3.5 Work Instructions .................................................................................................. 14

3.6 Checks................................................................................................................. 14

3.7 Parking ................................................................................................................ 14

4. Servicing and Maintenance .......................................................... 15

4.1 Servicing .............................................................................................................. 15

4.2 Cleaning ............................................................................................................... 15

4.3 Storage / Parking ................................................................................................. 15

4.4 Operator Support ................................................................................................. 15

4.5 Maintenance Intervals ........................................................................................... 15

4.6 Maintenance Overview ......................................................................................... 16

5. Parts and Assembly .......................................................................... 17

Operating Instructions

7Single Beam Toolbar

Introduction

Introduction

Foreword

Make sure you have read and follow the

Operating Instructions carefully before using

the machine. By doing so, you will avoid

accidents, reduce repair costs and downtime

and increase the reliability and service life

of your machine. Pay attention to the safety

instructions!

SIMBA will not accept any responsibility for

any damage or malfunctions resulting from

failure to comply with the Operating

Instructions.

These Operating Instructions will assist you

in getting to know your component and in using

it correctly for its intended purposes. First, you

are given general instructions in handling the

component. This is followed by sections on

servicing, maintenance and the action to be

taken should a malfunction occur.

We reserve the right to alter

illustrations as well as technical data

and weights contained in these

Operating Instructions for the purpose

of improving the component.

Warranty Guidelines

1. The period of liability for material defects

(warranty) relating to our products is 12

months. In the case of written deviations

from the statutory provisions, these

agreements shall apply.

They shall become effective upon installation

of the machine with the end customer. All wear

parts are excluded from the warranty.

2. Warranty claims must be submitted to the

SIMBA Customer Service Department in

Sleaford via your dealer. It is only possible

to process claims which have been correctly

completed and submitted no later than 14

days after the date of repair.

These operating instructions are to be read

and followed by all persons working on or

with the component, e.g.:

• Operation (including preparation, remedying

of faults in the operating sequence and

servicing).

• Maintenance (maintenance and inspection)

• Transportation.

Together with the Operating Instructions, you

receive a Spare Parts List and a Machine

Registration form. Field service technicians

will instruct you in the operation and

servicing of your machine. Following this,

the Machine Registration form is to be

returned to SIMBA. This confirms your

formal acceptance of the machine. The

warranty period begins on the date of delivery.

3. In the case of deliveries made under the

warranty which are subject to the return of

the old parts, the old parts must be returned

to SIMBA within 28 days after the damage

occurred.

4. In the case of deliveries made under the

warranty which are not subject to the return

of the old parts, these parts must be kept for

the purpose of further decisions for a period

of 3 months after receipt of the warranty claim.

5. Warranty repairs to be carried out by

outside companies, or repairs which are

expected to take more than 10 working

hours, must be agreed upon in advance with

the Customer Service Department.

Single Beam Toolbar

8

Operating Instructions

Safety Data

1. Safety Data

The following warnings and safety instructions

apply to all sections of these Operating

Instructions. All safety instructions for the

machine should be followed.

1.1 Operating Instructions:

The Operating Instructions distinguish

between three different types of warning and

safety instructions. The following graphic

symbols are used:

Important!

Risk of injury!

Risk of fatal and serious injuries!

It is important that all the safety instructions

contained in these Operating Instructions

and all the warning signs on the machine

are read carefully.

1.2 Use for the Intended

Purpose

The SIMBA Single Beam Toolbar is built using

the latest technology and in accordance with

the relevant recognised safety regulations.

However, risks of injury for the operator or third

parties and impairment of the machine or

other tangible assets can arise during use.

The Toolbar unit is only to be operated when

in a technically perfect condition and for the

intended purpose, taking into consideration

safety and risks and following the Operating

Instructions. In particular, faults that can

impair safety are to be remedied

immediately.

Original parts and accessories from SIMBA

have been specially designed for this unit.

Spare parts and accessories not supplied by

us have not been tested or authorised.

Installation or use of non-original SIMBA

products may have a detrimental effect on

specific design features of the unit and affect

the safety of machine operators. SIMBA will

accept no liability for damage resulting from

the use of non-original parts or accessories.

Ensure that the warning signs are legible.

Replace any signs that are missing or

damaged.

These instructions must be followed in order

to prevent accidents. Inform other users of

the warnings and safety instructions.

Do not carry out any operations which may

affect safe use of the machine.

The SIMBA Single Beam Toolbar is designed

solely as a Toolbar unit. Use for any other

purpose, e.g., as a means of transport, will

be deemed to be improper use. SIMBA will

accept no liability for damage resulting from

improper use. The risk will be borne solely by

the operator.

Operating Instructions

9Single Beam Toolbar

Safety Data

1.3 Operational Safety

All protective and safety equipment, such as

removable protective equipment, must be in

place and functioning reliably before the

machine is put in use.

Check screws and bolts regularly for

tightness and retighten if necessary.

In the event of malfunctions, stop and

secure the machine immediately.

Ensure that any faults are remedied

immediately.

1.4 No Liability for

Consequential Damage

The Single Beam Toolbar has been

manufactured by SIMBA with great care.

However, problems may still occur when it is

used for the intended purpose. This may

include:

• Worn wearing parts.

• Damage caused by external factors.

• Incorrect driving speeds.

• Incorrect setting of the unit (incorrect

attachment, non-adherence to the Setting

instructions).

Therefore, it is crucial to always

check your Toolbar unit before and

during operation for correct

operation and adequate application

accuracy.

1.5 Changing Equipment

• Use suitable supports to secure any raised

frame sections suspended above you!

• Caution! Risk of injury due to projecting parts!

1.6 During Operation

The person in charge must:

• provide the operator with a copy of the

Operating Instructions.

• ensure that the operator has read and

understood the instructions.

1.7 Servicing &

Maintenance

Ensure that regular checks and inspections

are always carried out within the periods

required by law or specified in these

Operating Instructions.

Prior to performing maintenance and

servicing work, ensure that the machine is

positioned on solid, level ground and is secure

and stable.

Before cleaning the unit with water, steam jets

(high-pressure cleaning apparatus) or other

cleaning agents, cover all openings into

which, for reasons of safety or operation, no

water, steam or cleaning agents are to

penetrate.

When carrying out servicing and maintenance

work, retighten any loose screw connections.

Compensation claims for damage which has

not occurred to the component is excluded.

This includes any consequential damage

resulting from incorrect operation.

Single Beam Toolbar

10

Operating Instructions

Transportation & Installation

2. Transportation and

Installation

Transportation and initial installation of the

machine are described in this chapter.

2.1 Delivery

The Toolbar unit is normally delivered, fully

assembled, on a (low-bed) truck.

The machine can be lifted off with a crane,

fork-lift truck, or other suitable lifting

equipment.

When doing so, the weight, the centre of

gravity and the attachment points on the unit

are to be taken into account.

Depending on the lifting gear, attachment is

only to be at appropriate points on the frame.

2.3 Installation

When carrying out installation and

maintenance work there is a higher risk of

injury. It is important that you familiarise

yourself with the component and read the

Operating Instructions beforehand.

2.4 Hitching-up the machine

When hitching-up the machine,

ensure that no-one is between the

tractor and the machine.

• Attach the machine to the tractor 3 point

linkage.

2.2 Transportation

The Single Beam Toolbar can be transported

on public roads by hitching it up to a tractor or

on a low-bed truck.

The Single Beam Toolbar unit must be lifted

clear of the ground for road transport if

transported behind a tractor.

• It is important to observe the permitted

dimensions and weights when transporting the

machine.

• Use suitable lifting gear, e.g. a fork-lift truck.

• If the machine is transported on a trailer or a

flat-bed truck, it must be secured using straps

or other devices.

• Before transporting the machine on public

roads, it must be adjusted to its transportation

position and the stipulations relating to road

transportation fulfilled.

• The maximum permissible speed is 25 km /h.

11Single Beam Toolbar

Operating Instructions

Adjustment / Operation

3. Adjustment/Operation

2

Fig. 3.01: Single Beam Toolbar Frame

3.1 Description

1. 3 Point Linkage (Cat 2/3)

2. Toolbar Beam

The SIMBA Single Beam Toolbar is designed

to be used with either Pro-Lift subsoiler tines

or furrower tines.

Single Beam Toolbars have standard Cat 2/

3 linkages.

1

Single Beam Toolbar

12

Operating Instructions

3.2 Pro-Lift Tines

Adjustment / Operation

Extra Lift Wing

P10392

Increased lift height and and rake angle

creates greater soil disturbance on all

soil types especially in moister

conditions.

Lower relative distance between edge

of wing and point reduces draft

requirement.

Has ability to work at lower depths with

no decrease in soil disturbance or risk

of smear.

Fig. 3.02: Pro-Lift Tine

Different wings are available to suit the soil

conditions and optimise the performance of

the machine when using subsoiler tines.

Tine depth is achieved by moving the tines

up and down in the adjustable clamps.

3.2.1 Pro-Lift Wings

Standard Wing

P09060

Maximum soil disturbance with

minimum draft requirement under

normal circumstances.

Extra Wide Wing

P10411

Improved lateral shatter in moist/wet

soils, or non-cohesive soils.

Ideal for deep vegetable applications

under light/medium soils.

Wear Shroud

P11181

Wear plate to take soil abrasion so

lower trailing edge of tine does not

wear.

Wing angle reduces wear rates on leg.

13Single Beam Toolbar

Operating Instructions

Adjustment / Operation

3.3 Furrower Tines

Furrower tines create ridges in the soil ideal

for root crop applications such as potatoes.

3.5 Work Instructions

Turning:

Before turning, the machine should

be eased out of work while driving.

Likewise, it should eased back into

work once the turn has been

completed.

3.6 Checks

The working quality depends on the

adjustments and checks made prior to and

during work, as well as on regular servicing

and maintenance of the component.

Before beginning work it is therefore

important to carry out any necessary servicing

required.

Working Elements

• Are the working elements in good working

order?

Fig. 3.03: Furrower Tine Leg

3.4 Marker Arms

Marker arms can be bolted to the Toolbar

beam in order to ensure a uniform finish when

using furrower tines.

Fig. 3.04: Marker Arm

3.7 Parking

The machine must be left in a stable,

supported position.

Single Beam Toolbar

14

Operating Instructions

Servicing and Maintenance

4. Servicing and

Maintenance

Follow the safety instructions for

servicing and maintenance.

4.1 Servicing

Your Single Beam Toolbar unit has been

designed and constructed for maximum

performance, operational efficiency and

operator friendliness under a wide variety of

operating conditions.

Prior to delivery, your Toolbar unit has been

checked at the factory and by your authorised

dealer to ensure that you receive it in optimum

condition.

To ensure trouble-free operation, it is

important that servicing and maintenance

work is performed at the recommended

intervals.

4.4 Operator Support

If you have a problem, please contact Your

dealer. They will endeavour to solve any

problems which may occur and provide you

with support at all times.

In order to enable your dealer to deal with

problems as quickly as possible, it helps if

you can provide them with the following data.

Always state the:

• Customer Number

• Name and Address

• Machine Model

• Serial Number

• Date of Purchase and Operating Hours

• Type of Problem

4.5 Maintenance Intervals

Apart from daily maintenance, the

maintenance intervals are based on the

number of operating hours and time data.

When changing points on tines

extreme care should be taken.

Wear goggles at all times when

changing tine points.

Donot attempt to assist fitting tine

points with a steel headed

hammer, as this can lead to

splintering of the metal due to it’s

hardness, which can cause injury.

If tine fitting requires assistance,

a copper/hide mallet should be

used. Wear eye protection.

4.2 Cleaning

In order to ensure that the Toolbar is always

in operating condition and to achieve

optimum performance, perform the cleaning

and servicing work at regular intervals.

4.3 Storage / Parking

In order to avoid damage as a result of

moisture, the machine should be parked, if

possible, indoors or under cover.

Keep a record of your operating

hours to ensure that the specified

maintenance intervals are adhered

to as closely as possible.

Never use a Single Beam Toolbar

unit that is due for maintenance.

Ensure that all deficiencies found

during regular checks are remedied

immediately.

Place the machine on suitable

supports when working

underneath! Do not work under a

machine which is not supported!

On a new machine tighten all nuts and bolts

after 5 hours work and again after 15 hours.

This also applies to parts that have been

moved or replaced. After the initial 15 hours

of work a once a week check should be

sufficient depending on daily work rates.

Operating Instructions

15Single Beam Toolbar

Servicing and Maintenance

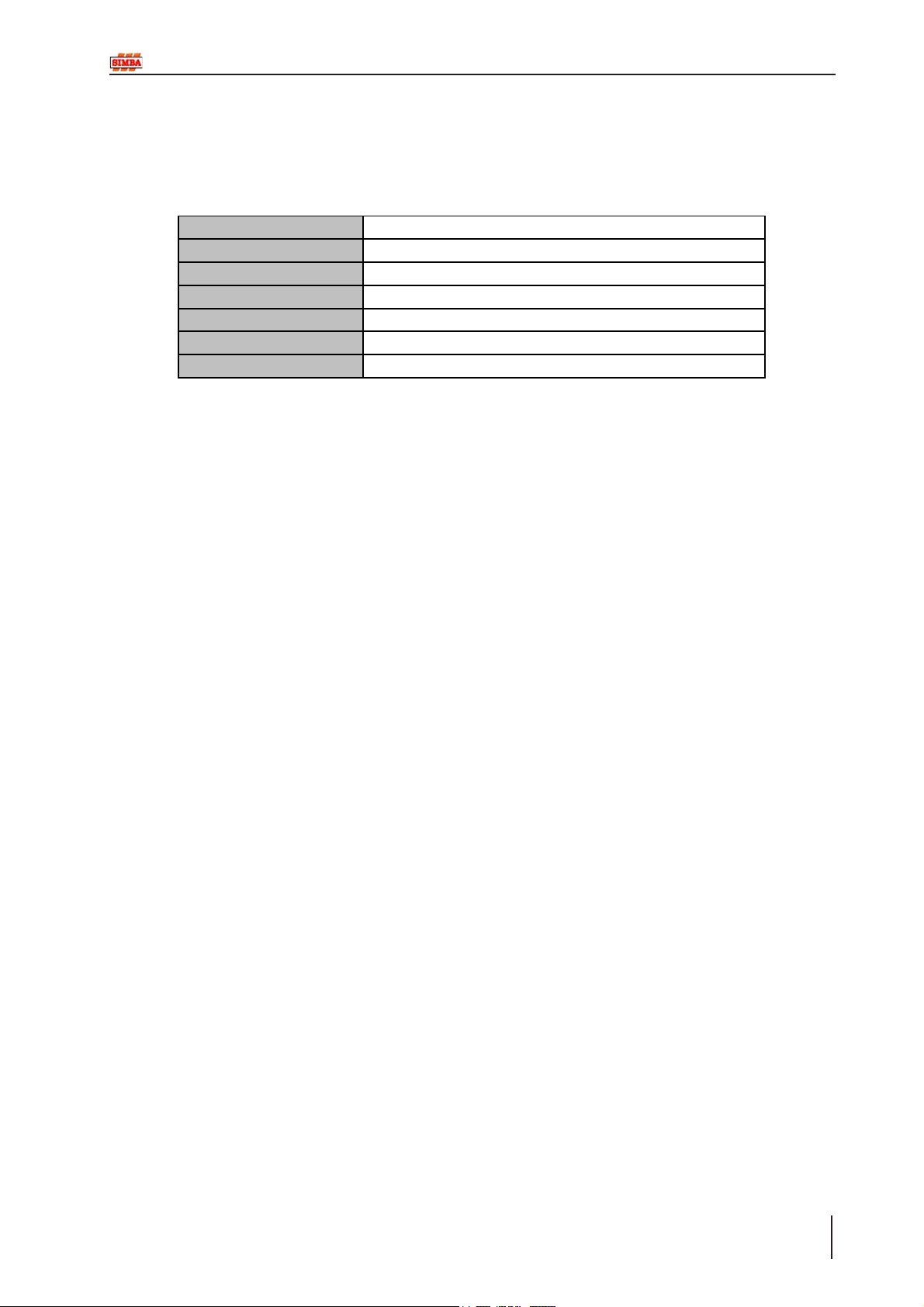

4.6 Maintenance Overview

Single Beam Toolbar Maintenance Overview

After first operation Instructions Interval

Chec k bolt tightness

During operation

Chec k bolt tightness

Tines

Working Depth Check setting and ensure implements are firmly secured daily

After season

Entire machine Carry out cleaning and m aintenance ---

Check they are firmly seated. Tighten / Secure if necessary Refer to table below for bolt torques

Check they are firmly seated. Tighten / Secure if necessary Refer to table below for bolt torques

Check setting and ensure implements are firmly secured.

Replac e tine points before the s hank begins to engage the

soil.

Max. Bolt Torques

M12 8.8 10 KgM ( 73 lb.ft)

M16 8.8 24 KgM ( 176 lb.ft)

M20 8.8 47 KgM ( 345 lb.ft)

M24 8.8 80 KgM ( 587 lb.ft)

M30 8.8 150 KgM (1100 lb.ft)

M36 8.8 280 KgM (2055 lb.ft)

5/8" UNC 24 KgM ( 175 lb.ft)

---

weekly

daily

Single Beam Toolbar

16

Operating Instructions

Loading...

Loading...