Page 1

P13114 23/03/05

Page 2

CultiPress

2

Operating Instructions

Page 3

Declaration of Conformity

DECLARATION OF CONFORMITY

Simba International Limited hereby declare that the Product described in this Operators Manual, and defined

by the Serial Number Plate attached to the Chassis of the Machine (a part copy of which is detailed overleaf

and must be completed indicating the relevant machine details), conforms with the following Directives and

Regulations, and has been certified accordingly.

EC Machinery Directive 89/392/EEC, as amended by 91/3688/EEC, 93/44/EEC, and

93/688/EEC.

In order to fulfill the requirements of health and safety described in the EC Directive, the following standards

and technical specifications have been taken into account:

EN 292 - 1

EN 292 - 2

THE MANUFACTURER

Simba International Limited

Woodbridge Road

SLEAFORD

NG34 7EW

Lincolnshire

NG34 7EW

England.

Telephone 01529 304654.

CERTIFIED ON BEHALF OF SIMBA INTERNATIONAL LIMITED.

Rod Daffern

Chairman

Simba International Limited

Operating Instructions

3CultiPress

Page 4

Warranty

WARRANTY

TERMS AND CONDITIONS

In this warranty Simba International Ltd., is referred to as “the Company”.

1. Subject to the provisions of this warranty the Company warrants each new machine sold by

it to be sold free from any defect in material or workmanship for a period of 12 months from

date of installation with the end-user.

Some specific items have additional warranty over and above the standard 12 months.

Details of these can be obtained upon request directly from the distributor or Simba

International Ltd.

2. If the machine or part thereof supplied by the Company is not in accordance with the

warranty given in clause 1 the Company will at its option:

(a) make good the machine or part thereof at the Company’s expense, or

(b) make an allowance to the purchaser against the purchase price of the machine or

part thereof, or

(c) accept the return of the machine and at the buyers option either:

I) repay or allow the buyer the invoice price of the machine or part thereof, or

II) replace the machine or part thereof as is reasonably practical.

3. This warranty shall not oblige the Company to make any payment in respect of loss of profit

or other consequential loss or contingent liability of the Purchaser alleged to arise from any

defect in the machine or impose any liability on the Company other than that contained in

clause 2.

4. Any claim under this warranty must be notified to the Company in writing specifying the

matters complained of within 14 days from the date of repair.

5. Any claim under this warranty must be made by the original purchaser of the machine and

is not assignable to any third party.

6. If the purchaser hires out the machine to any third party the warranty shall apply only to

matters notified to the Company in writing within 90 days of the date of delivery and clause

1 shall be read as if the period of 90 days were substituted for the period of 12 months.

7. The warranty will cease to apply if:

(a) any parts not made, supplied or approved in writing by the Company are fitted to the

machine or

(b) any repair is carried out to the machine other than by or with the express written approval

of the Company or

(c) any alterations not expressly authorized by the Company in writing are made to the

machine or

(d) the machine is damaged by accident or

(e) the machine is abused or overloaded or used for a purpose or load beyond its design

capabilities, or used in conjunction with a tractor whose power output capability exceeds

the stated implement power requirement by more than 40%. For the purpose of these

terms and conditions, “stated implement power requirement” refers to wheeled tractors

unless specifically stated. These power requirements should be reduced by 20% when

used in conjunction with tracked tractors.

(f) the machine is operated as part of a ‘cultivation train’ where more than one implement is

being towed, without the express written approval of Simba International Ltd.

(g) any maintenance is not carried out in accordance with the service schedules in the

operator’s manual.

(h) the Installation and Warranty Registration Certificate is not received by Simba International

Ltd., Service Dept., Woodbridge Road, Sleaford, Lincolnshire, England, NG34 7EW, within

7 days of installing a new machine.

CultiPress

4

Operating Instructions

Page 5

Machine Identification

Enter the relevant data in the following list upon

acceptance of the machine:

Serial Number

Type of Machine

Machine Width

Year of Construction

Delivery Date

First Operation

Accessories

Operating Instructions/Spare Parts List: March 2005

Machine Identification

Dealer Address: Name: ......................................................................

Street: ......................................................................

Place: ......................................................................

Tel.: ................................................................. ....

Dealer's Customer No.: ............................................................

SIMBA Address: SIMBA

Woodbridge Road Ind. Est.

Sleaford

Lincolnshire

NG34 7EW

Tel.: 01529 304654

Fax: 01529 413468

E-Mail: simba.international@simba.co.uk

SIMBA Customer No.: .................................................................

Operating Instructions

5CultiPress

Page 6

Table of Contents

Contents

Machine Identification .................................................................................................................... 5

Introduction ....................................................................................................... 8

Foreword .......................................................................................................................................8

Warranty Guidelines ......................................................................................................................8

1. Safety Data ................................................................................................ 9

1.1 Safety Symbols ................................................................................................................... 9

1.2 Use for the Intended Purpose ........................................................................................... 11

1.3 Operational Safety ............................................................................................................ 11

1.3.1 No Liability for Consequential Damage ............................................................................. 11

1.4 Road Traffic Safety ........................................................................................................... 12

1.5 Accident Prevention ..........................................................................................................12

1.5.1 Hitching-up the machine ...................................................................................................12

1.5.2 On the Hydraulic System ..................................................................................................12

1.5.3 Changing Equipment ........................................................................................................ 13

1.5.4 During Operation ...............................................................................................................13

1.6 Servicing & Maintenance ................................................................................................... 13

1.7 Operating Areas ................................................................................................................ 14

1.8 Authorised Operators ........................................................................................................ 14

1.9 Protective Equipment ........................................................................................................ 14

2. Transportation and Installation ............................................................. 15

2.1 Delivery ............................................................................................................................. 15

2.2 Transportation ................................................................................................................... 15

2.3 Installation .........................................................................................................................15

2.4 Hitching Up........................................................................................................................ 16

2.4.1 Hitching up a Tractor to the CultiPress / Preparing for Transport ......................................16

2.5 Folding and Unfolding ........................................................................................................17

2.5.1 Unfolding into the Work Position .......................................................................................17

2.6 Preceding and Trailing Implements ................................................................................... 18

2.6.1 Hitching a Disc Harrow to the CultiPress ......................................................................... 18

2.6.2 Transporting an CultiPress Towed Behind a Disc Harrow ................................................ 18

2.6.3 Changing from Work to Road Transport (Disc Harrow Towed Behind a CultiPress). ...... 19

2.6.4 Hitching a Rear Roll to the CultiPress .............................................................................. 19

2.7 When driving on the road .................................................................................................. 20

2.8 Parking the machine ......................................................................................................... 20

3. Technical Data CultiPress ...................................................................... 21

4. Adjustment/Operation ............................................................................ 22

4.1 Description ........................................................................................................................22

4.2 Pro-Active Tines ................................................................................................................ 24

4.3 Levelling Boards ................................................................................................................ 24

4.4 Double Disc Roller ............................................................................................................25

4.5 Work Settings ...................................................................................................................26

4.5.1 Levelling Boards ................................................................................................................26

4.7 Work Instructions ..............................................................................................................28

4.8 Checks.............................................................................................................................. 28

CultiPress

6

Operating Instructions

Page 7

Table of Contents

5. Servicing and Maintenance .................................................................... 29

5.1 Servicing ...........................................................................................................................29

5.2 Cleaning ............................................................................................................................29

5.3 Double Disc Axles ............................................................................................................. 29

5.4 Hydraulics ......................................................................................................................... 29

5.5 Preparation for Storage .....................................................................................................30

5.6 Operator Support ..............................................................................................................30

5.7 Maintenance Intervals........................................................................................................30

5.8 Maintenance Overview ...................................................................................................... 31

5.9 Overview of Lubricating Points ......................................................................................... 32

5.10 Lubricating the Machine ....................................................................................................33

5.11 Handling of Lubricants....................................................................................................... 33

5.12 Lubricants & Hydraulic Oil .................................................................................................34

6. Faults and Remedies .............................................................................. 35

7. Parts & Assembly ................................................................................... 37

7.1 Parts & Assembly Contents .............................................................................................. 37

Operating Instructions

7CultiPress

Page 8

Introduction

Introduction

Foreword

Make sure you have read and follow the

Operating Instructions carefully before using

the machine. By doing so, you will avoid

accidents, reduce repair costs and downtime

and increase the reliability and service life

of your machine. Pay attention to the safety

instructions!

SIMBA will not accept any responsibility for

any damage or malfunctions resulting from

failure to comply with the Operating

Instructions.

These Operating Instructions will assist you

in getting to know your machine and in using

it correctly for its intended purposes. First,

you are given general instructions in

handling the machine. This is followed by

sections on servicing, maintenance and the

action to be taken should a malfunction

occur.

We reserve the right to alter

illustrations as well as technical data

and weights contained in these

Operating Instructions for the purpose

of improving the CultiPress.

Warranty Guidelines

1. The period of liability for material defects

(warranty) relating to our products is 12

months. In the case of written deviations

from the statutory provisions, these

agreements shall apply.

They shall become effective upon installation

of the machine with the end customer. All wear

parts are excluded from the warranty.

2. Warranty claims must be submitted to the

SIMBA Customer Service Department in

Sleaford via your dealer. It is only possible

to process claims which have been correctly

completed and submitted no later than 14

days after the date of repair.

These operating instructions are to be read

and followed by all persons working on or

with the machine, e.g.:

• Operation (including preparation, remedying

of faults in the operating sequence and

servicing).

• Maintenance (maintenance and inspection)

• Transportation.

Together with the Operating Instructions, you

receive a Spare Parts List and a Machine

Registration form. Field service technicians

will instruct you in the operation and

servicing of your machine. Following this,

the Machine Registration form is to be

returned to SIMBA. This confirms your

formal acceptance of the machine. The

warranty period begins on the date of delivery.

3. In the case of deliveries made under the

warranty which are subject to the return of

the old parts, the old parts must be returned

to SIMBA within 28 days after the damage

occurred.

4. In the case of deliveries made under the

warranty which are not subject to the return

of the old parts, these parts must be kept for

the purpose of further decisions for a period

of 3 months after receipt of the warranty claim.

5. Warranty repairs to be carried out by

outside companies, or repairs which are

expected to take more than 10 working

hours, must be agreed upon in advance with

the Customer Service Department.

CultiPress

8

Operating Instructions

Page 9

1. Safety Data

1. Safety Data

The following warnings and safety

instructions apply to all sections of these

Operating Instructions.

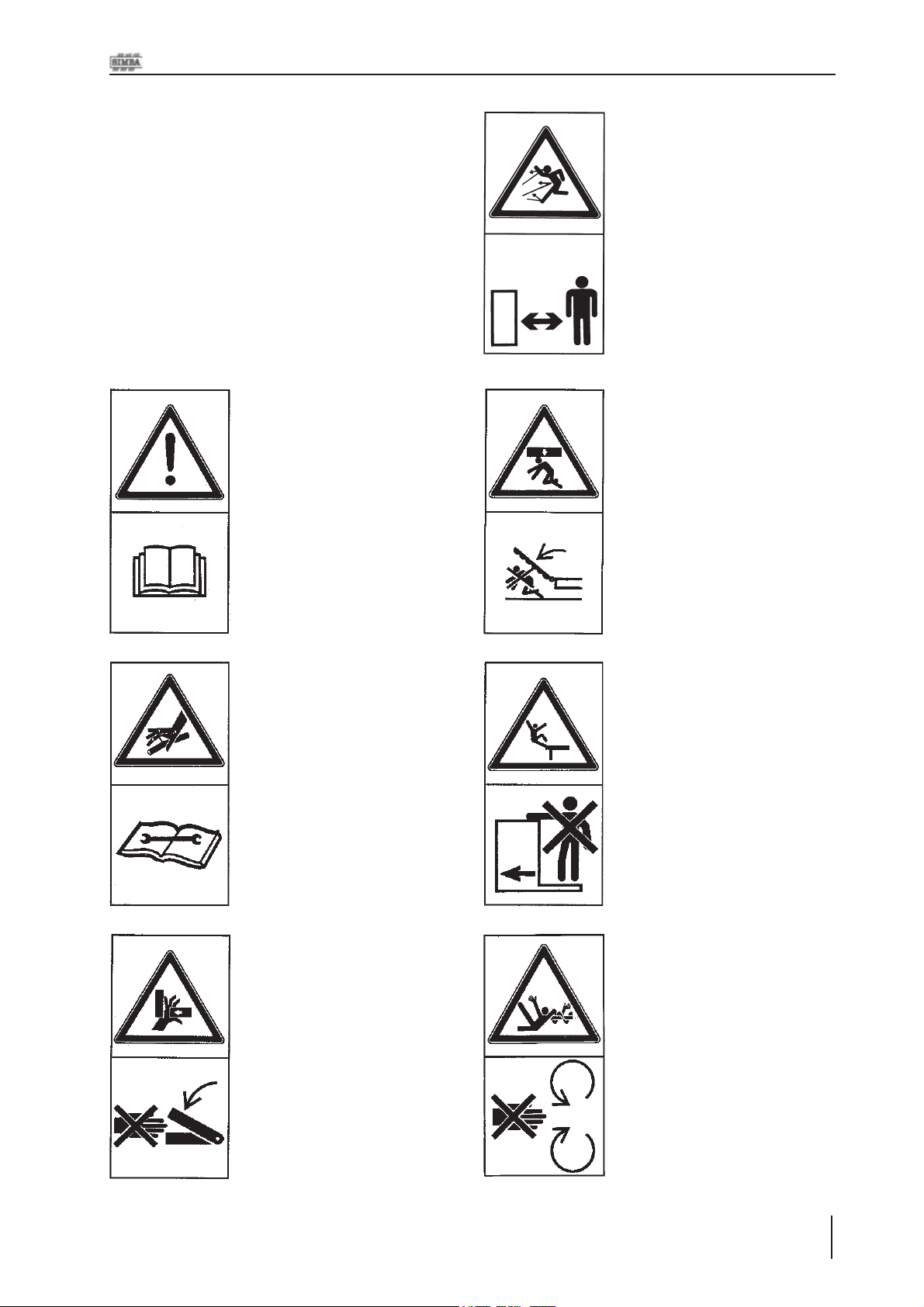

1.1 Safety Symbols

On the machine

Read and observe the Operating Instructions before

starting up the machine!

Parts may fly off during

operation. Keep a safe

distance away from the

machine!

Keep clear of the working

range of foldable machine

components!

Watch out for escaping

pressurised fluids! Follow

the instructions in the

Operating Instructions!

Never reach into areas

where there is a danger of

being crushed by moving

parts!

No passengers are allowed

on the machine!

Never reach into any

revolving parts!

Operating Instructions

9CultiPress

Page 10

1. Safety Data

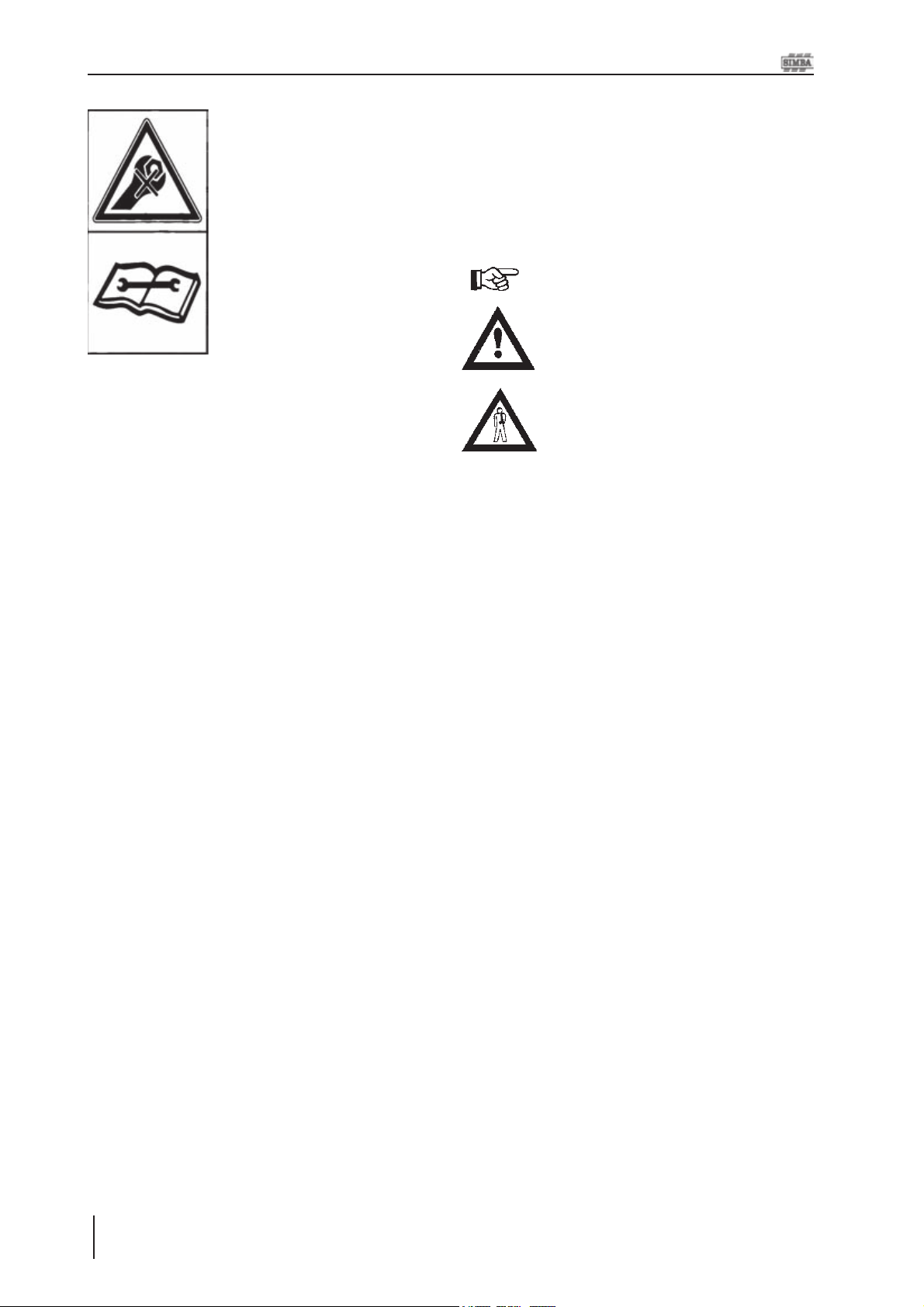

Refer to Operating

Instructions before

attempting maintenance.

Operating Instructions:

The Operating Instructions distinguish

between three different types of warning and

safety instructions. The following graphic

symbols are used:

Important!

Risk of injury!

Risk of fatal and serious injuries!

It is important that all the safety instructions

contained in these Operating Instructions

and all the warning signs on the machine

are read carefully.

Ensure that the warning signs are legible.

Replace any signs that are missing or

damaged.

These instructions must be followed in order

to prevent accidents. Inform other users of

the warnings and safety instructions.

Do not carry out any operations which may

affect safe use of the machine.

CultiPress

10

Operating Instructions

Page 11

1. Safety Data

1.2 Use for the Intended

Purpose

The SIMBA CultiPress is built using the latest

technology and in accordance with the relevant recognised safety regulations. However,

risks of injury for the operator or third parties

and impairment of the machine or other

tangible assets can arise during use.

The machine is only to be operated when in

a technically perfect condition and for the

intended purpose, taking into consideration

safety and risks and following the Operating

Instructions. In particular, faults that can

impair safety are to be remedied

immediately.

Original parts and accessories from SIMBA

have been specially designed for this

machine. Spare parts and accessories not

supplied by us have not been tested or

authorised. Installation or use of non-original

SIMBA products may have a detrimental

effect on specific design features of the

machine and affect the safety of machine

operators and the machine itself. SIMBA will

accept no liability for damage resulting from

the use of non-original parts or accessories.

1.3 Operational Safety

The machine is to be put in operation only

after instruction has been provided by an

employee of the authorised dealer or an

employee of SIMBA. The “Machine

Registration” form is to be completed and

returned to SIMBA.

All protective and safety equipment, such

as removable protective equipment, must be

in place and functioning reliably before the

machine is put in use.

Check screws and bolts regularly for

tightness and retighten if necessary.

In the event of malfunctions, stop and

secure the machine immediately.

Ensure that any faults are remedied

immediately.

1.3.1 No Liability for

Consequential Damage

The CultiPress has been manufactured by

SIMBA with great care. However, problems

may still occur when it is used for the intended

purpose. These may include:

The SIMBA CultiPress is designed solely as

a cultivation implement. Use for any other

purpose, e.g., as a means of transport, will

be deemed to be improper use. SIMBA will

accept no liability for damage resulting from

improper use. The risk will be borne solely by

the operator.

• Worn wearing parts.

• Damage caused by external factors.

• Incorrect driving speeds.

• Incorrect setting of the unit (incorrect

attachment, non-adherence to the Setting

instructions).

Therefore, it is crucial to always

check your machine before and

during operation for correct

operation and adequate application

accuracy.

Compensation claims for damage which has

not occurred to the machine is excluded. This

includes any consequential damage resulting

from incorrect operation.

Operating Instructions

11CultiPress

Page 12

1. Safety Data

1.4 Road Traffic Safety

When driving on public roads, tracks and

areas, it is important to observe the relevant

road traffic laws as well as the specific

regulations relating to this machine.

Pay attention to the permitted axle

loads, tyre carrying capacity, and

total weight in order to maintain

adequate braking and steerability.

Passengers on the machine are

strictly forbidden!

Max. road transport speed 16mph

(25km/h).

1.5 Accident Prevention

In addition to the Operating Instructions, it is

important to observe the accident prevention

regulations specified by agricultural trade

associations.

1.5.1 Hitching-up the

machine

There is a risk of injury when hitching/

unhitching the machine. Observe the following:

• Secure the machine against rolling.

• Take special care when reversing the tractor!

• There is a risk of being crushed between

the machine and the tractor!

• Park the machine on firm, level ground.

1.5.2 On the Hydraulic

System

Do not connect the hydraulic lines to the tractor

until both hydraulic systems (machine and

tractor) are depressurised.

Only use appropriate aids when checking for

leaks. Repair any damage immediately.

Spurting oil can cause injuries and fires!

In case of injury, contact a doctor immediately.

The socket and plugs for the hydraulic

connections between the tractor and the

machine should be colour-coded in order to

avoid incorrect use.

CultiPress

12

Operating Instructions

Page 13

1. Safety Data

1.5.3 Changing Equipment

• Secure the machine to prevent it from

accidentally rolling away!

• Use suitable supports to secure any raised

frame sections suspended above you!

• Caution! Risk of injury due to projecting parts!

Never climb on to rotating parts such

as the roll unit. These parts may

rotate causing you to slip and suffer

serious injury!

1.5.4 During Operation

Ensure that the working range and the area

around the machine are clear (children!)

before operating the machine.

Always ensure adequate visibility!

Do not stand on the machine while it is in

operation!

Operators must have a valid driving licence

in order to drive on public roads. In the

operating area, the operator is responsible

for third parties.

The person in charge must:

• provide the operator with a copy of the

Operating Instructions.

1.6 Servicing &

Maintenance

Ensure that regular checks and inspections

are always carried out within the periods

required by law or specified in these

Operating Instructions.

When carrying out service and maintenance

work always:

• switch off the tractor engine and remove

the ignition key.

• wait until all the machine parts have

stopped moving.

• depressurize the hydraulic system.

Prior to performing maintenance and

servicing work, ensure that the machine is

positioned on solid, level ground and is

secured to prevent it rolling away. Do not

use any parts to climb on to the machine

unless they are specifically designed for this

purpose.

Before cleaning the machine with water,

steam jets (high-pressure cleaning

apparatus) or other cleaning agents, cover

all openings into which, for reasons of safety

or operation, no water, steam or cleaning

agents are to penetrate (bearings, for

instance).

• ensure that the operator has read and

understood the instructions.

• make sure that the operator is aware of

the specific regulations relating to the

machine when driving on public roads.

Next, check all hydraulic lines for leaks, loose

connections, chafe marks and damage.

Remedy any deficiencies immediately!

Lubricate all the lubricating points to force

out any trapped water.

When carrying out servicing and maintenance

work, retighten any loose screw connections.

13CultiPress

Operating Instructions

Page 14

1. Safety Data

1.7 Operating Areas

The operating areas include the drawbar,

hydraulic connections and depth adjustment

equipment as well as all operating points

requiring maintenance.

All operating areas will be specified and

described in detail in the following chapters

on servicing and maintenance.

Observe all safety regulations included in the

Section dealing with Safety, and in the subsequent sections.

1.8 Authorised Operators

Only those persons who have been

authorised and instructed by the operator may

operate the machine. The operator must be

at least 16 years of age.

1.9 Protective Equipment

For operation and maintenance, you require:

• Tight fitting clothing.

•Strong protective gloves (to provide

protection against sharp-edged machine

components).

• Protective goggles (to stop dirt getting into

your eyes).

CultiPress

14

Operating Instructions

Page 15

2. Transportation / Installation

2. Transportation and

Installation

Transportation and initial installation of the

machine are described in this chapter.

2.1 Delivery

The machine is normally delivered fully

assembled.

• The machine can be lifted off with a crane

or other suitable lifting equipment.

• The machine should be hitched to a tractor

and driven off a low-loader.

2.2 Transportation

The CultiPress can be transported on public

roads by hitching it up to a tractor or on a lowloader.

• It is important to observe the permitted

dimensions and weights when transporting the

machine.

2.3 Installation

When carrying out installation and

maintenance work there is a higher risk of

injury. It is important that you familiarise

yourself with the machine and read the

Operating Instructions beforehand.

Operator instruction and initial installation of

the machine are carried out by our service

technicians or authorised distributors.

The machine must not be used in any way

beforehand! The machine can only be

released for operation after instructions have

been provided by our service technicians or

authorised distributors.

• If any modules or parts have been removed

for transportation, these shall be mounted by

our service technicians/authorised dealers

before the instruction takes place.

• Check all important screw connections!

• Lubricate all nipples and joints!

• Check all hydraulic connections and lines

for damage.

• If the machine is transported on a trailer or a

low-loader, it must be secured using straps

or other devices.

• Before transporting the machine on public

roads, it must be adjusted to its transportation

position and the stipulations relating to road

transportation fulfilled.

• The maximum permissible speed is 25 km /h.

Operating Instructions

15CultiPress

Page 16

2. Transportation / Installation

2.4 Hitching Up

2.4.1 Hitching up a Tractor

to the CultiPress / Preparing

for Transport

When hitching-up the machine,

ensure that no-one is between the

tractor and the machine.

When the CultiPress is parked for

extended periods of time it should

ideally be left in the unfolded, i.e.

work, position for stability, safety and

ease of access for maintenance.

However, parking the CultiPress in

the folded position (using the parking

stands provided) is acceptable in

the normal course of operation.

Tractor Oil Flow Adjustment:

As a general rule the tractor oil flow

rate should be set in the lowest

setting before starting. This can then

be increased to allow the desired

rate of operation as applicable. This

will minimise excessive oil flow and

consequent power usage and heat

generation.

4. Fully raise the levelling board.

5. Close the tap on the drawbar cylinder.

Folding Machines

1. Couple the six hydraulic hoses to the

tractor ensuring that the two wing hoses

are together, the two drawbar cylinder

hoses are together and the two levelling

board hoses are together.

2. Connect the tractor to the drawbar using

the hydraulics to raise or lower the height

of the shackle.

3. Carefully operate the hydraulics to lower

the drawbar and tilt the CultiPress onto

the road transport wheels. Fully extend

the drawbar cylinders.

4. This allows the levelling boards to be

fully raised so that when the CultiPress

is folded the levelling boards do not

protrude beyond the 3m transport width.

Fully raise the levelling boards.

5. Operate the hydraulics to fold the wings.

(4.6m, 5.5m and 6.6m):

Rigid Machines (3.3m and 4.0m):

1. Couple the four hydraulic hoses to the

tractor ensuring that the two levelling

board hoses are together and the two

drawbar cylinder hoses are together.

2. Connect the tractor to the drawbar using

the hydraulics to raise or lower the

shackle.

3. Carefully operate the hydraulics to lower

the drawbar and tilt the CultiPress onto

the road transport wheels. Fully extend

the drawbar cylinder.

CultiPress

16

Operating Instructions

6. Ensure that the wing strap is fitted to tie

the two wing sections together.

7. Ensure that parking stands are locked

in the transport position, ie. fully raised.

Page 17

2.5 Folding and Unfolding

Folding Machines (4.6m, 5.5m and 6.6m)

2.5.1 Unfolding into the Work

Position

1. Ensure that the parking stands are in the

fully raised position.

2. Remove the transport strap from the

rear wing cylinders.

3. Open the taps on the hosemast.

4. Operate the hydraulics to fully unfold the

wings.

2. Transportation / Installation

5. Lower the machine to the ground until

the chassis is level front to rear or the

drawbar cylinders touch the depth

stops.

2.5.2 Folding into the

Transport Position

1. Fully raise the levelling boards so that

they do not protrude beyond the 3m

transport width.

2. Raise the machine onto the transport

wheels.

3. Operate the hydraulics to fully fold the

wings.

4. Fit the transport strap across the pins

on the rear wing cylinders for transport

safety.

5. Close the taps on the hosemast.

6. Lower the parking stands if the

CultiPress is to be unhitched from the

tractor in the folded position.

17CultiPress

Operating Instructions

Page 18

2. Transportation / Installation

2.6 Preceding & Trailing

Implements

2.6.1 Hitching a Disc Harrow

to the CultiPress

1. Remove the transport straps from the

disc harrow, exercise great CARE

when extending the axle cylinder.

2. Reverse the disc harrow up to the

CultiPress drawbar ensuring that the

two drawbars are aligned allowing a

slight clearance to enable the machines

to be coupled together.

3. Lower the disc harrow to the ground.

4. Connect the four hydraulic hoses from

the CultiPress into the disc harrow rear

outlets ensuring that the two wing hoses

are together and the two drawbar

cylinder hoses are together. Ensure that

the folding circuits and lift drawbar

circuits are coupled correctly.

5. Raise the CultiPress drawbar above the

disc drawbar (200mm approx.). Depth

control shims may need to be removed.

6. Raise the disc harrow to the same height

as the CultiPress drawbar then reverse

the disc harrow to couple the two

machines together.

7. Fit the drawbar pin.

8. Operate the hydraulics to lower the rear

axle and drawbar, tilting the CultiPress

onto the road transport wheels. Fully

extend the drawbar cylinders.

10. Operate the hydraulics to fold the wings.

11. Operate the hydraulics to lift the disc

harrow into the transport position.

12. Fit the disc harrow transport straps.

13. Fit the CultiPress wing transport strap

to tie the two wing sections together.

14. Ensure that parking stands are locked

up in their work position.

When the CultiPress is used in tandem with

a disc harrow the disc should be set to the

operators manual i.e. front disc gang to be

50mm closer to the ground than the

corresponding disc blade on the rear gang.

With both machines in the transport position

i.e. raised and folded, the top frame of the

disc harrow should be slightly nose down or

horizontal even when the downward load from

the CultiPress is applied to the drawbar of

the disc harrow.

The frame may be levelled by altering the

rearward tilt of the CultiPress to increase or

reduce the loading on the disc rear drawbar.

2.6.2 Transporting a

CultiPress Towed Behind a

Disc Harrow

With both machines in the transport position

i.e. raised and folded, the top frame of the

disc harrow should be slightly nose down or

horizontal even when the downward load from

the CultiPress is applied to the drawbar of

the disc harrow. The top frame should NEVER

be tail low in transport as this will give a high

negative loading on the tractor which could

lead to loss of traction to the rear wheels.

9. Fully raise the levelling boards.

CultiPress

18

Operating Instructions

Extreme caution must be taken when the

CultiPress is transported up steep gradients

Page 19

2. Transportation / Installation

and across side slopes. Higher drawbar

loading can be achieved by shortening the

drawbar cylinder.

Prior to leaving the field to travel on a public

highway ensure that any clods of soil are

removed from the machine to prevent them

from fouling the road.

MAXIMUM ROAD TRANSPORT SPEED 18

MPH (25 KPH).

2.6.3 Changing from Work to

Road Transport (CultiPress

Towed Behind a Disc Harrow)

1. Operate the hydraulics to raise the disc

and CultiPress.

2. Operate the hydraulics to fold the wings

on both the disc harrow and the

CultiPress.

3. Fit the transport straps to both

machines.

2.6.4 Hitching a Rear Roll to

the CultiPress

Follow procedure 2.4 (page 16) to couple a

tractor to the CultiPress. Once the tractor is

safely connected to the implement and in its

folded setting, raise the machine fully clear of

the ground.

1. Reverse the CultiPress up to the roller.

2. Align the CultiPress and roller drawbars,

lower the CultiPress to the ground and

depressurise the lift hydraulics.

3. Raise / lower the axle as required to

align the respective machines‘

drawbars and couple together.

4. Couple the rear roll to the lift circuit of

the CultiPress, ensuring that the hoses

are connected to the corresponding

circuit on the trailing machine.

It may be necessary to shorten the

levelling springs until the top frame

of the disc harrow is horizontal or

slightly nose down before moving the

machines.

Shortening the CultiPress drawbar cylinder

will increase the loading on the rear of the disc

frame. If necessary this can be used to level

the disc top frame for road transport.

5. Couple the rear roll wing (fold) circuit to

the wing (fold) circuit of the CultiPress.

6. Fully raise the CultiPress and the roll

clear of the ground.

7. Check that all transport straps / devices

are fitted or closed.

Operating Instructions

19CultiPress

Page 20

2. Transportation / Installation

2.7 When driving on the

road

When driving on the road the machine must

be converted to the transportation position.

When driving on the road, raise the

machine completely to prevent the

working elements dragging on the

ground.

2.8 Parking the machine

In order to avoid damage as a result of

moisture, the machine should be parked, if

possible, indoors or under cover.

When manoeuvring the machine,

pay attention to your surroundings.

Ensure that nobody is in the

manoeuvring area (watch for

children!).

• Park the machine on level and solid ground.

• With the machine raised move the parking

stands into position.

• Lower the machine onto the parking stands

ensuring that it is stable.

• Remove the drawbar pin and drive forward

slowly until hitch is clear of tractor drawbar.

• Lower the drawbar to the ground.

• Switch off the tractor.

• Disconnect hydraulic lines from the tractor.

CultiPress

20

Operating Instructions

Page 21

3. Technical Data

3. Technical Data CultiPress

3.3m 4.0m 4.6m 5.5m 6.6m

Working Width

Transport Width

Transport Height

Length

Weight

Tractor Power Required (H.P.)*

* It is important to correctly match your implement to your tractor for optimum performance.

Two power ratings are listed above. The lower HP figure relates to tracked tractors, the

higher HP figure relates to wheeled tractors.

3300mm 4000mm 4600mm 5500mm 6600mm

3300mm 4000mm 2900mm 2900mm 2900mm

2700mm 2700mm 3600mm 3800mm 3950mm

6400mm 6400mm 6800mm 6800mm 6800mm

3480kg 3910kg 5660kg 6630kg 7220kg

85/115 100/140 115/160 140/195 165/230

Operating Instructions

21CultiPress

Page 22

4. Adjustment / Operation

4. Adjustment/Operation

4.1 Description

Fig. 4.01: CultiPress

1. Drawbar

2. Pro-Active Tines

3. Levelling Board

4. Intermeshed DD600 Rolls

5. Transport Wheels

6. Rear Drawbar (if fitted)

The SIMBA CultiPress is a versatile

implement designed to perform an excellent

shallow cultivation combined with effective

consolidation. The CultiPress may be towed

on its own or in tandem behind another

implement e.g. Disc Harrow.

It can be used in reduced tillage systems

behind a disc harrow to incorporate stubble

or to work down ploughing on medium to

heavy soil types. Like all Simba machines it

features the latest innovations which combine

to give an efficient, well-built unit with

unrivalled reliability.

The CultiPress consists of two rows of tines

followed by a hydraulically operated levelling

board then a double row of press rings.

Pro-Active tines are spaced at 300mm

centres using shear bolt protected tines with

point options available to suit conditions.

The levelling board consists of a series of

sprung leaves with each leaf set between each

front ring. The levelling board carries soil

ahead of the rings to fill low areas. The sprung

CultiPress

22

Operating Instructions

Page 23

leaves crush clods as they pass under the

levelling board and align clods with the front

row of press rings.

The levelling boards are hydraulically

controlled for height with contour following and

board pressure maintained by means of a

pair of accumulators. The hydraulic cylinders

on each levelling board are a matched

master and slave pair for parallel travel.

The rear row of press roll rings are

intermeshed with the front row, overall ring

spacing across the machine is thereby

reduced to 115mm (4.5"). The action of the

second row of rings is to ensure that large

clods chopped by the front rings are chopped

a second time to reduce overall clod size. The

second row of rings are then scraped by a

set of rigid scrapers attached to the rear gang

beam.

4. Adjustment / Operation

The use of the CultiPress in tandem with a

disc harrow for straw incorporation, is to

consolidate the straw soil mix through the soil

profile ensuring maximum straw soil contact

to increase the breakdown process, minimise

slug problems and to leave a firm

weatherproof finish.

Operating Instructions

23CultiPress

Page 24

4. Adjustment / Operation

4.2 Pro-Active Tines

The Pro-Active tines are designed to move

soil and shatter clods to a greater degree than

traditional rigid leading tines. The ability to

move in all directions (upwards and

sideways) allows them to clear stones and

other obstructions. They feature simple,

pinned tine depth adjustment for easy depth

variation.

4.3 Levelling Boards

The action of the sprung leaf type levelling

boards is to carry and drop soil to level in front

of the press rings, to rub clod against clod for

additional soil breakdown, to force clods

down into the soil profile and to present remaining clods passing between the leaves

into the front row of press rings.

Fig. 4.02: Pro-Active Tines

Fig. 4.03: Levelling Board Adjustment

Fig. 4.04: Levelling Board Adjustment

CultiPress

24

Operating Instructions

Page 25

4.4 Double Disc Roller

The standard DD600 roller is made up of

individual Double Disc (patented) Ring

segments.

The DD rings are designed to consolidate the

soil whilst cutting and crushing any clods.

Even in heavy, wet soils it can easily be

operated with minimal blockages occurring.

The rear DD roller carries a proportion of the

machine’s weight to ensure consolidation.

The corrugated surface left by the roller is

weatherproof both for wet or dry situations.

4. Adjustment / Operation

Fig. 4.05: Double Disc Rollers

25CultiPress

Operating Instructions

Page 26

4. Adjustment / Operation

4.5 Work Settings

In work the wing cylinders should be fully

extended. The gangs are able to float over

any undulations on the ground due to their

floating frames.

Optimum performance has been found to be

achieved when the press roll rings have worn

away the painted finish leaving a smooth shiny

surface. When the press roll rings are new or

rusty, soil may tend to pick up on the surface

and blockage may occur, this will reduce when

the rings are shiny again.

The CultiPress should be run with the chassis

level front to rear by extending the drawbar

cylinders to the necessary position. The

cylinders should not be over extended as this

will remove the load on the front row of rings

which could lead to reduced drive and hence

blockage of the axles.

It is not necessary to tilt the CultiPress onto

the transport wheels during headland turns

whether the machine is used independently

or in tandem with a disc harrow. Normally,

the CultiPress should be tilted sufficiently for

the tines and levelling boards to clear the

ground (at which point the rear axle wheels

will still be clear of ground contact).

When reversing the CultiPress into corners

when working headlands ensure that the levelling boards are fully raised and the machine

tilted onto the rear set of rings far enough to

allow the lower ends of the sprung leaves to

clear the ground.

General Rules when Setting

the CultiPress

• Run the chassis horizontal to give even

drive on both sets of rings.

• Run slightly tail low to give increased clod

cutting and consolidation in harder

conditions.

• In trashy conditions the use of the

levelling board may be limited due to raking

trash.

• Increase the rake angle of the levelling

board in spring time operation to carry more

soil for levelling.

• Reduce rake angle on levelling board to

hold soil and rub clod against clod in harder

conditions. This will also align clods with

the DD rings facilitating better cutting.

4.5.1 Levelling Boards

With the chassis set level, lower the levelling

boards until they are carrying soil. The levelling boards will need to be set higher during

1st pass operations especially on ploughed

land where large clods may not be able to

pass under or between the sprung leaves.

The boards need to carry a certain amount of

soil to effect a levelling operation and also to

give a clod to clod crushing action. Use the

hydraulics to raise and lower the boards to

carry more or less soil when levelling the headland troughs for example.

CultiPress

26

Operating Instructions

Page 27

4. Adjustment / Operation

4.6 Pitch Control

Pitch control on the CultiPress is governed

by the quantity of shims fitted to the depth

stops attached to the drawbar cylinders. Increasing the number of shims will lift the front

of the chassis when lowered into the work

position. Ensure that equal quantities of shims

are added or removed from each cylinder.

Running the CultiPress level allows the front

and rear press rings to give an even consolidation and clod crushing action, with the

sprung leaves of the levelling board aiding the

clod crushing action, aligning the clods for the

front row of rings.

Running the machine significantly nose down

or raised will reduce the load on the rear axle

leading to loss of drive of the axle and then

blockage, together with a reduced consolidation effect.

is advisable to check on the cultivation effect

of the CultiPress. Often the use of the press

12 - 24 hours after the disc or longer following the plough gives a far superior surface

consolidation effect.

When the CultiPress is used tilted onto the

rear row of rings the loading on the disc harrow or tractor drawbar is increased. This will

cause the rear of the disc to dig deeper moving the rear gang to the right. Shortening the

disc harrow levelling springs should allow the

disc harrow to pull straight again. Equally, increased tractor drawbar loadings will deepen

wheelings requiring more effort to eradicate

these.

It is not necessary to tilt the CultiPress onto

the transport wheels during headland turns

whether the machine is used independently

or in tandem with a disc harrow.

If any roll axle starts to block regularly, this is

generally an indication that the roll axle is not

tight. Failure to keep the axles tight results in

loss of drive between each pair of rings allowing rings to turn individually on the axle.

Should this occur the axle must be tightened

immediately to prevent any damage occurring to the axle shaft.

If the roll axles start to block regularly this may

also be an indication that the ground conditions are too wet for the CultiPress to be effective.

In practice it is possible to use the CultiPress

on ground conditions that are unsuitable to

achieve the desired effect, and it is usually

possible to operate the machine without regular blockage under such unsuitable conditions,

assuming that the axles are tight and rings

smooth.

As such, especially under wet conditions, it

Fully extending the drawbar cylinders and then reversing into the

headland furrow could lead to damage of the cylinders.

Operating Instructions

27CultiPress

Page 28

4. Adjustment / Operation

4.7 Work Instructions

Driving speed

The CultiPress can be driven at speeds of up

to 12 km/h.

This depends on the field conditions (type of

soil, surface trash, etc.).

Drive more slowly if the conditions are difficult

or a firmer finish is required.

Parking the Machine

In order to avoid damage as a result of

moisture, the machine should be parked, if

possible, indoors or under cover.

When manoeuvring the machine,

pay attention to your surroundings.

Ensure that nobody (children!) is in

the manoeuvring area.

• Park the machine on level and solid ground.

• With the machine raised, lower the parking

stands into position.

• Lower the machine onto the parking stands

ensuring that it is stable.

• Remove the drawbar pin and drive forward

slowly until hitch is clear of tractor drawbar.

• Lower the drawbar to the ground.

• Switch off the tractor.

• Disconnect hydraulic and electric lines from

the tractor.

4.8 Checks

The working quality depends on the

adjustments and checks made prior to and

during work, as well as on regular servicing

and maintenance of the machine.

Before beginning work it is therefore

important to carry out any necessary servicing

and to lubricate the machine as required.

Checks prior to, and during

work:

• Is the machine correctly hitched up and the

coupling device locked?

• Have the hydraulic and electric lines been

connected according to the colour coding?

• Is the machine in a level operating position

and the working depth set correctly?

Working Elements

• Are the double disc rings and other

cultivation tools in a serviceable condition?

• Are the scrapers still operable, so that the

rolls do not jam?

CultiPress

28

Operating Instructions

Page 29

5. Servicing and Maintenance

5. Servicing and

Maintenance

Follow the safety instructions for

servicing and maintenance.

5.1 Servicing

Your machine has been designed and

constructed for maximum performance,

operational efficiency and operator

friendliness under a wide variety of operating

conditions.

Prior to delivery, your machine has been

checked at the factory and by your authorised

dealer to ensure that you receive a machine

in optimum condition.

To ensure trouble-free operation, it

is important that servicing and

maintenance work is performed at

the recommended intervals.

5.2 Cleaning

5.3 Double Disc Axles

The axles on this roller are tensioned by the

main axle through the centre of the rings and

bearings.

Specialist equipment is required

for the disassembly of Double Disc

axles. Please consult your dealer

under any circumstances that

require disassembly of these

axles.

Maintenance of these rollers is limited to daily

greasing of the bearings to flush out dirt, and

regular inspection to ensure the assemblies

are tight, and scrapers are correctly set. The

axles can be tightened provided the bearing

pillar ‘U’ bolts are loosened to avoid

preloading the bearings as they move

sideways to each other. Ensure the bearing

pillars are re- tightened to the mainframe after

this.

5.4 Hydraulics

In order to ensure that the machine is always

in operating condition and to achieve

optimum performance, perform the cleaning

and servicing work at regular intervals.

Avoid cleaning the roll / disc bearings with a

high- pressure hose or a direct water jet. The

housing, screwed connections and ball

bearings are not watertight.

A low oil flow should be used, i.e.,

tractor tickover or low flow

selected.

The wing circuit is controlled by an

overcentre valve contained within

the manifold block which positively

locks oil flow until pressurised by

the tractor. System pressure can

be retained in the circuit even after

depressurisation of the tractor

quick release couplings.

Exercise extreme care when

checking the valve or circuits, and

under no circumstances attempt

to adjust or loosen fittings without

prior reference to your authorised

Simba dealer, and detailed

maintenance instructions.

Operating Instructions

29CultiPress

Page 30

5. Servicing and Maintenance

5.5 Preparation for Storage

If you need to store the machine for a longer

period, observe the following points:

• Park the machine undercover if possible.

• Protect the roll / discs against rust. If you

need to spray the implements with oil, use

light biologically degradable oils, e.g. rape

oil.

Cover any rubber sections before

using oil sprays. These sections

must not be oiled.

Remove any traces of oil with a

suitable cleaning agent.

5.6 Operator Support

If you have a problem, please contact your

dealer. They will endeavour to solve any

problems which may occur and provide you

with support at all times.

In order to enable your dealer to deal with

problems as quickly as possible, it helps if

you can provide them with the following data.

Always state the:

5.7 Maintenance Intervals

Apart from daily maintenance, the

maintenance intervals are based on the

number of operating hours and time data.

Keep a record of your operating hours to

ensure that the specified maintenance

intervals are adhered to as closely as

possible.

Never use a machine that is due for

maintenance. Ensure that all deficiencies

found during regular checks are remedied

immediately.

Avoid sharp-edged and pointed

parts (disc blades, etc.) when

working on the machine.

Place the machine on suitable

supports when working

underneath! Do not work under a

machine which is not supported!

• Customer Number

• Name and Address

• Machine Model

• Serial Number of Machine

• Date of Purchase and Operating Hours

• Type of Problem

CultiPress

30

Operating Instructions

Page 31

5.8 Maintenance Overview

5. Servicing and Maintenance

CultiPress Maintenance Overview

After first operation Instructions Interval Note

Check all screw, bolt and plug connections Check they are firmly seated. Tighten / Secure if necessary --- ---

Check wheel studs for tightness Check on delivery and before transporting the machine --- ---

During operation

Lubricate machine See overview of lubricating points --- Page 32

Lubricate machine See overview of lubricating points --- Page 32

Wheel studs Check tightness before transporting the machine daily ---

Levelling Board, Machine Pitch, Working Depth Check settings and ensure they are firmly secured daily Page 26, 27

Hydraulic system and components Check seals, signs of crushing/wear, function and condition daily Page 29

Roll bearings Check condition, mountings and smooth operation daily Pages 25, 29

Double Disc roller ring segments Check condition and ensure they are firmly secured daily Pages 25, 29

After season

Safety devices (Parking stands, transport strap) Check condition and function daily ---

Lubricate machine See overview of lubricating points --- Page 32

Toplinks / Bolts Grease any exposed threads --- ---

Entire machine Carry out cleaning and maintenance --- ---

After 4 years

Spray Double Disc roll with oil Use biological oil if possible - cover rubber elements --- ---

Operating Instructions

Hydraulic pipes Replace MRL Anh I EN 1533

31CultiPress

Page 32

5. Servicing and Maintenance

5.9 Overview of Lubricating Points

CultiPress Lubrication Points Interval Diag. No.

DD Roll Bearings Daily 5.01

Pivot Points on Drawbar 50 hrs. 5.02

Pivot Points on W ings (folding machines only) 50 hrs. 5.03

Levelling Board Cylinder Pivots 50 hrs. 5.04

Wheel Bearings 50 hrs. 5.05

Fig. 5.01: DD Roll Grease Points Fig. 5.02: Drawbar Pivot Grease Points

Fig. 5.03: Wing Pivot Grease Points Fig. 5.04: Levelling board Grease Points

Fig. 5.05: Wheel Bearing Grease Points

CultiPress

32

Operating Instructions

Page 33

5. Servicing and Maintenance

5.10 Lubricating the

Machine

Please read the section entitled "Using

Lubricants" carefully before lubricating the

machine.

The machine must be lubricated regularly in

order for it to remain serviceable. Regular

lubrication also contributes towards extending

the service life of your machine.

The recommended lubricating intervals are

specified in "Inspection" and "Maintenance

Intervals".

After it has been washed using a highpressure hose or steam cleaned, the machine

should always be lubricated using a grease

gun.

5.11 Handling of

Lubricants

Please ensure that you read the following

instructions as well as the relevant

information. This also applies to any of your

employees who handle lubricants.

Hygiene

Lubricants do not present a health hazard

provided they are used for their specified

purpose.

Always exercise extreme care and observe

the recommended hygiene rules when

handling mineral oil products. Details of these

handling regulations can be found in

information provided by the health authorities.

Storage and Handling

• Always store lubricants where they cannot be

accessed by children.

• Never store lubricants in open or unlabelled

containers.

Fresh Oil

• Apart from taking the usual care and observing hygiene rules, there is no need to take

any special precautions when handling fresh

oil.

Waste Oil

• Waste oil can contain harmful contaminants

which may cause skin cancer, allergies and

other illnesses.

Attention!

Oil is a toxic substance. Should you swallow

any oil, do not try to vomit. Contact a doctor

immediately.

Protect your hands with barrier cream or wear

gloves to avoid contact with the skin. Wash

off any traces of oil thoroughly with soap and

hot water.

In the case of prolonged skin contact,

lubricants - especially low-viscosity oils - may

remove the natural layer of fat contained in

the skin, resulting in dryness and possible

irritation .

It is important to take extreme care when

handling waste oil as it may contain other

irritants.

Vapours given off by cleaning agents and oils

are also a potential health hazard.

You should therefore not carry any oily cloths

around. Change soiled work clothing as soon

as possible.

• Wash your skin thoroughly with soap and water.

• Use special cleaning agents to clean any

dirt off your hands.

• Never wash oil residue from your skin with

petrol, diesel fuel or paraffin.

• Avoid skin contact with any oily clothing.

• Do not keep any oily rags in your pockets.

• Wash soiled clothing before wearing it

again.

• Ensure that any oily footwear is disposed of in

the proper manner.

33CultiPress

Operating Instructions

Page 34

5. Servicing and Maintenance

Measures in case of injury

through oil

Eyes:

Should any oil be splashed into your eyes,

rinse with water for 15 minutes. If the eye is

still irritated, contact a doctor immediately

If oil is swallowed

If oil is swallowed, it is important not to induce

vomiting. Contact a doctor immediately.

Skin irritation caused by oil

In case of prolonged skin contact, wash off

the oil with soap and water.

Oil Spills

Use either sand or a suitable granular

absorbent to soak up any spilt oil. Dispose of

the oil-contaminated absorbent in the proper

manner.

5.12 Lubricants &

Hydraulic Oil

Hydraulic System

The hydraulic fluid from the tractor is mixed

with the hydraulic fluid from the machine.

The supplied machine hydraulic system

contains Total AZOLLA ZS 32 oil.

Lubricants

All lubricating points on the machine can be

lubricated with multigrade lubricating grease

as specified in DIN 51825 KP/2K - 40.

Oil Fires

Never use water to extinguish an oil fire. The

oil will float on the water causing the fire to

spread.

Burning oil-lubricant must be extinguished

using a carbon dioxide powder or foam

extinguisher. Always wear respiratory

equipment when dealing with fires of this type.

Waste Oil Disposal

Oil-contaminated waste and used oil must be

disposed of in accordance with current

legislation.

Waste oil must be collected and disposed of

in accordance with local regulations. Never

pour used oil into unsealed sewage systems

or drains or onto the ground.

CultiPress

34

Operating Instructions

Page 35

6. Faults and Remedies

CultiPress Troubleshooting

Fault Possible cause Remedy

6. Faults and Remedies

Front roll axle starts to

block regularly.

Rear roll axle starts to

block regularly.

Shorten work drawbar cylinder

Machine running too tail low.

Front to rear ring tracking out

of alignment.

Roll axle is not tight. Tighten axle.

Ground condi tions too wet.

Machine running too tail high.

until main frame is horizontal or

just tail low.

Reduce quantity of shims in

depth stop unit.

Reset ring centres to run rear

rings centrally between the front

Wait for more suitable

condi tions.

Lengthen work drawbar cylinder

until main frame is horizontal or

just tail low.

Increase quantity of shims in

depth stop unit.

rings.

Levelling boards drop at

headland turns.

Levelling boards become

unphased.

Roll axle is not tight. Tighten axle.

Ground conditions too wet

Front to rear ring tracking out

of alignment

Rear roll scrapers incorrectly

adjusted.

Tractor spool valve in float

position.

Tractor spool valve in float

position.

Wait for more suitable

conditions

Reset ring centres to run rear

rings centrally between the front

Set scrapers to run just clear of

rings and centrally between each

Operate levelling boards using

pressure only.

Operate levelling boards using

pressure only.

rings

ring.

Operating Instructions

35CultiPress

Page 36

Notes

Space for Notes:

CultiPress

36

Operating Instructions

Loading...

Loading...