Page 1

NTA607HD Lift Assist Adjustments

Great Plains Manufacturing, Inc. 1

Null4:

General Information

This manual is an instruction guide for reducing load on

the caster wheels or for operating with the caster wheels

fully off the ground. The result will make the NTA607HD

unit more suitable for conventional soil conditions rather

than no-till conditions.

Removing weight bar sets and adjusting the pressure

reducing valve will result in less load on the caster

wheels and less severe tracks in the field, especially in

muddy conditions.

Tools Required

• basic hand tools

• a forklift or similar hoist capable of lifting a minimum of

374kg (825 lbs)

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

Your life and the lives of others depend on it!

Work Location

Move the implement to a flat location

Notations and Conventions

Null4:

U

F

L

D

“Left” and “Right” are facing in the

direction of machine travel. An orienta-

R

tion rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

B

Figure 1

Standard (3 Weight) NTA607HD

R

F

U

B

L

D

31285

© Copyright 2010 Printed 12/02/2010 166-365M

Page 2

2 Great Plains Manufacturing, Inc. NTA607HD Lift Assist Adjustments

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

166-365M 12/02/2010

Page 3

Important Safety Information Great Plains Manufacturing, Inc. 3

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment.

▲ Work in a clean, dry area.

▲ Unfold and lower the drill, put tractor in park, turn off

engine, and remove key before performing maintenance. If

work must be performed with implement raised, use center

section lift lock and gauge lock channels provided.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow drill to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems.

▲ Welding: Disconnect battery ground. Protect hydraulic

lines. Avoid fumes from heated paint.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from air drill before

operation.

MetaData: End of <Safety Topics>

Null4:

12/02/2010 166-365M

Page 4

4 Great Plains Manufacturing, Inc. NTA607HD Lift Assist Adjustments

Before Starting

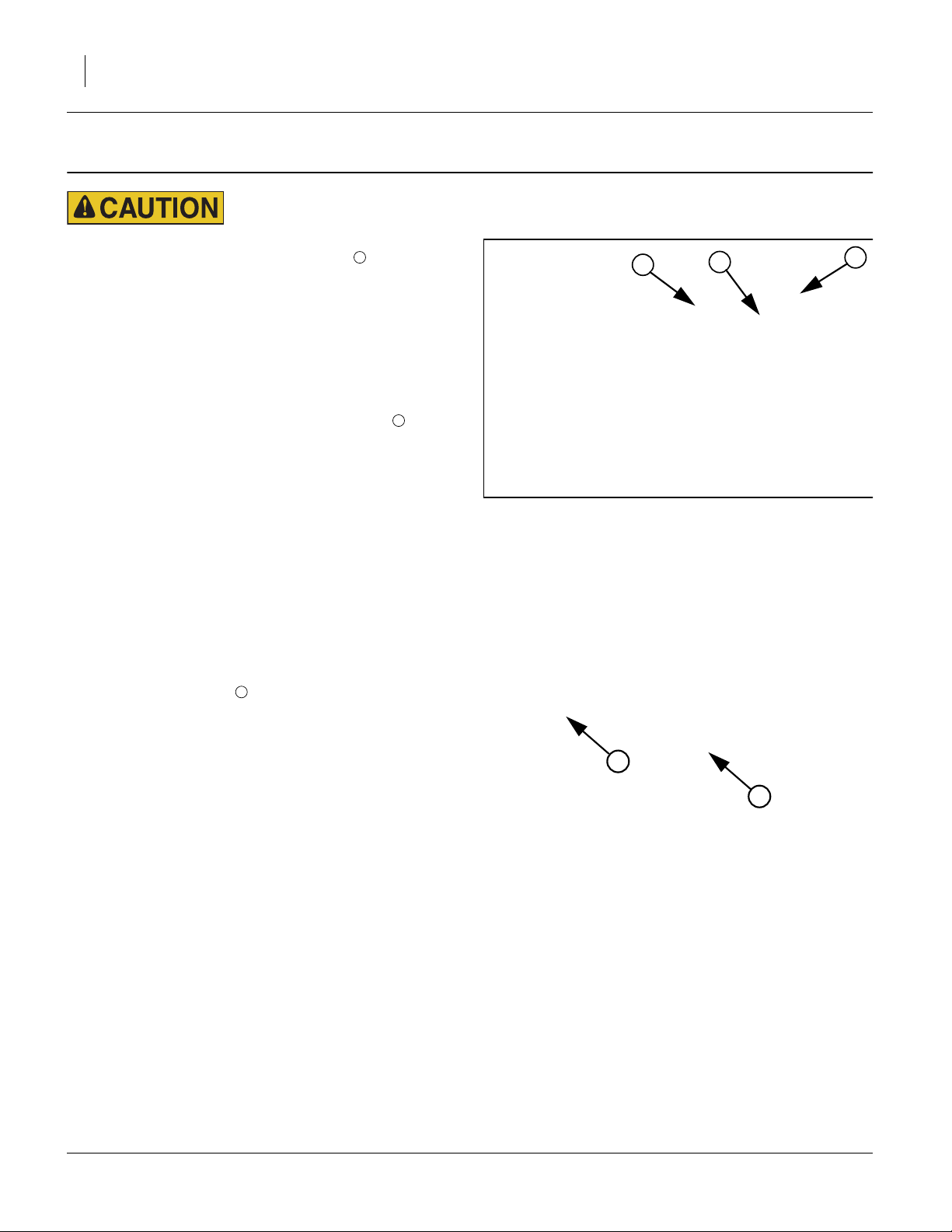

Dense Heavy Overhead Object Hazard:

Use adequate lifting means. Use both mounts for lifting.

Keep all workers clear of area while a weight is overhead.

Keep hands away from underside of weights, and out of stackto-stack contact regions. Weight stacks have a mass of 374kg

(825 pounds). A hoist failure could result in substantial equipment damage, serious injury or death. Hands in the path of

weight movement can be crushed.

Refer to Figure 2 (6in 80-row model with blockage module)

There are three sets of weights bolted to the center

frame weldment. Remove the mid weight stack first.

This may be the only weight that needs to be removed if

it satisfactorily produces the result you desire. The only

way to judge the result is by running the unit in the field

once the weight is removed.

2

1

2

1

2

Null4:

Before Proceeding with Instructions

Refer to Figure 3

Check caster stabilizers are properly adjusted. It is

unlikely, but casters may want to swing out of position.

Stabilizer bolts should be adjusted tightly enough to

ensure this does not occur. See “Caster Brakes” in the

lubrication section of the Operator Manual (166-283M).

Do not set cart weight transfer higher than necessary.

Values close to 1000 psi can lift the rear of an empty cart

off the ground see “Cart Weight Transfer Adjustment

(Inner Valve)” on page 6.

3

Figure 2

Weight Stacks

3

3

Figure 3

Caster Stabilizers

166-365M 12/02/2010

Page 5

Remove Mid Weight Set Great Plains Manufacturing, Inc. 5

Remove Mid Weight Set

Refer to Figure 4 and Figure 5

1. Remaining clear of seed towers and hoses, disas-

semble mid weight set from the center frame

4

tubes .

1

2

Remove the1⁄2x11⁄2in bolt , hex nut and lock

washer from each top mount that hook the mid

weight and rear weight top mounts together.

(Retain bolt, nut and washer by securing them back

in the top mount holes of the mid weight after the

stack is removed.)

2. Remove the two weight bracket bolt channels that

keep the weights attached to the frame (only the left

one is visible in Figure 4). This requires removing the

nut and lock washer on the bottom of the bracket

securing each5⁄8x9in bolt .

When you take the nut off the bolt should slip out.

8

6

7

Before Proceeding:

The individual weight bars, two top mounts and long

weight mount channel weldment remain assembled as

one unit.

3. There are two weight bracket mounts on the top of

each stack of weights. Secure lifting hooks or chains

to these two mounts on the mid weight. (Take up

slack gradually to avoid deforming mounts. Minimize

load sway to avoid damage to nearby objects and the drill.)

4. Hoist mid weight up and away from implement. Place

in storage along with the two weight bracket bolt

channels (Note: channels may be used later).

6

5

2

2

R

F

1

U

D

2

4

4

B

L

Figure 4

Remove Mid Weight Stack

8

7

5

6

31736

Adjust Back Pressure

5. To manipulate the amount of down force:

In addition to removing the mid weight stack you will

need to adjust the back pressure at the pressure

reducing valve located on the left wing. See “Adjust

Weight Transfer Valves” on page 6.

Figure 5

Place Hooks on Top Weight Mounts

12/02/2010 166-365M

Page 6

6 Great Plains Manufacturing, Inc. NTA607HD Lift Assist Adjustments

Adjust Weight Transfer Valves

Refer to Figure 6 and Figure 7

Do not set cart weight transfer higher than necessary. Values

close to 1000 psi can lift the rear of an empty cart off the

ground. As a cart nears empty, the main tires can begin to slip,

or stop turning altogether, resulting in irregular seeding rates

or stoppages.

Wing Weight Transfer Adjustment (Outer Valve)

Note: This valve will most likely not need adjusting. It will

already be set to meet your requirements.

1. Release lock ring on wing-transfer valve .

Adjust knob while observing gauge .

Increase weight transfer to wings by turning knob

clockwise. Reduce weight transfer to wings by turning knob counter-clockwise.

Set pressure to at least 250 psi.

Secure setting with lock ring.

3 1

4 5

Cart Weight Transfer Adjustment (Inner Valve)

Note: This valve will need adjusting to get the results

you require.

2. Release lock ring on cart-transfer valve .

Adjust knob while observing gauge .

6 2

7 8

8

2

5

1

6

3

7

4

Figure 6

Pressure Reducing Valve

Inner Valve Controls Cart

Outer Valve Controls Wings

To avoid planting problems, do not exceed 1500 psi for wingtransfer, and 1000 psi for cart-transfer. A relief valve prevents

operating the wing-transfer at over 1500 psi.

31192

Increase weight transfer from cart by turning knob

clockwise. Reduce weight transfer from cart by turning knob counter-clockwise.

Set pressure to at least 100 psi.

Secure setting with lock ring.

3. Pull forward in ground. Assess opener penetration,

and coulter (option) penetration. Compare wings to

center section.

4. During field operations, monitor coulter and opener

depth of wings and center section. Adjust weight

transfer as required for consistent depth across drill.

5. Once the cart weight transfer has been adjusted,

adjust the rear lift assist adjustment linkage as

described in “Adjust Linkage” on page 7.

Figure 7

Pressure Reducing Valve Decals

Cart: Decal on Left

Wing: Decal on Right

166-365M 12/02/2010

Page 7

Adjust Linkage Great Plains Manufacturing, Inc. 7

Adjust Linkage

Refer to Figure 8

The factory setting of the lift assist link has approximately

7.62cm (3in) of exposed threads outside the fixed end of

the lift assist link. Adjust the link (extend it out) by only

2.54cm to 3.81cm (1 to 11⁄2in). Anymore than that could

be unsafe and lead to machine damage.

Caster Failure Hazard:

Never exceed 13.97cm (51⁄2in) of exposed threads on the lift

assist adjustment link. Exceeding this measurement could

result in linkage failure leading to severe machine damage,

bodily injury or death.

1. With drill (unfolded and lowered) place a jack stand

underneath the rear part of the frame near the caster

wheels. Support is required to take weight off the

casters for ease of adjustment. If you do not have a

jack stand, an alternative method to reduce weight

on the casters is to do the following four steps:

• turn the 90 degree ball valve on the fan to transport position

• activate the tractor remote lever to supply oil to

the fan/weight transfer circuit

• set the cart weight transfer to 100 psi

• set the wing weight transfer to the maximum

pressure setting of 1500 psi.

2. Measure from the inside face of the square nut to

the inside face of the adjuster nut (see Figure 8).

2

1

The factory setting is approximately 7.62cm (3in).

Adjust it out 2.54cm (1in) to start with. The measurement from the face of the square nut to the face of

the adjuster nut will now be 10.16cm (4in).

3. Determine if adjusting the link 2.54cm (1in) provides

a satisfactory result. See “Determine Results” on

page 8. If frame drops back too much it indicates

there is still too much weight. Follow instructions for

removng rear weight set.

Adjust Lift Assist Link

2

Figure 8

1

Null4:

31747

12

Null4:

31755

Link Adjust

factory set 7.62cm (3in)

2.54cm (1in) 10.16cm (4in)

3.81cm (1.5in)

5.08cm (2in) 12.7 (5in)

6.35cm (2.5in)

12/02/2010 166-365M

Thread

Measurement

11.43cm

(4.5in)

13.97cm

(5.5)in

PW Transport

Clearance

27.94cm (11in)

22.86cm (9in)

20.32cm (8in)

17.78cm (7in)

less than12.7cm

(5in)

Comments Casters

factory setting

moves casters 10.16cm (4in)

more than factory setting

maximum recommended link

adjustment

not recommended

start losing PW clearance

NEVER EXCEED UNSAFE thread engagement not enough

moves casters 15.24cm (6in)

more than factory setting

moves casters 20.32cm (8in)

more than factory setting

for safe transport

Page 8

8 Great Plains Manufacturing, Inc. NTA607HD Lift Assist Adjustments

Determine Results

1. Run implement in field.

2. If removing the mid weight stack satisfactorily gets

the result you desire (the tires are off the ground as

you want) you are done. Make sure to reset valve:

back pressure must be set to at least 100 psi.

3. If the result is not satisfactory and further adjustment

is desired it will be necessary to set the pressure

back down and then proceed with the rest of these

instructions to remove the rear set of weights.

Insufficient Opener Weight Risk:

It is not recommended to remove the front weight stack. If the

implement is used in heavier till field conditions there will be

insufficient down force over the coulters for penetration in the

soil.

166-365M 12/02/2010

Page 9

Remove Rear Set of Weights Great Plains Manufacturing, Inc. 9

Remove Rear Set of Weights

Refer to Figure 9

About the Weights

The 6in 80-row drill model has an extra (fifth) blockage

module that the other models (6in 40-row, 7.5in 32-row,

7.5in 64-row) do not require. It is mounted on the double

shoot blockage module mount on the rear set of

weights . It needs to be dismantled and moved as per

the following instructions. If the implement you have does

not have this mount bracket, disregard references to it

and follow all other instructions.

13

12

11

13

14

12

11

Remove Rear Weight Set

1. If you have the double shoot 6in 80-row model:

Remove double shoot blockage module mount

keeping DICKEY-john® module attached and save

along with any hardware to remount. This will be

remounted in Step 5 to the angle tower bracket.

2. Remove the5⁄8x9in bolts at either end of the two

center tower mount brackets that the rear weight

13

stack is bolted to (only left frame side is visible in

Figure 9). The U-bolt remains permanently

attached.

3. Secure lifting hooks or chains to the two mounts

on the top of the rear weight stack. (Take up slack

gradually to avoid deforming mounts. Minimize load

sway to avoid damage to nearby objects and the

drill.)

4. Hoist rear weight stack up and away from implement and place in storage along with all associated

hardware.

15

14

16

13

Reattach Mount Bracket and Module

Refer to Figure 10 and Figure 11

5. If you have the double shoot 6in 80-row model:

Attach double shoot blockage module mount

bracket with attached DICKEY-john® module

to upper set of holes in double shoot tower mount

angle bracket (Figure 10) using two bolts currently in place on the tower bracket.

Note: This bracket must be centered to connect to all

12 17

18

seed hoses.

12

11

R

F

U

D

B

L

15

Figure 9

Rear Weight Stack

17

18

14

16

31738

12

6

6

Figure 10

Blockage Monitor Mount Bracket

12/02/2010 166-365M

Page 10

10 Great Plains Manufacturing, Inc. NTA607HD Lift Assist Adjustments

Reattach Bolt Channel Brackets

6. Take the two weight bracket bolt channels and two

5

⁄8x9in bolts per bracket that were removed from

the bottom of the mid weight set and remount one

each on top of the left and right frame tubes as pictured (Figure 10 and Figure 11).

15

6

6

Adjust Back Pressure

7. To manipulate the amount of down force:

In addition to removing the rear weight stack you

should adjust the back pressure at the pressure

reducing valve located on the left wing See “Adjust

Weight Transfer Valves” on page 6.

15

6

Null4:

Determine Results

1. Run implement in field.

2. If removing the rear weight stack satisfactorily gets

the result you desire (the tires are off the ground as

you want) you are done. Make sure to reset pressure valve: back pressure must be set to at least

100 psi.

Insufficient Opener Weight Risk:

It is not recommended to remove the front weight stack. If the

implement is used in heavier till field conditions there will be

insufficient down force over the coulters for penetration in

the soil.

R

F

U

B

L

D

Figure 11

Weight Bracket Bolt Channels

15

166-365M 12/02/2010

Page 11

Appendix Great Plains Manufacturing, Inc. 11

Appendix

Abbreviations

in. inch/inches PW press wheel

kg kilograms W/ With

psi pounds per square inch X by

12/02/2010 166-365M

Page 12

12

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

166-365M 12/02/2010

Loading...

Loading...