Page 1

Great Plains Mfg., Inc.

Blockage Monitor Kits

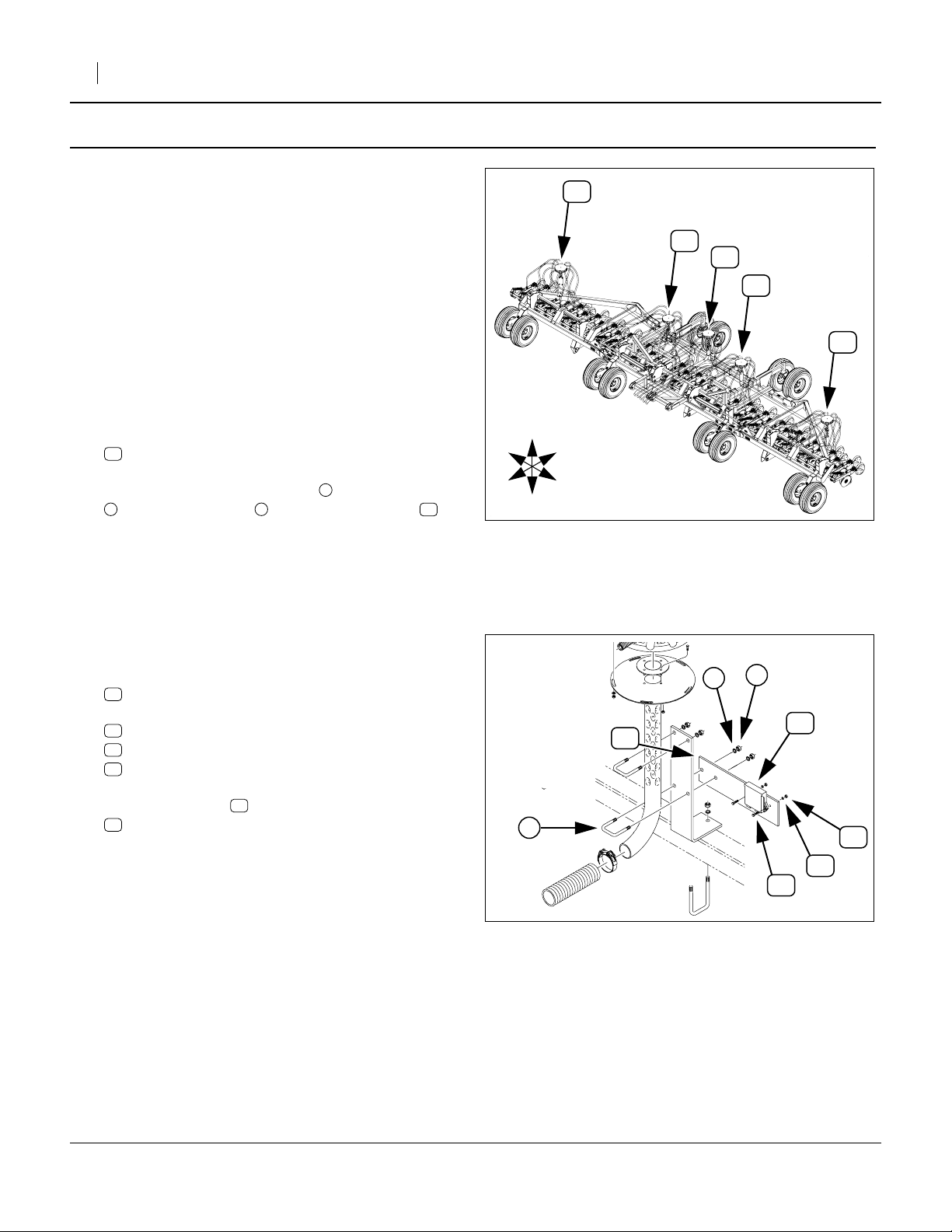

Air Drills

Used with:

• 3N-4010HDA

• CTA4000 and CT4000HD

• NTA3010 and NTA3510

General Information

Blockage monitor kits upgrade the existing DICKEY-john

Intelli-ag AirCart Controlsystem,adding the capability to

detect extreme variations in seed flow to individual rows.

These instructions explain how to install any of the following Blockage Monitor Kits:

Kit Kit Description

168-404A NTA30-4875 DICKEY JOHN BLOCKAG

168-405A NTA30-3610 DICKEY JOHN BLOCKAG

168-406A NTA35-5575 DICKEY JOHN BLOCKAG

168-407A NTA35-4010 DICKEY JOHN BLOCKAG

168-408A CTA40-8006 DICKEY JOHN BLOCKAG

168-409A CTA40-6575 DICKEY JOHN BLOCKAG

168-410A CTA40-5010 DICKEY JOHN BLOCKAG

168-411A 3N40HD-6675 DICKEY JOHN BLOCK

168-412A 3N40HD-4810 DICKEY JOHN BLOCK

If installation is being done on a new 3N-4010HDA, use

the instructions in the 196-444Q Pre-Delivery manual.

The instructions in this manual (168-414M) presume a

drill originally delivered and setup without blockage.

Each kit updates one drill. Kits are specific to drill models

and row spacings:

Installation Instructions 1

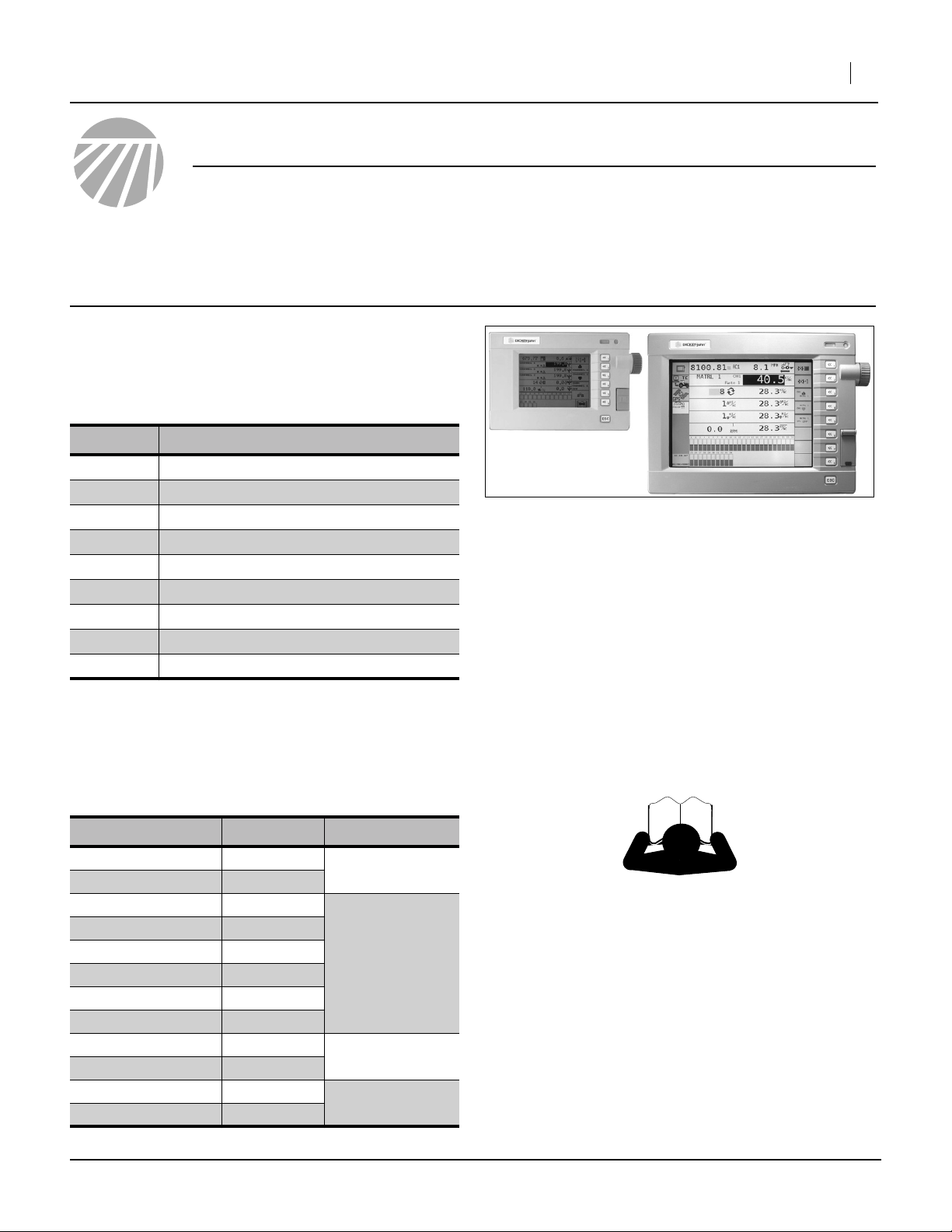

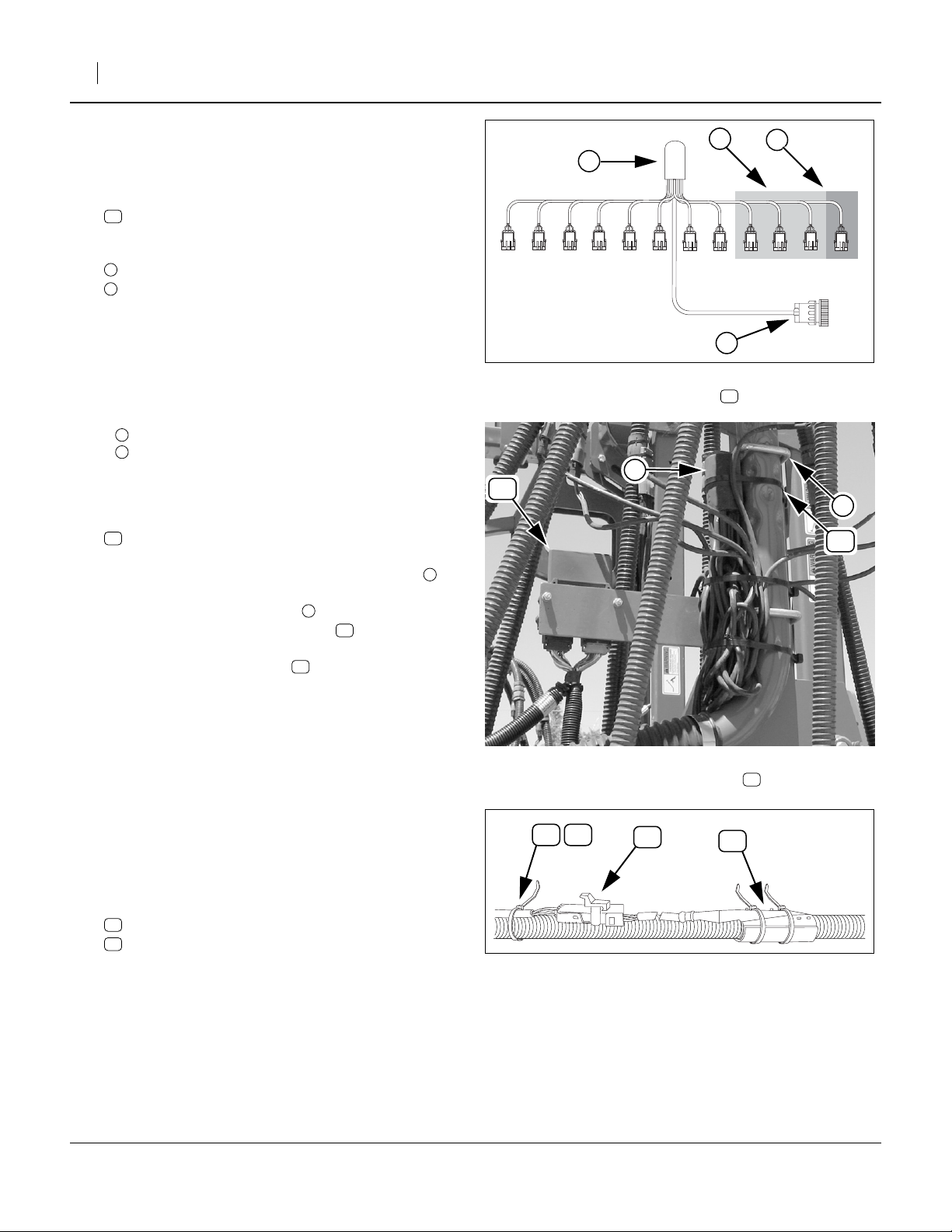

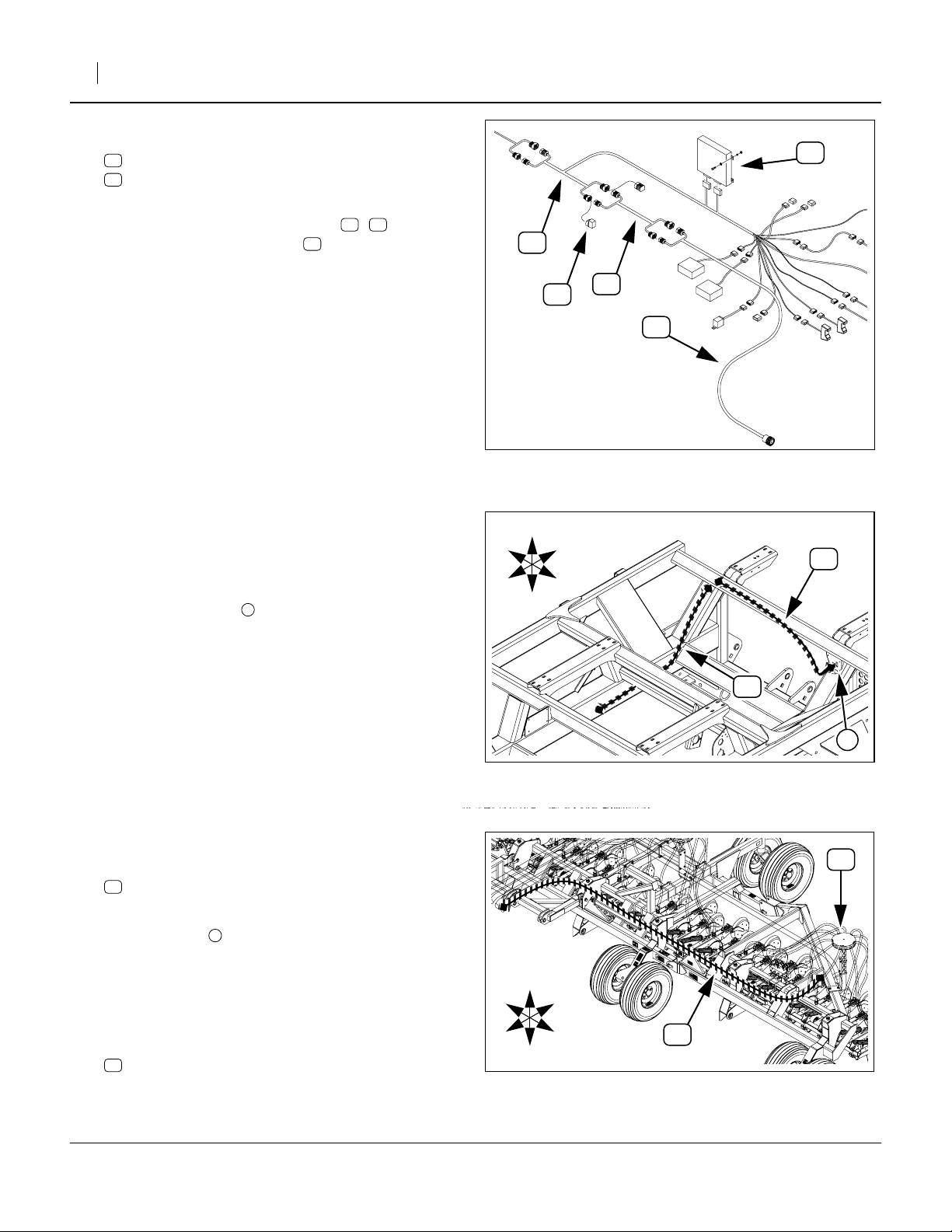

Figure 1

Existing Intelli-ag Console

Note: The air drill must already be equipped with a

DICKEY-john Intelli-ag Air Cart Control system,

which includes a 5in or 10in LCD console (shown

above) for the tractor cab. This system is standard

with the ADC2350 and ADC2350B air drill carts.

Air drills using ADC1150, ADC2220and ADC2250

carts, and equipped with Loup monitor systems,

cannot use these blockage kits.

25421

Air Drill Models Use Kit Pages

3N4010HDA-4810

3N4010HDA-6675

CTA4000-5010

CTA4000HD-5010

CTA4000-6575

CTA4000HD-6575

CTA4000-8006

CTA4000HD-8006

NTA3010-3610

NTA3010-4875

NTA3510-4010

NTA3510-5575

©Copyright 2008 Printed 10/29/2008 168-414M

168-412A

168-411A

168-410A

168-410A

168-409A

168-409A

168-408A

168-408A

168-405A

168-404A

168-407A

168-406A

2-9, 29

2-3, 10-16, 29

2-3, 17-22, 29

2-3, 23-29

Before You Start

Review these instructions, with the following objectives:

• Compatibility: make sure the correct kit has been

ordered, and the air drill has the necessary DICKEYjohn Intelli-ag Air Cart Control system.

• Inventory: make sure all parts are present.

• Comprehension: make sure the installers understand

where each part is installed, and what tools are

required for the task.

Page 2

2 Blockage Monitor Kits

Notati

Great Plains Mfg., Inc.

Tools Required

• Current Operator manual:

3N4010HDA 196-444M

CTA4000 160-269M-A

CTA4000HD 160-037M

NTA3010 160-219M-A

NTA3510 160-219M-A

• Updated Parts manual:

3N4010HDA 196-444P

CTA4000 160-269P

CTA4000HD 160-037P

NTA3010 160-219P

NTA3510 160-219P

• tractor or hydraulic power source, and;

• basic hand tools, including a power drill and

11

3

⁄

to

⁄

16

in (17-19mm) hole saw.

4

ons and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

Call-Outs

1 9

to ,

a z

to

11 40

to

91 98

to

Single-character callouts identify components in the currently referenced Figure or

Figures. These numbers may be reused for

different items from page to page.

Two-digit callouts in the range 11 to 40 reference new parts from the new parts list on

page 40. The descriptions match those on

the parts, bags or cartons, and in your

updated Parts Manual.

Two-digit callouts in the range 91 to 98 reference existing parts from the list on page 41.

The descriptions match those your Parts

Manual.

U

F

L

R

B

D

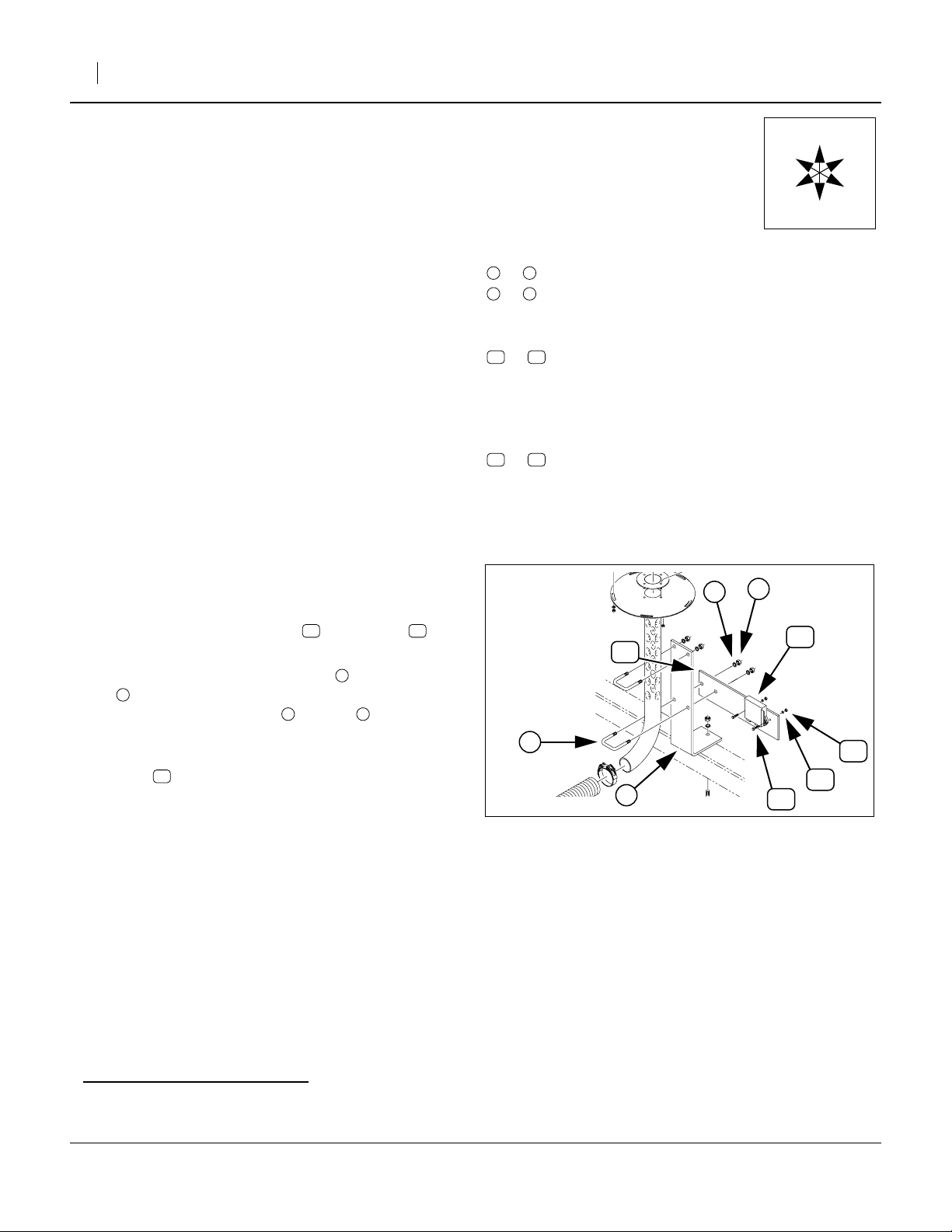

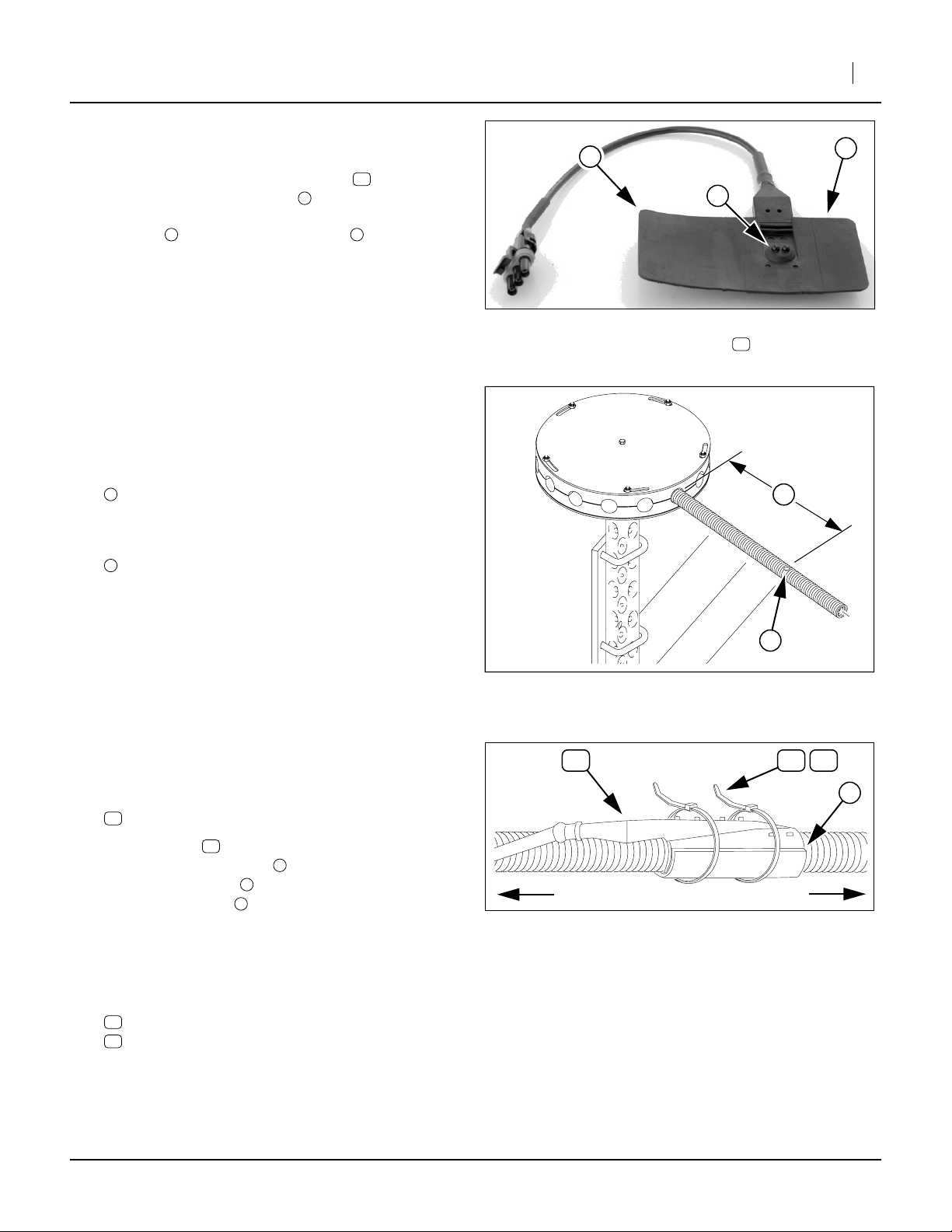

Mount and WSMBa Orientation

Refer to Figure 2

The kit includes a mounting plate and WSMB for

each tower.

The plate attaches to the tower mount , at an existing

U-bolt located just above the bend in the tower tube,

and under the existing washer and nut . The plate

orientation (left, right, front or back) is described in the

detailed steps.

The WSMB mounts to the tower side of the plate, with

mount ears flat against the plate, and connectors facing

down.

2

39

12 39

1

3 4

4

3

39

12

2

15

16

1

Figure 2

Typical Module Mount

14

27058

a. WSMB: DICKEY-john Working Set MemBer module

168-414M 10/29/2008

Page 3

Great Plains Mfg., Inc.

Pre-Assembly Preparation

Work Location

1. Move the drill to a location with:

• room to unfold it,

• adequate illumination, and;

• a clear surface beneath for recovery of any

dropped parts.

Prepare Drill

2. Position the drill at the work location.

3. Unfold the drill.

4. Lower the row units.

5. Set tractor hydraulic remotes to Float, to relieve

pressure in the lines.

Port Numbering

Tower Ports are numbered Clockwise from mount center

(Port 1) to the last port number, which is the same for all

towers on the same drill.

As an aid to installation, mark the port numbers after

checking Port 1. If the tower weldment has shifted position since initial delivery, Port 1 may not be exactly at the

mount.

PORT 2

Installation Instructions 3

PORT

1

PORT 8, 9, 10, 11,

12, 13 or 16

Refer to Figure 3

6. Verify Port 1. Consult the Port Assignments table

for the drill and row spacing (found in the Appendix

of this manual). The first Opener entry in the table is

Port 1. Openers are numbered from 1 at drill left.

Follow the seed hose from that opener to the tower.

This is Port 1.

7. Mark the Port numbers on the tower cap, moving

clockwise (looking down on the cap) from Port 1.

8. Turn to pages for your drill:

3N-4010HDA Installation.....................................page 4

CTA-4000 and 4000HD Installation...................page 10

NTA-3010 Installation........................................page 17

NTA-3510 Installation........................................page 23

Figure 3

Tower Port Numbering

Facing Tower At Mount

m

28185

m

10/29/2008 168-414M

Page 4

4 Blockage Monitor Kits

3N-4010HDA Installation

This installation requires one of the following kits:

168-411A 3N4010HDA-6675 (66 row, 7.5in)

168-412A 3N4010HDA-4810 (48 row, 10in)

If installation is being done on a new 3N-4010HDA, use

the instructions in the 196-444Q Pre-Delivery manual.

The instructions in this manual (168-414M) presume a

drill originally delivered and setup without blockage.

Additional installation information is found in the

DICKEY-john IntelliAg Air Cart Control Operator’s manual.

Note: The DICKEY-john manual has only general har-

ness routing for the Great Plains air drills, and

somecable part numbers areslightly differentfrom

those in the kits.

Refer to Figure 4 and Figure 5

9. Select six (6):

12

168-465D DIST TOWER MODULE MOUNT PLATE

At each tower, remove the nuts andlock washers

2 312

at the lower U-Bolt , and mount the plate .

Plate orientation is small holes to top, and:

on Towers 1 & 6: extension to drill center

on Towers 2 & 5: extension away from drill center

on Towers 3 & 4: extension to drill rear

1

Great Plains Mfg., Inc.

1

2

39

12

3

15

16

14

Figure 4: 3N:

Tower 2 Module Mount

27058

3N: Install WSMBs

Start with the left tower (Tower 1).

Refer to Figure 4 and Figure 5

10. Select one:

39

467981100S1 INTAG WSMB/FLW MNTR MODULE 18R

and two sets:

14

802-224C HHCS 1/4-20X1 1/4 GR5

16

804-006C WASHER LOCK SPRING 1/4 PLT

15

803-006C NUT HEX 1/4-20 PLT

Mount the WSMB on the front of the plate ,

with the connector ports down.

11. Repeat step 10 for the remaining towers.

The WSMB orientation is:

on Wing towers (Figure 4):

connectors down, module to front

on Center towers (Figure 5):

connectors down, module to center

39 12

1

2

39

12

3

14

15

Figure 5: 3N

Tower 3 Module Mount

16

28182

168-414M 10/29/2008

Page 5

Great Plains Mfg., Inc.

3N: Prepare Hoses for Sensors

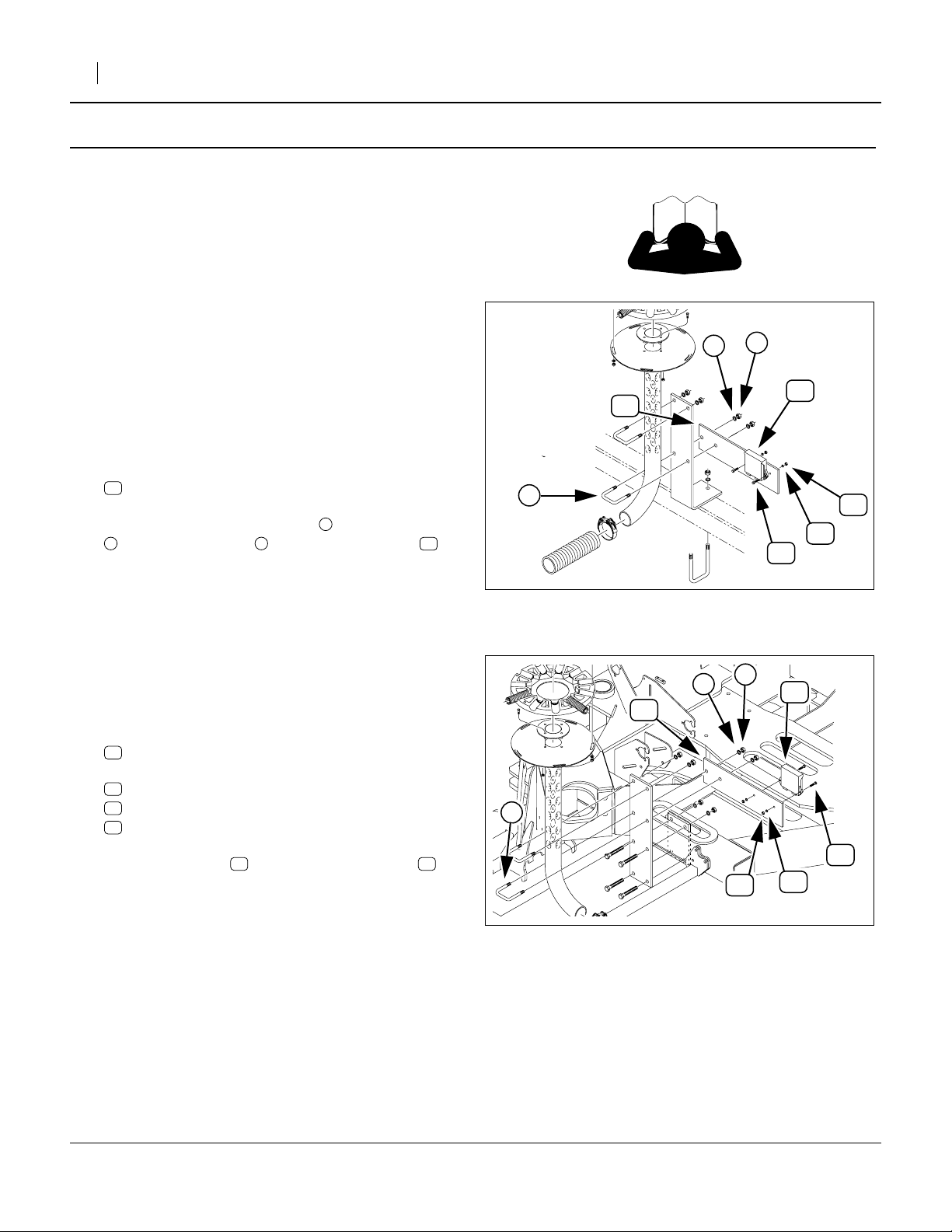

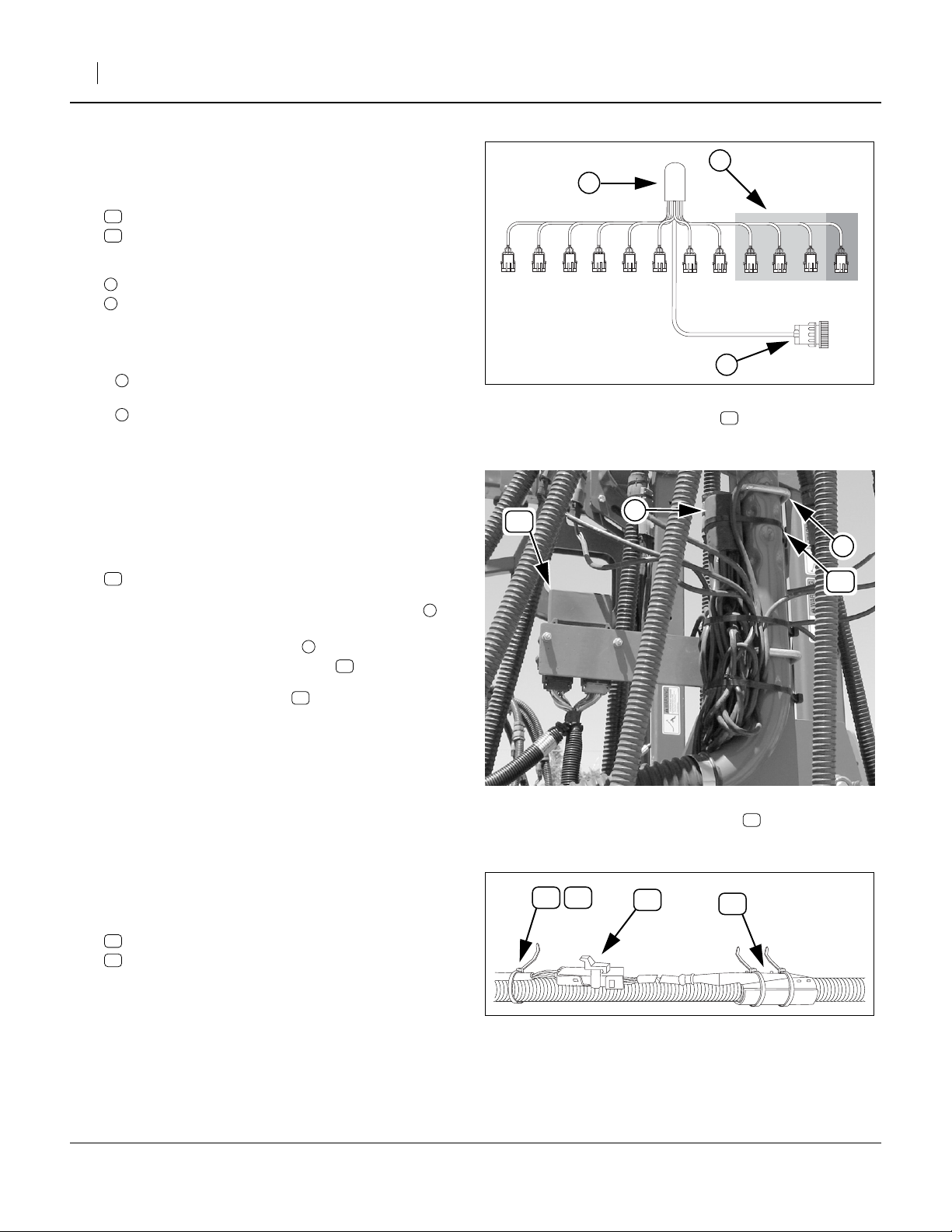

Refer to Figure 6

DICKEY-john Recon-II blockage sensors require a

hole in the hose for the detectors . The sensor has flex-

1

ible flaps which are tie-wrapped around the seed hose.

The long flap goes over the short flap .

2 3

Note: Usea holesawto makethehole. Use a high speed

drill (to minimize rough edges), and cut slowly (to

minimize risk of drill-through).

30

Installation Instructions 5

2

3

1

Using a drill bit is likely to damage the hose.

Refer to Figure 7 (showing hole on top)

12. Drill one hole in each secondary seed hose at each

tower. Check the first hole for sensor fit before drilling the remaining holes.

The hole location is approximately:

4

13in (33cm)

from where the hose enters the tower.

The hole diameter is:

11

5

3

⁄

to

⁄

16

in (17-19mm)

4

Make the hole on the underside of the hose (toward

center of tower), or rotate the hose to hole-under

after drilling or installing sensor.

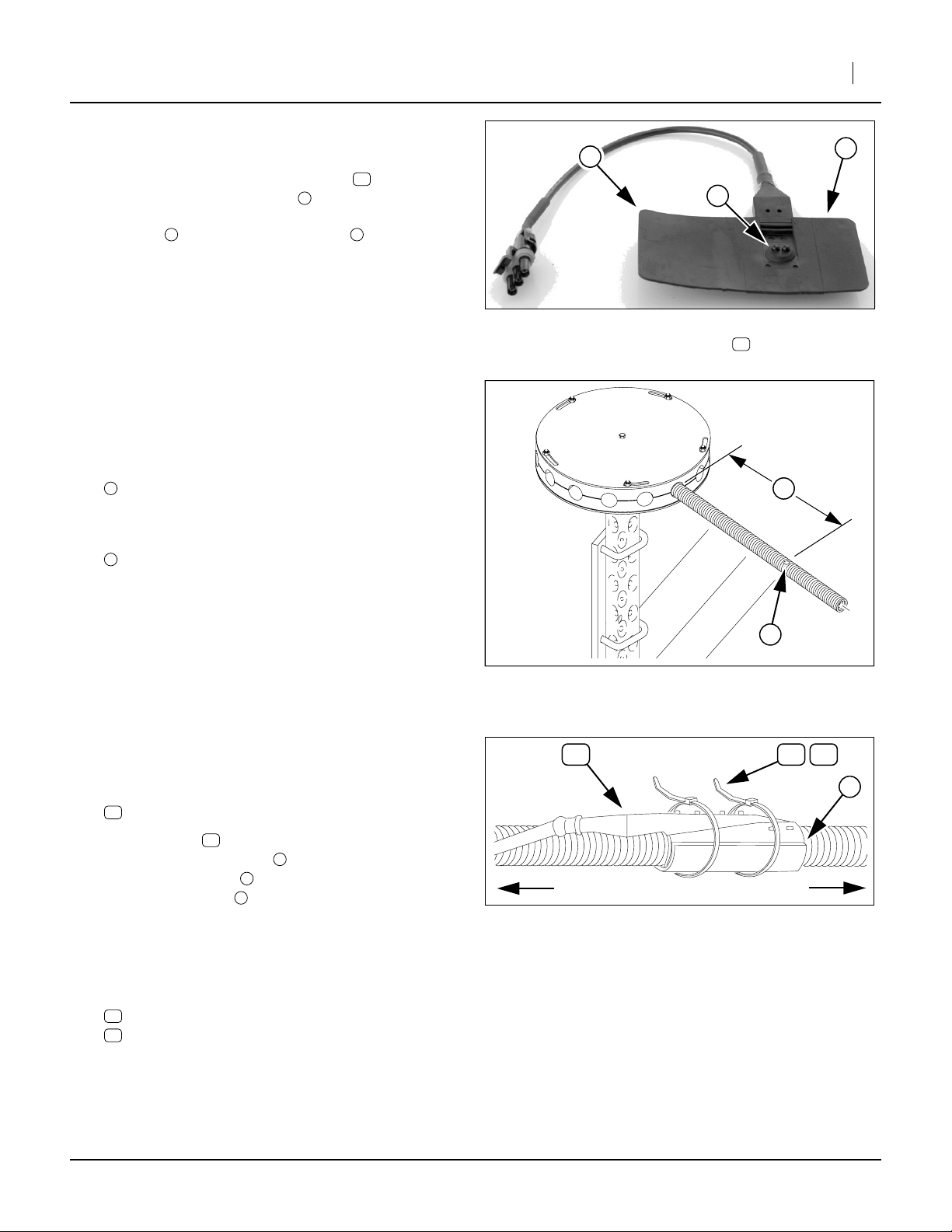

3N: Install Blockage Sensors

Refer to Figure 8 and Figure 6

13. Select one:

30

467420352S1 RECON II

Figure 6: 3N

Blockage Sensor

30

4

5

Figure 7: 3N:

Sensor Hole Location

30 26 27

28197

28194

2

14. Orient sensor with signal lead toward opener.

Insert the detector head in the hose hole.

Wrap the short flap around the hose.

Wrap the long flap over the short flap.

Check that the long flap overlaps by at least

30

1

3

2

1

⁄

in

4

Opener

Figure 8: 3N:

Mount Sensor

Tower

28195

(6mm), but by no more than 1in (25mm). If the flap

is too long, cut off any excess. Re-check overlap.

15. Select two ties from either:

26

110110050 TY WRAP BUNDLE 50-14"

27

110110099 TY WRAP BUNDLE 100-14"

Secure the sensor to the hose with ties.

10/29/2008 168-414M

Page 6

6 Blockage Monitor Kits

Great Plains Mfg., Inc.

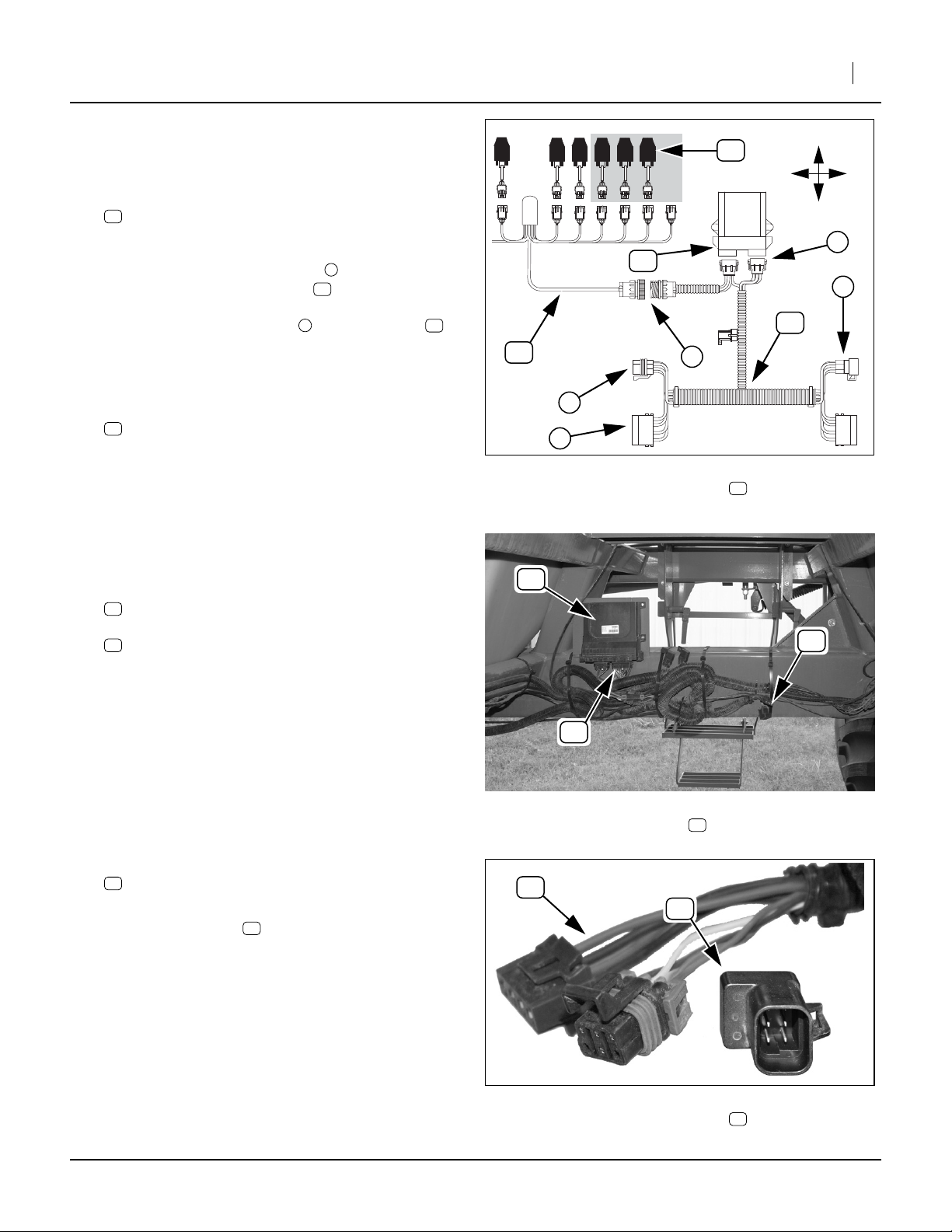

3N: Mount Row Harnesses

Start with Tower 1 (left wing, left tower).

Refer to Figure 9

16. Select one:

31

467751320S1 12 ROW HARNESS

Observe that the assembly has:

1

one large connector (for the WSMB);

2

a sealed weather-cap module; and,

12 row sensor connectors,

numbered “ROW 1” through “ROW 12”

Note: Connector numbering matches harness-to-row

only on Tower 1. At connection step 19, see “Port

Assignment” table on page 31 or page 32.

Note: There are more sensor leads than drills rows.

3

“ROW 12” is unused on 3N-4010HDA-6675.

4

“ROW 9” through “ROW 12” are unused on

3N-4010HDA-4810.

Refer to Figure 10

17. Select one:

13

800-082C CABLE TIE .31X21.5 6DIA 120LB

At the tower, position the weather-cap module :

- lead bundle down,

- just under the upper U-bolt , and;

- on the same side as the WSMB .

3

39

4

3

2

1

345678

2

10 11 12

9

1

Figure 9: 3N:

Row Harness

31

28198

2

39

3

13

2

Secure the module with tie around the tower

weldment and mounting plate.

18. Repeat step 16 and step 17 for Tower 2 through 6.

13

3N: Sensors to Harnesses

Start with opener 1 (left opener, left wing).

Refer to Figure 11

19. Using the table on page 31 or 32, determine the

Harness lead (“ROW”) to tower Port assignment.

Isolate each lead from the bundle, and plug the

assigned harness lead and sensor cable together.

20. Select one tie from either:

26

110110050 TY WRAP BUNDLE 50-14"

27

110110099 TY WRAP BUNDLE 100-14"

Tie the harness lead to the same seed hose as its

assigned sensor. Tie about 1in (2.5cm) behind the

cable sheath

21. Repeat step 19 and step 20 for each port on the

tower, and then for each tower. One or four leads

per tower are not connected. Excess cable is tiewrapped at step 25.

26 27

Figure 10: 3N:

Install Row Harness

31

Figure 11: 3N:

Row Harness to Sensor

31

30

28199

28196

168-414M 10/29/2008

Page 7

Great Plains Mfg., Inc.

Installation Instructions 7

3N: Salvage Harness

Refer to Figure 12

The existing monitor harness on the drill simply routes

the bus from front to rear hitch, and consists of three

cable assemblies. The blockage sensor system “splices”

into the harness. Two existing cables are re-positioned.

22. Remove and save:

93

467980141 10’ EXT HARNESS

23. Locate cable:

92

467980130 40’ HITCH HARNESS

Leave it secured to the tongue, but release it from

straps or ties on the drill frame.

Note: The rear hitch cable:

94

467980360 3’ REAR HITCH HARNESS

is left in place.

3N: Install WSMB Harnesses

Start with Tower 1 (left wing, left tower)

Refer to Figure 13

24. Select one:

40

467981201 INT AG HARNESS, WSMB MOD-

ULE

31

93

92

R

F

Figure 12: 3N:

Harness Route (w/o Blockage)

30

94

U

B

L

D

28443

39

Join the row harness connector to the mating

connector on the row harness .

Plug the WSMB connectors into the WSMB .

These connectors are not interchangeable, and are

keyed to ensure correct insertion.

Refer to Figure 10 on page 6

25. Select two:

13

800-082C CABLE TIE .31X21.5 6DIA 120LB

Coil up excess rowharness leads and tie the bundle

to the tower, above and below the lower U-bolt.

26. Repeat step 24 and step 25 for each tower.

1

31

239

R

U

D

2

5

40

L

1

3

4

Figure 13: 3N:

WSMB Harness

40

28200

10/29/2008 168-414M

Page 8

8 Blockage Monitor Kits

3N: Interconnect WSMBs

Start with the left wing.

Refer to Figure 14

27. At the left wing WSMB harnesses , interconnect

3

the female (receptacle) of left (outer) CAN bus

with

5

the male (plug) end of the mid-wing CAN bus.

Also connect the

4

power receptacle and plug

Note: The unconnected mid-wing CAN bus connector,at

right (near drill center) must be a receptacle.

28. At drill center, interconnect the center WSMB harnesses as shown in Figure 14, so that the free end

of the CAN bus at right is a receptacle .

29. At the right wing, interconnect the wing WSMB harnesses as shown in Figure 14, so that the free end

of the CAN bus at right is a receptacle .

3N: Route Drill Harness

When routing harness extensions, allow slack at towers for raising and lowering.

40

3

5

40

3

Left Wing Interconnect

U

D

R

5

L

3

4

Figure 14: 3N:

Great Plains Mfg., Inc.

3

40

28201

3N: Route Front Hitch Harness

Refer to Figure 15 and Figure 16 on page 9

30. Locate the rear end of:

92

467980130 40’ HITCH HARNESS

released at step 23.

Route the free rear end of this cable to Tower 1 ,

and connect it to the Tower 1 WSMB harness .

Secure hitch harness and Tower 1 WSMB harness

with ties.

3N: Route Wing Harnesses

31. Select one saved and one new:

93

467980141 10’ EXT HARNESS

35

467980141 10’ EXT HARNESS

Plug cables together. Connect plug end of the

assembly to WSMB harness at Tower 2 (left mid-

wing). Route the harness through the hoop at the

left wing pivot. Connect the receptacle end to the

WSMB harness at Tower 3 (left side of center).

32. Select one new:

34

467980140 DJ 20’ HARNESS EXT

Connect the plug end of the extension to the

WSMB harness at Tower 4 (right center). Route

the harness through the hoop at the right wingpivot.

Connect the receptacle end to the WSMB harness

at Tower 5 (right mid-wing).

T5

T3

T4

T2

34

40

T1

T6

T5

T4

34

T3

93

92

Figure 15

Blockage Harness Route (1 of 2)

35

R

F

U

B

L

D

T2

T1

28443

168-414M 10/29/2008

Page 9

Great Plains Mfg., Inc.

3N-4010HDA Blockage Harness Diagram

92

T2

T1

T3

Callout

New Ex.

31

92

34

35 93

37

94

40

T4

Installation Instructions 9

Harness ID

Part

Number

467751320S1 12 ROW HARNESS

467980130 40’ HITCH HARNESS

467980140 DJ 20’ HARNESS EXT

467980141 10’ EXT HARNESS

467980143 INT AG 25’ HARNESS, WSMB EXT

467980360 3’ REAR HITCH HARNESS

467981201 INT AG HARNESS, WSMB MODULE

T5

Description

T6

40

3N: Install Right-Rear Extension

Refer to Figure 16 and Figure 17

33. Select one new:

37

467980143 INT AG 25’ HARNESS, WSMB EXT

Connect the plug end of extension to the WSMB

harness at Tower 6 (right wing, right end). Route the

harness through the hoop at the right wing pivot.

Route it down the center section to the rear hitch

and connect it to existing rear hitch harness .

Secure with ties.

34. Skip to “Close-Out” on page 29.

35

93

3N-4010HDA Harness Block Diagram

37

94

Figure 16

94

34

T6

37

37

94

31

F

L

R

B

28439

U

R

F

B

L

D

Figure 17

Blockage Harness Route (2 of 2)

10/29/2008 168-414M

28443

Page 10

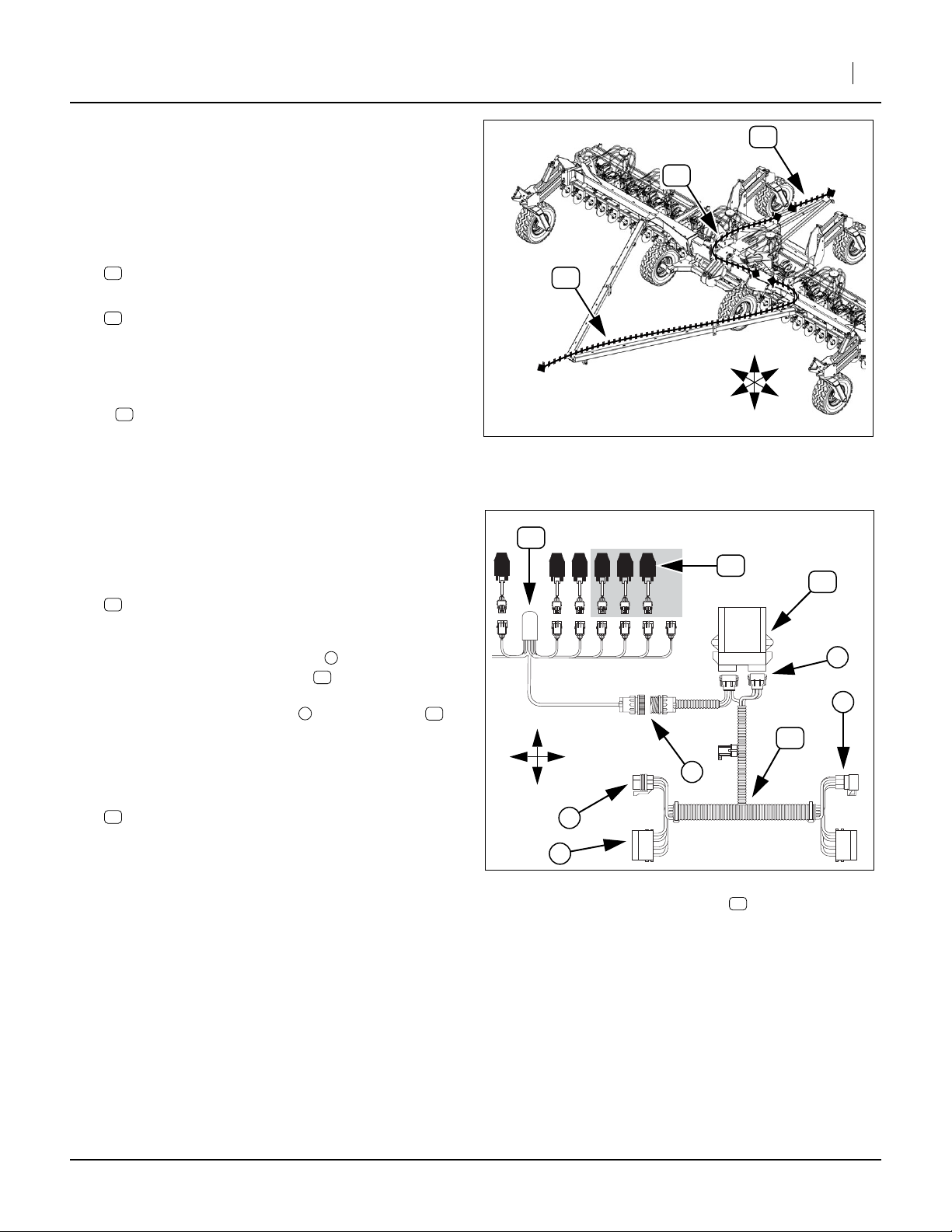

10 Blockage Monitor Kits

CTA-4000 and 4000HD Installation

This installation requires one of the following kits:

168-408A CTA4000/HD-8006 (80 row, 6in)

168-409A CTA4000/HD-6575 (65 row, 7.5in)

168-410A CTA4000/HD-5010 (50 row, 10in)

Additional installation information is found in the

DICKEY-john IntelliAg Air Cart Control Operator’s manual.

Note: The DICKEY-john manual has only general har-

ness routing for the Great Plains air drills, and

somecable part numbers areslightly differentfrom

those in the kits.

Continuing from step 8 on page 3.

Great Plains Mfg., Inc.

T5

T4

T3

T2

T1

Refer to Figure 18 and Figure 19

9. Select five (5):

12

168-465D DIST TOWER MODULE MOUNT PLATE

At each tower, remove the nuts and lock washers

2 312

at the lower U-Bolt , and mount the plate .

Plate orientation is small holes to top, and:

on Towers 1 & 5: extension to drill center

on Towers 2 & 4: extension to drill rear

on Tower 3: extension to left

1

R

F

CTA: Install WSMBs

Start with the left tower (Tower 1).

10. Select one:

39

467981100S1 INTAG WSMB/FLW MNTR MODULE 18R

and two sets:

14

802-224C HHCS 1/4-20X1 1/4 GR5

16

804-006C WASHER LOCK SPRING 1/4 PLT

15

803-006C NUT HEX 1/4-20 PLT

Mount the WSMB on the tower side of the plate

12

, with the mounting ears flush against the plate

and the connector ports facing down.

11. Repeat step 10 for the remaining towers

39

U

D

3

B

L

Figure 18: CTA:

CTA4000 Tower Arrangement

2

12

17186

1

39

15

16

14

Figure 19: CTA:

Module Mount

168-414M 10/29/2008

27058

Page 11

Great Plains Mfg., Inc.

CTA: Prepare Hoses for Sensors

Refer to Figure 20

DICKEY-john Recon-II blockage sensors require a

hole in the hose for the detectors . The sensor has flex-

1

ible flaps which are tie-wrapped around the seed hose.

The long flap goes over the short flap .

2 3

Note: Usea holesawto makethehole. Use a high speed

drill (to minimize rough edges), and cut slowly (to

minimize risk of drill-through).

30

Installation Instructions 11

2

3

1

Using a drill bit is likely to damage the hose.

Refer to Figure 21 (showing hole on top)

12. Drill one hole in each secondary seed hose at each

tower. Check the first hole for sensor fit before drilling the remaining holes.

The hole location is approximately:

4

13in (33cm)

from where the hose enters the tower.

The hole diameter is:

11

5

3

⁄

to

⁄

16

in (17-19mm)

4

Make the hole on the underside of the hose (toward

center of tower), or rotate the hose to hole-under

after drilling or installing sensor.

CTA: Install Blockage Sensors

Refer to Figure 22 and Figure 20

13. Select one:

30

467420352S1 RECON II

Figure 20: CTA:

Blockage Sensor

30

4

5

Figure 21: CTA:

Sensor Hole Location

30 26 27

28197

28194

2

14. Orient sensor with signal lead toward opener.

Insert the detector head in the hose hole.

Wrap the short flap around the hose.

Wrap the long flap over the short flap.

Check that the long flap overlaps by at least

30

1

3

2

1

⁄

in

4

Opener

Figure 22: CTA:

Mount Sensor

Tower

28195

(6mm), but by no more than 1in (25mm). If the flap

is too long, cut off any excess. Re-check overlap.

15. Select two ties from either:

26

110110050 TY WRAP BUNDLE 50-14"

27

110110099 TY WRAP BUNDLE 100-14"

Secure the sensor to the hose with ties.

10/29/2008 168-414M

Page 12

12 Blockage Monitor Kits

CTA Mount Row Harnesses

Start with Tower 1 (left wing, left tower).

Refer to Figure 23

16. Select one of:

31

467751320S1 12 ROW HARNESS, or

32

467751330S1 16 ROW HARNESS

Observe that the assembly has:

1

one large connector (for the WSMB);

2

a sealed weather-cap module; and,

12 or 16 row sensor connectors, numbered

“ROW 1” through “ROW 12” or “ROW 16“.

Note: There may be more sensor leads than drills rows.

4

“ROW 11” and “ROW 12” are unused on

CTA4000/HD-5010

4

“ROW 14” through “ROW 16” are unused on

CTA4000/HD-6575

All leads are used on CTA4000/HD-8006.

Note: Connector numbering matches harness-to-row

only on Tower 1. At connection step 19, see “Port

Assignment” table on page 33, 34 or 35.

Refer to Figure 24

17. Select one:

13

800-082C CABLE TIE .31X21.5 6DIA 120LB

At the tower, position the weather-cap module :

- lead bundle down,

- just under the upper U-bolt , and;

- on the same side as the WSMB .

3

39

2

1

39

2

345678

2

Figure 23: CTA:

Row Harness

2

Great Plains Mfg., Inc.

4

10 11 12

9

1

31

28198

3

13

Secure the module with tie around the tower

weldment and mounting plate.

18. Repeat step 16 and 17 for Tower 2 through Tower 5.

13

CTA: Sensors to Harnesses

Start with opener 1 (left opener, left wing).

Refer to Figure 25

19. Using the table on pages 33 to 35, determine the

Harness lead (“ROW”) to tower Port assignment.

Isolate each lead from the bundle, and plug the

assigned harness lead and sensor cable together.

20. Select one tie from either:

26

110110050 TY WRAP BUNDLE 50-14"

27

110110099 TY WRAP BUNDLE 100-14"

Tie the harness lead to the same seed hose as its

assigned sensor. Tie about 1in (2.5cm) behind the

cable sheath

21. Repeat step 19 and step 20 for each port on the

tower, and then for each tower. One or four leads

per tower are not connected. Excess cable is tiewrapped at step 23.

26 27

Figure 24: CTA:

Install Row Harness

31

Figure 25: CTA:

Row Harness to Sensor

31

30

28199

28196

168-414M 10/29/2008

Page 13

Great Plains Mfg., Inc.

Installation Instructions 13

CTA: Install WSMB Harnesses

Start with Tower 1 (left wing, left tower)

Refer to Figure 26

22. Select one:

40

467981201 INT AG HARNESS, WSMB MOD-

ULE

Join the row harness connector to the mating

connector on the row harness .

Plug the WSMB connectors into the WSMB .

These connectors are not interchangeable, and are

keyed to ensure correct insertion.

Refer to Figure 24 on page 12

23. Select two:

13

800-082C CABLE TIE .31X21.5 6DIA 120LB

Coil up excess rowharness leads and tie the bundle

to the tower, above and below the lower U-bolt.

24. Repeat step 22 and step 23 for each tower.

1

31

239

CTA: Extend Cart Harness

Refer to Figure 27

25. Locate the existing cart WSMT:

95

467980817S1 WSMTII GP AIR CART MODULE

and the harness connected to it:

96

467980856 GP WSMTII AIR CART HARNESS

31

95

30

U

R

L

D

2

39

5

40

1

3

4

Figure 26: CTA:

WSMB Harness

40

28200

91

96

Figure 27: CTA:

Cart Harness Location

Refer to Figure 28 and Figure 32 on page 15

26. Remove and save the CAN bus terminator:

91

467980126 MINI CAN TERMINATOR

27. At Tower 5, plug the saved CAN bus terminator into

the WSMB harness .

10/29/2008 168-414M

40

96

Figure 28: CTA:

CAN Terminator

96

91

91

28430

28429

Page 14

14 Blockage Monitor Kits

Refer to Figure 29

28. Select one each:

35

467980141 10’ EXT HARNESS

38

467980360 3’ REAR HITCH HARNESS

Interconnect these cables.

Great Plains Mfg., Inc.

95

29. Connect the new cable assembly ( + ) to the

existing cart WSMT harness .

Refer to Figure 30

30. Route the extended cart harness along the right

lower frame tube, up the right rear angled corner

tube, and left across the upper rear tube.

Mount the receptacle end of the harness in the

available large hole at the inside (electrical) bulk-

head at the left rear of the cart.

Secure the harness with ties.

1

35 38

96

R

F

96

U

D

91

B

L

35

38

Figure 29: CTA:

Extend Cart Harness

26400

38

CTA: Complete Drill Harness

Refer to Figure 31 and Figure 32 on page 15

31. Select one new:

33

467980131 20’ HITCH HARNESS

Route the single-connector end from the cart electrical bulkhead . Leave ample slack for hitch

movement.

Follow the left wing hydraulic hoses to the Tower 1

WSMB harness. Leave ample slack near the wing

pivots for folding.

Join the two-connector end to the WSMB harness

40

at Tower 1. Secure hitch harness with ties.

1

R

F

Figure 30: CTA:

Cart Harness Extension Routing

U

B

L

33

D

Figure 31: CTA:

Hitch Harness Routing

35

1

28432

T1

17186

168-414M 10/29/2008

Page 15

Great Plains Mfg., Inc.

CTA Blockage Harness Diagram

Harness ID

Callout

New Ex.

31

32

91

33

35

36

95

96

40

Part

Number

467751320S1 12 ROW HARNESS

467751330S1 16 ROW HARNESS

467980126 MINI CAN TERMINATOR

467980131 20’ HITCH HARNESS

467980141 10’ EXT HARNESS

467980142 5’ EXT HARNESS

467980817S1 WSMTII GP AIR CART MODULE

467980856 GP WSMTII AIR CART HARNESS

467981201 INT AG HARNESS, WSMB MODULE

Description

T1

T2

96

35

T3

33

Installation Instructions 15

L

95

31

32

T4

F

R

B

T5

40

Refer to Figure 32 and Figure 33

32. Select one new:

35

467980141 10’ EXT HARNESS

Connect one end to the WSMB harness at

Tower 1.

Route the harness to Tower 2, following the

large seed inlet hose.

Connect extension to WSMB harness at

Tower 2. Secure extension with ties.

33. Select one new:

36

467980142 5’ EXT HARNESS

Connect one end to the WSMB harness at

Tower 2.

Route the harness to Tower 3, following the

nearest cross-tube.

Connect extension to WSMB harness at

Tower 3. Secure extension with ties.

35

35

36

36

35

CTA-4000/HD Harness Block Diagram

40

40

40

36

Figure 32

40

36

40

35

40

91

28431

T1

T2

35

T3

36

F

L

R

B

Figure 33: CTA:

Tower 1 to Towers 2 and 3

28436

10/29/2008 168-414M

Page 16

16 Blockage Monitor Kits

Refer to Figure 34 and Figure 32 on page 15

34. Select one new:

36

467980142 5’ EXT HARNESS

Connect one end to the WSMB harness at

Tower 3.

Route the harness to Tower 4, following the

nearest cross-tube.

36

40

T3

Great Plains Mfg., Inc.

T5

T4

35

36

Connect extension to WSMB harness at

Tower 4. Secure extension with ties.

35. Select one new:

35

467980141 10’ EXT HARNESS

Connect one end to the WSMB harness at

Tower 4.

Route the harness to Tower 5, following the

large seed inlet hose.

Connect extension to WSMB harness at

Tower 2. Secure extension with ties.

36. Skip to “Close-Out” on page 29.

36

35

35

40

Figure 34: CTA:

Tower 3 to Towers 4 and 5

F

L

R

B

28436

168-414M 10/29/2008

Page 17

Great Plains Mfg., Inc.

NTA-3010 Installation

This installation requires one of the following kits:

168-404A NTA3010-4875 (48 row, 7.5in)

168-405A NTA3010-3610 (36 row,10in)

Additional installation information is found in the

DICKEY-john IntelliAg Air Cart Control Operator’s manual.

Note: The DICKEY-john manual has only general har-

ness routing for the Great Plains air drills, and

somecable part numbers areslightly differentfrom

those in the kits.

Continuing from step 8 on page 3.

Refer to Figure 35 and Figure 36

9. Select four (4):

12

168-465D DIST TOWER MODULE MOUNT PLATE

At each tower, remove the nuts and lock washers

2 312

at the lower U-Bolt , and mount the plate .

1

R

F

U

D

Installation Instructions 17

T4

B

L

Figure 35

NTA3010 Tower Arrangement

T3

T2

T1

28437

Plate orientation is small holes to top, and

extensions to drill center.

NTA30: Install WSMBs

Start with the left tower (Tower 1).

10. Select one:

39

467981100S1 INTAG WSMB/FLW MNTR MODULE 18R

and two sets:

14

802-224C HHCS 1/4-20X1 1/4 GR5

16

804-006C WASHER LOCK SPRING 1/4 PLT

15

803-006C NUT HEX 1/4-20 PLT

Mount the WSMB on the tower side of the plate

12

, with the mounting ears flush against the plate

and the connector ports facing down.

11. Repeat step 10 for the remaining towers

39

1

2

39

12

3

15

16

14

Figure 36: NTA30:

Module Mount

27058

10/29/2008 168-414M

Page 18

18 Blockage Monitor Kits

NTA30: Prepare Hoses for Sensors

Refer to Figure 37

DICKEY-john Recon-II blockage sensors require a

hole in the hose for the detectors . The sensor has flex-

1

ible flaps which are tie-wrapped around the seed hose.

The long flap goes over the short flap .

2 3

Note: Usea holesawto makethehole. Use a high speed

drill (to minimize rough edges), and cut slowly (to

minimize risk of drill-through).

30

Great Plains Mfg., Inc.

2

3

1

Using a drill bit is likely to damage the hose.

Refer to Figure 38 (showing hole on top)

12. Drill one hole in each secondary seed hose at each

tower. Check the first hole for sensor fit before drilling the remaining holes.

The hole location is approximately:

4

13in (33cm)

from where the hose enters the tower.

The hole diameter is:

11

5

3

⁄

to

⁄

16

in (17-19mm)

4

Make the hole on the underside of the hose (toward

center of tower), or rotate the hose to hole-under

after drilling or installing sensor.

NTA30: Install Blockage Sensors

Refer to Figure 39 and Figure 37

13. Select one:

30

467420352S1 RECON II

Figure 37: NTA30:

Blockage Sensor

30

4

5

Figure 38: NTA30:

Sensor Hole Location

30 26 27

28197

28194

2

14. Orient sensor with signal lead toward opener.

Insert the detector head in the hose hole.

Wrap the short flap around the hose.

Wrap the long flap over the short flap.

Check that the long flap overlaps by at least

30

1

3

2

1

⁄

in

4

Opener

Figure 39: NTA30:

Mount Sensor

Tower

28195

(6mm), but by no more than 1in (25mm). If the flap

is too long, cut off any excess. Re-check overlap.

15. Select two ties from either:

26

110110050 TY WRAP BUNDLE 50-14"

27

110110099 TY WRAP BUNDLE 100-14"

Secure the sensor to the hose with ties.

168-414M 10/29/2008

Page 19

Great Plains Mfg., Inc.

NTA30 Mount Row Harnesses

Start with Tower 1 (left wing, left tower).

Refer to Figure 40

16. Select one of:

31

467751320S1 12 ROW HARNESS, or

32

467751330S1 16 ROW HARNESS

Observe that the assembly has:

1

one large connector (for the WSMB);

2

a sealed weather-cap module; and,

12 or 16 row sensor connectors, numbered

“ROW 1” through “ROW 12”.

Note: There may be more sensor leads than drills rows.

4

“ROW 10” through “ROW 12” are unused on

NTA3010-3610

All leads are used on NTA3010-4875.

Note: Connector numbering matches harness-to-row

only on Tower 1. At connection step 19, see “Port

Assignment” table on page 36 or 37.

Refer to Figure 41

17. Select one:

13

800-082C CABLE TIE .31X21.5 6DIA 120LB

At the tower, position the weather-cap module :

- lead bundle down,

- just under the upper U-bolt , and;

- on the same side as the WSMB .

3

39

2

39

Installation Instructions 19

4

2

1

345678

2

10 11 12

9

1

Figure 40: NTA30:

Row Harness or

31

32

28198

2

3

13

Secure the module with tie around the tower

weldment and mounting plate.

18. Repeat step 16 and step 17 for Tower 2 through

Tower 4.

13

NTA30: Sensors to Harnesses

Start with opener 1 (left opener, left wing).

Refer to Figure 42

19. Using the table on pages 36 or 37, determine the

Harness lead (“ROW”) to tower Port assignment.

Isolate each lead from the bundle, and plug the

assigned harness lead and sensor cable together.

20. Select one tie from either:

26

110110050 TY WRAP BUNDLE 50-14"

27

110110099 TY WRAP BUNDLE 100-14"

Tie the harness lead to the same seed hose as its

assigned sensor. Tie about 1in (2.5cm) behind the

cable sheath

21. Repeat step 19 and step 20 for each port on the

tower, and then for each tower. One or four leads

per tower are not connected. Excess cable is tiewrapped at step 23.

26 27

Figure 41: NTA30:

Install Row Harness

31

Figure 42: NTA30:

Row Harness to Sensor

31

30

28199

28196

10/29/2008 168-414M

Page 20

20 Blockage Monitor Kits

Great Plains Mfg., Inc.

NTA30: Install WSMB Harnesses

Start with Tower 1 (left wing, left tower)

Refer to Figure 43

22. Select one:

40

467981201 INT AG HARNESS, WSMB MODULE

Join the row harness connector to the mating

connector on the row harness .

Plug the WSMB connectors into the WSMB .

These connectors are not interchangeable, and are

keyed to ensure correct insertion.

Refer to Figure 41 on page 19

23. Select two:

13

800-082C CABLE TIE .31X21.5 6DIA 120LB

Coil up excess rowharness leads and tie the bundle

to the tower, above and below the lower U-bolt.

24. Repeat step 22 and step 23 for each tower.

Refer to Figure 44, 45 and Figure 46 on page 21

25. Select one new:

34

467980140 DJ 20’ HARNESS EXT

26. At the front center of the drill, locate the existing

implement WSMB:

97

467982000S1 PLNTR CNTRL OUTPUT MODULE(POM)

1

31

239

31

30

U

R

L

D

2

39

5

40

1

3

4

Figure 43: NTA30:

WSMB Harness

40

28200

97

At the WSMB connectors, follow harness:

98

467983502 DJ 2SOL YP24LIFT/HITCH FCM HRN

Locate the CAN bus terminator:

91

467980126 MINI CAN TERMINATOR

27. Remove and save the terminator .

Connect the 20ft harness extension in its place

(two connectors).

Refer to Figure 45 and Figure 46 on page 21

28. At Tower 4, plug the saved CAN bus terminator

into the WSMB harness .

40

91

34

91

98

98

Figure 44: NTA30:

Existing WSMB Location

97

91

Figure 45: NTA30:

CAN Terminator

98

28438

28429

168-414M 10/29/2008

Page 21

Great Plains Mfg., Inc.

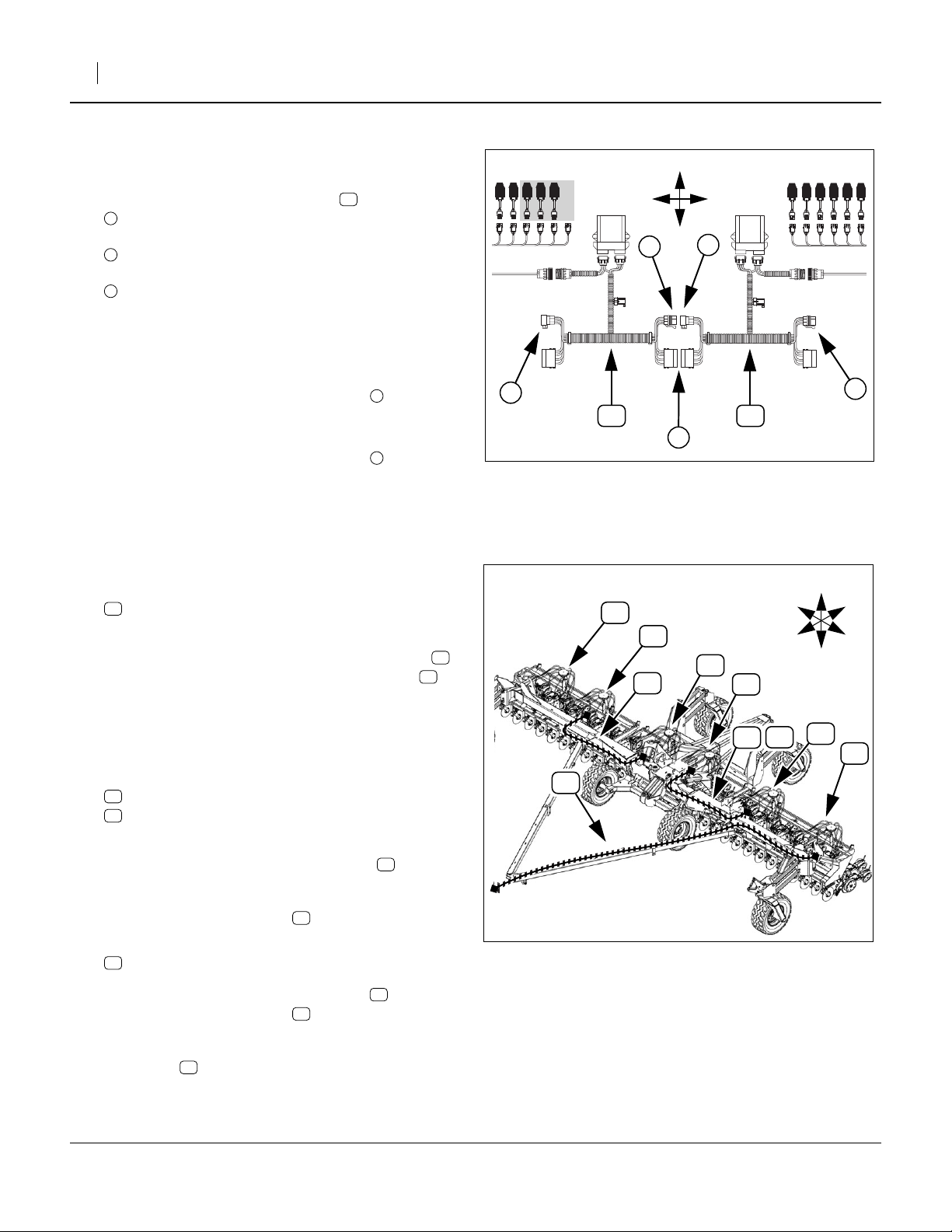

NTA30 Blockage Harness Diagram

Harness ID

Callout

New Ex.

31

91

34

35

36

40

97

98

Part

Number

467751320S1 12 ROW HARNESS

467980126 MINI CAN TERMINATOR

467980140 DJ 20’ HARNESS EXT

467980141 10’ EXT HARNESS

467980142 5’ EXT HARNESS

467981201 INT AG HARNESS, WSMB MODULE

467982000S1

467983502

PLNTR CNTRL OUTPUT MODULE(POM)

DJ 2SOL YP24LIFT/HITCH FCM HRN

Description

98

97

Installation Instructions 21

F

L

R

B

31

T1

34

40

Refer to Figure 46 and Figure 47

29. Following the large inlet seed tube to Tower 1, route

20ft extension harness to the WSMB at Tower

one. Connect it to the WSMB harness . Do not

secure harness with ties until the next step.

34

35

NTA-3010 Harness Block Diagram

40

40

Figure 46

T2

36

T3

T4

91

40

35

40

28440

F

97

L

R

B

34

T2

T1

Figure 47: NTA30:

Implement WSMB to Tower 1

10/29/2008 168-414M

16899

Page 22

22 Blockage Monitor Kits

Great Plains Mfg., Inc.

Refer to Figure 48 and Figure 46 on page 21

30. Select one new:

35

467980141 10’ EXT HARNESS

Following the Tower 1 inlet seed tube again, route

this extension between the WSMB harness at

Tower 1 and the WSMB harness at Tower 2. Connect both ends of the extension.

Allowing slack for wing folding, secure harnesses

34 35

and with cable ties.

Refer to Figure 49 and Figure 46 on page 21

31. Select one new:

36

467980142 5’ EXT HARNESS

Route this extension between the WSMB harness

at Tower 2 and the WSMB harness at Tower 3. Connect both ends of the extension.

Secure harness to the cross-tube with cable ties.

36

F

L

R

B

35

T2

T1

Figure 48: NTA30:

Tower 1 to Tower 2

16899

F

L

R

B

36

Refer to Figure 50 and Figure 46 on page 21

32. Select one new:

35

467980141 10’ EXT HARNESS

Following the inlet seed hose for Tower 4, route this

extension between the WSMB harness at Tower 3

and the WSMB harness at Tower 4. Connect both

ends of the extension.

Allowing slack for wing folding, secure harness

with cable ties.

33. Skip to “Close-Out” on page 29.

35

T3

T2

Figure 49: NTA30:

Tower 2 to Tower 3

35

Figure 50: NTA30:

Tower 3 to Tower 4

T3

16899

F

L

R

B

T4

16899

168-414M 10/29/2008

Page 23

Great Plains Mfg., Inc.

NTA-3510 Installation

This installation requires one of the following kits:

168-406A NTA3510-5575 (55 row, 7.5in)

168-407A NTA3510-4010 (40 row,10in)

Additional installation information is found in the

DICKEY-john IntelliAg Air Cart Control Operator’s manual.

Note: The DICKEY-john manual has only general har-

ness routing for the Great Plains air drills, and

somecable part numbers areslightly differentfrom

those in the kits.

Continuing from step 8 on page 3.

Refer to Figure 51 and Figure 52

9. Select five (5):

12

168-465D DIST TOWER MODULE MOUNT PLATE

At each tower, remove the nuts and lock washers

2 312

at the lower U-Bolt , and mount the plate .

1

R

F

U

D

Installation Instructions 23

T5

B

L

Figure 51

NTA 3510 Tower Arrangement

T4

T3

T2

T1

29020

Plate orientation is small holes to top, and

T1 T5

, : plate to drill center,

T2 T4

, : plate to drill center,

T3

: plate to drill rear.

NTA35: Install WSMBs

Start with the left tower (Tower 1).

10. Select one:

39

467981100S1 INTAG WSMB/FLW MNTR MODULE 18R

and two sets:

14

802-224C HHCS 1/4-20X1 1/4 GR5

16

804-006C WASHER LOCK SPRING 1/4 PLT

15

803-006C NUT HEX 1/4-20 PLT

Mount the WSMB on the tower side of the plate

12

, with the mounting ears flush against the plate

and the connector ports facing down.

11. Repeat step 10 for the remaining towers

39

1

2

39

12

3

15

16

14

Figure 52: NTA35:

Module Mount

27058

10/29/2008 168-414M

Page 24

24 Blockage Monitor Kits

NTA35: Prepare Hoses for Sensors

Refer to Figure 53

DICKEY-john Recon-II blockage sensors require a

hole in the hose for the detectors . The sensor has flex-

1

ible flaps which are tie-wrapped around the seed hose.

The long flap goes over the short flap .

2 3

Note: Usea holesawto makethehole. Use a high speed

drill (to minimize rough edges), and cut slowly (to

minimize risk of drill-through).

30

Great Plains Mfg., Inc.

2

3

1

Using a drill bit is likely to damage the hose.

Refer to Figure 54 (showing hole on top)

12. Drill one hole in each secondary seed hose at each

tower. Check the first hole for sensor fit before drilling the remaining holes.

The hole location is approximately:

4

13in (33cm)

from where the hose enters the tower.

The hole diameter is:

11

5

3

⁄

to

⁄

16

in (17-19mm)

4

Make the hole on the underside of the hose (toward

center of tower), or rotate the hose to hole-under

after drilling or installing sensor.

NTA35: Install Blockage Sensors

Refer to Figure 55 and Figure 53

13. Select one:

30

467420352S1 RECON II

Figure 53: NTA35:

Blockage Sensor

30

4

5

Figure 54: NTA35:

Sensor Hole Location

30 26 27

28197

28194

2

14. Orient sensor with signal lead toward opener.

Insert the detector head in the hose hole.

Wrap the short flap around the hose.

Wrap the long flap over the short flap.

Check that the long flap overlaps by at least

30

1

3

2

1

⁄

in

4

Opener

Figure 55: NTA35:

Mount Sensor

Tower

28195

(6mm), but by no more than 1in (25mm). If the flap

is too long, cut off any excess. Re-check overlap.

15. Select two ties from either:

26

110110050 TY WRAP BUNDLE 50-14"

27

110110099 TY WRAP BUNDLE 100-14"

Secure the sensor to the hose with ties.

168-414M 10/29/2008

Page 25

Great Plains Mfg., Inc.

NTA35 Mount Row Harnesses

Start with Tower 1 (left wing, left tower).

Refer to Figure 56

16. Select one new:

31

467751320S1 12 ROW HARNESS

Observe that the assembly has:

1

one large connector (for the WSMB);

2

a sealed weather-cap module; and,

12 or 16 row sensor connectors, numbered

“ROW 1” through “ROW 12”.

Note: There may be more sensor leads than drills rows.

4

“ROW 9” through “ROW 12” are unused on

NTA3510-4010

All leads are used on NTA3510-5575.

Note: Connector numbering matches harness-to-row

only on Tower 1. At connection step 19, see “Port

Assignment” table on page 36 or 37.

Refer to Figure 57

17. Select one:

13

800-082C CABLE TIE .31X21.5 6DIA 120LB

At the tower, position the weather-cap module :

- lead bundle down,

- just under the upper U-bolt , and;

- on the same side as the WSMB .

3

39

2

Installation Instructions 25

4

2

1

345678

2

10 11 12

9

1

Figure 56: NTA35:

Row Harness

31

28198

2

3

39

13

Secure the module with tie around the tower

weldment and mounting plate.

18. Repeat step 16 and step 17 for Tower 2 through

Tower 5.

13

NTA35: Sensors to Harnesses

Start with opener 1 (left opener, left wing).

Refer to Figure 58

19. Using the table on pages 38 or 39, determine the

Harness lead (“ROW”) to tower Port assignment.

Isolate each lead from the bundle, and plug the

assigned harness lead and sensor cable together.

20. Select one tie from either:

26

110110050 TY WRAP BUNDLE 50-14"

27

110110099 TY WRAP BUNDLE 100-14"

Tie the harness lead to the same seed hose as its

assigned sensor. Tie about 1in (2.5cm) behind the

cable sheath

21. Repeat step 19 and step 20 for each port on the

tower, and then for each tower. One or four leads

per tower are not connected. Excess cable is tiewrapped at step 23.

26 27

Figure 57: NTA35:

Install Row Harness

31

Figure 58: NTA35:

Row Harness to Sensor

31

30

28199

28196

10/29/2008 168-414M

Page 26

26 Blockage Monitor Kits

Great Plains Mfg., Inc.

NTA35: Install WSMB Harnesses

Start with Tower 1 (left wing, left tower)

Refer to Figure 59

22. Select one:

40

467981201 INT AG HARNESS, WSMB MODULE

Join the row harness connector to the mating

connector on the row harness .

Plug the WSMB connectors into the WSMB .

These connectors are not interchangeable, and are

keyed to ensure correct insertion.

Refer to Figure 57 on page 25

23. Select two:

13

800-082C CABLE TIE .31X21.5 6DIA 120LB

Coil up excess rowharness leads and tie the bundle

to the tower, above and below the lower U-bolt.

24. Repeat step 22 and step 23 for each tower.

1

31

239

NTA35: Interconnect Center WSMBs

The center section Towers 2, 3 and 4 are close enough

that their WSMB harnesses are directly interconnected.

Refer to Figure 60

25. At the center section WSMB harnesses for

Tower 2 and Tower 3, interconnect

3

the female (receptacle) of left (outer) CAN bus

with

5

the male (plug) end of the mid-wing CAN bus.

Also connect the

4

power receptacle and plug

Note: The unconnected Tower 3 CAN bus connector (at

drill center) must be a receptacle.

26. Interconnect the WSMB harnesses for Tower 3

and Tower 4.

Refer to Figure 61, and Figure 62 and 63 on page 27

27. Select one new:

34

467980140 DJ 20’ HARNESS EXT

28. At the front center of the drill, locate the existing

implement WSMB:

97

467982000S1 PLNTR CNTRL OUTPUT MODULE(POM)

40

40

31

5

39

1

3

4

Figure 59: NTA35:

WSMB Harness

U

L

3

D

40

4

Figure 60: NTA35:

Center Towers Interconnect

30

U

R

L

D

2

5

40

28200

40

R

5

3

40

28201

97

At the WSMB connectors, follow harness:

98

467983502 DJ 2SOL YP24LIFT/HITCH FCM HRN

Locate the CAN bus terminator:

91

467980126 MINI CAN TERMINATOR

168-414M 10/29/2008

Figure 61: NTA35:

Existing WSMB Location

98

28438

97

Page 27

Great Plains Mfg., Inc.

Installation Instructions 27

29. Remove and save the terminator .

Connect the 20ft harness extension in its place

(two connectors).

Refer to Figure 62 and Figure 63

30. At Tower 5, plug the saved CAN bus terminator

into the WSMB harness .

40

91

34

NTA35 Blockage Harness Diagram

Harness ID

Callout

New Ex.

31

91

34

35

40

97

98

Part

Number

467751320S1 12 ROW HARNESS

467980126 MINI CAN TERMINATOR

467980140 DJ 20’ HARNESS EXT

467980141 10’ EXT HARNESS

467981201 INT AG HARNESS, WSMB MODULE

467982000S1

467983502

PLNTR CNTRL OUTPUT MODULE(POM)

DJ 2SOL YP24LIFT/HITCH FCM HRN

Description

91

98

98

97

91

Figure 62: NTA35:

CAN Terminator

98

28429

F

L

R

B

34

40

T1

T3

T2

35

NTA-3510 Harness Block Diagram

40

40

Figure 63

40

T4

35

31

T5

91

40

28441

10/29/2008 168-414M

Page 28

28 Blockage Monitor Kits

Great Plains Mfg., Inc.

Refer to Figure 63 on page 27 and Figure 64

31. Following the large inlet seed tube to Tower 1, route

20ft extension harness to the WSMB at Tower

one. Connect it to the WSMB harness . Do not

secure harness with ties until the next step.

Refer to Figure 65 and Figure 63 on page 27

32. Select one new:

35

467980141 10’ EXT HARNESS

Following the Tower 1 inlet seed tube again, route

this extension between the WSMB harness at

Tower 1 and the WSMB harness at Tower 2. Connect both ends of the extension.

34

40

L

L

T1

F

B

F

B

R

34

Figure 64: NTA35:

Implement WSMB to Tower 1

R

35

97

T3

T2

16201

Allowing slack for wing folding, secure harnesses

34 35

and with cable ties.

Refer to Figure 66 and Figure 63 on page 27

33. Select one new:

35

467980141 10’ EXT HARNESS

Following the inlet seed hose for Tower 5, route this

extension between the WSMB harness at Tower 4

and the WSMB harness at Tower 5. Connect both

ends of the extension.

Allowing slack for wing folding, secure harness

with cable ties.

34. Skip to “Close-Out” on page 29.

35

T1

T3

T4

Figure 65: NTA35:

Tower 1 to Tower 2

35

Figure 66: NTA35:

Tower 4 to Tower 5

L

T2

T3

16201

F

R

B

T5

16201

168-414M 10/29/2008

Page 29

Great Plains Mfg., Inc.

Close-Out

Refer to Figure 67

37. Select all of:

29

464211090 DUST PLUG

Insert these at all unused row sensor leads on row

harnesses.

38. Select all remaining cable ties. Use them to further

secure all harnesses.

Check Operation

39. Hitch to suitable tractor.

40. Power-up seed monitor. Consult DICKEY-john Air

Cart Control operator manual and run Auto Configuration.

41. Fold, unfold,raise and lower drill while checkingthat

hoses and sensor lines remain clear of moving

parts and retain some slack at all times.

42. Fold the drill. Move it to a suitable parking location.

Installation Instructions 29

29

Figure 67

Dust Plugs

29

28442

10/29/2008 168-414M

Page 30

30 Blockage Monitor Kits

Appendix

Torque Chart

Great Plains Mfg., Inc.

Bolt

Size

in-tpi

1

1

5

⁄16-18

5

⁄16-24

3

3

7

⁄16-14

7

⁄16-20

1

1

9

⁄16-12

9

⁄16-18

5

5

3

3

7

7

1-12

11⁄8-7

11⁄8-12

11⁄4-7

11⁄4-12

13⁄8-6

13⁄8-12

11⁄2-6

11⁄2-12

25199

Bolt Head Identification

Bolt Head Identification

Bolt

Size

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

1

N-m2ft-lb

⁄4-20

⁄4-28

⁄8-16

⁄8-24

⁄2-13

⁄2-20

⁄8-11

⁄8-18

⁄4-10

⁄4-16

⁄8-9

⁄8-14

1-8

7.4 5.6 11 8 16 12

8.5 6 13 10 18 14

15 11 24 17 33 25

17 13 26 19 37 27

27 20 42 31 59 44

31 22 47 35 67 49

43 32 67 49 95 70

49 36 75 55 105 78

66 49 105 76 145 105

75 55 115 85 165 120

95 70 150 110 210 155

105 79 165 120 235 170

130 97 205 150 285 210

150 110 230 170 325 240

235 170 360 265 510 375

260 190 405 295 570 420

225 165 585 430 820 605

250 185 640 475 905 670

340 250 875 645 1230 910

370 275 955 705 1350 995

480 355 1080 795 1750 1290

540 395 1210 890 1960 1440

680 500 1520 1120 2460 1820

750 555 1680 1240 2730 2010

890 655 1990 1470 3230 2380

1010 745 2270 1670 3680 2710

1180 870 2640 1950 4290 3160

1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

3

N-m ft-lb N-m ft-lb

mm x pitch

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

1. in-tpi = nominal thread diameter in inches-threads per inch

2. N· m = newton-meters

3. ft-lb = foot pounds

4. mm x pitch = nominal thread diameter in millimeters x thread

pitch

4

5.8 8.8 10.9

N-m ft-lb N-m ft-lb N-m ft-lb

43659 7

7 5 11 8 15 11

17 12 26 19 36 27

18 13 28 21 39 29

33 24 52 39 72 53

39 29 61 45 85 62

58 42 91 67 125 93

60 44 95 70 130 97

90 66 105 77 145 105

92 68 145 105 200 150

99 73 155 115 215 160

145 105 225 165 315 230

155 115 240 180 335 245

195 145 310 230 405 300

220 165 350 260 485 355

280 205 440 325 610 450

310 230 650 480 900 665

480 355 760 560 1050 780

525 390 830 610 1150 845

960 705 1510 1120 2100 1550

1060 785 1680 1240 2320 1710

1730 1270 2650 1950 3660 2700

1880 1380 2960 2190 4100 3220

168-414M 10/29/2008

Page 31

Great Plains Mfg., Inc.

Installation Instructions 31

3N4010HDA Port Assignments, 10in (25.4cm) Drill

Drill Model: 3N-4010HDA-4810

Towers are numbered from drill left (Tower 1).

Harness connectors are numbered on the cable:“Row 1”

through “Row 12” (some are not connected [n/c]).

Tower Harness Port Opener Tower Harness Port Opener

ROW 3 Port 1 3

ROW 1 Port 2 1 ROW 4 Port 2 28

ROW 2 Port 3 2 ROW 6 Port 3 30

ROW 4 Port 4 4 ROW 8 Port 4 32

Tower 1

Tower 2

Tower 3

ROW 6 Port 5 6 ROW 7 Port 5 31

ROW 8 Port 6 8 ROW 5 Port 6 29

ROW 7 Port 7 7 ROW 3 Port 7 27

ROW 5 Port 8 5 ROW 1 Port 8 25

ROW 9-12 n/c - ROW 9-12 n/c -

ROW 3 Port 1 11

ROW 1 Port 2 9 ROW 3 Port 2 35

ROW 2 Port 3 10 ROW 1 Port 3 33

ROW 4 Port 4 12 ROW 2 Port 4 34

ROW 6 Port 5 14 ROW 4 Port 5 36

ROW 8 Port 6 16 ROW 6 Port 6 38

ROW 7 Port 7 15 ROW 8 Port 7 40

ROW 5 Port 8 13 ROW 7 Port 8 39

ROW 9-12 n/c - ROW 9-12 n/c -

ROW 7 Port 1 23

ROW 5 Port 2 21 ROW 1 Port 2 41

ROW 3 Port 3 19 ROW 2 Port 3 42

ROW 1 Port 4 17 ROW 4 Port 4 44

ROW 2 Port 5 18 ROW 6 Port 5 46

ROW 4 Port 6 20 ROW 8 Port 6 48

ROW 6 Port 7 22 ROW 7 Port 7 47

ROW 8 Port 8 24 ROW 5 Port 8 45

ROW 9-12 n/c ROW 9-12 n/c

Tower Ports are numbered Clockwise from mount center

(Port 1) to Port 8.

Openers are numbered from drill left (Row 1).

ROW 2 Port 1 26

Tower 4

ROW 5 Port 1 37

Tower 5

ROW 3 Port 1 43

Tower 6

10/29/2008 168-414M

Page 32

Great Plains Mfg., Inc.

32 Blockage Monitor Kits

3N4010HDA Port Assignments, 7.5in (19.2cm) Drill

Drill Model: 3N-4010HDA-6675

Towers are numbered from drill left (Tower 1).

Harness connectors are numbered on the cable: “ROW

1” through “ROW 12” (some are not connected [n/c]).

Tower Harness Port Opener Tower Harness Port Opener

ROW 6 Port 1 6

ROW 4 Port 2 4 ROW 4 Port 2 37

ROW 2 Port 3 2 ROW 6 Port 3 39

ROW 1 Port 4 1 ROW 8 Port 4 41

ROW 3 Port 5 3 ROW 10 P ort 5 43

Tower 1

Tower 2

Tower 3

ROW 5 Port 6 5 ROW 11 P ort 6 44

ROW 7 Port 7 7 ROW 9 Port 7 42

ROW 9 Port 8 9 ROW 7 Port 8 40

ROW 11 Port 9 11 ROW 5 Port 9 38

ROW 10 Port 10 10 ROW 3 Port 10 36

ROW 8 Port 11 8 ROW 1 Port 11 34

ROW 12 n/c - ROW 12 n/c -

ROW 5 Port 1 16

ROW 3 Port 2 14 ROW 4 Port 2 48

ROW 1 Port 3 12 ROW 2 Port 3 46

ROW 2 Port 4 13 ROW 1 Port 4 45

ROW 4 Port 5 15 ROW 3 Port 5 47

ROW 6 Port 6 17 ROW 5 Port 6 49

ROW 8 Port 7 19 ROW 7 Port 7 51

ROW 10 Port 8 21 ROW 9 Port 8 53

ROW 11 Port 9 22 ROW 11 Port 9 55

ROW 9 Port 10 20 ROW 10 Port 10 54

ROW 7 Port 11 18 ROW 8 Port 11 52

ROW 12 n/c - ROW 12 n/c ROW 11 Port 1 33

ROW 10 Port 2 32 ROW 3 Port 2 58

ROW 8 Port 3 30 ROW 1 Port 3 56

ROW 6 Port 4 28 ROW 2 Port 4 57

ROW 4 Port 5 26 ROW 4 Port 5 59

ROW 2 Port 6 24 ROW 6 Port 6 61

ROW 1 Port 7 23 ROW 8 Port 7 63

ROW 3 Port 8 25 ROW 10 Port 8 65

ROW 5 Port 9 27 ROW 11 Port 9 66

ROW 7 Port 10 29 ROW9 Port 10 64

ROW 9 Port 11 31 ROW7 Port 11 62

ROW 12 n/c - ROW 12 n/c -

Ports are numbered Clockwise from mount center (Port

1) to Port 11.

Openers are numbered from drill left (Row 1).

ROW 2 Port 1 35

Tower 4

ROW 6 Port 1 50

Tower 5

ROW 5 Port 1 60

Tower 6

168-414M 10/29/2008

Page 33

Great Plains Mfg., Inc.

Installation Instructions 33

CTA4000/HD Port Assignments, 10in (25.4cm) Drill

Drill Model: CTA4000-5010, CTA4000HD-5010

Towers are numbered from drill left (Tower 1).

Harness connectors are numbered on the cable:“Row 1”

through “Row 12” (some are not connected [n/c]).

Tower Harness Port Opener Tower Harness Port Opener

ROW 7 Port 1 7

ROW 9 Port 2 9 ROW 2 Port 2 32

ROW10 Port3 10 ROW5 Port3 35

ROW 8 Port 4 8 ROW 7 Port 4 37

ROW 6 Port 5 6 ROW 9 Port 5 39

Tower 1

Tower 2

Tower 3

ROW4 Port6 4 ROW10 Port6 40

ROW 2 Port 7 2 ROW 8 Port 7 38

ROW 1 Port 8 1 ROW 6 Port 8 36

ROW 3 Port 9 3 ROW 4 Port 9 34

ROW 5 Port 10 5 ROW 2 Port 10 32

ROW 11-12 n/c - ROW 11-12 n/c -

ROW 10 Port 1 20

ROW 8 Port 2 18 ROW 7 Port 2 47

ROW 6 Port 3 16 ROW 9 Port 3 49

ROW 4 Port 4 14 ROW 10 Port 4 50

ROW 2 Port 5 12 ROW 8 Port 5 48

ROW 1 Port 6 11 ROW 6 Port 6 46

ROW 3 Port 7 13 ROW 4 Port 7 44

ROW 5 Port 8 15 ROW 2 Port 8 42

ROW 7 Port 9 17 ROW 1 Port 9 41

ROW 9 Port 10 19 ROW 3 Port 10 43

ROW 11-12 n/c - ROW 11-12 n/c -

ROW 4 Port 1 24

ROW 2 Port 2 22

ROW 1 Port 3 21

ROW 3 Port 4 23

ROW 5 Port 5 25

ROW 7 Port 6 27

ROW 9 Port 7 29

ROW10 Port8 30

ROW 8 Port 9 28

ROW 6 Port 10 26

ROW 11-12 n/c -

Tower Ports are numbered Clockwise from mount center

(Port 1) to Port 10.

Openers are numbered from drill left (Row 1).

ROW 1 Port 1 31

Tower 4

ROW 5 Port 1 45

Tower 5

10/29/2008 168-414M

Page 34

Great Plains Mfg., Inc.

34 Blockage Monitor Kits

CTA4000/HD Port Assignments, 7.5in (19.2cm) Drill

Drill Model: CTA4000-6575, CTA4000HD-6575

Towers are numbered from drill left (Tower 1).

Harness connectors are numbered on the cable: “ROW

1” through “ROW 16” (some are not connected [n/c]).

Tower Harness Port Opener Tower Harness Port Opener

ROW 8 Port 1 8

ROW10 Port2 10 ROW4 Port2 43

ROW13 Port3 13 ROW6 Port3 45

ROW12 Port4 12 ROW8 Port4 47

ROW11 Port5 11 ROW10 Port5 49

ROW9 Port6 9 ROW12 Port6 51

Tower 1

Tower 2

Tower 3

ROW7 Port7 7 ROW13 Port7 52

ROW6 Port8 6 ROW11 Port8 50

ROW 5 Port 9 5 ROW 9 Port 9 48

ROW 2 Port 10 2 ROW 7 Port 10 46

ROW 1 Port 11 1 ROW 5 Port 11 44

ROW 3 Port 12 3 ROW 3 Port 12 42

ROW 4 Port 13 4 ROW 1 Port 13 40

ROW 14-16 n/c - ROW 14-16 n/c -

ROW 13 Port 1 26

ROW 11 Port 2 24 ROW 7 Port 2 59

ROW 9 Port 3 22 ROW 9 Port 3 61

ROW 7 Port 4 20 ROW 11 Port 4 63

ROW 5 Port 5 18 ROW 13 Port 5 65

ROW 3 Port 6 16 ROW 12 Port 6 64

ROW 1 Port 7 14 ROW 10 Port 7 62

ROW 2 Port 8 15 ROW 8 Port 8 60

ROW 4 Port 9 17 ROW 6 Port 9 58

ROW 6 Port 10 19 ROW 4 Port 10 56

ROW 8 Port 11 21 ROW 2 Port 11 54

ROW 10 Port 12 23 ROW 1 Port 12 53

ROW 12 Port 13 25 ROW 3 Port 13 55

ROW 14-16 n/c - ROW 14-16 n/c -

ROW 8 Port 1 34

ROW 6 Port 2 32

ROW 4 Port 3 30

ROW 2 Port 4 28

ROW 1 Port 5 27

ROW 3 Port 6 29

ROW 5 Port 7 31

ROW 7 Port 8 33

ROW 9 Port 9 35

ROW11 Port10 37

ROW13 Port11 39

ROW12 Port12 38

ROW10 Port13 36

ROW 14-16 n/c -

Ports are numbered Clockwise from mount center (Port

1) to Port 13.

Openers are numbered from drill left (Row 1).

ROW 2 Port 1 41

Tower 4

ROW 5 Port 1 57

Tower 5

168-414M 10/29/2008

Page 35

Great Plains Mfg., Inc.

Installation Instructions 35

CTA4000/HD Port Assignments, 6in (15.2cm) Drill

Drill Model: CTA4000-8006, CTA4000HD-8006

Towers are numbered from drill left (Tower 1).

Harness connectors are numbered on the cable: “ROW

1” through “ROW 16”

Tower Harness Port Opener Tower Harness Port Opener

ROW 13 Port 1 13

ROW 14 Port 2 14 ROW 5 Port 2 53

ROW 15 Port 3 15 ROW 6 Port 3 54

ROW 16 Port 4 16 ROW 7 Port 4 55

ROW 12 Port 5 12 ROW 11 Port 5 59

ROW 10 Port 6 10 ROW 12 Port 6 60

ROW 8 Port 7 8 ROW 13 Port 7 61

Tower 1

Tower 2

Tower 3

ROW 6 Port 8 6 ROW 15 Port 8 63

ROW 4 Port 9 4 ROW 16 Port 9 64

ROW 2 Port 10 2 ROW 14 Port 10 62

ROW 1 Port 11 1 ROW 10 Port 11 58

ROW 3 Port 12 3 ROW 9 Port 12 57

ROW 5 Port 13 5 ROW 8 Port 13 56

ROW 7 Port 14 7 ROW 4 Port 14 52

ROW 9 Port 15 9 ROW 3 Port 15 51

ROW 11 Port 16 11 ROW 1 Port 16 49

ROW 14 Port 1 30

ROW 12 Port 2 28 ROW 7 Port 2 71

ROW 10 Port 3 26 ROW 11 Port 3 75

ROW 16 Port 4 32 ROW 13 Port 4 77

ROW 6 Port 5 22 ROW 15 Port 5 79

ROW 4 Port 6 20 ROW 16 Port 6 80

ROW 2 Port 7 18 ROW 14 Port 7 78

ROW 1 Port 8 17 ROW 12 Port 8 76

ROW 3 Port 9 19 ROW 10 Port 9 74

ROW 5 Port 10 21 ROW 9 Port 10 73

ROW 7 Port 11 23 ROW 8 Port 11 72

ROW 8 Port 12 24 ROW 6 Port 12 70

ROW 9 Port 13 25 ROW 4 Port 13 68

ROW 11 Port 14 27 ROW 2 Port 14 66

ROW 13 Port 15 29 ROW 1 Port 15 65

ROW 15 Port 16 31 ROW 3 Port 16 67

ROW 7 Port 1 39

ROW 6 Port 2 38

ROW 3 Port 3 35

ROW 4 Port 4 36

ROW 5 Port 5 37

ROW 1 Port 6 33

ROW 2 Port 7 34

ROW 8 Port 8 40

ROW 9 Port 9 41

ROW 10 Port 10 42

ROW 11 Port 11 43

ROW 14 Port 12 46

ROW 16 Port 13 48

ROW 15 Port 14 47

ROW 13 Port 15 45

ROW 12 Port 16 44

Ports are numbered Clockwise from mount center (Port

1) to Port 11.

Openers are numbered from drill left (Row 1).

ROW 2 Port 1 50

Tower 4

ROW 5 Port 1 69

Tower 5

10/29/2008 168-414M

Page 36

Great Plains Mfg., Inc.

36 Blockage Monitor Kits

NTA-3010 Port Assignments, 10in (25.4cm) Drill

Drill Model: NTA3010-3610

Towers are numbered from drill left (Tower 1).

Harness connectors are numbered on the cable:“Row 1”

through “Row 12” (some are not connected [n/c]).

Tower Harness Port Opener Tower Harness Port Opener

ROW 5 Port 1 5

ROW 3 Port 2 3 ROW 3 Port 2 21

ROW 1 Port 3 1 ROW 1 Port 3 19

ROW 2 Port 4 2 ROW 2 Port 4 20

Tower 1

Tower 2

ROW 4 Port 5 4 ROW 4 Port 5 22

ROW 6 Port 6 6 ROW 6 Port 6 24

ROW 8 Port 7 8 ROW 7 Port 7 25

ROW 9 Port 8 9 ROW 9 Port 8 27

ROW 7 Port 9 7 ROW 8 Port 9 26

ROW 10-12 n/c - ROW 10-12 n/c -

ROW 5 Port 1 14

ROW 4 Port 2 13 ROW 4 Port 2 31

ROW 2 Port 3 11 ROW 2 Port 3 29

ROW 1 Port 4 10 ROW 1 Port 4 28

ROW 3 Port 5 12 ROW 3 Port 5 30

ROW 6 Port 6 15 ROW 5 Port 6 32

ROW 7 Port 7 16 ROW 7 Port 7 34

ROW 9 Port 8 18 ROW 9 Port 8 36

ROW 8 Port 9 17 ROW 8 Port 9 35

ROW 10-12 n/c - ROW 10-12 n/c -

Tower Ports are numbered Clockwise from mount center

(Port 1) to Port 9.

Openers are numbered from drill left (Row 1).

ROW 5 Port 1 23

Tower 3

ROW 6 Port 1 33

Tower 4

168-414M 10/29/2008

Page 37

Great Plains Mfg., Inc.

Installation Instructions 37

NTA-3010 Port Assignments, 7.5in (19.2cm) Drill

Drill Model: NTA3010-4875

Towers are numbered from drill left (Tower 1).

Harness connectors are numbered on the cable:“Row 1”

through “Row 12”.

Tower Harness Port Opener Tower Harness Port Opener

ROW 5 Port 1 5

ROW 4 Port 2 4 ROW 5 Port 2 29

ROW 3 Port 3 3 ROW 3 Port 3 27

ROW 1 Port 4 1 ROW 1 Port 4 25

ROW 2 Port 5 2 ROW 2 Port 5 26

Tower 1

Tower 2

ROW 6 Port 6 6 ROW 4 Port 6 28

ROW 8 Port 7 8 ROW 6 Port 7 30

ROW10 Port8 10 ROW7 Port8 31

ROW12 Port9 12 ROW8 Port9 32

ROW 11 Port 10 11 ROW 10 Port 10 34

ROW 9 Port 11 9 ROW 12 Port 11 36

ROW 7 Port 12 7 ROW 11 Port 12 35

ROW 5 Port 1 17

ROW 2 Port 2 15 ROW 7 Port 2 43

ROW 1 Port 3 13 ROW 5 Port 3 41

ROW 2 Port 4 14 ROW 2 Port 4 38

ROW 4 Port 5 16 ROW 1 Port 5 37

ROW 6 Port 6 18 ROW 3 Port 6 39

ROW 8 Port 7 20 ROW 6 Port 7 42

ROW 10 Port 8 22 ROW 8 Port 8 44

ROW 12 Port 9 24 ROW 9 Port 9 45

ROW 11 Port 10 23 ROW 10 Port 10 46

ROW 9 Port 11 21 ROW 12 Port 11 48

ROW 7 Port 12 19 ROW 11 Port 12 47

Tower Ports are numbered Clockwise from mount center

(Port 1) to Port 12.

Openers are numbered from drill left (Row 1).

ROW 9 Port 1 33

Tower 3

ROW 4 Port 1 40

Tower 4

10/29/2008 168-414M

Page 38

Great Plains Mfg., Inc.

38 Blockage Monitor Kits

NTA-3510 Port Assignments, 10in (25.4cm) Drill

Drill Model: NTA3510-4010

Towers are numbered from drill left (Tower 1).

Harness connectors are numbered on the cable:“Row 1”

through “Row 12” (some are not connected [n/c]).

Tower Harness Port Opener Tower Harness Port Opener

ROW 8 Port 1 8

ROW 3 Port 2 3 ROW 1 Port 2 25

ROW 1 Port 3 1 ROW 4 Port 3 28

ROW 2 Port 4 2 ROW 5 Port 4 29

Tower 1

Tower 2

Tower 3

ROW 4 Port 5 4 ROW 6 Port 5 30

ROW 5 Port 6 5 ROW 7 Port 6 31

ROW 6 Port 7 6 ROW 8 Port 7 32

ROW 7 Port 8 7 ROW 3 Port 8 27

ROW 9-12 n/c - ROW 9-12 n/c -

ROW 7 Port 1 15

ROW 6 Port 2 14 ROW 1 Port 2 33

ROW 1 Port 3 9 ROW 2 Port 3 34

ROW 2 Port 4 10 ROW 3 Port 4 35

ROW 3 Port 5 11 ROW 4 Port 5 36

ROW 4 Port 6 12 ROW 5 Port 6 37

ROW 5 Port 7 13 ROW 7 Port 7 39

ROW 8 Port 8 16 ROW 8 Port 8 40

ROW 9-12 n/c - ROW 9-12 n/c -

ROW 7 Port 1 23

ROW 8 Port 2 24

ROW 5 Port 3 21

ROW 3 Port 4 19

ROW 1 Port 5 17

ROW 2 Port 6 18

ROW 4 Port 7 20

ROW 6 Port 8 22

ROW 9-12 n/c -

Tower Ports are numbered Clockwise from mount center

(Port 1) to Port 8.

Openers are numbered from drill left (Row 1).

ROW 2 Port 1 26

Tower 4

ROW 6 Port 1 38

Tower 5

168-414M 10/29/2008

Page 39

Great Plains Mfg., Inc.

Installation Instructions 39

NTA-3510 Port Assignments, 7.5in (25.4cm) Drill

Drill Model: NTA3510-5575

Towers are numbered from drill left (Tower 1).

Harness connectors are numbered on the cable:“Row 1”

through “Row 12”. Lead “ROW 12” is unused (n/c).

Tower Harness Port Opener Tower Harness Port Opener

ROW10 Port1 10

ROW 4 Port 2 4 ROW 4 Port 2 37

ROW 2 Port 3 2 ROW 3 Port 3 36

ROW 1 Port 4 1 ROW 2 Port 4 35

ROW 3 Port 5 3 ROW 1 Port 5 34

Tower 1

Tower 2

Tower 3

ROW 5 Port 6 5 ROW 7 Port 6 40

ROW6 Port7 6 ROW10 Port7 43

ROW 7 Port 8 7 ROW 9 Port 8 42

ROW8 Port9 8 ROW11 Port9 44

ROW 9 Port 10 9 ROW 8 Port 10 41

ROW11 Port11 11 ROW6 Port11 39

ROW 12 n/c - ROW 12 n/c -

ROW 7 Port 1 18

ROW 6 Port 2 17 ROW 4 Port 2 48

ROW 5 Port 3 16 ROW 2 Port 3 46

ROW 3 Port 4 14 ROW 1 Port 4 45

ROW 1 Port 5 12 ROW 3 Port 5 47

ROW 2 Port 6 13 ROW 5 Port 6 49

ROW 4 Port 7 15 ROW 7 Port 7 51

ROW 8 Port 8 19 ROW 9 Port 8 53

ROW 10 Port 9 21 ROW 11 Port 9 55

ROW 11 Port 10 22 ROW 10 Port 10 54

ROW 9 Port 11 20 ROW 8 Port 11 52

ROW 12 n/c - ROW 12 n/c ROW10 Port1 32

ROW 8 Port 2 30

ROW 6 Port 3 28

ROW 2 Port 4 24

ROW 1 Port 5 23

ROW 3 Port 6 25

ROW 4 Port 7 26

ROW 5 Port 8 27

ROW 7 Port 9 29

ROW 9 Port 10 31

ROW11 Port11 33

ROW 12 n/c -

Tower Ports are numbered Clockwise from mount center

(Port 1) to Port 11.

Openers are numbered from drill left (Row 1).

ROW 5 Port 1 38

Tower 4

ROW 6 Port 1 50

Tower 5

10/29/2008 168-414M

Page 40

40 Blockage Monitor Kits

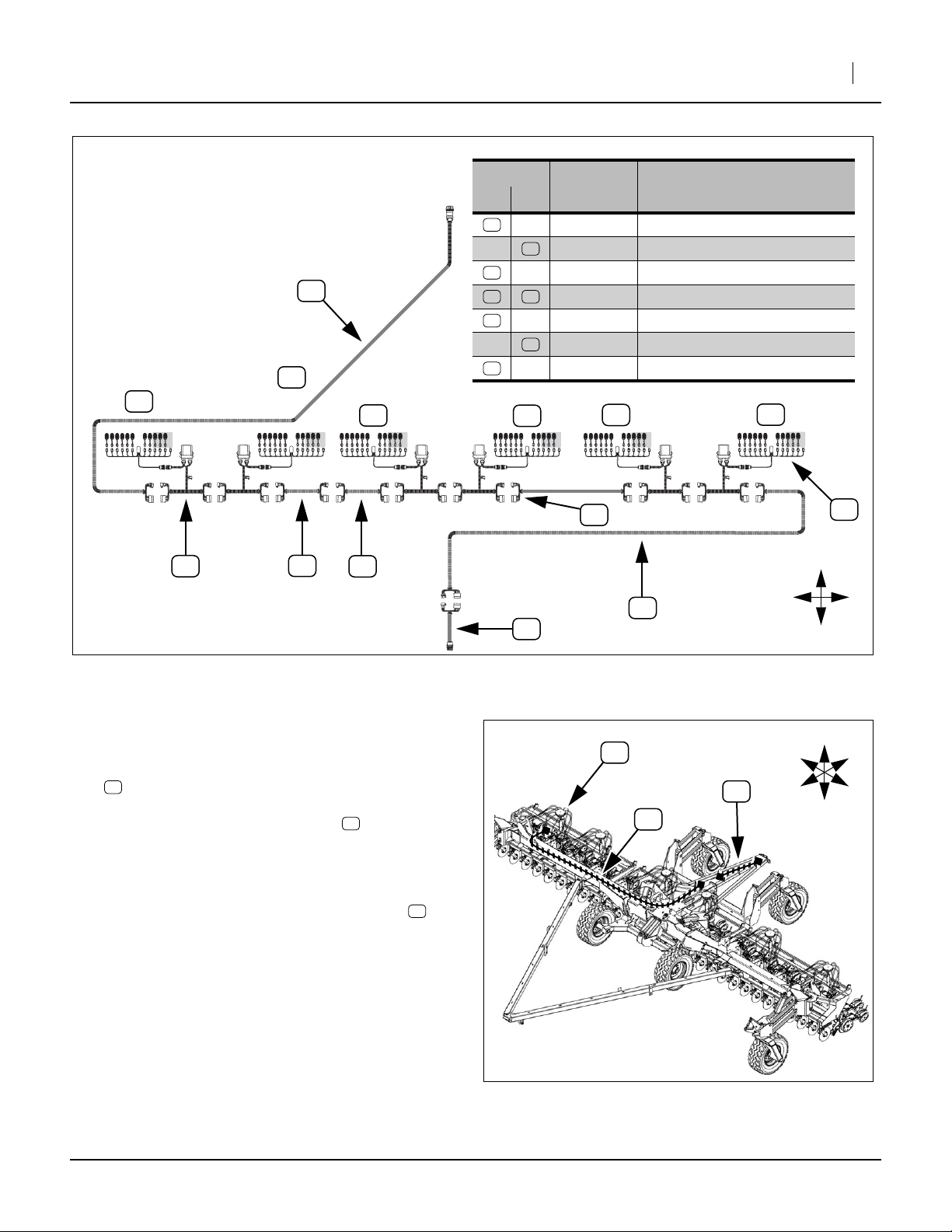

New Parts

Quantities are units (“ea”). Not all parts are in all kits.

Quantity in Kit 168-

Part

Callout

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Number

-404A

-405A

-406A

-407A

-408A

-409A

-410A

-411A

-412A

111111111 168-414M MANUAL IA BLOCK MONITOR INSTAL

5 5 5 5 5 5 5 6 6 168-465D DIST TOWER MODULE MOUNT PLATE

30 30 30 30 30 30 30 30 30 800-082C CABLE TIE .31X21.5 6DIA 120LB

10 10 10 10 10 10 10 12 12 802-224C HHCS 1/4-20X1 1/4 GR5

10 10 10 10 10 10 10 12 12 803-006C NUT HEX 1/4-20 PLT

10 10 10 10 10 10 10 12 12 804-006C WASHER LOCK SPRING 1/4 PLT

000010000 823-275C INTELLIAG CTA 80 ROW BLOCKAGE

0 0 0 0 0 1 0 0 0 823-276C INTELLIAG CTA 65 ROW BLOCKAGE

000000100 823-277C INTELLIAG CTA 50 ROW BLOCKAGE

0 0 1 0 0 0 0 0 0 823-278C INTELLIAG NTA35 55 ROW BLOCKAG

000100000 823-279C INTELLIAG NTA35 40 ROW BLOCKAG

1 0 0 0 0 0 0 0 0 823-280C INTELLIAG NTA30 48 ROW BLOCKAG

010000000 823-281C INTELLIAG NTA30 36 ROW BLOCKAG

0 0 0 0 0 0 0 1 0 823-282C INTELLIAG 3N40HD 66 ROW BLOCKG

000000001 823-283C INTELLIAG 3N40HD 48 ROW BLOCKG

Quantity in Intelli-Ag Bundle 823-

Part Description

Great Plains Mfg., Inc.

Callout

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

DICKEY-john

-280C

-281C

-278C

-279C

-275C

-276C

-277C

-282C

Part Number Part Description

-283C

3 0 1 3 1 0 3 0 3 110110050 TY WRAP BUNDLE 50-14"

011022020 110110099 TY WRAP BUNDLE 100-14"

1 1 1 1 1 1 1 1 1 110112820 TY WRAP BUNDLE 28-7" & 20-14"

01252001510624 464211090 DUST PLUG

48 36 55 40 80 65 50 66 48 467420352S1 RECON II

445500566 467751320S1 12 ROW HARNESS

0 0 0 0 5 5 0 0 0 467751330S1 16 ROW HARNESS

000011100 467980131 20’ HITCH HARNESS

1 1 1 1 0 0 0 1 1 467980140 DJ 20’ HARNESS EXT

222233311 467980141 10’ EXT HARNESS

1 1 0 0 2 2 2 0 0 467980142 5’ EXT HARNESS

000000011 467980143 INT AG 25’ HARNESS, WSMB EXT

0 0 0 0 1 1 1 0 0 467980360 3’ REAR HITCH HARNESS

445555566 467981100S1 INTAG WSMB/FLW MNTR MODULE 18R

4 4 5 5 5 5 5 6 6 467981201 INT AG HARNESS, WSMB MODULE

168-414M 10/29/2008

Page 41

Great Plains Mfg., Inc.

Installation Instructions 41

Existing Parts Affected

The following existing parts are involved in the kit installation.

Callout Part No. Part Description Part Disposition

91

467980126 MINI CAN TERMINATOR Moved to right-most Tower WSMB harness.

92

467980130 40’ HITCH HARNESS Rear end repositioned

93

467980141 10’ EXT HARNESS Entirely repositioned

94

467980360 3’ REAR HITCH HARNESS Disconnected and reconnected

95 96

467980817S1 WSMTII GP AIR CART MODULE

96

467980856 GP WSMTII AIR CART HARNESS Extended to cart bulkhead (CTA & NTA only)

97 98

467982000S1 PLNTR CNTRL OUTPUT MODULE(POM)

98