Part Lists Great Plains Manufacturing, Inc. 1

Contact Drive Wheel Update

NTA907HD and NTA3007HD

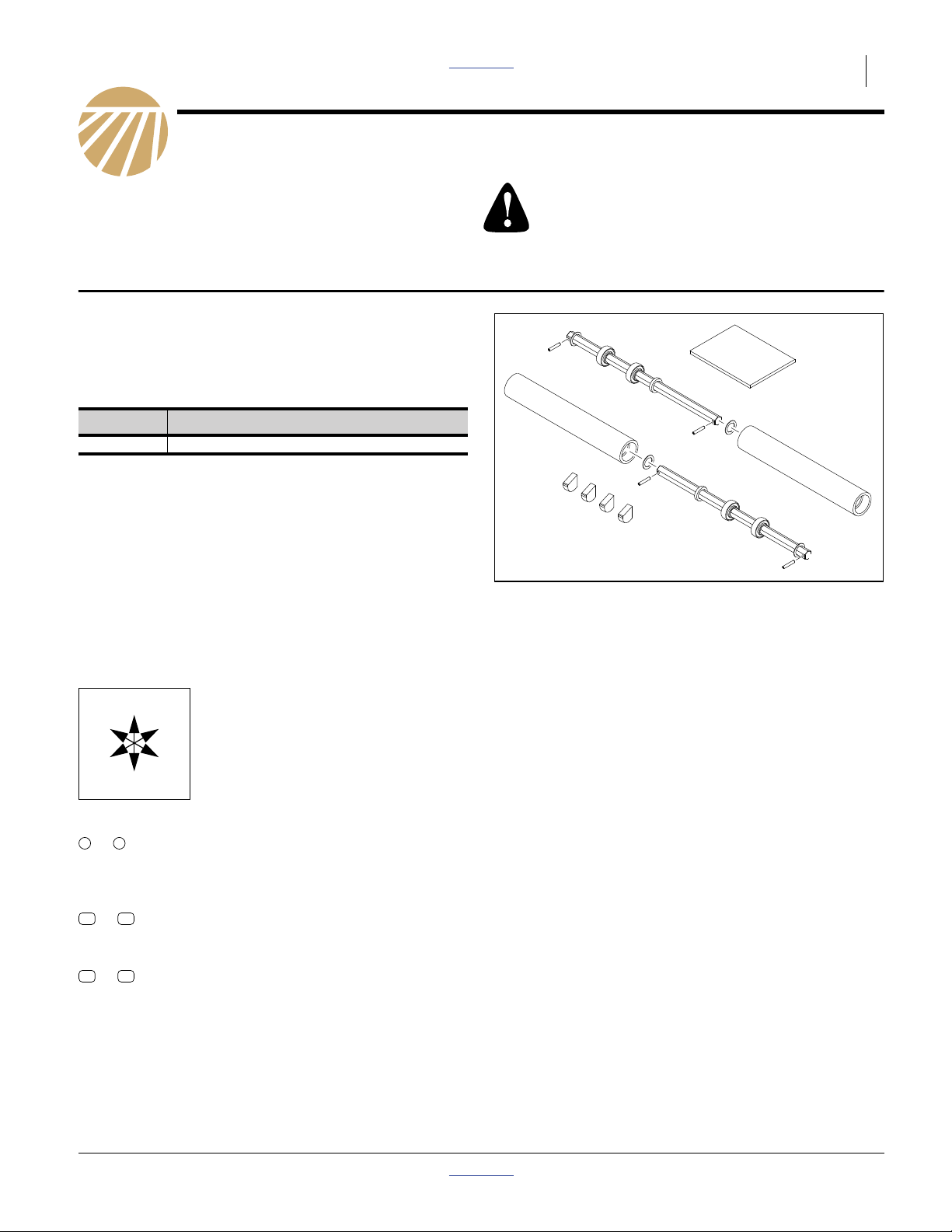

General Information

These instructions explain how to update the contact

drive wheel on an NTA907/3007HD. The kit improves the

reliability of the drive system in challenging field conditions. One kit updates one air drill.

These instructions apply to an installation of:

Kit Kit Description

166-366A NTA 907 CONTACT DR WHL UPDATE

This kit is not required for drills manufactured in 2011 or

later.

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

Your life and the lives of others depend on it!

Update

Manual

Related Documents

Have the following manuals available for implement operations and parts identification:

166-207M Operator Manual

166-207P Parts Manual

Notations and Conventions

U

F

L

D

Call-Outs

1 9

to

19

11

to

51 71

to

Single-digit callouts identify components in

the currently referenced Figure. These numbers may be reused for different items from

page to page.

Two-digit callouts in the range 11 to 19 reference new parts from the lists on

page 13page 15.

Two-digit callouts in the range 51 to 71 reference existing parts from the list on page 15.

“Left” and “Right” are facing in the

direction of machine travel. An orienta-

R

tion rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

B

Figure 1

Kit Components

32009

© Copyright 2011 Printed 2012-02-21 Part Lists 166-367M

2 Great Plains Manufacturing, Inc. Front Page Part Lists Contact Drive Update

Pre-Assembly Preparation

Tools Required

• cutting torch

• wire or rod welder, and welding safety equipment,

including a fire extinguisher

• ground (earthing) rod, cable and clamp (or access to

suitable electrical safety ground reference conductor)

• suitable tractor for raising and unfolding air drill

• Great Plains 821-001C spray paint, or green exterior

enamel close to Pantone 356C, DuPont 262 or

PPG 43817

• basic hand tools

Work Location

1. Move the air drill to a location with:

• flat, non-combustible surface free of flammable

materials

• adequate illumination

• clear surface beneath for recovery of any falling or

dropped parts

Prepare Air Drill

2. Raise implement with tractor.

3. Unfold implement.

4. Install lift and transport locks.

5. Disconnect all harnesses to tractor.

6. Connect a grounding cable from the center section

main frame to earth ground

Burn and Fire Hazards:

This update requires cutting and welding thick metal. Perform

the work clear of flammable materials. Wear suitable protective equipment. Allow hot parts to cool before continuing

work.

Crushing and Sharp Object Hazards:

Be careful working near openers. Discs and other parts may

be sharp.

Equipment Damage Risk:

Disconnect harnesses and ground frame before welding.

Connected harnesses or ungrounded frame during welding

can result in permanent damage to seed monitor components.

166-367M Front Page Part Lists 02/21/2012

Dismount Contact Drive Front Page Part Lists Great Plains Manufacturing, Inc. 3

Dismount Contact Drive

Start with the right side of the implement.

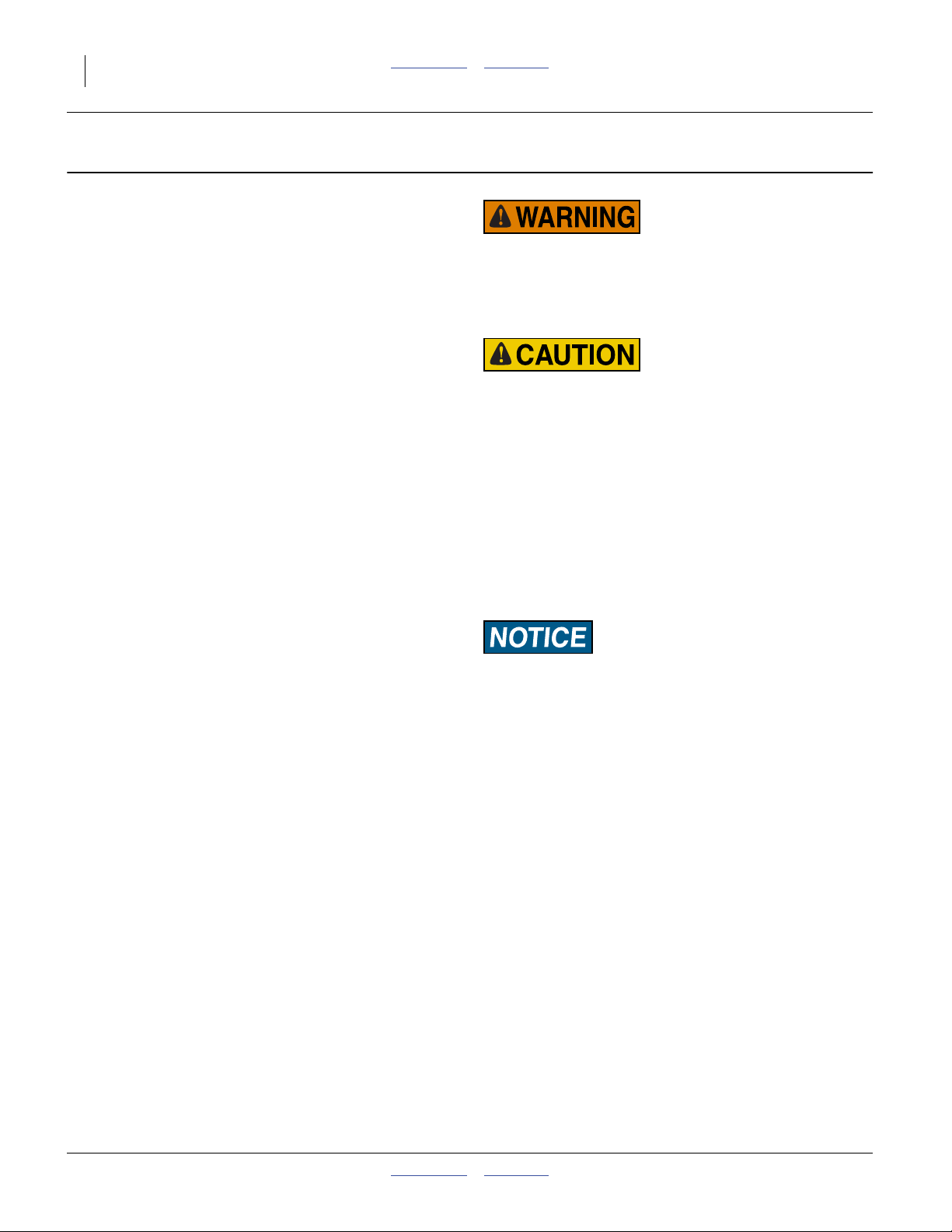

Dismount Input Shaft

Refer to Figure 2

64

1

69

65

64

1

69

65

1

64

67

7. Relax the idler on the contact drive chain . Lift the

chain off 27T driving sprocket .

8. At the front shaft, remove and save two sets:

65

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

69

814-134C TIRE/WHEEL ASSY 13/5 X 6

9. Remove and save one 27T sprocket:

67

808-311C SPKT 50C27 X 7/8 HEX BORE

10. Remove, record and save all:

64

804-061C WASHER MACH 1.50 X 1.00 X 18GA

Record the count here:

67

Input Shaft Washer Count

Right, Outside

Right, Inside

Left, Outside

Left, Inside

11. Remove and save the shaft:

57

266-003D SHAFT 7/8 HEX 32.75

Disconnect Hold-Down Spring

Refer to Figure 3

12. At each of the hold-down springs , remove and

save one set:

61

803-020C NUT HEX 1/2-13 PLT

63

804-015C WASHER LOCK SPRING 1/2 PLT

58

266-250D TUBE RND 1OD X 7/32W X 1.44 L

59

802-226C HHCS 1/2-13X2 3/4 GR5

13. Leave the spring in place, but tie it up out of the

way. The lower lug (not shown in the figure) is torch

cut at step 31 on page 5.

66

66

Figure 2

Contact Drive Input Shaft

61

66

58

59

63

Figure 3

Disconnect Hold-Down Spring

32066

32066

02/21/2012 Front Page Part Lists 166-367M

4 Great Plains Manufacturing, Inc. Front Page Part Lists Contact Drive Update

Dismount Output Sprockets

Refer to Figure 4

14. Relax the idler on the contact drive output chain .

Lift the 144P chain off the 30T sprocket .

15. Remove and save 117P chain:

51

136-259D CHAIN RL #50 117 PITCHES

16. At the sprocket end of the shaft , drive out the roll

65

pin . This pin is not re-used.

17. Remove and save the first of two sprockets:

68

808-319C SPKT 50C30 X 7/8 HEX BORE

18. Remove and save any spacer washers (not shown):

64

804-061C WASHER MACH 1.50 X 1.00 X 18GA

in between the sprockets and the bearing.

Record the count here:

56

Output Shaft Washer Count

Right

68

64

2

56

68

65

68

2

51

Figure 4

Existing Drive Shaft

32066

Left

19. Remove and save the second of two 30T sprockets:

68

808-319C SPKT 50C30 X 7/8 HEX BORE

Remove Pivots and Arms

Refer to Figure 5

20. At the pivot shaft , drive all inside roll pins .

Optionally remove the outside pin as well. These

pins are not re-used.

21. Remove the shaft . It is not re-used.

22. Remove six sets of lock nuts and round head

shank neck bolts ( ), four flangettes and two

spherical bearings . These are not re-used.

The bearings in the drive arms remain installed.

23. Remove and save one of:

54

166-201H CONTACT DRIVE WELDMENT RIGHT

55

166-205H CONTACT DRIVE WELDMENT LEFT

24. Repeat step 7 through step 23 for the left side.

56 65

56

62

60 71

70

62

71

71

65

60

70

65

Figure 5

Existing Pivot Bearings at Frame

56

54

32066

166-367M Front Page Part Lists 02/21/2012

Cut Clearances Front Page Part Lists Great Plains Manufacturing, Inc. 5

Cut Clearances

Elongate Input Shaft Slot

The curved slots (4 places) for the contact drive input

shaft need to be elongated by 21.0 mm (0.83 in).

Refer to Figure 6 and Figure 21 on page 12

25. Make two copies of page 12 at 1:1 (100%) size (or

print at 100% size from the PDF of this manual), for

use as marking templates. A ruler image is included

on the page to verify that the copy is 1:1 scale.

26. Mark the elongation boundary (the dashed line) on

the tongue mount plates.

27. Use a torch, or similar tool capable of cutting thick

steel, to elongate the four curved slots . Check the

final edge against the template.

3

Notch Spring Brackets

Figure 6

Input Shaft Slot

3

29379

The parallel arm spring brackets (where the bottom

of the hold-down springs attach) need to have a notch

cut in them (8 places) to allow spring clearance at the

limits of the arm movement now allowed by the longer

curved slots.

Refer to Figure 7 and Figure 20 on page 11

28. Make four copies of page 11 at 1:1 (100%) size (or

print at 100% size from the PDF of this manual), for

use as marking templates. A ruler image is included

on the page to verify that the copy is 1:1 scale.

29. Mark the notch boundary (the dashed line) on the

tongue mount plates.

30. Protect neighboring machine parts from being overheated.

31. Use a torch, or similar tool capable of cutting thick

steel, to cut the notches. Check the final edges

against the template.

53 4

4

Figure 7

Spring Brackets with Notches

53

29434

02/21/2012 Front Page Part Lists 166-367M

6 Great Plains Manufacturing, Inc. Front Page Part Lists Contact Drive Update

Install Welded Parts

Install Down Stops

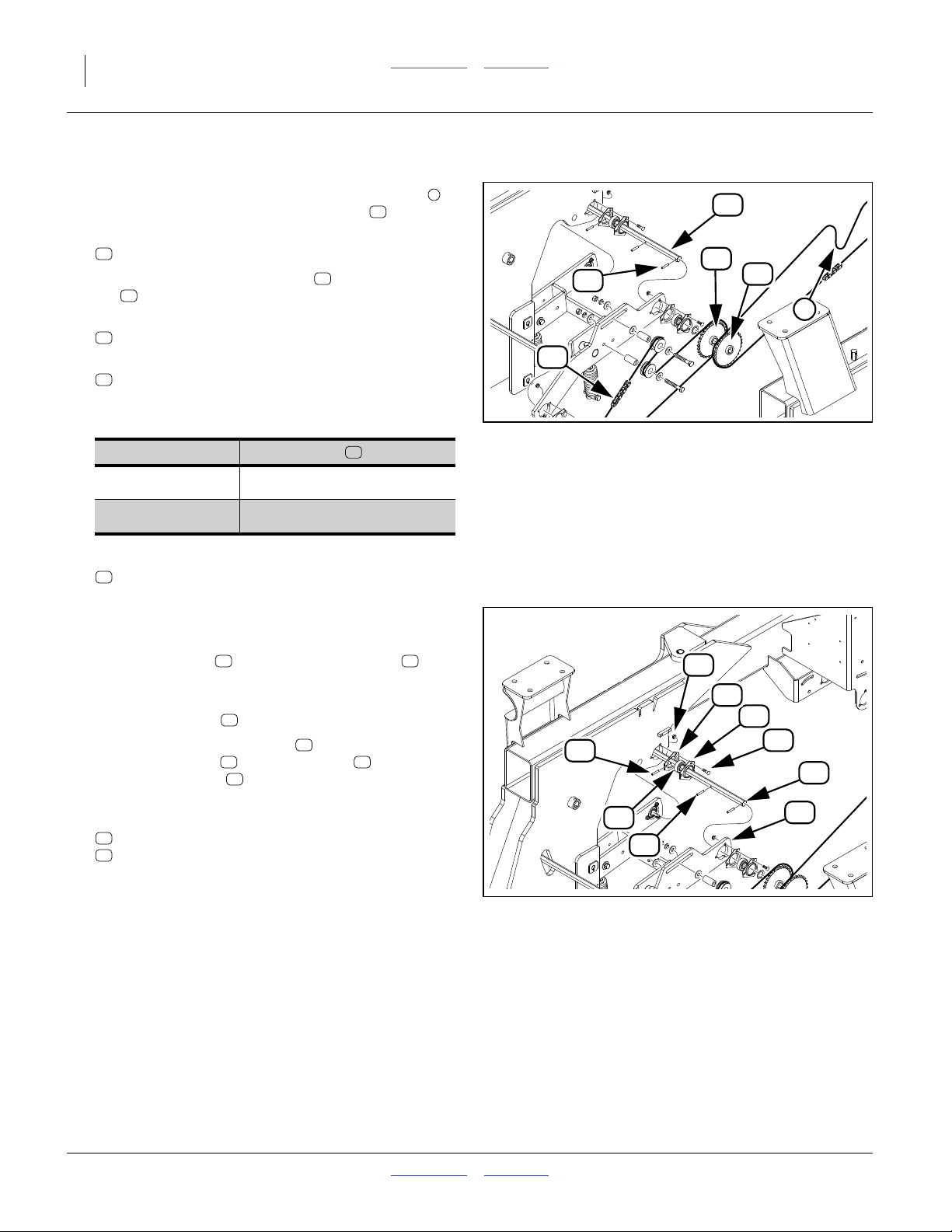

Lugs (4 places) are added to the tongue mount plates to

provide limit stops. This protects against machine damage in the event of low tire pressures.

Refer to Figure 8, Figure 9, Figure 22 (on page 13) and

Figure 23 (on page 14)

32. Remove paint from the area to be welded.

33. Make two copies each of page 13 and page 14

(4 total) at 1:1 (100%) size (or print at 100% size

from the PDF of this manual), for use as marking

templates. A ruler image is included on the pages to

verify that the copy is 1:1 scale.

34. Mark the location for each lug. Center-punching the

corners suffices.

35. Select four new:

13

266-294D CONTACT WHL DOWN STOP

Note: The lugs are symmetrical. The flat sides are iden-

tical.

36. Position each lug with one flat side to frame, the

other flat side up, curved side out, and canted 17

degrees forward. Tack weld. Re-check dimensions or

against template.

37. Allow tack welds to cool. Final weld all around with a

9 mm (3⁄8in) weld fillet.

Figure 8

Down Stop Installed

13

32075

17°

2.1 mm

2.1 mm (0.08 in) from bottom rear

13

77.6 mm

Figure 9

Down Stop Placement Dimensions

166-367M Front Page Part Lists 02/21/2012

corner of lug to vertical rear edge of

tongue mount plate.

77.6 mm (3.06 in) from bottom front

corner of lug to top edge of parallel

arm reinforcement plate below.

32076

Install Welded Parts Front Page Part Lists Great Plains Manufacturing, Inc. 7

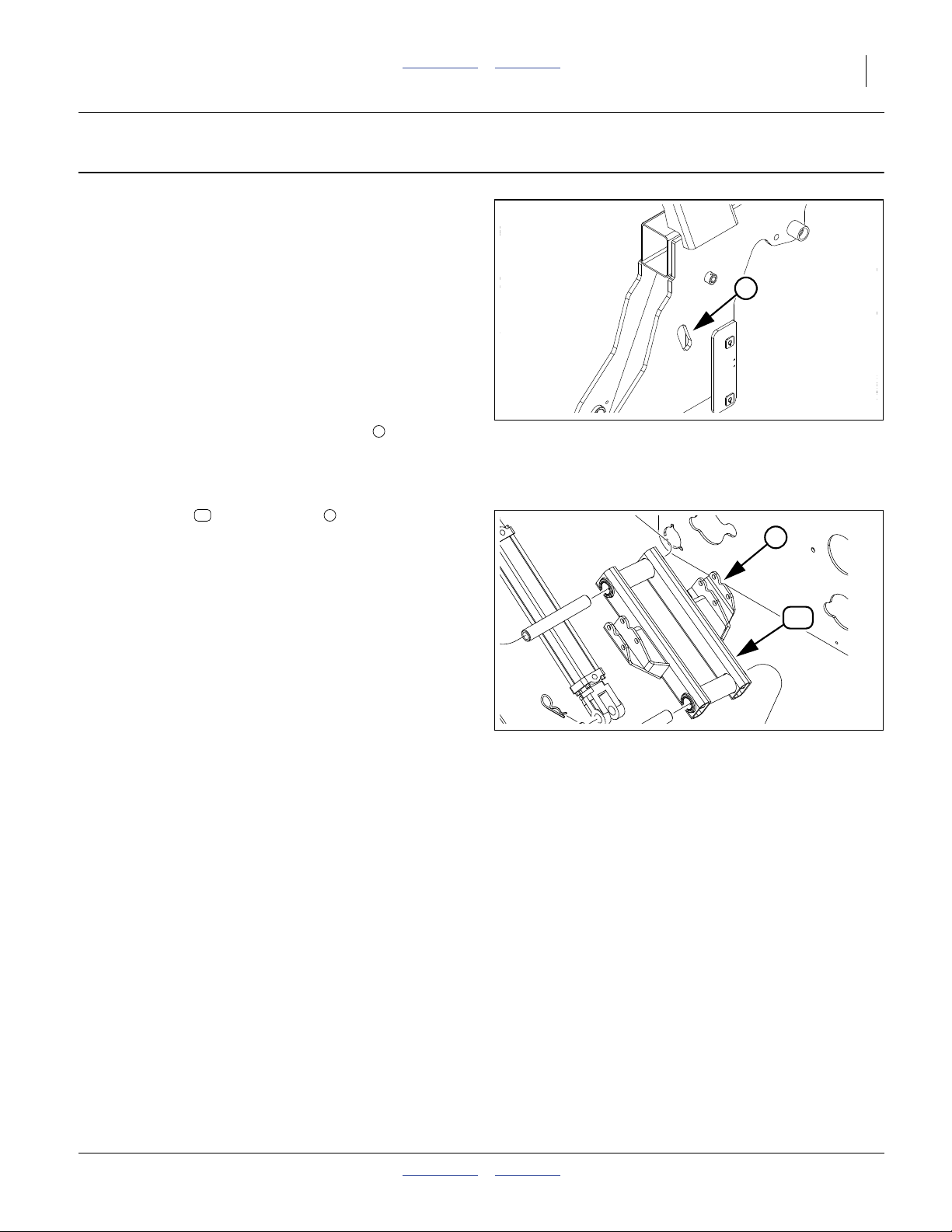

Install Pivot Tubes

Start with the right side of the implement.

Refer to Figure 10, Figure 11and Figure 12

38. Remove paint from the frame around the former

bearing mount holes.

39. Select one new:

14

266-295D CONTACT WHL PVT TUBE

Insert the tube through the frame holes where the

previous pivot shaft was removed.

40. Adjust the tube position for a reveal of 81.0 mm

(3.10 in) on the outside of the frame (left reveal on

left side; right reveal on right side). Tack weld the

tube. Recheck the reveal.

41. At the outside face of the outside frame plate, and

the inside face of the inside frame plate, weld the

contact circumference of the tube/frame joints with a

9mm (3⁄8in) weld fillet .

Note: It is not necessary to fill the former bolt holes

during welding.

42. Repeat step 38 through step 41 for the left side.

43. Wait for the welds to cool.

44. At all welds, remove welding residue and any

charred paint. Apply matching green paint.

45. Allow paint to dry.

4

14

18

Figure 10

Pivot Tube and Bearings

4

12

12

16

15

29379

14

.epsi

100%

Figure 11

Pivot Tube Placement

14

5

Figure 12

Pivot Tube Weld

81.0 mm

(3.19 in)

32067

6

32067

02/21/2012 Front Page Part Lists 166-367M

8 Great Plains Manufacturing, Inc. Front Page Part Lists Contact Drive Update

Re-install Contact Drive Arms

Start with the right side of the implement. Two workers

may be needed due to parts that are held in alignment

for shaft insertion.

14

7

12

Install New Pivot Shaft

Refer to Figure 14

46. Select two new:

12

188-006V BEARING .880 HEX BORE 205DD

Insert and seat one bearing at each of the pivot

14 7

tubes . The orientation groove is to the inside of

the tube . The raised face of the inner race is to

the outside of the tube.

47. Select one new:

15

48. Select the saved:

54

55

depending on the side being worked on.

49. Select one each new:

16

Note: Make sure that the arms are above the new down

50. Hold the spacer tube against the inside face of

the inside arm bearing . Bring the existing arm

bearings into alignment with the new bearings .

From the inside, insert the shaft through the existing bearing, spacer tube and both pivot tube

bearings .

51. Select one new:

17

Slide this washer between the outside pivot tube

bearing and the outside arm bearing , Slide the

shaft through the washer and the outside arm

bearing .

52. Select the number of saved:

64

per the “Output Shaft” table (page 4) for the side of

the implement being worked on. Place these on the

inside end of the shaft.

53. Select two saved 30T sprockets:

68

Place them on the inside end of the shaft

54. Select two:

18

Drive the pins through the ends of the shaft.

55. Repeat step 46 through step 54 for the left side.

14

266-296D CONTACT WHEEL PIVOT SHAFT

166-201H CONTACT DRIVE WELDMENT RIGHT

166-205H CONTACT DRIVE WELDMENT LEFT

402-266D 7/8 HEX SHAFT SPACER TB X 9

stops (not shown) before the next step.

16

70 12

12

804-061C WASHER MACH 1.50 X 1.00 X 1

12 70

15 17

70

804-061C WASHER MACH 1.50 X 1.00 X 18GA

808-319C SPKT 50C30 X 7/8 HEX BORE

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

12

8

70

15

15

Figure 13

Bearing Orientation

17

14

70

18

70

Figure 14

Pivot Tube and Bearings

8

32104

12

12

16

15

54

68

64

68

29379

166-367M Front Page Part Lists 02/21/2012

Re-install Contact Drive Arms Front Page Part Lists Great Plains Manufacturing, Inc. 9

Re-Mount Drive Wheels

Start with the right side of the implement.

Refer to Figure 15

56. Select one saved:

57

266-003D SHAFT 7/8 HEX 32.75

Insert the shaft through the forward bearings on

the arms, and the curved slots in the tongue mount

plates.

57. Select the number of saved:

64

804-061C WASHER MACH 1.50 X 1.00 X 18GA

per the “Input Shaft” table (page 3) for the side of

the implement being worked on. Place these on their

respective ends of the shaft.

58. Select one saved:

67

808-311C SPKT 50C27 X 7/8 HEX BORE

Add it to the inside end of the shaft.

59. Select a saved 117P chain:

51

136-259D CHAIN RL #50 117 PITCHES

Route the chain over the sprocket .

60. Select two sets saved:

69

814-134C TIRE/WHEEL ASSY 13/5 X 6

65

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Add one wheel to each end of the shaft. Secure with

roll pins.

51 67

70

69

65

51

70

57

64

67

Figure 15

Re-Install Drive Wheels

69

65

29379

Re-Install Chains

Refer to Figure 16

61. Route contact drive chain through idlers and

over driven sprocket (closest to contact drive

arm). Engage idlers .

62. Route contact drive output chain over driving

sprocket (furthest from contact drive arm).

Engage idlers .

68

2

51 1

68

1

52

1

Figure 16

Re-Install Chains

68

2

68

52

51

29379

02/21/2012 Front Page Part Lists 166-367M

10 Great Plains Manufacturing, Inc. Front Page Part Lists Contact Drive Update

Re-Connect Springs

Refer to Figure 17

63. Check spring rod length. Unless you have developed

a customer setting for your conditions, verify that the

spring is adjusted to factory default length.

6.7 cm (2.63 in)

27.3 cm (10.75 in)

with spring relaxed

Refer to Figure 18 and Figure 19

64. Select one set saved:

59

802-226C HHCS 1/2-13X2 3/4 GR5

58

266-250D TUBE RND 1OD X 7/32W X 1.44 L

63

804-015C WASHER LOCK SPRING 1/2 PLT

61

803-020C NUT HEX 1/2-13 PLT

65. Insert a tube into the lower hook of a hold-down

spring. Align the hold-down spring with the lower/

forward hole of the notched bracket . Secure with

59

bolt , lock washer and nut .

66. Repeat step 63 for the other spring on this side.

67. Repeat step 46 through step 66 for the left side of

the implement.

58

66

4

63 61

Figure 17

Hold-Down Spring Length

61

66

58

59

63

Figure 18

Re-connect Hold-Down Spring

66

32080

32066

53

4

59

Figure 19

Notched Hold-Down

166-367M Front Page Part Lists 02/21/2012

32079

Appendix Front Page Part Lists Great Plains Manufacturing, Inc. 11

Appendix

Notch Cutting Template

New Edge

New Edge

Figure 20: Notching Template

Existing Edge

Existing Edge

32072

02/21/2012 Front Page Part Lists 166-367M

12 Great Plains Manufacturing, Inc. Front Page Part Lists Contact Drive Update

Plate Cutting Template

Existing Bottom

New Bottom

21mm (0.83 in)

Figure 21: Plate Cutting Template

166-367M Front Page Part Lists 02/21/2012

32071

Appendix Front Page Part Lists Great Plains Manufacturing, Inc. 13

Stop Placement Template LH

Figure 22: Stop Placement Template - Left Hand

02/21/2012 Front Page Part Lists 166-367M

32073

14 Great Plains Manufacturing, Inc. Front Page Part Lists Contact Drive Update

Stop Placement Template - RH

Figure 23: Stop Placement Template - Right Hand

166-367M Front Page Part Lists 02/21/2012

32073

Appendix Front Page Part Lists Great Plains Manufacturing, Inc. 15

Part Lists

New Parts

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Quantities are units (“ea”).

166-366A Kit Contents

Callout Quantity Part Number Part Description

11 1 166-367M MANUAL NTA 907 CONT DR UPDA

12 4 188-006V BEARING .880 HEX BORE 205DD

13 4 266-294D CONTACT WHL DOWN STOP

14 2 266-295D CONTACT WHL PVT TUBE

15 2 266-296D CONTACT WHEEL PIVOT SHAFT

16 2 402-266D 7/8 HEX SHAFT SPACER TB X 9

17 2 804-061C WASHER MACH 1.50 X 1.00 X 1

18 4 805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Other Parts

Callout Quantity Part Number Part Description

19 1 821-001C PAINT GP GREEN SPRAY CAN

Existing Parts Affected

The following existing parts are involved in the kit installation. The Disposition column indicates whether the part

is left in place, moved or not re-used.

The part call-out numbers in the list matches all Figures

in the installation instructions. The descriptions match

those in your air drill Parts manual.

Callout Qty Part No. Part Description Part Disposition

51 2 136-259D CHAIN RL #50 117 PITCHES Removed and re-installed.

52 2 136-260D CHAIN RL #50 144 PITCHES Removed and re-installed.

53 2 166-196H ARM PARALLEL W/ SPNG BRKT WELD Modified in place.

54 1 166-201H CONTACT DRIVE WELDMENT RIGHT Removed and re-installed.

55 1 166-205H CONTACT DRIVE WELDMENT LEFT Removed and re-installed.

56 2 166-953D HEX SHAFT 7/8X20.56 LONG Removed. Not re-used.

57 2 266-003D SHAFT 7/8 HEX 32.75 Removed and re-installed.

58 4 266-250D TUBE RND 1OD X 7/32W X 1.44 L Removed and re-installed.

59 4 802-226C HHCS 1/2-13X2 3/4 GR5 Removed and re-installed.

60 6 802-282C RHSNB 5/16-18X1 GR5 Removed and re-installed.

61 4 803-020C NUT HEX 1/2-13 PLT Removed and re-installed.

62 12 803-177C NUT HEX FLG TP LK 5/16-18ZNYCR Removed and re-installed.

63 2 804-015C WASHER LOCK SPRING 1/2 PLT Removed and re-installed.

64 4-8 804-061C WASHER MACH 1.50 X 1.00 X 18GA Removed and re-installed.

65 8 805-180C PIN ROLL 1/4 X 1 1/2 LG PLT Removed. Not re-used.

66 4 807-055C SPRING HOLD DOWN HD COULTER Disconnected and re-connected.

67 2 808-311C SPKT 50C27 X 7/8 HEX BORE Removed and re-installed.

68 4 808-319C SPKT 50C30 X 7/8 HEX BORE Removed and re-installed.

69 4 814-134C TIRE/WHEEL ASSY 13/5 X 6 Removed and re-installed.

70 4 822-119C BRG 7/8HEXX2.05OD SPH Removed and re-installed.

71 8 822-175C FLANGETTE 52 3-BOLT PLT Removed and re-installed.

02/21/2012 Front Page Part Lists 166-367M

16 Great Plains Manufacturing, Inc. Front Page Part Lists Contact Drive Update

Abbreviations

#50 Number 50 chain link OD Outside Diameter

ASSY Assembly PLT Plated

BRG Bearing PVT Pivot

BRKT Bracket RHSNB Round Head Shank Neck Bolt

DR Drive RL Roller

FLG Flanged SPH Spherical

GA Gauge SPKT Sprocket

GP Great Plains TB Tube

GR5 Grade 5 TP LK Top Lock

HD Heavy Duty UPDA Update

HEX Hexagonal W Width

HHCS Hex Head Cap Screw W/ with

L, LG Long WHL Wheel

MACH Machined X By

NTA No-Till Air (drill) ZNYCR Zinc Chromate

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

166-367M Front Page Part Lists 02/21/2012

Loading...

Loading...