Page 1

Table of Contents Index

9 Meter/30 Foot No-Till Air Drills

Operator Manual

2012+ NTA907 or NTA3007

Manufacturing, Inc.

www.greatplainsmfg.com

Read the Operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

32440

Illustrations may show optional equipment not supplied with standard unit, and may

show model NTA907, NTA907HD, NTA3007 or NTA3007HD air drills.

ORIGINAL INSTRUCTIONS

© Copyright 2011 Printed 2012-07-02 166-371M

Table of Contents Index

EN

Page 2

Table of Contents Index

166-371M Table of Contents Index 2012-07-02

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Equipment Identification .............................................1

North American Models NTA3007..................................1

Export Models NTA907 ..................................................1

Machine Record .............................................................2

Machine Log...............................................................2

Machine Details..........................................................2

Dealer Information......................................................2

Great Plains Regional Agent ...................................... 2

Introduction ..................................................................3

Description of Unit ..........................................................3

Intended Usage ..............................................................3

Using This Manual

Document Family........................................................4

Definitions................................................................... 4

Owner Assistance ..........................................................4

Important Safety Information ......................................5

Safety Decals ...............................................................11

Preparation and Setup ...............................................26

Initial Setup...................................................................26

Seasonal Setup ............................................................26

Pre-Planting Setup .......................................................26

Hitching Tractor to Drill.................................................27

Hydraulic Hose Hook-Up..............................................28

Brake Hook-Up (Option)...............................................29

Electrical Hook-Up........................................................30

Beacon Operation (NTA907 only) ............................31

Stow Wheel Chocks .....................................................31

Heights and Levelling ...................................................32

Marker Setup................................................................32

Operating Instructions...............................................33

Pre-Start Checklist .......................................................33

CFM Overview.......................................................... 33

Unfolding the Drill .........................................................34

Unfold: Summary of Steps........................................35

Lowering and Raising Drill............................................42

Lowering...................................................................42

Raising .....................................................................43

Folding the Drill ............................................................44

Fold: Summary of Steps...........................................45

Fold: Set Tractor for Fold..........................................47

Fold: Fold Wings.......................................................47

Transporting the Air Drill...............................................50

Tractor Requirements............................................... 51

Transport Checklist .................................................. 51

Brake Operation (Option)............................................. 52

Single-Line Hydraulic Brake Operation ................ 52

Dual-Line Air/Hydraulic Brake Operation .............52

Ladder Operations ....................................................... 54

Using Ladder............................................................54

Storing Ladder.......................................................... 54

Hopper Lids.................................................................. 55

Strainer..................................................................... 57

Meter Doors ................................................................. 57

Meter Door Opening................................................. 58

Meter Door Closing .................................................. 58

Auger Operations (Option)........................................... 59

Deploying Auger....................................................... 60

Auger Hydraulic Controls ......................................... 62

Tractor Lever for Auger ........................................ 62

Selector Valve ...................................................... 62

Auger Direction Valve .......................................... 63

Storing Auger ........................................................... 64

Orient Inlet and Outlet .......................................... 64

Loading Materials......................................................... 65

Loading Material Safely............................................ 65

Loading: Use a Tractor............................................. 66

Loading: Select Hoppers to Use .............................. 66

Loading: Air-Out System .......................................... 66

Loading: Prepare Hopper(s)..................................... 66

Loading: with Auger ................................................. 67

Loading: Close-Out .................................................. 67

Collection Chute Operation.......................................... 68

Using the Collection Chute....................................... 68

Calibration Crank ......................................................... 69

Fan Operation .............................................................. 71

Marker Operation (Option) ........................................... 73

Field Operations........................................................... 75

Field Operation ............................................................ 76

Seed Monitor............................................................76

Unloading Materials ..................................................... 77

Unloading Without Auger ......................................... 77

Auger Unloading: Rear Hopper................................ 78

Auger Unloading: Front Hopper ............................... 80

Parking......................................................................... 81

Storage ........................................................................ 82

Adjustments ............................................................... 83

Setting Material Rates.................................................. 84

Check Contact Tires................................................. 84

© Copyright 2009, 2010, 2011 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2012-07-02 Cover Index 166-371M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Verti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Check Flute Shaft Type ........................................... 84

Find Your Chart and Rate ........................................ 85

Monitor Material Configuration................................. 86

Meter Rate Adjustment ............................................ 87

Seed Meter Final Drive Range............................. 88

Disable a Seed Meter........................................... 88

Setting Variable Rate Gearbox ............................ 89

Manual Rate Setting............................................. 89

Variable Rate (Servo) Rate Setting...................... 89

Meter Calibration.......................................................... 90

Calibration Crank Revolutions.............................. 92

Variable Rate (Servo) Calibration ............................ 95

Calibration Crank Revolutions.............................. 95

Contact Drive Adjustment ............................................ 97

Fan Speed Adjustments............................................... 98

Recommended Fan Speeds ................................ 98

Implement Lift Switch Adjustment................................ 99

Planting Depth Adjustments....................................... 100

Opener Down-Force (Hydraulic) ................................ 101

Adjusting Hydraulic Down Pressure....................... 102

Control Valve Overview ......................................... 103

Setting the Bypass Valve ....................................... 104

Bypass with LS or PFC Closed Systems ............... 105

Priority Flow Hydraulic Systems............................. 105

Opener Sub-Frame Adjustment ................................. 106

Adjusting Weight Transfer...................................... 107

Frame-Mounted Coulters (Option) ............................. 108

Frame-Mounted Coulter Force............................... 109

07 Series Row Unit Adjustments ............................... 110

Row Unit Spring Adjustment .................................. 111

Disc Blade Adjustments ......................................... 111

Adjusting Disk Contact ....................................... 112

Disc Scraper Adjustments...................................... 112

Seed Firmer Adjustments ...................................... 113

Opener Depth (Press Wheel Height) ..................... 114

Marker Adjustments ................................................... 115

Marker Disc Adjustment......................................... 115

Troubleshooting....................................................... 116

Brake Troubleshooting (Option)................................. 120

Maintenance and Lubrication ................................. 122

Maintenance .............................................................. 123

Chain Maintenance ................................................ 123

Material Clean-Out................................................. 124

Problem Clean-Out ............................................ 125

Removing Meter Box.......................................... 125

Hopper Entry ...................................................... 126

Hydraulic Maintenance .......................................... 128

Hydraulic Maintenance Safety Information ........ 128

Bleeding Hydraulics ........................................... 128

Bleeding Tilt Hydraulics ......................................129

Bleeding Fold Hydraulics ....................................130

Bleeding Hook Hydraulics...................................130

Bleeding Down-Pressure Hydraulics ..................131

In-Line Filter........................................................132

Marker Maintenance ...............................................133

Marker Shear Bolt...............................................133

Marker Hydraulic Bleeding..................................133

Marker Chain Length ..........................................134

Marker Grease Seal............................................134

Brake Maintenance (Option)...................................135

Brake Line Charge and Bleed.............................135

Air Brake Maintenance .......................................137

Brake Drum and Liner Maintenance ...................138

Brake Shoe Replacement...................................139

Brake Drum Maintenance ...................................143

Mounting Wheels ................................................144

Test and Adjust Brakes.......................................144

Levelling Drill ..........................................................145

Section Alignment...................................................145

Tool Bar Heights .................................................146

Seed Flap Replacement .........................................147

Beacon Maintenance (NTA907 only)..........................147

Lubrication and Scheduled Maintenance ...................148

Options ......................................................................157

Appendix A - Reference Information ......................163

Specifications and Capacities.....................................163

NTA907 Export Models...........................................163

NTA3007 North America Models ............................164

Dimensions (Transport) NTA907 Export Models........165

Tire Inflation Chart ......................................................166

Hydraulic Connectors and Torque..............................166

Torque Values Chart ..................................................167

Seed Hose Port Maps ................................................168

Monitor Setup Data.....................................................174

Chain Routing.............................................................175

LH Contact Drive Chains ........................................175

Gearbox and Meter Chains.....................................176

Hydraulic Diagrams ....................................................177

Appendix B - Initial Setup ........................................183

Console Installation ....................................................183

Initial Marker Setup.....................................................183

Marker Extension....................................................183

Marker Speed .........................................................184

Appendix C - Option Installation.............................185

Changing Meter Flutes ...............................................185

Warranty .....................................................................187

Index ..........................................................................189

166-371M Table of Contents Index 2012-07-02

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Equipment Identification

This Operator manual applies to the following Great

Plains pull-type integrated air drill seeders:

NTA907-3610 9m, 36-row, 25.4cm (10in) spacing

NTA907-4875 9m, 48-row, 19.1cm (7.5in) spacing

NTA907-6006 9m, 60-row, 15.0cm (5.9in) spacing

NTA3007-3610 30 foot, 36-row, 10 inch spacing

NTA3007-4875 30 foot, 48-row, 7.5 inch spacing

NTA3007-6006 30 foot, 60-row, 6 (5.9) inch spacing

See “Specifications and Capacities” on page 163 for

precise swath information.

Refer to Figure 1

For positive equipment identification, consult the serial

number plate located on the rear frame cross-member

1

below and left of fan.

Note: The present manual does not apply to “HD” models

NTA907HDor NTA3007HD. See manual 166-207M

for HD drills.

Label/Plate Location

N

*P 2 *

1

Figure 1

32450

North American Models NTA3007

Models NTA3007 are built to North American highway

transport standards.

Refer to Figure 2 (which is NOT from an actual machine)

The serial number plate provides the model number and

serial number specific to your machine.

See “Transporting the Air Drill” on page 50

and “Specifications and Capacities” on page 163 for

additional weights and measurements.

Export Models NTA907

Models NTA907 are built to European highway transport

standards.

Refer to Figure 3 (which is NOT from an actual machine)

If you, or the dealer, have added Options not originally

ordered with the machine, or removed Options that were

originally ordered, the weights and measurements no

longer are accurate for your machine. Update the Record

on the next page upon modifications.

Figure 2: NTA3007:

Example Serial Number Plate

32162

Figure 3: NTA907:

32230

Example Machine Label

2012-07-02 Table of Contents Index 166-371M

Page 6

2 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Machine Record

Machine Details

Record your machine details in the Log at right. If you

replace this manual, be sure to transfer this information

to the similar page of the new manual.

If you add or remove Options, update the Log. If the page

cannot be legibly updated, request or print a new

Operator manual.

Dealer Information

My Customer

Number / ID

Dealer Name

Street

Place

Post Code

Country

Voice

Machine Log

Machine Model

Serial Number

Working Width

Transport Width

Maximum Tare Weight

Maximum Payload

Maximum Gross Weight

Maximum Axle Load

Year of Manufacture

Date of Delivery

Date in Service

Options

Fax

Web

Email

Great Plains Regional Agent

(If different than those on page 4)

Agent Voice

Street Fax

Place Web

Post Code Email

Country

166-371M Table of Contents Index 2012-07-02

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index 3

Introduction

Great Plains welcomes you to its growing family of new

product owners. Your 9m/30ft No-Till Air Drill has been

designed with care and built by skilled workers using

quality materials. Proper setup, maintenance, and safe

operating practices will help you get years of satisfactory

use from the machine.

Before placing the machine into service for the first time,

read and understand this manual, in particular the

“Important Safety Information”, pages 5 to 25. Have

all operators read this manual before allowing them to

work with the machine.

Description of Unit

The NTA907 or NTA3007 is a pull-type integrated air drill

seeder. The implement folds for narrow 3 m (9 ft. 81⁄2in.)

transport.

A hydraulic fan supplies the material delivery system.

Ground-driven fluted shafts below the hoppers meter the

seed or fertilizer (the materials) into the air flow. Meter

chambers and tower manifolds evenly divide the material

flow, and deliver equal volumes to each opener row.

The cart has dual 3500 litre (100 bu) hoppers for

separate or simultaneous delivery of seed and/or

granulated dry fertilizer. Each hopper has an

independent metering system with user-preset infinite

ratio gearboxes. Console-controlled variable rate meter

servos are optional.

The NTA907 or NTA3007 has double-disc Series 07

openers, suitable for conventional till and, minimum-till

conditions. With optional coulters, the air drill is suitable

for moderate no-till conditions.

Brakes are standard on model NTA907 and optional on

model NTA3007. Service brakes are operated by air or

hydraulic lines to the tractor.

Hydraulic weight transfer (of cart weight to implement,

and from implement centre section to wings) is standard.

Other options include auger, field markers, tramline kits,

high rate flutes, and alternate discs, scrapers and

firmers.

Do not modify the drill except as instructed by Great

Plains. Do not use attachments other than as provided

by or authorized by Great Plains.

Figure 4

NTA907 or NTA3007 Drill

Intended Usage

Use the NTA907 or NTA3007 to seed and fertilize

production-agriculture crops only.

The intended use requires that safety features are

unimpaired, that machine systems be in proper working

order, and that the material rates have been correctly

configured and verified. Use only Great Plains

authorized replacement parts.

Faults in safety features, including missing or illegible

safety decals, must be remedied prior to machine use.

To keep the machine in proper working order, comply

with operating instructions, perform periodic

maintenance, and repair or replace worn or damaged

parts.

This is a volumetric seeding implement. The provided

seed rate charts (manual 167-085B) are based on

materials which likely vary from yours. Grain size, grain

shape, density, surface texture, foreign matter,

treatments, coatings, humidity, field speed, soil

conditions and normal wear on tires and meters cause

rates to vary from the charts. Calibration is essential for

satisfactory results.

32440

2012-07-02 Table of Contents Index 166-371M

Page 8

4 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Using This Manual

This manual will familiarize you with safety, hitching,

operation, adjustments, troubleshooting, and

maintenance. Read this manual and follow the

recommendations to help ensure safe and efficient

operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Document Family

166-371M Operator Manual (thisa document)

167-085B Seed Rate Charts

166-371P Parts Manual

166-263M Variable Rate Kit Installation

113-850M Marker Installation

110011516 DICKEY-john® Quick Start Guide

110011375 DICKEY-john® Air Cart Control manual

110111543 DICKEY-john® Tramline Kit instructions

Definitions

Safety admonishment signal words are described on

page 5.

The following terms are also used throughout this

manual.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts. Always

use the serial and model number (page 2) when ordering

parts from your Great Plains dealer.

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

For further assistance contact Great Plains via the Agent

recorded on page 2, or at:

For U.K. and Europe

SIMBA Great Plains

Woodbridge Road Ind. East

Sleaford

Lincolnshire NG34 7EW England

Identifies an Economic (not a Safety) Risk:

NOTICE provides a crucial point of information related to the

current topic. Read and follow the instructions to avoid damage

to equipment and ensure desired field results.

Note: This form sets off useful information related to the

current topic, or forestalls possible

misunderstanding.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

a. If you prefer a manual that is metric-only, request a copy of 166-371M-ENG from your dealer or from Great Plains.

R

F

U

B

L

D

Voice: +44 (0) 1529 304654

Fax: +44 (0) 1529 413468

Email: simba.international@simba.co.uk

For Other Regions

Great Plains Manufacturing, Inc.

PO Box 5060

Salina KS 67402-5060 USA

Voice: +1 785-823-3276

Fax: +1 785-822-6722

Email: gp_web_cs@greatplainsmfg.com

166-371M Table of Contents Index 2012-07-02

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index 5

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOLa indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER, and the colour Safety Red, indicate an

imminent hazard which, if not avoided, will result in death

or serious injury. This signal word is limited to the most

extreme situations, typically for machine components

that, for functional purposes, cannot be guarded.

WARNING, and the colour Safety Orange, indicate a

potential hazard which, if not avoided, could result in

death or serious injury, and includes hazards that are

exposed when guards are removed. It may also be used

to alert against unsafe practices.

CAUTION, and the colour Safety Yellowb, indicate a

potential hazard which, if not avoided, may result in

minor or moderate injury. It may also be used to alert

against unsafe practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “WarningSafety Reflectors and

Decals” on page 11, thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

a. Symbols and safety colours in this manual, and on machine model NTA3007, are based on ANSI standard Z535.

Pictogram symbols and colours on model NTA907 are based on ISO standard 3864.

b. Pictograms (language-free safety decals), found on models NTA907, are generally on a Safety Yellow background regardless of

hazard severity. Rely on the illustrations, and the manual, and not the colour, to classify the severity of the hazard.

2012-07-02 Table of Contents Index 166-371M

Page 10

6 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to loud noise can cause

hearing impairment or hearing loss, wear suitable hearing

protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

Use A Safety Chain

▲ Use a safety chain to help control drawn machinery should

it separate from tractor draw-bar.

▲ Use a chain with a strength rating equal to or greater than

the gross weight of towed machinery.

▲ Attach chain to tractor draw-bar support or other specified

anchor location. Allow only enough slack in chain to permit

turning.

▲ Replace chain if any links or end fittings are broken,

stretched or damaged.

▲ Do not use safety chain for towing.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

166-371M Table of Contents Index 2012-07-02

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper use

can seriously injure persons, animals, plants, soil and

property.

▲ Do not use liquid seed treatments with the NTA907 or

NTA3007.

▲ Read and follow chemical manufacturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Avoid inhaling smoke from any type of chemical fire.

▲ Never drain, rinse or wash dispensers within 30m (100 feet)

of a freshwater source, nor at a car wash.

▲ Store or dispose of unused chemicals as specified by

chemical manufacturer.

▲ Dispose of empty chemical containers properly. Laws

generally require power rinsing or rinsing three times,

followed by perforation of the container to prevent re-use.

Confined Space

With materials loaded, or once used for hazardous

fertilizers, or seeds with hazardous treatments, a hopper

may become

“permit-required confined space”

under applicable statutes, regulations, insurance rules or

business policy. The vent tube structure in the hopper

has features to assist escape, and is not for routine entry.

▲ A hopper that is full or merely appears full can be an

entrapment hazard. You can sink entirely into the material,

or into an oxygen-deficient void, and suffocate in a matter

of seconds. Bridges and crusts are especially dangerous.

▲ When hazardous fumes are present, you can be quickly

overcome even with the hopper lid open.

▲ Do not enter a hopper for material loading, material

unloading, hopper cleaning or meter maintenance.

▲ Clean hopper by power washing from outside hopper top.

▲ Perform meter maintenance by removing meters from

bottom of empty hopper.

▲ If obstruction removal or repair requires hopper entry, have

the work performed by a team trained in confined space

procedures. See “Hopper Entry” on page 126.

2012-07-02 Table of Contents Index 166-371M

Page 12

8 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

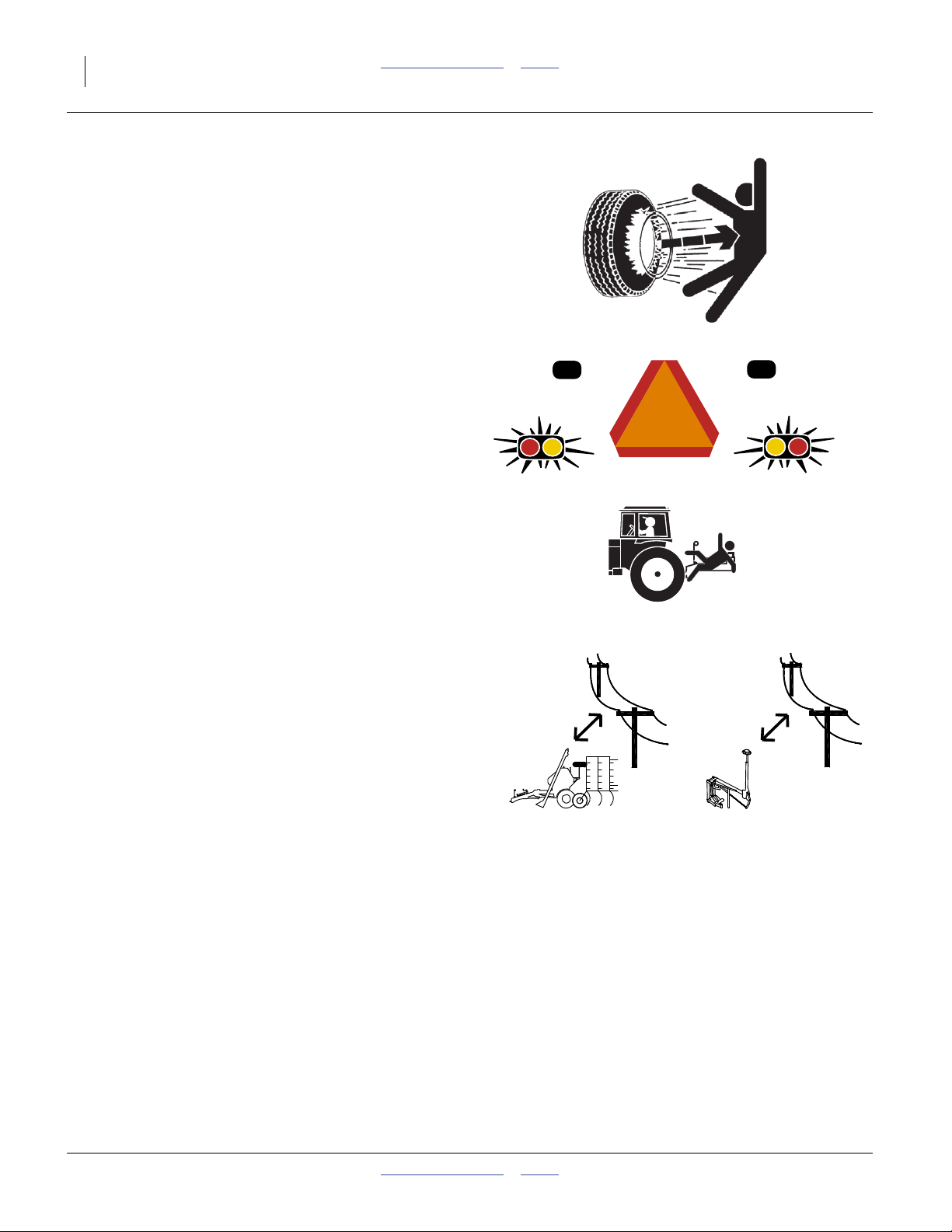

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever

driving on public roads.

Use lights and devices provided with implement

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

Remain Clear of Overhead Lines

▲ If the drill contacts a power line, lethal voltage may be

present on all metal parts. At higher voltage, the drill does

not need to be in line contact for the hazard to exist.

Maintain at least 3 m (10 foot) clearance.

▲ Electrocution can occur without direct contact between the

energized drill and a person near the drill.

▲ Watch for sagging, damaged or low electrical lines. The

auger could contact lines lower than 5.3 m (17.5 feet).

Overhead lines at farm structures are a particular hazard.

An auger is at risk from lines lower than 9 m (28 feet).

▲ Watch for all electrical lines during folding, unfolding,

marker and most especially auger operations. Use a spotter

during these operations. Know the location and height of all

lines during loading, transport and in fields.

▲ If an electrical hazard is observed while on the ground near

the applicator, hop at least 30 m (100 feet) away with both

feet together and summon professional help. At higher

voltage, lethal voltage gradients can also be present at the

soil surface.

▲ Consult your tractor manual for advice on how to respond

to an electrical hazard event while in the cab.

166-371M Table of Contents Index 2012-07-02

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 9

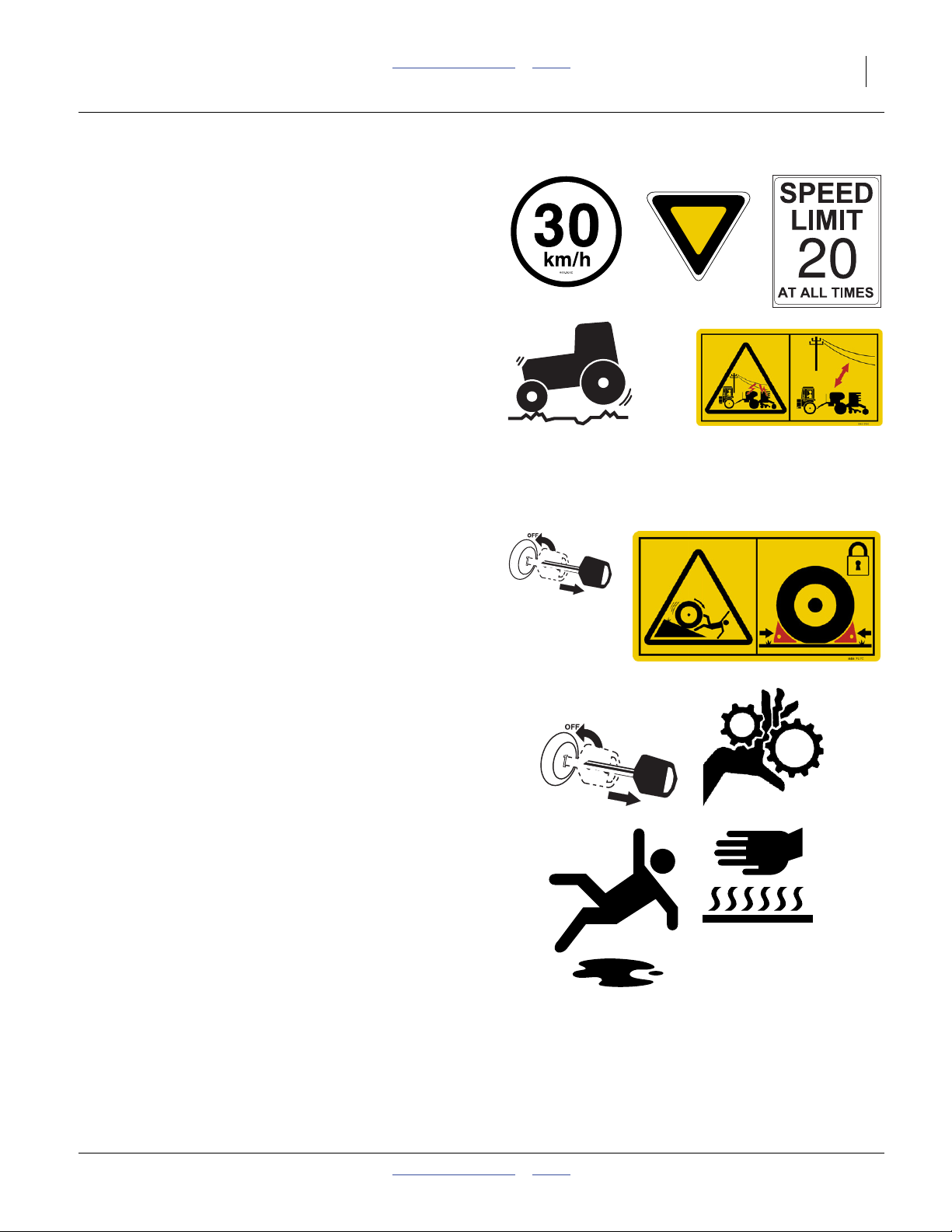

Transport Machinery Safely

Maximum transport speed for implement is

30 km/h or 20 mph. Some rough terrains require a

slower speed. Sudden braking can cause a towed load to

swerve and upset.

▲ Do not exceed 30 km/h or 20 mph. Never travel at a speed

which does not allow adequate control of steering and

stopping. Reduce speed if towed load is not equipped with

brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully loaded, weighs

more than 1.5 times the weight of towing vehicle.

▲ Carry reflectors or flags to mark drill in case of breakdown

on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions under

“Specifications and Capacities” on page 163.

▲ Do not fold or unfold the drill while the tractor is moving

Shutdown and Storage

▲ Unfold and lower drill.

▲ Block tires with wheel chocks provided.

▲ Detach and store drill in an area where children normally

do not play.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual. For brake

work, see specific safety information beginning on

page 138.

▲ Work in a clean, dry area.

▲ Unfold and lower the drill, put tractor in park, turn off

engine, and remove key before performing maintenance. If

work must be performed with implement raised, use centre

section lift lock and gauge lock channels provided.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow drill to cool completely.

▲ Disconnect battery grounding cable (-) before servicing or

adjusting electrical systems.

▲ Welding: Disconnect battery grounding. Protect hydraulic

lines. Avoid fumes from heated paint.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from drill before

operation.

2012-07-02 Table of Contents Index 166-371M

Page 14

10 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all drill functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave drill unattended with tractor engine running.

▲ Do not stand between the tractor and drill during hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

▲ Watch out for wires, trees, etc., when folding and raising

drill. Make sure all persons are clear of working area.

166-371M Table of Contents Index 2012-07-02

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 11

Safety Decals

WarningSafety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decal and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

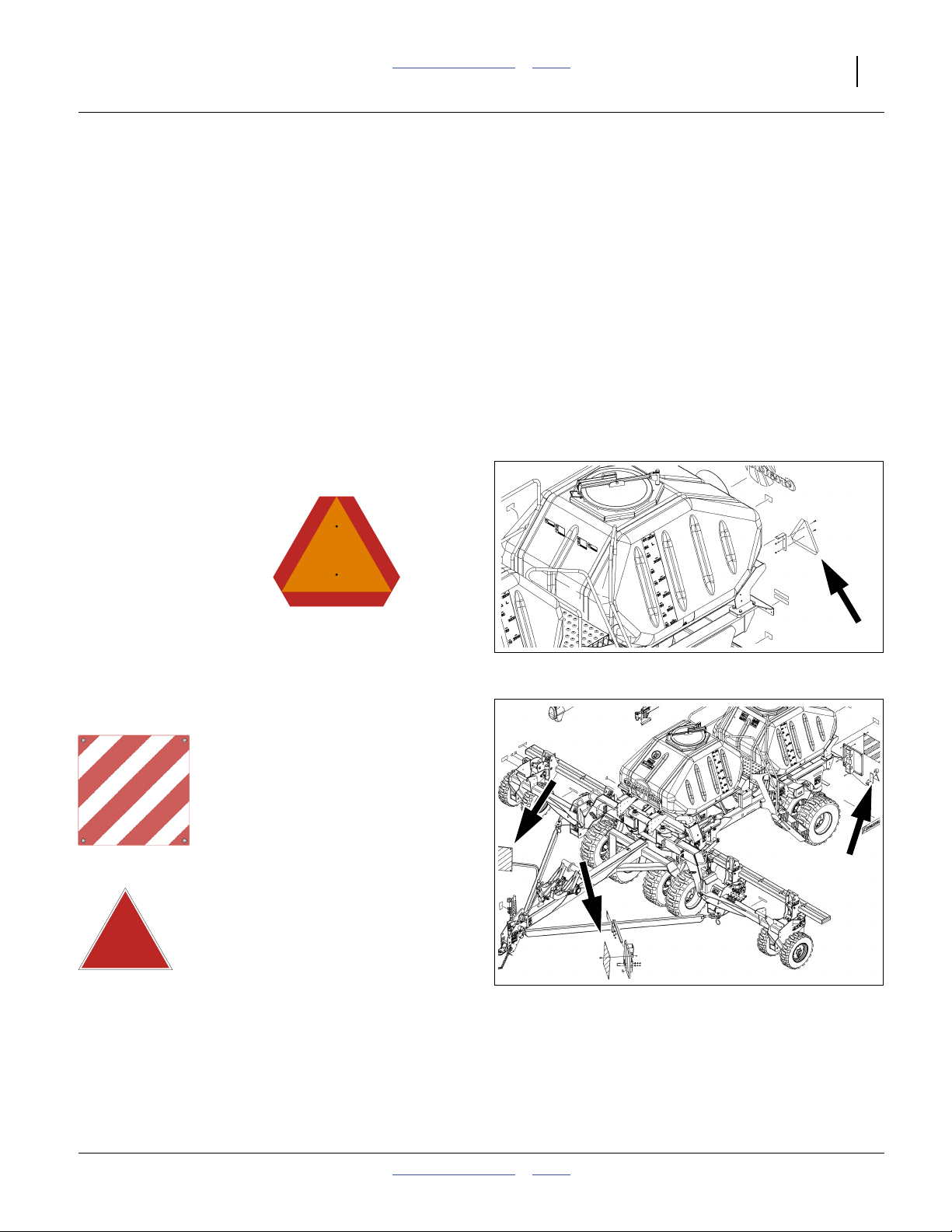

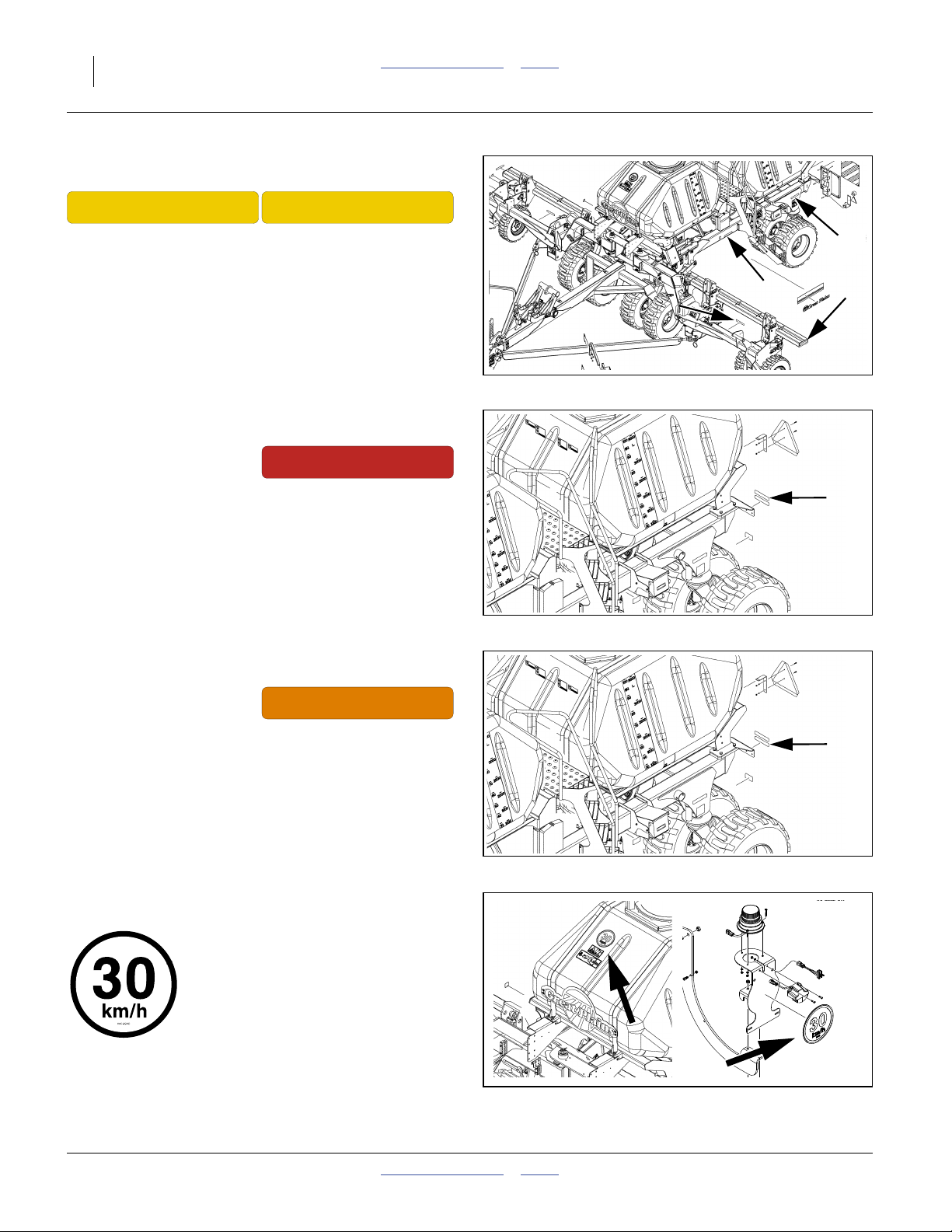

Reflector: Slow Moving Vehicle (SMV)

NTA907: n/a

(International models use

833-398C panels and

833-399C reflectors)

NTA3007: 818-055C

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

At centre of rear caster sub-frame cross-tube;

1 total

See “Transport Safety Information” on page 50.

Reflectors: Fluorescent Panels

NTA907: 833-398C NTA3007: n/a

(North American models use

818-055C SMV reflectors,

838-266C red reflectors &

838-267C amber reflectors.)

Reflectors: Red Triangle

NTA907: 833-399C NTA3007: n/a

(North American models use

818-055C SMV reflectors,

838-266C red reflectors &

838-267C amber reflectors.)

panels: one each tongue draw bar,

panels and triangles: one each corner, rear mainframe;

4 panels and 2 triangles total

See “Transport Safety Information” on page 50.

32439

32422

2012-07-02 Table of Contents Index 166-371M

Page 16

12 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Reflectors: Amber

NTA907: 838-265C NTA3007: 838-265C

On outside end face, each wing opener tool bar,

on rear face, each wing main tool bar,

on outside face, mainframe sides ahead of ladder,

on outside face, rear caster mount weldment;

8 total.

See “Transport Safety Information” on page 50.

32422

Reflectors: Red

NTA907: n/a

(International models use

833-398C panels and

833-399C reflectors)

On upper rear corners of mainframe (below Daytime);

2 total

See “Transport Safety Information” on page 50.

NTA3007: 838-266C

Reflectors: Daytime

NTA907: n/a

(International models use

833-398C panels and

833-399C reflectors)

On upper rear corners of mainframe (above Red);

2 total

See “Transport Safety Information” on page 50.

NTA3007: 838-267C

Transport: Warning: Speed

NTA907: 848-398C NTA3007:

See 818-188C

32439

32439

32422

On front upper face of front hopper, and

on decal plate below rear beacon;

32377

2 total

See “Transport Safety Information” on page 50.

166-371M Table of Contents Index 2012-07-02

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 13

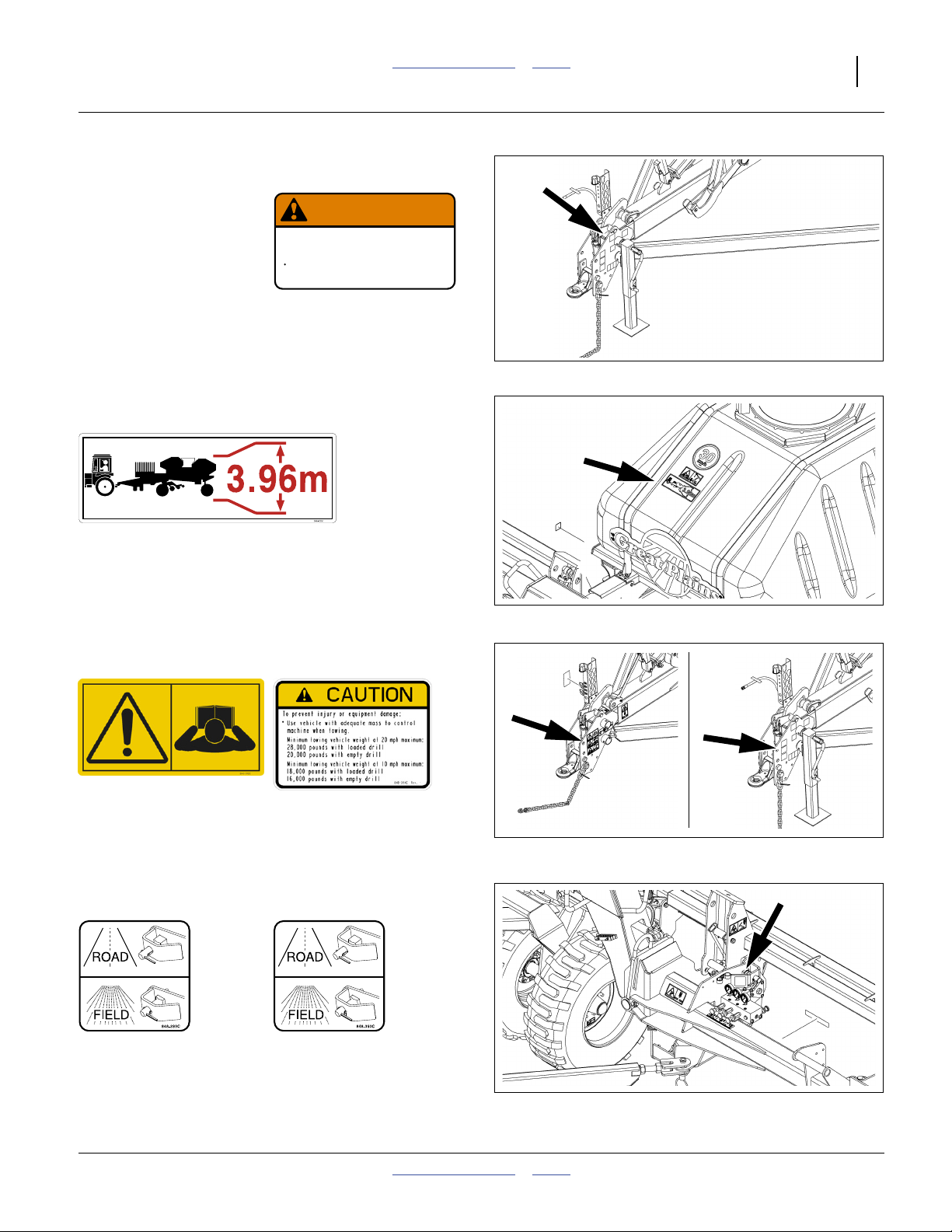

Transport: Warning: Speed

NTA907:

See 848-398C

NTA3007: 818-188C

WARNING

EXCESSIVE SPEED HAZARD

To Prevent Serious Injury or Death:

Do Not exceed 20 mph maximum transport

speed. Loss of vehicle control and/or machine

can result.

On side of tongue near hitch;

one total

See “Transport Safety Information” on page 50.

Transport: Warning: Clearance

NTA907: 848-828C NTA3007: n/a

818-188C R v C

On front upper face on front hopper;

1 total

See “Transport Safety Information” on page 50.

Transport: Caution: Towing

NTA907: 848-512C NTA3007: 848-394C

On left side of tongue at hitch;

4 total

See “Transport Safety Information” on page 50.

Transport: Road/Field

NTA907: 848-393C NTA3007: 848-393C

32422

On mid-wing transport locks;

2 total

See “Transport Safety Information” on page 50.

2012-07-02 Table of Contents Index 166-371M

Page 18

14 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

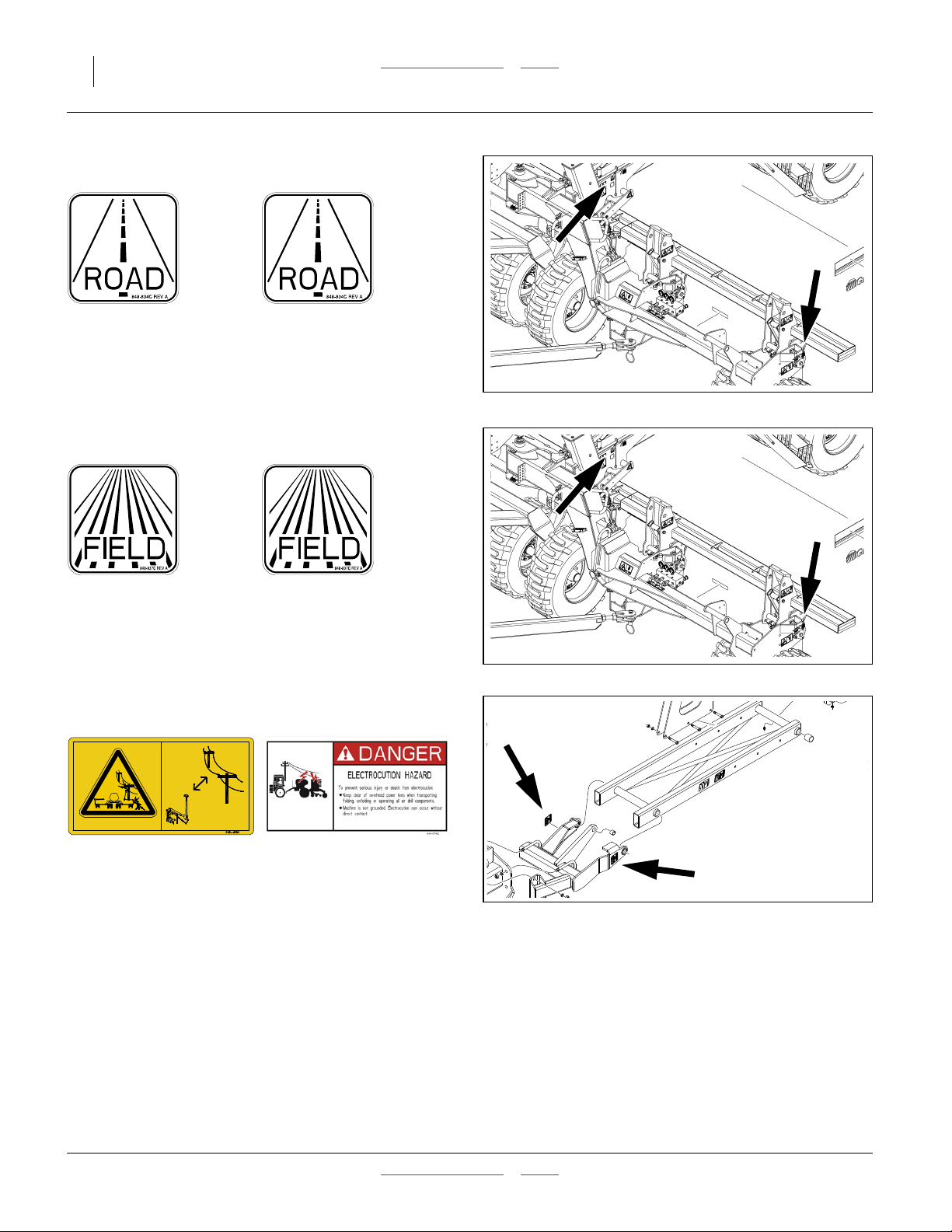

Transport: Road

NTA907: 848-834C NTA3007: 848-834C

On frame sides at centre section transport locks,

and on wing end transport locks;

4 total

See “Transport Safety Information” on page 50.

32422

Transport: Field

NTA907: 848-837C NTA3007: 848-837C

On frame sides at centre section transport locks,

and on wing end transport locks;

4 total

See “Transport Safety Information” on page 50.

Danger: Electrocution, Marker (Option)

NTA907: 848-408C NTA3007: 848-574C

On marker mount weldment at end of wing;

4 total

See “Marker Safety Information” on page 73.

32422

29433

166-371M Table of Contents Index 2012-07-02

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 15

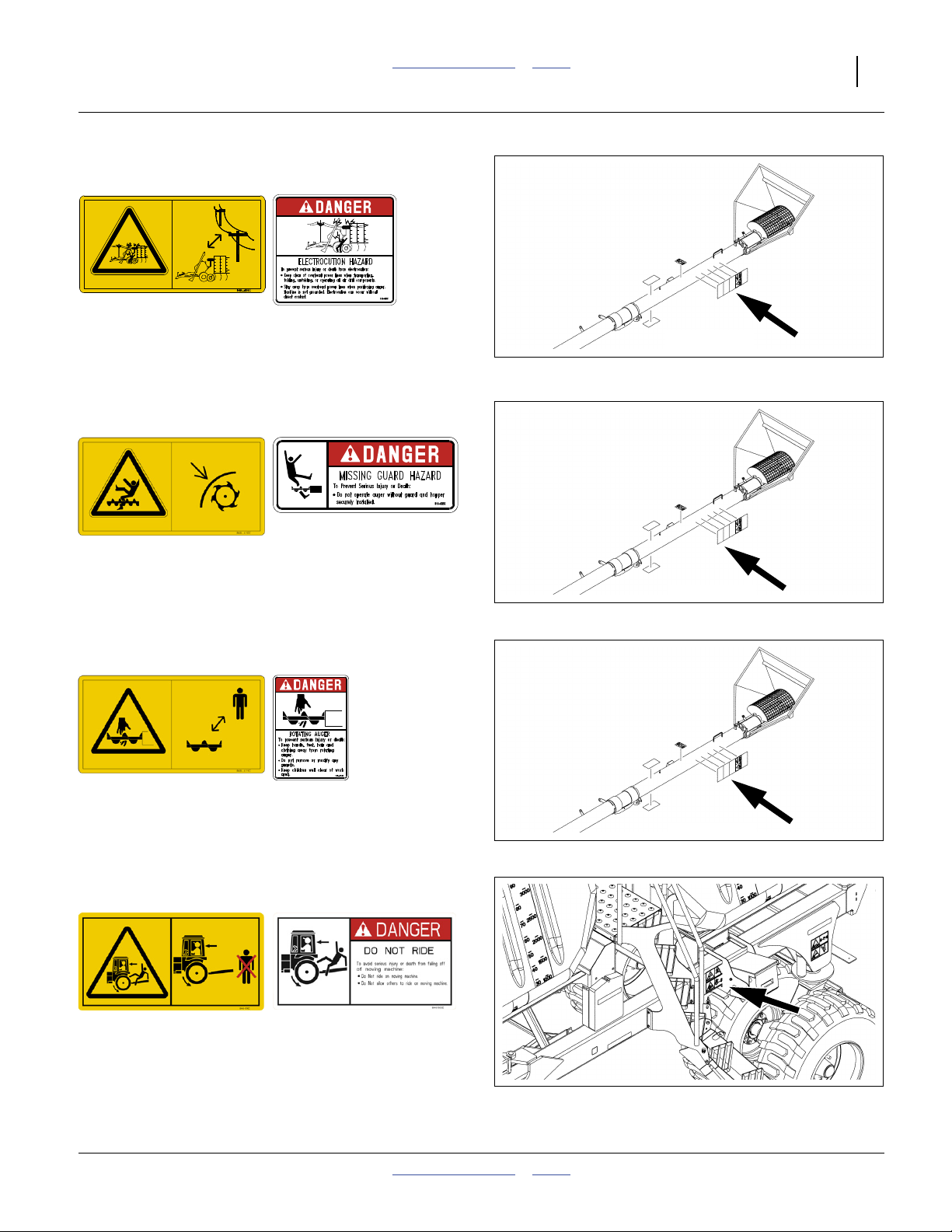

Danger: Electrocution, Auger (Option)

NTA907: 848-409C NTA3007: 818-627C

On auger tube near lower handles;

one total

32422

See “Auger Safety Information” on page 59.

Danger: Missing Guard (Option)

NTA907: 848-410C NTA3007: 818-633C

On auger tube nearest inlet;

1 total

See “Auger Safety Information” on page 59.

Danger: Rotating Auger (Option)

NTA907: 848-411C NTA3007: 818-634C

On auger tube near Missing Guard decal;

1 total

See “Auger Safety Information” on page 59.

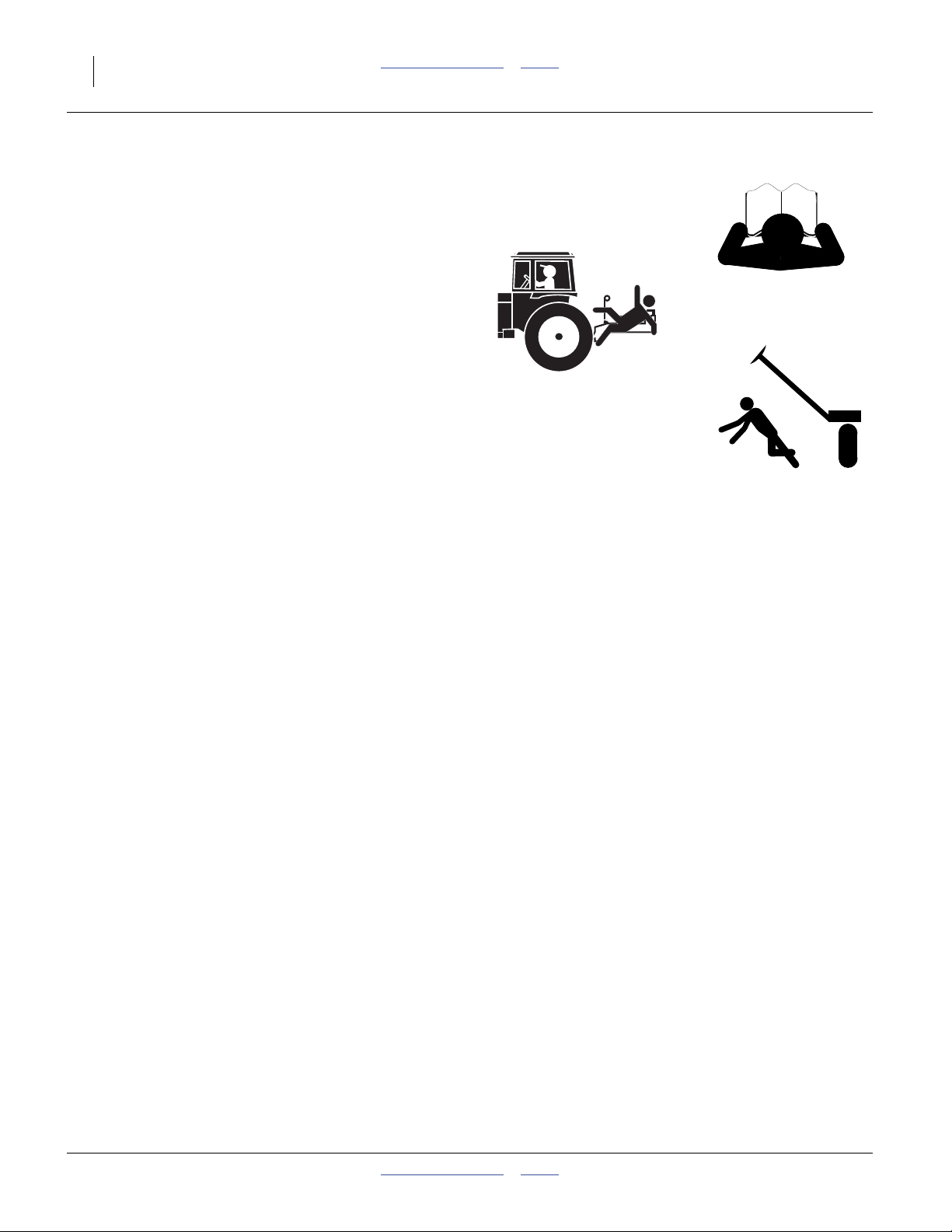

Danger: Do Not Ride

NTA907: 848-511C NTA3007: 848-583C

32422

32422

On cart side frame, left of ladder;

1 total

32422

2012-07-02 Table of Contents Index 166-371M

Page 20

16 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

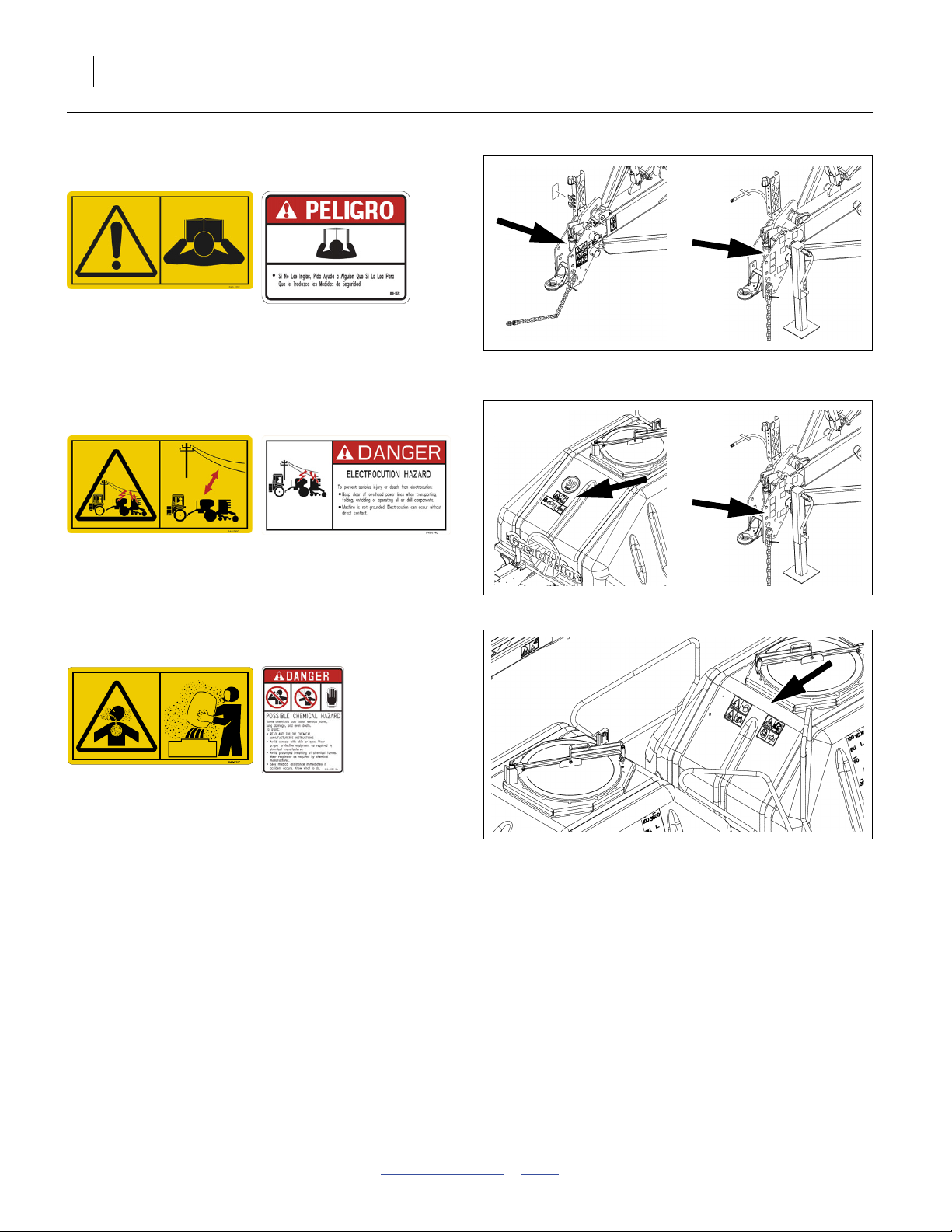

Danger: Read Manual

NTA907: 848-512C NTA3007: 818-557C

(818-557C Spanish text advises

readers to seek translation)

On left side of tongue near hitch;

32422

32439

1 each total

Danger: Electrocution

NTA907: 848-516C NTA3007: 848-574C

32422

NTA907: front upper face of front hopper,

NTA3007: left side of tongue near hitch;

1 total

Danger: Chemicals

NTA907: 848-520C NTA3007: 818-323C

On each hopper near lid, walkboard side;

2 total

See “Loading Material Safely” on page 65.

32439

32422

166-371M Table of Contents Index 2012-07-02

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 17

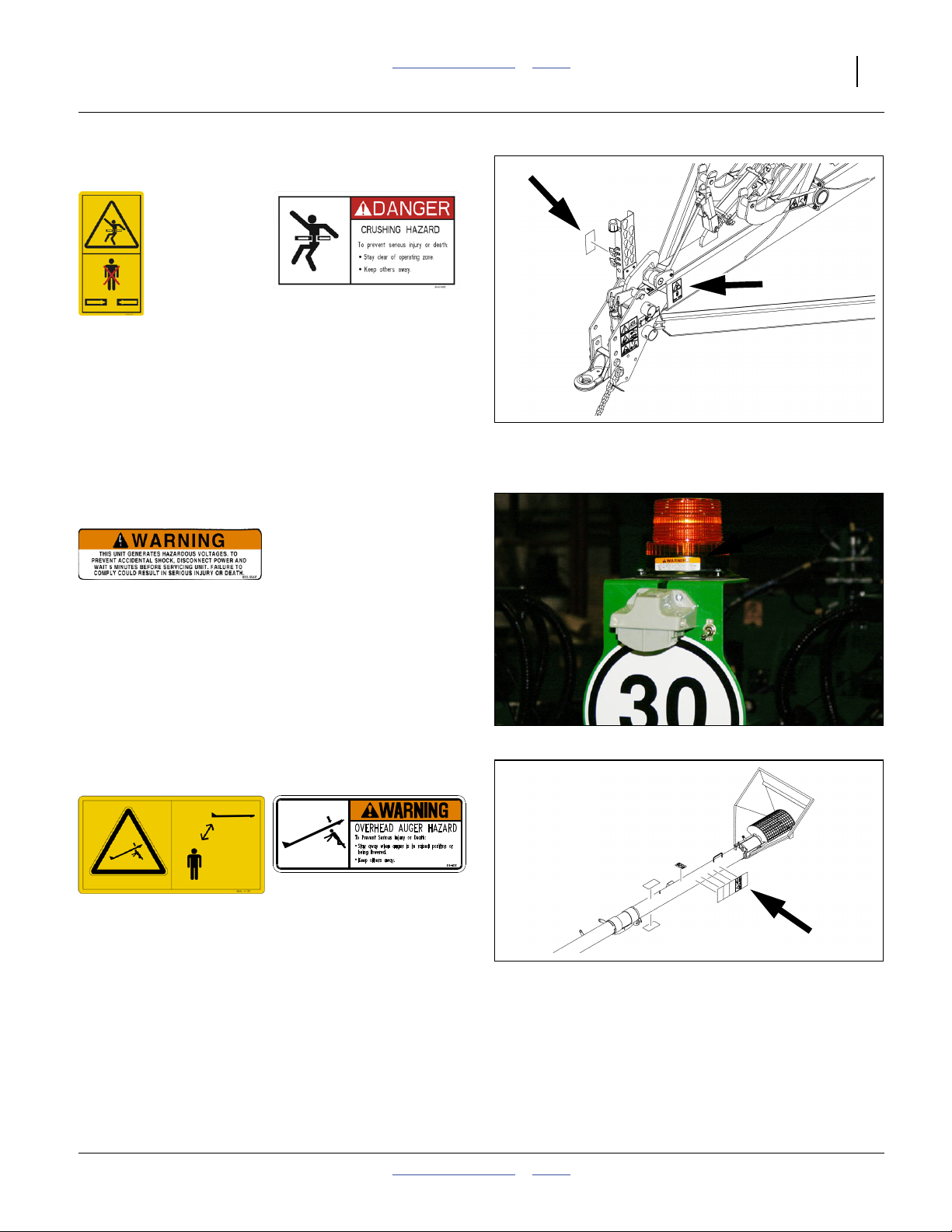

Danger: Hitch Crushing

NTA907: 848-523C NTA3007: 848-581C

On left side of hitch near behind pull bars;

2 total

See “Hitching Tractor to Drill” on page 27.

See “Unfolding Safety Information” on page 34.

See “Lowering/Raising Safety Information” on

32422

page 42.

See “Folding Safety Information” on page 44.

See “Down-Force Safety Information” on page 101.

Warning: Shock Hazard

NTA907: 833-563C NTA3007: n/a

On base of strobe beacon;

one total

This decal is not separately available. If missing or

damaged, replace entire 833-365C beacon unit.

See “Beacon Operation (NTA907 only)” on page 31

and “Beacon Maintenance (NTA907 only)” on

page 147.

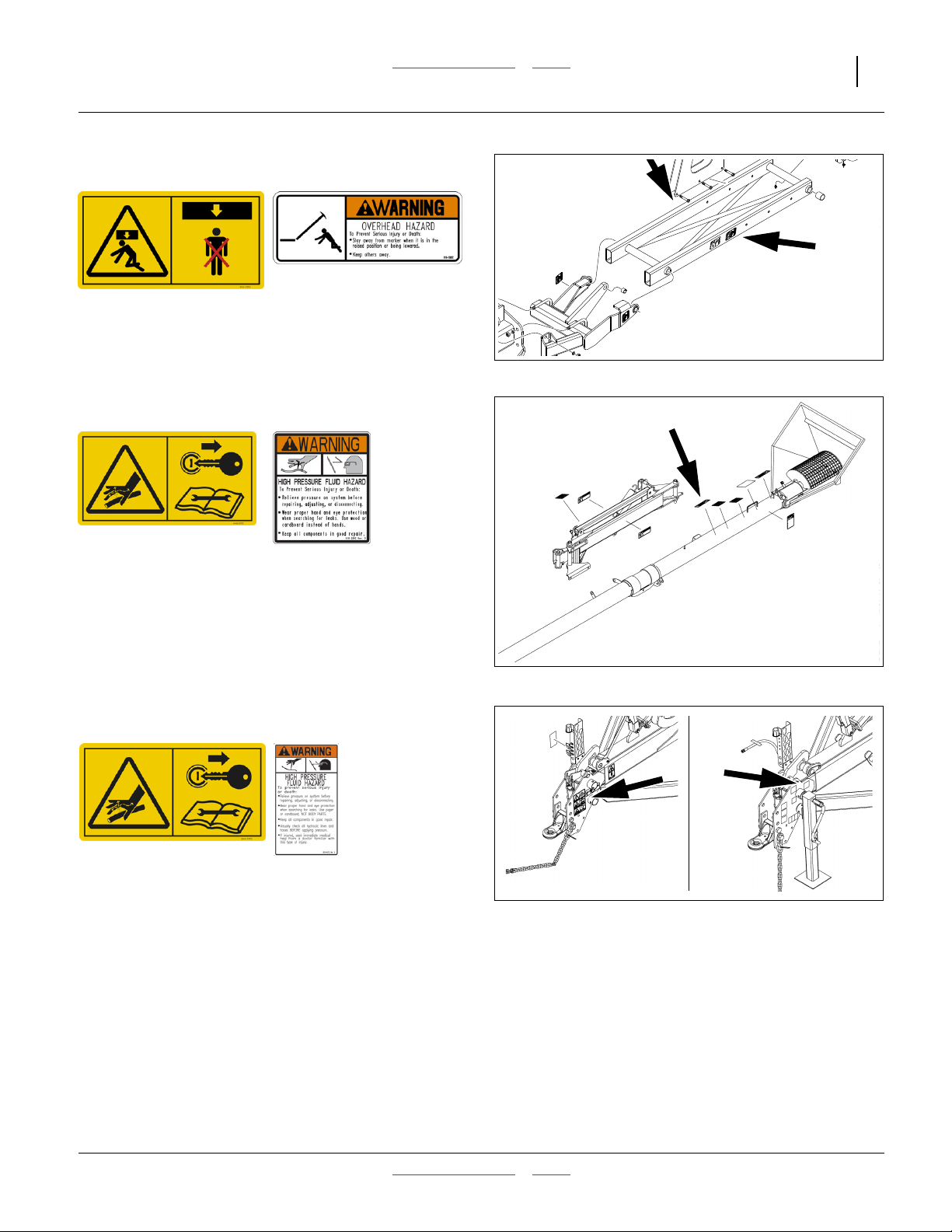

Warning: Overhead Auger (Option)

NTA907: 848-413C NTA3007: 818-622C

On outside face of auger arm,

on each end of auger tube;

3 total

See “Remain Clear of Overhead Lines” on page 8 and

“Auger Safety Information” on page 59.

31234

32422

2012-07-02 Table of Contents Index 166-371M

Page 22

18 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

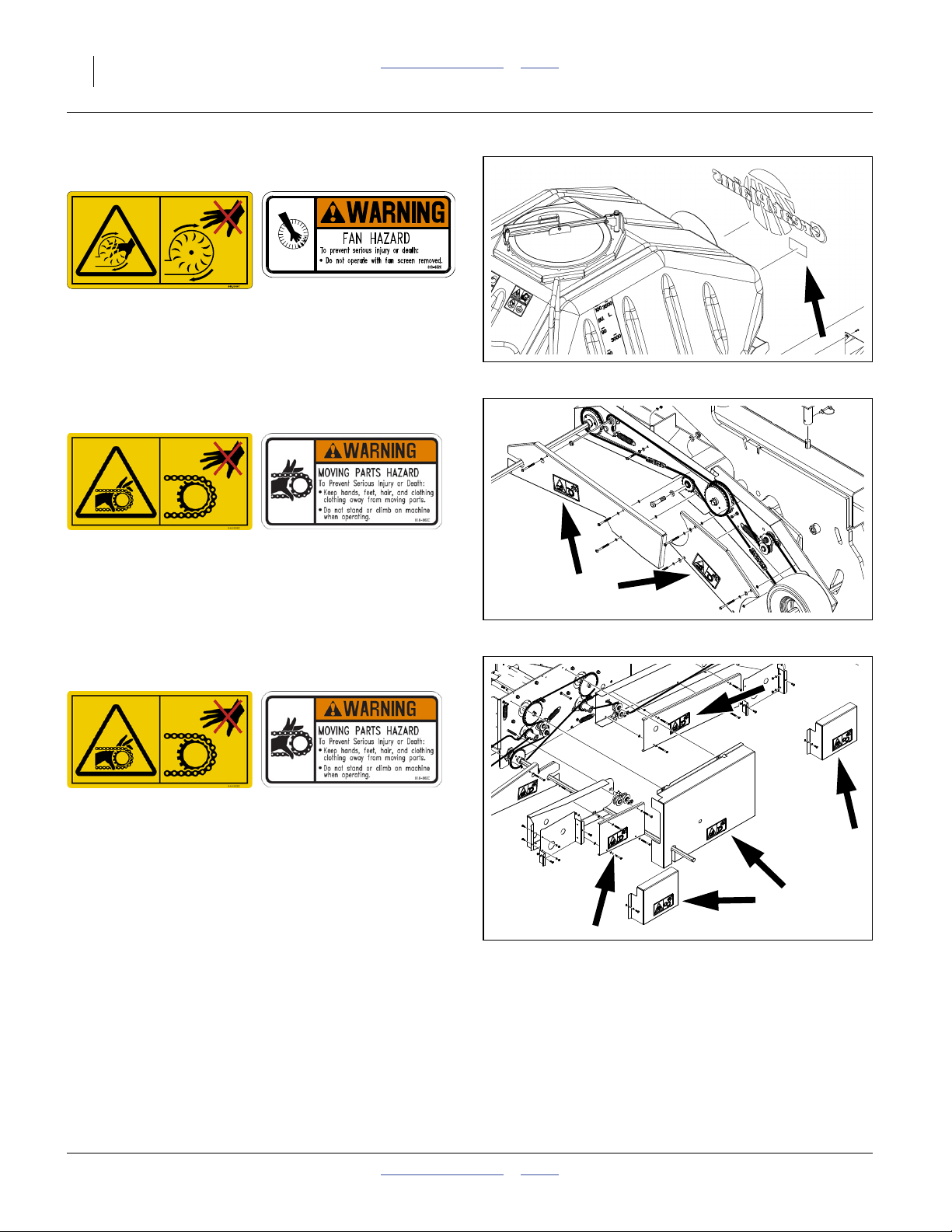

Warning: Fan Hazard

NTA907: 848-508C NTA3007: 818-632C

On rear main frame below fan screen cage;

one total

See “Fan Safety Information” on page 71.

32422

Warning: Moving Chain

NTA907: 848-509C NTA3007: 818-860C

On guards of contact to jackshaft drive system;

4 total

See “Calibration Crank Safety Information” on

page 69.

Warning: Moving Chain

NTA907: 848-509C NTA3007: 818-860C

On guards of main jackshaft to gearbox,

on guards of gearbox output drive systems, and

on meter box input guards;

5 total

See “Calibration Crank Safety Information” on

page 69.

32399

32397

166-371M Table of Contents Index 2012-07-02

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 19

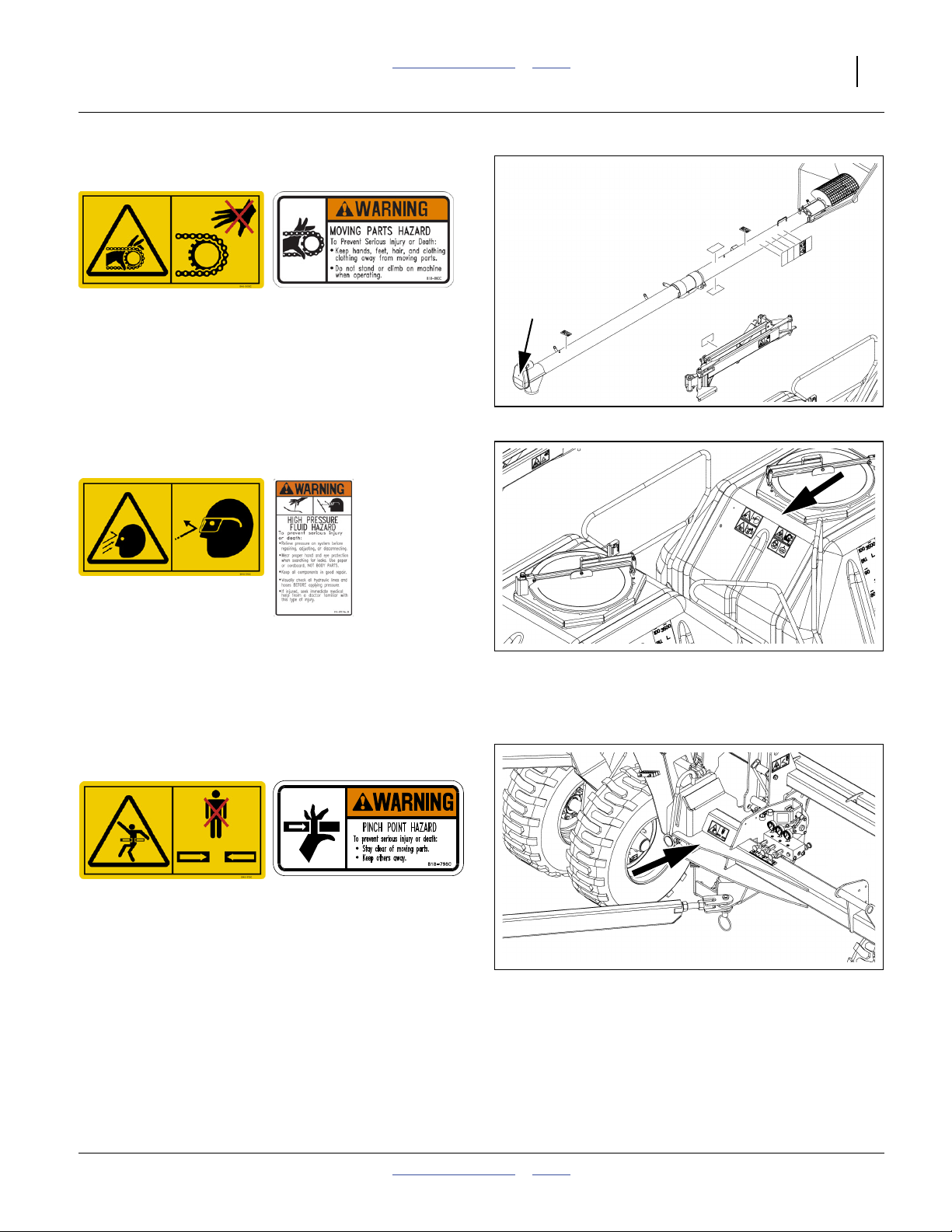

Warning: Moving Chain (Option)

NTA907: 848-509C NTA3007: 818-860C

On guard at auger hydraulic motor;

1 total

See “Auger Safety Information” on page 59.

32422

Warning: Wear Eye Protection

NTA907: 848-510 NTA3007: 818-437C

On each hopper near lid, walkboard side;

2 total

See “Hydraulic Hose Hook-Up” on page 28.

See “Hydraulic Maintenance Safety Information” on

page 128.

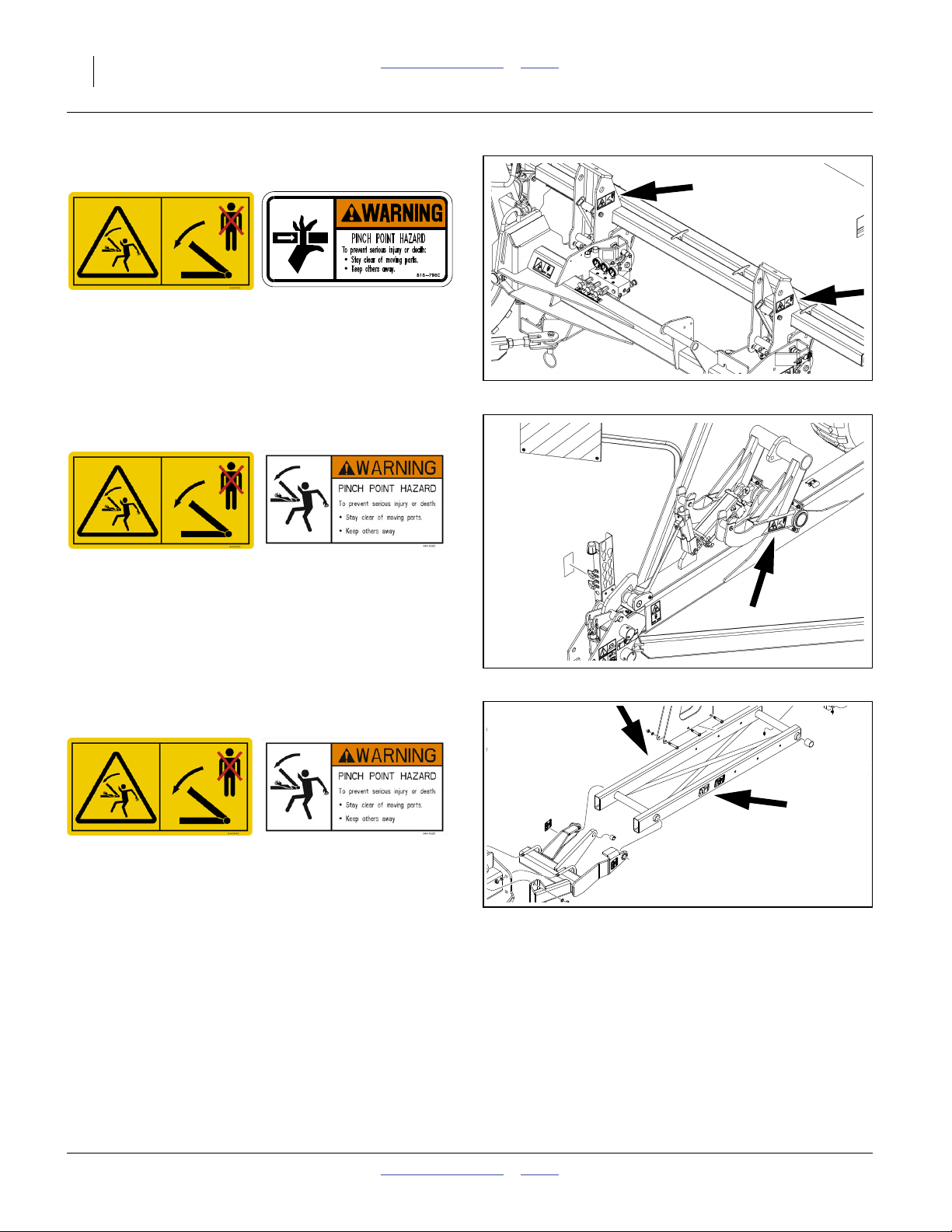

Warning: Pinch Point

NTA907: 848-513C NTA3007: 818-798C

On each wing weldment above pull bar attach point;

2 total

32422

32422

2012-07-02 Table of Contents Index 166-371M

Page 24

20 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Warning: Pinch Point

NTA907: 848-514C NTA3007: 818-798C

On outside faces of wing parallel arm mount weldments;

4 total

Warning: Pinch Point

NTA907: 848-514C NTA3007: 848-582C

On outside faces transport hook;

2 total

32422

Danger: Marker Pinch/Crush (Option)

NTA907: 848-514C NTA3007: 848-582C

On each side of inner marker arm or arm pivot;

4 total

See “Marker Safety Information” on page 73.

32422

29433

166-371M Table of Contents Index 2012-07-02

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 21

Warning: Overhead Marker (Option)

NTA907: 848-515C NTA3007: 818-580C

On each side of inner marker arm or arm pivot;

4 total

See “Marker Safety Information” on page 73.

29433

Warning: High Pressure Fluid (Option)

NTA907: 848-517C NTA3007: 818-339C

On (optional) auger near lower operating control;

1 total

See “Auger Safety Information” on page 59.

See “Fan Safety Information” on page 71.

See “Down-Force Safety Information” on page 101.

See “Weight Transfer Safety Information” on

page 107.

Warning: High Pressure Fluid

NTA907: 848-517C NTA3007: 818-437C

32439

On side of tongue at hitch;

one total

32422

32439

See “Hydraulic Hose Hook-Up” on page 28.

See “Hydraulic Maintenance Safety Information” on

page 128

2012-07-02 Table of Contents Index 166-371M

Page 26

22 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

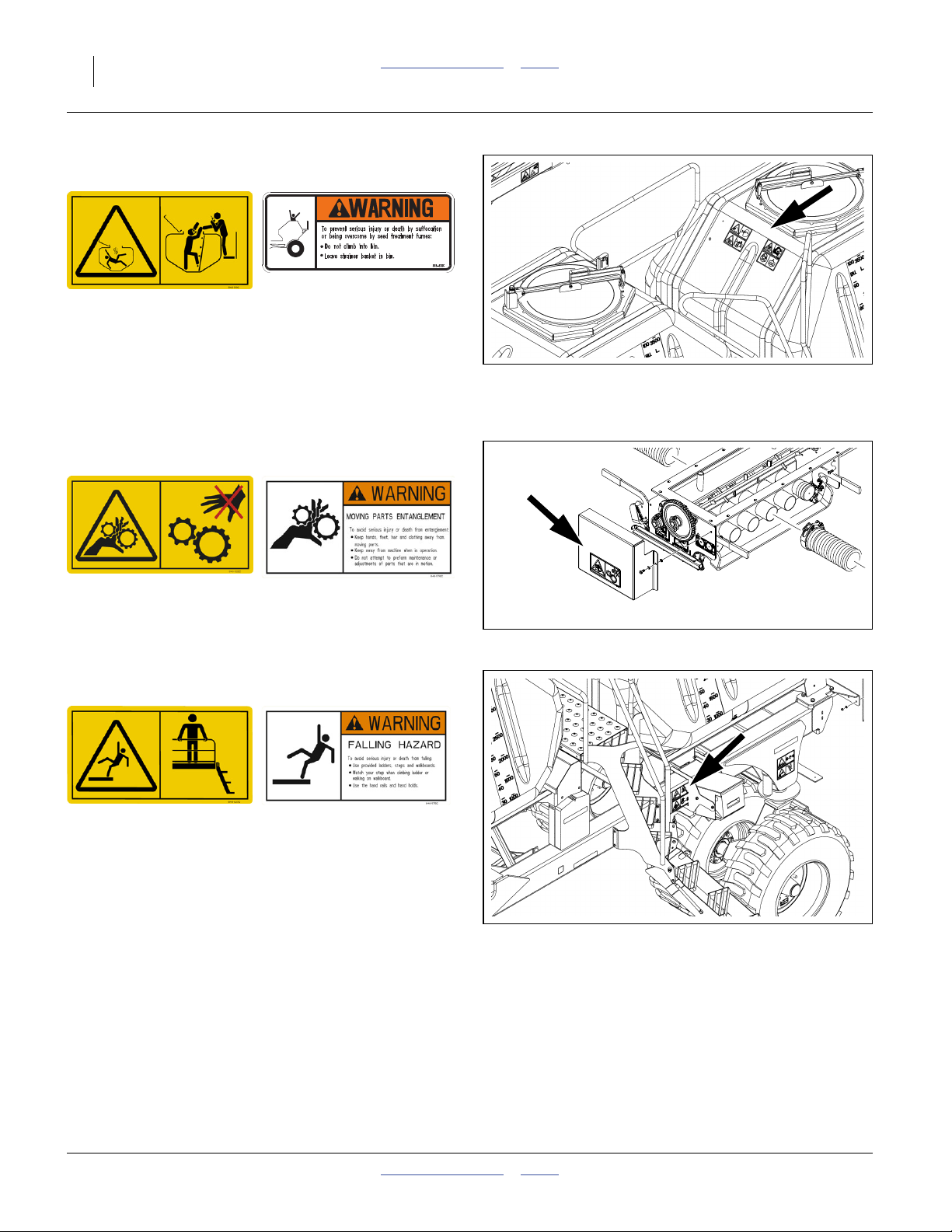

Warning: Confined Space

NTA907: 848-519C NTA3007: 818-628C

On each hopper near lid, walkboard side;

2 total

See “Hopper Lid Safety Information” on page 55.

See “Loading Material Safely” on page 65.

See “Material Clean-Out” on page 124.

Warning: Moving Gears

NTA907: 848-522C NTA3007: 848-576C

On bottom of hoppers above final Range gears;

1 or 2 total

See “Seed Meter Final Drive Range” on page 88.

32422

32414

Warning: Falling Hazard

NTA907: 848-527C NTA3007: 848-575C

On left side of mainframe near ladder;

1 total

See “Ladder Operations” on page 54.

32422

166-371M Table of Contents Index 2012-07-02

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 23

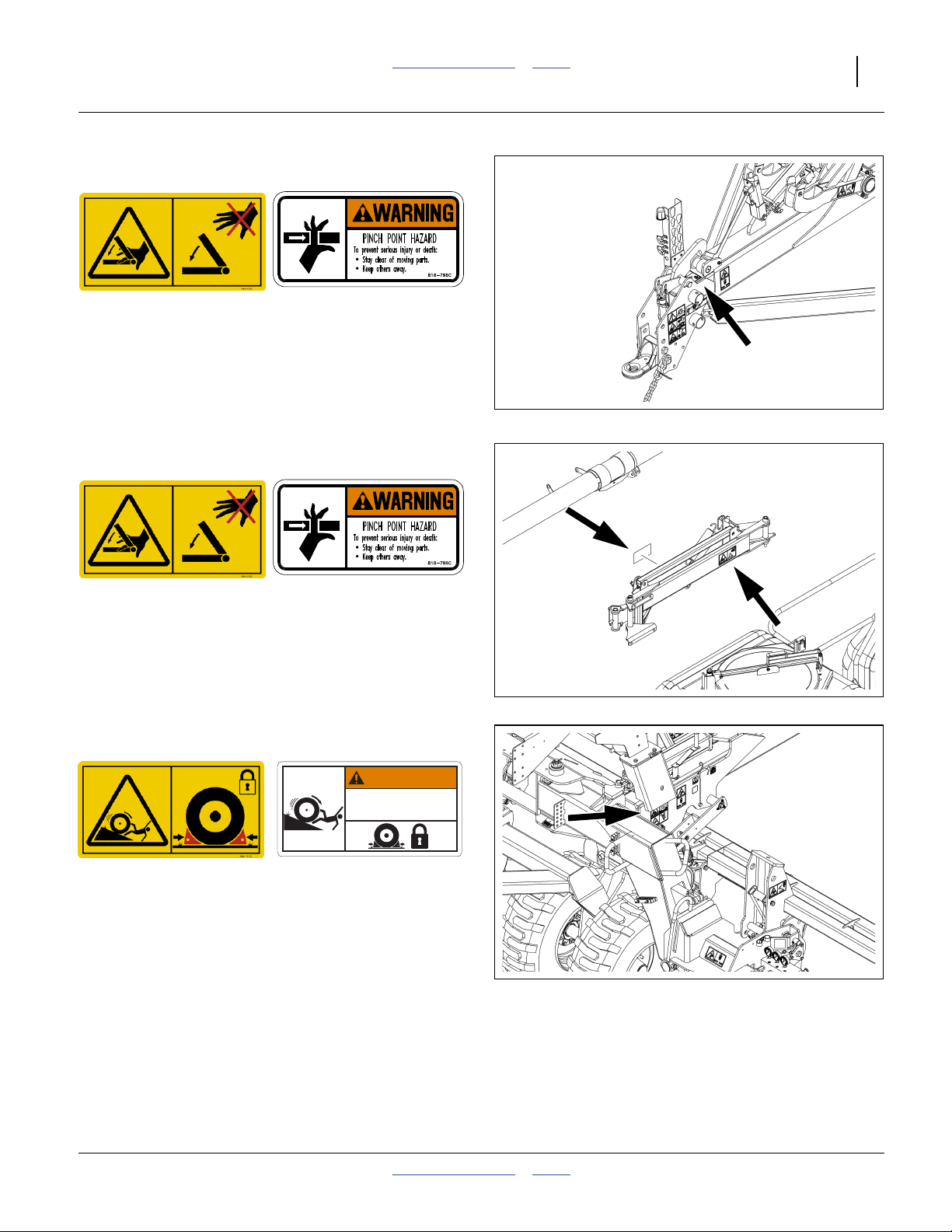

Warning: Pinch Point

NTA907: 848-531C NTA3007: 818-798C

Under tongue hook near hitch;

1 total

See “Unfolding Safety Information” on page 34.

32422

Warning: Pinch Point, Auger (Option)

NTA907: 848-531C NTA3007: 818-798C

On rear* faces of auger arms;

4 total

* When arms are fully extended.

Warning: Roll-Away

NTA907: 848-757C NTA3007: 818-760C

WARNING

ROLLING HAZARD

To avoid serious injury or death rom free ro ling machine

Use prov ded chock blocks to chock cart tires in

•

direction of grade when mach ne is parked

Chock both sides of wheel f grade is undetermined

•

On mainframe side above front transport tires;

2 total

See “Transporting the Air Drill” on page 50.

8 8-7 0C

2012-07-02 Table of Contents Index 166-371M

Page 28

24 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Warning: Unexpected Movement

NTA907: 848-838C NTA3007: 848-841C

CRUSHING HAZARD

To avod serious injury or death from crushing:

Mach ne moves rearward when fod ng w ngs forward

Stay away f om machne whi e folding and unfolding

On mainframe above rear casters;

2 total

See “Transporting the Air Drill” on page 50.

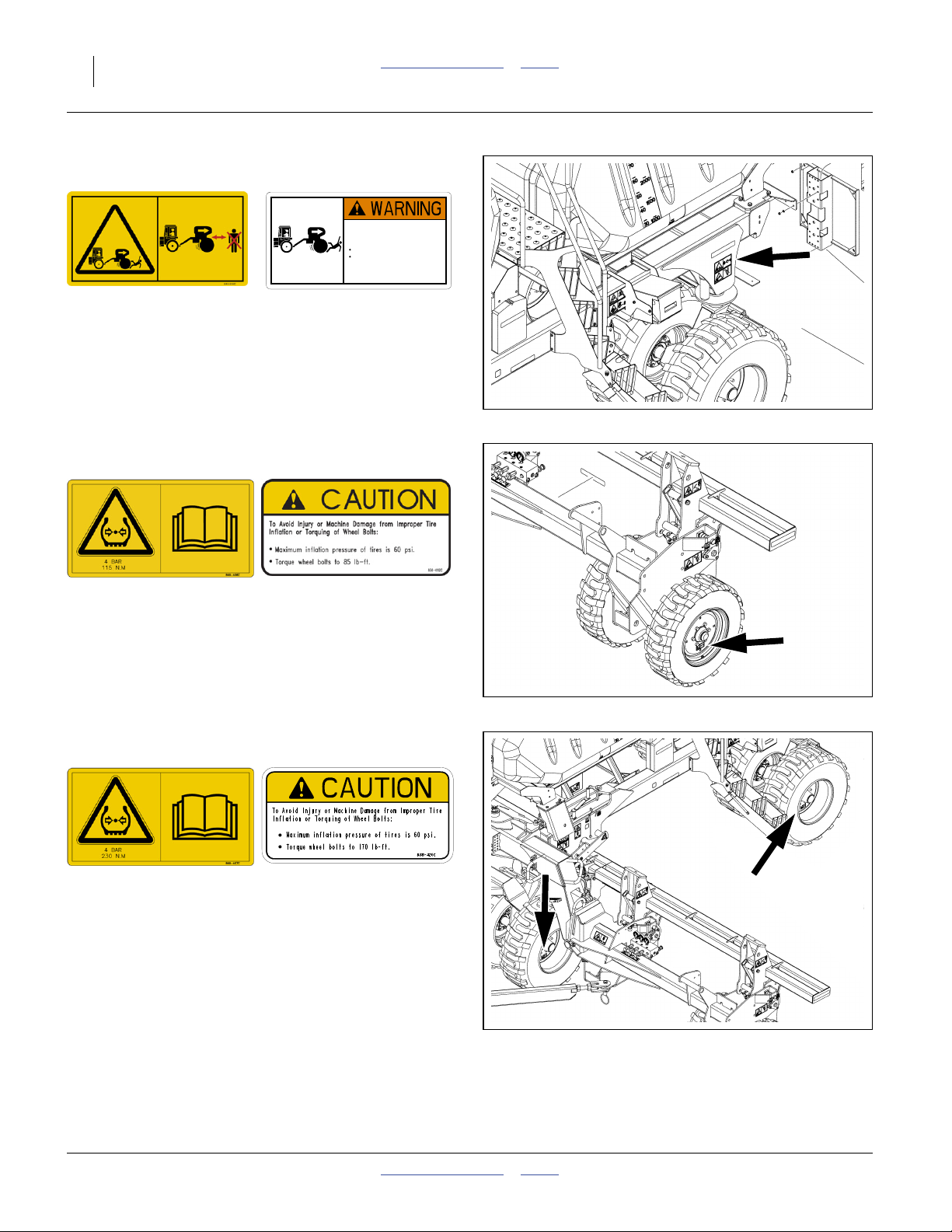

Caution: Tire Pressure and Torque

NTA907: 848-406C NTA3007: 838-092C

On outside of each wing gauge wheel tire;

4 total

See “Transport Safety Information” on page 50.

8 8 841C

32422

Caution: Tire Pressure and Torque

NTA907: 848-407C NTA3007: 838-426C

On outside of each transport wheel tire;

8 total

See “Transport Safety Information” on page 50.

166-371M Table of Contents Index 2012-07-02

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 25

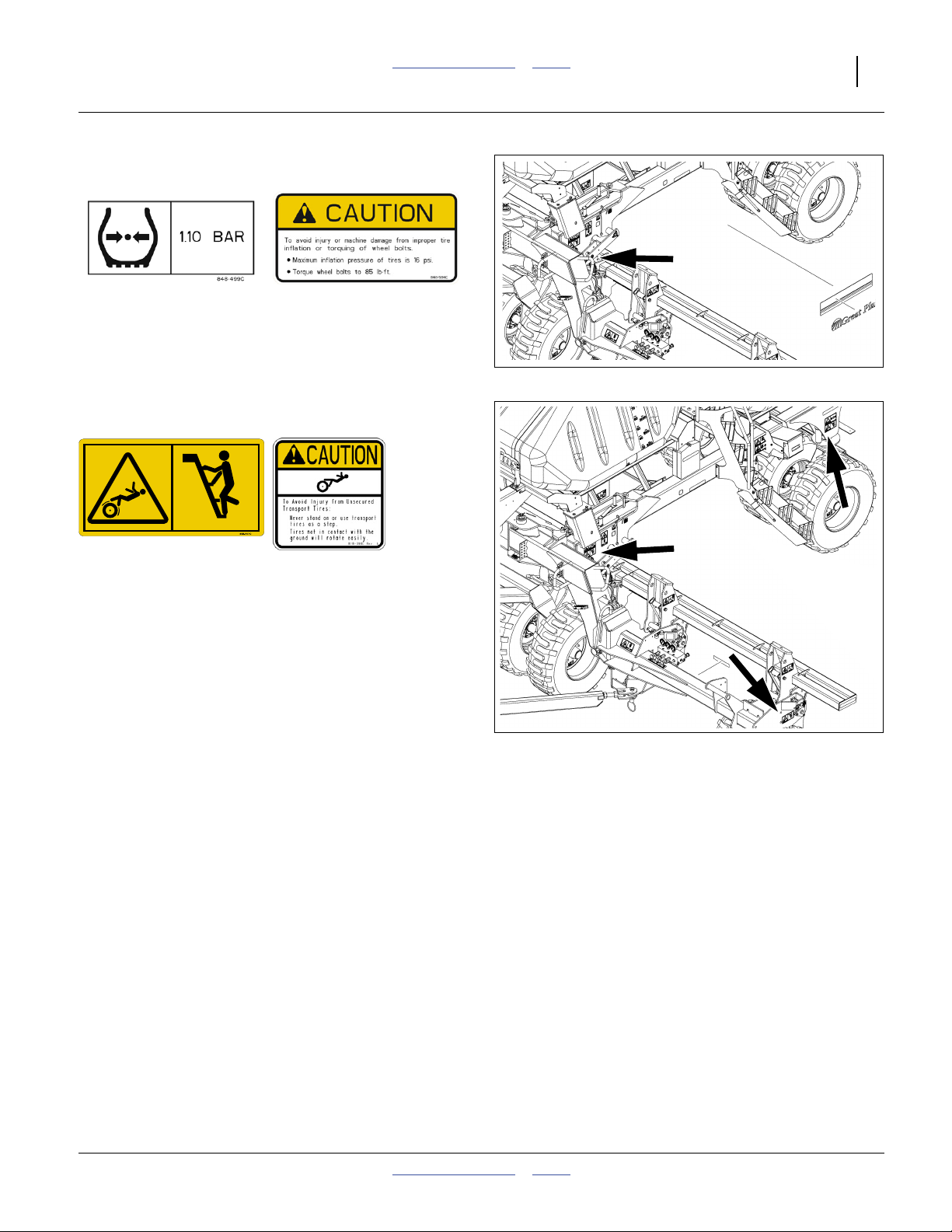

Caution: TyreTire Pressure and Torque

NTA907: 848-499C NTA3007: 848-584C

One each contact drive arm;

2 total

See “Transport Safety Information” on page 50.

32422

Caution: Tires Not A Step

NTA907: 848-507C NTA3007: 818-398C

On outside face of caster weldments,

on side face of mainframe above transport tires,

on outside face of wing gauge wheel weldments;

6 total

See “Unfolding Safety Information” on page 34.

See “Folding Safety Information” on page 44.

See “Down-Force Safety Information” on page 101.

See “Weight Transfer Safety Information” on

page 107.

32422

2012-07-02 Table of Contents Index 166-371M

Page 30

26 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Preparation and Setup

This section helps you prepare your tractor and NTA907

or NTA3007 for use, and covers seasonal tasks, and task

when the tractor/drill configuration changes.

Before using the NTA907 or NTA3007 in the field, you

must hitch the drill to a suitable tractor, inspect systems

and level the drill. Before using the drill for the first time,

and periodically thereafter, certain adjustments and

calibrations are required.

Initial Setup

See “Appendix B - Initial Setup” on page 183 and

“Appendix C - Option Installation” on page 185 for

pre-delivery items (normally completed by dealer), and

first-time/infrequent setup tasks, including:

❑ Install seed monitor console in tractor (page 183).

❑ Remove protective film from large highway

reflectors.

❑ Set marker extension (page 183) and speed.

Seasonal Setup

On initial delivery, use with a new tractor, and seasonally,

check and as necessary, complete these items before

continuing to the routine setup items:

❑ Bleed hydraulic system (page 128).

❑ Wing levelling and alignment (page 145).

❑ Speed sensor calibration (DICKEY-john® Air Cart

Control manual).

❑ Blow out entire air system to remove condensation.

Check air flow at each row, for evidence of plugging.

❑ De-grease exposed cylinder rods if so protected at

last storage.

Pre-Planting Setup

Complete this checklist before routine setup:

❑ Read and understand “Important Safety

Information”, pages 5 through 10.

❑ Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

❑ Check that all grease fittings are in place and

lubricated. See “Lubrication and Scheduled

Maintenance” on page 148.

❑ Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged.

See “Safety Decals” on page 11.

❑ Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Tire Inflation Chart”

on page 166.

166-371M Table of Contents Index 2012-07-02

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 27

Hitching Tractor to Drill

Crushing Hazard:

You may be severely injured or killed by being crushed

between the tractor and drill. Do not stand or place any part of

your body between drill and moving tractor. Stop tractor

engine and set tractor parking brake before attaching cables

and hoses.

1. Move the tractor to near hitching position.

2. Put the tractor in Park.

Set the tractor’s parking brake.

Shut down the tractor.

Refer to Figure 5 (which depicts the parking jack removed,

but not yet stored)

3. Adjust the NTA907 or NTA3007 hitch to match your

tractor draw bar height, using crank of tongue jack on

side of tongue.

Note: The precise height is not critical, as the NTA907 or

NTA3007 levelling is set at the mainframe and is

independent of tongue level.

4

Figure 5

Drill Hitched

29522

Hitch Failure Risk:

The hitch may be mounted inverted if necessary, but always

have two (2) bolts in two holes of both tongue and hitch. A

hitch failure could result in a serious accident and is likely to

result in implement and/or tractor damage.

4. Securely attach the safety chain to an anchor on a

tractor capable of pulling the NTA907 or NTA3007.

Refer to Figure 5 and Figure 6

5. Use crank to raise parking jack foot . Remove

3

pin and jack.

6. Move jack to upper stob . Rotate to horizontal.

Re-pin.

Equipment Damage Risk:

Store the parking jack on the upper stob in a horizontal

orientation, foot to rear. Using the lower stob, or any other

orientation, will result in jack and tongue damage.

7. Connect hydraulic hoses (page 28).

8. Connect brake hoses (option, page 29).

9. Connect electrical cables (page 30).

10. Remove and store main tongue parking stand.

1 2

4

4

3

Figure 6

Jack in Storage Location

1

2

32384

2012-07-02 Table of Contents Index 166-371M

Page 32

28 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Hydraulic Hose Hook-Up

High Pressure Fluid Hazard:

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs,

seek immediate medical assistance from a physician familiar

with this type of injury.

Only trained personnel should work on system hydraulics!

Great Plains hydraulic hoses are colour coded to help

you hook-up hoses to your tractor outlets. Hoses that go

to the same remote valve have the same colour bands.

The fan pressure hose (black) must be connected to a

circuit capable of continuous flow at high volume.

The lift/down-pressure hose (blue) must be connected to

a circuit capable of continuous pressure.

Note: This implement is compatible only with tractors

having Closed Centre hydraulics.

Refer to Figure 7

To distinguish hoses on the same hydraulic circuit, refer

to handle symbols. The hose with an extended-cylinder

symbol feeds a cylinder base end. The hose with a

retracted-cylinder symbol feeds a cylinder rod end.

For the hydraulic fan, connect the hose with a retracted

cylinder symbol to the pressure side of the motor.

The fan motor further requires hook-up of a (third) case

drain line, which returns lubricating/cooling fluid.

marker hoses are provided on the cart even if markers

are not installed on the implement. See “Console

Installation” on page 183 prior to first hitching.

Figure 7

Hose Handles

Colour Hydraulic Function

Black Fan / Auger (Option)

Blue Opener Lift / Down-Pressure

Gray Weight Transfer

Green Fold / Tilt / Bout Marker (Option)

Yellow Transport Hook

“SUMP” Sump

“BRAKES” Hydraulic trailer brakes (Option)

31733

Protecting Fan Hydraulic Motor Seals

Low Pressure (Case) Drain Connection:

1. Attach case drain hose to low pressure drain

connection. See Notice at right.

2. Connect low pressure motor return hose, marked

“SUMP”, to a high volume low pressure return port.

The sump line is distinguished by a large

2.7 cm (1.06 inch) diameter) quick coupler.

3. Connect hydraulic hoses to tractor remotes.

166-371M Table of Contents Index 2012-07-02

Equipment Damage Risk:

Case Drain Hose must be attached first, prior to inlet and

return hoses being connected, to prevent damage to hydraulic

motor seals. The case drain has the smaller 6.4 mm (1⁄4inch)

I.D. hose and small, flat-face, low-seep connector. DO NOT

connect the case drain line to a power-beyond port.

Case Drain Hose must be detached last, to prevent damage to

the fan motor. To allow pressure relief during temperature

cycles, it is normal for this line to release small amounts of oil

even when stored with the connector elevated.

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 29

Brake Hook-Up (Option)

Two drill braking (trailer braking) systems are available:

• Dual-line air system (Figure 8), and

• Single-line hydraulic system (Figure 9).

In both systems, the tractor’s trailer brake remote port(s)

operate a hydraulic slave cylinder on the drill.

Tractor trailer braking systems are normally integrated

with the tractor brakes, and operate the trailer brakes

when tractor brakes are used during tractor movement.

Trailer brakes typically are not automatically engaged

when the tractor transmission is in Park, and may not be

engaged by any tractor Emergency Brake.

Braking Hazards:

Make sure the operator understands when drill brakes are

engaged and when they are released (record tractor behaviour

on page 52).

Also understand and implement tractor operational

restrictions when trailer brakes are used. For example, it is

generally necessary to inter-tie split brakes, and avoid

differential (steering braking) if trailer brakes are used.

Air Brake Hook-Up (Option)

Refer to Figure 10

1. Open petcock at reservoir tank. Drain any water

from tank. Close petcock.

Refer to Figure 11

2. Inspect gladhands before connecting. Clean

elastomer seal surfaces . Blow debris out of inlet

ports. Check screen condition.

3. Connect the “Brake”, “Service” or “Control” line first.

This line is Blue-coded.

1

2

Figure 8

Air Brake System

Figure 9

Hydraulic Brake System

29578

29588

1

This line operates the drill brakes.

Figure 10

29578

Air Brake Reservoir

2012-07-02 Table of Contents Index 166-371M

Page 34

30 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

4. Connect the “Provision” or “Supply” line. This line is

Red-coded.

The Provision line charges a reservoir tank on the

drill. The Brake line operates a valve system which

meters tank air to the master cylinder on the drill.

Braking Hazard:

Do not use the NTA907 or NTA3007 with a “single-line” air

brake system. This drill is designed for transport speeds that

require an air brake system to be “dual-line”. A single-line

tractor system cannot charge the tank that powers the drill

brakes.

Roll-Away Hazard:

When unhitching, disconnect the red (control) line first. This

sets the brakes on the drill.

Hydraulic Brake Hook-Up (Option)

Refer to Figure 12

This is a single hydraulic line, connected to the tractor

“Brake” outlet.

The factory default connector is a3⁄4inch poppet-style

QD (Quick Disconnect). If this is incompatible with your

tractor, it may be replaced by a connector that mates to,

or can be adapted to:

3

⁄4inch male ORB (O-Ring Boss), or

3

⁄4inch female JIC (Joint Industry Conference, 37°

flare).

RED

Figure 11

Air Brake Connectors

Figure 12

Hydraulic Brake Connector

BLU

2

29646

29647

Electrical Hook-Up

Refer to Figure 13

Make sure tractor is shut down with accessory power off

before making connections.

1. Mate lighting connector to tractor outlet.

2. Mate monitor connector to tractor harness.

3. Mate any optional or after-market electrical

connectors.

Make connections prior to drill movement. Some drill

hydraulic circuits are under monitor control.

Figure 13

Lighting Connector (N.American)

and Monitor Connector

166-371M Table of Contents Index 2012-07-02

26467

27080

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 31

Beacon Operation (NTA907 only)

Refer to Figure 14

The flash strobe beacon and rear plate illumination lamp

may be disabled for field operations using a switch

below the beacon.

This switch does not control the brake/turn/running lights

at left and right rear.

See also “Beacon Maintenance (NTA907 only)” on

page 147.

1

1

Stow Wheel Chocks

• IMPROPER USE MAY RESULT IN PRODUCT FAILURE

• SELECT WHEEL CHOCK ACCORDING TO VEHICLE TYPE AND SIZE

• ALWAYS USE IN PAIRS AND ON FIRM SURFACES

• MULTIPLE PAIRS MAY BE REQUIRED IN EXTREME CONDITIONS

• CHOCK IN DIRECTION OF GRADE

• CHOCK BOTH SIDES OF WHEEL IF DIRECTION OF GRADE IS UNDETERMINED

• USE ONLY AFTER PARKING BRAKE IS APPLIED AND TESTED

• CENTER CHOCKS SNUGLY ANDSQUARELY AGAINST TREAD OF EACH WHEEL

• ALWAYS TEST CHOCKS TO INSURE THEY MEET REQUIREMENTS

• DO NOT DRIVE OVER WHEEL CHOCKS

1. Verify that the tractor transmission is in Park, and

that the tractor’s parking brake is set (per step 2).

Refer to Figure 15 and Figure 16

Two sets of wheel chocks (4 chocks total) are provided

to secure the drill when parked. These provide the most

safety when installed ahead and behind the outside front

transport tires.

When not in use, the chocks are stored in holders

mounted on the side frames. The chocks are held in

place by gravity when correctly stowed in the holders.

2. Remove the chocks from the wheel on one side.

WARNING

817-925C

1

2

Figure 14

Beacon Switch (Off)

2

1

Figure 15

Front Outside Wheels Chocked

32472

32375

Roll-Away Hazard:

If one chock is extremely difficult to remove, or the drill moves

significantly when the chock is removed, investigate the cause

before removing the chocks on the other side. If no tractor is

hitched, or the tractor is not securely parked, the drill could

roll away after chock removal, and cause an accident resulting

in death, serious injury and substantial property damage.

3. Store one chock in the bottom of a holder,

upside-right, tall end of chock toward frame.

4. Store the other chock in the top channel guides of

the holder, upside-down, short end toward frame.

5. Repeat step 2 through step 4 for the other side.

2012-07-02 Table of Contents Index 166-371M

2

Figure 16

Wheel Chocks Stowed

32376

1

Page 36

32 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Heights and Levelling

All frame sections must be at the correct height and level

to maintain even planting depth.

Periodic frame-levelling adjustments should not be

necessary. If you are having problems with uneven

depth, check drill levelness and follow these procedures.

1. Complete “Bleeding Hydraulics” on page 128.

2. Unfold the drill fully (page 34).

Set Tongue Height

Drill must be unfolded for this procedure.

Refer to Figure 17

Set the initial tongue height, tractor hitch, and changing

implement hitch configuration as necessary. Distance is

measured at top of tongue to ground level

If desired height cannot be attained with normal range of

hitch, hitch may be relocated in tongue bolt holes.

Always have two bolts in use, through two sets of hitch

holes and two sets of tongue holes.

Checking Drill Height

The drill is designed to operate with all sections of the

main tool bar nominally 76.2 cm (30 inch) above the

planting surface. The height of the centre section is not

routinely adjustable. Set planting depth with row unit

adjustments.

When lowering the drill for the first time on the planting

ground:

1. Completely lower the main tool bar. If necessary, first

lift off transport locks, remove and stow locks.

2. Set hitch to planting height.

3. Pull forward a meter or so (a few feet).

Note: Level frame in planting conditions.

Failure to do so may result in implement not

producing desired results.

49.5 cm

(19.5 in)

Figure 17

Initial Tongue Height

29523

Mis-Adjustment Risk:

Drill must be fully lowered to field position (with openers into

ground) and hitch height must be set before making

side-to-side adjustments.

Refer to Figure 18

4. Check tool bar height across drill. See page 145 for

further detail and adjustment.

Figure 18

Tool Bar Height Check

29519

Marker Setup

Prior to first use, check and adjust:

• See “Initial Marker Setup” on page 183.

166-371M Table of Contents Index 2012-07-02

Prior to each planting session, check and adjust:

• See “Marker Disc Adjustment” on page 115.

Page 37

Great Plains Manufacturing, Inc. Table of Contents Index 33

Operating Instructions

This section covers general operating procedures.

Experience, machine familiarity, and the following

information will lead to efficient operation and good

working habits. Always operate farm machinery with

safety in mind.

Pre-Start Checklist

Perform the following steps before transporting the

NTA907 or NTA3007 drill to the field.

High Pressure Fluid Hazard:

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure. Fluid escaping from a very small hole can

be almost invisible. Use paper or cardboard, not body parts,

and wear heavy gloves to check for suspected leaks. If an

accident occurs, seek immediate medical assistance from a

physician familiar with this type of injury.

❑ Review “Important Safety Information” on page 5.

❑ Lubricate as indicated at “Lubrication and

Scheduled Maintenance” on page 148.

❑ Check all tires for proper inflation. See “Tire

Inflation Chart” on page 166.

❑ Check all bolts, pins, and fasteners. Torque as

shown in “Torque Values Chart” on page 167.

❑ Check drill for worn or damaged parts. Repair or

replace parts before going to the field.

❑ Check hydraulic hoses, fittings, and cylinders for

leaks. Repair or replace before going to the field.

29382

CFM Overview

The Control Function Module (CFM) is located below the

DICKEY-john® console terminal. The CFM controls a

bank of solenoid valves on the drill, in the

Fold/Tilt/Marker circuit.

On/Up opens the solenoid valve for the function.

Off/Down closes the solenoid valve for the function.

Control Function Module

Pre-Start Configuration

Figure 19

CFM Switch Operation

MASTER Fold Tilt Marker

Off (down) Off (down) Off (down) Off (down)

When MASTER is On, turn On only one function switch at a

time. To avoid unexpected movement of unintended drill

hydraulic components, no more than one of the Fold, Tilt or

Marker switches should ever be On at the same time.

Note: The CFM “MASTER” switch is the master for the

CFM only. It does not affect power to the monitor

terminal or other drill functions.

2012-07-02 Table of Contents Index 166-371M

Neutral Neutral Neutral Neutral

Hydraulic Circuit Operation

Lift

Fan,

Auger

Fold, Tilt,

Marker

29380

Transport

Hooks

Page 38

34 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Unfolding the Drill

Unfolding Safety Information

Roll-Away Hazard:

Unfold only on hard level ground. Allow ample room. Drill,

tractor, or both must be free to move during unfolding. On a

slope, roll away could occur, causing an accident resulting in

death, serious injury and substantial property damage.

Electrocution Hazard:

Keep clear of overhead power lines when unfolding, operating,

folding or transporting the drill. Machine is not grounded. At

higher voltages, electrocution can occur without direct

contact. Any line voltage present on implement, cart or tractor

can cause severe injury or death.

Pinch Point and Crushing Hazards:

Keep people away from the drill and tractor during unfolding.

The distance between the tractor and the seed structure

decreases by 3.2 m (7.5 feet) during unfolding. Drill, tractor,

or both will move during this operation. Wings will tilt down

and swing out. Risks include:

▲ Pinching or crushing at pivot points and at multiple sites in

pivoting assemblies. Stay clear of the wing sweep arcs.

Coulters and row openers are sharp.

▲ Crushing under lowering/moving wing wheels, under

moving transport wheels, under lowering wings or under

lowering openers.

Falling Hazard - Tires Not a Step:

Do not use tires as steps or platforms. Wing gauge wheel tires

are off the ground in transport lift. Front and rear main

transport tires may be lifted and free to spin on unlevel ground

and at some weight-transfer and row down-force settings.

CRUSHING HAZARD

To avoid serious injury or death from crushing:

Machine moves rearward when foldng wings forward.

Stay away from machine while folding and unfolding

848-841C

General Cautions:

▲ Unfold only with markers resting in transport cradles.

Do not unfold with openers lowered, or machine damage will

result.

▲ Unfold only if hydraulics are bled free of air and fully

charged with hydraulic oil.

166-371M Table of Contents Index 2012-07-02

Page 39

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 35

Unfold: Summary of Steps

Follow the detailed instructions in step 1 through step 14

until this is a familiar operation.

❑ Check markers, auger and ladder stowed (below).

❑ Set mainframe transport locks to FIELD (below).

❑ Release transport hook (page 36).

❑ Set tractor for unfold (page 36).

❑ Unfold wings (page 37).

❑ Check openers raised (page 41).

❑ Set outer wing locks to FIELD (page 39).

❑ Tilt down wings (page 39).

Unfold: Check Drill Configuration

Wings can collide with a deployed auger or ladder.

1. Make sure:

ladder (page 54),

auger (page 64) and

markers (page 73)

are secured in their transport positions before

unfolding.

2. Move to level ground.

Pre-Unfold: Hydraulic Circuit Operation

Fan,

Lift

Neutral Neutral Neutral Neutral

Auger

Fold, Tilt,

Marker

Transport

Hooks

Sudden Implement Movement Risk:

Always have hydraulic levers in Neutral when operating CFM

switches.

3. Set/check that CFM switches (see page 33) are all

Off and hydraulic circuits are all in Neutral.

Shut off tractor.

Unfold: Two Mainframe Locks: ROAD to FIELD

Refer to Figure 21

4. On both sides of the mainframe, pull the wire handle

outward and move to rear slot. This allows hooks

(not shown) to move forward and enables lowering of

the centre section openers (after unfold). If the

openers are not fully raised, the hooks may not move

immediately. Tension in the wire loop handle is

expected in that case.

Note: Lowering the openers is not part of the unfold

operation, but these locks are easier to reach

before the wings are unfolded.

ROAD

Figure 20

CFM All Off

FIELD

Figure 21

Centre Locks: ROAD to FIELD

29380

32388

2012-07-02 Table of Contents Index 166-371M

Page 40

36 NTA907 or NTA3007 Table of Contents Index Great Plains Manufacturing, Inc.

Unfold: Release Transport Hook

5. Extend the Transport Hook circuit.

Set it to Neutral.

Note: Transport hook is on a dedicated circuit.

Refer to Figure 22 (which depicts the transport hook unlocked

and disengaged)

6. Pull the lift lock handle forward to disengage the

transport hook lock channel . Pull the handle until

the lock channel rests at fully open.

1

2

Un-Weight: Hydraulic Circuit Operation

Fan,

Lift

Neutral Neutral Neutral Extend

Auger

Fold, Tilt,

Marker

Transport

Hooks

2

1

7. Have everyone move clear of the drill. Retract the

transport hook cylinder:

Refer to Figure 23

8. Observe wings and gauge wheels lowering during

un-hook.

9. When the cylinder is fully retracted, set the transport

hook circuit to Neutral.

Unfold: Set Tractor

10. To allow tractor movement:

set steering straight ahead,

put tractor transmission in neutral and

release tractor parking brake.

Figure 22

Transport Hook Lock Channel

Un-Hook: Hydraulic Circuit Operation

Fan,

Lift

Neutral Neutral Neutral Retract

Auger

Wing Movement During Un-Hook

Fold, Tilt,

Figure 23

Transport

Marker

Un-Hook: Hydraulic Circuit Operation

Fan,

Lift

Neutral Neutral Neutral Neutral

Note: If tractor movement is not desired:

put tractor transmission in Park,

set tractor parking brake, and

release drill brakes (if drill is brake-equipped, and

tractor can separately control drill brakes).

Auger

Fold, Tilt,

Marker