Page 1

Operator’s Manual

NTA 2000D

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

© Copyright 2002 Printed

4/14/2005

Cover illustration may show optional equipment not supplied with standard unit.

148-632M

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Description of Unit . . . . . . . . . . . . . . . . . . . . . . . 12

Intended Usage . . . . . . . . . . . . . . . . . . . . . . . . . 12

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . 12

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . 12

Preparation and Set-Up . . . . . . . . . . . . . . . . . . . . . 13

Hitching Tractor to Implement . . . . . . . . . . . . . . 13

Hydraulic Hook-up . . . . . . . . . . . . . . . . . . . . . . . 14

Bleeding Hydraulic Systems . . . . . . . . . . . . . . . 15

Bleeding Lift Hydraulics. . . . . . . . . . . . . . . . 15

Bleeding Tongue Cylinder . . . . . . . . . . . . . . 15

Bleeding Marker Hydraulics . . . . . . . . . . . . 16

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . 17

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . 17

Field Operation . . . . . . . . . . . . . . . . . . . . . . . . . 17

Opener Operation . . . . . . . . . . . . . . . . . . . . 18

Fan Operation . . . . . . . . . . . . . . . . . . . . . . . 18

Marker Operation . . . . . . . . . . . . . . . . . . . . 18

Folding the Drill . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unfolding the Drill . . . . . . . . . . . . . . . . . . . . . . . 22

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Seeding Depth. . . . . . . . . . . . . . . . . . . . . . . . . . 26

Coulters. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Openers . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Coulter Depth . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Hydraulic Control. . . . . . . . . . . . . . . . . . . . . 27

Coulter Wing Adjustment . . . . . . . . . . . . . . 28

Coulter Mounting Height . . . . . . . . . . . . . . . 29

Coulter Down Pressure . . . . . . . . . . . . . . . . . . . 29

Added Weight . . . . . . . . . . . . . . . . . . . . . . . 29

Coulter Springs . . . . . . . . . . . . . . . . . . . . . . 29

Opener Depth . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Press Wheel Adjustment. . . . . . . . . . . . . . . 30

Opener Mounting Height . . . . . . . . . . . . . . . 30

Opener Down Pressure . . . . . . . . . . . . . . . . . . . 31

Disk Scraper Adjustment . . . . . . . . . . . . . . . . . . 31

Leaf Spring Adjustment . . . . . . . . . . . . . . . . . . . 31

Harrow Adjustments . . . . . . . . . . . . . . . . . . . . . . 32

Marker Adjustments . . . . . . . . . . . . . . . . . . . . . . 33

Folding Speed . . . . . . . . . . . . . . . . . . . . . . . 33

Disk Adjustments . . . . . . . . . . . . . . . . . . . . . 33

Cylinder Lock Channel. . . . . . . . . . . . . . . . . 33

Seed-Lok Lock Up . . . . . . . . . . . . . . . . . . . . . . . 34

Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Variator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Feed Flaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Half Width Shut-Off . . . . . . . . . . . . . . . . . . . . . . 35

Checking the Seeding Rate . . . . . . . . . . . . . . . . . . 36

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Calibrations for Number of Turns . . . . . . . . . . . . 37

Tramlining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Setting up for Tramlines . . . . . . . . . . . . . . . . . . . 38

Monitor Operation. . . . . . . . . . . . . . . . . . . . . . . . . 38a

Forward Speed/Sensor Calibration . . . . . . . . . 38d

Area/Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38f

Tramlining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38h

Fan Speed/Speed Alarms . . . . . . . . . . . . . . . . 38o

Seed Distribution Shaft Speed . . . . . . . . . . . . . 38p

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Maintenance and Lubrication . . . . . . . . . . . . . . . . 41

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Specifications and Capacities . . . . . . . . . . . . . . . . 47

Seed Rate Charts . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 58

Torque Values Chart for Common Bolt Sizes . . . 58

Hose Connection and Routing . . . . . . . . . . . . . . 59

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

© Copyright 2000 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains, Seed-Lok

All other brands and product names are trademarks or registered trademarks of their respective holders.

NTA 2000D 148-632M 9/13/2006

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Page 3

Great Plains Mfg., Inc.

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to

personal safety involved and extra

safety precaution must be taken.

When you see this symbol, be alert

and carefully read the message that

follows it. In addition to design and

configuration of equipment, hazard

control and accident prevention are

dependent upon the awareness, concern, prudence and proper training of

personnel involved in the operation,

transport, maintenance and storage

of equipment.

!

Be Aware of Signal Words

Signal words designate a degree or

level of hazard seriousness. The signal words are:

!

DANGER!

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for functional purposes, cannot be guarded.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

!

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Keep Riders

Off Machinery

Riders obstruct the operator’s view.

Riders could be struck by foreign

objects or thrown from machine.

▲ Never allow riders on implement.

▲ Never allow children to operate

equipment.

For Your Protection

▲ Thoroughly read and understand

Safety Decals, page 4. Read all

instructions noted on decals.

OFF

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine,

and remove key.

▲ Detach and store implement in an

area where children normally do

not play. Secure implement with

blocks and supports.

Handle

Chemicals Properly

Agricultural chemicals can be dangerous. Improper use can seriously

injure persons, animals, plants, soil

and property.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Follow instructions on container

label.

▲ Avoid inhaling smoke from any

type of chemical fire.

▲ Store or dispose of unused chem-

icals as specified by chemical

manufacturer.

9/13/2006

NTA 2000D 148-632M

1

Page 4

Great Plains Mfg., Inc.

Use Safety

Lights and Devices

Slow-moving tractors, self-propelled

equipment and towed implements

can create a hazard when driven on

public roads. They are difficult to see,

especially at night.

▲ Use flashing warning lights and

turn signals whenever driving on

public roads.

▲ Use lights and devices provided

with implement.

Transport

Machinery Safely

Maximum transport speed for implement is 20 mph. Some rough terrains

require a slower speed. Sudden

braking can cause a towed load to

swerve and upset.

▲ Do not exceed 20 mph. Never

travel at a speed that does not

allow adequate control of steering

and stopping.

▲ Comply with state and local laws.

▲ Reduce speed if towed load is not

equipped with brakes.

▲ Do not tow an implement that,

when fully loaded, weighs more

than 1.5 times the weight of towing vehicle.

Use A Safety Chain

▲ Use a safety chain to help con-

trol drawn machinery should it

separate from tractor drawbar.

▲ Use a chain with a strength rat-

ing equal to or greater than

gross weight of towed machinery.

▲ Attach chain to tractor drawbar

support or other specified

anchor location. Allow only

enough slack in chain to permit

turning.

▲ Replace chain if any links or end

fittings are broken, stretched or

damaged.

▲ Do not use safety

chain for towing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment. Refer to this manual

for additional information.

▲ Work in a clean, dry area.

▲ Lower implement to ground, put

tractor in park, turn off engine,

and remove key before performing

maintenance.

▲ Allow implement to cool completely.

▲ Inspect all parts. Make sure parts

are in good condition and installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before operation.

NTA 2000D 148-632M 9/13/2006

2

Page 5

Great Plains Mfg., Inc.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first-aid kit and fire extin-

guisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to

loud noise can cause hearing

impairment or hearing loss, wear

suitable hearing protection such

as earmuffs or earplugs.

▲ Because operating equipment

safely requires your full attention,

avoid wearing radio headphones

while operating machinery.

Avoid High

Pressure Fluids Hazard

Escaping fluid under pressure can

penetrate skin, causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or card-

board, not body parts, to check for

suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a doc-

tor immediately. Any fluid injected

into the skin must be surgically

removed within a few hours or

gangrene may result.

Safety at All Times

Thoroughly read and understand this

manual before operation. Refer to

Safety Decals, page 4. Read all

instructions noted on decals.

▲ Be familiar with all implement

functions.

▲ Operate implement from driver’s

seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Do not dismount a moving tractor.

Dismounting a moving tractor could

cause serious injury or death.

▲ Do not stand between tractor and

implement during hitching.

▲ Keep hands, feet and clothing

away from power-driven parts.

▲ Wear snug-fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of working area.

▲ Do not turn tractor too tight, caus-

ing implement to ride up on

wheels. This could result in injury

or equipment damage.

Tire Safety

Tire changing can be dangerous and

should be performed by trained personnel using correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side–NOT in front of or over

the tire assembly. Use a safety

cage if available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for weight

involved.

9/13/2006

NTA 2000D 148-632M

3

Page 6

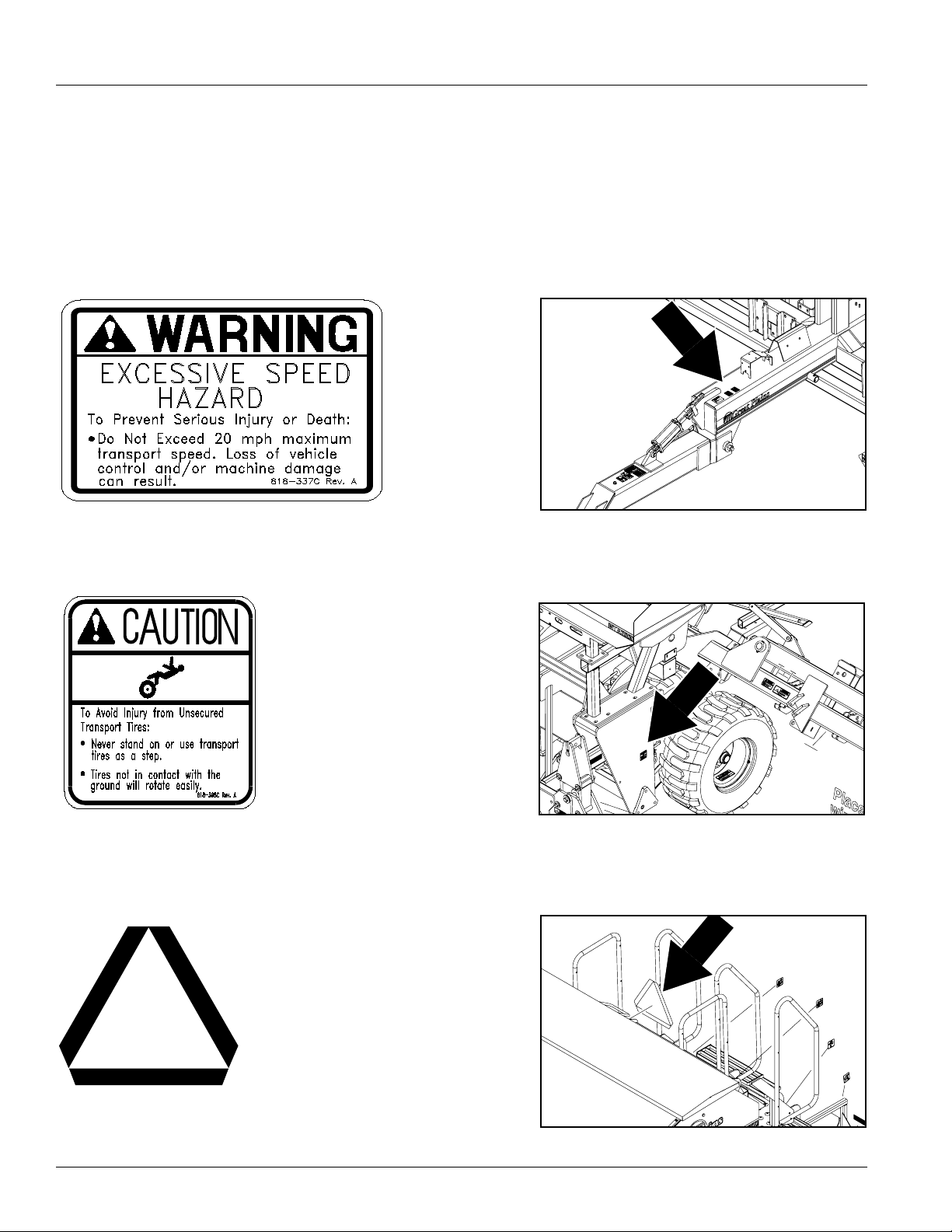

Safety Decals

Your implement comes equipped with all safety decals in place.

They were designed to help you safely operate your implement.

1. Read and follow decal directions.

2. Keep all safety decals clean and legible.

3. Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

Great Plains Mfg., Inc.

4. When ordering new parts or components, also request corresponding safety decals.

5. To install new decals:

a. Clean the area on which the decal is to be placed.

b. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

818-337C

Excessive Speed Hazard

One decal on tongue.

818-398C

Not a Step

One decal on each side of main frame.

Two decals total.

19761

19761

818-003C

Slow Moving Vehicle

One decal on rear of box.

NTA 2000D 148-632M 9/13/2006

4

19761

Page 7

Great Plains Mfg., Inc.

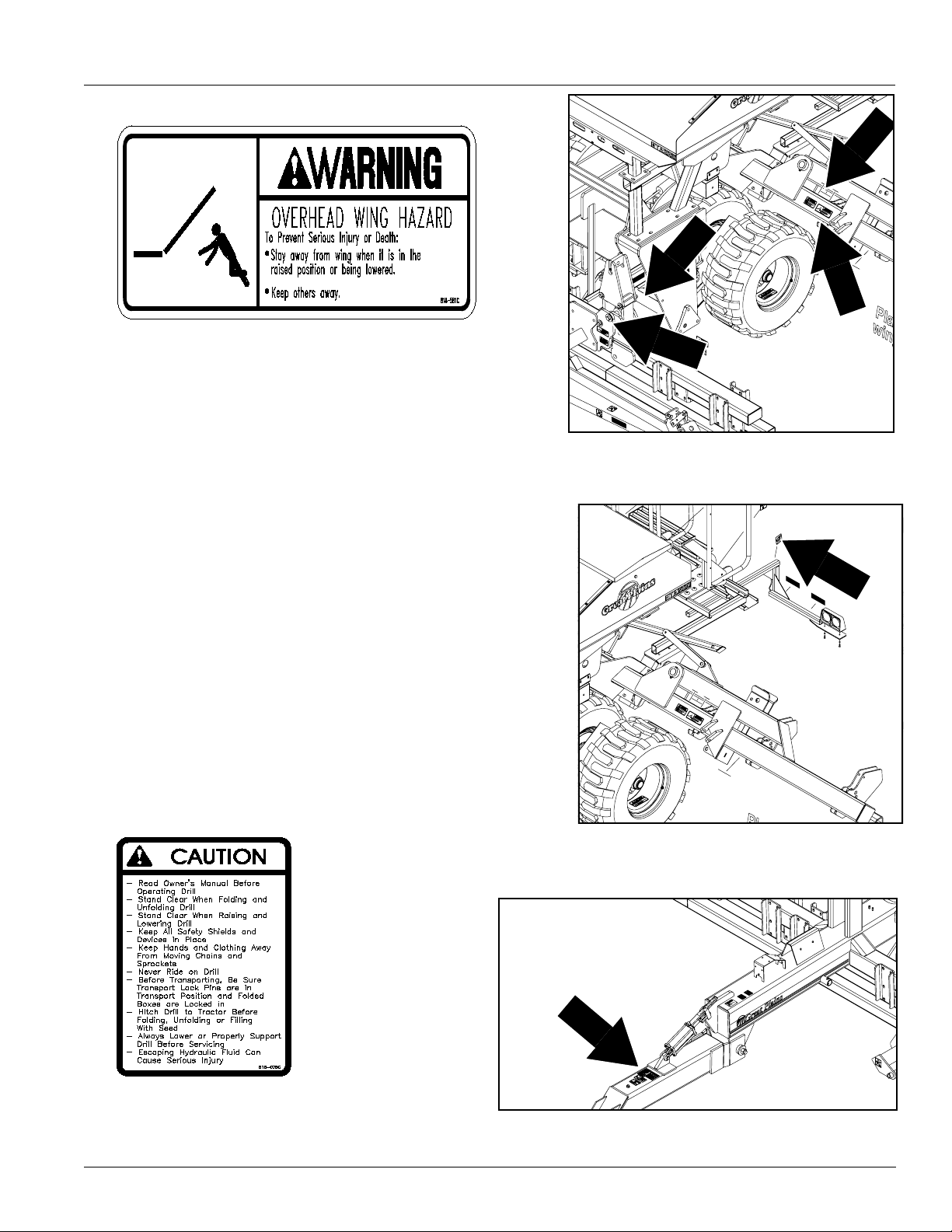

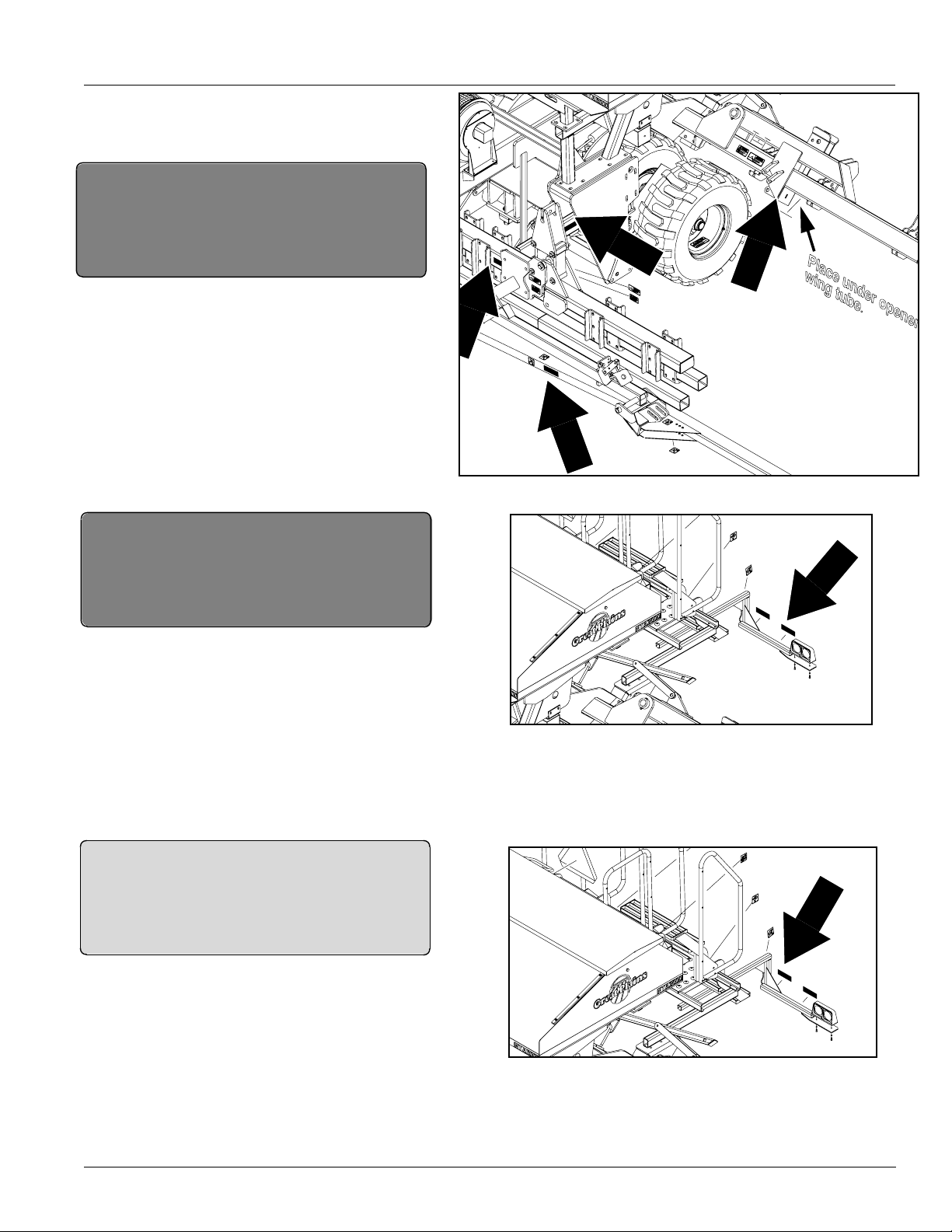

818-581C

Overhead Crushing

Two decals on each side of the opener frame hinges. Two

decals on each side of the coulter frame hinges. One decal

on light bar bracket near lower platform.

Nine decals total.

19761

818-078C

Read Manual

One decal on tongue.

9/13/2006

19761

NTA 2000D 148-632M

19761

5

Page 8

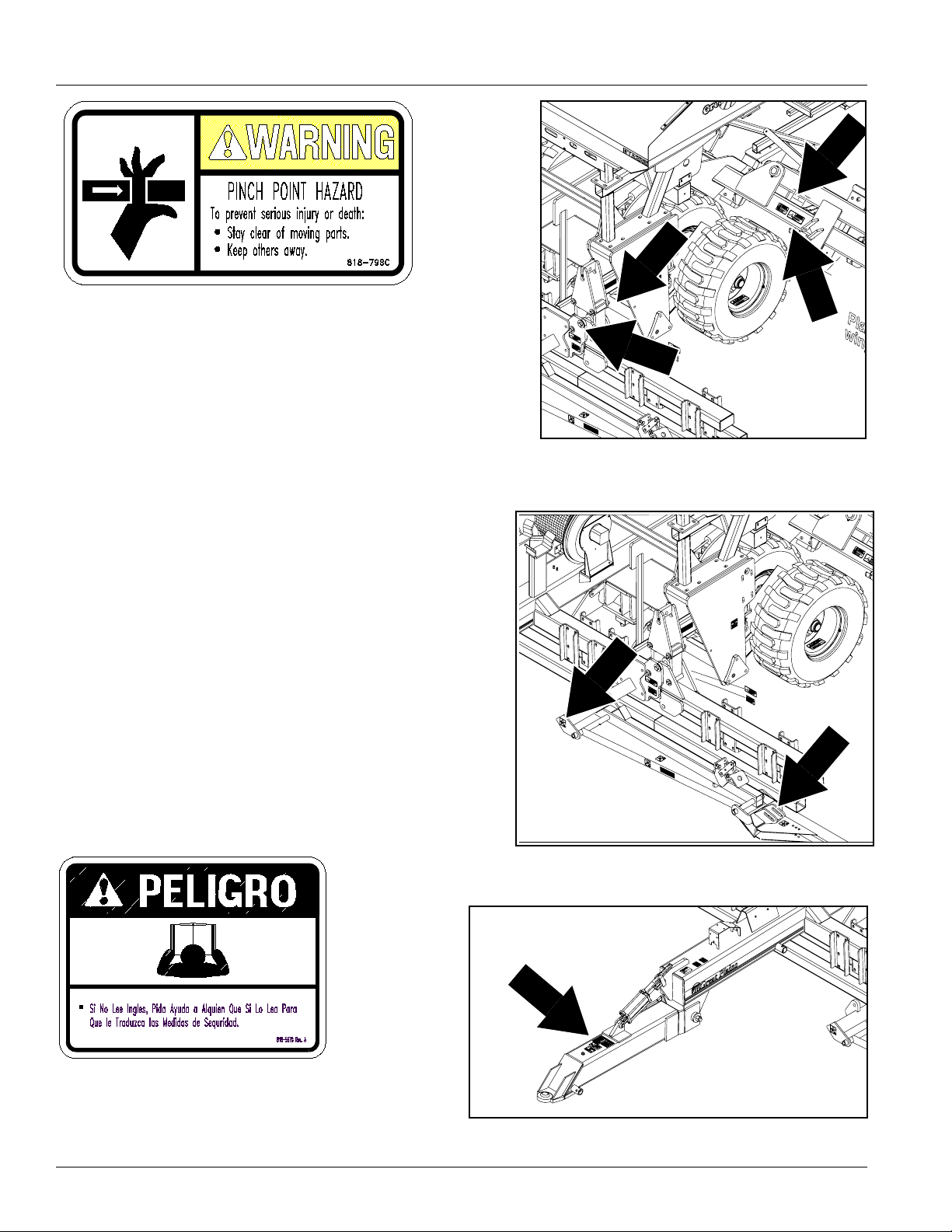

818-798C

Pinch Point

Two decals on each side of both opener frame hinges. Two

decals on each side of both coulter frame hinges. One decal

on each marker mount. One decal on top side of second

marker sections.

Twelve decals total.

Great Plains Mfg., Inc.

19761

818-557C

Cannot Read English

One decal on tongue.

NTA 2000D 148-632M 9/13/2006

6

19761

19761

Page 9

Great Plains Mfg., Inc.

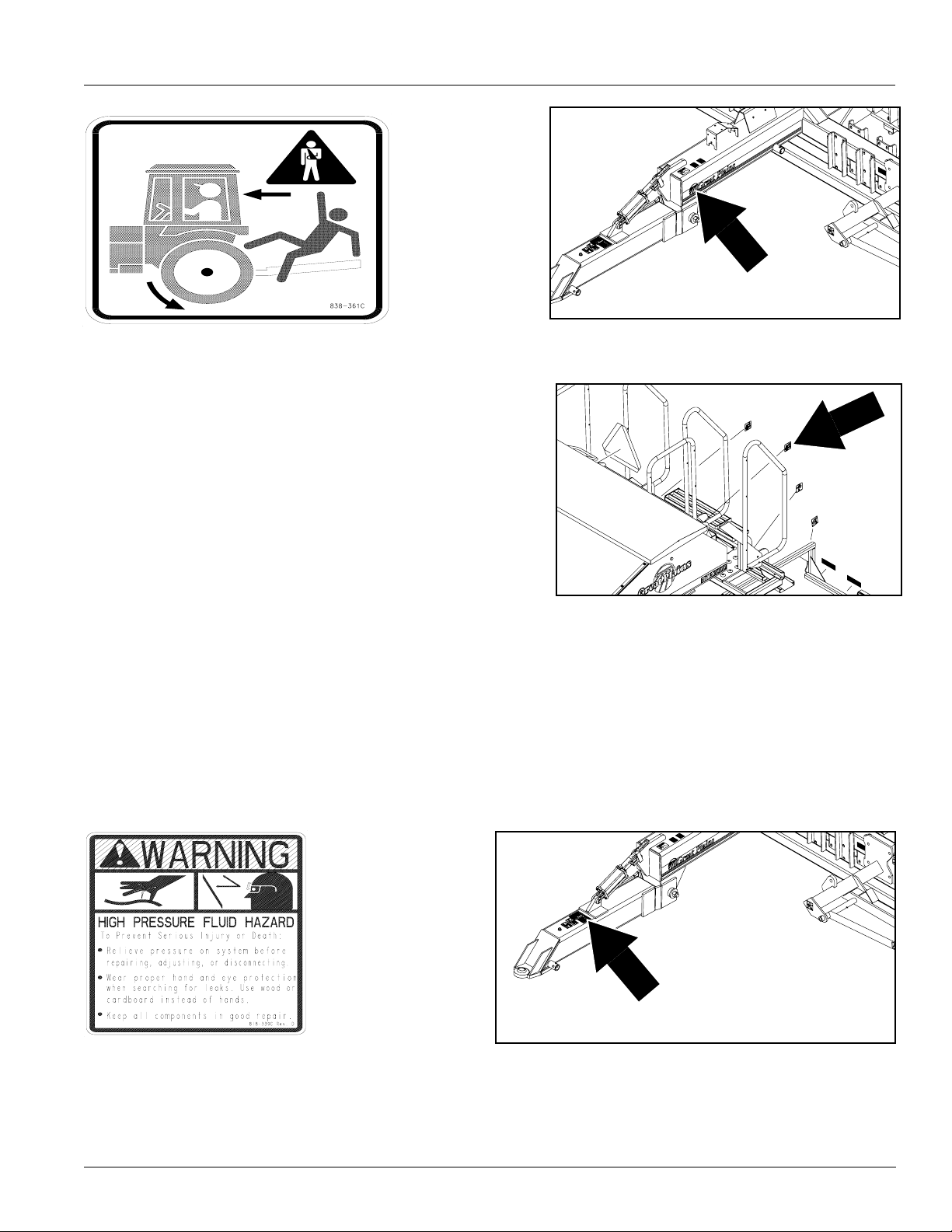

838-361C

Do Not Ride

One decal on tongue and one decal on the back of the upper

work platform.

Two decals total.

19761

818-339C

High Pressure Fluids

One decal on tongue.

.

19761

19761

9/13/2006

NTA 2000D 148-632M

7

Page 10

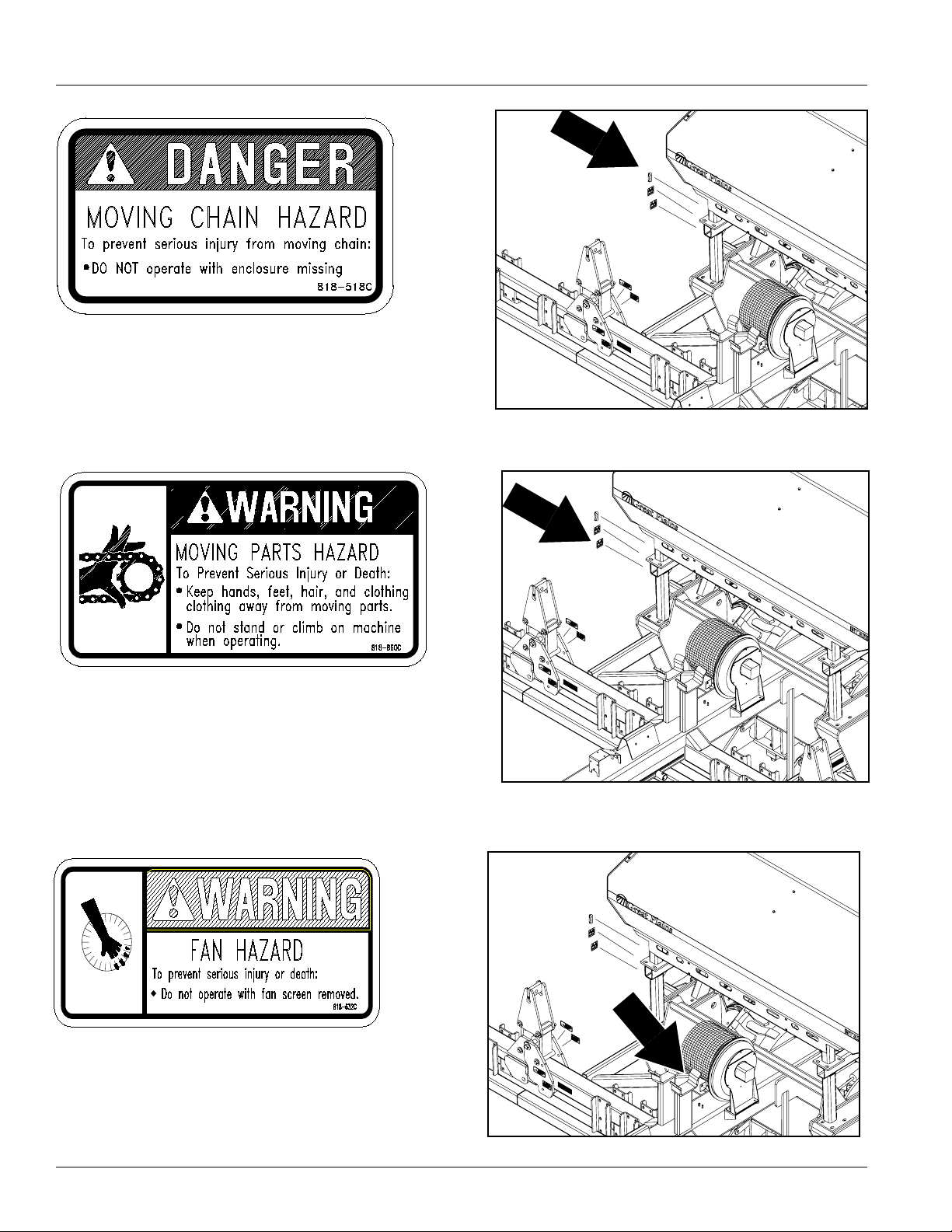

818-518C

Moving Chain Danger

One decal behind chain guard.

Great Plains Mfg., Inc.

19761

818-860C

Moving Chain

One decal on hopper frame near gearbox.

818-632C

Fan Hazard

One decal near fan.

19761

19761

NTA 2000D 148-632M 9/13/2006

8

Page 11

Great Plains Mfg., Inc.

838-265C

Amber Reflectors

One reflector under both opener wings. One reflector

on each side of coulter frame. Two on the front side of

coulter frame. One on the front side of each marker.

Eight reflectors total.

19761

838-266C

Red Reflectors

One reflector on outside ends of light mounting tubes.

Two reflectors total.

838-267C

Day Time Reflectors

One reflector on inside ends of light

mounting tubes.

Two decals total.

19761

19761

9/13/2006

NTA 2000D 148-632M

9

Page 12

Great Plains Mfg., Inc.

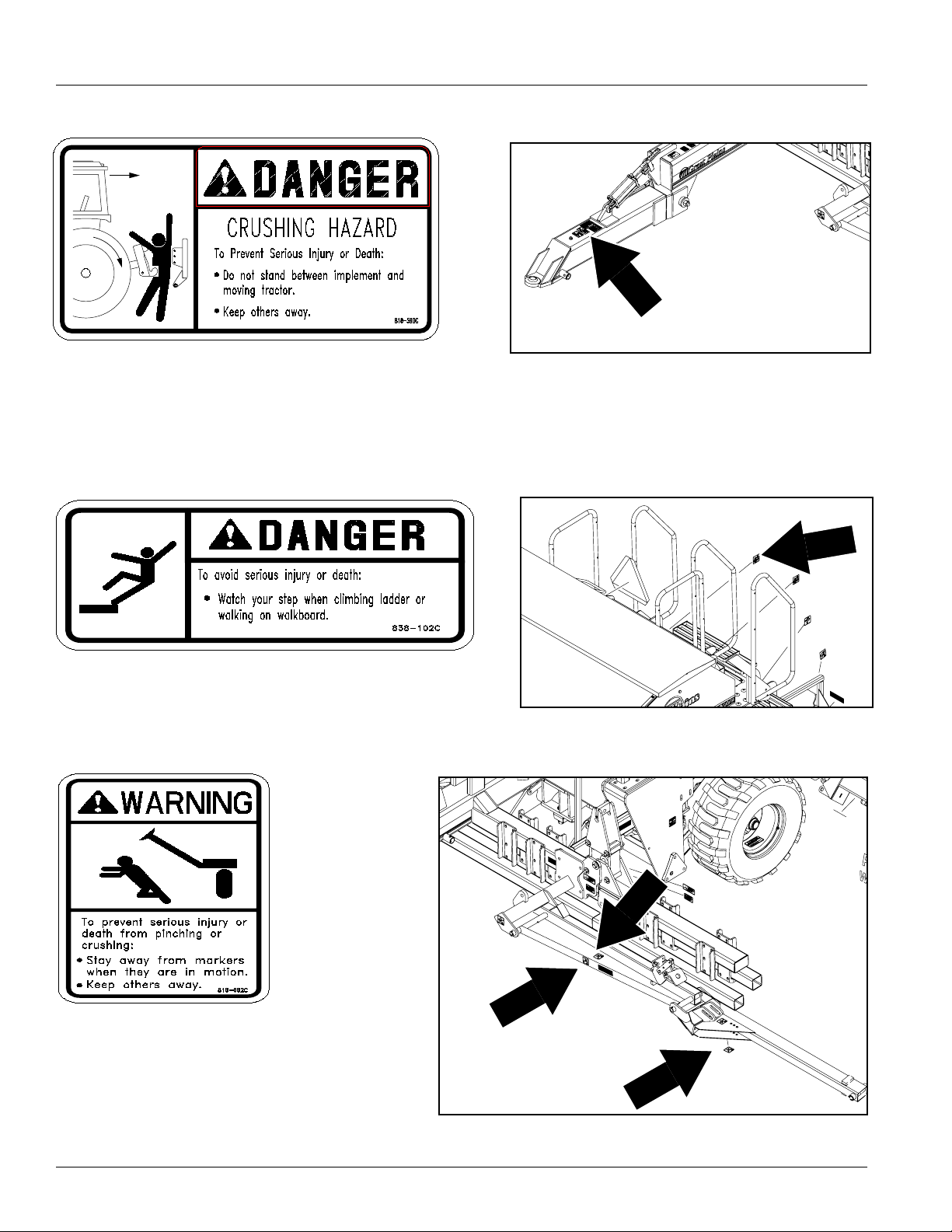

818-590C

Crushing Hazard

One decal on tongue.

838-102C

Falling Hazard

One decal on upper platform.

19761

19761

818-682C

Crushing Hazard

One decal on underside first marker sections. One

decal on front side of first marker sections. One decal on underside of second marker sections.

Six decals total.

NTA 2000D 148-632M 9/13/2006

10

19761

Page 13

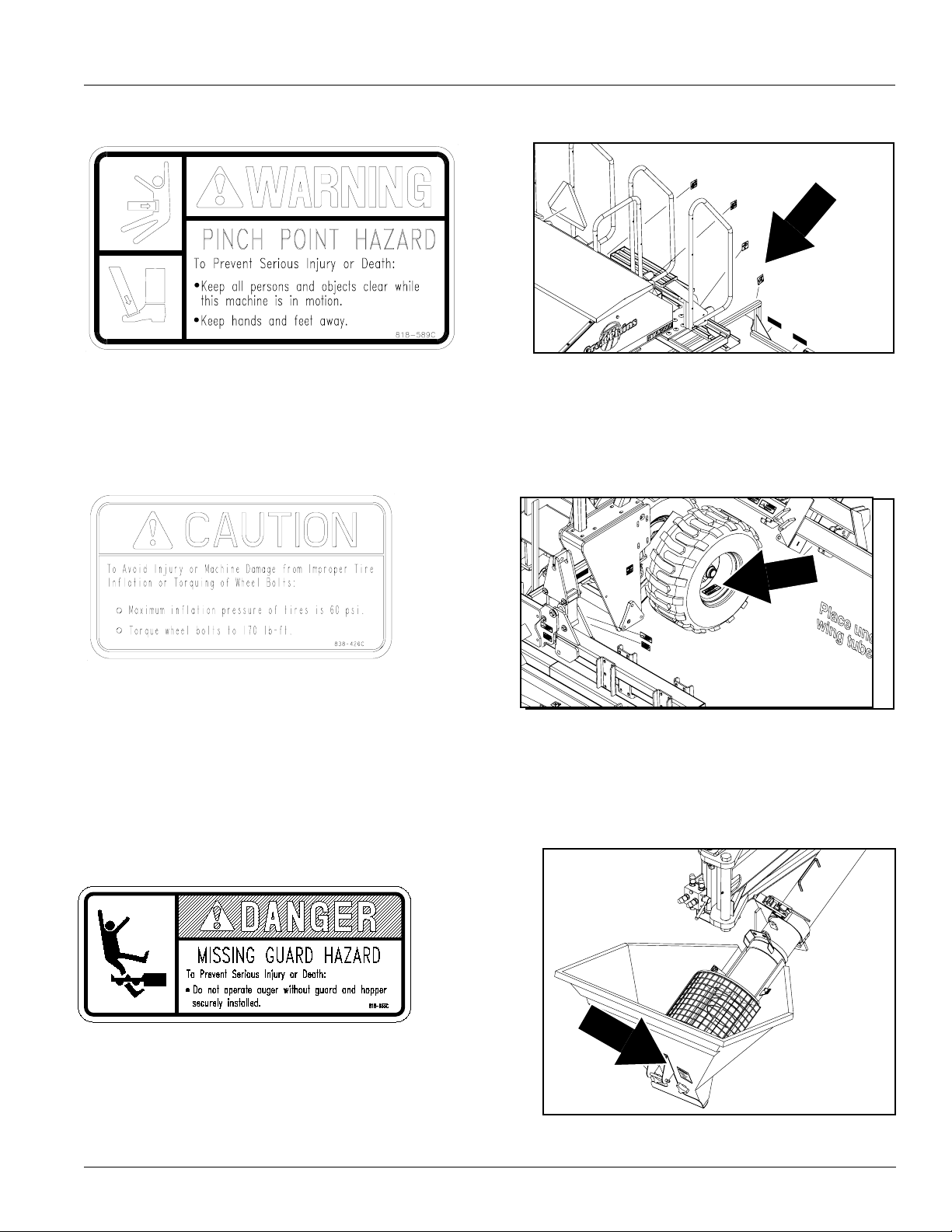

Great Plains Mfg., Inc.

818-589C

Pinch Point Hazard

One decal on light bar near lower platform.

19761

838-426C

Tire Pressure

One decal on each tire rim.

Four decals total.

818-633C

Missing Guard Hazard

One decal on the auger hopper.

19761

9/13/2006

NTA 2000D 148-632M

11

Page 14

Introduction

Great Plains Mfg., Inc.

Great Plains welcomes you to its growing family of new

product owners. This implement has been designed with

care and built by skilled workers using quality materials.

Proper setup, maintenance and safe operating practices

will help you get years of satisfactory use from the

machine.

Description of Unit

The NTA 2000D is a pull-type seeding implement. The

implement has No-till coulters and openers intricately connected on a center pivot. No-till coulters mounted on the

front frame zone-till strips for seed furrows. Straight-arm

openers on the rear frame prepare seedbeds and place

the seed. The pivoting action of the frames allows drill

openers to track the coulters. A contact-drive tire powers

the seed meter from a transport tire. The tongue cylinder

and transport tires control the coulter and opener depth.

Transport cylinders raise the drill for turns and transport.

Intended Usage

Use this implement for seeding production-agriculture

crops only. Do not modify implement for use with attachments other than those specified by Great Plains. Use

implement in no till or minimum tillage.

Using This Manual

This manual will familiarize you with safety, assembly,

operation, adjustments, troubleshooting and maintenance. Read thismanual and follow the recommendations

to help ensure safe and efficient operation.

The information in this manual is current at printing. Some

parts may change to assure top performance.

Definitions

Right-hand and left-hand as used in this manual are determined by facing the direction the machine will travel while

in use unless otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct operation,

read and follow the directions provided before continuing.

NOTE: Useful information related to the preceding topic.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and should

only be replaced with Great Plains parts. Always use

serial and model numbers when ordering parts from your

19731

Great Plains dealer. The serial-number plate is located on

the implement as shown in Figure A.

Figure A

Serial Number Plate

Record your implementmodel and serial numbers here for

quick reference:

Model Number: _________________________________

Serial Numbers: _________________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service manager. Make sure they are aware of any problems so

they can assist you.

2. If you are still not satisfied, seek out the owner or general manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

USA

NTA 2000D 148-632M 9/13/2006

12

Page 15

Great Plains Mfg., Inc.

Preparation and Set-Up

This section will help you prepare your tractor and implement for use.

Hitching Tractor to Implement

!

DANGER!

You may be severely injured or killed by being crushed between the tractor and drill. Do not stand or place any part of

your body between drill and moving tractor. Stop tractor engine and set park brake before installing pins.

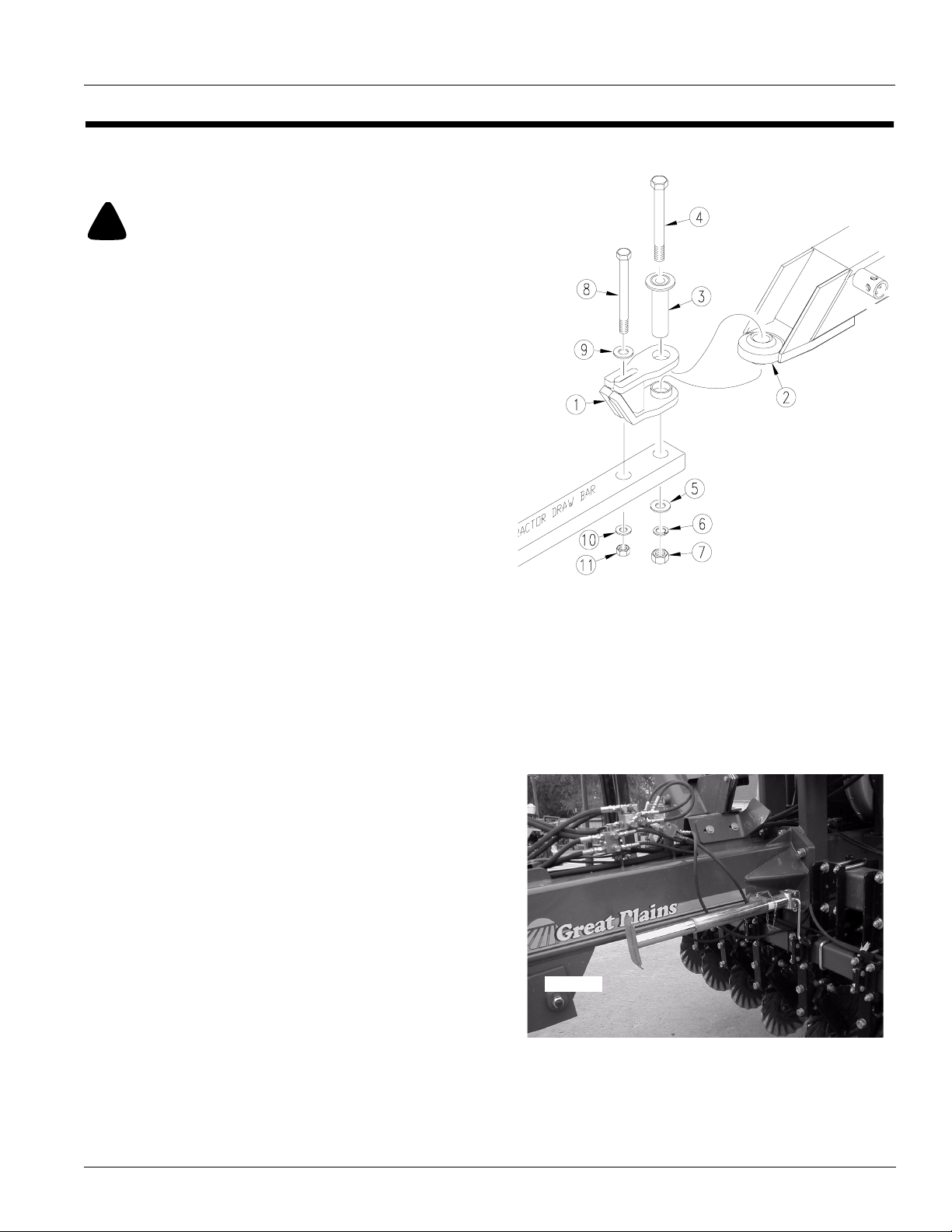

Refer to Figure 1

1. Place hitch weldment (1) over ball swivel on hitch

tongue (2). Hold hitch weldment in place by inserting

spacer tube (3) through hitch clevis and ball swivel.

2. Back tractor up to hitch and bolt hitch weldment to

tractor drawbar using 1” x 10" bolt (4), large flat

washer (5), lock washer (6), and nut (7).

3. Use 3/4” x 9" bolt (8) to bolt hitch weldment through

its slotted hole and onto secondary hole of tractor

drawbar. Install a 3/4” flat washer (9) next to top slotted hole and fasten with a lock washer (10) and nut

(11). Tighten both bolts.

4. Securely attach safety chain to tractor-drawbar

frame.

5. Plug light harness and monitor leads into tractor connections.

6. Connect hydraulic hoses to the tractor remotes.

Refer to Figure 2

7. Remove jack from stob on side of hitch tongue and

place in transport position on implement.

17215

Figure 1

Hitch

9/13/2006

19730

Figure 2

Jack in Transport

NTA 2000D 148-632M

13

Page 16

Hydraulic Hook-up

!

WARNING!

Escaping fluid under pressure can have sufficient force to penetrate the skin. Check all hydraulic lines and hoses before applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check for suspected leaks. If injured, seek medical assistance

from a doctor that is familiar with this kind of injury. Foreign

fluids in the tissue must be surgically removed within a few

hours or gangrene will result.

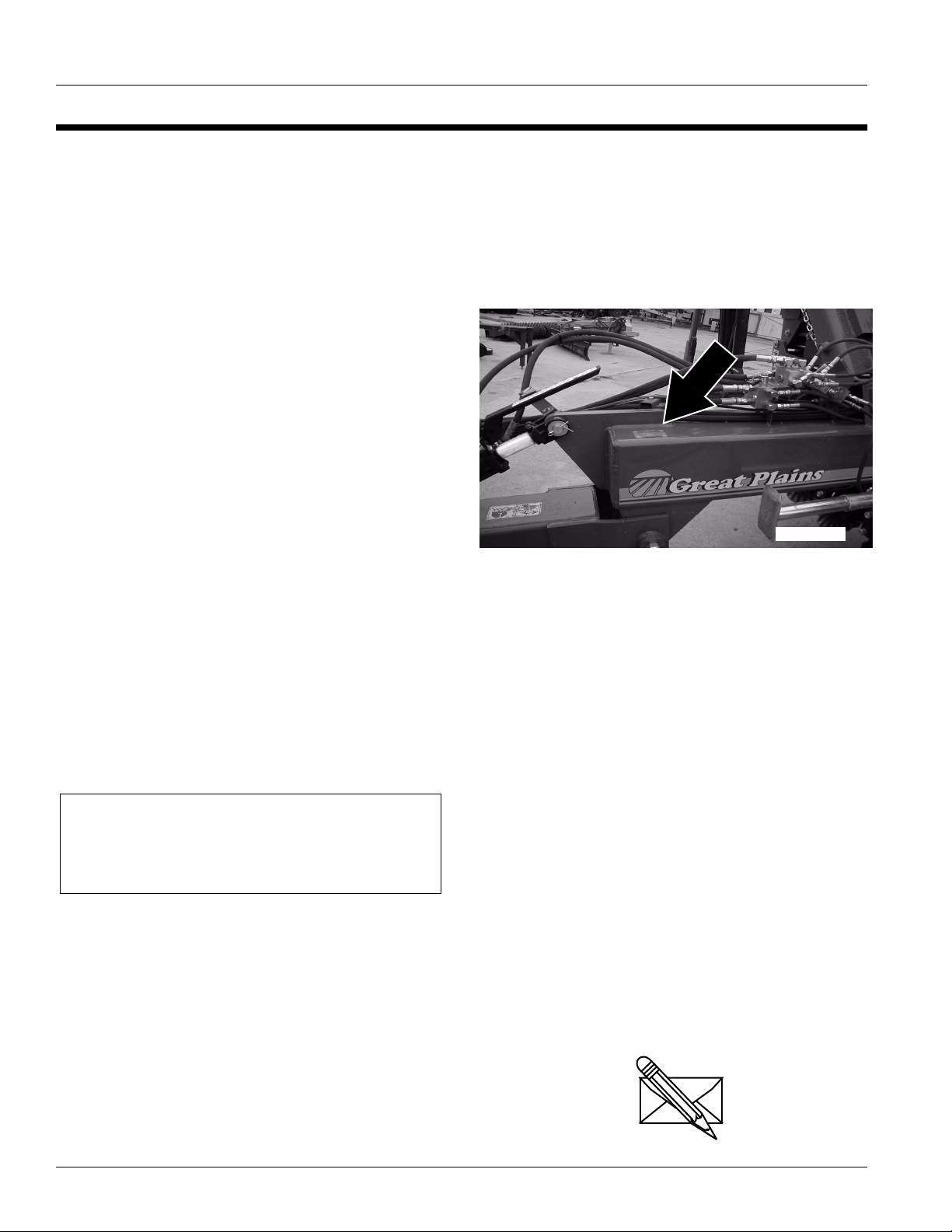

Great Plains hydraulic hoses are color coded to help you

hook-up hoses to your tractor outlets. Hoses that go to the

same remote valve are marked with the same color.

Colour Hydraulic Function

Red Transport Lift Cylinders

Great Plains Mfg., Inc.

Blue Tongue Cylinder

Yellow Fan and Fold

Orange Marker

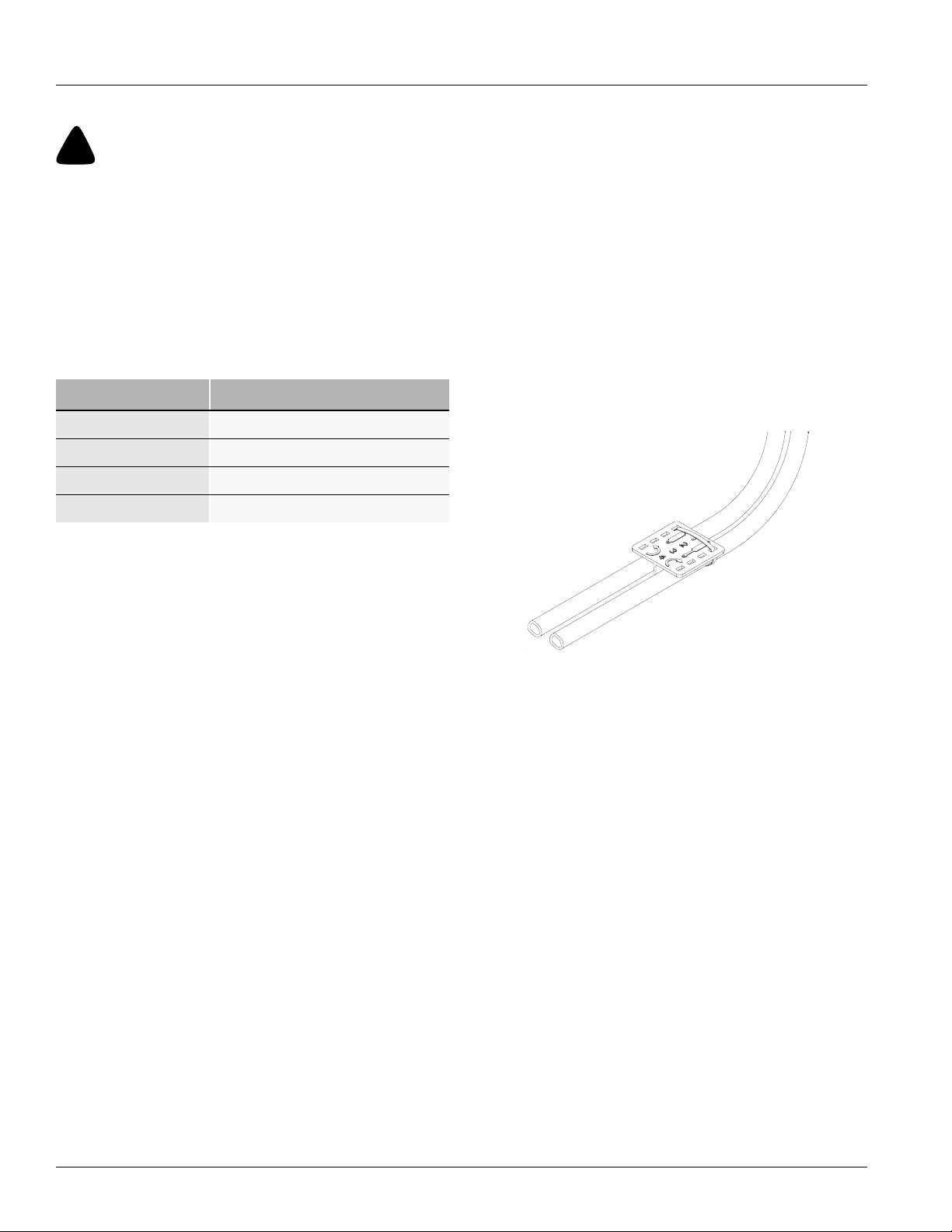

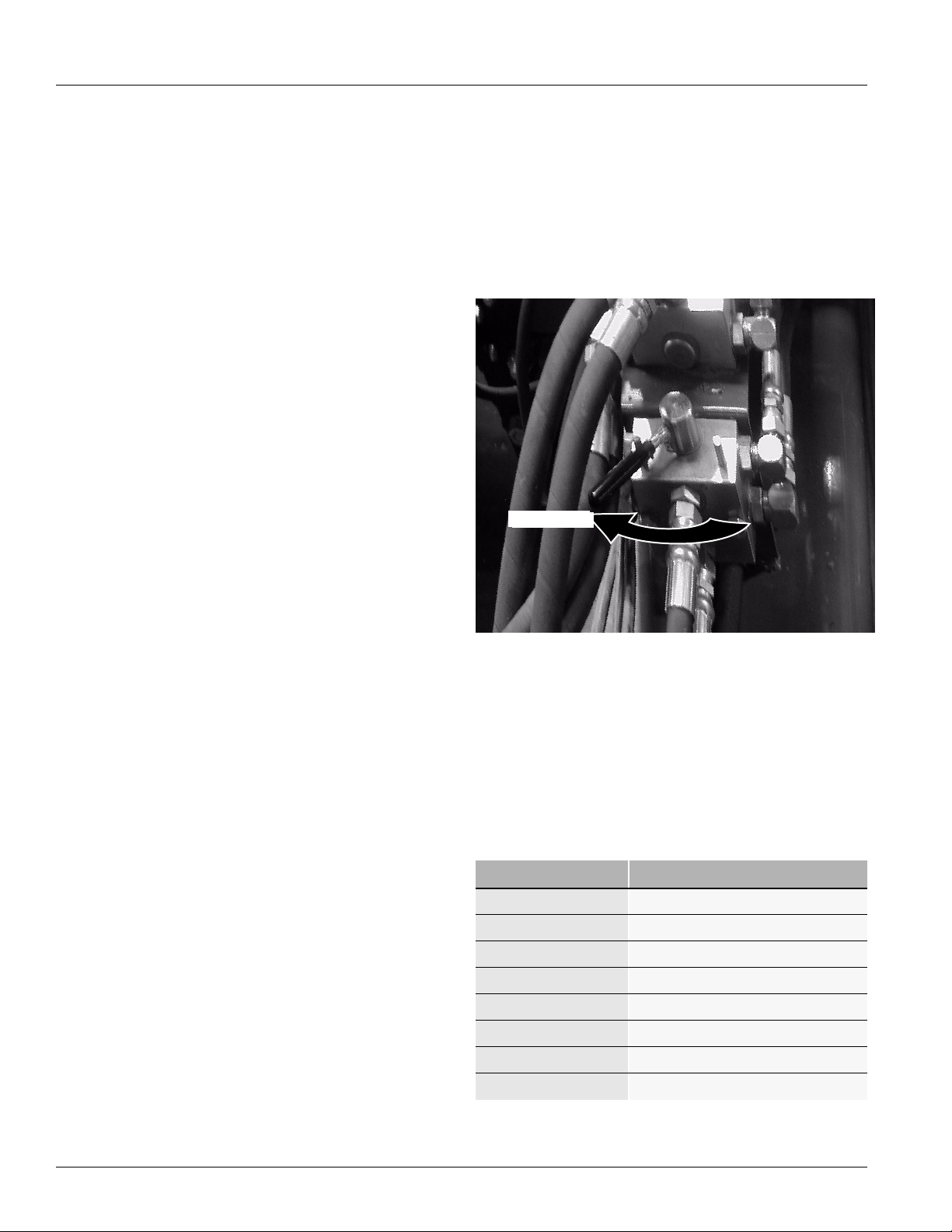

Refer to Figure 3

To distinguish hoses on the same hydraulic circuit, refer to

plastic hose holder. Connect hose under extended cylinder to outlet you choose for cylinder extension. Connect

hose under retracted symbol to outlet for cylinder

retraction.

Connect hydraulic hoses from tongue cylinder to one tractor remote valve. Connect hoses from transport-lift

cylinders to another tractor remote valve.

.

17641

Figure 3

Hydraulic Hose Color Ties

NTA 2000D 148-632M 9/13/2006

14

Page 17

Great Plains Mfg., Inc.

Bleeding Hydraulic Systems

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, and

wear heavy gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with this type

of injury. Foreign fluids in the tissue must be surgically removed

within a few hours or gangrene will result.

Note: For safe and smooth operation, the hydraulic systems must be free of air. The hydraulic systems should be

bled during initial implement set-up. If they were not bled,

or if you replace a hydraulic component during the life of

the drill, bleed the hydraulics.

Bleeding Lift Hydraulics

1. Check hydraulic fluid level in tractorreservoir and fill to

proper level. Add fluid to system as needed while cycling new cylinders. LIft hydraulic capacity is 2 gallons

(7.5 liters).

2. Lower drill to ground.

3. Loosen the fittings at the base end of each transport

lift cylinder. Supply oil to the base ends of the cylinders until oil seeps from loosened fittings. Tighten

those fittings.

4. Supply oil to the base ends and completely extend the

cylinders. Insert transport lock channels.

5. Loosen the fittings at the rod end of each transport lift

cylinder. Supply oil to the rod ends of the cylinders until oil seeps from loosened fittings. Tighten those fittings.

6. Remove transport lock channels and cycle drill up and

down three times.

Bleeding Tongue Cylinder

1. Check hydraulic fluid in tractor reservoir and fill to

proper level. Add fluid to system as needed. Tongue

cylinder capacity is 1/2 gallon (1.9 litres).

2. Raise and safely support hitch, transport frame and

front tongue.

3. Unpin rod end of tongue cylinder. Block, wire or other-

wise safely support cylinder so when rod end is fully

extended it does not contact anything.

4. Cycle cylinder completely in and out at least three

times to purge air from cylinder and hoses.

5. Fully extend cylinder and repin rod end.

6. Recheck tractor reservoir and fill to proper level.

!

CAUTION!

You may be injured or killed by a folding or unfolding opener or

coulter frame.

Bleeding Fold Hydraulics

Check hydraulic fluid level in tractor reservoir and fill to

proper level. Add fluid to system as needed while cycling

new cylinders. Fold hydraulic capacity is 2 gallons (7.5

liters).

If drill is folded:

1. Make sure the opener fold lock pins are in place. Loosen the fittings at the rod end of each coulter fold cylinder and at the base end of each opener fold cylinder.

Supply oil as to unfold the drill. As oil begins to seep

from the loosened fittings, tighten those fittings. Do

not unfold the wing sections at this time.

2. Make sure the opener fold lock pins are in place. Loosen the fittings at the base end of each coulter fold cylinder and at the rod end of each opener fold cylinder.

Supply oil as to fold the drill. As oil begins to seep from

the loosened fittings, tighten those fittings. Continue

supplying oil as to completely fold the drill for at least

five seconds.

3. Remove the fold lock pins and unfold the drill.

!

CAUTION!

Use extreme caution because some sudden dropping of the

wings may occur if a small amount of air still remained in the

cylinders.

4. Fold and unfold the drill three more times.

9/13/2006

NTA 2000D 148-632M

15

Page 18

If drill is unfolded:

1. Make sure the wing sections are on the ground. Loosen the fittings at the base end of each coulter fold cylinder and at the rod end of each opener fold cylinder.

Supply oil as to fold the drill. As oil begins to seep from

the loosened fittings, tighten those fittings. Do not fold

the wing sections yet.

2. Make sure the wing sections are still on the ground.

Loosen the fittings at the rod end of each coulter fold

cylinder and at the base end of each opener fold cylinder. Supply oil as to unfold the drill. As oil begins to

seep from the loosened fittings, tighten those fittings.

Continue supplying oil as to completely unfold the drill

for at least five seconds.

3. Fold the drill.

!

CAUTION!

Use extreme caution because some sudden dropping of the

wings may occur if a small amount of air still remained in the

cylinders.

Great Plains Mfg., Inc.

2. With tractor idling, activate tractor hydraulic valve until

oil seeps out around a loosened fitting. Tighten that fitting.

IMPORTANT: JIC fittings do not require high torque. JIC

and O-ring fittings do not require sealant. Always use liquid pipe sealant when adding or replacing pipe-thread fittings. To avoid cracking hydraulic fittings from over

tightening, do not use plastic sealant tape.

3. Reactivate tractor hydraulic valve until oil seeps out

around another loosened fitting. Tighten that fitting.

Repeat process until all loosened fittings have been

bled and tightened.

4. Cycle both cylinders completely in and out at least

three times to completely purge air from cylinders and

hoses.

5. Repin cylinders and cycle markers at least three

times.

4. Fold and unfold the drill three more times.

Bleeding Marker Hydraulics

To fold properly, the marker hydraulics must be free of air.

If the markers fold in jerky, uneven motion, follow these

steps.

!

CAUTION!

You may be injured if hit by a folding or unfolding marker.

Markers may fallquickly and unexpectedly if the hydraulics fail.

Never allow anyone near the drill when folding or unfolding the

markers.

Check that tractor hydraulic reservoir is full. Marker hydraulic capacity is 1 1/2 gallons (5.8 liters).

1. With both markers lowered into field position, unpin

rod end of each cylinder andblock cylinder up so it can

be extended and retracted safely and without contacting anything. Loosen hydraulic-hose fittings at rod and

base ends of marker cylinders. Loosen fittings on

back side of sequence valve.

IMPORTANT: Never bleed an O-ring fitting. Instead,

bleed a nearby pipe or JIC fitting.

NTA 2000D 148-632M 9/13/2006

16

Page 19

Great Plains Mfg., Inc.

Operating Instructions

This section covers general operation. Experience,

machine familiarity, and the following information will lead

to efficient operation and good working habits. Always

operate farm machinery with safety in mind.

Prestart Checklist

1. Carefully read “Important Safety Information,” be-

ginning on page 1.

2. Lubricate implement as indicated under Lubrication,

“Maintenance and Lubrication,” page 42.

3. Check all tires for proper inflation as indicated on Tire

Inflation Chart,“Appendix,” page 53.

4. Check all bolts, pins and fasteners. Torque as speci-

fied on Torque Values Chart,“Appendix,” page 53.

5. Check implement for worn or damaged parts. Repair

or replace before going to the field.

6. Check hydraulic hoses, fittings and cylinders for leaks.

Repair or replace before going to the field.

Field Operation

1. Hitch implement to a suitable tractor. Refer to Hitching

Tractor to Implement,“Preparation and Setup,” page

13.

2. Set seeding rate. Refer to “Checking the Seeding

Rate,” page 36.

3. Load box with clean seed.

4. Lower the drill and hydraulically adjust coulters to de-

sired depth. Note reference measurement on tonguecylinder gauge to help you achieve the same coulter

depth with each field pass. Refer to Coulter Depth,

“Adjustments,” page 27, for further adjustment instructions.

5. Retract transport cylinders until opener bodies are

level with the ground when the coulters are at the desired depth. Cylinder depth rings are provided to hold

the openers to the desired setting. Set opener depth

and begin seeding. Refer to Opener Depth,“Adjust-

ments,” page 30.

6. Always lift drill out of ground when turning at row ends

and for other sharp turns. Seeding will stop automatically as drill is raised and contact drive wheels lose

contact with drive tires.

9/13/2006

NTA 2000D 148-632M

17

Page 20

Opener Operation

Never back up with openers in ground. If you do, check all

openers to be sure none are clogged or damaged.

For information on seeding depth and opener adjustments, refer to Seeding Depth,“Adjustments,” page 26.

For more information on troubleshooting opener problems, see “Troubleshooting,” page 39.

Fan Operation

Refer to Figure 4

The selector valve diverts the folding circuit to the fan

circuit.

The fan must be operated with the return oil line connected to a low back pressure sump return on the tractor.

Check with tractor manufacturer for proper connection of

oil sump return line. A low back pressure quick disconnect

is supplied with the drill for ease of connection to the tractor sump return line.

Use tractor remote hydraulic valve flow control to set fan

speed.

Run fan for at least 15 minutes before seeding. Hydraulic

fluid must be warm before fan will operate properly.

Watch monitor and adjust fan speed by increasing or

decreasing hydraulic flow from tractor.

Use the fan speed chart as a guide. Actual fan speeds will

vary with seeding rates, seed weights and seed size.

Increase fan speed for heavier seeding rate or seed.

Reduce fan speed for lighter seeding rates and seed more

prone to cracking.

Set the fan speed for the type of seed and seed rate being

planted. Refer to “Seed Rate Charts,” page 48. Operating

the fan at higher than recommended speeds can cause

seeds to be blown out of the opener seed trench.

Note: Do not operate fan above 4500 RPM.

Fan

Figure 4

Turn Selector Valve

Great Plains Mfg., Inc.

19879

Follow the chart at the right as a guide. Actual fan speeds

will vary with seeding rates, seed weights and seed size.

Increase fan speed for heavier seeding rates or seed.

Reduce fan speed for lighter seeding rates and seed more

prone to cracking.

Marker Operation

Optional markers are on their own hydraulic circuit. They

operate through a sequence valve which alternates lower

and lift cycles between the right hand and left hand

marker.

NTA 2000D 148-632M 9/13/2006

18

Fan Speed Chart

Seeds Fan RMP

Sunflowers 2250-3000

Wheat 2800-3200

Soybeans 2750-3500

Milo 2250-3000

Barley 2800-3500

Peas 3200-3500

Canola 2000-2200

Grass 2000-2200

Page 21

Great Plains Mfg., Inc.

Folding the Drill

Fold the drill on level ground. Be aware of clearance

required to fold implement. Refer to “Specifications and

Capacities,” page 47.

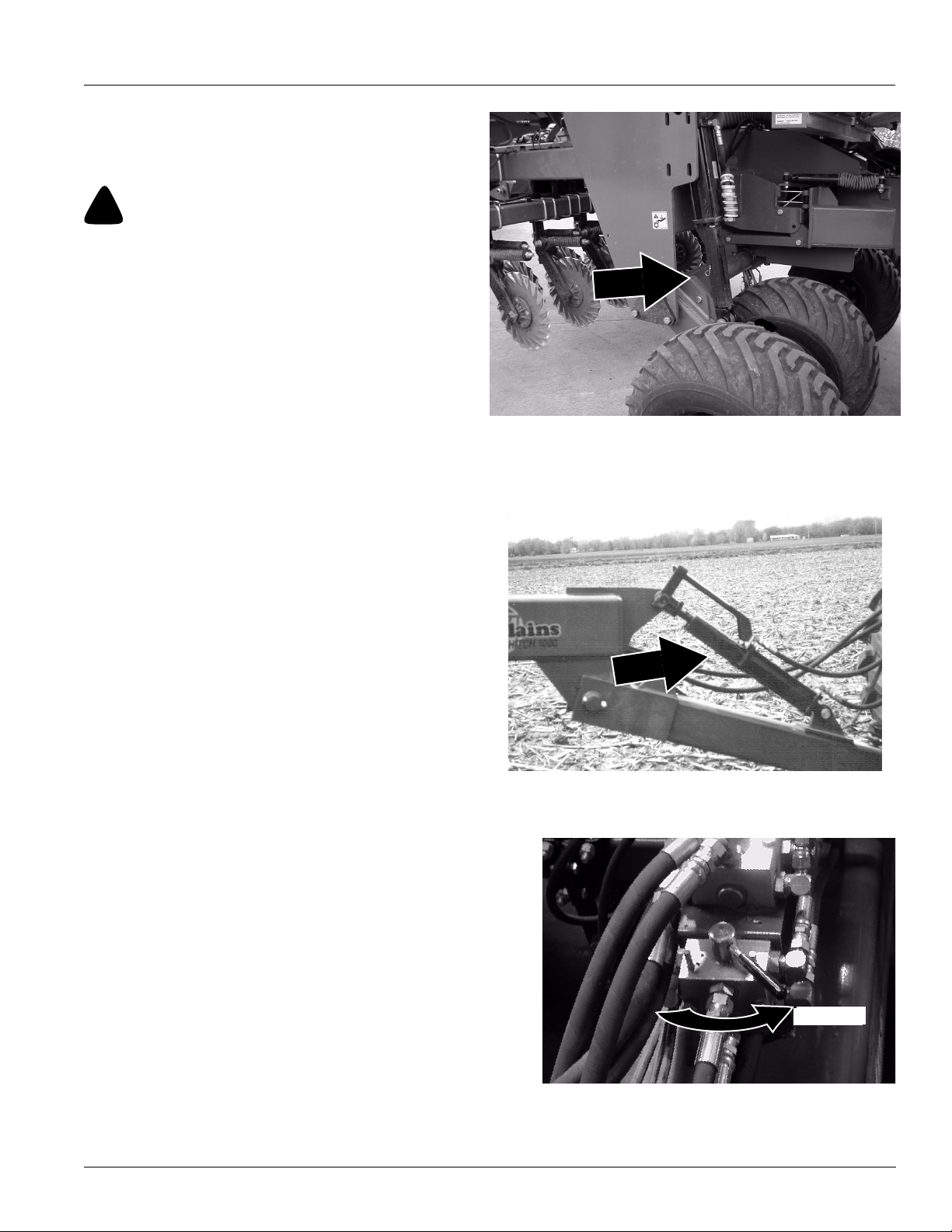

!

WARNING!

Pinch Point and Crushing Hazard. To prevent serious injury or

death. Be certain the drill is hitched securely to your tractor

drawbar and the hitch safety chain is securely attached to the

tractor before raising or folding the drill.

• Always lift drill when before folding.

• Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

• Keepaway and keep others away when folding or unfolding

drill.

Note: Fold the drill on level ground with the tractor in neutral.

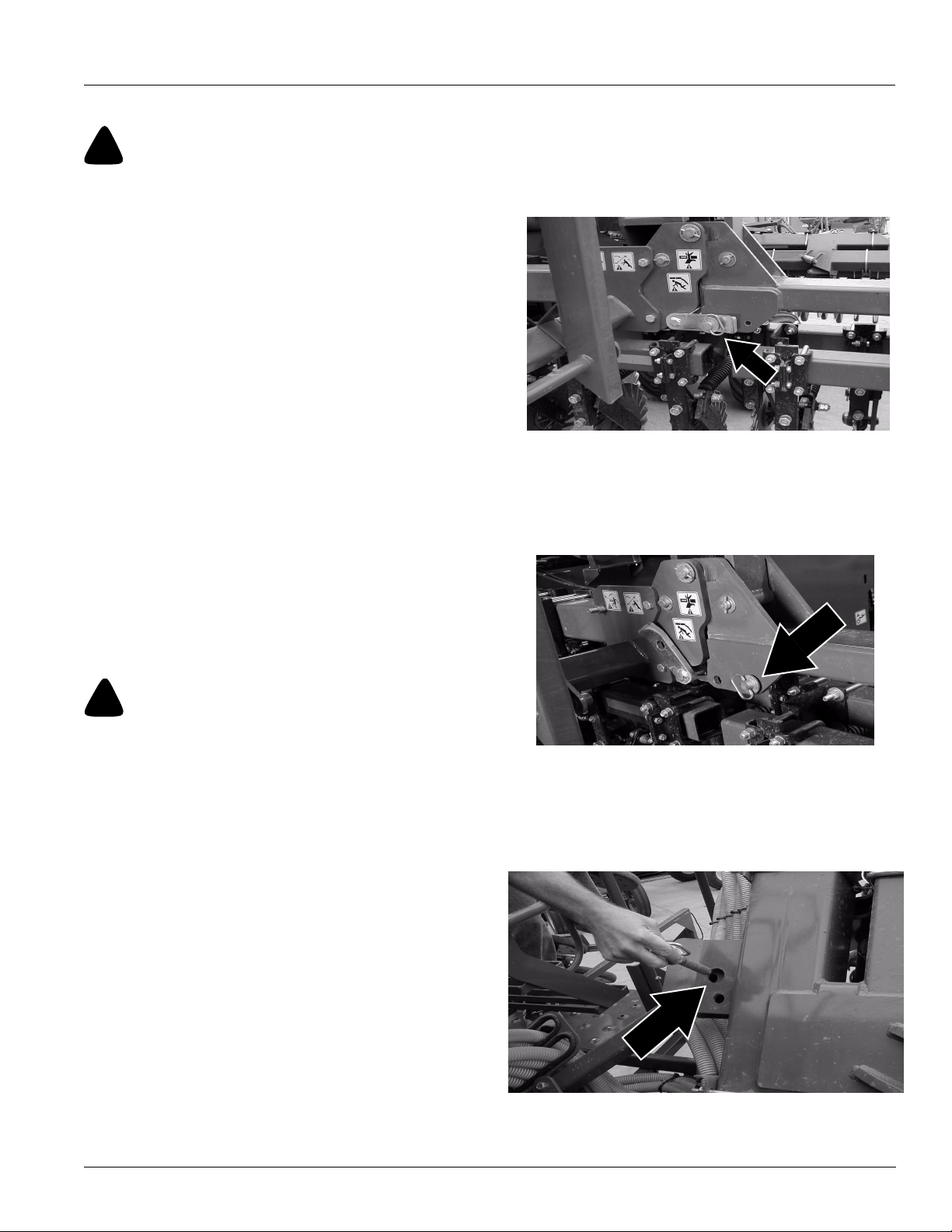

Figure 5

Lock Guard Installed

19733

1. Hydraulically lift drill with transport-lift cylinders and

tongue cylinder.

Refer to Figure 5

2. Install transport lock channels on the extended gauge

wheel cylinder rods.

Refer to Figure 6

3. Install lock channel over extended tongue-cylinder

rod.

Refer to Figure 7

4. Turn handle counterclockwise on valve to folding posi-

tion.

Figure 6

Lock Channel Installed

17217

9/13/2006

Figure 7

Valve

NTA 2000D 148-632M

Folding

19732

19

Page 22

Folding the Drill

!

WARNING!

Pinch Point and Crushing Hazard. To prevent serious injury or

death. Be certain the drill is hitched securely to your tractor

drawbar and the hitch safety chain is securely attached to the

tractor before raising or folding the drill.

• Always lift drill when before folding.

• Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

Great Plains Mfg., Inc.

• Keepaway and keep others away when folding or unfolding

drill.

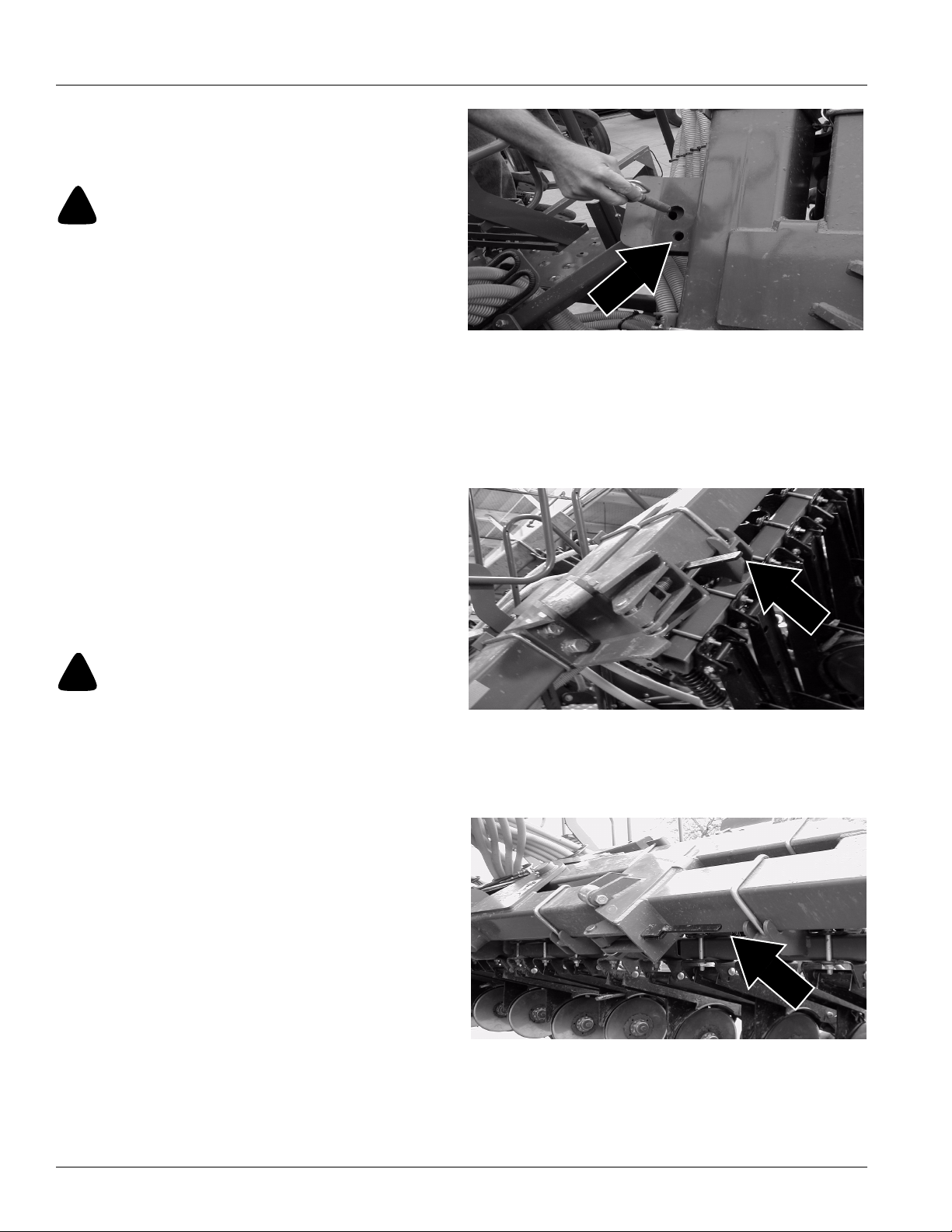

Markers

Note: If maker option is installed, markers must be folded

before coulter wings can be folded.

Refer to Figure 8

5. Before folding markers remove cylinder lock channels

from cylinders and place in storage positions. Failure

to do so will not allow the markers to travel to their

transport positions.

Refer to Figure 9

6. Fold markers to their transport positions. The second

marker section should rest on top of drill frame main

tube.

:

Figure 8

Marker Cylinder Lock Channel

Figure 9

Marker, Transport Position

19894

19877

Opener Wing Frame

Refer to Figure 10

7. Turn opener wing frame lock handles down to unlock

opener wing frames.

Figure 10

Opener Wing Frame Lock

NTA 2000D 148-632M 9/13/2006

20

19734

Page 23

Great Plains Mfg., Inc.

Folding the Drill

!

WARNING!

Pinch Point and Crushing Hazard. To prevent serious injury or

death. Be certain the drill is hitched securely to your tractor

drawbar and the hitch safety chain is securely attached to the

tractor before raising or folding the drill.

• Always lift drill when before folding.

• Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

• Keepaway and keep others away when folding or unfolding

drill.

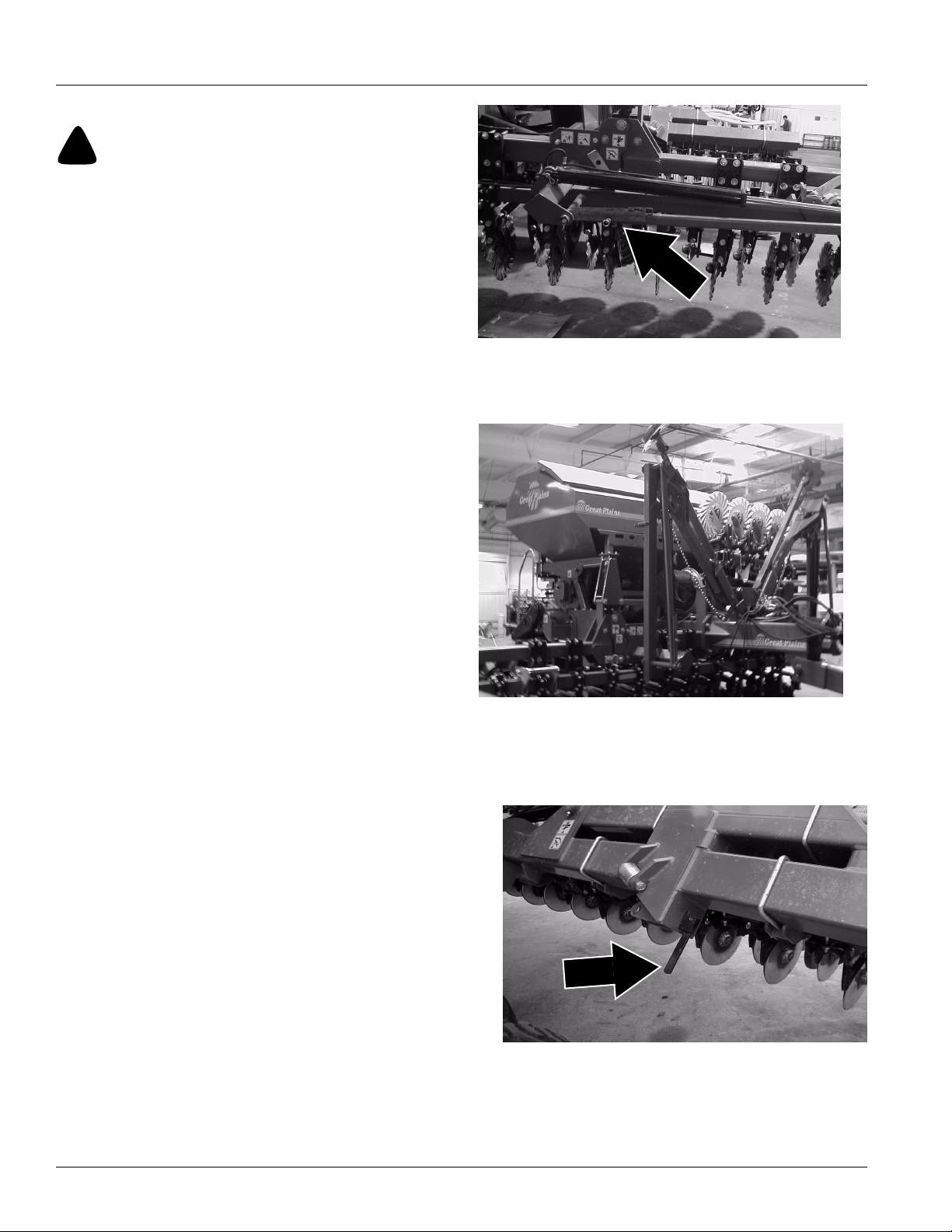

Coulter Wing Frame

Refer to Figure 11

8. Remove lock pins from lock links

Figure 11

Coulter Extension

19736

Refer to Figure 12

9. Store lock pins in storage hole as shown. Flip up lock

links to keep the drill transport width below 118” (3

meters).

10. Allow tongue and transport cylinders to settle back

against the lock channels.

!

DANGER!

Electrocution hazard. To prevent serious injury or death from

electric shock, keep clear of overhead power lines when transporting, folding, unfolding or operating all air-drill components. Machine is not grounded. Electrocution can occur

without direct contact.

11. Fold opener and coulter wings.

Refer to Figure 13

12. Install opener wing frame lock pin to keep opener wing

frames secure in their transport position.

Figure 12

Lock Link Pin Storage

19738

9/13/2006

Figure 13

Opener Wing Frame Lock Pin

NTA 2000D 148-632M

19736

21

Page 24

Unfolding the Drill

Unfold the drill on level ground. Be aware of clearance

required to fold implement. Refer to “Specifications and

Capacities,” page 47.

!

WARNING!

Pinch Point and Crushing Hazard. To prevent serious injury or

death. Be certain the drill is hitched securely to your tractor

drawbar and the hitch safety chain is securely attached to the

tractor before raising or unfolding the drill.

Great Plains Mfg., Inc.

• Unfold the wings with the drill raised.

• Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

• Keepaway and keep others away when folding or unfolding

drill

Opener Extensions.

Refer to Figure 14

1. Remove transport lock pins from opener wings and

place in storage holes indicated by arrow.

Refer to Figure 15

2. Make sure the lock levers are in the unlock position.

The levers should be in a position which is pointing

away from the frame.

3. Unfold the drill on level ground with the tractor in neutral.

!

DANGER!

Electrocution hazard. To prevent serious injury or death from

electric shock, keep clear of overhead power lines when transporting, folding, unfolding or operating all air-drill components. Machine is not grounded. Electrocution can occur

without direct contact.

Figure 14

Lock Pin

Figure 15

Lock Lever

19736

19740

Refer to Figure 16

4. When opener wings are in their lowered position lock

in place by engaging thelock levers. The levers should

be pushed towards the frame to lock.

Figure 16

Lock Lever

NTA 2000D 148-632M 9/13/2006

22

19741

Page 25

Great Plains Mfg., Inc.

Unfolding the Drill

!

WARNING!

Pinch Point and Crushing Hazard. To prevent serious injury or

death. Be certain the drill is hitched securely to your tractor

drawbar and the hitch safety chain is securely attached to the

tractor before raising or unfolding the drill.

• Unfold the wings with the drill raised.

• Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

• Keepaway and keep others away when folding or unfolding

drill

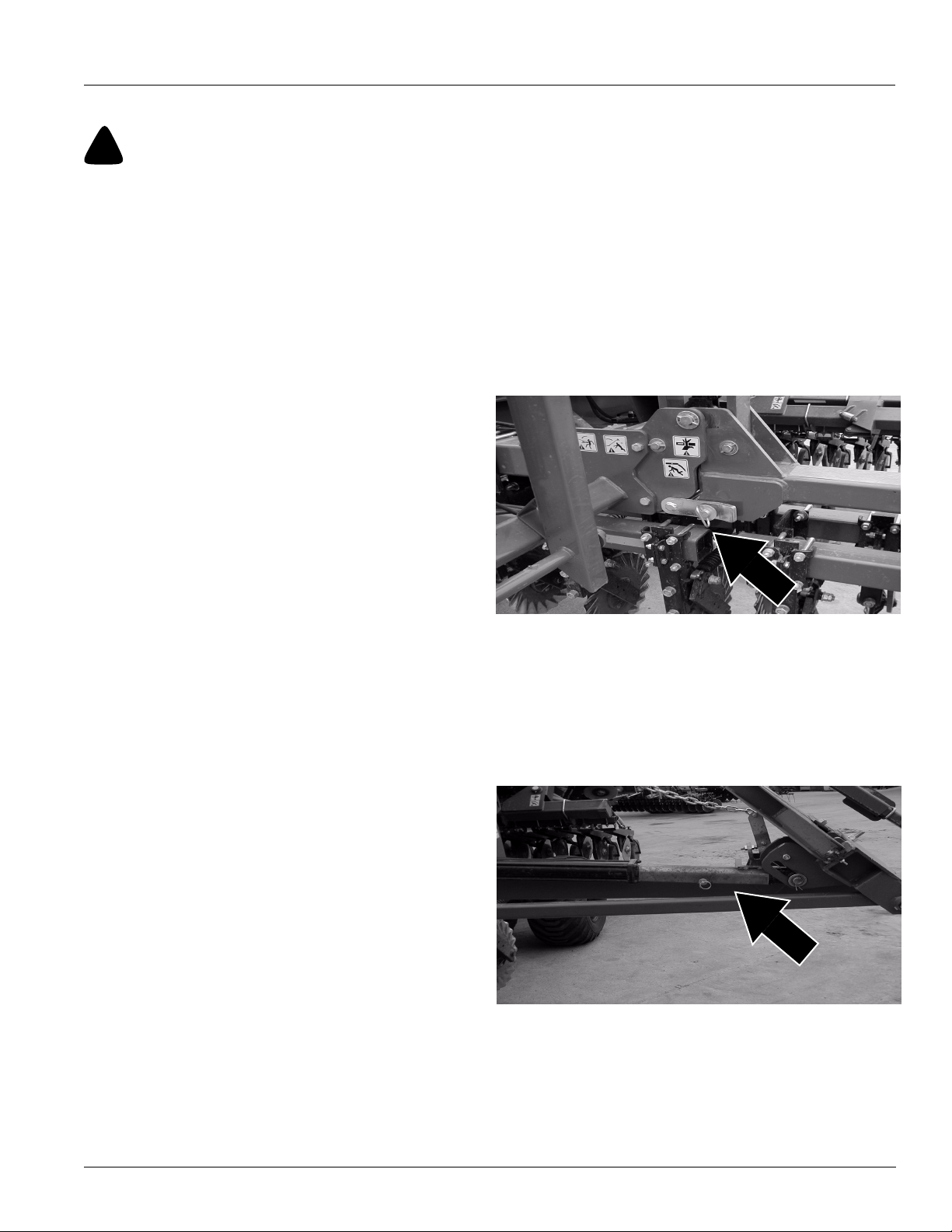

Coulter Extensions

Refer to Figure 17

5. After unfolding the coulter wing extensions, secure in

place with lock links and lock pins.

Makers

Note: For drills with maker option installed.

Refer to Figure 18

6. After the drill has been unfolded lower the makers and

install the lock channels over the cylinder rod as

shown. This allows the maker cylinders to retract for

field operation without retracting all the way to transport position.

Figure 17

Lock Link and Pin

Figure 18

Lock Channel

19743

19744

9/13/2006

NTA 2000D 148-632M

23

Page 26

Unfolding the Drill

!

WARNING!

Pinch Point and Crushing Hazard. To prevent serious injury or

death. Be certain the drill is hitched securely to your tractor

drawbar and the hitch safety chain is securely attached to the

tractor before raising or unfolding the drill.

• Unfold the wings with the drill raised.

• Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

• Keepaway and keep others away when folding or unfolding

drill

Refer to Figure 19 and 20

1. After the drill has been unfolded remove the lock

channels from the tongue cylinder and the gauge

wheel cylinders. Slowly lower drill and place lock

channels in their storage positions.

Figure 19

Lock Channel

Great Plains Mfg., Inc.

19878

Refer to Figure 21

2. Turn selector valve handle to the left for fan position.

Fan

Figure 20

Lock Channel

Figure 21

Valve

19733

19732

NTA 2000D 148-632M 9/13/2006

24

Page 27

Great Plains Mfg., Inc.

Transporting

!

WARNING!

Towing the implement at high speeds or with a vehicle that is

not heavy enough can lead to loss of vehicle control. Loss of vehicle control can lead to serious road accidents, injury and

death. To reduce the hazard:

• Do not exceed 20 mph (25kph).

• Do not tow an implement that, when fully loaded, weighs

more than 1.5 times the weight of the towing vehicle.

1. Check that implement is securely hitched to a suffi-

cient tractor. Refer to Hitching Tractor to Implement,

“Preparation and Setup,” Page 13. Make sure safety

chain is secured to tractor.

2. Unload seed box before transporting if at all possible.

The implement can be transported with a full box of

grain, but added weight will increase stopping distance and decrease maneuverability.

3. Check that tires are properly inflated. Refer to Tire In-

flation Chart,“Appendix,” page 53.

4. Know implement dimensions in transport position.

Choose a route that provides adequate clearance

from all obstructions. Refer to “Specifications and

Capacities,” page 47, for dimensions.

5. Plug light-harness lead into tractor connector. Always

use warning lights when transporting drill.

Comply with all laws when travelling on public roads.

Parking

Perform the following steps when parking implement.

Refer to Storage ,“Maintenance and Lubrication,” page

41, for information on long-term storage preparation.

6. Raise and install cylinder locks

7. Fold and lock wings.

8. Block tires securely to prevent rolling.

9. Release pressure on hydraulic system, then discon-

nect hydraulic lines. Check that hose ends do not rest

on ground.

Refer to Figure 22

10. Move jack from transport position and place it on stob

on side of hitch tongue.

11. Extend jack until all weight is off tractor drawbar. Re-

move 1” x 10” bolt and 3/4” x 3” drawbar bolt.

12. Disconnect implement light harness, monitor and

power cord.

Figure 22

Tongue Jack

19752

9/13/2006

NTA 2000D 148-632M

25

Page 28

Adjustments

Seeding Depth

To set drill seeding depth, you must:

• Set coulter depth with tongue cylinder and gauge

wheels.

• Set opener depth with T-handles on press wheel.

• If field conditions make it necessary, increase coulter

down pressure by adding tractor weights to frame. Refer to Added Weight, page 29.

• If necessary, adjust individual coulters or openers to

seed in tire tracks.

The following is an introduction to how the coulters and

double-disk openers are designed to control seeding

depth.

Coulters

A no-till coulter is mounted on the coulter frame directly

ahead of each opener on the drill. The coulters cut through

heavy trash and make a tilled path in the soil for the

openers.

Coulter cutting depth is controlled by the tongue cylinder

and the gauge wheels. You also can change the depth of

individual coulters by changing coulter-mounting height.

Refer to Coulter Depth, page 27, for information on these

adjustments.

The amount of coulter down pressure needed to cut a soil

groove varies with soil conditions. Adding weight or shortening the coulter spring increases coulter down pressure

and cutting force. Refer to Coulter Down Pressure, page

29, for more information on these adjustments.

Openers

Opener double disks travel in the coulter path to make a

seed bed. Mounted on the rear of each opener is a press

wheel. The press wheels control opener seeding depth

and firms the seed into the soil.

To maintain a consistent seeding depth, upward press

wheel movement is restricted by an independently adjustable stop on each opener. Moving this stop changes the

depth at which seed is placed. The mounting height of

openers that run in tire tracks also can be changed. Refer

to Opener Depth, page 30, for information on these

adjustments.

The amount of opener down pressure needed to cut and

widen the coulter groove and to firm the seed into the soil

varies with soil conditions. Opener down pressure can be

adjusted for all openers or individual openers. Refer to

Opener Down Pressure, page 31, for information on how

to make these adjustments.

Great Plains Mfg., Inc.

NTA 2000D 148-632M 9/13/2006

26

Page 29

Great Plains Mfg., Inc.

Coulter Depth

Adjust coulters to run 1/2” to 1” (13 to 25 mm) below the

drill openers. Coulter depth can be adjusted hydraulically

for all coulters or manually for individual coulters.

Hydraulic Control

Make the following adjustment when drilling in level

ground with the seed box half full.

1. Retract tongue cylinder to transfer the tractor weight to

the coulter toolbar.

17218

Refer to Figure 23

2. Lower the drill and set tongue cylinder so coulters are

at desired depth. Note the setting on cylinder gauge

so you can return to the same depth.

NOTE: Use cylinder gauge only as a reference. Gauge

does not measure actual coulter depth.

Refer to Figure 24

3. Adjust the cylinder spacers on the transport cylinders

so the opener bodies are level with the ground when

the coulters and openers are at the desired depth.

Figure 23

Cylinder Gauge

Figure 24

Spacers

19750

Refer to Figure 25

4. The bottom of the 3 x 3 opener frame tube should be

16 1/2” to 18 1/4” off the ground with the opener at the

desired depth and the opener bodies level with the

ground.

9/13/2006

Levelling Implement

Figure 25

Opener Depth

NTA 2000D 148-632M

19885

12961

27

Page 30

Coulter Wing Adjustment

Set the coulter wing frames so the wing coulters run at

exactly the same depth as the center frame coulters. This

is accomplished with two adjustments.

Refer to Figure 26

1. Add or remove spacer shims from behind coulter

frame stop studs. The studs should allow the coulters

to drop slightly below the desired operating depth to

allow the coulter lock pins to be installed and removed

easily.

Great Plains Mfg., Inc.

Refer to Figure 27

2. Adjust the lock link trunnion nuts so the wing coulters

run exactly the same depth as the center frame coulters. The coulters must be lowered into the ground so

soil pressure is forcing the wings upward to make sure

the lock link trunnions are properly set.

Figure 26

Stop Stud Spacers

19882

Figure 27

Lock Link Trunnion

19883

Note: This view is looking straight up from beneath

the coulter wing hinge.

NTA 2000D 148-632M 9/13/2006

28

Page 31

Great Plains Mfg., Inc.

Coulter Mounting Height

You can change the depth of individual coulters by adjusting coulter-mounting height. If you adjust coulter height,

be sure to rebolt coulters vertically straight and correctly

spaced. To raise or lower individual coulters:

1. Loosen mounting clamps and adjust coulterto desired

height. Do not lower coulter spring bar below top Ubolts on coulter clamp.

Refer to Figure 28

2. To re-tighten clamps. Snug hex-head clamp bolts (1)

just until U-bolts are tight on each side of spring bar.

3. Tighten nuts (2) on U-bolts.

4. Finish tightening hex-head clamp bolts (1).

NOTE: Even when coulter is held securely, there may be a

gap between clamp halves.

Coulter Down Pressure

Added Weight

Refer to Figure 29

In hard soil conditions where coulter penetration is limited,

you can add suitcase weights to brackets on the hitch

frame. The weight brackets are locatedon each side of the

drill fan. Adding weight on the hitch frame provides the

best weight distribution for no-till drilling.You can add up to

2000lbs (907kg) of additional weight. Place an equal

amount of weight on each weight bracket.

Coulter Springs

Refer to Figure 30

Coulter-spring length is preset at the factory to10” (254

mm), giving coulters an initial operating force of 400

pounds (181 kg). This setting is adequate for many difficult

no-till conditions. For lighter no-till conditions where rocks

or other obstructions are a problem, you can reduce

coulter down pressure to give coulters better impact protection. Refer to the following chart for adjusting coulter

down pressure.

10300

Figure 28

Individual Coulter Mounting

19884

Figure 29

Weight Brackets

Spring Length Coulter Down Pressure

10 1/2 in (267 mm) 175 lbs (79 kg)

10 1/4 in (260 mm) 300 lbs (136 kg)

10 in (254 mm) 400 lbs (181 kg)

9 3/4 in (248 mm) 525 lbs (238 kg)

NOTE: Do not reset coulter spring length shorter than

9 3/4” (248 mm). Shortening coulter springs more than

9 3/4” (248 mm) may contribute to premature failure of

parts and warranty will be voided.

9/13/2006

Figure 30

Coulter Spring

NTA 2000D 148-632M

13990

29

Page 32

Opener Depth

When making opener adjustments, keep in mind that

openers will not run any deeper than coulters till the soil.

Press Wheel Adjustment

Refer to Figure 31

Changing the height of the press wheels automatically

changes seeding depth. To adjust, lift T-handle and slide

forward or back.

• For shallower seeding, slide handle ahead toward implement.

• For deeper seeding, slide handle back away from implement.

Great Plains Mfg., Inc.

Shallower

Deeper

16671

Figure 31

Press Wheel Adjustment

Opener Mounting Height

Refer to Figure 32

You also can lower individual opener bodies that run in tire

tracks. To lower an opener, move opener-pivot bolt to

lower hole in opener mount.

Figure 32

Opener Adjustment

16672

NTA 2000D 148-632M 9/13/2006

30

Page 33

Great Plains Mfg., Inc.

Opener Down Pressure

Refer to Figure 33

To adjust down pressure on individual openers that run in

tire tracks, change opener-spring length.

1. To increase down pressure, loosen the jam nut at the

lower end of opener spring, then turn flange nut. Each

additional 1/4” (6 mm) of spring compression adds

about 13 pounds (6 kg) of pressure. After adjusting

flange nut, tighten jam nut.

IMPORTANT: Do not compress spring more than one

inch (25 mm). Compressing spring more than one inch

(25 mm) could cause opener damage and void the warranty.

Disk Scraper Adjustment

Refer to Figure 34

To keep opener disks turning freely, dirt scrapers are

mounted between disks to clean as the disks rotate. As

field conditions vary, you may need to adjust the scrapers.

2. To adjust, loosen 3/8” bolt and raise or lower scraper

as needed.

Leaf Spring Adjustment

Refer to Figure 35

A leaf spring is located just ahead of the vertical pivot. The

spring is designed to provide just enough force to keep the

opener frame square and stable for turning at field ends

and to add stability for drilling in rough field conditions.

Proper leaf-spring adjustment is important for smooth

implement operation.

1. To adjust properly, square the opener frame to the

coulter frame and adjust 3/8” U-bolts (1) on each side

until leaf-spring rollers (2) just make contact with roller

pads (3) on opener frame. When the U-bolts are adjusted properly the opener frame should be square

with the coulter frame when the drill is raised.

16634

Figure 33

Individual Spring Adjustment

Figure 34

Disk Scraper

19895

19888

9/13/2006

Figure 35

Leaf Spring Adjustment

NTA 2000D 148-632M

31

Page 34

Harrow Adjustments

Refer to Figure 36

The illustration shows a successful harrow position for notill conditions. Because of different soil moisture, trash levels and trash types, you may need to reposition the tube

frame or tines. Initially position the frame and tines as

shown, then readjust as necessary.

1. To adjust the frames, loosen the hex nuts (1) on the

U-bolts and rotate the frame tube (2) as necessary.

Tighten nuts.

Refer to Figure 37

2. To adjust the tines, loosen the 1/2” hex nuts (3) on the

1/2” U-bolts that attach the tine tubes to the harrow

frames.

3. Rotate tine tubes (4) so the tines are against the stop

bushings and are angled back as necessary. Retighten hex nuts on U-bolts.

!

CAUTION!

Before working around the drill make sure it is properly hitched

to the tractor and that the tractor is turned off and the transmission is in the park position. Make sure the drill is on level

ground and the coulter and opener wing frames are in their unfolded position. For proper hitching and unfolding instructions

refer to the operators manual for this drill.

Figure 36

Frame Adjustment

Great Plains Mfg., Inc.

19887

Refer to Figure 38

Note: The light bar brackets on the drill must be adjusted

so the lights are just behind the wing opener press

wheels and just ahead of the wing harrow when the drill

is folded. Use extreme caution when folding the drill for

the first time after the harrows are installed. Slide the light

bar brackets forward or backward as necessary so the

wing opener press wheels and wing harrows do not contact the lights.

4. To adjust the transport height of the center harrow

section, raise the drill and install the transport lock

channels on the transport cylinders and the tongue

cylinder.

5. Remove the 7/16” lock nuts (1) and 7/16” x 2 3/4” bolts

(2) from the center pull arms and the chain links on

chain (3).

6. The center section must rest low enough in the transport position to allow the wing sections to fold over the

top of the center section without contacting it. This position is slightly lower than the maximum down position of the wing sections.

7. Select a chain link to adjust the transport height of the

center section. Carefully fold the drill to make sure the

wing harrow sections do not contact the center section. Make adjustments as necessary to get the maximum center section transport height without wing

section contact.

8. Make sure both chains are adjusted to the same

length so the section raises and lowers evenly.

19886

Figure 37

Tine Adjustment

Figure 38

Chain Adjustment

19913

NTA 2000D 148-632M 9/13/2006

32

Page 35

Great Plains Mfg., Inc.

Marker Adjustments

Folding Speed

Refer to Figure 39

1. Adjust folding speed with hex adjustment screws on

the sequence-valve body. There is one adjustment

screw for raising speed (1) and one for lowering speed

(2). Identify adjustment screws by markings stamped

in valve body.

2. With tractor idling at a normal operating speed, adjust

marker folding to a safe speed.Turn adjustment

screws clockwise to decrease folding speed and

counterclockwise to increase folding speed. Excessive folding speed could damage markers and void

the warranty.

3. After adjusting the folding speed, tighten jam nuts on

hex adjustment screws to hold settings.

Disk Adjustments

Refer to Figure 40

If mark left by marker disk is not easy to see, change disk

angle to make a wider mark.

1. Loosen two 1/2” carriage bolts (1) holding disk mount.

Rotate disk mount as desired.

If the marker disk is not square with the ground when the

marker is lowered in the field, or if marker arm tends to fold

up while lowered in the field, change disk angle relative to

ground.

2. Loosen 1/2” bolts (2) and rotate marker mount until

marker disk is square with ground.

3. To adjust where the disk marks, loosen U-bolt (3) and

slide marker-mount tube in or out as necessary. Retighten U-bolt.

Cylinder Lock Channel

Refer to Figure 41

The markers should be in transport position when opening

a field or when drilling next to obstructions.

14048

Figure 39

Speed Adjustment, Sequence Valve

Figure 40

Disk Angle

Refer to Figure 42

1. For field operation the cylinder lock channels must be

placed on the cylinder rods so only the outer two sections of the markers fold. This speeds up marker cycle

time and reduces wear on markers.

2. The markers have breakaway protection to keep them

from being damaged if the marker strikes a solid object. The breakaway bolt should only be replaced with

a 3/8-16 x 2” Gr 5 bolt (Great Plains P/N 802-143C)

and two 3/8” nuts (Great Plains P/N 803-014C). It is

important to use two nuts on the breakawaybolt. Extra

bolts and nuts can be purchased and stored in the extra holes of the breakaway plate.

9/13/2006

Figure 41

Marker Transport Position

2

1

Figure 42

Marker Field Position and Marker Breakaway Bolts

NTA 2000D 148-632M

33

Page 36

Seed-Lok Lock Up

Refer to Figure 43

Optional Seed-Lok firming wheels provide additional

seed-to-soil contact. The wheels are spring loaded and do

not require adjusting. In some wet and sticky conditions

the wheels may accumulate soil.

1. To lock up Seed Lok wheels, hook bottom of hanger

(1) under Seed Lok arm (2) as shown.

Meter

Variator

Drive to the feed mechanism is by two landwheels through

an infinitely adjustable variator which selects the speed of

the feed rollers to increase or decrease the seeding rate.

Feed Roller speed is adjusted by:

a. Operating the lever on the Variator against the

scale which gives stepless increased from 0

(slow) to 90 (fast).

b. By selecting the output speed of the Variator to

High (for high rates of larger seeds) or Low (for

low rates of small seeds) using a selector lever

behind the variator.

Refer to Figure 44

1. To adjust speed, release the locking knob, move the

lever to zero then up to the required position and retighten locking knob.

Figure 43

Seed Lock

Great Plains Mfg., Inc.

18944

Refer to Figure 45

2. Use lever to adjust between High and Low output. To

go to the High output pull the lever back, (away from)

the drill hopper. To go to the Low output push the lever

forward, (toward) the drill hopper.

It may be necessary to turn the output shaft in the direction

of the arrow with the calibration crank in order for the Hi-Lo

gears to move and completely engage in the new position.

Always use the calibration crank to turn the output shaft

and make sure the high and low are completely meshed

after making an adjustment.

19762

Figure 44

Variator

Low

High

19762

Figure 45

High Low Lever

NTA 2000D 148-632M 9/13/2006

34

Page 37

Great Plains Mfg., Inc.

Feed Flaps

Spring loaded flaps, one below each roller allows the

seeding of a wide range of seed sizes and are used to positively control the flow of small seeds to large seeds

through the feed rollers without causing bruising or crushing. They also act as a safety devise for the feed rollers.

The spring loaded flap “gives” to allow a stone or other

obstructions through without damaging the rollers.

Refer to Figure 46

1. The flaps under all the rollers are adjusted by a single

lever at the right hand end of the hopper. A series of

notches in the guide bracket set the lever to the required flap opening. Position 1 is the upper setting at

which the flaps are closest to the feed roller.

Refer to Figure 47

Note: Each flap should just touch the feed roller at position

1. This is factory set, however, if adjustment is required,

tighten or slacken the lock screw below the required flap to

keep all flaps equal across the meter.

The recommended position for the Feed Flap lever setting

for different seed types is as follows:

• Position 1: Small seeds e.g. rape, when the flap is

closest to the feed roller.

• Position 2: Cereals e.g. wheat and barley.

• Position 3: Large seeds e.g. peas and beans.

Note: Refer to the seed rate charts for proper feed flap setting.

Half Width Shut-Off

Refer to Figure 48

Half width shut-off provides for:

a. Seeding of a narrow width when finishing a field to

prevent double seeding.

b. To start a field in the correct sequence when tram-

lining.

To disengage, insert tool into clutch grooves and rotate

the clutch until the two drive roll pins are in line. Slide

clutch to the left until the right drive roll pin is disengaged.

Rotate clutch one quarter turn back to lock it onto the left

drive roll pin to prevent the clutch from reengaging.

Note: The left- hand side of the feed mechanism is disengaged. Re-engage by rotating the clutch from it’s lock

position and allow it to slide back to the right.

NOTE: CHECK TO BE SURE THE CLUTCH HAS

FULLY RE-ENGAGED.

19766

Figure 46

Feed Flap Adjustment

19922

Figure 47

Feed Flap Adjustment Screw

9/13/2006

19774

Figure 48

Half Width Clutch

NTA 2000D 148-632M

35

Page 38

Checking the Seeding Rate

The following procedure should be followed to calibrate

the drill for different seed types. Note that the following

factors may affect seeding accuracy:

• Errors in land area which are affected by wheel slip,

operator judgement and by inaccurate knowledge of

field size.

• Errors in metering which are affected by seed treatments, seed size, variety, moisture content and seed

bulk density.

To calibrate the drill, an accurate set of scales will be

required. Other equipment is supplied with the drill and

includes calibration trays and handle.

Procedure

Refer to Figure 49

1. Release the two black plastic lock screws above each

venturi unit by loosening, sliding the knob up and retightening.

2. Push the left and right venturi units forward to clear the

feed units.

Refer to Figure 50

3. Remove calibration tray (a) from storage position

above the feed rollers by loosening center knob (b)

and sliding lock tab down.

Refer to Figure 51

4. Position the calibration trays under the feed rollers.

5. Refer to the “Seed Rate Charts,” page 48, for the

seed to be sown. Set to the “High” or “Low” speed, adjust the flaps below the feed rollers to the required position and adjust the variator lever to the setting

indicated on the guide chart to give the target rate.

6. Ensure that the drill is not in a tramlining bout so that

all the feed rollers turn when the seed shaft is rotating.

7. Fill the hopper with at least 110 lbs. (50 kg) of seed to

ensure that all the feed rollers are covered throughout

the test.

Refer to Figure 52

8. Position the crank handle on the input point of the Variator and rotate clockwise to “prime” the feed mechanism. It is important to turn the handle at least 50 turns

before calibrating to ensure seed is flowing correctly

through the system. Empty the calibration trays before

carrying out a full test.

9. Rotate the crank handle 41 turns. (For extra accuracy

it is recommended to carry out a Calibrations for Num-

ber of Turns, described on the next page).

10. Weigh the seed collected from both trays in pounds.

Use an accurate set of scales. This amount is equivalent to 1/10th acre.

Seeding Rate (lb/ac)=Weight Collected (lb) x 10

Great Plains Mfg., Inc.

19769

Figure 49

Venturi Unit

b

a

19924

Figure 50

Venturi Unit

19768

Figure 51

Calibration Tray

19770

Figure 52

Calibration Crank Handle

NTA 2000D 148-632M 9/13/2006

36

Page 39

Great Plains Mfg., Inc.

11. If the result is different to the required rate, adjust the

Variator to increase or decrease the seeding rate. Remember to re-prime the feed mechanism with at least

50 turns before re-calibrating.

Note: Always move the Variator handle down to zero then

back up to the required setting.

Calibrations for Number of Turns

As indicated at the start of this section, accuracy in calibration can be affected by a number of factors not least of

which is soil type, wheel slip and sinkage. The number of

turns recommended for the calibration crank handle are

based on “average” figures in normal field conditions. If

farm conditions are very stony (so little sinkage) or very

sandy (so greater sinkage) then using the recommended

number of crank handle turns may be inaccurate.

To check the number of turns for individual field

conditions:

Refer to Figure 53

1. Shut down the shut-off slide above each roller to prevent seeding.

2. Fill the drill half to two-thirds full of seed.

3. Mark out 218 feet of seedbed.

4. Position the calibration handle on the Variator input

and rotate to the upright (12 o’clock) position to give a

clear starting point.

5. Drive the distance marked-off in the seedbed and

count the number of turns the calibration handle

makes.

6. Note the number of turns and use this figure in the

Checking the Seeding Rate procedure in the previous

section in place of the standard.

Hopper Clean-out

Refer to Figure 54

The seed hopper has two slide gates connected to discharge hoses for cleaning out the bulk of the seed from the

hopper. Each slide gate is controlled by a handle that

extends out beyond the end of the meter assembly. The

discharge hose can be directed into a bag or into the

auger hopper.

Final meter clean-cut must be done using the calibration

trays. Slide the venturi units forward and place the calibration trays under the feed rolls. Move the flap adjustment

handle to the full open position and empty the remaining

seed into the trays. The flap handle can be closed when

the trays are emptied.

Refer to Figure 55

The air distribution chamber must be inspected and keep

clean daily.

1. Remove end caps and visually inspect chamber.

2. To clean chamber, remove end caps and blow out

chamber with the fan.

Make sure the area around the openings is clear and that

no one will enter the area before starting fan.

Figure 53

Individual Shut Off

Figure 54

Clean-out Handle

Figure 55

Air Box End Cap

19934

19938

19936

9/13/2006

NTA 2000D 148-632M

37

Page 40

Tramlining

The meter can automatically leave tractor track marks or

“tramlines” in the correct position for subsequent accurate

bout matching of spraying and fertilizing applications.

The system operates by stopping the drive to2+2feed

rollers (two in the left side of the hopper for the left track

mark and two in the right side of the hopper for the right

track mark) as factory fitted, these will give a tramline track

width of 3 times the drill row spacing.

Refer to Figure 56

Drive to the two feed rollers at the left end of each half of

the meter assembly is disengaged by arms attached to an

electric actuator. These feed rollers are marked with tractor tread decals on the back of the meter assembly.

Drive is automatically engaged/disengaged in the

required sequence by the monitor control box positioned

in the cab. A magnet and sensor on the contact drive

record the bout count. See separate monitor instruction

section for further information and programming

instruction.

Setting up for Tramlines

The drill is set up to do “symmetrical tramlining” for 60 ft.

applicator booms, or “asymmetrical right tramlining” for 40

ft. and 80 ft. applicator booms. See Tramlining instructions

in the Monitor section of this manual. With the optional

NTA2000 dual tramline controls kit, (Great Plains P/N

890-785C) the drill can be set up for 10 bout tramlining for

50 ft. applicator booms or 18 bout tramlining for 90 ft.

applicator booms.

Any seed hose can be connected to the tramline marked

feed rolls on the air distribution chamber. For symmetrical

tramlining, connect the right tramline marked feed rolls to

the desired two rows right of center to leave a mark for the

right sprayer track, and connect the left tramline marked

feed rolls to the desired two rows left of center to leave a

mark for the left sprayer track

Asymmetrical Right Tramlining

Asymmetrical right tramlining only requires the use of the

right tramline marked feed rolls. The actuator arm to the

left tramline marked feed rolls must be disconnected.

For asymmetrical right tramlining connect the right tramline marked feed rolls to the desired two rows at the right

end of the drill to leave a mark for the sprayer tracks on

two consecutive passes.

Refer to Figure 57

Disconnect the actuator arm at the left side of the meter

assembly that operates the left feed roll tramline clutch.

This arm will have to be tied over to the right so the “star

shaped” teeth on the arm do not slide over and contact the

feed roll clutch spring.

Note: With the optional NTA2000 dual tramline controls kit,

(Great Plains P/N 890-785C) it will not be necessary to

disconnect the actuator arm.

Figure 56

Tractor Tread Decal

Figure 57

Actuator Arm

Great Plains Mfg., Inc.

19937

19923

NTA 2000D 148-632M 9/13/2006

38

Page 41

Multi-function Drill Control

Monitor

The multi-function drill monitor controls the operation and tramlining functi on of pneumatic type seed drills.

The instrument has an illuminated 4 digit display with 6 display functions and alarm functions for forward

speed, fan rpm and seed distribution shaft rpm. The speed and area functions can be displayed in either

metric or imperial units.

The instrument indicates:

• Forward Speed (plus low speed alarm)

• Part Area and Total Area worked

• The current bout number and tramline bouts for the selected tramlining sequence.

• Fan rpm (plus low/high speed alarm)

• Seed Distribution Shaft rpm (plus low speed alarm)

• Hopper level low

The tramlining function is the priority display. The instrument will default to this channel display 10 sec onds

after selecting another display function (with the exception of displa ying an area t otal or when the drill is out of

work).

It has two memory registers (Total 1 and Total 2) to record area worked. The area is accumulated to both

memory registers. Area totals and all calibration data are automatically stored in memory when the instrument

is powered off.

The instrument must be initially calibrated to suit the implement being co ntrolled. Three program mod es allow

the default settings to be altered as required. Most of these settings do not need to be accessed in normal

use.

Calibration and Operation

Software Ref: WZ 304-001 rev.03

38a

Page 42

Multi-function Drill Control

The Control Switches

There are three active switches on the front panel used in dividually or in combination to program set/reset or

select a function. The two small outer buttons have no function.

Current Bout No.

Channel /

In-Out of Work Indicator

Not used

Program Key

1. Select the channel then

PRESS to switch between

Area Total 1 and 2.

2. Select the channel then

PRESS to manually advance

the Bout Number.

3. HOLD continuously to select the

programming mode. (Normal Mode