Great Plains Blockage Monitor User Manual

Great Plains Mfg., Inc.

Installation Instructions

Air Drill

Blockage Monitor

Used with:

NTA3510 and NTA3010

•

CTA4000

•

ADI334 and ADI345

•

General Information

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

!

the lives of others depend on it!

These instructions explain how to install the blockage monitor.

The blockage monitors work with the system monitor to alter the

operator when a seed-delivery hose is plugged. When a monitored hose is plugged, the system sounds an alarm and identifies

the location of the plugged hose.

These instructions apply to:

168-256A NTA3510 55-Row Blockage Monitor

168-257A NTA3510 40-Row Blockage Monitor

168-260A NTA3010 48-Row Blockage Monitor

168-261A NTA3010 36-Row Blockage Monitor

168-267A ADI345 75-Row Blockage Monitor

168-318A CTA4000 80-Row Blockage Monitor

168-319A CTA4000 65-Row Blockage Monitor

168-320A CTA4000 50-Row Blockage Monitor

Assembly Instructions

Module and Sensor Installation

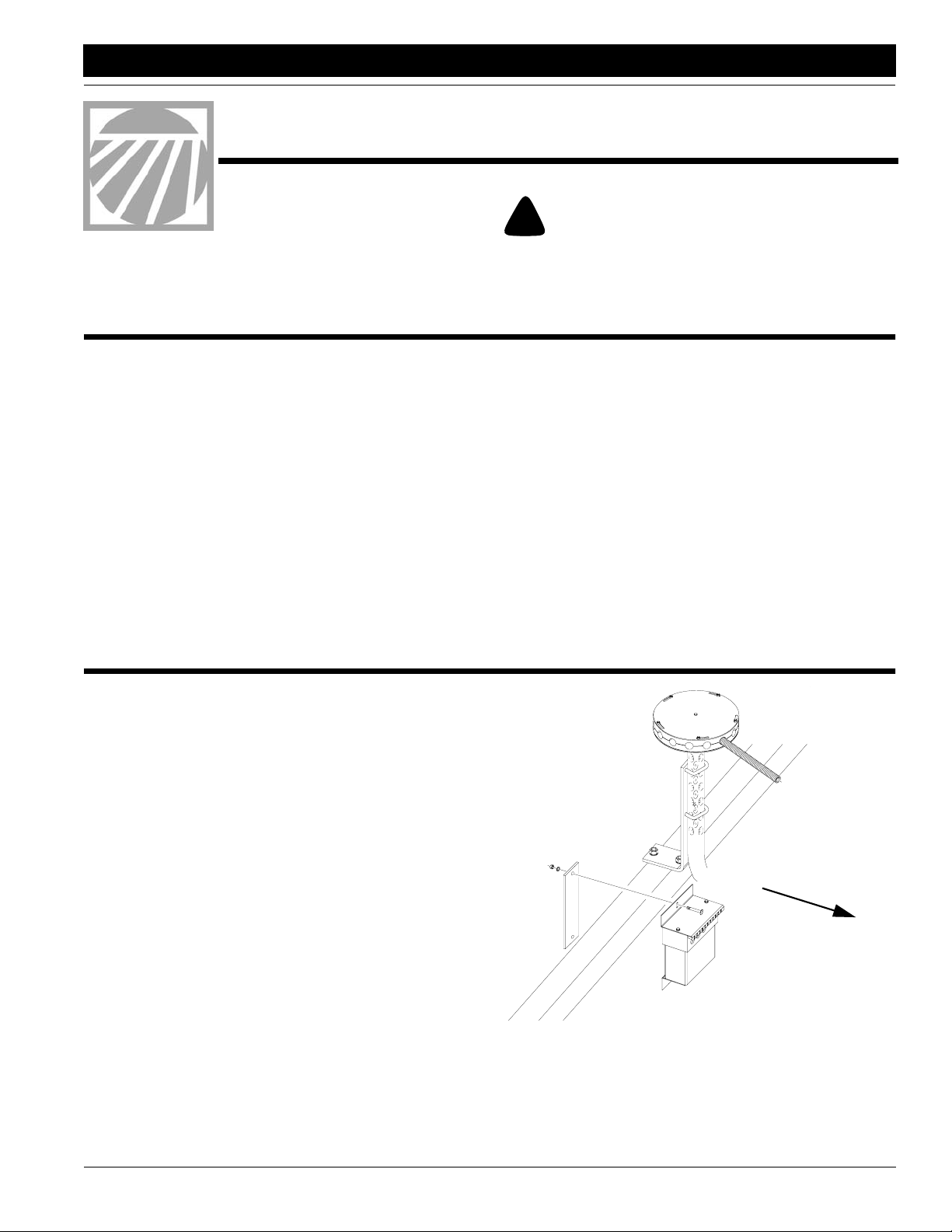

1. Mount each module on rear frame

tube of implement near tower to be

monitored. Clamp modules to frame

so modules are to the inside of implement and connector panels face

up.

Manual Update

Refer to air drill cart operator’s manual f or detailed information on

safely operating, adjusting, troubleshooting and maintaining the

blockage monitors. Refer to the parts manual for part identification.

• ADC1150 Air Drill Cart Operator’s Manual. . . . . . .167-101M

• ADC1150 Air Drill Cart Parts Manual. . . . . . . . . . . 167-101P

• ADC2220 Air Drill Cart Operator’s Manual. . . . . . .167-073M

• ADC2220 Air Drill Cart Parts Manual. . . . . . . . . . . 167-073P

Before You Start

Starting on page 6 are detailed listings of parts included in the

blockage monitor packages. Use these lists to inventory parts re-

ceived.

© Copyright 1999 Printed 7/1/99

T

o

war

d T

ractor

168-258M

18088

1

Assembly

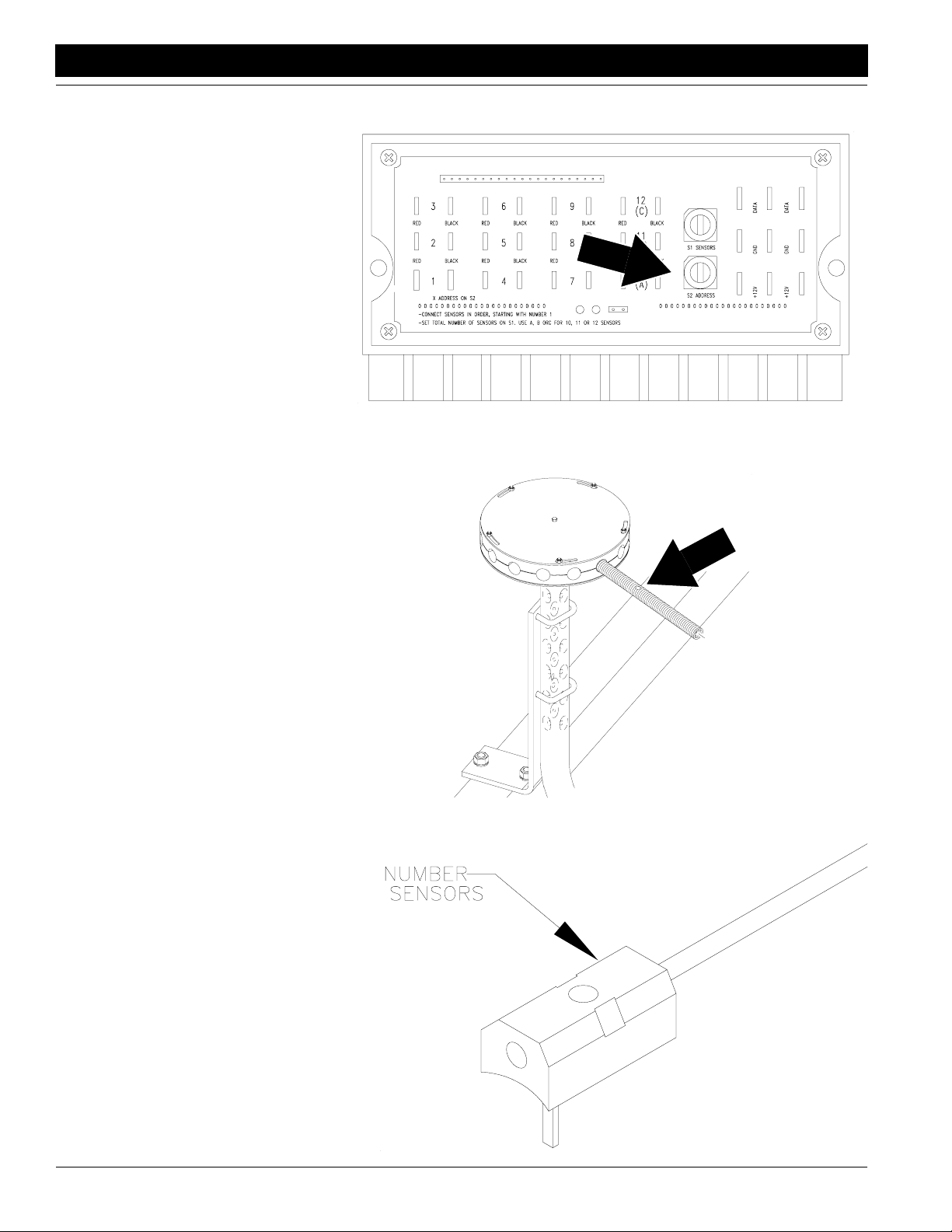

2. On each module connector panel,

set rotary switch marked S2 ADDRESS. Set rotary switch on far left

module to 1, rotary switch on second

module from left to 2 and so forth.

Continue until each module is set to

a unique address.

3. In each secondary seed hose to be

monitored, use a die grinder to make

a 1/2-inch hole in top of hose near

seed-distribution tower .

NOTE: Do not use a drill bit to make

holes in secondary seed hoses. Using a

drill bit will damage the seed hose.

Great Plains Mfg., Inc.

18093

4. Gather enough sensors for hoses to

be monitored on far-left tower . Using

marking chalk, number sensors in

sequential order.

Air Drill Blockage Monitor 168-258M 4/8/04

2

18090

18091

Great Plains Mfg., Inc.

Assembly

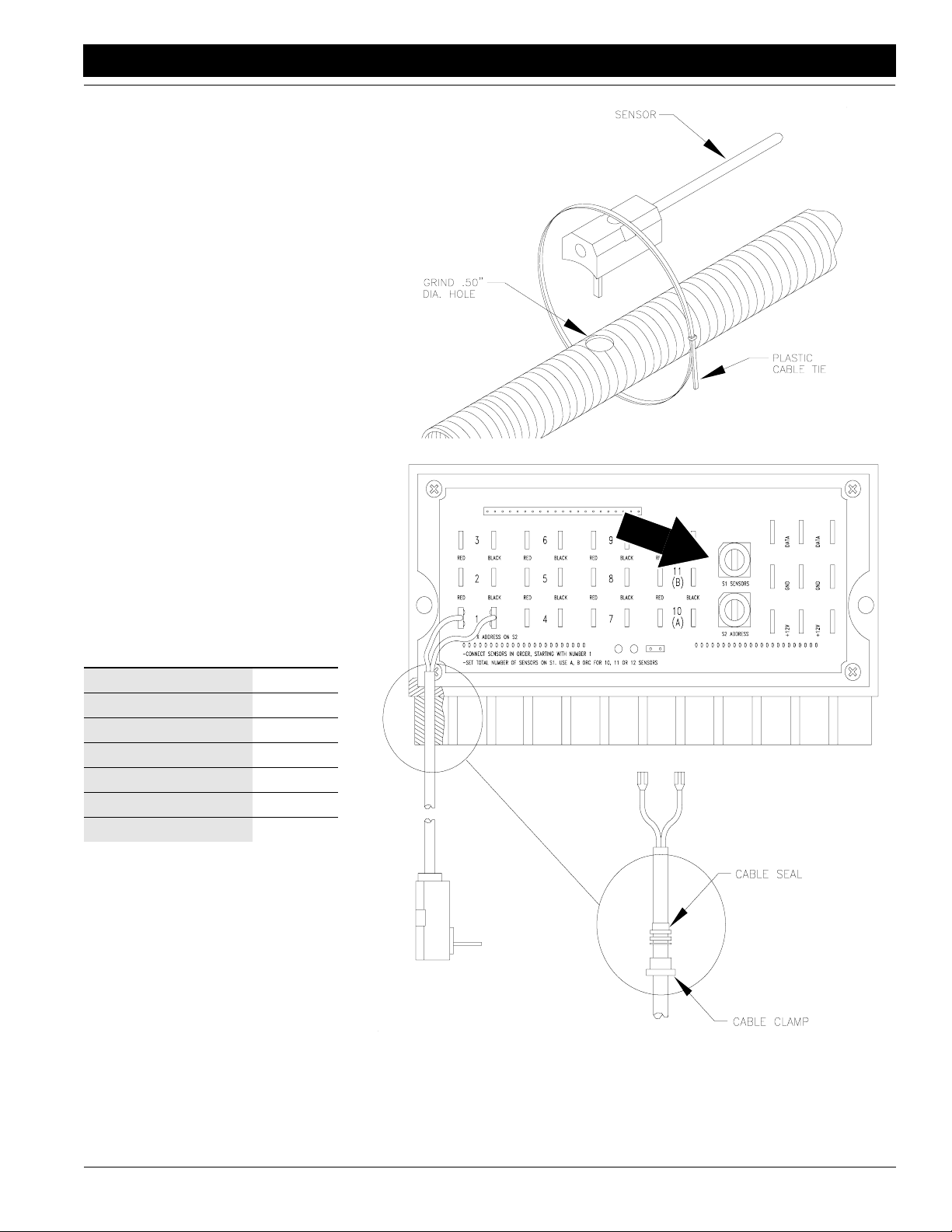

5. Install sensor number 1 on a second-

ary seed hose. To install, insert sensor pin into 1/2-inch hole and secure

sensor body to secondary seed hose

with a cable tie. Working clockwise

around distribution tower , contin ue

installing sensors into hoses until all

sensors for tower are installed.

6. Connect sensors to modules. On

connector panel, find numbered connector pins. Connect lead from sensor 1 to pins marked 1. Connect lead

from sensor 2 to pins marked 2. Proceed until all senors for tower are

connected to module for that tower.

7. After connecting sensors to module,

set S1 SENSOR rotary switch on

connector panel. Refer to the follo wing table for proper s witch setting

Number of sensors con-

nected to module:

1 1

2 2

3 3

9 9

10 A

11 B

12 C

8. Repeat steps 3 through 7 for each

implement tower .

S1 SENSOR

Setting

18092

18089

4/8/04

Air Drill Blockage Monitor 168-258M

3

Loading...

Loading...