Great Plains Auxiliary Hydraulic User Manual

Great Plains Mfg., Inc.

Auxiliary Hydraulic Kit

Yield-Pro Planters

Used with:

• All model year YP1225 and YP1625 (pull type) planters

General Information

These instructions explain how to install the Auxiliary

Hydraulic Kit. When the planter is not in motion, this kit

enables the marker hydraulic circuit to be used to drive

off-planter equipment, such as a seed auger.

Note: These instructions apply only to planters with

markers (which are standard). If your initial planter

order deleted the markers, have your dealer contact the factory for special instructions.

These instructions apply to:

Option Packages Part Number

YP1225 Auxiliary Hydraulic Kit 401-435A

YP1625 Auxiliary Hydraulic Kit 407-441A

Installation Instructions 1

Before You Start

Each kit converts one planter.

For each kit, inventory the contents per the “Parts Lists”

on page 13.

Review the instructions, to make sure the steps are

understood and what tools are expected.

If necessary, move the planter to a dry well-lighted location suitable for disassembly.

1. Unfold and lower the planter. Although this kit can

be installed on a folded and/or raised planter,

access to the hose support bracket to be replaced,

and the marker sequence valve, is much easier

when unfolded/lowered.

2. Select the Marker circuit in the tractor. Set control to

float (to drain pressure in that circuit). Shut down

hydraulics.

Secure the tractor if left connected.

Figure 1

Installed Auxiliary Ports

“Left” and “Right” are facing in the direction of machine

travel.

1

callouts are local to the current Figure(s)

11

callouts reference the parts lists on page 13.

Have the following tools at hand:

• Snap ring pliers

• Basic hand tools

25394

©Copyright 2007 Printed 05/05/2009 401-466M

2 Auxiliary Hydraulic Kit

Installation

Replace Existing Hose Support Bracket

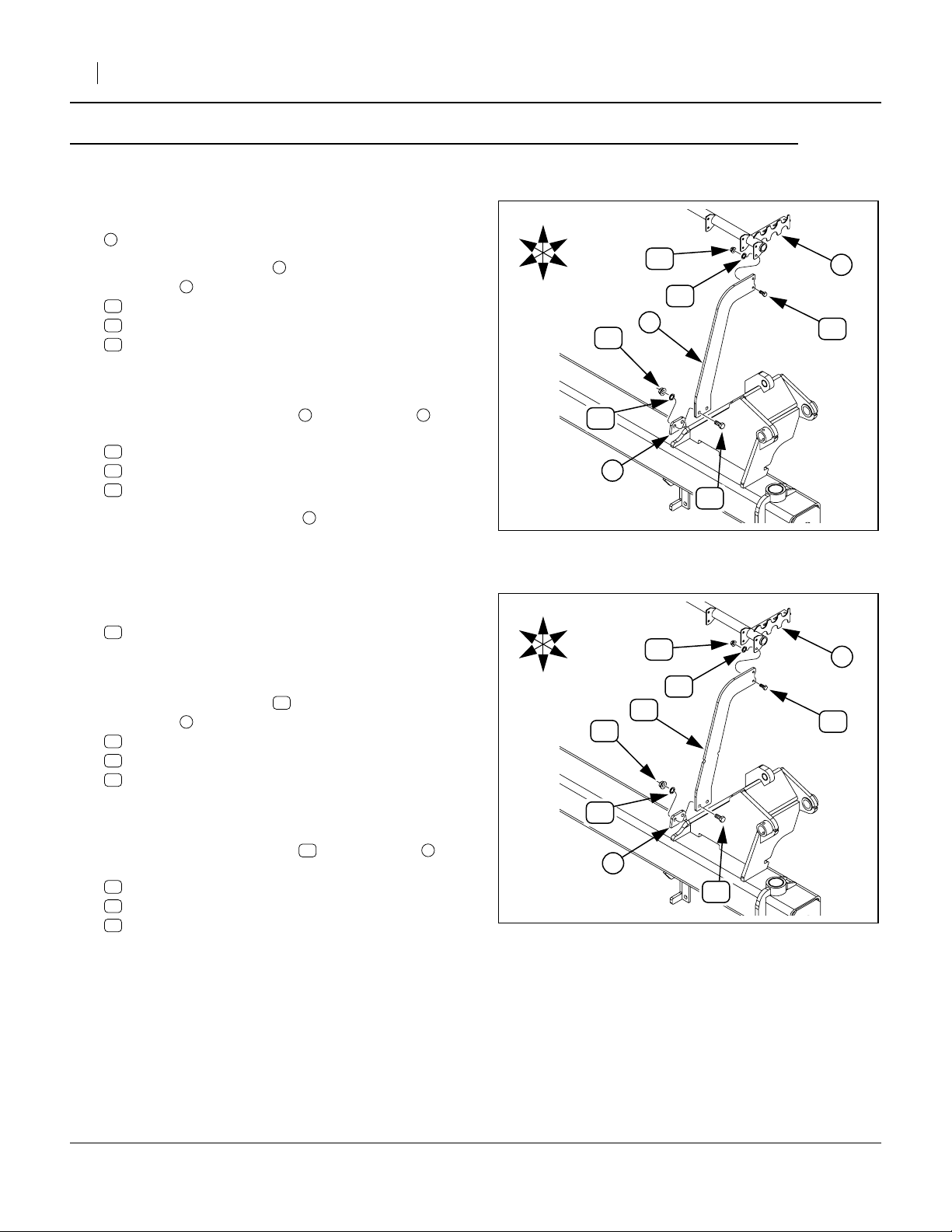

Refer to Figure 2

3. Locate the outer-most air system standoff bracket

1

on the left wing of the planter.

4. At the top of the bracket , at the seed tube support frame , remove and save two each:

39

NUT HEX 5/16-18 PLT

42

WASHER LOCK SPRING 5/16 PLT

38

HHCS 5/16-18X1 GR5

Note: Some older planters may have a lock nut and no

lock washer.

2

1

R

F

U

D

B

L

40

39

1

Great Plains Mfg., Inc.

2

42

38

5. At the bottom of the bracket , at the toolbar ,

remove and save two each:

40

NUT HEX 1/2-13 PLT

43

WASHER LOCK SPRING 1/2 PLT

37

HHCS 1/2-13X1 1/4 GR5.

6. Remove the existing bracket .

It is not reused.

Refer to Figure 3

7. Select one:

12

403-382D AIR SYS BRKT F/ AUX HOSE KIT

Note: The new bracket has notches for the bolts that

attach the new selector valve.

8. At the top of the bracket , at the seed tube support frame , re-install two each:

38

HHCS 5/16-18X1 GR5

42

WASHER LOCK SPRING 5/16 PLT

39

NUT HEX 5/16-18 PLT

Note: Some older planters may have a lock nut and no

lock washer. Use the existing fasteners.

9. At the bottom of the bracket , at the toolbar ,

re-install two each:

37

HHCS 1/2-13X1 1/4 GR5

43

WASHER LOCK SPRING 1/2 PLT

40

NUT HEX 1/2-13 PLT

2

1 3

1

12

12 3

R

F

U

D

43

3

Remove Old Bracket

B

39

L

12

40

43

3

Install New Bracket

37

Figure 2

42

Figure 3

25395

2

38

37

25396

401-466M 05/05/2009

Great Plains Mfg., Inc.

Mount and Assemble Selector Valve

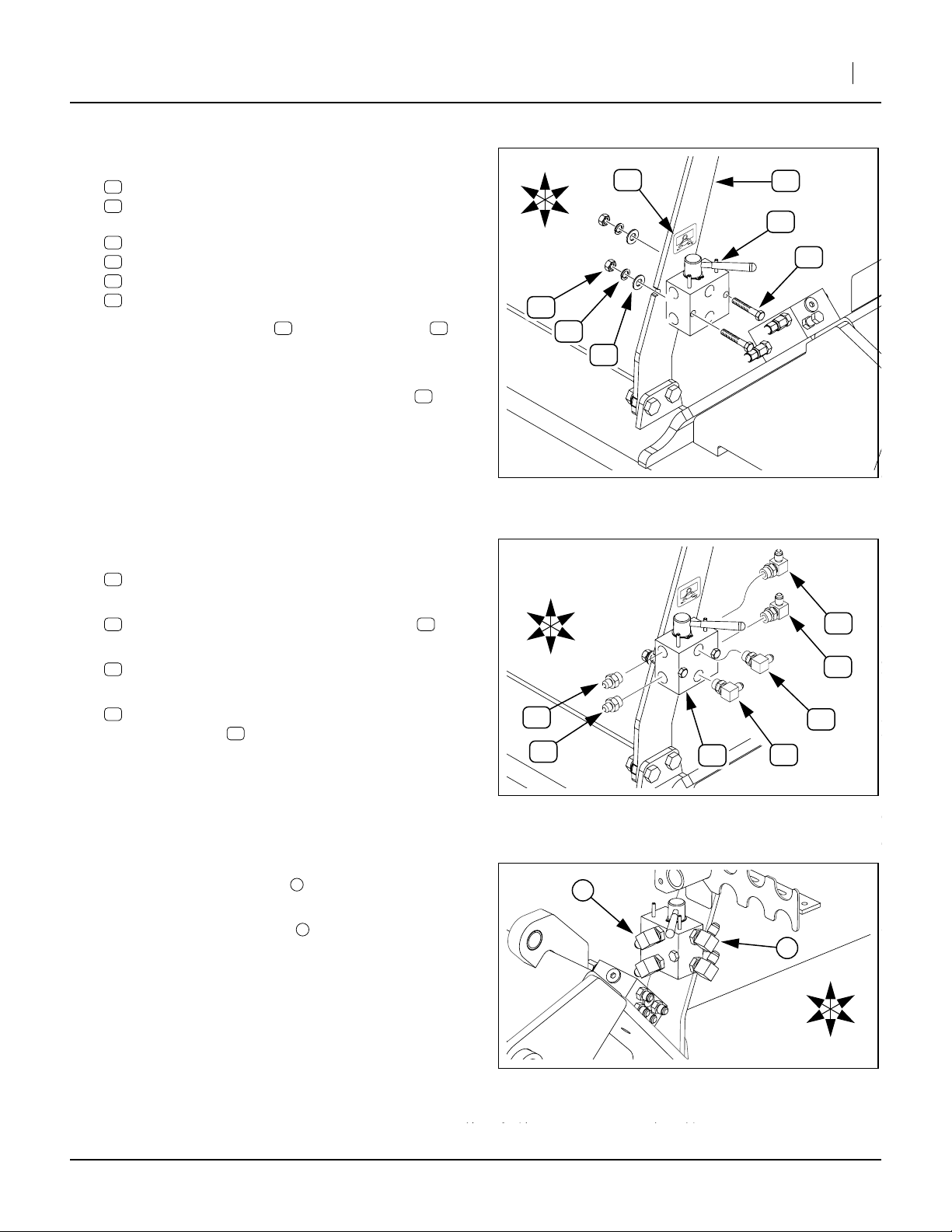

Refer to Figure 4

10. Select one:

28

810-274C DOUBLE SELECTOR VALVE 3/4FORB

36

848-083C DECAL AUX HYD SELECTOR VALVE

and two each:

19

802-024C HHCS 3/8-16X3 GR5

24

804-011C WASHER FLAT 3/8 USS PLT

25

804-013C WASHER LOCK SPRING 3/8 PLT

22

803-014C NUT HEX 3/8-16 PLT

11. Mount the selector valve on the new bracket

at the notches, using the3⁄8in fasteners.

12. De-grease the bracket surface immediately above

the new valve, and apply the operating decal .

28 12

36

R

F

U

D

22

25

B

L

24

36

Installation Instructions 3

12

28

19

Refer to Figure 5

13. Select two each:

29

811-133C AD 9/16MJIC 3/4MORB

14. Loosely install the O-ring boss end of each adaptor

29 28

in one of the Front (marker) ports of valve .

15. Select four each:

30

811-171C EL 3/4MORB 9/16MJIC

16. Loosely install the O-ring boss end of each elbow

30

in each remaining face (Left) and rear (Back)

ports of the valve .

Refer to Figure 6

17. Orient the Left (face) ports so that the JIC ends

point Down and Front.

18. Orient the Back (Aux) ports so that the JIC end

point Up and Right (toward machine center).

28

1

2

F

R

29

29

U

D

Figure 4

Mount Selector Valve

B

L

Figure 5

Install Valve Fittings

1

28

30

2

25397

30

30

30

25398

U

F

R

L

B

D

Figure 6

Fitting Orientation

05/05/2009 401-466M

25399

4 Auxiliary Hydraulic Kit

Install Wing Hose Mounts

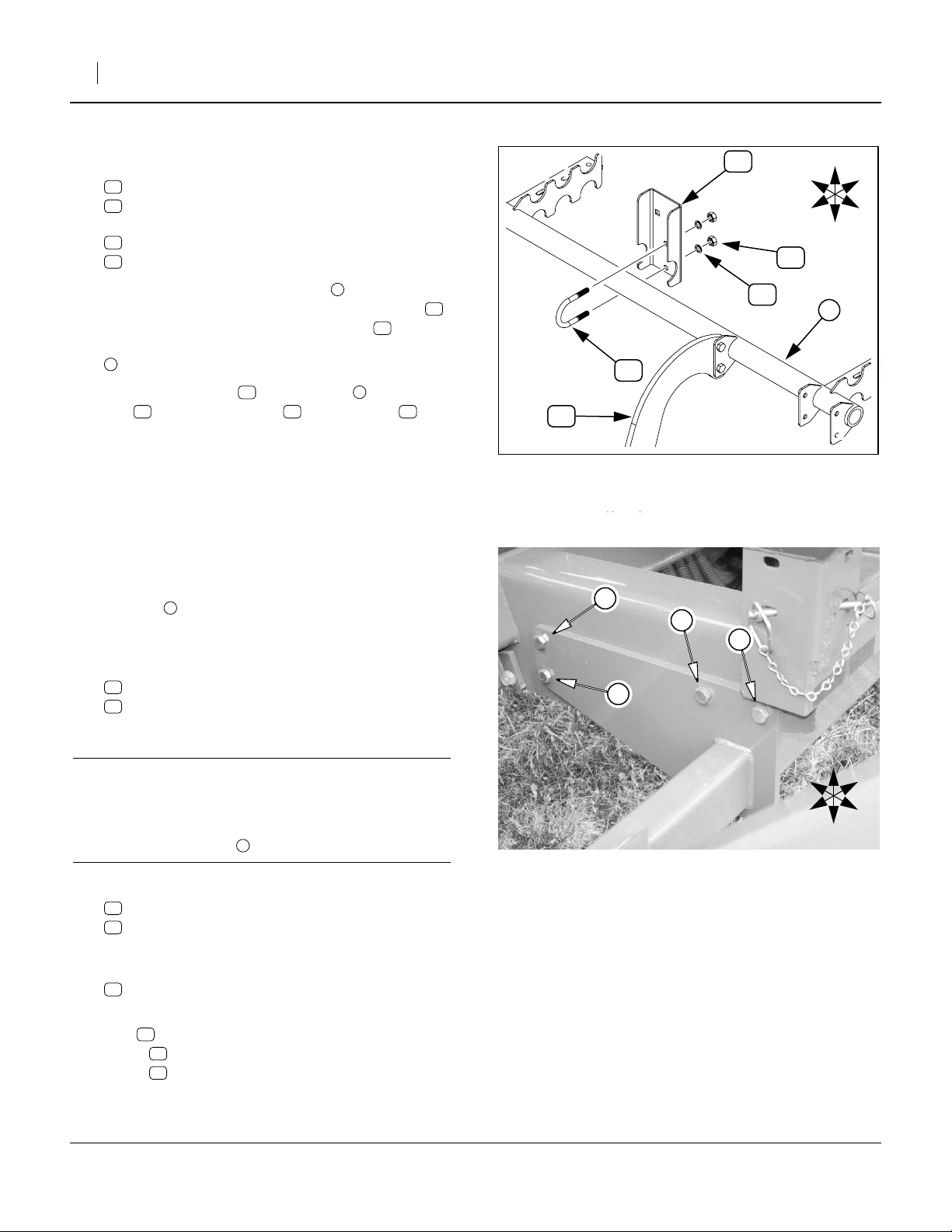

Refer to Figure 7

19. Select six:

14

411-272D AUX HYD HOSE MNT

27

806-192C U-BOLT 5/16-18X1 1/2X2 1/2 RND

and twelve each:

23

804-009C WASHER LOCK SPRING 5/16 PLT

21

803-008C NUT HEX 5/16-18 PLT

Great Plains Mfg., Inc.

14

R

F

21

U

B

L

D

20. On the air system support frame , starting at a

position about 12in inboard of the new bracket ,

mark locations for the six hose mounts about

equally spaced along the entire length of the frame

1

.

21. Attach each mount on the frame , using a U-

27 23 21

bolt , two lock washers and two nuts .

14

1

12

14

1

Install Bulkhead

Refer to Figure 8

22. Locate the four bolts that attach the left side of the

walkboard support to the rear frame. The top three

of these (on the left side only) are replaced by

new bolts in this kit. The bolts are left loose so that

the bulkhead can be added at step 29.

23. Select three:

20

26

Repeat step 24 through step 26 for each bolt.

Do not remove and replace more than one bolt at a

time.

The lower (4th) bolt is not disturbed at all.

24. Remove a3⁄4x10 2in GR5 bolt. Save the:

41

44

The old bolt is not re-used.

25. Install one:

20

26. Loosely spin on one each:

new 804-025C WASHER FLAT 3/4 SAE PLT

saved WASHER LOCK SPRING 3/4 PLT

saved NUT HEX 3/4-10 PLT

27. Repeat step 24 - step 26 for all three new bolts.

1

802-212C HHCS 3/4-10X2 1/2 GR5

804-025C WASHER FLAT 3/4 SAE PLT

IMPORTANT !

2

NUT HEX 3/4-10 PLT

WASHER LOCK SPRING 3/4 PLT

802-212C HHCS 3/4-10X2 1/2 GR5

26

44

41

12

23

27

Figure 7

Place Hose Mounts

1

1

1

2

Figure 8

Walkboard Support Bolts

1

25400

U

F

L

R

B

D

25401

401-466M 05/05/2009

Great Plains Mfg., Inc.

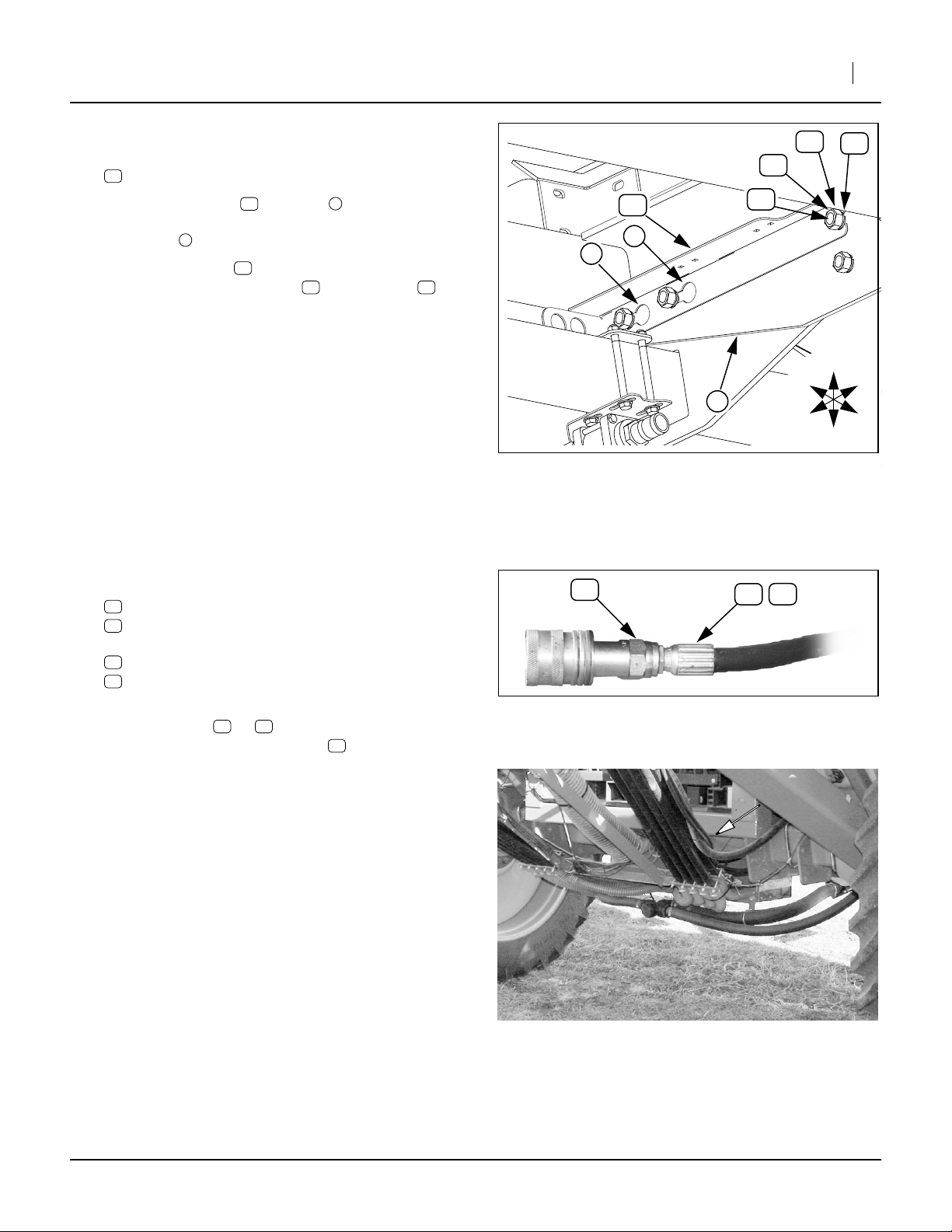

Refer to Figure 9, which is a view back, left and up into the seed cart

frame (with the airbox deleted for clarity)

28. Select one:

13

411-271D BULKHEAD HOSE MNT

29. Place the bulkhead keyholes over the rear

two loose nuts, and press it flush against the seed

cart frame .

30. Slide the bulkhead forward until all three narrow

openings are under the nuts and washers .

Tighten nuts.

3

13 1

13

41 44

13

1

1

Install Bulkhead

Installation Instructions 5

44

26

41

20

U

R

3

B

D

Figure 9

25402

F

L

Assemble and Route Auxiliary Hoses

Refer to Figure 10

31. Select two of each, per YP model:

YP1225:

32

811-204C CP 3/4FORB QD BH

31

841-365C HH3/8R2 300 9/16FJIC 3/4MORB

YP1625:

32

811-204C CP 3/4FORB QD BH

34

811-960C HH3/8R2 360 9/16FJIC 3/4MORB

32. Insert the male O-ring Boss (MORB) end of the

hydraulic hose ( or ) into the female O-Ring

boss (FORB) end of the coupler . Tighten.

Refer to Figure 11

33. Route the hose ends with the couplers into the left

side of the seed box frame, from above the seed

tube rack. They will be tie-wrapped to the left seed

tube bundle at step 65. Align them with that in

mind.

31 34

32

32

Figure 10

Assemble Port Hoses

31

34

25403

Figure 11

Route Hoses into Seed Frame

05/05/2009 401-466M

25404

Loading...

Loading...