Page 1

Great Plains Mfg., Inc.

Update Instructions

30’ No-Till Precision Seeding System

Auxiliary Down Pressure Spring

Assembly Option

Used with:

• 3N-3010P

• 3N-3020P

General Information

When you see this symbol, the subsequent instructions and

warnings areserious - follow withoutexception.Your life and

!

!

the lives of others depend on it!

These instructions explain how to install the Auxiliary

Down Pressure Spring Assembly. This kit increases the

down pressure on the contact wheel allowing for more

positive contact between the contact wheel and the gage

wheel. This modification improves the performance and

reliability of the original equipment.

These instructions apply to:

198-957K Aux. Down Pressure Spring Assy.

Manual Update

Refer to the 30’ No-Till Precision Seeding System operator’smanualfordetailed information on safelyoperating,

adjusting, troubleshooting and maintaining the Auxiliary

Down Pressure Spring Assembly. Refer to the parts man-

ual for part identification.

196-248M Operator’sManual

196-248P Parts Manual

Before You Start

Page3is a detailed listingofparts includedintheAuxiliary

DownPressure Spring Assembly option. Use thislistto inventory parts received.

Tools Required

• Basic hand tools

Definitions

Right-handand left-hand as used in this manual are determined by facing the direction the machine will travel while

in use unless otherwise stated.

© Copyright 2002 Printed

6/25/2002

20179

198-962M

Page 2

Auxiliary Down Pressure Spring

2

Assembly Option

Assembly Instructions

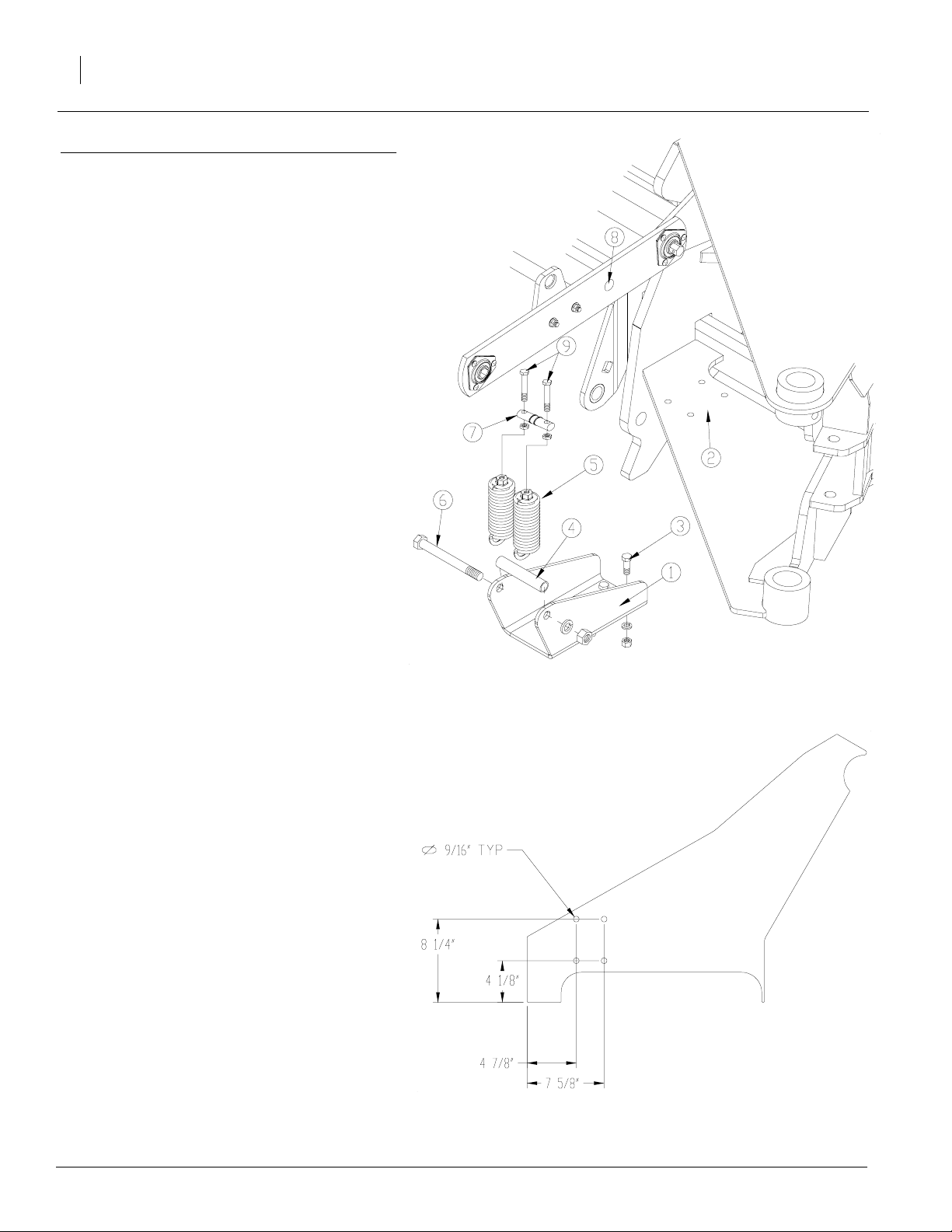

Refer to Figure 1

Note: Before performing this installation unfold

the drill on level ground. Raise the drill to the

transport position and install the transport locks.

Turn the tractor off and remove the key.

1. Mountthedownpressurespringanchor(1)to

the drill frame at the holes (2). Place the anchor (1) so the holes for the spacer tube are

facing towards the front of the drill. Use four

1/2" x 1 1/2"bolts, 1/2" lock washers and 1/2"

nuts. Tighten bolts to secure anchor.

Note:Ifyourdrilldoesnothave holes it will be necessary to drill them. Usedimensionsinfigure2for

location.

2. Insert the spacer tube (4) through the loop

endsoftwoof thespringassemblies(5). Align

the spacer tube (4) between the two holes in

the spring anchor (1) and secure it in place

with a 3/4" x 7" bolt (6), 3/4" lock washer and

3/4" nut. Tighten bolt.

Great Plains Mfg., Inc.

3. Locate the hole marked (8) in the contact

wheel mounting arm. (This hole will be directlyabovethespacertubeholdingthesprings).

Insert the down pressure spring rod (7) in

hole (8) and hold it in place with a 1" external

snap ring on each side of the arm.

4. Insert a 1/2" x 4" bolt (9) in each of the two

holes located in the spring rod (7). Thread a

1/2"jamnutoneachbolt then thread the bolts

in to the tops of the springs (5).

5. Adjust the tension on the springsbyscrewing

the bolts (9) down. Adjust to be 1/2" less tension than on original springs. Be sure to adjust the bolts evenly. This can be checked by

measuring the distance between the top of

the springs (5) andthetop of the bolts (9).Do

not adjust top bolt anycloser than 1" to avoid

premature bearing failure. When the desired

tension has been set, lock bolts (9) in place

with the 1/2" jam nuts.

6. Repeat above steps to install down pressure

springs on the other contact wheel.

Refer to Figure 2

Figure 1

Installation

20178

For drills without holes use the measurements in

figure 2. Figure 2 shows measurements forthe

left-hand side of the drill, mirror the measurements to drill holes on the right-hand side of the

Figure 2

Dimensions

20177

drill.

198-962M 4/8/2004

Page 3

Great Plains Mfg., Inc.

198-957K Aux Down Pressure Spring Assy

Your kit includes:

Qty. Part No. Part Description

2 198-258D DOWNPRESS SPRING ANCHOR

2 198-259D DOWNPRESSURE SPRING ROD

2 198-260D DP SPRING ANCHOR SPACER TUBE

1 198-962m INSTALLATION MANUAL

4 204-005S HD DOWN PRESSURE SPRING ASSY

4 800-085C SNAP RING EXT 1 HEAVY

8 802-091C HHCS 1/2-13X1 1/2 GR5

2 802-095C HHCS 3/4-10X7 GR5

4 802-424C HHCS 1/2-13X4 FTHD

8 803-020C NUT HEX 1/2-13 PLT

2 803-027C NUT HEX 3/4-10 PLT

4 803-036C NUT HEX JAM 1/2-13 PLT

8 804-015C WASHER LOCK SPRING 1/2 PLT

2 804-023C WASHER LOCK SPRING 3/4 PLT

Installation Instructions

3

198-962M4/8/2004

Loading...

Loading...