Page 1

Great Plains Mfg., Inc.

Installation Instructions

Application Systems

PTO Sprayer Pump

Used with:

3P300

•

TA500

•

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

!

the lives of others depend on it!

General Information

These instructions explain how to install the Application Systems

PTO pump. The pump pressurizes spra y er contents for application.

These instructions apply to:

507-041A PUMP TA 540 DRIVE SHAFT ASSY

507-042A PUMP TA 1000 1 3/8 DRV SHAFT

507-051A PUMP 3-POINT 540 ASSY

507-052A PUMP 3-POINT 1000 1-3/8 ASSY

Manual Update

Refer to the operator’ s manual f or detailed inf ormation on safely

operating, adjusting, troubleshooting and maintaining the Application Systems PTO pump. Ref er to the parts manual for part

identification.

• 3P300 Operator’s Manual . . . . . . . . . . . . . . . . . . .500-103M

• 3P300 Parts Manual. . . . . . . . . . . . . . . . . . . . . . . .500-062P

• TA500 Operator’s Manual. . . . . . . . . . . . . . . . . . . .500-102M

• TA500 Parts Manual. . . . . . . . . . . . . . . . . . . . . . . . 500-061P

Before You Start

Beginning on page 3 are detailed listings of parts included in the

Application Systems PTO pump pac kages . Use these lists to inventory parts received.

Assembly Instructions

TA500 Assembly

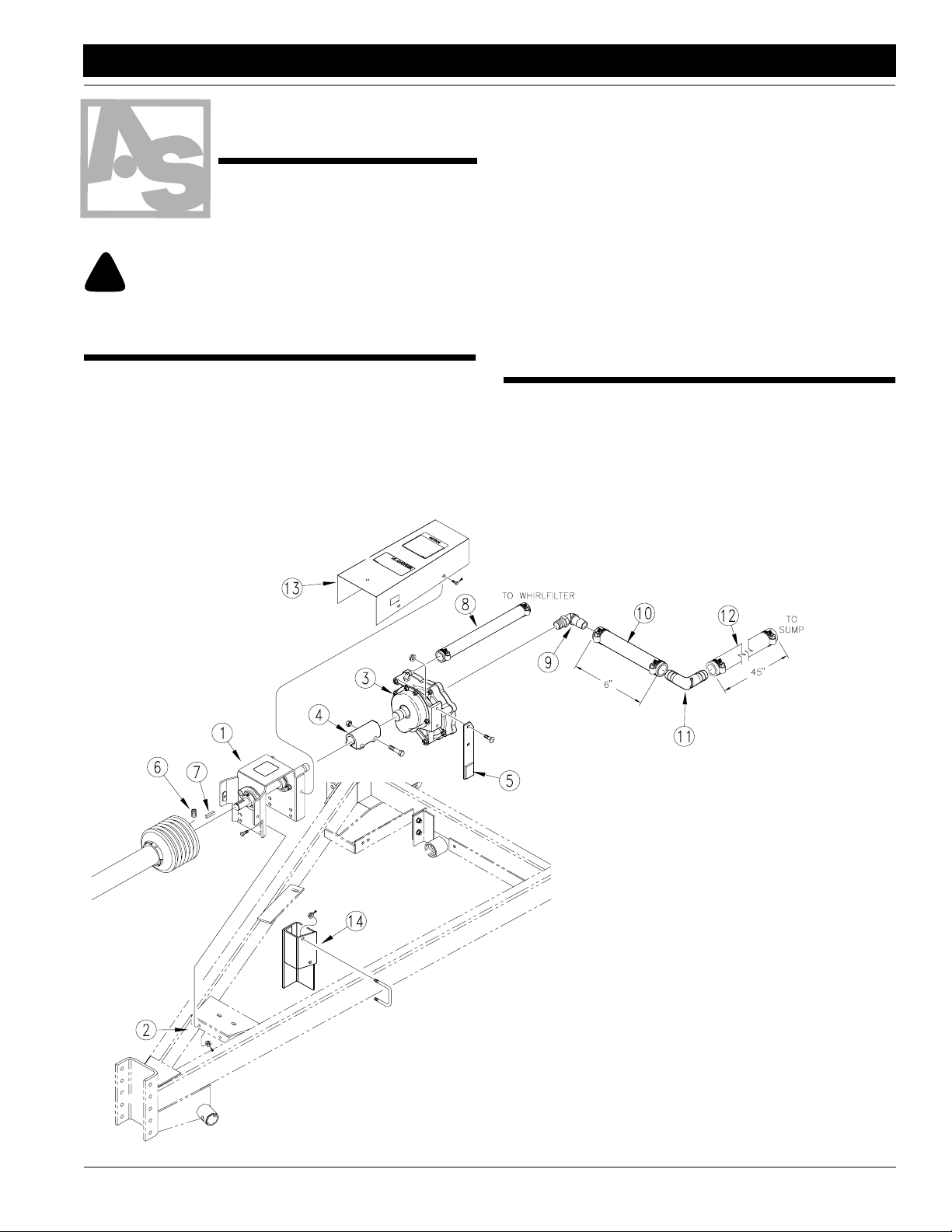

Refer to Figure 1

1. Attach driveline-bearing mount (1) to sprayer tongue (2) using 3/8-inch bolts and flange nuts.

2. Mount pump (3) onto output shaft of driveline-bearing

mount. Secure shaft coupler (4) with 1/2-inch bolts and ny

lock nuts.

3. Mount torque arm (5) on pump using 5/16-inch carriage bolts and flange nuts.

4. Thread set screws (6) into yoke of PTO shaft and

7. Using 1 1/4-by-1 1/2-inch elbow (9), install 6-inch

8. Install 45-inch section of hose (12) between elbow

9. Mount driveline shield (13) onto driveline-bearing

10. Mount torque-arm stop (14) onto left side of tongue

11. Tighten all hardware and clamps. Refer to opera-

install key (7) into input shaft of bearing mount.

Slide PTO shaft onto

input

shaft and

tighten

set screws.

5. Install 1inch hose (8)

between pump

outlet and Whirlfilter

inlet. Secure with worm

clamps.

6. Cut 1 1/2-inch hose into a 6inch-long section and a 45-

inch-long section.

section of hose (10) onto pump inlet. Install 1 1/2-

inch elbow (11) in other end of 6-inch section. Secure with worm clamps.

and tee prior to Quick-Fill inlet under sprayer tank.

Secure with worm clamps.

mount using 5/16-inch flange bolts.

using u-bolt and flange nuts. Adjust stop to line up

with torque arm.

tor’s manual for setup and operating instructions.

-

© Copyright 1998 Printed 4/8/04

17392

■

Figure 1

TA500 Assembly

507-095M

1

Page 2

Assembly

3P300 Assembly

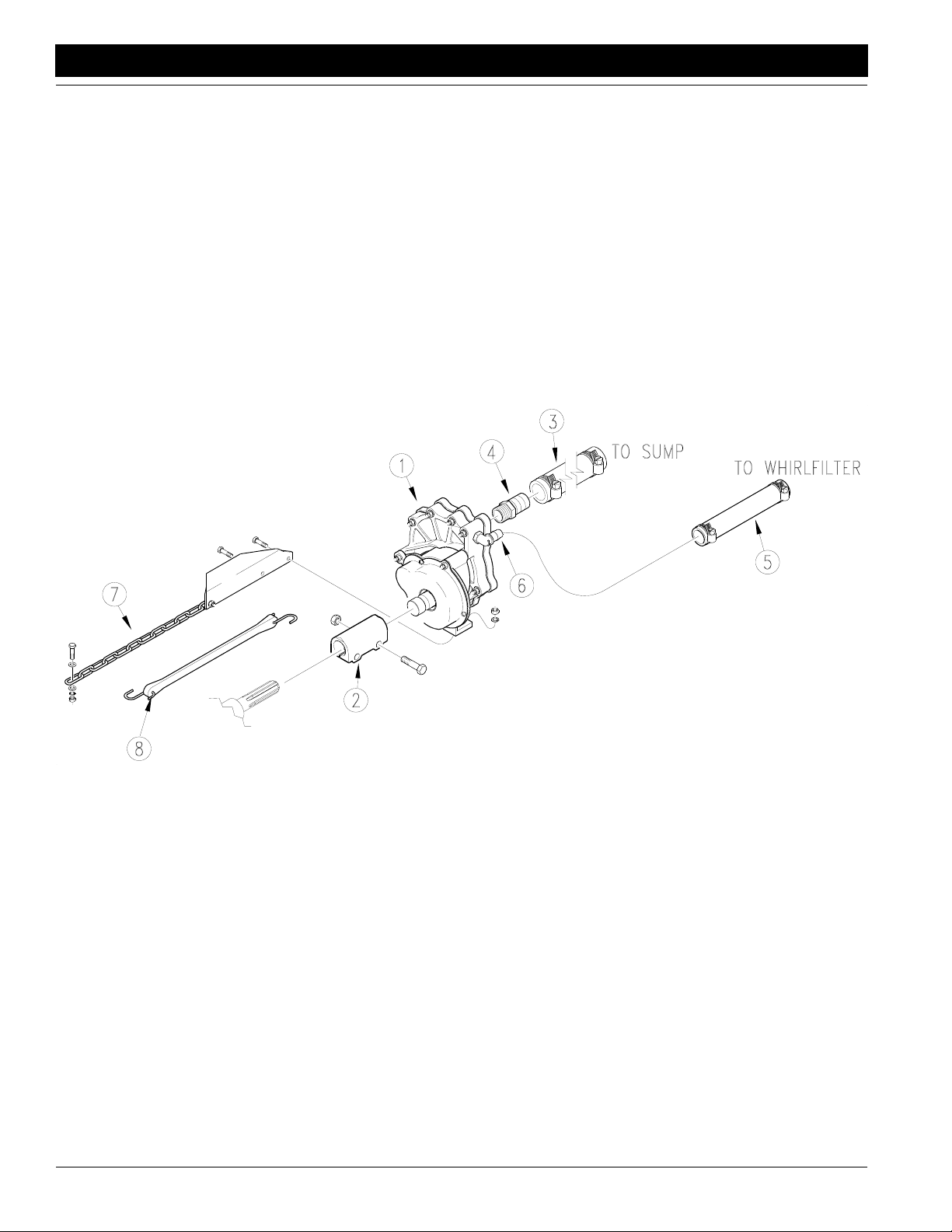

Refer to Figure 2.

1. Mount pump (1) on tractor PTO shaft using shaft coupler (2).

Leave 1/2-inch bolt and nyloc k nut on tractor end of coupler

loose. Turn pump so coupler is aligned with notch in tractor

PTO shaft. Tighten bolt in coupler.

2. Using 1 1/2-inch hose (3), connect pump inlet (4) to hose

barb on sump valve under sprayer tank. Use worm clamps

to secure hose.

3. Using 1-inch hose (5), connect pump outlet (6) to Whirlfilter.

Use worm clamps to secure hose.

4. Turn PTO shaft b y hand to make sure pump and its hardware does not interfere with PT O shields . When satisfied

with pump mounting, torque bolts in shaft coupler to 105

foot-pounds.

5. Use 5/16-inch bolts, flat washers and nuts to secure chain

(7) to tractor drawbar.

6. Hook tarp strap (8) to chain and tractor drawbar so chain

slack is taken up slowly when PTO is engaged.

7. Use cable ties provided to secure hoses. Secure hoses so

they will not be kinked, caught or damaged during sprayer operation.

Great Plains Mfg., Inc.

Figure 2

3P300 Assembly

17393

Application Systems PTO Sprayer Pump 507-095M 4/8/04

2

■

Page 3

Great Plains Mfg., Inc.

Listing of Parts

507-041A Pump TA 540 Drive Shaft Assy

Your Kit Includes:

Qty. Part No. Part Description

1 161-104D 5/16 SQ CR X 1 1/2 LONG

1 507-014K 540 PUMP ASSY

1 507-017D SHIELD - TA DRIVELINE 540 R

1 507-025D DRIVELINE SHAFT PUMP COUPLI

1 507-046H TA DRIVELINE PUMP MOUNT WLD

1 507-050K DRIVELINE TORQUE ARM W/RUBB

1 507-054K DRIVELINE BRG MOUNT ASSY 54

2 800-123C CLAMP WRM DRV #16 SS (.68-1

4 800-125C CLAMP WRM DRV#28 SS(1.31-2.

2 801-023C SCREW SET SH 3/8-16X3/8 TYP

4 802-017C HHCS 3/8-16X1 GR5

2 802-282C RHSNB 5/16-18X1 GR5

2 802-365C HHCS 1/2-13X3 GR8

4 802-387C HFS 5/16-18X3/4 GR5

6 803-068C NUT HEX FLANGE 3/8-16 PL +

2 803-147C NUT HEX NYLOCK 1/2-13

2 803-199C NUT HEX FLANGE 5/16-18 PLT

1 806-111C U-BOLT 3/8-16 X 4 1/32 X 2

1 818-142C DECAL DANGER PTO DRIVELINE

1 818-349C DECAL GREASE 10 HRS LH

1 818-464C DECAL DRVLNE ATTACH SPECS 5

1 826-236C PTO 540 2200 X 18.11 NO CLU

1 830-106C EL 1 1/2HB POLYPROP

1 830-131C EL 1 1/4MNPT X 1 1/2HB POLY

4.250 990-079R HOSE 1 1/2ID EPDM SUCTION H

1.833 990-082R HOSE 1 ID 200PSI EPDM

507-042A Pump TA 1000 Drive Shaft Assy

Your Kit Includes:

Qty. Part No. Part Description

1 161-104D 5/16 SQ CR X 1 1/2 LONG

1 507-015K 1000 PUMP ASSY

1 507-018D SHIELD - TA DRIVELINE 1000

1 507-025D DRIVELINE SHAFT PUMP COUPLI

1 507-046H TA DRIVELINE PUMP MOUNT WLD

1 507-050K DRIVELINE TORQUE ARM W/RUBB

1 507-055K DRIVELINE BRG MOUNT ASSY 10

2 800-123C CLAMP WRM DRV #16 SS (.68-1

4 800-125C CLAMP WRM DRV#28 SS(1.31-2.

2 801-023C SCREW SET SH 3/8-16X3/8 TYP

4 802-017C HHCS 3/8-16X1 GR5

2 802-282C RHSNB 5/16-18X1 GR5

2 802-365C HHCS 1/2-13X3 GR8

4 802-387C HFS 5/16-18X3/4 GR5

6 803-068C NUT HEX FLANGE 3/8-16 PL +

2 803-147C NUT HEX NYLOCK 1/2-13

2 803-199C NUT HEX FLANGE 5/16-18 PLT

1 806-111C U-BOLT 3/8-16 X 4 1/32 X 2

1 818-142C DECAL DANGER PTO DRIVELINE

1 818-349C DECAL GREASE 10 HRS LH

1 818-465C DECAL DRVLNE ATTACH SPECS 1

1 826-237C PTO 1000 2200X 22.05 NO CLU

1 830-106C EL 1 1/2HB POLYPROP

1 830-131C EL 1 1/4MNPT X 1 1/2HB POLY

4.25 990-079R HOSE 1 1/2ID EPDM SUCTION H

1.833 990-082R HOSE 1 ID 200PSI EPDM

4/8/04

■

Application Systems PTO Sprayer Pump 507-095M

3

Page 4

Listing of Parts

507-051A Pump 3-Point 540 Assy

Your Kit Includes:

Qty. Part No. Part Description

1 507-006D 507P025 - 540

1 507-007D TORQUE BAR

1 507-013D CHAIN - TORQUE BAR

1 507-014K 540 PUMP ASSY

1 507-095M MANUAL INSTALL, AS PTO PUMP

4 800-082C CABLE TIE 21" LONG

2 800-123C CLAMP WRM DRV #16 SS (.68-1

2 800-124C CLAMP WRM DRV #24 SS (1.064 802-159C HHCS 5/16-18X1 GR5

2 802-365C HHCS 1/2-13X3 GR8

4 803-008C NUT HEX 5/16-18 PLT

2 803-147C NUT HEX NYLOCK 1/2-13

4 804-009C WASHER LOCK SPRING 5/16 PLT

2 804-036C WASHER FLAT 5/16 SAE PLT

1 816-169C TARP STRAP 15 WITH HOOKS +

1 830-092C AD 1 1/4MNPT X 1 1/2HB POLY

4 990-079R HOSE 1 1/2ID EPDM SUCTION H

4 990-082R HOSE 1 ID 200PSI EPDM

Great Plains Mfg., Inc.

507-052A Pump 3-Point 1000 1 3/8 Assy

Your Kit Includes:

Qty. Part No. Part Description

1 507-001D COUPLER - 1000 1 3/8

1 507-007D TORQUE BAR

1 507-013D CHAIN - TORQUE BAR

1 507-015K 1000 PUMP ASSY

1 507-095M MANUAL INSTALL, AS PTO PUMP

4 800-082C CABLE TIE 21" LONG

2 800-123C CLAMP WRM DRV #16 SS (.68-1

2 800-124C CLAMP WRM DRV #24 SS (1.064 802-159C HHCS 5/16-18X1 GR5

2 802-365C HHCS 1/2-13X3 GR8

4 803-008C NUT HEX 5/16-18 PLT

2 803-147C NUT HEX NYLOCK 1/2-13

4 804-009C WASHER LOCK SPRING 5/16 PLT

3 804-036C WASHER FLAT 5/16 SAE PLT

1 816-169C TARP STRAP 15 WITH HOOKS +

1 830-092C AD 1 1/4MNPT X 1 1/2HB POLY

4 990-079R HOSE 1 1/2ID EPDM SUCTION H

4 990-082R HOSE 1 ID 200PSI EPDM

Application Systems PTO Sprayer Pump 507-095M 4/8/04

4

■

Loading...

Loading...