Page 1

Operator’s/Parts Manual

All Seeds Hitch

Flat Fold Marker

Manufacturing, Inc.

P.O. Box 5060 ● Salina, Kansas 67402-5060

Read the Operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

© Copyright 1995 Printed 3/19/03

12432

Cover illustration may show optional equipment not supplied with standard unit.

113-476M

Page 2

General Information

General Information

Important Notice

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either

expressed or implied, while every precaution has been

taken in the preparation of this manual, Great Plains

Manufacturing, Inc. assumes no responsibility for errors

or omissions. Neither is any liability assumed for damages resulting from the use of the information contained

herein. Great Plains Manufacturing, Inc. reserves the

right to revise and improve its products as it sees fit. This

publication describes the state of this product at the time

of its publication, and may not reflect the product at all

times in the future.

Printed in the United States of America.

For your convenience, record your Serial Number, Mod-

el Number and the Date Purchased, of your drill, in the

spaces provided below. Have this information before

you when calling a Great Plains Authorized Dealer.

This Operator’s Manual applies to the All Seeds Hitch Flat Fold Marker listed below:

113-469A 15’ All Seeds Dual Marker

113-470A 20’ All Seeds Dual Marker

Owner’s Information

Name: _____________________________________

Address ____________________________________

City________________State ____ Zip ___________

Phone_______________________

Name of Dealership ___________________________

Dealer’s Name _______________________________

Address ____________________________________

City________________State ____ Zip ___________

Phone_______________________

Model Number_______________________________

Date Purchased______________________________

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04Great Plains Mfg., Inc.

Page 3

Table of Contents

Table of Contents

Using this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 1Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Operation & Repair . . . . . . . . . . . . . . . . 3

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 2 Assembly Instructions & Set-Up . . . . . . 4

Torque Values Chart. . . . . . . . . . . . . . . . . . . . . . . 4

Installation Instructions . . . . . . . . . . . . . . . . . . . . 5

Section 3 Hydraulic System . . . . . . . . . . . . . . . . . . 9

Adjusting The Hydraulics . . . . . . . . . . . . . . . . . . . 9

Section 4 Maintenance & Lubrication. . . . . . . . . . 10

Section 5 Troubleshooting . . . . . . . . . . . . . . . . . . 12

Section 6 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . 12

Parts Section

Section 7 Assembly . . . . . . . . . . . . . . . . . . . . . . . . 14

Flat Fold Marker Assembly . . . . . . . . . . . . . . . . 14

Disk Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 8 Hydraulics . . . . . . . . . . . . . . . . . . . . . . . 18

Hydraulic Assembly . . . . . . . . . . . . . . . . . . . . . . 18

Hydraulics Cylinder (810-196C). . . . . . . . . . . . . 20

Sequence Valve (810-197C) . . . . . . . . . . . . . . . 22

4/8/04 Great Plains Mfg., Inc.

All Seeds Hitch Flat Fold Marker 113-476M

-1

Page 4

Using this Manual

Using this Manual

For your safety and to help in developing a better understanding of your equipment we highly recommend that

you read the operator sections of this manual. Reading

these sections not only provides valuable training but

also familiarizes you with helpful information and its lo

Introduction

This manual has been prepared to instruct you in the

safe and efficient operation of your All Seeds Hitch Flat

Fold Marker. Read and follow all instructions and safety

precautions carefully.

The parts on your All Seeds Hitch Flat Fold Marker have

been specially designed and should only be replaced

with genuine Great Plains parts. Therefore, should your

All Seeds Hitch Flat Fold Marker require replacement

parts go to your Great Plains Dealer.

The right hand and left hand as used throughout this

manual is determined by facing in the direction the ma

chine will travel when in use unless otherwise stated.

!

The SAFETY ALERT SYMBOL indicates that there is a

potential hazard to personal safety involved and extra

safety precautions must be taken. When you see this

symbol, be alert and carefully read the message that fol

lows it. In addition to design and configuration of

equipment; hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

cation. The parts sections are for reference only and

don’t require cover to cover reading. After reviewing

your manual store it in a dry, easily accessible location

for future reference.

-

Watch for the following safety notations throughout your Operators Manual:

!

DANGER!

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury. This

signal word is limited to the most extreme situations.

!

-

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

-

WARNING!

!

CAUTION!

NOTE: Indicates a special point of information which

requires your attention.

2

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Great Plains Mfg., Inc.

Page 5

Section 1 Safety Rules

Section 1 Safety Rules

Most accidents are the result of negligence and carelessness, usually caused by failure of the operator to

follow simple but necessary safety precautions. The fol

lowing safety precautions are suggested to help prevent

such accidents. The safe operation of any machinery is

a big concern to consumers and manufacturers. Your All

Seeds Hitch Flat Fold Marker has been designed with

many built-in safety features. However, no one should

operate this product before carefully reading this Oper

ators Manual.

!

General Operation & Repair

1. Never allow the Flat Fold Marker to be operated by anyone who is unfamiliar with the operation of all functions

of the unit. All operators should read and thoroughly understand the instructions given in this manual prior to

moving the unit.

2. Make sure safety rules are understood before operating

machinery or tractor.

3. Never permit any persons other than the operator to ride

on the tractor.

4. Never permit any persons to stand near the Flat Fold

Marker while it is in operation.

5. Regulate your speed to the field conditions, maintaining

complete control at all times.

6. After repairing or adjusting, make sure all tools and

parts are removed from the implement before attempting

to operate it.

7. Do not grease or oil machine while it is in operation.

8. Loose fitting clothing should not be worn as it may catch

in moving parts.

9. Never dismount from a moving tractor.

10. Do not leave the tractor or the implement unattended

with the engine running.

11. Do not stand between the tractor and the implement dur-

ing hitching.

12. Detach and store implements in an area where children

-

-

normally do not play. Stabilize implements by using suit

able supports and block wheels.

13. If a hydraulic leak develops, correct it immediately. Escaping hydraulic oil can have extremely high pressure. A

stream of high pressure oil may easily penetrate the skin

as with modern needle-less vaccination equipment - but

with the exception that hydraulic fluid may cause blood

poisoning. It is imperative that the connections are tight

and that all lines and pipes are in good condition. If an

injury is caused by the escaping hydraulic fluid, see doctor at once!

14. Use a piece of cardboard or wood to detect leaks of hydraulic oil under pressure.

15. Be sure to relieve all hydraulic pressure before disconnection any lines or pipes between the implement and the tractor hydraulic system. Keep all guards and shields in place.

Transporting

1. Use good judgement when transporting tractor and implements on the highway. Always maintain complete control of the machine.

2. Limit transport speed to 20 mph. Transport only with a

farm tractor of sufficient size and horse power.

3. Always make sure flashing safety lights, “Slow Moving

Vehicle” emblem, and reflectors are in place and visible

prior to transporting the machine on public roads.

4. Know your state and local laws concerning highway

safety and regulations. Comply with these laws when

transporting machinery.

5. Use warning flags or approved warning lights at night

and during other periods of poor visibility. Do your best

to prevent highway accidents

-

4/8/04 Great Plains Mfg., Inc.

All Seeds Hitch Flat Fold Marker 113-476M

-3

Page 6

Section 2 Assembly Instructions & Set-Up

Section 2 Assembly Instructions & Set-Up

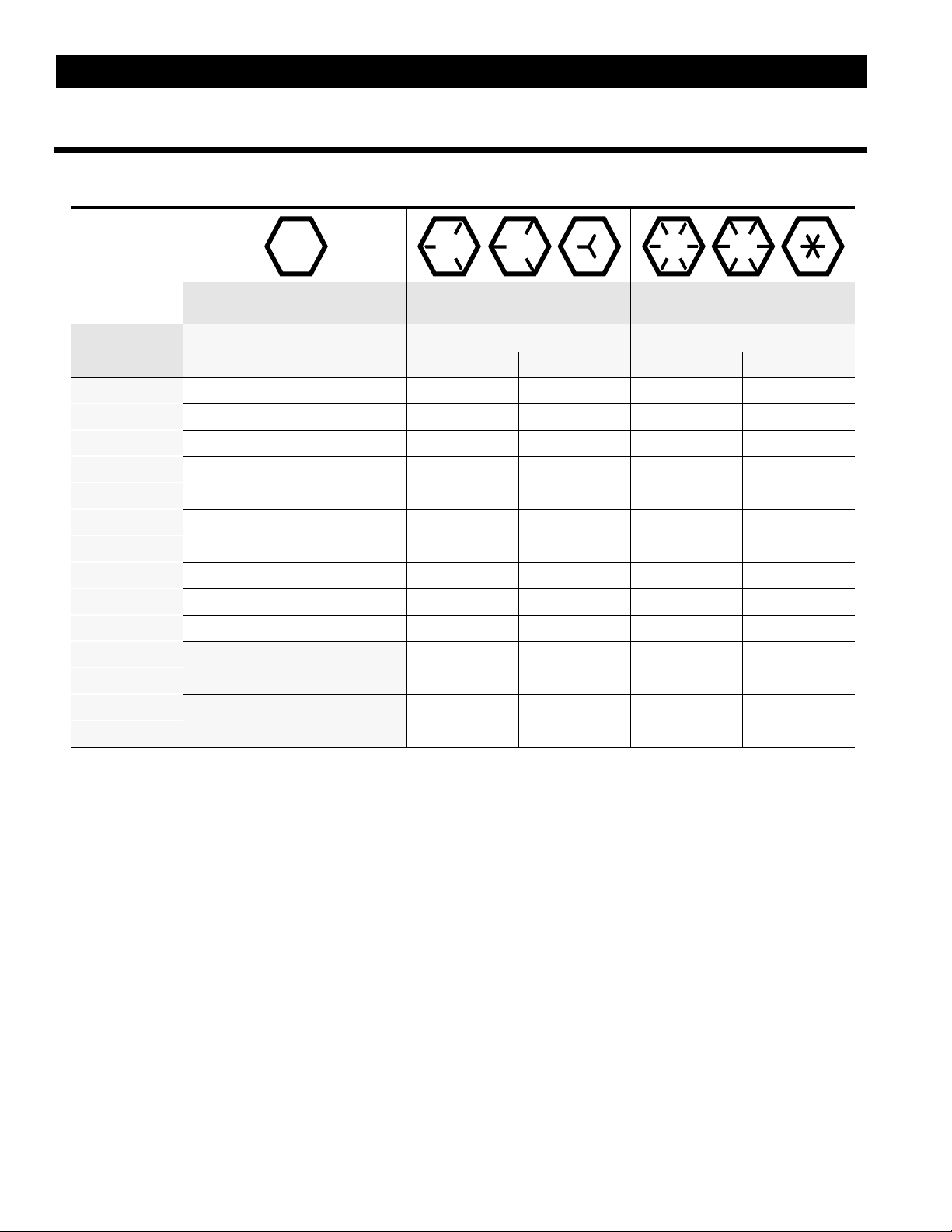

Torque Values Chart for UNC Threads

Bolt head

identification

marks are as per

grade.

NOTE: Manufacturing marks will vary.

Bolt Size

inches mm Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.

1/4" 6.35

5/16" 7.94

3/8" 9.53

7/16" 11.11

1/2" 12.70

9/16" 14.29

5/8" 15.88

3/4" 19.05

7/8" 22.23

1" 25.40

1 1/8" 25.58

1 1/4" 31.75

1 3/8" 34.93

1 1/2" 38.10

Foot Pounds Newton-Meters Foot Pounds Newton-Meters Foot Pounds Newton-Meters

5 6 6.8 8.13 9 11 12.2 14.9 12 15 16.3 20.3

10 12 13.6 16.3 17 20.5 23.1 27.8 24 29 32.5 39.3

20 23 27.1 31.2 35 42 47.5 57.0 45 54 61.0 73.2

30 35 40.7 47.4 54 64 73.2 86.8 70 84 94.9 113.9

45 52 61.0 70.5 80 96 108.5 130.2 110 132 149.2 179.0

65 75 88.1 101.6 110 132 149.2 179.0 160 192 217.0 260.4

95 105 128.7 142.3 150 180 203.4 244.1 220 254 298.3 358.0

150 185 203.3 250.7 270 324 366.1 439.3 380 456 515.3 618.3

160 200 216.8 271.0 400 480 542.4 650.9 600 720 813.6 976.3

250 300 338.8 406.5 580 596 786.5 943.8 900 1080 1220.4 1464.5

Grade 2 Grade 5 Grade 8*

800 880 1084.8 1193.3 1280 1440 1735.7 1952.6

1120 1240 1518.7 1681.4 1820 2000 2467.9 2712.0

1460 1680 1979.8 2278.1 2380 2720 3227.3 3688.3

1940 2200 2630.6 2983.2 3160 3560 4285.0 4827.4

* Thick nuts must be used with Grade 8 bolts

NOTE: Torque requirements listed above do not apply to self-locking nuts . For self-locking nuts increase the torque requirements listed by 15%.

4

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Great Plains Mfg., Inc.

Page 7

Section 2 Assembly Instructions & Set-Up

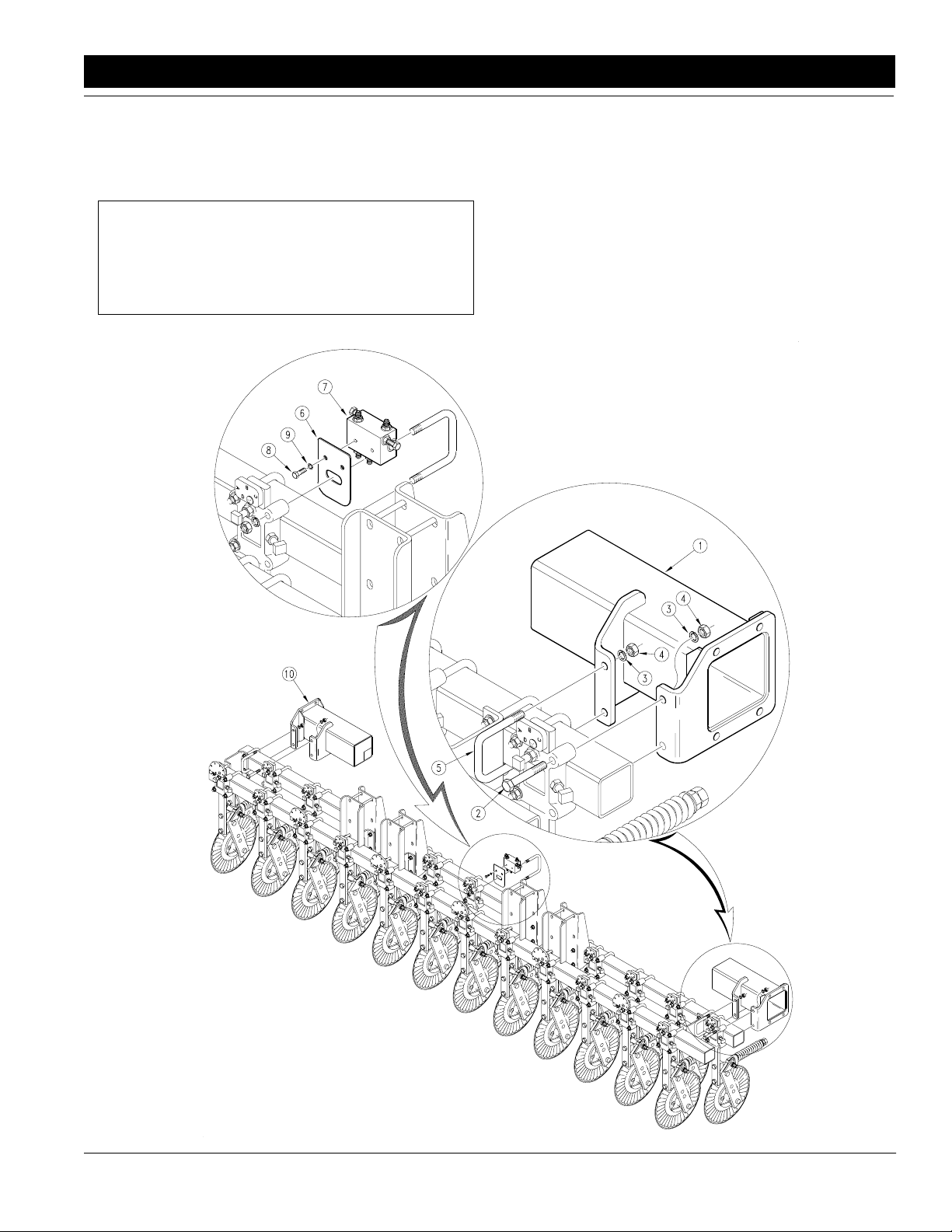

All Seeds Hitch Marker

Installation Instructions

NOTE: While using the following text to install your

flat fold marker, you may need to refer back to the

parts section of this manual for more details and for

positive identification of related items not mentioned

in these instructions.

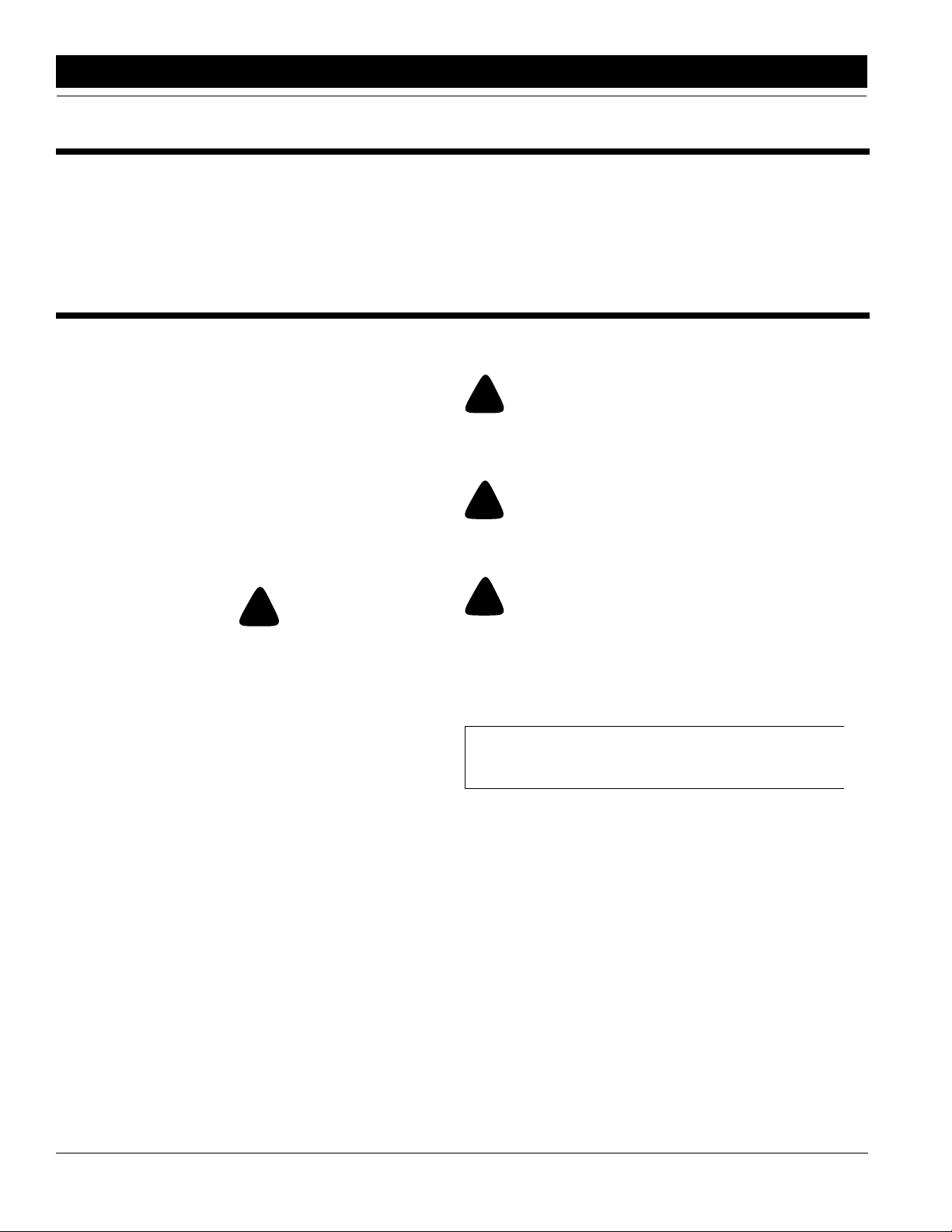

Refer to Figure 2-1 for Installation Instructions steps 1,

2, and 3.

1. Lower the hitch to field position. Allow clearance of

9’ on a 15’ drill and 11’ on a 20’ drill from each end of

the coulter tool bar for marker assembly.

2. Remove the outside u-bolt on the rear, left and right

hand coulter clamp. Position the left marker mount

(#1) so the outer flange can be bolted through the

coulter clamp with 5/8" x 7" bolts, lockwashers and

nuts (#2, 3 & 4). The inside flange of the mount is

fastened to the tube with a 5/8" x 4 1/32" x 6" u-bolt,

Assembly Diagram

Figure 2-1

4/8/04

Great Plains Mfg., Inc.

12428

All Seeds Hitch Flat Fold Marker 113-476M

-5

Page 8

Section 2 Assembly Instructions & Set-Up

lock washers and nuts, (#5, 3, & 4).

NOTE: The offset of the mount must be in the upward direction.

The right hand mount (#10) is mounted similar to the

left mount only the u-bolt is installed in the outside

flange and the inside flange is bolted through the

coulter clamp (See

3. Install the marker valve mount (#6) under the inner

coulter clamp u-bolt of the coulter that is just to the

right of center on the coulter frame tube. Assemble

the valve (#7) to the mount with the 4-port side

downward using two 3/8" x 3/4" long bolts (#8) and

lock washers (#9).

NOTE: JIC fittings do not require high torque. JIC

and O-Ring fittings do not require sealant. Always

use liquid pipe sealant when adding or replacing

pipe thread fittings. To avoid possible danger of

cracking hydraulic fittings from over tightening, DO

NOT use plastic sealant tape.

Refer to Figure 2-2 for Installation Instructions steps 4,

5, and 6.

Figure 2-1).

4. Route the hoses from each marker through the

mount and out the opening in the inside end of the

mount. Slide the cylinder and first section assembly

(#1) into the mount and manually swing the first sec

tion into the lowered position. Bolt the flanges of the

assembly and mount together with four 5/8" x 1 3/4"

long bolts (#2), lockwashers (#3), and nuts (#4) in

each mount.

5. Route the hoses along the coulter frame tube and tie

them to the tube with the releasable cable ties (#6)

Figure 2-2.

See

NOTE: If your hitch is equipped with the fertilizer option, the hydraulic hose can be ran with the fertilizer

hoses.

Connect the hoses to the sequence valve (#7) with

four JIC elbows (#5). Note the port markings and re

fer to the drawing below for proper connections.

6. Connect the two 156" long hoses (#8) to the two top

ports of the sequence valve with two elbows (#5)

and route them to the tongue and through the hose

loop. Use releasable cable ties to secure hose to

frame.

-

-

6

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Great Plains Mfg., Inc.

Page 9

Section 2 Assembly Instructions & Set-Up

12553

4/8/04 Great Plains Mfg., Inc.

Marker Hydraulics Assembly

Figure 2-2

All Seeds Hitch Flat Fold Marker 113-476M

-7

Page 10

Section 2 Assembly Instructions & Set-Up

NOTE: Check the hydraulic fluid in the tractor reservoir and fill it to the proper level. Add fluid to the system as needed. A low reservoir may draw air back

into the system causing jerky or uneven movement.

The fluid capacity of the markers is.75 gallons.

7.

With the first section in the lowered position, connect the hoses to the tractor and cycle each cylinder

3 or 4 times. Both arms should move to the vertical

position on the first move and then they should lower

and raise alternately as the hydraulic lever is oper

ated.

!

Keep all persons clear of the marker when operating. Air in

the hydraulic system can cause the marker arm to dr op quick

ly. Make sure the system is properly charged.

Refer to Figure 2-3 for Installation Instructions steps 8

and 9.

8. Check the orientation of the second section mount-

9. Remove the rear 1/2 x 3 1/2 long bolt (#2) from the

DANGER!

ing pin (#1). The second stage mounting pin (#1)

must be assembled into the hinge with the flanged

head toward the tongue end of the hitch for the

breakaway to work properly,

out and insert it from the other direction.

second section mount and install the second marker

section (#3) between the plates. Align the holes and

replace the bolt and lock nut. Bolt the front flange on

the second section to the flange on the second sec

tion mounting pin with a 5/16 x 1 1/2 long grade 5 bolt

(#4) and locknut (#5).

Figure 2-3. If not, pull it

Disk Adjustments

The aggressiveness and the mark left by the disk may

be changed by two methods:

1. Disk Angle

To change the angle of cut, loosen the two bolts (#1)

Figure 2-4, rotate the disk assembly and retighten.

2. Direction Of Cut

The disk may be mounted to throw dirt either in or

out which will give different marks in different soil

-

-

-

12433

Disk Adjustments

Figure 2-4

conditions. To change the direction of cut:

a. Reverse the blade and depth band by removing

the four lug bolts on the disk hub.

b. Reverse the angle of the assembly by loosening

the u-bolt (#2), pulling the disk assembly out

and rotate it one half turn. Reinstall and tighten

all bolts.

3. Marker Width

Marker width adjustments are made by loosening

the marker tube u-bolt (#2) and sliding it in or out to

the desired width and retightening the u-bolt.

12551

8

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Mounting Pin Orentation

Figure 2-3

Great Plains Mfg., Inc.

Page 11

Section 3 Hydraulic System

Section 3 Hydraulic System

Adjusting The Hydraulics

1. Be sure tractor hydraulic reservoir is full

2. Fold and unfold the marker(s) slowly in order to work

all the air out of your marker hydraulics. Use caution

when folding and unfolding the marker for the first

time, and check for pinching and kinking of hoses.

!

Never allow anyone near the drill when cycling the markers.

3. The marker hydraulic system is equipped with nee-

CAUTION!

dle valves to control how fast each marker operates.

The needle valves are built into the sequence valve

body. There are two hex adjustment heads, one for

raising the markers, and one for lowering the mark

ers. These are stamped in the valve body. To adjust

the speed of each marker, screw the needle valve

clockwise to adjust the raise or lower marker speed

to a low setting. Fold the marker up and down a few

times and recheck for pinching and kinking of hoses.

With the tractor engine at an operating rpm, adjust

the needle valve to limit the marker to a safe operat

ing speed. Excessive folding speeds can cause

marker damage.

!

Escaping Fluid under pressure can have sufficient force to

penetrate the skin. Check all hydraulic lines and hoses

1fpbefore applying pr essure. Fluid escaping fr om a very small

hole can be almost invisible. Use paper or cardboard, not

body parts, to check for suspected leaks. If injur ed, seek med

ical assistance form a doctor that is familiar with this type of

injury. For eign fluids in the tissue must be surgically r emo ved

within a few hours or gangrene will result.

General Notes

The markers cycle in the following sequence

-

-

CAUTION!

(1) Right Up, Left Up

(2) Right Down, Left Up

(3) Right Up, Left Up

(4) Right Up, Left Down

(5) Sequence Repeats

NOTE: JIC fittings do not require high torque. JIC and ORing fittings do not require sealant. Always use liquid pipe

sealant when adding or replacing pipe thread fittings. To

avoid possible danger of cracking hydraulic fittings from

over tightening,

DO NOT use plastic sealant tape.

-

4/8/04

Great Plains Mfg., Inc.

All Seeds Hitch Flat Fold Marker 113-476M

-9

Page 12

Section 4 Maintenance & Lubrication

Section 4 Maintenance & Lubrication

Maintenance

Proper servicing and adjustment is the key to the long

life of any farm implement. with careful and systematic

inspection, you can avoid costly maintenance, time and

repair.

Breakaway Protection

The marker arm is attached to the marker body with a

5/16" breakaway bolt. If excessive force is put on the

marker during operation, the bolt will break, allowing the

marker arm to swing away rather than cause damage to

the marker.

Lubrication Symbols

50

Lubrication is required every 50 hours of operation.

10

Lubrication is required every 10 hours of operation.

NOTE: The breakaway bolt is a 5/16"-18 x 1 1/2" long

grade 5 (G.P. # 802-012C). It is identified as a grade

5 by having three marks on the head. If it breaks, it

must be replaced by an equivalent grade 5 bolt to

prevent marker damage.

Marker Transporting

Always transport the marker with it folded in the flat fold

position.

Lubrication

12434

As

Required

Use a multipurpose spray lube. Use as required.

Do not over lubricate.

Seasonally

Lubrication is required

10

Zerks

Type of Lubrication: Grease

10

Zerks

Type of Lubrication: Grease

12435

10

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Great Plains Mfg., Inc.

Page 13

Section 4 Maintenance & Lubrication

Seasonally

Disk Bearings

Type of Lubrication: Grease

12436

Maintenance & Lubrication Record

Item to be Serviced When to Perform Reference Date

4/8/04

Great Plains Mfg., Inc.

All Seeds Hitch Flat Fold Marker 113-476M

-11

Page 14

Section 5 Troubleshooting

Section 5 Troubleshooting

Problem Solution

Hydraulic marker functioning

improperly

Blade does not mark

Section 6 Warranty

Great Plains Manufacturing, Incorporated warrants to the original purchaser that this seeding equipment will

be free from defects in material and workmanship for a period of one year from the date of original purchase

when used as intended and under normal service and conditions for personal use; 90 days for commercial

or rental purposes. This Warranty is limited to the replacement of any defective part by Great Plains Manufacturing, Incorporated and the installation by the dealer of any such replacement part. Great Plains reserves

the right to inspect any equipment or part which are claimed to have been defective in material or workmanship.

This Warranty does not apply to any part or product which in Great Plains’ judgement shall have been misused or damaged by accident or lack of normal maintenance or care, or which has been repaired or altered

in a way which adversely affects its performance or reliability, or which has been used for a purpose for which

the product is not designed. This Warranty shall not apply if the product is towed at a speed in excess of 20

miles per hour.

Claims under this Warranty must be made to the dealer which originally sold the product and all warranty

adjustments must by made through such dealer. Great Plains reserves the right to make changes in materials

or design of the product at any time without notice.

This Warranty shall not be interpreted to render Great Plains liable for damages of any kind, direct, consequential, or contingent, to property. Furthermore, Great Plains shall not be liable for damages resulting from

any cause beyond its reasonable control. This Warranty does not extend to loss of crops, losses caused by

harvest delays or any expense or loss for labor, supplies, rental machinery or for any other reason.

No other warranty of any kind whatsoever, express or implied, is made with respect to this sale; and

all implied warranties of merchantability and fitness for a particular purpose which exceed the obligations set forth in this written warranty are herby disclaimed and excluded from this sale.

This Warranty is not valid unless registered with Great Plains Manufacturing, Incorporated with 10 days from

the date of original purchase.

Check all hose fittings and connections for air and oil leaks.

Check tractor hydraulic oil level.

Check all bolts and fasteners.

If needle valve is plugged; open valve, cycle markers, and reset the needle valve.

The maximum marker down float is limited by the slot in the pivot link. If the blade does

not drop down to follow depressions in the field, make sure the marker cylinder is fully

extended.

The blade may be reversed to pull dirt in or throw dirt out depending on soil conditions.

Warranty

12

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Great Plains Mfg., Inc.

Page 15

Notes:

4/8/04 Great Plains Mfg., Inc. All Seeds Hitch Flat Fold Marker 113-476M

-13

Page 16

Section 7 Flat Fold Marker Assembly

12425

14

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Great Plains Mfg., Inc.

Page 17

Section 7 Flat Fold Marker Assembly

Ref. Part No. Part Description

1. 804-017C WASHER FLAT 1/2 USS PLT

2. 802-041C HHCS 1/2-13X3 1/2 GR5

3. 113-564S 2020 MARKER DISC & HUB ASSY

113-372S REPLACED BY 113-564S

4. 803-019C NUT LOCK 1/2-13 PLT

5. 113-353D MARKER TUBE 51 LG

6. 113-449H 6 ROW 2ND STAGE ARM WMNT

113-450H 8 ROW 2ND STAGE ARM WMNT

7. 113-440H 2ND STAGE MOUNT WMNT

8. 803-011C NUT LOCK 5/16-18 PLT

9. 113-442H 2ND STAGE MOUNT PIN

10. 802-012C HHCS 5/16-18X1 1/2 GR5

11. 113-439D 1ST STAGE MOUNTING PIN

12. 810-196C CYL 2.5X10X1.12 ROD(TIE)NOPINS

13. 113-435H PLANTER MARKER MOUNT WMNT

14. 805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

15. 113-435D CYLINDER LUG PIN

16. 113-437D CYLINDER SPACER W/ HOLE

17. 113-436D CYLINDER SPACER

18. 801-045C SCREW SET 1/4-28X1/4 KNL CUP

19. 817-145C THREAD PROTECTOR-DELRIN

20. 113-444H CYLINDER TANG WMNT

21. 890-143C BUSHING HARDENED 1 1/4-1-3/4 L

22. 113-438D CYLINDER LINK PIN

23. 113-437H 1ST STAGE ARM WELDMENT

24. 113-448H CYL. PIVOT PIN WMNT

25. 800-001C GREASE ZERK STRAIGHT 1/4-28

26. 805-060C PIN COTTER 7/32 X 2

27. 113-447E PIVOT LINK WELDMENT

28. 113-453S PIVOT LINK BUSHING ASSY

29. 113-446H TRANSFER LINK WMNT

30. 816-166C O-RING 1 ID X 1 1/4 OD X 1/8

31. 806-103C U-BOLT 1/2-13 1 17/32 X 2 3/4

32. 802-053C HHCS 5/8-11X1 3/4 GR5

33. 804-022C WASHER LOCK SPRING 5/8 PLT

34. 803-021C NUT HEX 5/8-11 PLT

35. 148-195H MARKER MOUNT WLMT LH

148-196H MARKER MOUNT WLMT RH

36. 806-105C U-BOLT 5/8-11 X 4 1/32 X 6

37. 802-262C HHCS 5/8-11X7 GR5

38. 804-022C WASHER LOCK SPRING 5/8 PLT

39. 803-021C NUT HEX 5/8-11 PLT

40. 818-349C DECAL GREASE 10 HRS LH

41. 818-402C DECAL GREASE 10 HRS RH

4/8/04 Great Plains Mfg., Inc. All Seeds Hitch Flat Fold Marker 113-476M

-15

Page 18

Section 7 Disk Assembly

12426

16

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Great Plains Mfg., Inc.

Page 19

Section 7 Disk Assembly

Ref. Part No. Part Description

1. 113-563S MARKER DISC & HUB ASSEMBLY

113-564S REP BY 113-563S

113-372S REP BY 113-564S

2. 113-562H 1 SPINDLE MARKER WELDMENT

3. 816-014C TINE GAUGE WHEEL HUB SEAL

4. 822-030C BEARING CONE L44643

5. 822-080C BEARING CUP L44610

6. 890-614C GREASE CAP #1505

7. 815-001C TINE GW HUB

8. 804-025C WASHER FLAT 3/4 SAE PLT

9. 803-053C NUT HEX SLOTTED 3/4-16

10. 805-019C PIN COTTER 5/32 X 1 PLT

11. 820-094C 16 4-BOLT NOTCHED MARKER DISK

12. 113-369H DEPTH BAND 10 4-BOLT 4B.C.

13. BO-47 NEILSON STUD 1/2-20UNF X 1 13/16

14. 803-159C NUT LUG 1/2-20 X 60 DEG PLT

4/8/04 Great Plains Mfg., Inc. All Seeds Hitch Flat Fold Marker 113-476M

-17

Page 20

Section 8 Hydraulic Assembly

12427

18

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Great Plains Mfg., Inc.

Page 21

Section 8 Hydraulic Assembly

Ref. Part No. Part Description

1. 810-196C Cylinder 2 1/2" x 10" Mid

2. 811-065C Hydraulic Fitting, Elbow 9/16" JIC Male x 9/16" O-Ring Male

3. 811-226C Hydraulic Hose 1/4" R1 x 127" Long x 9/16" JIC Female F/20’

811-230C Hydraulic Hose 1/4" R1 x 95" Long x 9/16" JIC Female F/15’

4. 811-436C Hydraulic Hose 1/4" R1 x 156" Long x 9/16" JIC Female x 1/2" NPT Male

5. 802-014C Bolt, Hex Head 3/8"-16 x 3/4" Gr 5

6. 804-013C Washer, Lock Spring 3/8"

7. 148-425D Marker Valve Mount

8. 811-169C Hydraulic Fitting, Elbow 9/16" JIC Male x 9/16" JIC Female

9. 800-035C Cable Tie 28 Long

10. 811-178C Hydraulic Hose 1/4" R1 x 114" Long x 9/16" JIC Female F/20’

811-211C Hydraulic Hose 1/4" R1 x 84" Long x 9/16" JIC Female F/15’

11. 810-197C Valve, Sequence Shoemaker

4/8/04 Great Plains Mfg., Inc. All Seeds Hitch Flat Fold Marker 113-476M

-19

Page 22

Section 8 Hydraulic Cylinder (810-196C)

12027

20

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Great Plains Mfg., Inc.

Page 23

Section 8 Hydraulic Cylinder (810-196C)

Ref. Part No. Part Description

1. 2A0022 Piston Nut

2. 4M3102 Piston

3. * Back-up

4. * O-Ring

5. 3R0310 MW Head

6. 2A0012 Tie Rod Nut

7. * O-Ring

8. * Back-up

9. * Wiper Seal

10. 2M3393 Rod

11. 5M3118 Tube

12. 7M3318 Tie Rod

13. 6R0154 Base Midway

14. 2A0126 Hex Port Plug

15. 810-210C Seal Kit

*Can Only Be Ordered In Seal Kit (15)

4/8/04 Great Plains Mfg., Inc. All Seeds Hitch Flat Fold Marker 113-476M

-21

Page 24

Section 8 Sequence Valve (810-197C)

12024

22

All Seeds Hitch Flat Fold Marker 113-476M 4/8/04

Great Plains Mfg., Inc.

Page 25

Section 8 Sequence Valve (810-197C)

Ref. Part No. Part Description

1. 3089 Body, Sequence Valve

2. 1088-908 O-Ring

3. 1132-08 Plug, Hex Socket

4. 1179 Needle, Flow Control

5. 1217 Pin, .125" Spring Pin

6. 1211 Spring, Compression

7. 1088-011 O-Ring

8. 1089-011 Ring, Teflon Back-Up

9. 1180 Screw, Flow Control Adjustment

10. 1218 Hex, Jam Nut Zink Plated

11. 1099 Spring, Detent

12. 1087-250 Chromium Steel Balls

13. 1087-437 ChromiumSteel Ball

14. 1042 Spring

15. 1088-906 O-Ring

16. 1182 Fitting, Port Adaptor

17. 1132-05 Hex, Socket O-Ring Plug

18. 1088-905 O-Ring

19. 1092-6 Connector, Straight

20. 2153 Spool, Marker Sequence .055" Orifice

4/8/04 Great Plains Mfg., Inc. All Seeds Hitch Flat Fold Marker 113-476M

-23

Page 26

Great Plains Manufacturing, Inc.

Corporate Offices: PO. Box 218

Assaria, Kansas 67416 USA

Loading...

Loading...