Page 1

Operator’ s Manual

AS15 and AS20

Planting System

Manufacturing, Inc.

www .g reatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious -follow without exception. Your life and thelivesof

others depend on it!

© Copyright 1998 Printed

4/14/2005

13621

Cover illustration may show optional equipment not supplied with standard unit.

148-153M

Page 2

General Information

General Information

Important Notice

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either

expressed or implied, while every precaution has been

taken in the preparation of this manual, Great Plains

Manufacturing,Inc. assumes no responsibility for errors

oromissions.Neither is any liability assumed for damages resulting from the use of the information contained

herein. Great Plains Manufacturing, Inc. reserves the

righttoreviseand improveitsproductsasitseesfit.This

This Operator’s Manual applies to:

The 15’ All Seeds Hitch

The 20’ All Seeds Hitch

Owner’s Information

publicationdescribesthe state of this product atthetime

of its publication, and may not reflect the product at all

times in the future.

Printed in the United States of America.

For your convenience, record your Serial Number,Mod-

el Number and the Date Purchased in the spaces

provided below. Have this information before you when

calling a Great Plains Authorized Dealer.

Name: _____________________________________

Address ____________________________________

City________________State ____ Zip ___________

Phone_______________________

Name of Dealership ___________________________

Dealer’s Name _______________________________

Address ____________________________________

City________________State ____ Zip ___________

Phone_______________________

Serial Number _______________________________

Model Number_______________________________

Date Purchased______________________________

AS15 and AS20 Planting System 148-153M 4/14/05Great Plains Mfg., Inc.

Page 3

Table of Contents

Table of Contents

Using this Manual . . . . . . . . . . . . . . . . . . . . .2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . .2

Section 1 Safety Rules . . . . . . . . . . . . . . . . . . 3

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . 3

Section 2 Assembly Instructions & Set-Up. . 6

Torque Values Chart . . . . . . . . . . . . . . . . . 6

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . .6

Assembling The All Seeds Hitch. . . . . . . . . 8

Tractor Drawbar Hookup. . . . . . . . . . . . . . . 8

Tractor Hydraulic Hookup . . . . . . . . . . . . . 10

Bleeding The Hydraulic Systems . . . . . . . 10

Drill and Planter Hookup. . . . . . . . . . . . . . 11

Transporting . . . . . . . . . . . . . . . . . . . . . . . 14

Section 3 Basic Operation . . . . . . . . . . . . . . 14

Pre Drilling/Planting Instructions. . . . . . . . 15

Basic Operating Rules. . . . . . . . . . . . . . . . 15

Operating Checklist . . . . . . . . . . . . . . . . . 17

Section 4 Hitch, Drill, & Planter Adjustments

For No-Till Planting Conditions . . . . . . . . . . 18

Hitch Adjustments . . . . . . . . . . . . . . . . . . . 18

Drill & Coulter Adjustments . . . . . . . . . . . . 19

Planter & Coulter Adjustments. . . . . . . . . . 22

Section 5 Maintenance & Lubrication . . . . . 25

General Maintenance . . . . . . . . . . . . . . . . 25

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . 25

Section 6 Troubleshooting . . . . . . . . . . . . . . 29

Section 7 Options. . . . . . . . . . . . . . . . . . . . . . 30

Section 8 Specifications & Warranty . . . . . . 32

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-1

Page 4

Using this Manual

Using this Manual

For your safety and to help in developinga better understanding of your equipment we highly recommend that

you read the operator sections of this manual. Reading

these sections not only provides valuable training but

also familiarizes you with helpful information and its lo-

Introduction

This manual has been prepared to instruct you in the

safe and efficient operation of your All Seeds Hitch.

Read and follow all instructions and safety precautions

carefully.

The parts on your All Seeds Hitch have been specially

designed and should only be replaced with genuine

Great Plains parts. Therefore, should your

All Seeds Hitch require replacement parts go to your

Great Plains Dealer.

The right hand and left hand as used throughout this

manual is determined by facing in the direction the machine will travel when in use unless otherwise stated.

Serial Number

The serial number plate is located on the front of the

Coulter Tool Bar support tube next to the 8" x 8" hitch

tubeItissuggestedthat the serialnumber andpurchase

datealso be recorded for your convenienceinthe space

provided on the checklist page at the beginning of this

manual.

Theserial number provides importantinformation about

your All Seeds Hitch and may be required to obtain the

correct replacement part. Alwaysuse the serial number

and model number when sending correspondence or

when ordering parts from your Great Plains Dealer.

cation. The parts sections are for reference only and

don’trequire covertocoverreading.Afterreviewingyour

manual store it in a dry,easily accessible location for future reference.

lows it. In addition to design and configuration of

equipment; hazard control and accident prevention are

dependentupon the awareness,concern,prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Watchforthe followingsafety notations through-out

your Operators Manual:

!

DANGER!

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury. This

signal word is limited to the most extreme situations.

!

WARNING!

Indicates a potentially hazardoussituation which, if not

avoided, could result in death or serious injury.

!

Indicates a potentially hazardoussituation which, if not

avoided, may result in minor or moderate injury.It may

also be used to alert against unsafe practices.

CAUTION!

!

The SAFETY ALERT SYMBOL indicates that there is a

potential hazard to personal safety involved and extra

safety precautions must be taken. When you see this

symbol, be alertand carefully read themessage that fol-

2

AS15 and AS20 Planting System 148-153M 4/14/05

NOTE: Indicates a special point of information which

requires your attention.

Great Plains Mfg., Inc.

Page 5

Section 1 Safety Rules

Section 1 Safety Rules

Most accidents are the result of negligence and carelessness, usually caused by failure of the operator to

follow simple but necessary safety precautions. The followingsafetyprecautions are suggested to help prevent

such accidents. The safeoperation of any machinery is

a big concern to consumers and manufactures.Your All

SeedsHitch has beendesignedwithmany built-insafety

features. However, no one should operate this product

before carefully reading this Operators Manual.

!

General Operation & Repair

1. Never permit anyone to ride on or walk beside the drill,

planter, or tillage equipment when moving.

2. Never permit anyone to ride on tractor, drill, planter or

hitch when they are being moved.

3. Never allow anyone to be near the drill or planter when

performing operating functions with the drill, planter,

hitch, or tractor.

4. Never load the drill or planter without being hooked up

to a tractor.

5. Always make sure the drill and planter are securely

locked in the quick hitch before raising.

6. Always put the transport lock lever into the transport

“Road” position and make sure transport lock blocks

havesnapped intotheir locked positionimmediately after

raising the unit for transporting and before making

adjustments.

7. Nevertransport the AllSeeds Hitch withoutthe pivot lock

tubes (correctly adjusted), and in the horizontal (locked)

position. The pivot lock tubes are located above and outside of the leaf springs. The lock tubes will lock automatically when the unit is raised, unless they are manually

pinned in the vertical position.

8. Extra care should be taken when transporting with seed

in the box or hoppers.

9. Reduce speed of the tractor when transporting over uneven or rough terrain, hills or steep slopes. Avoid all

chuck holes and washboard areas in roads.

10. Do not pull the All Seeds Hitch faster than 20 miles per

hour.

11. Never turn a shorter radiusthan the All SeedsHitch pivot

stops will allow.

12. When in transport, use accessory lights and devices for

adequate warning to operators of other vehicles and use

safety hitch chain. Comply with all federal, state and local laws when traveling on public roads.

13. Use “slow moving vehicle” emblem for warning vehicles

approaching from the rear.

14. When transporting, remember the All Seeds Hitch is wider than your tractor and extreme care must be taken to

allow for safe clearance.

15. Never back up with the drill openers, planter openers or

coulters in the ground.

16. Always set the drill or planter in the field position before

lubrication, making adjustments, or servicing. Periodically check bolts for tightness and lubricate all fittings.

17. Do not lubricate or adjust the drill or planter while it is

in operation.

18. Do not permit smoking, sparks, or an open flame where

combustible lubricants or liquids are being used.

19. When using treated seed, avoid direct contact with the

seed. Do not breath or ingest chemicals.

20. When using compressed air to clean the drill boxes or

planter hoppers wear safety glasses.

21. Never unhook hitch from tractor when attached to a

raised drill or planter.

22. Escaping fluid under pressure can have sufficient force

to penetrate the skin. Check all hydraulic lines and hoses

before applying pressure. Fluid escaping from a very

small hole can be almost invisible. Use paper or cardboard, not body parts, to check for suspected leaks. If injured, seek medical assistance from a doctor that is

familiar with this type of injury. Foreign fluids in the tissue must be surgically removed within a few hours or

gangrene will result.

23. Do not allow anyone to operate the machine who has not

been properly trained in its safe operation.

24. Consult your drill operator’s manual for safe drill operation.

25. Consult your planter operator’s manual for safe planter

operation.

26. Do not operate equipment while under the influence of

drugs or alcohol.

27. Keep hands, feet, hair, and clothing away from all moving parts.

28. Clear the area of bystanders, especially small children

and animals before moving or operating equipment.

29. Support implement with blocks or safety stands when

changing tires or working on equipment.

30. Review the Safety instructions annually.

Safety Decals

1. Your All Seeds Hitch comes equipped with all safety decals in place. They were designed to help you safely operate your All Seeds Hitch. Read and follow their

directions.

2. Keep safety decals clean and legible.

3. Replace all damaged or missing safety decals. To order

new safety decals go to your Great Plains Dealer and orderpart no. 148-179A. Refer tothe parts section for Alldecals package part numbers.

4. Replace these decals whenever they become worn or unreadable. To instal new safety decals:

a. Clean the area the decal is to be placed

b. Peel backing from the decal. Press firmly on to sur-

face being careful not to cause air bubbles under the

decal.

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-3

Page 6

Section 1 Safety Rules

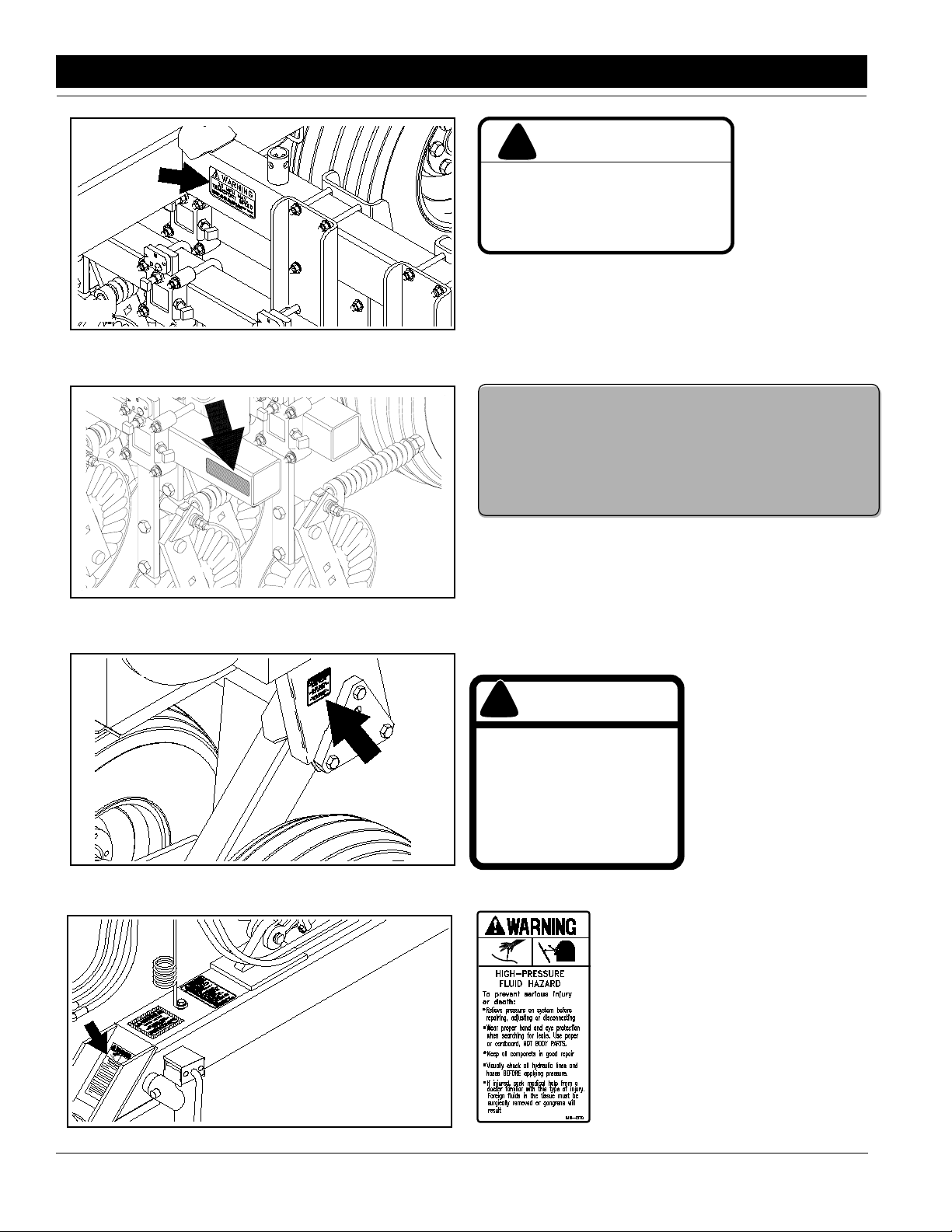

12306

!

WARNING

20 MPH MAX.

TRANSPORT SPEED

EXCEEDING 20 MPH MAY RESULT IN LOSS OF VEHICLE

CONTROL AND/OR IMPLEMENT DAMAGE

818-188C

Transport Speed Warning

818-188C

12307

12309

838-265C

Amber Reflector

CAUTION

!

AVOID INJURY

DO NOT STAND ON

TRANSPORT TIRESOR USE

TIRES AS A STEP

THE TIRES MAY NOT BE IN

CONTACT WITH THE GROUND AND

WILL

ROTATE EASILY

818-398C

818-398C

Caution - Tires Not A Step

818-437C

12308

4

AS15 and AS20 Planting System 148-153M 4/14/05

Warning - High Pressure

12423

Great Plains Mfg., Inc.

Page 7

Section 1 Safety Rules

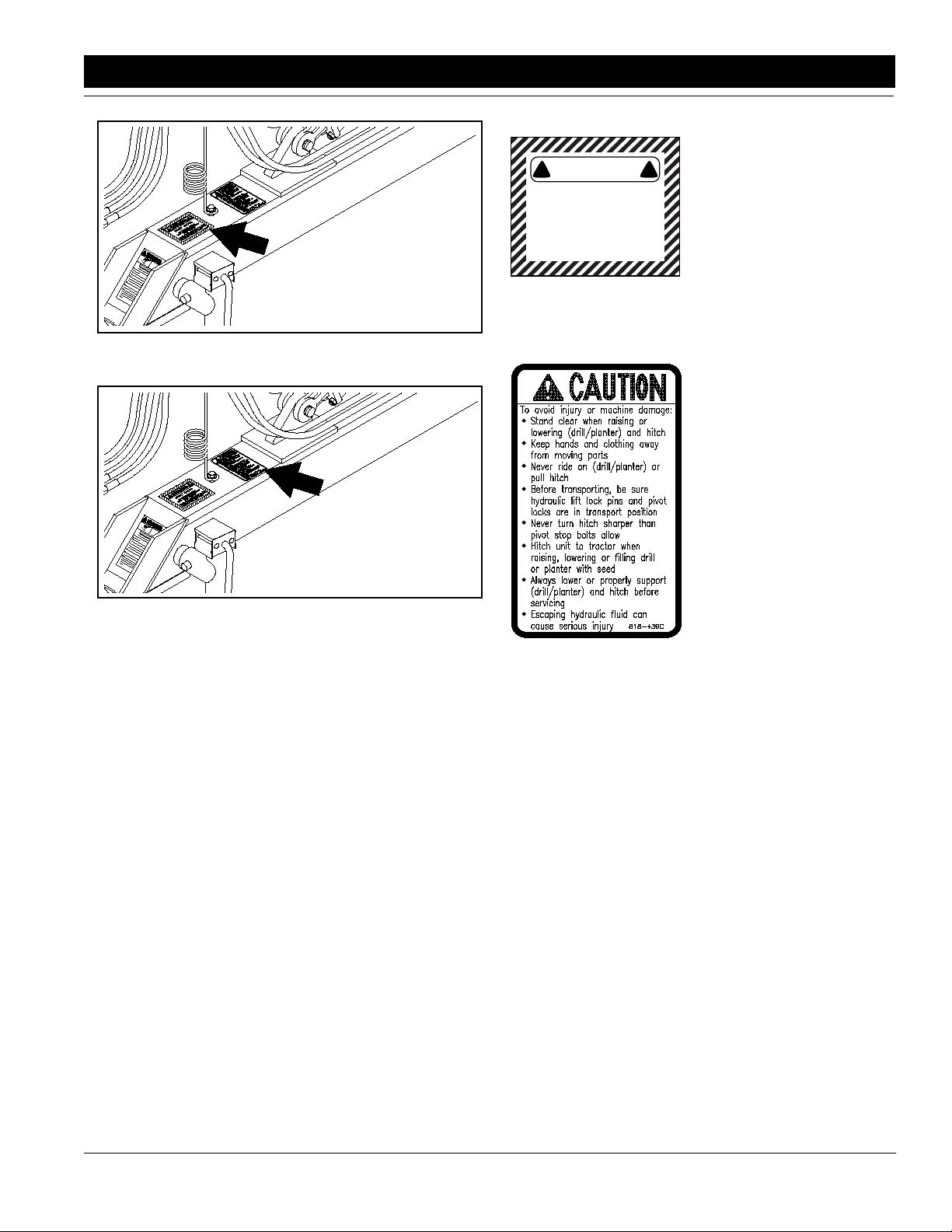

12447

! !

WARNING

SAFETY HAZARD

USE EXTREME CAUTION

WHEN UNHITCHING IMPLEMENT

FROM TRACTOR.

Negative tongue weight may cause immediate

elevation of tongue resulting

in damage or personal injury.

818-019C

818-019C

Warning - Negative Tongue Weight

12448

818-439C

All Seeds General Caution

12424

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-5

Page 8

Section 2 Assembly Instructions & Set-Up

Section 2 Assembly Instructions & Set-Up

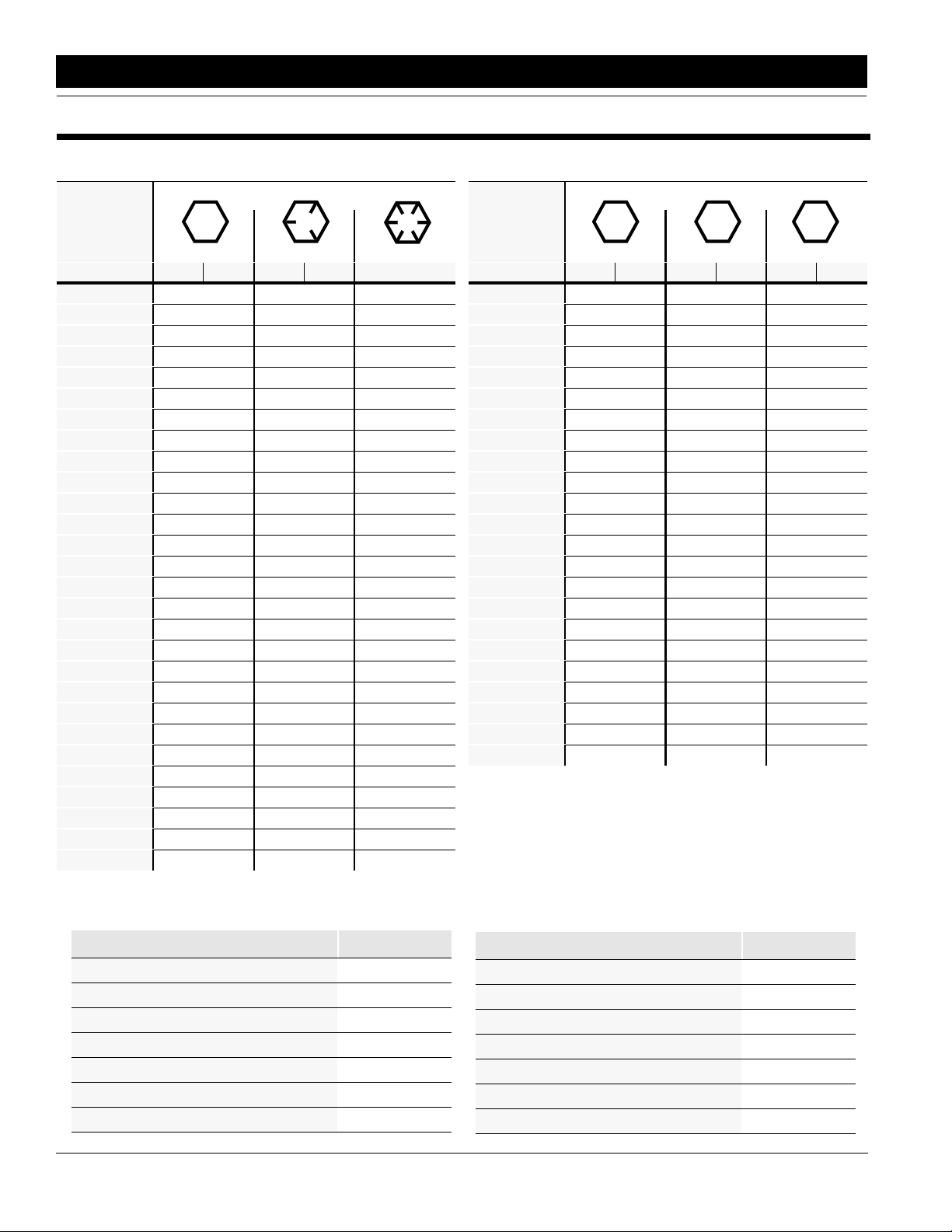

Torque Values Chart for Common Bolt Sizes

Bolt Head Identification

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 436597

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch

Grade 8

Bolt Size

(Metric)

4

1

in-tpi = nominal thread dia .in inches-threads per inch

2

N· m = newton-meters

3

ft-lb= foot pounds

4

mm x pitch = nominal thread dia. in millimeters x thread pitch

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

N · m ft-lb N · m ft-lb N · m ft-lb

Tire Inflation Chart

Tire Size Inflation PSI

7.50 x 20" 4-Ply Drill Rib 28

9.0 x 22.5 10-Ply Highway Service 70 70

9.0 x 24" 8-Ply Rib Implement 40

9.5L x 15" 6-Ply Rib Implement 32

9.5L x 15" 8-Ply Rib Implement 44

9.5L x 15" 12-Ply Rib Implement 60

5.00 x 15" 4-Ply T r action Type Implement 36

6

AS15 and AS20 Planting System 148-153M 4/14/05

Tire Size Inflation PSI

11L x 15" 6-Ply Rib Implement 28

11L x 15" 12-Ply Rib Implement 52

11L x 15" 18-Ply Rib Implement 76

12.5L x 15" 8-Ply Rib Implement 36

12.5L x 15" 10-Ply Rib Implement 44

16.5L x 16.1" 10-Ply Rib Implement 36

41 x 15" x 18 - 22-Ply Rib Implement 44

Great Plains Mfg., Inc.

Page 9

Section 2 Assembly Instructions & Set-Up

NOTE: All tires are warranted by the original manufacturer of the tire. Tire warranty information can be found in the

brochures included with your Operator’s and Parts Manuals or online at the manufacturer’s websites. For service assistance or information, contact your nearest Authorized Farm Tire Retailer.

Manufacturer Websites

Titan www.titan-intl.com

Goodyear www.goodyearag.com

Firestone www.firestoneag.com

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-7

Page 10

Section 2 Assembly Instructions & Set-Up

Read and understand the owner’s manual for your All

Seeds Hitch. A basic understanding of how the hitch

works will aid in the assembly and setup of your hitch.

The followinginformation is general in nature and was

written to aid the operator in preparation of the tractor

Pre-Assembly Checklist

Check Reference

All major components Operator’s

Fasteners that were shipped with the All

Seeds Hitch.

NOTE: Some of the hardware from the

factory has been installed in the location

where it will be used.

Have a minimum of 2 people at hand while

assembling the All Seeds Hitch.

Manual

Section

page 9

Section 2

page 8

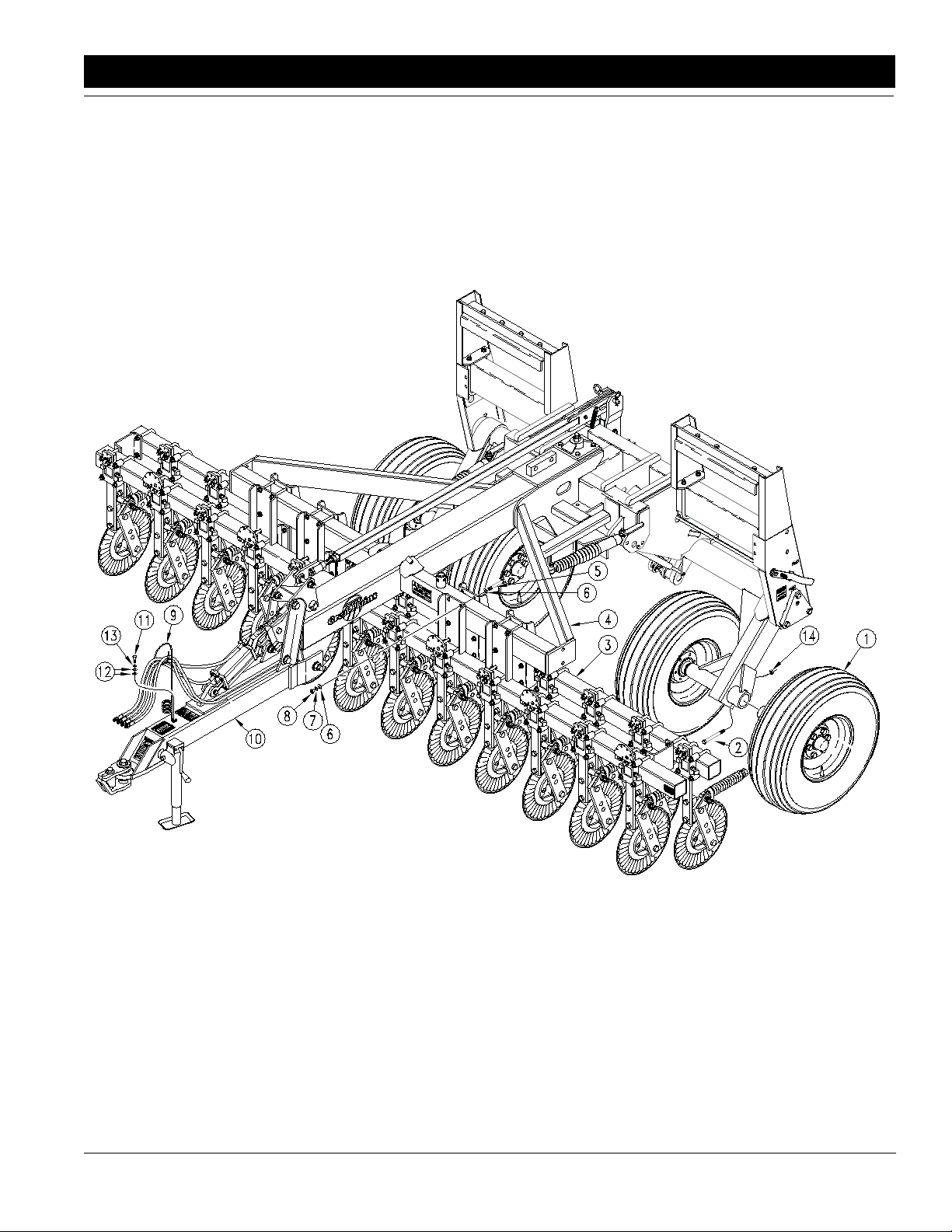

Assembling The All Seeds Hitch

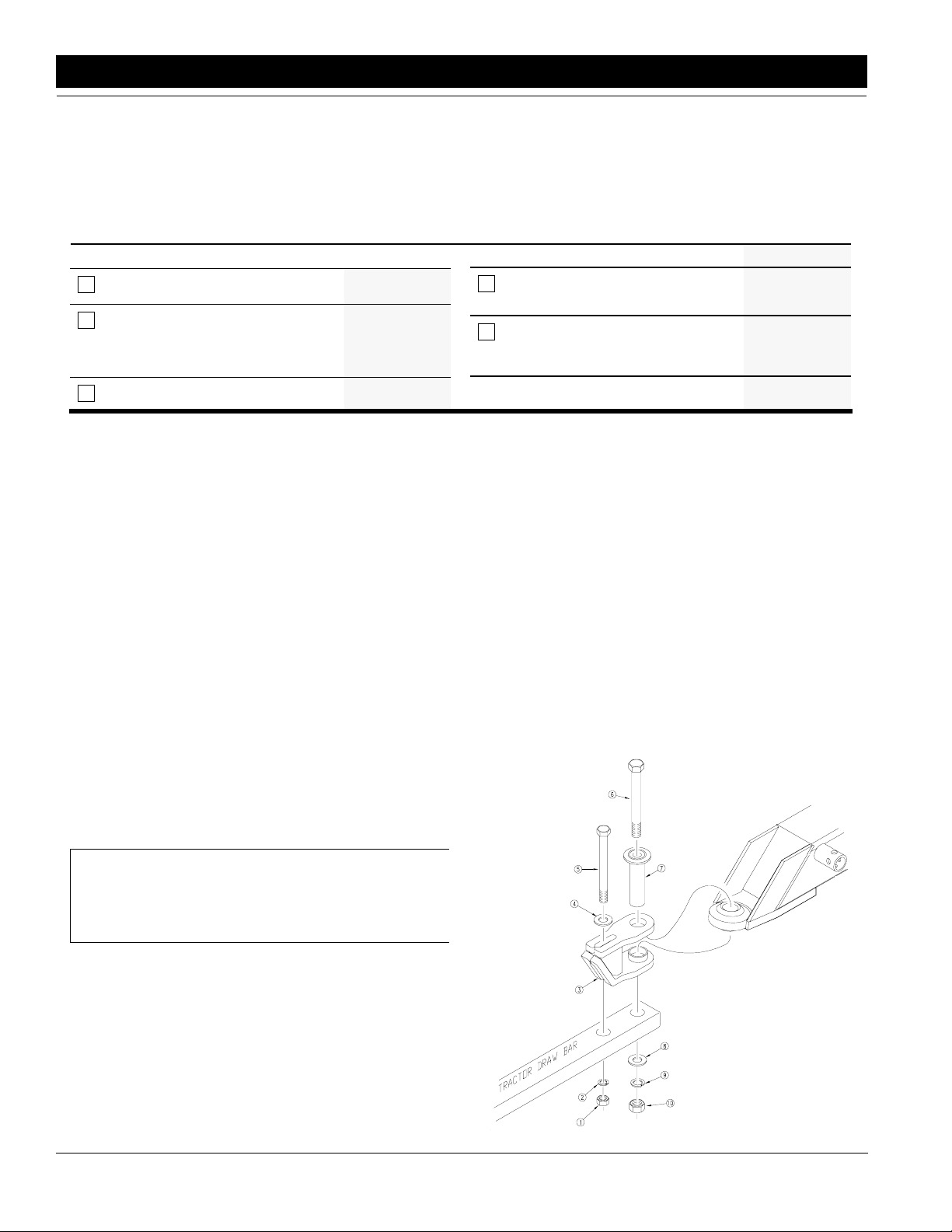

For the following assembly instructions refer to Figure 2-2.

1. Remove the transport tire, hub, and spindle assemblies(#1) whicharebandedto the hitchandslidethe

spindlesintothe outer spindle tubes of the transport

rockshaft.Secure the spindles in place with the 1/2"

x 4 3/4" long bolts (#2) and the 1/2" lock nuts (#14).

Cut the bands that hold the tongue and tongue cylinder to the hitch and swing it into position and pin

the cylinder to the cylinder lug on the hitch. Swing

the tongue links into position and bolt them to the

ears on the front tongue.

2. Center the coulter tool bar assembly (#3) under the

hitch (#4) and fasten to upper coulter tool bar support with the 5/8” x 6” long bolts (#5), 5/8” flat washers (#6), 5/8” lock washers (#7), and 5/8" nuts (#8).

It is criticalthat the coulters are centered under the

All Seeds Hitch to insure proper tracking with the

drill. Use extra care when assembling the coulter

tool bar assembly to the hitch. The coulter tool bar

assemblies should have a coulter blade gap centered on the center line of the hitch.

and hitch for use, and to provide general operating procedures. The operator’s experience, familiarity with the

machine and the following information should combine

for efficient hitch operation and good working habits.

Having all the parts and equipment readily at hand will

speed up your assembly task.

Check Reference

Havea fork lift or loader along with chains

and safety stands ready for the assembly

task.

If you are unsure where a fastener is

used, use the partssection of this manual

to identify it. Be sure the part gets used in

the correct location.

Section 1

page 3

Parts Manual

263M)forassembly of optional Coulter Depth Control

Attachments.

Tractor Drawbar Hookup

For the followingassembly instructions refer to Figure 2-1.

1. Place hitch weldment (#1) over the ball swivel of the

front hydraulictongue and hold in place by inserting

theinner spacer tubeweldment(#2) through the large

hole in the hitch clevis and ball swivel.

2. Back tractor up to the machine and bolt hitch weldmentassembly (#1)&(#2) to tractordrawbarlargepin

holeusingthe1"x10"longbolt(#3),largeflatwasher

(#4), 1" lock washer (#5), and 1" nut (#6). Use 3/4" x

9" long bolt (#7) to bolt the hitch weldment through its

slotted hole and into thesecondary hole of the tractor

drawbar. Install a 3/4" flat washer (#8) nextto the top

slotted hole and fasten with a 3/4" lock washer (#9)

and 3/4" nut (#10). Tighten both bolts.

NOTE: The center of the coulter blade is approximately 1/4" to the right of the coulter mount casting

and coulter spring bar.

3. Assemblethe springhose loop (#9) on the hydraulic

tongue(#10)witha 1/2" x 1" long bolt (#11), two 1/2"

flat washers (#12), and a 1/2" lock washer (#13).

The spring hose loop bolts to a coupler nut welded

near the front of the hydraulic tongue.

Drawbar

Assembly Illustration

Figure 2-1

4. Referto Fertilizer Option Manual (GP 148-152M) for

assembly of optional Liquid Fertilizer Attachments.

5. Referto Coulter Command Option Manual(GP 148-

8

AS15 and AS20 Planting System 148-153M 4/14/05

Great Plains Mfg., Inc.

12073

Page 11

Section 2 Assembly Instructions & Set-Up

13620

M

E

T

S

Y

S

G

N

I

T

N

A

L

P

S

D

E

E

S

L

L

A

Dealer Assembly Illustration

Figure 2-2

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-9

Page 12

Section 2 Assembly Instructions & Set-Up

Your AllSeedsHitch comes equipped with a hitch safety

chain. The safety chain should be securely attached to

the All Seeds Hitch and the tractor drawbar whenever

towing or planting.

Remove the jack from the storage position on the front

hydraulictongue as shown in Figure 2-3 and place in the

transport position on top of the coulter tool bar support

tube as shown in Figure 2-4.

12084

Jack In Storage Position

Figure 2-3

Tractor Hydraulic Hookup

The tractor should be equipped with 4 remote outlets (2

pair). The 1/2" hoses from the front tongue cylinder connect to one set of tractor remote outlets. The 1/2" hoses

from the transportlift cylinders connect to another set of

tractor remote outlets.

Bleeding The Hydraulic Systems

!

WARNING!

Escaping fluidunder pressurecan have sufficient forceto penetrate the skin. Check all hydraulic lines and hoses before applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check for suspected leaks. If injured, seek medical assistance

froma doctor that is familiar with this kind of injury. Foreign

fluids in the tissue must be surgically removed within a few

hours or gangrene will result.

Front Hydraulic Tongue Cylinder

NOTE: Check the hydraulic fluid in the tractor reservoir and fill to the proper level. Add fluid to the system as needed. A low reservoir level may draw air

back into the system, causing jerky or uneven cylinder movement. Front tongue cylindercapacity is 0.5

gallons.

1. Raise and safely support hitch, transport frame and

front tongue in order to unpin the rod end of the

tongue cylinder. Block, wire or otherwise safelysupport the cylinder so when the rod end is fully extended it does not contact anything.

2. Cycle the cylinder completely in and out a minimum

of three times to purge the air from the cylinder and

hoses.

3. Fully extend the cylinder to repin the rod end.

4. Recheck the tractor reservoir and fill to its proper

level.

NOTE: The SAE O-ring and JIC 37° flare type hose

connections DO NOT require sealant for reconnecting. They DO NOT require high torque for a good

seal. Whenusingsealantonpipethreads the friction

between the threads is reduced; therefore, be certain not to over tighten causing damage to the cylinder port or fitting.

Hydraulic Lift System

12310

NOTE: Check the hydraulic fluid in the tractor reservoir and fill to the proper level. Add fluid to the sys-

Jack In Transport Position

Figure 2-4

10

AS15 and AS20 Planting System 148-153M 4/14/05

tem as needed. A low reservoir level may draw air

back into the system, causing jerky or uneven cylinder movements. Transport lift hydraulic capacity is

approximately 2 gallons.

Great Plains Mfg., Inc.

Page 13

Section 2 Assembly Instructions & Set-Up

NOTE: The hydraulic lift cylinders are not the

rephasing type cylinders. Bleeding these cylinders

require a special procedure which involves loosening hose connections at the cylinder fittings. Bleed

the circuit at a JIC Connection or Pipe connection.

Do not attempt to bleed an o-ring connection, as oring damage may occur.

1. Makesure the transportlock handle is in the “Road”

position,andthatthetransport lock blocksaredown

in their transport position. The all seeds hitch is normally shipped this way. If not, lift up and supportthe

hitch transport frame so the cylinders can be unpinned.

2. Unpin the rod end clevis pins. The cylinder rod

should be completely extended at this time. If not,

manuallyextendthe cylinder rods. With the cylinder

rods completely extended, loosen the connection

between the hose end and the tee at the rod end of

the transportlift cylinder. Slowly work the remote lever to feed oil to the cylinder rod ends, stopping

when oil is seen coming from around the fitting. Retightenthe rod end hose fitting.(Do not attemptto retractthe cylinder rods while bleeding the air from the

cylinder rod ends to minimize the air space at rod

ends of the cylinders.)

3. Once the rod end hose fitting has been retightened,

completely retract the cylinder rods. After the rods

areretracted,loosen the hose fitting to the hoserunning between the base end tee and the relief valve

which is connected to the rod end of the same cylinder. Loosen the hose fitting on the end which connects to the base end tee. Slowly work the remote

leverto feed oil to base ends of the cylinders, stoppingwhenoil is seen coming from around the fitting.

Once the air is expelled, retighten the base end

hose fitting. (Do not attempt to extend the cylinder

rods while bleeding the air from the cylinder base

ends to minimize the air space at the base ends of

the cylinders.)

4. Extendandretract the transportlift cylindersseveral

times.The majority oftheairshould nowbeexpelled

from the lift system. The remaining air will gradually

be pushed to the tractor during day-to-day operations.

5. Repinthe transport lift cylindersand movethetransport lock leverto the “Field” position. Raise and lower the hitch several times to check for proper

operation. The hitch will first have to be completely

raised for the transport locks to snap out of their

locked position.

6. Recheck the tractor hydraulic reservoir level and

add clean fluid as necessary.

Drill and Planter Hookup

The All Seed Hitch is a complete planting system designed to accommodate all your planting needs. It

comescomplete with all the hardware to turnyour Great

Plainsdrill and Great Plainsplanterinto a no-till planting

system capable of handling a range of planting conditions from tough no-till to conventional tillage planting.

The All Seeds Hitch allows you to quickly change from

no-till planting to no-till drilling.The following section explains the procedure for drill and planter hookup.

Top Hitch Extension Assembly

Place the top hitch extension (#1) between the top hitch

plates of your drill or planter and bolt in place as shown

in Figure 2-5, using two 1" X 5 1/2" long bolts (#2), lockwashers (#3), and hex nuts (#4). The All Seeds Hitch

comes with two top hitch extensions and hardware for

both a drill and a planter.

12085

Lower Hitch Links

Great Plains 10 Series Drills with parallel linkage openers require the use of special lower hitch links to

maintain a more level coulter and drill arrangement in

the field as well as allow greater transport clearance on

the road. The lower hitch links bolt to the lower hitch

plates of the 3-Point 10 Series Drill with two 1 1/8" x

2 1/2" long bolts (#1), lockwashers (#2), and hex nuts

(#3) as shown in Figure 2-6. Two 5/8" X 2" long bolts

(#4),USS washers (#5), lockwashers(#6), and hexnuts

(#7) are also requiredand fasten through the top slotted

holes in the lower hitch plates.

Top Hitch Extension

Figure 2-5

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-11

Page 14

Section 2 Assembly Instructions & Set-Up

12329

Lower Hitch Links for 10 Series Drills

Figure 2-6

Quick Hitch Links

Positionthe All seeds Hitch in front of the drillor planter

so that the quick hitch links of the All seeds Hitch are in

line with the lowerhitch pins of the planting unit. Hydraulically retract the lift cylinders of the All Seeds Hitch to

positionthe quick hitch links slightly lower than the planting unit hitch pins.

Positionthe handle of the quickhitch to the locking position as shown in Figure 2-8. This will allow the planting

unit hitch pins to snap into the quick hitch links securing

the unit to the quick hitch.

Transport Locks

With the All Seeds Hitch properlysecured to the tractor

drawbar, positionthe transport lockhandle to the “Field”

position as shown in Figure 2-7. The transport lock handleis located ontheleftend panel ofthetransportframe.

Raisethehitchall the wayup to takethe pressure off the

transport lock blocks and allow them to slide free from

their locked position.

12331

Quick Hitch Links in the locking position

Figure 2-8

Backthe All Seeds Hitch uptotheunituntilthe hitch pins

contact the quick hitch. Hydraulically raise theAll Seeds

Hitchuntilthehitchpinsare attached securely inside the

quickhitch links. DO NOT RAISE THE PLANTING UNIT

ANY HIGHER ATTHIS TIME.

Level Link Attachment

Once the hitch pins are securely attached inside the

quickhitch links, attach the slotted levellinkbaroftheAll

Seeds Hitch (#1) to the top hitch extension of the planting unit. Use the 1" X 3 3/4" long top hitch pin (#2), and

bushing (#3) and secure with the clip pin provided (#4)

as shown in Figure 2-9.

Now you are ready to proceed to “Transporting” in

“Section 3 Basic Operation” starting on page 14.

!

CAUTION!

Always makesure the All Seeds Hitch is securely lockedin the

quick hitch before raising!

12330

!

Transport Lock Handle in "Field" Position

Figure 2-7

12

AS15 and AS20 Planting System 148-153M 4/14/05

CAUTION!

This All Seeds Hitch should never be pulled faster than 20

miles per hour!

Great Plains Mfg., Inc.

Page 15

Section 2 Assembly Instructions & Set-Up

12086

Top Hitch Pin and Bushing

Figure 2-9

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-13

Page 16

Section 3 Basic Operation

Section 3 Basic Operation

Transporting

Transport Locks

The All Seeds Hitch has two transportlockblockswhich

are controlled by a springloaded handle located on the

left end panel of the transport frame. The handle can be

moved from “Field” to “Road” position or “Road” to

“Field” position regardless of the position of transport

rockshaft or transport lock blocks. This allows the operator to rotate the transport lock handle to the desired

position and then operate the hydraulics to allow the

transport locks to “lock in” or “lock out” automatically.

To lock the All Seeds Hitch for transport, pull the transport lock handle outward and rotate the handle

counterclockwise to the “Road” position and hook the

handle back over the receiver tab, Figure 3-1. Then, lift

the machine completely until the transport lock blocks

snap into position against the rockshaft lugs. Once the

transport lock blocks are in position, the hydraulics can

be activated to set the machine down against the blocks

and relieve the pressure on the cylinders.

3-2. The machine must then be completely raised to allow the transport lock blocks to slide free before the

machine can be lowered.

12330

12332

Transport Lock Handle in Transport "Road" Position

Figure 3-1

Lockingthemachine fortransport is essentialto prevent

damage to the hitch or operator should hydraulic failure

occur during transport or when working around the machine in the raised position.To lower the All SeedsHitch

forplanting or storage, reposition the transportlockhandle clockwise to the “Field” position as shown in Figure

Transport Lock Handle in "Field" Position

Figure 3-2

Pivot Lock Tubes

The adjustable pivot lock tubes, located on the front of

the transport frameand next to the leaf spring rollers, restrict the pivot movement between the transport frame

and the coulter hitch to allow for safer transport. They

can be adjusted by loosening the jam nut and screwing

the bolt in or out to the desired setting and retightening

the jam nut. When the transport frame is 90 degrees to

the tongue, each bolt head should be about 1/16" away

from its stop pad on the pivot hitch.

The pivot lock tubes are controlled automatically by

spring loaded links connected to the rockshaft. When

the All Seeds Hitch is completely raised, the pivot lock

tubesrotatedown and contact the stop padsonthepivot

hitch to restrict pivoting during transport and when turning at the end of the field. When the All Seeds Hitch is

lowered, the pivot lock tubes rotate up and allow the

hitch and frame to pivot freely in the field.

The pivot lock tubes can be manually locked down or

locked up by swinging the lock tube (down/up) and inserting the 3/4" X 5 1/4" long hitch pin to hold it in place

as shown in Figure 3-3. The 3/4" hitch pin is normally

stored in the storage hole just behind the pivot lock

tubes.

14

AS15 and AS20 Planting System 148-153M 4/14/05

Great Plains Mfg., Inc.

Page 17

Section 3 Basic Operation

12333

Pivot Lock Tube Manually Locked Down

Figure 3-3

It may be necessary to lock the pivot locks down when

planting on steep side slopes or when backing the All

Seeds Hitch to hook up to a drill or planter.Since the automaticcontrollinks on the pivotlocksare spring loaded,

they do not have to be disconnected when manually

locking the pivot locks up or down.

Tongue Transport Channels

A transport lock channel is availableto lock up the front

tongue cylinder.After the unit is raised for transporting,

thetransport lockchannel should ALWAYSbe placed on

the cylinder rod to preventdamage should hydraulicfailure occur.

It fits over the cylinder rod and is held in place with a

keeper pin as shown in Figure 3-4. Before lowering the

All Seeds Hitch for planting, place the transport lock

channelinits storageposition on the coulter bar support

gusset as shown in Figure 3-5.

11871

Tongue Transport Channel in Storage Position

Figure 3-5

Pre Drilling/Planting Instructions

Beforeoperating the AllSeeds Hitch check the following

items and operating rules.

Transport Locks

Rotate the transport lock handle to the field position as

shown in Figure 3-1. The hitch will have to be raised

completely to remove the pressure on the transportlock

blocksand allowthemtoslidefreebeforethe unit can be

lowered.

Pivot Lock Tubes

Make sure the pivot lock tubes are not manually locked

down as shown in Figure 3-3 to allow them to automatically swing free from the pivot stop plates during field

operation. This allows for proper tracking between

coulters and openers as shown in Figure 3-6.

Tongue Transport Channel

Removethetonguetransportchannelfromthe transport

position Figure 3-4 and place it in the storage position

Figure 3-5.

Tongue Transport Channel in Transport Position

Figure 3-4

4/14/05 Great Plains Mfg., Inc.

12483

Basic Operating Rules

1. Neverback up with openers and coulters in the

ground.

2. Do not turn a shorter radius than the pivot stops will

allow.

AS15 and AS20 Planting System 148-153M

-15

Page 18

Section 3 Basic Operation

NOTE: 3-point planters and 3-point drills are not designed to be turned with the openers in the ground.

Damage may occur to the openers and press

wheels.

3. DO NOTunhitch from tractor with the All Seeds

Hitch with the planter or drill in the raised position.

The negative tongue weight present may cause immediateelevationof the tongue resulting indamage

or personal injury. Always have planting units lowered when unhitching from tractor.

4. Neverallow anyone to ride on the All Seeds Hitch,

planter, or drill.

5. Neverexceedspeedsof 20 MPH when transporting.

16

AS15 and AS20 Planting System 148-153M 4/14/05

Great Plains Mfg., Inc.

Page 19

Section 3 Basic Operation

Proper Tracking Of Drill Openers To Coulters

Figure 3-6

Operating Checklist

Check Reference

“Safety Rules” in this Manual Section 1

“HookUp” & “Operating Instructions” in

this Manual

Tire pressure Section 2

Lubricate the hitch as needed Section 6

Drill & Hitch; initially and periodically for

loose bolts, pins, and chains.

Leaks in the hydraulic system Operator’s

Adjustments Operator’s

12092

Page 3

Section 2

Page 8, 10, 11

Page 6

Page 25 - 28

Operator’s

Manual

Manual

Manual

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-17

Page 20

Section 4 Hitch, Drill, & Planter Adjustments For No-Till Planting Conditions

Section 4 Hitch, Drill, & Planter Adjustments For No-Till Planting Conditions

Hitch Adjustments

Level Link Adjustment

1. Thethreaded adjustment at the front ofthe levellink

is to lengthen or shorten the link. Make this adjustment with the unit lowered to field position and with

the cotters at the desired depth. With the lock plate

flippeddownasshownin Figure 4-1, loosen the jam

nutand turnthe adjuster nut to levelthe planting unit

front to back. Tighten jam nut to hold this position.

2. The lock plate at the rear of the level link can be

used for three different conditions:

a. Normally the lock plate is held down in the

locked position to keep the planting unit level

Figure4-1. This doesnotallowthetrailingunit to

tip forwardor backward independently of the

hitch.

12088

Level Link In Unlocked Position

Figure 4-2

12087

Level Link In Locked Position

Figure 4-1

b. The lock plate can be held up in the unlocked

position with the level link adjusted so the top

hitch extension pin is in the back of the slot, Figure 4-2. This holds the plantingunit from tipping

backward, but allows it to tip forward independent of the hitch.

c. With the lockplate held up in the unlockedposi-

tion and the level link adjusted so the top hitch

extension pin is in the center of the slot, Figure

4-3, the trailing unit is allowed to tip forwardand

backward independent of the hitch.

12089

Level Link In Middle, Unlocked Floating Position

Figure 4-3

18

AS15 and AS20 Planting System 148-153M 4/14/05

Great Plains Mfg., Inc.

Page 21

Section 4 Hitch, Drill, & Planter Adjustments For No-Till Planting Conditions

Leaf Spring Adjustment

Theleafspringlocatedjustaheadofthevertical pivoton

the All Seeds Hitch is designed to provide just enough

forceto help keepthe hitch square andstablefor turning

around at the ends of a field, and to add stability for operating in rough and irregular field conditions. Proper

leafspring adjustment is importantfor smooth operation

between the hitch and the planter or drill. During assembly, the 3/8" u-bolt on the outer ends of the leaf spring

must be tightened enough to pull the ends of the leaf

spring forward so the force from the leaf spring doesn’t

interferewiththeinstallationof thecenterpivotpin.Once

thepivot pins areassembled,the nutsonthe3/8"u-bolts

must be backed off to set the proper leaf spring stabilizing force.For proper adjustment, square the hitch with

the transport frame and adjust the 3/8" u-bolt lock nuts

on each side until the leaf spring rollers just make contact with the roller pads on the transport frame. Make

sure both the right and left sides are adjusted properly

when the hitch is square to the transport frame.

Drill & Coulter Adjustments

Down Floating Gauge Wheels

When using a 3-point mounted drill on a All Seeds NoTill Hitch, the drill should be equipped with downward

floatinggauge wheel links.Downwardfloat on thegauge

wheels is necessary to maintain a constant uninterrupted drive wheel rotation in no-till conditions.

Current Great Plains drills have down floating gauge

wheelsas standard equipment. Older Great Plains drills

require two slotted gauge wheel links (Great Plains part

no. 120-171A) or two spring loaded gauge wheel links

(Great Plains part no. 120-106A) to achieve the necessary down float for no-till drilling.

Drill Adjustments

The followingadjustments should be made with a half

full seed box:

1. Lowerthe AllSeedsHitch and completely retractthe

transport lift cylinders. Set the front tongue cylinder

so that your coulters are at the desired depth. Note

the setting on the cylinder depth gauge so that you

can return to the same depth after lifting the drill.

2. Make sure your 3-point drill is equipped with down

floating gauge wheels. Set the drill gauge wheel to

the desired setting to maintain the proper frame

height for your style of drill.

• For 00 Series drills with straight arm double disk

openers, the bottom of the opener frame tube

should run approximately 17 1/2 inches above

the ground.

• For 10 Series drills with parallel arm double disk

openers, the bottom of the opener frame tube

should run approximately 21 inches above the

ground.

Maintaining the proper opener frame height allows the

double disk openers to contact the soil properlyand follow uneven terrain while maintaining the proper seed

placement.

3. Next level the drill with the level link adjustment or

top link adjustment trunnion.

• For 00 Series drills with straight arm double disk

openers, there should be about 2" of gap between the spring rod casting and the spring rod

cross bolt when the drill is level as shown in

Figure 4-4.

10548

Normal Spring Rod Setting

Figure 4-4

• For 10 Series drills with parallel arm double disk

openers, the drill is level when the openermount

is about 1" to 1 1/2" higher than the opener body

as shown in Figure 4-5.

12163

Leveling the Drill

Figure 4-5

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-19

Page 22

Section 4 Hitch, Drill, & Planter Adjustments For No-Till Planting Conditions

4. Set the individual opener down pressure springsto

their lowest spring setting.

a. For00 Series drillswith straightarm doubledisk

openers, set the opener spring rod so the “W”

clip is in the lowest hole as shown in

Figure 4-6.

12102

Minimum Pressure

Figure 4-6

b. For10 Seriesdrills with parallel armdoubledisk

openers, set the down pressure spring to its

lowest setting. The spring adjustment cam is

positioned with the lock pin in the rear most slot

for the lowest spring setting. See Figure 4-7.

Minimum

Pressure

Maximum Pressure

12104

12100

Press Wheel Adjustment

Figure 4-8

Refer to your 3-PointDrill Operator’s manual for additional setting information.

NOTE: When drilling in soft soil conditions where

sinkingofyourdrillgauge wheels may be a problem,

cylinder stop bushings may be added to the lift cylinders of the All Seeds Hitch to allow your transport

tires to run on the ground and assist in supporting

the drill and hitch weight. Cylinder Stop Bushing

Sets (G.P. #810-120C) are available through your

Great Plains Dealer.Two Cylinder Bushing Sets are

required for the All Seeds Hitch; (One for each lift

cylinder). Make sure when adding cylinder stops

that your downward floating gauge wheels are adjustedto the top of theirmotionrange.This will allow

your gauge wheel to follow the ground when drilling

in rough terrain and keep constant seed metering. If

the transport wheels carry too much of the weight,

the drill gauge wheels may raise off the ground and

cause skips to occur.

Coulter Adjustments

12132

Parallel Linkage Opener At Minimum Spring Setting

Figure 4-7

The coulters on the All Seeds Hitch are designed with

theversatilitytobe used with either a drill or a planter for

no-till seeding. They are adjustable both vertically and

horizontallytotrack in linewithdrillopenersortoprovide

some zone tillage for no till planter row units.

5. Adjust the seeding depth of the individual openers

by lifting up and sliding the press wheel adjustment

knob until the desired depth is achieved Figure 4-8.

20

AS15 and AS20 Planting System 148-153M 4/14/05

Thecoulterson the All Seeds Hitch are set at thefactory

to track in line with the openers on a 7 1/2" row spacing

3-point drill. Nevermove the coulters horizontally with-

Great Plains Mfg., Inc.

Page 23

Section 4 Hitch, Drill, & Planter Adjustments For No-Till Planting Conditions

outfirst marking theiroriginalposition.It is important that

the coulters are always returned to their original lateral

position to provide a tilled path for drill openers to follow.

Coulter penetration is dependent on the soil condition,

the weight available to force the coulters into the soil,

and the coulter spring preload. In hard soil conditions,

additional weight may haveto be added to the All Seed

Hitch and the coulter spring preload may have to be

increased.

The followingsteps should be used to achieve the desired coulter penetration. All adjustments and settings

should made with a half full seed box.

1. The depth of the All Seeds Coulters is controlled by

the Fronthydraulic tongue cylinder. In most conditions,the coulterswillpenetratetoadesirabledepth

by running with the coulter hitch main 8" X 8" beam

levelwith the ground.To achievethe desired coulter

penetration, retract the front tongue cylinder to

transfer tractor weight to coulter tool bar. When the

desired coulter depth is achieved on level ground,

take note of the stroke pointer location on the front

tongue cylinder,Figure 4-9. This amount of cylinder

extension can be used when drilling in level fields.

NOTE: The cylinder stroke gauge on the front

tongue cylinder is to be used only as a reference to

the amount of front cylinder extension. It does not

designate inches of coulter depth.

2. In hard soil conditions where coulter penetration is

limited or where maintaining coulter penetration

tends to lift the drill box, suitcase weights can be

added to the weight brackets located on the All

Seeds transportframe. No more than 2000 pounds

should ever be added to the transport frame weight

brackets,(1000 pounds per weightbracket).Adding

weight on the transport frame provides the best

weight distribution for the no-till drilling system. Be

sure to place an equal amount of weight on each

weight bracket. If your All Seeds Hitch is equipped

with the liquid fertilizer option, liquid fertilizer tanks

replace the weight brackets. If the tanks are not being used for fertilizer, water can be added to the liquid tanks to provide the needed weight for coulter

penetration.Generallyeach tank should not haveto

be more than half full to provide sufficient weight for

coulterpenetration.Be sure to add an equal amount

of water to each liquid tank.

3. The coulter spring length is preset at the factory to

10"which givesthecoultersan initial operatingforce

of400 pounds. This setting is adequate for many difficult no-till planting conditions. For lighter no-till

conditions where rocks or other obstructions are a

problem, it may be desirable to reduce the initial

coulter preload to give the coulters better impact

protection.Refertothe chartbelow for adjusting the

initial coulter force setting.

10741

Tongue Cylinder With Depth Gauge Decal

Figure 4-9

4/14/05 Great Plains Mfg., Inc.

Coulter Down Pressure Chart

Spring Length Initial Vertical

Coulter Force

10 1/2" 175 lbs.

10 1/4" 300 lbs.

10" 400 lbs.

9 3/4" 525 lbs.

!

Any attempt to reset the coulter spring length shorter than

9 3/4" may contribute to premature failure of parts and

warranty shall be voided.

CAUTION!

AS15 and AS20 Planting System 148-153M

-21

Page 24

Section 4 Hitch, Drill, & Planter Adjustments For No-Till Planting Conditions

4. For extremely hard soil conditions, where 2000

poundsonthe transportframe weightbracketsdoes

not achieve the required coulter penetration, a tool

bar weight bracket kit (see the "Options" Section on

page 30 for ordering these kits) is available. Each

weight bracket kit contains two weight brackets

whichwill bolt abovethe ends of the coulter tool bar.

Anequal amount ofweightshould beaddedon each

end of the coulter tool bar. With the transport frame

weight brackets weighted to the maximum recommendations,orwiththeuse of liquid fertilizer,a maximum total of 2400 pounds can be added to the tool

barweightbrackets.(1200poundsperweightbracket).

!

If the tool bar weight brackets contain the maximum recommended weight, the All Seeds Hitch should NOT be transported full of liquid fertilizer.

5. In some extremely hard soil conditions, 20' coulter

6. The individual coulters on the All Seeds Hitch are

To adjust an individual coulter:

CAUTION!

tool bars may tend tohavesome upward flex, which

would affect the coulter penetration out on the ends

of the coulter tool bars. For these conditions, a

coulter tool bar brace kit (GP part no. 149-188A) is

available. This kit contains braceswhichsupport the

ends of 20' coulter tool bars to keep the coulter tool

bars rigid.A coulter tool bar brace kit is not needed

andwill not fit if tool bar weightbracketsare used on

the ends of the coulter tool bars.

designed for quick, easy vertical adjustment.

Coulterswhich trackintiretracksor whichseemore

useaszone tillage coulters forplanterrow units may

requiredownwardadjustment to compensate foradditional wear. Each coulter has a depth indicator

camwhich pivotsonthe coulter spring bar and rests

against the top of the coulter clamp. The cams are

lettered A through D or A through G with each letter

indicating an additional 1/2" of coulter depth.

1. Loosen the 5/8" jam nuts on the 5/8" square

head set screws, and then loosen the set

screws.

2. Raise the coulter slightly and rotate the depth

cam to desired setting andallowthe cam to rest

against the top of the coulter clamp.

3. Tighten the set screw on the side of the coulter

clamp first. This squares the coulter bar in the

clamp.

4. Tighten the set screw on the front of the coulter

clamp and then tighten both 5/8" jam nuts on

each set screw.

NOTE: Torque 5/8" set screws 85-100 ft-lbs to

obtain adequate holding force.

Planter & Coulter Adjustments

Down Floating Gauge Wheels

When using a 3-point mounted planter on an All Seeds

No-Till Hitch, the planter should be equipped with downward floating gauge wheels. Downward Float on the

gauge wheels is necessary to maintain a constant uninterrupted drive wheel rotation in no-till conditions.

Current Great Plains Planters have spring loaded down

floating gauge wheels as standard equipment.

Planter Adjustments

1. Lowerthe AllSeedsHitch and completely retractthe

transport lift cylinders. Set the front tongue cylinder

so the zone till and fertilizer coulters are at the desired depth. Note the setting on the cylinder depth

gaugesothat you can return to the samedepthafter

lifting the planter.

2. Set the planter gauge wheels to maintain a frame

height of 21" from the bottom of the main frame to

the ground. Maintaining the proper frame height

sets the planter row units into the best position for

following uneven terrain while maintaining proper

seed placement.

3. Leveltheplanterframewith the levellink adjustment

trunnion or top link adjustment trunnion. A level

planter is essential for proper depth control and

seed placement.

4. Setthe depth ofeachindividual rowunitbyadjusting

the position of the sidedepth gauge wheels with the

sliding tee handle. With the depth set, adjust the

pressureonthefurrow closing wheels to match your

soil conditions. It is also important to maintain the

proper depth on the row mounted coulter to provide

a tilled path for the planter row unit to follow.Set the

rowmounted coulter at or 1/4"abovethe levelof the

doubledisk openers. Referto your planter operators

manual for additional and more specific planter adjustments.

Coulter Adjustments

The coulters on the All Seeds Hitch are designed with

theversatilitytobe used with either a drill or a planter for

no-till seeding. They are adjustable both vertically and

horizontally to band liquid fertilizer and to provide zone

tillage for no till planter row units.

Thecoulterson the All Seeds Hitch are set at thefactory

to track 3 3/4" on either side of a planter row unit. This

provides a tilled zone in front of each no-till planter row

unit and allows you to band liquid fertilizer3 3/4" off the

planter row with no lateral adjustment of the coulters

22

AS15 and AS20 Planting System 148-153M 4/14/05

Great Plains Mfg., Inc.

Page 25

Section 4 Hitch, Drill, & Planter Adjustments For No-Till Planting Conditions

e

Zone Tilage and Fertilizer Placement With The All Seeds Hitch.

havecams lettered A through G. Each successive letter

indicates an additional 1/2" of coulter depth with “A” being the baseline.

To adjust an individual coulter:

1. Loosen the 5/8" jam nuts on the 5/8" square head

set screws, and then loosen the set screws.

2. Raisethe coulterslightlyandrotate thedepthcam to

desiredsetting and allow the cam to rest against the

top of the coulter clamp.

3. Tighten the set screw on the side of the coulter

clamp first. This squares the coulter bar in the

clamp.

4. Tighten the set screw on the front of the coulter

clamp and then tighten both 5/8" jam nuts on each

set screw.

Zone Tilage and Fertilizer Placement With The All Se

Figure 4-10

Other tilled paths and banding distances can be

achievedby moving the coulters horizontally, but the operator must keep in mind that these coulters will need to

be moved back if used with a drill. Never move coulters

horizontally without first marking their original position

so they can be returned to those positions.

The individual coulters on the All Seeds Hitch are designed for quick, easy vertical adjustment. All of the

coulters can be raised up 5 1/2” to make them inactive

and 1/4 of the coulters can be lowered up to 3" for banding liquid fertilizer. Each coulter has a depth indicator

cam which pivots on the coulter spring bar and rests

against the top of the coulter clamp. The cams are lettered A through D except for the banding coulters which

4/14/05 Great Plains Mfg., Inc.

NOTE: Torque 5/8" set screws 85-100 ft-lbs to obtain adequate holding force.

When completely lifting a coulter, only the front set

screw needs tightening to hold the coulter up, but both

5/8" jam nuts should be snugged to keep the set screws

in place.

For general zone-till planting, the coulter to the right of

each planter row unit is not moved and is used for zone

tillage. The coulter to the left of each planter row unit is

lowered to the desired fertilizer banding depth. All other

coulters are raised up to get them out of the ground. Always raise a coulter when it is not in use to eliminate

undue wear on that coulter.

Coulter penetration is dependent on the soil condition,

the weight available to force the coulters into the soil,

AS15 and AS20 Planting System 148-153M

-23

Page 26

Section 4 Hitch, Drill, & Planter Adjustments For No-Till Planting Conditions

weight distribution for the no-till planting system. Be

NOTE: The cylinder stroke gauge on the front

tongue cylinder is to be used only as a reference to

the amount of front cylinder extension. It does not

designate inches of coulter depth.

and the coulter spring preload. In hard soil conditions,

additional weight may haveto be added to the All Seed

Hitch and the coulter spring preload may have to be

increased.

Once the individual coulters are arranged for your specific planting situation, the following steps should be

used to achieve the desired coulter penetration:

1. The depth of the All Seeds Coulters is controlled by

the front hydraulic tongue cylinder.In most conditions,the coulterswillpenetratetoadesirabledepth

by running with the coulter hitch main 8" X 8" beam

levelwith the ground.To achievethe desired coulter

penetration, retract the front tongue cylinder to

transfer tractor weight to coulter tool bar. When the

desired coulter depth is achieved on level ground,

take note of the stroke pointer location on the front

tonguecylinder Figure 4-11. This amountofcylinder

extension can be used when planting in level fields

.

sure to place an equal amount of weight on each

weight bracket. If your All Seeds Hitch is equipped

with the liquid fertilizer option, liquid fertilizer tanks

replace the weight brackets. If the tanks are not being used for fertilizer, water can be added to the liquid tanks to provide the needed weight for coulter

penetration.Generallyeach tank should not haveto

be more than half full to provide sufficient weight for

coulterpenetration.Be sure to add an equal amount

of water to each liquid tank.

3. The coulter spring length is preset at the factory to

10"which givesthecoultersan initial operatingforce

of400 pounds. This setting is adequate for many difficult no-till planting conditions. For lighter no-till

conditions where rocks or other obstructions are a

problem, it may be desirable to reduce the initial

coulter preload to give the coulters better impact

protection.Refertothe chartbelow for adjusting the

initial coulter force setting. Fertilizer banding

coulters may require higher spring preload to allow

for the additional depth needed for fertilizer placement.Referto the chartbelow foradjustingthe initial

coulter force setting.

Coulter Down Pressure Chart

Tongue Cylinder With Depth Gauge Decal

Figure 4-11

2. In hard soil conditions where coulter penetration is

limited or where maintaining coulter penetration

tendstoliftthe planter tool bar,suitcaseweightscan

be added to the weight brackets located on the All

Seeds transportframe. No more than 2000 pounds

should ever be added to the transport frame weight

brackets,(1000 pounds per weightbracket).Adding

weight on the transport frame provides the best

10741

Spring Length Initial Vertical

Coulter Force

10 1/2" 175 lbs.

10 1/4" 300 lbs.

10" 400 lbs.

9 3/4" 525 lbs.

!

CAUTION!

Any attempt to reset the coulter spring length shorter than 9

3/4" may contribute to prematurefailure of parts and warranty shall be voided.

4. For extremely hard soil conditions, where 2000

poundsonthe transportframe weightbracketsdoes

not achieve the required coulter penetration,a tool

bar weight bracket kit (see the "Options" Section on

page 30 for ordering these kits) is available. Each

weight bracket kit contains two weight brackets

whichwill bolt abovethe ends of the coulter tool bar.

Anequal amount ofweightshould beaddedon each

end of the coulter tool bar. The addition of tool bar

weight bracketsmake it difficult to move the outside

coulters laterally. With the transport frame weight

brackets weighted to the maximum recommendations, or with the use of liquid fertilizer, a maximum

total of 2400 pounds can be added to the tool bar

24

AS15 and AS20 Planting System 148-153M 4/14/05

Great Plains Mfg., Inc.

Page 27

Section 5 Maintenance & Lubrication

Section 5 Maintenance & Lubrication

General Maintenance

Proper servicing and adjustment is the key to the long

life of any farm implement. With careful and systematic

inspection, you can avoid costly maintenance, time and

repair.

• After using your All Seeds Hitch for several hours,

check all bolts to be sure they are tight.

• Always maintain the proper air pressure in the trans-

port tires.

• Before the hitch is transported and regularly during

normal operation, check the hitch safety chain. Make

sure the chain is properly attached to both the hitch

and the tractor draw bar. Inspect the chain and hardware for wear or other damage. Replace immediately

if needed.

Storage

• Clean the drill and planter as necessary. Be sure that

the seed boxes and hoppers are completely cleaned

before storing.

• Lubricate and adjust all roller chains.

• The square bore of the feed cup drive sprocket hub

should be oiled to prevent seizing. Squirt oil on to the

square feed cup shaft and move feed cup adjustment

leverback and forth in order toget the oil back into the

square.This is most important before puttingthe hitch

in storage.

• Lubricate all fittings as indicated in “Lubrication” be-

low.

• When in storage, lower the hitch with openers on a

board or hard surface. Apply a light coat of oil to exposed cylinder rods.

• Store thehitch inside if possible.Inside storage will re-

duce maintenance, and make for a longer hitch life.

front hydraulic tongue cylinder

d. Center rockshaft bearings located below the

quick hitch hooks.

e. Centerrockshaft 3-boltbearingcastingslocated

on the ends of the transport rockshaft.

f. Cylinder rod end bushings located on the rock-

shaft cylinder lugs.

Listed below is the item you need to lubricate every

20-24 hours of operation:

a. Top of coulter casting.

Listed below is the item you need to lubricate once

every season:

a. Coulter hub bearings (zerk provided).

b. Dual transport wheel timken bearings (repack

and check seals).

Lubricate drill as noted in your 3-Point Drill manual. Lubricate planter as noted in your planter manual.

Lubrication Symbols

50

Lubrication is required every 50 hours of operation.

10

Lubrication is required every 10 hours of operation.

As

Required

Lubrication

• Listed below are the items you need to lubricate every

8-10 hours of operation:

a. Topand bottomverticalpivotshaft bushing.The

grease fittings are located on the back side of

the vertical pivot tube on the transport frame.

b. Front tongue pivot.

c. Level link pivot lever tube located behind the

4/14/05 Great Plains Mfg., Inc.

Use a multipurpose spray lube. Use as required.

Do not over lubricate.

Seasonally

Lubrication is required.

AS15 and AS20 Planting System 148-153M

-25

Page 28

Section 5 Maintenance & Lubrication

12334

8

Front Tongue To Main Frame Pivot

Located at rear of tongue (1 Only)

Type of grease = Multi-purpose lithium base grease

Quantity = Until grease begins to emerge

12112

8

Top And Bottom Vertical Pivot

Bushings

Located on the back side of the vertical pivot tube on

the transport frame (2 Total)

Type of grease = Multi-purpose lithium base grease

Quantity = Until grease begins to emerge

12113

13618

8

Level Link Pivot Tube

Located on top of main frame under level link (1 only)

Type of grease = Multi-purpose lithium base grease

Quantity = Until grease begins to emerge

8

Center Rockshaft Bearings

Located on bottom of Rockshaft Bearing Assembly

(3 places)

Type of grease = Multi -purpose lithium base grease

Quantity = Until grease begins to emerge

26

AS15 and AS20 Planting System 148-153M 4/14/05

Great Plains Mfg., Inc.

Page 29

Section 5 Maintenance & Lubrication

12460

8

Center Rockshaft 3-Bolt

Bearing Castings

Located at rear of tongue (1 Only)

Type of grease = Multi -purpose lithium base grease

Quantity = Until grease begins to emerge

8

Coulter Swing Arm Pivot

Located on the top of coulter castings (one per coulter).

12406

12461

Type of grease = Multi -purpose lithium base grease

Quantity = Until grease begins to emerge

Seasonally

Coulter Hub Bearings

Located at each coulter hub (1 per coulter)

Type of grease = Multi-purpose high temperature lithi-

um grease

Quantity=Force grease into tapered roller bearingsbut

do not pressurize cavity enough to blow out seal or hub

cap

Seasonally

4/14/05 Great Plains Mfg., Inc.

12335

Transport Hub Wheel Bearings

Located in each transport wheel (2 total)

Type of grease = Multi -purpose high pressure wheel

bearing grease

Quantity = Repack bearings & check seals

AS15 and AS20 Planting System 148-153M

-27

Page 30

Section 5 Maintenance & Lubrication

25

Pivot Locks

Located below each stabilizer cylinder (2 Total)

Type of grease = Oil

12457

Maintenance & Lubrication Record

Item to be serviced When to perform Reference Date

28

AS15 and AS20 Planting System 148-153M 4/14/05

Great Plains Mfg., Inc.

Page 31

Section 6 Troubleshooting

Section 6 Troubleshooting

All Seeds Hitch Troubleshooting

Problem Possible Cause Solution

Coulters not going deep enough Tongue cylinder is extended to much Retract front tongue cylinder.

To much weight is being use by openers Set drill openers to lightest spring setting.

Not enough weight Add suitcase weights to transport frame

weight brackets (DO NOT add more than

2000#)

Coulters are not set to a high enough initial

spring compression

Not enough weight Add coulter tool bar weight brackets & suit-

To high of setting on coulters Lowerindividual coulter spring bars on tool bar.

Drill not tracking behind coulters.

Uneven seed spacing or uneven

stand.

Openers plugging in no-till conditions.

Drill is planting too deep. Level link is letting drill tip back to much Adjust top level link so that drill will not tip

Coulters out of alignment with openers Check that coulters and drill openers are

Pivot locks are not in drilling position Checkthat pivot locks are in the up position

Leaf spring is out of alignment Check for proper adjustment of leaf spring.

Drive gauge wheel are not making enough

contact with ground

Binding in gauge wheel link Check that gauge wheel link is free to float

Drilling parallel to standing residue Plant at a slight angle to the rows.

To deep of setting on press wheels Move press wheel adjustment on openers

Increase initial compression on individual

coulter springs.

case weights to ends of coulter tool bars.

(DO NOT add more than 2400#) on coulter

tool bars.

same distance from center.

while drilling. Make sure they were not

manually locked down.

Make sure drill and planter are equipped

with down floating drive gauge wheels

in slotted hole

back in planting position

to shallower depth.

To much drill weight for conditions Add cylinder stops to lift cylinders so that

Planter planting too deep Level link is pushing planter back too far. Adjust top level link so planter frame is

Too deep of side depth gauge wheel setting.

Too much weight for conditions.

Planter gauge wheels sinking too deep.

Transport lift cylinders

loosing lift height

4/14/05 Great Plains Mfg., Inc.

Rod end of clevis pin and bushing wear Inspect and replace rod end cylinder clevis

AS15 and AS20 Planting System 148-153M

transport tires are on the ground.

level.

Move side depth wheel adjustment too

shallower setting

Add cylinder stops to lift cylinders so that

transport tires are on the ground.

pin and bushings.

-29

Page 32

Section 7 Options

Section 7 Options

12432

Markers

DualSequencingMarkersare availablewhich bolt to the

All Seeds Hitch. These markers can be used with both

drills and planters.

113-469A 15’ All Seeds Dual Markers

113-470A 20’ All Seeds Dual Markers

Fertilizer

12407

•

FertilizerTanks with a6or 8-Row SqueezePumpsare

available to band fertilizer beside the planter rows.

• Fertilizer Tanks with Piston Pumps are available to

place liquid fertilizer on all rows behind the coulters.

148-241A 6-Row Fertilizer Update Kit

148-242A 8-Row Fertilizer Update Kit

Coulter Command

Automatic coulter depth control is available to

electronically maintain coulter depth on uneven ground.

148-243A Coulter Command Field Update Kit

12482

30

AS15 and AS20 Planting System 148-153M 4/14/05

Great Plains Mfg., Inc.

Page 33

Section 7 Options

12328

Coulter Tool Bar Weight Bracket

Assemblies

TheToolBarWeightBracketOption is used when added

weight is needed to get proper penetration on the

coulters. (Weights not included)

149-192A 15’ All Seeds Tool Bar Weight Brackets

149-186A 20’ All Seeds Tool Bar Weight Brackets

149-032A John Deere Weight Mounting

Bracket - 2 required

149-034A I.H. Case Weight Mounting

Bracket - 2 required

Coulter Tool Bar Brace Assembly

TheCoulter Tool Bar BraceIsUseWhen 20’ coulter bars

areflexing upwardon the ends becauseofextremelydry

or hard ground.

Great Plains part # 149-189A

12337

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-31

Page 34

Section 8 Specifications & Warranty

Section 8 Specifications & Warranty

Specifications

Transport Tires 11L - 5 18 ply 11L - 15 18 ply

Transport Width 15’ 4" 20’

Hitch Height 7’-6" 7’-6"

Hitch Length 19’ 19’

Transport Cylinders 4 1/4" x 10" 4 3/4" x 10"

Tongue Cylinder 3" x 8" 3" x 8"

15’ 20’

Number of Rows Per Drill Approx. Weights of All Seeds Hitch

Row

Spacing

7.5’ 24 32 All Seeds Hitch

15' 20' 15' 20‘

3800 3825

less Coulter Tool Bar

& Options

Coulter Tool Bars 2340 3120

Fertilizer Option 760 800

Markers 540 570

12313

32

AS15 and AS20 Planting System 148-153M 4/14/05

Great Plains Mfg., Inc.

Page 35

Section 8 Specifications & Warranty

Great Plains Manufacturing, Incorporated warrants to the original purchaser that this seeding equipment will be free from defects in material

and workmanship for a period of one year from the date of original purchasewhen used as intended and undernormal service and conditions

for personal use; 90 days for commercial or rental purposes. This Warranty is limited to the replacement of any defective part by Great Plains

Manufacturing, Incorporated and the installation by the dealer of any

such replacement part. Great Plains reserves the right to inspect any

equipment or part which are claimed to have been defective in material

or workmanship.

This Warranty does not apply to any part or product which in Great

Plains’ judgement shall have been misused or damaged by accident or

lack of normal maintenance or care, or which has been repaired or altered in a way which adversely affects its performance or reliability, or

which has been used for a purpose for which the product is not designed. This Warranty shall not apply if the product is towed at a speed

in excess of 20 miles per hour.

Claims under this Warranty must bemade to the dealer whichoriginally

sold the product and all warranty adjustments must by made through

such dealer. Great Plains reserves the right to make changes in materials or design of the product at any time without notice.

This Warranty shall not be interpreted to render Great Plains liable for

damages of any kind, direct, consequential, or contingent, to property.

Furthermore,GreatPlainsshallnot be liable for damages resulting from

any cause beyond its reasonable control. This Warranty does not extend to loss of crops, losses caused by harvest delays or any expense

or loss for labor, supplies, rental machinery or for any other reason.

No other warranty of any kind whatsoever, expressed or implied,

is made with respect to this sale; and all implied warranties of

merchantability and fitness for a particular purpose which exceed the obligations set forth in this written warranty are hereby

disclaimed and excluded from this sale.

This Warranty is not valid unless registered with Great Plains Manufacturing, Incorporated within 10 days from the date of original purchase.

Warranty

4/14/05 Great Plains Mfg., Inc.

AS15 and AS20 Planting System 148-153M

-33

Page 36

Great Plains Manufacturing, Inc.

Corporate Offices: PO. Box 218

Assaria, Kansas 67416 USA

Loading...

Loading...