Page 1

Quick Reference Guide for Daily

2012-12

1

401-909M

use of Yield-Pro® Planter

Caution Please Read!!

• Note:

• This guide is intended for quick reference only. For complete set-up

see owners manual, quick start guides and or your dealer.

• The use of this guide is assuming that your system is set up and

READY to go to the field.

• The factory sets planters up generically.

• Make sure that any and all calibrations are done before going to

the field (see owners manual, dealer, or quick start guides).

• This guide will help you get started planting by showing you how to

get to the settings summary page, from which you can quickly

adjust planting rates, meter pressure, Row Pro settings, and Swath

Control settings.

• Follow all safety rules and recommendations in Operator’s Manual.

Page 2

In order to plant, the following steps are required:

2012-12

2

401-909M

1.) Check that correct seed discs are present in meter.

2.) Check that seed gates at Y-splitters are all open for seed delivery.

3.) Check that no foreign matter is present in air box, then open hopper door.

4.) Turn on fan and set oil flow to get XXXXRPM.

5.) Check that Marker/Fold switch is set to “marker” even if you do not have them.

6.) Fill meters with seed by performing “Row Fill”, and waiting 2 minutes.

7.) Check that correct seed and target population is set on monitor/controller.

8.) Perform “Fill Disk” to avoid leaving a skip when starting. If fan is stopped for any

reason, then repeat this step.

9.) For hydraulic drive planters, turn on channel to enable meter operation. Valve

calibration is strongly recommended.

10.) Pull forward and lower planter to begin planting. If there is a delay before starting to

plant, you will need to re-enable seed meter drive due to safety delay.

YIELD-PRO® PLANTER

Model # ____________ Serial # ____________

Configurations

4 – Hyd. Drive 5 – Grd. Drive 6 – Air-Pro® 7 – Row-Pro™ 9 – Sw ath Command™

Level 2 Access

Unit has been configured at factory and operated with these configurations.

Material Configuration - Population Split-Air Target Rate Row-Pro Target Rate Swath Command Setback

1. ______ _______ ________

2.

Page 3

Yield-Pro®Planter w/AI-120 Terminal

2012-12

3

401-909M

Sections

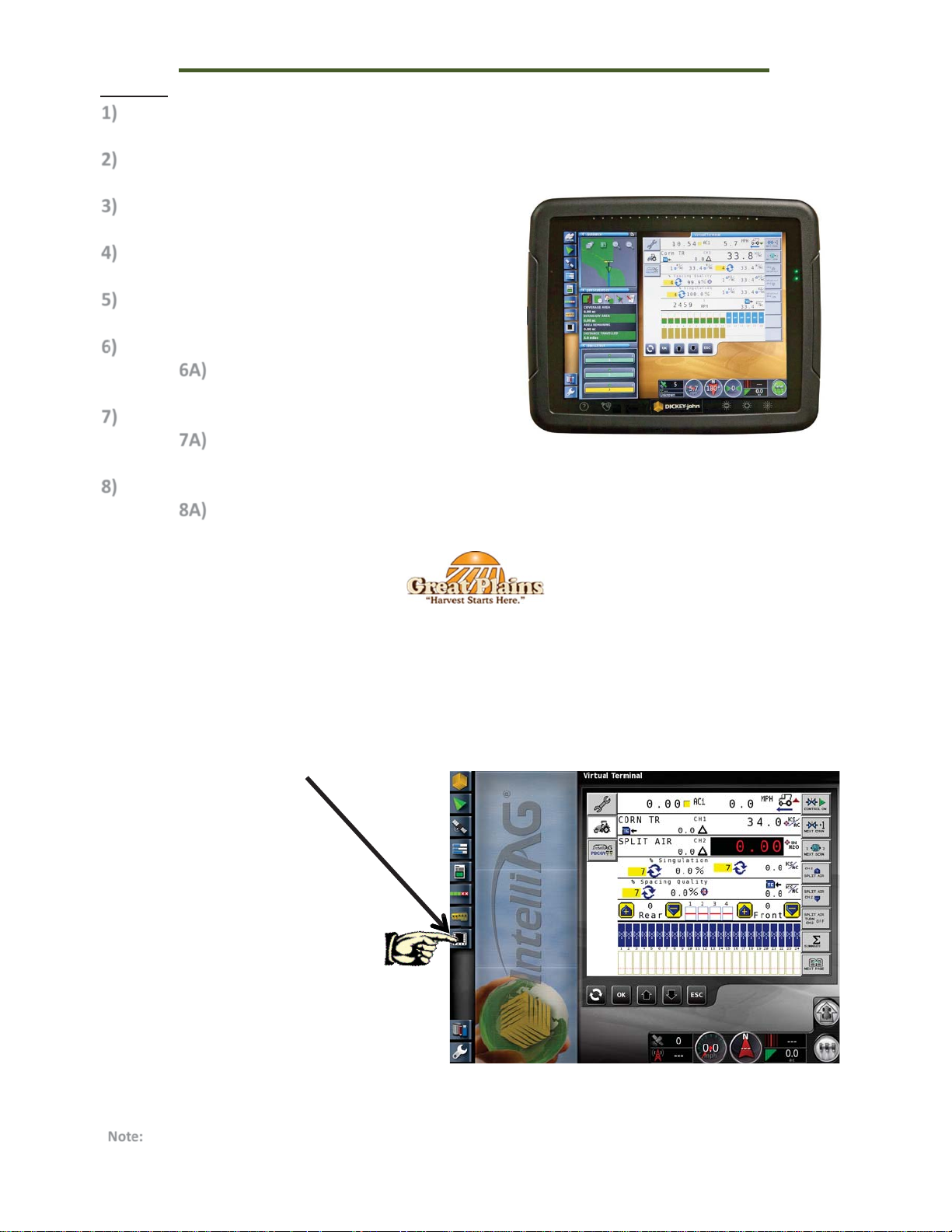

1) Explanation of the buttons on the screen.

2) How to unlock the system.

3) How to find my WSMT II Serial Number.

4) Hyd. Drive - Changing Populations.

5) Grd. Drive – Changing Populations.

6) Changing Split-Air Settings.

6A) Zeroing the Split-Air pressure.

7) Changing Row Pro Settings.

7A) Re-setting load cell values.

8) Engaging planter Hydraulic Drive.

8A) Explanation of button function.

9) Swath Command Settings.

Sec. 1

To see your work screen you

must touch the terminal

icon as shown here.

Once you have touched it

the work screen will appear

as a small window. You may

then slide this to your large

view.

***More information on

this function is explained in

more detail in the operators

manual.

Explanation of on screen buttons

Note: If your work screen is not your main screen,

then you need to review your owners manual for

further information on how to configure your screen.

Page 4

Explanation of on screen buttons

2012-12

4

401-909M

These buttons on

the left are very

seldom used for

daily functions.

The PDCGY is the

most important

button for daily

use

The PDCGY button HOLDS all the buttons on right. The only way to see the right

hand set of buttons you MUST have this button selected (as shown in the

picture above).

These buttons

that are on the

right of the

screen are used

to OPERATE the

planter and also

change or adjust

different settings

for the planter.

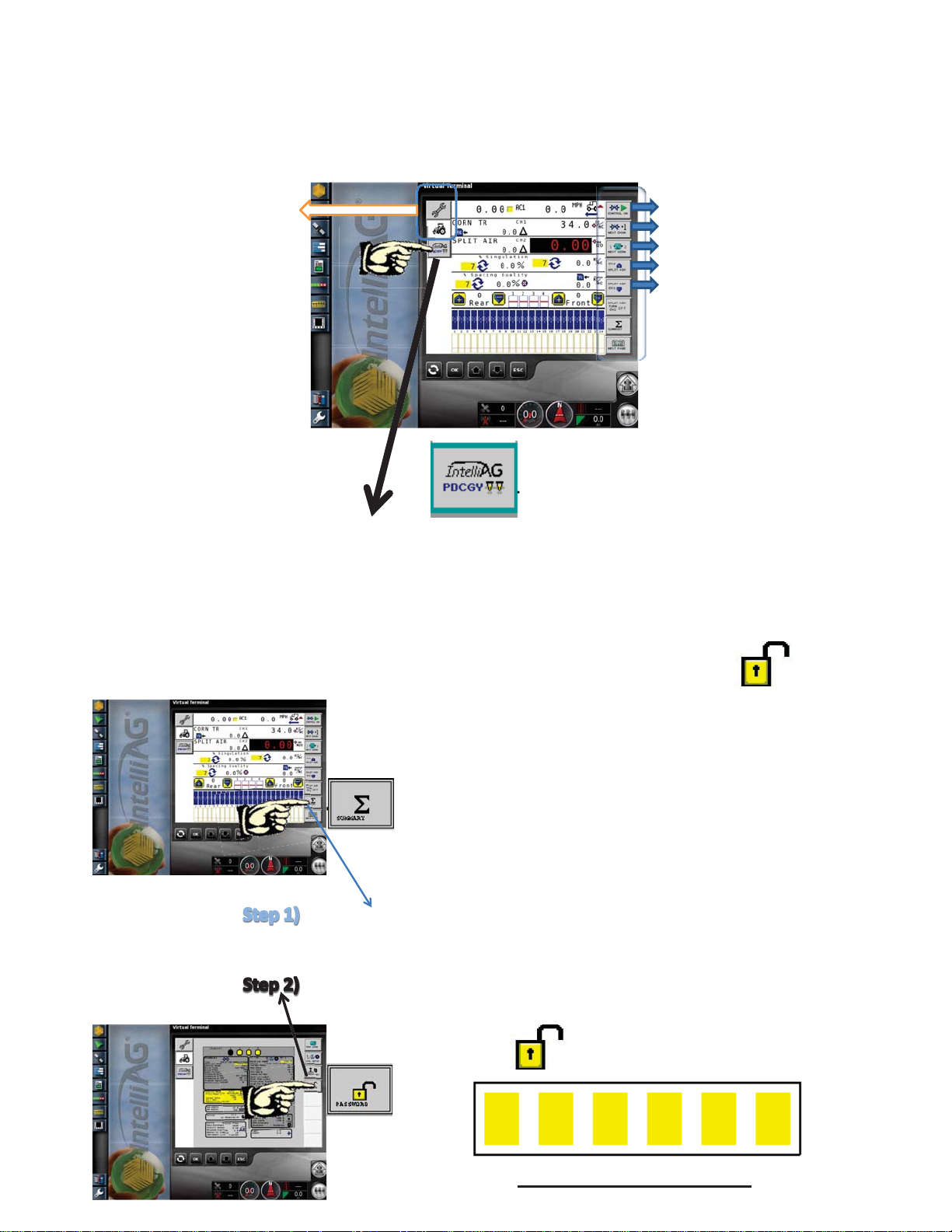

Sec. 2

How to unlock the system

To unlock the system we must enter the unlock code.

- The unlock code is the WSMT serial

number with a 2 in front of it (for level 2)

- More info is toward the bottom of this

section on how to find the S/N for the

WSMT.

Select the summary button.

Select the padlock option.

Write in your password here:

Page 5

-Enter 2 followed by the WSMT Serial Number

2012-12

5

401-909M

which is found in the INFO screen. This is

explained on the last page of this section.

Example: If the S/N is 10663 then the unlock code is 210663

-

Then touch OK

Once you have correctly entered the

unlock code then the words “Dealer

screens on” should appear at the

bottom of the screen as shown

here.

You have unlocked the system to

level 2.

Now your summary screen should be

all yellow instead of gray.

This is an example of a system that is not unlocked,

when most of the screen is gray.

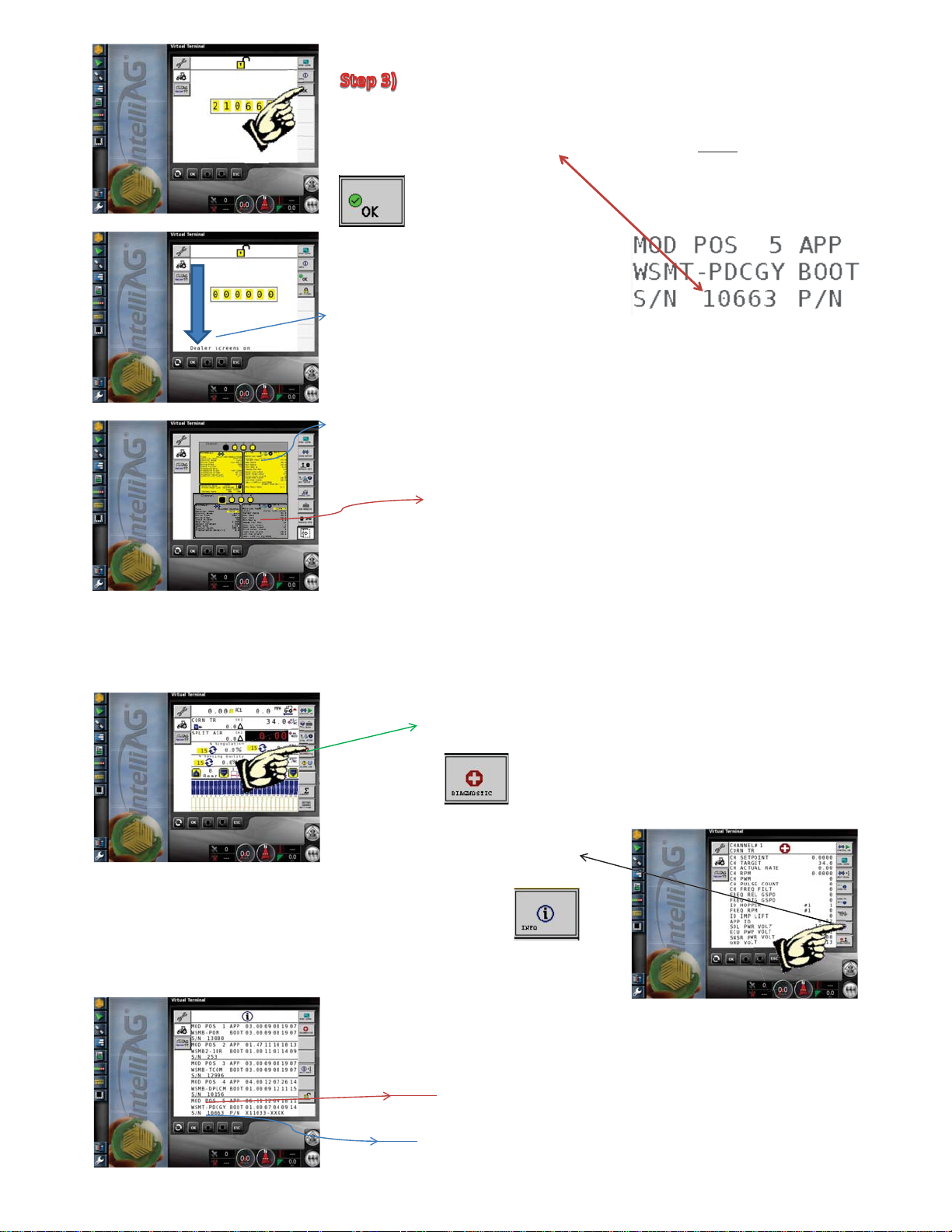

Sec. 3

How to find my WSMT Serial Number

Select the Diagnostic button from the main work screen

From there touch the INFO button

This brings you to the INFO

screen. From here you can

locate WSMT and below this

is your S/N number. This is

your code.

Page 6

Sec. 4

2012-12

6

401-909M

Hyd. Drive - Changing Populations

**Note: This is assuming that the system is unlocked. See the unlock section on how to unlock the

system.

This is the Summary Page

Select the Summary Button

Next make sure that Channel 1

is a black box , as shown here,

by touching it.

This will take you to the

summary page. From there

touch the yellow box as shown

here.

** Preset Method is disabled in this example.

NOTE: Once you have entered your changes

by touching the highlighted area to be changed

you MUST touch the

to

accept.

This will bring you to the area you can

change your Populations. NOTICE: Enter

the amount in THOUSAND SEEDS per

acre. Example: If you wish to plant 34,000

seeds per acre then you would enter 34.0

This is your target rate, the

amount you wish to seed or your

population.

Next you would make sure your

MAX Rate is set (maximum rate you wish

to plant).

Then you would make sure your

MIN Rate is set (minimum rate you wish

to plant).

Enter the percentage you wish to

increase or decrease your population on

the go.

Page 7

Once you have made your changes

2012-12

7

401-909M

now return to your “Home screen”

or another name is “Work screen”

by touching the WORK SCRN

button.

Notice: This will take you to the

Work Screen

Notice: Your New Population

should appear as shown here.

Sec. 5

Grd. Drive - Changing Population

Select the SUMMARY button

Now make sure that the word PopMon

shows at the top right of the screen as

shown here.

If you see PopMon then touch the yellow

area as shown here.

Page 8

This will take you to the screen where you

2012-12

8

401-909M

can change your Target Population. NOTICE:

Enter the amount in THOUSAND SEEDS per

acre. Example: If you wish to plant 34,000

seeds per acre then you would enter 34.0

Once you have entered your

target you may touch the

work screen button to

return to the home screen.

Sec. 6

Changing Split-Air Settings

Select the Summary Button

Next make sure that Channel 2

is a black box as shown here,

by touching it.

Page 9

This will take you to the Material

2012-12

9

401-909M

Setup screen.

Once you have blackened in Ch. 2 box

you may now touch the area shown

here.

Change your target air pressure

to what is desired.

NOTE: Once you have entered your values by

touching the highlighted area to be changed

you MUST touch the

to

accept it.

Once you have changed your Split-Air, then

return to your “Home screen” or another

name is “Work screen” by touching the

WORK SCRN button.

Notice: This will take you back

to the Work Screen

Page 10

Sec. 6A

2012-12

10

401-909M

Zeroing the Split-Air Pressure

Select the Summary Button

Next make sure that Channel 2

is a black box , as shown here,

by touching it.

This will take you to the Channel

Setup screen.

Once you have blackened in Ch. 2 box

you may now touch the area shown

here.

Zeroing the pressure in the split air is

recommended throughout the day due

to barometric pressure changes.

This is done by touching the area

shown here. Fan must be off to enable

pressure reset.

Page 11

Once you have zeroed out your Split-Air,

2012-12

11

401-909M

now return to your “Home screen” or

“Work screen” by touching the WORK

SCRN button.

Notice: This will take you to the

Work Screen

Sec.7

Changing Row Pro Settings

Select the Summary Button

Next select the highlighted RowPro box.

Page 12

Enter your Target rate as shown here.

2012-12

12

401-909M

Note: Once you have entered your values by

touching the highlighted area to be changed,

you MUST touch the

accept it.

Note: For full instructions on the Row Pro, see

owners manual.

Next return to the home screen by

touching the work screen button, or

you may need to Zero your load cells

out. See next section for this.

to

Sec. 7A

Re-setting Load Cell Values

If you have a weight reading when the planter

is up, or if you have a false reading it is

recommended that you reset the load cell

values.

From the Summary page select the DPRESS SET

button

Next touch the SET OFFSET button.

Page 13

Once you get here you must read the screen

2012-12

13

401-909M

and make sure you are ready to continue.

Next touch OK.

After you are done then touch the

Work Screen to return home.

Sec. 8

Option 1

Using the “soft key” on the screen.

Engaging planter hydraulic drive

Two ways to do this.

Select the Control On button to

engage the Planter .

*Note. Make sure that the planter is in the

ground and you are ready to plant.

**** All “soft key” (touch screen

buttons) that control a function are

buttons of intent!! This means that if

you want to turn your planter on you

must touch.

last page in this section.

If you wish to shut it off you must

touch

This is explained on the

Page 14

Option 2

2012-12

14

401-909M

Using the external switch.

*Note

To use the External Switch you

must first configure it on the IA

Screen first. To configure this

option see owners manual.

*Notice the Control On button is not

present when the external switch is

configured.

When using the External Switch the icon

will leave and the Control On becomes

the switch that is wired to the main

harness.

This External Switch becomes the

new Control ON.

To engage the planter toggle the

switch to the On position to “turn”

the planter on.

Sec. 8A

Explanation of button function

This button (when shown like this

means the planter is off) when

touched turns the planter on!

This button (when shown like this

means the planter is on) when

touched turns the planter off!

Note: In short it is the opposite of what most people would

think, meaning that if it says on it is really off.

Page 15

Sec. 9

2012-12

15

401-909M

Important: Accuracy of Swath Command is dependent upon accurate measurements

between the GPS receiver and where seed is placed in the ground. Failure to enter

exact measurements will impact the system’s performance to shut row sections off at

the proper location within the field. Refer to AI-120 & IntelliAg manual that these

measurements are entered correctly before making any further adjustments.

Timing

Timing is an adjustment to gap or overlap of product application when entering a

headland and using section control. Two timing options to turn sections on and off are

required.

• ON TIME- On Time establishes when actual product application starts after

the sections are switched on.

• OFF TIME- Off Time establishes when actual product application stops after

the sections are switched off. Off time cannot exceed the On time setting.

• **Note: This is a SPEED based timing, meaning that you must maintain the SAME

speed when entering and leaving your headlands.

Dialing in Swath Command

Setting Timing

- 1. Select the wrench button

- 2. Select Implement

- 3. Select Section Control

-4. Select Timing

From this screen you may dial in your Swath

Command by touching one of these 2 options.

4

2

3

When done setting timing then

return to the home screen by

touching this button.

Page 16

**Disclaimer**

2012-12

16

401-909M

Any and all information that was presented in this guide can be found in more detail

-

in the owners manual, quick start guides, and on our website.

-Each quick start guide is specific to your

model of planter.

-This book is intended to explain and show one how to change or modify settings for

daily operation basis and NOT intended for sole operation of your planter.

-Please contact your dealer for complete set-up, calibration, and operation of your

YP planter.

Loading...

Loading...