Page 1

Operator’ s Manual

Model 2250

Air Drill Implement

Manufacturing, Inc.

www .g reatplainsmfg.com

Read the Operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions andwarnings are serious- follow without exception. Your life and the lives of

others depend on it!

© Copyright 1997 Printed

5/11/2005

15075

Cover illustration may show optional equipment not supplied with standard unit.

160-192M

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . . . . 1

Safety Notations . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description of Unit . . . . . . . . . . . . . . . . . . . . . . . . . 9

Features include:. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 3 Adjustments . . . . . . . . . . . . . . . . . . . . . . 33

Intended Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . . 9

Terminology: . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Definitions: . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 1 Assembly and Setup. . . . . . . . . . . . . . . . 11

Pre-Assembly Checklist. . . . . . . . . . . . . . . . . . . . 11

General Description. . . . . . . . . . . . . . . . . . . . . . . 11

Shipping Information . . . . . . . . . . . . . . . . . . . 11

Implement Main Frame . . . . . . . . . . . . . . . . . . . . 11

Hydraulic Cylinder Mounting Locations . . . . . . . . 13

Dual Gauge Wheels. . . . . . . . . . . . . . . . . . . . . . . 13

Wing Lift Assist . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lift System

Hydraulic Hose Connections . . . . . . . . . . . . . . . . 14

Fold Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mounting the Cart Links. . . . . . . . . . . . . . . . . . . . 16

Attaching the Cart to the Implement . . . . . . . . . . 16

Section 4 Troubleshooting. . . . . . . . . . . . . . . . . . . 37

Section 5 Maintenance and Lubrication . . . . . . . . 39

Bleeding the Hydraulic Lifting System. . . . . . . . . 16

Pre-Fold Coulter Settings . . . . . . . . . . . . . . . . . . 18

Bleeding the Folding System. . . . . . . . . . . . . . . . 19

Side to Side Frame Leveling . . . . . . . . . . . . . . . . 19

Implement Frame Leveling . . . . . . . . . . . . . . 19

Distribution Towers and Hoses . . . . . . . . . . . . . . 20

2 1/2" Primary Distribution Hoses . . . . . . . . . . . . 21

1" Secondary Distribution Hoses. . . . . . . . . . . . . 26

Light Harness and Brackets. . . . . . . . . . . . . . . . . 28

Section 2 Operating Instructions . . . . . . . . . . . . . . 29

General Description. . . . . . . . . . . . . . . . . . . . . . . 29

Prestart Checklist: . . . . . . . . . . . . . . . . . . . . . . . . 29

Recommended Tractor Size . . . . . . . . . . . . . . . . 29

Recommended Minimum Tractor Size. . . . . . . . . 29

Safety Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Field Operations . . . . . . . . . . . . . . . . . . . . . . . . . 29

Section 6 Specifications and Capacities . . . . . . . 43

Implement Lifting System . . . . . . . . . . . . . . . . . . 30

Folding the Drill . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Unfolding the Drill . . . . . . . . . . . . . . . . . . . . . . . . 31

Section 7 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . 44

Opener Operation . . . . . . . . . . . . . . . . . . . . . . . . 31

© Copyright 1996 All rights Reserved

Great Plains Manufacturing, Inc. providesthis publication“as is” without warrantyof any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing,Inc. assumes no responsibility for errorsor omissions. Neither is anyliability assumed fordamages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reservesthe right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Great Plains Manufacturing, IncorporatedTrademarks

Printed in the United States of America.

General Opener Operation. . . . . . . . . . . . . . 31

C-Shank Style Opener. . . . . . . . . . . . . . . . . 31

Floating Hoe Opener . . . . . . . . . . . . . . . . . . 31

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting the Seeding Depth

And Leveling Front to Rear. . . . . . . . . . . . . . . . . 33

Individual Opener Adjustments. . . . . . . . . . . . . . 33

C-Shank Style Openers . . . . . . . . . . . . . . . . 33

Floating Hoe Openers . . . . . . . . . . . . . . . . . 33

Shear Bolt and Spring Reset

Opener Depth. . . . . . . . . . . . . . . . . . . . . . . . 33

Shear Bolt and Spring Reset

Opener Down Pressure . . . . . . . . . . . . . . . . 34

Hoe Tip Angle . . . . . . . . . . . . . . . . . . . . . . . 34

Coulter Adjustments. . . . . . . . . . . . . . . . . . . . . . 35

Individual Coulter Depth Adjustments . . . . . 35

Coulter Spring Adjustments . . . . . . . . . . . . . 35

Fertilizer Tine Adjustments. . . . . . . . . . . . . . . . . 35

Dry Fertilizer Tine Depth Adjustments . . . . . 35

Electric Clutch Height Switch . . . . . . . . . . . . . . . 36

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Lift Assist and Gauge Wheel Pivots. . . . . . . 39

Press Wheel Pivot Bearings. . . . . . . . . . . . . 40

Cart Link Pivots . . . . . . . . . . . . . . . . . . . . . . 40

Castor Wheel Shafts . . . . . . . . . . . . . . . . . . 40

Press Wheel Gang Bearings . . . . . . . . . . . . 40

Press Wheel Screw Adjustment Thread . . . 41

Hinge Pivots. . . . . . . . . . . . . . . . . . . . . . . . . 41

Parallel Arm Pivots. . . . . . . . . . . . . . . . . . . . 41

Press Wheel Screw Adjustments. . . . . . . . . 41

Coulters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Floating Hoes. . . . . . . . . . . . . . . . . . . . . . . . 42

Wheel or Axle Bearings . . . . . . . . . . . . . . . . 42

Floating Hoe Option. . . . . . . . . . . . . . . . . . . 43

C-Shank Option . . . . . . . . . . . . . . . . . . . . . . 43

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 44

Torque Values Chart for Common Bolt Sizes. . . 44

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Model 2250 Air Drill Implement 160-192M 5/11/05

Page 3

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

For your safety and to develop a better understanding of

your equipment, thoroughly read the Operator’s Sections

of this manual before operation.

Safety Notations

The SAFETY ALERT SYMBOL indicates that there is a

potential hazard to personal safety involved and extra

safetyprecautions mustbe taken. When you see this symbol,bealert and carefully readthemessage that followsit.

In addition to design and configuration of equipment; hazard control and accident prevention are dependent upon

the awareness, concern, prudence and proper training of

personnel involved in the operation, transport, maintenance and storage of equipment.

Watch for the following Safety Notations throughout

your Operator’s Manual:

!

DANGER!

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal word

is limited to the most extreme situations.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

!

Prior To Operation

1. Do not stand between the cart and implement during hitching.

2. Do not operate without safety chain properly attached to

tractor.

3. Make sure hydraulic lines are attached to correct ports.

4. Handle and apply chemically treated seeds according to

manufacturer’s recommendations.

!

CAUTION!

Some illustrations in this manual may show shields or cover

panels removed for clarity. Never operate unit without all

shields and cover panels in place.

During Operation

1. Do not allow anyone to operate this machine who has not

been properly trained in its safe operation.

2. Do not let children operate the implement.

3. Never dismount from a moving tractor.

4. Put tractor in park, shut off engine, and remove key before

making any adjustments to the implement.

5. Do not leave the tractor or the implement unattended with

the engine running.

6. Never allow passengers

7. Never permit anyone to ride on or walk beside the implement.

8. Always fold and unfold implement SLOWLY and on level

ground.

9. Allow proper clearance both overhead and on the ground

when folding or unfolding.

!

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may also be used

to alert against unsafe practices

!

Safety Rules

These rules and instructions

must be revie wed at least ann uall y

by all operators!

Most accidents are the result of negligence and carelessness, caused by failure of the operator to follow safety

precautions. Even though your implement is designed

with many built-in safety features, the following precautions are mandatory to prevent such accidents.

Make sure everyone that uses this machine has read the

Operator’sManual and understands how to operate it

safely.

This Operator’sManual is considered a part of the implement and should remain so when loaned or sold.

!

DANGER!

Contact with overhead power lines can cause severe electrical

burns or death from electrocution. Make sure there is enough

clearancebetween all airdrill components and overheadpower

lines. Do not fold or unfold implement near power lines.

Transporting

1. Be alert to traffic when crossing or operating near road-

ways. Always maintain complete control of the machine.

Know your state and local laws concerning highway safety

and regulations. Comply with these laws when transporting

machinery.

2. Do not exceed 20 mph when transporting. Transport only

with a farm tractor of sufficient size and horsepower. Refer

to Recommended Tractor Size under the “Operating In-

structions” section on page 29.

3. Be aware of any overhead or roadside obstructions when

transporting (i.e., power lines, bridges, fence rows, culverts, etc.).

4. Always make sure flashing lights, slow moving vehicle emblem, and reflectors are in place and visible prior to transporting the machine.

5. Use warning flags or approved warning lights when transporting at night or at other times of low visibility.

6. Always be aware that towing a large implement can signif-

5/11/05

Model 2250 Air Drill Implement 160-192M

1

Page 4

Important Safety Information

Great Plains Mfg., Inc.

icantly increase stopping times and distances.

7. Reduce speed when transporting over hills or steep slopes.

8. Use caution and reduce speed when transporting or operating with full seed bins.

9. Never transport without all transport and fold locks in

place. See Folding the Drill under the “Operating Instruc-

tions” on page 30.

After Operation

1. Detach and store implement in an area where children do

not play. Stabilize implement by using suitable supports and

wheel blocks.

2. Always store implement with all transport and fold locks in

place See Parking under the “Operating Instructions” on

page 32.

During Maintenance

1. Tire changing can be dangerous and should be performed

by trained personnel using the correct tools and equipment.

2. Do not re-inflate a tire that has been run flat or seriously

under inflated. Have it checked by qualified personnel.

3. When removing or installing wheels, use wheel handling

equipment adequate for the weight involved.

4. Do not grease or oil implement while it is in use.

5. Always unfold implement and have cylinder lock channels

in place when lubricating or maintaining implement. See

Unfolding the Drill under the “Operating Instructions”

section on page 31.

6. After repairing or adjusting, make sure all tools and loose

parts are removed from the implement before attempting to

operate it.

Agricultural Chemicals

1. Agricultural chemicals can be dangerous. Always select the

correct chemical for the job. Improper usage of fertilizers,

fungicides, herbicides, insecticides, and pesticides could

cause injury to all living things.

2. Always read instructions supplied by the manufacturers before opening chemical containers. Carefully read and follow instructions supplied by the chemical manufacturer

before each use.

3. Apply the same precautions when adjusting, servicing,

cleaning, or storing this implement as you would when putting chemicals into it.

4. Advise anyone who may come into contact with chemicals

of all safety precautions that should be observed.

5. Avoid inhaling smoke from any type of chemical fire.

6. Store or dispose of all unused chemicals and chemical containers as specified by the chemical manufacturer.

Model 2250 Air Drill Implement 160-192M 5/11/05

2

Page 5

Great Plains Mfg., Inc.

Important Safety Information

Safety Labels

Your implement comes equipped with all safety labels in place.

They were designed to help you safely operate your implement.

1. Read and follow label directions.

2. Keep all safety labels clean and legible.

3. Replace all damaged or missing labels.

4. Some new equipment installed during repair require safety

labels to be affixed to the replaced component as specified

15078

by the manufacturer. When ordering new components make

sure the correct safety labels are included in the request. To

order new labels go to your Great Plains dealer.

5. Refer to this section for proper label placement.

To install new labels:

a. Clean the area where the label is to be placed.

b. Peel backing from label. Press firmly on surface

being careful not to cause air bubbles under label.

818-055C

Slow Moving Vehicle Label

15098

15104

838-266C

Red Reflector

Located on each lift as-

sist arm.

838-265C

Amber Reflector

5/11/05

Model 2250 Air Drill Implement 160-192M

3

Page 6

Important Safety Information

Great Plains Mfg., Inc.

838-265C

Amber Reflector

15100

838-265C

Amber Reflector

15101

15372

838-265C

Amber Reflector

15101

Model 2250 Air Drill Implement 160-192M 5/11/05

4

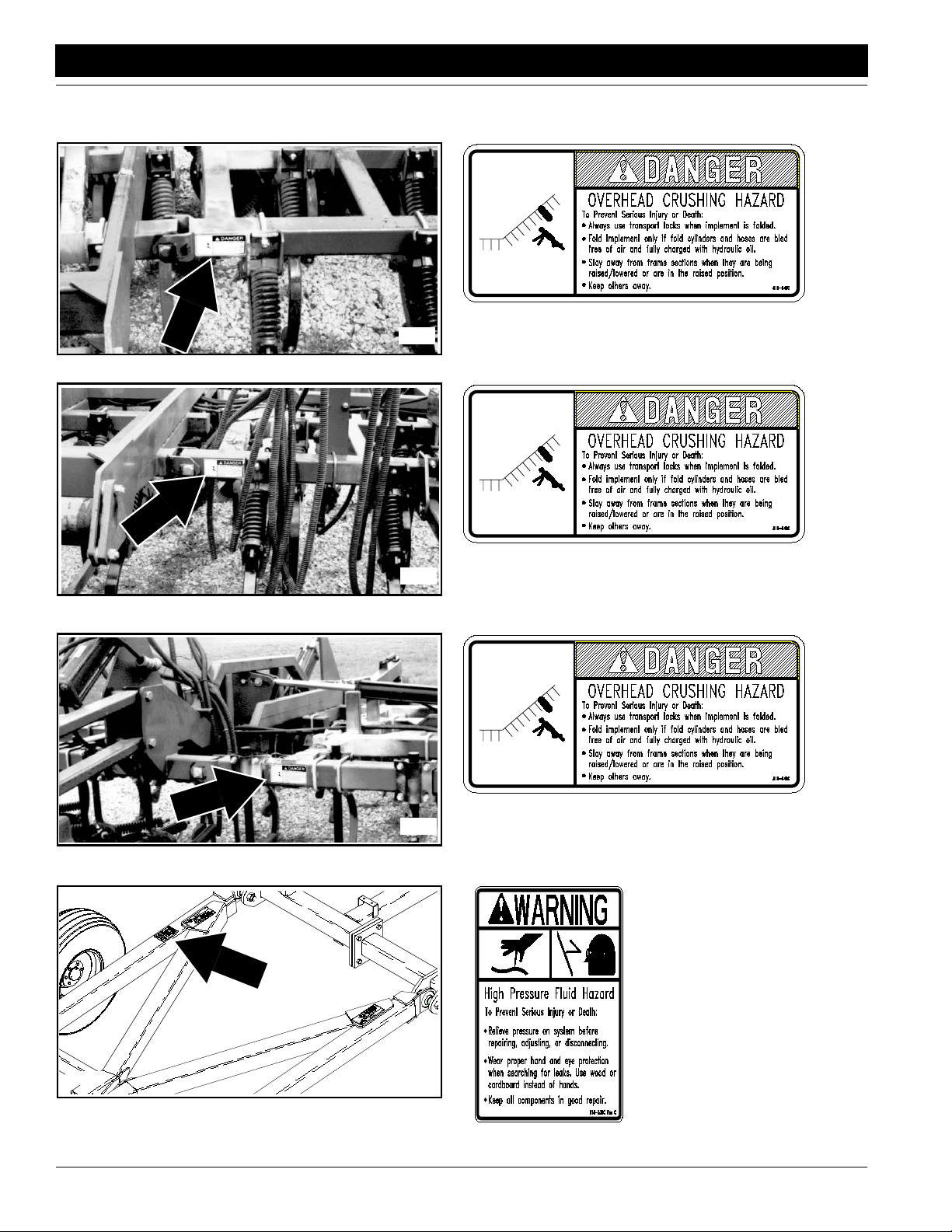

818-046C

Overhead Crushing Hazard

Page 7

Great Plains Mfg., Inc.

Important Safety Information

15102

15105

818-046C

Overhead Crushing Hazard

818-046C

Overhead Crushing Hazard

15081

5/11/05

15086

818-046C

Overhead Crushing Hazard

818-046C

Overhead Crushing Hazard

Model 2250 Air Drill Implement 160-192M

5

Page 8

Important Safety Information

Great Plains Mfg., Inc.

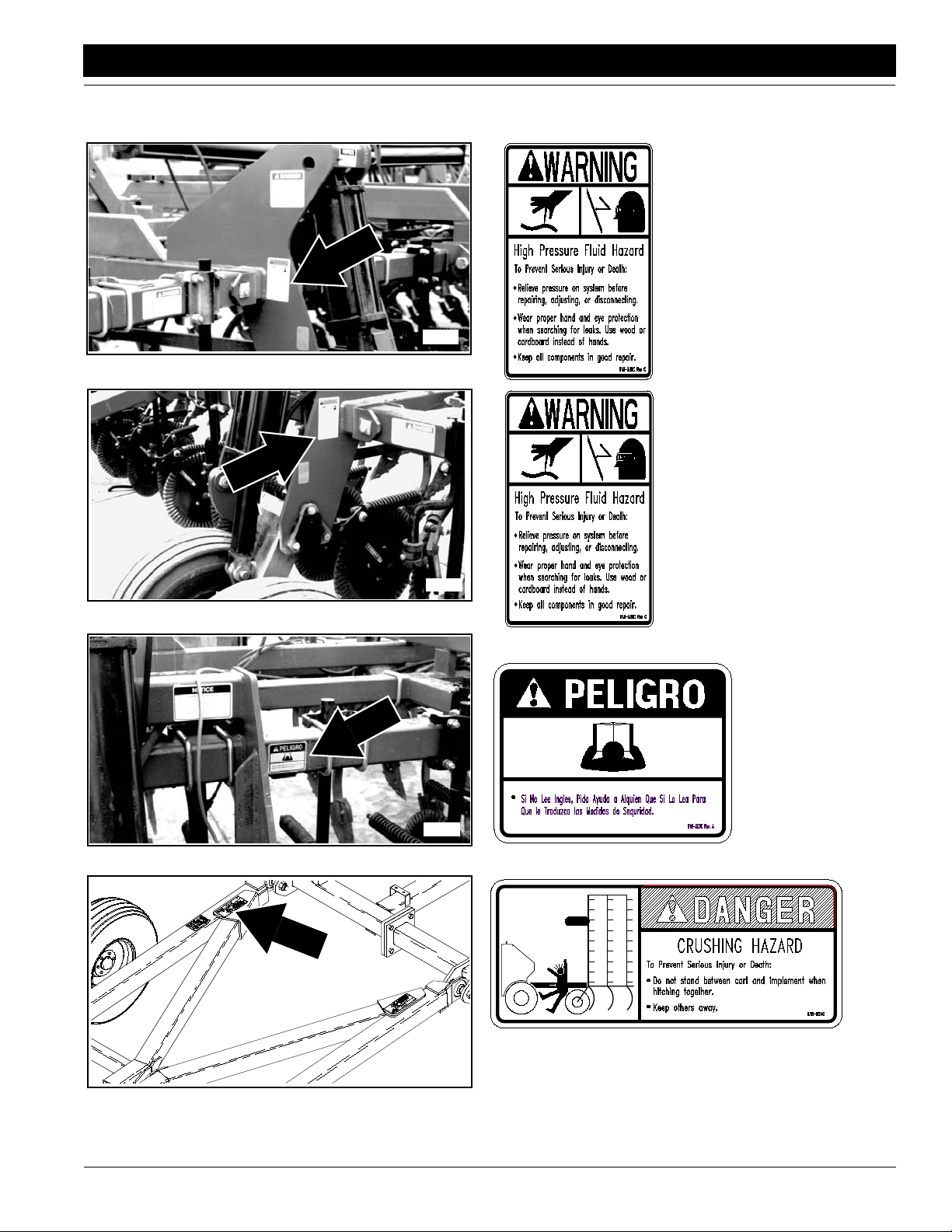

15370

15371

818-046C

Crushing Hazard

818-046C

Crushing Hazard

15505

818-046C

Crushing Hazard

15081

Model 2250 Air Drill Implement 160-192M 5/11/05

6

15088

818-339C

High Pressure Fluid

Page 9

Great Plains Mfg., Inc.

Important Safety Information

15101

15100

818-339C

High Pressure Fluid

818-339C

High Pressure Fluid

5/11/05

15106

15088

818-624C

Crushing Hazard

818-557C

Cannot Read English

Model 2250 Air Drill Implement 160-192M

7

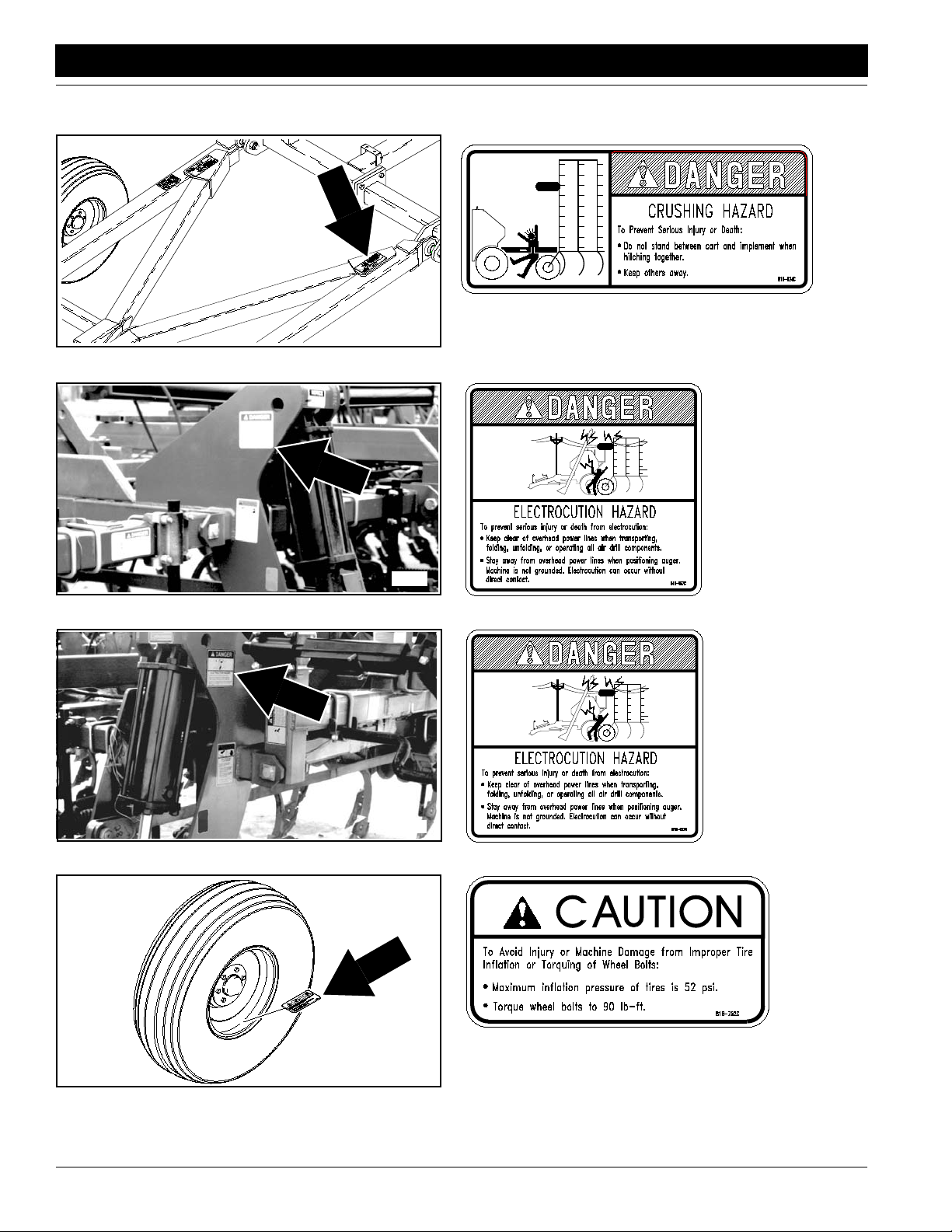

Page 10

Important Safety Information

Great Plains Mfg., Inc.

15088

15101

818-624C

Crushing Hazard

818-627C

Electrocution Hazard

15102

15597

Model 2250 Air Drill Implement 160-192M 5/11/05

8

818-752C

Improper Tire Inflation or Torquing

Electrocution Hazard

818-627C

Page 11

Great Plains Mfg., Inc.

Introduction

Introduction

Great Plains welcomes you to the growing family of new

product owners. This implement has been designed with

care and built by skilled workers using quality materials.

Proper assembly, maintenance, and safe operating practices will help you get years of satisfactory use from the

machine.

Description of Unit

The 45', 7" row spacing air drill implement is a tillage-type

seedingimplement designed to tow behind a Great Plains

airdrill cart.The implement is configuredwith75 hoe-type

openers spaced 7 inches apart. The implement can also

be equipped with coulters spaced on 14” centers that split

every two openers. The cart suppliespneumatically conveyedseed or fertilizer to the implement where it is distributed to each opener. Seed and fertilizer can be delivered

separately (double shoot) to either the opener or the

coulter.

Features include:

• Minimum 28” distance from frame to ground for trash

clearance.

• Three ranks of openers and one rank of coulters or

openers spread across all four ranks for greater trash

clearance.

• Coulters which can be used for cutting residue in front of

openers and can also be used to apply fertilizer.

• Integral-style hitch which simplifies backing and elimi-

nates side to side motion on hillsides.

• Easily adjustable electric clutch height switch to shut off

metering system during headland turns.

• Low maintenance seed distribution tower system.

• Single and double shoot capabilities.

• C-Shank or Floating Hoe opener options.

• Five press wheel options.

dealer the white copy and send the pink copy to Great

Plains. Keep your copy in the manual for use when corresponding with the dealer.

To order a new Operator or Parts Manual contact your authorized dealer or write to the address listed below in the

Owner Assistance paragraph. Include the model and serial numbers of your unit.

The information contained within this manual was current

at the time of printing. Some parts may change slightly to

assure you of the best performance.

Terminology:

"Right" or "Left" as used in this manual is determined by

facingthe direction the machine will travelwhile in use unless otherwise stated.

Definitions:

NOTE: A special point of information related to it’s

preceding topic. The author’s intention is that you

read and note this information before continuing.

IMPORTANT: Information, related to it’s proceeding topic

that the author feels would be of use.

Owner Assistance

If customer service or repair parts are required contact

your local Great Plains dealer. He has trained personnel,

repair parts, and the equipment needed to service your

implement.

These parts have been specially designed and should

only be replaced with genuine Great Plains parts.

Serial Number Plate

Referto the Figure 1 for the location of your serialnumber

plate.

Intended Usage

This machine is intended to be used primarily for seeding

small grains and legumes in conventional tillage or no-till

applications. When used in conjunction with a Great

Plains air drill cart, the implement will evenly distribute

seed and fertilizer to each opener or coulter at an even

depth thereby promoting consistent seed emergence.

Using This Manual

ThisOperator’sSection is designed to help familiarize you

with safety, assembly, operation, adjustments, troubleshooting, and maintenance. Read this manual and follow

the recommendations to help ensure safe and efficient

operation.

The warranty sheet should be filled out by the owner and

dealer at the time of purchase. After completion give the

5/11/05

Serial Number Plate Location

Figure 1

Forpromptservicealwaysusetheserial numberandmodel

Model 2250 Air Drill Implement 160-192M

15162

9

Page 12

Introduction

Great Plains Mfg., Inc.

numberwhenordering partsfrom your Great Plains dealer.

Be sure to include your serial and model numbers in correspondence also.

Your dealer wants you to be satisfied with your new machine. If for any reason you do not understand any part of

this manual or are not satisfied with the service received,

the following actions are suggested:

1. Discussthe matter with your dealership Service Manager make sure he is aware of any problems you may

haveand that he has had the opportunityto assist you.

2. If you are still not satisfied, seek out the Owner or

General Manager of the dealership, explain the problem and request assistance.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

P.O. Box 245

Assaria, Ks. 67416

Model 2250 Air Drill Implement 160-192M 5/11/05

10

Page 13

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

Section 1 Assembly and Setup

The following information is general in nature and was

written to aid the operator in preparing the tractor and air

drill implement for use as well as to provide general operating procedures. The operator’s experience, familiarity

with the machine,and the followinginformation combined

should provide efficient drill operation and good working

habits.

Having all the parts and equipment readily at hand will

speed your assembly task and make the job as safe as

possible.

Pre-Assembly Checklist

Check Reference

All major frame components Operator’s

Fasteners and pins that were shipped with

the drill.

NOTE: If a pre-assembled part or fastener

is temporarily removed for assembly reasons, remember where it goes. Keep the

parts separated.

All working parts are moving freely, bolts

are tight and cotter pins are spread.

All grease fittings are in place and lubricated.

Safety labels are correctly located and legi-

pre-assemb

ble. Replace if damaged.

Get

Red and amber reflectors are correctly

located and visible when the drill is in the

transport position.

Inflate tires to specified air pressure. Tighten

wheel bolts to specified torque.

Have a minimum of 2 people at hand while

assembling the drill.

Have a fork lift or hoist along with chains

and safety stands that are sized for the job

ready for the assembly task.

ly chec

from

list

k

John

Operator’s

Operator’s

Section 5

.

P

page 39

ImportantSafety

Information

ImportantSafety

Information

Section 11

page 44

Operator’s

Operator’s

The air drill implement is shipped via flat bed truck. The

implement is not fully assembled.

Make sure the assembly area is level and free of obstructions (preferablyan open concrete area). Make sure the

assembly area is large enough for the assembled machine. Final assembled width of implement will be 45'.

Unload all equipment before beginning assembly. Do not

attempt any assembly work while the drill is onthe truck.

Separatestackedframes.Leaveshipping standsattached

to the bottom of each frame section.

Read and understand the previous section, “Important

Safety Information” beginning on page 1, before starting

assembly.

Implement Main Frame

!

DANGER!

Crushing hazard. You may be severely injured or killed by the

implement frames if they fall. Always support the implement

frames with jack stands or blocks before working on implement

raised off the ground.

!

WARNING!

Obeyall safety instructions from lifting equipment manufacturer.

Do not walk or place any part of the body under the raised sections. Be sure shipping stands ar e securely attached prior to lifting.Be sure lifting equipment has enough capacity to lift sections.

NOTE:Each stack of frame sections can weigh up to

8,000 pounds depending on opener, press wheel,

and coulter options.

General Description

This section covers the dealer’s requirements to assemble

the drill.

Tools Required:

• Fork lift or overhead hoist with 8000# capacity.

• Tractor of sufficient size and horsepower with remote hy-

draulics.Refer to the RecommendedTractorSizeportion

of the “Assembly and Setup” section on page 29.

• General hand tools.

• Jack stands or blocks and safety chain.

Shipping Information

NOTE:You will also need approximately20gallonsof

hydraulic oil to refill the tractor’s hydraulic reservoir

after initial bleeding and cycling of the hydraulic lift

and fold systems.

5/11/05

1. Remove the stacked implement sections fromthe

truck and placethem on the ground.

2. With all stacks securely on the ground, remove the u-

bolts from the bottom of the shipping stand on the

highestsectionssothatthe stand remains attached to

the upper section.

3. Carefully lift the section off of the stackand place it on

solid, levelground or concrete if available.

4. Repeat steps 2 and 3 with each section until all sec-

tions are separated and unstacked. Refer to for location of frame sections.

NOTE:Be sure that the pivot bushings are in place in

the pivot tubes before positioning sections.

Model 2250 Air Drill Implement 160-192M

11

Page 14

Section 1 Assembly and Setup

Great Plains Mfg., Inc.

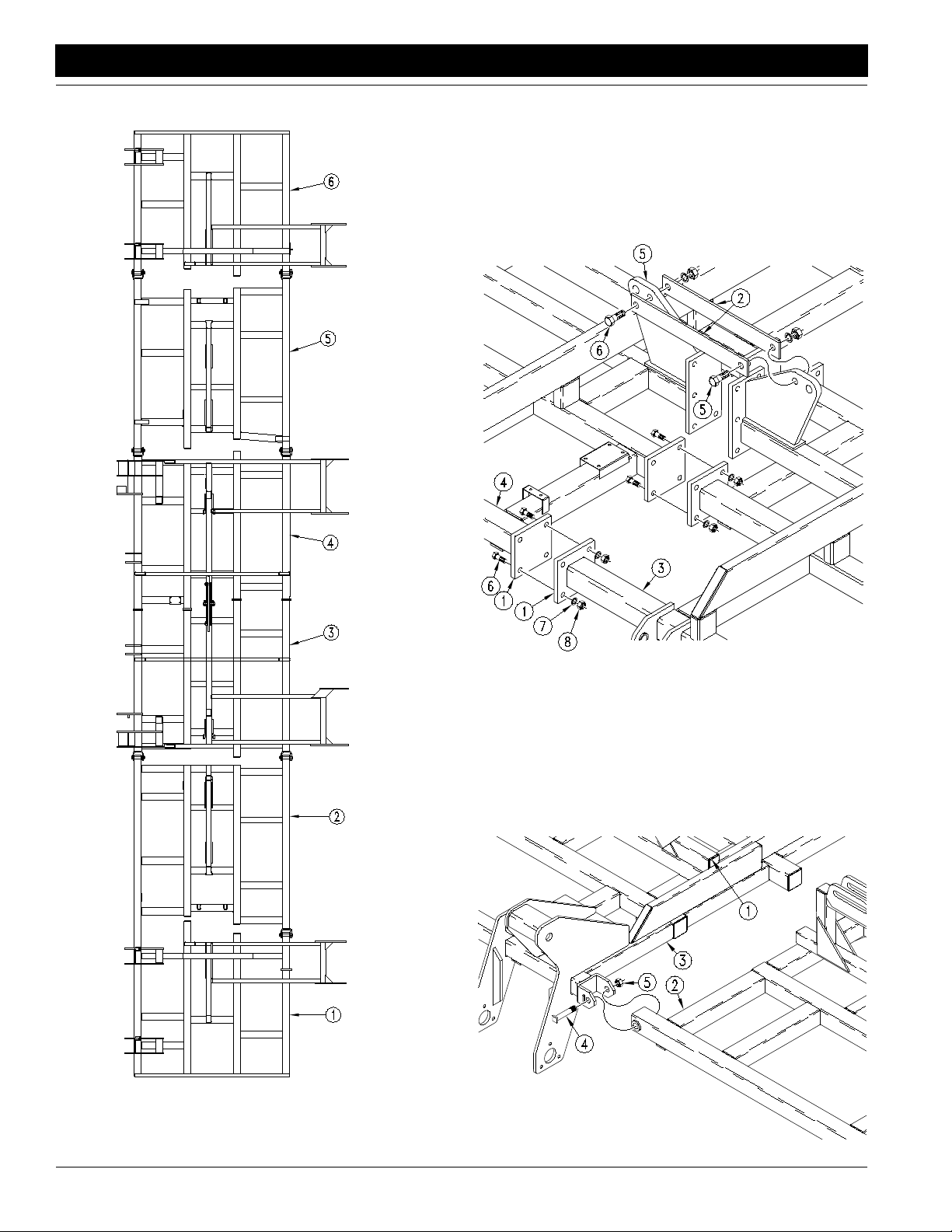

With the shipping stands still bolted to each frame section,

usethe hoist orforkliftto moveframesections three(#3)and

four(#4) to center of assembly area, refer to Figure 1-1 and

Figure 1-2. Alignflanges (#1) on each frame section and

bolt together using 3/4” x 2 3/4” bolts (#6), 3/4” lock washers (#7), and 3/4” hex nuts (#8). Attach a flex-limiter strap

(#2) to each side of cylinder lugs (#5) using a 1” x 3 1/2”

bolt (#6).

15379

15108

Frame Sections #3 and #4 Assembly

Figure 1-2

Refer to Figure 1-3:

Withtheshippingstands still bolted to each frame section,

moveframe section two (#2) so that the pivotbushingend

is aligned with the clevis end of frame section three (#3).

Be sure frame section two is not confused with frame section five. This can be avoided by making sure the fold

tubes (#1) are aligned before the frame sections are

joined.

Frame Locations

Figure 1-1

Model 2250 Air Drill Implement 160-192M 5/11/05

12

Frame Sections #2 & #3,

and #4 & #5 Assembly

Figure 1-3

15109

Page 15

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

Connectframe section two(#2)toframesection three (#3)

usingtwo pivotclevisbolts(#4)and1” locknuts(#5). Make

sure the pivot clevis bolt heads are oriented to the outside

of the clevis and seated next to the welded key stock on

the clevis.This will preventrotation of the bolt in the clevis.

Repeat the above steps when joining frame section five to

frame section four.

Refer to Figure 1-4:

Moveframe section one(#1) so that the pivotbushing end

is aligned with the clevisend of frame section two (#2). Be

sure frame section one is not confused with frame section

six.Thiscan be avoidedbymaking sure the liftassistarms

(#3) are positioned in the same direction as that of frame

sections three and four.

Connect frame section one (#1) to frame section two (#2)

using two pivot clevis bolts (#4), and 1” nuts (#5). Make

sure the pivot clevis bolt heads are oriented to the outside

of the clevis and seated next to the welded key stock on

the clevis.

15110

Frame Sections #1 & #2, and #5 & #6 Assembly

Figure 1-4

Repeat the above steps when joining frame section 6 to

frame section 5.

The frame sections should now be assembled and still

supported by the shipping stands.

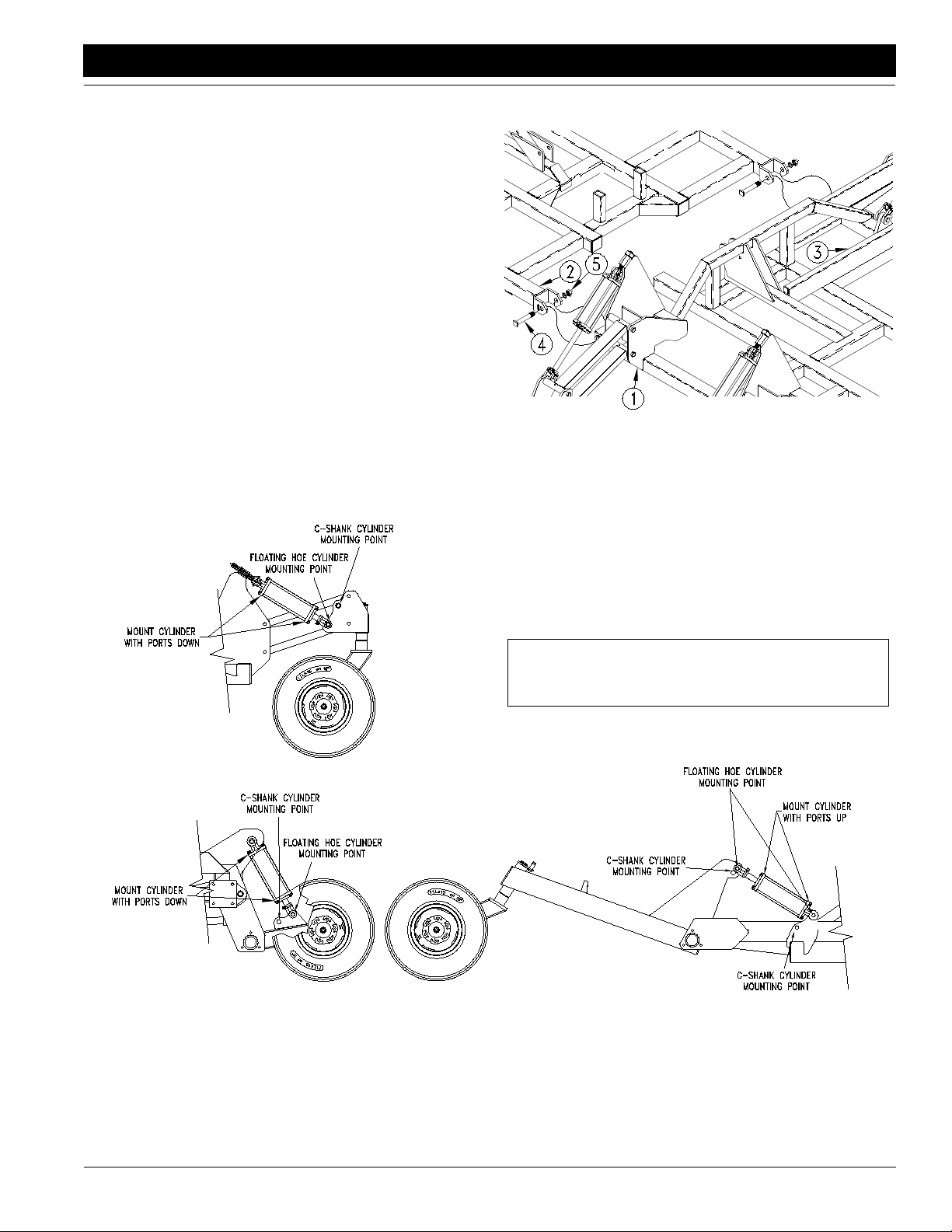

Hydraulic Cylinder Mounting Locations

Refer to Figure 1-5:

NOTE: Failure to correctly mount cylinders could

cause damage to the implement voiding the warranty.

5/11/05

Dual Gauge Wheels Wing Lift Assist

Hydraulic Cylinder Mounting Locations for Floating Hoe vs. Spring Shank

Figure 1-5

Model 2250 Air Drill Implement 160-192M

15149

13

Page 16

Section 1 Assembly and Setup

Great Plains Mfg., Inc.

Lift System

Hydraulic Hose Connections

NOTE: The SAE O-Ring and JIC 37˚ flare type hose

connections do not require sealant for reconnecting.

They do not require high torque for a good seal.

Uncoil the hoses from the first and the sixth frame sectionsand route them on the frame as showninFigure1-6.

The hoses from the rod end of the outer-most wing cylinders will connect to the elbows on the flow divider on the

center frame. The hoses from the base end of the wing

rear lift assist cylinders will attach to the rod end of the

master cylinders on the center section. Secure the hoses

to the frame with the 22”long cable ties provided. Avoid

routing the hoses where they could get pinched or worn

fromfolding,unfolding,raising, orloweringthe implement.

Do not let the hose rub on sharp edges and make sure

there is enough slack for down flex of the wing sections.

Lifting Hydraulics

Donottry to raiseorlowerimplement until circuit is bled of

air.Referto theBleedingtheHydraulic LiftingSystem,this

section starting on page 16.

Fold Cylinders

!

DANGER!

The folding cylinders must be bled free of air and implement

should be hooked to cart and tractor before attempting to fold

implement, otherwise severe property damage and bodily damage or death could result.

Positionthe main and outer fold cylinders with base ends

towardthe center of the drill. Pin the base ends to the fold

cylinderlugs. Secure thepinwiththeprovided clip,refer to

Figure 1-7. Leave rod end unhooked and block up in the

air so that the rod will not come into contact with any object when extended.Do not connect rod end until after air

is bled from fold circuit.

Hydraulic Hose Sizes

Item Part Number I.D. Length

1 811-054C 1/2" 97"

2 811-537C 1/2" 100"

3 811-541C 1/2" 256"

4 811-539C 1/2" 318"

5 811-437C 1/2" 90"

6 811-617C 1/2" 140"

7 811-538C 1/2" 288"

8 811-573C 1/2" 126"

Lift Cylinders

Item Part Number Bore

9 810-124C 4"

10 810-221C 4.25"

11 810-218C 4.5"

12 810-287C 4.75"

Lifting Hydraulics

Figure 1-6

Model 2250 Air Drill Implement 160-192M 5/11/05

14

15151

Page 17

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

15111

Folding Hydraulics

Folding Hydraulics

Hydraulic Hose Sizes

Hydraulic Hose Sizes

Item Part Number I.D. Length

Item Part Number I.D. Length

1 811-558C 3/8" 85"

1 811-553C 3/8" 85"

2 811-556C 3/8" 85"

2 811-556C 3/8" 85"

3 811-555C 3/8" 55"

3 811-555C 3/8" 55"

4 811-557C 3/8" 108"

4 811-557C 3/8" 108"

5 811-237C 3/8" 174"

5 811-237C 3/8" 174"

6 811-583C 3/8" 158"

6 811-583C 3/8" 158"

9 811-630C 3/8” 44”

9 811-630C 3/8” 44”

Hydraulic Cylinders

Installing Fold System

Figure 1-7

Refer to Figure 1-8:

Installhydraulichoses. Note the hose lengths and be sure

to use the correct length hose in each location. Start with

the longest hose and work to the shortest.

Be sure to use the provided cable ties to help route the hydraulichoses so that they willnotgetpinchedorwornfrom

folding, unfolding, raising, or lowering the implement. Do

not let the hoses rub on sharpedges and make sure there

is enough slack for down-flex.

NOTE: The SAE O-Ring and JIC 37˚ flare type hose

connections do not require sealant for reconnecting.

They do not require high torque for a good seal.

7 810-292C 5" 7

8 810-309C 4" 8

Fittings & Misc.

Item Description

10 TEE 3/4 FJIC 3/4 MJIC 3/4 MJIC

11 ELBOW 3/4 MJIC 3/4 MOR

12 1” FOLD CYLINDER PIN

13 1” FLA T WASHER

14 3/16 X 1 3/4 COTTER PIN

15 1 1/4 CLEVIS PIN

16 TEE 3/4 MJIC 3/4 MOR 3/4 MJIC

17 1 1/4 FOLD CYLINDER PIN

18 1 1/4” FLA T WASHER

19 3/16 X 2 COTTER PIN

5/11/05

Folding Hydraulics

Figure 1-8

Model 2250 Air Drill Implement 160-192M

15150

15

Page 18

Section 1 Assembly and Setup

Mounting the Cart Links

Refer to Figure 1-9:

1. Bolttheoutside cartlink mounts (#1) to the backofthe

cart using the 3/4” x 2 1/2” bolts (#2), 3/4” lock washers (#3), and nuts (#4).

2. The center cartlink mount (#5) should be attached so

thatitisexactly centered betweenthetwooutsidecart

link mounts. Use the 3/4” x 8 1/32” x7 3/4” u-bolts

(#6), 3/4” lock washers (#3), and nuts (#4).

3. Attach the cart links (#7) to the mounts using 8 1/2”

(#8) and 14 1/2” (#9) cart link pins. Use 5/16” x 2 1/4”

bolt (#10) and 5/16” lock nut (#11) to secure the cart

link pins.

15122

Great Plains Mfg., Inc.

15123

Attaching Cart to Implement

Figure 1-10

2. Attach the light harnesslead on the implement to the

light harnesslead on the cart.If the light harnessand

brackets have not been assembled refer to Light Har-

ness and Brackets on page 28 for assembly instructions. Also connect the electric clutch switch lead to

the lead on the back of the cart.

3. Connect the two hoses for the fold circuit to the quick

couplers designated as the fold outlets on the cart.

4. Connect the two hoses for the lift circuit to the quick

couplers designated as the lift outlets on the cart.

Cart Link Assembly

Figure 1-9

Attaching the Cart to the Implement

!

WARNING!

You may be severely injured or killed by being crushed between

the tractor and cart or between the cart and implement. Do not

stand or place any part of your body between the cart and implement while hooking up the implement.

Refer to Figure 1-10:

1. With cart links tied up, slowly back cart towards the

center of the implement. When cart link ball swivels

(#1) are between and aligned with cartlink implement

lug (#2), pin link to lugs using 1 1/4” x 8” bolt (#3),

1 1/4” lock washer (#4), and nut (#5).

NOTE: When all connections have been made, carefully check all lines to make sure none will be damaged when the implement is operated. Re-route the

lines or use cable ties to keep them in a safe place.

Bleeding the Hydraulic Lifting System

The implement lifting system is equipped with rephasing

type hydraulic cylinders that require a special procedure

forbleedingairfromthehydrauliccircuits. Readandfollow

the procedure carefully. The rephasing type cylinders will

not function properly with air in the hydraulic circuit. This

will cause uneven seeding depth across the implement.

!

WARNING!

Seriousinjury or deathcould resultfromescaping high pressure

hydraulicfluid. Use paper or cardboard,NOTBODY PARTS, to

check for suspected leaks.

Model 2250 Air Drill Implement 160-192M 5/11/05

16

Page 19

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

!

WARNING!

Before attempting to hydraulically lift the implement, air drill

cart must be attached to the implement and to a tractor of sufficient size. Failure to do so could result in severe equipment

damage and bodily injury or death.

NOTE: Check the hydraulic fluid level in the tractor

reservoir and fill to the proper level. Add fluid to the

system as needed. A low reservoir level may draw air

back into the system and cause jerky or uneven cylinder movement. During initial cycling of new hydraulic cylinders, approximately8 3/4 gallons of oil will be

used to fill the new cylinders.

1. Make sure implement frame sections are supported

by jack stands or blocks.

2. With the frame blocked and supported, unpin the rod

endof the gauge wheel andlift assist wheel cylinders.

Pivot the cylinders up and wire or otherwise safely

support the rod end port higher than the base end

port, refer to Figure 1-11. The center dual gauge

wheel cylinders may have to be removed from the

frame so that they can be oriented with therod end

higher than the base end.

ed, hold the remote leveron for one minute.Check all

hydraulic hoses, cylinders, and fittings for leaks.

4. Retract the cylinder rods. Extend the rods again and

hold the remote leveron for one more minute. Repeat

this step two more times tocompletely bleed the system.Ifthe gauge wheel levelingadjustments aretobe

made, see Side to Side Frame Leveling, this section,

on page 19. Leave the cylinders unpinned and the implement frame supported. Again, check all hydraulic

hoses, cylinders, and fittings for leaks.

5. Recheck the tractor hydraulic reservoir and fill to the

proper level.

6. Repin all cylinders. Be sure implement is hooked to

cart and tractor. See Attaching the Cart to the Imple-

ment, this section, on page 16.

7. Slowlyextendcylinders until all cylinder rods are completely extended.

8. Place cylinder lock channels on the front center dual

gauge wheel cylinder rods on both front dual gauge

wheels, see Figure 1-12.

14124

Bleeding Lift Hydraulic System

Figure 1-11

3. With the tractor engine at idlespeed, move the hydraulic remote lever so that hydraulic fluid is moved

into the lifting circuit. When the outboard cylinders on

both sides of the implement have completely extend-

5/11/05

15125

Cylinder Lock Channels in Place

Figure 1-12

9. If this is the first time the implement has been raised,

the shipping stands can now be removed. Make sure

cylinder lock channels are in place and implement

frame sections are sufficiently blocked up before attempting to remove shipping stands.

!

WARNING!

You may be severely injured or killed by being crushed from a

falling implement. Always have gauge wheel cylinder lock

channels in place and frame sufficiently blocked up when working on or around the implement.

Model 2250 Air Drill Implement 160-192M

17

Page 20

Section 1 Assembly and Setup

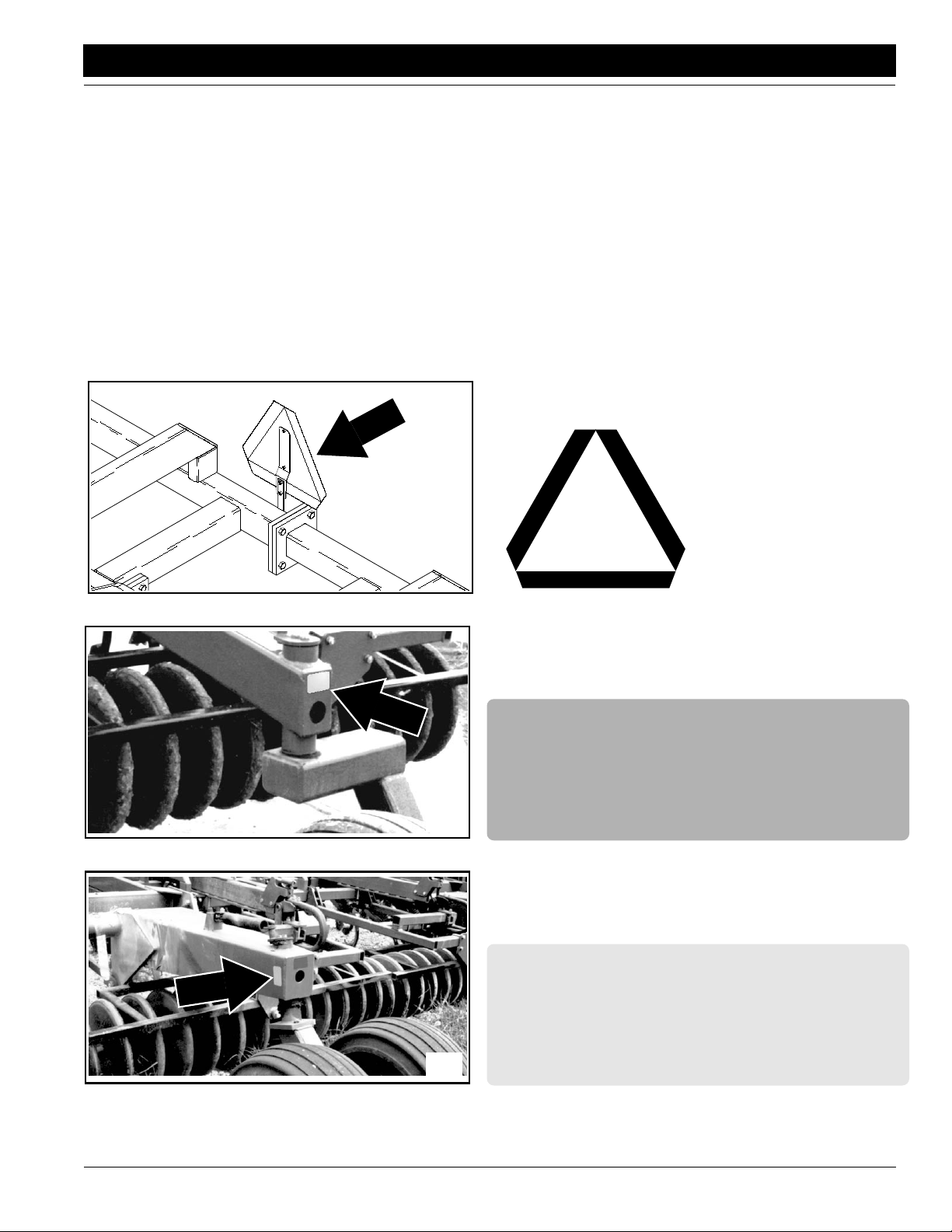

Pre-Fold Coulter Settings

IMPORTANT: Failure to understand the following instructions may result in equipment damage. Please read instructions and perform the steps required before

attempting to fold the implement for the first time.

Ifyourimplement comes equipped with coulters, you must

make additional adjustments before folding your implement for the first time. In order to ship yourimplement in a

more compact and efficient manner,the coulters were assembled in a raised position. This leaves the coulter

shanks extended far above the frame tube to which they

are mounted. If folding the implement is attempted while

the coulter shanks are extended in this manner, the top of

the shanks may bind at pivot points and equipment damage may result.

To avoid potential damage, coulters adjacent to fold pivot

pointsshould be adjusted so their shankextendsanallowable distance above the frame tube (see coulter adjustmentsinSection3ofyouroperator’smanual).Figure1-13

shows an example of an adjusted coulter.

Great Plains Mfg., Inc.

Coulter Shank Height

Figure 1-13

15274

Figure1-14 showswhichcoulters needtobeadjusted before

folding and how much their shanks may extend above the

frame tubes. All other coulters may be left in their shipping

positions if desired until field adjustments are necessary.

The coulter shanks sent with your unit maybe longer than

necessaryforyourapplication.The shanksweredesigned

to work with a variety of hoe boot lengths and operator

preferences.Atsome normaloperatingdepths, thecoulter

shank may extend too far above the frame tube. If this occurs,the top of the coulter shank may be trimmed or cut so

that the implement may fold without interference.

15240

Model 2250 Air Drill Implement 160-192M 5/11/05

18

Pre-Fold Coulter Shank Adjustments

Figure 1-14

Page 21

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

Bleeding the Folding System

!

DANGER!

The folding cylinders must be bled free of air and implement

should be hooked to cart and tractor before attempting to fold

implement, otherwise severe property damage and bodily damage or death could result.

NOTE: Check the hydraulic fluid level in the tractor

reservoir and fill to the proper level. Add fluid to the

system as needed. A low reservoir level may draw air

back into the system and cause jerky or uneven cylinder movement. During initial cycling of new hydraulic cylinders, approximately 9.5 gallons of oil will be

used to fill the new cylinders.

1. Unpin the rod end of the fold cylinders and block up,

wire, or otherwise safely support the cylinders so that

when extended the rod end will not contact any objects.

2. Cycle the cylinders completely in and out a minimum

of three times to purge all air from the fold system. Inspect all hoses, cylinders, and fittings for hydraulic oil

leaks.

ment. Periodic frame leveling should not be necessary.

You may, however, field check the levelness of the implement by laying a straight edge across the top of at least

two members of a frame section and measuring the distance from the bottom of the straight edge to the center of

the gauge wheel axle.By comparing this measurement to

the measurements taken from other frame sections and

gauge wheels, an indication of levelnesscan be obtained.

If levelingis necessary, follow the instructions listed.

Implement Frame Leveling

1. Thegauge wheel hydrauliccircuitshould be bledofair

and full of oil, see Bleeding the Hydraulic Lifting Sys-

tem, this section, page 16.

2. Hydraulically lower the entire implement frame. The

frame should then be jacked up and supported, see

Bleeding the Hydraulic Lifting System,this section,

page 16.

3. Retract the lift cylinders fully. Because the front dual

gaugewheelsonthe implement frames three and four

are non-adjustable, all adjustments will be made with

these as a reference.A referencemeasurement must

be taken by laying a straight edge across the top of at

leasttwotubes on the implement frame and takea reference measurement from the bottom of the straight

edgeto the center of one dual gauge wheel axle, refer

to Figure 1-15.

!

WARNING!

Seriousinjury or deathcould resultfromescaping high pressure

hydraulicfluid. Use paper or cardboard,NOTBODY PARTS, to

check for suspected leaks.

3. Fullyextendthe cylinders torepinthe rod ends in their

respective slots.

NOTE:If cylinders on left or right side will not extend,

release the tractor hydraulic lever momentarily, reverse the lever, and then tryagain. This switches the

sequence valve used to unfold one side at a time

!

CAUTION!

Never fold implement unless gauge wheel cylinder lock channels are installed.

4. Recheckthe tractor hydraulic reservoirlevel and fill to

the proper level.

5. Slowlyfoldand unfold implement. Checkforhydraulic

leaks. Be aware of any pinch points that might damage or cause accelerated wear on hydraulic hoses.

Side to Side Frame Leveling

Equal seeding depth across the implement can only be

maintained if all frame sections are level.Leveling adjustments should be done during initial setup of the imple-

15126

Frame Leveling Measurement

Figure 1-15

4. Move the straight edge to the four castored gauge

wheels on sections one and six. Removethe cylinder

pins from the base ends of the hydraulic cylinders on

the castored gauge wheels. Block or support the

gauge wheels so that the measurement from the bottom of the straight edge tothe center of the gauge

wheelaxle is the same asthereferencemeasurement

takenon the dual gaugewheelsonsectionsthreeand

four. Loosen the jam nuts on the eye-bolts that the

base of the cylinders were fastened to and screw the

eye-boltsin or out until they can be pinnedto the base

endofthehydrauliccylinders.Securetheeye-boltsby

tightening the jam nuts, refer to Figure 1-16.

5/11/05

Model 2250 Air Drill Implement 160-192M

19

Page 22

Section 1 Assembly and Setup

Frame Leveling Measurement

Figure 1-16

Great Plains Mfg., Inc.

Distribution Towers and Hoses

NOTE:For best results, distribution towers should be

mounted as vertically as possible. A tower that leans

significantly to one side may cause uneven distribution, particularly when operating on hillsides.

Referto Figure 1-19 fortower mounting locations. Choose

implement configuration to determine tower placement.

1. Referto Figure1-17, install a tower supportbracketat

each location using the 1/2” u-bolt (#1), 1/2” lock

washers (#2), and 1/2” nuts (#3)

Mounting Tower

Figure 1-17

15207

2. Positiona tower on the bracketand secure with 2 1/2”

x 2 1/2” u-bolts. The bottom of the lower round plate

should be approximately 31 1/2 inches above the

frame members. The tower should be turned so that

inlet tube is pointed toward the center of the implement. The center tower inlet should face the front of

the implement, see Figure 1-18.

14546

Model 2250 Air Drill Implement 160-192M 5/11/05

20

Tower Positioning

Figure 1-18

14499

Page 23

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

NOTE: Towers must be located so that there is no interference when wings are folded or unfolded. After

towers have been installed and before any seed hoses are installed, slowly fold the implement while

watching to be sure there are no interferences. Do

not stand under a wing while it is being folded or unfolded! If towers interfere with any other part of the

implement, completely unfold the implement and reposition the tower. Repeat these steps until implement folds without tower interference.

2 1/2" Primary Distribution Hoses

Chooseimplementconfigurationtodetermine correct hose

routing.

1. Start with center tower(s). Route hose as shown in

Figure 1-21. Slide hose at least two inches onto tower

inlet (slide clamp over the end of hose first).

2. Allowenoughhose so that implementraising,lowering,

folding, and unfolding will not pinch or bind the hose.

3. Using a hacksaw, cut hose so that it will slide at least

twoinches on to meter outlet or up to end of outlet flare.

NOTE: Each tower should be connected to its corresponding outlet at the back of the cart. For example,

the center tower should be connected to the center

outlet on the meter box, the far right hand tower

should be connected to the far right hand outlet on

the meter box, etc.

4. When using double shoot towers, be sure to connect

thetower hoses totheappropriateoutletattheback of

thecart(refertohoseinstallationprocedure in the cart

manual). Slide clamp over hose end then slide hose

onto meter outlet. Install the clamp so it will not interfere with other hoses, clamps, or meter door latch

handles.

5. Repeat the above procedure on the remaining towers

working from the center towers toward the outside.

6. Secureall hoses to the frameusingthe provided cable

ties. Be sure hoses will not be damaged by drill operation.

5/11/05

Model 2250 Air Drill Implement 160-192M

21

Page 24

Section 1 Assembly and Setup

Great Plains Mfg., Inc.

1513115130

Single Shoot Tower Mounting Locations

Figure 1-19

Model 2250 Air Drill Implement 160-192M 5/11/05

22

Page 25

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

5/11/05

15132

Double Shoot Tower Mounting Locations

Figure 1-20

Model 2250 Air Drill Implement 160-192M

15133

23

Page 26

Section 1 Assembly and Setup

Great Plains Mfg., Inc.

15134

Single Shoot

15135

Double Shoot Coulters

3 Rank Seed Hose Routings

Figure 1-21

Model 2250 Air Drill Implement 160-192M 5/11/05

24

Page 27

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

15136

Single Shoot

15137

5/11/05

Double Shoot

4 Rank Seed Hose Routings

Figure 1-22

Model 2250 Air Drill Implement 160-192M

25

Page 28

Section 1 Assembly and Setup

Great Plains Mfg., Inc.

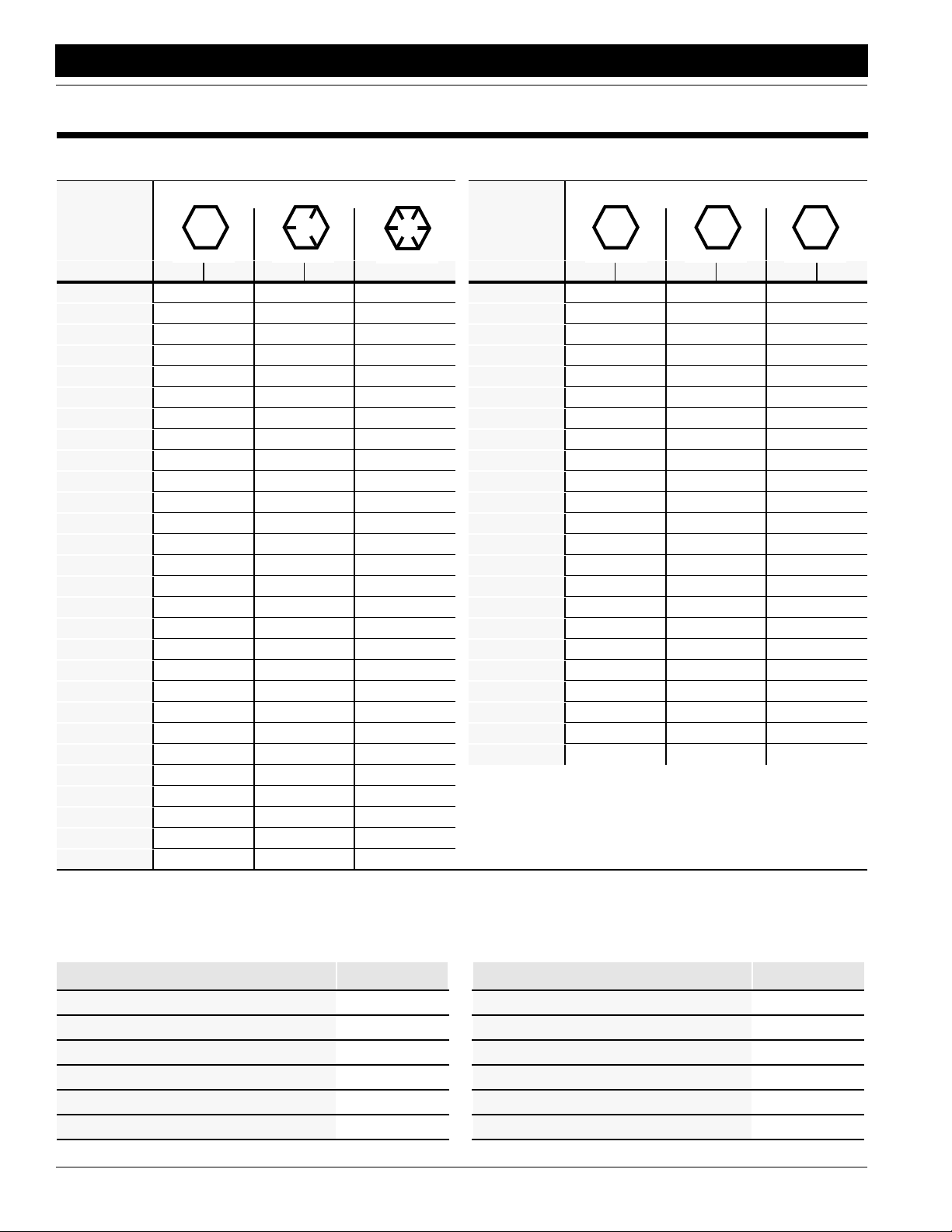

1" Secondary Distribution Hoses

NOTE: Seed hoses must be routed to prevent them

from rubbing on sharp edges or being damaged

when the implement is raised, lowered, folded, or unfolded. Hoses must be pushed fully into distribution

tower ports until they are seated against the stop.

With the implement configuration in mind, refer to the appropriate hose routing illustration for the correct assembly

of hoses, Figure 1-21 and Figure 1-22.

1. Loosen bolts holding tower halves together, refer to

Figure 1-23.

Do not remove bolts.

3. To avoid serious injury or death from crushing, make

sure cylinder lockchannels are in place, implement is

sufficiently blockedup, and the tractor is shut off with

the key removed before attempting to route hoses to

openers.

Forfloating hoe openers, slide the clamp overthe end

of the hose approximately 6”. Put the end of the hose

in the seed tube approximately 6”. Hook the clamp

ends in the holes at the top of the seed tube,

see Figure 1-24.

14449

Tower Assembly

Figure 1-23

2. Attach the end of the hose to the opener (or coulter

fertilizer tube).

!

DANGER!

To avoid serious injury or death from crushing, make sure cylinder locks channels are in place, implement is sufficiently

blocked up, and tractor is shut off with the key removed before

attempting to route hoses to openers.

Model 2250 Air Drill Implement 160-192M 5/11/05

26

For coulters with fertilizer attachments, Figure 1-25, attach

seedbrake(#1)tocoulter fertilizer tube (#2) using provided

hoseclamp (#3). Make sure plastic tube (#4) is placed over

fertilizer tube. Connect 1” seed hose (#5) to other end of

seed brake using hose clamp (#3).

Floating Hoe Hose Attachment

Figure 1-24

14563

Page 29

Great Plains Mfg., Inc.

Section 1 Assembly and Setup

Coulter Fertilizer Assembly and Hose Attachment

Figure 1-25

For all other openers, refer to manufacturer’ sdirections for

connecting the seed hose.

4. Route the hose to the tower outlet. Allow just enough

slack for down flex of wings. Be sure to use outlet as

shown in Figure 1-21 and Figure 1-22.

5. Allow2 1/4” of hose toextendpast the edge of the tow-

er.Cut off hose as smoothly and squarely as possible

to allow a good fit in the tower.

6. Push the end of the hose into the port until it contacts

the stop, refer to Figure 1-23. This should require approximately 2 1/4” of hose.

7. Repeat steps1through6forall 1” hoses on each tower.

15157

8. When all hoses are installed on a tower,tighten the

bolts holding the halves together.

NOTE:The tower bolts areequipped with nylock nuts

and should not be over-tightened. Tighten the bolts

only until the hose is held securely against being

blown out. Do not bend tower plates.

9. Checkall hoses tobesurethatthey are notrubbingon

sharp edges and will not be damaged when the drill is

raised, lowered, folded, or unfolded. Re-route if necessary to prevent damage.

5/11/05

Model 2250 Air Drill Implement 160-192M

27

Page 30

Section 1 Assembly and Setup

Great Plains Mfg., Inc.

Light Harness and Brackets

Refer to Figure 1-26:

Attach the left (#1) and right (#2) side light brackets to the

left and right center section lift assist arms of the implement. Use the 3/4 x 3” bolts (#3) to secure them to the outer lift assist pivot bearings. Install the left (#4) and right

(#5) ag lights to the brackets using the 1/4 x 1 1/4” bolts

(#6). The lights should be installed with the red lenses to

the inside and facing the rear.Attach the light harness “Y”

connector(#9)totheterminal at the back of the cart(#10).

Route the wires along the frame members back to the

lights and plug in.

NOTE: The lead with the green wire goes to the right

sidelights,the lead with the yellow wire goes to theleft

side.

Securethe wire in place using thecableties (#11). Coil the

excess wire and cable tie it securely to the implement

frame.

Light Package Assembly

Figure 1-26

Model 2250 Air Drill Implement 160-192M 5/11/05

28

15159

Page 31

Great Plains Mfg., Inc.

Section 2 Operating Instructions

Section 2 Operating Instructions

General Description

This unit is a tillage-type seeding implement that can be

usedin both conventionalandno-till seeding applications.

It is designed to be used in conjunction with and towed behind a Great Plains air drill cart. Thecart supplies pneumatically conveyed seed or fertilizer through five or ten

2 1/2” primary hoses. Each 2 1/2” hose is connected to a

distribution tower where the seed or fertilizer is evenlydistributedandcarried by air and gravitythrough a 1” secondary hose to each opener or coulter. The implement frame

acceptstwotypes of openers: a floating hoeopener or a cshank-style opener. The openers, configured in a 7” row

spacing,can be mounted across four ranks 28” apart.The

openerscan also beplacedona 7” rowspacingacross the

rear three ranks 28” apart thereby allowing the use of

coulters on the front rank. The coulters are placed so that

they run inbetween every two rows (14” apart). The

coulters are used to cut through residue and can be

equipped to apply dry fertilizer.

Seeding depth is controlled by front gauge wheel and

press wheel gang height. Coulter depth can be adjusted

individually.

The implement is equipped with an electricclutch switch to

stop and startmetering at the cartwhen the implement is

raised and lowered. The switch is adjustable so that the

height at which metering is stopped or started can be varied.

Prestart Checklist:

• Lubricate the implement as indicated in the Lubrication

portion of the “Maintenance and Lubrication” section

starting on page 39.

• Check all tires for proper inflation. See the Tire Inflation

Chart in the “Appendix” section on page 44.

• Perform all beginning of season and daily service items

discussed in the “Maintenance and Lubrication” section starting on page 39.

• Check the implement for worn or damaged parts and re-

pair or replace them before going to the field.

• All nuts, bolts, and screws should be checked. Refer to

the Torque Value Chart in the “Appendix” section on

page 44.

Recommended Tractor Size

NOTE: The tractor must be of adequate size to pull

the drill. When determining size of the tractor, soil

type, terrain, opener type, and tillage practices must

be considered.

Recommended Minimum Tractor Size

Standard openers and coulters - 240 HP

Double shoot openers - 300 HP

!

CAUTION!

The tractor or towing vehicle must have adequate unladen mass

to controlthe drill when towing. Do not exceed 20 miles per hour.

Minimum towing vehicle weight - loaded drill:

up to 20 mph maximum - 45,000 lbs.

up to 10 mph maximum - 22,000 lbs.

Minimum towing vehicle weight - empty drill:

up to 20 mph maximum - 28,000 lbs.

up to 10 mph maximum - 14,000 lbs.

NOTE: The tractor must have at least three sets of

hydraulic outlets and be capable of supplying 15-30

gallons per minute at 2000 psi.

Safety Lights

The light package your drill comes equipped with requires

that your tractor be wired for the standard 7-pin electrical

connector which will work with the tractor’s flashers and

signals.The harness from the air drill cart should be ready

to plug into the connector.

If your tractor is not equipped with this connector, please

consult your dealer for installation to the tractor manufacturer’s specifications.

Field Operations

1. Be sure that all tires are properly inflated as indicated

in the Tire Inflation Chart in the “Appendix” section

on page 44.

2. Be sure that all hoses are connected and clear of foreign material. Make sure openers are not plugged.

3. Neverback up with the openers in the ground. Do not

turn sharply with openers in the ground, doing so will

causeopeners to plug and couldcausedamagetothe

implement.

4. Make sure that nobody is in the way of the drill before

moving. Do not allow anyone to ride on the drill.

5. Follow all cart field operation instructions as found in

the cart operator’s manual.

6. Witha properly adjusted implement height switch,itis

not necessary to turn the electric clutch switchon and

off manually while turning. The clutch switch should

be turned off while transporting.

7. Beawareof a slight 5' to 10' delayneededfor the seed

toreachtheopeners when startingto moveforward.If

youstopin the middle of the field, lift the drill and back

up 10' and then proceed from that point.

8. Always operate farm machinery with safety in mind.

5/11/05

Model 2250 Air Drill Implement 160-192M

29

Page 32

Section 2 Operating Instructions

Implement Lifting System

The implement lifting system is equipped with rephasingtype hydraulic cylinders in a master-slave configuration.

Theymust be bledfreeofairusingtheprocedureslistedin

Bleeding the Hydraulic Lifting System inthe “Assembly

and Setup” section on page 16 for proper operation. The

cylindersmay,aftera period of time, get out of phase. This

will cause one section of the implement to run higher or

lower than other sections because the cylinders lifting it

areextendedmoreor less than the others.To rephase the

cylinders,raise the implement completely up and hold the

hydraulicleveronforseveralsecondsuntilallcylinders are

fully extended. This should be done every time the implement is raised out of the ground. Once all cylinders are fully extended, the hydraulic control should be momentarily

reversedtoallowthecylinderstoretract1/2”. This will help

maintain a level implement.

Fordepthcontrol,theimplement uses stopcollarsoneach

of the outside castor wheel cylinders, see Figure 2-1.

Along with the press wheel adjustments, the stopcollars

can be added and removed to adjust the seeding depth of

the openers. When not in use, the stop collars can be

stored on the hydraulic hose connected to the cylinders.

Great Plains Mfg., Inc.

!

DANGER!

Electrocution hazard to prevent serious injury or death from electrocution: Keep

clear of overhead power lines when transporting, folding, unfolding, or operating all air drill components. Machine is not

grounded. Electrocution can occur without direct contact.

1. Foldingis to be done on levelground only. Be awareof

the clearance required to fold the implement. Do not

fold the implement where it may come into contact

with obstructionsor overhead lines. Keep all persons

clear of this area.

2. Raise implement until all lift cylinders are completely

extended.

3. Install the lift cylinder lock channels.

NOTE: Never attempt to fold the implement without

first completely raising it and installing the gauge

wheel cylinder lock channels or serious equipment

damage will occur.

4. Be sure that folding lock pins are removed from the

folding lock plates, see Figure 2-2.

15186

Cylinder Stop Collars

Figure 2-1

Theliftsystem has cylinder lock channels for the front center dual gauge wheel cylinders. These channels must be

used every time the drill isfolded or transported. The cylinder lock channels must also be used any time maintenance or lubrication is being performed on the implement.

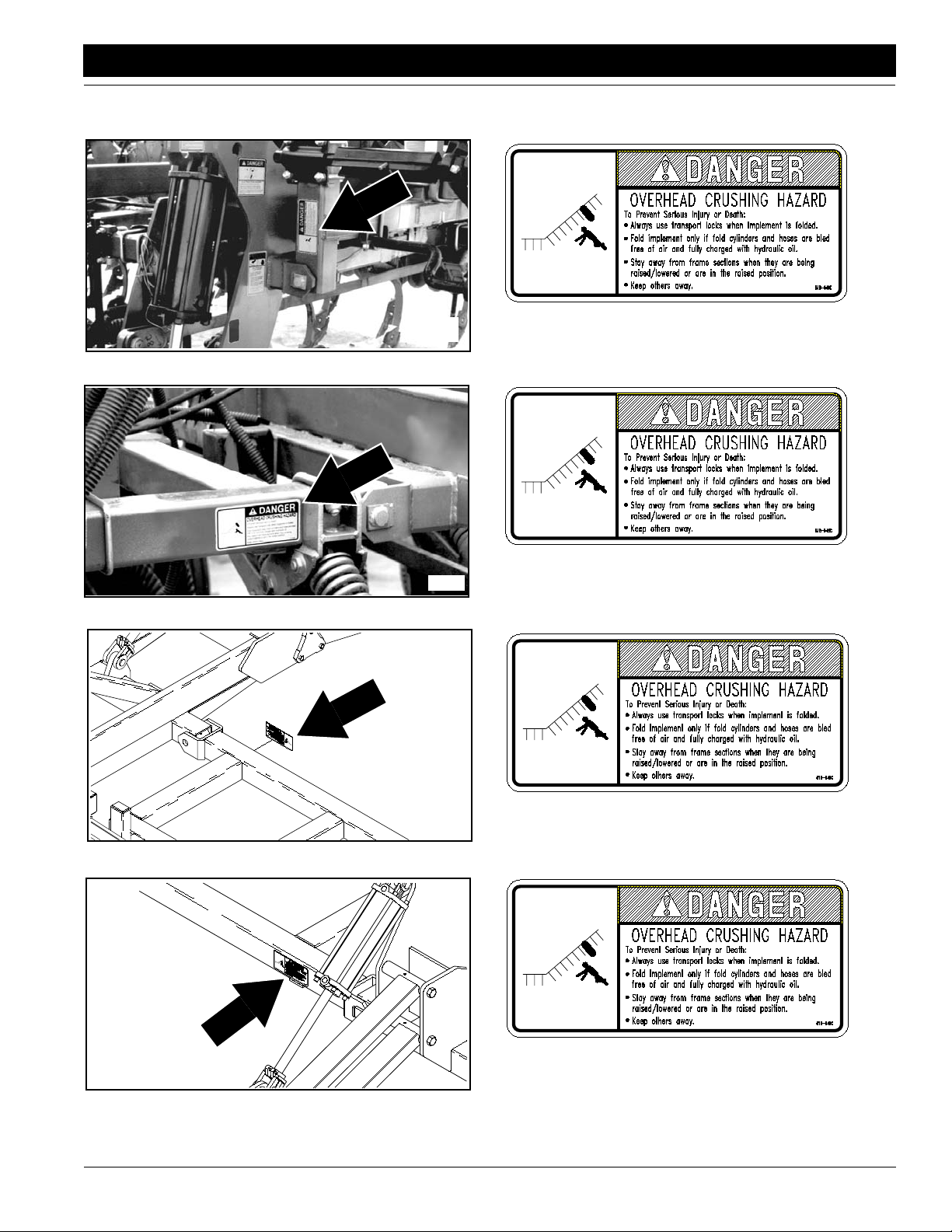

Folding the Drill

!

DANGER!

Overhead crushing hazard - to prevent serious injury or death:

•Always use transport locks when implement is folded.

•Fold implement only if fold cylinders and hoses are bled free

of air and fully charged with hydraulic oil.

•Stay away from frame sections when they are being

raised/lowered or are in the raised position.

•Keep others away.

Folding Lock Pin Removed

Figure 2-2

5. Set tractor at slow idle speed.

6. Engage the folding system hydraulics and slowly fold

the implement. During folding, both outside frame

sections should foldup first followedby one or both of

the inside sections.

7. When folding is complete, insertthe foldinglock pins in

place to prevent the wings from falling, see Figure 2-3.

15188

Folding Lock Pin in Place

Figure 2-3

15187

Model 2250 Air Drill Implement 160-192M 5/11/05

30

Page 33

Great Plains Mfg., Inc.

Section 2 Operating Instructions

8. Do not remove cylinder lock channels from a folded

implement.

Unfolding the Drill

!

DANGER!

Overhead crushing hazard. To prevent serious injury or death:

● Always use cylinder lock channels when folding or unfolding

implement.

● Fold or unfold implement only if fold cylinders and hoses are

bled free of air and are fully charged with hydraulic oil.

● Stay away from frame sections when they are being folded,

unfolded, or are in the folded position.

● Keep bystanders well away from the implement.

!

DANGER!

Electrocution hazard To prevent serious injury or death from electrocution: Keep

clear of overhead power lines when transporting, folding, unfolding, or operating all air drill components. Machine is not

grounded. Electrocution can occur without direct contact

1. Unfolding the drill is to be done on level ground only.

Be aware of the clearance required to unfold the drill.

Do not unfold the drill where it may come into contact

with any obstructions or overhead lines. Keep all bystanders clear awayfrom the area.

2. Remove folding lock pins and place them in the storage rings.

3. Set tractor at low idle speed.

4. Slowlyunfoldthe implement. During unfolding,one inner-framesection will unfold to approximately a 45 degreeangle and stop. The outer frame section will then

fold out straight. Both frame sections will then unfold

until the outside gauge wheels support the two frame

sections. When one side has completely unfolded, release and momentarily reverse the hydraulic lever.

Thiswillshift the spool in the sequencing valveso that

the other wing will unfold when the hydraulic lever is

again moved to unfold.

5. When the sections are unfolded, hold the lever until

the cylinders are completely extended to ensure that

wing flexibility will not be limited.

Opener Operation

General Opener Operation

1. Neverback up or turn sharply with openers in the

ground. Doing so will plug openersand may result in

equipment damage.

2. Check periodically for plugged openers and hoses.

With the fan running, manually operate the metering

system. Look below each opener for seed or fertilizer.

Do not crawl among the openers unless cylinder lock

channels are installed, the implement is sufficiently

blockedup, and the tractor is shut off with the key removed.

Forinformation on setting seed depth and making opener

adjustments, see Setting Seeding Depth and Leveling

Front-to-Rear in the “Adjustments” section on page 33.

C-Shank Style Opener

The C-shank style opener is designed to accept many different hoe openers. The C-shank opener should provide

about 350 pounds of resistance at the hoe tip in the first

inch of travel. If the opener encounters an immovable object, the shank will trip back in order to travel over the object after which it will spring back to its normal operating

position.

!

DANGER!

The C-shank opener comes equipped with a pre-compressed

spring.Any attempt to removeor adjust the spring could release

the spring’s stored energy and could result in serious injury or

death.

Floating Hoe Opener

The floating hoe openers (shear bolt and spring reset)

bothhavean ability to “give”when theyencounter obstructions. The spring reset hoe will trip when a large obstacle

is encountered. If the opener does not fully return to its

originalposition,liftthedrillout ofthegroundand allow the

spring to pull the opener back down.

For shear bolt openers, you must replace broken shear

bolts to reset the openers. Use 5/16” x 3”grade 5 bolts

only (Great Plains part number 802-131C).

Transporting

!

CAUTION!

This implement should never be towed faster than 20 miles per

hour.

Beforetransportingthe implement, checkandpracticethe

following items.

• When hitched to an air drill cart, the combined weight of

thisimplementandcartmustalwaysbekeptinmind.Be

sure that sufficient stopping distance is allowed at all

times and speed is reduced prior to making any turns or

other maneuvers.

• Besurethat the towingvehicleislarge enough tocontrol

the drill and implement on the road. Refer to Tractor Requirements, this section, on page 29.

• Know the maximum dimensions of the cart and imple-

ment in transport position and follow a route that provides adequate clearance from all obstructions. Be

especially observant of low overhead power lines.

• Besurethatallcylinder lock channels and transportlock

pins are in place.

5/11/05

Model 2250 Air Drill Implement 160-192M

31

Page 34

Section 2 Operating Instructions

NOTE: Never remove cylinder lock channels from a

folded implement.

• Be certain that all tires are properly inflated as listed in

the Tire Inflation Chart in the “Appendix” section on

page 44.

• Comply with all Federal, State, and local laws when

transporting on public roads.

• Rememberthattheairdrillcartbinsandthewingsofthe

folded implement can obstruct your view. Be prepared

for sudden maneuvers from following vehicles.

Great Plains Mfg., Inc.

Parking

Thefollowingsteps should beperformedwhen parking the

drill. Refer to Storage under the “Maintenance and Lu-

brication”section on page39forinformationon long term

storage preparation.

1. Raise and lock implement in storage position.

2. Place implement on a firm level area.

3. Securely block the drill tires to prevent rolling.

4. Unhook electrical lines and install plugs as provided.

5. Release pressure on the hydraulic system, then disconnect hydraulic lines. Be sure the ends do not rest

on the ground.

Model 2250 Air Drill Implement 160-192M 5/11/05

32

Page 35

Great Plains Mfg., Inc.

Section 3 Adjustments

Section 3 Adjustments

Setting the Seeding Depth

And Leveling Front to Rear

NOTE:In order to provide equal seeding depth for all

openers, the drill must be levelfrom front to rear and

fromsidetoside.Side to side levelingshouldbe done

when the drill is assembled, refer to Side to Side

Frame Leveling under the “Assembly and Setup”

section on page 19 and should not require readjustment.Makesure that the lift cylindersare in phase as

instructed in the “Operating Instructions” section

on page 29. Make sure the fold cylinders are fully extended.

IMPORTANT: When setting the depth and leveling from

front to rear, remember that the gauge wheels set the

depth for the front of the drill and press wheels are used

to level the drill from front to rear.

1. Aset of depthcontrolstopcollars aresuppliedwiththe

implement for adjusting the depth of the front of the

implement. This is accomplished by adding or removing the collars on the outside caster wheel cylinder refer to Figure 3-1.

the press wheels decreases.

Thepress wheel down force tube has twosets of holes

for the press wheel adjustment handle weldment. The

adjustment weldment should be in the lower two holes

iftheimplementisequippedwithC-shankopenersand

the upper two holes if the implement is equipped with

floating hoe openers. Illustration shows weldment in

position for C-shank operation.

Floating

Hoe

Position

C-Shank

Position

Press Wheel Adjustment

Figure 3-2

15189

15186

2. Set the lifting hydraulics so that the front rank of the

openers or coulters is operating at the desired depth.

3. Add or remove stop collars on both outside caster

wheel cylinders until collars coverextended portionof

the cylinder rods.

4. Check the depth of the back rank openers. If they are

not the same as the front rank, the press wheels must

be adjusted.

Refer to Figure 3-2:

5. To adjust the press wheels, remove the handle lock

pin and slide the handle back. Toraise the seeding

depth, turn the handle counter-clockwise (as viewed

from above). Tolower the seeding depth turn the handle clockwise so that the distance from the handle to

Depth Control Stop Collars

Figure 3-1

Individual Opener Adjustments

C-Shank Style Openers

The C-shank style openers do not require any adjustments. The hoe boot selected by the owner to be put on

the C-shank may need to be adjusted according to its

manufacturer’s recommendations.

!

DANGER!

The C-shank opener comes equipped with a pre-compressed

spring.Any attempt to removeor adjust the spring could release

the spring’s stored energy and could result in serious injury or

death.

Floating Hoe Openers

Spring reset and shear bolt floating hoe openers are adjustable for both depth and down pressure. Before adjustingany openers be suretheimplementislevelfromside to

side, see Side to Side Frame Levelingunder the “Assem-

bly and Setup” section on page 19. Also be sure the implement is level from front to rear.

Shear Bolt and Spring Reset Opener Depth

Somefloating hoe openerdepthsmayneedtobe adjusted

independentlyof the others (openers running in tire tracks

for example). To change individual floating hoe opener

depths, remove the lower spring rod retaining bolt, move

the rod to a hole ahead or behind the current one, and reinstall the bolt, refer to Figure 3-3.

5/11/05

Model 2250 Air Drill Implement 160-192M

33

Page 36

Section 3 Adjustments

Great Plains Mfg., Inc.

NOTE: Moving the “W” clip to a higher hole will increase the down pressure of the opener.

Hoe Tip Angle

For maximum hoe tip life, the tip should be set so that the

pointofthetipruns1/8”lowerthan the heel, refer to Figure

3-5. This adjustment may be required if the opener depth

is adjusted.

Depth Adjustment

Figure 3-3

14531

NOTE:Moving the rod to a higher hole will cause the

seedtobeplaceddeeper into the soil. Moving the rod

to a lower hole will cause shallower seeding to occur.

NOTE: If the opener depth is adjusted, check the tip

angleandadjustifneeded.Referto the followingHoe

Tip Angle section for adjustment and instructions.

Shear Bolt and Spring Reset Opener Down Pressure

To adjust the down pressure of individual openers, such as

thoserunningintire tracksor veryhardground, movethe“W”

clip to a different hole in the springrod, refer to Figure 3-4.

14537

Depth Adjustment

Figure 3-5

• Shear bolt openers: To adjust the tip angle, move the

shearbolttoahigher or lower hole. (Use 5/16 x 3” grade

5 bolt only), refer to Figure 3-6.

Down Pressure Adjustment

Figure 3-4

14532

14538

Tip Angle Adjustment (Shear Bolt)

Figure 3-6

• Springresetopeners:Toadjustthetipangle, turn the trun-

ion bolt, refer to Figure 3-7, until the tip angle is correct.

Model 2250 Air Drill Implement 160-192M 5/11/05

34

Page 37

Great Plains Mfg., Inc.

Section 3 Adjustments

14539

Tip Angle Adjustment (Spring Reset)

Figure 3-7

Coulter Adjustments

If your implement is equipped with optional coulters or

coulter fertilizer attachments, the following adjustments

can be made to optimize coulter performance.

Individual Coulter Depth Adjustments

Each coulter is independently mounted in front of and between two openers. The coulters cut through residue

and/or cut grooves in the soil for fertilizer application. The

coulters are mounted on the front rank of the implement.

Therefore, the cutting depth of all the coulters on the implementwill change as the unit israisedandlowered, refer

to Setting Seeding Depth And Leveling Front to Rear on

page 33 for information on how to make this depth adjustment. The operator will want to adjust the coulters so that

they are operating at a relative depth to the openers.

Those coulters which run directly in implement, cart, or

tractor tire tracks mayneed to be adjusted differentlythan

the rest of the coulters. Coulter depth can beadjusted independently of other coulters and openers by using the

following procedures.

!

WARNING!

Be sure cylinder lock channels are in place and wheels are

blockedto keep implement from rolling.Serious injury or death

could result from a falling or rolling implement.

Refer to Figure 3-8:

1. Besurethecoulterassemblyissupported by blocking

up the coulter.

2. Loosen the u-bolts holding the coulter clamp.

3. Slidecoulter shank up or down so thatthe coulter is at

the desired height.

4. Support thecoulterat the newheight and retightenthe

u-bolts holding the coulter clamp.

15273

Coulter Adjustments

Figure 3-8

NOTE:Many times the coulter depth will be adjusted

relative to the opener tip. The implement should be

parked on a clean, level area (preferably concrete)