Page 1

Predelivery Instructions

Models ADI334 and ADI345

Air Drill Implement

Manufacturing, Inc.

P.O. Box 5060 ● Salina, Kansas 67402-5060

Read this manual entirely . When y ou see this symbol, the subsequent instructions and

!

warnings are serious - follow without exception. Your life and the lives of others depend

on it!

© Copyright 1998 Printed

06/03/98

14576

Cover illustration may show optional equipment not supplied with standard unit.

160-243M

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . . . 1

Safety Notations. . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Description of Unit . . . . . . . . . . . . . . . . . . . . . . . . 2

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . 2

Assembly and Setup Assistance . . . . . . . . . . . . . 2

Section 1 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pre-Assembly Checklist. . . . . . . . . . . . . . . . . . . . 3

Assemble Implement Frame . . . . . . . . . . . . . . . . 3

Flex Limiter Bars . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lift Cylinder Hydraulic Hoses. . . . . . . . . . . . . . . . 4

Fold Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hitching Cart to Implement. . . . . . . . . . . . . . . . . . 9

Bleeding the Lift Hydraulics . . . . . . . . . . . . . . . . 10

Bleeding the Folding Hydraulics. . . . . . . . . . . . . 11

Leveling Frame Side-to-Side. . . . . . . . . . . . . . . . 12

45-Foot Drill . . . . . . . . . . . . . . . . . . . . . . . . . 12

34-Foot Drill . . . . . . . . . . . . . . . . . . . . . . . . . 13

Distribution Towers and Hoses . . . . . . . . . . . . . .14

Primary Distribution Hoses. . . . . . . . . . . . . . . . . 16

Secondary Hoses . . . . . . . . . . . . . . . . . . . . . . . .16

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 21

Torque Values Chart for Common Bolt Sizes . . .21

© Copyright 1997 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warr anty of any kind, either expressed or implied. W hile ev ery precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions . Neither is any liability assumed for damages resulting from the use of the inf ormation contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, A usherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Page 3

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

For your safety, thoroughly read “Important Safety Information” and “Operating Instructions” in the operator’s manual

before proceeding.

Safety Notations

The SAFETY ALERT SYMBOL indicates there is a potential

hazard to personal safety involved and extra safety precautions

must be taken. When you see this symbol, be alert and carefully

read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation, transport, maintenance and storage of equipment.

Watch for the following safety notations throughout these instructions and the operator’s manual.

!

DANGER!

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal word

is limited to the most extreme situations.

!

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

!

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moder ate injury. It may also be used

to alert against unsafe practices.

Safety Rules

Most accidents are the result of negligence, carelessness or

failure to follow safety precautions. Though your implement is

designed with many built-in safety features, safety precautions

are mandatory to prevent accidents.

4/7/04

Models ADI334 and ADI345 Air Drill Implement 160-243M

1

Page 4

Introduction

Introduction

Great Plains Mfg., Inc.

Great Plains Manufacturing wants y ou to be satisfied with

any new machine delivered b y the Great Plains Trucking

network. To ease the assembly task and produce a prop

erly working machine, read this entire manual before assembling or setting up new equipment.

Description of Unit

The three-rank air drill implement is a towed seeding implement used with a Great Plains air-drill cart. Seed is delivered by a pressurized air stream to the floating-hoe

openers via primary seed hoses, distribution towers and

secondary seed hoses.

The implement has a working width of 34 or 45 feet. The

implement has three ranks of staggered openers for easy

residue flow . Opener depth is controlled by a hydraulic

stop. Press wheels follo w the openers to firm and close the

seedbed. An electric-clutch drive with an adjustable height

switch turns seeding off automatically for headland turns.

Openers and press wheels are spaced over f our frame

sections on the 34-foot or six sections on the 45-foot im

plement. Floating arms link the cart to the implement, allowing the implement to move independently of the tractor

and cart for increased front-to-rear flexibility.

The implement folds to a transport height of 15 feet, eight

inches (45-foot drill) or 13 feet, two inches (34-foot drill).

Rear castor wheels are used for transport and field turns

and are lifted for seeding.

-

An operator’s man ual is also pro vided with the ne w machine. Read and understand “Important Safety Informa-

tion” and “Operating Instructions” in the operator’ s

manual before assembling the machine . As a reference,

keep the operator’ s man ual on hand while assembling.

The information in this manual is current at printing. Some

parts may change to assure top performance.

Definitions

Right and left as used in this manual are determined by

facing the direction the machine will trav el while in use un

less otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct oper ation,

read and follow the directions provided before continuing.

NOTE: Useful inf ormation related to the preceding topic.

Assembly and Setup Assistance

To order additional dealer assembly instructions or operator’s and parts manuals, write to the following address . Include model numbers in all correspondence.

If you do not understand any part of this manual or have

other assembly or setup questions, assistance is av ail

able. Contact

-

-

Using This Manual

This manual was written to help you assemble and prepare the new machine for the customer. The manual includes instructions for assembly and set up . Read this

manual and follow the recommendations f or safe, efficient

and proper assembly and setup.

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

2

Page 5

Great Plains Mfg., Inc.

Section 1 Assembly

Section 1 Assembly

This section covers dealer requirements f or assembly. As

the dealer, it is y our responsibility to unload, assemble and

prepare the implement for use.

The implement is shipped via flat bed truck. It is not fully

assembled. Unload all equipment before beginning as

sembly. Do not attempt any assembly work while the implement is on the truck.

The following are step-by-step instructions f or assembling

the implement. Each heading is a step in the assembly

process. Begin with Tools Required and Pre-Assembly

Checklist to ensure you have all necessary parts and

equipment at hand. Then proceed with Assemble Imple

ment Frame . Follow each step to make the job as quick

and safe as possible and produce a properly working ma

chine.

-

-

Tools Required

• Forklift or overhead hoist with 6,500-pound capacity

• A tractor of sufficient size and horsepower with remote

hydraulics. Refer to Tractor Requirements, “Setup,”

page 9.

• General hand tools

• Jack stands or blocks and safety chain

NOTE: You will need about 12 gallons of h ydraulic oil to refill the tractor hydraulic reservoir after initial bleeding and

cycling of the hydraulic systems.

10. Inflate tires and torque all wheel bolts as recommended in the “Appendix,” page 21.

Assemble Implement Frame

!

WARNING!

Obey all safety instructions fr om lifting equipment manufactur er.

Do not walk or place any part of the body under the raised sections. Be sure transport stands are securely attached prior to lifting. Be sure lifting equipment has enough capacity to lift sections.

1. Remove the implement sections from the truck and

place them on the ground.

2. With all stacks securely on the ground, remov e the u-

-

bolts from the bottom of the shipping stands on the

highest sections so that the stand remains attached to

the upper section.

3. Carefully lift the top section off of the stack and place

it on solid, level ground or concrete if available.

4. Repeat steps 2 and 3 with each section, placing the

sections approximately in the position for assemb ly.

5. Check that the pivot bushings are in place in the piv ot

tubes in all sections

6. Use the hoist or forklift to position adjacent sections so

that the holes in the clevis line up with the holes in the

pivot tubes.

Pre-Assembly Checklist

1. Read and understand “Important Safety Information” on page 1 before assemb ling.

2. Have at least two people on hand while assemb ling.

3. Make sure the assembly area is le vel and free of obstructions (preferably an open concrete area).

4. Make sure the assembly area is large enough f or the

assembled drill. Assembled width is 34 or 45 feet.

5. Have all major frame components .

6. Have all f asteners and pins shipped with drill

IMPORTANT: If a pre-assembled part or fastener is

temporarily removed, remember where it goes. Keep

the parts separated.

7. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

8. Have a cop y of the parts manual on hand. If unsure of

proper placement or use of any part or fastener, ref er

to the parts manual.

9. Check that all safety labels and reflectors are correctly

located and legible. Replace if damaged. Refer to

Safety Labels, “Important Safety Information, ” in the

operator’s man ual.

.

!

WARNING!

Do not place any part of the body between the frame sections

when aligning holes or severe injury may result.

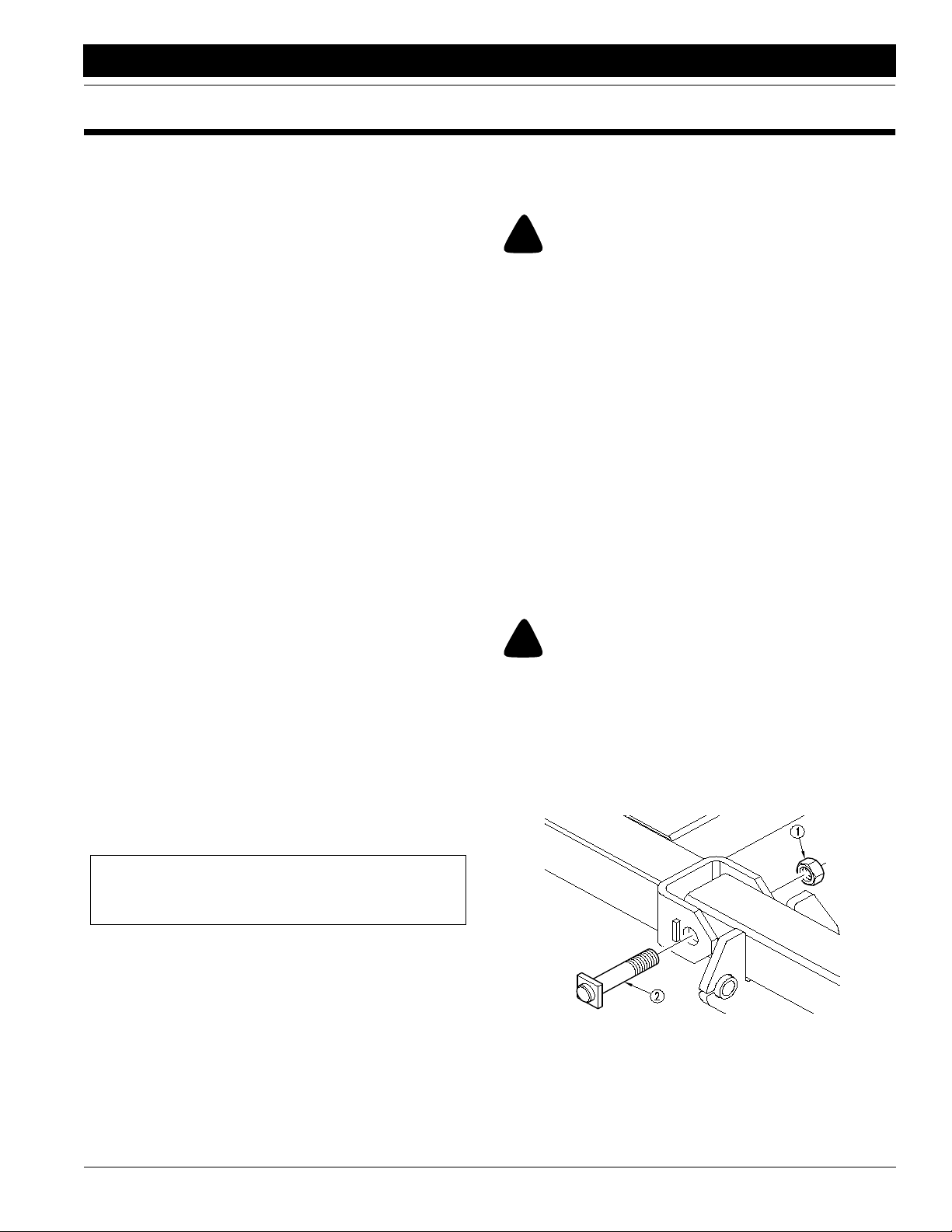

7. Refer to Figure 1-1. When the holes are aligned, install the pivot clevis bolts (2) in place and secure them

with one-inch nylock nuts (1).

Install bolts so that the flat section of bolt head is

aligned with the square stock on the clevis to pre v ent

the bolt from rotating in the clevis.

14441

Figure 1-1

Pivot Pin Installation

8. Repeat steps 6 and 7 until all sections are bolted together.

4/7/04

Models ADI334 and ADI345 Air Drill Implement 160-243M

3

Page 6

Section 1 Assembly

Flex Limiter Bars

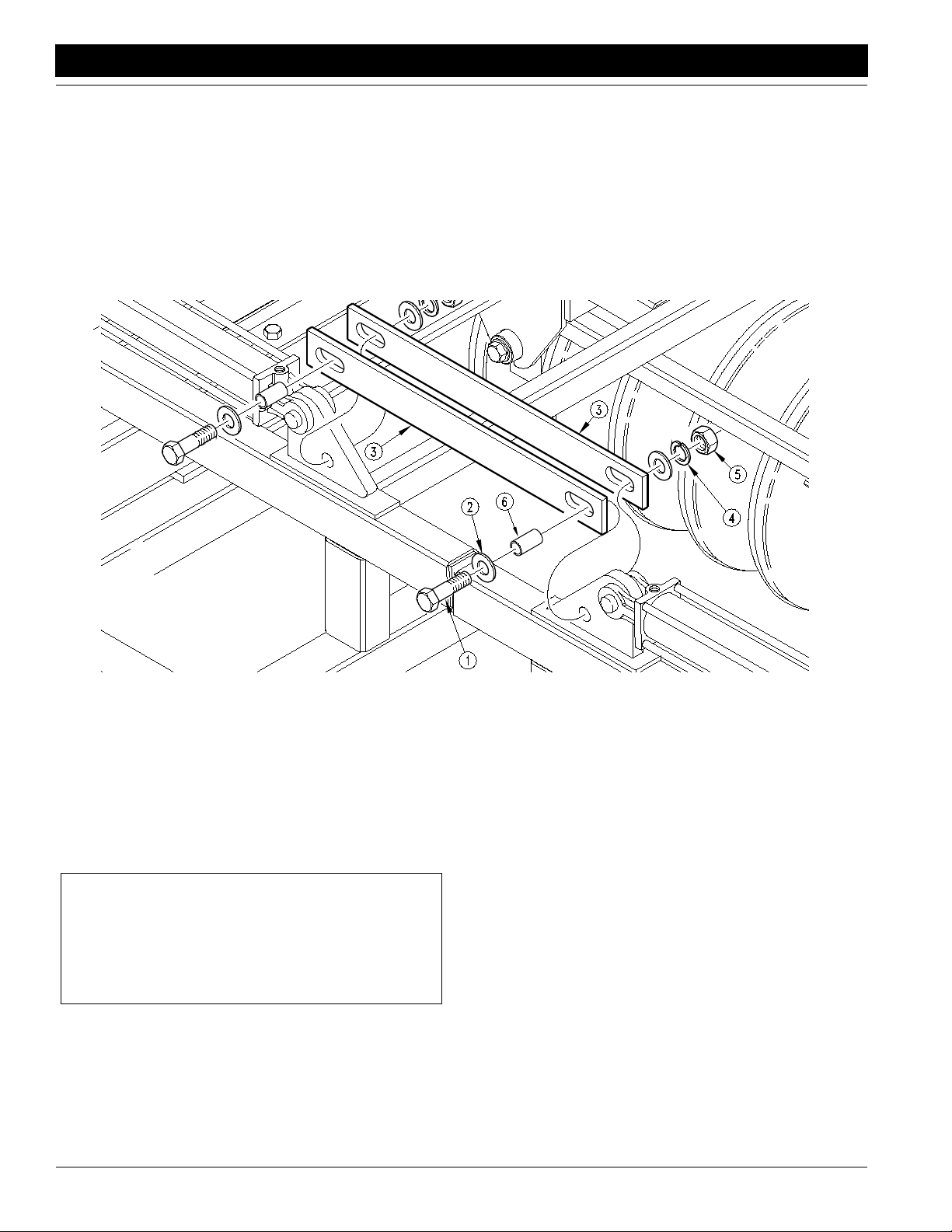

Refer to Figure 1-2:

1. Position the flex-limiter bars so that the slots line up with

the holes in the lugs near the center of the implement.

2. Install the 7/8 x 3 1/2-inch bolts (1), flat washers (2),

spacer tubes (6), flex-limiter bars (3), lock washer (4),

and nut (5) at each end of tube. The flex-limiter bars

should be free to move from side-to-side on the bolts.

Great Plains Mfg., Inc.

Figure 1-2

Flex Limiter Bar Installation

14483

Lift Cylinder Hydraulic Hoses

Refer to Figure 1-4 or Figure 1-5. Install the hydr aulic hoses on the lift wheels. Note the hose lengths listed and be

sure to use the correct length of hose in each location. In

stall the longest hose first and work down to the shortest

hose length.

Refer to Figure 1-3. The row openers in some locations ha ve

hose clips (1) mounted on them. Always route h ydraulic hoses through the clips to prevent damage .

IMPORTANT: Carefully check hoses to be sure they

are not rubbing on any sharp edges. Check that the

hoses are loose enough to allow the implement to fold

or unfold and raise or lower without damage. Be sure

that hoses will not bind or get pinched during operation.

NOTE: The SAE O-ring and JIC 37˚ flare-type hose connections do not require sealant for reconnecting. They do

not require high torque for a good seal.

-

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

4

Page 7

Great Plains Mfg., Inc.

Section 1 Assembly

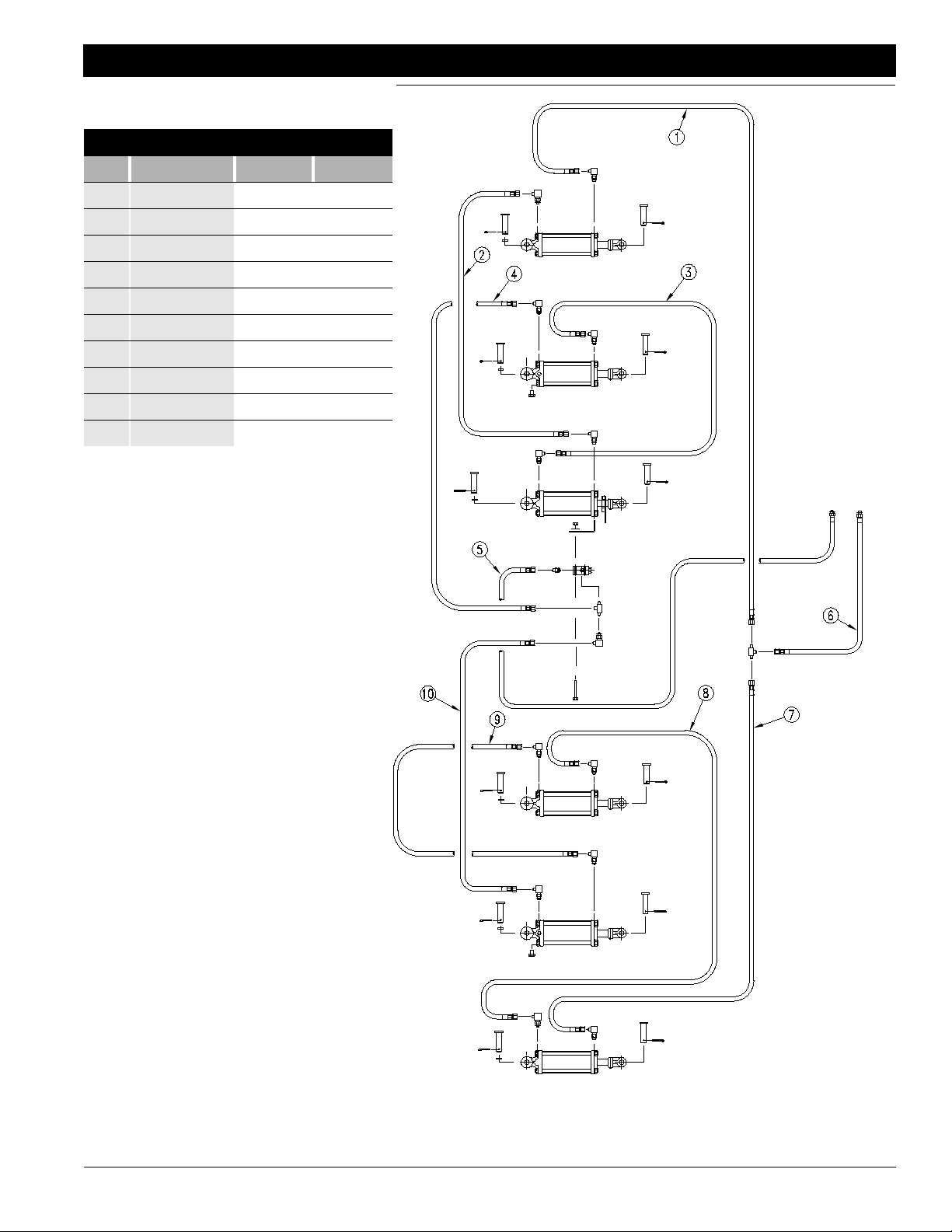

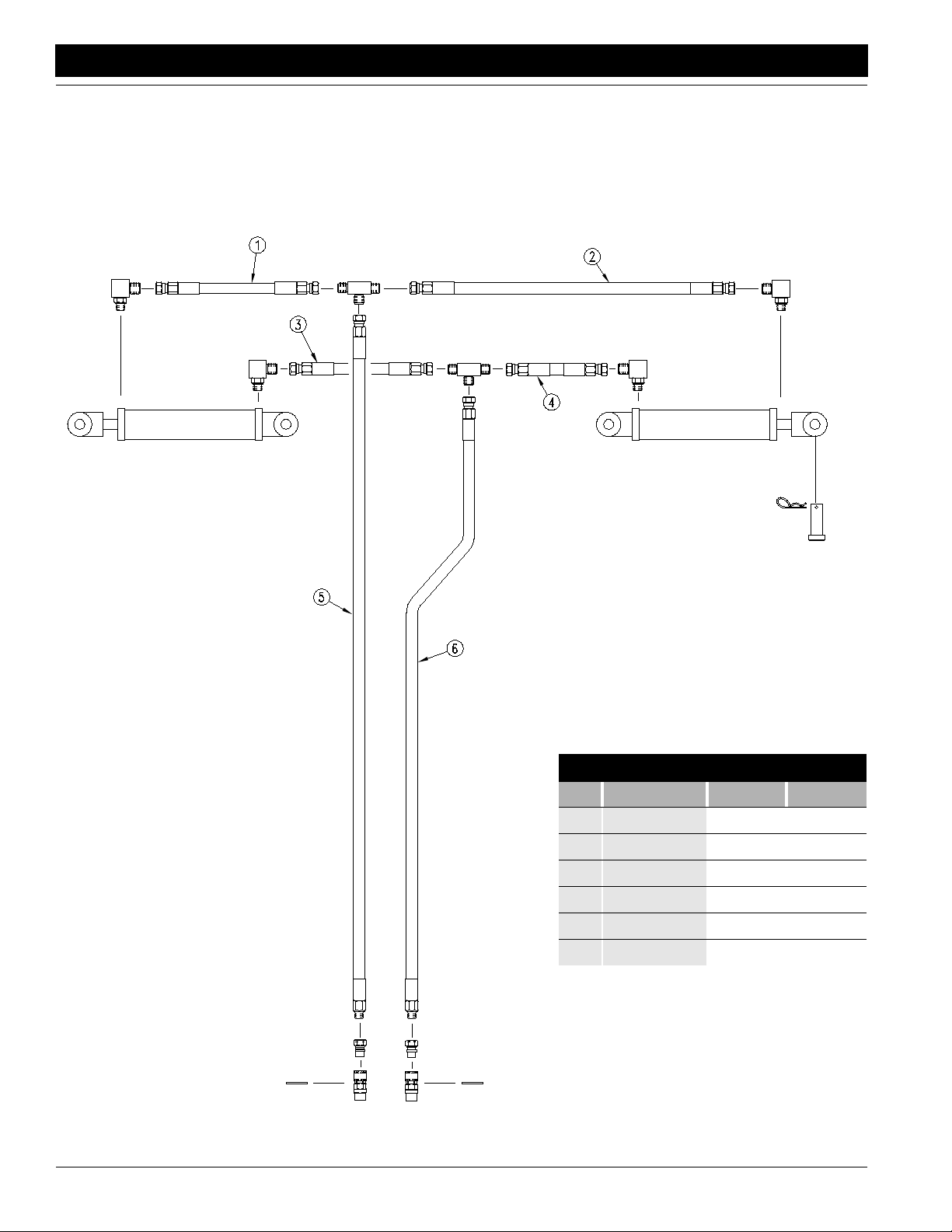

34-Foot Lifting Hydraulics

Hydraulic Hose Sizes

Item Part Number I.D. Length

1 811-235C 3/8 222

2 811-237C 3/8 174

3 811-245C 3/8 74

4 811-245C 3/8 74

5 811-236C 3/8 84

6 811-123C 3/8 51

7 811-237C 3/8 174

8 811-235C 3/8 222

9 811-127C 3/8 111

10 811-127C 3/8 111

4/7/04

14464

Models ADI334 and ADI345 Air Drill Implement 160-243M

5

Page 8

Section 1 Assembly

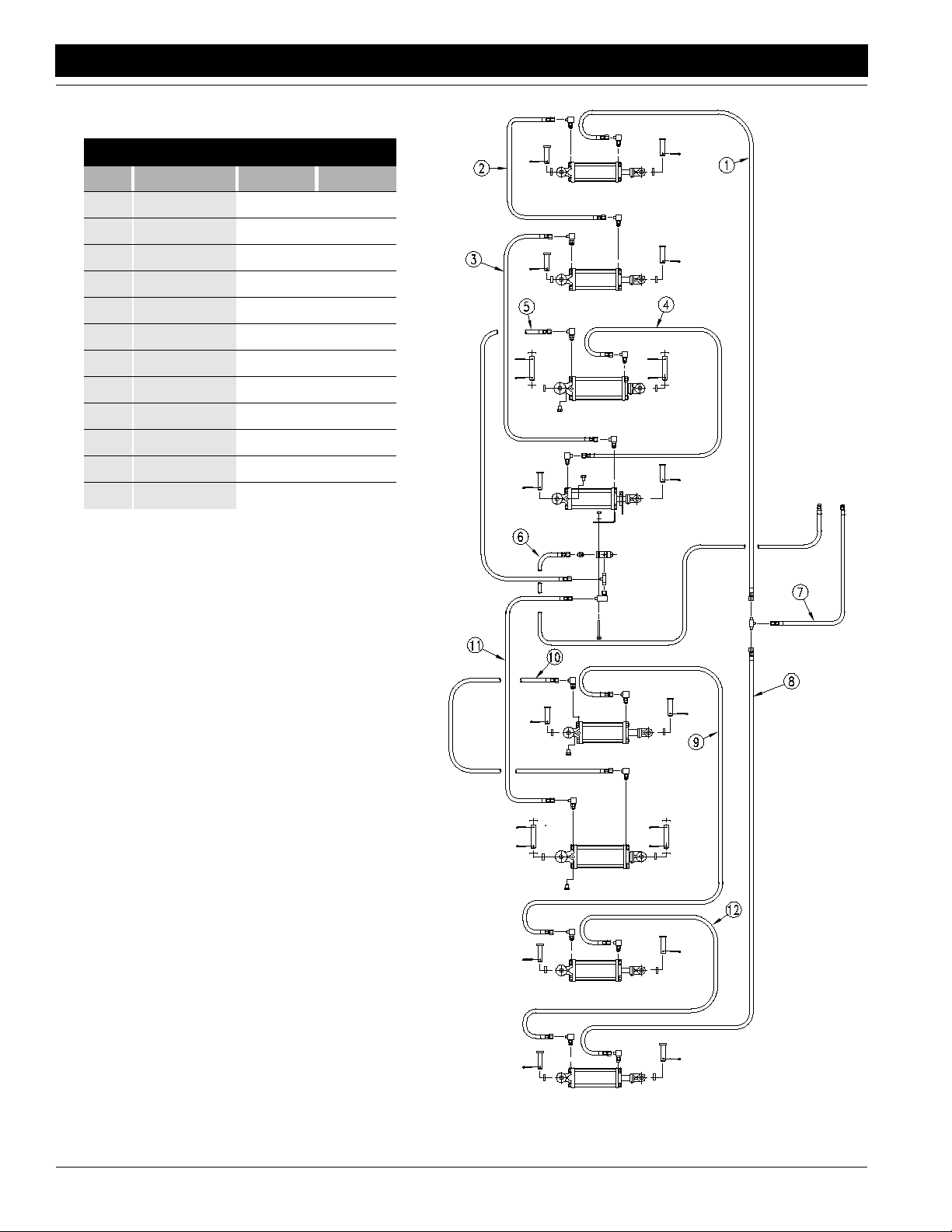

45-Foot Lifting Hydraulics

Hydraulic Hose Sizes

Item Part Number I.D. Length

1 811-124C 3/8 268

2 811-125C 3/8 82

3 811-310C 3/8 198

4 811-245C 3/8 74

5 811-245C 3/8 74

6 811-236C 3/8 84

7 811-123C 3/8 51

8 811-124C 3/8 268

9 811-311C 3/8 242

10 811-127C 3/8 111

11 811-127C 3/8 111

12 811-125C 3/8 82

Great Plains Mfg., Inc.

Figure 1-4

34-Foot Lifting Hydraulics

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

6

14465

Page 9

Great Plains Mfg., Inc.

Section 1 Assembly

Figure 1-7

34-Foot Folding Hydraulics

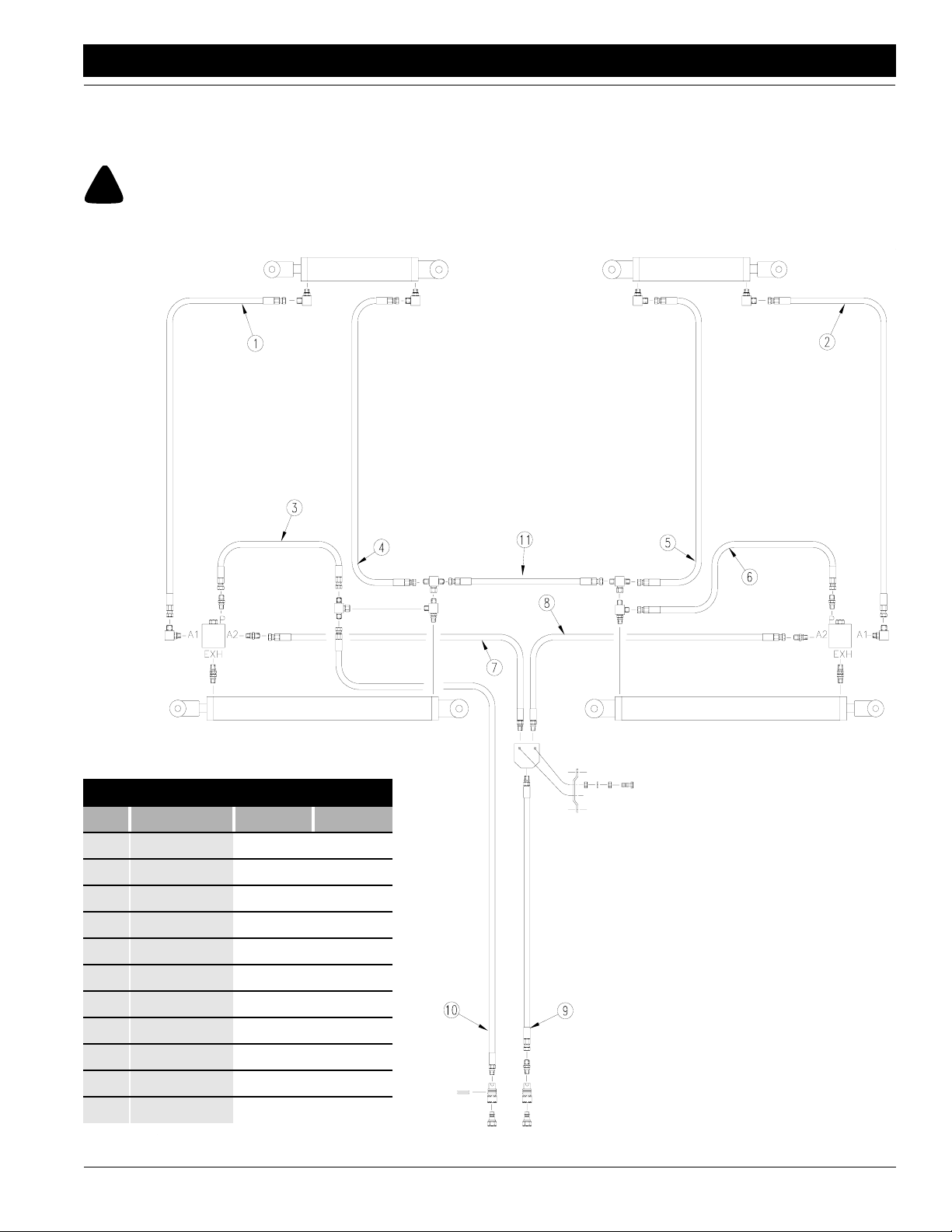

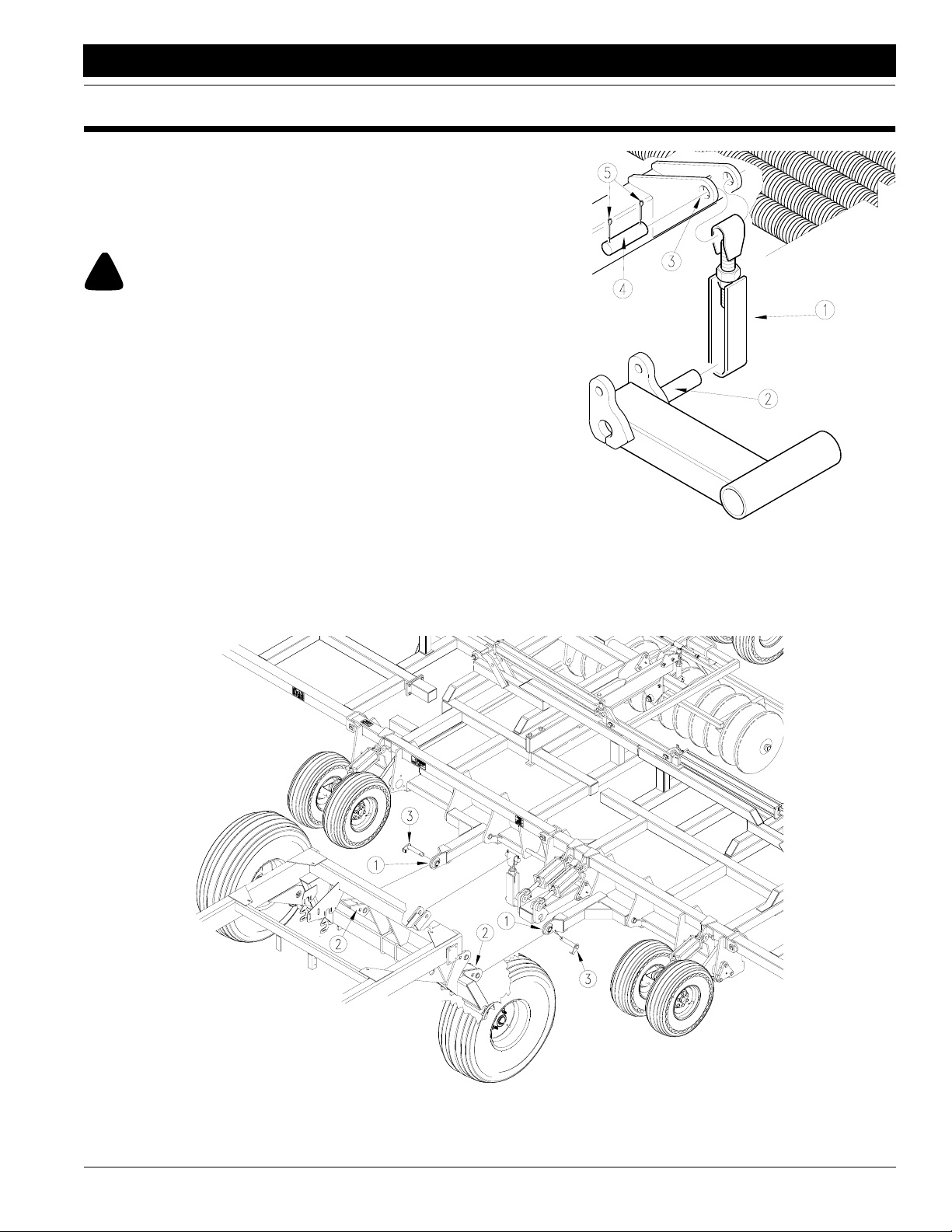

Fold Cylinders

!

DANGER!

The folding cylinders must be bled free of air befor e attempting

to fold implement. Otherwise severe damage and bodily injury

may result.

Position f old cylinders with base end to w ard center of the

drill and the rod end toward wings. Pin the base end to the

fold cylinder lug. Secure the pin with the provided clip .

Leave rod end unhooked until after air is b led from fold cir -

45-Foot Folding Hydraulics

Hydraulic Hose Sizes

Item Part Number I.D. Length

1 811-095C 3/8 158

2 811-095C 3/8 158

3 811-118C 3/8 41

4 811-094C 3/8 176

5 811-094C 3/8 176

6 811-118C 3/8 41

7 811-096C 3/8 108

8 811-096C 3/8 108

9 811-117C 3/8 90

10 811-096C 3/8 108

11 811-093C 3/8 47

4/7/04

Figure 1-5

45-Foot Lifting Hydraulics

14478

Models ADI334 and ADI345 Air Drill Implement 160-243M

7

Page 10

Section 1 Assembly

Great Plains Mfg., Inc.

cuit.

Install hydraulic hoses. Ref er to Figure 1-6 or Figure 1-7.

Note the hose lengths and be sure to use the correct length

hose in each location. Start with the longest hose and work

to the shortest.

When installing, route hoses through the hose clips on the

openers. See Figure 1-3. Be sure hoses are not twisted

and will not get pinched when the implement is raised, lowered, folded or unfolded. Do not let the hoses rub on sharp

edges, and be sure there is enough slack for do wn-flex.

NOTE: The SAE O-ring and JIC 37˚ flare-type hose connections do not require sealant for reconnecting. They do

34-Foot Folding Hydraulics

Hydraulic Hose Sizes

Item Part Number I.D. Length

1 811-240C 3/8 75

2 811-240C 3/8 75

3 811-241C 3/8 21

4 811-241C 3/8 21

5 811-239C 3/8 75

Figure 1-6

45-Foot Folding Hydraulics

14479

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

8

6 811-239C 3/8 75

Page 11

Great Plains Mfg., Inc.

Section 2 Setup

Section 2 Setup

This section covers dealer requirements f or implement

setup, including hitching the cart to the implement, bleeding air from the hydraulics, leveling the frame, and installing seed towers and hoses.

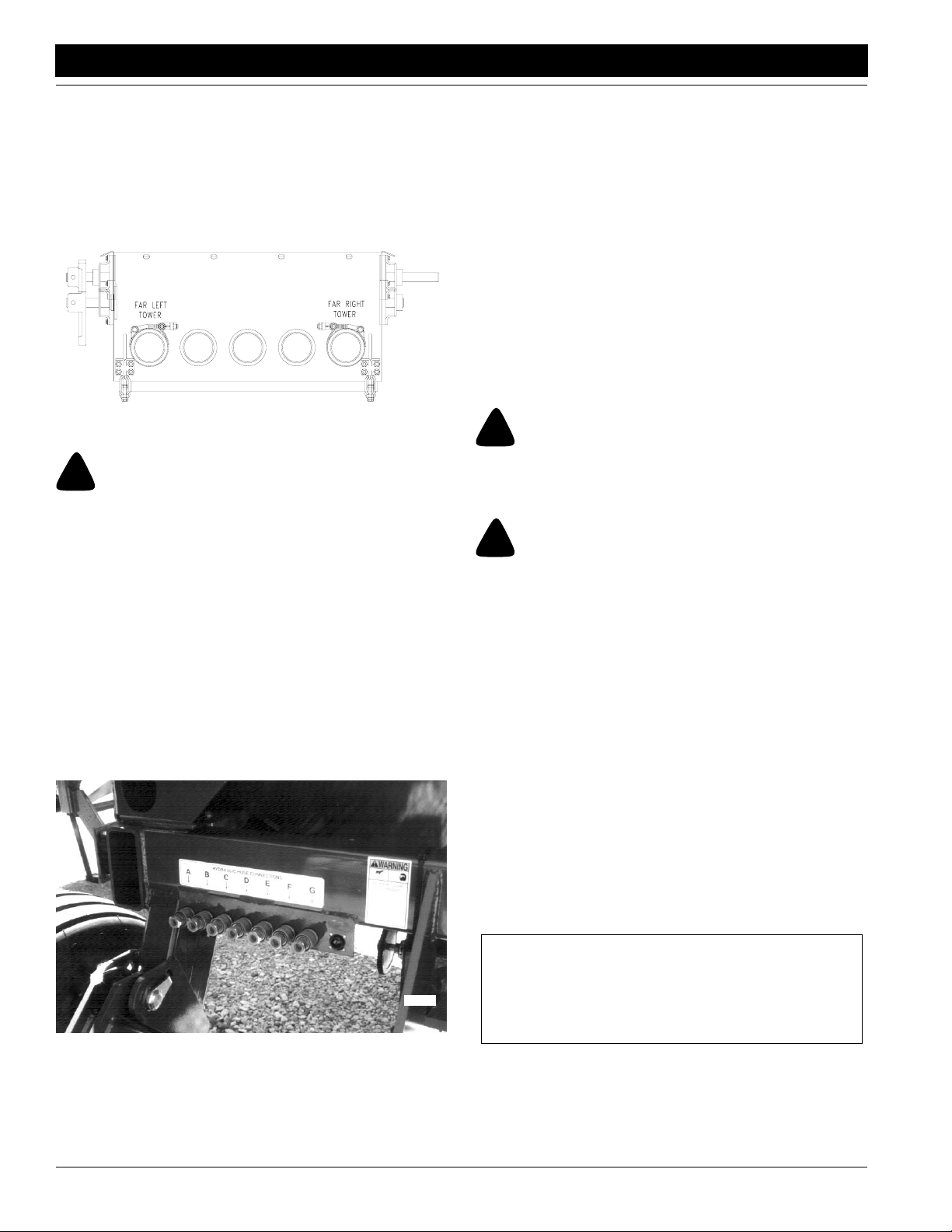

Hitching Cart to Implement

!

DANGER!

Y ou may be se ver ely injur ed or killed by being crushed between

the cart and the implement. Do not stand or place any part of

your body between the cart and implement while hooking up the

air drill.

Refer to Figure 2-1.

1. With cart links tied up, slowly back cart toward the

center of the implement.

2. When cart links (1) are aligned with the lower hitch

plates on the cart (2), drive link pins (3) in place. Secure with roll pins.

Refer to Figure 2-2.

3. Make sure the cart sling (1) is connected to the cylinder lift arm (2), then align the top hole with the support

plates (3) on the back of the cart frame.

4. Install the cart sling pin (4) and secure it with the 1/4 x

2-inch cotter pins (5). Be sure cotter pins are spread.

14461

Figure 2-2

Hose Routing and Sling Installation

5. Connect the primary seed hoses to the cart meter

box. Connect the hoses left-to-right in the same order

4/7/04

Figure 2-1

Hitching Cart to Implement

Models ADI334 and ADI345 Air Drill Implement 160-243M

16547

9

Page 12

Section 2 Setup

Great Plains Mfg., Inc.

towers are installed on the implement. Route the hoses above the cart-axle tube. Allow only enough slack

for implement to be fully raised and lowered without

binding. Use cable ties to secure hoses in a safe location. Secure hoses to metering-box-outlet tubes using

2 1/2-inch band clamps and tighten securely . Be sure

outer clamps do not interfere with meter-box latches .

Refer to Figure 2-3.

14467

Figure 2-3

Clamp Positioning

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs, see

a doctor immediately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene will result.

Connect hydraulic hoses to rear of cart. Refer to Figure 2-

4. Working from left to right, connect hoses in the following

order.

a. Connect fold hoses to outlets on the far right (out-

lets A and B).

b. Connect lift hoses to the next set of outlets (out-

lets C and D).

NOTE: The SAE O-ring and JIC 37˚ flare-type hose connections do not require sealant for reconnecting. They do

not require high torque for a good seal.

6. Plug the lead from the electrical harness on the implement into the cart.

7. When all connections have been made, carefully

check all lines to make sure none will be damaged

when the implement is operated. Re-route the lines or

use cable ties to keep them in a saf e place . Chec k

warning lights for correct operation.

Bleeding the Lift Hydraulics

The implement lift system is equipped with rephasing hydraulic cylinders that require a special procedure for bleeding air from the circuit. Read and follow the procedure

carefully . The rephasing cylinders will not function properly

with air in the circuit.

!

WARNING!

Y ou may be sever ely injur ed or killed by being crushed by a falling implement. Always have the frame sufficiently blocked up

when working on implement.

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs, see

a doctor immediately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene will result.

1. Check the hydraulic fluid level in the tractor reservoir

and fill to the proper level. Add fluid to the system as

needed while cycling new cylinders. About 5 gallons

of oil will be used to fill new cylinders. A low oil le vel

may draw air into the system, causing jerky or une ven

cylinder movement.

2. Jack up and support the front member of each frame

section at a point close to each gauge wheel.

3. With the frame block ed and supported, unpin the rod

end of the gauge-wheel cylinders. Pivot the cylinders

up. Wire or otherwise safely support the rod-end port

higher than the base-end port.

IMPORTANT: The cylinders located directly behind

the cart will not pivot upward for bleeding. Unpin and

17189

Figure 2-4

Hydraulic Hose Connections

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

10

remove these cylinders from the implement, then

support rod-end port higher than the base-end port.

Refer to Figure 2-5.

Page 13

Great Plains Mfg., Inc.

Section 2 Setup

14447

Center Hydraulic Cylinders

2. Unpin the rod end of the fold cylinders. See Figure 2-

6. Wire or otherwise safely support the cylinders so

when the rod is fully extended it does not contact anything.

Figure 2-5

4. With the tractor engine at an idle speed, engage the

remote lever for the lifting circuit. When the outside

cylinders on both sides of the implement have completely extended, hold the remote lever on for one

minute.

5. Retract the cylinder rods. Extend the rods again and

hold the remote lever on f or one more minute. Repeat

this step two more times to completely bleed the system.

6. Repin cylinders.

7. Recheck the tractor reservoir and fill to the proper level.

Bleeding the Folding Hydraulics

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs, see

a doctor immediately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene will result.

1. Check the hydraulic fluid in the tr actor reservoir and fill

to the proper level. Add fluid to the system as needed.

A low oil lev el may draw air bac k into the system, causing jerky or uneven cylinder movement.

14446

Figure 2-6

Bleeding Fold Cylinders

3. Cycle the cylinders completely in and out at least

three times to purge the air from the fold system.

NOTE: On the 45-f oot implement, if the fold cylinders on

one side of the drill will not move after the other side has

completely extended or retracted, release the remote lever momentarily, reverse the lev er, then try again.

4. Fully extend the cylinders and repin the rod ends.

!

CAUTION!

Do not fold implement unless gauge-wheel transport locks are

installed.

5. Repin cylinders.

6. Recheck the tractor reservoir and fill to the proper level.

4/7/04

Models ADI334 and ADI345 Air Drill Implement 160-243M

11

Page 14

Section 2 Setup

Leveling Frame Side-to-Side

45-Foot Drill

Since the dual gauge wheels on frame sections three and

four are not adjustable, mak e all adjustments with these as a

reference.

!

WARNING!

You may be severely injured or killed by being crushed from a

falling implement. Always have the frame sufficiently blocked

up when working on implement.

1. Check that the lift circuit is free of air and full of oil. Refer to Bleeding the Hydraulics, page 10.

2. Hydraulically lower the entire implement frame. Fully

retract all gauge-wheel cylinders. Block up or otherwise

safely support the implement frame.

3. T ak e a ref erence measurement off one dual gaugewheel as show in Figure 2-7. Lay a straight edge

across at least two tubes of frame section three or

four . Extend the str aight edge out o ver the axle. Measure the distance from the bottom of the straight edge

to the center of the dual gauge-wheel axle.

Great Plains Mfg., Inc.

16566

Figure 2-8

Eye-Bolt Adjustment, Non-Castored Gauge Wheel

7. Move the straight edge so it lies over the castored

gauge-wheel axle. Adjust the eye bolt at the base of

the cylinder (see Figure 2-9) until the center of the axle

is about 1/2-inch higher than the reference measurement. Secure eye-bolt by tightening the jam n uts .

14575

Figure 2-7

Reference Measurement

4. Move the straight edge out to the first frame section.

Lay the straight edge across at least two frame tubes .

Extend the straight edge over the non-castored,

gauge-wheel axle. Measure the distance from the bottom of the straight edge to the center of the axle. If the

dimension is the same as the reference measurement, no adjustment is necessary . Proceed to step 7.

5. If the wing measurement differs from the reference

measurement, unpin the gauge-wheel arm. Position

and support the arm to match the reference measurement.

6. Swing the cylinder down and adjust the eye-bolt until

the pin holes line up. Secure the ey e bolt with the jam

nut and repin the cylinder to the gauge-wheel arm.

See Figure 2-8.

Figure 2-9

Eye-Bolt Adjustment, Castored Gauge Wheel

8. Repeat steps 5, 6 and 7 for sixth frame section.

9. Make sure all cylinders are securely pinned.

10. With the drill on level ground, note where the fr ame

sections three and four hinge. If the sections bow at

their hinge point, adjust the cart sling so the center of

the machine is level during field operation. To adjust:

c. Lower the implement until all weight is on the

openers.

d. Unpin the sling from the cart. Loosen the jam nut

shown in Figure 2-10.

• To raise center of frame, turn the threaded link

clockwise.

• To lower the center, turn link counterclockwise.

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

12

Page 15

Great Plains Mfg., Inc.

Section 2 Setup

e. Tighten jam nut and repin sling to cart. Recheck

levelness and re-adjust as necessary.

16569

Figure 2-10

Cart Sling

34-Foot Drill

Since the dual gauge wheels on frame sections three and

four are not adjustable, mak e all adjustments with these as a

reference.

!

WARNING!

Y ou may be sever ely injur ed or killed by being crushed by a falling implement. Always have the frame sufficiently blocked up

when working on implement.

1. Check that the lift circuit is free of air and full of oil. Refer to Bleeding the Hydraulics, page 10.

2. Hydraulically lower the entire implement frame. Fully

retract all gauge-wheel cylinders. Block up or otherwise

support the implement frame.

3. T ak e a ref erence measurement from the top of the implement frame to the center of one dual gauge-wheel

axle as show in Figure 2-7, page 12. Lay a straight

edge across at least two tubes of frame section three

or four . Extend the str aight edge out o ver the axle.

Measure the distance from the bottom of the straight

edge to the center of the axle.

4. Move the straight edge out to the first frame section.

Lay the straight edge across at least two frame tubes .

Extend the straight edge out over the non-castored,

gauge-wheel axle. Measure the distance from the bottom of the straight edge to the center of the axle. If the

dimension is the same as the reference measurement, no adjustment is necessary . Proceed to step 7.

5. If the wing measurement differs from the reference

measurement, unpin the gauge-wheel arm. Position

and support the arm to match the reference measurement.

6. Swing the cylinder down and adjust the eye-bolt (Figure 2-8) until the pin holes line up. Secure the ey e bolt

with the jam nut and repin the cylinder to the gaugewheel arm.

7. Repeat steps 5 and 6 for implement section four.

8. Make sure that all cylinders are securely pinned.

9. With the drill on level ground, note where the frame

sections three and four hinge. If the sections bow at

their hinge point, adjust the cart sling so the center of

the machine is level during field operation. To adjust:

a. Lower the implement until all weight is resting on

the openers.

b. Unpin the sling from the cart.

c. Loosen the jam nut shown in Figure 2-10, page

13.

• To raise the center of the frame, turn the thread-

ed link clockwise.

• To lower the center, turn the threaded link coun-

terclockwise.

d. When satisfied with adjustment, tighten jam nut

and repin sling to cart. Recheck levelness and re-

adjust as necessary .

4/7/04

Models ADI334 and ADI345 Air Drill Implement 160-243M

13

Page 16

Section 2 Setup

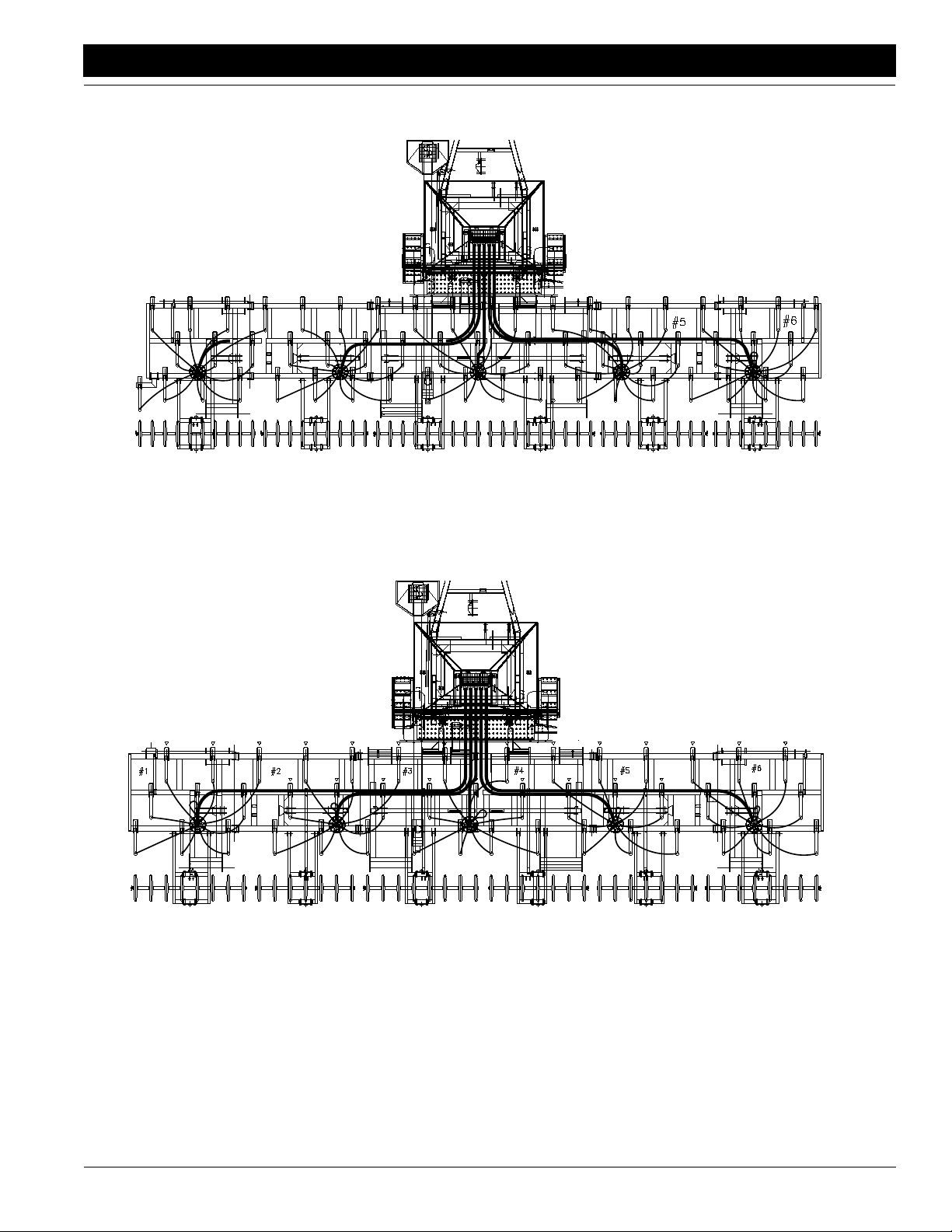

Distribution Towers and Hoses

1. Refer to Figure 2-13 for to w er mounting locations .

Mount towers so there is no interference when wings

are folded or unfolded.

2. Refer to Figure 2-11. Install a tower support bracket at

each location using the 1/2-inch u-bolts (1), lock

washers (2) and nuts (3).

Great Plains Mfg., Inc.

14546

Mounting Tower Brackets

Figure 2-11

3. Refer to Figure 2-12. P osition a tower on bracket so

the lower round plate is about 31 1/2-inches above the

frame rails. Turn tower so that inlet tube is pointed toward the center of the drill. Secure tower with two ubolts.

IMPORTANT: Mount towers as v ertically as possible.

Installing towers so that they lean to one side may

cause uneven distribution, especially on hillsides.

14499

Figure 2-12

Inlet Tube Alignment

4. When towers hav e been installed, fold implement very

slowly while watching to be sure there is no interference. If towers hav e any interference, unf old wing then

move towers until they clear.

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

14

Page 17

Great Plains Mfg., Inc.

Section 2 Setup

4/7/04

45-Foot Drill

Figure 2-13

Tower Mounting Locations

Models ADI334 and ADI345 Air Drill Implement 160-243M

34-Foot Drill

14486

15

Page 18

Section 2 Setup

Primary Distribution Hoses

1. Start with the third, or center tower. Route hose as

shown in Figure 2-16 and Figure 2-17. Slide clamp

over end of hose, then slide hose at least two inches

onto tower inlet.

2. Allow enough hose so that implement raising, lowering, folding and unfolding will not pinch or bind hose .

3. Using a hacksaw, cut hose so that it will slide onto

meter outlets up to end of flare.

4. Slide clamp over hose end, then slide hose onto meter

outlet. Install clamp so that it will not interfere with other hoses, clamps or meter-door latches. Figure 2-14.

Great Plains Mfg., Inc.

14467

Figure 2-14

Clamp Positioning

5. Repeat this procedure on towers two and four. Cut

these two the same length but longer than the center

hose.

6. Repeat the same procedures for towers one and fiv e.

These two hoses should also be the same length, but

longer than the others.

7. Secure all hoses to the frame using 24-inch cable ties.

Make sure hoses will not be damaged during drill operation.

Secondary Hoses

Secondary seed hose is one inch in diameter and comes

in 100-foot rolls. Cut secondary hoses to connect each

opener to a distribution tower . Refer to the appropriate

hose routing illustration for the correct hose routings.

IMPORTANT: Do not cut hose until routed ov er implement.

See Figure 2-15.

1. Start with tower 1 (far left tower). Loosen but do not remove bolts holding tower halves together.

Figure 2-15

Tower Assembly

2. Insert hose into port. Push hose into port until seated

against the stop.

3. Keeping your implement ro w spacing in mind, refer toFigure 2-16 or Figure 2-17 to find which opener to connect the hose.

!

T o avoid serious injury or death fr om crushing, make sur e transport locks are in place, the drill is sufficiently blocked up, and

the tractor is shut off with the ke y r emoved befor e attempting to

route hoses to openers.

4. Route hose over implement frame as shown in Figure

5. When you are satisfied you have the proper hose

DANGER!

2-16 or Figure 2-17. Route hoses to prevent rubbing

on sharp edges or damage when the implement is

raised, lowered, folded or unfolded. Allow enough

hose slack for implement f olding and down-flex.

length, cut hose.

14449

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

16

Page 19

Great Plains Mfg., Inc.

Section 2 Setup

34-Foot Drill, 7-Inch Row Spacing

34-Foot Drill, 10-Inch Row Spacing

14542

14533

4/7/04

Figure 2-16

Seed Hose Routings

Models ADI334 and ADI345 Air Drill Implement 160-243M

17

Page 20

Section 2 Setup

Great Plains Mfg., Inc.

34-Foot Drill, 12-Inch Row Spacing

14534

45-Foot Drill, 7-Inch Row Spacing

Figure 2-17

Seed Hose Routings (con’t.)

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

18

14543

Page 21

Great Plains Mfg., Inc.

Section 2 Setup

14535

45-Foot Drill, 10-Inch Row Spacing

4/7/04

45-Foot Drill, 12-Inch Row Spacing

Figure 2-17

Seed Hose Routings (con’t.)

Models ADI334 and ADI345 Air Drill Implement 160-243M

14536

19

Page 22

Section 2 Setup

Great Plains Mfg., Inc.

Refer to Figure 2-18:

8. Attach the end of the hose to opener.

Slide clamp over the end of the hose six inches. Put

the end of the hose in the seed tube six inches. Hook

the clamp ends in the holes at the top of the seed tube.

9. Repeat steps 1 through 8 for all one-inch hoses on each

tower .

10. When all hoses are installed on a tower, tighten the

bolts holding the halves together .

IMPORTANT: The tower bolts are equipped with nylock nuts and should not be over-tightened. Tighten

the bolts only until the hose is held securely against

being blown out.

11. Check all hoses to be sure that they are not rubbing on

sharp edges and will not be damaged when the drill is

raised, lowered, folded or unfolded. Re-route if needed to prevent damage .

14563

Figure 2-18

Hose Installation On Openers

Models ADI334 and ADI345 Air Drill Implement 160-243M 4/7/04

20

Page 23

Great Plains Mfg., Inc.

Appendix

Appendix

Torque Values Chart for Common Bolt Sizes

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 4 3 6 5 9 7

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch

Grade 8

Bolt Size

(Metric)

4

N · m ft-lb N · m ft-lb N · m ft-lb

1

in-tpi = nominal thread dia.in inches-threads per inch

2

N· m = newton-meters

3

ft-lb= foot pounds

4

mm x pitch = nominal thread dia. in millimeters x thread pitch

Bolt Head Identification

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

Tire Inflation Chart

Tire Size Inflation PSI Tire Size Inflation PSI

7.50 x 20" 4-Ply Drill Rib 28 11L x 15" 6-Ply Rib Implement 28

9.0 x 22.5 10-Ply Highway Service 70 70 11L x 15" 12-Ply Rib Implement 52

9.0 x 24" 8-Ply Rib Implement 40 12.5L x 15" 8-Ply Rib Implement 36

9.5L x 15" 6-Ply Rib Implement 32 12.5L x 15" 10-Ply Rib Implement 44

9.5L x 15" 8-Ply Rib Implement 44 16.5L x 16.1" 10-Ply Rib Implement 36

9.5L x 15" 12-Ply Rib Implement 60 41 x 15" x 18 - 22-Ply Rib Implement 44

4/7/04

Models ADI334 and ADI345 Air Drill Implement 160-243M

21

Page 24

Great Plains Manufacturing, Inc.

Corporate Office: PO. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...