Page 1

Great Plains Mfg., Inc.

Installation Instructions 1

Auger Carrier Update

ADC2350 Air Carts

Used with:

• ADC2350B

General Information

These instructions explain how to install an Auger Carrier

Update on a pre-2009 “pull-behind” air cart. This update

improves clearance between the auger and air drill in

some configurations. It also provides a new auger pivot

mount that eases any future major auger maintenance.

These instructions apply to an installation of:

Kit Kit Description

166-247A

One kit updates one air cart.

Cart Model Kit Compatibility

ADC2350B

ADC2350 Not compatible and not required.

ADC2350B AUGER CARRIER UPDATE

serial number A1159T or lower, which

includes all manufactured in 2008

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

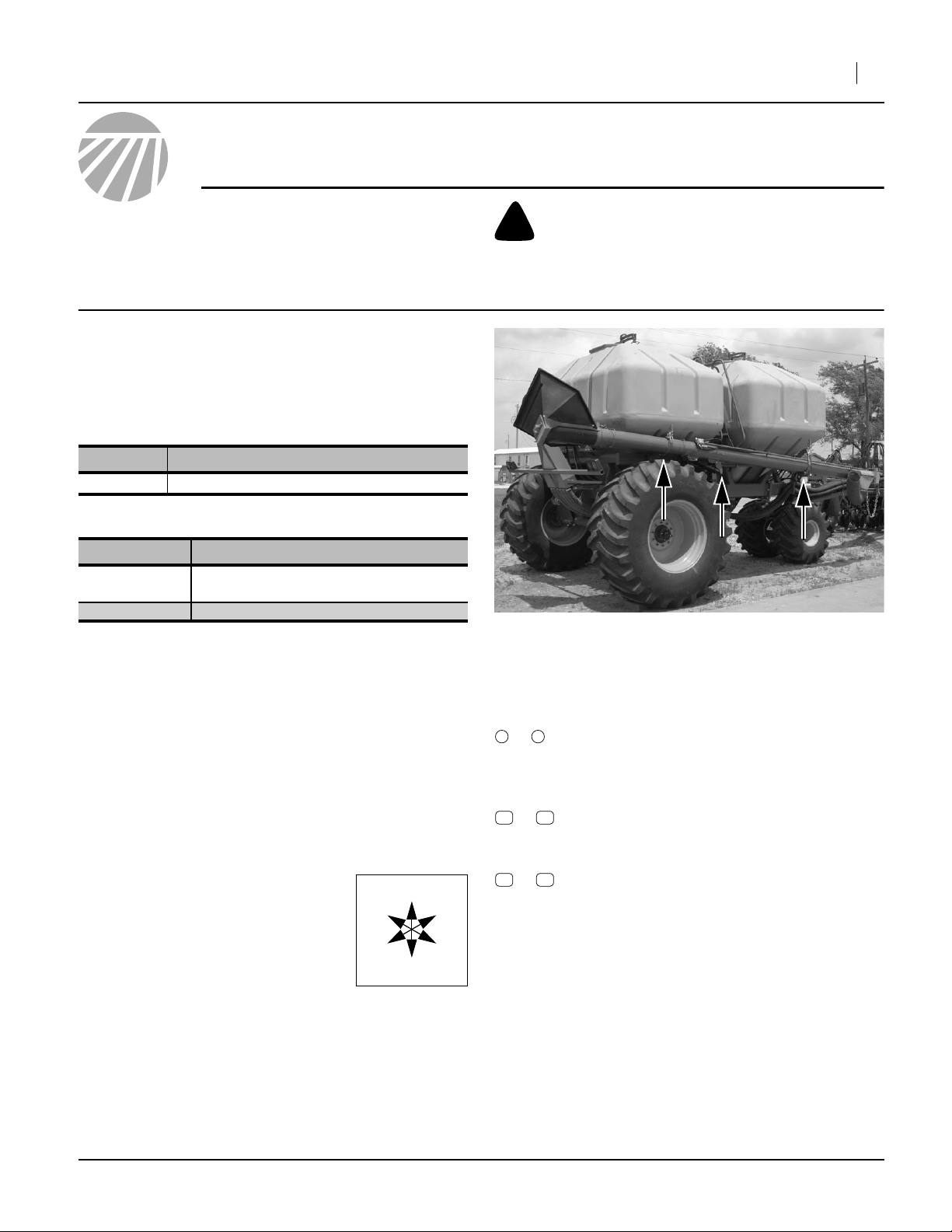

Figure 1

Auger Update Sites

29370

Related Documents

Have the Operator Manual at hand for cart and drill

movements.

167-085M Operator, ADC2350B cart

196-444M Operator, 3N-4010HDA implement

Have the current Parts Manual at hand for parts ID.

167-085P ADC2350B

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

U

F

L

D

R

B

Call-Outs

1 9

to

11 39

to

51 63

to

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts in the range 11 to 39 reference new parts from the new parts lists

beginning on page 8.

Two-digit callouts in the range 51 to 63 reference affected existing parts from the table on

page 10. The descriptions match those in

your Parts Manual. The narrative and table

indicate any re-use of the parts.

©Copyright 2009 Printed 03/05/2009 166-255M

Page 2

2 Auger Carrier Update

Before You Start

Compatibility

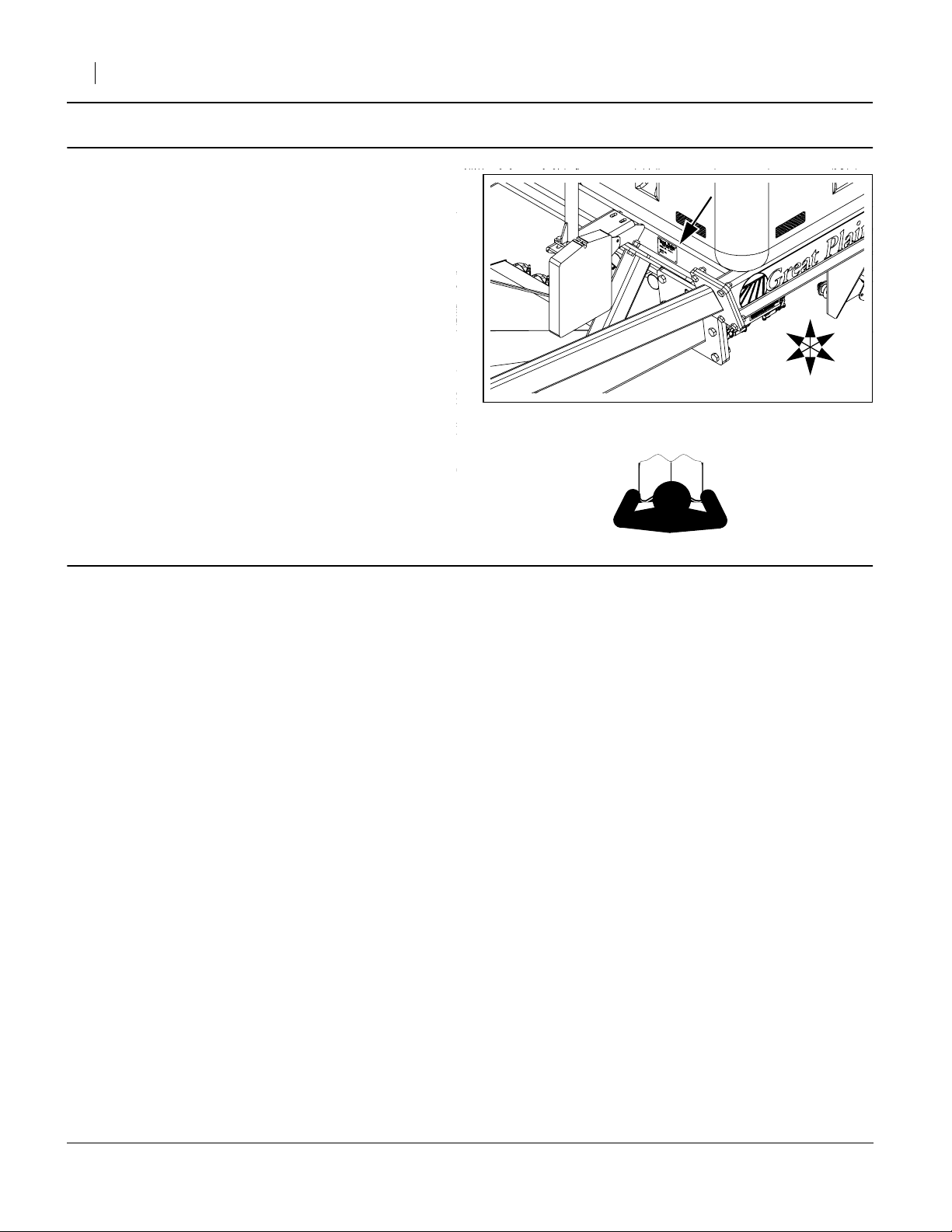

Refer to Figure 2

Check the cart serial number plate against the table on

page 1. Verify that

the model is ADC2350B, and

the serial number is A1159T or lower.

Great Plains Mfg., Inc.

Inventory

1. Make sure all parts are present.

Comprehension

2. Review these instructions. Make sure the installers

understand where each part or assembly is

installed, and what tools are required for the task.

Note: Illustrations in this manual, based on the parts

manuals for this family of drills, may show

exploded views that are fully disassembled. Rely

on the instructions for required disassembly and

reassembly steps.

Pre-Assembly Preparation

Tools Required

• hoist with 300 pounds (150 kg) capacity at a height of

ten feet (3m), for supporting the dismounted auger

• updated cart Parts Manual (see page 1)

• basic hand tools, including:

9

⁄

in / K / 7.2mm punch or drill.

32

Work Location

3. Clear the auger of any residual seed or fertilizer.

4. Move the air cart to a location with:

• adequate illumination,

• hoist access, and;

• a means of obtaining lower than normal depres-

sion of the inlet end of the auger (about

18in (46cm) below normal ground level), to

relieve as much tension as possible from the

auger balance springs; for example:

- a dock, with auger off right edge,

- a solid platform or blocks under right main tire,

- jack and supports for right side of frame.

Note: If the depression cannot be accomplished at the

hoist location, disconnect the springs (step 23 and

24), then move the cart to the hoist site.

Note: Once the old springs are disconnected, auger end

depression is no longer required. The new spring

anchor engages at zero spring extension.

R

F

Figure 2

ADC2350B Serial Number Plate

U

B

L

D

26428

166-255M 03/05/2009

Page 3

Great Plains Mfg., Inc.

Pre-Assemble Components

Assemble New Auger Carrier Latches

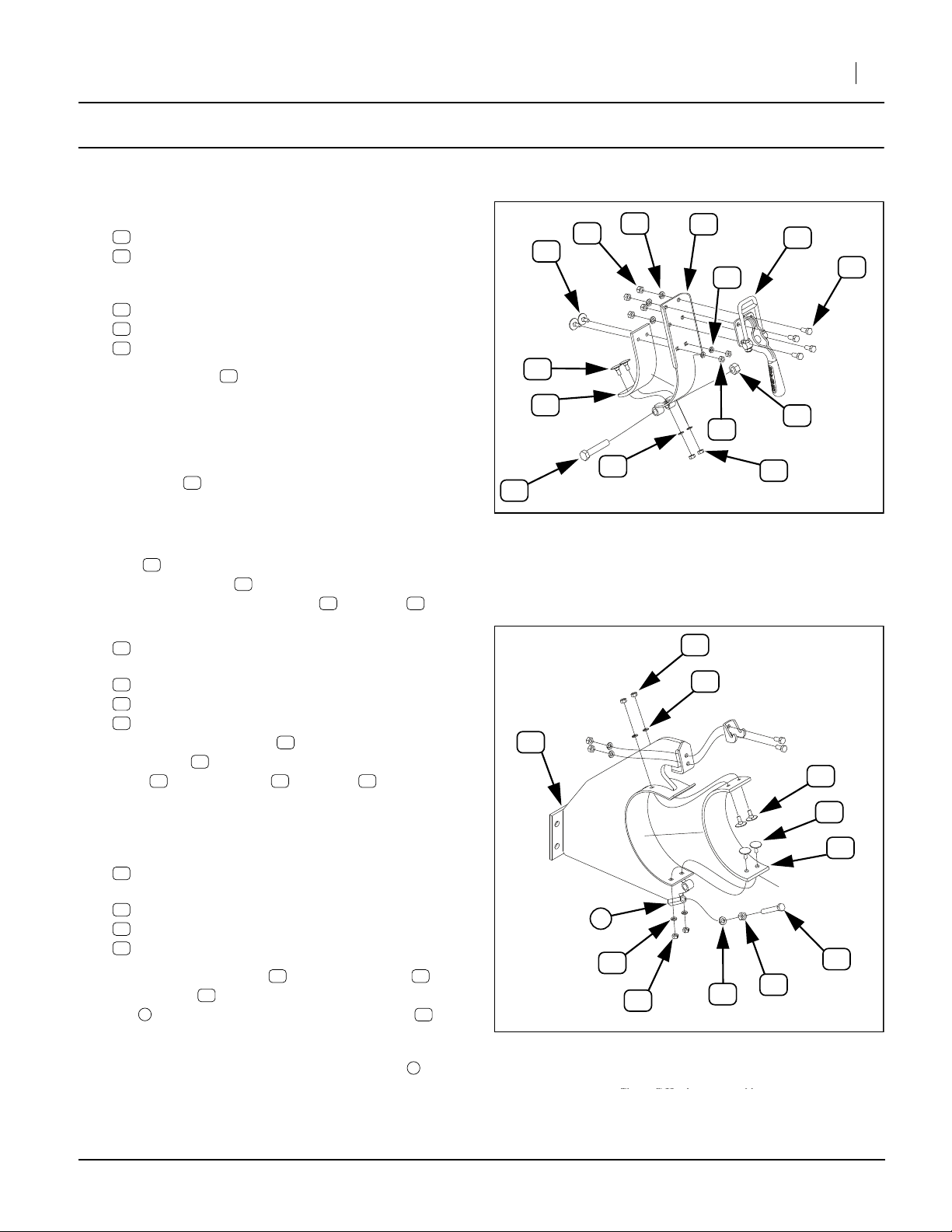

Refer to Figure 3

5. Select two (2) each new:

13

166-188H AUGER TRANS LATCH PULL BEHIND

39

816-570C 8 INCH AUGER CLAMP PAD

(this is the shorter of the two sizes of EPDM pads)

and eight (8) sets new:

25

802-888C ELEVATOR BOLT 1/4-20X3/4 PLT:

32

804-006C WASHER LOCK SPRING 1/4 PLT

26

803-006C NUT HEX 1/4-20 PLT

6. The clamp pad may have two, four or no holes,

and may or may not have adhesive on one side,

protected by release paper. If four holes are not

present, it is necessary to assembly-drill them.

39

25

25

39

27

33

Installation Instructions 3

13

17

32

18

29

26

Position the pad so that it is centered in the latch

weldment . Mark holes for fractional size

(letter size K, 7.2mm). Remove pad and punch or

drill holes.

7. Remove any release paper. Position a clamp

pad , adhesive side to inside of latch face. Insert

the elevator bolts through the inside of the pad

and secure with lock washers and nuts

8. Select the latch side of two (2) each new:

17

800-285C AUGER LATCH CLAMP

and eight (8) sets new:

18

802-007C HHCS 5/16-18X3/4 GR5

33

804-009C WASHER LOCK SPRING 5/16 PLT

27

803-008C NUT HEX 5/16-18 PLT

Mount the latch clamps at the top of the latch

weldments , inside the double break, using the

bolts , lock washers and nuts

13

39

25

32 26

17

13

18 33 27

9

⁄

in

32

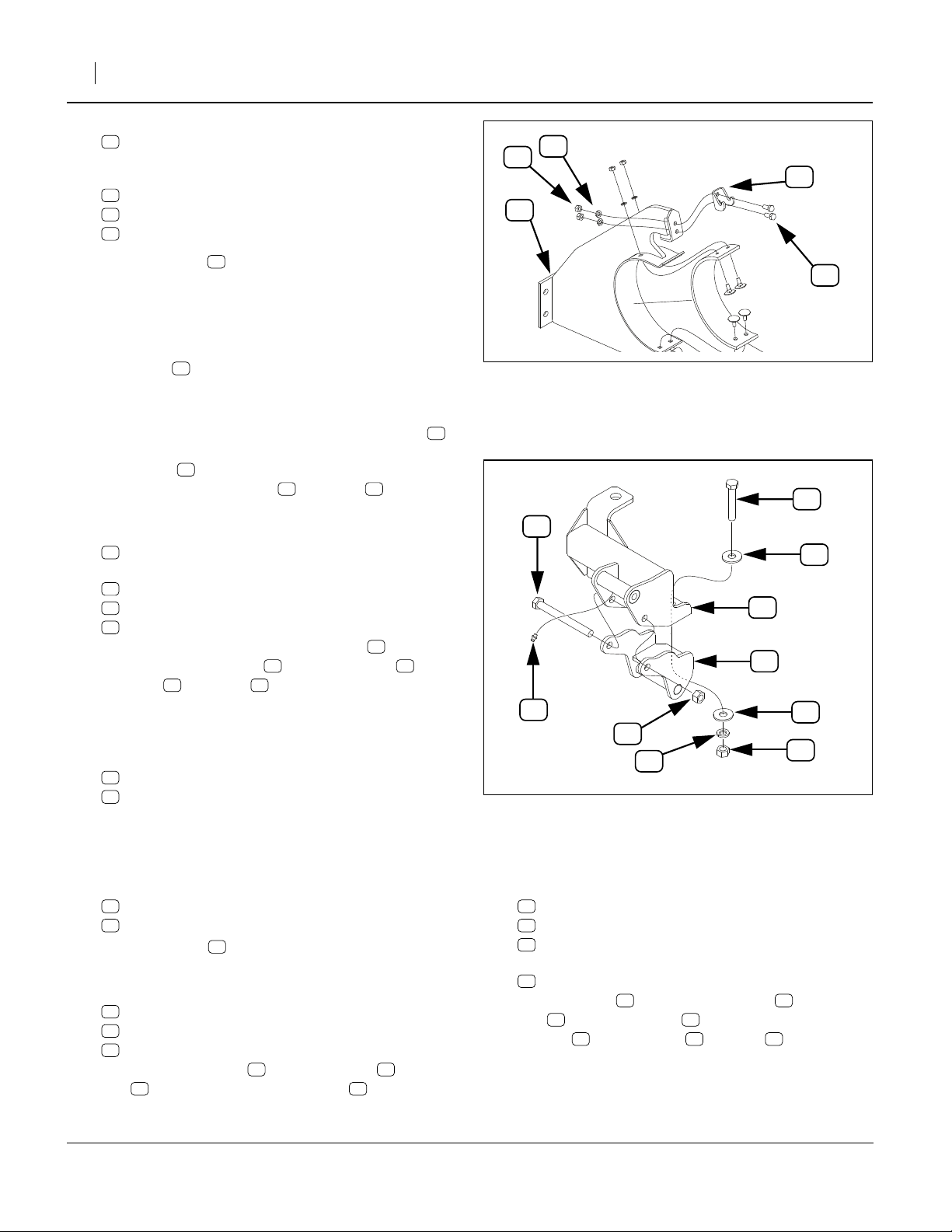

Assemble New Auger Carrier Rests

Refer to Figure 4

9. Select two new:

12

166-187H AUGER CARRIER PULL BEHIND

and one each new:

21

802-114C HHCS 3/8-16X2 1/2 GR5

28

803-014C NUT HEX 3/8-16 PLT

34

804-013C WASHER LOCK SPRING 3/8 PLT.

10. Loosely thread the nut fully onto the bolt , add

lock washer , and loosely thread fully into coupler

112

nut at the bottom of the carrier weldment .

34

28 21

22

12

1

32

32

Figure 3

Auger Latch

26

26

32

34

26

29373

25

25

38

21

28

This carrier is designated the rear carrier, and is the

only one with a stop bolt in the coupler nut .

03/05/2009 166-255M

1

Figure 4

(Rear) Auger Carrier

29373

Page 4

4 Auger Carrier Update

11. Select two (2) each new:

38

816-562C 8 INCH AUGER REST PAD

(this is the longer of the two sizes of EPDM pads)

and eight (8) sets new:

25

802-888C ELEVATOR BOLT 1/4-20X3/4 PLT:

32

804-006C WASHER LOCK SPRING 1/4 PLT

26

803-006C NUT HEX 1/4-20 PLT

27

12

Great Plains Mfg., Inc.

33

17

12. The clamp pad may have no holes (or two holes,

38

or four), and may or may not have adhesive on one

side, protected by release paper. If four holes are

not present, it is necessary to assembly-drill them.

Position the pad so that it is centered in the latch

weldment . Mark holes for fractional size

13

9

⁄

in

32

(letter size K, 7.2mm). Remove pad and punch or

drill holes.

13. Remove any release paper. Position a rest pad ,

38

adhesive side to inside of latch face. Insert the elevator bolts through the inside of the pad and

secure with lock washers and nuts .

25

32 26

Refer to Figure 5

14. Select the hook side of two (2) each new:

17

800-285C AUGER LATCH CLAMP

and four (4) sets new:

18

802-007C HHCS 5/16-18X3/4 GR5

33

804-009C WASHER LOCK SPRING 5/16 PLT

27

803-008C NUT HEX 5/16-18 PLT

Mount the hook side of the latch clamp at the top

of the carrier weldment , using the bolts , lock

washers and nuts .

33 27

12 18

17

Assemble New Auger Carriers

Refer to Figure 4 on page 3 and Figure 3

15. Select two (2) sets new:

22

802-130C HHCS 1/2-13X2 1/2 GR5

29

803-019C NUT LOCK 1/2-13 PLT

Mount latch assemblies at the bottom of carriers.

Assemble New Pivot Mount

Refer to Figure 6

16. Select one each new:

15

166-190H 20’ AUGER PIVOT MOUNT WELDMENT

16

800-001C GREASE ZERK STRAIGHT 1/4-28

Screw the zerk into the

16

the mount cross-tube.

17. Select one each new:

14

166-189H AUGER BALANCE SPRING ANCHOR

20

802-045C HHCS 1/2-13X5 GR5

29

803-019C NUT LOCK 1/2-13 PLT

Mount spring anchor on pivot mount with

20 29

bolt . Do not fully tighten lock nut .

1

⁄

-28 threaded hole of

4

14 15

Figure 5

Auger Carrier Latch Hook

20

15

14

16

29

35

Figure 6

Assemble Pivot Mount

18. Select one each new:

23

802-412C HHCS 1/2-13X2 3/4 FTHD

35

804-015C WASHER LOCK SPRING 1/2 PLT

30

803-020C NUT HEX 1/2-13 PLT

and two:

37

804-113C WASHER FLAT 1/2 USS HARD PLT

Swing anchor up into pivot mount . Insert

23 37

bolt with flat washer . Add second flat

washer , lock washer and nut . Thread nut

on just a few turns. Do not fully seat nut at this time.

14 15

37 35 30

30

18

29373

23

37

37

29372

166-255M 03/05/2009

Page 5

Great Plains Mfg., Inc.

Remove Old Parts

19. Unlatch the auger, and swing it out as if loading the

forward hopper.

Remove Old Carriers

Refer to Figure 7

20. At each existing carrier, remove two (2) sets each,

or four (4) sets total:

55

802-034C HHCS 1/2-13X1 1/4 GR5

62

804-015C WASHER LOCK SPRING 1/2 PLT

59

803-020C NUT HEX 1/2-13 PLT

These fasteners are not re-used.

21. Remove one each:

53

166-179H

54

166-180H AUGER REAR CARRIER PULL BEHIND

These assemblies are not re-used.

AUGER FRNT CARRIER PULL BEHIND

59

55

Installation Instructions 5

62

54

3

2

22. Support auger with hoist. Loops at lower handles

and between the outlet spout and motor housing ,

can safely support the auger without slipping.

3

Disconnect Balance Springs

Refer to Figure 8

23. Take steps to permit depressing the auger inlet end

below normal ground level, to fully relieve tension in

the counterbalance springs .

24. Lift the springs off the upper pin .

63

807-016C SPRING RESET HOE

Leave springs on auger for re-use.

63

4

Dismount Auger

25. Check that the hoist is supporting the auger.

Remove one set:

56

802-045C HHCS 1/2-13X5 GR5

58

803-019C NUT LOCK 1/2-13 PLT

These parts are not re-used.

26. Use hoist to lift auger clear of pivot mount .

51

Remove Old Pivot Mount

Refer to Figure 8 and Figure 12 on page 10

27. Remove one each:

60

803-025C NUT HEX 3/4-10 PLT NYLOCK

57

802-469C HHCS 3/4-10X8 GR5 PLT

61

804-008C WASHER FLAT 3/4 HARD USS

51

166-071H AUGER PIVOT BRACKET WELDMENT

These parts are not re-used.

2

53

Figure 7

Remove Old Carriers

26264

51

56

60

58

63

57

4

Figure 8

Disconnect Springs

29374

03/05/2009 166-255M

Page 6

6 Auger Carrier Update

Install New Parts

Install New Pivot Mount

Refer to Figure 9

28. Select one each new:

24

802-469C HHCS 3/4-10X8 GR5 PLT

36

804-093C WASHER FLAT 3/4 HARD ASTMF436

31

803-025C NUT HEX 3/4-10 PLT NYLOCK

15

166-190H

Place the washer on the bolt . Secure the

pivot mount , assembled at step 16, on the outer

52 31

arm using lock nut .

Re-Mount Auger

29. Select one each new:

20

802-045C HHCS 1/2-13X5 GR5

29

803-019C NUT LOCK 1/2-13 PLT

30. Use hoist to align auger pivot lugs with bottom

cross-tube of spring anchor . Secure auger to

anchor with bolt and lock nut .

20’ AUGER PIVOT MOUNT WELDMENT

36 24

15

5

14

20 29

Great Plains Mfg., Inc.

7

15

24

30

52

36

31

35

19

20

14

6

5

29

Figure 9

Install Pivot Mount and Auger

29372

Install New Carriers

31. Select one each new:

6

Rear carrier from step 10 (with stop bolt).

7

Front carrier from page 4 (without stop bolt)

and four sets new:

19

802-034C HHCS 1/2-13X1 1/4 GR5

35

804-015C WASHER LOCK SPRING 1/2 PLT

30

803-020C NUT HEX 1/2-13 PLT

Mount carriers at locations where old carriers were

removed. Open latches.

Re-Connect Balance Springs

Refer to Figure 10

32. Adjust hoist to allow auger to swing to normal loading position (inlet low).

33. Connect top end of springs to lower cross-tube

of new anchor . Tighten bolt and nut fully.

14 23 30

63

Auger Closeout

34. Check range of motion of new auger pivot mount.

35. Adjust rear clamp stop so that latch clamp cannot strike rear tire.

36. Stow auger in new carriers.

37. Adjust new clamps so that handles snap into position, but do not crush auger tube.

21

21

63

Figure 10

Re-Connect Springs

14

23

30

29375

166-255M 03/05/2009

Page 7

Great Plains Mfg., Inc.

Auger Maintenance

Installation Instructions 7

Auger Storage Clamps

50

2 clamps

Type of Lubrication: Spray

Quantity: Coat thoroughly

Auger Swing Arm: Mount Pivot (Pivot)

50

1 zerk each pivot; 1 total

Type of Lubrication: Grease

Quantity: Until Grease emerges

26329

29372

Auger Swing Arm: Mount Pivot (Tilt)

50

1 zerk each pivot; 1 total

Type of Lubrication: Grease

Quantity: Until Grease emerges

29377

03/05/2009 166-255M

Page 8

8 Auger Carrier Update

Appendix

New Parts

Great Plains Mfg., Inc.

36

24

30

35

19

12

32

27

26

33

34

17

28

18

21

38

25

20

15

16

20

31

37

35

25

23

14

30

37

32

52

63

26

13

33

27

39

17

22

29

Figure 11

New Parts

166-255M 03/05/2009

29376

Page 9

Great Plains Mfg., Inc.

Installation Instructions 9

This manual covers the installation of several different

hold-down kits. Parts are listed for each kit separately.

Quantities are units (“ea”).

166-247A Kit Contents

Callout

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

51 63

-

Quantity

in Kit

1 166-255M

2 166-187H

2 166-188H

1 166-189H

1 166-190H

1 800-001C

2 800-285C

12 802-007C

4 802-034C

2 802-045C

1 802-114C

2 802-130C

1 802-412C

1 802-469C

16 802-888C

16 803-006C

16 803-008C

1 803-014C

4 803-019C

5 803-020C

1 803-025C

16 804-006C

12 804-009C

1 804-013C

5 804-015C

1 804-093C

2 804-113C

2 816-562C

2 816-570C

- Existing See next two pages.

Part

Number

MANUAL 2350B AUGER CARRIER UPD

AUGER CARRIER PULL BEHIND

AUGER TRANS LATCH PULL BEHIND

AUGER BALANCE SPRING ANCHOR

20’ AUGER PIVOT MOUNT WELDMENT

GREASE ZERK STRAIGHT 1/4-28

AUGER LATCH CLAMP

HHCS 5/16-18X3/4 GR5

HHCS 1/2-13X1 1/4 GR5

HHCS 1/2-13X5 GR5

HHCS 3/8-16X2 1/2 GR5

HHCS 1/2-13X2 1/2 GR5

HHCS 1/2-13X2 3/4 FTHD

HHCS 3/4-10X8 GR5 PLT

ELEVATOR BOLT 1/4-20X3/4 PLT

NUT HEX 1/4-20 PLT

NUT HEX 5/16-18 PLT

NUT HEX 3/8-16 PLT

NUT LOCK 1/2-13 PLT

NUT HEX 1/2-13 PLT

NUT HEX 3/4-10 PLT NYLOCK

WASHER LOCK SPRING 1/4 PLT

WASHER LOCK SPRING 5/16 PLT

WASHER LOCK SPRING 3/8 PLT

WASHER LOCK SPRING 1/2 PLT

WASHER FLAT 3/4 HARD ASTMF436

WASHER FLAT 1/2 USS HARD PLT

8 INCH AUGER REST PAD

8 INCH AUGER CLAMP PAD

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Part Description

03/05/2009 166-255M

Page 10

10 Auger Carrier Update

Existing Parts Affected

Great Plains Mfg., Inc.

59

62

54

55

57

61

51

56

52

58

60

63

53

Figure 12

Old Parts

166-255M 03/05/2009

26264

Page 11

Great Plains Mfg., Inc.

Installation Instructions 11

The following existing parts are involved in the kit installation. The Disposition column indicates whether the part

is left in place, moved or not re-used.

The part call-out numbers in the list matches all Figures

in the installation instructions. The descriptions match

those in your air cart Parts manual.

Callout Part No. Part Description Part Disposition

51

52

53

54

55

56

57

58

59

60

61

62

63

166-071H

166-169H

166-179H

166-180H

802-034C

802-045C

802-469C

803-019C

803-020C

803-025C

804-008C

804-015C

807-016C

AUGER PIVOT BRACKET WELDMENT Removed. Not re-used.

AUGER PIVOT ARM - OUTSIDE Partially dismantled. Left in place.

AUGER FRNT CARRIER PULL BEHIND Removed. Not re-used.

AUGER REAR CARRIER PULL BEHIND Removed. Not re-used.

HHCS 1/2-13X1 1/4 GR5 Removed. Not re-used.

HHCS 1/2-13X5 GR5 Removed. Not re-used.

HHCS 3/4-10X8 GR5 PLT Removed. Not re-used.

NUT LOCK 1/2-13 PLT Removed. Not re-used.

NUT HEX 1/2-13 PLT Removed. Not re-used.

NUT HEX 3/4-10 PLT NYLOCK Removed. Not re-used.

WASHER FLAT 3/4 HARD USS Removed. Not re-used.

WASHER LOCK SPRING 1/2 PLT Removed. Not re-used.

SPRING RESET HOE Partially dismantled. Left in place.

Abbreviations

ASTM

FTHD

GR5

HEX

HHCS

American Society for Testing and Materials

Full-Threaded

Grade 5

Hexagonal

Hex Head Cap Screw (Bolt)

PLT

UPD

USS

X

Plated

Update

United States Standard (heavy duty)

by

03/05/2009 166-255M

Page 12

12 Auger Carrier Update

Torque Values

Great Plains Mfg., Inc.

Bolt

Size

in-tpi

1

⁄4-20

1

⁄4-28

5

⁄16-18

5

⁄16-24

3

⁄8-16

3

⁄8-24

7

⁄16-14

7

⁄16-20

1

⁄2-13

1

⁄2-20

9

⁄16-12

9

⁄16-18

5

⁄8-11

5

⁄8-18

3

⁄4-10

3

⁄4-16

7

⁄8-9

7

⁄8-14

1-8

1-12

11⁄8-7

11⁄8-12

11⁄4-7

11⁄4-12

13⁄8-6

13⁄8-12

11⁄2-6

11⁄2-12

Bolt Head Identification

Bolt Head Identification

Bolt

Size

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

1

N-m2ft-lb

7.4 5.6 11 8 16 12

8.5 6 13 10 18 14

15 11 24 17 33 25

17 13 26 19 37 27

27 20 42 31 59 44

31 22 47 35 67 49

43 32 67 49 95 70

49 36 75 55 105 78

66 49 105 76 145 105

75 55 115 85 165 120

95 70 150 110 210 155

105 79 165 120 235 170

130 97 205 150 285 210

150 110 230 170 325 240

235 170 360 265 510 375

260 190 405 295 570 420

225 165 585 430 820 605

250 185 640 475 905 670

340 250 875 645 1230 910

370 275 955 705 1350 995

480 355 1080 795 1750 1290

540 395 1210 890 1960 1440

680 500 1520 1120 2460 1820

750 555 1680 1240 2730 2010

890 655 1990 1470 3230 2380

1010 745 2270 1670 3680 2710

1180 870 2640 1950 4290 3160

1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

3

N-m ft-lb N-m ft-lb

EOD

mm x pitch

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

1. in-tpi = nominal thread diameter in inches-threads per inch

2. N· m = newton-meters

3. ft-lb = foot pounds

4. mm x pitch = nominal thread diameter in millimeters x thread

pitch

4

5.8 8.8 10.9

N-m ft-lb N-m ft-lb N-m ft-lb

43659 7

7 5 11 8 15 11

17 12 26 19 36 27

18 13 28 21 39 29

33 24 52 39 72 53

39 29 61 45 85 62

58 42 91 67 125 93

60 44 95 70 130 97

90 66 105 77 145 105

92 68 145 105 200 150

99 73 155 115 215 160

145 105 225 165 315 230

155 115 240 180 335 245

195 145 310 230 405 300

220 165 350 260 485 355

280 205 440 325 610 450

310 230 650 480 900 665

480 355 760 560 1050 780

525 390 830 610 1150 845

960 705 1510 1120 2100 1550

1060 785 1680 1240 2320 1710

1730 1270 2650 1950 3660 2700

1880 1380 2960 2190 4100 3220

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

166-255M 03/05/2009

Loading...

Loading...