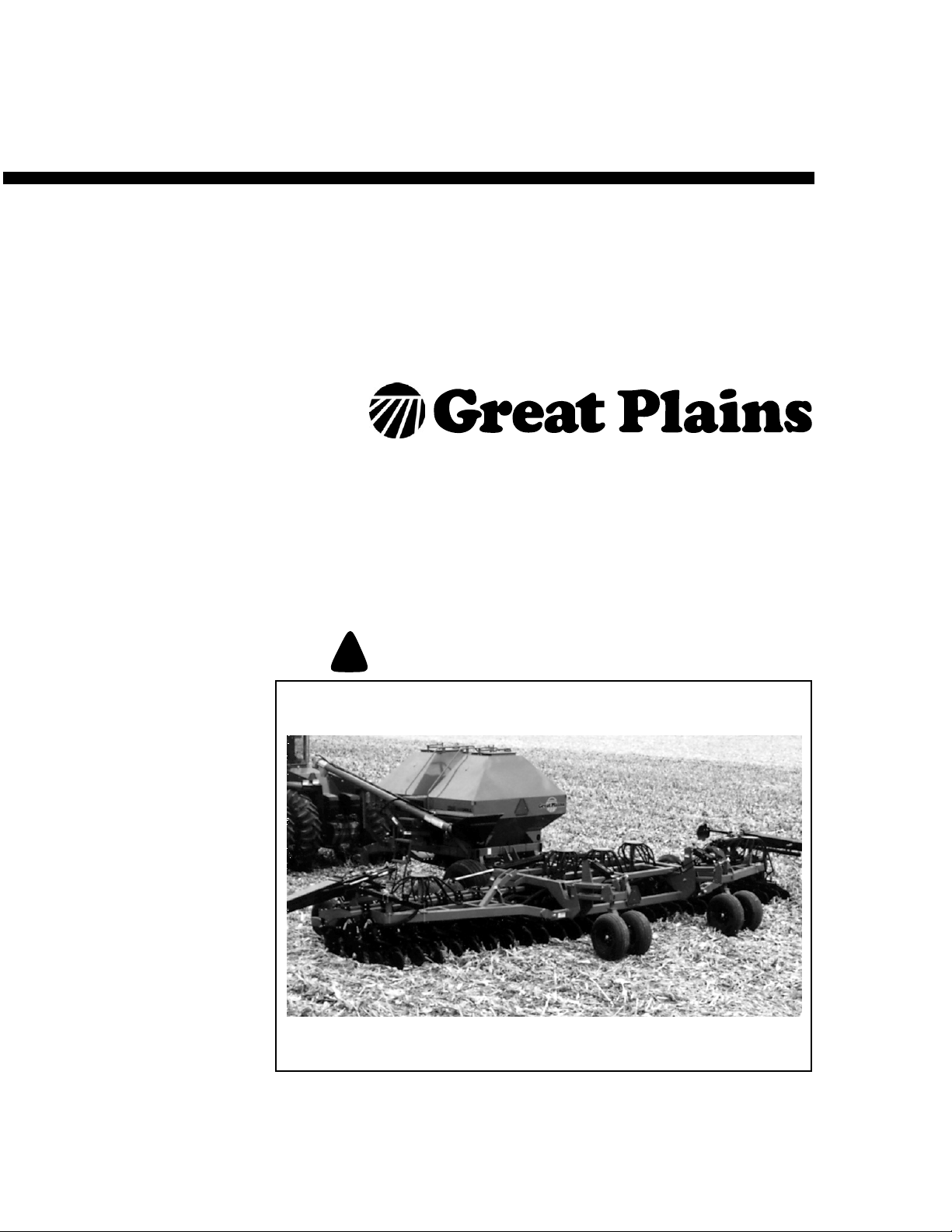

Page 1

Export Predelivery Instructions

ADC2220 & NTA 3510

Air Drill Cart & Air Drill Implement

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

16178

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 2005 Printed 3/3/2006

167-088Q-RUS

Page 2

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Description of Unit . . . . . . . . . . . . . . . . . . . . . 6

Intended Usage . . . . . . . . . . . . . . . . . . . . 6

Using This Manual . . . . . . . . . . . . . . . . . . . . . 6

Definitions . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembly and Setup Assistance . . . . . . . . . . 6

Before You Start . . . . . . . . . . . . . . . . . . . . . . . 7

Pre-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . 8

Pre-Assembly Checklist . . . . . . . . . . . . . . . . . 8

Unload Center Section Rack . . . . . . . . . . . . . 8

Cart Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drive Wheels . . . . . . . . . . . . . . . . . . . . . . . . 12

Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hitch Strap . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Engage/Disengage Levers . . . . . . . . . . . . . . 16

Unload Bins Rack . . . . . . . . . . . . . . . . . . . . . 16

Meterboxes. . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fan and Fan Outlet Transition. . . . . . . . . . . . 22

Auger Support Weldments . . . . . . . . . . . . . . 23

Auger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Gearbox Levers . . . . . . . . . . . . . . . . . . . . . . 25

Walkboard. . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Bin Lids . . . . . . . . . . . . . . . . . . . . . . . . . 27

Hose Guide Attachment . . . . . . . . . . . . . . . . 28

Implement Assembly . . . . . . . . . . . . . . . . . . . . 29

Center Section Frame . . . . . . . . . . . . . . . . . . . 29

Coulter Blades. . . . . . . . . . . . . . . . . . . . . . 32

Parallel Arm Lift Assembly . . . . . . . . . . . . 32

Parallel Arm Dual Gauge Wheels . . . . . . . 34

Parallel Arm Gauge Wheel Hydraulics . . . 35

Dual Gauge Wheel Tires. . . . . . . . . . . . . . 36

Rockshaft . . . . . . . . . . . . . . . . . . . . . . . . . 36

Rockshaft Gauge Wheel Tires . . . . . . . . . 37

Left Wing Frame . . . . . . . . . . . . . . . . . . . . . . . 38

Gauge Wheels. . . . . . . . . . . . . . . . . . . . . . 39

Right Wing Frame . . . . . . . . . . . . . . . . . . . . . . 40

Coulter Blade Arms . . . . . . . . . . . . . . . . . . 40

Coulter Blades. . . . . . . . . . . . . . . . . . . . . . 40

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Gauge Wheels. . . . . . . . . . . . . . . . . . . . . . 42

Coulter Blades. . . . . . . . . . . . . . . . . . . . . . 43

Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Openers and Press Wheels . . . . . . . . . . . 44

Air Towers . . . . . . . . . . . . . . . . . . . . . . . . . 46

Folding Hydraulic Cylinder . . . . . . . . . . . . 47

Cart Hook-Up . . . . . . . . . . . . . . . . . . . . . . 48

Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Torque Values Chart . . . . . . . . . . . . . . . . . . . . 49

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . 49

© Copyright 2006 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

3/3/2006

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

167-088Q-RUS

Page 3

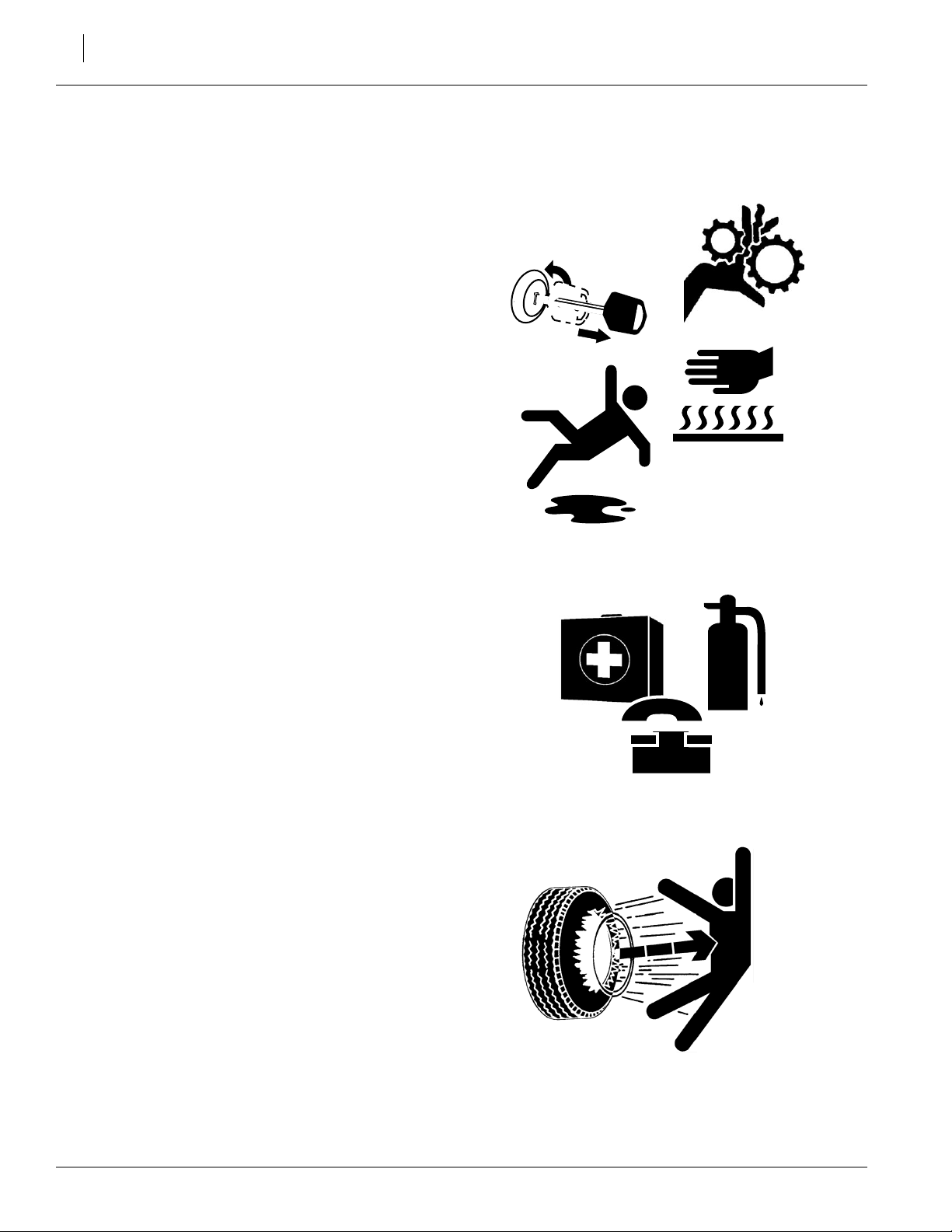

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is

a potential hazard to personal safety involved and

extra safety precaution must be taken. When you

see this symbol, be alert and carefully read the

message that follows it. In addition to design and

configuration of equipment, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence and proper training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

Important Safety Information

!

1

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme situations, typically for machine

components that, for functional purposes, cannot

be guarded.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be

used to alert against unsafe practices.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

DANGER

!

WARNING

!

CAUTION

!

3/3/2006

167-088Q-RUS

Page 4

ADC2220 & NTA 3510

2

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals,” thor-

oughly.

▲ Read all instructions noted on the decals.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could

be struck by foreign objects or thrown from the

machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine dur-

ing operation.

Shutdown and Storage

▲ Put tractor in park, turn off engine, and

remove the key.

▲ Secure implement using blocks and supports

provided.

OFF

▲ Detach and store implement in an area where

children normally do not play.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can

create a hazard when driven on public roads.

They are difficult to see, especially at night.

▲ Use flashing warning lights and turn signals

whenever driving on public roads.

▲ Use lights and devices provided with imple-

ment.

Use A Safety Chain

▲ Use a safety chain to help control drawn

machinery should it separate from tractor

drawbar.

▲ Use a chain with a strength rating equal to or

greater than the gross weight of towed

machinery.

▲ Attach chain to tractor drawbar support or

other specified anchor location. Allow only

enough slack in chain to permit turning.

▲ Replace chain if any links or end fittings are

broken, stretched or damaged.

▲ Do not use safety chain for towing.

167-088Q-RUS 3/3/2006

Page 5

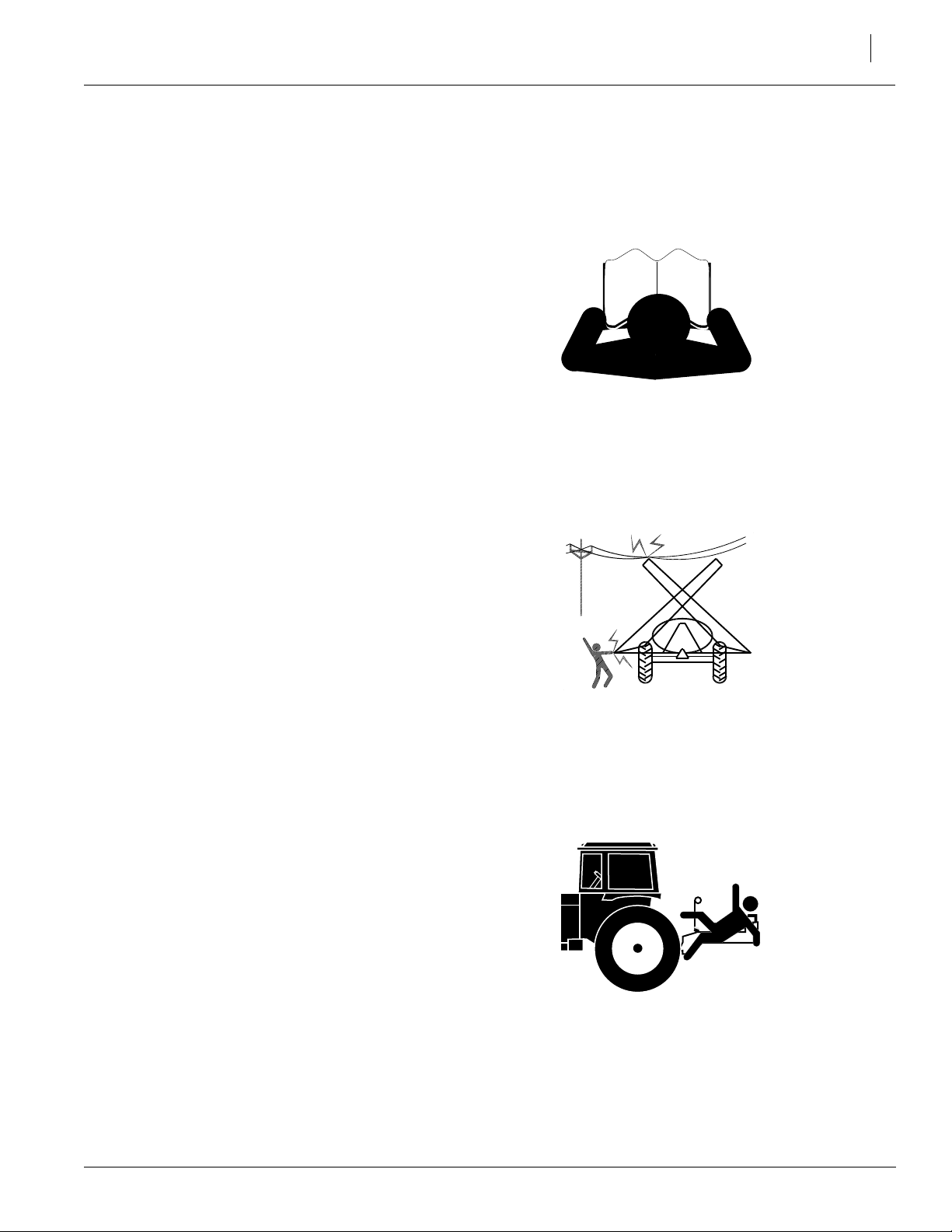

Transport Machinery Safely

Maximum transport speed for implement is 20

mph. Some rough terrains require a slower

speed. Sudden braking can cause a towed load to

swerve and upset.

▲ Do not exceed 20 mph. Never travel at a

speed which does not allow adequate control

of steering and stopping. Reduce speed if

towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully

loaded, weighs more than 1.5 times the weight

of towing vehicle.

▲ Carry reflectors or flags to mark Front Fold

Boom Sprayer in case of breakdown on the

road.

Important Safety Information

3

▲ Keep clear of overhead power lines and other

obstructions when transporting. Refer to transport dimensions under “Specifications and

Capacities,” in the operator’s manual.

▲ Do not fold or unfold the implement while trac-

tor is moving.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the

skin, causing serious injury.

▲ Avoid the hazard by relieving pressure before

disconnecting hydraulic lines.

▲ Use a piece of paper or cardboard, NOT

BODY PARTS, to check for suspected leaks.

▲ Wear protective gloves and safety glasses or

goggles when working with hydraulic systems.

▲ If an accident occurs, see a doctor immedi-

ately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene may result.

3/3/2006

167-088Q-RUS

Page 6

ADC2220 & NTA 3510

4

Practice Safe Maintenance

▲ Understand procedure before doing work. Use

proper tools and equipment. Refer to this manual for additional information.

▲ Work in a clean, dry area.

▲ Fold the implement, put tractor in park, turn off

engine, and remove key before performing

maintenance.

▲ Make sure all moving parts have stopped and

all system pressure is relieved.

▲ Allow the implement to cool completely.

▲ Disconnect battery ground cable (-) before

servicing or adjusting electrical systems or

before welding on the implement.

▲ Inspect all parts. Make sure parts are in good

condition and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from the

implement before operation.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

OFF

▲ Keep emergency numbers for doctor, ambu-

lance, hospital and fire department near

phone.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct

tools and equipment.

▲ When inflating tires, use a clip-on chuck and

extension hose long enough for you to stand

to one side–not in front of or over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use

wheel-handling equipment adequate for

weight involved.

911

167-088Q-RUS 3/3/2006

Page 7

Safety At All Times

Thoroughly read and understand the instructions

in this manual before operation. Read all instructions noted on the safety decals.

▲ Be familiar with all implement functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave implement unattended with trac-

tor engine running.

▲ Do not dismount a moving tractor. Dismount-

ing a moving tractor could cause serious injury

or death.

▲ Do not stand between the tractor and imple-

ment during hitching.

▲ Keep hands, feet and clothing away from

power-driven parts.

Important Safety Information

5

▲ Wear snug-fitting clothing to avoid entangle-

ment with moving parts.

▲ Watch out for wires, trees, etc., when folding

and raising implement. Make sure all persons

are clear of working area.

▲ Do not turn tractor too tightly, causing imple-

ment to ride up on wheels. This could cause

personal injury or equipment damage.

3/3/2006

167-088Q-RUS

Page 8

ADC2220 & NTA 3510

6

Introduction

Great Plains welcomes you to its growing family

of new product owners. This Air Drill Cart and

this Air Drill Implement have been designed with

care and built by skilled workers using quality

materials. Proper setup, maintenance and safe

operating practices will help you get years of satisfactory use from the machine.

Description of Unit

The ADC2220 is a grain drill cart that uses air to

move seed or fertilizer from the cart bins to the

implement. Air is supplied by a fan driven by a

hydraulic motor. Pressurized meters under the

bins dispense material into the air stream at a

rate proportional to distance traveled. The meter

rate can be adjusted.

The NTA3510 is a seeding implement, with a

working width of 35 feet, designed to tow behind

a Great Plains air drill cart. This implement is designed for no-till field conditions. Coulters open a

narrow seedbed. Disk-type, parallel-linkage

openers follow each coulter, widening the seedbed and delivering seed to the trench.

Intended Usage

Use this cart with a Great Plains air drill implement. Use the cart for seeding small grains and

legumes or applying dry, granular fertilizer.

Models Covered

ADC2220, NTA 3510

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct operation,

read and follow the directions provided before continuing.

Definitions

Right and left as used in this manual are determined by facing the direction the machine will

travel while in use unless otherwise stated.

NOTE: Useful information related to the preceding topic.

Assembly and Setup Assistance

To order additional copies of dealer assembly instructions or operator’s and parts manuals, write

to the following address. Include model numbers

in all correspondence.

If you do not understand any part of this manual

or have other assembly or setup questions, assistance is available. Contact

Product Support

Great Plains Mfg. Inc., Service Department

P.O. Box 5060

Salina, KS 67402-5060

Using This Manual

This manual was written to help you assemble

and prepare the new machine for the customer.

The manual includes instructions for assembly

and setup. Read this manual and follow the recommendations for safe, efficient and proper assembly and setup.

An operator’s manual is also provided with the

new machine. Read and understand “Important

Safety Information” and “Operating Instructions” in the operator’s manual before assem-

bling the machine. As a reference, keep the

operator’s manual on hand while assembling.

The information in this manual is current at printing. Some parts may change to assure top performance.

167-088Q-RUS 3/3/2006

Page 9

Before You Start

Read and understand the owners manual for your

implement. A basic understanding of how the drill

works will aid in the pre-assembly, assembly, setup and operation of your drill.

Perform these checks before setting up your

implement.

1. Read and understand “Important Safety Information,” beginning on page 1.

2. Check that all working parts are moving freely, bolts are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and

lubricated.

Introduction

7

4. Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged.

3/3/2006

167-088Q-RUS

Page 10

ADC2220 & NTA 3510

8

Pre-Assembly

The following headings are step-by-step instructions

for assembling the cart. Begin with Tools Required

and Pre-Assembly Checklist to make sure you have

all necessary parts and equipment. Then proceed

with Unload Center Section Rack. Follow each step to

make the job as quick and safe as possible and produce a properly working machine.

It is the dealer’s responsibility to unload the new machine. Unload all equipment before beginning assembly. Do not attempt any assembly work while the cart

is on the truck.

Tools Required

•

Forklift or overhead hoist with 8,000-pound capacity

• Hand jack with 4-ton capacity

• General hand tools

• Jack stands, blocks and safety chain

Pre-Assembly Checklist

1. Read and understand “Important Safety Information” on page 1 before assembling.

2. Have at least two people on hand while assembling.

3. Make sure the assembly area is level and free of

obstructions (preferably an open concrete area).

4. Have all major components.

5. Have all fasteners and pins shipped with cart.

Unload Center Section Rack

!

DANGER!

Crushing hazard. You may be severely injured or killed by

the cart if it falls. Secure cart to lifting equipment so it cannot fall. Do not walk or place any body part under the

raised sections of the cart.

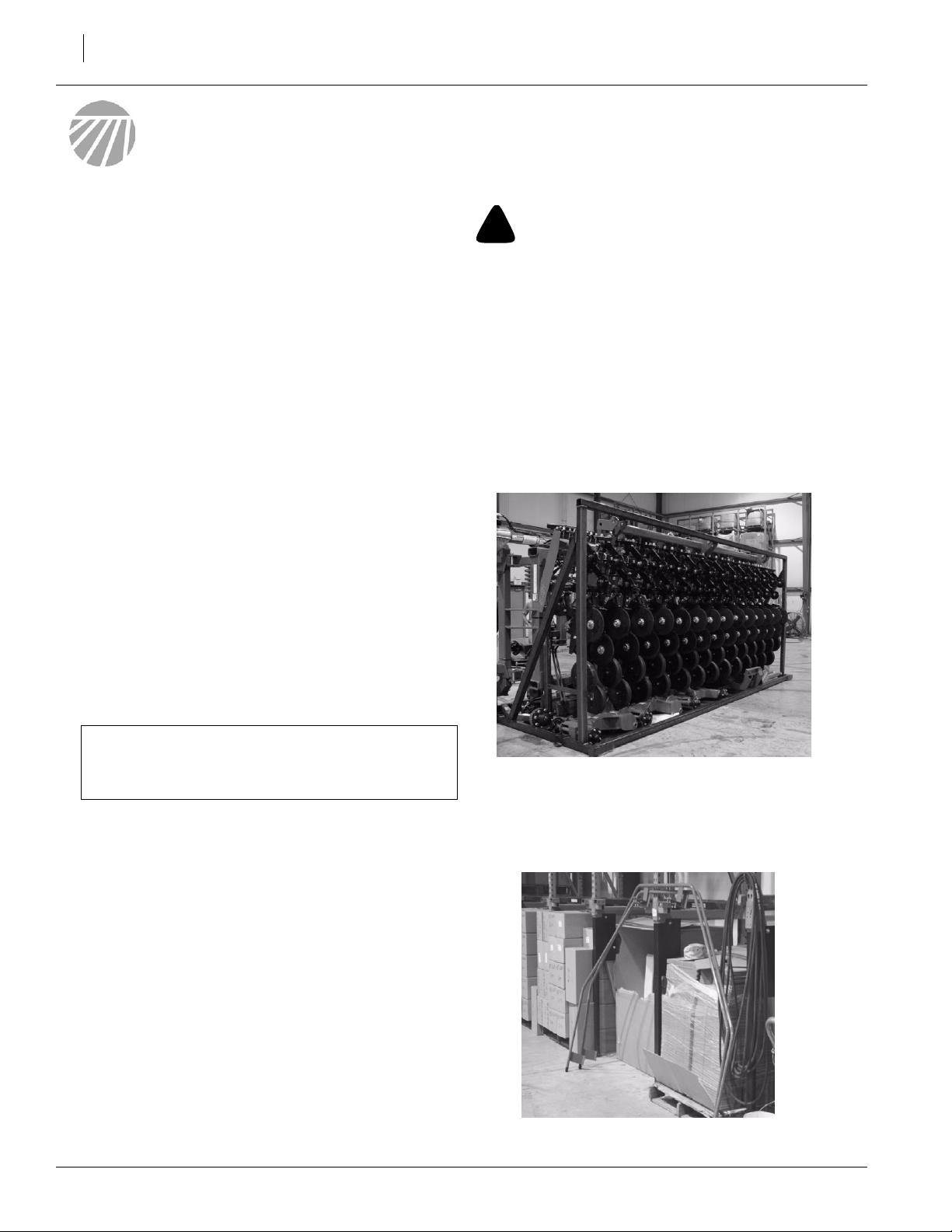

NOTE: The air drill cart and air drill implement are

shipped on racks via containers.There are three

racks total: the wing rack, the center section rack, and

the bins rack.

Refer to Figure 1

1. Unload the center section rack first. Remove as

many loose pieces as possible from rack. Keep

pieces separate.

IMPORTANT: If a pre-assembled part or fastener is

temporarily removed, remember where it goes. Keep

the parts separated.

6. Have a copy of the parts manual on hand. If unsure of proper placement or use of any part or

fastener, refer to the parts manual.

7. Check that all working parts are moving freely,

bolts are tight, and cotter pins are spread.

8. Check that all safety labels and reflectors are correctly located and legible. Replace if improperly

located or damaged. Refer to Safety Labels, “Im-

portant Safety Information” in the operator’s

manual.

9. Inflate tires to recommended pressure as listed

on the Tire Inflation Chart on the “Appendix” on

page 49. Tighten wheel bolts as specified on

Torque Values Chart on the “Appendix” on page

49.

167-088Q-RUS 3/3/2006

Refer to Figure 2

2. Unbolt walkboard rails from rack.

23492

Remove Walkboard Handrails

Figure 1

Center Section

Figure 2

23429

Page 11

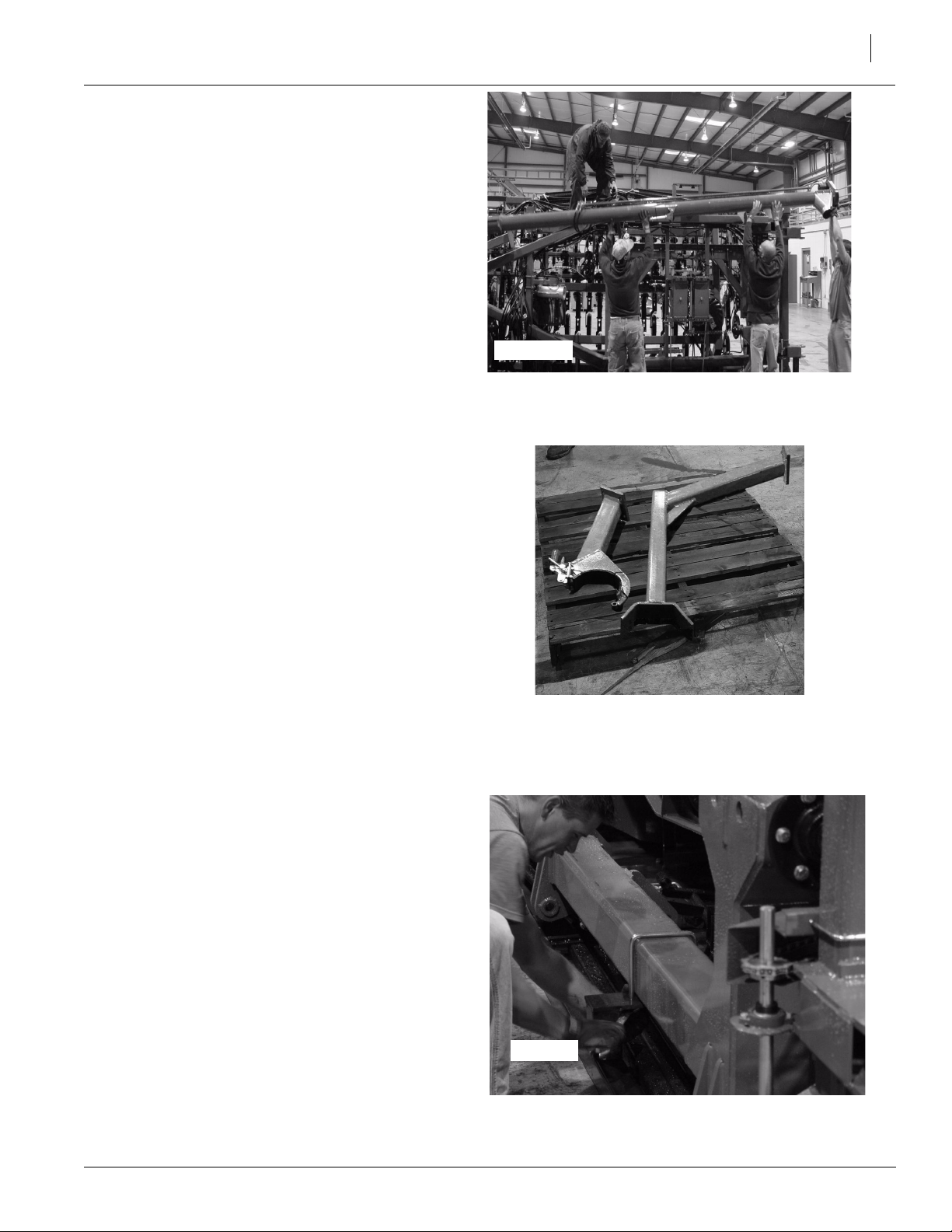

Refer to Figure 3

3. Unbolt and remove auger from rack.

23430

Figure 3

Detach Auger

Pre-Assembly

9

Refer to Figure 4

4. Unbolt and remove outer support arm

weldment and rear transport support from

ADC2220 frame in rack.

Refer to Figure 5

5. Detach rockshaft from rack by removing ubolts.

23437

Figure 4

Remove Support Weldments

3/3/2006

23436

Figure 5

Remove U-bolts

167-088Q-RUS

Page 12

ADC2220 & NTA 3510

10

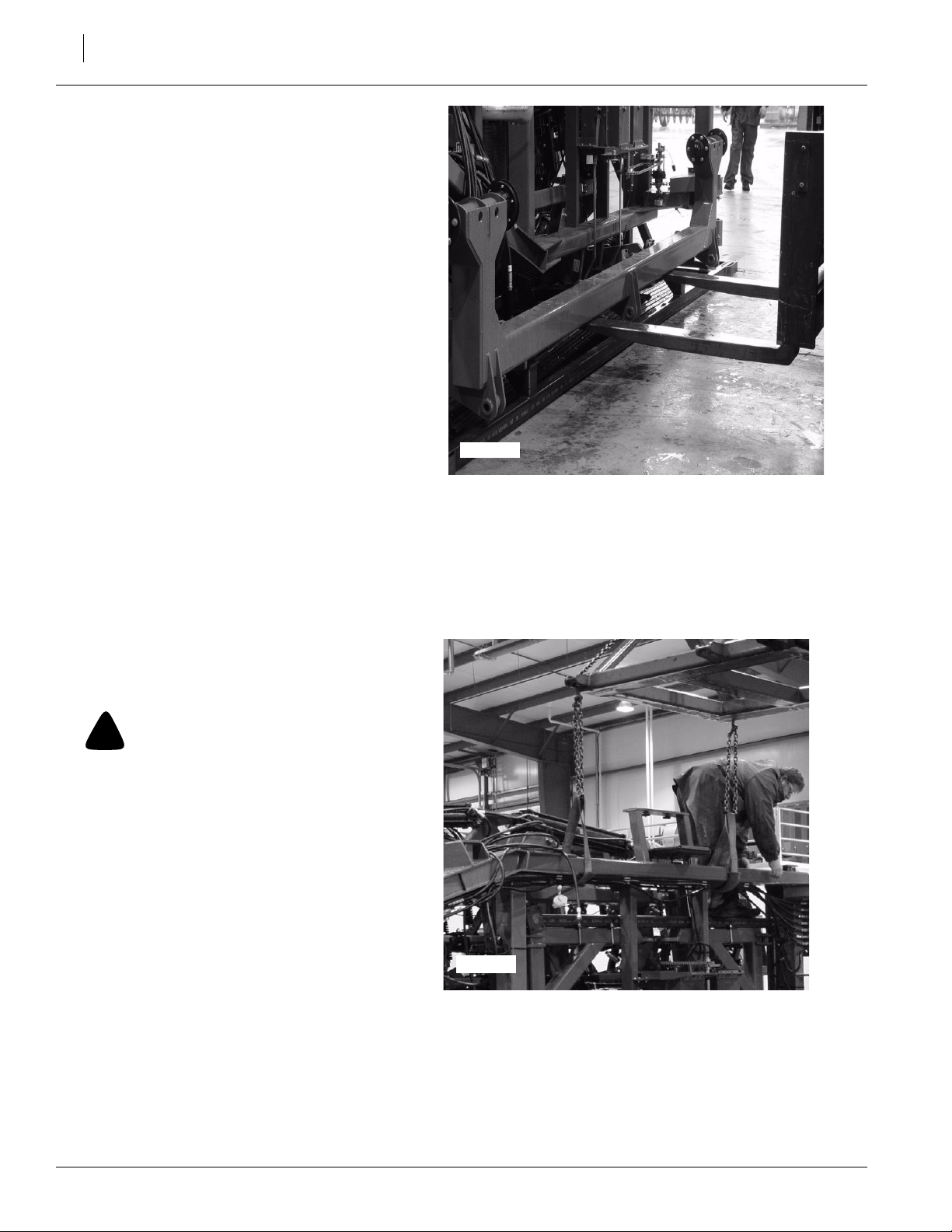

Refer to Figure 6

6. Using forklift or other implement, remove

rockshaft from rack.

7. Unload remaining loose parts from rack.

Set parts aside for use later.

23431

Figure 6

Remove Rockshaft with Forklift

Refer to Figure 7

8. Attach lift straps to air drill cart frame. Unbolt air drill cart frame from rack. Use forklift

or other implement to lift drill from rack.

!

CAUTION!

Obey all safety instructions from lifting equipment

manufacturer. Be sure lift straps are securely attached prior to lifting. Be sure lifting equipment has

enough capacity to lift cart.

23441

Figure 7

Attach Lift Straps to ADC2220

Frame

167-088Q-RUS 3/3/2006

Page 13

Refer to Figure 8

9. Unscrew and remove all bolts securing ADC2220 frame to rack.

23432

23440

Figure 8

Remove Bolts

Pre-Assembly

11

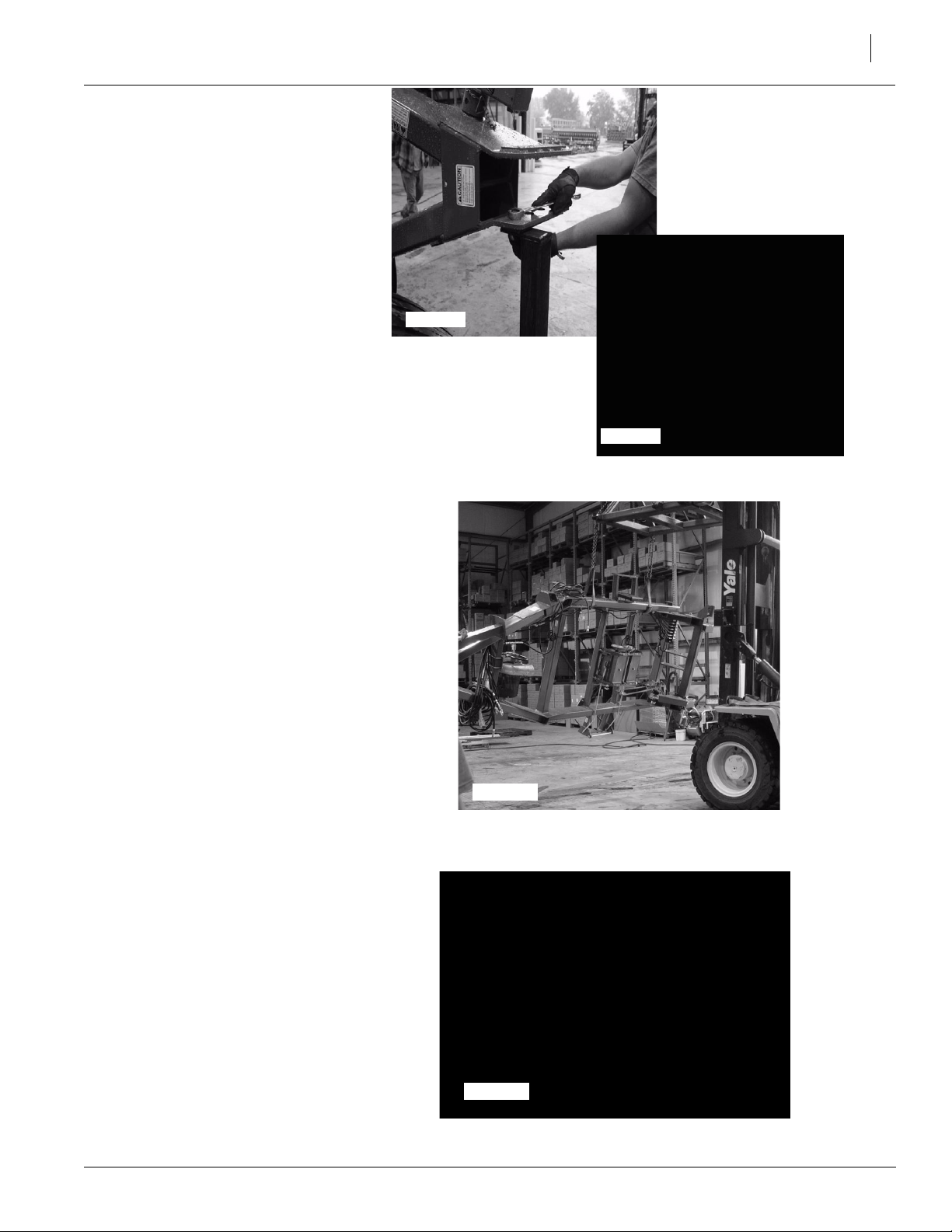

Refer to Figure 9

10. Using forklift or other implement,

carefully raise ADC2220 frame from

rack.

Refer to Figure 10

NOTE: To finish assembling ADC2220

frame, two forklifts will be needed so

frame can be suspended horizontally

while tires are attached.

11. While frame is attached to forklift, secure opposite side of frame to another forklift using lift straps.

12. Using forklifts, level frame horizontally so tires may be attached.

23433

Figure 9

Remove Frame from Rack

23495

Figure 10

Level Frame

3/3/2006

167-088Q-RUS

Page 14

ADC2220 & NTA 3510

12

Cart Assembly

Drive Wheels

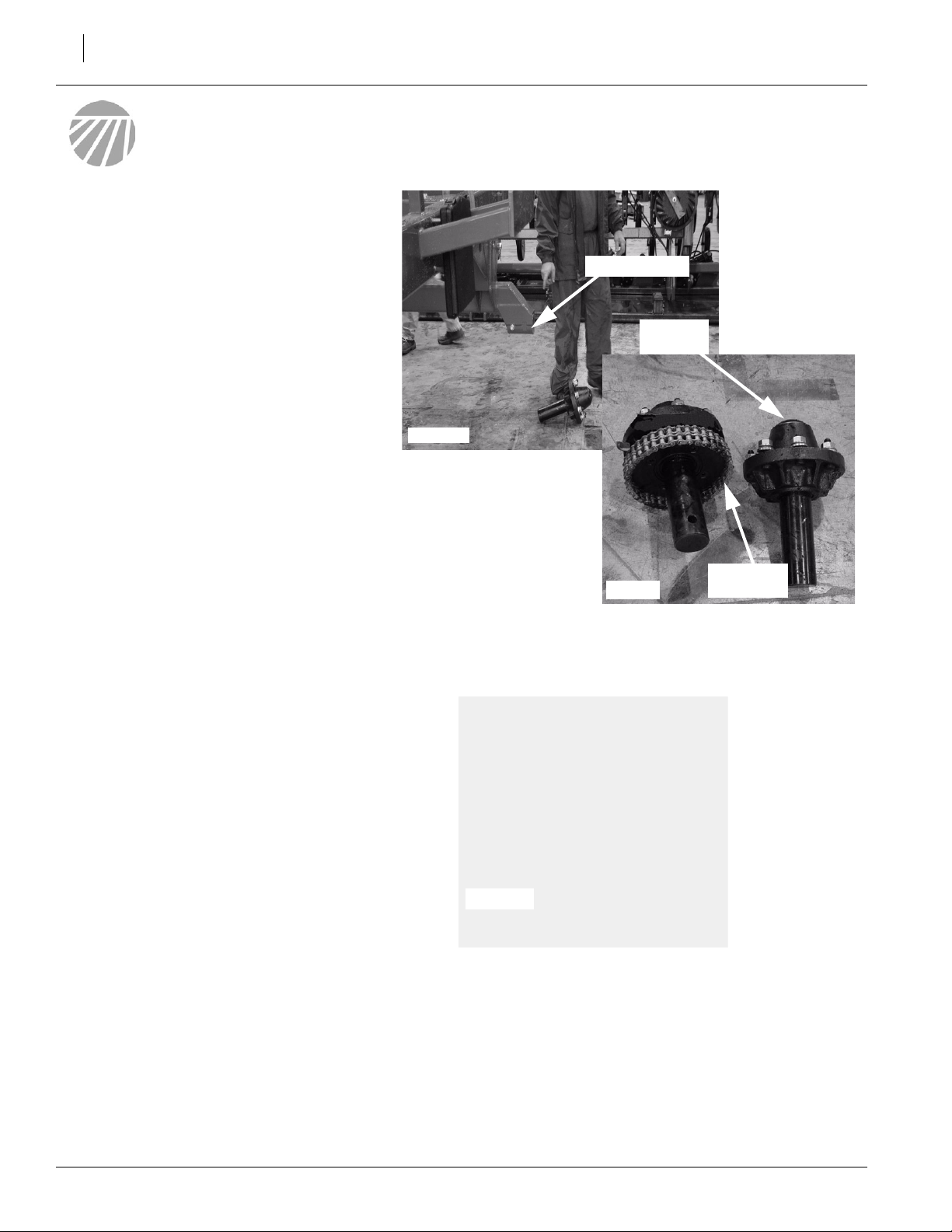

Refer to Figure 11

NOTE: The air drill cart tires come with two hub

assemblies - a drive hub assembly and a standard hub assembly. The drive hub assembly attaches to the right-hand side of the spindle tube.

The standard hub assembly attaches to the lefthand side of the spindle tube. Follow the instructions below to assemble hubs to spindle tube.

Spindle Tube

Hub

Assembly

23434

Refer to Figure 12

13. Unscrew and remove bolt in left-hand side of

spindle tube.

23442

Figure 11

Attach Hub Assembly to Spindle Tube

23493

Figure 12

Remove Bolt from Spindle Tube

Drive Hub

Assembly

167-088Q-RUS 3/3/2006

Page 15

Refer to Figure 13

14. Insert standard hub assembly into spindle tube align-

ing hole in hub assembly with hole in spindle tube.

15. Secure standard hub assembly to spindle tube with

bolt removed in step 1 on previous page.

Refer to Figure 14

16. On opposite side of air drill cart frame, remove bolt

in spindle tube.

Cart Assembly

23435

Figure 13

Attach Standard Hub to Spindle Tube

13

Refer to Figure 15

17. Insert drive hub assembly into spindle tube aligning

hole in hub assembly with hole in spindle tube.

18. Secure drive hub assembly to spindle tube with bolt

removed in step 4 above.

23444

Figure 14

Remove Bolt from Spindle Tube

23446

Figure 15

Attach Drive Hub to Spindle Tube

3/3/2006

167-088Q-RUS

Page 16

ADC2220 & NTA 3510

14

Refer to Figure 16

19. Loosen sprocket on drive shaft located on right-hand

side of frame.

23494

Figure 16

Drive Shaft and Sprocket

Refer to Figure 17

20. Adjust drive shaft, sprocket, and hub assembly so

when sprocket rotates it rotates chain as well.

NOTE: Make sure key is in sprocket on drive chain.

Refer to Figure 18

21. Remove all wheel nuts from hub assembly.

23447

Figure 17

Drive Shaft, Sprocket, and Hub Assembly

23445

Figure 18

Remove Wheel Nuts/Lug Nuts

167-088Q-RUS 3/3/2006

Page 17

Refer to Figure 19

22. Attach tire to hub assembly.

23. Using previously removed wheel nuts, secure tire to

hub assembly.

24. Tighten all wheel nuts.

25. Repeat steps 9 - 12 on opposite side of frame.

NOTE: Always check to make sure that tires are properly

inflated. Refer to Tire Inflation Chart on page 49.

Jack

Refer to Figure 20

1. Attach jack to frame. Use pin to secure jack to frame.

NOTE: At this point during setup, it is okay to remove lift

straps so that assembly may be completed.

Cart Assembly

Figure 19

Attach Tire to Frame

15

23438

Hitch Strap

Refer to Figure 21

1. Attach hitch strap to tongue. Align top hole of

hitch strap with 2nd hole from top in the frame.

Insert 1 1/4-7 X 11 bolt through frame and hitch.

Secure with washer and hex nut.

2. Insert 1 1/4-7 x 9 1/2 bolt, washer and safety

chain through 3rd hole from top in the frame and

bottom hole in the hitch. Secure with washer

and hex nut.

23439

Figure 20

Jack (in use)

23448

Figure 21

Hitch Strap

3/3/2006

167-088Q-RUS

Page 18

ADC2220 & NTA 3510

16

Engage/Disengage Levers

Refer to Figure 22

1. Remove flat washer and lock nut from bolt on clutch

linkage rod.

2. Secure linkage rod to lever with flat washer and lock

nut.

NOTE: Leave bolts secured loosely. Do NOT tighten

bolts down as levers will not function properly. Refer to

Figure 22.

Clutch Linkage Rod

Engage/Disengage Lever

23450

Unload Bins Rack

Refer to Figure 23

NOTE: The air drill cart and air drill implement are

shipped on racks via containers. There are three

racks total: the center section rack, the wing rack,

and the bins rack.

1. Unload all loose pieces from bins rack. Keep all

pieces separate. NOTE: DO NOT try to un-

load weight brackets from rack. A forklift

will be needed to unload brackets.

Clutch

Linkage

Rod

23045

Engage/Disengage

Lever

Figure 22

Engage/Disengage Levers

23049

Figure 23

Bin Rack

167-088Q-RUS 3/3/2006

Page 19

Refer to Figure 24

2. With use of a forklift or other implement, unload

weight brackets from bins rack.

23050

Cart Assembly

Figure 24

Unload Weight Brackets

17

Refer to Figure 25

3. Remove all parts, hoses, and bags from inside

the bins.

Refer to Figure 26

4. Attach lift straps to front bin. NOTE: This will

be the bin without the slow moving vehicle

decal.

23051

Figure 25

Inside of Bin

3/3/2006

23451

Figure 26

Attach Lift Straps

167-088Q-RUS

Page 20

ADC2220 & NTA 3510

18

Refer to Figure 27

5. Unscrew and remove all bolts securing bin to

the rack.

6. Using forklift or other implement, carefully

raise bin from rack.

23046

Figure 27

Remove Bolts

Refer to Figure 28

7. Once bin is removed from rack, carefully lower

bin on its side as shown in Figure 28. Remove

lift straps from forklift.

NOTE: Be careful when handling bins. To prevent damage, bins should be supported at all

times.

8. Gently maneuver bin to sit upright.

Refer to Figure 29

9. Reposition lift straps on bin so bin may be

raised with forklift as shown in Figure 29.

10. Raise bin from ground using forklift.

23453

Figure 28

Bin

23454

Figure 29

Front Bin

167-088Q-RUS 3/3/2006

Page 21

Refer to Figure 30

11. Place front bin (1) on air drill cart frame. Make

sure front of the bin (1) is toward front of frame

(2). NOTE: The flat side of the front bin is

the back.

Cart Assembly

19

Refer to Figure 31

12. Align holes in bottom of bin with holes in frame

so bin can secure to frame with bolts.

23057

Figure 30

Front Bin to Frame

Figure 31

Align Box and Frame

23047

Refer to Figure 32

13. Secure the bin to the air drill cart frame using

hardware located in bags attached to the

frame.

3/3/2006

23048

Figure 32

Bag of Hardware

167-088Q-RUS

Page 22

ADC2220 & NTA 3510

20

Refer to Figure 33

14. Attach lift straps to rear bin. NOTE: This will

be the bin with the slow moving vehicle decal.

15. Unscrew and remove all bolts securing rear

bin to rack.

16. Using forklift or other implement, carefully remove rear bin from rack.

Refer to Figure 34

17. Once bin is removed from rack, carefully

lower bin to ground. Remove lift straps from

bin.

NOTE: Be careful when handling bins. To

prevent damage, bins should be supported

at all times.

18. Reposition lift straps on bin so bin may be

raised with forklift as shown in Figure 34.

19. Raise bin from ground using forklift.

23058

Figure 33

Attach Lift Straps to Rear Bin

Refer to Figure 35

20. Place rear bin (1) on air drill cart frame. Make

sure front of the bin (1) is toward front of frame

(2). NOTE: The flat side of the rear bin is

the front.

23059

Figure 34

Rear Bin

23061

Figure 35

Rear Bin to Frame

167-088Q-RUS 3/3/2006

Page 23

Refer to Figure 36

21. Align holes in bottom of bin with holes in frame

so bin can secure to frame with bolts.

Refer to Figure 37

22. Secure bin to air drill cart frame using hardware located in bags attached to the frame.

Meterboxes

Refer to Figure 38

1. Place a thin bead of silicon around the top

edge of one meterbox (1). Attach meterbox (1)

to front bin with flared outlets toward the back.

2. Use vise grips to hold meterbox (1) to bin. Se-

cure box (1) to bin using bolts (4), washers (2),

and nuts (3).

3. Repeat steps 1-2 to attach second meterbox

to rear bin.

23061

23048

Cart Assembly

Figure 36

Align Rear Bin to Frame

Figure 37

Bag of Hardware

21

3/3/2006

Front Bin

NOTE: ADC2220 frame is removed for clarity.

Figure 38

Meter Boxes

Rear Bin

23460

167-088Q-RUS

Page 24

ADC2220 & NTA 3510

22

Fan and Fan Outlet Transition

Refer to Figure 39

1. Remove set screws from fan. Keep set screws

for reuse.

Refer to Figure 40

2. Attach fan outlet transition to fan as shown in

Figure 40.

3. Secure fan outlet transition to fan with set

screws removed in step 1.

23053

Figure 39

Remove Set Screws

23064

Figure 40

Attach Fan to Fan Outlet Transition

Refer to Figure 41

4. Remove bolt from fan.

5. Attach fan outlet transition to fan.

23065

Figure 41

Attach Fan to Fan Outlet Transition

167-088Q-RUS 3/3/2006

Page 25

Refer to Figure 42

6. Secure transition to fan with previously removed bolt.

Refer to Figure 43

7. Attach hoses from fan outlet transition (5) to

front meterbox (1) inlets. Secure with hose

clamps (3).

8. Using hose clamps (3), attach hose (4) from

front (1) meterbox outlets to rear meterbox (2)

inlets.

9. Secure hose (4) on rear meterbox (2) inltets

with hose clamps (3).

2306623066

Figure 42

Fan

Cart Assembly

23

Auger Support Weldments

Refer to Figure 44

1. Attach auger front storage support arm (2) to

mounting plate (1) located on the frame. Use

bolts (3) to secure arm (2) to plate (1).

2. Attach inner support arm (6) to frame using

inner support arm shaft (4). Secure inner

support arm shaft with bolt (5) and lock nut.

3. Insert outer pivot shaft tube into outer support arm weldement (7). Secure outer arm to

inner support arm (6) using bolt (8), lock

washer, and hex nut.

4. Insert auger swivel support (11) through two

flat washers (9), outer support arm weldment

(7), and a flat washer (9). Secure with pin roll

(10).

23449

Figure 43

Fan Hose with Clamps

3/3/2006

Figure 44

Install Auger Support Weldments

23459

167-088Q-RUS

Page 26

ADC2220 & NTA 3510

24

Auger

Refer to Figure 45

1. Attach auger (1) to auger swivel

support (2).

2. Insert bolt and flat washer

through holes in auger (1) and

secure with flat washer, lock

washer, and hex nut.

23458

Figure 45

Install Auger

Refer to Figure 46

3. Secure auger hopper to auger

using bolts, flat washer, and lock

washer.

Refer to Figure 47

4. Attach auger strap handle to auger

hopper.

23457

Figure 46

Auger Hopper and Auger

23260

Figure 47

Auger Strap Handle

167-088Q-RUS 3/3/2006

Page 27

Chains

Refer to Figure 48

1. Unwrap and route chain from front gearbox

to front meterbox as shown in Figure 48.

NOTE: Chain will wrap the same from rear

gearbox to rear meterbox.

Gearbox Levers

Refer to Figure 49

1. Slide gearbox levers (3) through holes in

mounting plate (2).

2. Attach levers (3) to gearboxes as shown.

Secure with cotter pin (1).

23496

Figure 48

Chain Routing

Cart Assembly

25

Walkboard

Refer to Figure 50

1. Attach walkboard handrail to rear bin using

bolts (2) and flat washers (3).

2. Secure handrail using flat washers (4) and

lock nuts (5).

3. Attach other walkboard handrail to rear of

front bin using steps 1 and 2 above.

3/3/2006

23497

23443

Figure 49

GearboxLevers

Figure 50

Handrail Assembly

167-088Q-RUS

Page 28

ADC2220 & NTA 3510

26

Refer to Figure 51

4. Attach upper ladder mount (2) to

bins using bolts (10), flat washers (4), lock washers (5), and

hex nuts (6).

5. Place upper ladder weldment (3)

on mount (2). Secure weldment

(3) to mount (2) and handrails (1)

using bolts (7), lock washers (9)

and hex nuts (8).

NOTE: Front bin removed for clarity.

Refer to Figure 52

6. Attach walkboard (1) to upper

ladder mount (2).

7. Secure walkboard (1) to mount

(2) with bolts (4), 3-point step

retainers (3), lock washers (5),

and hex nuts (6).

23068

Figure 51

Upper Ladder Mount and Weldment

23498

Figure 52

Walkboard

167-088Q-RUS 3/3/2006

Page 29

Bins

Refer to Figures 53 and 54

1. Plastic tubes should be installed inside the

bins - two per bin.

2. Install plastic tubes from rear of bin to rear

of metering device in front bin.

3. Install plastic tubes from front of bin to rear

of metering device in rear bin.

NOTE: It is important that the plastic tubes are

installed properly to equalize air pressure. If

they are not installed correctly, the implement

may produce undesirable results.

Metering

Device

Cart Assembly

Front

Rear

Figure 53

View of Front Hopper from Above

27

23257

Bin Lids

Refer to Figure 55

1. Place bin lid on top of bin. Bin lid hinge will

bolt to bin on opposite side across from ubolt.

2. Attach bin lid to top of bin using bolts and

flat washers.

3. Secure lid with flat washers and lock nuts.

4. Repeat steps 1-3 to attach second bin lid to

other bin.

23256

Front

Metering

Rear

Figure 54

View of Rear Hopper from Above

Device

23070

3/3/2006

Figure 55

Bin Lid

167-088Q-RUS

Page 30

ADC2220 & NTA 3510

28

Hose Guide Attachment

Refer to Figure 56

1. Secure hose guide attachment to tongue of air

drill cart with bolt.

23067

Figure 56

Hose Guide Attachment

167-088Q-RUS 3/3/2006

Page 31

Implement Assembly

Center Section Frame

Refer to Figure 57

NOTE: The air drill implement comes shipped in

racks via containers. There are two racks; the

center section rack and the wings rack. The center section of the implement will need to be unloaded first.

Refer to Figure 58

2. Remove all sections of the rack obstructing

center section removal from rack.

23499

Implement Assembly

Figure 57

Center Section Rack

29

Refer to Figure 59

3. Loosen u-bolts securing center section

frame to rack.

IMPORTANT: DO NOT completely remove ubolts securing frame to rack. This will be done

once the lift straps have been attached to frame.

3/3/2006

24102

Figure 58

Remove Bolts

24103

Figure 59

Loosen U-bolts

167-088Q-RUS

Page 32

ADC2220 & NTA 3510

30

Refer to Figure 60

NOTE: Hydraulic cylinders need to be secured to

frame before removing frame from rack. Secure

cylinders with bungee strap or tie-down strap.

Refer to Figure 61

4. Remove both wing pivot pin weldments from

frame. Pins are located in frame at top of

rack. NOTE: Keep pins and hardware for reuse.

24104

Figure 60

Secure Hydraulic Cylinders to Frame

Refer to Figure 62

5. Attach lift straps to center section frame.

!

CAUTION!

Obey all safety instructions from lifting equipment

manufacturer. Be sure lift straps are securely attached

prior to lifting. Be sure lifting equipment has enough

capacity to lift implement.

6. Completely remove u-bolts securing frame to

rack.

7. Using forklift or other implement, carefully lift

center section frame from rack.

24105

Figure 61

Remove Pivot Pin from Frame

24106

Figure 62

Attach Lift Straps and Lift Frame from Rack

167-088Q-RUS 3/3/2006

Page 33

Refer to Figures 63 and 64

8. With help of second forklift,level center section frame. Frame should sit upright resting

gently on press wheels.

Figure 63

Lowering Frame

Implement Assembly

24107

31

Refer to Figure 65

NOTE: Be sure frame sits upright as shown in Figure 65. Do not detach lift straps from frame. Lift

straps will be detached later in assembling process.

24108

Figure 64

Righting Frame

24109

Figure 65

Center Section Frame

3/3/2006

167-088Q-RUS

Page 34

ADC2220 & NTA 3510

32

Coulter Blades

Refer to Figure 66

9. Attach coulter blade to coulter hub assembly

using bolts

.

NOTE: If attaching turbo coulter blades, blades

m

ust attach properly with rotation arrow pointing

toward direction of travel.

10. Attach remaining blades to coulter hub assemblies.

24110

23343

Figure 66

Attach Coulter Blades

Parallel Arm Lift Assembly

Refer to Figure 67

11. Using forklift, remove parallel arm lift assembly from rack.

24111

Figure 67

Remove Parallel Arms from Rack

167-088Q-RUS 3/3/2006

Page 35

Refer to Figure 68

12. Remove bolts and hardware from parallel arm

lift assembly.

Refer to Figure 69

13. Loosen bolt on pivot bolt holder. NOTE: Holder should be loose enough to move freely.

Implement Assembly

24113

Figure 68

Remove Bolts from Parallel Arms Assembly

33

24112

24114

Figure 69

Loosen Pivot Bolt Holder

3/3/2006

167-088Q-RUS

Page 36

ADC2220 & NTA 3510

34

Refer to Figure 70

14. Align parallel arm assembly with frame. Top

set of parallel arms align with top hole of frame

and pivot bolt holder. NOTE: Make sure to bolt

parallel arm assembly to frame with eyebolt

weldment on top.

Refer to Figure 71

15. Insert bolt removed in step 11 through pivot

bolt holder, frame, and parallel arm lift assembly.

16. Secure with hardware removed in step 11.

17. Repeat steps for installing parallel arm lift assembly on opposite side of the implement.

Frame

Parallel Arms

24138

Figure 70

Align Parallel Arms with Frame

24115

Parallel Arm Dual Gauge Wheels

Refer to Figure 72

1. Remove tape from gauge wheel.

2. Remove caster retainer cap and pivot thrust

washer from gauge wheel.

24116

Figure 71

Bolt Parallel Arms to Frame

24117

Figure 72

Gauge Wheel

167-088Q-RUS 3/3/2006

Page 37

Refer to Figure 73

3. Slide pivot thrust washers down shaft of

gauge wheel.

4. Attach gauge wheel to parallel arm lift assembly by sliding gauge up through assembly.

Refer to Figure 74

5. Place caster retainer cap on top of gauge

wheel.

6. Secure caster retainer cap to gauge wheel using bolt and lock washer.

7. Repeat steps to install gauge wheel on opposite side of implement.

Implement Assembly

Figure 73

Gauge Wheel

35

24118

Parallel Arm Gauge Wheel Hydraulics

Refer to Figure 75

1. Remove hydraulic cylinder that is secured to

fr

ame via bungee cord or tie-down strap.

NOTE: Use the cylinder closest to the

gauge wheel each gauge wheel.

2. Remove pin, washer, and cotter pin from base

end of hydraulic cylinder.

3. Align base end of hydraulic cylinder with

frame.

4. Insert pin through cylinder and frame.

5. Slide washer on pin and secure with cotter

pin.

24119

Figure 74

Secure Gauge Wheel and Caster Retainer Cap

24120

Figure 75

Gauge Wheel Hydraulic Cylinders

3/3/2006

167-088Q-RUS

Page 38

ADC2220 & NTA 3510

36

Refer to Figure 76

6. Using pin, pull rod end of cylinder until cylinder can be secured to eyebolt weldment.

7. Once hydraulic cylinder and eyebolt weldment

are aligned, insert pin completely.

8. Slide washer on pin and secure with cotter

pin.

9. Complete previous steps on opposite side of

implement to attach hydraulic cylinder to

gauge wheel.

Dual Gauge Wheel Tires

Refer to Figure 77

10. Reattach lift straps to implement frame and

raise frame so that gauge wheel tires can be

installed.

11. Remove wheel nuts from gauge wheel hub

assembly.

12. Attach gauge wheel tire to gauge wheel hub.

13. Secure tire to hub with previously removed

wheel nuts.

14. Repeat process on second tire on gauge

wheel.

15. Complete steps 10-14 to install gauge

wheels on opposite side of implement.

24121

Figure 76

Gauge Wheel Hydraulic Cylinder

24140

Figure 77

Attach Gauge Wheel Tires

24139

Rockshaft

Refer to Figure 78

NOTE: Rockshaft installs on opposite

side of center frame from dual guage

wheels.

1. Align rockshaft with holes in center

frame.

24122

167-088Q-RUS 3/3/2006

Figure 78

Attach Rockshaft

Page 39

Refer to Figure 79

2. Once rockshaft is aligned with frame, insert

pins through frame and rockshaft.

3. Secure pins with pin rolls.

Refer to Figure 80

4. Attach hydraulic cylinder to rockshaft.

5. Secure cylinder to rockshaft with pin. Slide

washer over pin and secure with cotter pin.

6. Complete steps 4 and 5 to attach remaining

hydraulic cylinders to rockshaft.

Implement Assembly

Figure 79

Secure Rockshaft to Frame

37

24123

Rockshaft Gauge Wheel Tires

Refer to Figure 81

1. Remove wheel nuts from gauge wheel hub

assembly.

2. Attach gauge wheel tire to gauge wheel hub.

3. Secure tire to hub with previously removed

wheel nuts.

4. Repeat process on second tire on gauge

wheel.

5. Complete steps 1-4 to install guage wheels

on opposite side of rockshaft.

24124

Figure 80

Attach Hydraulic Cylinder to Rockshaft

24141

Figure 81

Attach Gauge Wheel Tires to Rockshaft

3/3/2006

167-088Q-RUS

Page 40

ADC2220 & NTA 3510

38

Left Wing Frame

Refer to Figure 82

1. Attach lift straps to the left wing frame in the

rack.

!

CAUTION!

Obey all safety instructions from lifting equipment

manufacturer. Be sure lift straps are securely attached prior to lifting. Be sure lifting equipment has

enough capacity to lift implement.

2. Unscrew and remove all bolts securing left

wing frame to rack.

3. Using a forklift or other implement, remove

left wing frame from rack.

Refer to Figure 83

4. Carefully lower wing frame onto ground. Remove lift straps. Replace straps so frame

can be lifted in position.

5. Align left wing frame and center section

frame.

24125

Figure 82

Attach Lift Straps to Left Wing Frame

Refer to Figures 84 and 85

6. Secure wing frame to center section in both

front (figure 84 ) and back (figure 85) of implement with pin.

24128

Figure 84

Secure Wing Frame to Center Frame

(Front of Implement)

24126

Figure 83

Align Frame

24127

Figure 85

Secure Wing Frame to Center Frame

(Back of Frame)

167-088Q-RUS 3/3/2006

Page 41

Gauge Wheels

Refer to Figure 86

1. Attach gauge wheel arm to backside of left

wing frame.

2. Secure gauge wheel arm to frame using

wing pivot pin (2) and pin roll (1).

Refer to Figure 87

3. Remove tie-down strap and hydraulic cylinder from frame.

4. Attach base end of gauge wheel hydraulic

cylinder to eyebolt weldment on gauge

wheel.

5. Secure rod end of hydraulic cylinder to

gauge wheel arm using pin and cotter pin.

Implement Assembly

Figure 86

Attach Gauge Wheel Arm

39

24142

Refer to Figure 88

6. Attach gauge wheel tire (1) to gauge wheel

hub assembly (2). Secure tire to hub with

wheel nuts.

7. Repeat step 6 to install gauge wheel tire on

other side of gauge wheel arm.

3/3/2006

24144

Figure 87

Attach Hydraulic Cylinder

24143

Figure 88

Gauge Wheel Tires

167-088Q-RUS

Page 42

ADC2220 & NTA 3510

40

Coulter Blades

Refer to Figure 89

1. Attach coulter blade to coulter hub assembly using bolts.

NOTE: If attaching turbo coulter blades,

blades must attach properly with rotation arrow pointing toward direction of travel.

2. Attach remaining blades to coulter hub assemblies.

24110

23343

Figure 89

Coulter Blades

Right Wing Frame

Coulter Blade Arms

Refer to Figure 90

NOTE: On the right wing frame, for shipping purposes, the coulter blade arms were turned to the

side. Coulter blade arms will need to be turned

back to the correct position.

Refer to Figure 91

1. Loosen back bolt of coulter arm with a

wrench.

2. Turn coulter blade arm to correct position.

Arm should be positioned straight out from

frame, not to the side.

24147

Figure 90

Coulter Blade Arm

24148

Figure 91

Loosen Back Bolt

167-088Q-RUS 3/3/2006

Page 43

Refer to Figure 92

3. Secure coulter arm in position with bolt and

nut.

Frame

Refer to Figure 93

1. Attach lift straps to the right wing frame in

the rack.

24149

Figure 92

Secure Arm

Implement Assembly

41

!

CAUTION!

Obey all safety instructions from lifting equipment

manufacturer. Be sure lift straps are securely attached prior to lifting. Be sure lifting equipment has

enough capacity to lift implement.

2. Unscrew and remove all bolts securing right

wing frame to rack.

3. Using a forklift or other implement, remove

right wing frame from rack.

Refer to Figure 94

4. Carefully lower wing frame onto blocks or

stands. Remove lift straps. Replace straps

so frame can be lifted in position.

5. Align right wing frame and center section

frame.

24145

Figure 93

Right Wing Frame

3/3/2006

24146

Figure 94

Righting Frame

167-088Q-RUS

Page 44

ADC2220 & NTA 3510

42

Refer to Figures 95

6. Secure wing frame to center section in both

front and back of implement with pin.

Right Wing

Frame

Pin

24150

Gauge Wheels

Refer to Figure 96

1. Attach gauge wheel arm to backside of right

wing frame.

2. Secure gauge wheel arm to frame using

wing pivot pin (2) and pin roll (1).

Pin

Center Section

Frame

Figure 95

Attach Wing to Center

24151

Figure 96

Attach Gauge Wheels

167-088Q-RUS 3/3/2006

Page 45

Refer to Figure 97

3. Remove tie-down strap and hydraulic cylinder

from frame.

4. Attach base end of gauge wheel hydraulic cylinder to eyebolt weldment on gauge wheel.

5. Secure rod end of hydraulic cylinder to gauge

wheel arm using pin and cotter pin.

Refer to Figure 98

6. Attach gauge wheel tire (1) to gauge wheel

hub assembly (2). Secure tire to hub with

wheel nuts.

7. Repeat step 6 to install gauge wheel tire on

other side of gauge wheel arm.

Implement Assembly

24152

Figure 97

Gauge Wheel Hydraulic Cylinder

43

Coulter Blades

Refer to Figure 99

1. Attach coulter blade to coulter hub assembly using bolts.

NOTE: If attaching turbo coulter blades,

blades must attach properly with rotation arrow pointing toward direction of travel.

2. Attach remaining blades to coulter hub assemblies.

24143

Figure 98

Attach Gauge Wheel Tires

24110

23343

3/3/2006

Figure 99

Coulter Blades

167-088Q-RUS

Page 46

ADC2220 & NTA 3510

44

Lights

Refer to Figures 100 and 101

1. Insert lights in to light bracket. Red light

needs placed on inside closest to center of

frame. Place amber light on outside farthest away from center of frame.

2. Connect lights to light harness.

24153

Figure 100

Insert Lights into Light Bracket

Openers and Press Wheels

Refer to Figure 102

1. Locate all openers to be attached to righthand side wing frame.

To Center of

Frame

24154

To Wing

Frame

Figure 101

Lights

24183

Figure 102

Openers

167-088Q-RUS 3/3/2006

Page 47

Refer to Figure 103

2. Stagger openers on wing frame as shown.

3. Secure each opener to frame and parallel

opener mount plate with a 5/8” bolt through top

hole of opener and opener mount plate.

4. Secure opener to frame and parallel opener

mount plate with a 5/8” u-bolt through the bottom holes of opener and opener and mount

plate.

5. Secure bolt and u-bolt with 5/8” lock washer

and 5/8” hex nut.

6. Repeat steps 2-5 to install openers.

24184

Figure 103

Openers on Frame

Implement Assembly

45

Refer to Figure 104

7. Insert pin roll (2) into press wheel arm adjustment handle (1).

8. Place press wheel arm adjustment handle (1)

down through opener. From underneath opener, attach opener trunion (4) to press wheel arm

adjustment handle (1). Secure with spring (3)

and pin clevis (5).

24155

24156

Figure 104

Press Wheel Arm Adjustment Handle

3/3/2006

167-088Q-RUS

Page 48

ADC2220 & NTA 3510

46

Refer to Figure 105

9. If not already attached, attach press

wheel (8) to press wheel arm (5) with

bolt (7) and lock washer (6).

10. Insert press wheel arm pivot tube (3)

and parallel arm pivot bushings (4) into

parallel arm (5).

11. Secure parallel arm (5) to opener body

with bolt (1) and hex nut (2).

12. Complete steps 9-11 for all press

wheels.

Air Towers

Refer to Figure 106

NOTE: On the NTA3510 frame there are several white markings. These markings indicate air tower placement.

24185

Figure 105

Press Wheel

24157

Figure 106

Marking for Air Tower

Refer to Figure 107

1. Attach air tower to NTA3510 frame

where indicated by white markings.

24158

Figure 107

Air Tower

167-088Q-RUS 3/3/2006

Page 49

Refer to Figure 108

2. Secure air tower to frame using u-bolt and hardware.

Refer to Figure 109

3. Attach 1 inch seed hoses from top of air tower to

openers.

4. Attach 2 1/2 seed hose to bottom of air tower. Secure with hose clamp.

Implement Assembly

Figure 108

Securing Air Tower

47

24159

Folding Hydraulic Cylinder

Refer to Figure 110

1. Attach folding hydraulic cylinder (2) to arm on

wing frame.

2. Insert bushing (1) through cylinder (2) and arm.

3. Secure hydraulic cylinder (2) to arm on wing

frame. Use pin clevis (5), flat washer (3), and cotter pin (4).

24186

Figure 109

Air Tower Hoses

3/3/2006

24160

Figure 110

Hydraulic Cylinder

167-088Q-RUS

Page 50

ADC2220 & NTA 3510

48

Cart Hook-Up

Refer to Figure 111

1. Attach one cart link weldment (5) to NTA3510

frame. Use cart link pin (1) and pin roll (2) to secure.

2. Attach the other cart link weldment (5) to

NTA3510 frame. Use cart link pin (1) and pin roll

(2) to secure.

To attach ADC2220 to NTA3510:

1. Attach center of cart to cart link weldment (5) using bushing spindles (3), center cart link pin (4),

and pin roll (2).

2. Attach each end of cart to cart link weldment (5)

using bushing spindles (3), cart link pin (1), and

pin roll (2).

Air Drill Cart

Frame

24173

Figure 111

Cart Hook-Up

167-088Q-RUS 3/3/2006

NTA3510

Frame

Page 51

Appendix

Torque Values Chart for Common Bolt Sizes

Appendix

49

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 436597

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch4N · m ft-lb N · m ft-lb N · m ft-lb

Grade 8

Bolt Size

(Metric)

1

in-tpi = nominal thread dia.in inches-threads per inch

2

N· m = newton-meters

3

ft-lb= foot pounds

4

mm x pitch = nominal thread dia. in millimeters x thread pitch

Bolt Head Identification

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

Tire Inflation Chart

Tire Size Inflation PSI Tire Size Inflation PSI

7.50 x 20" 4-Ply Drill Rib 28 11L x 15" 6-Ply Rib Implement 28

9.0 x 22.5 10-Ply Highway Service 70 70 11L x 15" 12-Ply Rib Implement 52

9.0 x 24" 8-Ply Rib Implement 40 12.5L x 15" 8-Ply Rib Implement 36

9.5L x 15" 6-Ply Rib Implement 32 12.5L x 15" 10-Ply Rib Implement 44

9.5L x 15" 8-Ply Rib Implement 44 16.5L x 16.1" 10-Ply Rib Implement 36

9.5L x 15" 12-Ply Rib Implement 60 21.5 x 16.1” SC 10-Ply Rib Implement 28

3/3/2006

167-088Q-RUS

Page 52

Great Plains Manufacturing, Inc.

Corporate Office: PO. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...