Page 1

Table of Contents Index

Operator Manual

ADC2220

Air Drill Cart

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

16263

Illustrations may show optional equipment not supplied with standard unit, may depict

an ADC1150 or ADC2350/B model where a topic is identical, and may depict any of

several air drill implements.

ORIGINAL INSTRUCTIONS

© Copyright 2012 Printed 2012-10-17 167-073M

Table of Contents Index

EN

Page 2

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ......................................1

Safety Decals .................................................................6

Introduction ................................................................12

Air Cart Document Family ............................................12

Description of Unit ........................................................ 12

Intended Usage ........................................................12

Using This Manual........................................................12

Definitions................................................................. 12

Owner Assistance ........................................................13

Preparation and Setup ............................................... 14

Initial Setup...................................................................14

Pre-Setup Checklist......................................................14

Hitching ........................................................................14

Hitching Air Cart to Tractor.......................................15

Make Electrical Connections ....................................15

Make Hydraulic Connections.................................... 16

Carts Y1007 and Earlier .......................................16

Carts Y1078 and Later .........................................16

Y1078+ Hydraulic Connections ............................17

Set Up the Implement............................................... 18

Operating Instructions...............................................19

General Description......................................................19

Pre-Start Checklist .......................................................19

Hopper Lids .................................................................. 20

Lid Opening ..............................................................20

Lid Closing................................................................ 20

Strainer.....................................................................20

Auger Operations .........................................................21

Deploying Auger.......................................................21

Auger Hydraulic Controls..........................................21

Verify Auger Off .................................................... 22

Diverter Valve ....................................................... 22

Auger Direction Valve...........................................22

Auger Inlet Orientation .............................................23

Auger Inner Arm Pin.................................................23

Storing Auger ...........................................................23

Auger Swing Arm......................................................23

Meter Doors..................................................................24

Meter Door Opening.................................................24

Meter Door Closing...................................................24

Meter Hand Crank ........................................................ 25

Operating the Hand Crank........................................25

Transport ...................................................................... 26

Minimum Towing Vehicle..........................................26

Approximate Assembly Weights .............................. 27

Pre-Transport Checklist ........................................... 28

Loading Material .......................................................... 29

Fan Operation .............................................................. 31

Acremeter Operation.................................................... 32

Normal Operating Sequence.................................... 32

Dormant Display................................................... 32

Field Operations........................................................... 33

Single Hopper Operation.......................................... 33

Final Field Checklist ................................................. 33

Planting Sequence ................................................... 33

Planting .................................................................... 33

Planting Speed..................................................... 33

Walkboard Steps.......................................................... 34

Removing the Left Lower Steps ............................... 34

Unloading the Cart ....................................................... 34

Unloading Closeout.................................................. 36

Parking......................................................................... 37

Storage ........................................................................ 37

Loup II Monitor Operation ......................................... 38

Normal Start-up............................................................ 38

Normal Operate Screen ........................................... 39

Changing Display Size ............................................. 40

Changing Displayed Functions ................................ 41

Alarms ...................................................................... 44

Should be Seeding............................................... 44

Low Fan Speed .................................................... 45

Empty Bin............................................................. 46

Blockage Module...................................................... 47

Communication Error ............................................... 49

Special Start-up........................................................ 50

Learn New System............................................... 50

System Settings ........................................................... 54

Installation ................................................................ 55

Install New System............................................... 55

Replace a Sensor................................................. 55

Add a Sensor ....................................................... 55

Remove a Sensor ................................................ 55

Implement Setup ...................................................... 56

Units ..................................................................... 56

Implement Width ..................................................56

Clear Field Area ...................................................56

Clear Total Area ................................................... 56

Speed Settings......................................................... 57

Pulses Per Rev .................................................... 57

© Copyright 1998, 2005, 2008, 2009, 2012 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2012-10-17 Cover Index 167-073M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Wheel Pulses Per 400 Feet ................................. 57

Speed Calibration................................................. 57

Bin Settings.............................................................. 60

Meter Shaft Settings ................................................ 61

Pulses per Rev (Meter) ........................................ 61

Low Alarm Point ................................................... 61

High Alarm Point .................................................. 61

Blockage Module Settings ....................................... 62

Runs per Module Setup ....................................... 62

Individual Runs Setup .......................................... 62

Blockage Module Test.......................................... 62

Blockage Calibration ............................................ 62

Global Settings......................................................... 64

Volume/Pitch ........................................................ 64

Backlight............................................................... 64

Contrast................................................................ 64

Adjustments ............................................................... 65

Meter Rate Adjustment ................................................ 66

Check Flute Shaft Configuration .............................. 66

Find Your Chart and Rate ........................................ 67

Target Rate Adjustments ..................................... 67

Meter Rate Adjustment ............................................ 67

Quick-Change Sprockets ..................................... 68

Meter Box Gears .................................................. 68

Gearbox Shifter .................................................... 68

Meter Calibration.......................................................... 69

Calibration Procedure and Example .................... 69

Changing Meter Flutes................................................. 72

Fan Speed Adjustment ................................................ 73

Hydraulic Fan Start-Up ............................................ 73

Recommended Fan Speeds ................................ 74

Clutch Lock-Up ............................................................ 74

Seed Rate Charts ....................................................... 75

Barley........................................................................... 75

Canary Bird Feed......................................................... 76

Canola.......................................................................... 77

Durum .......................................................................... 78

Flax .............................................................................. 79

Hybrid Pearl Millet........................................................ 80

Oats ............................................................................. 81

Oats ............................................................................. 82

Sorghum ...................................................................... 83

Soybeans ..................................................................... 84

Sunflower......................................................................85

Hard Wheat ..................................................................86

Soft Wheat....................................................................87

Fertilizer Rate Charts....................................................88

11520 Fertilizer .........................................................88

Urea Fertilizer ...........................................................89

Troubleshooting .........................................................90

Maintenance and Lubrication....................................95

Chain Maintenance.......................................................96

Chain Clips ...............................................................96

Chain Slack...............................................................96

Hub Chain.............................................................96

Clutch Input Chain ................................................97

Gearbox Input Chains...............................................98

Gearbox Output Chains ............................................98

Lubrication and Scheduled Maintenance .....................99

Options ......................................................................105

Appendix A - Reference Information ......................107

Specifications and Capacities.....................................107

Tire Inflation Chart ......................................................107

Chain Routing.............................................................108

Torque Values Chart ..................................................113

Appendix B - Initial Setup ........................................114

Cart Drive System ......................................................114

ADC2220 Sprocket Sizes .......................................114

Install Loup II Console ................................................115

Console Harness ....................................................115

About Radar............................................................116

Power Connection ..................................................116

Monitor Harness to Hitch Connection .................116

Harness Interconnection.........................................116

Initial Loup-II Setup.................................................116

Appendix C - Vintage Carts .....................................117

Hook-Up: Y1077 and Earlier Carts .............................117

Y1077- Hydraulic Connections for NTA..............117

Y1077- Hydraulic Connections for ADI ...............118

Implement Lift .....................................................118

Loup (I) Setup and Operation .....................................119

Warranty .....................................................................126

Index ..........................................................................127

167-073M Table of Contents Index 2012-10-17

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals”onpage6,

thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

2012-10-17 Table of Contents Index 167-073M

Page 6

2 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

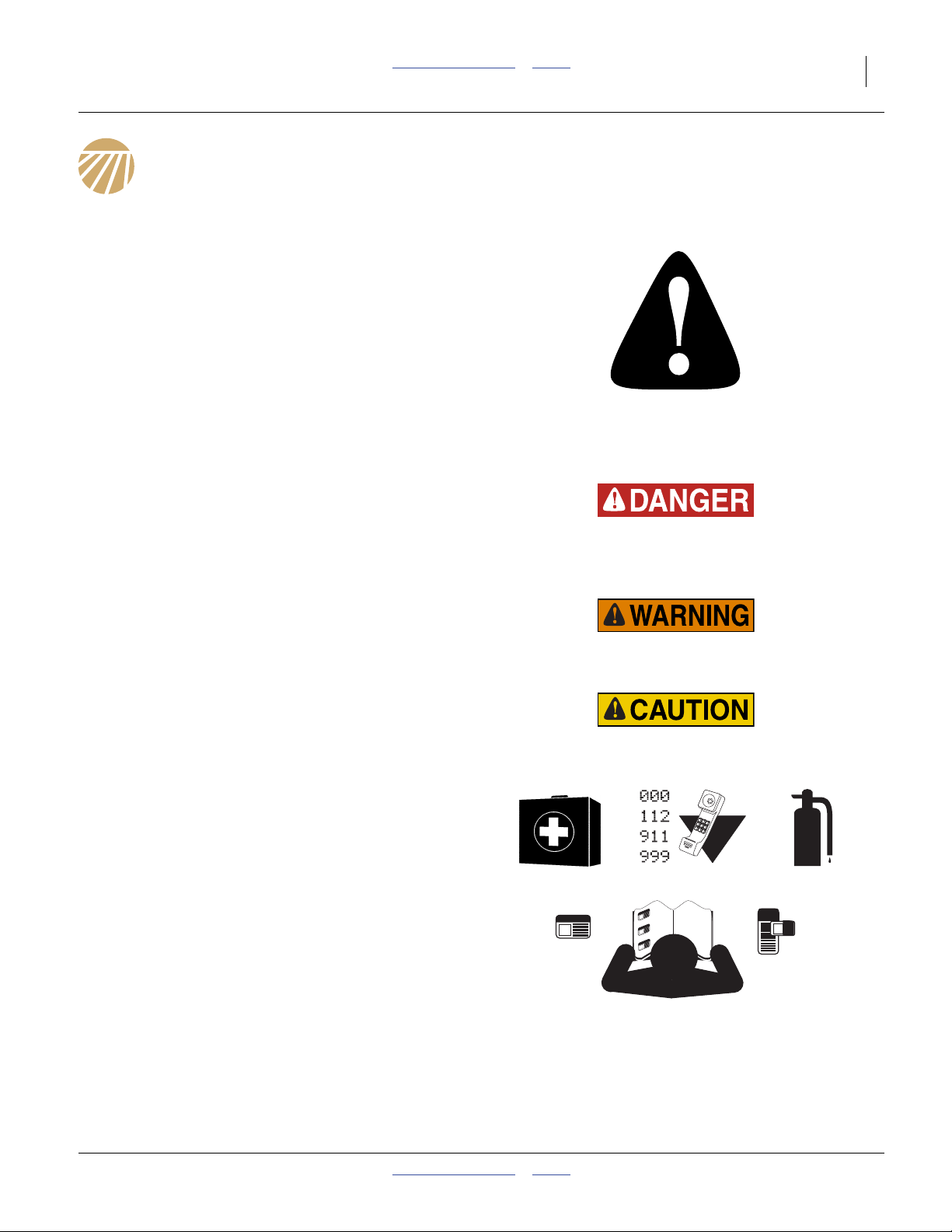

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical attention

from a health care provider familiar with this type of injury.

Use A Safety Chain

▲ Use a safety chain to help control drawn machinery should

it separate from tractor drawbar.

▲ Use a chain with a strength rating equal to or greater than

the gross weight of towed machinery.

▲ Attach chain to tractor drawbar support or other specified

anchor location. Allow only enough slack in chain to permit

turning.

▲ Replace chain if any links or end fittings are broken,

stretched or damaged.

▲ Do not use safety chain for towing.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever

driving on public roads.

▲ Use lights and devices provided with air cart and drill.

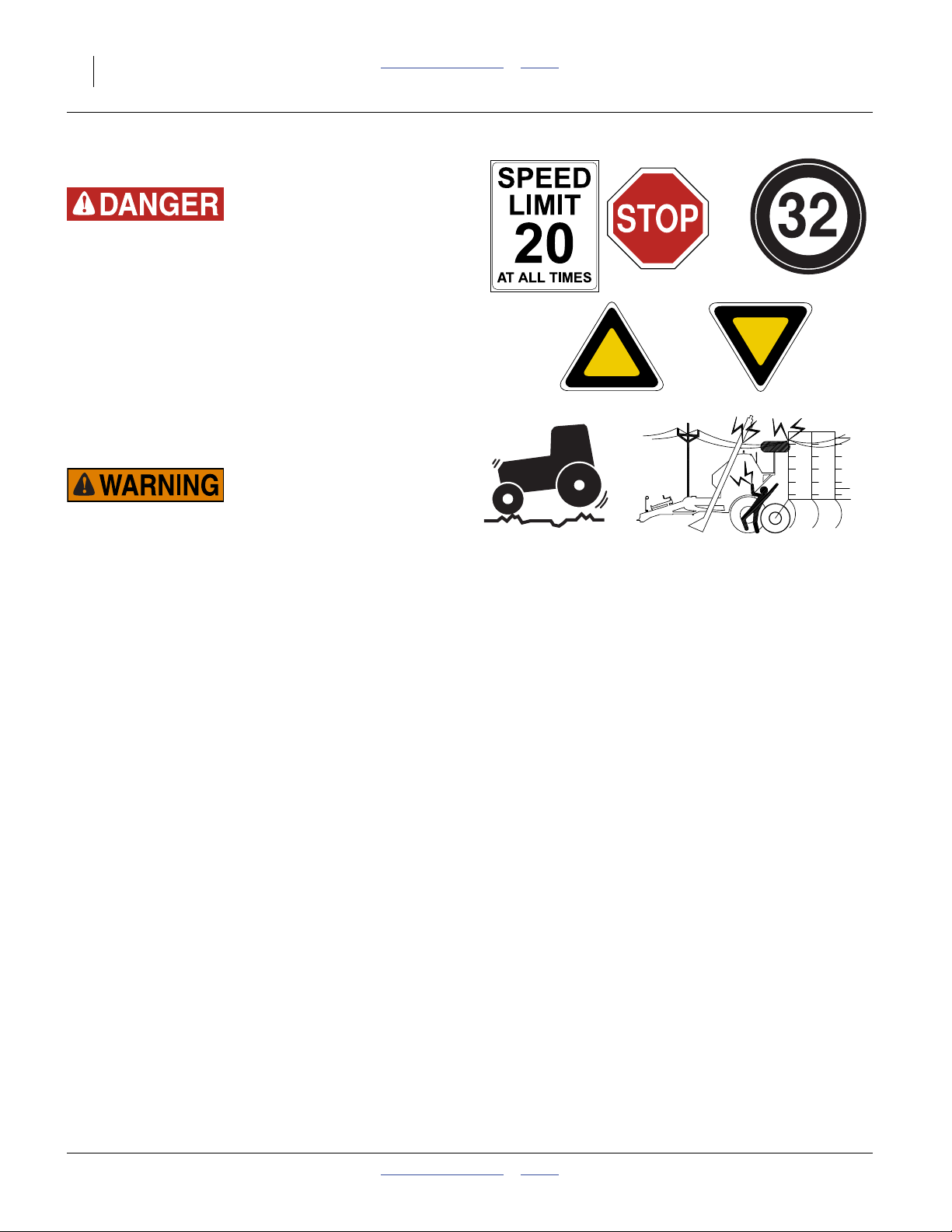

Check for Overhead Lines

Seed auger or drill markers contacting overhead

electrical lines can introduce lethal voltage levels on air

cart, drill and tractor frames. A person touching almost

any metal part can complete the circuit to ground,

resulting in serious injury or death. At higher voltages,

electrocution can occur without direct contact.

▲ Avoid overhead lines during seed loading, unloading and

marker operations.

167-073M Table of Contents Index 2012-10-17

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

Transport Machinery Safely

Maximum transport speed for air cart is 20 mph

(32 km/h). Some rough terrains require a slower speed.

Sudden braking can cause a towed load to swerve and

upset.

▲ Do not tow a load which weighs more than 1.5 times the

weight of the tractor.

▲ Latch auger properly before transporting.

▲ Do not exceed 20 mph (32 km/h). Never travel at a speed

which does not allow adequate control of steering and

stopping. Reduce speed if towed load is not equipped with

brakes.

▲ Comply with national, regional and local laws.

▲ Follow your tractor manual recommendations for maximum

hitch loads. Insufficient weight on tractor steering wheels

will result in loss of control.

▲ Carry reflectors or flags to mark air cart and drill in case of

breakdown on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions under

“Specifications and Capacities” on page 107.

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to loud noise can cause

hearing impairment or hearing loss, wear suitable hearing

protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

2012-10-17 Table of Contents Index 167-073M

Page 8

4 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper use

can seriously injure persons, animals, plants, soil and

property.

▲ Do not use liquid treatments with air cart.

▲ Read and follow chemical manufacturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Avoid inhaling smoke from any type of chemical fire.

▲ Never drain, rinse or wash dispensers within 100 feet of a

freshwater source, nor at a car wash.

▲ Store or dispose of unused chemicals as specified by

chemical manufacturer.

▲ Dispose of empty chemical containers properly. Laws

generally require power rinsing or rinsing three times,

followed by perforation of the container to prevent re-use.

Confined Space

With grain or fertilizer present, and once used for

hazardous fertilizers, or seeds with hazardous

treatments, your hoppers may become

“permit-required confined spaces”

under applicable statutes, regulations, insurance rules or

business policy.

▲ A full, encrusted or bridged grain hopper can be a rapid

suffocation hazard.

▲ Even when empty, hazardous fumes or low oxygen may be

present. You can be quickly overcome even with the hopper

lid open.

▲ Do not enter a hopper for material loading, material

unloading, hopper cleaning or meter maintenance.

▲ Clean hopper by power washing from outside the hopper

top.

▲ Remove large obstructions, perform meter maintenance,

and perform sensor maintenance by removing meters from

bottom of empty hopper.

Shutdown and Storage

▲ Clean out and safely store or dispose of residual chemicals.

▲ Secure air cart using blocks and the stand provided.

▲ Store in an area where children normally do not play.

+

167-073M Table of Contents Index 2012-10-17

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

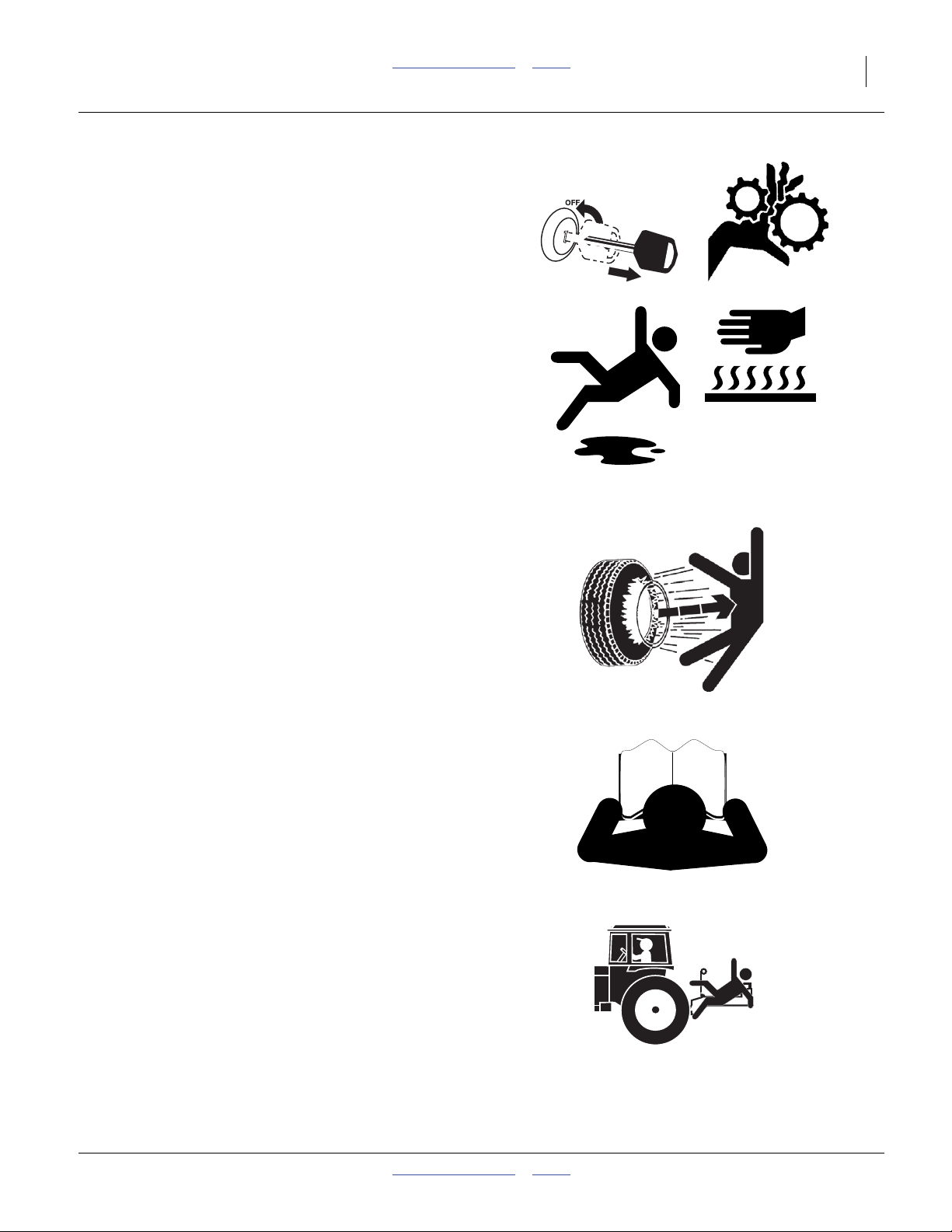

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper tools

and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Put tractor in park, turn off engine, and remove key before

performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on cart.

▲ Inspect all parts. Make sure parts are in good condition and

installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from drill before

operation.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all air cart and drill functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave air cart unattended with tractor engine

running.

▲ Do not dismount a moving tractor. Dismounting a moving

tractor could cause serious injury or death.

▲ Do not stand between the tractor and air cart during

hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

2012-10-17 Table of Contents Index 167-073M

Page 10

6 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

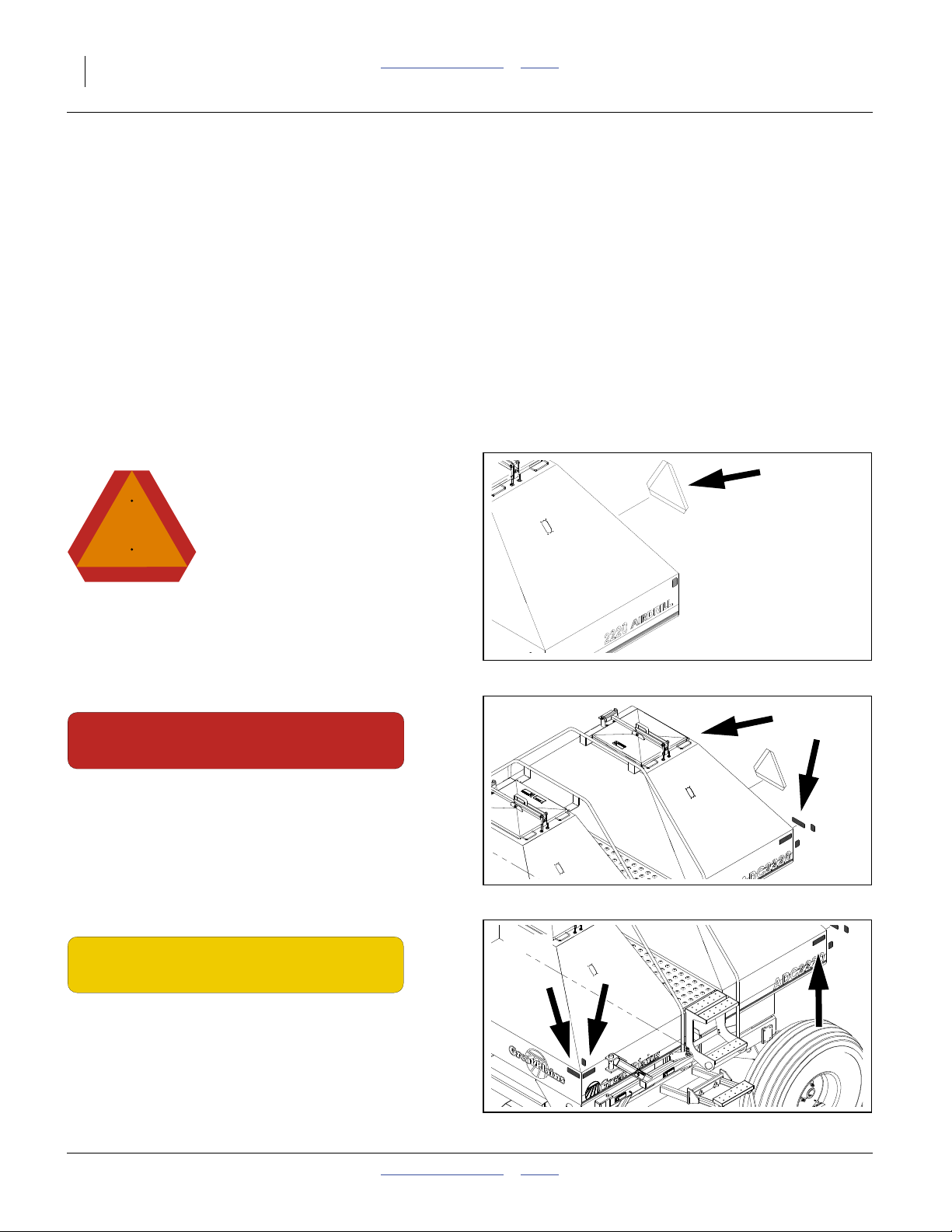

Safety Decals

Safety Reflectors and Decals

Your air cart comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your air cart.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

818-055C

Slow Moving Vehicle Reflector

On the back of the aft hopper, frame center;

1 total

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

16192

838-266C

Red Reflectors

On the outside corners of aft hopper;

2 total

838-265C

Amber Reflectors

Front and outside leading corner of front hopper,

outside rear corner of rear hopper;

6 total

16251

16251

167-073M Table of Contents Index 2012-10-17

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

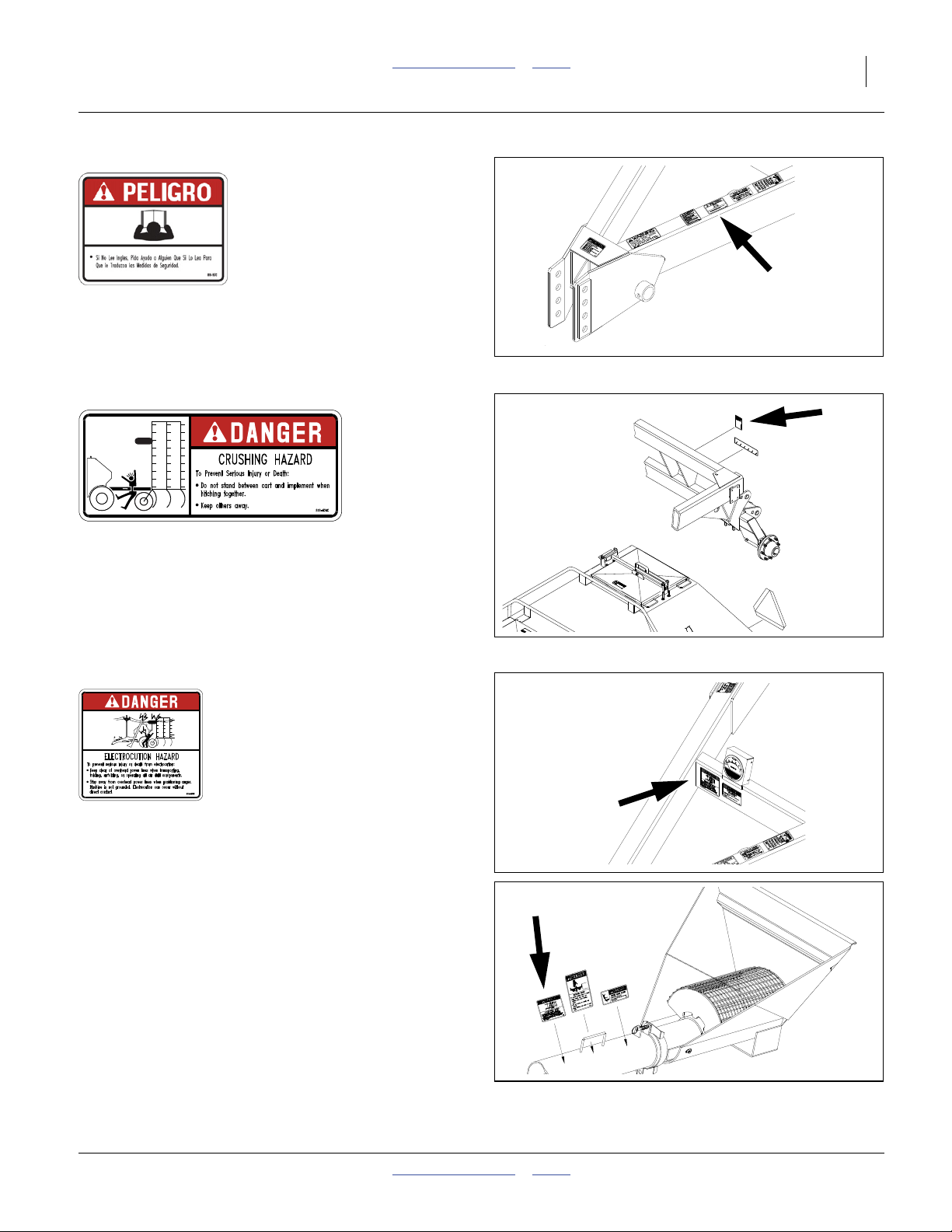

818-557C

Danger: Cannot Read English

On top of left draw bar near hitch,

1 total

16193

818-624C

Danger: Hitch Crushing Hazard

On the left vertical beam at rear hitch

CTA 4000 setup option only);

1 total

818-627C

Danger: Electrocution Hazard

On the right side, outside face of front frame;

2 total

16251

16193

16190

2012-10-17 Table of Contents Index 167-073M

Page 12

8 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

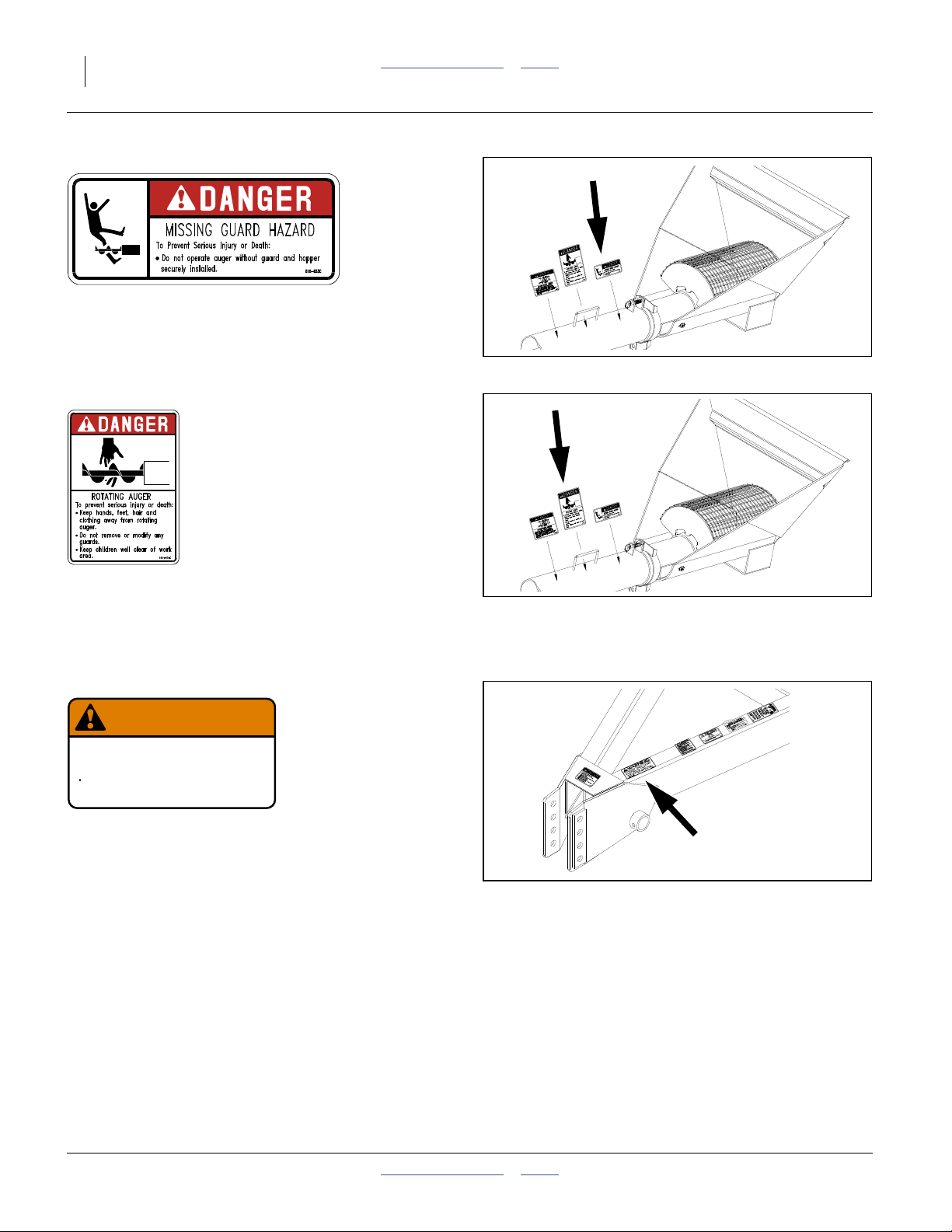

818-633C

Danger: Missing Guard Hazard

On the auger tube near inlet,

1 total

16190

818-634C

Danger: Rotating Auger

On the auger tube near inlet,

1 total

818-188C

WARNING

EXCESSIVE SPEED HAZARD

To Prevent Serious Injury or Death:

Do Not exceed 20 mph maximum transport

speed. Loss of vehicle control and/or machine

can result.

Warning: Excessive Speed

On top of tongue at hitch;

1 total

818-188C Rev. C

16190

16193

167-073M Table of Contents Index 2012-10-17

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 9

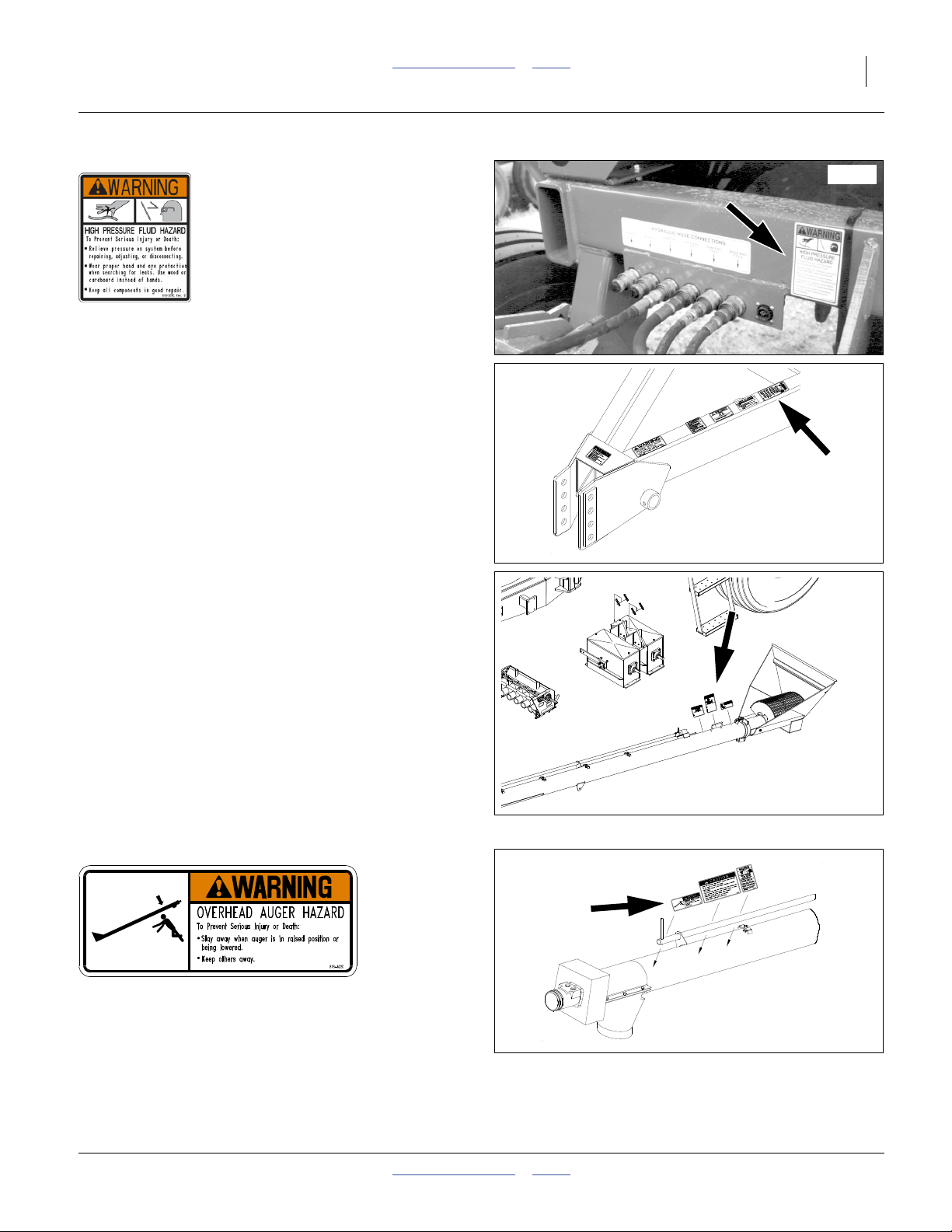

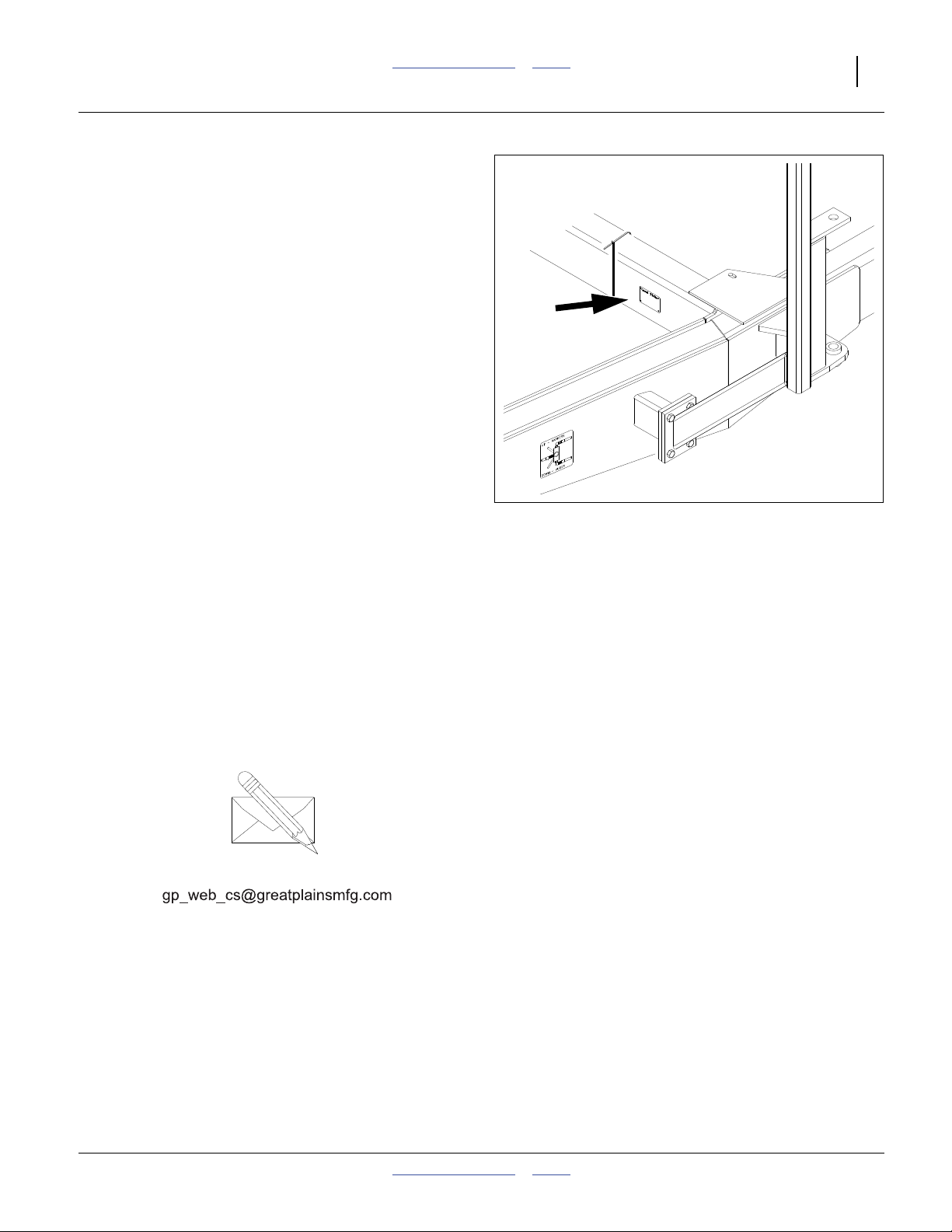

818-339C

Warning: High Pressure Fluid Hazard

At hydraulic connection panel,

on hitch right drawbar,

on seed auger near hand-hold;

3 total

16191

16193

16251

818-622C

Warning: Overhead Auger Hazard

On auger near each end,

2 total on auger tube

2012-10-17 Table of Contents Index 167-073M

16189

Page 14

10 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

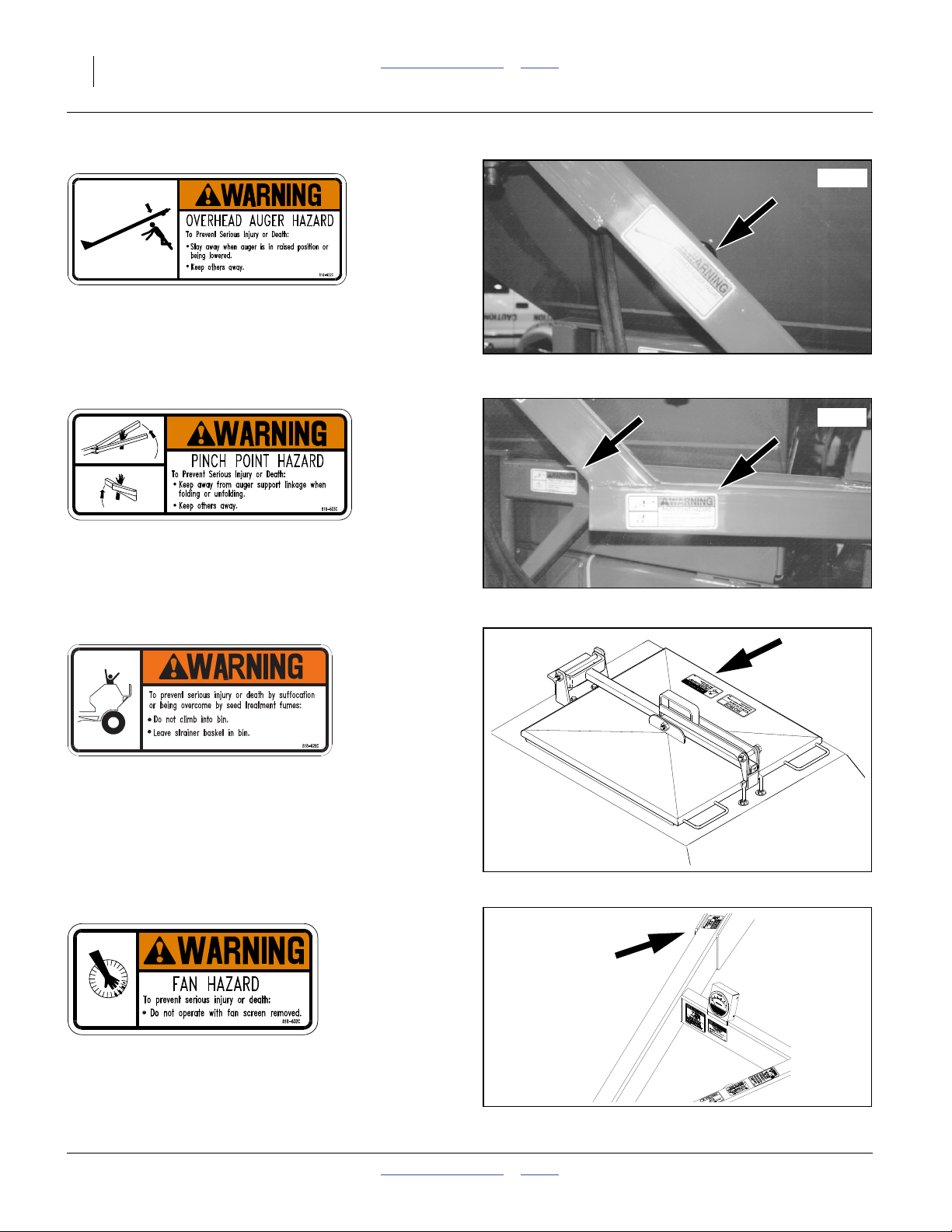

818-622C

16183

Warning: Overhead Auger Hazard

On auger swing arm,

1 total on arm

818-623C

16182

Warning: Pinch Point Hazard

On both sides of auger swing arm;

2 total

818-628C

Warning: Confined Space

On lid, walkboard side, each hopper;

2 total

818-632C

16191

Warning: Fan Hazard

On the left tongue tube at fan,

1 total

167-073M Table of Contents Index 2012-10-17

16193

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 11

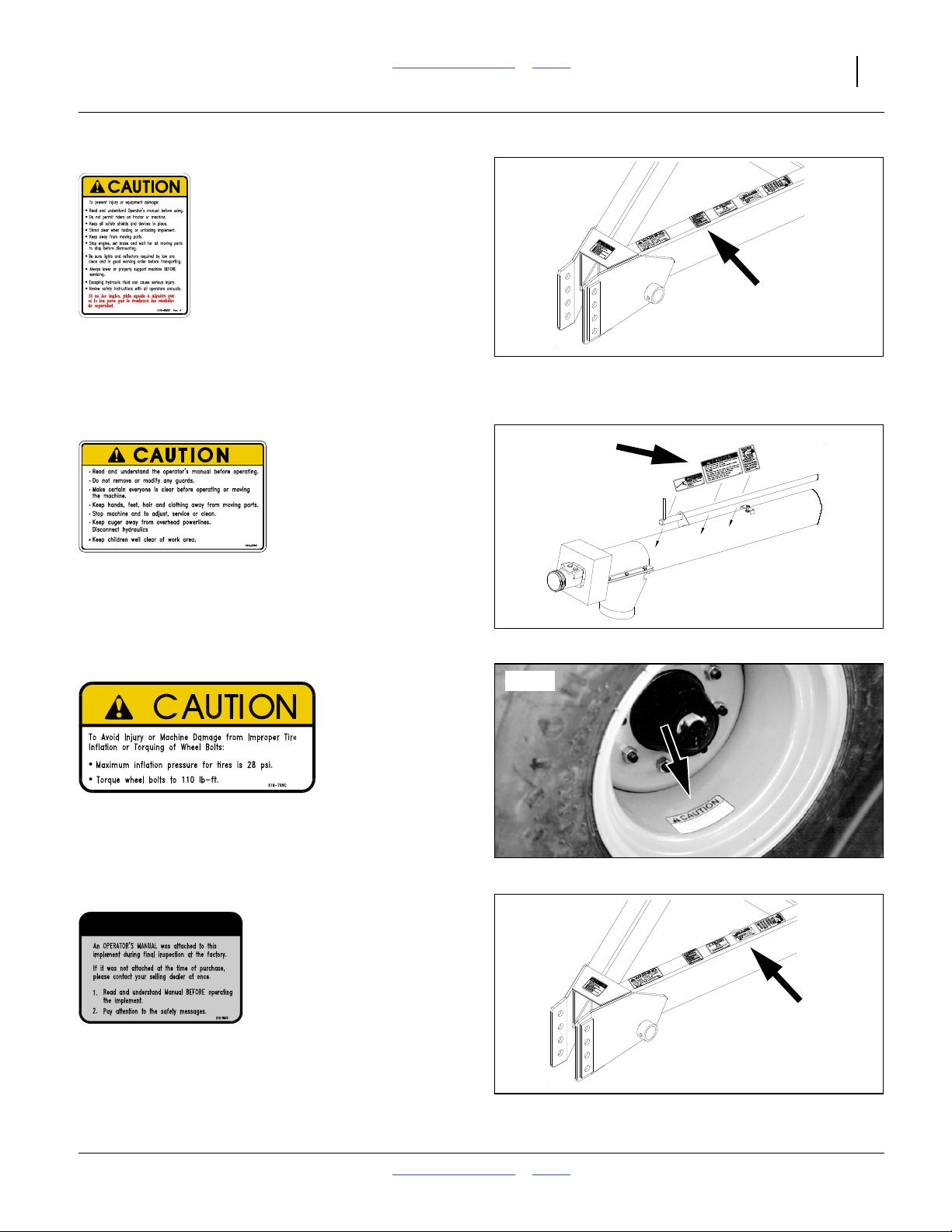

818-630C

Caution: General

On the main tool bar at hitch;

1 total

818-635C

Caution: Auger General

On discharge end of auger:

1 total

818-789C

16193

16189

16247

Caution: Tire Pressure

On each wheel rim:

2 total

818-560C

NOTICE TO OWNER

Safety: Notice to Owner

On tongue near hitch;

1 total

2012-10-17 Table of Contents Index 167-073M

16193

Page 16

12 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Introduction

Great Plains welcomes you to its growing family of new

product owners. Your Air Drill Cart has been designed

with care and built by skilled workers using quality

materials. Proper setup, maintenance, and safe

operating practices will help you get years of satisfactory

use from the machine.

Air Cart Document Family

167-073M Owner’s Manual (this document)

including Seed Rate charts

167-073P Parts Manual

Description of Unit

The ADC2220 is a pull-type implement for volumetric

seeding. A hydraulic fan creates an airflow to supply

seed and dry treatments to a compatible trailing Great

Plains drill.

The ADC2220 Air Drill Cart is compatible with the

following Great Plains air drills:

ADI334 34-foot Air Drill Implement

ADI345 45-foot Air Drill Implement

CTA4000 40-foot Conventional Tillage Air Drill

CTA4000HD Heavy Duty Tillage Air Drill

NTA3010 30-foot No-Till Air Drill

NTA3510 35-foot No-Till Air Drill

Note: If the air cart and drill were not purchased on the

same original factory order, one or both may not

include compatible components. The implements

above may be configured for use with other air

carts. Check with your dealer before hitching.

Intended Usage

Use the air cart and drill to seed production-agriculture

crops only. Do not modify the air cart for use with

attachments other than Great Plains options and

accessories specified for use with the air cart.

Using This Manual

This manual will familiarize you with safety, assembly,

operation, adjustments, troubleshooting, and

maintenance. Read this manual and follow the

recommendations to help ensure safe and efficient

operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Figure 1

Air Cart and Drill

16179

R

L

R

F

16263

U

B

L

D

Figure 2

Left/Right Notation

Definitions

The following terms are used throughout this manual.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

A crucial point of information related to the preceding topic.

For safe and correct operation, read and follow the directions

provided before continuing.

Note: Useful information related to the preceding topic.

167-073M Table of Contents Index 2012-10-17

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 13

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Refer to Figure 3

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts. Always

use the serial and model number when ordering parts

from your Great Plains dealer. The serial-number plate is

located on the left side of the cart frame below the front

hopper.

Record your air cart model and serial number here for

quick reference:

Model Number:__________________________

Serial Number: __________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

For further assistance write to:

Figure 3

Serial Number Plate

16194

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

785-823-3276

2012-10-17 Table of Contents Index 167-073M

Page 18

14 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Preparation and Setup

This section helps you prepare your tractor, air cart and

drill for use. Before using the air cart in the field, you

must hitch the air cart to a suitable tractor, compatible

drill, and also setup the drill.

Initial Setup

Prior to first use, the following items need to be checked

or completed:

• The cart must have the correct sprockets for your drill.

See “Cart Drive System” on page 114.

• The seed monitor console must be installed in the

tractor cab. See “Install Loup II Console” on

page 115.

• Initial configuration data must be loaded in the

console. See “Initial Loup-II Setup” on page 116.

Pre-Setup Checklist

1. Read and understand “Important Safety

Information” on page 1.

2. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and

lubricated. See “Lubrication and Scheduled

Maintenance” on page 99.

4. Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged.

See “Safety Decals” on page 6.

5. Inflate tires to pressure recommended and tighten

wheel bolts as specified. “Appendix A - Reference

Information” on page 107.

Hitching

When ready for planting, the air cart is part of an

assembly that includes the tractor, the air cart, and the

drill. When hitching for the first time, hitch cart to tractor

first.

Note: Static tongue weight of a loaded cart is about 5,500

pounds on level ground and more when facing

downhill.

Once the air cart and drill are hitched together, they are

usually left connected, unless parking or storage

considerations require separation.

This manual includes full details only for the leading air

cart’s forward hitch. Consult the drill manual for trailing

drill hitching.

Crushing Hazard:

You may be severely injured or killed by being crushed

between the tractor, air cart and drill. Do not stand or place

any part of your body between machines being hitched. Stop

tractor engine and set park brake before installing hitch pins.

167-073M Table of Contents Index 2012-10-17

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 15

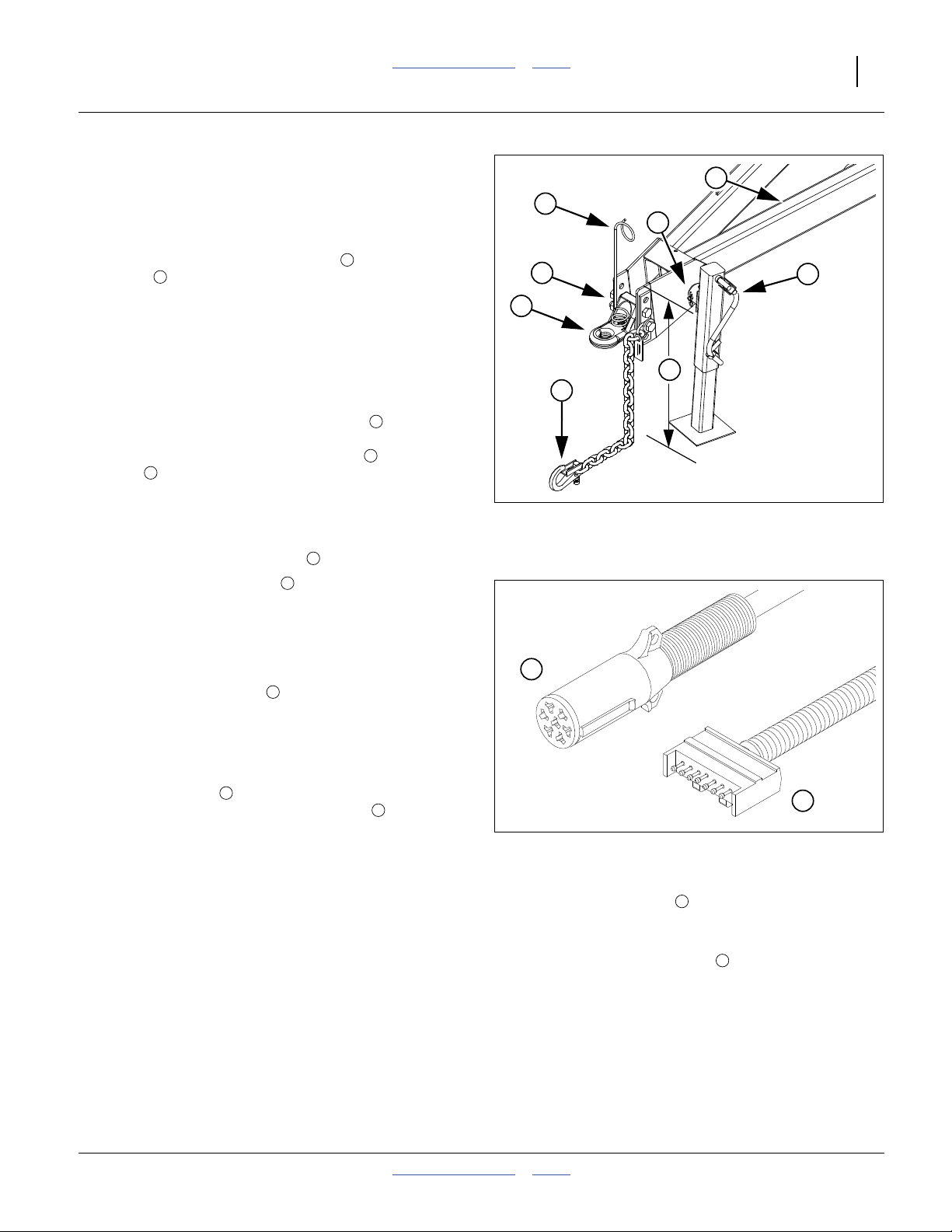

Hitching Air Cart to Tractor

To ensure consistent planting at the drill, the main frame

of the air cart needs to be level. Set the tongue height

before hitching for the first time.

Refer to Figure 4

1. Using the crank on the jack stand , adjust the

height of the tongue to:

as measured from the ground to the top of the

tongue above the hitch holes center-line. The cart

frame is level at this height.

2. Back the tractor up to the cart, and confirm that

when hitched, the cart tongue will remain at this

height. If not, adjust either the height of the tractor

hitch, or the location of the hitch strap .

2

30 inches (76.2cm).

1

5

3

7

4

5

6

8

1

2

To adjust the height of the hitch strap , remove the

4

bolts , and reset the strap up or down.

If the strap needs to be moved so far that only one

bolt would be holding it, the strap may be inverted.

Strap inversion requires removing the bolt that

retains the spring hose loop , and re-mounting it.

3. Use the jack stand crank to raise the hitch strap

slightly. Back the tractor so that its drawbar is aligned

with the strap hole.

4. Shut off the tractor and set the parking brake.

5. Insert and secure the hitch pin.

6. Attach the safety chain to a suitable anchor on the

tractor.

7. Operate the jack stand crank to retract the inner leg

and base several inches. Secure the crank handle in

the spring clip on the stand.

8. Remove the pin at the stand swivel. Remove the

stand and re-pin it on the storage stob (not visible

in figure) inside the hitch beam.

7

3

1

6

5

8

Make Electrical Connections

The cart has connections in front and back.

Refer to Figure 5

Make sure tractor is shut down with accessory power off

before making connections.

Figure 4

Hitch

26300

1

2

Figure 5

Cart Front Hitch Connections

1. Mate the lighting plug to the outlet connector on

the tractor. This connection is also passed through to

the back of the cart for the trailing drill.

2. Mate the seed monitor plug to the outlet

connector on the tractor. This connection is also

passed through to the back of the cart.

3. Secure cables so they are clear of moving parts at

the hitch.

1

2

26467

29099

2012-10-17 Table of Contents Index 167-073M

Page 20

16 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Make Hydraulic Connections

High Pressure Fluid Hazard:

Only trained personnel should work on system hydraulics!

Escaping fluid under pressure can penetrate the skin causing

serious injury. Check all hydraulic lines and fittings before

applying pressure. Use paper or cardboard, NOT BODY

PARTS, to check for suspected leaks. Wear protective gloves

and safety glasses or goggles when working with hydraulic

systems. If an accident occurs, seek immediate medical

attention from a physician familiar with this type of injury.

The air cart itself consumes hydraulic power for one or

two circuits, and has a low pressure sump return line.

The cart also passes through three circuits necessary for

drill operations.

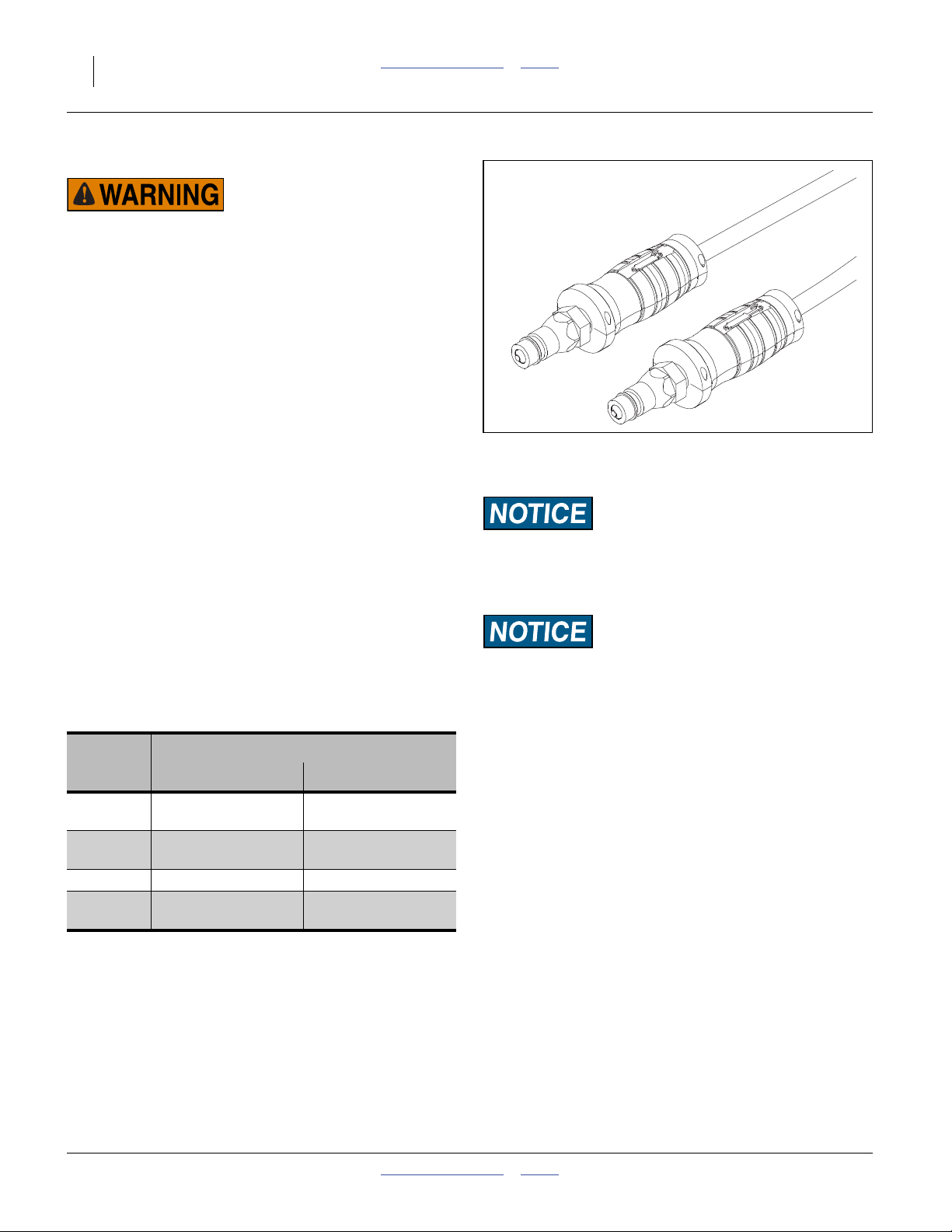

Current Style Color Coded Hose Handles

Refer to Figure 6

Great Plains hydraulic hoses have color coded handle

grips to help you hookup hoses to your tractor outlets.

Hoses that go to the same remote valve are marked with

the same color.

To distinguish hoses on the same hydraulic circuit, refer

to the symbol molded into the handle grip. Hoses with an

extended-cylinder symbol feed cylinder base ends.

Hoses with a retracted-cylinder symbol feed cylinder rod

ends.

Hose connections are also passed through to a rear

panel when the air cart leads the drill. Hoses that go to

the same remote valve are marked with the same color.

Color

Code

<none>

(decal)

Black Hydraulic Fan

(Extend side only)

Blue <no function> Lift Cylinders

Green

Hydraulic Function

on Cart on Drill

SUMP return (available)

Fold Cylinders

(ADI & NTA only)

Auger

Fold (ADI only)

Marker Cylinders

Figure 6

Color Coded Hose Grips

For CTA implements, some tractors require an auxiliary flow

kit to prevent damage to the hydraulic pump. Contact a factory

trained service technician before hooking to cart and CTA

implement.

The hose and large connector labeled sump refers to high

volume hydraulic motor return and should always be

connected to the port on the tractor capable of handling high

volume low pressure return oil. DO NOT connect this line to

low volume case drain lines or low volume sump lines on the

tractor. See tractor manufacturer’s recommendations for high

volume hydraulic motor return.

31733

1. Make sure all tractor levers are in neutral or float, or

tractor hydraulics are off, before making connections.

Carts Y1007 and Earlier

Air carts serial number Y1077 and earlier have different

hydraulic connections. See “Hook-Up: Y1077 and

Earlier Carts” on page 117.

Carts Y1078 and Later

See “Y1078+ Hydraulic Connections” on page 17.

167-073M Table of Contents Index 2012-10-17

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 17

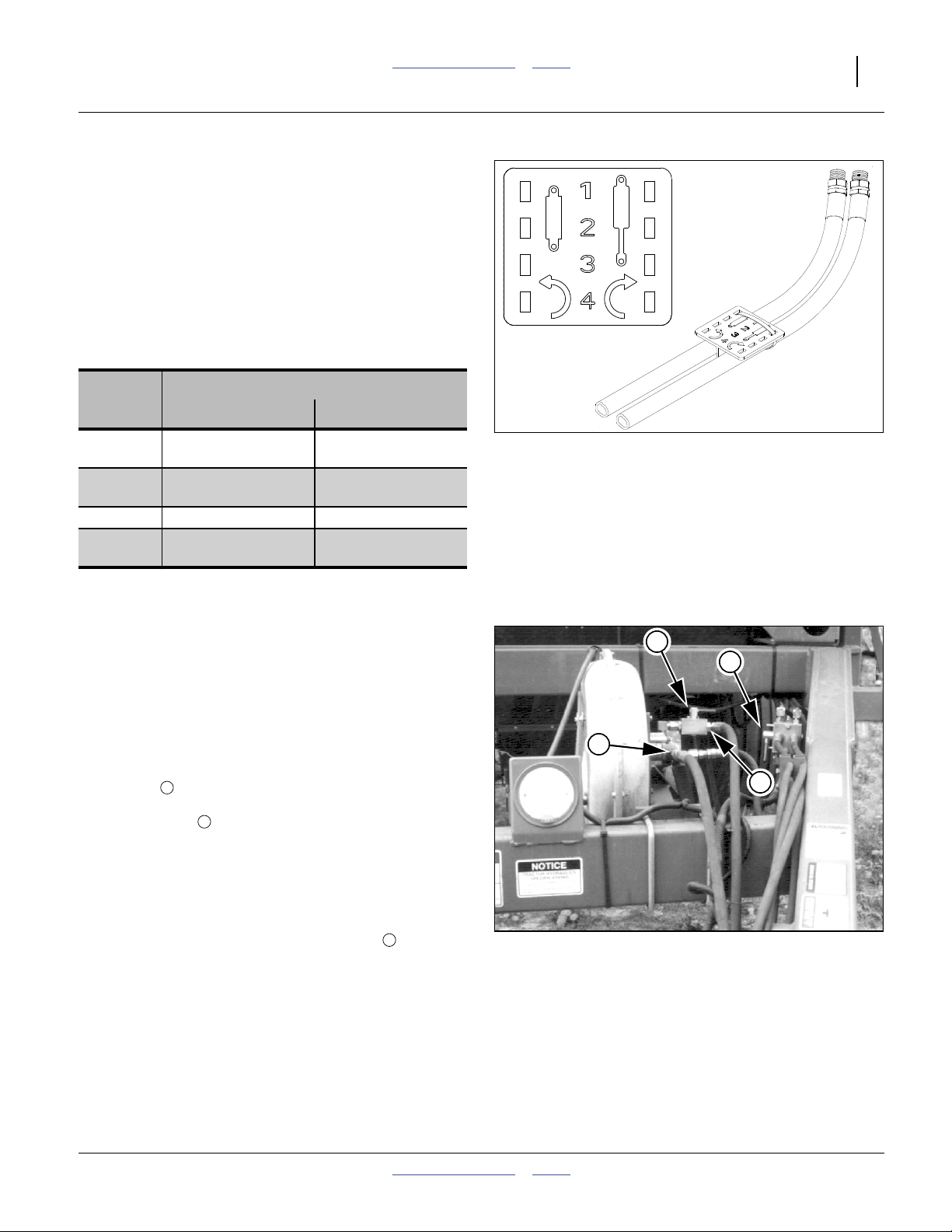

Older Style Hoses with Color Ties

Refer to Figure 7

To distinguish hoses on the same hydraulic circuit, refer

to plastic hose label. The hose under an

extended-cylinder symbol feeds a cylinder base end. The

hose under a retracted-cylinder symbol feeds a cylinder

rod end.

Hose connections are also passed through to a rear

panel when the air cart leads the drill. Hoses that go to

the same remote valve are marked with the same color

tie.

Color

Code

<none>

(decal)

Yellow Hydraulic Fan

(Extend side only)

Blue <no function> Lift Cylinders

0range

Make sure all tractor levers are in neutral or float, or

tractor hydraulics are off, before making connections.

Y1078+ Hydraulic Connections

Black (hose grips) or Yellow (ties): Fan/Fold

If your tractor has a priority circuit for hydraulic motors,

connect the fan (yellow) to this circuit.

Note: Fan hoses are not the same size. A1⁄2inch and a

3

⁄8inch hose are paired together.

Refer to Figure 8

2. Connect the hose with the Extended-Cylinder

symbol to the side of the circuit you choose to be

the pressure side. This hose supplies the fan (at fan

shutoff valve ) and rear port F.

3. Hook fan hose under Retracted-Cylinder symbol to

the other tractor outlet. This hose is not used by the

fan, and passes directly to rear port E.

4. Connect hose with SUMP decal to the tractor

hydraulic reservoir. Refer to your tractor operator’s

manual for instructions. The sump hose is also

routed to rear port G.

Note: Rear ports E and F are Fold on ADI and NTA

1

implements.

Hydraulic Function

on Cart on Drill

SUMP return (available)

Fold Cylinders

(ADI & NTA only)

Auger

2

Fold (ADI only)

Marker Cylinders

3

Figure 7

Plastic Hose Label

2

3

Figure 8

Y1078+ Fan Hook-Up

817-348c

17641

4

1

17172

2012-10-17 Table of Contents Index 167-073M

Page 22

18 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Sump First and Last

Machine Damage Risk:

Seals in the hydraulic fan motor can be damaged if the return

line is pressurized. Always connect the SUMP hose first and

disconnect it last. The sump hose has a larger (1.06in)

quick-connect coupling.

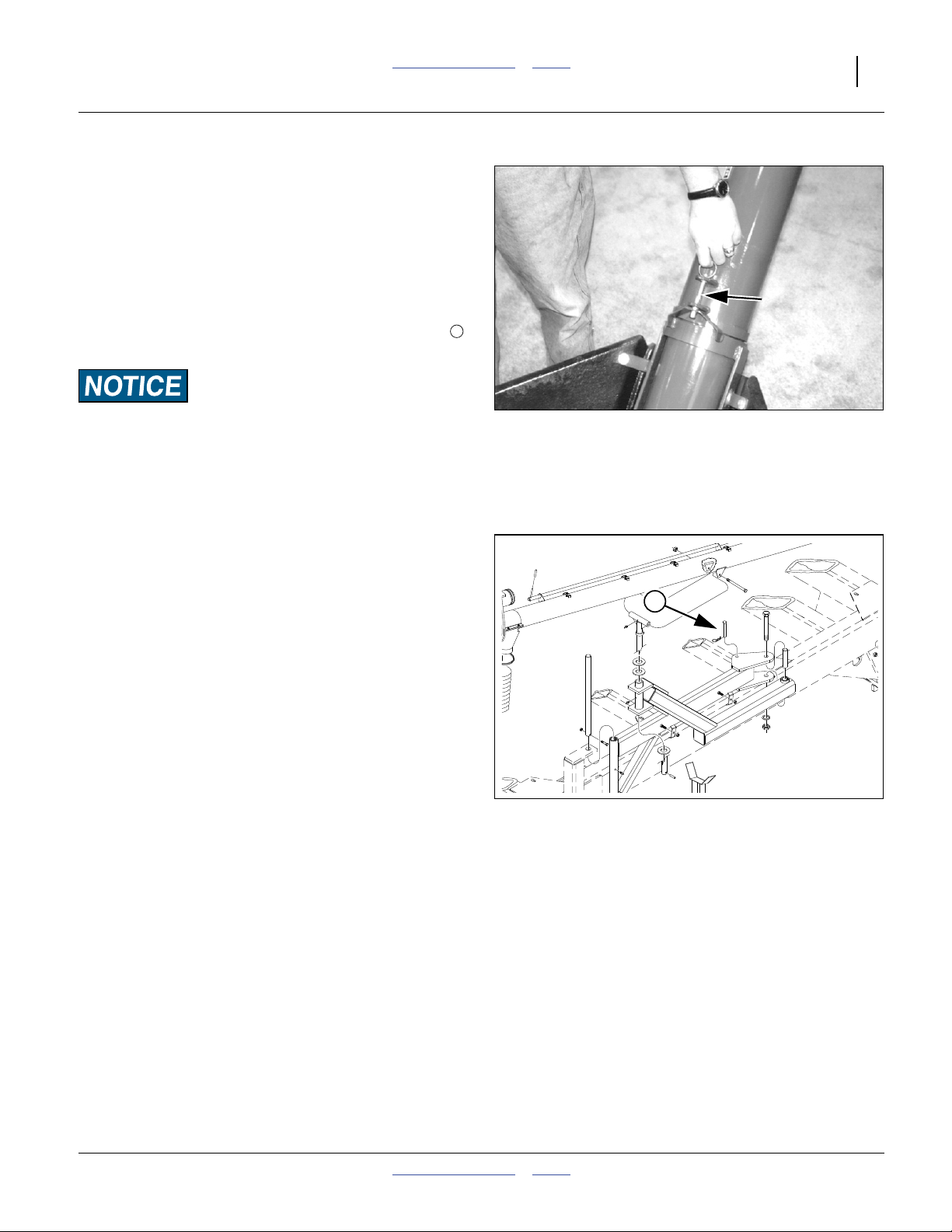

Refer to Figure 9

Note: For proper hydraulic flow, use a poppet-style,

Pioneer quick coupler to connect sump hose to

tractor.

Green (hose grips) or Orange (ties): Auger/Marker (& Fold on ADI)

Connect orange-coded hoses to tractor outlets capable

Figure 9

Poppet-Style Coupler for Sump

17646

of continuous flow (although less than required for the

fan). This circuit is used by the cart for the auger, and

may also be directed to rear ports A and B for use by

Markers (not all implements have Markers).

A diverter valve on the cart ( in Figure 8) switches flow

4

between auger and rear ports.

Blue: Implement Lift

Connect blue-coded lift hoses to tractor outlets. This

3

⁄8inch hose circuit is unused by the air cart, passing

through to rear ports C and D. It is used for Lift by all

implements.

Set Up the Implement

This manual only covers air cart setup. Consult the

Operator’s Manual for the implement for additional setup

steps required prior to operation.

167-073M Table of Contents Index 2012-10-17

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index 19

Operating Instructions

This section covers general operating procedures. It

assumes that setup items have been completed for both

air cart and implement.

Experience, machine familiarity and the following

information will lead to efficient operation and good

working habits. Always operate farm machinery with

safety in mind.

General Description

Seed metering is powered by a cart tire and driven at a

rate proportional to distance traveled. Each seed bin is

self-contained and has its own metering device. The

seed bins are sealed and held at the same pressure as

the meter boxes so metering is controlled

mechanically–not by air-flow fluctuations. The metered

seed is carried by air through the hoses to the

distribution towers on the implement. These towers then

divide the air and seed into individual rows.

The metering devices are driven through an

electromagnetic clutch. The clutch only engages if the

implement is lowered, operating an adjustable lift switch.

Seed metering is shut off automatically when the drill is

lifted for headland turns.

Pre-Start Checklist

❑ Lubricate the cart as indicated under Lubrication,

“Maintenance and Lubrication” on page 95.

❑ Check the tires for proper inflation according to “Tire

Inflation Chart” on page 107.

❑ Check the chains for proper tension and alignment

as shown under Drive System Adjustments,

“Adjustments” on page 65.

❑ Check for worn or damaged parts and repair or

replace before going to the field.

❑ Check all nuts, bolts and screws. Tighten bolts as

specified on “Torque Values Chart” on page 113

❑ Check height switch on implement.

2012-10-17 Table of Contents Index 167-073M

Page 24

20 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Hopper Lids

Keep lids closed. Keep tightly closed for operations.

Keep loosely closed for storage. Open only for material

loading, hopper clean-out and lid maintenance.

Lid Opening

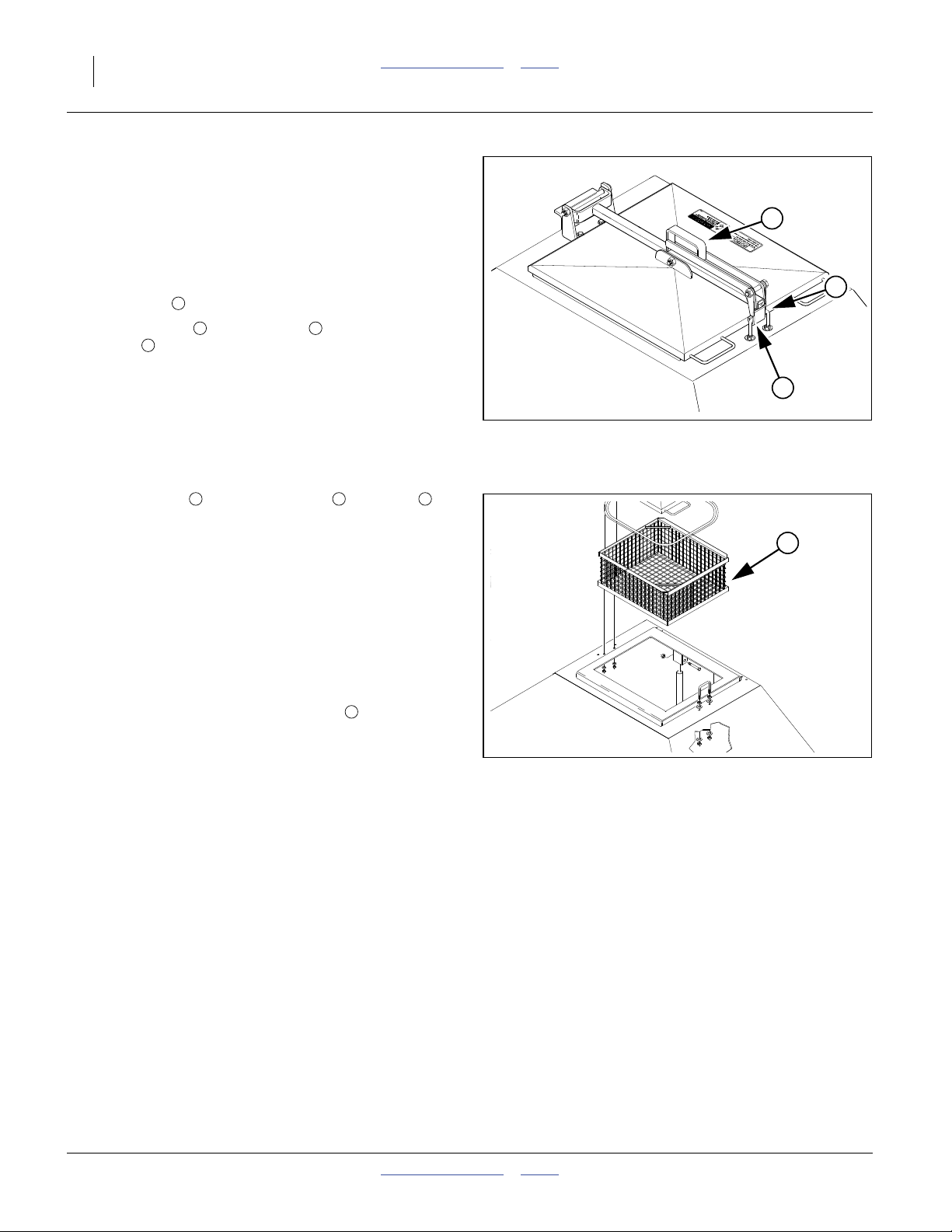

Refer to Figure 10

1. Lift handle .

2. Swing handle out until hook releases from

U-bolt .

3. Move hook clear of U-bolt and re-close handle.

4. Swing lid open.

2

2 3

4

2

4

3

Lid Closing

1. Open handle and engage hook on U-bolt .

2. Close handle with hook engaged for operations or

short-term parking.

For long-term storage, do not engage hook or latch

handle, to avoid deforming the seal.

3. For storage, particularly unlatched, a locked chain

deters entry.

2 3 4

Strainer

Refer to Figure 11

Each hopper is equipped with a strainer intended to:

• capture foreign matter in seed and materials that is too

large to pass through the meter, and

• prevent entry.

Leave the strainer in place except during strainer and

hopper cleaning.

Check the strainer for residue prior to each loading

operation. Remove, empty and return it to the hopper.

For strainer or hopper cleaning, the strainer lifts out when

the lid is fully open.

5

Figure 10

Hopper Lid Latched

Figure 11

Hopper Strainer

16191

5

16137

167-073M Table of Contents Index 2012-10-17

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 21

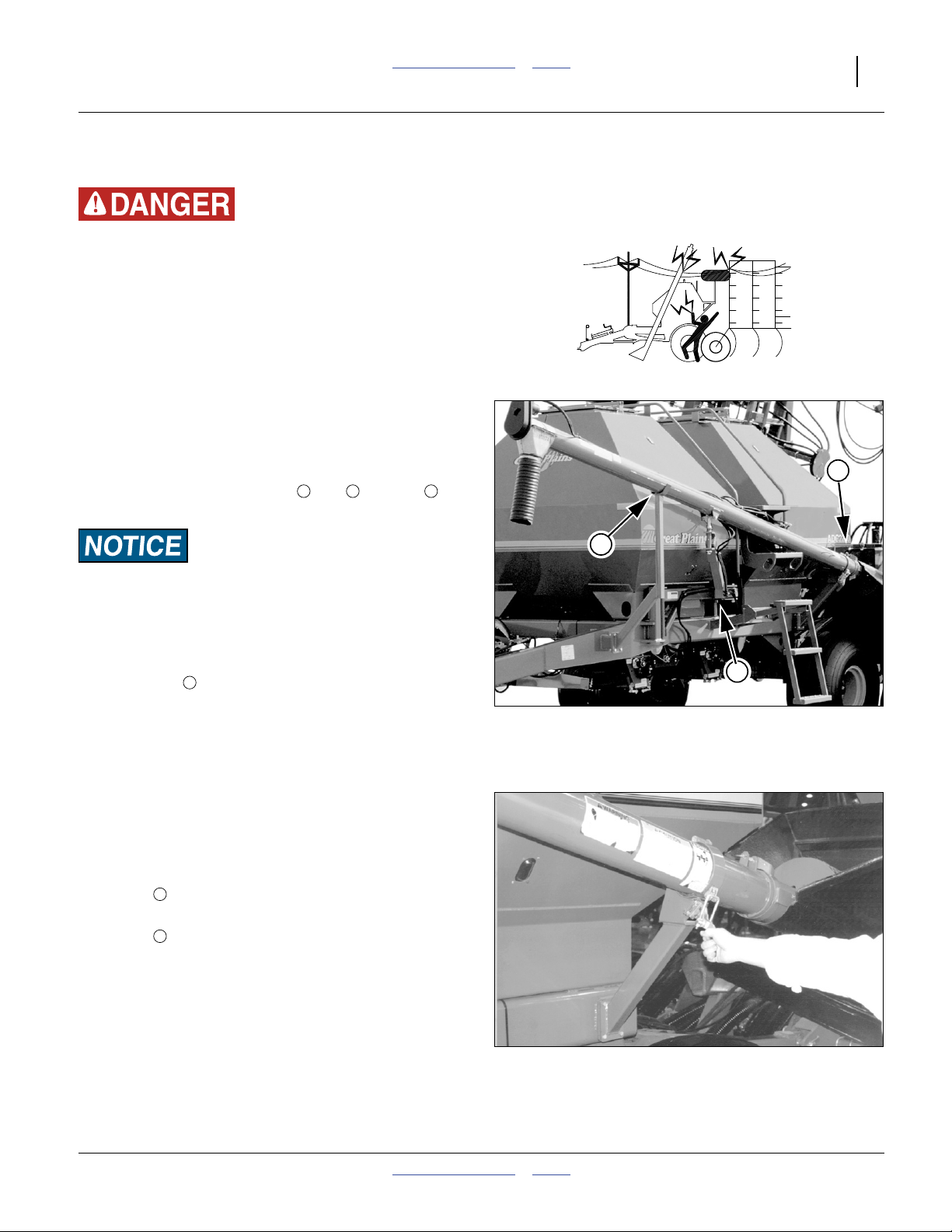

Auger Operations

Electrocution Hazard:

Keep clear of overhead power lines when positioning auger.

The auger can reach 15 feet (4.6 m) above ground level during

positioning operations. If it contacts a power line, nearly all

metal parts of the cart, tractor and drill will have lethal

voltage present, and anyone touching them can complete the

circuit to ground, resulting in serious injury or death. With

very high voltages, electrocution can occur without direct

contact.

This section covers only basic auger operations. For

specific tasks, see:

“Unloading the Cart” on page 34, and

“Loading Material” on page 29.

Refer to Figure 12

Latch the auger into its cradles ( and ) and pin the

inner arm pivot, whenever the auger is not in use.

1 2 3

2

Machine Damage Risk: To avoid auger damage during cart

movement, do not rely solely on the arm pin to secure the

auger in the stored configuration. Use both pin and latch.

Deploying Auger

For material loading, the inner arm is left pinned to the

frame. The pin is located at the mid pivot of the auger

arm assembly.

The back (inlet) end of the auger has a grasp handle.

Refer to Figure 13 and Figure 12

1. If hopper is facing to the side or down, turn it upright

(page 23).

2. Release the rear latch clamp and strap.

3. Hold a grasp handle near the auger inlet hopper.

4. Pull the rear end of the auger out of the rear

cradle .

5. Tilt the forward end of the auger up out of the forward

cradle .

6. Pull the auger away from the cart and set the inlet

end on the ground.

3

2

1

1

3

Figure 12

Auger Latched for Movement

29012

Auger Hydraulic Controls

Operating the auger involves one or two valves on the

cart, in addition to the tractor lever for the hydraulic

circuit.

7. Set the tractor circuit for Auger/Marker to Neutral or

Float before setting the cart diverter valve.

2012-10-17 Table of Contents Index 167-073M

Figure 13

Auger Latch Clamp

16120

Page 26

22 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Verify Auger Off

A valve at the inlet end of the auger controls On/Off and

direction of auger rotation. It has an operating handle at

each end of the auger tube.

Refer to Figure 14

Make sure the control at the auger itself is set to Off

before operating any other hydraulic controls.

If this valve is not Off, the auger may begin rotating

unexpectedly when other controls are operated.

8. Set the auger direction valve to the middle position

for Off.

Diverter Valve

This valve is located on the inside of the left tongue tube.

It selects whether the circuit supplies the auger, or the

trailing implement.

Refer to Figure 15

Do not operate this valve with the hydraulic circuit energized.

Unexpected drill/marker movements or auger rotation can

result.

Do not use this valve as the Start-Stop control for the auger.

Operate the valve with the tractor hydraulic circuit off, or

set to neutral or float. The handle has two positions.

Auger Diverter Valve Positions

U

Handle Up: Marker-enable (make sure other Marker

controls are off before moving handle to ).

D

Handle Down: Auger (make sure Auger control is in

center-off position before moving handle to ).

U

D

Figure 14

Auger Direction Valve Off

U

D

Figure 15

Auger Diverter Valve

16172

16221

Auger Direction Valve

Refer to Figure 16

The valve at the inlet end of the auger tube controls the

direction of auger helicoid screw rotation.This valve is

“center off”.

Figure 16

Auger Direction Valve

14884

12713

To allow flow control by an operator at the outlet end, the

control handle for the valve has an extension and second

handle.

9. Use this valve as the Start-Stop and

Forward-Reverse control for the auger. Set the valve

to center-Off when not moving material at the

moment.

Rotating auger.

To prevent serious injury or death:

▲ Read instructions and safety information before operation.

▲ Keep hands, feet, hair and clothing away from rotating

auger.

▲ Do not remove or modify any guards.

▲ Keep children well clear of work area.

167-073M Table of Contents Index 2012-10-17

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 23

Auger Inlet Orientation

During material loading and unloading, a snap pin may

be used to keep the auger inlet hopper upright.

Auger Inner Arm Pin

The auger may also be used to collect material being

unloaded from the hoppers, from beneath the meters

(see “Unloading the Cart” on page 34).

Refer to Figure 18

To allow the inlet to reach under the cart, remove a pin

securing the inner swing arm to the cart frame.

3

Machine Damage Risk:

Be aware of the location of the outlet end of the auger during

positioning. In addition to overhead line hazards, if a trailing

implement is folded, the auger can strike it during positioning,

with possible damage to the auger or implement.

Storing Auger

The auger inlet hopper may be oriented as desired when

stowed, based on road and weather conditions.

1. Orient hopper.

If storing for transport, orient the inlet hopper up and

toward cart center. This protects the auger from

damage from movement of the trailing implement on

uneven terrain, and minimizes collection of debris

thrown by the tire.

If securing the auger for cart storage, orient the inlet

hopper out and down. This minimizes collection of

airborne debris and precipitation. See also

“Storage” on page 37.

2. Fold arm with center pivot forward.

3. Push auger to cradles.

4. Seat auger in cradles.

5. Pin inner arm (if unpinned).

6. Secure rear latch.

Figure 17

Auger Inlet Snap Pin

3

Figure 18

Auger Inner Arm Pin

16116

16101

Auger Swing Arm

The auger arm may be completely unfolded to straight

out, or folded, with the middle pivot pointing to cart front

or back, as needed, to meet your loading or unloading

requirements.

2012-10-17 Table of Contents Index 167-073M

Page 28

24 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

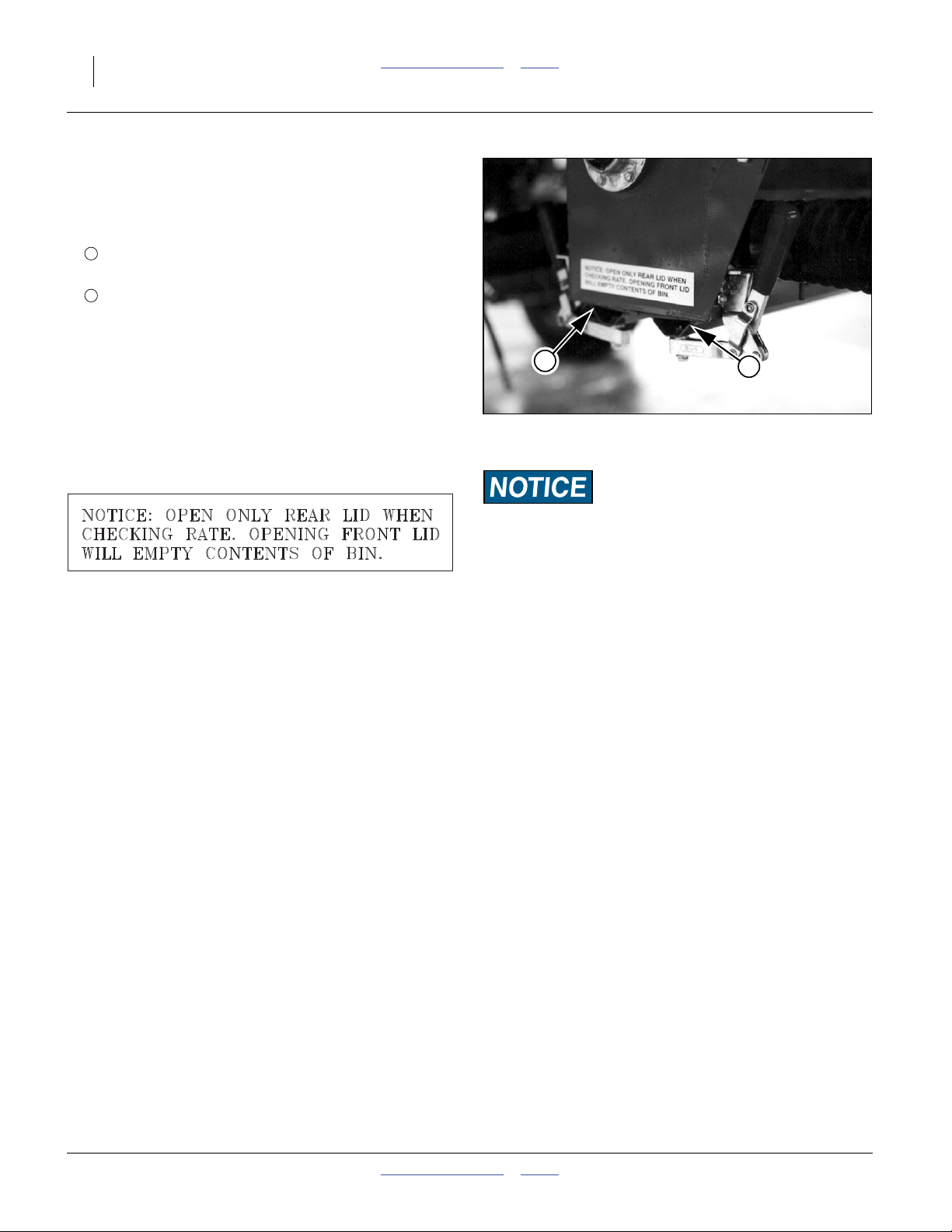

Meter Doors

Refer to Figure 19

Each meter box has two distinct access doors on the

bottom:

1

• Front: Clean-Out

(for emptying hopper)

2

• Rear: Calibration

(for meter sampling and meter clean-out)

The doors are closed during transport, loading and

planting. They may be open slightly in storage if the

hopper was not completely dry at clean-out.

The doors need to close and seal tightly during planting.

Check for leaks with cart fan running. Periodically inspect

the lever clamps for proper tension, and inspect the

elastomer seals for integrity and resiliency.

Meter Door Opening

2

Figure 19

Meter Doors Closed

1

14874

1. Pull out on a clamp handle just until it is loose.

2. Pull out on the other clamp handle. The door

normally will swing down on its own. If not, pull it

open by hand.

Meter Door Closing

Make sure the clamp handles are out or down (not up),

or it will not be possible to close the door.

1. Use a clean rag to wipe any residual material from

the face of the elastomer seals on the door, and from

the bottom face of the meter box.

2. Swing the door up into closed position.

3. While holding the door closed, swing one clamp

handle up, past vertical.

4. Swing the other clamp handle up past vertical.

5. Inspect the door closure for possible air leaks.

Replace any deformed elastomer seal or damaged

latch clamp.

Material Loss Risk:

Do not open the (forward) clean-out door unless preparations

have been made to capture any material to be re-used. Any

material present will flow immediately, possibly in large

volume, as soon as the door is open. Re-closing the clean-out

door, and obtaining an air-tight seal, is usually not possible

until the hopper is completely empty.

167-073M Table of Contents Index 2012-10-17

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 25

Meter Hand Crank

A hand crank is provided on the right side of the cart for

manual operation of the meters (the meters otherwise

turn only when the cart is in motion with the clutch

engaged).

The crank is stored in a ring on the frame just aft of the

right lower steps. Place it over the notched end of the

gearbox jackshaft.

Population Risk:

Rotate the hand crank only in the clockwise direction.

Operating in reverse (counter-clockwise) meters material at

incorrect rates (far too low).

The crank is used for two common tasks:

• calibration of the meter setting for planting, and

• clean-out of the meter flute chamber.

Operating the Hand Crank

Turn the hand crank clockwise to simulate meter

operation during planting.

Specific recommendations may be made in applicable

manual sections. See:

see “Meter Calibration” in the Seed Rate manual,

see “Unloading the Cart” on page 34, and

see “Storage” on page 37.

In general, you may operate the crank as fast as is

comfortable.

To shift gearbox and change quick-change and final drive

range gearing see “Meter Rate Adjustment” on

page 66.

Note: If gearbox clutch is disengaged, operating the hand

crank may fail to clear the meters of seed.

Figure 20

Hand Cranking Direction

16115

2012-10-17 Table of Contents Index 167-073M

Page 30

26 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Transport

Electrocution Hazard.

To prevent serious injury or death from electric shock, keep

clear of overhead power lines when transporting, folding,

unfolding or operating all air drill components. Machine is not

grounded. At higher voltages, electrocution can occur without

direct contact.

Great Plains recommends transporting the air cart

without seed loaded. Although designed for highway

movement with full hoppers, the additional weight of

seed may cause the implement assembly to exceed the

rated ability of the tractor, makes the assembly more

difficult to control and stop, and increases wear on cart

tires and wheel bearings.

Loss of Control Hazard:

Towing the drill at high speeds or with a vehicle that is not

heavy enough can lead to loss of vehicle control. Loss of

vehicle control can lead to serious road accidents, injury and

death. To reduce the hazard:

• Do not exceed 20 mph (32 km/h).

• Do not tow an assembly that, when fully loaded,

weighs more than 1.5 times the weight of the towing

vehicle.

In the tables on page 27, the tractor must weight at

least2⁄3(67%) of the weights shown.

The tractor must also be rated for towing and braking

the total load shown.

Minimum Towing Vehicle

To be safe compute the weight of your configuration from

the “Specifications and Capacities” information in each

manual, plus any material data, or have the assembly

weighed at a scale.

Note: The table weights are approximate. Actual

assembly weights can vary by hundreds of pounds

depending on options, openers, material density

and aftermarket equipment.

Note: A loaded seed cart can easily cause the total

assembly weight to exceed 1.5 times (150% of) the

weight of a fully ballasted tractor. Great Plains

recommends transport with the cart empty.

For transport weight of the ADC2220 without an

implement, see “Specifications and Capacities” on

page 107.

167-073M Table of Contents Index 2012-10-17

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 27

Approximate Assembly Weights

2012-10-17 Table of Contents Index 167-073M

Page 32

28 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Pre-Transport Checklist

Before transporting the cart, check and observe the

following items.

❑ Make sure the weight of the tractor equals or

exceeds 67% your air drill assembly. Be sure to

include hopper contents if materials are pre-loaded,

and markers. If weights are added to the tractor or

drill, or to reach the tractor-weight figure, make sure

the grand total weight including tractor is still within

the rated capacity of the tractor.

❑ Auger Latch

Properly pin and latch auger to cart and rear storage

arm before transporting.

See “Storing Auger” on page 23.

❑ Hopper Lids

Closed and secured.

See “Lid Closing” on page 20.

❑ Transport Locks

Check that all implement transport locks are securely

in place.

❑ Tires

Check that all tires are properly inflated as listed on

“Tire Inflation Chart” on page 107.

❑ Bystanders

Check that no one is in the way before moving. Do

not allow any one to ride on the cart or implement.

❑ Warning Lights

Always use tractor, cart and implement warning

lights when transporting the air drill.

❑ Clearance

Know the maximum dimensions of the cart and

implement in transport position and follow a route

that provides adequate clearance from all

obstructions, including overhead lines.

See “Specifications and Capacities” on page 107.

❑ Stopping Distance

Allow sufficient stopping distance and reduce speed

prior to any turns or maneuvers. If the cart is

transported full, allow extra stopping distance.

❑ Road Rules

Comply with all national, regional and local laws

when transporting on public roads.

❑ Watch Traffic

The bins obstruct a portion of your rear view. Be

prepared for sudden maneuvers from following

vehicles.

167-073M Table of Contents Index 2012-10-17

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 29

Loading Material

Confined Space Entrapment/Suffocation Hazard:

Never enter a hopper for loading or unloading.

Once used for hazardous fertilizer or treated seed, dangerous

concentrations of fumes may be present even in an empty

hopper with the lid open.

Even with small amounts of otherwise harmless material

loaded, the atmosphere inside the hopper may have insufficient

oxygen or high levels of choking dust.

1. Securely hitch cart or drill+cart to a tractor with

adequate weight and power. Park cart on solid, level

ground. See Tractor Requirements, “Specifications

and Capacities” on page 107.

Note: Static tongue weight of a loaded cart is about

5,500 pounds (2500 kg) on level ground and more

when facing downhill.

Refer to Figure 21

2. At each hopper to be loaded, if meter box clean-out

1

door was completely closed, open it. See “Meter

Doors” on page 24. If the cart has been parked for

more than a day, condensation may have caused

moisture to accumulate.

3. Wipe seals and meter bottom flanges clean. Close

and latch clean-out doors.

4. With the cart fan running, check hopper-lid and

meter-box seals carefully for air leaks. Adjust bin

latch or replace seals to prevent leakage.

5. Shut off all hydraulic power to the cart.

+

2

Figure 21

Calibration and Clean-Out Doors

1

14876

Population Risk:

Before first cart use, and at the beginning of each season,

check the entire bin for leaks. A small air leak can cause large

variations in seeding rates.

Refer to Figure 22

6. Set the Auger Direction Valve control handle to

center, off position.

Refer to Figure 23

7. Set the cart diverter valve to the down (Auger)

position. See “Diverter Valve” on page 22.

8. Climb the steps to the cart walkboard. Unlatch and

open the lid. See “Lid Opening” on page 20.

9. Check that the strainer basket is in place in the top of

the bin. Remove any foreign material from the

basket.

2012-10-17 Table of Contents Index 167-073M

Auger Direction Valve Off

Figure 22

U

D

Figure 23

Diverter Valve to Auger

16172

16221

Page 34

30 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

10. Unlatch the auger, and swing the inlet end to the

ground. See “Deploying Auger” on page 21.

Machine Damage Risk:

If the trailing implement is folded, mind the outlet end of the

auger, as the auger can strike components of a folded trailing

implement.

Refer to Figure 24

11. Pull up on the hopper snap pin and pivot the auger

Keep clear of overhead power lines when positioning auger.

hopper until its opening is facing up, and the snap

pin is captured in a locking hole.

12. Swing the auger so the spout is centered over the

hopper opening. Position your grain container for

unloading into the auger hopper.

13. Energize tractor hydraulics for auger. You may need

to tie the control lever in place or adjust the detent

pressure on your tractor.

14. Start the auger by turning the auger direction valve

off center to the left or right. Visually check auger for

correct rotation direction. Reverse handle if needed.

See “Auger Hydraulic Controls” on page 21.

15. Slowly turn on material flow and fill hopper.

Note: When leveled off, the top cone of the bin holds

Figure 24

Auger Inlet Snap Pin

16116

about one-third of bin capacity, the center area

one-third and the lower cone one-third.

16. When hopper is full, turn off the auger by moving the

auger direction control to the center position.

17. Briefly run auger in reverse to return any residual

material to the inlet hopper for recovery or disposal.

12713

18. Return auger to storage position. See “Storing

Auger” on page 23.

19. Turn off the tractor hydraulics.

20. When circuit is off, set diverter to up (pass-through to

markers or fan). See “Auger Hydraulic Controls”

on page 21.

Rotating Auger.

To prevent serious injury or death:

▲ Read instructions and safety information before operation.

▲ Keep hands, feet, hair and clothing away from rotating

auger.

▲ Do not remove or modify any guards.

Do not turn the auger hydraulic diverter handle until the

▲ Keep children well clear of work area

hydraulics have been shut off. If the diverter is moved with

hydraulics on, other equipment may suddenly begin moving.

21. Remove any foreign matter from the strainer basket.

22. Wipe any grain or foreign matter from lid-seal area

on top of cart bin. Close lids and latch securely.

167-073M Table of Contents Index 2012-10-17

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 31

Fan Operation

Fan speed is monitored and reported by the seed

monitor, but is manually controlled by the tractor circuit

lever. The optimum rate depends on the seed type, any

treatments. “Fan Speed Adjustment” on page 73 for

further information.

Refer to Figure 25

On newer air carts, there is a fan shut-off valve that must

must be open for the fan to operate.

1. With the tractor at a low idle speed, energize tractor

hydraulics for fan. Lock hydraulic lever in place for

continuous operation. Refer to your tractor operator’s

manual for instructions on operating hydraulic motor.

Always engage the fan with the tractor at a low engine speed.

Engaging the fan when the tractor is at high speed may cause

fan damage.

2. Check that the bottom of the fan rotor rotates toward

the rear of the cart. If not, reverse the direction of the

hydraulic flow from the tractor.

Figure 25

Y1078+ Fan Shut-Off

17172

Do not reverse hydraulic flow with the fan running.

3. Run fan for at least 15 minutes before seeding.

Hydraulic fluid must be warm before fan (and wing

down pressure on some implements) operates

properly.

Refer to Figure 26

The proper reading for the magnehelic air pressure gauge is

12 to 25 inches of water. A sudden drop in pressure is a sign of

a possible leak which can negatively affect seeding.

4. Check bin-lid and meter-box seals for air leaks.

Adjust the latch or replace the seals to prevent

leakage.

Note: It only takes a very small air leak to cause large

variations in the seeding rate and pattern.

Do not exceed a fan speed of 5000 rpm. Set your monitor to

alarm before reaching this speed.

Figure 26

26425

Fan Air Pressure

2012-10-17 Table of Contents Index 167-073M

Page 36

32 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Acremeter Operation

The acremeter, located on the air cart clutch shaft,

counts shaft rotations whenever the shaft is rotating - this

is with the drill lowered and in motion or during

calibration crank operation. The meter is programmed to

display rotations as acres or hectaresa, when using all

rows, factory-specified tires and tire inflations.

Note: Unusual conditions and/or non-standard row

spacings can cause the acremeter tally to vary

from actual acres planted.

Normal Operating Sequence

Note: The acremeter counts rotations during air cart

calibration (and if so, can be useful for calibration).

1. Record the acremeter reading at the start of planting

(and after calibration). The large “12345.6” format

display is the grand total area since meter

installation. The smaller number in the lower left

corner is the number of revolutions per acre for

which the meter was factory-programmed. If the

display is blank, see “Dormant Display” below.

2. Lower air cart and plant. Acremeter counts shaft

rotations, calculates acres or hectares, and adds to

the running grand total.

3. During planting (air cart lowered and moving

forward), the display blanks (goes dormant), but area

tally continues.

4. When raised for turns, obstructions and transport,

the clutch disengages, the shaft stops, and the meter

counts no additional (non-planting) rotations.

5. Whenever shaft rotation stops, the LCD display

activates after 30 to 60 seconds, and remains visible

for 30 to 45 minutes.

6. At the completion of planting, record the final reading

or the grand total. If the display goes dormant before

you can read it, see “Dormant Display”.

7. Subtract the reading at Step 1 from the reading at

Step 6 for the total planted in the present session.

Dormant Display

Refer to Figure 28

To conserve power, the LCD display blanks itself most of

the time. If you need to read the display after it has

“timed out” and gone dormant:

• use the calibration crank to turn the jackshaft once, or

• gently tap or wave a magnet at either of the Great

Plains logo spots on the lower region of the display.

1

Be careful not to scratch the window.

Figure 27

Electronic Acremeter

1

Figure 28

Meter Display (Acres)

27378

29016

a. See page 106 for replacement and alternate meters.

167-073M Table of Contents Index 2012-10-17

Page 37

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 33

Field Operations

This section presumes that all pre-operation checks have

been made on both air cart and drill, the cart is loaded

with seed and any treatments, and the rate has been set

and calibrated.

Rate setting, and gearbox operation, are covered at

“Meter Rate Adjustment” on page 66.

Refer to Figure 29

Seed meter gearboxes are ground driven through an

electric clutch. The clutch is controlled by an implement

lift switch, which is in series with an On/Off switch at

the seed monitor console. The implement must be

lowered, and the console switch must be ON (|) for seed

to meter. This switch also controls valves on NTA drills,

and must be off for folding.

Note: The switch can only override the automatic

metering to Off. It does not engage the clutch if the

implement is lifted.

See “Loup II Monitor Operation” on page 38.

1

Figure 29

Monitor Console and Switch

1

29013

Single Hopper Operation

If materials are being applied from a single bulk hopper,

disengage the gearbox clutch for the other gearbox.This

minimizes wear on the gearbox.

Final Field Checklist

❑ Check tire inflation (page 107).

❑ Check all seed hoses connected.

❑ Check for openers for plugging.

❑ Set seed meters per chart and calibration.

❑ Set seed monitor alarm limits.

❑ Check diverter valve set to implement.

❑ Check fan shut-off valve open (fan enabled)

❑ Set fan to speed suitable for seed. Watch fan at

start-up to ensure correct direction of rotation.

❑ Run fan for at least 15 minutes before planting.

❑ Check air pressure gauge for 12 to 25 inches of

water pressure.

❑ Check for air leaks at lids and meter box seals.

❑ Set electric clutch rocker switch (at console) to On.

❑ Complete drill checklist.

Planting Sequence

1. Lower drill 5 to 10 feet (1.5 to 3 m) before initial

seeding point.

2. Pull forward and begin planting.

3. Raise drill for turns (meters stop automatically - it is

not necessary to use the cab rocker switch).

Planting

Be aware of the 5 to 10 feet (1.5 to 3 m) of drill-lowered

operating distance required for seed to reach the row

units.

If you stop in the middle of a pass, raise the drill and back

up 10 feet (3 m) before resumption of seeding.

Planting Speed

The seed rate charts were developed at a field speed of

6.5 mph (10.5 km/h) using a single hopper, standard

2-star flutes and the seed density shown in the chart.

The chart or calibrated rates also apply to lower speeds.

Higher speeds are possible, particularly with dual hopper

operation and/or optional high-rate flutes. Test to make

sure that material is being delivered at the desired rates,

and that seeding depth is maintained.

At higher speeds, check for signs of:

low seed flow (due to seed cavitation in the meter),

seed plugging (due to fan air flow insufficiency),

row-to-row rate variation (insufficient fan) and;

inconsistent seeding depth (due to opener bounce).

2012-10-17 Table of Contents Index 167-073M

Page 38

34 ADC2220 Table of Contents Index Great Plains Manufacturing, Inc.

Walkboard Steps

The walkboard between the hoppers is served by two

steps, one on each side of the cart.

The lower steps are removable, to allow auger access

under the rear meter box.

1

1

Removing the Left Lower Steps

Refer to Figure 30

If unloading the rear hopper, the lower section of the left

side walkboard steps must be removed for auger access