Page 1

Operator’s Manual

Model 1150

Air Drill Cart & Implement

1995 - 1997

Manufacturing, Inc.

P.O. Box 5060

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

l Salina, Kansas 67402-5060

© Copyright 1998 Printed

Cover illustration may show optional equipment not supplied with standard unit.

6/12/2002

14576

167-058M

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information. . . . . . . . . . . . . . . . . . . . . . . .1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Description of Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Intended Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Section 1 Cart Assembly and Setup . . . . . . . . . . . . . . . . .15

Pre-Assembly Checklist. . . . . . . . . . . . . . . . . . . . . . . . .15

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Shipping information. . . . . . . . . . . . . . . . . . . . . . . .15

Top Steps & Rear Handrail . . . . . . . . . . . . . . . . . . . . . .15

Spindles, Hubs, Wheels, & Drive Chain . . . . . . . . . . . .17

Hitch, Safety Chain, & Jack. . . . . . . . . . . . . . . . . . . . . .18

Lower Ladder Weldment & Support Weldment . . . . . . .19

Slow Moving Vehicle Bracket & Emblem . . . . . . . . . . . .19

Section 2 Implement Assembly and Setup . . . . . . . . . . .20

Flex Limiter Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Implement Lift Cylinder Hydraulic Hoses. . . . . . . . . . . .21

Bleeding the Hydraulic Lifting System. . . . . . . . . . . . . .24

Fold Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

34’ and 45’ Drills. . . . . . . . . . . . . . . . . . . . . . . . . . .24

45’ Drills . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Bleeding the Folding System. . . . . . . . . . . . . . . . . . . . .28

Side-to Side Frame Leveling . . . . . . . . . . . . . . . . . . . . .28

45’ Drill Frame Leveling . . . . . . . . . . . . . . . . . . . . .28

34’ Drill Frame Leveling . . . . . . . . . . . . . . . . . . . . .29

Distribution Towers and Hoses . . . . . . . . . . . . . . . . . . .29

Primary 2 1/2” Distribution Hoses . . . . . . . . . . . . . . . . .31

1” Secondary Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Light Harness and Brackets . . . . . . . . . . . . . . . . . . . . .36

Section 3 Operating Instructions . . . . . . . . . . . . . . . . . . .37

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Attaching the Drill to the Tractor . . . . . . . . . . . . . . . . . .37

Recommended Minimum Tractor Size . . . . . . . . . .37

Safety Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Attaching 1150 Air Drill Cart to Implement . . . . . . . . . .38

Hydraulic Hose Hook-up . . . . . . . . . . . . . . . . . . . . . . . .39

Filling the Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Field Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Implement Lifting System . . . . . . . . . . . . . . . . . . . . . . .41

Folding the Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Unfolding the Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Opener Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Unloading the Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Section 4 Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Setting the Drill Seeding Rate . . . . . . . . . . . . . . . . . . . .46

Setting Seeding Depth/Leveling Front-to-Rear . . . . . . .60

Individual Opener Adjustments . . . . . . . . . . . . . . . . . . .60

Shear Bolt &Spring Reset Opener Depth. . . . . . . .61

Reset Opener Down Pressure . . . . . . . . . . . . . . . .61

Hoe Tip Angle. . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Drive System Adjustment . . . . . . . . . . . . . . . . . . . . . . .62

Main Drive Chain from Wheel to Clutch . . . . . . . . .62

Chain from Speed Change to Gearbox . . . . . . . . .62

Drive Chain from Clutch to Speed Change . . . . . .62

Chain from Gearbox Output to Jackshaft . . . . . . . .63

Chain from Jackshaft to Meter . . . . . . . . . . . . . . . .63

Electric Clutch Height Switch. . . . . . . . . . . . . . . . . . . . .63

Section 5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . .65

Section 6 Maintenance and Lubrication . . . . . . . . . . . . . .69

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Main Drive Chain . . . . . . . . . . . . . . . . . . . . . . . . . .70

Clutch Output Chain . . . . . . . . . . . . . . . . . . . . . . . .70

Gearbox Input Chain . . . . . . . . . . . . . . . . . . . . . . .70

Gearbox Output Chain . . . . . . . . . . . . . . . . . . . . . .70

Jackshaft Output Chain . . . . . . . . . . . . . . . . . . . . .71

Clutch Shaft Bearings. . . . . . . . . . . . . . . . . . . . . . .71

Jackshaft Bearings . . . . . . . . . . . . . . . . . . . . . . . . .71

Gauge Wheel Pivots. . . . . . . . . . . . . . . . . . . . . . . .71

Castor Wheel Shafts . . . . . . . . . . . . . . . . . . . . . . .72

Lift Assist Pivots . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Press Wheel Gang Bearings . . . . . . . . . . . . . . . . .72

Press Wheel Pivot Bearings. . . . . . . . . . . . . . . . . .72

Implement Hinge Pivots . . . . . . . . . . . . . . . . . . . . .73

Cart Pull Link Pivots . . . . . . . . . . . . . . . . . . . . . . . .73

Parallel Arm Pivots . . . . . . . . . . . . . . . . . . . . . . . . .73

Press Wheel Screw Adjustments . . . . . . . . . . . . . .73

Auger Pivot Arms . . . . . . . . . . . . . . . . . . . . . . . . . .74

Floating Hoe Opener Pivots . . . . . . . . . . . . . . . . . .74

Auger Pivot Arms . . . . . . . . . . . . . . . . . . . . . . . . . .74

Meter Lid Clamp Pivots . . . . . . . . . . . . . . . . . . . . .74

Bin Lid Pivot Bar and Latch . . . . . . . . . . . . . . . . . .75

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Wheel or Axle Bearings . . . . . . . . . . . . . . . . . . . . .75

Section 7 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Loading/Unloading Auger . . . . . . . . . . . . . . . . . . . . . . .76

Vansco Electronis Monitor. . . . . . . . . . . . . . . . . . . . . . .77

Section 8 Specifications and Capacities . . . . . . . . . . . . .81

Section 9 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Torque Values Chart for Common Bolt Sizes . . . . . . . .86

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

© Copyright 1995 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Model 1150 1995 - 1997 167-058M 7/28/10Great Plains Mfg., Inc.

Page 3

Great Plains Mfg., Inc.

!

!

!

!

!

Important Safety Information

Important Safety Information

For your safety and to develop a better understanding of

your equipment, thoroughly read the Operator’s Sections

of this manual before operation.

Safety Notations

The SAFETY ALERT SYMBOL indicates that there is a

potential hazard to personal safety involved and extra

safety precautions must be taken. When you see this symbol, be alert and carefully read the message that follows it.

In addition to design and configuration of equipment; hazard control and accident prevention are dependent upon

the awareness, concern, prudence and proper training of

personnel involved in the operation, transport, maintenance and storage of equipment.

Watch for the following Safety Notations throughout

your Operator’s Manual:

DANGER!

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal word

is limited to the most extreme situations.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may also be used

to alert against unsafe practices

Safety Rules

These rules and instructions

must be reviewed at least annually

by all operators!

Most accidents are the result of negligence and carelessness, caused by failure of the operator to follow safety

precautions. Even though your implement is designed

with many built-in safety features, the following precautions are mandatory to prevent such accidents.

Make sure everyone that uses this machine has read the

Operator’s Manual and understands how to operate it

safely.

!

This Operator’s Manual is considered a part of the implement and should remain so when loaned or sold.

Prior To Operation

1. Do not stand between tractor and implement during hitching.

2. Do not stand between cart and implement during hitching.

3. Do not operate without safety chain properly attached to

tractor.

4. Make sure hydraulic lines are attached to the correct ports.

5. Handle and apply chemically treated seeds according to

manufacturer's recommendations.

CAUTION!

Some illustrations in this manual may show shields or cover

panels removed for clarity. Never operate unit without all

shields and cover panels in place.

During Operation

1. Do not allow anyone to operate this machine who has not

been properly trained in its safe operation.

2. Do not let children operate the implement.

3. Never dismount from a moving tractor

4. Put tractor in park turn off engine and remove key when

making any adjustments to the implement

5. Do not leave the tractor or the implement unattended with

the engine running.

6. Never allow passengers.

7. Travel slowly over rough terrain and be alert to holes and

gullies.

8. Loose fitting clothing should not be worn as it may catch in

moving parts.

9. If a hydraulic leak develops, correct it immediately. Escaping hydraulic oil can have extremely high pressure. A

stream of high pressure oil may easily penetrate the skin as

with modern needle-less vaccination equipment - but with

the exception that hydraulic fluid may cause blood poisoning. It is imperative that the connections are tight and that

all lines and pipes are in good condition. If an injury is

caused by the escaping hydraulic fluid, seea doctor at once!

Use a piece of cardboard or wood to detect leaks of hydraulic oil under pressure. Be sure to relieve all hydraulic pressure before disconnecting any lines or pipes between the

implement and the tractor hydraulic system.

10. Keep all guards and shields in place.

11. Do not turn tractor too tight; implement may ride up on

wheels causing machine and bodily damage.

DANGER!

Contact with overhead power lines can cause severe electrical

burns or death from electrocution. Make sure there is enough

clearance between all air drill components and overhead power

lines. Do not use loading auger near power lines. Do not climb

on walkboard near power lines.

7/28/10

Model 1150 1995 - 1997 167-058M

1

Page 4

Important Safety Information

!

!

WARNING!

You may be overcome by fumes from seed treatment or chemicals in bin, resulting in severe injury or death by poisoning. You

may become trapped in bin due to height of opening or falling

through bridged material. Never climb into bin! Leave strainer

basket in bin to prevent dropping objects in bin.

DANGER!

Augers can be very dangerous and can cause severe injury or

death by entanglement. Read and understand manual before attempting to operate it.

After Operation

1. Detach and store implement in an area where children normally do not play. Stabilize implements by using suitable

supports and block wheels.

2. Be alert to traffic when crossing or operating near road-

ways. Always maintain complete control of the machine.

Know your state and local laws concerning highway safety

and regulations. Comply with these laws when transporting

machinery.

Great Plains Mfg., Inc.

3. Limit transport speed to 20 mph. Transport only with a farm

tractor of sufficient size and horsepower. Refer to Attaching

the Drill to the Tractor under the “Operating Instructions”

section page 37. Always make sure flashing safety lights,

slow moving vehicle emblem, and reflectors are in place

and visible prior to transporting the machine on public

roads.

4. Use warning flags or approved warning lights at night and

during other periods of poor visibility. Do your best to prevent highway accidents.

During Maintenance

1. Tire changing can be dangerous and should be performed

by trained personnel using the correct tools and equipment.

2. Do not re-inflate a tire that has been run flat or seriously

under inflated. Have it checked by qualified personnel.

3. When removing and installing wheels, use wheel handling

equipment adequate for the weight involved.

4. Do not grease or oil implement while it is in use.

5. After repairing or adjusting, make sure all tools and parts

are removed from the implement before attempting to operate it.

Model 1150 1995 - 1997 167-058M 7/28/10

2

Page 5

Great Plains Mfg., Inc.

Important Safety Information

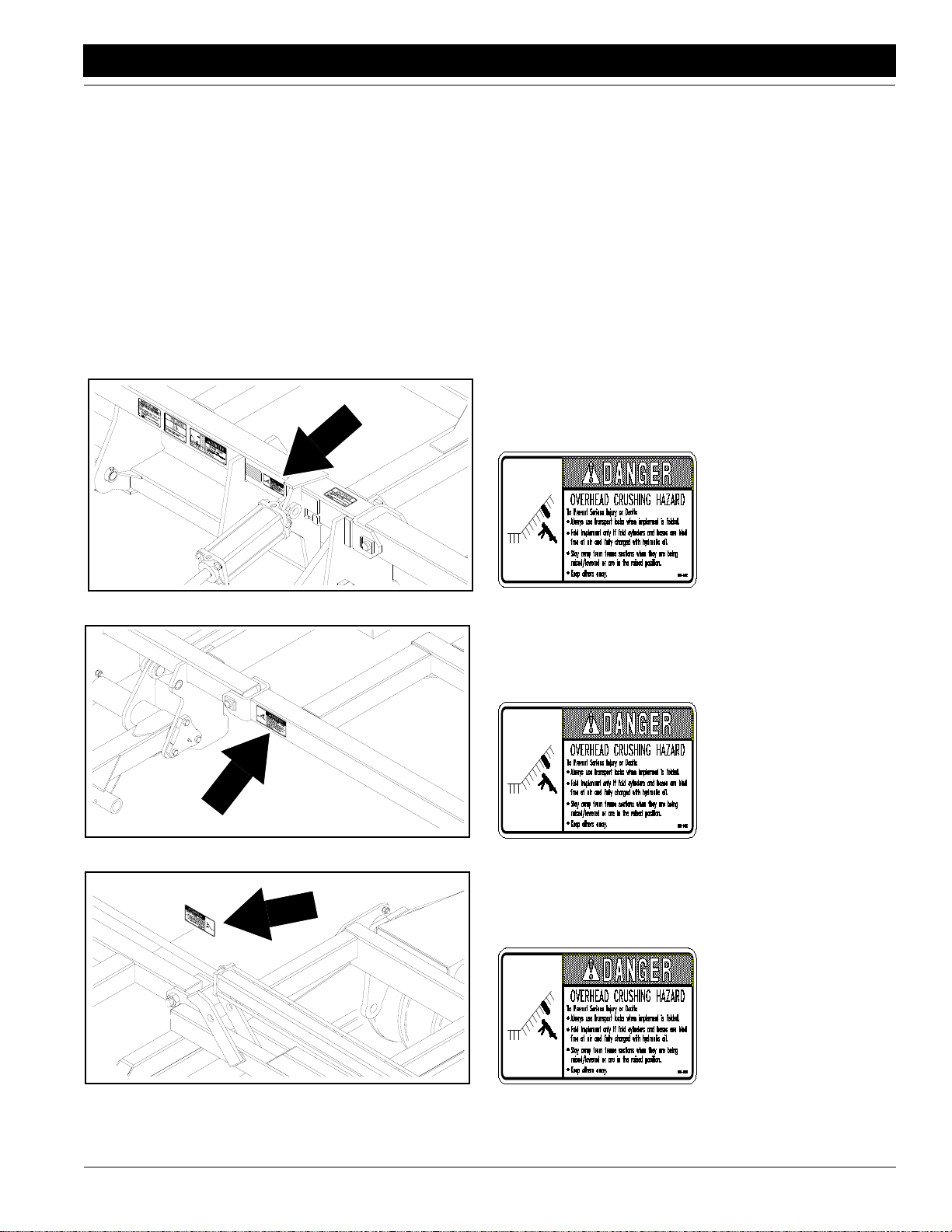

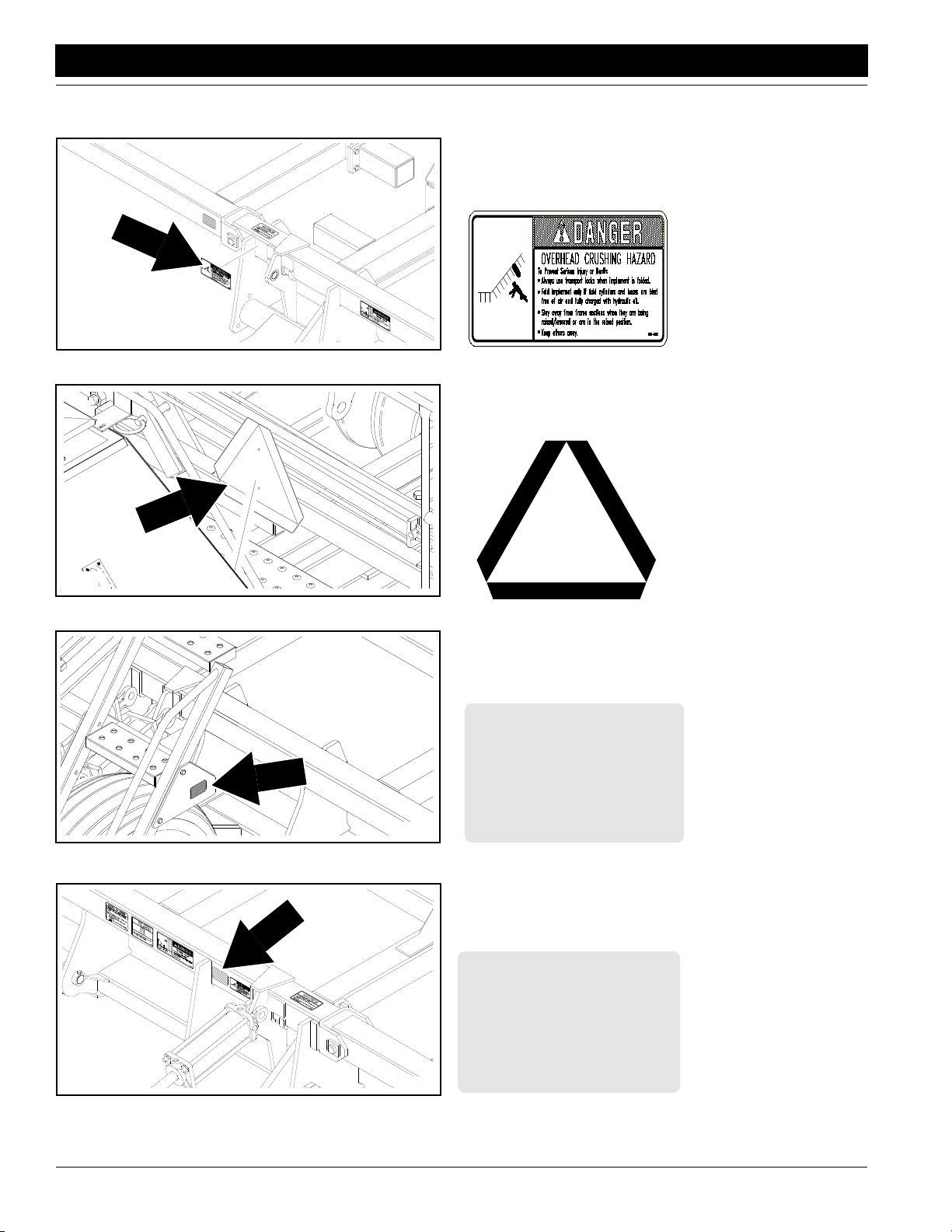

Safety Labels

Your implement comes equipped with all safety labels in place.

They were designed to help you safely operate your implement.

1. Read and follow label directions.

2. Keep all safety labels clean and legible.

3. Replace all damaged or missing labels.

4. Some new equipment installed during repair require safety

labels to be affixed to the replaced component as specified

14356

by the manufacturer. When ordering new components make

sure the correct safety labels are included in the request. To

order new labels go to your Great Plains dealer.

5. Refer to this section for proper label placement.

To install new labels:

a. Clean the area the label is to be placed.

b. Peel backing from label. Press firmly on surface

being careful not to cause air bubbles under label.

818-046C

Charge Fold Cylinder

14348

14349

7/28/10

818-046C

Charge Fold Cylinder

818-046C

Charge Fold Cylinder

Model 1150 1995 - 1997 167-058M

3

Page 6

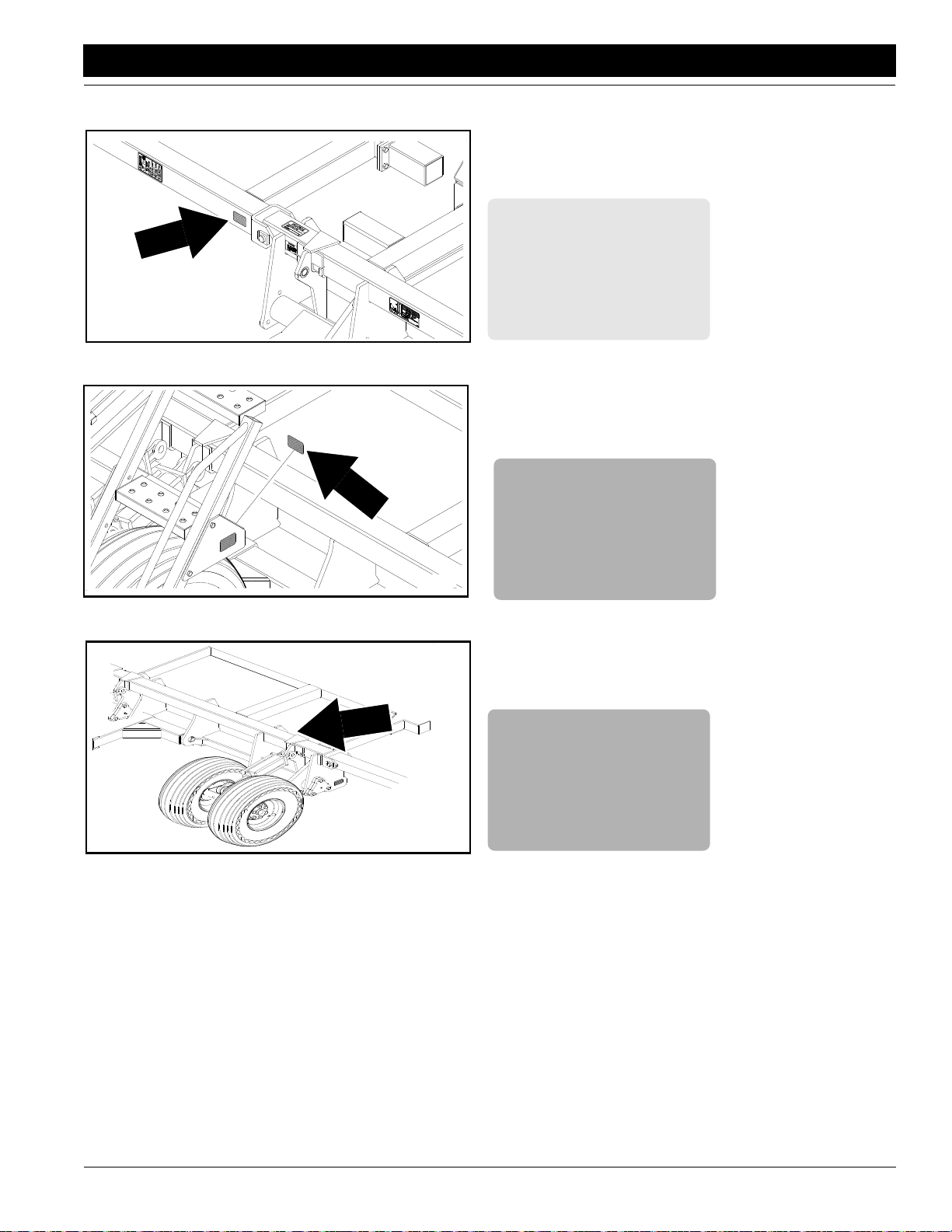

Important Safety Information

14350

Great Plains Mfg., Inc.

818-046C

Charge Fold Cylinder

14346

14777

818-055C

Slow Moving Vehicle Label

818-229C

Amber Reflector (2 places)

818-229C

14356

Model 1150 1995 - 1997 167-058M 7/28/10

4

Amber Reflector (2 places)

Page 7

Great Plains Mfg., Inc.

Important Safety Information

14811

14343

818-229C

Amber Reflector (2 places)

818-230C

Red Reflector (2 places)

7/28/10

14347

818-230C

Red Reflector (2 places)

Model 1150 1995 - 1997 167-058M

5

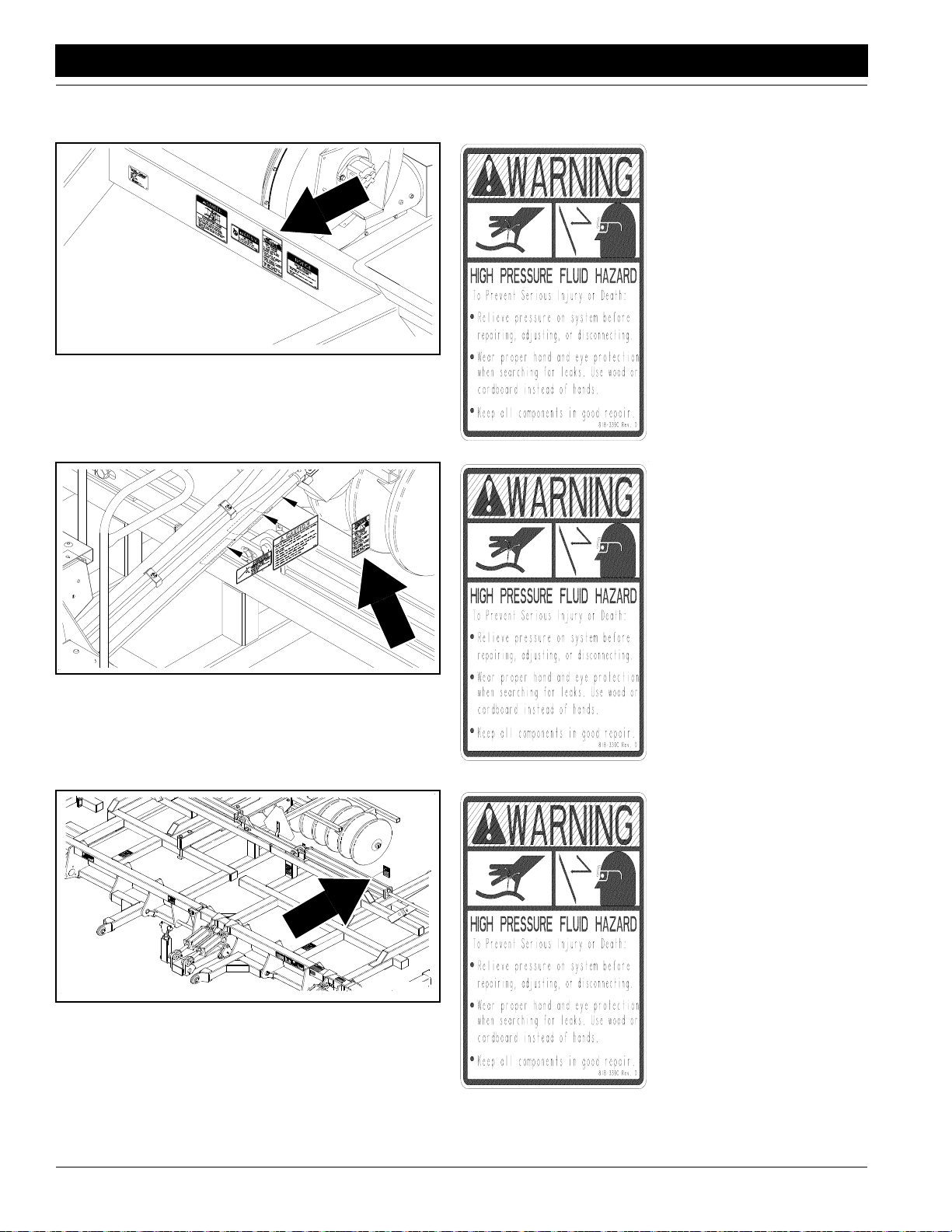

Page 8

Important Safety Information

14340

Great Plains Mfg., Inc.

818-339C

High Pressure

14344

14352

818-339C

High Pressure

818-339C

High Pressure

Model 1150 1995 - 1997 167-058M 7/28/10

6

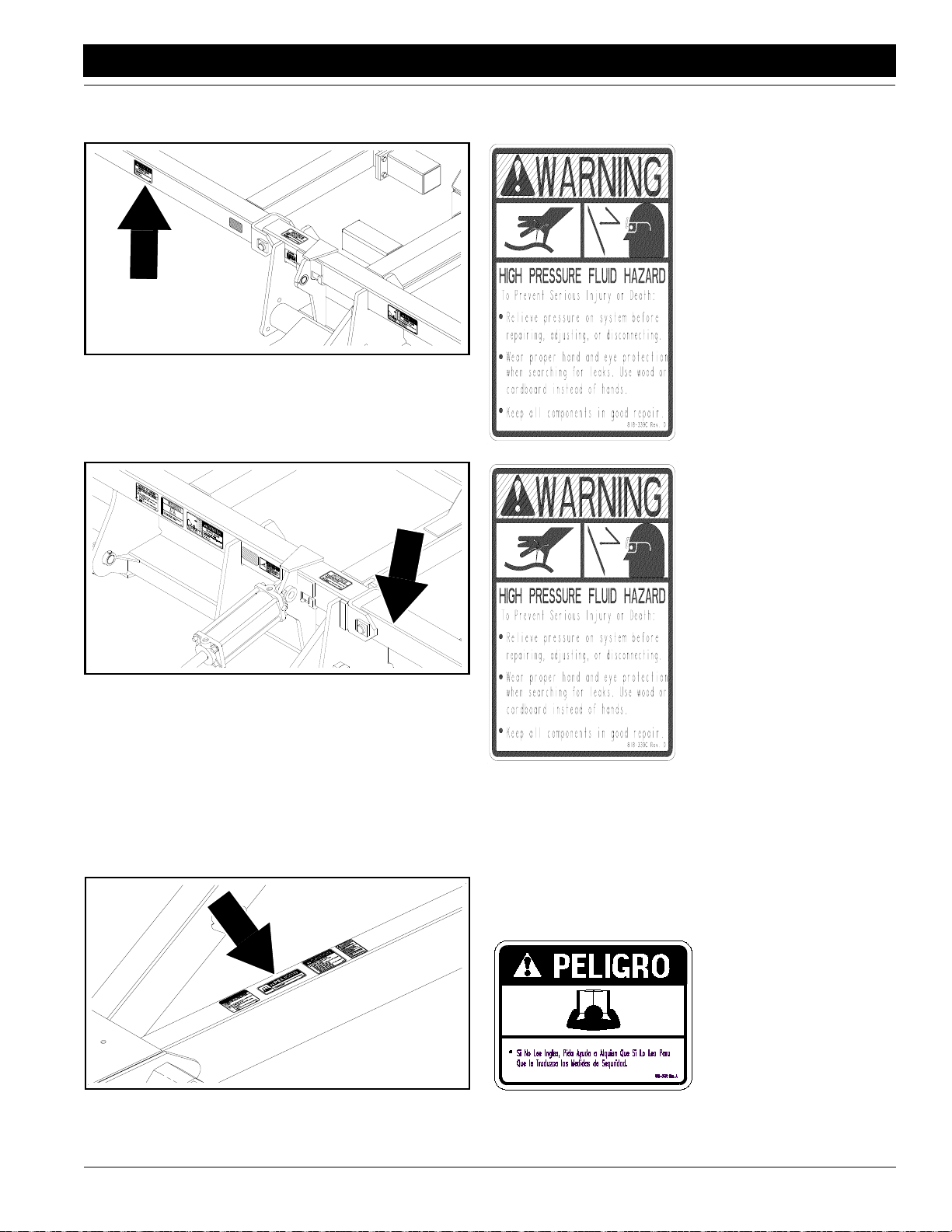

Page 9

Great Plains Mfg., Inc.

Important Safety Information

14804

14356

818-339C

High Pressure

818-339C

High Pressure

7/28/10

14339

818-557C

Cannot Read English

Model 1150 1995 - 1997 167-058M

7

Page 10

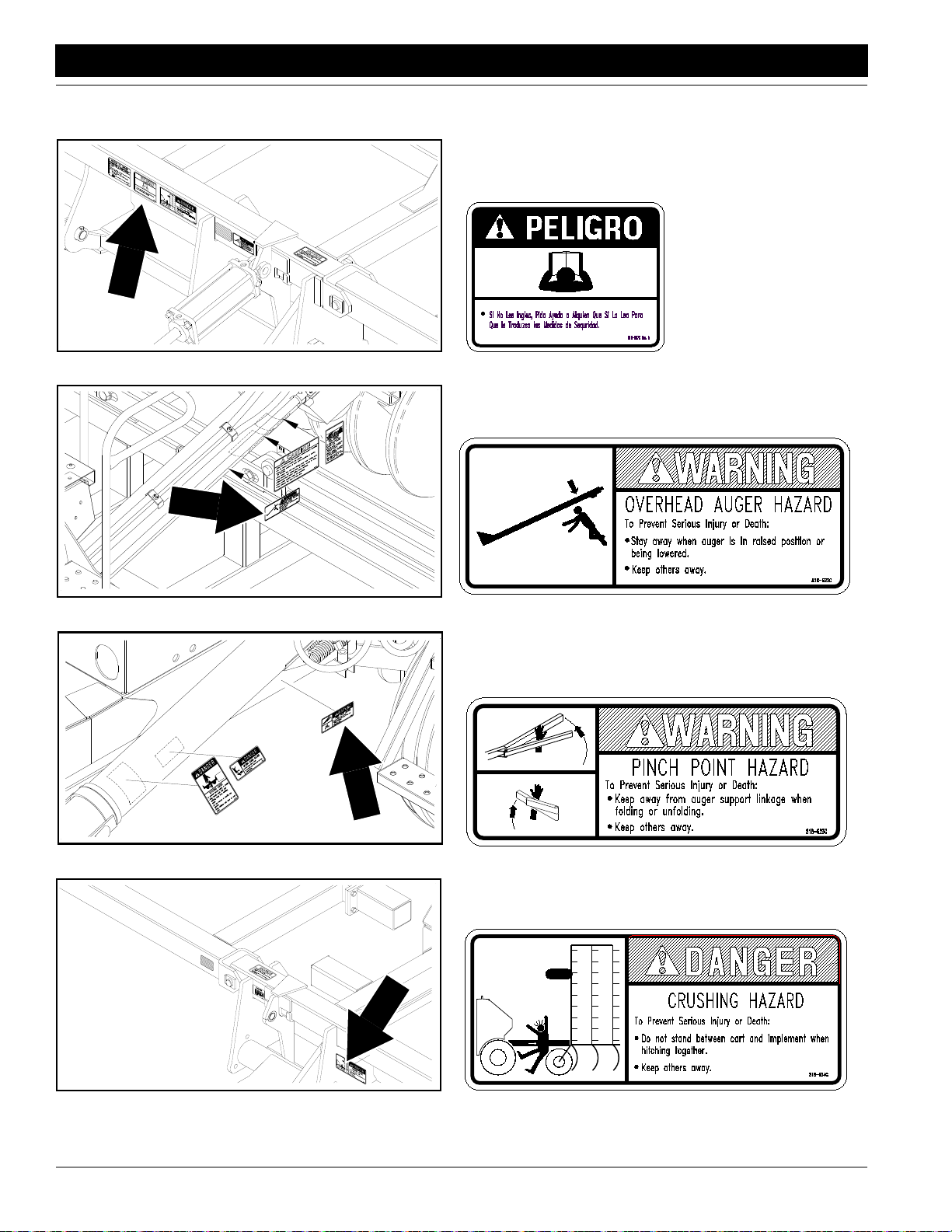

Important Safety Information

14356

Great Plains Mfg., Inc.

818-557C

Cannot Read English

818-622C

Overhead Auger

14806

818-623C

Pinch Point Auger

14342

818-624C

Crush Ad/Implement

14805

Model 1150 1995 - 1997 167-058M 7/28/10

8

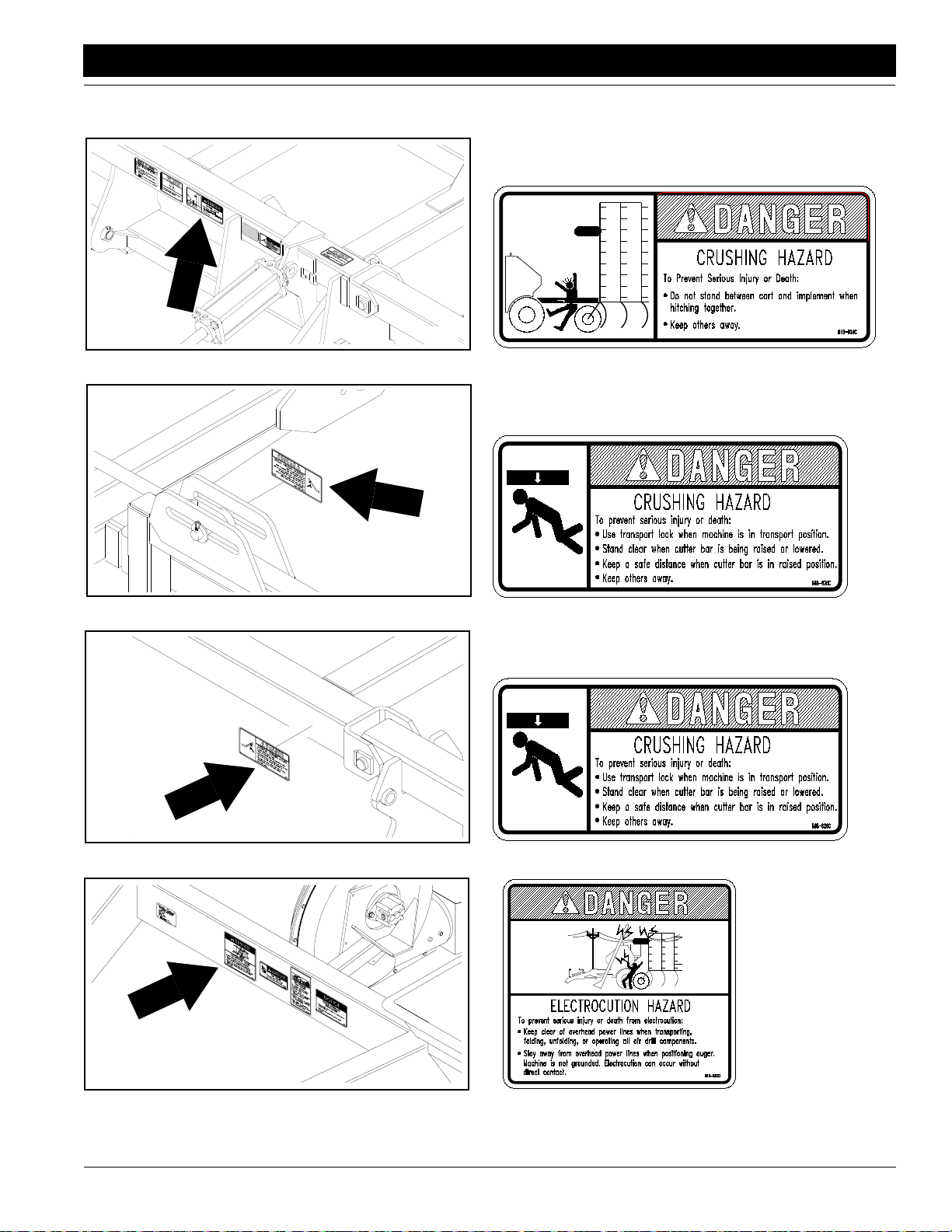

Page 11

Great Plains Mfg., Inc.

Important Safety Information

818-624C

Crush Ad/Implement

14356

818-626C

Overhead Crush Ad

14354

14355

818-626C

Overhead Crush Ad

14340

7/28/10

818-627C

Electrocution Auger

Model 1150 1995 - 1997 167-058M

9

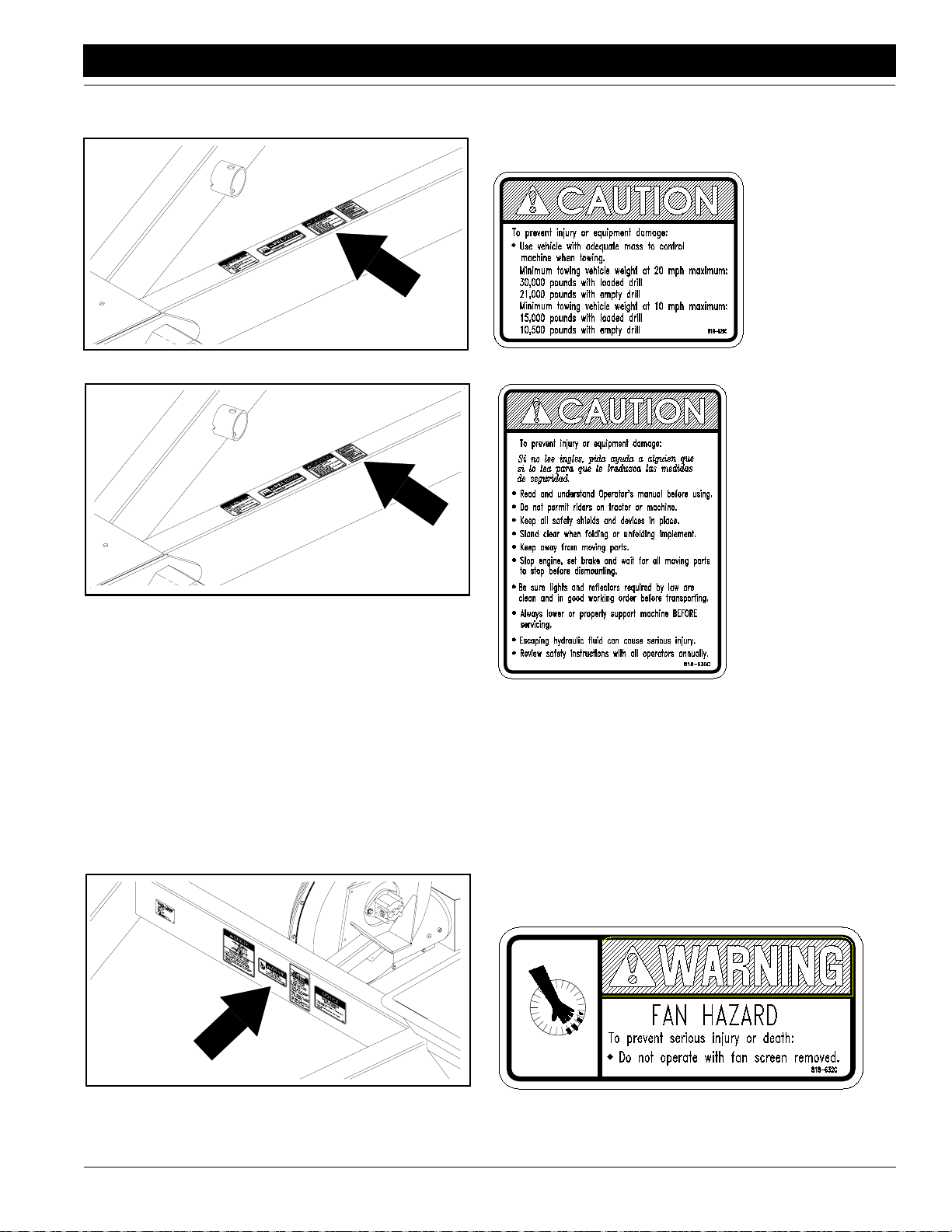

Page 12

Important Safety Information

Great Plains Mfg., Inc.

14351

14808

818-627C

Electrocution Auger

818-627C

Electrocution Auger

818-628C

AD Bin Hazards

14345

Model 1150 1995 - 1997 167-058M 7/28/10

10

Page 13

Great Plains Mfg., Inc.

Important Safety Information

14339

14339

818-629C

AD Tow Vehicle

818-630C

AD General Instructions

14339

7/28/10

818-632C

AD Fan Hazard

Model 1150 1995 - 1997 167-058M

11

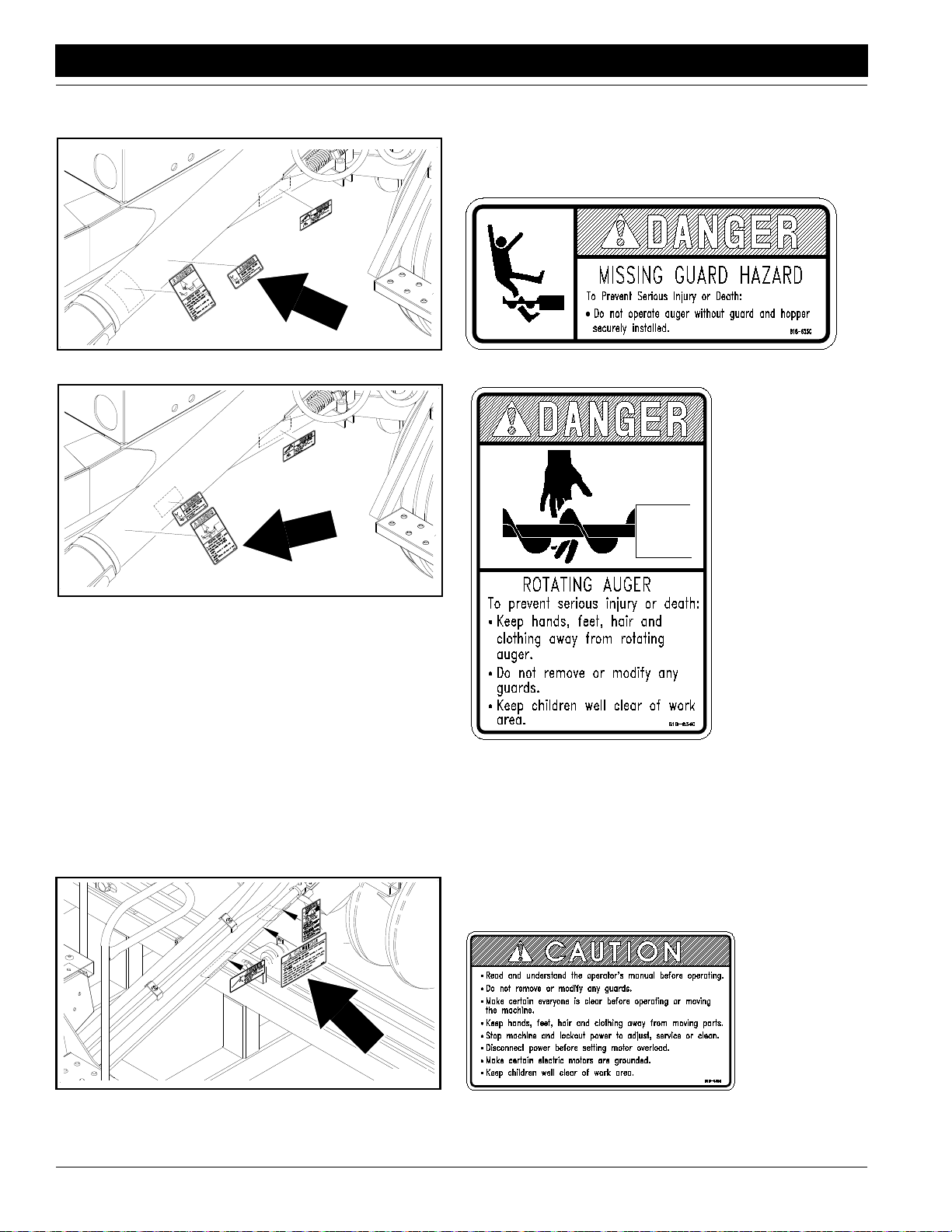

Page 14

Important Safety Information

Great Plains Mfg., Inc.

818-633C

Guard Missing Auger

14809

14810

818-634C

AD Rotating Auger

818-635C

14807

Model 1150 1995 - 1997 167-058M 7/28/10

12

AD Auger General

Page 15

Great Plains Mfg., Inc.

Introduction

Introduction

Great Plains welcomes you to the growing family of new

product owners. This implement has been designed with

care and built by skilled workers using quality materials.

Proper assembly, maintenance, and safe operating practices will help you get years of satisfactory use from the

machine.

Description of Unit

The 1150 Air Drill is a grain drill using air to move seed

from the metering device under the grain bin to the opener

units on the implement. The air is supplied by a hydraulic

motor driven fan. The seed is held in a pressurized bin and

is metered into the air stream in a pressurized meter. The

1150 Cart is designed to pull between the tractor and the

seeding implement andwill pull up to 45’ wide implements.

The metering device is driven at a rate proportional to

ground speed and the rate can be set using the gearbox

and other means.

Features include:

• Ladders to walkboard on both sides for easy access

• Electric clutch drive with adjustable heightcontrol switch

for automatic shut off on headlands

• Large bin opening with over-center lid latch

• Seed level sight glasses in multiple locations

• Easy open meter lids and hand drive crank for checking

seeding rate while stationary

• Bin has large angles on side slopes to provide complete

filling and emptying without hand stuffing.

• 150 bushel bin capacity

• Integral style hitch to implement prevents skewing on

hillsides and make backing up easy

• Three shank options and three opener options for imple-

ment

Intended Usage

This machine is intended to be used primarily for seeding

small grains and legumes in conventional tillage. It can

also be used in many reduced tillage applications and with

other crops.

assure you of the best performance.

Terminology:

"Right " or "Left" as used in this manual is determined by

facing the direction the machine will travel while in use unless otherwise stated.

Definitions:

NOTE: A special point of information related to it’s

preceding topic. The author’s intention is that you

read and note this information before continuing.

IMPORTANT: Information, related to it’s proceeding topic,

that the author feels would be of use.

Owner Assistance

If customer service or repair parts are required contact

your local Great Plains Dealer. He has trained personnel,

repair parts, and the equipment needed to service your

implement.

These parts have been specially designed and should

only be replaced with genuine Great Plains parts.

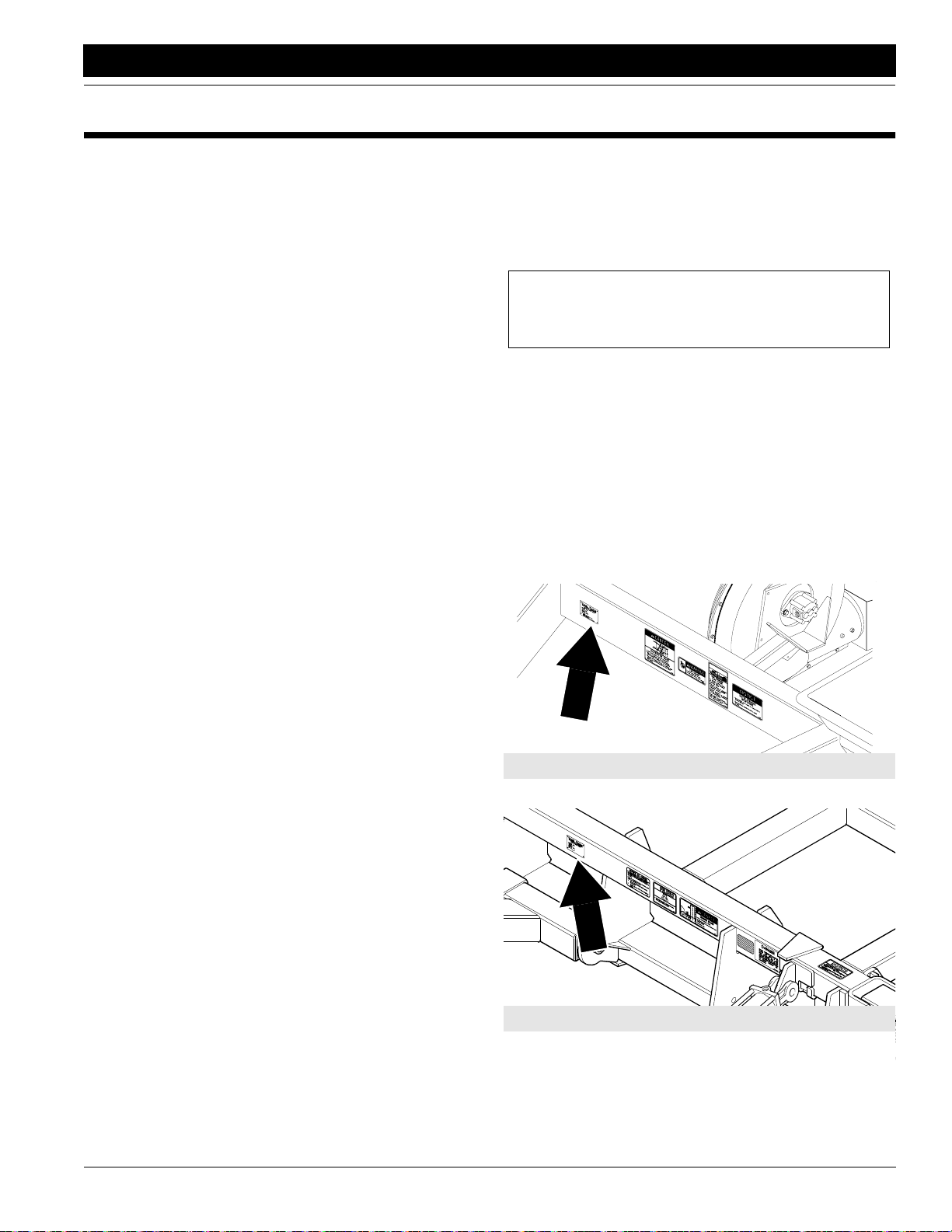

Serial Number Plate

Refer to Figure1 forthe location of your serial number plates.

14340

Air Drill Cart

Using This Manual

This Operator’s Section is designed to help familiarize you

with safety, assembly, operation, adjustments, troubleshooting, and maintenance. Read this manual and follow

the recommendations to help ensure safe and efficient

operation.

The warranty sheet should be filled out by the owner and

dealer at the time of purchase. After completion give the

dealer the white copy and send the pink copy to Great

Plains. Keep your copy in the manual for use when corresponding with the dealer.

To order a new Operator or Parts Manual contact your authorized dealer or write to the address listed below in the

Owner Assistance paragraph. Include the model and serial numbers of your unit.

The information contained within this manual was current

at the time of printing. Some parts may change slightly to

7/28/10

14595

Air Drill Implement

Serial Number Plate Locations

Figure 1

Model 1150 1995 - 1997 167-058M

13

Page 16

Introduction

Great Plains Mfg., Inc.

For prompt service always use theserial numberand model

number when ordering parts from your Great Plains Dealer.

Be sure to include your serial and model numbers in correspondence also.

Your dealer wants you to be satisfied with your new machine. If for any reason you do not understand any part of

this manual or are not satisfied with the service received,

the following actions are suggested:

1. Discuss the matter with your dealership Service Manager make sure he is aware of any problems you may

have and that he has had the opportunity to assist you.

2. If you are still not satisfied or do not understand any

part of this manual seek out the Owner or General

Manager of the dealership, explain the problem and

request assistance.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

P.O. Box 245

Assaria, Ks. 67416

Model 1150 1995 - 1997 167-058M 7/28/10

14

Page 17

Great Plains Mfg., Inc.

!

Section 1 Cart Assembly and Setup

Section 1 Cart Assembly and Setup

The following information is general in nature and was

written to aid the operator in preparing the tractor and drill

for use, and to provide general operating procedures. The

operator’s experience, familiarity with the machine, and

the following information combined should provide efficient drill operation and good working habits.

Having all the parts and equipment readily at hand will

speed your assembly task and make the job as safe as

possible.

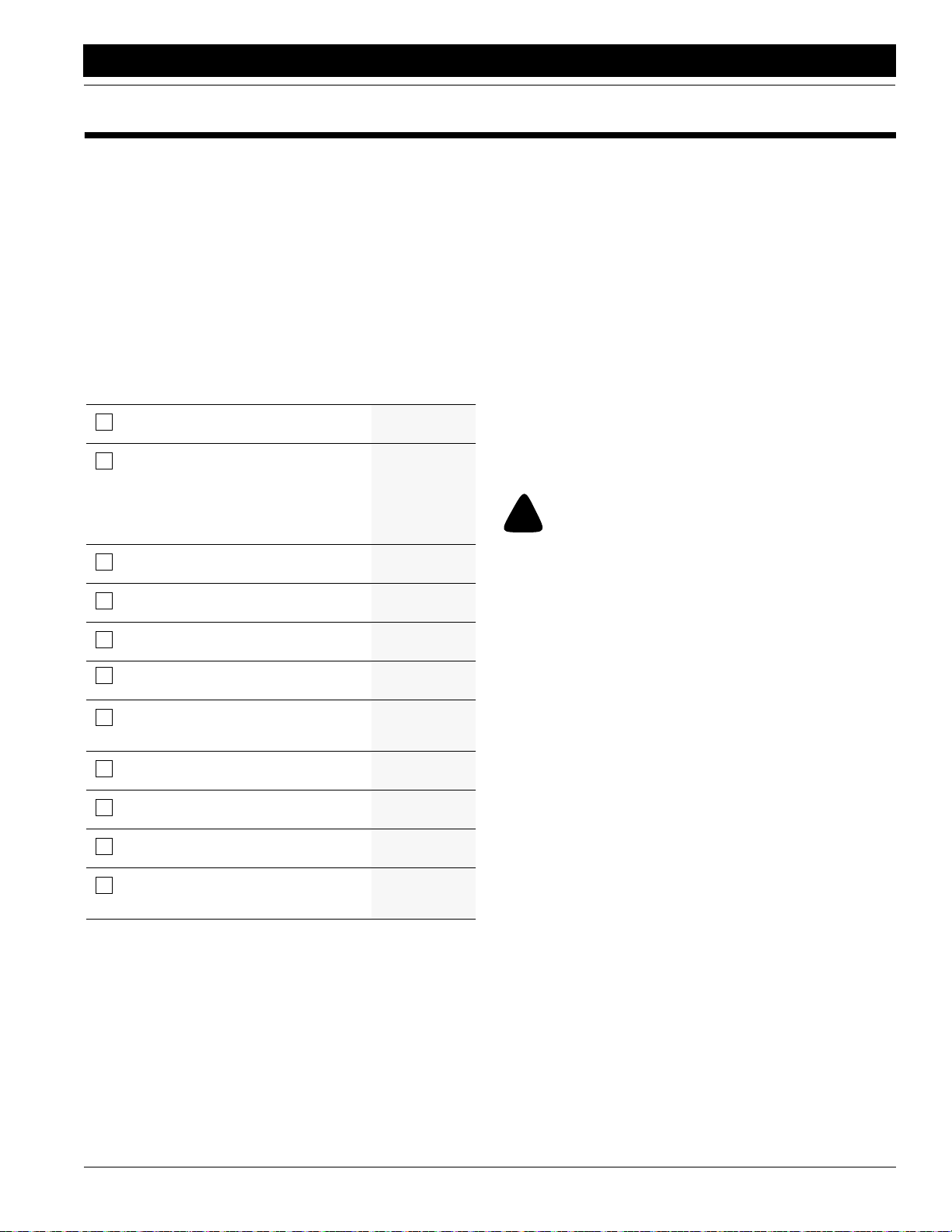

Pre-Assembly Checklist

Check Reference

All major frame components Operator’s

Fasteners and pins that were shipped with

the drill.

NOTE: All hardware from the factory has

been installed in the location where it will

be used. If a part or fastener is temporarily

removed for assembly reasons, remember

where it goes. Keep the parts separated.

All working parts are moving freely, bolts

are tight and cotter pins are spread.

All grease fittings are in place and lubricated.

Proper tension and alignment on all drive

chains.

Safety labels are correctly located and legible. Replace if damaged.

Red and amber reflectors are correctly

located and visible when the drill is in the

transport position.

“Slow moving vehicle” emblem is in place. Important Safety

Inflate tires to specified air pressure. Tighten

wheel bolts to specified torque.

Have a minimum of 2 people at hand while

assembling the drill.

Have a fork lift or hoist along with chains

and safety stands that are sized for the job

ready for the assembly task.

Manual

Operator’s

Manual

Operator’s

Manual

Section 6

page 69

Operator’s

Manual

Important Safety

Information

Important Safety

Information

Information

Section 9

page 86

Operator’s

Manual

Operator’s

Manual

General Description

This section covers the dealer’s requirements to assemble

the drill.

Tools required

• Fork lift or overhead hoist with 6500# capacity.

• General hand tools

• Jack stands or blocks and safety chain

Shipping information

Your drill is shipped via flat bed truck.. The drill is not fully

assembled.

Unload all equipment before beginning assembly. Do not

attempt any assembly work while drill is on the truck.

Read and understand the previous section, “Important

Safety Information” page 1, before starting assembly.

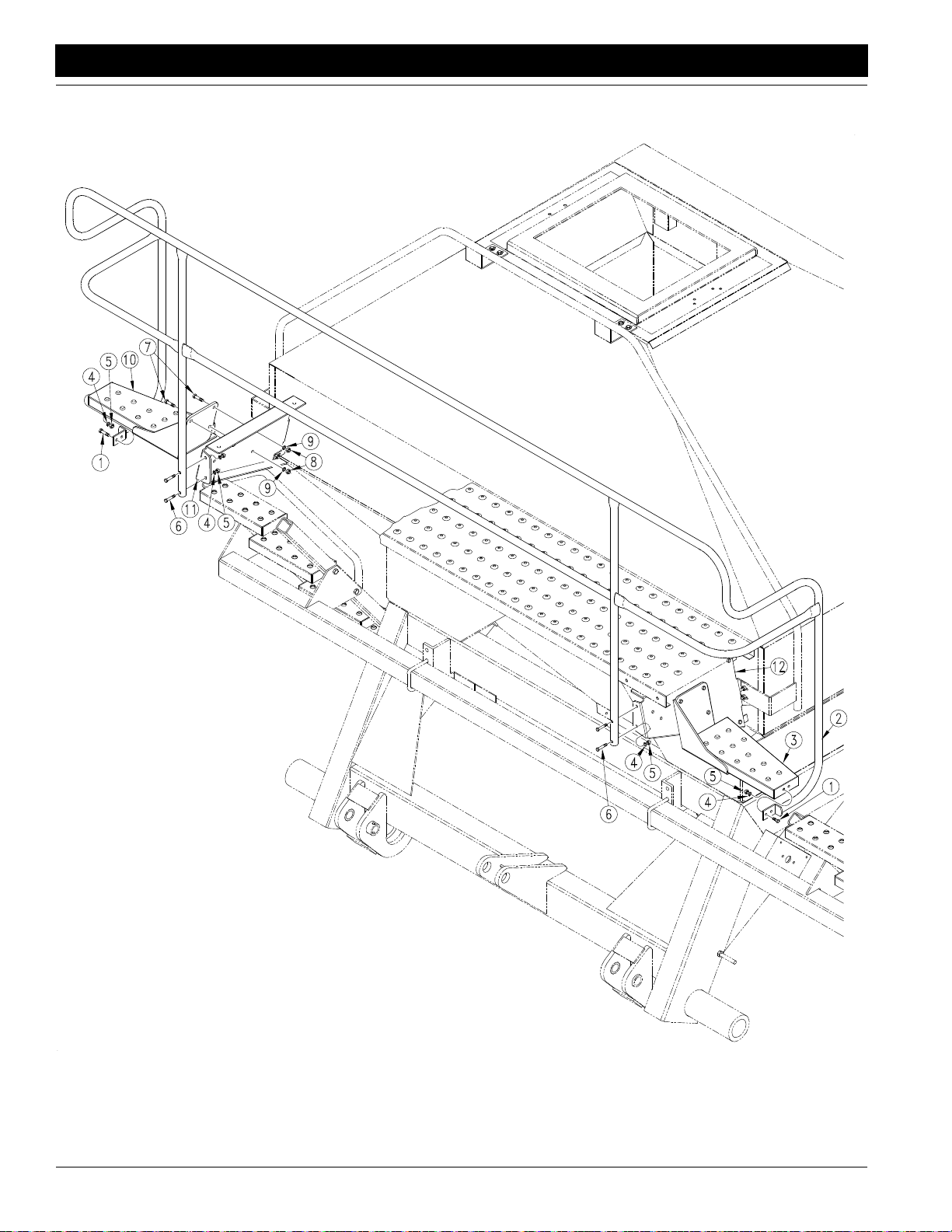

Top Steps & Rear Handrail

WARNING!

Do not climb on walkboard unless top ladder steps and handrails are securely installed.

Refer to Figure 1-1:

Working from the ground, attach the top step weldment,

left hand (#10), to the left side walkboard support (#11) using three 3/8” x 1” long bolts, (#7) 3/8” nuts (#8), and 3/8”

lockwashers (#9). Install the bolts so that the nuts are toward the center of the drill. Use the same method to attach

the top step weldment, right hand (#3), to the right side

walkboard support.

Use a fork lift or hoist to raise the rear handrail into position. Bolt the handrail (#2) to the rear of the left and right

walkboard supports (#11 & #12) using the 5/16” x 1 3/4”

long bolts (#6), 5/16” lockwasher (#4), and 5/16” nuts (#5).

Install the bolts so that the nuts are towards the front of the

drill. Do not over-tighten bolts, refer to the Torque Values

Chart in the “Appendix” section on page 86. Attach the

handrail end to the left and right ladder top steps (#3 &

#10) using the5/16” x 1” long bolts (#1), 5/16”lockwashers

(#4), and 5/16” nuts (#5). Install the bolts so that the nuts

are toward the center of the drill, refer to Figure 1-1.

7/28/10

Model 1150 1995 - 1997 167-058M

15

Page 18

Section 1 Cart Assembly and Setup

Great Plains Mfg., Inc.

14775

Top Step and Rear Handrail Installation

Figure 1-1

Model 1150 1995 - 1997 167-058M 7/28/10

16

Page 19

Great Plains Mfg., Inc.

!

Section 1 Cart Assembly and Setup

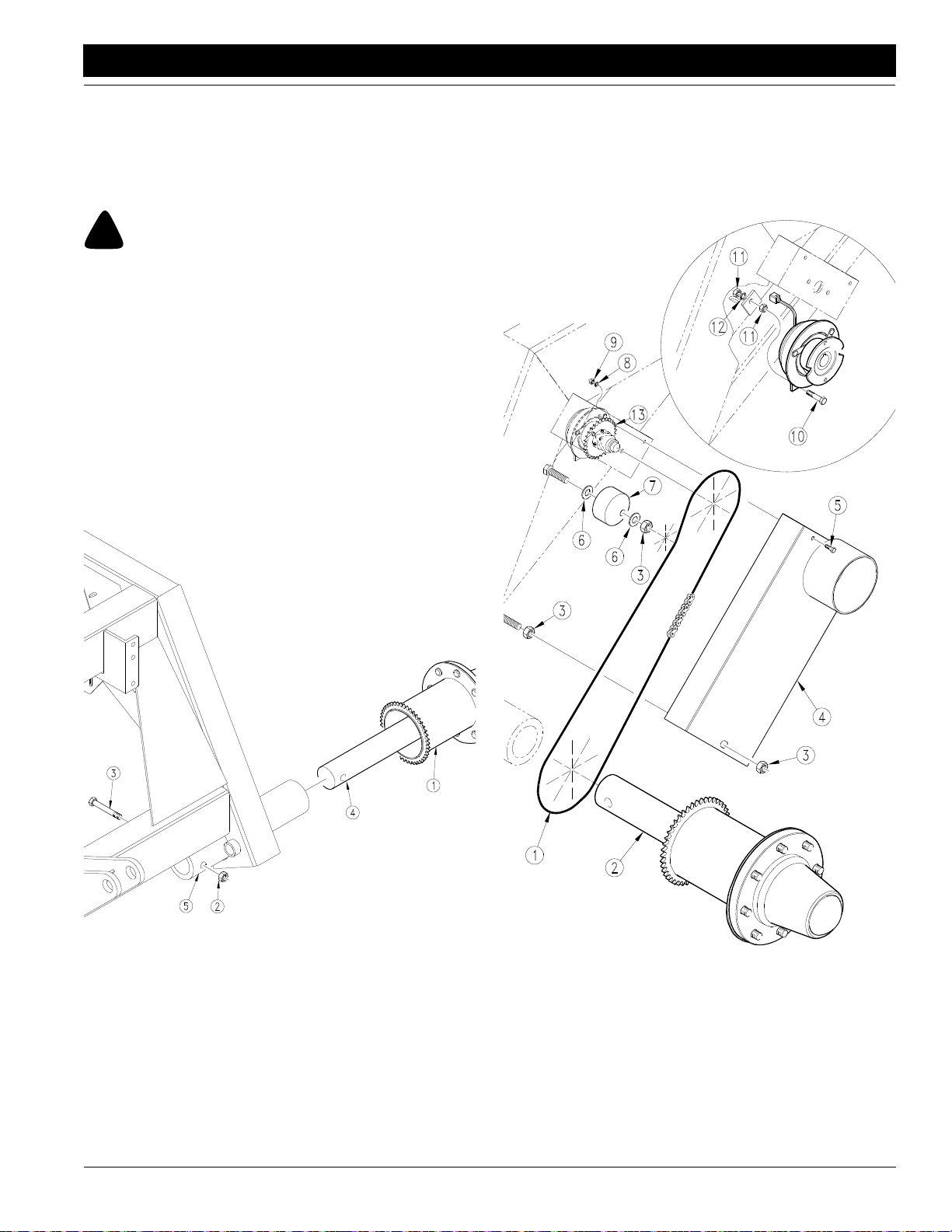

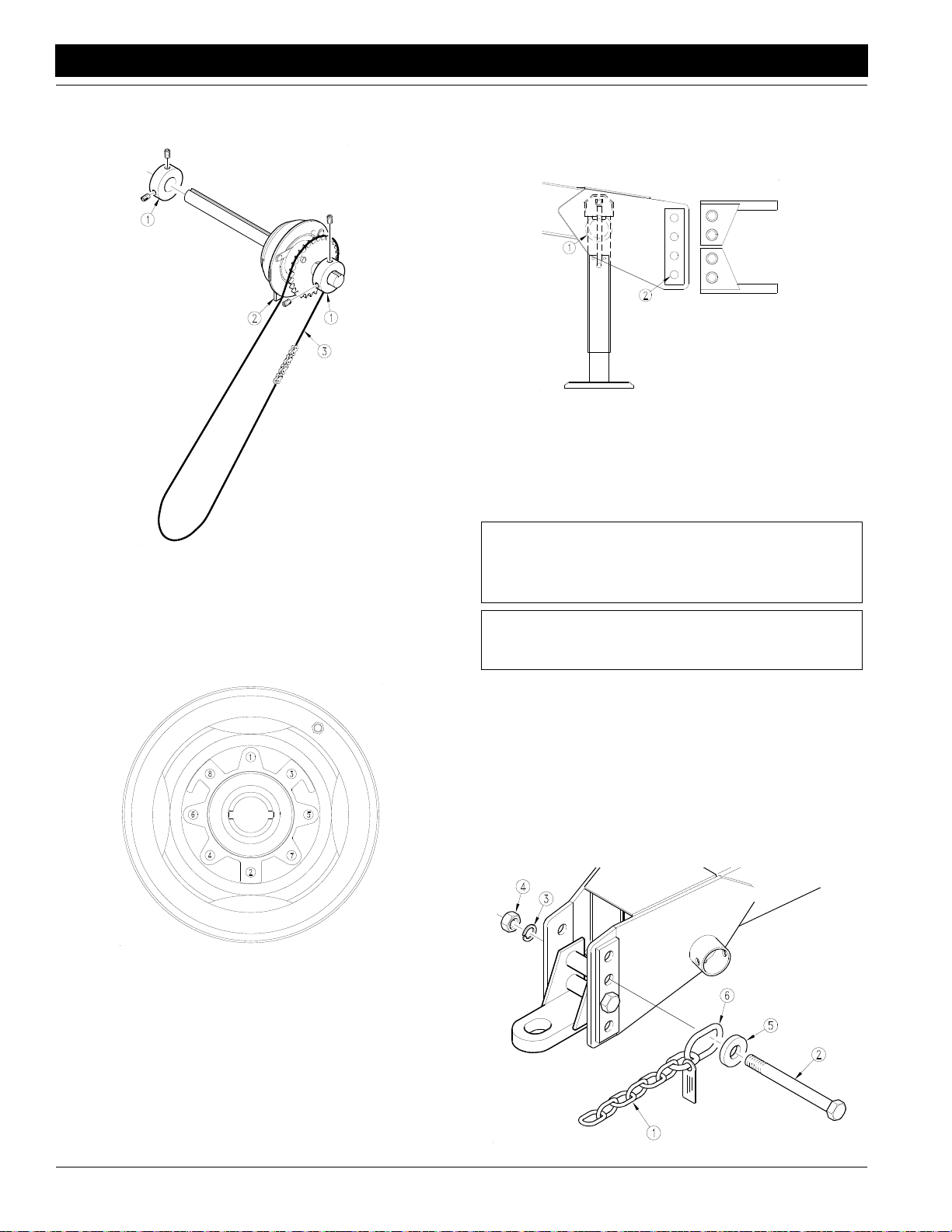

Spindles, Hubs, Wheels, & Drive Chain

Raise the rear of the cart off the ground high enough to let

the spindles slide into the tubes with hubs attached (the

spindle tube should be approximately 6” above the ground

at lowest point).

DANGER!

Crushing hazard. You may be severely injured or killed by the

drill if it falls. Always support the drill securely with jack stands

or blocks before working on unit raised off of the ground.

IMPORTANT: Put the hub and spindle assembly with the

drive sprocket on the right side of the drill. Install the assembly without the drive sprocket on the left side of the

drill.

Refer to Figure 1-2 to and line up the bolt hole (#4) in the

hub and spindle assembly with the bolt hole in the spindle

tube (#5). Slide the hub and spindle assembly (#1) into the

tube until the holes are aligned, refer to Figure 1-2. Secure

the hub and spindle assembly in the tube using the 3/4” x

5” long bolt (#3) and the 3/4” lock nut (#2).

implement and that a 29 tooth sprocket is used on the

clutch for the 45’ implement.

Install the main drive chain (#1) on the hub drive sprocket

(#2) and electric clutch sprocket (#16). The chain goes in

front of the drive chain tensioner (#9).

14459

Spindle Installation

Figure 1-2

Refer to Figure 1-3:

Remove the drive chain mud guard (#5). Loosen the nut

(#7) securing the drive chain tensioner (#9). Turn tensioner until the thinnest area is toward the front of the drill.

IMPORTANT: Before installing the drive chain make sure

that a 38 tooth sprocket is used on the clutch for the 34’

7/28/10

14436

Main Drive Chain Installation

Figure 1-3

Rotate the drive chain tensioner counterclockwise to remove excess chain slack then re-tighten nut (#7) to secure. Check alignment of the chain and sprockets. If

adjustment is needed, loosen the set collars (#1) holding

Model 1150 1995 - 1997 167-058M

17

Page 20

Section 1 Cart Assembly and Setup

Great Plains Mfg., Inc.

the electric clutch (#2) in place and slide the clutch over to

align chain, refer to Figure 1-4.

Drive Chain Alignment

Figure 1-4

14462

Re-tighten the set collars (#1) on both sides of the clutch

and re-tension chain. When the chain has been installed

and adjusted replace the drive chain mud guard. Raise the

rear of the cart until the center of the hubs are approximately 21” above the ground and securely block. Install

the tires and wheels on the hubs and tighten using recommended pattern, refer to Figure 1-5.

pin. With the drill on level ground adjust the jack until the

center of the frame and bin are level. There are three sets

of holes (#2) in the tongue, with the reversible hitch this

provides six different hitch heights, refer to Figure 1-6.

14439

Hitch Height Adjustment

Figure 1-6

Measure the height at the top of the drawbar on the tractor

that the drill is to be attached to. Install the hitch so that the

bottom of the strap is at the position closest to the height of

the tractor drawbar.

NOTE: When hitching the drill to a different tractor

check for a difference in the drawbar heights and readjust as needed.

NOTE: Make sure that the hitch is securely bolted to

the drill tongue.

14440

Pattern of Tire and Wheel Installation

Figure 1-5

Remove the blocks and lower the cart to the ground.

Check air pressure in tires and inflate to value listed in the

Tire Inflation Chart in the “Appendix” section starting on

page 86.

Hitch, Safety Chain, & Jack

Raise the tongue off the ground until the jack slides into

the jack stob (#1). Place the jack in the stob and securely

Refer to Figure 1-7:

Your drill comes equipped with a safety chain (#1). The

safety chain should be attached securely to the drill

tongue with a 1 1/4” x11” bolt (#2), 1 1/4” lock washer (#3),

and 1 1/4” nut (#4). The safety chain washer (#5) must be

installed outside of the safety chain attaching ring (#6).

The chain must always be securely fastened to a suitable

anchor on the towing vehicle before moving the drill.

Retract and unpin the jack. Store the jack horizontally in

the stob between the tongue rails when moving drill.

14568

Safety Chain

Figure 1-7

Model 1150 1995 - 1997 167-058M 7/28/10

18

Page 21

Great Plains Mfg., Inc.

Section 1 Cart Assembly and Setup

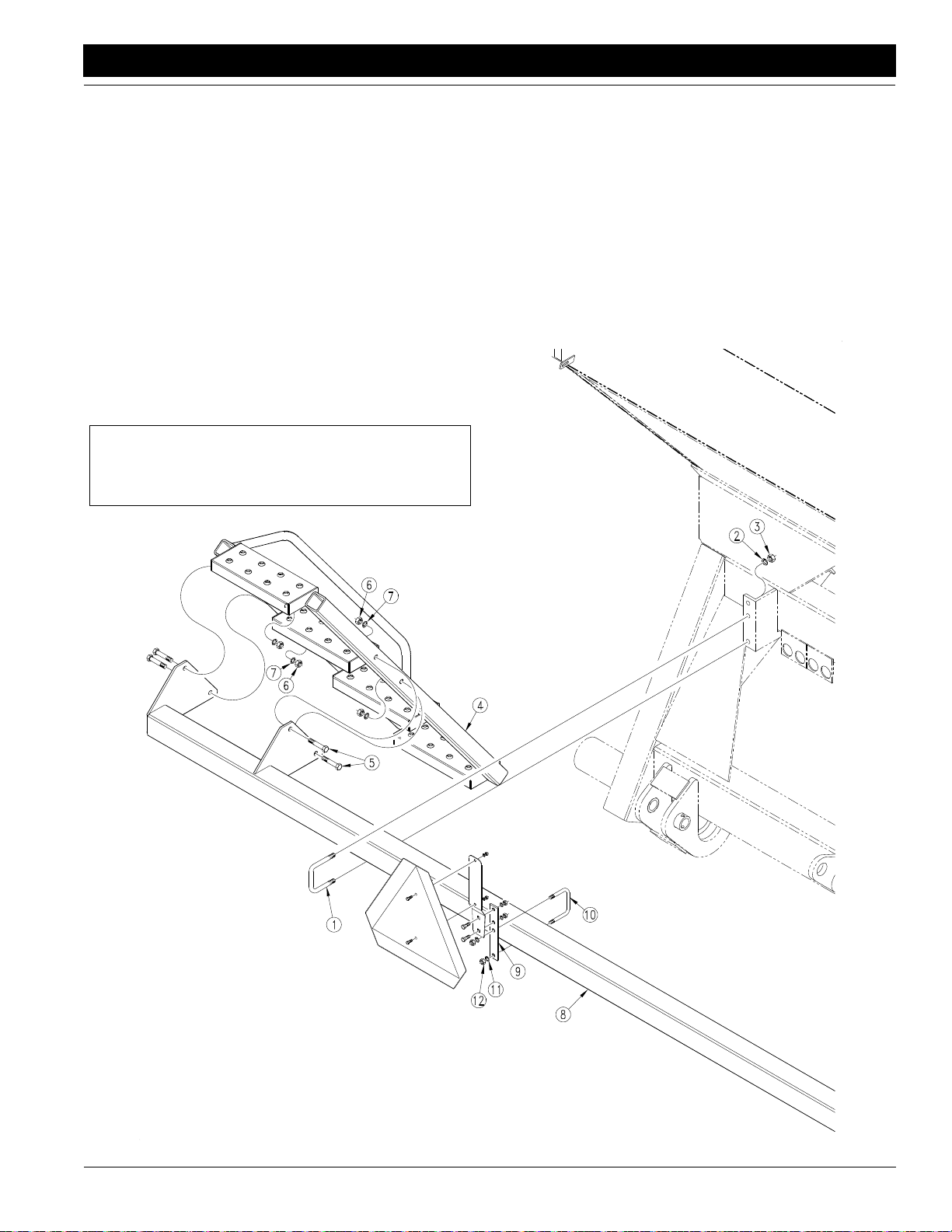

Lower Ladder Weldment

and Lower Ladder Support Weldment

Refer to Figure 1-8:

Install the lower ladder support weldment (#8) to the rear

of the cart with the 1/2”-13 x 3 1/32” x 4” u-bolts (#1), 1/2”

lock washers (#2), and 1/2” nuts (#3). Attach the lower ladder support so that the longest edge, along the mounting

plates, is on the bottom and that the mounting plates face

toward the front.

Be sure that the lower ladder support weldment is centered from side to side before tightening the u-bolts.

Install the left hand lower ladder weldment on the left side

of the drill using four 1/2” x 3” bolts (#5) with the 1/2” lockwashers (#7), and the 1/2” nuts (#6). Install the bolts so

that the nuts are toward the center of the ladder. Use this

procedure for installing the right side ladder.

NOTE: The lower ladders are identified left and right

by orienting them so that the handrails are located toward the outside of the drill, refer to Figure 1-8.

Slow Moving Vehicle

Bracket & Emblem

Bolt the slow moving vehicle (SMV)support bracket (#9) to

the center of the lower ladder support weldment (#8)

using one 3/8” x 3 1/32” x 4” u-bolt (#10), the 3/8” lock

washers (#11), and 3/8” nuts (#12). Install the bracket on

the rear edge of the tube with the remaining holes in the

bar on the top. Attach the SMV emblem and bracket to the

support using the supplied hardware. Install the SMV

bracket with the offset to the rear.

7/28/10

Lower Ladder Installation

Figure 1-8

14463

Model 1150 1995 - 1997 167-058M

19

Page 22

Section 2 Implement Assembly and Setup

!

!

Section 2 Implement Assembly and Setup

WARNING!

Obey all safety instructions from lifting equipment manufacturer.

Do not walk or place any part of the body under the raised sections. Be sure transport stands are securely attached prior to lifting. Be sure lifting equipment has enough capacity to lift sections.

NOTE: Each implement section in a stack can weigh

2100 pounds with 7” row spacing and spring reset

openers. Each 9 1/2’ wing section used on 34’ implements weighs approximately 2400 pounds.

1. Remove the implement sections from the truck and

place them on the ground.

2. With all stacks securely on the ground remove the ubolts from the bottom of the shipping stand on the

highest sections so that the stand remains attached to

the upper section.

3. Carefully lift the section off of the stack and place it on

solid, level ground or concrete if available.

4. Repeat steps 2 and 3 with each section, placing the

sections approximately in the position for assembly.

Great Plains Mfg., Inc.

6. When the holes are aligned install the pivot clevis bolts

(#2) in place and secure them with 1” nylock nuts (#1).

When installing the bolts install so that the flat section

of bolt head is aligned with the square stock on the

clevis.This is to prevent the bolt from rotating in the

clevis, refer to Figure 2-1.

14441

Pivot Pin Installation

Figure 2-1

Repeat steps 5 and 6 until all sections are bolted

together.

NOTE: Be sure that the pivot bushings are in place in

the pivot tubes before positioning sections.

5. Use the hoist or forklift to position adjacent sections so

that the holes in the clevis line up with the holes in the

pivot tubes.

WARNING!

Do not place any part of the body between the frame sections

when aligning holes or severe injury may result.

Flex Limiter Bars

Refer to Figure 2-2:

1. Position the flex limiter bars so that the slots line up with

the holes in the lugs near the center of the implement.

2. Install the 7/8” x 3 1/2” bolts (#1), 7/8” flat washers

(#2), 7/8” flex limiter bar space tubes (#6), flex-limiter

bars (#3), 7/8” lock washer (#4), and 7/8” nut (#5) at

each end of tube. The flex limiter bars should be free

to move from side-to-side on the bolts.

Flex Limiter Bar Installation

Figure 2-2

14483

Model 1150 1995 - 1997 167-058M 7/28/10

20

Page 23

Great Plains Mfg., Inc.

Section 2 Implement Assembly and Setup

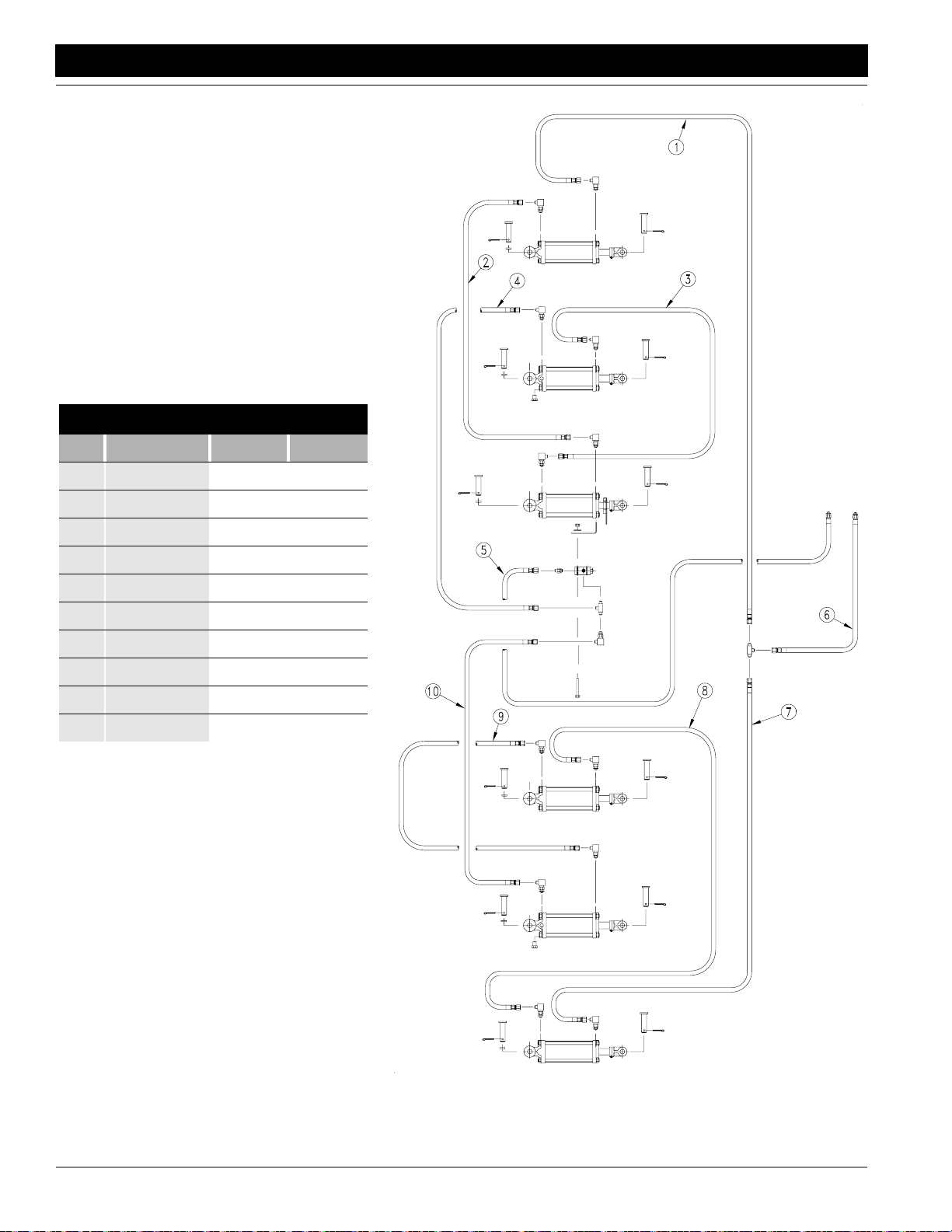

Implement Lift

Cylinder Hydraulic Hoses

NOTE: The SAE o-ring and JIC 37˚ flare type hose

connections do not require sealant for reconnecting.

They do not require high torque for a good seal.

Refer to Figure 2-3 and Figure 2-4. Install the hydraulic

hoses in place on the lift wheels. Note the hose lengths

listed and be sure to use the correct length of hose in each

location. Install the longest hose first and work down to the

shortest hose length.

The row openers in some locations have hose clips (#1)

mounted on them,refer to Figure2-5. Hydraulic hoses should

always be routed through the clips to prevent damage.

7/28/10

Model 1150 1995 - 1997 167-058M

21

Page 24

Section 2 Implement Assembly and Setup

34’ Lifting Hydraulics

Hydraulic Hose Sizes

Item Part Number I.D. Length

1 811-235C 3/8 222

Great Plains Mfg., Inc.

2 811-237C 3/8 174

3 811-245C 3/8 74

4 811-245C 3/8 74

5 811-236C 3/8 84

6 811-123C 3/8 51

7 811-237C 3/8 174

8 811-235C 3/8 222

9 811-127C 3/8 111

10 811-127C 3/8 111

34’ Lifting Hydraulics

Figure 2-3

Model 1150 1995 - 1997 167-058M 7/28/10

22

14464

Page 25

Great Plains Mfg., Inc.

Section 2 Implement Assembly and Setup

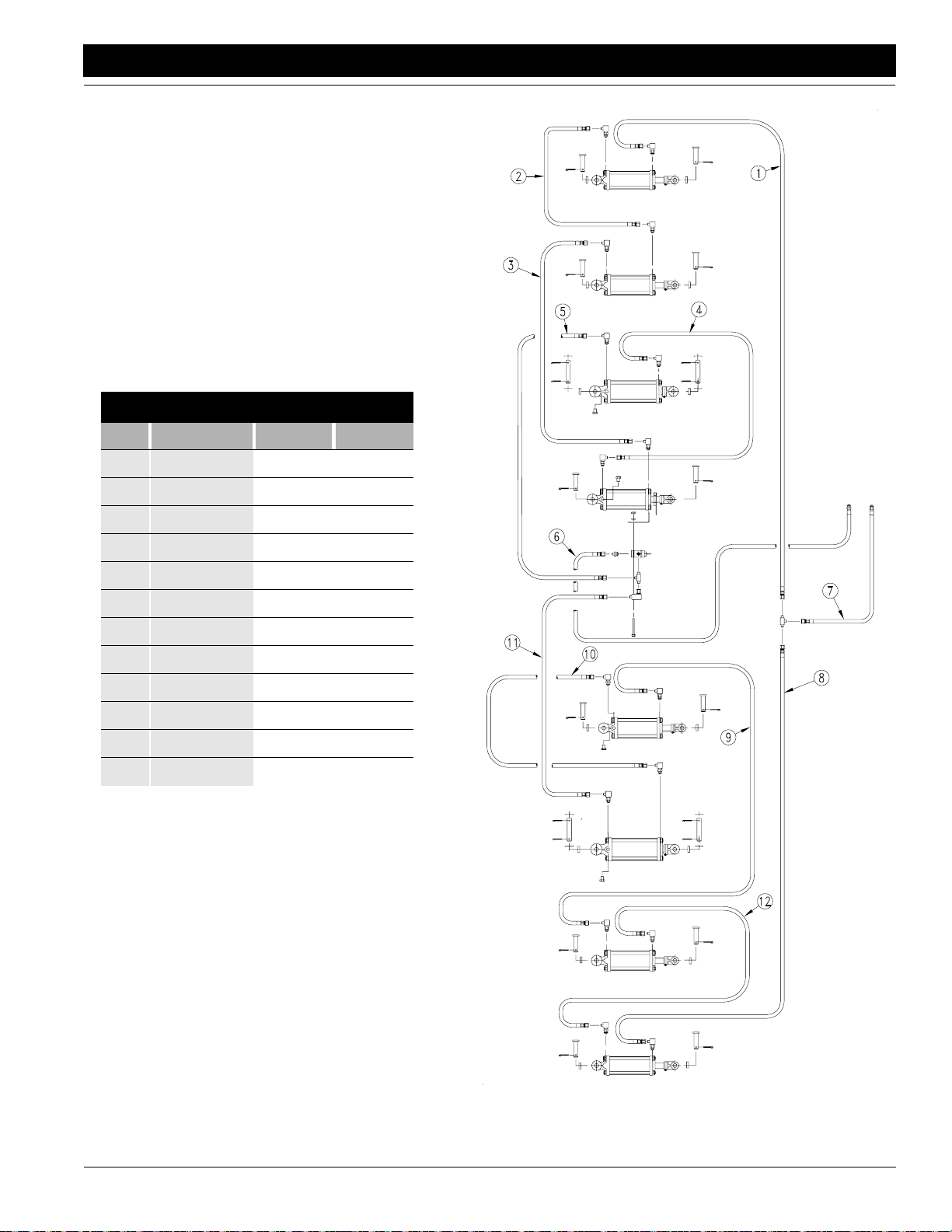

45’ Lifting Hydraulics

Hydraulic Hose Sizes

Item Part Number I.D. Length

1 811-124C 3/8 268

2 811-125C 3/8 82

3 811-310C 3/8 198

4 811-245C 3/8 74

5 811-245C 3/8 74

6 811-236C 3/8 84

7 811-123C 3/8 51

8 811-124C 3/8 268

9 811-311C 3/8 242

10 811-127C 3/8 111

11 811-127C 3/8 111

12 811-125C 3/8 82

7/28/10

45’ Lifting Hydraulics

Figure 2-4

Model 1150 1995 - 1997 167-058M

14465

23

Page 26

Section 2 Implement Assembly and Setup

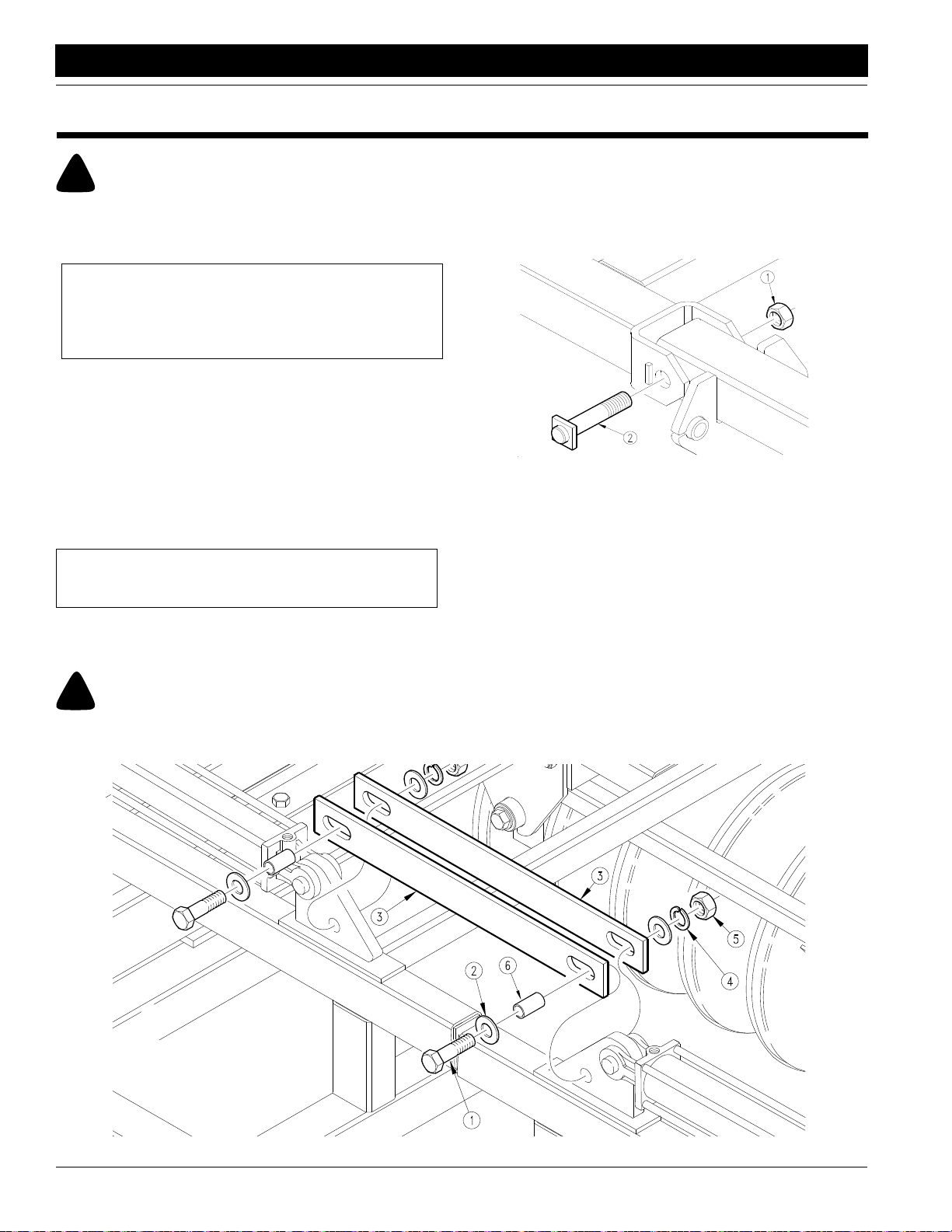

!

Great Plains Mfg., Inc.

NOTE: The cylinders located directly behind the cart

will not pivot upward for bleeding, and must be unpinned at both ends and then supported with the rod

end port higher than the base end port. Refer to Figure 2-6.

port higher than the base end port.

14444

Hydraulic Hose Clips

Figure 2-5

IMPORTANT: When the lift cylinder hoses are installed

carefully check them to be sure they are not rubbing on

any sharp edges. Check that the hoses are loose enough

to allow the implement to fold or unfold and raise or lower

without damage. Be sure that hoses will not bind or get

pinched during operation. If hoses are in a position where

they might get damaged change their route until they are

safe.

Bleeding the Hydraulic Lifting System

The implement lifting system is equipped with rephasing

type hydraulic cylinders thatrequire a special procedure for

bleeding air from the hydraulic circuits. Read and follow the

procedure carefully. The rephasing type cylinders will not

function properly with air in the hydraulic circuit. This will

cause uneven seeding depth across the implement.

NOTE: Check the hydraulic fluid in the tractor reservoir and fill to the proper level. Add fluid to the system

as needed. A low reservoir level may draw air back

into the system, causing jerky or uneven cylinder

movement.

1. Jack up and support the front member of each implement frame section at a point close to each gauge

wheel.

2. With the frame blocked and supported, unpin the rod

end of the gauge wheel cylinders. Pivot the cylinders

up and wire; or otherwise safely support the rod end

14447

Center Hydraulic Cylinders

Figure 2-6

3. With the tractor engine at an idle speed, hold the remote lever on to put fluid into the lifting circuit. When

the outboard cylinders on both sides of the implement

have completely extended, hold the remote lever on

for one minute.

4. Retract the cylinder rods. Extend the rods again and

hold the remote lever on for one more minute. Repeat

this step two more times to completely bleed the system. If the gauge wheel leveling adjustments are to be

made, leave the cylinders unpinned and the implement frame supported.

5. Recheck the tractor reservoir and fill to the proper level.

Fold Cylinders

DANGER!

The folding cylinders must be bled free of air before attempting

to fold implement, otherwise severe damage and bodily injury

may result. Refer to Figure 2-7:

34’ and 45’ Drills

Position main foldcylinders with base end toward center of

the drill, rod end toward wings. Pin the base end to the fold

cylinder lug. Secure the pin with the provided clip, refer to

Figure 2-7. Leave rod end unhooked and block up in the

air so that the rod will not come in contact with anything

when extended. Do not connect rod end until after air is

bled from fold circuit.

Model 1150 1995 - 1997 167-058M 7/28/10

24

Page 27

Great Plains Mfg., Inc.

Section 2 Implement Assembly and Setup

45’ Drills

Position the outer fold cylinders with the base end toward

the center of dill and rod ends out. Pin the base end to the

cylinder lug and secure with clip. Leave rod end unhooked

and block up so that the rod will not come in contact with

anything when extended. Do not connect the rod end until

after air is bled from the fold circuit.

Refer to Figure 2-8 and Figure 2-9. Install hydraulic hoses.

Note the hose lengths and be sure to use the correct length

hose in each location. Start with the longest hose and work

to the shortest.

Be sure to use the hydraulic hose clips on the openers and

route the hoses through them. When the hoses are

hooked up be sure that they are not twisted and will not get

pinched when the implement is raised, lowered, folded or

unfolded. Do not let the hoses rub on sharp edges and be

sure there is enough slack for down-flex.

NOTE: The SAE o-ring and JIC 37˚ flare type hose

connections do not require sealant for reconnecting.

They do not require high torque for a good seal.

NOTE: Do not try to fold the implement unless the flex

limiter bars are installed.

14446

Bleeding Fold Cylinders

Figure 2-7

7/28/10

Model 1150 1995 - 1997 167-058M

25

Page 28

Section 2 Implement Assembly and Setup

Great Plains Mfg., Inc.

45’ Folding Hydraulics

Hydraulic Hose Sizes

Item Part Number I.D. Length

1 811-095C 3/8 158

2 811-095C 3/8 158

3 811-118C 3/8 41

4 811-094C 3/8 176

5 811-094C 3/8 176

6 811-118C 3/8 41

7 811-096C 3/8 108

8 811-096C 3/8 108

9 811-117C 3/8 90

10 811-116C 3/8 66

45’ Folding Hydraulics

Figure 2-8

14478

Model 1150 1995 - 1997 167-058M 7/28/10

26

Page 29

Great Plains Mfg., Inc.

Section 2 Implement Assembly and Setup

7/28/10

34’ Folding Hydraulics

Figure 2-9

14479

34’ Folding Hydraulics

Hydraulic Hose Sizes

Item Part Number I.D. Length

1 811-240C 3/8 75

2 811-240C 3/8 75

3 811-241C 3/8 21

4 811-241C 3/8 21

5 811-239C 3/8 75

6 811-239C 3/8 75

Model 1150 1995 - 1997 167-058M

27

Page 30

Section 2 Implement Assembly and Setup

!

Bleeding the Folding System

NOTE: Check the hydraulic fluid in the tractor reservoir and fill to the proper level. Add fluid to the system

as needed. A low reservoir level may draw air back

into the system, causing jerky or uneven cylinder

movement.

1. Unpin the rod end of the fold cylinders and block up.

Wire or otherwise safely support the cylinders so

when the rod end is fully extended it does not contact

anything.

2. Cycle the cylinders completely in and out a minimum

of three times to purge the air from the fold system.

NOTE: On the 45‘ model if one side is completely in or

out and the other side is not moving release the tractor

hydraulic lever momentarily, reverse it and try again.

3. Fully extend the cylinders to repin the rod ends.

CAUTION!

Do not fold implement unless gauge wheel transport locks are

installed.

4. Recheck the tractor reservoir and fill to the proper level.

Side-to Side Frame Leveling

Equal seeding depth across the drill can only be maintained if all frames are level. Leveling adjustments should

be done during the initial setup of the drill. Periodic frame

leveling should not be necessary, however, you may field

check the level by laying a straight edge across at least

two frame members and out over a gauge wheel of that

frame. Measure the distance from the bottom of the

straight edge to the top of the gauge wheel tire. Compare

this measurement at the other gauge wheel tires, step 4. If

leveling is necessary follow the instructions listed.

45’ Drill Frame Leveling

1. The gauge wheel hydraulic circuit should be bled of air

and full of oil, see Bleeding the Hydraulic Lifting Sys-

tem, this section, on page 24.

2. Hydraulically lower the entire implement frame. The

frame should then be jacked up and supported, see

Bleeding the Hydraulic Lifting System, this section, on

page 24, and implement sections one and six noncastored gauge wheel cylinders should be unpinned

at the rod end and safely supported.

3. Retract all gauge wheel cylinders fully. Since the dual

gauge wheels on the implement sections three and four

are non-adjustable all adjustments will be made with

these as a reference. A reference measurement must

be taken from the top of the implement frame to the center of one dual gauge wheel axle, refer to Figure 2-10.

Great Plains Mfg., Inc.

14575

Dual Gauge Wheel Arm

Figure 2-10

4. With all cylinders fully retracted lay a straight edge

across at least two frame members of either implement section three or four and extend the straight

edge out over the dual gauge wheel axle of that implement section. Measure the distance from the bottom

of the straight edge to the center of the dual gauge

wheel axle, approximately 11 5/8”.

Implement sections one and six non-castored gauge

wheels (inboard) should center on the measurement

determined above. Implement sections one and six

(outboard) gauge wheels should measure approximately 1/2” higher (subtract 1/2” from your measurement) because they carry less weight.

5. Lay a straight edge across the top of at least two frame

members of implement section one and out over the

non-castored gauge wheel axle. Raise the unpinned

gauge wheel and arm assembly up to where the center of the gauge wheel axle is at the measurement determined in step 4 above. Support the gauge wheel at

that point. Swing the cylinder down to the gauge

wheel arm and adjust the eye-bolt (#1), Figure 2-11,

until the pin holes line up. Secure the eye-bolt with the

jam nut and repin the cylinder to the gauge wheel arm.

Eye-bolt Adjustment

Figure 2-11

14448

Model 1150 1995 - 1997 167-058M 7/28/10

28

Page 31

Great Plains Mfg., Inc.

Section 2 Implement Assembly and Setup

6. Now move the straight edge so it lies over the castored gauge wheel axle. Adjust the eye-bolt at the

base end of the cylinder until the center of the axle is

approximately 1/2” higher (subtract 1/2” from your

measurement) than the measurement determined in

step 4. Secure eye-bolt by tightening the jam nuts.

7. Repeat steps 5 and 6 for implement section six.

8. Make sure that all cylinders are securely pinned.

9. The center of the implement is held by the cart sling.

This should be adjusted so the center of the machine

is level during field operation., refer to Figure 2-12.

10. For front-to-back leveling of the implement frame see

Cart Sling

Figure 2-12

14432

NOTE: Towers must be located so that there is no interference when wings are folded or unfolded. When

towers have been installed very slowly fold implement

while watching to be sure there is no interference. Do

not stand under a wing while it is being folded or unfolded! If towers have any interference lower wing then

move them slightly until they clear. Check clearance

before installing hoses.

5. Implement sections one and fourgauge wheels should

center on the measurement determined above. Lay a

straight edge across the top of at least two frame members of implement section one and out over the noncastored gauge wheel axle. Raise the unpinned gauge

wheel and arm assembly up to where the center of the

gauge wheel axle is at the measurement determined in

step 4 above. Support the gauge wheel at that point.

Swing the cylinder down to the gauge wheel arm and

adjust the eye-bolt (#1), refer to Figure 2-11, until the

pin holes line up. Secure the eye-bolt with the jam nut

and repin the cylinder onto the gauge wheel arm.

6. Repeat step 5 for implement section four.

7. Make sure that all cylinders are securely pinned.

8. The center of the implement is held by the cart sling,

refer to Figure 2-12. This should be adjusted so the

center of the machine is level during field operation.

9. For front-to-back leveling of the implement frame see

Setting the Seeding Depth and Leveling Front-to-Rear

under “Adjustments” on page 60.

Distribution Towers and Hoses

Setting the Seeding Depth and Leveling Front-to-Rear

under “Adjustments” on page 60.

34’ Drill Frame Leveling

1. The gauge wheel hydraulic circuit should be bled of air

and full of oil, see Bleeding the Hydraulic Lifting Sys-

tem, this section, on page 24.

2. Hydraulically lower the entire implement frame. The

frame should then be jacked up and supported, see

Bleeding the Hydraulic Lifting System, this section, on

page 24, and implement sections one and six noncastored gauge wheel cylinders should be unpinned

at the rod end and safely supported.

3. Retract all gauge wheel cylinders fully. Since the dual

gauge wheels on implement sections two and three

are non-adjustable all adjustments will be made with

these as a reference. A reference measurement must

be taken from the top of the implement frame to the

center of one dual gauge wheel axle.

4. With all cylinders fully retracted lay a straight edge

across at least two frame members of either implement

section two or three and extend the straight edge out

over the dual gauge wheel axle of that implement section. Measure the distance from the bottom of the

straight edge to the center of the dual gauge wheel axle, approximately 11 5/8”, refer to Figure 2-10.

NOTE: For best results distribution towers should be

mounted as vertically as possible. Installing towers

so that they lean strongly to one side may cause uneven distribution, especially on hillsides.

Refer to Figure 2-14 for tower mounting locations.

1. Install a tower support bracket at each location using

the 1/2” u-bolt (#1), 1/2” lock washers (#2), and 1/2”

nuts (#3), refer to Figure 2-13.

14546

Mounting Tower Brackets

Figure 2-13

7/28/10

Model 1150 1995 - 1997 167-058M

29

Page 32

Section 2 Implement Assembly and Setup

Great Plains Mfg., Inc.

34’ Drill

45’ Drill

Tower Mounting Locations

Figure 2-14

Model 1150 1995 - 1997 167-058M 7/28/10

30

14486

Page 33

Great Plains Mfg., Inc.

Section 2 Implement Assembly and Setup

2. Position a tower on bracket and secure with 2 u-bolts.

The bottom of lower round plate should be approximately 31 1/2 inches above the frame rails. Tower

should be turned so that inlet tube is pointed toward

the center of the drill. The center tower inlet should

face the front, refer to Figure 2-15.

These 2 hoses should also be the same length, (longer than the others.)

7. Secure all hoses to the frame using 24” cable ties being sure hose will not be damaged during drill operation.

1” Secondary Hoses

NOTE: Seed hoses must be routed to prevent them

from rubbing on sharp edges or being damaged

when the implement is raised, lowered, folded, or unfolded. Hoses must be pushed fully into distribution

tower ports until they contact their stop.

With the implement width and row spacing in mind refer to

the appropriate hose routing illustration for the correct assembly of hoses.

1. Loosen bolts holding tower halves together, refer to

Figure 2-16.

Do not remove bolts.

14499

Inlet Tube Alignment

Figure 2-15

Primary 2 1/2” Distribution Hoses

1. Start with center tower #3. Route hose as shown in

Figure 2-17. Slide hose at least two inches onto tower

inlet. (Slide clamp over the end first)

2. Allow enough hose so that implement raising, lowering, folding and unfolding will not pinch or bind hose.

3. Using a hacksaw cut hose so that it will slide onto

meter outlets up to end of flare.

4. Slide clamp over hose end then slide hose onto meter

outlet. Install clamp so that it will not interfere with other hoses, clamps, or meter door latch handles.

5. Repeat this procedure on towers #2 and #4. Cut these

two the same length but longer than the center hose.

6. Repeat the same procedures for towers #1 and #5.

Tower Assembly

Figure 2-16

14449

7/28/10

Model 1150 1995 - 1997 167-058M

31

Page 34

Section 2 Implement Assembly and Setup

Great Plains Mfg., Inc.

34’ Drill 7” Row Spacing

34’ Drill 10” Row Spacing

14542

14533

Seed Hose Routings

Figure 2-17

Model 1150 1995 - 1997 167-058M 7/28/10

32

Page 35

Great Plains Mfg., Inc.

Section 2 Implement Assembly and Setup

34’ Drill 12” Row Spacing

14534

7/28/10

45’ Drill 7” Row Spacing

Seed Hose Routings (con’t.)

Figure 2-17

Model 1150 1995 - 1997 167-058M

14543

33

Page 36

Section 2 Implement Assembly and Setup

45’ Drill 10” Row Spacing

Great Plains Mfg., Inc.

14535

45’ Drill 12” Row Spacing

14536

Seed Hose Routings (con’t.)

Figure 2-17

Model 1150 1995 - 1997 167-058M 7/28/10

34

Page 37

Great Plains Mfg., Inc.

Section 2 Implement Assembly and Setup

Refer to Figure 2-18:

2. Attach the end of the hose to opener.

For floating hoe openers slide clamp over the end of

the hose 6”. Put the end of the hose in the seed tube

6”. Hook the clamp ends in the holes at the top of the

seed tube.

3. Route the hose to the tower outlet. Allow just enough

slack for down flex of wings. Be sure to use outlet as

shown on routing diagram.

4. Allow 2 1/4” of the hose to extend past the edge of the

tower then squarely and smoothly cut off the hose.

5. Push the end of the hose into the port until it contacts

the ridge and stops, this is approximately 2 1/4”.

6. Repeat steps 1 through 6 for all 1” hoses on each tower.

7. When all hoses are installed on a tower, tighten the

bolts holding the halves together.

NOTE: The tower bolts are equipped with nylock nuts

and should not be over-tightened. Tighten the bolts

only until the hose is held securely against being

blown out. Do not bend tower plates.

8. Check all hosesto be sure that they are not rubbing on

sharp edges and will not be damaged when the drill is

raised, lowered, folded, or unfolded. Re-route if needed to prevent damage.

7/28/10

Hose Installation On Openers

Figure 2-18

14563

Model 1150 1995 - 1997 167-058M

35

Page 38

Section 2 Implement Assembly and Setup

Great Plains Mfg., Inc.

Light Harness and Brackets

Refer to Figure 2-19:

Attach the left (#11) and right (#3) side light brackets to the

left and right center sections of the implement. Use the

5/8”-11 x 2 3/4” bolts (#6) to secure them to the outer lift

assist pivot bearings. Install the left (#2) and right (#9) ag

lights on the brackets using the 1/4” x 1 1/4” bolts (#10),

lockwashers (#7), and nuts (#8). The lights should be installed with the red lenses to the inside and facing the rear.

Attach the light harness “Y” connector (#4) to the terminal

.

at the back of the cart (#1). Route the wires along the

frame members back to the lights and plug in.

NOTE: The lead with the green wire goes to the right

side lights, the lead with the yellow wire goes to the

left side when facing forward.

Secure the wire in place using the cable ties (#5). Coil the

excess wire and tie it securely to the implement frame

Safety Light Kit Installation

Figure 2-19

Model 1150 1995 - 1997 167-058M 7/28/10

36

14573

Page 39

Great Plains Mfg., Inc.

!

!

Section 3 Operating Instructions

Section 3 Operating Instructions

General Description

The seed metering mechanism of this drill is powered by

the cart tire and is driven at a rate proportional to distance

driven. This ensures that the rate applied in pounds per

acre remains constant as ground speed is varied. The

pounds per acre rate is adjustable and can be set using

the gearbox, speed change sprocket and hi-low gears on

the meter. The metering device is driven through an electro-magnetic clutch which will not engage unless the fan

motor is running at high speed and the implement is lowered past an adjustable height switch. This prevents the

primary seed hoses from being plugged by seed being

metered into them without the fan running and also allows

the seed to be shut off automatically when the drill is lifted

on head lands. The seed bin is sealed and held at the

same pressure as the meter chamber so that metering is

controlled mechanically and not by air flow fluctuations.

The metered seed is carried by air through the 5 primary

hoses to the distribution towers on the implement. These

towers then divide the air and seed into individual rows

and it is carried to the openers in the secondary hoses.

Prestart Checklist

• Lubricate the drill as indicated in the Lubrication portion

of the “Maintenance and Lubrication” section starting

on page 69.

• Check the tires for proper inflation, see the Tire Inflation

Chart in the “Appendix” section starting on page 86.

• Check the chains for proper tension and alignment as

shown in the Lubrication portion of the “Maintenance

and Lubrication” section starting on page 69.

• Perform all beginning of season and daily service items

discussed in the “Maintenance and Lubrication” section starting on page 69.

• Check the drill for worn or damaged parts and repair or

replace them before going to the field.

• All nuts, bolts and screws should be checked. Refer to

the Torque Value Chart in the “Appendix” section starting on page 86.

Attaching the Drill to the Tractor

NOTE: The tractor must be of adequate size to pull

the drill. When determining size of tractor keep in

mind the soil, terrain and row spacing.

NOTE: The tractor, or towing vehicle, must have adequate mass to control the drill when towing. Do not

exceed 20 miles per hour.

Minimum vehicle weight - loaded drill:

up to 20 mph maximum - 30,000 lbs.

up to 10 mph maximum - 15,000 lbs.

Minimum vehicle weight - empty drill:

up to 20 mph maximum - 21,000 lbs.

up to 10 mph maximum - 10,500 lbs.

DANGER!

You may be severely injured or killed by being crushed between

the tractor and the drill. Do not stand or place any part of your

body between the tractor and drill while hooking up the drill.

Back the tractor drawbar up to the drill until the holes in the

drill tongue and the tractor drawbar are in line. Use the

jack to make the height adjustments. Be sure that the hitch

is properly adjusted for level operation, refer to Hitch,

Safety Chain, and Jack in the “Cart Assembly and Set-

up” section on page 15. Install the drawbar pin and the pin

retainer clip. Remove the jack and store on the stob between the tongue side rails in horizontal position. Attach

the safety chain on the drill to an anchor on the tractor capable of pulling the unit.

NOTE: The tractor must have at least 3 sets of hydraulic outlets and be capable of supplying 15-30 gallons per minute at 2000 psi.

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, and

wear heavy gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with this type

of injury. Foreign fluids in the tissue must be surgically removed

within a few hours or gangrene will result.

Recommended Minimum Tractor Size

34’ Implement - 180 HP

45’ Implement - 240 HP

7/28/10

NOTE: The SAE o-ring and JIC 37˚ flare type hose

connections do not require sealant for reconnecting.

They do not require high torque for a good seal.

IMPORTANT: when using sealant on pipe threads the friction between the threads is reduced; therefore, be certain

not to overtighten or damage to the components may occur.

Model 1150 1995 - 1997 167-058M

37

Page 40

Section 3 Operating Instructions

!

When drawbar pin and safety chain have been installed

and jack has been removed the hydraulic hoses may be

connected. See your Great Plains dealer if you require

new quick coupler ends for your hoses.

Make sure that each pair of hoses connected to your tractor outlets are from the same circuit (lift, fold, or fan)

Hook up the electric clutch cable to the clutch harness on

the tractor.

If the tractor does not have a clutch harness installed it

must be installed now. Attach the switch box solidly to the

tractor in a convenient location not exposed to rain. Attach

the power leads to a 12 volt D.C. power supply, polarity is

not critical. Be sure that the wire is safely routed where it

will not be pinched or rubbed through. Before drilling any

holes always check on the back side to make sure no hidden components will be damaged by the drill.

Great Plains Mfg., Inc.

14452

Cart Link Attachment

Figure 3-1

Safety Lights

The light package your drill comes equipped with requires

that your tractor be wired for the standard 7-pin electrical

connector which will work with the tractor’s flashers and

signals. All that should be necessary is to plug in the connector.

If your tractor is not equipped with this connector please

consult your dealer for installation to tractormanufacturers

specifications.

Attaching 1150 Air Drill Cart to

Great Plains 34’ or 45’ Implement

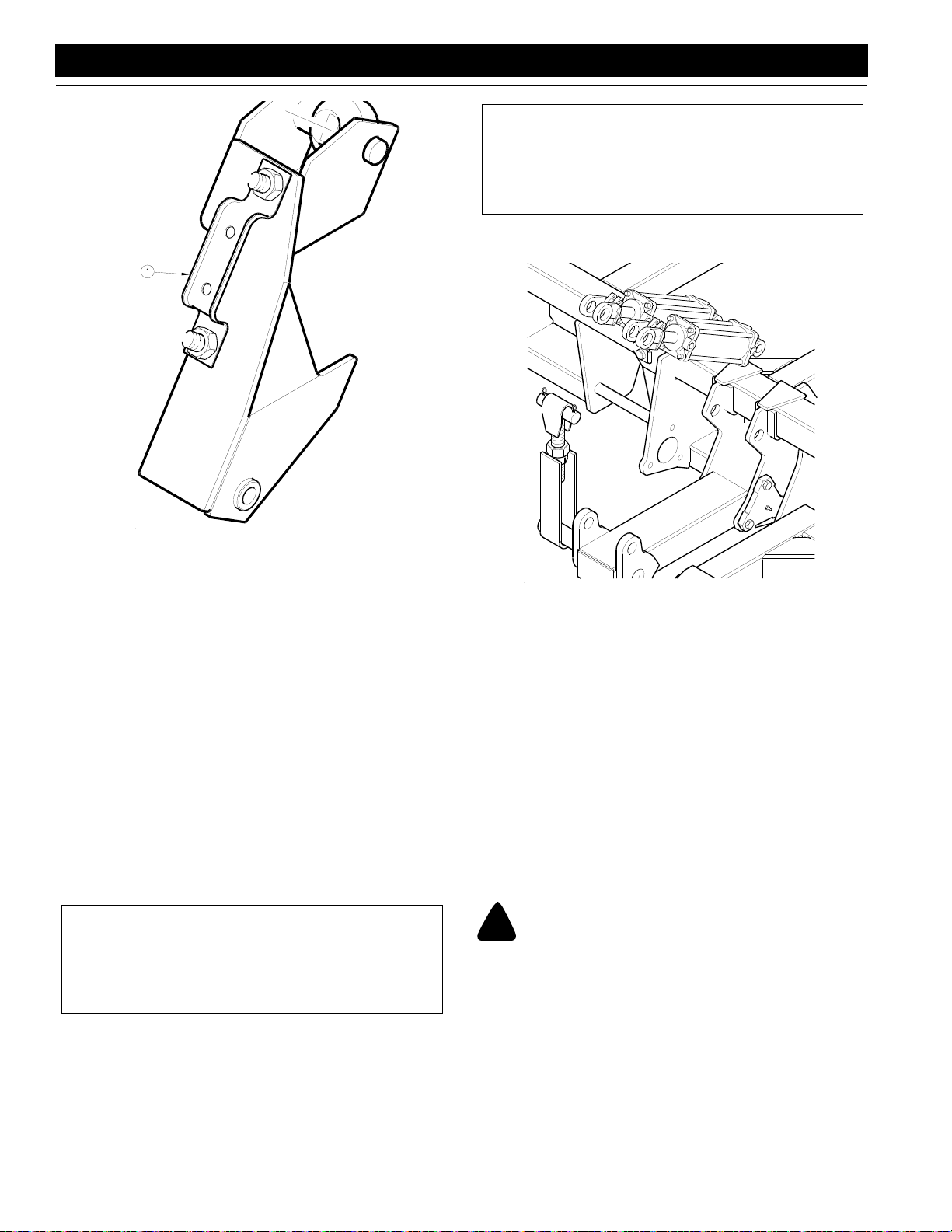

DANGER!

You may be severely injured or killed by being crushed between

the tractor and the drill. Do not stand or place any part of your

body between the cart and implement while hooking up the drill.

Block the implement cart links (#1) so that the center of the

pin hole is approximately 22 3/4” above ground. If the cart

sling is present, pull it back towards implement to keep it

out of the way until ready to attach. Pull all seed and hydraulic hoses back away from the implement hitch to prevent damage. Line the cart up squarely in front of the

center of the implement. Back the cart up until both of the

cart links are between the hitch plates on the cart frame

and the pin holes are aligned. Re-adjust the height of links

by changing the blocks if required. When the holes are

aligned place the cart link pin (#2) in position, secure the

cart link pin with the 5/16” dia. lynch pins (#3). Be sure that

the tab on the link pin securely engages the square hole in

the hitch plate, refer to Figure 3-1.

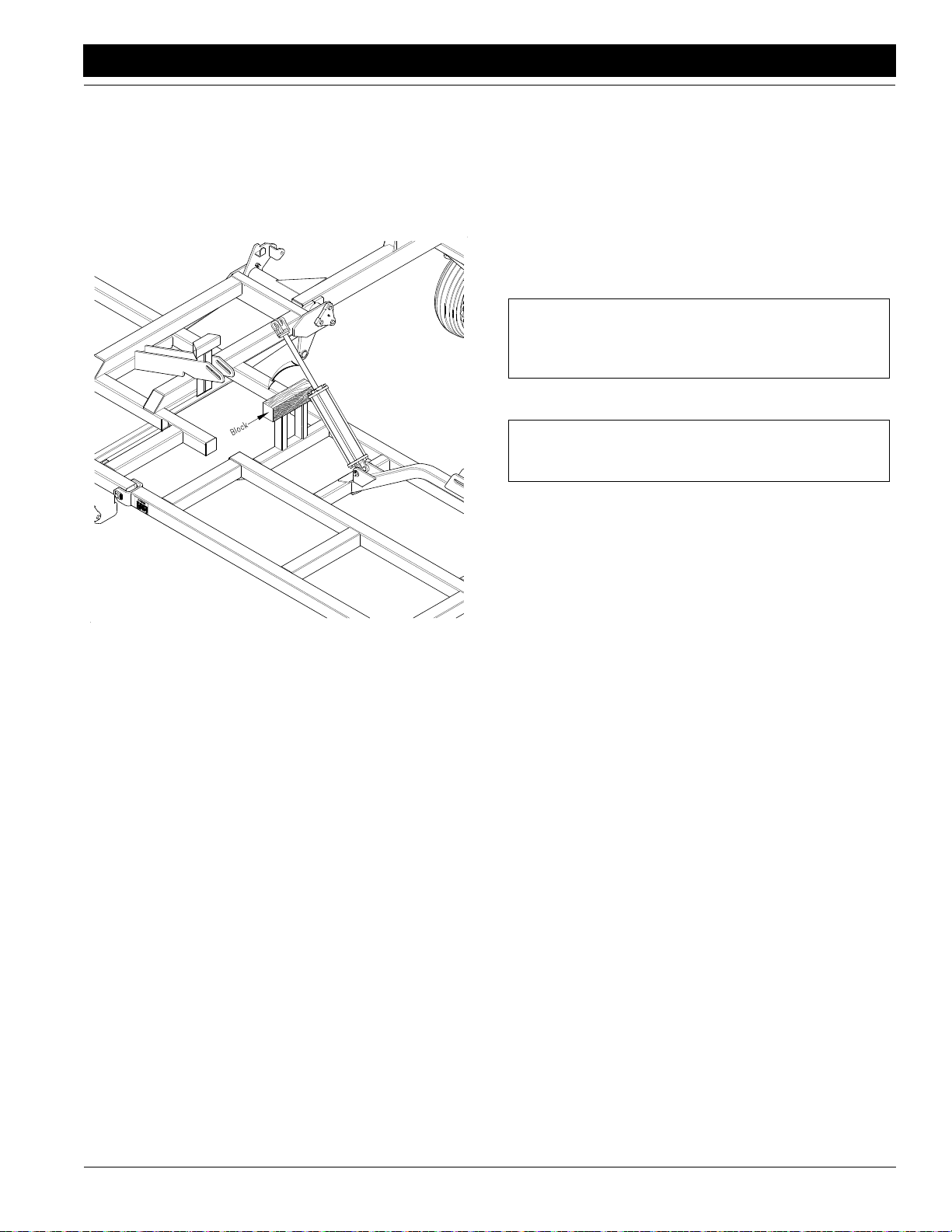

Refer to Figure 3-2:

Make sure that the cart sling is connected to the pin on the

cylinder lift arm then align the top hole with the hole in the

cart sling support plates on the back of the cart frame. Install the cart sling pin (#2) and secure it with the 1/4” x 2”

cotter pins (#1). Be sure that the legs on the cotter pins are

spread apart.

Attach the 2 1/2” primary hosesfrom implement distributor

towers to metering box outlet tubes. Hoses should be connected left-to-right on the box in the same order as the

towers are installed on the implement. Route the hoses

above the axle tube cross member on the cart and allow

only enough slack for implement to be raised and lowered

fully without binding.

Hose Routing and Sling Installation

Figure 3-2

14461

Model 1150 1995 - 1997 167-058M 7/28/10

38

Page 41

Great Plains Mfg., Inc.

!

Section 3 Operating Instructions

If any hoses appear to be rubbing on sharp edges or are in

danger of getting pinched use cable ties to secure in a safe

location. Secure hoses to metering box outlet tubes using

2 1/2” air hose band clamps and tighten securely. Be sure

that placement of outer clamps does not interfere with operation of metering box calibration door latch clamps, refer

to Figure 3-3.

14467

Clamp Positioning

Figure 3-3

Hydraulic Hose Hook-up

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, and

wear heavy gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with this type

of injury. Foreign fluids in the tissue must be surgically removed

within a few hours or gangrene will result.

Connect the lead from the height switch on the implement

to the connector on the electric clutch wiring harness.

If equipped with the blockage monitor option, connect the

4-pin connector on the implement to the connector on the

cart monitor harness.

NOTE: When all connections have been made carefully check all lines to make sure none will be damaged when the implement is operated. Re-route the

lines or use cable ties to keep them in a safe place.

Check warning lights for correct operation.

Connect the light harness lead on the implement to the

lead on the cart.

Filling the Drill

1. Be certain the drill is securely hitched to an adequate

tractor, see Recommended Tractor Size on page 37.

NOTE: Static tongue weight of a full drill is approximately 2600 lbs. on level ground, more when facing

downhill.

2. Be sure that the bin unloading door (#1) on the bottom

of the meter is securely closed and latched, refer to

Figure 3-5.

NOTE: The SAE o-ring and JIC 37˚ flare type hose

connections do not require sealant for reconnecting.

They do not require high torque for a good seal.

Refer to Figure 3-4:

Connect the 2 hoses for the fold circuit to the quick couplers nearest to the outside of the cart.

Connect the 2 hoses for the lift circuit to the quick couplers

nearest to the center of the cart. If the drill is equipped with

an auger the diversion valve should be in the fold circuit.

14791

Hose Locations

Figure 3-4

14466

Unload Door

Figure 3-5

3. Prior to filling the drill for the first time, and at least

once per season thereafter, check the drill bin for air

leaks as described in the field operations section.

4. Place the drill on solid, level ground prior to attempting

to fill.

5. Shut off all hydraulic power to the drill.

7/28/10

Model 1150 1995 - 1997 167-058M

39

Page 42

Section 3 Operating Instructions

!

!

Great Plains Mfg., Inc.

6. Climb the ladder to the top of the drill walk board, lift

the lid latch handle and move the latch hook off of the

u-bolt catch. Lift the lid by its handle and open fully.

Lower the lid onto the pivot stop by hand, do not drop.

7. Check that the strainer basket is in place and remove

any foreign material from basket.

8. Fill the bin to the top with seeds. If using optional loading auger continue to steps 9 through 20 below.

DANGER!

Keep hands, feet, hair, clothing, or any item that could get

caught in the auger away from the inlet. If the auger becomes

plugged, turn off the auger and tractor before attempting to unplug.

9. Remove the storage lock pin from auger bracket.

Store in a safe place until filling is completed, refer to

Figure 3-6.

12. Pull the auger out away from the drill taking care not to

damage the auger tube on the ladder steps.

13. Lower the hopper end of the auger and swivel the auger and support arm until the discharge is centered

over the opening in the bin.

14. Position grain container so that it will unload into auger.

15. Move the handle on the auger flow diverter valve to

the outer most position, refer to Figure 3-8. Be sure

that the control valve on the auger body is in the off position.

14497

Diverter Valve

Figure 3-8

Storage Lock Pin

Figure 3-6

10. Pivot the auger hopper until opening is facing up. The

hopper may be swiveled around on the tube to facilitate clean-out.

11. Lift the auger latch handle until the stop clears the retaining rod, refer to Figure 3-7.

14421

16. Energize the fold circuit on the tractor. The control lever may have to be tied in place.

DANGER!

Rotating auger - To prevent serious injury or death:

•Read all instructions and safety information prior to opera-

tion.

•Keep hands, feet, hair, and clothing away from rotating auger.

•Do not remove or modify any guards.

•Keep children well clear of work area.

17. Be sure that nobody is in danger from the auger, then

before starting the grain flow turn on the auger control

valve,refer to Figure 3-13. Visually check theauger for

correct direction of rotation. Reverse tractor lever if

needed.

14530

Auger Latch Handle

Figure 3-7

Model 1150 1995 - 1997 167-058M 7/28/10

40

On/Off Control Valve

Figure 3-9

14450

Page 43

Great Plains Mfg., Inc.

!

Section 3 Operating Instructions

18. Slowly turn on flow of grain and fill bin. Slow down and

then stop flow of grain as level nears the top of the bin

to avoid overflow.

19. Turn off the auger and return to storage position. Replace the storage lock pin and clip. Be sure that the

handle latch is secure.

20. Turn off the tractor hydraulics and then return the flow

diverter valve handle to innermost (fold) position.

CAUTION!

Do not turn the diverter handle until the hydraulics have been

shut off. If it is moved with hydraulics still on, the implement

wings will suddenly begin folding.

21. Remove any foreign matter from strainer basket.

22. Wipe any grain or foreign matter from lid seal flange

area on top of bin. Close lid and securely latch.

23. Before moving the drill check that the bin lid is latched,

the auger control is off, the flow diverter handle is inward, and the auger is securely latched in transport

storage position.

NOTE: When leveled off, the top cone of the bin holds

approximately 50 bushels; the center area 50 bushels; and the lower cone 50 bushels.

Field Operations

1. Be sure that the cart tires are properly inflated as indicated in the Tire Inflation Chart in the “Appendix”

section on page 86.

2. Be sure that all hoses are connected and clear of foreign material. Make sure openers are not plugged.

3. Never back up with the openers in the ground. Do not

turn sharply with openers in the ground, doing so will

cause openers to plug.

4. Set the seed rate as described in the Setting the Drill

Seeding Rate portion of the “Adjustments” section

on page 46.

5. Turn on the fan hydraulic motor. Be sure the fan rotates correctly.

NOTE: Fan motor circuit is equipped with a check

valve to allow the fan to wind down freely when shut

off. The bottom of the fan rotor should rotate towards

rear of the cart.

6. Check all bin seals to make sure no air is leaking. Adjust the latch or replace the seals to prevent leakage.

NOTE: It only takes a very small air leak to cause a

large variation in the seeding rate.

7. Make sure that nobody is in the way of the drill before

moving. Do not allow anybody to ride on the drill.

8. Set the tractor engine idle to an approximate field

speed. Adjust thetractor flow control valve until the fan

pressure gauge reaches approximately 21” of water

(12 ounces per square inch).

Heavy seeding rates may require a higher setting.

Light rates or very fragile seeds may require a lower

setting for best distribution or if excessive crackage is

evident.

NOTE: Always engage the fan motor with the tractor

at a low idle speed. Do not reverse hydraulic flow with

the fan running.

9. Turn on the electric clutch switch in the cab. With the

fan running drive forward and lower the implement to

begin seeding.

NOTE: The electric clutch circuit contains 2 switches

besides the in-cab control. One switch requires that

the fan be running at a suitable speed before seed is

metered to prevent the hose from plugging. The other

switch is on the implement and only turns on the

clutch when the implement is lowered below the adjusted height. See Electric Clutch Height Switch in

the “Adjustments” section, on page 63, for more information. If you wish to run seed through the system

while the drill is stationary you must use the hand

crank as described in Setting Seeding Depth and

Leveling Front-to-Rear in the “Adjustments” section

on page 60.

10. Do not shut off the fan motor while seed is being metered. Doing so will cause the distribution hose to

plug. Do not rely on the tractor detent to hold the lever

on. Use a rapidly removable strap or hook to hold the

lever in place.

11. With a properly adjusted implement height switch it is

not necessary to turn the electric clutch switch on and

off manually while turning. The clutch switch should

be turned off while transporting.

12. Be aware of a slight 5‘-10’ delay needed for the seed

to reach the openers when starting. If you stop in the