Page 1

Operator’s Manual

60303P and 80303P

Three-Point Planter

Model Serial No.

60303P F1079 and Earlier

80303P G1021 and Earlier

Manufacturing, Inc.

P.O. Box 5060 ● Salina, Kansas 67402-5060

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

© Copyright 1999 Printed

03/02/99

14911

Cover illustration may show optional equipment not supplied with standard unit.

401-008M

Page 2

General Information

General Information

Important Notice

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either

expressed or implied, while every precaution has been

taken in the preparation of this manual, Great Plains

Manufacturing, Inc. assumes no responsibility for errors

or omissions. Neither is any liability assumed for damages resulting from the use of the information contained

herein. Great Plains Manufacturing, Inc. reserves the

right to revise and improve its products as it sees fit. This

publication describes the state of this product at the time

of its publication, and may not reflect the product at all

times in the future.

Printed in the United States of America.

For your convenience, record your serial number, model

number and the date purchased in the spaces provided

below. Have this information before you when calling a

Great Plains Authorized Dealer.

This Operator’s Manual applies to the 6-Row/8-Row 3-Point Planter listed below:

401-001A 6-Row 30" Planter

401-002A 8-Row 30" Planter

Owner’s Information

Name: _____________________________________

Address ____________________________________

City________________State ____ Zip ___________

Phone_______________________

Name of Dealership ___________________________

Dealer’s Name _______________________________

Address ____________________________________

City________________State ____ Zip ___________

Phone_______________________

Serial Number _______________________________

Model Number _______________________________

Date Purchased ______________________________

60303P and 80303P Three-Point Planter 401-008M 5/15/06Great Plains Mfg., Inc.

Page 3

Table of Contents

Table of Contents

Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 1 Safety Rules . . . . . . . . . . . . . . . . . . . . . . . 3

General Operation & Repair. . . . . . . . . . . . . . . . . 3

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tire Handling & Repair . . . . . . . . . . . . . . . . . . . . . 3

Agricultural Chemicals . . . . . . . . . . . . . . . . . . . . . 3

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 2 Planter Operation. . . . . . . . . . . . . . . . . . . 6

Initial Preparation of the Planter . . . . . . . . . . . . . . 6

Tractor Preparation . . . . . . . . . . . . . . . . . . . . . . . . 6

Attaching the Planter to the Tractor . . . . . . . . . . . 6

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Leveling the Planter . . . . . . . . . . . . . . . . . . . . . . . 7

Section 3 Row Unit Operation . . . . . . . . . . . . . . . . . 8

Finger Pickup Meter . . . . . . . . . . . . . . . . . . . . . . . 8

Seed Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chemical Hopper . . . . . . . . . . . . . . . . . . . . . . . . . 9

Seed and Chemical Meter Drive Adjustments . . . 9

Down Force Springs. . . . . . . . . . . . . . . . . . . . . . 10

Row Unit Mounted Coulter . . . . . . . . . . . . . . . . . 11

Depth Adjustment. . . . . . . . . . . . . . . . . . . . . . . . 11

1 x 12 Closing Wheel Adjustments. . . . . . . . . . . 11

Closing Disk Adjustments. . . . . . . . . . . . . . . . . . 12

Seed Lok . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 4 Adjusting Planting Rates . . . . . . . . . . . 14

Planting Rates . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting Granular Chemical Rates . . . . . . . . . . 15

Planting Rates for Finger Pickup Corn Meters. . 16

Granular Chemical Rate Charts . . . . . . . . . . . . . 22

Section 5 Troubleshooting. . . . . . . . . . . . . . . . . . . 23

Finger Pickup Corn Meter . . . . . . . . . . . . . . . . . 23

Section 6 Lubrication . . . . . . . . . . . . . . . . . . . . . . . 24

Section 7 Maintenance. . . . . . . . . . . . . . . . . . . . . . 26

Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Finger Pickup . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Spreader and Scraper . . . . . . . . . . . . . . . . . . . . 27

Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Gauge Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Shear Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chain Tension . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Outside Scrapers . . . . . . . . . . . . . . . . . . . . . . . . 27

Chain Routing Diagram . . . . . . . . . . . . . . . . . . . 28

Maintenance & Lubrication Record . . . . . . . . . . 29

Section 8 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Section 9 Specifications . . . . . . . . . . . . . . . . . . . . 31

Torque Values Chart. . . . . . . . . . . . . . . . . . . . . . 33

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 33

Metric Conversion Chart . . . . . . . . . . . . . . . . . . 34

Section 10 Attachments & Options. . . . . . . . . . . . 35

Section 11 Warranty . . . . . . . . . . . . . . . . . . . . . . . . 36

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-1

Page 4

Using this Manual

Using this Manual

For your safety and to help in developing a better understanding of your equipment we highly recommend that

you read the operator sections of this manual. Reading

these sections not only provides valuable training but

also familiarizes you with helpful information and its lo-

Introduction

This manual has been prepared to instruct you in the

safe and efficient operation of your 6-Row/8-Row 3Point Planter. Read and follow all instructions and safety

precautions carefully.

Read and follow all instructions and safety precautions

carefully.

The parts on your 6-Row/8-Row 3-Point Planter have

been specially designed and should only be replaced

with genuine Great Plains parts. Therefore, should your

6-Row/8-Row 3-Point Planter require replacement parts

go to your Great Plains Dealer.

The right hand and left hand as used throughout this

manual is determined by facing in the direction the machine will travel when in use unless otherwise stated.

Serial Number

The serial number plate is located on the left hand side

of the upper hitch plate. It is suggested that the serial

number and purchase date also be recorded for your

convenience in the space provided on the checklist

page at the beginning of this manual.

The serial number provides important information about

your Planter and may be required to obtain the correct

replacement part. Always use the serial number and

model number when sending correspondence or when

ordering parts from your Great Plains Dealer.

cation. The parts sections are for reference only and

don’t require cover to cover reading. After reviewing

your manual store it in a dry, easily accessible location

for future reference.

safety precautions must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of

equipment; hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Watch for the following safety notations throughout your Operators Manual:

!

DANGER!

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury. This

signal word is limited to the most extreme situations.

!

WARNING!

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

!

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

CAUTION!

!

The SAFETY ALERT SYMBOL indicates that there is a

potential hazard to personal safety involved and extra

2

60303P and 80303P Three-Point Planter 401-008M 5/15/06

NOTE: Indicates a special point of information which

requires your attention.

Great Plains Mfg., Inc.

Page 5

Section 1 Safety Rules

Section 1 Safety Rules

Most accidents are the result of negligence and carelessness, usually caused by failure of the operator to

follow simple but necessary safety precautions. The following safety precautions are suggested to help prevent

such accidents. The safe operation of any machinery is

a big concern to consumers and manufactures. Your

3-Point Planter has been designed with many built-in

safety features. However, no one should operate this

product before carefully reading this Operators Manual.

General Operation & Repair

1. Practice safety by always thinking before acting.

2. Never allow the planter to be operated by anyone who is

unfamiliar with the operation of all functions of the unit.

All operators should read and thoroughly understand the

instructions given in this manual prior to moving the

unit.

3. Make sure safety rules are understood before operating

machine or tractor.

4. Never permit any persons other than the operator to ride

on the tractor.

5. Regulate your speed to the field conditions, maintaining

complete control at all times.

6. Always lower the implement and shut off the tractor engine before making any adjustments.

7. After repairing or adjusting, make sure all tools and

parts are removed from the implement before attempting

to operate it.

8. Never work under a raised planter.

9. Do not grease or oil machine while it is in operation.

10. Loose fitting clothing should not be worn as it may catch

in moving parts.

11. Never attempt to operate the implement unless you are in

the driver’s seat.

12. Never dismount from a moving tractor.

13. Do not leave the tractor or the implement unattended

with the engine running.

14. Do not stand between the tractor and the implement during hitching.

15. Always make sure there are no persons near the planter

when the marker assemblies are in operation.

16. Watch for obstructions such as wires, tree limbs etc.,

when folding markers.

17. disk edges are sharp! Be careful when working in this area.

18. Detach and store implements in an area where children

normally do not play. Stabilize implements by using suitable supports and block wheels.

19. If a hydraulic leak develops, correct it immediately. Escaping hydraulic oil can have extremely high pressure. A

stream of high pressure oil may easily penetrate the skin

as with modern needless vaccination equipment - but

with the exception that hydraulic fluid may cause blood

poisoning. It is imperative that the connections are tight

and that all lines and pipes are in good condition. If an

injury is caused by the escaping hydraulic fluid, see doctor at once!

20. Use a piece of cardboard or wood to detect leaks of hydraulic oil under pressure.

21. Be sure to relieve all hydraulic pressure before disconnection any lines or pipes between the implement and the tractor hydraulic system. Keep all guards and shields in place.

Transporting

1. Use good judgement when transporting tractor implements on the highway. Always maintain complete control

of the machine.

2. Limit transport speed to 20 mph. Transport only with a

farm tractor of sufficient size and horse power. (See

“Section 2 Planter Operation” on page 6)

3. Always make sure “Slow Moving Vehicle” emblem, and

reflectors are in place and visible prior to transporting

the machine on public roads.

4. Know your state and local laws concerning highway

safety and regulations. Comply with these laws when

transporting machinery.

Tire Handling & Repair

1. Tire changing can be dangerous and should be preformed by trained personnel using the correct tools and

equipment.

2. Do not re-inflate a tire that has been run flat or seriously

under inflated. Have it checked by qualified personnel.

3. When removing and installing wheels, use wheel handling equipment adequate for the weight involved.

Agricultural Chemicals

1. Agricultural chemicals can be dangerous. Always select

the correct chemical for the job. Improper usage of fertilizers, fungicides, herbicides, insecticides, and pesticides could cause injury to all living things.

2. Always read instructions supplied by the manufactures

before opening chemical containers. Read and follow instructions supplied by the chemical manufacturer carefully before each use.

3. Apply the same precautions when adjusting, servicing,

cleaning, or storing the planter as you would when putting chemicals into the planter.

4. Inform anyone who may come in contact with chemicals,

or a planter with chemicals, of any potential hazard or

safety precaution that should be observed.

5. Avoid inhaling smoke from any type of chemical fire.

6. Store or dispose of all unused chemicals as specified by

the chemical manufacturer.

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-3

Page 6

Section 1 Safety Rules

Safety Decals

1. Your 3-Point Planter comes equipped with all safety decals in place. They were designed to help you safely operate your planter. Read and follow their directions.

2. Keep safety decals clean and legible.

3. Replace all damaged or missing safety decals. To order

new safety decals go to your Great Plains Dealer and refer

to the parts section for safety decal package part number.

4. Replace these decals whenever they become worn or unreadable. See the parts section for the correct location of

these decals. To install new safety decals:

a. Clean the area the decal is to be placed

b. Peel backing from the decal. Press firmly on to

surface being careful not to cause air bubbles under

the decal.

12414

12356

818-003C

Slow Moving Vehicle Emblem

818-230C

Red Reflectors

818-229C

Amber Reflectors

12357

4

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 7

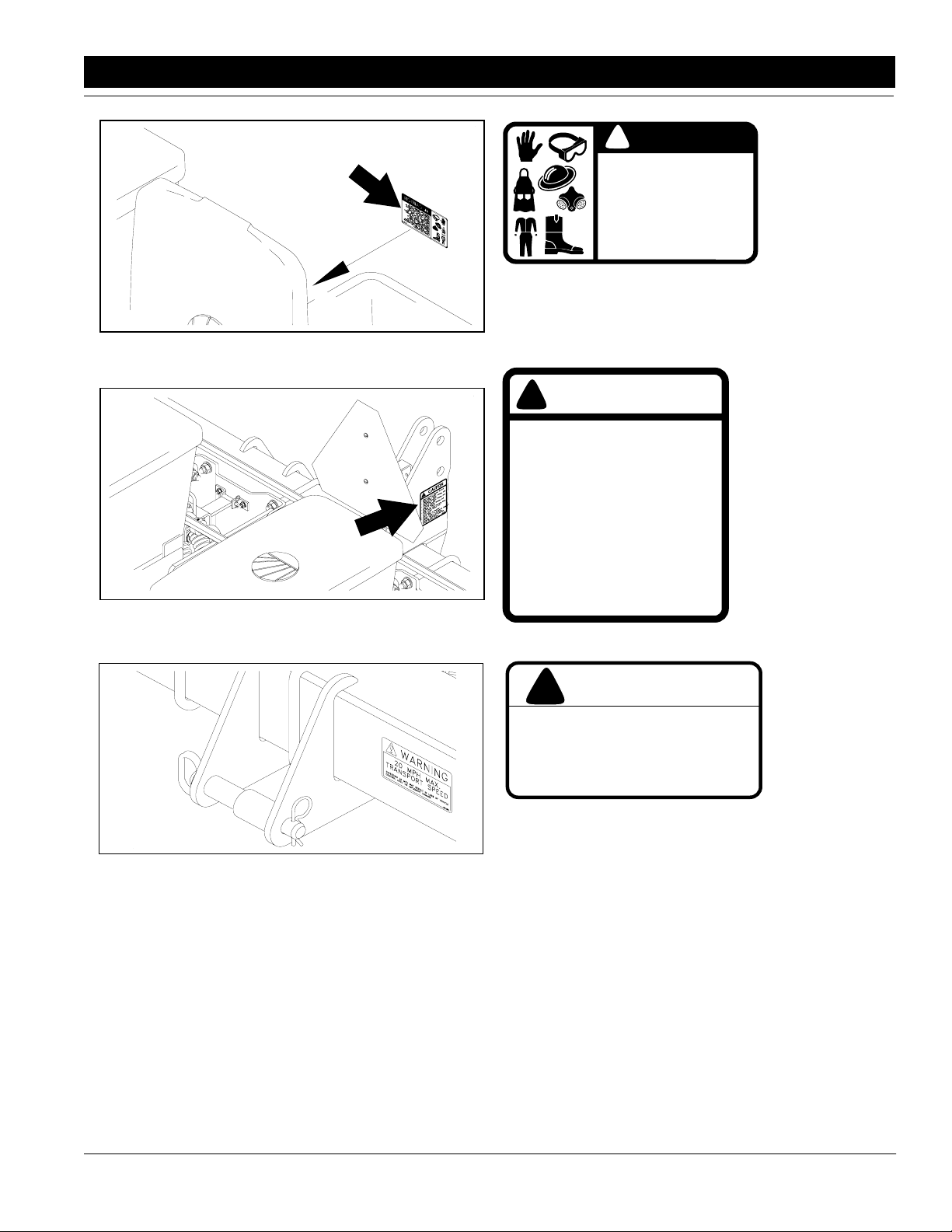

Section 1 Safety Rules

12359

12392

!

CAU-

AGRICULTURAL CHEMICALS CAN BE

DANGEROUS. IMPROPER SELECTION OR

USE CAN SERIOUSLY INJURE PERSONS,

ANIMALS, PLANTS, SOIL OR OTHER

PROPERTY. BE SAFE. SELECT

THE RIGHT CHEMICAL FOR THE JOB. HANDLE

IT WITH CARE. FOLLOW THE INSTRUCTIONS

ON THE CONTAINER LABEL.

PRECAUTIONS SHOULD BE TAKEN TO

PREVENT EXPOSURE. PROTECTIVE

CLOTHING AND EQUIPMENT IS TO BE

WORN. REFER TO THE OWNERS MANUAL

FOR INFORMATION ABOUT THE PROTECTIVE

818-323C

Ag Chemicals Caution

(Located inside the chemical lid)

CAU-

!

- Read Operator’s Manual before

operating planter

- Stand clear when folding and

unfolding markers

- Stand clear when raising and

lowering planter

- Keep hands and clothing away

from moving chains and sprockets

- Never ride on the planter

- Always lower or properly support

the planter before servicing

- Escaping hydraulic fluid can

cause serious injury.

818-399C

818-323C

818-399C

Planter Operational Cautions

12415

!

WARNING

20 MPH MAX.

TRANSPORT SPEED

EXCEEDING 20 MPH MAY RESULT IN LOSS OF VEHICLE

CONTROL AND/OR IMPLEMENT DAMAGE

818-188C

Transport Speed Warning

818-188C

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-5

Page 8

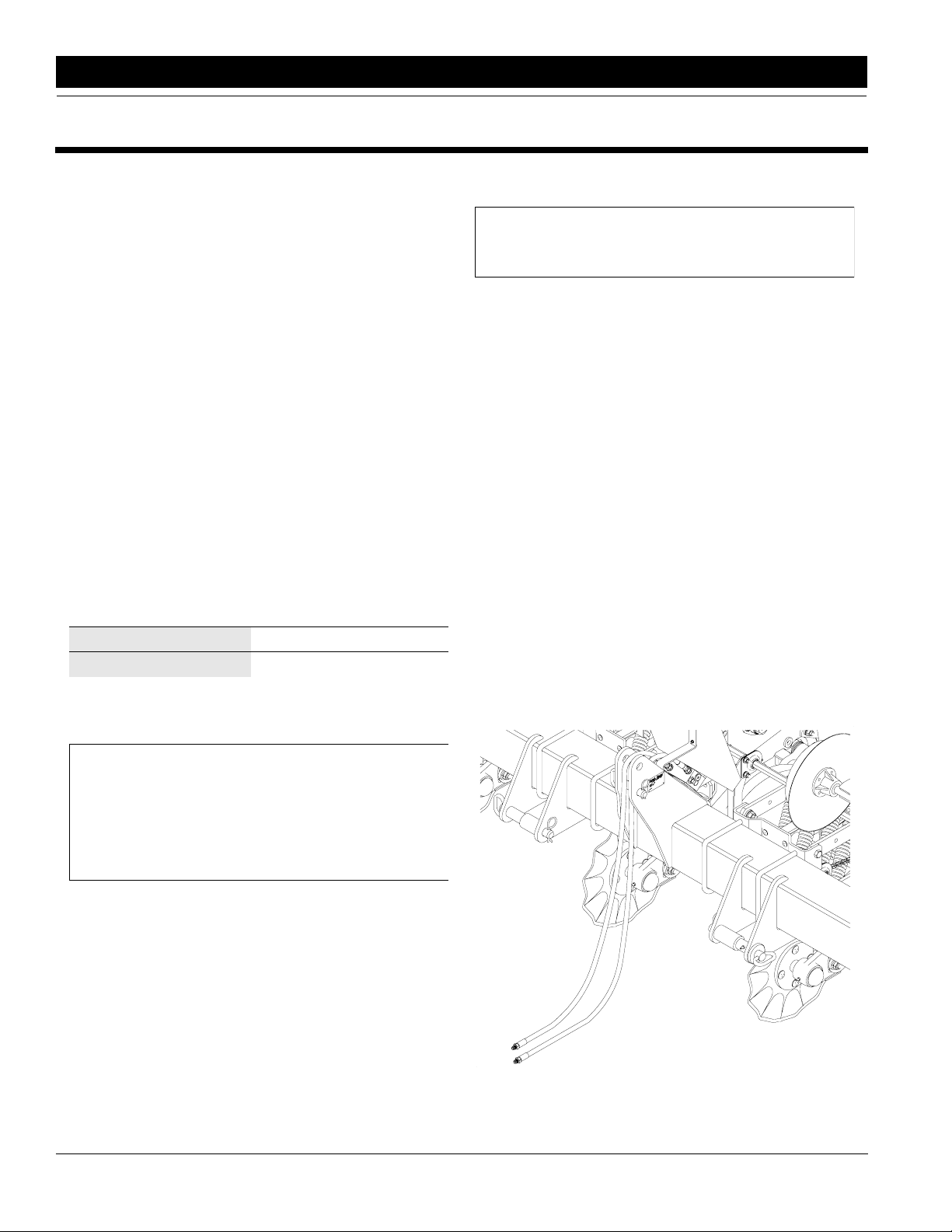

Section 2 Planter Operation

Section 2 Planter Operation

The following section was written to provide general information on the planter and tractor operation.

Initial Preparation of the Planter

•

Lubricate the planter and markers as shown in

“Section 6 Lubrication” on page 24.

• Check the tires for proper inflation, refer to the Tire In-

flation Chart in "Section 9 Specifications" on

page 33.

• Check the chains for proper tension and alignment as

shown in "Section 7 Maintenance" on page 28.

• Perform all beginning of season and daily planter ser-

vice as discussed in “Section 8 Storage” on

page 30.

• Check over the planter and replace worn or damaged

parts before going to the field.

• All nuts, bolts and screws should be checked per the

Torque Value Chart in "Section 9 Specifications" on

page 33.

• The legs of the cotter pins should be spread.

Tractor Preparation

Recommended Tractor Horsepower

Minium required draw bar horsepower for field work

6-row planter 60 - 90 HP

8-row planter 80 - 120 HP

2. Adjust the tractor lower lift links to maximize lifting

height.

NOTE: To keep the planter level make sure that the

lower lift links are adjusted evenly.

Set the tractor sway blocks to minimize side sway.

Position the lift controls in float position.

3. Back the tractor up to the planter. Align the lower

links with the lower hitch holes on the planter. Insert

the hitch pins and the spacers, supplied with the

planter, according to the category of your tractor,

Figure 2-1. Lock the pins in place.

4. There are two holes on the planter for the upper

hitch point. The the tractor’s top link should be attached in the lower hole for Category II, see Figure

2-1. Some Category II quick couplers and all Category III top links should be attached in the upper hole,

Figure 2-1. To attach the top link some adjustment

may be required.

5. Raise the planter and look for any interference while

standing between the planter row units. Remove the

pin holding the parking stand and raise the stands to

the transport position. Put the pin in the lowest hole

in each stand, see Figure 2-1. Never work under a

raised Planter.

6. On level ground, lower the planter onto the gauge

wheels. If the planter is not level see Leveling the

Planter page 7.

NOTE: The tractor must have adequate 3 point hitch

lift capacity to lift the machine weight, attachments,

seeds and dry chemicals. Shipping weights, (refer to

“Section 9 Specifications” on page 31), do not include seed, dry chemicals or optional attachments.

For tractor front end stability additional tractor ballast

may be required. Add front ballast according to your

tractor's operator’s manual.

Attaching the Planter to the Tractor

For the planter to function properly, attach the planter to

the tractor in the following manner.

1. Set the tractor wheels at double the planter row

spacing. Example: For a planter with 30" rows the

front and rear wheels should be set at 60" center to

center. This prevents soil compaction on the rows.

On hillsides andsteep slopes set the wheels as wide

as possible for maximum stability.

6

60303P and 80303P Three-Point Planter 401-008M 5/15/06

12340

Hitch on Planter

Figure 2-1

Great Plains Mfg., Inc.

Page 9

Section 2 Planter Operation

Transporting

!

The planter should never be transported faster than

20 miles per hour!

Before transporting the planter, check and practice the

following items:

CAUTION!

•The planter can be transported with full boxes of seed.

It is best NOT to because the extra weight increases

the chances for problems on the road. Do not exceed

20 miles per hour.

NOTE: In order to maintain steering control, ballast

may need to be added to tractor front end. To determine the amount of ballast required refer to your tractor’s operator manual.

•Check to see that the gauge tires on the planter have

the proper inflation as listed in the Tire Inflation Chart

in "Section 9 Specifications" on page 33.

•Comply with all Federal, State and Local Safety Laws

when traveling on public roads.

•Remember, the planter is wider than the tractor and

extreme care must be taken to allow for safe clearance.

Leveling the Planter

The planter must be level for the row units to function

correctly. Before leveling the planter check tire pressures as specified in the Tire Inflation Chart in “Section

9 Specifications” on page 31.

Adjust the lower links on the tractor to level the planter

side to side. It is best to adjust the links evenly before the

planter is attached to the tractor.

After setting the row units to the proper planting depth in

the field, stop the tractor on flat ground with the planter

lowered. Check the front-to-back level of the planter.

The bottom of the frame tube should be parallel to the

ground. If this is not parallel, adjust the upper link on the

tractor accordingly. See Figure 2-3.

If the row unit arms are not parallel to the ground, the

gauge wheel modules must be adjusted equally. Measure the vertical distance between the front pivot and

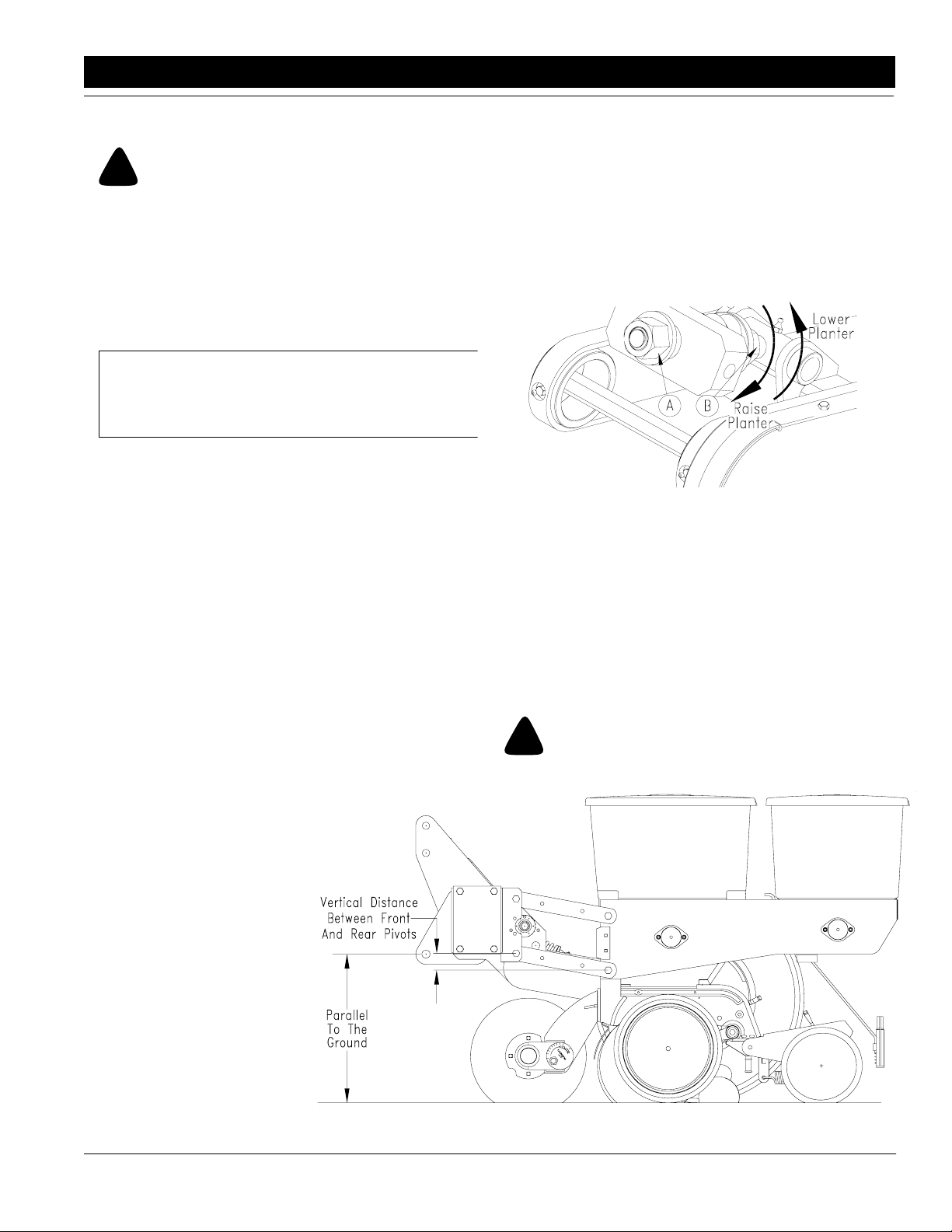

10495

Gauge Wheel Module Adjustment

Figure 2-2

rear pivot of a row unit arm, see Figure 2-2. This is the

amount that the gauge wheel needs to be adjusted.

Raise the planter and loosen the jam nut (A) on the

wheel module. To lower the planter, turn the nut (B) at

the opposite end of the link counter-clockwise and clockwise to raise the planter, see Figure 2-2. Tighten the jam

nut after reaching the desired wheel location.

!

Never work under the planter while in the raised position.

WARNING!

Leveling the Planter

Figure 2-3

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

12466

-7

Page 10

Section 3 Row Unit Operation

Section 3 Row Unit Operation

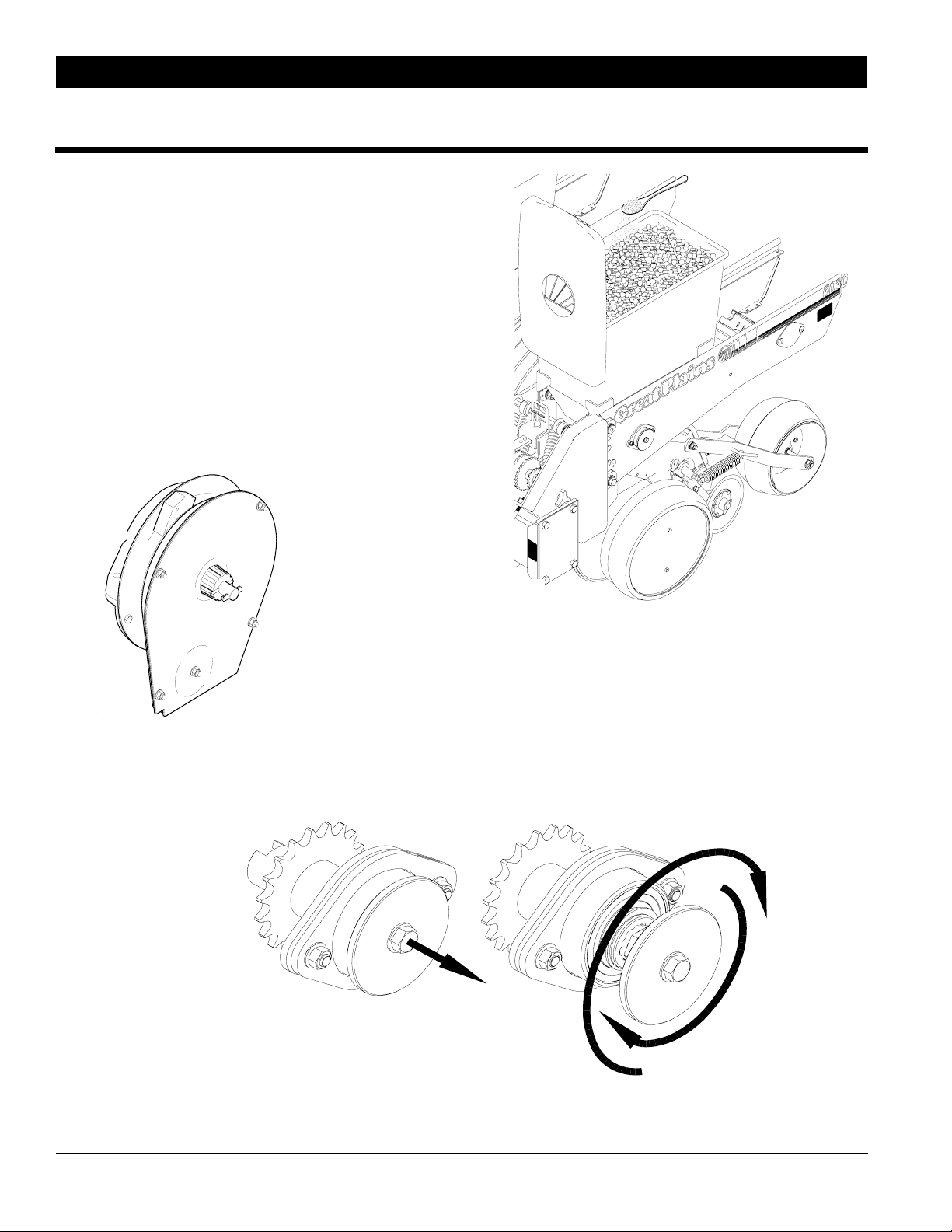

Finger Pickup Meter

This planter is equipped with a 12 finger mechanical

corn meter see Figure 3-1. Refer to the Planter Rate for

Finger Pickup CornMeter chart in “Section 4 Adjusting

Planting Rates” on page 14 for adjusting the planting

rates and sprocket combinations.

IMPORTANT: To extend the life and maximize efficiency of the finger pickup meter, sprinkle 1 teaspoon of

powdered graphite on top of the seeds in the hopper,

see Figure 3-2. The graphite will work its way down to

lubricate the meter mechanism.

For more information on the meter, see “Section 5

Troubleshooting” on page 23 & “Section 7 Maintenance” on page 26.

12341

Finger Pickup

Meter

Figure 3-1

12342

Graphite Applied To

Top Of Seeds

Figure 3-2

Meter Clutches

To disengage either the seed hopper clutch or the chemical hopper clutch pull the knob and rotate 30 degrees

clockwise or counter-clockwise until the points on the

hex shaft align with the indentations in the end of the

drive hub then release knob. See Figure 3-3.

To engage the clutches, pull and rotate the knob until the

shaft aligns with the drive hub then release.

12467

Disengage Meter Clutch

Figure 3-3

8

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 11

Section 3 Row Unit Operation

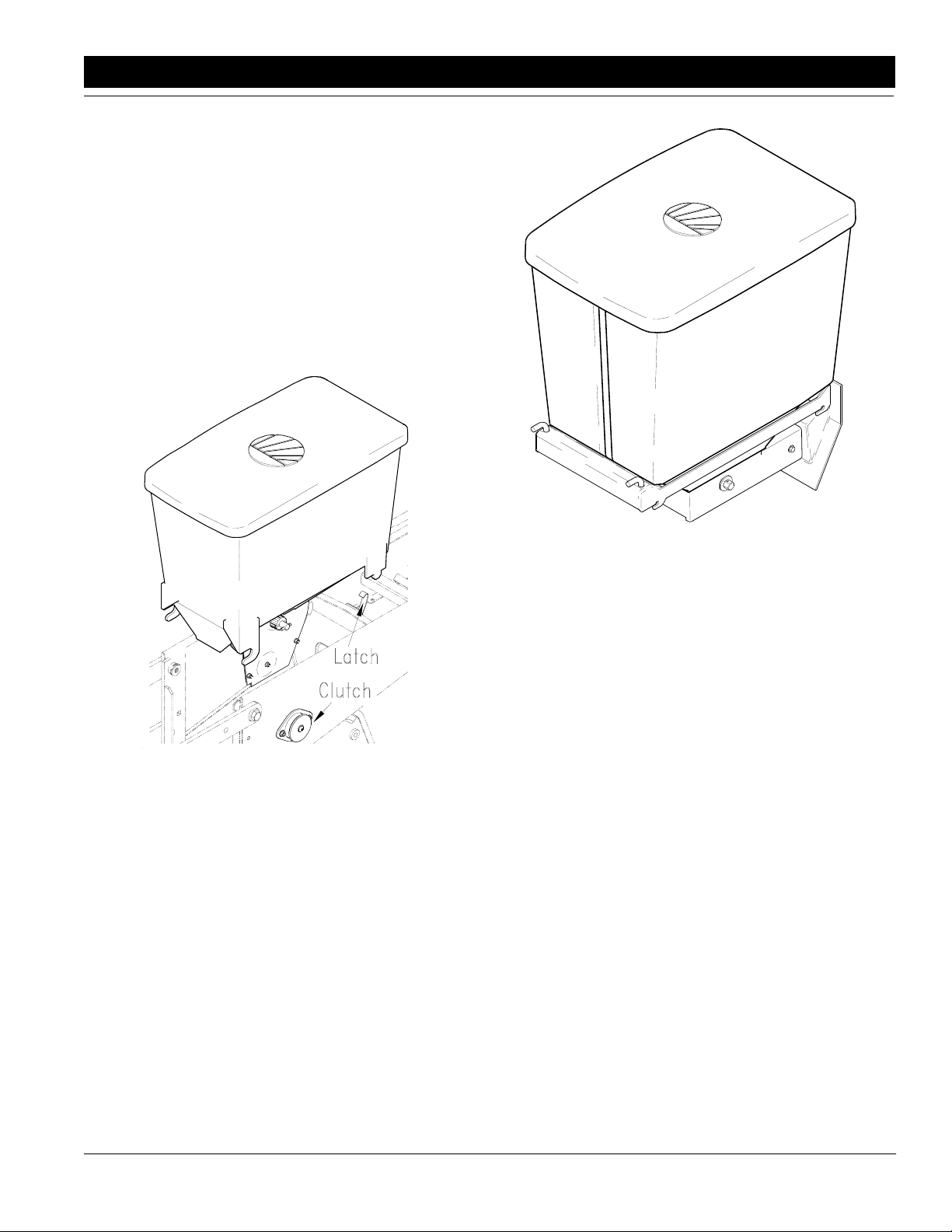

Seed Hopper

The row unit is equipped with one 2-bushel translucent

seed hopper.

Before filling the seed hopper, clear it of foreign objects.

After filling the hopper with clean seeds always replace

the hopper lid. Operating with the lids attached prevents

objects from entering the hopper and also aids in keeping out moisture.

Empty the contents of the hopper periodically to avoid

the collection of dirt and other materials. To remove the

hopper, disengage the meter drive clutch and the hopper latch, see arrows Figure 3-4.

14912

12343

Meter Clutch, Latch & Seed Hopper

Figure 3-4

Chemical Hopper

The optional chemical hopper comes in 2 versions:

• 1 chemical meter and an 80 lb. capacity translucent

hopper

• 2 chemical meters and 1 divider that separates the 80

lb. hopper into 2 compartments - approximately 40 lbs.

each.

Before filling the chemical hopper(s) clear it/them of foreign objects. After filling the hopper(s) replace the

hopper(s) lid(s). Operating with the lids attached prevents objects from entering the hopper and also aids in

keeping out moisture

Meter Clutch, Latch & Chemical Hopper

Figure 3-5

Empty the contents of the hopper(s) periodically to avoid

the collection of dirt and other materials. To remove the

hopper(s), disengage the meter drive clutch and the 2

latch pins at the front of the hopper, see Figure 3-5.

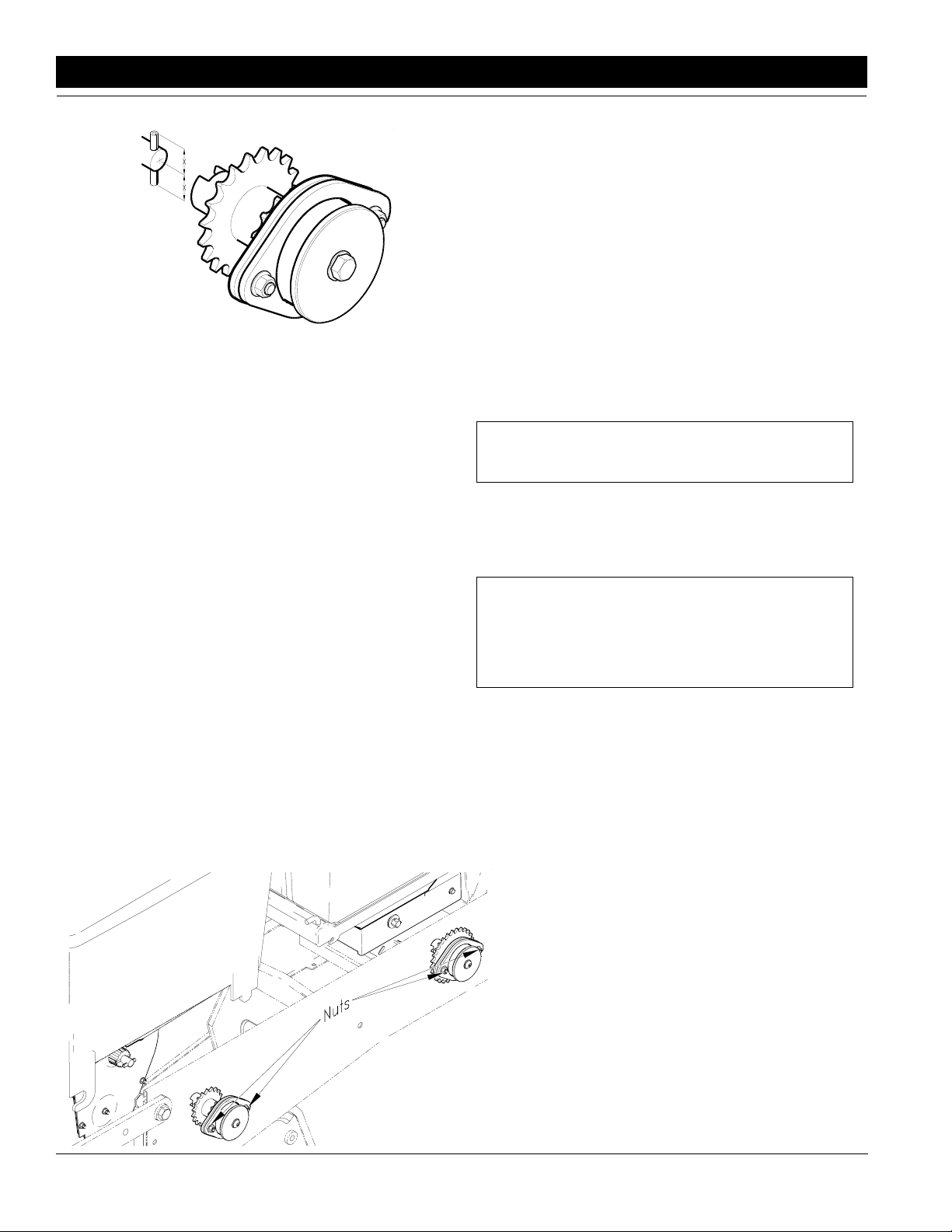

Seed and Chemical

Meter Drive Adjustments

The alignment between the meter clutch and the input

shaft is important. If there is misalignment the meter will

not function properly. Excessive wear and damage can

also occur to the meter housings. When replacing the

meter the vertical and horizontal alignment should be

checked.

Check for Vertical Alignment (Refer to Figure 3-6):

1. Latch the appropriate hopper into place on the support.

2. The roll pin in the end of meter input shaft should be

centered (equal distances of the roll pin should protrude from both sides of the shaft).

3. Rotate the input shaft so that the roll pin is vertical.

4. Rotate the drive coupler so that the slots are vertical.

5. Release the clutch to engage the drive coupler with

the input shaft.

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-9

Page 12

Section 3 Row Unit Operation

12417

Vertical Alignment

Figure 3-6

If the alignment is correct the coupler will engage with

the shaft freely and the roll pin will extend equally on

each side of the coupler. Disengage the clutch and

check the horizontal alignment.

Check for Horizontal Alignment (Refer to Figure 3-7):

1. Latch the appropriate hopper into place on the hopper support.

2. The roll pin in the end of meter input shaft should be

centered (equal distances of the roll pin should protrude from both sides of the shaft).

3. Rotate the input shaft so that the roll pin is horizontal.

4. Rotate the drive coupler so that the slots are horizontal.

5. Release the clutch to engage the drive coupler with

the input shaft.

To adjust alignment:

• With the hopper in place loosen the two 5/16" nuts.

• Engage the clutch to the meter input shaft.

• Align clutch with shaft and tighten 5/16" nuts to torque

values in the Specifications section.

Down Force Row

Standard Spring Package

The standard down force spring package, consists of 2

non-adjustable springs applying approximately

90 lbs. of down force.

Optional Medium and Heavy Duty Spring Package

The medium and heavy duty spring packages consist of

2 or 4 adjustable springs, respectively.The medium duty

package can be adjusted from approximately 100 to 200

lbs. down force. The heavy duty package can be adjusted from approximately 200 to 400 lbs. of down force.

Spring Adjustments

• All spring adjustments must be made with the planter

in the fully raised position.

NOTE: The maximum down force stated before is

reached when the parallel arms are all the way up.

• The spring package is adjustable from 90 lbs. to 325

lbs. of down force when the parallel arms are horizontal. Consult the Down Force Pressure Chart on

page 11 to obtain the desired down force.

NOTE: To adjust the spring tension, lift the plunger by

pulling up on the roll pin handle and sliding the handle

adjustment assembly into the appropriate hole, see

Figure 3-8.

• Two springs can be purchased at your Great Plains

Dealer to make the medium duty package into a heavy

duty package or two springs can be removed from the

heavy duty package to make a medium duty package.

Add or subtract springs by removing the cotter key at

the end of the spring pivot rod. Slide the rod inward to

add or remove a spring from each side. Then attach or

remove the other spring end on the hex bar support.

Reinstall the spring rod and snap ring on each side.

Horizontal Alignment

Figure 3-7

12396

10

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 13

Section 3 Row Unit Operation

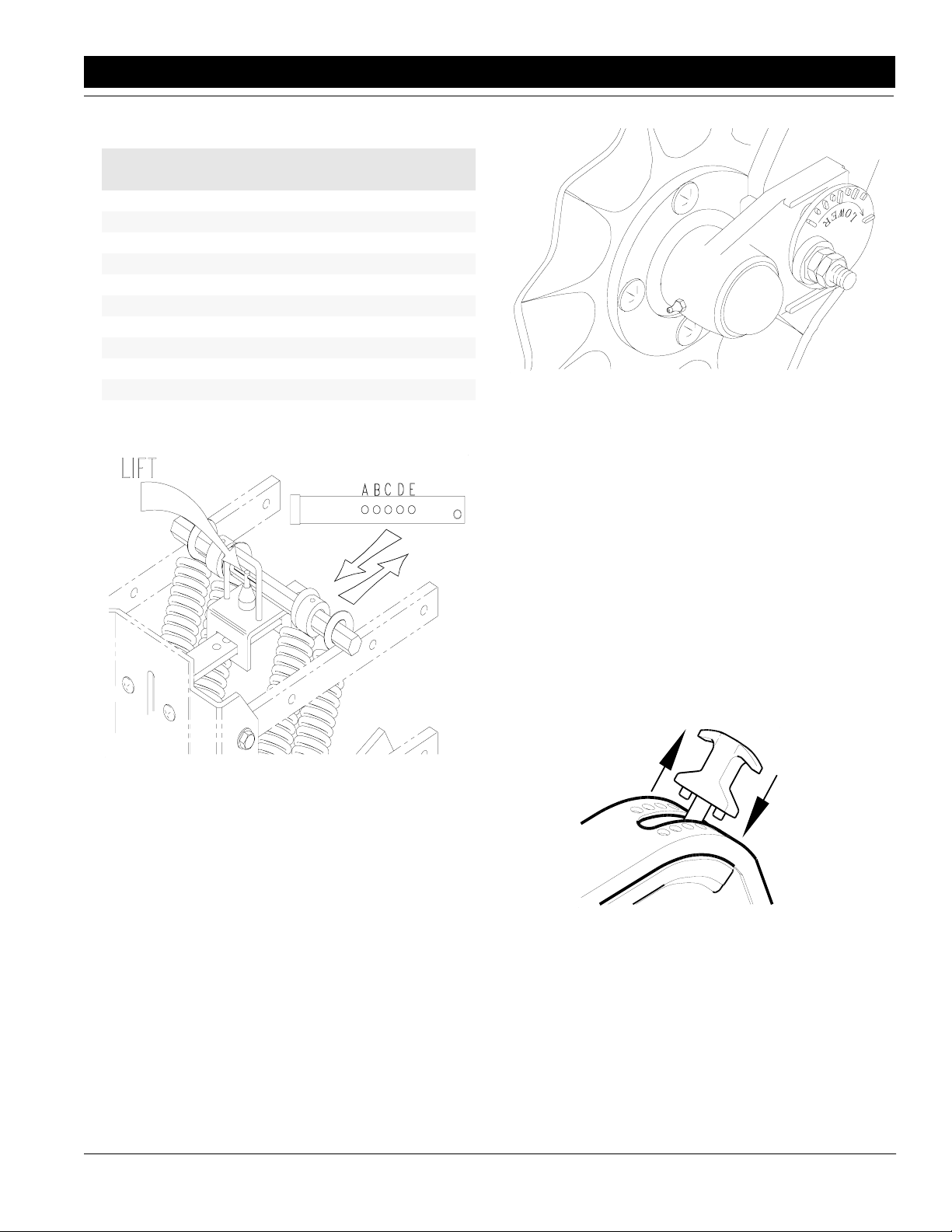

Down Force Pressure Chart

To Obtain This

* Down Force

90 lbs. 2 A

105 lbs. 2 B

125 lbs. 2 C

140 lbs. 2 D

160 lbs. 2 E

185 lbs. 4 A

215 lbs. 4 B

245 lbs. 4 C

285 lbs. 4 D

325 lbs. 4 E

* Force when arms are parallel.

Use This # of

Springs

In This

Hole

12208

Row Unit Mounted Coulter

Figure 3-9

Depth Adjustment

The planting depth of the row unit is controlled by 2 walking gauge tires located next to the disks.

Adjust the planting depth as follows:

1. Raise the planter to remove weight from the gauge

tires.

2. Raise the T-handle and move it forward to decrease

the planting depth, see Figure 3-10. Moving the handle rearward increases the planting depth. Small increments of depth adjustment can be made by

walking the T-handle from side to side.

3. After one row is set to the desired depth, move the

T-handle on the other rows to the same location.

12137

Adjustment Bar

Figure 3-8

Row Unit Mounted Coulter

The optional coulter allows the planter to penetrate

tough ground conditions. It is recommended that either

the medium duty or heavy duty spring package be used

in conjuction with this coulter.

Coulter Adjustments

1. To adjust the coulter vertically, loosen the 3/4" jam

nut and the 3/4" x 3" long hex bolt, see Figure 3-9.

2. By turning the cam hex, rotate the cam casting to set

the desired height. For wavy coulter blades, it is recommended that the coulter blade should be run

even to 1" below the disks on the row unit.

3. Tighten the bolt and jam nut to torque values in the

Torque Value Chart in "Section 9 Specifications"

on page 33.

5/15/06 Great Plains Mfg., Inc.

12345

T-Handle Adjustment

Figure 3-10

1 x 12 Closing Wheel Adjustments

The 1 X 12 closing wheel option can be adjusted for

down force, alignment, and offset.

Closing Wheel Down Force Adjustment

Adjust the closing wheel down force to permit proper

closing of the seed trench. It is recommended tostart with

the T-handle in the first of 4 notches, see Figure 3-11.

60303P and 80303P Three-Point Planter 401-008M

-11

Page 14

Section 3 Row Unit Operation

If the seed trench is not closing move the handle to the

next notch back and try again. Keep moving the handle

back until the seed trench is closing, by doing this eliminates unnecessary down force and compaction. In

some field conditions, the T-handle can be left in the forward slot to minimize down force.

Closing Wheel Adjuster

Figure 3-11

12346

Closing Wheel Alignment (Refer to Figure 3-12)

If one closing wheel is running in the seed trench or the

wheels are not centered over the seed trench, adjust the

closing wheels as follows:

1. Raise the planter slightly to remove weight from the

closing wheels.

2. Loosen the two 1/2" bolts.

3. Turn the press wheel adjuster left or right to center

the wheels over the seed trench.

4. Tighten the 1/2" bolts to the correct torque value listed in theTorque Values Chart in "Section 9 Speci-

fications" on page 33.

from plugging the closing wheels. If the closing wheels

are not offset, the wheels should be located in the front

holes of the press wheel arm.

To offset the wheels, do as follows:

1. Raise planter slightly to remove weight on the closing wheels.

2. Remove the 3/4” bolt holding the wheel,

see Figure 3-13.

3. Move the wheel to the rear hole and attach with the

3/4" bolt. Tighten the bolt to the correct torque value

listed in theTorque Values Chart in "Section 9

Specifications" on page 33.

12347

Closing Wheel & Offset

Figure 3-13

Closing Disk Adjustments

The closing disk options consists of two disks and a

6 1/2 x 12 press wheel. The disk down pressure can be

adjusted to provide closing of the seed trench.

To adjust the down pressure, ratchet the spring cam to

the next cam height by turning the head of the support

bolt clockwise. Refer to Figure 3-14.

12418

Closing Wheel Alignment

Closing Wheel Offset

Figure 3-12

Closing disk & Tube Holes

Figure 3-14

14913

The 1x12 wheels can be offset to help prevent trash

12

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 15

Section 3 Row Unit Operation

Seed Lok

The seed lok option provides additional seed to soil contact. The seed lok is spring loaded and does not require

adjusting. In some wet and sticky conditions the wheel

may accumulate soil and may require removal of the

seed lok until conditions improve.

The seed lok is attached to the shank with a 1/2" clevis pin, see

Figure 3-15. To remove the seed lok, remove the clevis pin and

pull down on the seed lok mount. Reattach in the reverse order.

12362

Seed Lok Assembly

Figure 3-15

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-13

Page 16

Section 4 Adjusting Planting Rates

Section 4 Adjusting Planting Rates

This section discusses the adjustments and settings for

seeding and chemical rates.

Planting Rates

Please read the following sections. Complete understanding of this process will help to prevent problems.

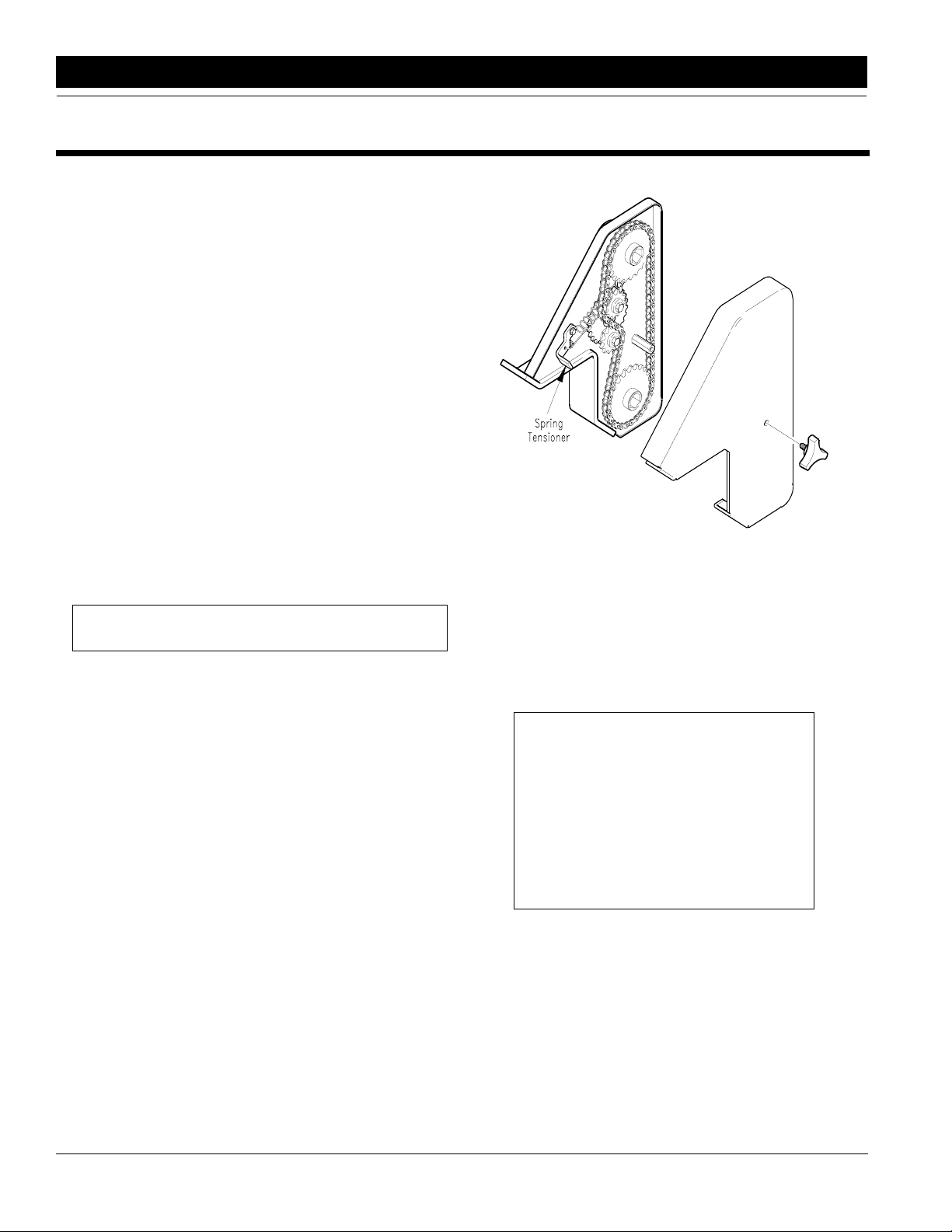

Transmission Adjustment

Planting population changes are accomplished by setting the sprocket transmission. By changing the

combination of sprockets the desired planting populations can be achieved.

To change the sprocket combination, do as follows:

1. Select the sprocket combination for your planting population from the" Planting Rates for Finger Pickup

Corn Meter Chart" in this section on page 21.

2. Remove the cover from the transmission by loosening the knob on the cover.

3. Release the spring tensioner on the idler,

see Figure 4-1.

4. Remove the chain and sprockets.

5. Exchange the sprockets with the desired sprockets,

selected in step 1, on the storage bracket.

Note: When not in use, keep all extra sprockets on the

storage bracket.

6. Place the sprockets on the drive/driven shafts according to the " Planting Rates for Finger Pickup

Corn Meter Chart" in this section on page 21.

7. Loop the chain over the sprockets and between the

2 idlers.

8. Turn the idler counter-clockwise (ccw) to take up the

slack. Just before the idler sprocket reaches its limit

place the head of the sleeve lever mount in between

the two most vertical teeth of the idler sprocket. Rotate the spring tensioner lever over-center to apply

spring tension to hold the idler tight.

9. Replace the transmission cover and hand tighten

the knob.

Checking Planting Population

After setting the transmission, ALWAYS check the planting population in the field.

Follow these steps to check the planting population:

1. Tie up 1 or more closing disks and wheels with a

chain or heavy wire to the hopper support. Releasing the spring pressure on the disks and wheels will

make this easier. Adjust the planting depth to a shallow setting. It may be necessary to tie up the seed

lok wheels so that the seeds are easier to find.

2. Plant at a normal speed for a short distance.

12349

Spring Tensioner on Transmission

Figure 4-1

3. Measure 1/1000 of an acre. For 30" row planter

1/1000 of and acre is 17' 6".

4. Multiply the number of seeds counted by 1000. This

gives you total population.

Example: (for one row)

• 30" row spacing

• 17' 6" of seed trench measured off

• 24 seeds counted in measured

distance

24 Seeds Counted X 1000 =

24,000 Plant Population Per Acre

If the planting population is significantly different than

the desired planting population, make the following

checks:

• Check the sprocket combination in the transmission,

refer to the " Planting Rates for Finger Pickup Corn

Meter Chart" in this section on page 21.

• Check the tire pressure in the gauge wheels, see Spec-

ification in " Section 9 Specifications" on page 33.

• Check for meter malfunction, see Finger Pickup Corn

14

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 17

Section 4 Adjusting Planting Rates

Meter in "Section 5 Troubleshooting" on page 23.

Planting recommendations

To get the best planting results, follow these

recommendations:

• Plant at 5 mph

• Add 1 teaspoon of graphite to each seed hopper.

• Maintain tire pressure in the gauge tires.

• Replace worn meter parts.

Adjusting Granular Chemical Rates

The optional chemical applicators are adjusted by

varying the opening on the chemical meter housing. The

field check is very important because temperature, humidity, speed, ground conditions, flow ability of

chemicals, and obstructions affect the application rate.

!

Agricultural chemicals can be dangerous if not selected and

handled with care. Always read and follow directions supplied by the chemical manufacturer.

To adjust the chemical rate do as follows:

1. Select a setting from the "Granular Chemical Rate

2. Slide the handle on the meter to the setting,

3. If the meter has a knob, turn until the display shows

4. Fill the hoppers with chemical.

WARNING!

Chart" on pages 16 through 24, as a starting point.

see Figure 4-2 and Granular Chemical Rate Chart

on pages 23 and 24.

the appropriate number, see Figure 4-2 and Granular Chemical Rate Chart on pages 16 through 20.

5. Attach a plastic bag to each chemical

diffuser.

6. Drive 1320’ at a normal planting speed.

7. Weigh the contents of the bag in ounces.

8. Multiply ounces by.83 to determine the pounds

per acre.

9. If required, adjust the meter setting and repeat steps

4 through 7 until the desired rate is reached.

Chemical Meter

Figure 4-2

12350

5/15/06 Great Plains Mfg., Inc.

Chemical Meter

Figure 4-3

60303P and 80303P Three-Point Planter 401-008M

14914

-15

Page 18

Section 4 Adjusting Planting Rates

Insecticide Application Rates

Clay Agrisorb 30/60 Chemical Rate Chart

Approximate Rate in Lbs/Acre

30 Inch Rows 36 Inch Rows 38 Inch Rows Ounces per 1000 Row Ft.

Meter

Setting

10 0.9 0.6 0.5 1.1 0.8 0.6 1.2 0.8 0.6 0.87 0.58 0.43

11 1.1 0.7 0.6 1.3 0.9 0.7 1.4 0.9 0.7 1.03 0.69 0.51

12 1.3 0.9 0.7 1.6 1.1 0.8 1.7 1.1 0.8 1.22 0.82 0.61

13 1.6 1.1 0.8 1.9 1.3 0.9 2.0 1.3 1.0 1.45 0.97 0.72

14 1.9 1.2 0.9 2.2 1.5 1.1 2.3 1.6 1.2 1.70 1.13 0.85

15 2.1 1.4 1.1 2.6 1.7 1.3 2.7 1.8 1.4 1.97 1.32 0.99

16 2.5 1.6 1.2 3.0 2.0 1.5 3.1 2.1 1.6 2.27 1.51 1.14

17 2.8 1.9 1.4 3.4 2.3 1.7 3.6 2.4 1.8 2.59 1.72 1.29

18 3.2 2.1 1.6 3.8 2.5 1.9 4.0 2.7 2.0 2.92 1.94 1.46

19 3.6 2.4 1.8 4.3 2.8 2.1 4.5 3.0 2.2 3.26 2.17 1.63

20 3.9 2.6 2.0 4.7 3.2 2.4 5.0 3.3 2.5 3.62 2.41 1.81

21 4.3 2.9 2.2 5.2 3.5 2.6 5.5 3.7 2.7 3.99 2.66 1.99

22 4.8 3.2 2.4 5.7 3.8 2.9 6.0 4.0 3.0 4.37 2.91 2.18

23 5.2 3.4 2.6 6.2 4.1 3.1 6.5 4.4 3.3 4.75 3.17 2.37

24 5.6 3.7 2.8 6.7 4.5 3.4 7.1 4.7 3.5 5.14 3.43 2.57

25 6.0 4.0 3.0 7.2 4.8 3.6 7.6 5.1 3.8 5.53 3.69 2.77

26 6.5 4.3 3.2 7.7 5.2 3.9 8.2 5.4 4.1 5.93 3.95 2.96

27 6.9 4.6 3.4 8.3 5.5 4.1 8.7 5.8 4.4 6.33 4.22 3.16

28 7.3 4.9 3.7 8.8 5.9 4.4 9.3 6.2 4.6 6.72 4.48 3.36

29 7.8 5.2 3.9 9.3 6.2 4.7 9.8 6.5 4.9 7.12 4.75 3.56

30 8.2 5.5 4.1 9.8 6.6 4.9 10.4 6.9 5.2 7.52 5.01 3.76

31 8.6 5.7 4.3 10.3 6.9 5.2 10.9 7.3 5.5 7.92 5.28 3.96

32 9.1 6.0 4.5 10.9 7.2 5.4 11.5 7.6 5.7 8.31 5.54 4.16

33 9.5 6.3 4.7 11.4 7.6 5.7 12.0 8.0 6.0 8.71 5.80 4.35

34 9.9 6.6 5.0 11.9 7.9 5.9 12.5 8.4 6.3 9.10 6.06 4.55

35 10.3 6.9 5.2 12.4 8.3 6.2 13.1 8.7 6.5 9.48 6.32 4.74

36 10.7 7.2 5.4 12.9 8.6 6.4 13.6 9.1 6.8 9.87 6.58 4.93

37 11.2 7.4 5.6 13.4 8.9 6.7 14.1 9.4 7.1 10.25 6.83 5.12

38 11.6 7.7 5.8 13.9 9.3 6.9 14.6 9.8 7.3 10.62 7.08 5.31

39 12.0 8.0 6.0 14.4 9.6 7.2 15.2 10.1 7.6 11.00 7.33 5.50

40 12.4 8.3 6.2 14.9 9.9 7.4 15.7 10.5 7.8 11.37 7.58 5.69

41 12.8 8.5 6.4 15.3 10.2 7.7 16.2 10.8 8.1 11.74 7.83 5.87

42 13.2 8.8 6.6 15.8 10.5 7.9 16.7 11.1 8.3 12.11 8.07 6.05

43 13.6 9.1 6.8 16.3 10.9 8.2 17.2 11.5 8.6 12.47 8.32 6.24

44 14.0 9.3 7.0 16.8 11.2 8.4 17.7 11.8 8.8 12.84 8.56 6.42

45 14.4 9.6 7.2 17.2 11.5 8.6 18.2 12.1 9.1 13.20 8.80 6.60

46 14.8 9.8 7.4 17.7 11.8 8.9 18.7 12.5 9.3 13.56 9.04 6.78

47 15.2 10.1 7.6 18.2 12.1 9.1 19.2 12.8 9.6 13.92 9.28 6.96

48 15.6 10.4 7.8 18.7 12.4 9.3 19.7 13.1 9.8 14.28 9.52 7.14

49 16.0 10.6 8.0 19.1 12.8 9.6 20.2 13.5 10.1 14.65 9.76 7.32

50 16.3 10.9 8.2 19.6 13.1 9.8 20.7 13.8 10.3 15.01 10.01 7.51

51 16.7 11.2 8.4 20.1 13.4 10.0 21.2 14.1 10.6 15.38 10.25 7.69

52 17.2 11.4 8.6 20.6 13.7 10.3 21.7 14.5 10.9 15.75 10.50 7.87

53 17.6 11.7 8.8 21.1 14.0 10.5 22.2 14.8 11.1 16.12 10.75 8.06

54 18.0 12.0 9.0 21.6 14.4 10.8 22.8 15.2 11.4 16.50 11.00 8.25

55 18.4 12.3 9.2 22.1 14.7 11.0 23.3 15.5 11.6 16.88 11.26 8.44

56 18.8 12.5 9.4 22.6 15.0 11.3 23.8 15.9 11.9 17.27 11.52 8.64

57 19.2 12.8 9.6 23.1 15.4 11.5 24.4 16.2 12.2 17.67 11.78 8.83

58 19.7 13.1 9.8 23.6 15.7 11.8 24.9 16.6 12.5 18.07 12.05 9.04

59 20.1 13.4 10.1 24.2 16.1 12.1 25.5 17.0 12.7 18.48 12.32 9.24

miles per hour miles per hour miles per hour miles per hour

4 6 84684 6 8468

16

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 19

Section 4 Adjusting Planting Rates

Clay Agrisorb 30/60 Chemical Rate Chart (Continued)

Approximate Rate in Lbs/Acre

30 Inch Rows 36 Inch Rows 38 Inch Rows Ounces per 1000 Row Ft.

Meter

Setting

60 20.6 13.7 10.3 24.7 16.5 12.4 26.1 17.4 13.0 18.90 12.60 9.45

61 21.1 14.0 10.5 25.3 16.8 12.6 26.7 17.8 13.3 19.33 12.89 9.67

62 21.5 14.4 10.8 25.8 17.2 12.9 27.3 18.2 13.6 19.77 13.18 9.89

63 22.0 14.7 11.0 26.4 17.6 13.2 27.9 18.6 13.9 20.22 13.48 10.11

64 22.5 15.0 11.3 27.0 18.0 13.5 28.5 19.0 14.3 20.68 13.79 10.34

65 23.0 15.4 11.5 27.6 18.4 13.8 29.2 19.4 14.6 21.16 14.10 10.58

66 23.6 15.7 11.8 28.3 18.9 14.1 29.8 19.9 14.9 21.64 14.43 10.82

67 24.1 16.1 12.1 28.9 19.3 14.5 30.5 20.3 15.3 22.14 14.76 11.07

68 24.7 16.4 12.3 29.6 19.7 14.8 31.2 20.8 15.6 22.65 15.10 11.33

69 25.2 16.8 12.6 30.3 20.2 15.1 32.0 21.3 16.0 23.18 15.45 11.59

70 25.8 17.2 12.9 31.0 20.7 15.5 32.7 21.8 16.3 23.72 15.81 11.86

71 26.4 17.6 13.2 31.7 21.1 15.9 33.5 22.3 16.7 24.27 16.18 12.13

72 27.0 18.0 13.5 32.5 21.6 16.2 34.2 22.8 17.1 24.84 16.56 12.42

73 27.7 18.5 13.8 33.2 22.1 16.6 35.0 23.4 17.5 25.42 16.95 12.71

74 28.3 18.9 14.2 34.0 22.7 17.0 35.9 23.9 17.9 26.02 17.34 13.01

75 29.0 19.3 14.5 34.8 23.2 17.4 36.7 24.5 18.4 26.63 17.75 13.31

76 29.7 19.8 14.8 35.6 23.7 17.8 37.6 25.1 18.8 27.25 18.17 13.63

77 30.4 20.3 15.2 36.5 24.3 18.2 38.5 25.6 19.2 27.90 18.60 13.95

78 31.1 20.7 15.5 37.3 24.9 18.7 39.4 26.2 19.7 28.55 19.03 14.28

79 31.8 21.2 15.9 38.2 25.5 19.1 40.3 26.9 20.1 29.22 19.48 14.61

80 32.6 21.7 16.3 39.1 26.1 19.5 41.2 27.5 20.6 29.90 19.94 14.95

81 33.3 22.2 16.7 40.0 26.7 20.0 42.2 28.1 21.1 30.60 20.40 15.30

82 34.1 22.7 17.0 40.9 27.3 20.5 43.2 28.8 21.6 31.31 20.87 15.65

83 34.9 23.3 17.4 41.9 27.9 20.9 44.2 29.4 22.1 32.03 21.35 16.01

84 35.7 23.8 17.8 42.8 28.5 21.4 45.2 30.1 22.6 32.76 21.84 16.38

85 36.5 24.3 18.2 43.8 29.2 21.9 46.2 30.8 23.1 33.50 22.33 16.75

86 37.3 24.9 18.6 44.8 29.8 22.4 47.2 31.5 23.6 34.25 22.83 17.12

87 38.1 25.4 19.1 45.7 30.5 22.9 48.3 32.2 24.1 35.00 23.33 17.50

88 38.9 26.0 19.5 46.7 31.2 23.4 49.3 32.9 24.7 35.76 23.84 17.88

89 39.8 26.5 19.9 47.7 31.8 23.9 50.4 33.6 25.2 36.53 24.35 18.27

90 40.6 27.1 20.3 48.7 32.5 24.4 51.4 34.3 25.7 37.30 24.87 18.65

miles per hour miles per hour miles per hour miles per hour

4 6 84684 6 8468

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-17

Page 20

Section 4 Adjusting Planting Rates

Insecticide Application Rates

Sand Granules Chemical Rate Chart

Approximate Rate in Lbs/Acre

30 Inch Rows 36 Inch Rows 38 Inch Rows Ounces per 1000 Row Ft.

Meter

Setting

5 1.7 1.1 0.8 2.0 1.3 1.0 2.1 1.4 1.1 1.53 1.02 0.76

6 2.2 1.4 1.1 2.6 1.7 1.3 2.7 1.8 1.4 1.98 1.32 0.99

7 2.7 1.8 1.3 3.2 2.2 1.6 3.4 2.3 1.7 2.47 1.65 1.23

8 3.3 2.2 1.6 3.9 2.6 2.0 4.1 2.8 2.1 3.00 2.00 1.50

9 3.9 2.6 1.9 4.7 3.1 2.3 4.9 3.3 2.5 3.56 2.38 1.78

10 4.5 3.0 2.3 5.4 3.6 2.7 5.7 3.8 2.9 4.17 2.78 2.08

11 5.2 3.5 2.6 6.3 4.2 3.1 6.6 4.4 3.3 4.82 3.21 2.41

12 6.0 4.0 3.0 7.2 4.8 3.6 7.6 5.1 3.8 5.50 3.67 2.75

13 6.8 4.5 3.4 8.1 5.4 4.1 8.6 5.7 4.3 6.23 4.15 3.12

14 7.6 5.1 3.8 9.1 6.1 4.6 9.6 6.4 4.8 7.00 4.66 3.50

15 8.5 5.7 4.2 10.2 6.8 5.1 10.8 7.2 5.4 7.80 5.20 3.90

16 9.4 6.3 4.7 11.3 7.5 5.7 11.9 7.9 6.0 8.65 5.77 4.32

17 10.4 6.9 5.2 12.5 8.3 6.2 13.1 8.8 6.6 9.53 6.35 4.77

18 11.4 7.6 5.7 13.7 9.1 6.8 14.4 9.6 7.2 10.45 6.97 5.23

19 12.4 8.3 6.2 14.9 9.9 7.5 15.7 10.5 7.9 11.41 7.60 5.70

20 13.5 9.0 6.7 16.2 10.8 8.1 17.1 11.4 8.5 12.39 8.26 6.20

21 14.6 9.7 7.3 17.5 11.7 8.8 18.5 12.3 9.2 13.41 8.94 6.71

22 15.8 10.5 7.9 18.9 12.6 9.5 19.9 13.3 10.0 14.47 9.64 7.23

23 16.9 11.3 8.5 20.3 13.5 10.2 21.4 14.3 10.7 15.55 10.36 7.77

24 18.1 12.1 9.1 21.8 14.5 10.9 23.0 15.3 11.5 16.65 11.10 8.33

25 19.4 12.9 9.7 23.2 15.5 11.6 24.5 16.3 12.3 17.78 11.86 8.89

26 20.6 13.7 10.3 24.7 16.5 12.4 26.1 17.4 13.1 18.94 12.62 9.47

27 21.9 14.6 11.0 26.3 17.5 13.1 27.7 18.5 13.9 20.11 13.41 10.06

28 23.2 15.5 11.6 27.8 18.6 13.9 29.4 19.6 14.7 21.30 14.20 10.65

29 24.5 16.3 12.3 29.4 19.6 14.7 31.0 20.7 15.5 22.51 15.01 11.26

30 25.8 17.2 12.9 31.0 20.7 15.5 32.7 21.8 16.4 23.73 15.82 11.87

31 27.2 18.1 13.6 32.6 21.7 16.3 34.4 22.9 17.2 24.97 16.64 12.48

32 28.5 19.0 14.3 34.2 22.8 17.1 36.1 24.1 18.1 26.21 17.47 13.10

33 29.9 19.9 14.9 35.9 23.9 17.9 37.8 25.2 18.9 27.45 18.30 13.73

34 31.3 20.8 15.6 37.5 25.0 18.8 39.6 26.4 19.8 28.71 19.14 14.35

35 32.6 21.8 16.3 39.2 26.1 19.6 41.3 27.5 20.7 29.96 19.97 14.98

36 34.0 22.7 17.0 40.8 27.2 20.4 43.0 28.7 21.5 31.21 20.81 15.61

37 35.4 23.6 17.7 42.4 28.3 21.2 44.8 29.8 22.4 32.46 21.64 16.23

38 36.7 24.5 18.4 44.0 29.4 22.0 46.5 31.0 23.2 33.71 22.47 16.85

39 38.1 25.4 19.0 45.7 30.4 22.8 48.2 32.1 24.1 34.95 23.30 17.47

40 39.4 26.3 19.7 47.3 31.5 23.6 49.9 33.2 24.9 36.17 24.12 18.09

41 40.7 27.1 20.4 48.9 32.6 24.4 51.6 34.4 25.8 37.39 24.93 18.70

42 42.0 28.0 21.0 50.4 33.6 25.2 53.2 35.5 26.6 38.60 25.73 19.30

43 43.3 28.9 21.7 52.0 34.7 26.0 54.9 36.6 27.4 39.79 26.53 19.90

44 44.6 29.7 22.3 53.5 35.7 26.8 56.5 37.7 28.2 40.97 27.31 20.48

45 45.9 30.6 22.9 55.1 36.7 27.5 58.1 38.7 29.0 42.13 28.08 21.06

46 47.1 31.4 23.6 56.5 37.7 28.3 59.7 39.8 29.8 43.27 28.85 21.63

47 48.3 32.2 24.2 58.0 38.7 29.0 61.2 40.8 30.6 44.39 29.59 22.20

48 49.5 33.0 24.8 59.5 39.6 29.7 62.7 41.8 31.4 45.49 30.33 22.75

49 50.7 33.8 25.4 60.9 40.6 30.4 64.2 42.8 32.1 46.58 31.05 23.29

50 51.9 34.6 25.9 62.3 41.5 31.1 65.7 43.8 32.8 47.64 31.76 23.82

51 53.0 35.3 26.5 63.6 42.4 31.8 67.1 44.7 33.6 48.68 32.45 24.34

52 54.1 36.1 27.1 64.9 43.3 32.5 68.5 45.7 34.3 49.70 33.13 24.85

53 55.2 36.8 27.6 66.2 44.2 33.1 69.9 46.6 34.9 50.70 33.80 25.35

54 56.3 37.5 28.1 67.5 45.0 33.8 71.2 47.5 35.6 51.68 34.45 25.84

miles per hour miles per hour miles per hour miles per hour

4 6 84684 6 8468

18

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 21

Section 4 Adjusting Planting Rates

Sand Granules Chemical Rate Chart (Continued)

Approximate Rate in Lbs/Acre

30 Inch Rows 36 Inch Rows 38 Inch Rows Ounces per 1000 Row Ft.

Meter

Setting

55 57.3 38.2 28.7 68.8 45.9 34.4 72.6 48.4 36.3 52.64 35.09 26.32

56 58.3 38.9 29.2 70.0 46.7 35.0 73.9 49.2 36.9 53.58 35.72 26.79

57 59.4 39.6 29.7 71.2 47.5 35.6 75.1 50.1 37.6 54.50 36.34 27.25

58 60.3 40.2 30.2 72.4 48.3 36.2 76.4 50.9 38.2 55.42 36.94 27.71

59 61.3 40.9 30.7 73.6 49.1 36.8 77.6 51.8 38.8 56.32 37.54 28.16

60 62.3 41.5 31.1 74.8 49.8 37.4 78.9 52.6 39.4 57.21 38.14 28.60

61 63.3 42.2 31.6 75.9 50.6 38.0 80.1 53.4 40.0 58.09 38.73 29.05

62 64.2 42.8 32.1 77.1 51.4 38.5 81.3 54.2 40.6 58.97 39.31 29.48

63 65.2 43.5 32.6 78.2 52.1 39.1 82.5 55.0 41.3 59.85 39.90 29.92

64 66.1 44.1 33.1 79.4 52.9 39.7 83.7 55.8 41.9 60.73 40.49 30.37

65 67.1 44.7 33.6 80.5 53.7 40.3 85.0 56.6 42.5 61.62 41.08 30.81

67 69.1 46.1 34.5 82.9 55.3 41.5 87.5 58.3 43.7 63.45 42.30 31.73

68 70.1 46.8 35.1 84.2 56.1 42.1 88.8 59.2 44.4 64.40 42.93 32.20

69 71.2 47.5 35.6 85.4 57.0 42.7 90.1 60.1 45.1 65.38 43.58 32.69

70 72.3 48.2 36.2 86.8 57.8 43.4 91.5 61.0 45.8 66.39 44.26 33.20

71 73.5 49.0 36.7 88.1 58.8 44.1 93.0 62.0 46.5 67.45 44.97 33.72

72 74.7 49.8 37.3 89.6 59.7 44.8 94.5 63.0 47.3 68.56 45.71 34.28

73 75.9 50.6 38.0 91.1 60.7 45.6 96.1 64.1 48.1 69.73 46.49 34.86

74 77.3 51.5 38.6 92.7 61.8 46.4 97.8 65.2 48.9 70.96 47.31 35.48

75 78.7 52.5 39.4 94.5 63.0 47.2 99.6 66.4 49.8 72.28 48.19 36.14

76 80.2 53.5 40.1 96.3 64.2 48.1 101.6 67.7 50.8 73.68 49.12 36.84

77 81.9 54.6 40.9 98.2 65.5 49.1 103.6 69.1 51.8 75.18 50.12 37.59

78 83.6 55.7 41.8 100.3 66.9 50.2 105.9 70.6 52.9 76.78 51.19 38.39

79 85.5 57.0 42.7 102.6 68.4 51.3 108.2 72.2 54.1 78.51 52.34 39.25

80 87.5 58.3 43.8 105.0 70.0 52.5 110.8 73.9 55.4 80.36 53.58 40.18

81 89.7 59.8 44.8 107.6 71.8 53.8 113.6 75.7 56.8 82.36 54.91 41.18

82 92.0 61.4 46.0 110.4 73.6 55.2 116.5 77.7 58.3 84.52 56.35 42.26

83 94.6 63.1 47.3 113.5 75.7 56.7 119.7 79.8 59.9 86.85 57.90 43.42

84 97.3 64.9 48.7 116.8 77.8 58.4 123.2 82.1 61.6 89.36 59.57 44.68

85 100.3 66.8 50.1 120.3 80.2 60.2 126.9 84.6 63.5 92.07 61.38 46.03

miles per hour miles per hour miles per hour miles per hour

4 6 84684 6 8468

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-19

Page 22

Section 4 Adjusting Planting Rates

Liquid Fertilizer Rate Chart

Transmission

Combination

Driver Driven Gallons/Acre Gallons/Acre

15 44 3.49 8.99

15 41 3.75 9.65

17 44 4.06 10.19

17 41 4.25 10.94

19 44 4.43 11.39

15 32 4.8 12.36

21 41 5.25 13.51

17 32 5.45 14.01

24 41 6.00 15.44

19 32 6.09 15.66

15 24 6.41 16.48

17 24 7.26 18.68

15 21 7.32 18.84

17 23 7.58 19.49

15 19 8.09 20.82

17 21 8.30 21.35

19 23 8.47 21.79

15 17 9.04 23.27

17 19 9.17 23.60

23 24 9.82 25.28

24 23 10.70 27.52

19 17 11.46 29.48

17 15 11.62 29.89

23 19 12.41 31.93

21 17 12.66 32.58

19 15 12.98 33.41

23 17 13.87 35.68

21 15 14.35 36.93

24 17 14.47 37.24

32 21 15.62 40.19

24 15 16.40 42.20

32 19 17.26 44.42

41 24 17.51 45.06

32 17 19.29 49.65

41 21 20.01 51.49

32 15 21.87 56.27

44 19 23.74 61.08

41 17 24.72 63.61

44 17 26.53 68.26

41 15 28.02 72.09

44 15 30.07 77.37

Hose Dia. at 5/16 Hose Dia. at 1/2

NOTE: The delivery rates are approximate and will vary with changes in temperature and the specific fertilizer

being used.

20

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 23

Section 4 Adjusting Planting Rates

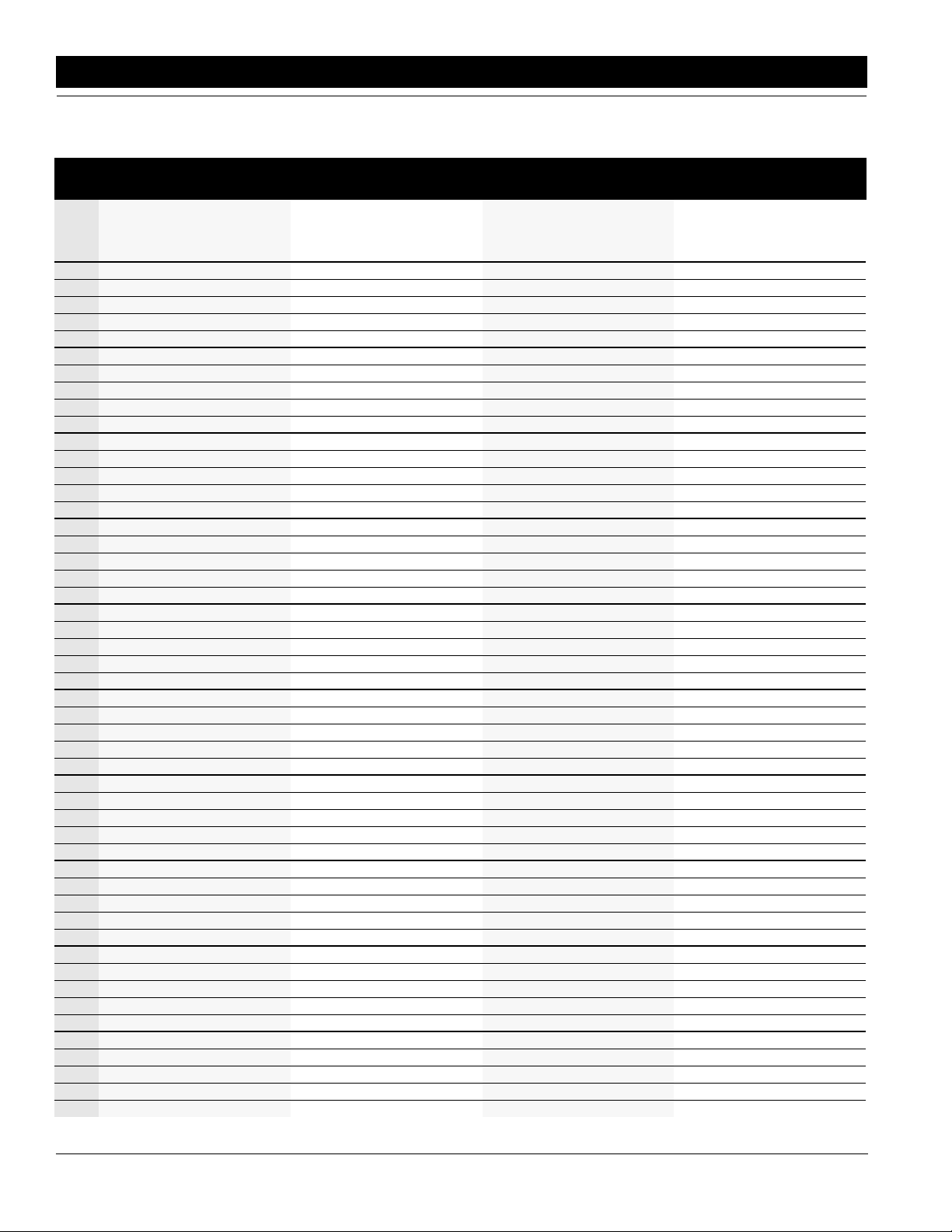

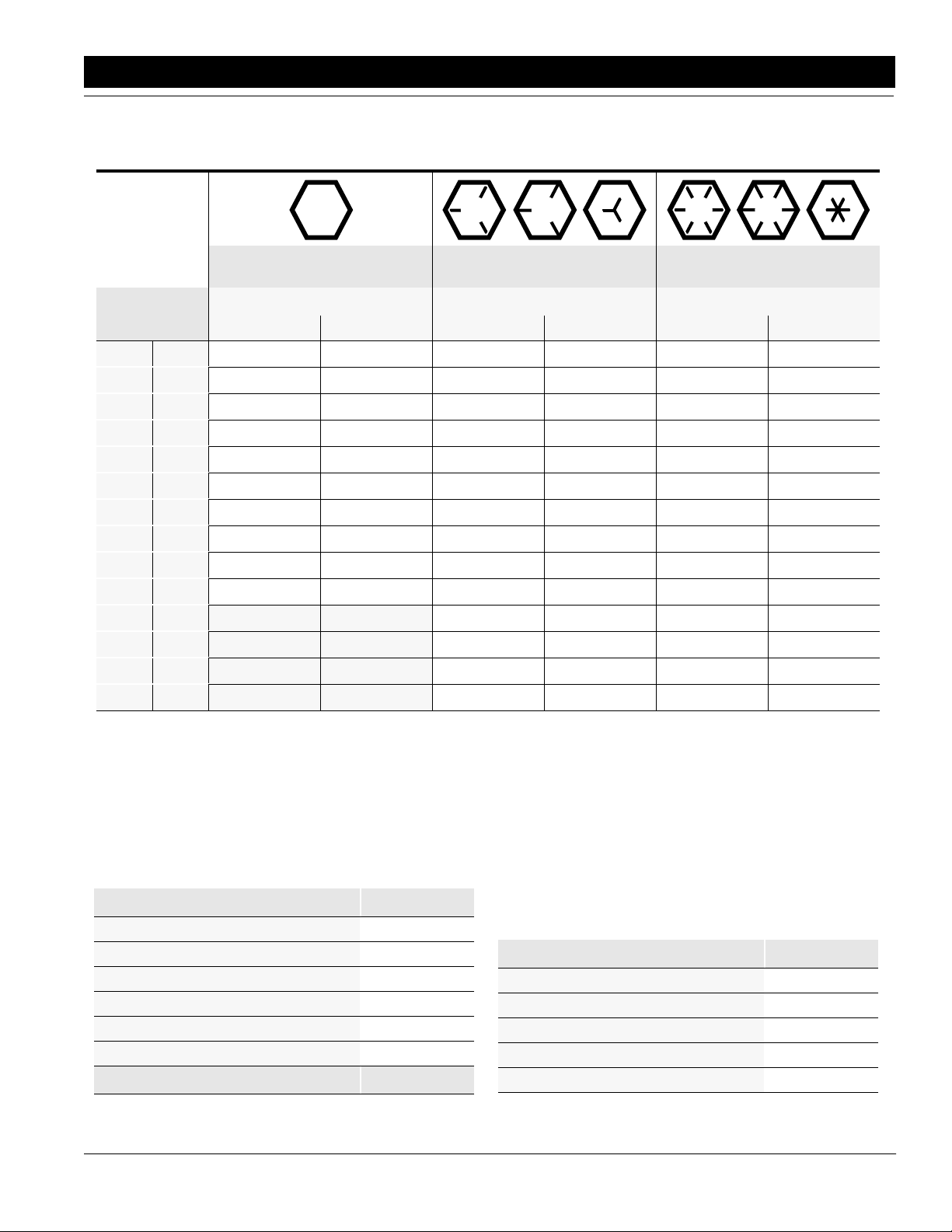

Planting Rates for Finger Pickup Corn Meters

Planting Rates 30" Row Width

Planting

Population/

Acre

24,849 17 19 4 to 7.5 8.4

25.550 23 25 4 to 7.5 8.2

25,636 24 26 4 to 7.5 8.2

25,715 25 27 4 to 7.5 8.1

25,788 26 28 4 to 7.5 8.1

26,615 23 24 4 to 7.5 7.9

26,661 24 25 4 to 7.5 7.8

26,704 25 26 4 to 7.5 7.8

26,743 26 27 4 to 7.5 7.8

26,780 27 28 4 to 7.5 7.8

27,772 23 23 4 to 7 7.5

28,800 28 27 4 to 7 7.3

28,840 27 26 4 to 7 7.3

28,929 25 24 4 to 7 7.2

28,979 24 23 4 to 7 7.2

29,908 28 26 4 to 6.5 7.0

29,994 27 25 4 to 6.5 7.0

30,187 25 23 4 to 6.5 6.9

31,039 19 17 4 to 6.5 6.7

31,103 28 25 4 to 6.5 6.7

31,243 27 24 4 to 6.5 6.7

31,394 26 23 4 to 6.5 6.7

32,401 28 24 3 to 6 6.5

32,602 27 23 3 to 6 6.4

33,619 23 19 3 to 5.5 6.2

33,809 28 23 3 to 5.5 6.2

35,080 24 19 3 to 5.5 6.0

36,542 25 19 3 to 5 5.7

37,574 23 17 3 to 5 5.6

38,004 26 19 3 to 5 5.5

39,207 24 17 3 to 5 5.3

39,465 27 19 3 to 5 5.3

40,841 25 17 3 to 4.5 5.1

40,927 28 19 3 to 4.5 5.1

42,475 26 17 3 to 4.5 4.9

44,108 27 17 3 to 4.5 4.7

45,742 28 17 3 to 4.5 4.6

Planting Rates 30" Row Width

Planting

Population/

Acre

16,862 17 28 4 to 8 12.4

17,486 17 27 4 to 8 12.0

18,159 17 26 4 to 8 11.5

18,845 19 28 4 to 8 11.1

18,885 17 25 4 to 8 11.1

19,543 19 27 4 to 8 10.7

19,672 17 24 4 to 8 10.6

20,295 19 26 4 to 8 10.3

20,527 17 23 4 to 8 10.2

21,107 19 25 4 to 8 9.9

21,986 19 24 4 to 8 9.5

22,813 23 28 4 to 8 9.2

22,942 19 23 4 to 8 9.1

23,658 23 27 4 to 8 8.8

23,805 24 28 4 to 8 8.8

24,568 23 26 4 to 8 8.5

24,686 24 27 4 to 8 8.5

24,796 25 28 4 to 8 8.4

Transmission

Sprockets

Drive Driven

Recommended

Speed Range

(mph)

Average Seed

12548

Spacing

(inches)

IMPORTANT: See “Planting Rates” and “Checking Planting Population”, on page 14 for additional information. Always check seed population in the field to ensure planting rates are correct.

Transmission

Sprockets

Drive Driven

Recommended

Speed Range

(mph)

Average Seed

Spacing

(inches)

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-21

Page 24

Section 4 Adjusting Planting Rates

Granular Chemical Rate Charts

Dry Insecticide Application Rates

Approximate Pounds/Acre at 5 mph

for a 30” Row Spacing

Meter Setting Clay Granules Sand Granules

5 --- 3.0

6 --- 5.0

7 --- 5.5

8 --- 6.5

9 --- 8.0

10 5.1 9.2

11 5.6 10.5

12 6.3 11.5

13 7.1 13.0

14 7.9 14.5

15 8.8 16.0

16 9.9 18.0

17 11.0 20.0

Dry Herbicide Application Rates

Approximate Pounds/Acre at 5 mph

for a 30” Row Spacing

Meter Setting Clay Granules

10 4.8

11 5.4

12 6.0

13 6.7

14 7.5

15 7.1

16 9.3

17 10.2

18 11.0

19 12.0

20 13.0

21 14.0

22 15.0

18 11.8 22.5

19 13.5 25.0

20 14.6 26.5

21 16.0 28.5

22 16.9 30.5

23 17.7 33.0

24 19.4 35.5

25 21.5 38.0

26 23.7 ---

27 24.8 ---

28 26.2 ---

29 28.7 ---

30 30.5 ---

23 16.2

24 17.5

25 18.7

26 20.0

27 21.5

28 23.3

29 25.0

30 27.5

22

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 25

Section 5 Troubleshooting

Section 5 Troubleshooting

Finger Pickup Corn Meter

Problem Possible Cause Solution

One row not planting seed.

Drive release does not engage properly.

Unit is skipping.

Planting too many doubles.

Over planting.

Under planting.

Irregular or incorrect seed spacing.

Seed spacing not as indicated in

charts.

Scattering of seeds.

Seed tubes and/or openers plugging.

Inconsistent seed depth.

Drive clutch release not engaged. Engaged clutch release mechanism.

Foreign material in hopper. Clean hopper and finger carrier mechanism.

Seed hopper empty. Fill seed hopper.

Row unit drive chain off of sprocket or broken. Repair or replace drive chain.

Drive release shaft isn’t aligned properly with

meter drive shaft.

Foreign material or obstruction in meter. Clean out and inspect.

Finger holder improperly adjusted. Adjust to proper setting. (22 to 25 inch pounds

Broken fingers. Replace fingers and/or springs as required.

Planting too slowly. Increase planting speed to within recommended

Planting too fast. Stay within recommended range.

Lose finger holder. Adjust to specifications (22 to 24 inch pounds

Worn brush in carrier plate. Inspect and replace if necessary.

Worn carrier plate. Inspect and replace if necessary.

Belt installed backwards. Remove and install correctly.

Weak springs. Replace.

Spring not properly installed. Remove finger holder and correct.

Seed belt catching or dragging. Replace belt.

Brush dislodging seed. Replace brush.

Driving too fast. Check chart for correct speed.

Wrong tire pressure. Inflate tires to correct air pressure.

Drive wheels slipping. Reduce down pressure on row unit down force

Wrong sprockets. Check planting rate charts for correct sprocket

Wrong tire pressure. Inflate tires to correct air pressure.

Inconsistent seed size. Do field check and adjust sprockets accordingly.

Wrong sprockets. Check chart for correct sprocket combination.

Charts are approximate. Slight variations due to wear may produce seed

Planting too fast. Reduce planting speed.

Seed tube improperly installed. Check seed tube installation.

Seed tube worn or damaged. Replace seed tube.

Allowing planter to roll backward when lowering. Lower planter only when tractor is moving forward.

Rough seed bed. Adjust down pressure springs

Partially plugged seed tube. Inspect and clean.

Seed tube improperly installed. Install properly.

Align drive mechanism. See “Meter Drive

Adjustment”.

torque)

range.

torque)

springs.

combinations.

spacing variations.

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-23

Page 26

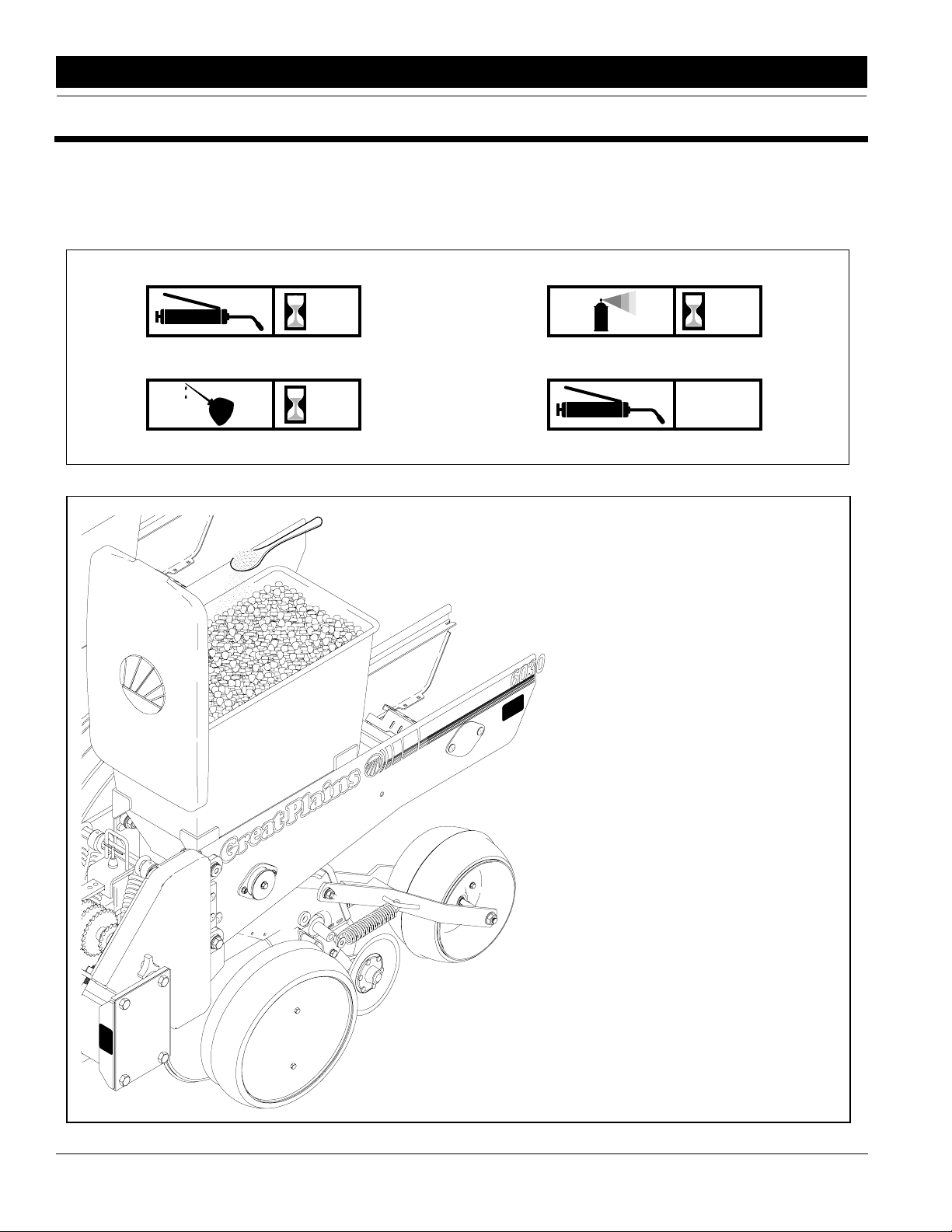

Section 6 Lubrication

Section 6 Lubrication

With proper lubrication and care of your planter you will

reduce costly repairs and extend the life of the planter.

Conditions in certain areas may require special lubricants. Contact your Great Plains Dealer if you have any

questions.

Lubrication Symbols

As

50

Lubrication is required every 50 hours of operation. Use a multipurpose spray lube. Use as required.

Do not over lubricate.

Required

10

Seasonally

Lubrication is required.Lubrication is required every 10 hours of operation.

Finger Pickup Meter

To prolong the life the finger pickup

meter and increase the planting accuracy, add a teaspoon of graphite to the

seeds every time you fill the hopper.

Sprinkle the graphite on top of the seeds

and it will filter down to lubricate the

finger pickup meter, see Figure 6-1.

Finger Pickup Meter Lubrication

Figure 6-1

12342

24

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 27

Section 6 Lubrication

12372

12351

Seasonally

Wheel Bearings

Pump grease into the hub until grease comes out

around the seals. Lift the wheel off the ground. Move the

tire in and out to check for end play. Check for roughness in the bearing by rotating the wheel. If the bearings

are rough they should be inspected and replaced if

necessary.

As

Required

Seed and Chemical Meter Chains

Lubricate all chains at intervals to maintain freedom at

every chain link joint. Use a multipurpose spray lubricant

on chains, because it penetrates into the rollers on the

chain. Spray chains if planter is going to be idle to prevent the chains from rusting and becoming stiff. Stiff

chains will cause metering inaccuracies.

10202

12352

As

Required

Gauge Wheel Chains

Lubricate all chains at intervals to maintain freedom at

every chain link joint. Use a multipurpose spray lubricant

on chains, because it penetrates into the rollers on the

chain. Spray chains if planter is going to be idle to prevent the chains from rusting and becoming stiff. Stiff

chains will cause metering inaccuracies.

50

Gauge Wheel Module

Lubricate gauge wheel module links every 50 hours.

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-25

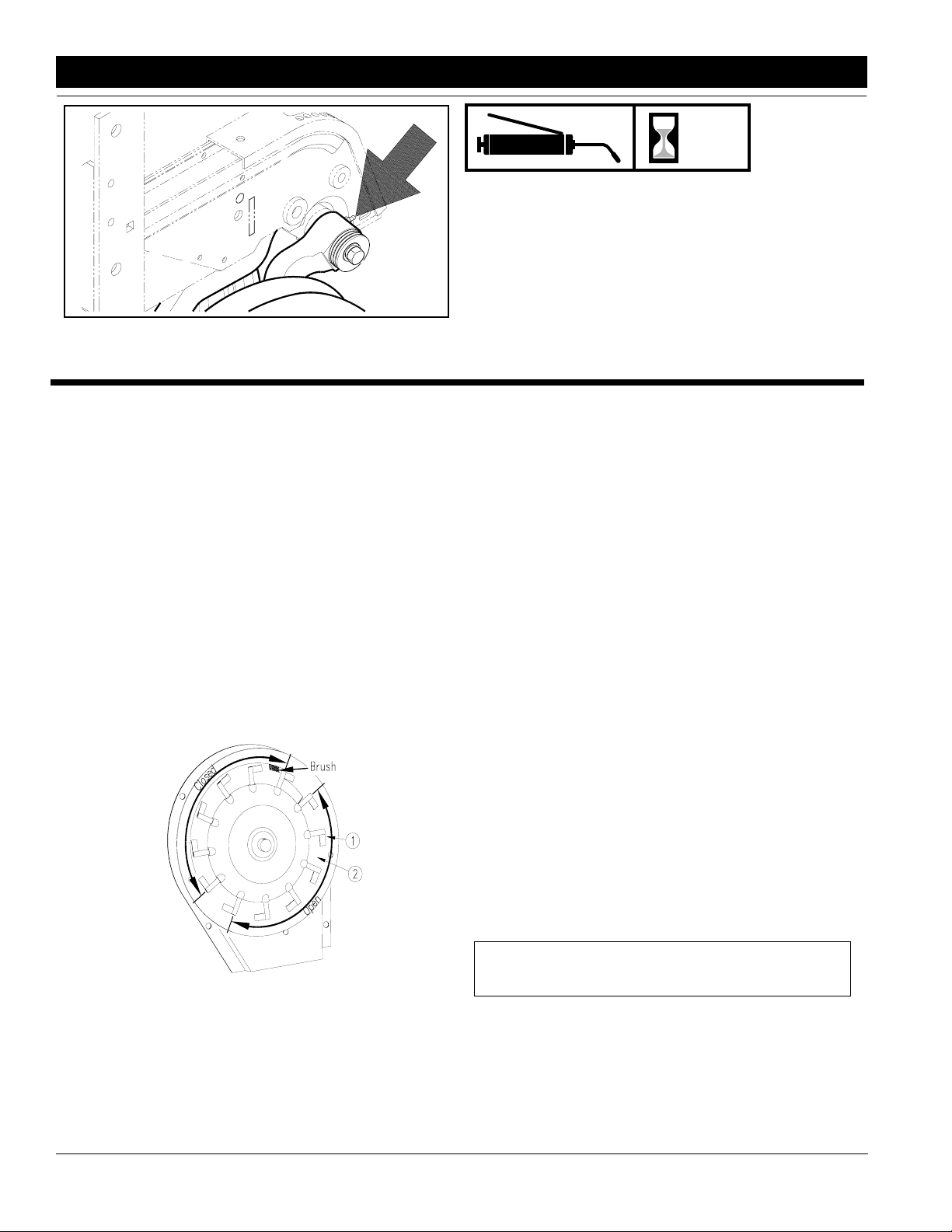

Page 28

Section 7 Maintenance

Section 7 Maintenance

13337

50

Gauge Wheel Side Arm

3 to 4 pumps of grease into the zerk with universal allpurpose grease every 50 hours.

Proper maintenance can prevent unnecessary down

time and prolong the life of your planter.

Fasteners

When working on the planter torque all bolts, screws,

and nuts to the correct values listed in the Torque Values Chart in "Section 9 Specifications" on page 33.

Check latches and other fasteners on the planter to prevent failures in the field.

Finger Pickup Meter

Inspect and repair the finger pickup meter by removing

the 2 bolts holding the meter to the hopper. Remove the

3 bolts on the meter baffle to gain access to the finger

mechanism.

Rotate the meter input shaft by hand to check the fingers. The fingers should be against the carrier plate in

the area shown closed and raised in the area shown

open in Figure 7-1.

To clean the corn meter:

1. Remove the cotter pin, lock nut, and adjusting nut

from the shaft.

2. Lift the finger assembly off the shaft and clean.

3. Replace worn fingersand springs by lifting thefinger

out of the slot. Average life expectancy of these

parts should be 250-300 acres of row operation.

When fingers are replaced, the open end of the

spring loop should be toward the inside of the finger

housing.

4. Inspect the indentations in the carrier plate for wear.

Replace the carrier plate when wear to the plate becomes excessive or the seeding accuracy will be affected.

5. Reassemble the meter in reverse order. Be sure the

fingers are installed correctly so the finger housing

is flush with the carrier plate. If the finger housing is

not flush with the carrier plate, make sure that the

projection on the cam is in the notch on the bearing

housing. The meter will not function properly if the

projection is not in the notch.

6. With the finger assembly against the plate, tighten

the adjusting nut until it is snug. Then turn an additional 1/3 turn. Turn the meter by hand making certain that the meter is not over tightened. Proper

meter resistance would be 22-25 in/lbs of torque applied at the meter input shaft.

7. Install the cage nut and the cotter pin.

8. Install the baffle and attach the meter to the hopper.

12353

Finger Raised/Location of Brush

Figure 7-1

Inspect the brush for wear and replace every 100 acres

of row operation, see Figure 7-1 for location.

Chaf and debris can build-up in the meter preventing

proper functioning of the fingers.

26

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Note: Check tightness of the adjusting nut on the

meter after the first day and periodically thereafter.

Check the belt on the meter periodically.

Use these steps:

1. Remove the 4 bolts located on the belt housing and

the bolt holding the belt roller.

2. Inspect or replace the seed belt.

3. Reassemble in the reverse order.

Great Plains Mfg., Inc.

Page 29

Section 7 Maintenance

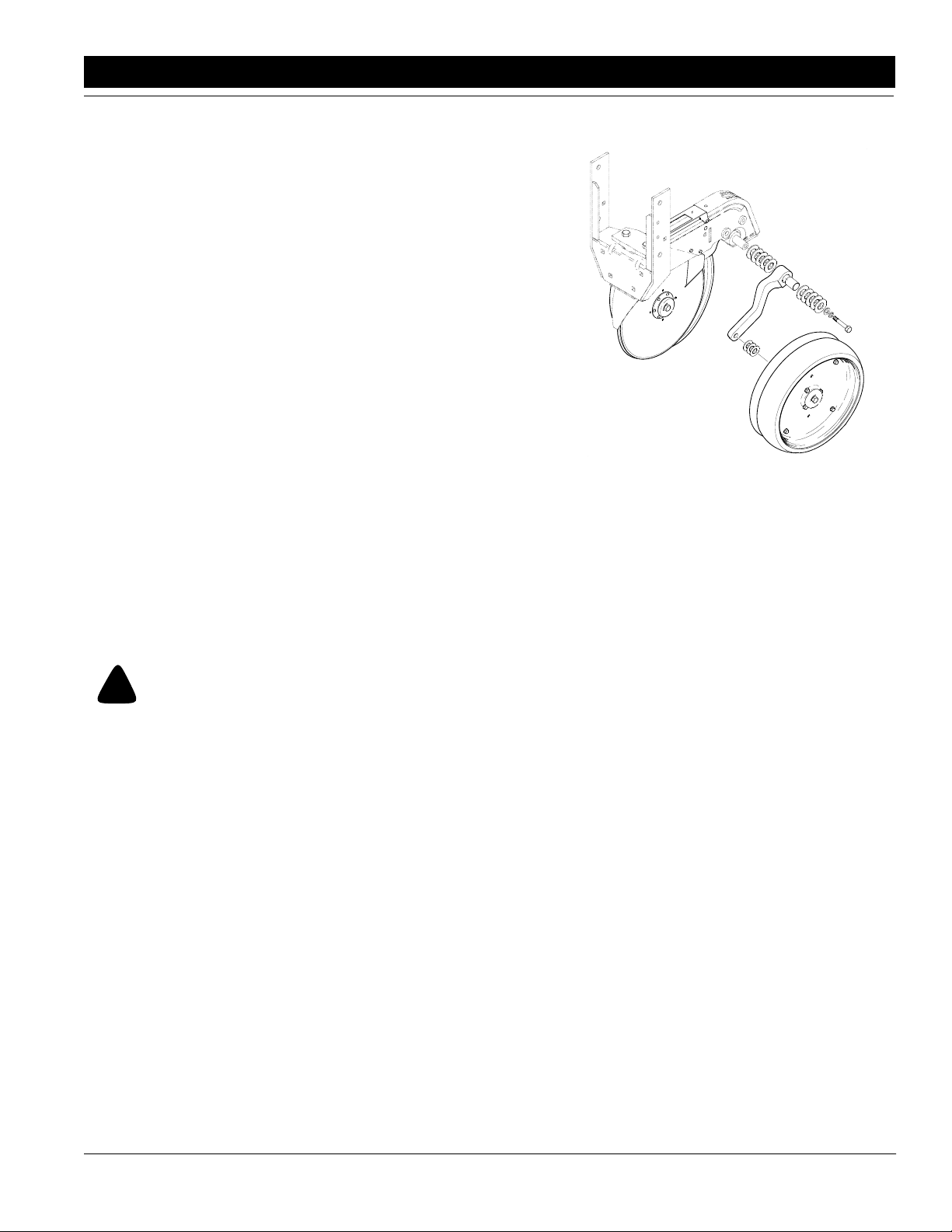

Spreader and Scraper

The spreader and scraper between the disks will periodically need replacing. These components scrape dirt off

the disks and protect the seed tube.

To inspect or replace the spreader or scraper do as

follows:

1. Remove the side gauge wheel and the arm from the

row unit.

2. Remove the disk blade. Be careful, disks wear very

sharp!

3. Remove both of the 1/4" bolts holding the scraper

and spreader.

4. If the sides of the seed tube are worn, replace the

scraper and spreader.

5. Install the scraper and spreader with 1/4" bolts.

Torque the bolts to the correct values as listed in the

Torque Values Chart in "Section 9Specifications"

on page 33.

6. Install the disk and torque the bolt to the correct value as listed in Torque Values Chart in "Section 9

Specifications" on page 33.

7. Install the gauge wheel according to directions under the Gauge Wheels heading on page 27, below.

Disk

As the disks on the row unit wear, removal of shims may

be required to maintain contact point. To remove disk do

as follows:

!

CAUTION!

Disk blades wear very sharp. Handle with care.

1. Remove side gauge wheels and arm from the row unit.

2. Remove 3/4" bolts retaining the disks.

3. Measure disk diameter, if disk measures 14 1/2" or

less replace disk.

4. If contact is to be increase, move shims from behind

disk to outside disks. This will increase the contact

between the disks.

5. Install disks and tighten 3/4" bolts to torque values in

Specification Section.

6. Install gauge wheels and arms according to directions in this section.

Gauge Wheels

Periodically check gauge tires to be sure there is contact

or a 1/16" gap between the tires and disks.

For installation or adjustments proceed as follows:

1. Remove the 1/2" bolt holding arm on to the shank.

2. If the tire needs to be closer to the disk, move an appropriate amount of shims from the inside of the arm

to the outside, see Figure 7-2. Each shim is .050

thick.

12354

Gauge Arm, Spindle, and Shims

Figure 7-2

3. Install the arm and the shims onto the spindle. Tighten 1/2" bolt to the correct torque value as listed in

the Torque Values Chart in "Section 9 Specifica-

tions" on page 33.

4. Check clearance or contact of the tire and disk. The

gauge wheel should fall freely when lifted. Repeat

steps 1 through 4 if necessary.

Outside Scrapers

The row units are equipped with outside disk scrapers to

remove dirt from the disks.

Periodically check the scrapers as follows:

1. Remove the gauge tires to inspect the scrapers.

2. Make sure the scrapers are contacting the disk with

some pressure.

3. If scrapers are not contacting the disks properly,

bend and twist the scrapers as required to establish

contact. If the scraper is worn too much, replace it by

removing the two 1/4" bolts. Bolt the new scraper in

place and torque the bolts to correct values as listed

in the Torque Values Chart in "Section 9 Specifica-

tions" on page 33.

Shear Pins

The planter drive line and row units are protected by

shear pins on transmission upper and lower shafts..

Check and replace bent or broken pins as required.

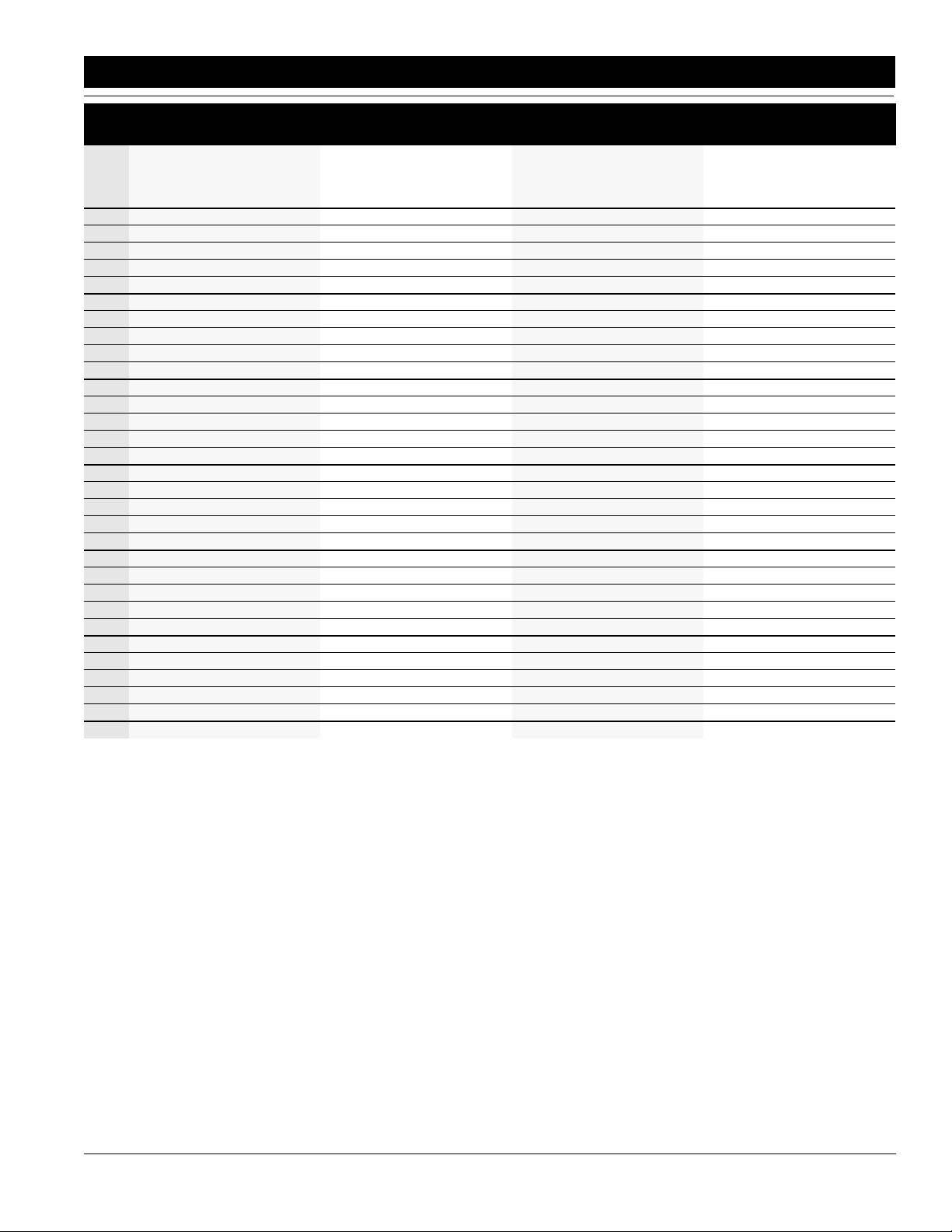

Chain Tension

The planter is equipped with spring loaded idlers to

maintain tension in the chains. As the chains wear and

stretch, the link(s) may be removed to provide proper

chain length and tension. Check and replace broken

springs and bushings on idlers. Forthe correct operation

of the planter check all chain routings. Refer to page 28

for the chain routing diagrams.

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-27

Page 30

Section 7 Maintenance

Drive Gauge Wheel Chain Routing

10202

Meter Drive Chain Routing

12358

Counter Shaft Support Chain Routing

12355

12351

Granular Chemical Drive Chain Routing

28

60303P and 80303P Three-Point Planter 401-008M 5/15/06

12349

Transmission Chain Routing

Great Plains Mfg., Inc.

Page 31

Section 7 Maintenance

Maintenance & Lubrication Record

Item to be Serviced When to Perform Reference Date

5/15/06 Great Plains Mfg., Inc.

60303P and 80303P Three-Point Planter 401-008M

-29

Page 32

Section 8 Storage

Section 8 Storage

To extend the life of your planter follow the recommendations for removing the planter from storage and

storing the planter during the off season.

Beginning of the Season

Inspect the hoppers for debris and clean if necessary to

prevent damage to the meters.

Clean dirt and grease from the chains and moving parts.

This will prevent the abrasive action of dirt from causing

excessive wear to chains and other parts. Lubricate the

planter according to the directions in "Section 6 Lubri-

cation" on page 26.

Check all bolts and replace worn parts on the planter to

prevent failure in the field. Make adjustments to the

planter for the field conditions to be encountered.

Ending of the Season

When planting is complete clean the seed and chemical

hoppers. Remove all dirt, debris, chemicals, and fertilizer from the planter that may hold moisture and cause

corrosion.

Use spray paint to cover scratches, chips, and worn ar-

eas on the planter to protect the metal.

Lubricate the planter as outlined in "Section 6 Lubrica-

tion" on page 26. Pay careful attention to the lubrication

of the chains to help prevent rusting.

Inspect the planter for worn or damaged parts. Make repairs and service during the off season to reduce down

time in the field.

Place the 1 X 12 closing wheel handle in the middle slot

to relieve the tension on the closing wheels. Move opener adjustment bar on heavy and medium down pressure

spring packages to hole A.

Remove the finger pickup meters from the hoppers. Disassemble the meters and inspect them for wear. Make

any repairs required at this time. Blow excessive debris

from the meter. Wash the meters with mild soap and water. Dry the meters and spray a light coat of rust inhibitor

on the meters. Reassemble and store in a dry place.

Store the planter in a clean, dry place with all tires out of

the sun. A sheltering structure is best for overall protection, but a high quality tarp would suffice.

30

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 33

Section 9 Specifications

Section 9 Specifications

6 - Row 30"

Frame 7" sq. 5/16" Wall 7" sq. 5/16" Wall

9.5L X 15 Drive Gauge Wheels 2 2

Planter Width 16' 15’

Planter Height 5' 4’

Planter Length 6' 6’

Shipping Weight (empty) 2800 lbs. 2400 lbs. (approx.)

8 - Row 30"

Frame 7" sq. 3/8" Wall 7" sq. 3/8" Wall

9.5L X 15 Drive Gauge Wheels 2 2

Planter Width 21' 20’

Planter Height 5' 4’

Planter Length 6' 6’

Shipping Weight (empty) 3800 lbs. 3380 lbs. (approx.)

With Markers Without Markers

With Markers Without Markers

Row Unit Equipment

Standard

2 bu. Seed Hopper (Standard with corn Meter)

Double disk staggered Openers

4" x 16" Gauge tires

Light Down Pressure Springs

5/15/06 Great Plains Mfg., Inc.

Optional

80 lbs. Insecticide/Herbicide Hopper with

7" & 14" Diffusers

1 x 12 Double “V” Press Wheels

Closing Disc’s with 6 1/2" x 12" Press Wheel

Medium & Heavy Down Pressure Springs

Seed Lok

60303P and 80303P Three-Point Planter 401-008M

-31

Page 34

Section 9 Specifications

12445

Specification Diagram

Figure 9-1

32

60303P and 80303P Three-Point Planter 401-008M 5/15/06

Great Plains Mfg., Inc.

Page 35

Section 9 Specifications

Torque Values Chart for UNC Threads

Bolt head

identification

marks are as per

grade.

NOTE: Manufacturing marks will vary.

Bolt Size

inches mm Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.

1/4" 6.35

5/16" 7.94

3/8" 9.53

7/16" 11.11

1/2" 12.70

9/16" 14.29

5/8" 15.88

3/4" 19.05

7/8" 22.23

1" 25.40

Foot Pounds Newton-Meters Foot Pounds Newton-Meters Foot Pounds Newton-Meters

5 6 6.8 8.13 9 11 12.2 14.9 12 15 16.3 20.3

10 12 13.6 16.3 17 20.5 23.1 27.8 24 29 32.5 39.3

20 23 27.1 31.2 35 42 47.5 57.0 45 54 61.0 73.2

30 35 40.7 47.4 54 64 73.2 86.8 70 84 94.9 113.9

45 52 61.0 70.5 80 96 108.5 130.2 110 132 149.2 179.0

65 75 88.1 101.6 110 132 149.2 179.0 160 192 217.0 260.4

95 105 128.7 142.3 150 180 203.4 244.1 220 254 298.3 358.0

150 185 203.3 250.7 270 324 366.1 439.3 380 456 515.3 618.3

160 200 216.8 271.0 400 480 542.4 650.9 600 720 813.6 976.3

250 300 338.8 406.5 580 596 786.5 943.8 900 1080 1220.4 1464.5

1 1/8" 25.58

1 1/4" 31.75

1 3/8" 34.93

1 1/2" 38.10

Grade 2 Grade 5 Grade 8*

800 880 1084.8 1193.3 1280 1440 1735.7 1952.6

1120 1240 1518.7 1681.4 1820 2000 2467.9 2712.0

1460 1680 1979.8 2278.1 2380 2720 3227.3 3688.3

1940 2200 2630.6 2983.2 3160 3560 4285.0 4827.4

* Thick nuts must be used with Grade 8 bolts

NOTE: Torque requirements listed above do not apply to self-locking nuts. For self-locking nuts increase the torque requirements listed by 15%.

Tire Inflation Chart

Tire Size Inflation PSI

7.50 x 20" 4-Ply Drill Rib 28

9.0 x 22.5 10-Ply Highway Service 70 70

9.0 x 24" 8-Ply Rib Implement 40

9.5L x 15" 6-Ply Rib Implement 32

9.5L x 15" 8-Ply Rib Implement 44

9.5L x 15" 12-Ply Rib Implement 60

Tire Size Inflation PSI

5/15/06 Great Plains Mfg., Inc.

Tire Inflation Chart

Tire Size Inflation PSI

7.50 x 20" 4-Ply Drill Rib 28

9.0 x 22.5 10-Ply Highway Service 70 70

9.0 x 24" 8-Ply Rib Implement 40

9.5L x 15" 6-Ply Rib Implement 32

9.5L x 15" 8-Ply Rib Implement 44

60303P and 80303P Three-Point Planter 401-008M

-33

Page 36

Section 9 Specifications

Metric Conversion Chart

Multiply By To Get

inches in. x 2.54 = centimeters cm