Page 1

Installation Instructions

8-Foot End-Wheel Drills

800EW Fertilizer Kits

Manufacturing, Inc.

www.greatplainsmfg.com

Read the installation manual entirely. When you see this symbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

29570

Cover illustration may show parts not supplied with all kits.

EN

© Copyright 2009 Printed 02/24/2010 175-253M

Page 2

Table of Contents

Important Safety Information.................................... 1

Introduction ................................................................ 4

Models Covered........................................................... 4

Kits Covered ................................................................ 4

Definitions ................................................................4

Call-Outs .................................................................. 4

Before You Start......................................................... 5

Drill Compatibility ......................................................... 5

Tools Required............................................................. 5

Related Documents ................................................. 5

Installing Multiple Options? .......................................... 5

Pre-Assembly Preparation ........................................... 6

Remove Existing Hardware....................................... 7

Remove Walkboard Ladder ......................................... 7

Remove Walkboard ..................................................... 7

Remove Walkboard Support(s).................................... 8

Remove Handles ......................................................... 8

Remove Transmission Chain....................................... 9

Release Hoses Near Drive .......................................... 9

Disconnect Small Seeds Hoses................................... 9

Remove Small Seeds Delivery Tubes ....................... 10

Remove Small Seeds Box ......................................... 10

Install Hardware ....................................................... 11

Install Fertilizer Box.................................................... 11

Install Drive System ................................................... 11

Install Gearbox Accessory Sprocket ...................... 11

Install Gearbox Accessory Idler/Bearing................ 12

Pre-Assemble Accessory Shaft Mount................... 13

Install Accessory Shaft Mount................................ 13

Install Accessory Shaft and Sprockets................... 14

Install Gearbox Output Chain................................. 15

Install Transmission Chain..................................... 15

Routing - Fertilizer Only ..................................... 15

Routing - Fertilizer and Agitator ......................... 15

Adjust Final Drive Chain Slack................................... 16

Install Fertilizer Delivery............................................. 16

Install Delivery Tubes............................................. 16

Install Delivery Hoses ............................................ 17

Re-Install Small Seeds Box ....................................... 18

Install SGS to Fertilizer Chain ................................... 18

Install Small Seeds Delivery ...................................... 19

Install Side Delivery Tubes ................................ 19

Install Seed Hoses................................................. 19

Install Supports and Walkboard................................. 20

Supports and Walkboard, w/o Small Seeds .......... 20

LH Walkboard Support (w/o SGS)..................... 20

Place Walkboard (w/o SGS) .............................. 21

RH Walkboard Support (w/o SGS) .................... 21

Secure Walkboard (w/o SGS)............................ 22

Supports and Walkboard, w/ Small Seeds ............ 22

Mount LH Support to Walkboard (with SGS) ..... 22

Mount RH Support to Walkboard (with SGS) .... 22

Position Walkboard on Drill (with SGS) ............. 23

Secure Walkboard (w/ SGS).............................. 23

Re-Install Ladder ....................................................... 24

Re-Install Handles ..................................................... 24

Close-Out ................................................................. 25

Apply Decals.............................................................. 25

Check Drive Operation .............................................. 25

Operation.................................................................. 26

Troubleshooting ...................................................... 27

Maintenance and Lubrication................................. 28

Chain Maintenance.................................................... 28

Maintenance .............................................................. 28

Lubrication ................................................................. 29

Appendix .................................................................. 31

New Parts .................................................................. 31

New Parts: Main Kits ............................................. 31

New Parts: Opener Side Delivery Hardware ......... 32

New Parts: Meter to Row Delivery Hardware ........ 32

New Parts: Fertilizer Trays .................................... 32

New Parts: Fertilizer Box and Lid .......................... 34

New Parts: Fertilizer Rate Adjuster Rod Assembly 35

New Parts: Accessory Drive .................................. 35

New Parts: Fertilizer Box Lid Hinge Assemblies.... 36

Existing Parts Affected .............................................. 36

Abbreviations............................................................. 38

Torque Values Chart ................................................. 39

Index ......................................................................... 41

© Copyright 2010 All rights Reserved

Great Plains Manufacturing, Inc. providesthis publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at

the time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

02/24/2010 175-253M

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Page 3

Important Safety Information

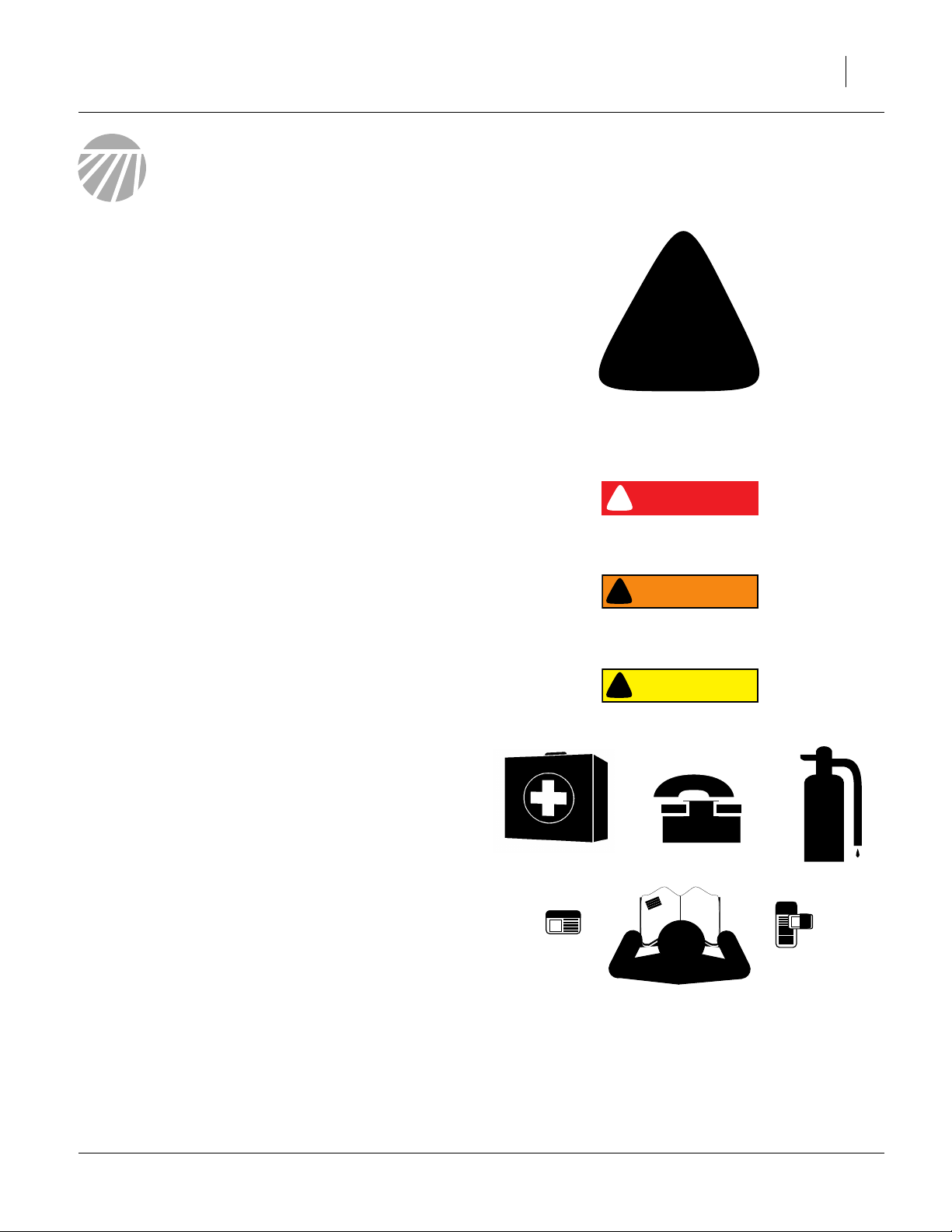

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

!

DANGER

!

WARNING

!

CAUTION

!

1

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

911

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 3, thor-

oughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

02/24/2010 175-253M

Page 4

2 175-248A, -249A, -250A, -251A

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to loud noise can cause hear-

ing impairment or hearing loss, wear suitable hearing protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper use

can seriously injure persons, animals, plants, soil and

property.

▲ Do not use liquid treatments with the fertilizer kit.

▲ Read and follow chemical manufacturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Avoid inhaling smoke from any type of chemical fire.

▲ Never drain, rinse or wash dispensers within 100 feet of a

freshwater source, nor at a car wash.

▲ Store or dispose of unused chemicals as specified by chemi-

cal manufacturer.

▲ Dispose of empty chemical containers properly. Laws gen-

erally require power rinsing or rinsing three times, followed

by perforation of the container to prevent re-use.

175-253M 02/24/2010

Page 5

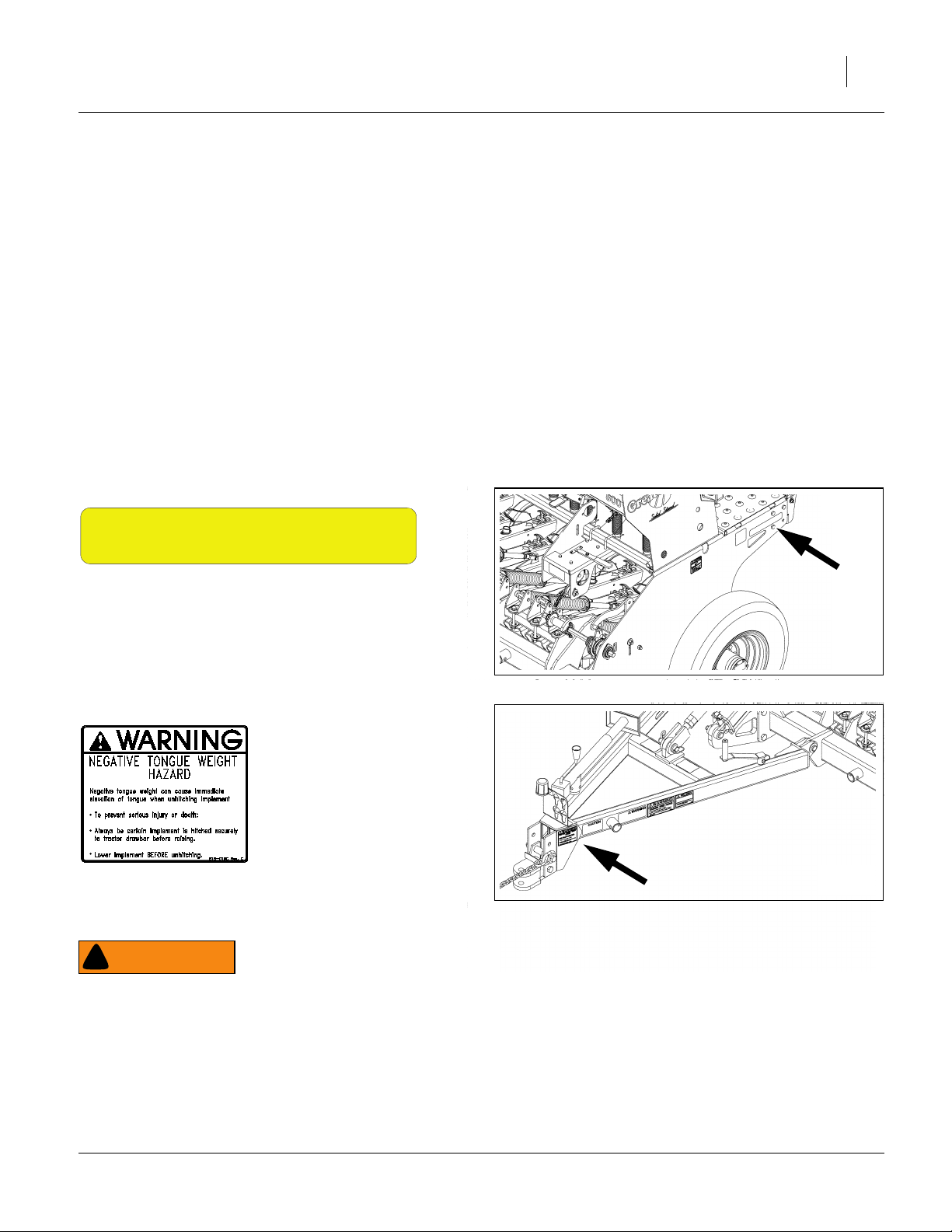

Safety Decals

Safety Reflectors and Decals

The kits covered by this manual may include new safety

decals that need to be applied. Existing safety decals on

the drill also apply during the installation. Both classes of

decals are re-listed here for emphasis.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request cor-

responding safety decals.

3

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

838-265C

Amber Reflectors

On wing walkboard end faces, above steps,

front face of frame, outside corners;

4 total

Kits include new amber reflectors for new walkboard supports.

818-019C

Warning: Negative Tongue Weight

Existing decal on tongue at hitch;

1 total

28203

28203

WARNING

!

Drill Becomes at Risk of Negative Tongue Weight:

An 800EW drill without the Fertilizer option would always

have positive tongue weight. With the Fertilizer option

installed, negative tongue weight is now possible when material is loaded in the fertilizer box, and when weight is on the

new extended walkboard. Unless tractor remains hitched during installation, lower drill before unhitching.

02/24/2010 175-253M

Page 6

4 175-248A, -249A, -250A, -251A

Introduction

The 800EW Fertilizer Kits add the capability to meter dry

fertilizer with the Great Plains 8-Foot End-Wheel Drill.

Material may be metered during seeding, or separately.

The fertilizer rate is independent of seed rates from main

box or Small Seeds box.

Models Covered

Drill Description

800-1275 8-Foot 12-Row 7.5in Spacing

800-1506 8-Foot 15-Row 6in Spacing

Kits Covered

This manual describes installation of four kits. Kits are

provided in two versions for each row spacing:

175-248A 800 FERT 6 FLD INST ON SGS

Use this kit with an 800-1506 drill which also has

the Small Seeds or Agitator options (or when

simultaneously installing another option which

includes an Accessory Drive).

175-249A 800 FERT 6 FLD INST WITH DRIVE

Use this kit with an 800-1506 drill which has only a

Main Seed Box without Agitator (or when simultaneously installing the Small Seeds option version

which does not include an Accessory Drive).

175-250A 800 FERT 7.5 FLD INST ON SGS

Use this kit with an 800-1275 drill which also has

the Small Seeds or Agitator options (or when

simultaneously installing another option which

includes an Accessory Drive).

175-251A 800 FERT 7.5 FLD INST WITH DRV

Use this kit with an 800-1275 drill which has only a

Main Seed Box without Agitator (or when simultaneously installing the Small Seeds option version

which does not include an Accessory Drive).

Note: These kits are for pull-type 8-foot end-wheel drill.

There are separate kits for three-point 8-foot drills.

Notations and Conventions

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

R

F

U

B

L

D

R

Figure 1

800 End Wheel Drill

L

29565

Definitions

The following terms are used throughout this manual.

IMPORTANT !

A crucial point of information related to the preceding

topic. Read and follow the directions to remain safe,

avoid serious damage to equipment and ensure

desired field results.

Note: Useful information related to the preceding topic.

Call-Outs

1 9

to

100

to

11 45

to

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

3-digit callouts in the range 100 to 242 refer-

242

ence new parts from the new parts lists

beginning on page 31.

2-digit callouts in the range 11 to 45 reference affected existing parts from the table

starting on page 36. The descriptions match

those in your Parts Manual. The narrative

and table indicate any re-use of the parts.

175-253M 02/24/2010

Page 7

Before You Start

Drill Compatibility

Refer to Figure 2

1. Check the drill serial number plate to ensure that

the model number is either 800-1275 or 800-1506.

These kits are not compatible with other row spacings, nor with model 3P806NT.

1

Before You Start 5

2

2. Check to see if an Accessory Drive system is

already installed (which is the case if a Main Box Agitator and/or Small Seeds is installed).

The 175-248A and 175-250A kits require that an

Accessory Drive already be present.

The 175-249A and 175-251A kits include an Accessory Drive.

2

Tools Required

• updated drill Parts manual (below) for parts I.D.

• suitable tractor for positioning and lowering drill

• chain lube

• a hoist, or at least four (4) people for large assembly

placement

• basic hand tools, including:

snap ring pliers

punch(es) for seating

Related Documents

To assist installation, and for complete and up-to-date

operating instructions for your fertilizer option, make sure

you have the current editions of the following manuals.

5

⁄

32

in and

1

⁄

in roll pins

4

1

Figure 2

Serial Number, Accessory Drive

29566

175-057M 800EW Owner’s Manual

175-057B 800EW Seed Rate Charts

175-057P 800EW Parts Manual

Updates are available on the Great Plains web, from your

dealer, or directly from Great Plains.

Installing Multiple Options?

If you are also installing a Main Box Agitator and/or the

Small Seeds attachment, perform the work in this order:

A. Agitator

B. Fertilizer

C. Small Seeds

02/24/2010 175-253M

Page 8

6 175-248A, -249A, -250A, -251A

Pre-Assembly Preparation

3. Clean out the Main and Small Seed boxes. These

boxes need to be empty for the installation.

4. Move the drill to a location with:

• room to maneuver large parts around it

• adequate lighting

• clear surface beneath for recovery of any falling or

dropped parts - if the surface is not clear, have a

tarp or drop cloth available

5. Park the drill at the work site. Install the parking jack

if unhitching (and see Warning at right).

6. Lower the openers to eliminate negative tongue

weight hazard.

7. Shut off tractor if left hitched.

CAUTION

!

Agricultural Chemical Hazard:

Installation requires hand work inside the Main seed box, and

if installed, the Small Seeds box. If treated seed has ever been

used in the seed box(es), follow seed or material supplier

instructions for safely removing residue from a seed box.

WARNING

!

Drill Becomes at Risk of Negative Tongue Weight:

An 800EW drill without the Fertilizer option has positive

tongue weight. After the Fertilizer option is installed, negative

tongue weight is possible when material is loaded in the fertilizer box, and possibly during installation when weight is on

the new extended walkboard. Unless tractor remains hitched

during installation, lower drill before unhitching

175-253M 02/24/2010

Page 9

Remove Existing Hardware

Note: Existing hardware may vary slightly from parts

called out in these instructions. Note such changes, so that parts are correctly re-installed.

Remove Existing Hardware 7

Remove Walkboard Ladder

One ladder mount is replaced when the walkboard is remounted. The ladder is re-installed at step 103 on

page 24.

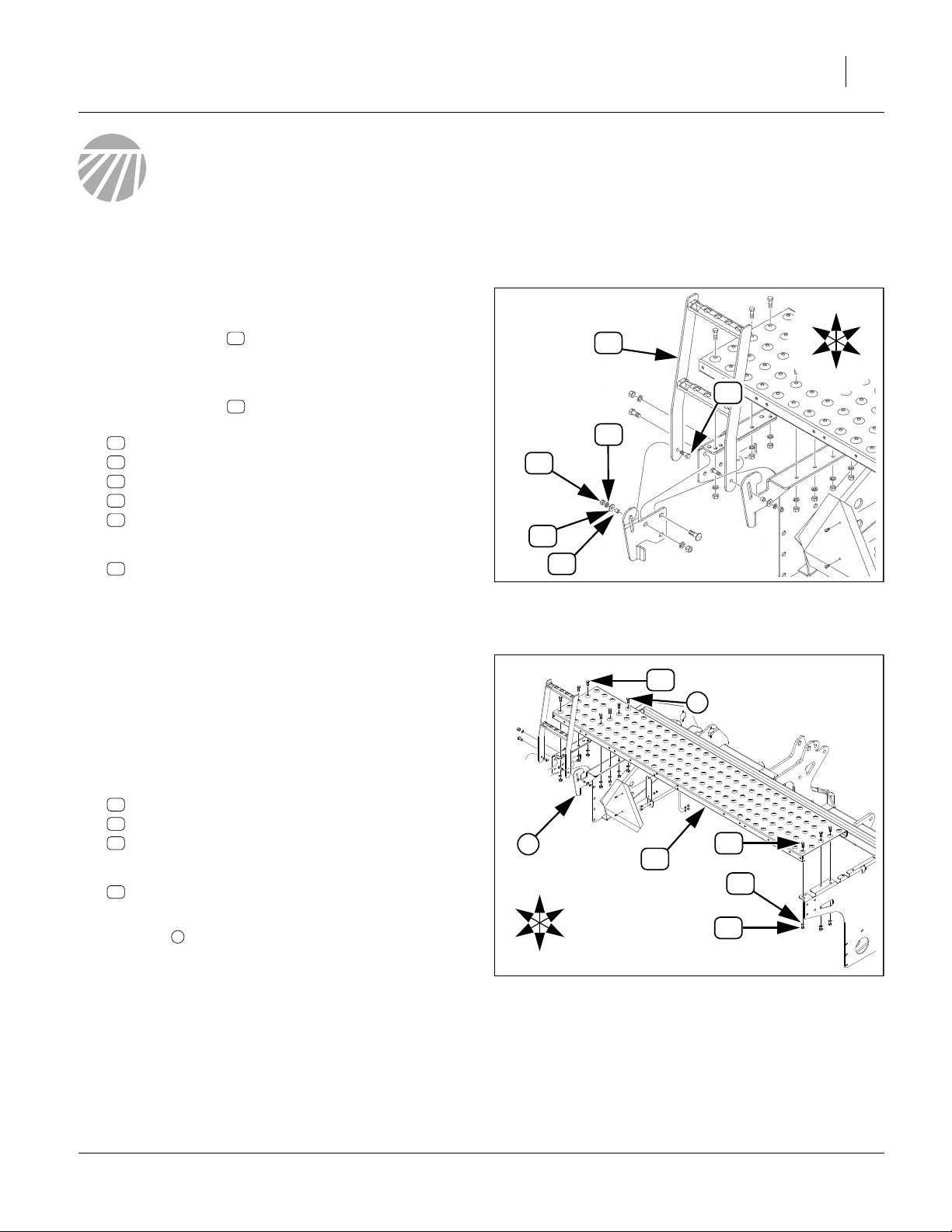

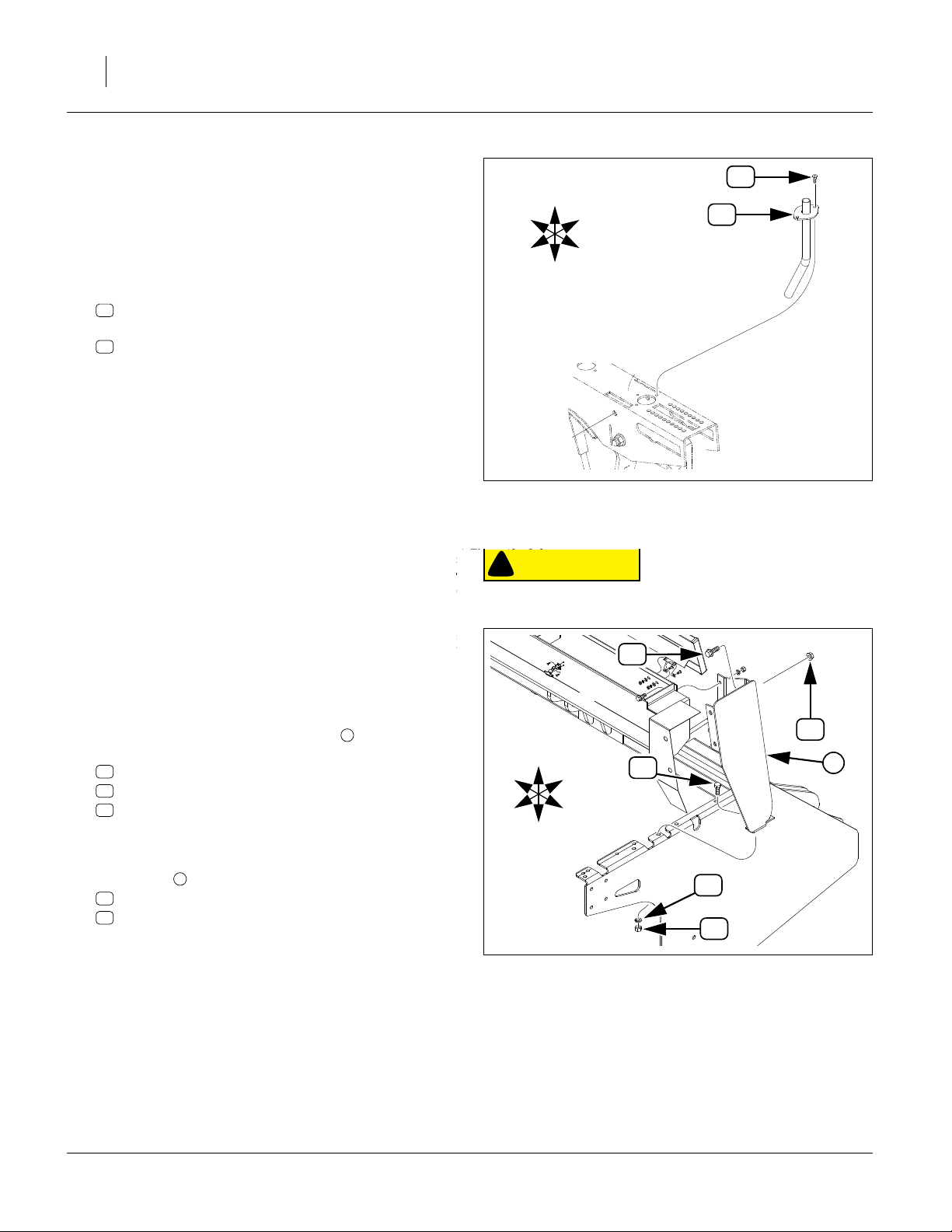

Refer to Figure 3

8. Swing the ladder down, then remove and save

two sets:

35

803-014C NUT HEX 3/8-16 PLT

42

804-013C WASHER LOCK SPRING 3/8 PLT

41

804-011C WASHER FLAT 3/8 USS PLT

12

119-278D

29

802-079C HHCS 3/8-16X1 1/4 GR5

then remove and save the ladder:

13

119-294H 3PT HINGED WALKBOARD LADDER

13

13

WALKBOARD LADDER PIVOT BUSHING

Remove Walkboard

The new fertilizer box mounts where the walkboard is

presently installed, requiring walkboard relocation. The

walkboard is re-installed on new supports at “Install

Supports and Walkboard” on page 20.

Refer to Figure 4

9. Remove and save six (6) sets:

36

803-015C NUT HEX 7/16-14 PLT

43

804-014C WASHER LOCK 7/16 PLT

33

802-673C HHCS 7/16-14X1 1/4 GR5 PLT

then remove and save the:

19

175-411D 8FT EW WALKBOARD

Note: Do not remove the hardware at the right ladder

mount . This mount stays with the walkboard and

is re-used as presently installed on the walkboard.

3

L

B

35

3

41

U

D

12

F

R

13

42

Figure 3

Dismount Ladder

33

3

19

Figure 4

Dismount Walkboard

29

33

36

43

L

B

U

F

R

D

28055

28055

02/24/2010 175-253M

Page 10

8 175-248A, -249A, -250A, -251A

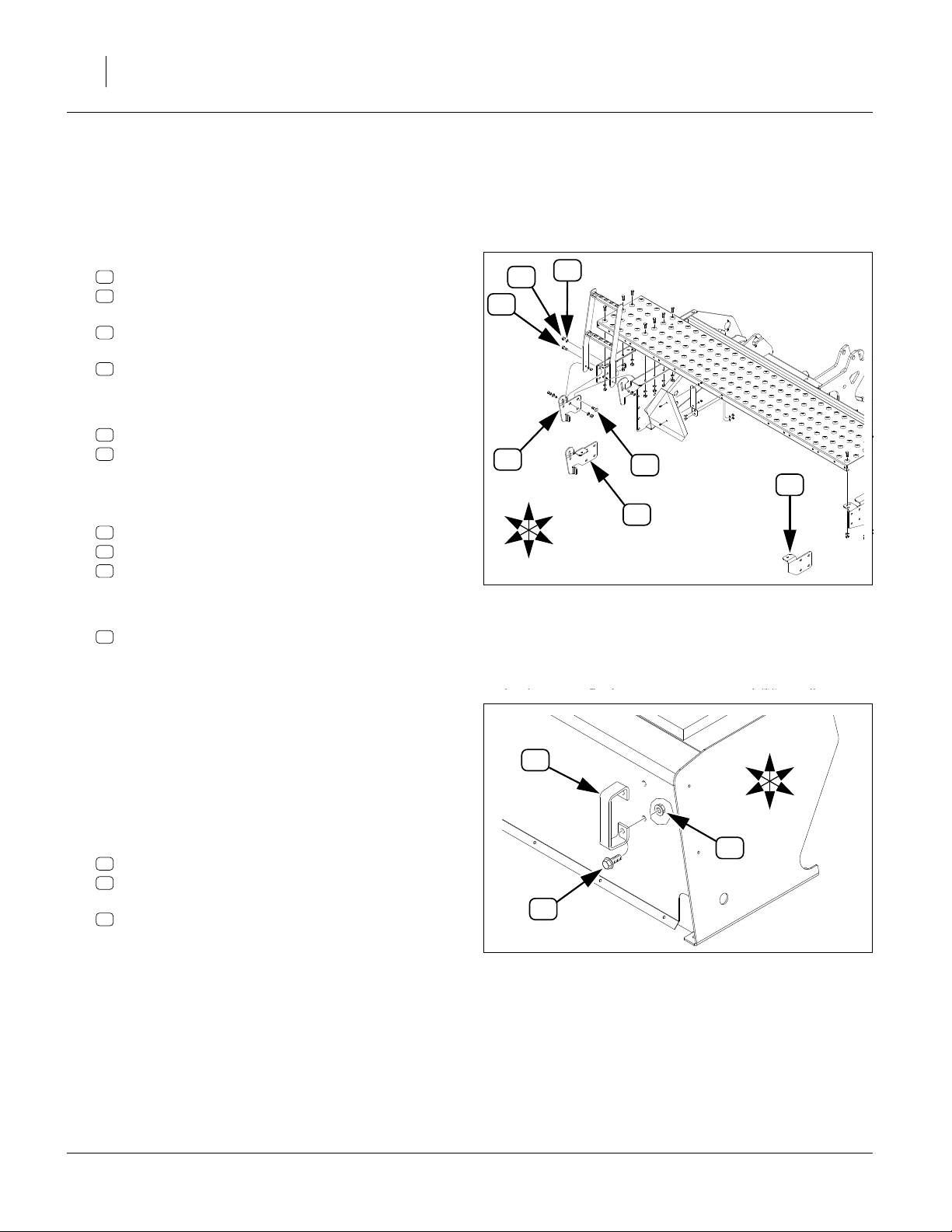

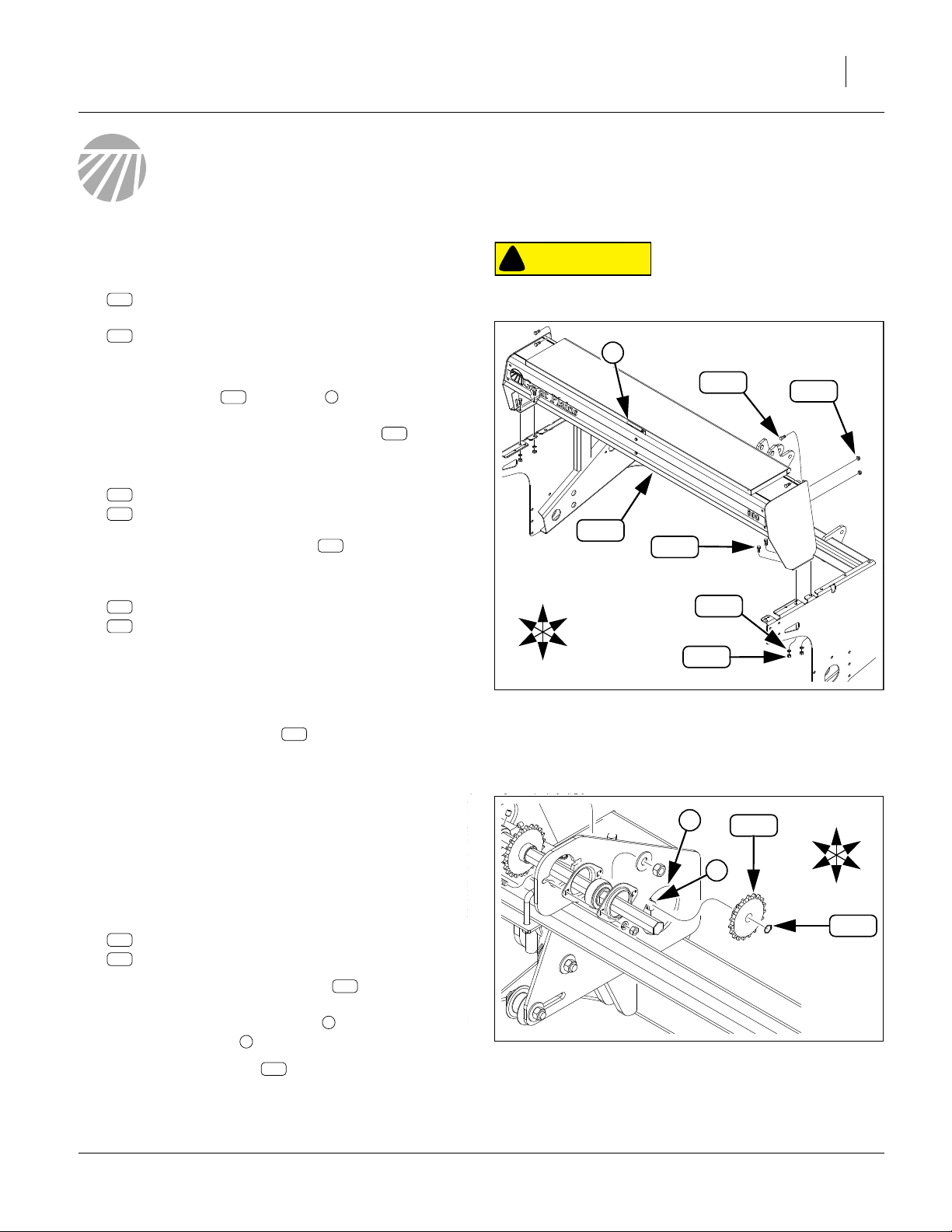

Remove Walkboard Support(s)

All short supports are replaced by longer supports in

“Install Supports and Walkboard” on page 20.

Refer to Figure 5

10. At the left frame, remove and save four (4) sets of:

37

803-020C NUT HEX 1/2-13 PLT

44

804-015C WASHER LOCK SPRING 1/2 PLT

and three (3)

29

802-079C HHCS 3/8-16X1 1/4 GR5

and one (1)

31

802-214C RHSNB 1/2-13X1 1/4 GR5

These parts are not re-used.

Then remove one of:

20

175-413D SEED ONLY LH LADDER MNT

21

175-416D LH WLK BRD SUPP SML SEEDS

This support is not re-used.

11. If the drill has the Small Seeds option, at the right

frame, remove and save four (4) sets of:

37

803-020C NUT HEX 1/2-13 PLT

44

804-015C WASHER LOCK SPRING 1/2 PLT

29

802-079C HHCS 3/8-16X1 1/4 GR5

These parts are not re-used.

Then remove one:

22

175-417D RH WLK BRD SUPP SML SEEDS

This support is not re-used.

29

L

B

20

37

44

31

U

F

21

R

D

Figure 5

Dismount Walkboard Extension(s)

22

28055

Remove Handles

If the Small Seeds attachment is installed, skip to

step 13, as the handles remain on the SGS box after

Fertilizer installation.

Refer to Figure 6

12. At each grab handle on the back corners of the main

seed box, remove and save two sets (four sets total)

of:

30

802-203C HFSS 1/2-13X1 1/2 GR5

38

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

and two:

11

119-190D HANDLE

The handles are re-mounted on the new Fertilizer

box at step 107 on page 24. The lights (not shown in

the Figure) remain on the Main Seed box.

11

30

L

B

38

Figure 6

Dismount Grab Handle

U

F

R

D

18651

175-253M 02/24/2010

Page 11

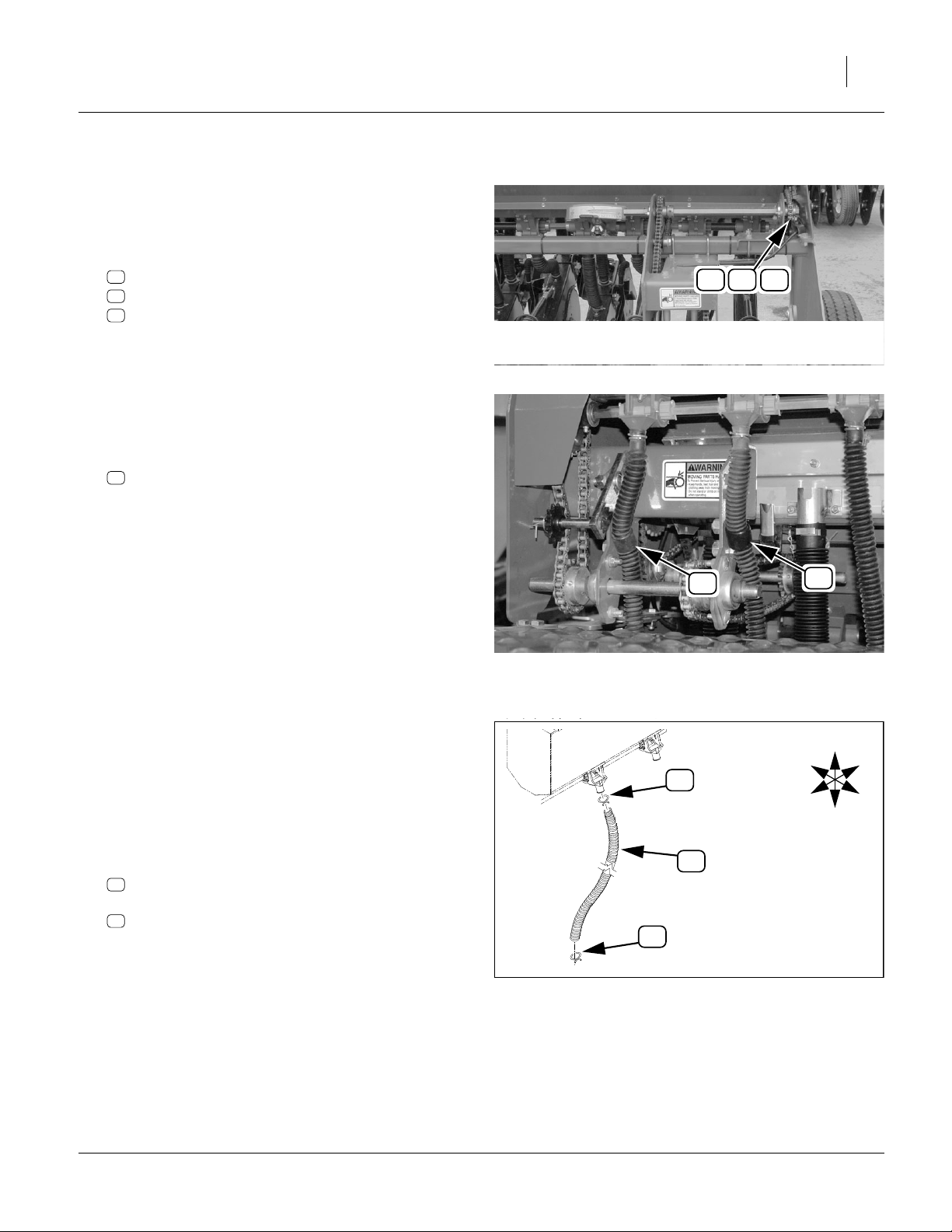

Remove Transmission Chain

If an Accessory Drive system is not yet installed on this

drill, skip to step 21 on page 11.

Refer to Figure 7

13. Remove one of:

16

136-014D CHAIN RL #40 79 PITCHES

17

136-096D CHAIN RL #40 76 PITCHES

18

136-250D CHAIN RL #40 96 PITCHES

This chain is replaced by a new chain in the kit,

which may or may not be the same part number.

Release Hoses Near Drive

Refer to Figure 8

14. Loosen fasteners securing each of two:

23

800-064C HOSE CLIP 13/16 ID

Remove Existing Hardware 9

16 17

Figure 7

Accessory Transmission Chain

18

29566

Disconnect Small Seeds Hoses

If Small Seeds (SGS) is not installed on this drill, continue at step 21 on page 11.

The existing SGS hoses are replaced by new hoses to

side delivery tubes, at step 75 on page 19.

Refer to Figure 9

15. At each row, release and remove two (2) each:

24

800-321C HOSE CLAMP NO.12 3/4 ID

and one (1)

45

816-513C SGS HOSE 85 RIBS

These parts are not re-used.

23

Figure 8

Small Seeds Final Drive

24

45

24

Figure 9

Remove Small Seeds Hose

23

29008

U

F

L

R

B

D

28212

02/24/2010 175-253M

Page 12

10 175-248A, -249A, -250A, -251A

Remove Small Seeds Delivery Tubes

If Small Seeds (SGS) is not installed on this drill, continue at step 21 on page 11.

The existing SGS delivery tubes occupy the row unit hole

required for fertilizer. New SGS side delivery hardware is

installed at step 70 on page 19.

16. At each row, remove two:

25

801-002C SCREW HEX SLT10-16X1/2P.THD CT

and one

14

123-939H SMALL SEEDS TUBE WELDMENT

These parts are not re-used.

Remove Small Seeds Box

If Small Seeds (SGS) is not installed on this drill, continue at step 21 on page 11.

The Small Seeds box is re-mounted, on the new Fertilizer box, at step 63 on page 18.

Refer to Figure 11 (shown in exploded view for clarity - remove only specified fasteners - in particular, do not removethe

jackshaft and final drive assembly at the left end)

17. At each base of the box end mount , remove and

save one sets (two sets total):

28

802-034C HHCS 1/2-13X1 1/4 GR5

44

804-015C WASHER LOCK SPRING 1/2 PLT

37

803-020C NUT HEX 1/2-13 PLT

18. Support the weight of the Small Seeds box.

19. At the upper forward faces of each base of the box

end mount , remove and save two sets (four total):

30

802-203C HFSS 1/2-13X1 1/2 GR5

38

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

20. Remove the Small Seeds box from the drill.

4

4

25

U

F

L

R

B

14

D

Figure 10

Remove Small Seeds Delivery

CAUTION

!

A hoist or at least three (3) people are required. The empty

Small Seeds assembly weighs approximately 200 pounds (91

28212

30

38

L

B

U

F

R

28

4

D

44

37

Figure 11

Dismount Small Seeds Box

28098

175-253M 02/24/2010

Page 13

Install Hardware

Install Fertilizer Box

Install Hardware 11

Refer to Figure 12

21. Select four (4) new:

172

802-034C HHCS 1/2-13X1 1/4 GR5

and one new:

135

142-266L FERT. BOX & LID ASY

(This box should have the 142-264K or 142-267K

tray assembly already mounted.)

22. Position the box , with latch to rear, fully forward against the main seed box (not shown). Tempo-

rarily secure it by inserting the four bolts through

holes in the lower side walls and drill side frames.

23. Select four (4) sets new:

204

804-015C WASHER LOCK SPRING 1/2 PLT

191

803-020C NUT HEX 1/2-13 PLT

Loosely add these to the bolts inserted at

step 22.

24. Select four (4) sets new:

172

802-034C HHCS 1/2-13X1 1/4 GR5

195

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

Insert these through the forward end wall flanges of

the fertilizer box, and into the main seed box holes

left open when removing the handles (step 12) or the

Small Seeds box (step 19).

25. Tighten all eight (8) bolts .

135

1

172

172

172

CAUTION

!

A hoist or at least four (4) people are required. The empty Fertilizer box weighs approximately 300 pounds (136 kg).

1

172

195

135

172

U

L

B

F

R

D

Install Fertilizer Box

204

191

Figure 12

29568

Install Drive System

If an Accessory Drive system is already installed, skip to

“Install Transmission Chain” on page 15, as only the

transmission chain needs to be installed.

Install Gearbox Accessory Sprocket

Refer to Figure 13

26. Select one (1) set new:

219

808-157C SPKT 40B19 X 36T SPLINE BORE

165

800-141C SNAP RING EXT F/PEERLESS G.B.

27. With the flat face of the sprocket to the right

(away from gearbox), place the sprocket through the

gearbox weldment access hole , and onto the front

right gearbox shaft .

28. Secure with snap ring .

02/24/2010 175-253M

3

165

219

2

Gearbox Accessory Sprocket

2

Figure 13

219

3

L

B

U

F

R

D

165

28230

Page 14

12 175-248A, -249A, -250A, -251A

Install Gearbox Accessory Idler/Bearing

Refer to Figure 14

29. Select one (1) set new:

179

802-226C HHCS 1/2-13X2 3/4 GR5

103

120-305D TUBE RND 1 OD X 7/32W X 1.56

229

817-406C IDLER 1 PC 2.38X1.01X1.062

195

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

and three (3) new:

206

804-017C WASHER FLAT 1/2 USS PLT

Place one washer , the tube , the idler

and a second washer on the bolt .

30. Insert this assembly, from drill left, into the vertical

idler slot (not shown) in the right plate of the gear-

box mount weldment.

31. Loosely secure idler assembly with a third

washer and lock nut .

32. Select one (1) new:

235

and two sets new:

232

181

201

188

33. Place the bearing between two flangettes .

Position assembly against the right side of the gear-

box weldment plate at the bearing cutout. Insert

bolts from left, and loosely secure with lock

washers and nuts .

206

822-195C BRG INS 7/8HEXX2.04OD SPH

822-032C FLANGETTE 52 MST

802-282C RHSNB 5/16-18X1 GR5

804-009C WASHER LOCK SPRING 5/16 PLT

803-008C NUT HEX 5/16-18 PLT

181

201 188

206 103 229

206 179

4

195

235 232

4

181

179

206

103

229

206

4

232

235

232

Figure 14

Gearbox Accessory Idler/Bearing

201

L

B

188

U

F

R

D

206

195

28230

175-253M 02/24/2010

Page 15

Pre-Assemble Accessory Shaft Mount

Refer to Figure 15

34. Select one (1) new:

149

175-414D 8FT EW AUX JACK SHAFT MNT

two (2) sets new:

179

802-226C HHCS 1/2-13X2 3/4 GR5

103

120-305D TUBE RND 1 OD X 7/32W X 1.56

229

817-406C IDLER 1 PC 2.38X1.01X1.062

195

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

and six (6) new:

206

804-017C WASHER FLAT 1/2 USS PLT

35. Place one washer , the tube , the idler

and a second washer on each bolt .

36. Insert each idler assembly into the idler slots of

the mount , from the (left) side of the mount

opposite the U-bolt mounting holes . Loosely

secure with lock washers and nuts .

37. Select one (1) new:

235

822-195C BRG INS 7/8HEXX2.04OD SPH

and two sets new:

232

822-032C FLANGETTE 52 MST

181

802-282C RHSNB 5/16-18X1 GR5

201

804-009C WASHER LOCK SPRING 5/16 PLT

188

803-008C NUT HEX 5/16-18 PLT

38. Place the bearing between two flangettes .

Position assembly against the right side of the mount

at the bearing cutout. Insert bolts from left, and

loosely secure with lock washers and nuts .

149

206 103 229

206 179

5

6

206

235 232

195

181

201 188

179

206

206

206

Install Hardware 13

229

103

232

5

195

Figure 15

Accessory Shaft Mount

181

235

149

6

L

B

232

U

F

R

D

188201

28230

Install Accessory Shaft Mount

Refer to Figure 16 (which depicts the completed installation)

39. Select and two (2) new:

214

806-004C U-BOLT 3/8-16 X 2 X 2 3/4

and four (4) sets new:

203

804-013C WASHER LOCK SPRING 3/8 PLT

190

803-014C NUT HEX 3/8-16 PLT

40. Position the accessory shaft mount , with the

bearing/idler break up and to drill left, on the top of

the front top tool bar , left of the gearbox. Loosely

secure with U-bolts , lock washers and

190

nuts .

41. Adjust the mount horizontally until there is a gap of:

02/24/2010 175-253M

3

2

2

⁄

in (52.4mm)

32

between the left face of the bearing/idler plate and

the right edge of the drill’s end wall breaks . It may

be necessary to adjust or relocate a cable , to

reach final mount position.

1

214

149

203

3

4

1

203

214

Figure 16

Install Accessory Shaft Mount

190

149

3

4

2

29562

Page 16

14 175-248A, -249A, -250A, -251A

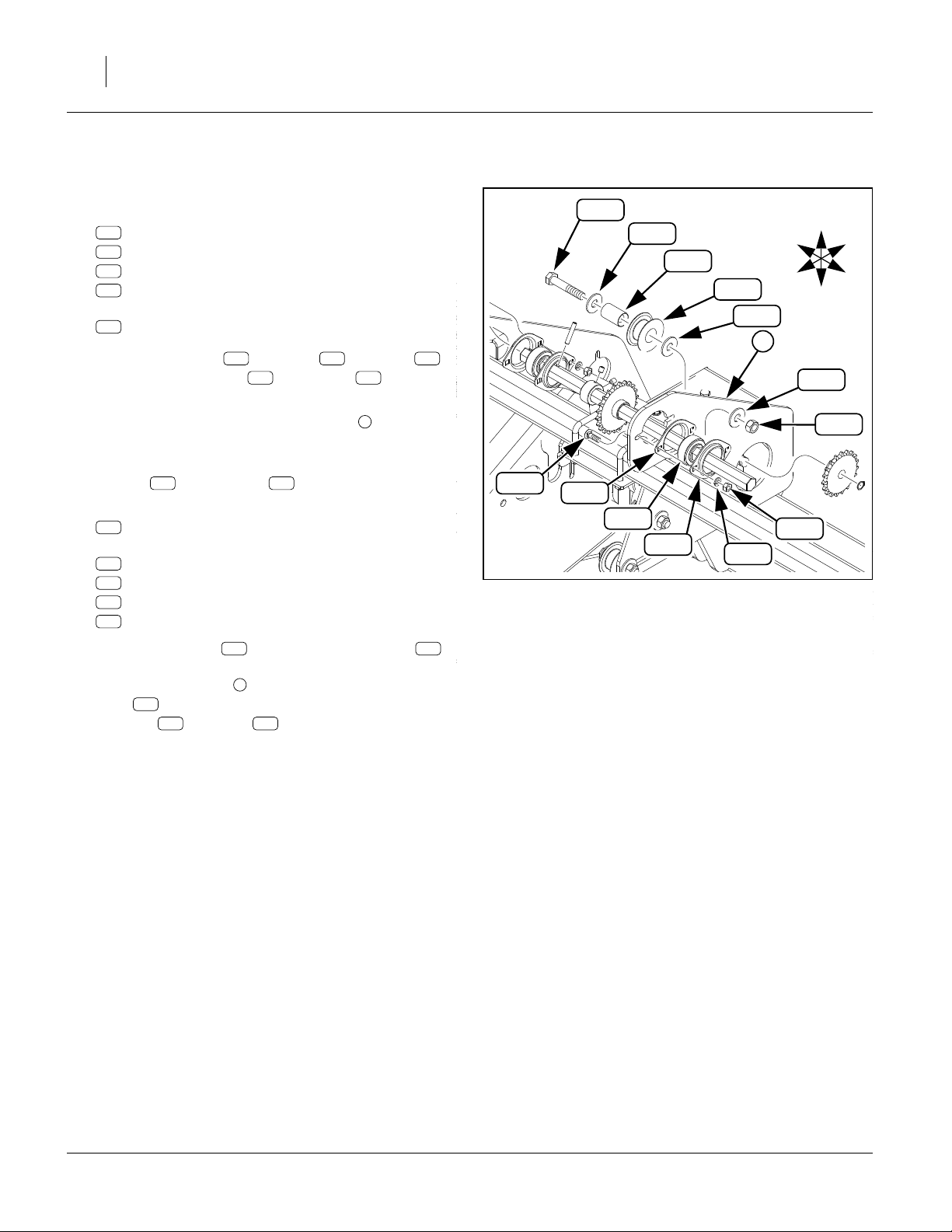

Install Accessory Shaft and Sprockets

Refer to Figure 17

42. Select one (1) each new:

150

175-415D 8FT EW AUX JACK SHAFT

222

808-250C SPKT 40C22 X 7/8 HEX BORE

159

402-058D COLLAR LOCK 7/8 HEX

43. One end of the shaft has two holes ( and ).

150

Insert this end, from drill right, through the right

(jackshaft input) bearing .

7

5 6

213

221

U

L

8

B

213

F

R

D

As the shaft clears the input bearing , add the

22T input sprocket . There is no preference on

150

222

7

hub orientation.

Continue inserting shaft, and add the lock collar .

Continue inserting the shaft through the left (jackshaft output) bearing . Leave the right shaft pin

6

hole visible on the right side of the output

bearing .

8

8

44. Select one (1) new:

213

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Check that the right shaft hole is on the right side

of the output bearing . Drive the pin through

the right hole in the shaft . Slide the shaft fully

5

8

to drill left, against the pin .

5

213

150

213

45. Select one (1) new:

221

808-219C SPKT 40C12 X 7/8 HEX BORE

Add the 12T output sprocket to the left end of

the shaft . There is no preference on hub orienta-

150

221

tion.

46. Select one (1) new:

213

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

159

6

5

159

Figure 17

Accessory Shaft

170

222

7

150

28230

Check that the left shaft hole is on the left side of

the output sprocket . Drive the pin through

the left hole in the shaft .

6

221

6

213

150

47. Check that shaft spins freely, and tighten the four

nuts holding the flangettes.

48. If not already present in the lock collar , select

159

two (2) new:

170

801-035C SCREW SET 5/16-18 SKT KP X 3/8

Slide the lock collar fully to drill right and secure with

set screws .

175-253M 02/24/2010

170

Page 17

Install Hardware 15

Install Gearbox Output Chain

Review chain clip and slack reference information on

page 28 before installation.

Refer to Figure 18

49. Select one (1) new:

111

136-036D CHAIN RL #40 70 PITCHES

Route chain :

around gearbox accessory sprocket ,

around accessory shaft input sprocket , and

over gearbox accessory idler .

50. Adjust idler for recommended slack.

111

219

222

229

229

Install Transmission Chain

51. Select one new:

113

136-250D CHAIN RL #40 96 PITCHES

Routing - Fertilizer Only If optional Agitator is installed, continue at “Routing -

Fertilizer and Agitator”.

Refer to Figure 19

52. Observing the clip orientation instructions on page

13, route the chain :

around accessory shaft output sprocket ,

around fertilizer jackshaft shaft input sprocket ,

under rear idler , and

over front idler .

53. Continue at step 55.

113

221

220

229

229

221

229

222

111

229

219

Figure 18

Gearbox/Jackshaft Chain Routing

113

229

Figure 19

Fertilizer Chain Routing

220

U

F

B

D

28304

U

F

B

D

28305

Routing - Fertilizer and Agitator

If optional Agitator is not installed, use the steps at

“Routing - Fertilizer Only” above.

Refer to Figure 20

54. Observing the clip orientation instructions on page

13, route the chain :

around accessory shaft output sprocket ,

over agitator shaft input sprocket ,

around fertilizer jackshaft shaft input sprocket ,

under rear idler , and

over front idler .

55. Adjust idlers for recommended slack.

02/24/2010 175-253M

113

221

9

220

229

229

229

221

229

229

Fertilizer+Agitator Chain Routing

9

Figure 20

113

F

220

U

B

D

28307

Page 18

16 175-248A, -249A, -250A, -251A

Adjust Final Drive Chain Slack

Refer to Figure 21

Although the final drive chain on the fertilizer box is

factory-installed, it may not be adjusted for ideal slack.

56. Review chain clip and slack reference information on

page 28. Adjust idler for recommended slack.

112

229

112

F

229

U

B

D

Install Fertilizer Delivery

Small Seeds hoses, if present, are reconnected at

step 77 on page 19.

Install Delivery Tubes

Tubes may be oriented forward or backward, based on

user preference and other installed options.

Refer to Figure 22

57. At each row unit, select one (1) each new:

107

133-065D SML SDS TB REINFORCEMENT RING

228

817-346C PLASTIC FERTILIZER TUBE

and two (2) new:

168

801-002C SCREW HEX SLT10-16X1/2P.THD CT

Insert the fertilizer tube in the rear delivery

2

hole of the opener frame. Add a reinforcement

107

ring and secure with two self-tapping

screws .

168

228

Figure 21

Fertilizer Final Chain Routing

168

2

Figure 22

Fertilizer Delivery Tube

28305

107

228

16459

175-253M 02/24/2010

Page 19

Install Delivery Hoses

Start with the left-most fertilizer meter (row 1) on the drill,

and complete both of the step 58 through step 61 for

each row before moving to the next row. Meters are not

always directly above the rows they serve.

Refer to Figure 23

58. At each row unit, select one (1) each new:

162

800-016C

223

816-239C SEED HOSE 56 RIBS X 11 LONG

UPPER FERT HOSE CLAMP RATCHET

Install Hardware 17

3

One end of the hose has a 1

and the other end a 1

clamp onto the larger 1

162

59. Slide the larger 1

223

1

⁄

in (31.8mm) I.D. Slide the

4

1

⁄

in end of the hose fully (about 2in

2

or 5cm) onto to the fertilizer drop tube for the cur-

1

⁄

in (38.1mm) I.D.,

2

1

⁄

in end of the hose.

2

3

rent row.

Slide the clamp until it is centered about 1in (2.5cm)

below the end of the hose. Tighten the clamp.

60. Select one (1) new:

160

800-008C CLAMP HOSE 1 1/2 NO. 24

Open this clamp and slide it fully onto the smaller

1

1

⁄

in end of the hose, up against the ribs.

4

61. Slide the smaller 1

top of the fertilizer tube .

Open the clamp and release it about

above the reinforcement ring , measured near

the screw .

168

1

⁄

in end of the hose fully over the

4

228

1

⁄

in (13mm)

2

107

62. Repeat step 58 through step 61 for each row.

168

Figure 23

Fertilizer Delivery Hose

162

223

160

107

228

16459

02/24/2010 175-253M

Page 20

18 175-248A, -249A, -250A, -251A

Re-Install Small Seeds Box

If the drill did not previously have a Small Seeds box

installed, continue at “Re-Install Ladder” on page 24.

Refer to Figure 24

63. Check that the four

the upper corners of the rear face of the fertilizer box

are open. If not remove any fasteners used to plug

those holes. This hardware is not re-used.

64. Select four (4) sets saved:

30

802-203C HFSS 1/2-13X1 1/2 GR5

38

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

65. Position the Small Seeds box , with lid latches (not

shown) to the rear, directly behind the new fertilizer

box. Insert bolts through forward face of end

plates, through handle holes in fertilizer box. Loosely

secure with lock nuts .

66. Select four (4) sets saved:

28

802-034C HHCS 1/2-13X1 1/4 GR5

44

804-015C WASHER LOCK SPRING 1/2 PLT

37

803-020C NUT HEX 1/2-13 PLT

67. Insert bolts through lower break of Small Seeds

box end plates, and then through top break of side

frame. Add lock washers and nuts . Tighten all

eight nuts ( , ).

28

37 38

9

/

in (14mm) handle holes at

16

2

30

38

44 38

1

CAUTION

!

A hoist or at least three (3) people are required.

The empty Small Seeds assembly weighs approximately

200 pounds (91 kg).

30

38

2

28

1

U

L

B

F

R

D

Figure 24

Re-mount Small Seeds Box

44

37

29569

Install SGS to Fertilizer Chain

If the drill did not previously have a Small Seeds box

installed, continue at “Re-Install Ladder” on page 24.

Review chain clip and slack reference information on

page 28 before installation.

Refer to Figure 25

68. Select one (1) new:

110

136-014D CHAIN RL #40 79 PITCHES

Route chain :

around fertilizer jackshaft output sprocket ,

around SGS jackshaft input sprocket , and

over SGS input idler .

69. Adjust idler for recommended slack.

110

217

17T

12i

12i

110

217

Figure 25

Fertilizer-SGS Chain Routing

F

U

B

D

17T

12i

28307

175-253M 02/24/2010

Page 21

Install Small Seeds Delivery

If the drill did not previously have a Small Seeds box

installed, continue at “Re-Install Ladder” on page 24.

197

Install Hardware 19

3

Install Side Delivery Tubes

Start with the left-most row unit.

Refer to Figure 26 (fertilizer delivery tube not depicted)

70. For each row, select one each new:

108

133-128H SGS SIDE DELIVERY TUBE

185

802-427C HFS 3/8-16X3 3/4 SPTHD

197

803-209C NUT FLANGE LOCK 3/8-16 PLT

71. Orient the side tube weldment with the delivery

tube to the left of the row unit, and the mount ahead

of the fertilizer delivery tube hole .

72. Insert a bolt through mount and the row unit

frame at hole . Secure with lock nut .

73. Repeat step 70 through step 72 for each row unit.

185

4

108

3

197

Install Seed Hoses

Start with the left-most row unit (row 1).

74. At rows 1 and 2, route the hose through clips of

the SGS final drive as shown in Figure 8 on page 9.

Refer to Figure 27

75. Select one new:

224

816-513C SGS HOSE 85 RIBS

and two new:

166

800-321C HOSE CLAMP NO.12 3/4 ID

23

108

185

4

U

R

F

B

L

D

Figure 26:

Small Seeds Side Delivery Tube

with Fertilizer

Note: Feeder cups may not be directly above the row unit

to which their hose connects.

27450

76. Open a hose clamp and place it over an end of

the hose . Move the clamp down to the start of

the ribbed section.

77. Slide the top of the hose onto the meter drop

tube of the fluted feed cup for that row, so that the

hose completely covers the straight portion of the

exit tube. Open the clamp and position it about

(6mm) above the bottom of the exit tube.

At rows 1 and 2, tighten hose clips (see Figure 8

on page 9).

78. Open a hose clamp and place it over the other

end of the hose . Move the clamp up from the

end of the hose.

79. Slide the bottom end of the hose onto the top of

the delivery tube , so that it completely covers the

exposed portion of the tube. Open the clamp and

position it about

hose.

80. Repeat step 75 through step 79 for each row unit.

02/24/2010 175-253M

224

5

166

224

23

166

224

224

6

1

⁄

in (13mm) from the end of the

2

5

166

1

⁄

in

4

L

B

U

224

6

F

R

166

D

Figure 27:

Small Seeds Drop Tubes

29576

Page 22

20 175-248A, -249A, -250A, -251A

Install Supports and Walkboard

Steps depend on drill configuration. The edge channels

of the walkboard wrap around support and/or frame

breaks. Using a specific order eases the tasks.

• If Small Seeds was not installed on the drill, continue

at step 81 below.

• If Small Seeds was installed on the drill, continue at

step 95 on page 22.

The decal application is covered in a later section of this

manual.

Supports and Walkboard, w/o Small Seeds

LH Walkboard Support (w/o SGS)

Refer to Figure 28

81. Select one (1) each new:

120

142-077D LH WLK BRD SUPP FERT

178

802-214C RHSNB 1/2-13X1 1/4 GR5

204

804-015C WASHER LOCK SPRING 1/2 PLT

191

803-020C NUT HEX 1/2-13 PLT

82. Position the support , break up, inside the left

side rear frame. Insert the round head bolt , from

outside drill left, at the top front hole . Loosely

secure with lock washer and nut .

83. Select and three (3) sets new:

172

802-034C HHCS 1/2-13X1 1/4 GR5

204

804-015C WASHER LOCK SPRING 1/2 PLT

191

803-020C NUT HEX 1/2-13 PLT

Insert hex head bolts from the outside, at the

remaining support-to-frame holes. Loosely secure

with lock washer and nut .

120

204

172

204 191

178

6

191

172

178

6

120

Figure 28

Walkboard Left Support (w/o SGS)

204

L

B

191

U

F

R

D

29572

175-253M 02/24/2010

Page 23

Place Walkboard (w/o SGS)

Refer to Figure 29

84. Two people are needed for the next three steps.

Select the saved:

19

175-411D 8FT EW WALKBOARD

and two saved:

33

802-673C HHCS 7/16-14X1 1/4 GR5 PLT

85. Elevate walkboard above side frames. Slide the left

end of the walkboard over the top break of the left

support and over the rear tab of the left side

frame top break. Insert a bolt in the front left end

tread hole.

86. Lower right front channel of walkboard into gap

ahead of rear tab of right frame top break. Insert a

bolt in the front right end tread hole.

120

33

19

7

33

8

L

120

U

Install Hardware 21

7

8

33

19

33

F

RH Walkboard Support (w/o SGS)

Refer to Figure 30

87. Select one (1) each new:

119

142-064D RH WLK BRD SUPP FERT

178

802-214C RHSNB 1/2-13X1 1/4 GR5

204

804-015C WASHER LOCK SPRING 1/2 PLT

191

803-020C NUT HEX 1/2-13 PLT

88. Maneuver the support so that the top break is

between the walkboard channels and the face with

the four bolt slots is inside the right drill frame.

89. Insert the round head bolt from the outside

(right) at the top front bolt hole. Loosely secure with

lock washer and nut .

90. Select and three (3) sets new:

172

802-034C HHCS 1/2-13X1 1/4 GR5

204

804-015C WASHER LOCK SPRING 1/2 PLT

191

803-020C NUT HEX 1/2-13 PLT

Insert hex head bolts from the outside, at the

remaining support-to-frame holes. Loosely secure

with lock washer and nut .

204 191

119

178

172

204 191

B

R

D

Figure 29

Position Walkboard (w/o SGS)

191

204

Figure 30

RH Walkboard Support (w/o SGS)

178

L

B

29572

U

F

R

D

172

119

29572

02/24/2010 175-253M

Page 24

22 175-248A, -249A, -250A, -251A

Secure Walkboard (w/o SGS)

Refer to Figure 31

91. Select four (4) saved:

33

802-673C HHCS 7/16-14X1 1/4 GR5 PLT

33

19

Insert bolts in rear corner, and center end tread

holes of walkboard .

92. Select six (6) sets saved:

43

804-014C WASHER LOCK 7/16 PLT

36

803-015C NUT HEX 7/16-14 PLT

Add lock washers and nuts to all walkboard

bolts.

93. Tighten all walkboard and support bolts.

94. Continue at “Re-Install Ladder” on page 24.

33

19

43 36

Supports and Walkboard, w/ Small Seeds

Mount LH Support to Walkboard (with SGS)

Refer to Figure 32

95. Select one (1) each new:

138

142-298D RH WLK BRD SUPP SML SDS-FERT

the saved:

19

175-411D 8FT EW WALKBOARD

and three (3) sets saved:

33

802-673C HHCS 7/16-14X1 1/4 GR5 PLT

43

804-014C WASHER LOCK 7/16 PLT

36

803-015C NUT HEX 7/16-14 PLT

96. With the break up, and the slotted end to the rear,

mount the LH support under the top left edge of

the walkboard . Insert bolts from above

through tread holes. Loosely secure with lock

washers and nuts .

19 33

43 36

138

36

43

36

Figure 31

Secure Walkboard (w/o SGS)

138

33

43

Figure 32

Walkboard LH Support (w/ SGS)

33

19

L

B

29572

U

F

R

D

29573

Mount RH Support to Walkboard (with SGS)

Refer to Figure 33

97. Select one (1) new:

139

142-312D LH WLK BRD SUPP SML SDS-FERT

and three (3) sets saved:

33

802-673C HHCS 7/16-14X1 1/4 GR5 PLT

43

804-014C WASHER LOCK 7/16 PLT

36

803-015C NUT HEX 7/16-14 PLT

98. With the break up, and the four-hole end to the front,

mount the LH support under the top left edge of

the walkboard . Insert bolts from above

through tread holes. Loosely secure with lock

washers and nuts .

175-253M 02/24/2010

19 33

43 36

138

43

36

Walkboard RH Support (w/ SGS)

19

33

Figure 33

B

U

L

F

R

D

139

29573

Page 25

Position Walkboard on Drill (with SGS)

Two people are needed for the next two steps.

Refer to Figure 34

99. Select and two (2) sets new:

172

802-034C HHCS 1/2-13X1 1/4 GR5

204

804-015C WASHER LOCK SPRING 1/2 PLT

191

803-020C NUT HEX 1/2-13 PLT

100.Maneuver the walkboard/support assembly so that

the four-hole bolt faces of the supports are inside

the rear side frames.

At each side, insert one hex head bolt from the

outside, at the upper rear hole. Loosely secure with

lock washer and nut .

204 191

9

172

Install Hardware 23

172

9

204

191

L

B

U

F

R

D

191

172

204

9

Secure Walkboard (w/ SGS)

Refer to Figure 35

101.Select four (4) sets new:

172

802-034C HHCS 1/2-13X1 1/4 GR5

204

804-015C WASHER LOCK SPRING 1/2 PLT

191

803-020C NUT HEX 1/2-13 PLT

Insert hex head bolts from the outside, at the

remaining support-to-frame holes. Loosely secure

with lock washer and nut .

102.Tighten all walkboard and support bolts.

172

204 191

191

Figure 34

Position Walkboard (w/ SGS)

1

204

Figure 35

Secure Walkboard (w/ SGS)

29573

172

29573

02/24/2010 175-253M

Page 26

24 175-248A, -249A, -250A, -251A

Re-Install Ladder

Refer to Figure 36

103.Select the saved:

13

119-294H 3PT HINGED WALKBOARD LADDER

and two saved:

29

802-079C HHCS 3/8-16X1 1/4 GR5

104.Position the ladder inverted (pivot holes at bottom), and with the side frame bend tipped forward,

between the slotted holes in the left end walkboard supports.

Hole in place by inserting the bolts through the

ladder pivot holes and support slots.

105.Select two (2) saved:

12

119-278D

13

9

29

WALKBOARD LADDER PIVOT BUSHING

13

9

29

Add a bushing to each bolt . Press the bushing

into the support slots.

106.Select two (2) sets saved:

41

804-011C WASHER FLAT 3/8 USS PLT

42

804-013C WASHER LOCK SPRING 3/8 PLT

35

803-014C NUT HEX 3/8-16 PLT

Add a flat washer , then lock washer to each

29 35

bolt . Secure with nuts .

12 29

41 42

Re-Install Handles

If Small Seeds is also installed, skip step 107 (handles

are already installed on the Small Seeds box).

Refer to Figure 37

107.Select two saved:

11

119-190D HANDLE

and four (4) sets saved:

30

802-203C HFSS 1/2-13X1 1/2 GR5

38

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

Position each the handle at the

handle holes at the upper corners of the rear face

of the fertilizer box. Insert a bolt from the outside

of the box, and secure with lock nuts inside the

box.

1

11

9

30

/

in (14mm)

16

38

L

B

U

D

11

30

9

F

12

R

Figure 36

Re-install Ladder

Figure 37

Re-install Grab Handle

41

1

42

L

B

38

35

29569

U

F

R

D

18651

175-253M 02/24/2010

Page 27

Close-Out

Apply Decals

Refer to Figure 38

108.At the new walkboard supports, clean, de-grease

and dry the outside faces .

109.Select two each new:

238

838-265C

DECAL REFLECTOR AMBER 1 1/2X9

At the right end of the walkboard, peel the release

paper from the back of the decal , and apply the

decal centered below the two unused holes.

At the left side, similarly apply the other decal (there

may be no holes for alignment).

1

238

Close-Out 25

1

191

Check Drive Operation

Refer to Figure 39

110.Check drive system operation with calibration crank.

The crank is now turning the fertilizer flutes as well

as the seed meters, and may require more effort. If

the effort is • excessive, check for:

• bearing centering and shaft alignment,

• insufficient chain slack,

• lock collar rubbing,

• chain rubbing and binding, and

• fouling of agitator paddles.

111.Perform a fertilizer box rate calibration. Use insert

test material unless fertilizer application is planned

within 24 hours.

112.Readjust chain slack after the first 8 hours of operation.

Fi S

Figure 38

Apply Amber Decals

Figure 39

Calibration Crank

29571

28068

02/24/2010 175-253M

Page 28

26 175-248A, -249A, -250A, -251A

Operation

The fertilizer metering system normally operates whenever the drill is in forward motion and lowered to field

position.

Fertilizer rate is set with the adjuster knob at the center

rear of the fertilizer box (below the Small Seeds box if

installed).

Fertilizer rate adjustment details, calibration procedure,

and rate charts, are found in the Model 800 Seed Rate

Manual (175-057B).

Fertilizer rate is independent of Drive Type selected at

the gearbox (the Accessory Shaft is driven from the input

side of the gearbox).

If fertilizer is not being applied, Great Plains recommends emptying and cleaning out the fertilizer box. You

can also disable the box by removing a chain in the

Accessory drive system - this may also disable the main

box Agitator or Small Seeds, if installed.

You can temporarily suspend fertilizer application by setting the rate adjuster to zero. This is not recommended

for more than brief operations.

IMPORTANT !

Always clean out the fertilizer box at completion of

application. Most fertilizers are corrosive, and only the

meter portion of the fertilizer option is fabricated from

stainless steel. The upper fertilizer box can be damaged if fertilizer is allow to stand for extended periods

of time.

175-253M 02/24/2010

Page 29

Troubleshooting

See also: “Troubleshooting” topic in the drill Operator Manual.

Problem Causes Solutions

No material flow

(all rows)

Incorrect Material Flow

(fewer than all rows)

Material Flow Irregular Material granularity too large for rate control

Material Flow too Low Planting per chart rate only Calibrate

Material Flow too High Planting per chart rate only Calibrate

Drill drive clutch not engaged Clean and lubricate clutch mechanism.

No material loaded Re-load material. Check setting and review

calibration if run-out was unexpected.

Old material has congealed across box Clean-out box. Replace material.

Rate Adjuster set to zero Set rate adjuster. Calibrate if not already

done.

Material granularity too large for rate control

gate opening - usually due to moisture causing clumping

Broken chain Inspect all chains. Adjust slack.

System jammed, usually due to solidified

congealed material left in fertilizer box

Obstruction in meter gate Clean-out materials. Remove foreign matter.

Plugged hoses Disconnect hoses and clear.

Old material has congealed at some rows Clean-out box. Replace material.

Broken meter flutes Clean-out box. Inspect and replace worn or

gate opening - usually due to moisture causing clumping

Material adhering to meter flutes Clean-out box. Inspect and clean flutes. Use

Check tire size and inflation

Ground speed too low or too high Plant at a reasonable speed.

Skipping chains Inspect all chains. Adjust slack.

Conditions may be too wet Wait for dryer conditions.

Check tire size and inflation

Excessive gaps between passes Check that pass gap is one row space.

Meter flutes worn Clean-out box. Inspect and replace worn or

Pass overlaps Check that pass gap is one row space.

Meter flutes worn (allowing too much mate-

rial to pass)

Replace with dry material.

Clean out box. Wash and dry meter flutes. In

extreme cases, this may require meter disas-

sembly.

damaged flutes.

Replace with dry material.

dry material.

damaged flutes.

Clean-out box. Inspect and replace worn or

damaged flutes.

Troubleshooting 27

02/24/2010 175-253M

Page 30

28 175-248A, -249A, -250A, -251A

Maintenance and Lubrication

Chain Maintenance

Initially check the drive chains after the first 10 hours of

drill use. The slack of new chains tends to increase during the first few hours of operation due to seating. Thereafter, check the chains every 100 hours.

Lubricate chains any time there is a chance of moisture,

and when being stored at the end of the planting season.

Chain Slack

Refer to Figure 40, which, for clarity, greatly exaggerates

slack, and omits the idlers.

1. Measure the span for allowable slack:

Locate the longest span of each chain (usually the

span which does not run through the idlers).

2. Determine the ideal slack:

Long chains (over 91cm/36in): 2.1cm/m (

Vertical short chains: 2.1cm/m (

Horizontal short chains: 4.2cm/m (

3. Measure the current slack :

Acting at a right angle to the chain span at the center

of the span, deflect the chain in both directions. The

slack is the distance of the movement.

4. Adjust the idlers for ideal slack.

Whenever mounting a chain, make sure the clip at the

removable link is oriented to minimize snags.

Refer to Figure 41 (arrow shows chain direction)

Install clip with open end facing away from direction of

chain travel (shown by gray or striped arrows in chain

routing diagrams).

1

1

⁄

in per ft)

1

⁄

in per foot)

4

1

⁄

2

2

4

in per foot).

1

2

Figure 40

Measuring Chain Slack

Figure 41

Chain Clip Orientation

27264

26482

175-253M 02/24/2010

Page 31

Lubrication

Maintenance and Lubrication 29

Multipurpose

spray lube

Multipurpose

grease lube

Fertilizer Shaft Bearings

15

1 zerk each bearing, 2 per shaft;

2 total

Type of Lubrication: Grease

Quantity: Until resistance is felt

Note: If Small Seeds is also installed, access these zerks

from below.

Felt Barrier Seals

30

16381

Multipurpose

oil lube

Intervals (service hours) at

which lubrication is required

50

16381

1 seal at each shaft end, 2 total

Type of Lubrication: Oil

Quantity: Soak seal

Note: If Small Seeds is also installed, access these zerks

from below or through the end wall gaps.

Gearbox Bypass Chain

As Required

1 chain:

Type of Lubrication: Chain Lube

Quantity: Coat thoroughly

28293

02/24/2010 175-253M

Page 32

30 175-248A, -249A, -250A, -251A

Option Transfer or Drive Chain

As Required

1 chain:

Type of Lubrication: Chain Lube

Quantity: Coat thoroughly

Fertilizer to SGS Transmission Chain

As Required

1 chain:

Type of Lubrication: Chain Lube

Quantity: Coat thoroughly

28295

29008

175-253M 02/24/2010

Page 33

Appendix

New Parts

New Parts: Main Kits

175-248A 800 FERT 6 FLD INST ON SGS

175-249A 800 FERT 6 FLD INST WITH DRIVE

Quantity in Kit 175-

Part

Callout

100

106

109

110

112

113

117

118

119

120

124

132

135

136

137

138

139

146

148

172

176

178

191

193

195

204

205

209

211

220

226

238

239

-248A

-249A

-250A

1 1 1 1 175-253M MANUAL 800 EW FERT FLD INST this manual

1 1 123-832H SLOTTED IDLER ARM 1/2 X 3 5/16 pre-installed

15 12 133-325L SGS OPENER SIDE DELIVERY BDL see page 32 for breakdown

1 1 136-014D CHAIN RL #40 79 PITCHES

1 1 1 1 136-153D CHAIN RL #40 55 PITCHES pre-installed

1 1 1 1 136-250D CHAIN RL #40 96 PITCHES

2 2 2 141-116H FERTILIZER LATCH WELDMENT pre-installed

2 2 2 142-009D COVER HANDLE CHAIN pre-installed

1 1 142-064D RH WLK BRD SUPP FERT

1 1 142-077D LH WLK BRD SUPP FERT

15 15 12 12 142-257L FERT TUBE AND HDWR BDL see page 32 for breakdown

1 1 142-264K 8FT EW FERT TRAY ASY 6 see page 32 for breakdown

1 1 1 1 142-266L FERT. BOX & LID ASY see page 34 for breakdown

1 1 142-267K 8FT EW FERT TRAY ASY 7 1/2 see page 32 for breakdown

2 2 2 142-273D FERT TRAY LATCH STRIKE pre-installed

1 1 142-298D RH WLK BRD SUPP SML SDS-FERT

1 1 142-312D LH WLK BRD SUPP SML SDS-FERT

1 1 168-127D 3/16 X 1 KEY pre-installed

1 1 175-266K 8FT EW AUX JACKSHAFT ASY see page 35 for breakdown

8 6 8 6 802-034C HHCS 1/2-13X1 1/4 GR5

18 18 18 18 802-148C HFSS 1/4-20X1/2 GR5

1 2 1 2 802-214C RHSNB 1/2-13X1 1/4 GR5

8 8 8 8 803-020C NUT HEX 1/2-13 PLT

18 18 18 18 803-088C NUT HEX LOCK 1/4-20 FLG pre-installed

1 1 803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

8 8 8 8 804-015C WASHER LOCK SPRING 1/2 PLT

1 1 804-016C WASHER FLAT 1/2 SAE PLT pre-installed

4 4 4 805-019C PIN COTTER 5/32 X 1 PLT pre-installed

1 1 805-067C PIN COTTER 1/8 X 3/4 pre-installed

1 1 808-170C SPKT 40B17 X 3/4BORE W/KW&SS pre-installed

1 1 817-025C NO. 40 12T IDLER SPKT. pre-installed

2 2 2 2 838-265C DECAL REFLECTOR AMBER 1 1/2X9

1 1 1 1 848-276C DECAL 800 pre-installed

Number

-251A

Appendix 31

175-250A 800 FERT 7.5 FLD INST ON SGS

175-251A 800 FERT 7.5 FLD INST WITH DRV

Description Remarks

02/24/2010 175-253M

Page 34

32 175-248A, -249A, -250A, -251A

New Parts: Opener Side Delivery Hardware

Subassembly: 133-325L SGS OPENER SIDE DELIVERY BDL Used in: 175-248A, 175-250A

Callout

108

166

185

197

224

Quantity

in Kit

1 133-128H SGS SIDE DELIVERY TUBE

2 800-321C HOSE CLAMP NO.12 3/4 ID

1 802-427C HFS 3/8-16X3 3/4 SPTHD

1 803-209C NUT FLANGE LOCK 3/8-16 PLT

1 816-513C SGS HOSE 85 RIBS

Part

Number

Description Remarks

New Parts: Meter to Row Delivery Hardware

Subassembly: 142-257L FERT TUBE AND HDWR BDL

Callout

107

160

162

168

223

228

Quantity

in Kit

1 133-065D SML SDS TB REINFORCEMENT RING

1 800-008C CLAMP HOSE 1 1/2 NO. 24

1 800-016C UPPER FERT HOSE CLAMP RATCHET

2 801-002C SCREW HEX SLT10-16X1/2P.THD CT

1 816-239C SEED HOSE 56 RIBS X 11 LONG

1 817-346C PLASTIC FERTILIZER TUBE

Part

Number

Description Remarks

New Parts: Fertilizer Trays

Subassembly:

142-264K 8FT EW FERT TRAY ASY 6

142-267K 8FT EW FERT TRAY ASY 7 1/2

Callout

104

114

115

116

127

128

130

133

134

142

145

147

151

152

Quantity in Kit

142-264K 142-267K

1 1 122-065D TENSION SPRING RETAINER pre-installed

15 12 141-011E FERT DROP TUBE ASSEMBLY BOX pre-installed

1 1 141-041E SLIDE STOP ASSEMBLY pre-installed

4 4 141-084D TRAY BRG SPACER pre-installed

1 142-260H 8FT EW FERT TRAY WLMT 6IN pre-installed

1 142-261H 8FT EW FERT TRAY WLMT 7.5IN pre-installed

1 142-263H FT EW FERT SLIDE GATE 6 pre-installed

1 1 142-265D FERT TRAY 3/4 HEX SHFT X88 3/4 pre-installed

1 142-265H 8FT EW FERT SLIDE GATE 7 1/2 pre-installed

1 1 150-044S FERTILIZER ADJUSTMENT ROD ASSY

1 1 150-051D ACME SLOTTED NUT pre-installed

2 2 175-102H 13’ EW FERT BRG RETAINER pre-installed

2 2 191-001D MF FERT .75 HEX BORE BUSHING pre-installed

1 1 191-001H FERTILIZER ADJ BRKT WELDMENT pre-installed

Part

Number

Used in: 175-248A, 175-249A

Used in: 175-250A, 175-251A

Description Remarks

Used in: 175-248A, 175-249A,

175-250A, 175-251A

pre-installed

see page 35

175-253M 02/24/2010

Page 35

Subassembly:

142-264K 8FT EW FERT TRAY ASY 6

142-267K 8FT EW FERT TRAY ASY 7 1/2

Appendix 33

Used in: 175-248A, 175-249A

Used in: 175-250A, 175-251A

Callout

153

154

155

156

157

161

163

167

169

171

174

175

180

186

187

188

190

192

198

199

200

201

203

207

210

215

218

225

227

231

233

240

242

Quantity in Kit

142-264K 142-267K

Part

Number

Description Remarks

2 2 191-002D MF FERT HEX BORE PLASTIC BUSH pre-installed

1 1 191-006H MF FERT TRAY END PLT WLDMT LH pre-installed

1 1 191-007H MF FERT TRAY END PLT WLDMT RH pre-installed

15 12 191-018D MF FERT STAR RETAINER SIDE PLT pre-installed

1 4 191-019D MF FERT TRAY SLIDE SUPPORT pre-installed

4 4 800-012C RIVET SS 1/8 DIA pre-installed

2 2 800-032C LATCH STRIKE pre-installed

2 2 801-001C SCREW RD HD 8-32 X 3/8 BRASS pre-installed

1 1 801-018C SCREW RD HD 1/4-20 X 5/8 pre-installed

2 2 802-017C HHCS 3/8-16X1 GR5 pre-installed

45 36 802-089C RHSNB 1/4-20X3/4 SS pre-installed

6 6 802-092C RHSNB 5/16-18X3/4 GR5 pre-installed

4 4 802-252C RHSNB 3/8-16X1 3/4 GR5 pre-installed

45 36 803-004C NUT HEX SS 1/4-20 pre-installed

1 1 803-006C NUT HEX 1/4-20 PLT pre-installed

6 6 803-008C NUT HEX 5/16-18 PLT pre-installed

4 4 803-014C NUT HEX 3/8-16 PLT pre-installed

2 2 803-035C NUT HEX 8-32 BRASS pre-installed

2 2 804-002C WASHER INTERNAL STAR #8 BRASS pre-installed

2 2 804-003C WASHER FLAT #8 BRASS pre-installed

1 1 804-006C WASHER LOCK SPRING 1/4 PLT pre-installed

6 6 804-009C WASHER LOCK SPRING 5/16 PLT pre-installed

6 6 804-013C WASHER LOCK SPRING 3/8 PLT pre-installed

45 48 804-033C WASHER LOCK 1/4 SS pre-installed

1 1 805-064C PIN COTTER 7/64 X 1 LONG pre-installed

1 1 807-020C SPRING SCREW ADJ TENSION STRHT pre-installed

1 1 808-086C SPKT 40B30 X 3/4 HEXBORE W/ SS pre-installed

1 1 817-021C KNOB P.W. ADJUSTMENT pre-installed

15 12 817-053C 6 POINT FERT METERING WHEEL pre-installed

1 1 819-034C FERTILIZER ADJUSTMENT GAUGE pre-installed

2 2 822-083C BRG FLG 1.25ID 3BOLT pre-installed

2 2 890-026C FELT SEAL pre-installed

15.12 FT 15.5 FT 990-024R SEAL 5/16 X 3/4 DOR-TITE TRAY pre-installed

02/24/2010 175-253M

Page 36

34 175-248A, -249A, -250A, -251A

New Parts: Fertilizer Box and Lid

Subassembly: 142-266L FERT. BOX & LID ASY

Callout

101

102

105

121

122

123

125

126

140

141

146

164

172

173

177

181

182

184

188

189

190

191

194

195

196

201

202

203

204

205

206

208

216

217

220

229

230

234

236

237

241

Quantity

in Kit

1 120-234D RND SHAFT 3/4 X 13 3/8 W/KW pre-installed

1 120-293D TUBE RND DOM. 1 OD X 7/32WX3.0 pre-installed

2 123-580D BRG PLATE - ASSEMBLY pre-installed

1 142-141D LID HANDLE pre-installed

1 142-236D FERT BOX PARTITION pre-installed

1 142-256D FERT BOX MOUNT BRACKET pre-installed

1 142-258H 8’ FERT BOX WELDMENT pre-installed

1 142-259H 8’ FERT/NG BOX LID WELDMENT pre-installed

1 142-589S 3PT FERT BOX LID HINGE ASSY LH pre-installed. see page 36

1 142-590S 3PT FERT BOX LID HINGE ASSY RH pre-installed. see page 36

2 168-127D 3/16 X 1 KEY pre-installed

2 800-121C BALL STUD 10MM X 5/16-18 UNC pre-installed

12 802-034C HHCS 1/2-13X1 1/4 GR5 pre-installed

1 802-044C HHCS 1/2-13X4 GR5 pre-installed

4 802-149C RHSNB 3/8-16X3/4 GR5 pre-installed

4 802-282C RHSNB 5/16-18X1 GR5 pre-installed

5 802-387C HFS 5/16-18X3/4 GR5 pre-installed

2 802-425C HHCS 5/16-18X1 1/4 NYL pre-installed

4 803-008C NUT HEX 5/16-18 PLT pre-installed

2 803-011C NUT LOCK 5/16-18 PLT pre-installed

4 803-014C NUT HEX 3/8-16 PLT pre-installed

8 803-020C NUT HEX 1/2-13 PLT pre-installed

1 803-147C NUT HEX NYLOCK 1/2-13 pre-installed

4 803-169C NUT HEX FLG. LOCK 1/2-13 PLT. pre-installed

5 803-199C NUT HEX FLANGE 5/16-18 PLT pre-installed

4 804-009C WASHER LOCK SPRING 5/16 PLT pre-installed

4 804-012C WASHER FLAT 3/8 SAE PLT pre-installed

4 804-013C WASHER LOCK SPRING 3/8 PLT pre-installed

8 804-015C WASHER LOCK SPRING 1/2 PLT pre-installed

4 804-016C WASHER FLAT 1/2 SAE PLT pre-installed

3 804-017C WASHER FLAT 1/2 USS PLT pre-installed

6 804-036C WASHER FLAT 5/16 SAE PLT pre-installed

2 807-106C SPRING .540 O.D.X 1 1/4 X.054W pre-installed

1 808-040C SPKT 40B12 X 3/4 B W/KW&SS pre-installed

1 808-170C SPKT 40B17 X 3/4BORE W/KW&SS pre-installed

1 817-406C IDLER 1 PC 2.38X1.01X1.062 pre-installed

1 817-805C LID LATCH pre-installed

2 822-126C BRG FLG .75ID 2BOLT pre-installed

7 838-160C DECAL 3 COLOR STRIPE 2.50 WIDE pre-installed

1 838-161C DECAL LOGO&GP F/STRIPE 4 X 24 pre-installed

1 890-308C 9 1/4-15 X 70LB GAS SPRING pre-installed

Part

Number

Description Remarks

Used in: 175-248A, 175-249A,

175-250A, 175-251A

175-253M 02/24/2010

Page 37

New Parts: Fertilizer Rate Adjuster Rod Assembly

Appendix 35

Subassembly: 150-044S FERTILIZER ADJUSTMENT ROD ASSY

Callout

143

144

212

Quantity

in Kit

1 150-049D HEX COUPLER ADJUSTMENT HANDLE pre-installed

1 150-050D FERTILIZER ADJUSTMENT ROD pre-installed

1 805-073C PIN ROLL 5/32 X 1 pre-installed

Part

Number

Description Remarks

New Parts: Accessory Drive

Subassembly: 175-266K 8FT EW AUX JACKSHAFT ASY

Callout

103

111

149

150

159

165

170

179

181

188

190

195

201

203

206

213

214

219

221

222

229

232

235

Quantity

in Kit

3 120-305D TUBE RND 1 OD X 7/32W X 1.56

1 136-036D CHAIN RL #40 70 PITCHES

1 175-414D 8FT EW AUX JACK SHAFT MNT

1 175-415D 8FT EW AUX JACK SHAFT

1 402-058D COLLAR LOCK 7/8 HEX

1 800-141C SNAP RING EXT F/PEERLESS G.B.

2 801-035C SCREW SET 5/16-18 SKT KP X 3/8

3 802-226C HHCS 1/2-13X2 3/4 GR5

4 802-282C RHSNB 5/16-18X1 GR5

4 803-008C NUT HEX 5/16-18 PLT

4 803-014C NUT HEX 3/8-16 PLT

3 803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

4 804-009C WASHER LOCK SPRING 5/16 PLT

4 804-013C WASHER LOCK SPRING 3/8 PLT

9 804-017C WASHER FLAT 1/2 USS PLT

2 805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

2 806-004C U-BOLT 3/8-16 X 2 X 2 3/4

1 808-157C SPKT 40B19 X 36T SPLINE BORE

1 808-219C SPKT 40C12 X 7/8 HEX BORE

1 808-250C SPKT 40C22 X 7/8 HEX BORE

3 817-406C IDLER 1 PC 2.38X1.01X1.062

4 822-032C FLANGETTE 52 MST

2 822-195C BRG INS 7/8HEXX2.04OD SPH

Part

Number

Description Remarks

Used in: 175-248A, 175-249A,

175-250A, 175-251A

Used in: 175-249A, 175-251A

02/24/2010 175-253M

Page 38

36 175-248A, -249A, -250A, -251A

New Parts: Fertilizer Box Lid Hinge Assemblies

Subassemblies:

142-589S 3PT FERT BOX LID HINGE ASSY LH

142-590S 3PT FERT BOX LID HINGE ASSY RH

Callout

129

131

158

183

197

Quantity in Kit

142-589S 142-590S

1 142-263D FERT BOX LID HINGE L.H. pre-installed

1 142-264D FERT BOX LID HINGE R.H. pre-installed

1 1 313-186D LID HINGE PIVOT pre-installed

1 1 802-411C RHSNB 3/8-16X2 GR5 pre-installed

1 1 803-209C NUT FLANGE LOCK 3/8-16 PLT pre-installed

Part

Number

Description Remarks

Existing Parts Affected

Part

Callout

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

32

33

34

Number

119-190D HANDLE

119-278D WALKBOARD LADDER PIVOT BUSHING 2 Removed at step 8 and re-installed at step 105

119-294H 3PT HINGED WALKBOARD LADDER 1 Removed at step 8 and re-installed at step 103

123-939H SMALL SEEDS TUBE WELDMENT 1/row Removed at step 16 and not re-used

133-045D SGS BOX SUPPORT STRAP

136-014D CHAIN RL #40 79 PITCHES 1 Removed at step 13 and not re-used

136-096D CHAIN RL #40 76 PITCHES 1 Removed at step 13 and not re-used

136-250D CHAIN RL #40 96 PITCHES 1 Removed at step 13 and not re-used

175-411D 8FT EW WALKBOARD

175-413D SEED ONLY LH LADDER MNT 1 Removed at step 10 and not re-used

175-416D LH WLK BRD SUPP SML SEEDS 1 Removed at step 10 and not re-used

175-417D RH WLK BRD SUPP SML SEEDS

800-064C HOSE CLIP 13/16 ID

800-321C HOSE CLAMP NO.12 3/4 ID 2/row Removed at step 15 and not re-used

801-002C SCREW HEX SLT10-16X1/2P.THD CT 2/row Removed at step 16 and not re-used

801-018C SCREW RD HD 1/4-20 X 5/8

801-151C SCR HEX SELF TAP 1/4-20X1TYPEF