Operator’s Manual

Series VII 6326, 6328, 6536, 6542, 7333, 7336, 7548 & 7552

Discovator (Disc & Coulter)

Manufacturing, Inc.

Read the operator’s manual entirely. When you see this symbol, the subsequent

!

instructions and warnings are serious - follow without exception. Your life and the

lives of others depend on it

Cover illustration may show optional equipment not supplied with standard unit.

©Copyright 2004 Printed 8/11/2008 550-221M

Great Plains Mfg., Inc. First Page ► Table of Contents

Table of Contents

Important Safety Information .......................... 1

Safety Rules................................................... 6

Safety Decals ................................................ 7

Introduction ........................................................ 12

Description of Unit........................................ 12

Using this Manual ........................................12

Definitions.............................................. 12

Owner Assistance .......................................... 12

Assembly and Setup Assistance .................... 13

Product Support .....................................13

Pre-Assembly Checklist ........................ 13

Section 1 Assembly ............................................. 14

Center Frame, Torque Tube & Walking

Beam Assembly ....................................... 14

Inside Wing and Wheel Arm Assembly .......15

Brace Bar, Wing Brace & Rocker/Fold

Bracket Assembly .................................... 16

Outside Wing Assembly ............................... 17

Connecting Outside Wing and Wing Brace

Assembly ................................................. 18

Center Gang & Gang Hanger Assembly. ...... 19

Center Truss, Hitch and Strut Assembly ...... 20

Hitch Tongue, Side Plate and Level Bar

Assembly ................................................. 21

Center Lift Cylinder, Rest Pads and

Hydraulic Valves Assembly ................... 22

Fold Cylinders, Rocker Arm and 3” Rollers

Assembly ................................................ 23

Center Wing Stop and Outside Wing Stop

Assembly ................................................ 24

Front Gauge Wheel Assembly .....................25

Hydraulic Gauge Wheel Assembly .............. 26

Completing Setup ......................................... 27

Section 2 Hydraulics .......................................... 28

Hydraulic Layout: 6326, 6328, 7333, 7336... 28

Hydraulic Layout: 6536................................. 30

Hydraulic Layout: 6542, 7548 & 7552 .........32

Hydraulic Gang Layout ................................ 34

Section 3 Replacement Parts .............................36

Magnum Shank Assembly ............................ 36

K-Flex Shank Assembly ............................... 38

Disc Gang Assembly .................................... 40

Disc Gang Identification .............................. 42

Coulter Gang Assembly ...............................44

Coulter Gang Identification .......................... 46

Center Walking Beam 6300DV (All S/N)

& 7300DV (S/N 1226DD-)...................... 48

Center Walking Beam 6500DV

(S/N 1329DD+) ....................................... 50

Center Walking Beam 7333DV

(S/N 1227DD+)........................................ 52

Center Walking Beam 7500DV ................... 54

Wing Walking Beam Assembly ................... 56

6536 & 6542 Outside Wing Transport

(Standard Hub) ........................................ 58

(Optional Heavy Hub) ............................. 60

8 & 6-Bolt Heavy Hub & Spindle Assy.

(S/N 1329DD+) ....................................... 62

6-Bolt Hub & Spindle Assembly ................. 64

Front Gauge Wheel Assembly ..................... 66

Hydraulic Gauge Wheel Assembly .............. 68

Section 4 Machine Layout ................................. 70

6326D Machine Layout, Disc ...................... 70

6326C Machine Layout, Coulter .................. 71

6328D Machine Layout, Disc ...................... 72

6328C Machine Layout, Coulter .................. 73

6536D Machine Layout, Disc

Single Fold (S/N 1329DD+) ................... 74

Double Fold (S/N 1329DD+) .................. 76

6536C Machine Layout, Coulter

Single Fold (S/N 1329DD+) ................... 78

Double Fold (S/N 1329DD+) .................. 80

6542D Machine Layout, Disc

(S/N 1329DD+) ....................................... 82

6542C Machine Layout, Coulter

(S/N 1329DD+) ....................................... 84

7333D Machine Layout, Disc

(S/N 1227DD+) ....................................... 86

7333C Machine Layout, Coulter

(S/N 1227DD+) ....................................... 87

7336D Machine Layout, Disc ...................... 88

7336C Machine Layout, Coulter .................. 89

7548D Machine Layout, Disc ...................... 90

7548C Machine Layout, Coulter .................. 92

7552D Machine Layout, Disc ...................... 94

7552C Machine Layout, Coulter .................. 96

1/19/2006 Series VII 6326-7552 Discovator 550-221M

Table of Contents Table of Contents ► Great Plains Mfg., Inc.

Section 5 Operating and Maintenance..............98

Prior to Going to the Field ............................ 98

First Time Machine Setup and Adjustments 98

General Operating Instructions and

In-Field Adjustments ............................... 100

Maintenance and Lubrication ....................... 102

Section 6 Specification and Capacities ............. 103

Appendix ............................................................. 104

Torque Values for Common Bolt Sizes ....... 104

Tire Inflation Chart ...................................... 104

Warranty ....................................................... 105

Series VII 6326-7552 Discovator 550-221M 1/19/2006

Great Plains Mfg., Inc. First Page ► Table of Contents

©

Copyright 2004 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it

sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

1/19/2006 Series VII 6326-7552 Discovator 550-221M

Great Plains Mfg., Inc. Table of Contents ► Important Safety Information

R

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is

a potential hazard to personal safety involved

and extra safety precaution must be taken.

When you see this symbol, be alert and carefully

read the message that follows it. In addition to

design and configuration of equipment, hazard

control and accident prevention are dependent

upon the awareness, concern, prudence and

proper training of personnel involved in the

operation, transport, maintenance and storage of

equipment.

Be Aware of Signal Words

!

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death

or serious injury. This signal word is limited to

the most extreme situations, typically for

machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous

situation, which, if not avoided, could result in

death or serious injury, and includes hazards

that are exposed when guards are removed. It

may also be used to alert against unsafe

practices.

CAUTION indicates a potentially hazardous situation, which, if not avoided, may result in minor

or moderate injury. It may also be used to alert

against unsafe practices.

!

DANGE

!

WARNING

!

CAUTION

3/31/2004 Series VII 6326-7552 Discovator 550-221M

1

Important Safety Information Table of Contents ► Great Plains Mfg., Inc.

Be Familiar with Safety Decals

• Read and understand “Safety Decals,” page

7, thoroughly.

• Read all instructions noted on the decals.

Keep Riders Off Machinery

• Riders obstruct the operator’s view. Riders

could be struck by foreign objects or thrown

from the machine.

• Never allow children to operate equipment.

• Keep all bystanders away from machine dur-

ing operation.

Shutdown and Storage

• Lower Series VII Discovator, put tractor in

park, turn off engine, and remove the key.

• Secure Series VII Discovator using blocks

and supports provided.

• Detach and store Series VII Discovator in an

area where children normally do not play.

Use Safety Lights and Devices

• Slow-moving tractors and towed implements

can create a hazard when driven on public

roads. They are difficult to see, especially at

night.

• Use flashing warning lights and turn signals

whenever driving on public roads.

• Use lights and devices provided with implement.

OFF

Series VII 6326-7552 Discovator 550-221M 3/31/2004

2

Great Plains Mfg., Inc. Table of Contents ► Important Safety Information

Transport Machinery Safely

Maximum transport speed for implement is 20

mph. Some rough terrains require a slower

speed. Sudden braking can cause a towed load

to swerve and upset.

• Do not exceed 20 mph. Never travel at a

speed which does not allow adequate

control of steering and stopping. Reduce

speed if towed load is not equipped with

brakes.

• Comply with state and local laws.

• Do not tow an implement that, when fully

loaded, weighs more than 1.5 times the

weight of towing vehicle.

• Carry reflectors or flags to mark tractor and

implement in case of breakdown on the

road.

• Keep clear of overhead power lines and

other obstructions when transporting. Refer

to transport dimensions under

“Specifications and Capacities,” page 103.

• Do not fold or unfold the wings while the

tractor is moving.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the

skin, causing serious injury.

• Avoid the hazard by relieving pressure

before disconnecting hydraulic lines.

• Use a piece of paper or cardboard, NOT

BODY PARTS, to check for suspected

leaks.

• Wear protective gloves and safety glasses

or goggles when working with hydraulic

systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be

surgically removed within a few hours or

gangrene may result.

3/31/2004 Series VII 6326-7552 Discovator 550-221M

1/19/2006

3

Important Safety Information Table of Contents ► Great Plains Mfg., Inc.

Practice Safe Maintenance

• Understand procedure before doing work.

Use proper tools and equipment. Refer to

this manual for additional information.

• Work in a clean, dry area.

• Lower the Series VII Discovator, put tractor

in park, turn off engine, and remove key

before performing maintenance.

• Make sure all moving parts have stopped

and all system pressure is relieved.

• Inspect all parts. Make sure parts are in

good condition and installed properly.

• Remove buildup of grease, oil or debris.

• Remove all tools and unused parts from

Series VII Discovator before operation.

Prepare for Emergencies

• Be prepared if a fire starts.

• Keep a first aid kit and fire extinguisher

handy.

• Keep emergency numbers for doctor, ambulance, hospital and fire department near

phone.

Wear Protective Equipment

• Wear protective clothing and equipment.

• Wear clothing and equipment appropriate for

the job. Avoid loose-fitting clothing.

• Because prolonged exposure to loud noise

can cause hearing impairment or hearing

loss, wear suitable hearing protection such

as earmuffs or earplugs.

• Because operating equipment safely

requires your full attention, avoid wearing

radio headphones while operating

machinery.

911

Series VII 6326-7552 Discovator 550-221M 3/31/2004

4

Great Plains Mfg., Inc. Table of Contents ► Important Safety Information

Handle Chemicals Properly

• Agricultural chemicals can be dangerous.

Improper use can seriously injure persons,

animals, plants, soil and property.

• Read and follow chemical manufacturer’s

instructions.

• Wear protective clothing.

• Handle all chemicals with care.

• Avoid inhaling smoke from any type of

chemical fire.

• Store or dispose of unused chemicals as

specified by chemical manufacturer.

Use A Safety Chain

• Use a safety chain to help control drawn

machinery should it separate from tractor

drawbar.

• Use a chain with a strength rating equal to or

greater than the gross weight of towed

machinery.

• Attach chain to tractor drawbar support or

other specified anchor location. Allow only

enough slack in chain to permit turning.

• Replace chain if any links or end fittings are

broken, stretched or damaged.

• Do not use safety chain for towing.

Tire Safety

• Tire changing can be dangerous and should

be performed by trained personnel using

correct tools and equipment.

• When inflating tires, use a clip-on chuck and

extension hose long enough to you to stand

to one side–not in front of or over tire

assembly. Use a safety cage if available.

• When removing and installing wheels, use

wheel-handling equipment adequate for

weight involved.

3/31/2004 Series VII 6326-7552 Discovator 550-221M

5

Important Safety Information Table of Contents ► Great Plains Mfg., Inc.

Safety Rules

• Thoroughly read and understand the

instructions in this manual before operation.

Read all instructions noted on the safety

decals.

• Be familiar with all Series VII Discovator

functions.

• Operate machinery from the driver’s seat

only.

• Do not leave Series VII Discovator unattended with tractor engine running.

• Do not transport Series VII Discovator

the transport pins and all wing locks are

installed.

• Limit transport speed to 20 m.p.h.

• Know the transport height of your unit and be

extremely careful of overhead electrical and

telephone lines when transporting the unit.

• Know the transport width of your machine and

the width of bridges, etc… on the transport

route.

• Make sure that no one is near the machine

during field operation and folding or unfolding

of wing sections.

• Prior to removing any lift cylinders from the

machine, lower implement to the ground, shut

off the tractor and release the pressure in the

lines.

• Do not depend on cylinders to hold the weight

of machine during storage; use the transport

locks.

• Do not walk or stand on any part of the

machine. Never allow anyone to ride on the

Series VII Discovator.

• Use extreme care when hitching or unhitching

the machine from the tractor. In some

situations with a heavy finishing attachment,

the machine may tip backward causing the

hitch to rise rapidly.

• Never stand with feet under any part of the

machine.

until

• Never allow anyone to walk between the

tractor and Series VII Discovator while

machine is in operation.

• Keep hands and feet away from turbo blades.

They are quite sharp.

• Any moving piece of equipment is potentially

dangerous. Do not operate until you are

absolutely sure the area is clear of children,

pets and irresponsible persons.

• Escaping hydraulic fluid under pressure can

have sufficient force to penetrate the skin,

causing serious injury. To prevent injury

when working with hydraulics, follow the

instructions on page 3.

• Before transporting the unit on public roads,

check to make sure the safety reflectors are

clean and visible, and not missing or

damaged. Turn on tractor warning lights

when transporting.

• Make sure all safety signs are clean, readable

and not damaged. Contact Great Plains Mfg.

for free replacements if necessary.

Series VII 6326-7552 Discovator 550-221M 3/31/2004

6

Great Plains Mfg., Inc. Table of Contents ► Important Safety Information

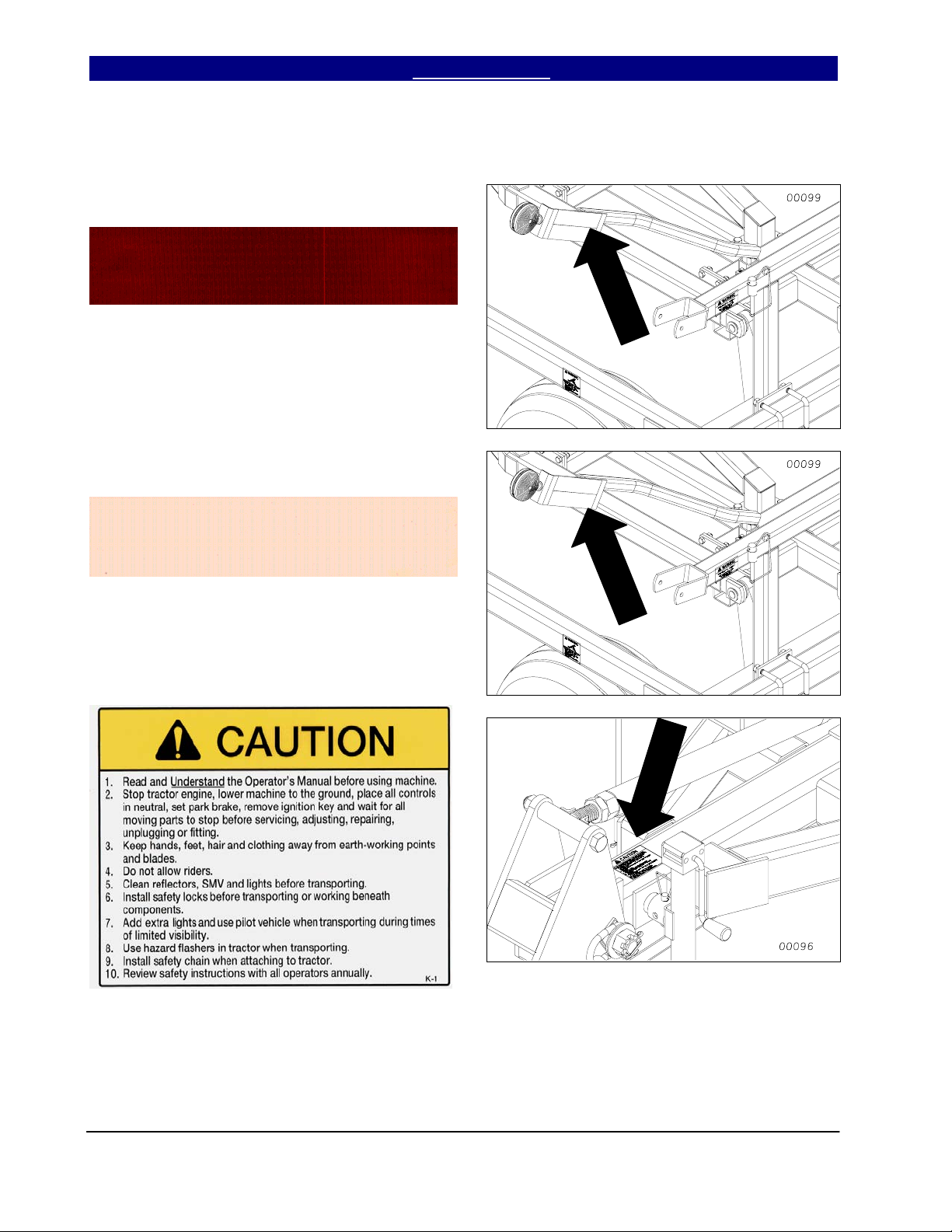

Safety Decals

Your implement comes equipped with all safety

decals in place. They were designed to help you

safely operate your implement.

• Read and follow decal directions.

• Keep all safety decals clean and legible.

• Replace all damaged or missing decals. Order

new decals from your Great Plains dealer.

Refer to this section for proper placement.

• When ordering new parts or components, also

request corresponding safety decals.

• To install new decals:

1. Clean the area on which the decal is to be

placed.

2. Peel backing from decal. Press firmly on

surface, being careful not to cause air

bubbles under decal.

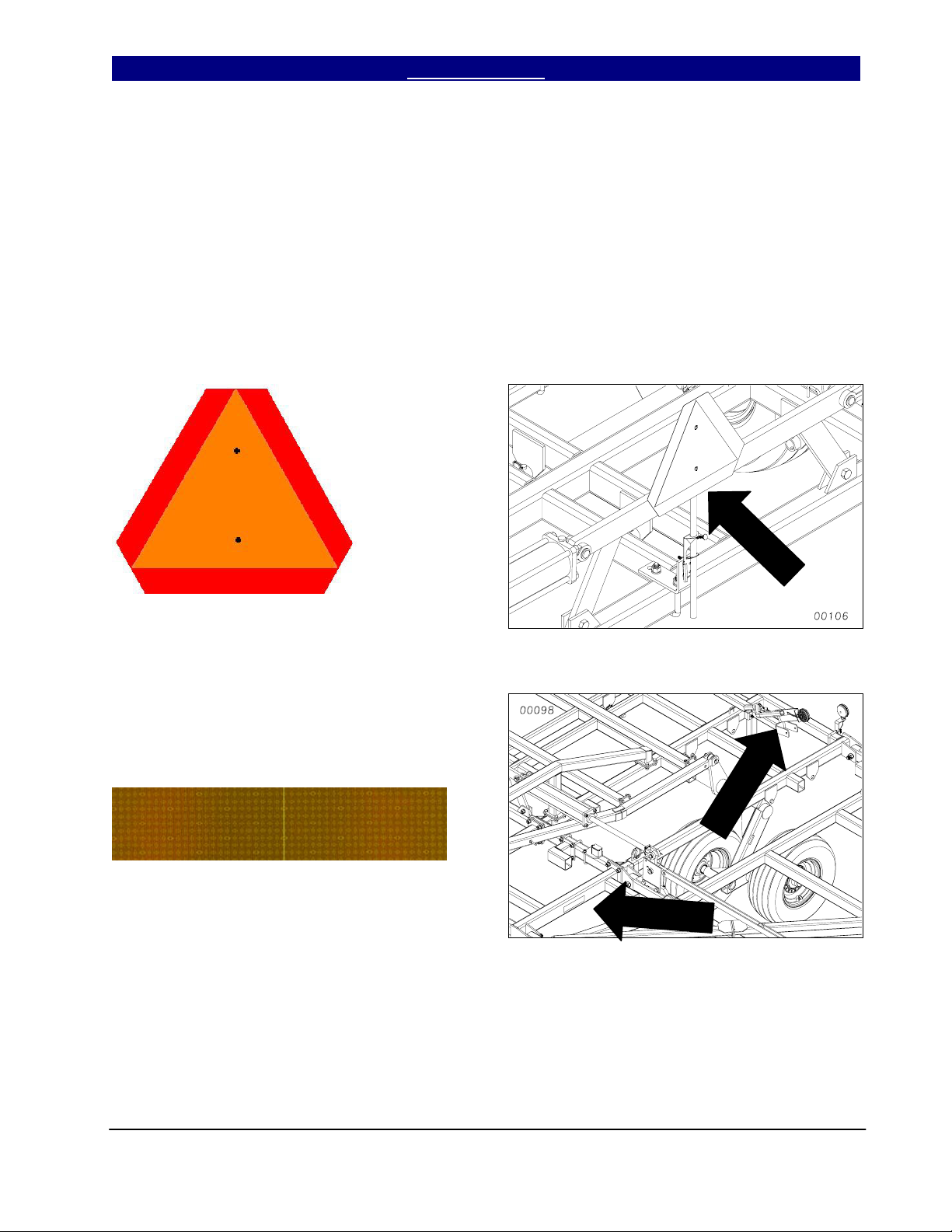

Slow Moving Vehicle Emblem

Quantity 1

Reflector – Amber

838-615C

Quantity 6: Two on light bracket and two on

center brace bar. Two on rear of finishing

attachment (not shown), visible from side

while folded for transport.

3/31/2004 Series VII 6326-7552 Discovator 550-221M

7

Important Safety Information Table of Contents ► Great Plains Mfg., Inc.

Reflector – Red

838-614C

Quantity 2:

Reflector – Florescent Orange

838-603C

Quantity 2:

Caution

838-598C

Quantity 1

Series VII 6326-7552 Discovator 550-221M 3/31/2004

8

Great Plains Mfg., Inc. Table of Contents ► Important Safety Information

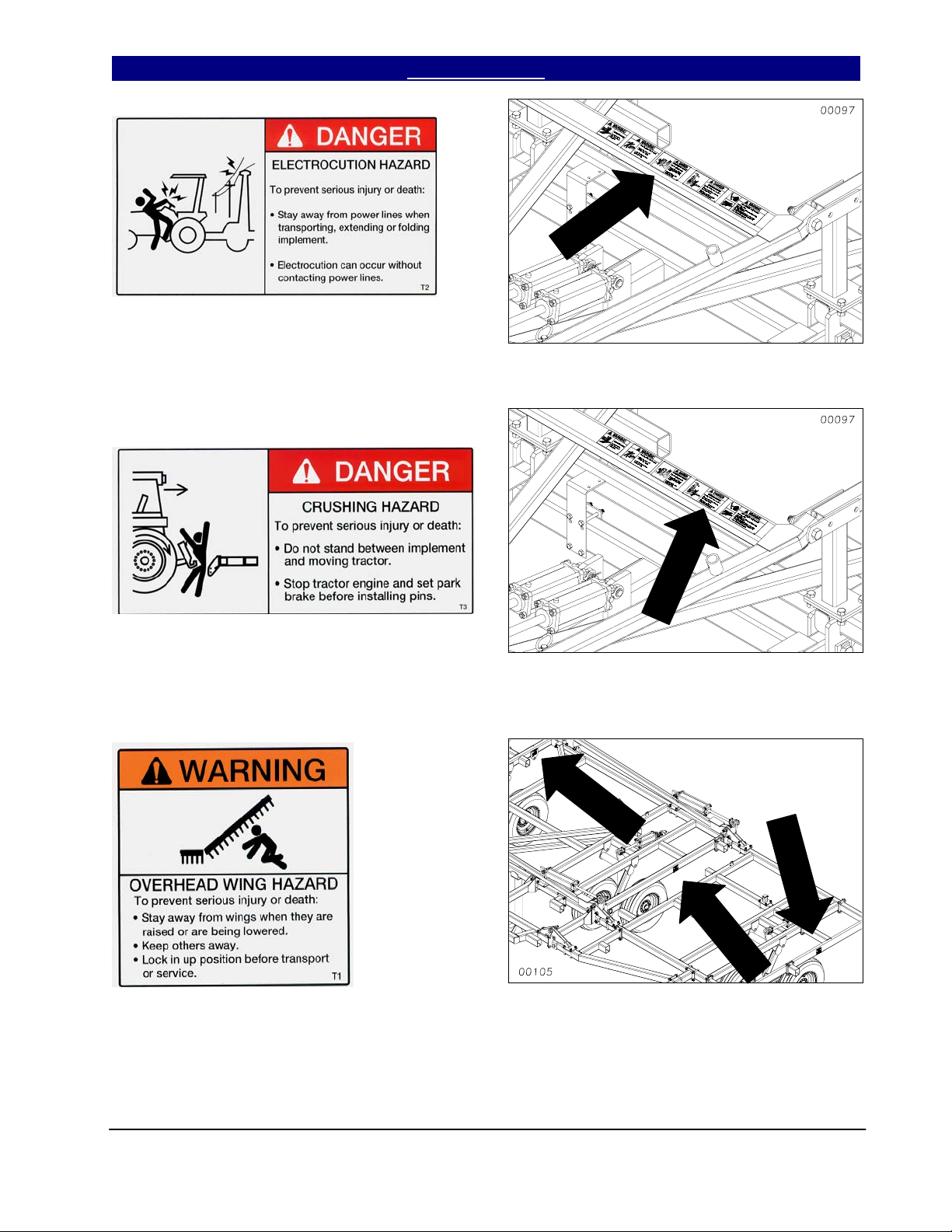

Danger Electrocution Hazard

838-599C

Quantity 1

Danger Crushing Hazard

838-600C

Quantity 1

Warning Overhead Wing Hazard

838-602C

Quantity 4: 6326, 6328, 7333 & 7336

Quantity 6: 6536, 6542, 7548 & 7552

3/31/2004 Series VII 6326-7552 Discovator 550-221M

9

Important Safety Information Table of Contents ► Great Plains Mfg., Inc.

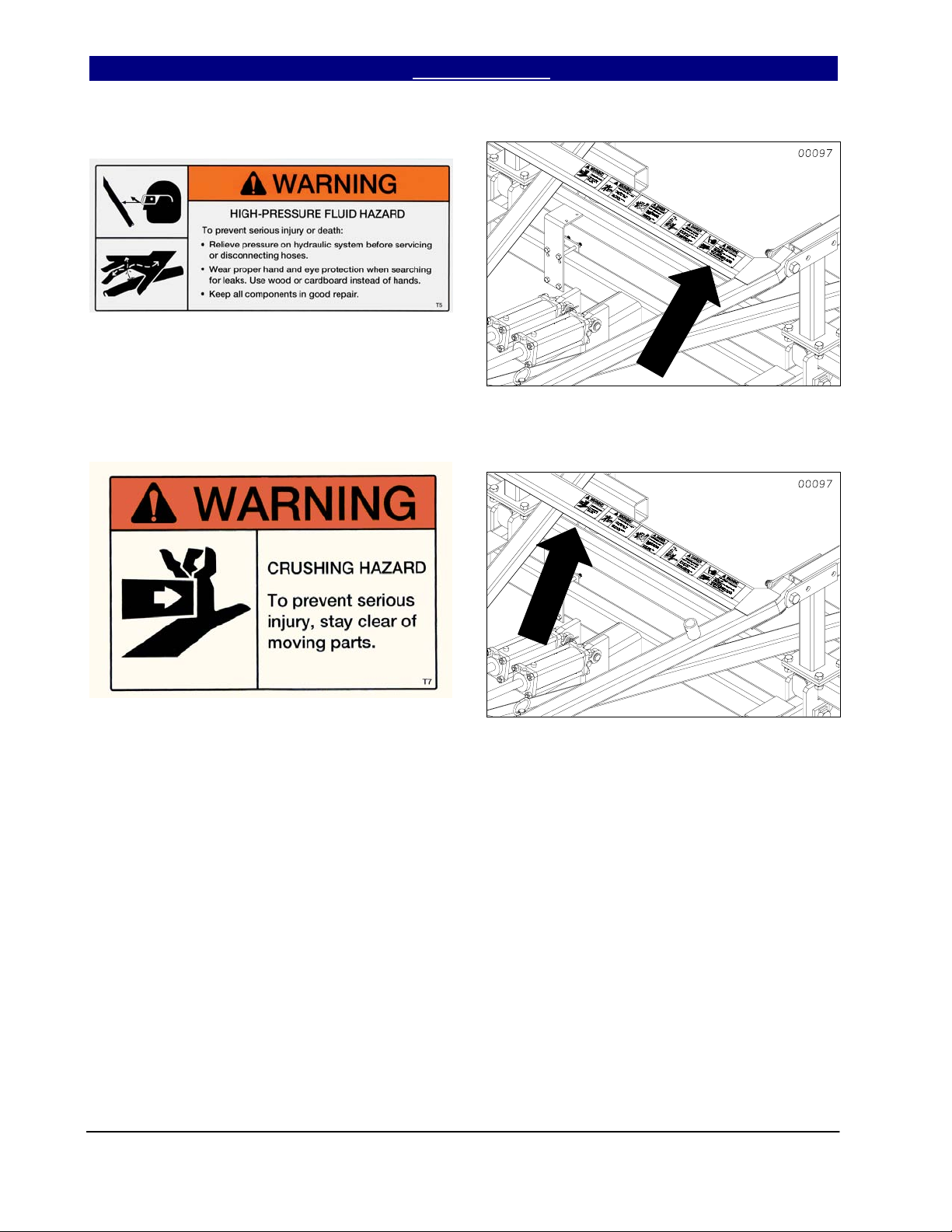

Warning High Pressure Fluid Hazard

838-610C

Quantity 1

Warning Crushing Hazard

838-611C

Quantity 1

Series VII 6326-7552 Discovator 550-221M 3/31/2004

10

Great Plains Mfg., Inc. Table of Contents ► Important Safety Information

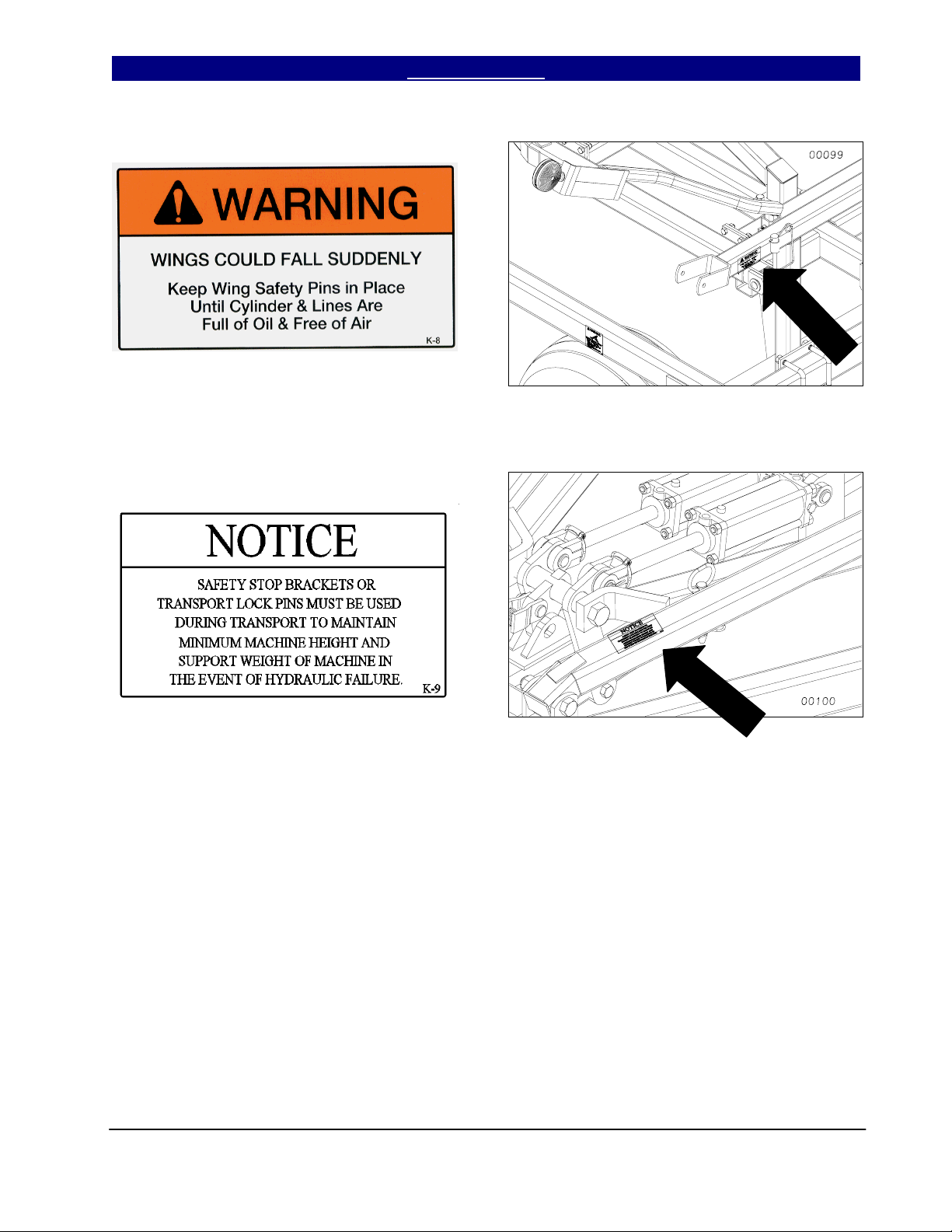

Warning Wing Falling Hazard

838-612C

Quantity 2

Notice

838-613C

Quantity 1

3/31/2004 Series VII 6326-7552 Discovator 550-221M

11

Introduction Table of Contents ► Great Plains Mfg., Inc.

Introduction

Great Plains welcomes you to its growing family of

new product owners. This implement has been

designed with care and built by skilled workers

using quality materials. Proper assembly,

maintenance and safe operation will help you get

years of satisfactory machine use from your

machine. To ease the assembly task and produce

a properly working machine, read this entire

manual before assembling or setting up new

equipment.

Description of Unit

The Series VII 6326-7552 Discovator is a three or

five-section field finishing, one-pass tillage tool.

Working width ranges from 26 to 52 feet. The

implement is designed to combine discing/slicing,

cultivating, harrowing and herbicide incorporation

in a single pass. Various finishing attachments

are available to customize your tillage and residue

requirements for your operation.

Using This Manual

This manual will familiarize you with safety,

assembly, operation, adjustment, troubleshooting

and maintenance. Read this manual and follow

the recommendations to help ensure safe and

efficient operation.

The information in this manual is current at printing. Some parts may change to assure top

performance.

Definitions

The following terms are used throughout this

manual.

Right and left as used in this manual are deter-

mined by facing the direction the machine will

travel while in use unless otherwise stated.

IMPORTANT: A crucial point of information

about the preceding topic. For safe and correct

operation, read and follow the directions provided

before continuing.

NOTE: Useful information about the preceding

topic.

Owner Assistance

If customer service or repairs are needed, contact

your Great Plains dealer. They have trained

personnel, parts and service equipment specially

designed for Great Plains products.

Your machine’s parts should only be replaced with

Great Plains parts. Always use the serial and

model number when ordering parts from your

Great Plains dealer. The serial-number plate is

on the center section of the implement on the front

frame tube.

Record your implement model and serial numbers

here for quick reference.

Model Number: __________________________

Serial Number: ___________________________

Your Great Plains dealer wants you to be satisfied

with your new machine. If you do not understand

any part of this manual or are not satisfied with

the service received, please take the following

actions:

1. Discuss the matter with your dealer’s service

manager. Make sure they are aware of any

problems so they can assist you.

2. If you are still not satisfied, seek out the

dealership owner or general manager.

3. For further assistance, write to:

Product Support

Great Plains Mfg. Inc.

Service Department

607 Main Street

Tipton, KS 67485

Series VII 6326-7552 Discovator 550-221M 3/31/2004

12

Great Plains Mfg., Inc. Table of Contents ► Introduction

Assembly and Setup Assistance

To order additional copies of operator’s and parts

manuals, write to the following address. Include

model numbers in all correspondence.

If you do not understand any part of this manual

or have other assembly or setup questions, assistance is available. Contact

Product Support

Great Plains Mfg. Inc., Service Department

607 Main Street

Tipton, KS 67485

Phone (800) 255-9215

Pre-Assembly Checklist

• Before assembling, read and understand “Im-

portant Safety Information,” beginning on

page 1.

• Have at least two people on hand while as-

sembling.

• Make sure assembly area is level and free of

obstructions (preferably an open concrete area).

• Have all major components.

• Have all fasteners and pins shipped with

Series VII Discovator.

• IMPORTANT: If a pre-assembled part or fas-

tener is temporarily removed, remember

where it goes. Keep the parts separated.

• Have a copy of the parts manual on hand. If

unsure of proper placement or use of any part

or fastener, refer to the parts manual.

• Check that all working parts are moving free-

ly, bolts are tight, and cotter pins are spread.

8/11/2008 Series VII 6326-7552 Discovator 550-221M

13

Section 1: Assembly Table of Contents ► Great Plains Mfg., Inc.

Assembly

This section covers the proper assembly of the implement. The reference numbers on the

figures give you an indication of the order of assembly. For a complete breakdown of any part not

shown in this assembly section, refer to the parts manual for proper location. Refer to the Appendix

for proper bolt torque values.

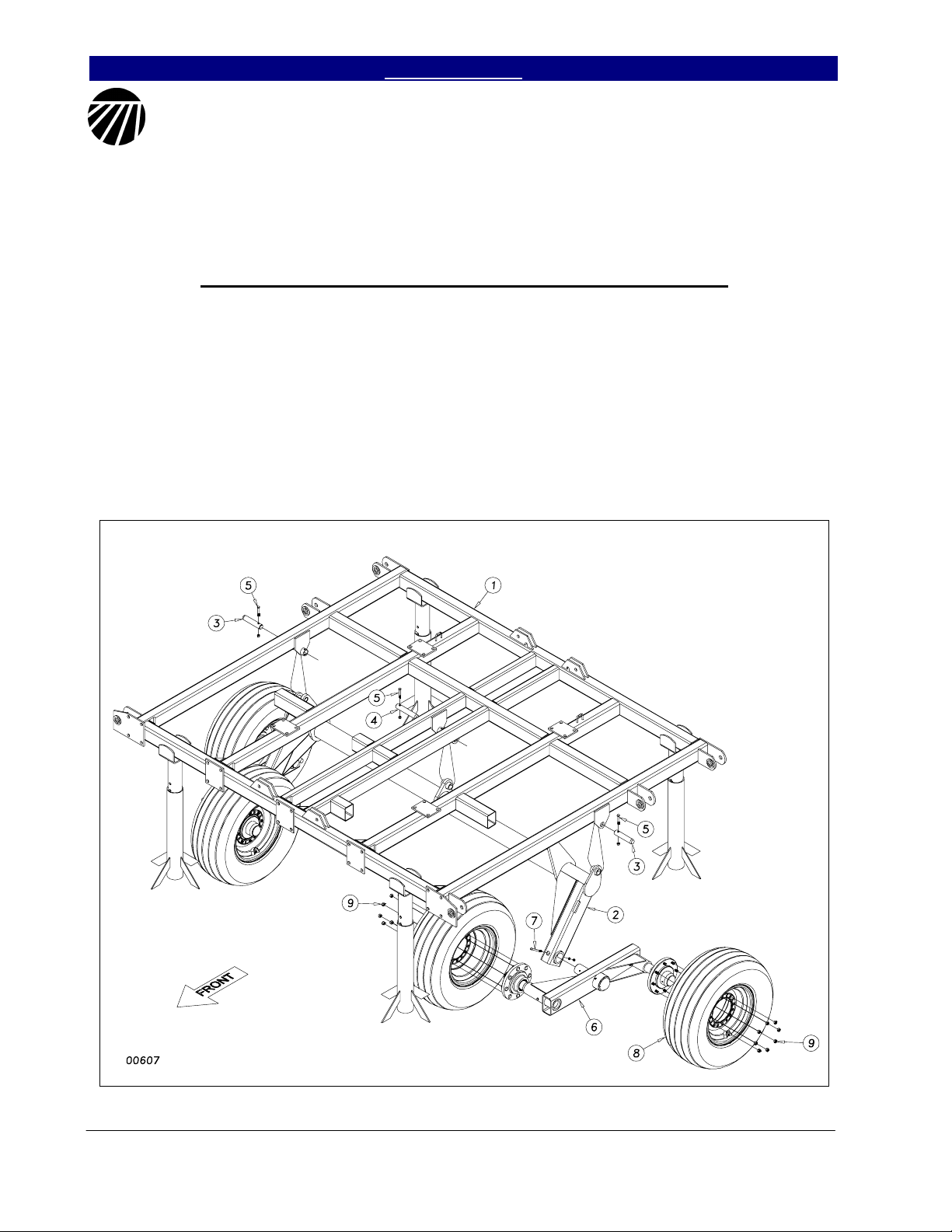

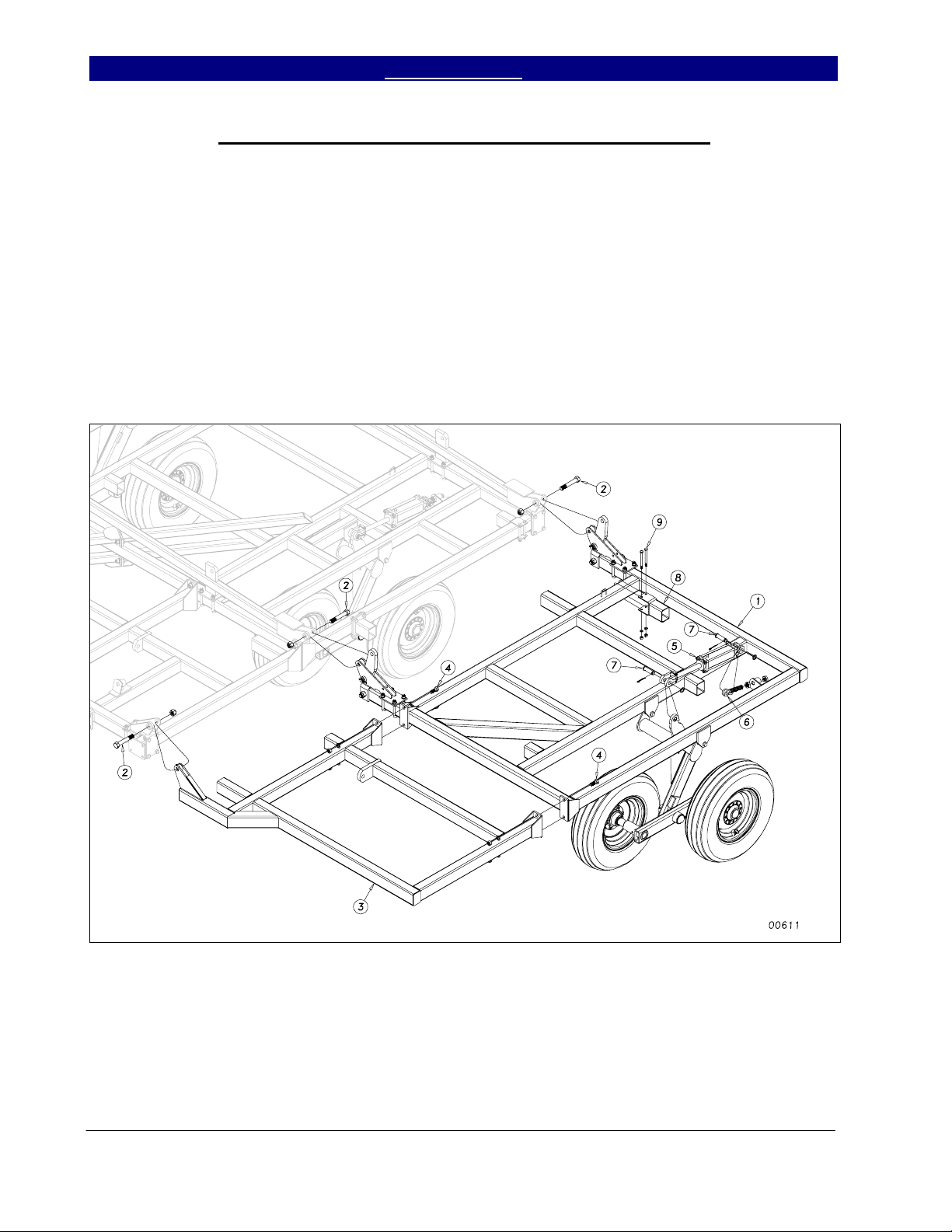

Center Frame, Torque Tube & Walking Beam Assembly

After uncrating the machine, place the

center frame (1) Figure 1, in the center of your

work area on stands. Pin the torque tube (2) to

the center frame with the 1¼ x 6 pins (3) and

1¼ x 7 pin (4) in center. Secure them with 3/8 x

2¼ GR 8 hex bolts (5) & lock nuts.

Slide the pivot spindle of the walking

beam assembly (6) into the sleeve at the end of

the torque tube wheel arm. It is a good idea to

put some form of anti-seize on the spindle

before you insert it. Line up the hole in the

spindle with the hole in the sleeve and secure

with 5/16 x 4 hex bolt (7) with lock washer and

hex nut.

When both walking beams have been

installed, bolt on the center transport tires (8),

using 1/2” or 5/8” lug nuts (9). See Section 3

Replacement Parts for proper transport parts

and sizes for your machine model.

Figure 1

Series VII 6326-7552 Discovator 550-221M 3/31/2004

11/22/2004

14

Great Plains Mfg., Inc. Table of Contents ► Section 1: Assembly

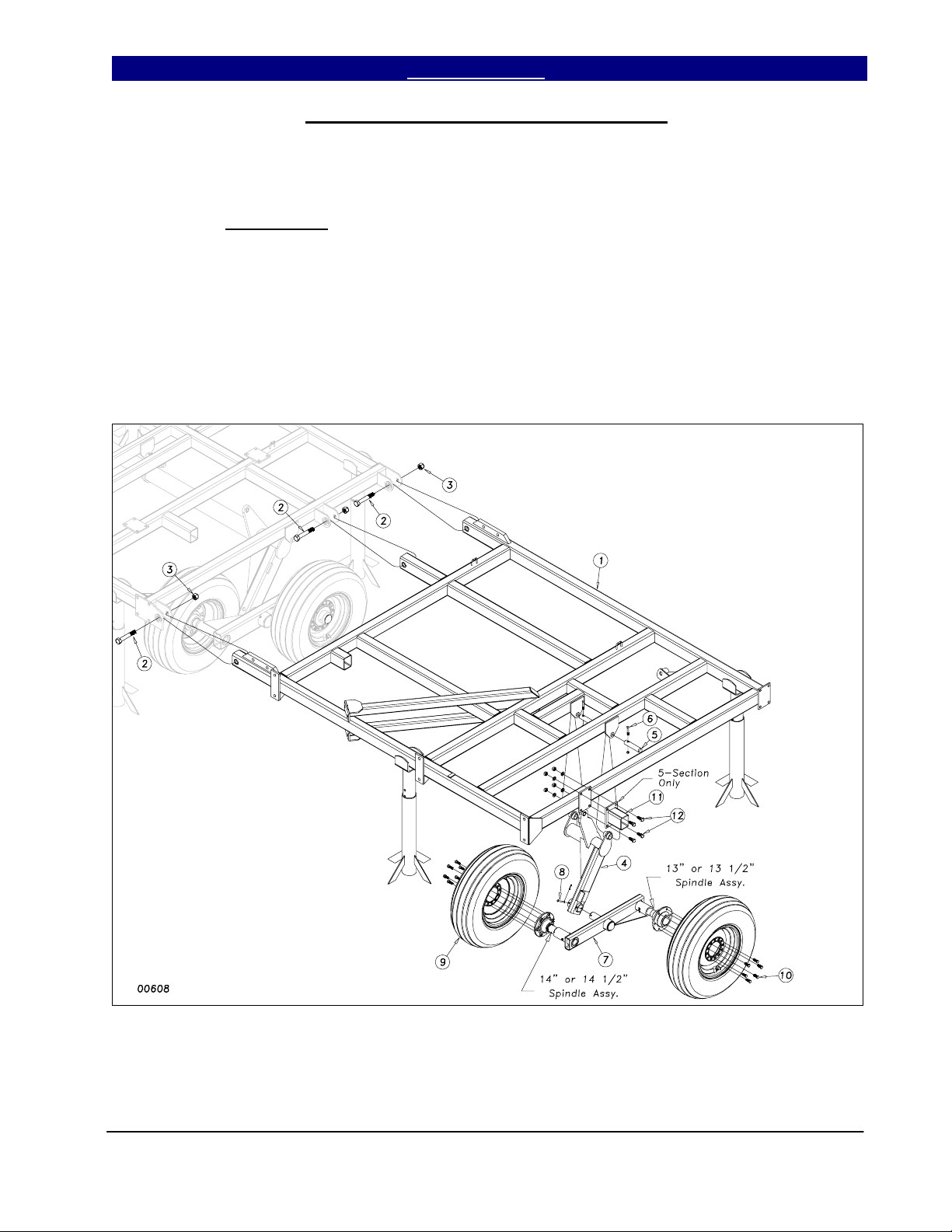

Inside Wing and Wheel Arm Assembly

Bolt the inside wing frames (1) Figure

2, to the center frame with three 1 x 6 hex bolts

(2) with nylon lock nuts (3). Draw the nuts

down tight but do not torque

Once the wings are attached, insert the

wheel arm bracket (4) into the wing frame

hangers and secure it just as you did on the

center with 1¼ x 6 pins (5). Secure the pins

with 3/8 x 2¼ GR 8 hex bolts (6) & lock nuts.

Install the wing walking beam assembly

(7) as shown in Figure 2 with the long 14” or

.

heavy hub 14 ½”, spindle toward the front. Use

anti-seize material on spindle. Secure the pivot

spindle in the sleeve with the 5/16 x 3 clevis

pin (8) and 1/8 x 1 cotter.

Bolt the 9.5L x 15, 8-ply tire (9) in

place with the ½ x 1¼ lug bolts (10), or ½” lug

nuts for heavy hub option. On 5-Section

models, bolt the 5” bolt on stub (11) to the

wing frame using 5/8 x 1½ hex bolts (12),

using lock washers and hex nuts.

Figure 2

3/31/2004 Series VII 6326-7552 Discovator 550-221M

11/22/2004

15

Section 1: Assembly Table of Contents ► Great Plains Mfg., Inc.

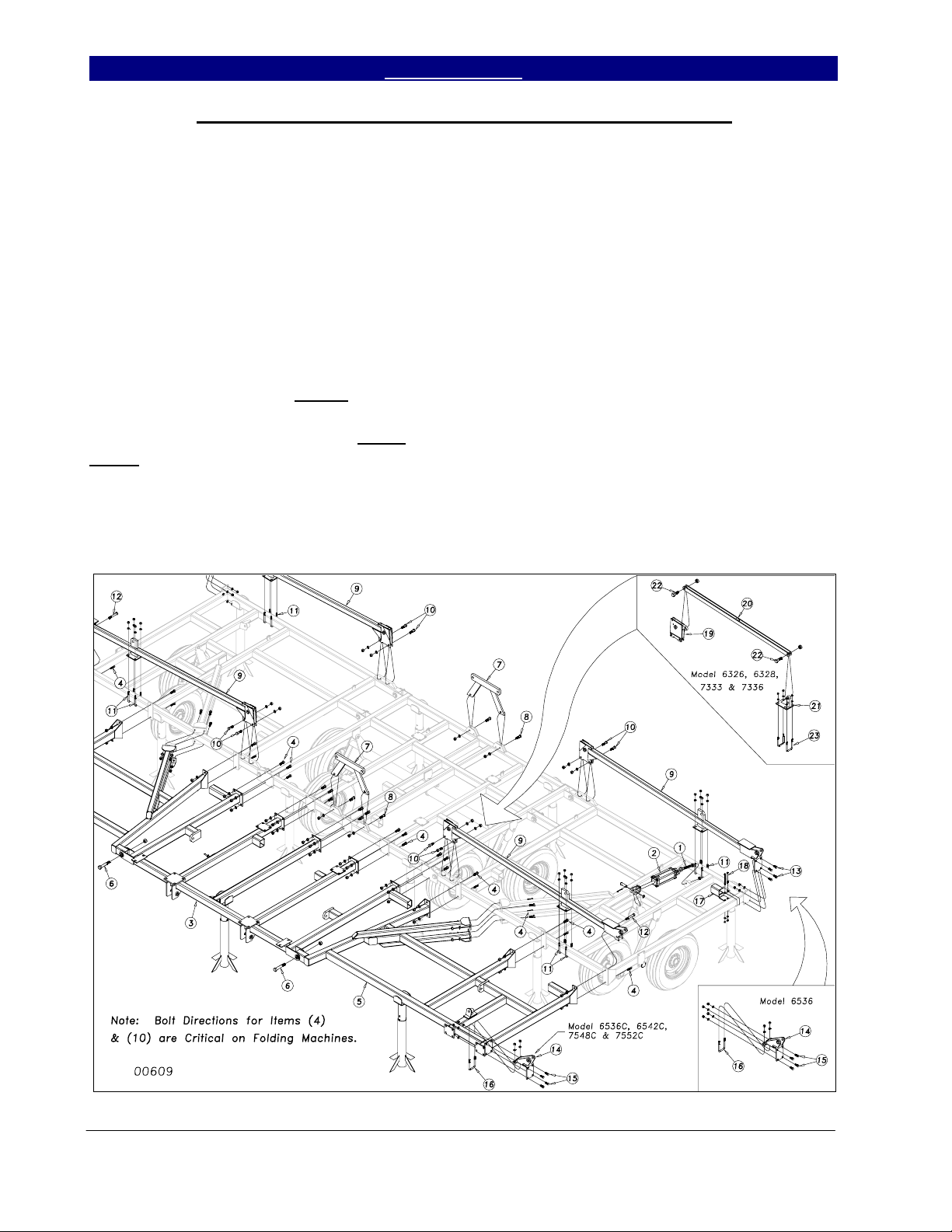

Brace Bar, Wing Brace & Rocker/Fold Bracket Assembly

Install the 1 x 7½ or the 1¼ x 9½ eyebolt (1) Figure 3, in the mounting bracket at the

back of the wing with a jam nut on each side of

the bracket. Install the 3¼ x 8 (3 3/4 x 8 for

7548 & 7552) rephasing wing cylinder (2)

between the eyebolt and the lever on the wheel

bracket. Pin the cylinder with 1 x 3 clevis pins,

1” machine washers and 3/16 x 2 cotter pin.

Bolt the center brace bar (3) and wing

brace bar (5) to the front of the center frame

and wing frame with ¾ x 2 hex bolts (4) with

lock washers and hex nuts. Do not tighten

bolts. Use a 1 x 6 hex bolt (6) and nylon lock

nut in the hinge. Draw nut tight but do not

torque. Tighten all other bolts evenly to

prevent bind at hinge.

Bolt the front (and rear on larger

models) center fold bracket(s) (7) to the center

frame with two ¾ x 2½ hex bolts (8) with lock

washer and hex nuts.

rocker/fold bracket(s) (9) to the wing using two

¾ x 2½ hex bolts (10) with lock washers and

hex nuts, along with two 5/8 x 3 x 5½ u-bolts

(11) with lock washer and hex nuts. The front

bracket uses a ¾ x 5 bolt (12) to attach the

outer end. The rear bracket uses four 5/8 x 1½

bolts (13) with lock washers and hex nuts to

attach the outer end. Bolt the inside hinge (14)

to the wing brace using 5/8 x 1½ bolts (15) and

one 5/8 x 3 x 5½ u-bolt (16) with lock washers

and hex nuts. On model 6542, bolt the 4” KFlex stub (17) to the wing frame using 1/2 x 5½

bolts (18) with lock washers and hex nuts.

(19), connecting link (20) and connecting link

bracket (21). Assemble with 1 x 3 hex bolts

(22) with 1” lock nuts, ½ x 3 x 5 u-bolts (23)

with lock washers and hex nuts.

On 5-section models, bolt the

3-Section models have rocker bracket

Figure 3

Series VII 6326-7552 Discovator 550-221M 3/31/2004

2/07/2005

16

Great Plains Mfg., Inc. Table of Contents ► Section 1: Assembly

Outside Wing Assembly

On 5-section models, assemble the

outside wing (1) by attaching the outside hinges

(2) to the wing with 1 x 6 hex bolt (3) and 5/8 x

3 x 5½ u-bolts (4) as shown in Figure 4. Use a

nylon lock nut on the 1 x 6 hex bolt (3) with

lock washers and hex nuts on the u-bolt.

Attach the 180 degree rocker (5), bulge side

out, with the 1 x 3 3/8 usable headed pin (6), 1”

machine washer and 3/16 x 2 cotter pin.

Attach the outside wheel bracket (7) just

as we did the inside ones, using the 1¼ x 6

pins (8) and 3/8 x 2¼ GR 8 hex bolts & lock

nuts. Slide the walking beam assembly (9) into

the wheel bracket sleeve as shown in Figure 4.

Again, it is recommended to use some form of

anti-seize product on the spindle. Secure with

5/16 x 3 clevis pin (10) and 1/8 x 1” cotter pin.

Note that the longer 14” long spindle assembly

(or 14 ½” with heavy hub option) goes to the

front. Bolt on the 9.5L x 15 tire and wheels

(11) with the ½ x 1¼ lug bolts (12) or ½” lug

nuts with the heavy hubs.

Models 6536 & 6542 use one tire and a

14 1/2” Hub & Spindle assembly (13) as shown

in insert.

Figure 4

3/31/2004 Series VII 6326-7552 Discovator 550-221M

11/22/2004

17

Section 1: Assembly Table of Contents ► Great Plains Mfg., Inc.

Connecting Outside Wing and Wing Brace Assembly

On 5-section models, bolt the outside

wing assembly (1) to the inside wing frame

with grade 8, 1 x 6 hex bolts, 1¾ thread (2)

Figure 5, securing with 1” nylon lock nuts.

Bolt the outside wing brace (3) to the

plate on the outside wing with ¾ x 2 hex bolts

(4), with lock washers and hex nuts.

Attach the 3 x 8 (3½ x 8 for 7548 &

7552) rephasing hydraulic cylinder (5) between

the lever on the wheel bracket and the 1 x 7½

eye bolt (6) mounted in the bracket in the back

of the wing. Use 1 x 3½ clevis pins (7) with 1”

machine washer and 3/16 x 2 cotter pins and 1”

jam nuts on the eye-bolt.

On model 6542, attach the 4x4 K-Flex

stub (8) as shown with ½ x 5½ hex bolts (9),

lock washers and hex nuts.

Figure 5

Series VII 6326-7552 Discovator 550-221M 3/31/2004

2/07/2005

18

Great Plains Mfg., Inc. Table of Contents ► Section 1: Assembly

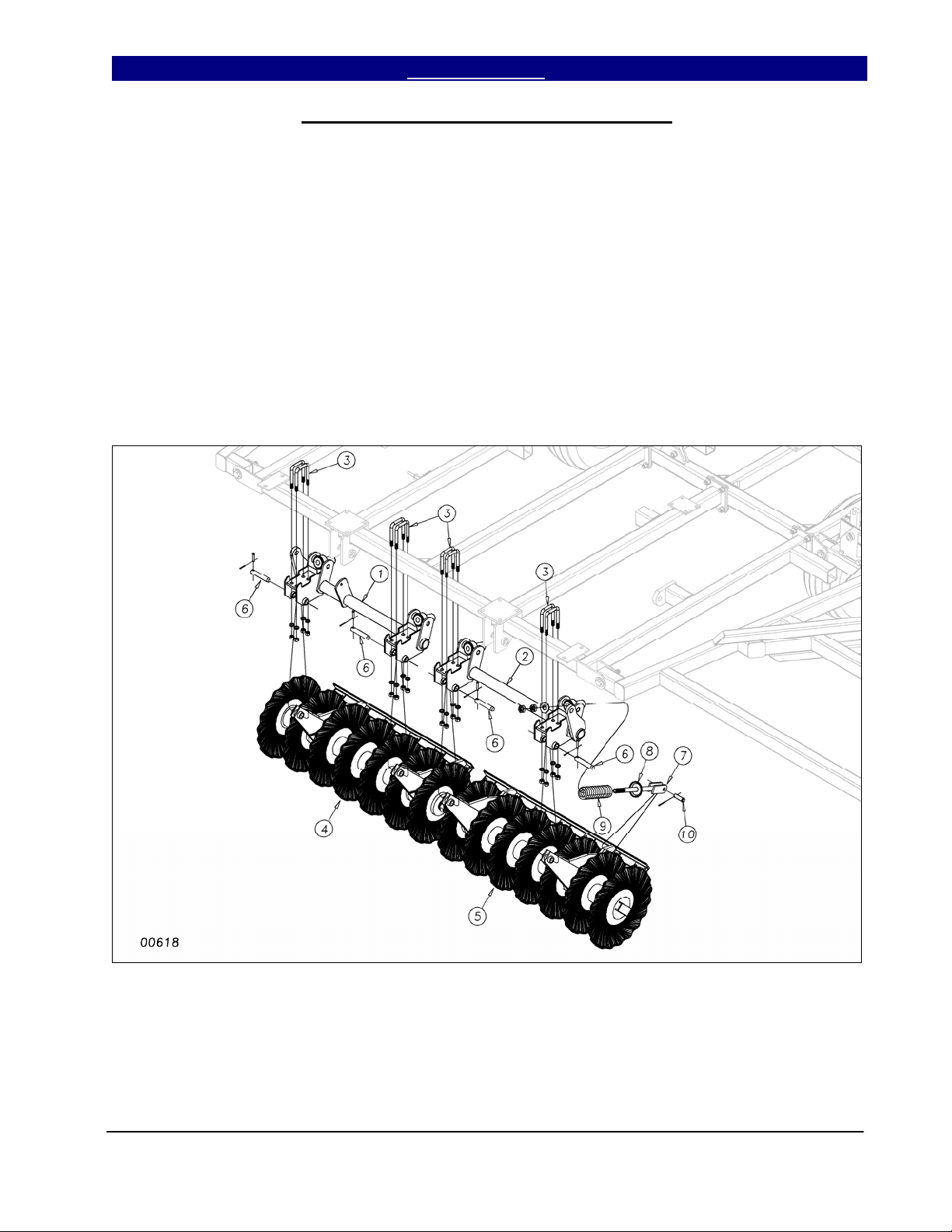

Center Gang & Gang Hanger Assembly

At this time it is best to hang the center

gangs and gang hanger tubes before you install

the hitch and hitch strut assembly, Figure 6.

U-bolt the center right and left gang

hanger tubes (1) & (2) to the center brace bar

with 5/8 x 3 x 5½ u-bolts (3), with lock washers

and hex nuts. Line up the levers on the hanger

tubes with the ratchet jack/cylinder mounts on

the brace bar. Pin the preassembled center

gangs (4) & (5) to the gang hanger tubes (1) &

(2) with the 1 x 5½ pins (6). Secure with 3/8 x

2 clevis pins & 1/8 x 1 cotters. Slide the

spring washer (8) & spring (9) on to the gang

spring bolt (7) as shown and slide it up into the

cast swivel on the gang hanger tubes. Place a

1” flat washer on the spring bolt and thread the

1” hex nut and 1” jam nut onto the spring bolt

(7). Pin the other end to the gang with ¾ x 2½

clevis pins (10), secure with 1/8 x 1½ cotters.

Finally tighten down the nuts on the spring bolt

until the spring has a preload length of 8 3/4”.

Figure 6

3/31/2004 Series VII 6326-7552 Discovator 550-221M

19

Section 1: Assembly Table of Contents ► Great Plains Mfg., Inc.

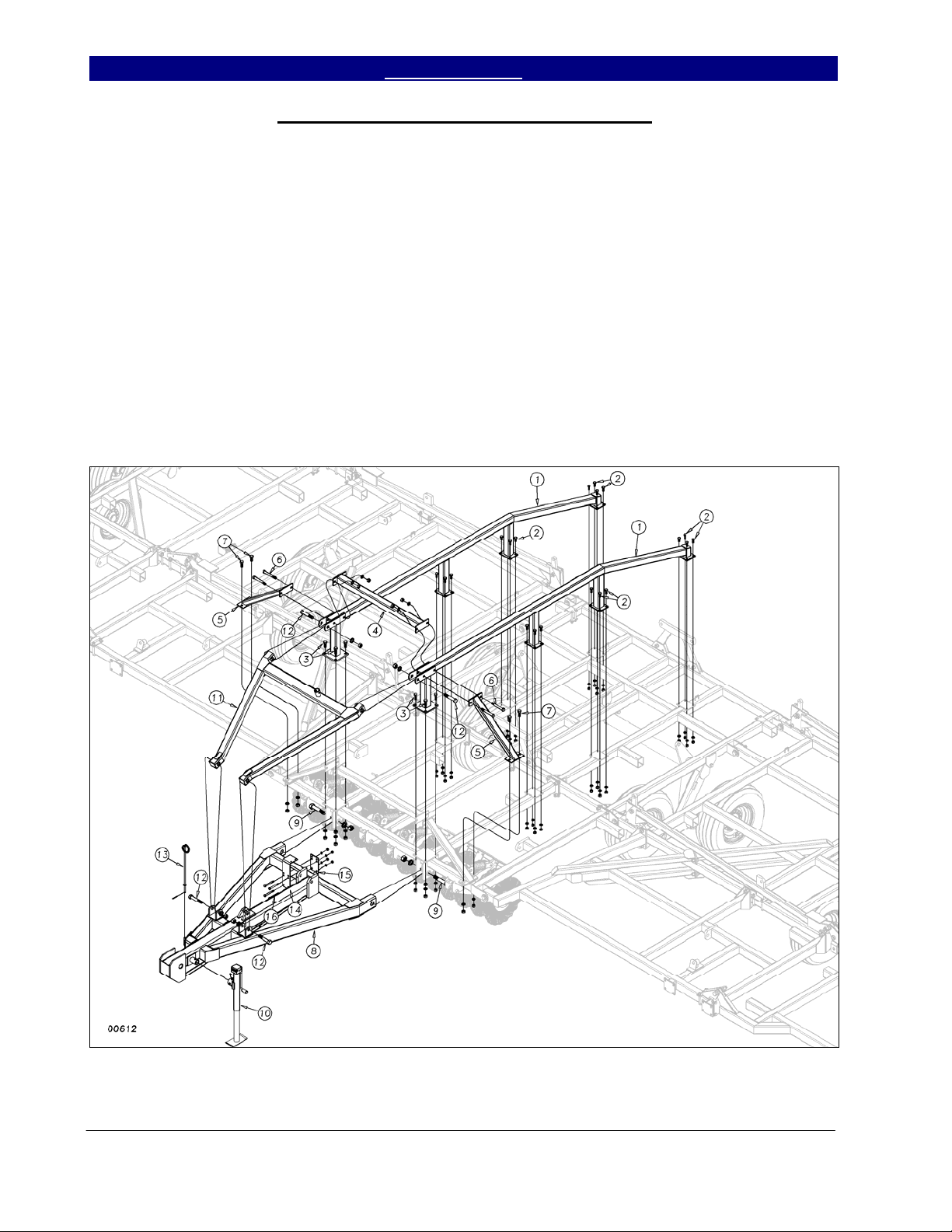

Center Truss, Hitch and Strut Assembly

Bolt the center frame truss (1) Figure 7,

to the top side of the center frame and brace

bar. Use 3/4 x 2 bolts (3) on the front plates

and 5/8 x 1½ bolts (2) on the rear two plates.

Use lock washers and hex nuts on all of these

bolts. On models 6536, 6542, 7333, 7336, 7548

& 7552, bolt the truss cross bar (4) with the

truss legs (5) through the truss frame (1) with

the ¾ x 6 bolt (6), lock washers and hex nuts.

Use two ¾ x 2 hex bolts (7) with lock washers

and hex nuts, at the base of the truss legs.

Slide the back of the hitch (8) between

the plates at the front of the brace bar as shown.

Use two 1¼ x 7 GR 8 bolts (9) and 1¼ lock

washers and hex nuts to secure the hitch.

Mount the tongue jack (10) to the front of the

hitch to support it.

Use 1 x 5½ bolts (12) to attach the hitch

strut (11) between the front of the truss and the

hitch. Use lock washers and hex nuts on these

bolts.

Slide the hose support (13) rod into the

tube at the front of the hitch and secure it with a

1/8 x 1½ cotter pin. Attach the rebound valve

mounting bracket (14) and valve mounting

bracket plate (15) with four ½ x 4½ bolts (16)

using lock washers and hex nuts.

Figure 7

Series VII 6326-7552 Discovator 550-221M 3/31/2004

8/11/2008

20

Great Plains Mfg., Inc. Table of Contents ► Section 1: Assembly

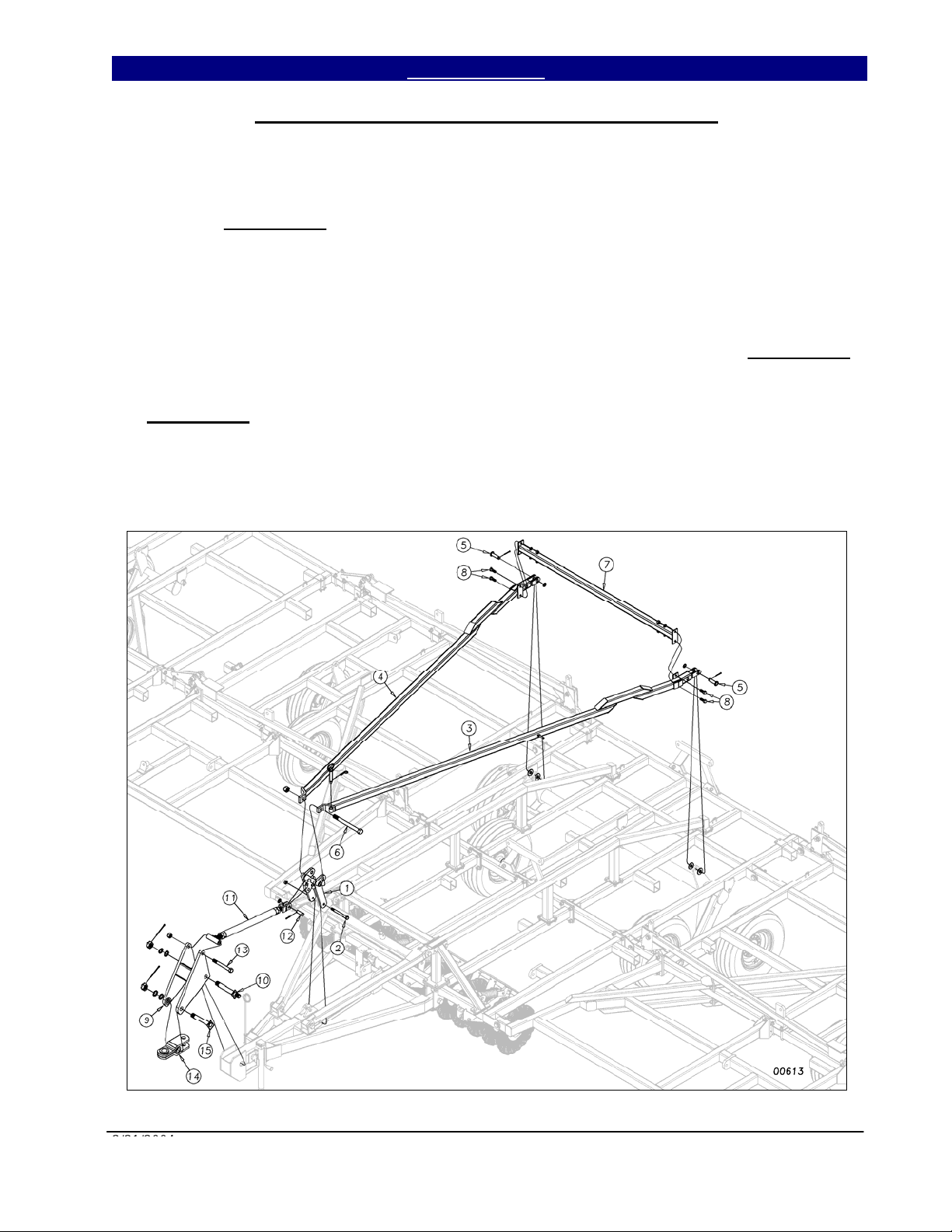

Hitch Tongue, Side Plate and Level Bar Assembly

Slide the H-bracket (1) down over the

hitch pole as shown in Figure 8. Bolt in place

with a ¾ x 8 bolt (2) and ¾” lock nut. Draw

this nut up but do not torque

pivot.

Insert the level bars (3) and (4) through

the previously assembled truss and connect to

the torque tube using two 1 x 3 3/8 usable

clevis pins (5), 1” flat washers, one 1” machine

washer and 3/16 x 2 cotter pins. Install the 1 ¼

x 13½ GR 8 bolt (6) through the level bars and

H-bracket. Draw up snug with a 1¼ top lock

nut (do not torque).

Connect the level bar cross brace (7)

between the level bars and bolt in place with ¾

x 2 hex bolts (8) using hex nuts and lock

washers. Slide the side plate weldment (9) over

the end of the hitch and bolt in place as shown

, as this part must

with the 1½ x 12 safety chain hitch bolt (10).

Secure with 1½ slotted hex nut and ¼ x 3 cotter

pin. Use the 1½ machine washers as needed

for proper fit. Connect the turnbuckle (11)

between the side plate assembly and the Hbracket (1). Use a 1 x 3 3/8 usable clevis pin

(12) with machine washer and 3/16 x 2 cotter

pin at the back end of turnbuckle. Use a 1 x 9

GR 8 bolt (13) with a nylon lock nut at the tee

end of the turnbuckle. Snug, but do not torque

nylon lock nut.

Insert the hitch clevis (14) into the front

of the side plate weldment (9) and bolt in place

with a 1½ x 9 3/8 hitch bolt (15). Secure with

slotted hex nut, machine washers and ¼ x 3

cotter pin, using the 1½ machine washers again

as needed for proper fit.

Figure 8

3/31/2004 Series VII 6326-7552 Discovator 550-221M

11/22/2004

21

Section 1: Assembly Table of Contents ► Great Plains Mfg., Inc.

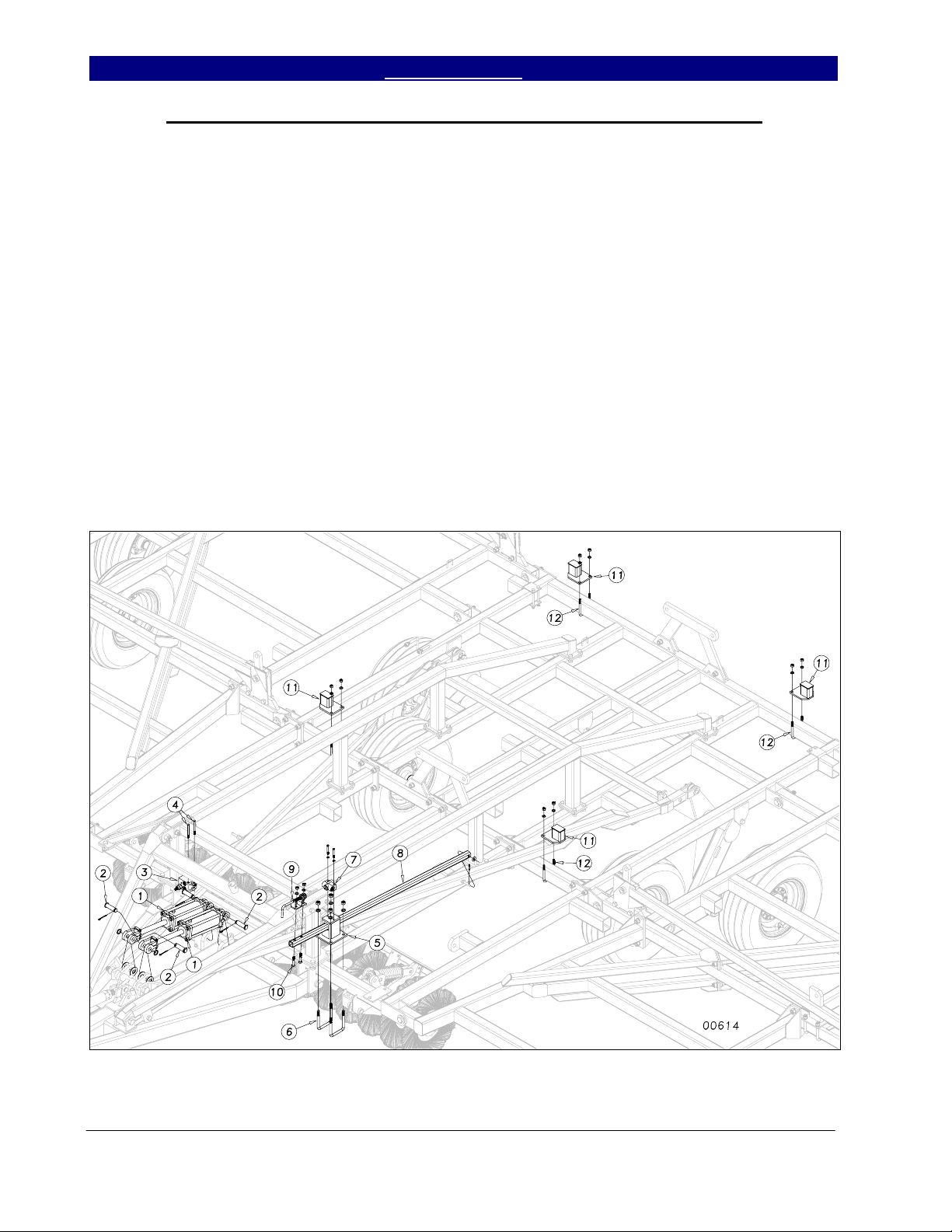

Center Lift Cylinder, Rest Pads and Hydraulic Valves Assembly

Connect the two 3½ x 8 (4 x 8 for 7548

& 7552) rephasing main lift cylinders (1) to

the center hitch pole as in Figure 9. Connect

the rod ends to the lugs on the H-bracket.

Place a 1” flat washer on each side of the lug

on the H-bracket to keep the hardened

bushings from coming out.

Secure the cylinders with 1 x 3½”

clevis pins (2), 1” machine washers and 3/16 x

2 cotter pins. Mount the rebound valve (3) as

shown with the V1 port to the front and top

using two 5/16 x 4 hex bolts (4) with lock

washers and hex nuts.

Install the depth stop mounting bracket

(5) to the center brace bar using two 5/8 x 3 x

5½, (Disc) or 5/8 x 4 x 5 ½ (Coulter) u-bolts

(6), lock washers and hex nuts. Bolt the depth

stop valve (7) on top of the bracket using the

5/16 x 2 hex bolts with lock washers. Insert

the depth stop tube (8) into the mounting

bracket (5) and attach to the level bar with ½

flat washer and 1/8 x 1 cotter pin. Bolt the

depth stop assembly (9) onto depth stop tube

(8) with two ½ x 2½ hex bolts (10) using ½”

lock washers and hex nuts.

U-bolt the 3 1/2” cylinder rest pads

(11) on the center bar as shown, using a ½ x 3

x 5 u-bolts (12) with lock washers and hex

nuts (see shank layout drawing for exact

placement). On double fold models, u-bolt the

3½” cylinder rest pads (11) on the back bar

using a ½ x 3 x 5 u-bolts (12) with lock

washers and hex nuts.

Figure 9

Series VII 6326-7552 Discovator 550-221M 3/31/2004

2/07/2005

22

Great Plains Mfg., Inc. Table of Contents ► Section 1: Assembly

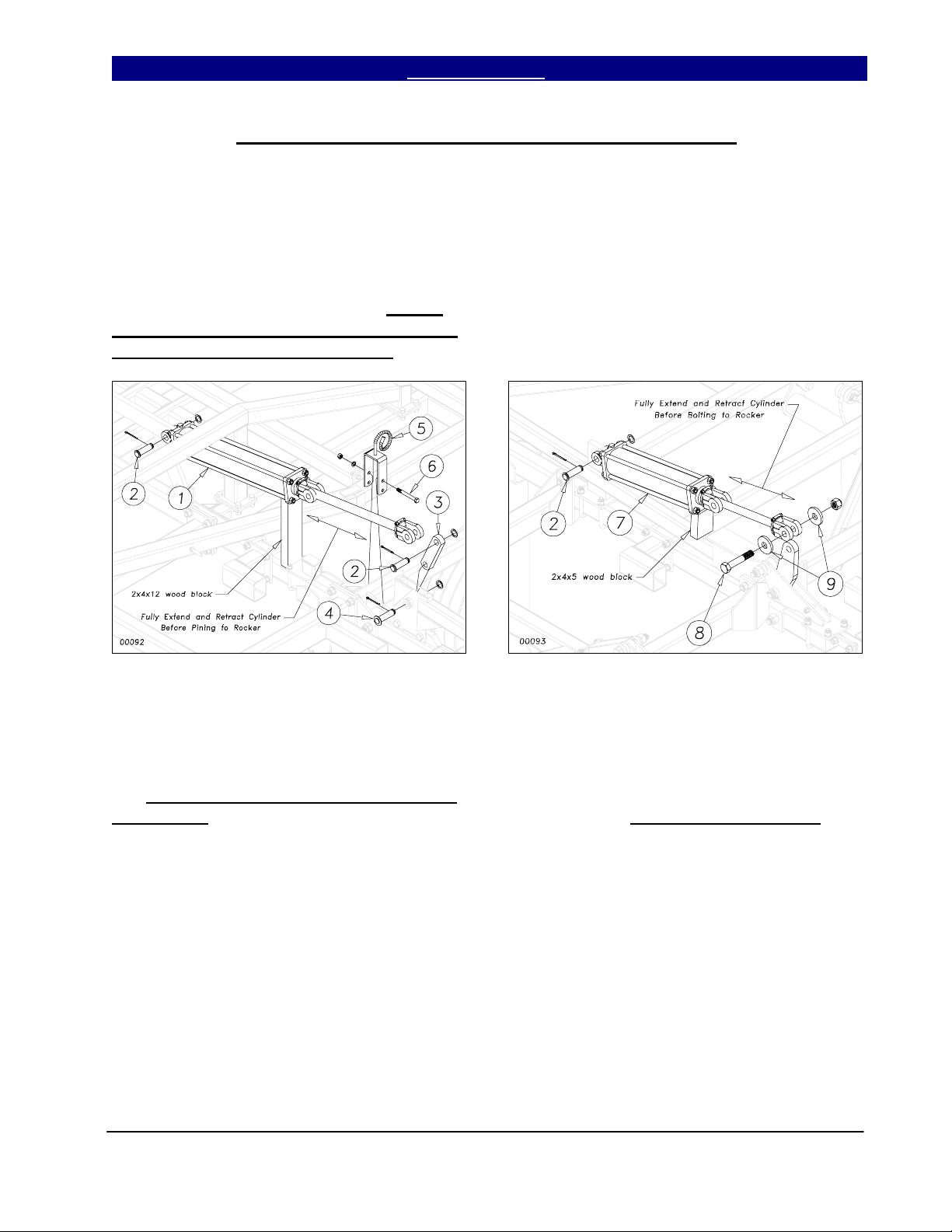

Fold Cylinders, Rocker Arm and 3” Rollers Assembly

Connect the center fold 4 x 24

cylinders (1) to the center fold bracket as

shown in Figure 10. Use the 1” x 3½ clevis

pin (2) with 1” machine washer and 3/16 x 2

cotter pin. Attach the rocker (3) to rocker

bracket with 1 x 3 Headed Pin (4) using 1”

machine washer and 3/16 x 2 cotter. Do Not

Connect Rod End Of Cylinders To Rockers

Before They Are Charged With Oil.

the cylinders, as shown, so they clear the

rockers in the extended position. You are now

ready to connect the hydraulic hoses to the

cylinders and charge the fold system (see

hydraulic layout).

Place a support block of wood under

Figure 10

On 5-section models, connect the base

of the 4 x 16 DB fold cylinders (7) to the

Rocker/Fold bracket with 1 x 3½ clevis pin

(2), 1” machine washer and cotter (see Figure

10). Do Not Connect Rod End Of Cylinders

To Rockers. Bolt the hose holders (5) to the

center frame with a ½ x 4½ hex bolt (6), using

a lock washer and hex nut.

Figure 11

Once the fold cylinders are fully

charged and free of air, connect them to the

rockers. Use a 1 x 5½ bolt (8) to bolt two 3”

rollers (9), one on each side, to the 180 degree

rocker as shown in Figure 11. Secure with 1”

nylon lock nut. Rollers must turn freely!

3/31/2004 Series VII 6326-7552 Discovator 550-221M

23

Section 1: Assembly Table of Contents ► Great Plains Mfg., Inc.

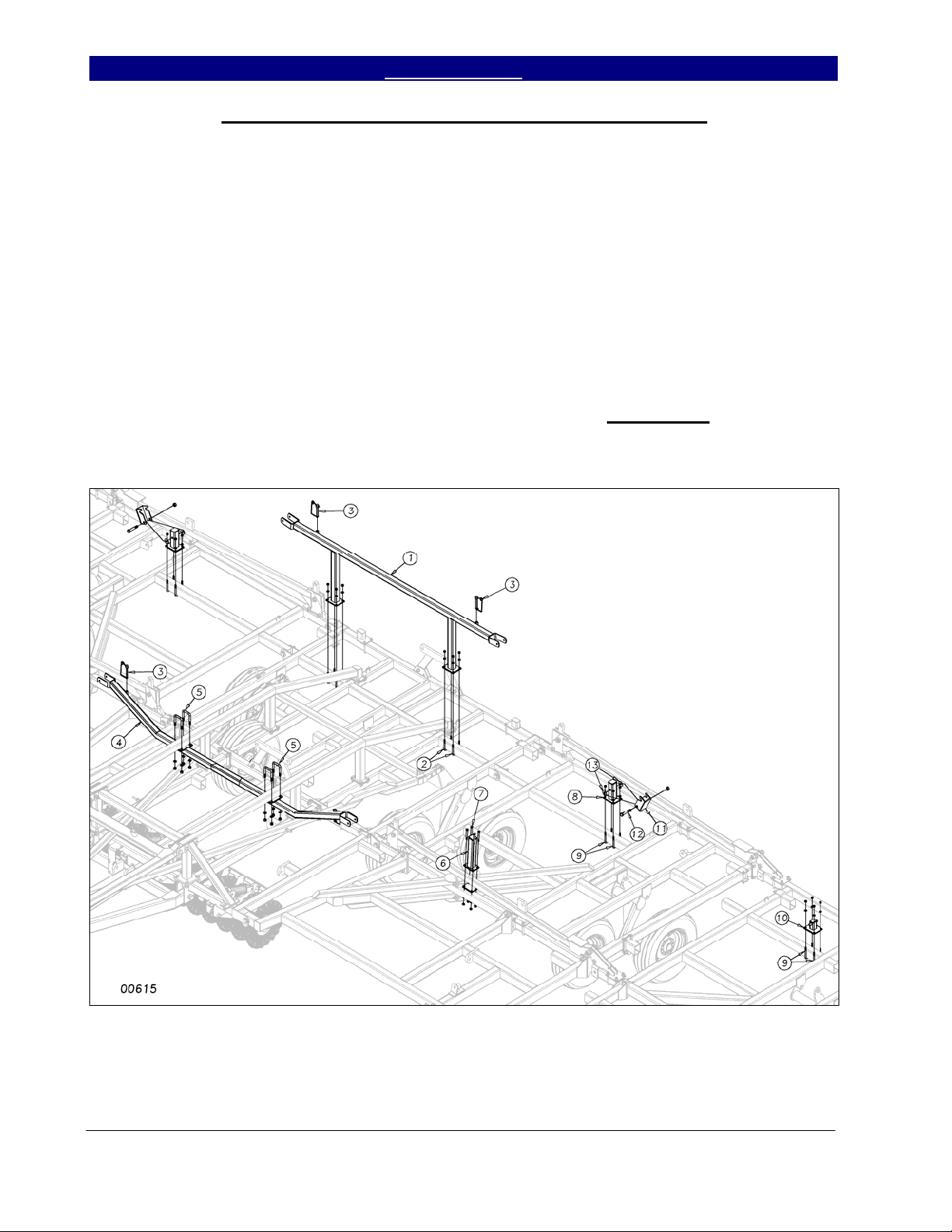

Center Wing Stop and Outside Wing Stop Assembly

U-bolt the center wing stop (1) to the

second bar from the rear on the center frame as

shown in Figure 12. Use 1/2 x 3 x 5 u-bolts

(2) with lock washers and hex nuts. Center the

wing stop from side to side. Insert the ½ x 4½

transport lock quick pins (3) in the holders on

the wing stop.

On models 7548 & 7552, u-bolt the

front center wing stop (4) to the bottom of the

center frame truss using 5/8 x 3 x 4½ u-bolts

(5), lock washers and hex nuts. Bolt the wing

rest (6) to the rocker/fold bracket with 4-hole

clamp plate and ½ x 4½ hex bolts (7), lock

washers and hex nuts (See layout for

placement).

lock mount (8) on the inside wing with ½ x 3 x

5 u-bolts (9). U-bolt the wing lock “T”

bracket (10) on the outside wing with the same

½ x 3 x 5 u-bolt (9). Refer to the shank layout

for your particular model for the exact location

of the wing lock mount and lock “T” bracket.

Use lock washers and hex nuts on these ubolts. Bolt the wing latch (11) to the wing lock

mount (8) with a ¾ x 4½ bolt (12). Slide a ¾

flat washer (13) between the latch and the

mount on each side to take out the slop. Use a

¾” lock nut but do not torque

latch must move freely.

On 5-section models, u-bolt the wing

down. The

Figure 12

Series VII 6326-7552 Discovator 550-221M 3/31/2004

24

Great Plains Mfg., Inc. Table of Contents ► Section 1: Assembly

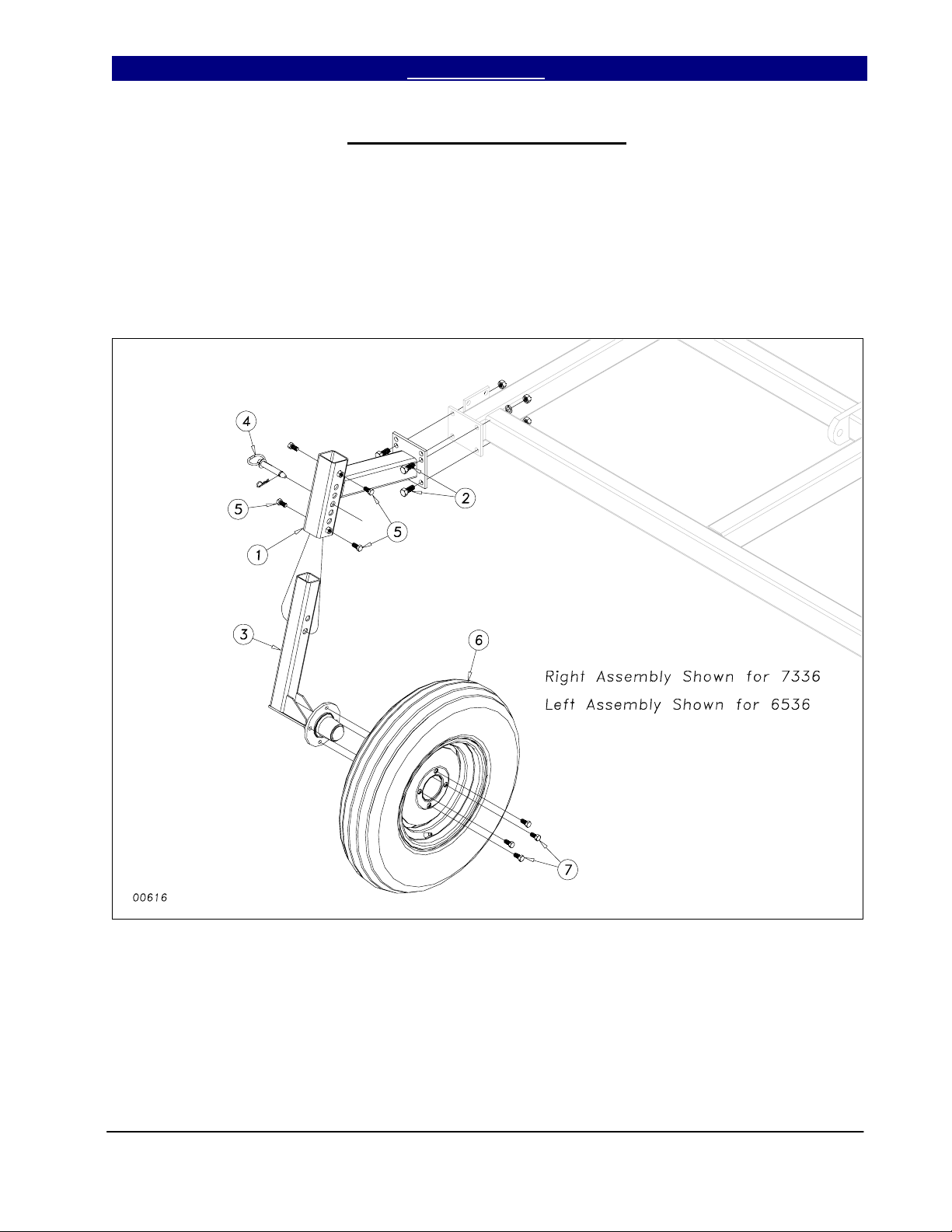

Front Gauge Wheel Assembly

On model 6536 and 7336, bolt the

gauge wheel bracket (1) to the front plate of

wing brace as shown in Figure 13 using the 5/8

x 1½ hex bolts (2), lock washers and hex nuts.

Slide the gauge wheel arm/hub assembly (3)

up into the gauge wheel bracket (1) and pin

with the ¾ x 5¼ usable pin (4). Use four ½ x

1 hex bolts (5) to secure the arm and make it

rigid. Bolt on the 4-bolt rim and tire (6) with

four ½ x 1 lug bolts (7). For directions on the

proper setting for the gauge wheel during

operation, refer to section 5.

Figure 13

3/31/2004 Series VII 6326-7552 Discovator 550-221M

2/07/2005

25

Section 1: Assembly Table of Contents ► Great Plains Mfg., Inc.

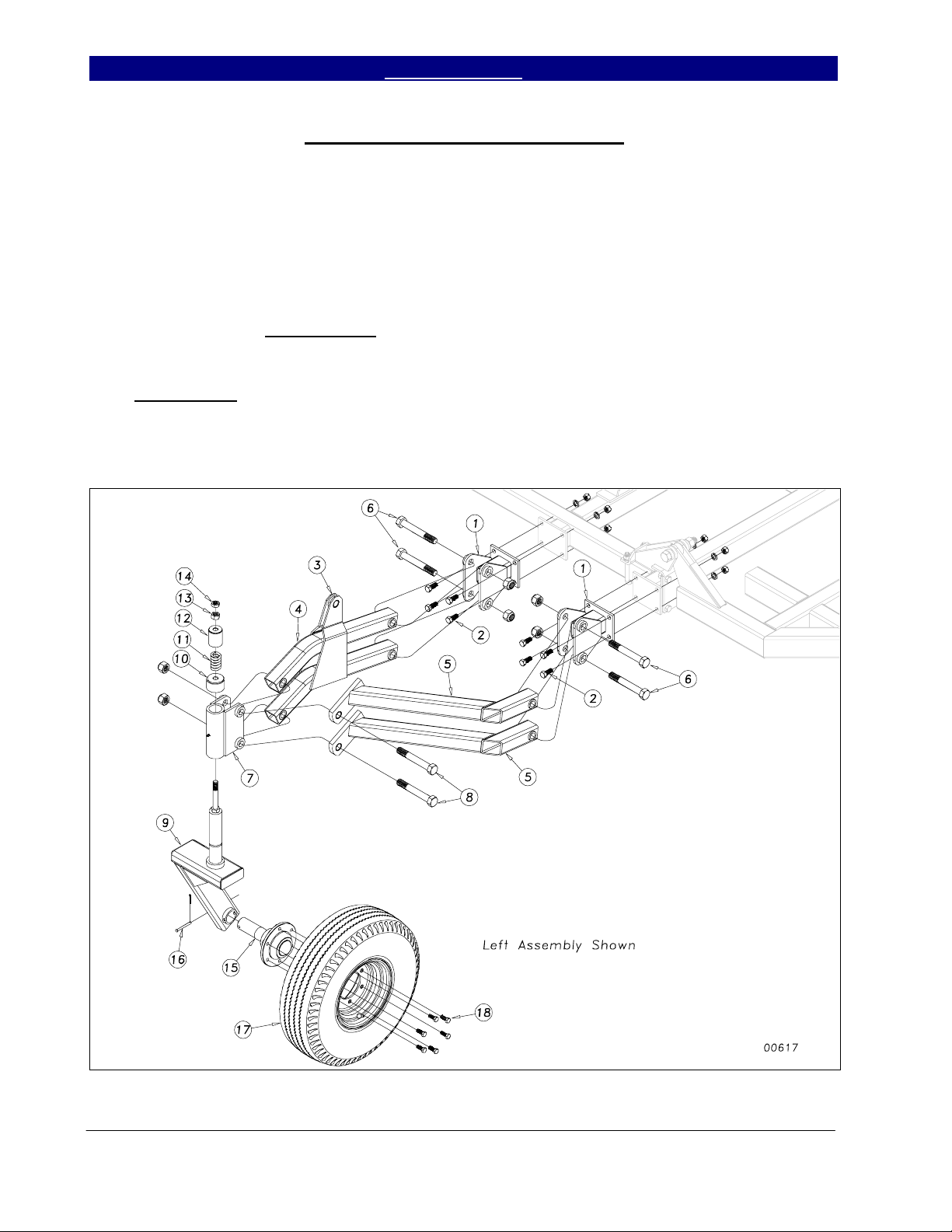

Hydraulic Gauge Wheel Assembly

On model 6542, 7548 & 7552, bolt the

gauge wheel arm mount clevis (1) to the front

bar of wing brace as shown in Figure 14 using

the 5/8 x 1½ hex bolts (2), lock washers and

hex nuts. Insert the linkage arms (3) and (4)

and hydraulic gauge wheel arms (5) into the

arm clevis (1). Assemble with 1 x 6 hex bolt

(6) and nylon lock nut. Do not torque down.

Bolt the pivot bracket (7) to the arms as shown

with 1 x 7 hex bolt (8) and nylon lock nut,

again do not torque. Insert the appropriate left

or right gauge wheel arm (9) into the pivot

bracket (7) and install the friction cap (10),

spring (11), spring cover (12), ¾” hex nut (13)

and ¾” jam nut (14) to secure the assembly.

Insert the hub and spindle assembly (15) into

the gauge wheel arm (9), using anti-seize

material on the spindle. Secure with 5/16 x 3

clevis pin (16) and 1/8 x 1 cotter. Bolt on the

rim and tire assembly (17) with six ½ x 1¼

lug bolts (18). Install the gauge wheel

hydraulic cylinders (or ratchet jacks) as per

hydraulic layout for your machine, section 2.

Use 1 x 8½ eye-bolts with 1” jam nuts at the

base of the cylinders. For directions on the

proper setting for the hydraulic gauge wheel

during operation, refer to section 5.

Figure 14

Series VII 6326-7552 Discovator 550-221M 3/31/2004

11/22/2004

26

Great Plains Mfg., Inc. Table of Contents ► Section 1: Assembly

Completing Setup

Install the plastic end caps into all the

open ends of all the 4x3 frame tubes.

You should now be ready to add

shanks and the remaining gangs to the

machine. If the machine has a finishing

attachment you would install it last. See the

machine layout Section 4 for proper shank and

gang locations for your unit. Section 3 in the

manual shows the individual shank assemblies

and parts for both the K-flex and magnum

shanks along with gang parts and identification

drawings.

Once the shanks and gangs are

installed and all of the hydraulic procedures

have been completed, you may fold the

machine to check for clearance and proper

shank placement. Slowly fold the machine

while watching that hoses do not become

pinched or kinked and watch that shanks clear

all obstructions.

begin to unfold slowly. Be Sure No One Is

Under The Wings When You Unfold The

Machine. Once the machine is unfolded, add

the safety decals and the product decals. Refer

to the Important Safety Information (page 7)

for the proper placement of safety decals.

safety lights in accordance with local and state

laws. See parts manual (Section 6: Safety) for

assembly drawings and parts list.

complete and you are ready to add any

finishing attachment, rear hitches, etc… to the

machine. Be sure to consult the operating

instructions, Section 5, for the first time field

adjustments before going to the field for the

first time.

Once the machine is folded completely,

Install the safety chain, SMV sign &

At this point, set up of the machine is

3/31/2004 Series VII 6326-7552 Discovator 550-221M

2/07/2005

27

Section 2: Hydraulics Table of Contents ► Great Plains Mfg., Inc.

Hydraulic Layout: 6326, 6328, 7333 & 7336

00653

Series VII 6326-7552 Discovator 550-221M 12/23/2004

2/07/2005

28

Great Plains Mfg., Inc. Table of Contents ► Section 2: Hydraulics

Hydraulic Layout: 6326, 6328, 7333 & 7336

Ref. Kent No. GP Part No. Part Description Comments

1. 810-479C CYL REP 3.50x8x1.25 Tie 3000# GP Seal Kit# 810-174C

2. 810-478C CYL REP 3.25x8x1.25 Tie 3000# GP Seal Kit# 810-173C

3. 810-487C CYL 4X24X1.5 Tie 34.63 CL 3000# GP Seal Kit# 810-060C

4. 810-622C Rebound Valve

FC1342 REP BY 810-622C

5. FC0218 810-511C Depth Control Valve Cartridge #3C7272

6. 811-088C Adaptor, AD 3/4 MORB 3/4 MJIC

7. 811-063C Elbow, EL 3/4MJIC 3/4MORB

8. 196-430D Orifice Restrictor, ORPL 1/16 3/4MORB

811- 845C Replaced by 196-430D

9. 811-078C Tee, TE 3/4MJIC

10. HF0034 811-857C 3/4 O-Ring Plug

11. 811-974C HH3/8R2 135 3/4MORB 3/4FJIC Models 6326 & 6328

811-893C HH3/8R2 147 3/4MORB 3/4FJIC Models 7333 & 7336

12. 811-977C HH3/8R 2 053 3/4FJIC

13. 811-949C HH3/8R 2 015 3/4FJIC

14. 811-889C HH3/8R 2 303 3/4FJIC Models 6326

811-981C HH3/8R2 317 3/4FJIC Models 6328

811-990C HH3/8R2 357 3/4FJIC Models 7333

811-994C HH3/8R2 359 3/4FJIC Models 7336

15. 811-976C HH3/8R 2 139 3/4FJIC Models 6326

811-975C HH3/8R2 153 3/4FJIC Models 6328

811-991C HH3/8R2 187 3/4FJIC Models 7333

811-884C HH3/8R2 209 3/4FJIC Models 7336

16. 811-975C HH3/8R 2 153 3/4FJIC Models 6326 & 6328 & 7336

811-909C HH3/8R2 163 3/4FJIC Models 7333

17. 811-965C HH3/8R2 207 3/4MORB 3/4FJIC Models 6326 & 6328

841-042C HH3/8R2 249 3/4MORB 3/4FJIC Models 7333

811-992C HH3/8R2 235 3/4MORB 3/4FJIC Models 7336

18. 811-943C HH3/8R 2 033 3/4FJIC

19. 811-952C HH3/8R 2 057 3/4FJIC

20. 811-826C Hydra Grip Handle, Black Extend

21. 811-913C Hydra Grip Handle, Black Retract

22. 811-919C Adaptor, AD 3/ 4 MORB 3/4 FORB (HG)

23. 548-001S HG Pair Black MORB-FORB Includes items 20, 21 & 22

24. 811-394C Coupler, CP 3/4 FORB MALE QD Poppet Type

25. 811-915C H ydra Grip Handle - Green Extend

26. 811-916C Hydra Grip Handle - Green Retract

27. 548-003S HG Pair Green MORB-FORB Includes items 25, 26 & 22

28. 575-268D Hose Wrap, Large Size, Short 8”

550-123D Hose Wrap, Small Size, Short 8”

Legend: = 1st revision; = 2nd revision, = 3rd revision; use up existing stock; ⊗ not interchangeable; ⊗Revision 2 is not interchangeable with 1

12/23/2004 Series VII 6326-7552 Discovator 550-221M

8/11/2008

29

Section 2: Hydraulics Table of Contents ► Great Plains Mfg., Inc.

Hydraulic Layout, 6536

00654

Series VII 6326-7552 Discovator 550-221M 12/23/2004

2/07/2005

30

Great Plains Mfg., Inc. Table of Contents ► Section 2: Hydraulics

Hydraulic Layout, 6536

Ref Kent No. GP Part No. Part Description Comments

29. 810-479C CYL REP 3.50x8x1.25 Tie 3000# GP Seal Kit# 810-174C

30. 810-478C CYL REP 3.25x8x1.25 Tie 3000# GP Seal Kit# 810-173C

31. 810-477C CYL REP 3x8x1.25 Tie 3000# GP Seal Kit# 810-211C

32. 810-487C CYL 4x24x1.5 Tie 34.63 CL 3000# GP Seal Kit# 810-060C

33. 810-486C CYL 4x16x1.25 Tie 26.63 CL 3000# GP Seal Kit# 810-013C

34. 810-622C Rebound Valve

FC1342 REP BY 810-622C

35. FC0218 810-511C Depth Control Valve Cartridge #3C7272

36. 811-088C Adaptor, AD 3/4 MORB 3/4 MJIC

37. 811-063C Elbow, EL 3/4MJIC 3/4MORB

38. 196-430D Orifice Restrictor, ORPL 1/16 3/4MORB

811- 845C Replaced by 196-430D

39. 811-078C Tee, TE 3/4MJIC

40. 811-077C Tee, TE 3/4MORB 3/4MJIC 3/4MJIC

41. HF0034 811-857C 3/4 O-Ring Plug

42. 811-974C HH3/8R2 135 3/4MORB 3/4FJIC

43. 811-977C HH3/8R 2 053 3/4FJIC

44. 811-949C HH3/8R 2 015 3/4FJIC

45. 811-889C HH3/8R 2 303 3/4FJIC

46. 811-983C HH3/8R 2 073 3/4FJIC

47. 811-884C HH3/8R 2 209 3/4FJIC

48. 811-975C HH3/8R 2 153 3/4FJIC

49. 811-965C HH3/8R2 207 3/4MORB 3/4FJIC

50. 811-943C HH3/8R 2 033 3/4FJIC

51. 811-905C HH3/8R 2 121 3/4FJIC

52. 811-127C HH3/8R 2 111 3/4FJIC

53. 811-952C HH3/8R 2 057 3/4FJIC

54. 811-826C Hydra Grip Handle, Black Extend

55. 811-913C Hydra Grip Handle, Black Retract

56. 811-919C Adaptor, AD 3/ 4 MORB 3/4 FORB (HG)

57. 548-001S HG Pair Black MORB-FORB Includes items 26,27 & 28

58. 811-394C Coupler, CP 3/4 FORB MALE QD Poppet Type

59. 811-915C H ydra Grip Handle - Green Extend

60. 811-916C Hydra Grip Handle - Green Retract

61. 548-003S HG Pair Green MORB-FORB Includes items 29, 30 & 28

62. FC1790 575-268D Hose Wrap, Large size, Short 8”

FC1792 550-123D Hose Wrap, Small size, Short 8”

12/23/2004 Series VII 6326-7552 Discovator 550-221M

8/11/2008

31

Section 2: Hydraulics Table of Contents ► Great Plains Mfg., Inc.

Hydraulic Layout: 6542, 7548 & 7552

00655

Series VII 6326-7552 Discovator 550-221M 12/23/2004

8/11/2008

32

Great Plains Mfg., Inc. Table of Contents ► Section 2: Hydraulics

Hydraulic Layout: 6542, 7548 & 7552

Ref Kent No. GP Part No. Part Description Comments

1. 810-479C CYL REP 3.50x8x1.25 Tie (Model 6542) GP Seal Kit# 810-174C

810-138C CYL REP 4x8x1.38 Tie (Model 7548 & 7552) GP Seal Kit# 810-151C

2. 810-478C CYL REP 3.25x8x1.25 Tie (Model 6542) GP Seal Kit# 810-173C

810-480C CYL REP 3.75x8x1.38 Tie (Model 7548 & 7552) GP Seal Kit# 810-373C

3. 810-477C CYL REP 3x8x1.25 Tie (Model 6542) GP Seal Kit# 810-211C

810-479C CYL REP 3.50x8x1.25 Tie (Model 7548 & 7552) GP Seal Kit# 810-174C

4. 810-476C CYL REP 2.75x8x1.12 Tie (Model 6542) GP Seal Kit# 810-513C

810-478C CYL REP 3.25x8x1.25 Tie (Model 7548 & 7552) GP Seal Kit# 810-173C

5. 810-487C CYL 4x24x1.5 Tie 34.63 CL 3000# GP Seal Kit# 810-060C

6. 810-486C CYL 4x16x1.25 Tie 26.63 CL 3000# GP Seal Kit# 810-013C

7. 810-622C Rebound Valve

FC1342 REP BY 810-622C

8. FC0218 810-511C Depth Control Valve Cartridge #3C7272

9. 811-088C Adaptor, AD 3/4 MORB 3/4 MJIC

10. 811-063C Elbow, EL 3/4MJIC 3/4MORB

11. 196-430D Orifice Restrictor, ORPL 1/16 3/4MORB

811- 845C Replaced by 196-430D

12. 811-078C Tee, TE 3/4MJIC

13. 811-077C Tee, TE 3/4MORB 3/4MJIC 3/4MJIC

14. 811-147C Cross, CR 3/4 MJIC

15. HF0034 811-857C 3/4 O-Ring Plug

16. 811-974C HH3/8R2 135 3/4MORB 3/4FJIC Model 6542

811-893C HH3/8R2 147 3/4MORB 3/4FJIC Model 7548 & 7552

17. 811-977C HH3/8R 2 053 3/4FJIC

18. 811-949C HH3/8R 2 015 3/4FJIC

19. 811-981C HH3/8R 2 317 3/4FJIC Model 6542

811-990C HH3/8R2 357 3/4F JIC Model 7548 & 7552

20. 811-127C HH3/8R 2 111 3/4FJIC Model 6542

811-671C HH3/8R2 099 3/4F JIC Model 7548

811-987C HH3/8R2 127 3/4F JIC Model 7552

21. 811-986C HH3/8R 2 241 3/4FJIC Model 6542, 7548

811-946C HH3/8R2 271 3/4FJIC Model 7552

22. 811-970C HH3/8R 2 219 3/4FJIC Model 6542

811-961C HH3/8R2 261 3/4FJIC Model 7548 & 7552

23. 811-978C HH3/8R 2 093 3/4FJIC

24. 811-965C HH3/8R2 207 3/4MORB 3/4FJIC Model 6542

811-995C HH3/8R2 237 3/4MORB 3/4FJIC Model 7548 & 7552

25. 811-943C HH3/8R 2 033 3/4FJIC

26. 811-906C HH3/8R 2 135 3/4FJIC Model 6542

811-982C HH3/8R2 149 3/4F JIC Model 7548 & 7552

27. 811-851C HH3/8R 2 126 3/4FJIC Model 6542

811-126C HH3/8R2 140 3/4F JIC Model 7548 & 7552

28. 811-952C HH3/8R 2 057 3/4FJIC

29. 811-988C HH3/8R 2 089 3/4FJIC

30. 811-826C Hydra Grip Handle, Black Extend

31. 811-913C Hydra Grip Handle, Black Retract

32. 811-919C Adaptor, AD 3/ 4 MORB 3/4 FORB (HG)

33. 548-001S HG Pair Black MORB-FORB Includes items 29,30 & 31

34. 811-394C Coupler, CP 3/4 FORB MALE QD Poppet Type

35.

811-915C Hydra Grip Handle - Green Extend

36. 811-916C Hydra Grip Handle - Green Retract

37. 548-003S HG Pair Green MORB-FORB Includes items 34, 35 & 31

38. FC1790 575-268D Hose Wrap, Large size, Short 8”

FC1792 550-123D Hose Wrap, Small size, Short 8”

12/23/2004 Series VII 6326-7552 Discovator 550-221M

8/11/2008

33

Section 2: Hydraulics Table of Contents ► Great Plains Mfg., Inc.

Hydraulic Gang Layout

00656

Series VII 6326-7552 Discovator 550-221M 12/23/2004

34

Great Plains Mfg., Inc. Table of Contents ► Section 2: Hydraulics

Hydraulic Gang Layout

Ref. Kent No. GP Part No. Part Description Comments

1. 810-479C CYL REP 3.50x8x1.25 rod GP Seal Kit # 810-174C

2. 810-478C CYL REP 3.25x8x1.25 rod GP Seal Kit # 810-173C

3. 810-477C CYL REP 3x8x1.25 rod GP Seal Kit# 810-211C

4. 811-063C Elbow, EL 3/4MJIC 3/4MORB

5. 811-078C Tee, TE 3/4MJIC

6. 811-121C Tee, TE 1/2 MNPT 3/4MJIC 3/4MJIC

7. HF0028 811-853C Restrictor, ORAD 1/8 1WAY 1/2MNPT 1/2FNPT

8. 811-290C Adaptor, AD 3/4MJIC 1/2FNPT

9. 811-979C HH3/8R2 177 3/4MORB 3/4F JIC Model 6326, 6328, 6536, 654 2

811-965C HH3/8R2 207 3/4FJIC Model 7333, 7336, 7548, 7552

10. 811-980C HH3/8R 2 047 3/4FJIC Model 6326, 6328, 6536, 6542

811-993C HH3/8R2 075 3/4FJIC Model 7333, 7336, 7548, 7552

11. 811-978C HH3/8R 2 093 3/4FJIC Model 6326 & 6536

811-687C HH3/8R2 108 3/4FJIC Model 6328 & 6542

811-897C HH3/8R2 123 3/4FJIC Model 7333, 7336, 7548, 7552

12. 811-985C HH3/8R 2 078 3/4FJIC Model 6536 & 6542

811-997C HH3/8R2 084 3/4FJIC Model 7548 & 7552

13. 811-906C HH3/8R 2 135 3/4FJIC Model 6326

811-982C HH3/8R2 149 3/4FJIC Model 6328

811-984C HH3/8R2 203 3/4FJIC Model 6536

811-989C HH3/8R2 213 3/4FJIC Model 6542

811-935C HH3/8R2 177 3/4FJIC Model 7333 & 7336

811-996C HH3/8R2 243 3/4FJIC Model 7548 & 7552

14. 811-914C Hydra Grip Handle, Red Extend

15. 811-827C Hydra Grip Handle, Red Retract

16. 811-919C Adaptor, AD 3/ 4 MORB 3/4 FORB (HG)

17. 548-002S HG Pair Red MORB-FORB Includes items 14, 15 & 16

18. 811-394C Coupler, CP 3/4 FORB MALE QD Poppet Type

19. FC1790 575-268D Hose Wrap, Large Size, Short 8”

FC1789 550-346D Hose Wrap, Large Size, Long 15”

12/23/2004 Series VII 6326-7552 Discovator 550-221M

35

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

Magnum Shank Assembly

00347

Series VII 6326-7552 Discovator 550-221M 1/19/2006

36

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Regular Magnum Shank Assembly (S/N 1172DD-)

Ref. Kent No. GP Part No. Part Description Comments

1. FC1200 820-297C Shank, 9/16 x 1 3/4 x 30 Min Draft (shown)

FC0032 820-293C Shank, 9/16 x 1 3/4 x 30 Flat

2. FC0001 552-014D Top Spring Plug

3. FC1109 Spring, Shank

4. FC0317 Bottom Spring Plug

5. FC2198 552-050V Spring/Plug Sub Assembly Includes items 2 thru 4

6. FC0331 552-043H Shank Cradle

7. FC1471 552-006D Shank Mount Upright, 4” Tube

8. FC0333 1 x 3/4 x 3 Hardened Bushing

9. UB0032 806-158C U-Bolt, 5/8 x 4 1/32 x 4 3/4

10. 3110 803-024C Lock Nut, 5/8

11. FC0320 802-507C Hex Bolt, 1/2 x 1 1/2, Special

12. FC0319 802-485C Carriage Bolt, 3/4 x 4 1/8 Special

13. 3612J 803-126C Nylon Jam Nut, 3/4

14. FC1169 802-535C Hex Bolt, 1/2 x 3 Gr. 5, Special

15. 3108 803-019C Lock Nut, 1/2

16. 111032 802-055C Hex Bolt, 5/8 x 2

17. 3610 803-148C Nylon Lock Nut, 5/8

18. 820-294C Sweep, 1/4 x 7"

820-292C Sweep, 1/4 x 7" Hard Faced

820-291C Sweep, 1/4 x 7" Ultra Wing

FC1875 Sweep, 1/4 x 9"

FC1879 Sweep, 1/4 x 9" Hard Faced

FC2042 Sweep, 1/4 x 9" Ultra Wing

FC1876 Sweep, 1/4 x 10"

FC1880 Sweep, 1/4 x 10", Hard Faced

FC2043 Sweep, 1/4 x 10" Ultra Wing

FC1877 Sweep, 1/4 x 11"

FC1881 Sweep, 1/4 x 11", Hard Faced

FC2044 Sweep, 1/4 x 11" Ultra Wing

19. 802-090C Plowbolt, 7/16 x 1 3/4, GR 5

20. 4007 804-204C Flat Washer, 7/16

21. 3607 803-245C Nylon Lock Nut, 7/16

22. FC0556 575-860V Sweep 7", w/Bolts Includes items 18 thru 21

575-862V Sweep 7", w/Bolts, Hard Faced Includes items 18 thru 21

575-861V Sweep 7", w/Bolts, Ultra Wing Includes items 18 thru 21

FC0019 570-219V Sweep 9", w/Bolts Includes items 18 thru 21

FC0559 575-809V Sweep 9", w/Bolts, Hard Faced Includes items 18 thru 21

FC1771 575-810V Sweep 9", w/Bolts, Ultra Wing Includes items 18 thru 21

FC0557 575-807V Sweep 10", w/Bolts Includes items 18 thru 21

FC0560 575-767V Sweep 10", w/Bolts, Hard Faced Includes items 18 thru 21

FC1772 575-811V Sweep 10", w/Bolts, Ultra Wing Includes items 18 thru 21

FC0558 575-808V Sweep 11", w/Bolts Includes items 18 thru 21

FC0561 575-804V Sweep 11", w/Bolts, Hard Faced Includes items 18 thru 21

FC1773 575-812V Sweep 11", w/Bolts, Ultra Wing Includes items 18 thru 21

Heavy-Duty Magnum Shank Assembly (S/N 1173DD+)

Ref. Kent No. GP Part No. Part Description Comments

1. FC1576 820-296C Shank, 5/8 x 1 3/4 x 30 Min Draft, Heavy

820-295C Shank, 5/8 x 1 3/4 x 30 Flat

820-351C Shank, 5/8 x 1 3/4 x 30 MD Offset 2

2. FC1970 552-030D 7/16x1.5 ID Top Spring Plug

3. 807-149C Spring Ext 2.42OD .438W 9.69 Lo ng

4. FC1971 812-143C 7/16 x 1.5 ID Bottom Spring Plug

5. 552-057V Heavy Spring/Plug Sub Assembl y Includes items 2 thru 4

All other items same as above.

1/19/2006 Series VII 6326-7552 Discovator 550-221M

37

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

K-Flex Shank Assembly

00029

Series VII 6326-7552 Discovator 550-221M 1/19/2006

38

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Regular K-Flex Shank Assembly

Ref. Kent No. GP Part No. Part Description Comments

1. FL1475 K-Flex Shank Mount, Regular, 3 x 4 Tube

2. FL1544 552-002D K-Flex Clamp, Regular, 3 x 4 Mount

3. FC1200 820-297C Shank, 9/16 x 1 3/4 x 30 Min Draft (shown)

FC0032 820-293C Shank, 9/16 x 1 3/4 x 30 Flat

820-354C Shank, 9/16 x 1 3/4 x 30 MD Offset 2

4. FC1508 552-001D K-Flex Clip, 4

5. 110880 802-045C Hex Bolt, 1/2 x 5

6. 4108 804-015C Lock Washer, 1/2

7. 3008 803-020C Hex Nut, 1/2

8. FC0320 802-091C Hex Bolt, 1/2 x 1 1/2

9. 111032 802-055C Hex Bolt, 5/8 x 2

10. 3610 803-148C Nylon Lock Nut, 5/8

11. 820-294C Sweep, 1/4 x 7"

820-292C Sweep, 1/4 x 7" Hard Faced

820-291C Sweep, 1/4 x 7" Ultra Wing

FC1875 Sweep, 1/4 x 9"

FC1879 Sweep, 1/4 x 9" Hard Faced

FC2042 Sweep, 1/4 x 9" Ultra Wing

FC1876 Sweep, 1/4 x 10"

FC1880 Sweep, 1/4 x 10", Hard Faced

FC2043 Sweep, 1/4 x 10" Ultra Wing

FC1877 Sweep, 1/4 x 11"

FC1881 Sweep, 1/4 x 11", Hard Faced

FC2044 Sweep, 1/4 x 11" Ultra Wing

12. 802-090C Plowbolt, 7/16 x 1 3/4, GR 5

13. 4007 804-204C Flat Washer, 7/16

14. 3607 803-245C Nylon Lock Nut, 7/16

15. FC0556 575-860V Sweep 7", w/Bolts Includes items 11 thru 14

575-862V Sweep 7", w/Bolts, Hard Faced Includes items 11 thru 14

575-861V Sweep 7", w/Bolts, Ultra Wing Includes items 11 thru 14

FC0019 570-219V Sweep 9", w/Bolts Includes items 11 thru 14

FC0559 575-809V Sweep 9", w/Bolts, Hard Faced Includes items 11 thru 14

FC1771 575-810V Sweep 9", w/Bolts, Ultra Wing Includes items 11 thru 14

FC0557 575-807V Sweep 10", w/Bolts Includes items 11 thru 14

FC0560 575-767V Sweep 10", w/Bolts, Hard Faced Includes items 11 thru 14

FC1772 575-811V Sweep 10", w/Bolts, Ultra Wing Includes items 11 thru 14

FC0558 575-808V Sweep 11", w/Bolts Includes items 11 thru 14

FC0561 575-804V Sweep 11", w/Bolts, Hard Faced Includes items 11 thru 14

FC1773 575-812V Sweep 11", w/Bolts, Ultra Wing Includes items 11 thru 14

16. FL1104 Trip Limiter Optional

17. 110888 802-046C Hex Bolt, 1/2 x 5 1/2 Optional, required with item 16

Heavy K-Flex Shank Assembly

Ref. Kent No. GP Part No. Part Description Comments

1. FL1666 820-299 C K-F lex Shank Mount, Heavy

2. FL1702 552-003D Mounting Clamp, Heavy, 3 x 4 Tube

3. FC1576 820-296C Shank, 5/8 x 1 3/4 x 30 Min Draft, Heavy

820-295C Shank, 5/8 x 1 3/4 x 30 Flat

820-351C Shank, 5/8 x 1 3/4 x 30 MD Offset 2

All other items same as above.

1/19/2006 Series VII 6326-7552 Discovator 550-221M

39

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

Disc Gang Assembly

00462

Series VII 6326-7552 Discovator 550-221M 1/19/2006

40

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Disc Gang Assembly

Ref. Kent No. GP Part No. Part Description Comments

4. FC0903R 551-032H Bearing Hanger, RH Disc Gang

FC0903L 551-042H Bearing Hanger, LH Disc Gang

5. FC0905 551-078H Gang Bolt, 6 Blade, 44” Models 6326, 6536 & 7552

FC0906 551-079H Gang Bolt, 7 Blade, 52” 6326, 6328, 6536, 6542, 7333 & 7552

FC0907 551-080H Gang Bolt, 8 Blade, 60” Models 7333, 7336, 7548 & 7552

FC0908 551-033H Gang Bolt, 9 Blade, 68” Models 7333, 7336, 7548 & 7552

FC0909 551-081H Gang Bolt, 10 Blade, 76” Models 6542 & 7548

6. PL0365 551-032D Shallow C-Concavity Convex Washer

7. FC1567 20” Disc Blade, Shallow Concavity

8. FC1568 820-274C 18” Disc Blade, Shall ow Concavity

9. FC1569 820-275C 16” Disc Blade, Shall ow Concavity No usage on these models

10. FC1572 551-039H 4 1/16” Half Spool

11. FC0481 822-208C Bearing Flange 1 1/2 ID 5 IN SQ

12. FC1573 551-040H 2” Half Spool

13. FC1574 551-041H Full Spool

14. FC0474 820-276C Washer 7X1.562 Dura-Tight

15. FC0682 804-063C Washer Machine 2.25 x 1.50 x 10GA

16. 3524 803-301C Nut Hex Slotted, 1 1/2-6

17. 260448 805-115C Cotter Pin, 1/4 x 3

18. FC0893 551-074H Scraper Bar, 23 1/4”

FC0894 551-075H Scraper Bar, 31 1/4”

FC0895 551-076H Scraper Bar, 39 1/4”

FC0896 551-077H Scraper Bar, 47 1/4”

FC1171 551-034H Scraper Bar, 55 1/4”

FC1172 551-408H Scraper Bar, 63 1/4”

19. FC0891 551-031H Scraper Stub, 4 3/8”

FC0892 551-073H Scraper Stub, 10 3/8”

FC1173 551-272H Scraper Stub, 14 3/8”

20. FC1570R 551-035S Spring Loaded Scraper Assy, RH

FC1570L 551-043S Spring Loaded Scraper Assy, LH

21. FC1571R 551-037H Rigi d Scraper Right Hand

FC1571L 551-044H Rigid Scraper Left Hand

22. 110840 802-130C Hex Bolt, 1/2-13 x 2 1/2

23. 4108 804-015C Lock Washer, 1/2

24. 3008 803-020C Hex Nut, 1/2

25. 110832 802-128C Hex Bolt, 1/2-13 x 2

26. 110824 802-091C Hex Bolt, 1/2-13 x 1 1/2 GR5

27. 110640 802-114C Hex Bolt, 3/8-16 x 2 1/2 GR5

28. 3606 803-078C Nut Lock 3/8-16 Nylon Insert

29. UB0021 806-191C U-Bolt 3/8-16 x 1 17/32 x 2 1/2

30. FC0595 551-036H Scraper Bracket, Disc

31. FL1686R 551-029D Scraper Blade Right

FL1686L 551-037D Scraper Blade Left

32. 4008 804-017C Flat Washer, 1/2 USS

33. FC0676 Spring, Scraper

34. 3108 803-019C Nut Hex Top Lock 1/2-13

Legend: = 1st revision; = 2nd revision, = 3rd revision; use up existing stock; ⊗ not interchangeable; ⊗Revision 2 is not interchangeable with 1

1/19/2006 Series VII 6326-7552 Discovator 550-221M

41

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

Disc Gang Identification

00603

Series VII 6326-7552 Discovator 550-221M 1/19/2006

42

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Disc Gang Identification

00604

1/19/2006 Series VII 6326-7552 Discovator 550-221M

43

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

Coulter Gang Assembly

00463

Series VII 6326-7552 Discovator 550-221M 1/19/2006

8/11/2008

44

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Coulter Gang Assembly

Ref. Kent No. GP Part No. Part Description Comments

1. FC0956R 551-052H Bearing Hanger, RH Coulter Gang

FC0956L 551-055H Bearing Hanger, LH Coulter Gang

2. FC0967 551-091H Gang Bolt, 6 Blade, Coulter

FC0968 551-092H Gang Bolt, 7 Blade, Coulter

FC0968 551-093H Gang Bolt, 8 Blade, Coulter

FC0970 551-094H Gang Bolt, 9 Blade, Coulter

FC0971 551-095H Gang Bolt, 10 Blade, Coulter

FC0972 551-096H Gang Bolt, 11 Blade, Coulter

3. FC1809 20” Turbo Coulter, Discovator

FC0220 Rippled Coulter, 20”

4. FC0932 551-083H Spool, Full 7 13/16” Long

5. FC0931 551-051H 3 3/4” Half Spool

6. FC0481 822-208C Bearing Flange 1 1/2 ID 5 IN SQ

7. FC0743 551-050H 2 1/2” Half Spool

8. PL0266 551-048D 3/4” Plate Washer

9. FC0682 804-063C Washer Machine 2.25 x 1.50 x 10GA

10. 3524 803-301C Nut Hex Slotted, 1 1/2-6

11. 260448 805-115C Cotter Pin, 1/4 x 3

12. 110824 802-091C Hex Bolt, 1/2-13 x 1 1/2 GR5

13. 4108 804-015C Lock Washer, 1/2

14. 3008 803-020C Hex Nut, 1/2

15. AG0050 551-143D Scraper Angle, 44”

AG0051 551-142D Scraper Angle, 52”

AG0052 550-132D Scraper Angle, 60”

AG0063 550-133D Scraper Angle, 68”

16. FL0797 551-057D Scraper 11 3/4”

17. FL0916 551-058D Scraper 7 1/4”

18. 110832 802-128C Hex Bolt, 1/2-13 x 2

1/19/2006 Series VII 6326-7552 Discovator 550-221M

8/11/2008

45

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

Coulter Gang Identification

00605

Series VII 6326-7552 Discovator 550-221M 1/19/2006

46

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Coulter Gang Identification

00606

1/19/2006 Series VII 6326-7552 Discovator 550-221M

47

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

Center Walking Beam, 6300DV (All S/N) & 7300DV (S/N 1226DD-)

00452

Series VII 6326-7552 Discovator 550-221M 1/19/2006

48

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Center Walking Beam, 6300DV (All S/N) & 7300DV (S/N 1226DD-)

Ref. Kent No. GP Part No. Part Description Comments

1. FC0950 550-021D Pivot Spindle, 2 1/2 x 10

2. 816-573C SEAL 2.50IDX3.251DX.47T

FC1072 REP BY 816-573C

3. 822-226C BRG CONE 1.97ID JLM104948

FC1071 REP BY 822-226C

4. 822-225C BRG CUP JLM104910

FC1070 REP BY 822-225C

5. FC1225 570-210H Walking Beam

6. FC0514 800-080C Grease Zerk, 1/4-28 Thread Forming

7. FC0296 822-053C Outer Cup (LM501310)

8. FC0299 822-048C Outer Cone (LM501349)

9. 804-193C Washer, Flat 7/8 Gr.8 2 1/4 OD

10. 804-055C Washer Spindle, 7/8

11. FC0253 805-089C Cotter Pin, 5/32 x 1 1/2

12. 803-029C Slotted Hex Nu t, 7/8-14

13. DC0166 890-886 C Grease Cap, 3.153x1.468x.312

14. 815-195C Hub 6-Bolt Spindle 2x14.5 890 Purchased Complete

FC1389 570-206S Replaced by 815-1 95C See pg. 3-17 for parts

15. 210548 805-324C Clevis Pin, 5/16 x 3 w/cotter

16. 260216 805-363C Cotter Pin, 1/8 x 1

17. FC1468 570-212L Walking Beam Assembly, HD Includes items 1 thru 16

18. 110564 802-279C Hex Bolt, 5/16 x 4

19. 4105 804-009C Lock Washer, 5/16

20. 3005 803-008C Hex Nut, 5/16

21. FC0360 814-220C Wheel, 15 x 6, 6-bolt, White

22. FC1763 814-009C T ire, 9.5L x 15, 12 ply

23. FC2275 814-231C Tire/Wheel 9.5Lx15 1 2-Ply White Includes items 21 & 22

24. 803-017C Nut Lug, 1/2-20x90 Deg

25. White Includes items 21 & 22

26. 803-017C Nut Lug, 1/2-20x90 Deg

Legend: = 1st revision; = 2nd revision, = 3rd revision; use up existing stock; ⊗ not interchangeable; ⊗Revision 2 is not interchangeable with 1

1/19/2006 Series VII 6326-7552 Discovator 550-221M

8/11/2008

49

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

Center Walking Beam, 6500DV (S/N 1329DD+)

00792

Series VII 6326-7552 Discovator 550-221M 1/19/2006

50

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Center Walking Beam, 6500DV (S/N 1329DD+)

Ref. Kent No. GP Part No. Part Description Comments

1. 550-259H Walking Beam Spindle

2. 550-258H Walking Beam

3. 550-244D Floating Sleeve

4. 804-063C Machine Washer, 2.25 x 1.5 x 10Ga

5. 803-239C Slotted Hex Nut, 1 1/2-12

6. 805-115C Cotter Pin, 1/4 x 3

7. 816-573C SEAL 2.50IDX3.251DX.47T

FC1072 REP BY 816-573C

8. 822-226C BRG CONE 1.97ID JLM104948

FC1071 REP BY 822-226C

9. 550-261L Walking Beam Assembly Includes Items 1 thru 8

10. 822-225C BRG CUP JLM104910

FC1070 REP BY 822-225C

11. FC0514 800-080C Grease Zerk, 1/4-28 Thread Forming

12. 815-277C Hub 8-Bolt Spindle 2.25 X 13.25 458 Purchased Complete

See pg. 3-19 for parts

13. 110564 802-279C Hex Bolt, 5/16 x 4

14. 4105 804-009C Lock Washer, 5/16

15. 3005 803-008C Hex Nut, 5/16

16. PW0090 814-222C Wheel, 15 x 8, 8-bolt, White

17. FC1767 814-226C Tire, 11L x 15, Load F

18. FC2279 814-235C Tire/Wheel 11Lx1 5 Load F White Includes items 19 & 20

19. 803-219C Nut Lug, 5/8-18x90 D eg

Legend: = 1st revision; = 2nd revision, = 3rd revision; use up existing stock; ⊗ not interchangeable; ⊗Revision 2 is not interchangeable with 1

1/19/2006 Series VII 6326-7552 Discovator 550-221M

8/11/2008

51

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

Center Walking Beam, 7333DV (S/N 1227DD+)

00649

Series VII 6326-7552 Discovator 550-221M 1/19/2006

52

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Center Walking Beam, 7333DV (S/N 1227DD+)

Ref. Kent No. GP Part No. Part Description Comments

1. 580-191D Pivot Spindle, 2 1/2 x 10

2. 816-573C SE AL 2.50IDX3.251DX.47T

FC1072 REP BY 816-573C

3. 822-226C BRG CONE 1.97ID JLM104948

FC1071 REP BY 822-226C

4. 822-225C BRG CUP JLM104910

FC1070 REP BY 822-225C

5. FC2091 560-126H Walking Beam

6. FC0514 800-080C Grease Zerk, 1/4-28 Thread Forming

7. FC0296 822-053C Outer Cup (LM501310)

8. FC0299 822-048C Outer Cone (LM501349)

9. 804-193C Washer, Flat 7/8 Gr.8 2 1/4 OD

10. 804-055C Washer Spindle, 7/8

11. FC0253 805-089C Cotter Pin, 5/32 x 1 1/2

12. 803-029C Slotted Hex Nu t, 7/8-14

890-886C GREASE CAP 3.153X1.468X.312

13. DC0166 REPL BY 890-886C

14. FC2083 560-128L Walking Beam Assembly Includes items 1 thru 13

15. 815-226C Hub 8-Bolt Spindle 2.25x16.5 458 Purchased Complete. See pg 3-17

16. 110564 802-279C Hex Bolt, 5/16 x 4

17. 4105 804-009C Lock Washer, 5/16

18. 3005 803-008C Hex Nut, 5/16

19. PW0090 814-222C Wheel, 15 x 8, 8-bolt, White

20. FC1767 814-226C Tire, 11L x 15, Load F

21. FC2279 814-235C Tire/Wheel 11Lx15 Load F, White Includes items 19 & 20

22. 803-219C Nut Lug, 5/8-18x90 Deg

1/19/2006 Series VII 6326-7552 Discovator 550-221M

8/11/2008

53

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

Center Walking Beam, 7500DV

00453

Series VII 6326-7552 Discovator 550-221M 1/19/2006

54

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Center Walking Beam, 7500DV (S/N 1219DD-)

Ref. Kent No. GP Part No. Part Description Comments

1. FC1755 570-054D Pivot Spindle, 3 x 10 1/2

2. FC1827 816-220C Seal Oil (CR27362)

3. 822-110C Inner Cone (JLM506849)

4. 822-109C Inner Cup (JLM506810)

5. 570-262H Walking Beam, RH 7500DV Center

570-209H Walking Beam, LH 7500DV Center (shown)

6. FC0514 800-080C Grease Zerk, 1/4-28 Thread Forming

7. FC0296 822-053C Outer Cup (LM501310)

8. FC0299 822-048C Outer Cone (LM501349)

9. 913624 148-404D Washer, Hardened Spindle, 1”

10. 905941 805-017C Cotter Pin, 3/16 x 1 3/4

11. 803-095C Slotted Hex Nu t, 1-14

12. 890-277C Grease Cap

13. 570-263L Center RH Walking Beam Assembly Includes items 1 thru 12

570-199L Center LH Walking Beam Assembly (shown) Includes items 1 thru 12

14. 815-194C Hub 8-Bolt Spindle 2.75 X 17 608 Purchased Complete

FC1826 570-220S Replaced by 815-194C See pg. 62 for parts

15. 110564 802-279C Hex Bolt, 5/16 x 4

16. 4105 804-009C Lock Washer, 5/16

17. 3005 803-008C Hex Nut, 5/16

18. 110572 802-474C Hex Bolt, 5/16 x 4 1/2 Gr.5

19. 4105 804-009C Lock Washer, 5/16

20. 3005 803-008C Hex Nut, 5/16

21. FC1836 814-223C Wheel, 15 x 10, 8-bolt, White

22. FC1769 814-227C Tire, 12.5L x 15, Load F

23. FC2282 814-236C Tire/Wheel 12.5Lx15 Load F, White Includes items 21 & 22

24. 803-219C Nut Lug, 5/8-18x90 Deg

Center Walking Beam, 7500DV (S/N 1220DD+)

1. FC1755 570-054D Pivot Spindle, 3 x 10 1/2

2. FC1827 816-220C Seal Oil (CR27362)

3. 822-110C Inner Cone (JLM506849)

4. 822-109C Inner Cup (JLM506810)

5. 576-107H Center Walking Beam, RH

576-106H Center Walking Beam, LH (shown)

6. FC0514 800-080C Grease Zerk, 1/4-28 Thread Forming

7. FC0296 822-053C Outer Cup (LM501310)

8. FC0299 822-048C Outer Cone (LM501349)

9. 913624 148-404D Washer, Hardened Spindle, 1”

10. 905941 805-017C Cotter Pin, 3/16 x 1 3/4

11. 803-095C Slotted Hex Nu t, 1-14

12. 890-277C Grease Cap

13. 576-109L Center Walking Beam RH Assembly Includes items 1 thru 12

576-108L Center Walking Beam LH Assembly (shown) Includes items 1 thru 12

14. 815-251C Hub 8-Bolt Spindle 2.75 X 17 608 Purchased Complete. See pg 62

15. 110872 802-413C Hex Bolt, 1/2 x 4 1/2 GR 5

16. 4108 804-015C Lock Washer, 1/2

17. 3008 803-020C Hex Nut, 1/2

18. 802-803C He x Bolt, 5/16 x 4 1/2 Gr.8

19. 4105 804-009C Lock Washer, 5/16

20. 3005 803-008C Hex Nut, 5/16

21. FC1836 814-223C Wheel, 15 x 10, 8-bolt, White

22. FC1769 814-227C Tire, 12.5L x 15, Load F

23. FC2282 814-236C Tire/Wheel 12.5Lx15 Load F, White Includes items 21 & 22

24. 803-219C Nut Lug, 5/8-18x90 Deg

Legend: = 1st revision; = 2nd revision, = 3rd revision; use up existing stock; ⊗ not interchangeable; ⊗Revision 2 is not interchangeable with 1

1/19/2006 Series VII 6326-7552 Discovator 550-221M

55

Section 3: Replacement Parts Table of Contents ► Great Plains Mfg., Inc.

Wing Walking Beam Assembly

00040

Series VII 6326-7552 Discovator 550-221M 1/19/2006

56

Great Plains Mfg., Inc. Table of Contents ► Section 3: Replacement Parts

Wing Walking Beam Assembly

Ref. Kent No. GP Part No. Part Description Comments

1. FC0347 550-015D Pivot Spindle, 2 x 8 1/16 (Q888)

2. FC0372 816-398C Seal (CR16286)

3. FC0250 816-396C Wear Sleeve (CR08 1071)

4. FC0373 822-198C Inner Cone (JL69349)

5. FC0371 822-197C Inner Cup (JL69310)

6. FC1329 550-006H Walking Beam

7. FC0514 800-080C Grease Zerk, 1/4-28 Thread Forming

8. FC0246 822-020C Outer Cup (LM67010)

9. FC0248 822-021C Outer Cone (LM67048)

10. FC0251 804-055C Washer, Spindle 7/8

11. FC0253 805-089C Cotter Pin, 5/32 x 1 1/2

12. FC0252 803-029C Slotted Hex Nut, 7/8-14

13. FC0254 890-781C Dust Cap

14. 815-216C Hub 6-Bolt Spindle 2x14 888 (Standard ) Purchased Complete

FC1206 550-005S Replaced by 815-216C Front Side Tandem. See pg. 64

815-195C Hub 6-Bolt Spindle 2x14.5 890 (Heavy Opt.) Purchased Complete

570- 206S Replaced by 815-195C Fro nt Side Tandem. See pg. 62

15. 815-214C Hub 6-Bolt Spindle 2x13 888 (Standard ) Purchased Complete

FC1334 550-007S Replaced by 815-214C Back Side Tandem. See pg. 64

815-221C Hub 6-Bolt Spindle 2x13.5 890 (Heavy Opt.) Purchased Complete

570- 205S Replaced by 815-221C Back Side T andem. See pg. 62

16. 210548 805-324C Clevis Pin, 5/16 x 3 w/cotter

17. 260216 805-363C Cotter Pin, 1/8 x 1

18. FC1332 560-079L Walking Beam Assembly (Standard option) Items 1 thru 17