Great Plains 7336 DH Operator Manual

Table of Contents Index

7000 Series II Disk Harrow

Operator Manual

7000 Series II

7323, 7326, 7329

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

43401

Illustrations may show alternate spacings and/or optional equipment not supplied with

standard unit.

ORIGINAL INSTRUCTIONS

© Copyright 2014 Printed 2014-06-30 556-235M

Table of Contents Index

EN

Table of Contents Index

Table of Contents Index

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ...................................... 1

Safety Decals ................................................................. 5

Introduction ................................................................10

Description of Unit ........................................................10

Intended Usage ........................................................10

Models Covered .......................................................10

Document Family......................................................10

Using This Manual........................................................10

Definitions................................................................. 10

Owner Assistance ........................................................11

Product Support .......................................................11

Preparation and Setup ...............................................12

Prior to Going to the Field Checklist.............................12

Hitching Disk Harrow to Tractor ...................................13

Electrical Hookup......................................................14

Hydraulic Hose Hookup............................................ 14

Clevis Hitch...............................................................15

Category III Hitch..........................................................15

Category IV Hitch ......................................................... 16

Category V Hitch .......................................................... 16

Transport Locks........................................................ 17

First time Field Adjustments .........................................17

Pre-Leveling of Machine........................................... 17

Scraper Adjustment..................................................18

Operating Instructions...............................................19

Pre-Start Checklist .......................................................19

Unfolding ...................................................................... 20

Folding..........................................................................20

Transporting the Disk Harrow...................................21

Transport Checklist...................................................21

Field Operations ...........................................................22

Field Set-Up Checklists............................................22

Operations Checklists .................................................. 23

Hitching .................................................................... 23

Transport..................................................................23

Field Start.................................................................23

Field Turns ............................................................... 23

End Field Work......................................................... 23

General Operation and In-Field Adjustments............... 23

Transport Locks ........................................................... 24

Manual Guage Wheel Adjustment ........................... 24

Hydraulic Gauge Wheel Adjustment ........................ 24

Thread Protectors ........................................................ 25

Adjusting and Using Tractor Hydraulics

Depth Control ................................................... 25

Tractor Detents ........................................................ 25

Leveling........................................................................ 27

Rear Attachment Settings ............................................ 28

Spike Drag Settings ................................................. 28

Heavy Coil Tine Settings..........................................28

Maintenance and Lubrication ................................... 29

Maintenance ................................................................ 29

Lubrication ................................................................... 30

End of Season.......................................................... 31

Beginning of Season ................................................ 31

Appendix A - Reference Information........................ 32

Specifications and Capacities ...................................... 32

Tire Inflation & Warranty .............................................. 33

Hydraulic Connectors and Torque ............................... 34

Warranty ...................................................................... 36

Index............................................................................ 37

© Copyright 2014 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2014-06-30 Cover Index 556-235M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

iv 7000 Series II Table of Contents Index Great Plains Manufacturing, Inc.

556-235M Table of Contents Index 2014-06-30

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 1

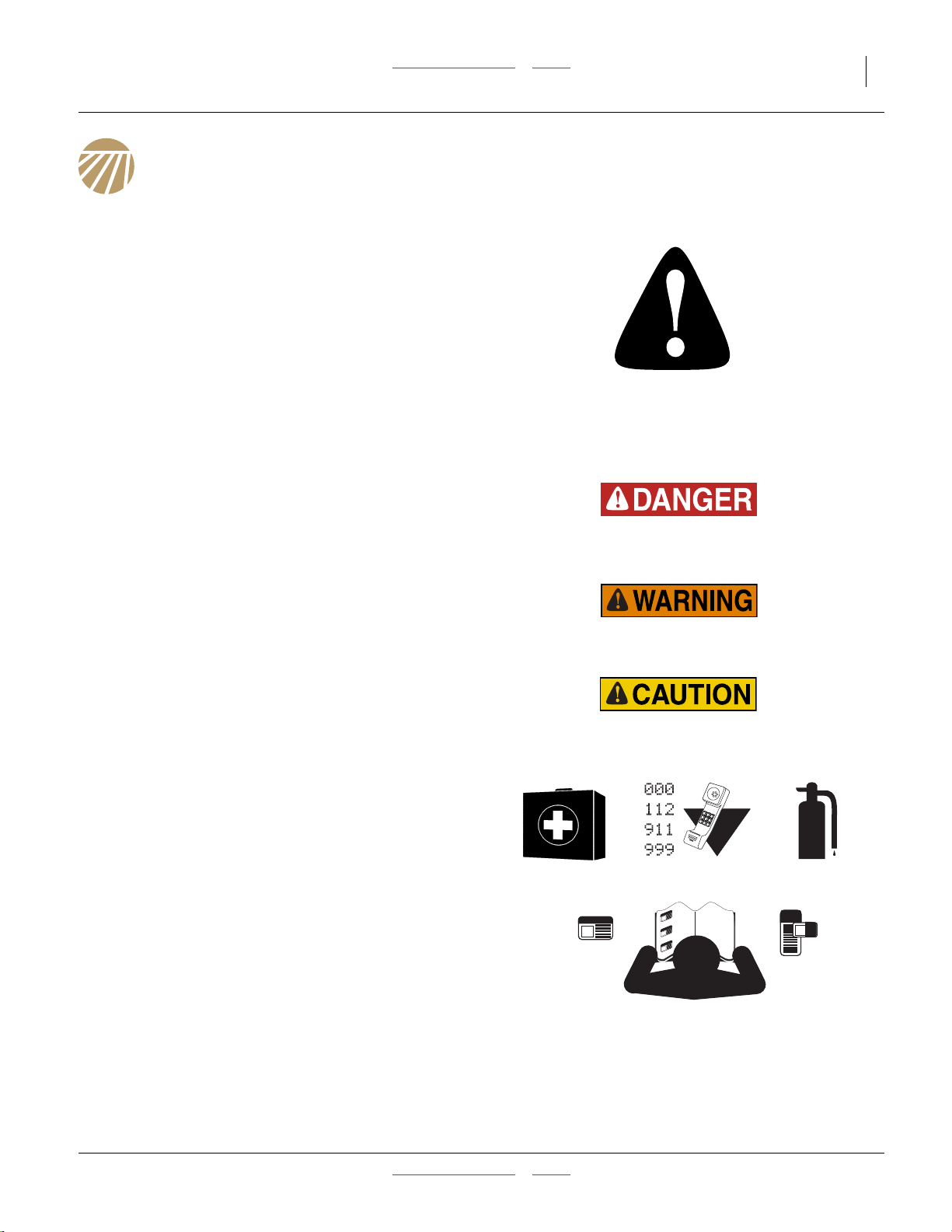

Important Safety Information

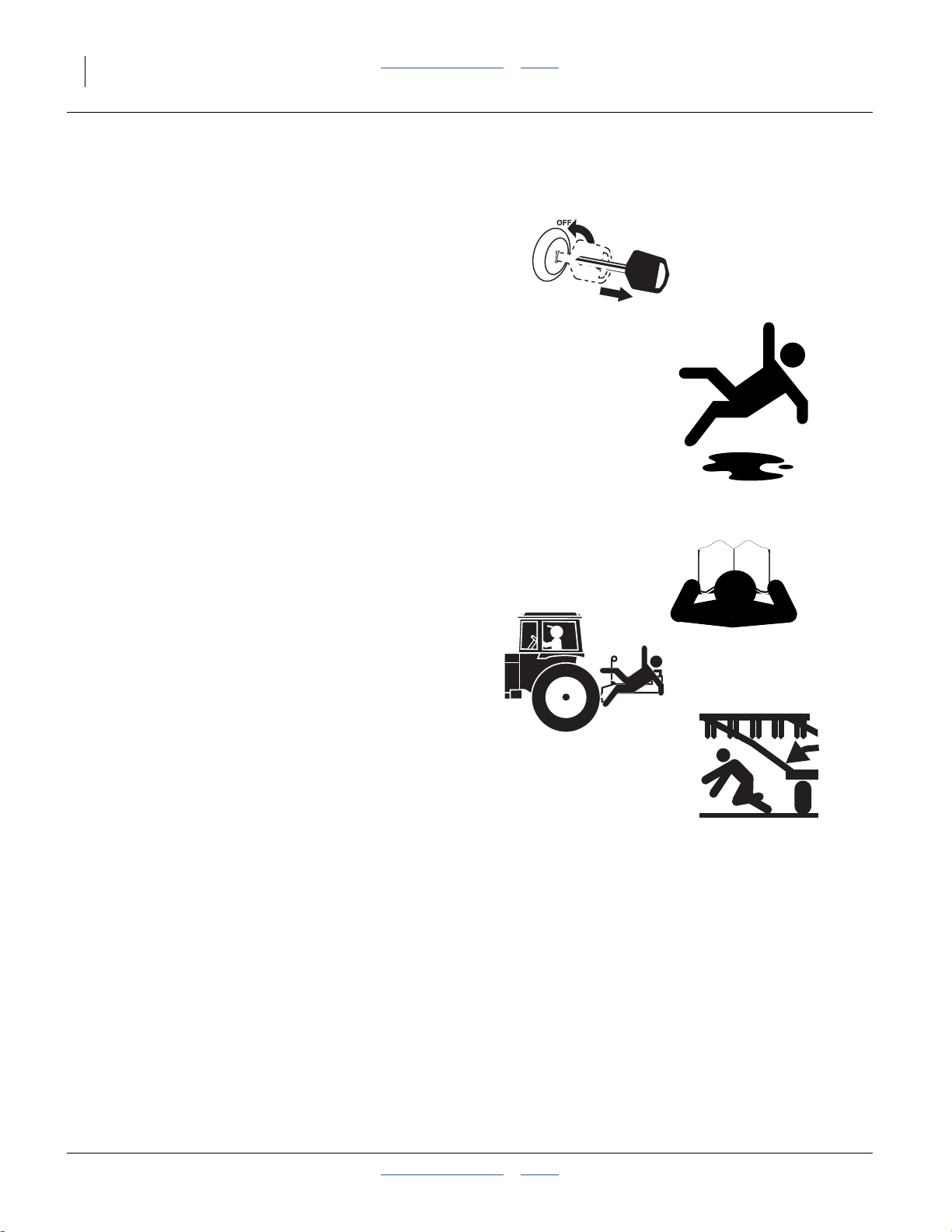

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 5,

thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

2014-06-30 Table of Contents Index 556-235M

2 7000 Series II Table of Contents Index Great Plains Manufacturing, Inc.

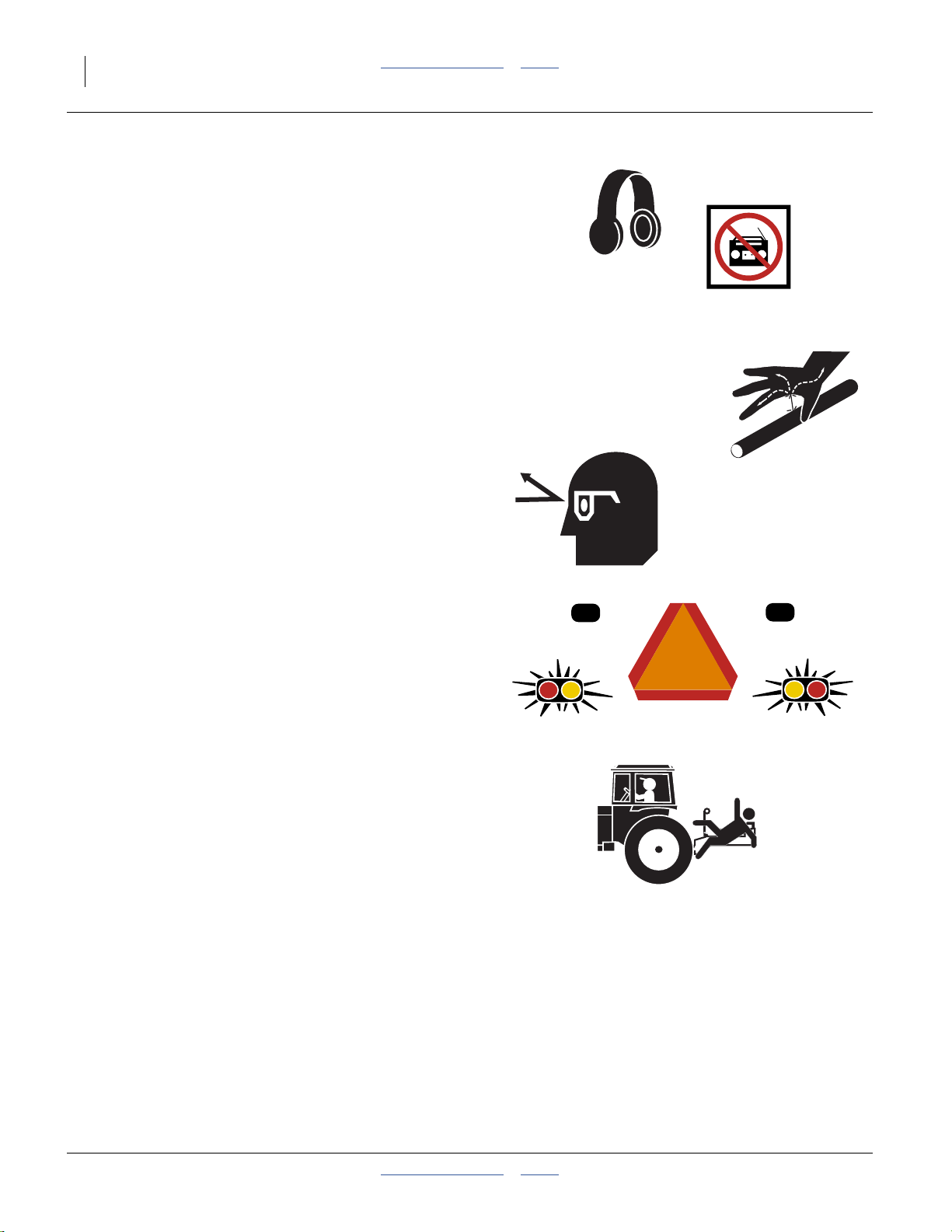

Wear Protective Equipment

▲ Wear clothing and equipment appropriate for the job.

▲ Prolonged exposure to loud noise can cause hearing

impairment or loss. Wear suitable hearing protection such

as earmuffs or earplugs.

▲ Avoid wearing entertainment headphones while operating

machinery. Operating equipment safely requires the full

attention of the operator.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever

driving on public roads.

Use lights and devices provided with implement.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

556-235M Table of Contents Index 2014-06-30

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

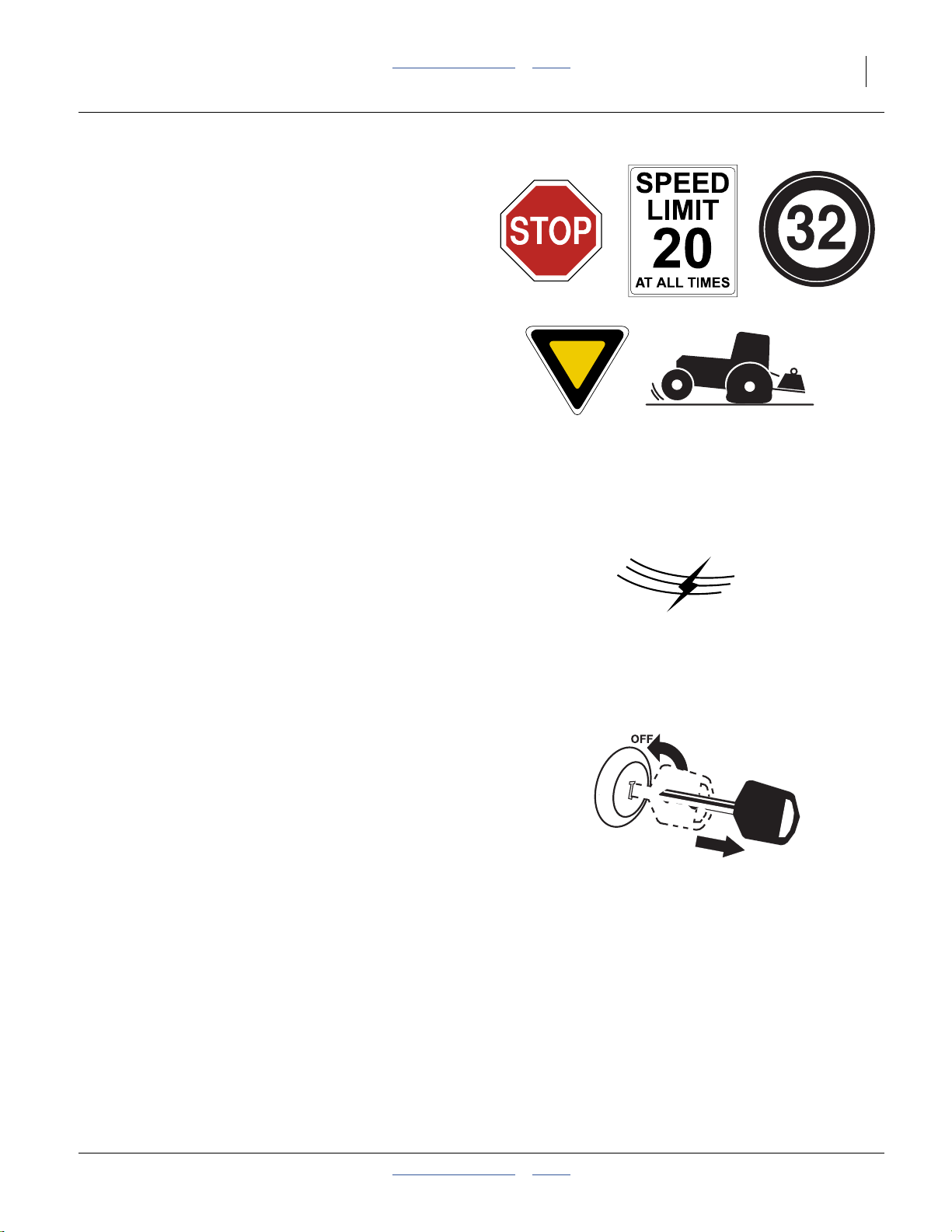

Transport Machinery Safely

Maximum transport speed for Disk Harrow is 20 mph

(32 kph). Some rough terrains require a slower speed.

Sudden braking can cause a towed load to swerve and

upset.

▲ Do not exceed 20 mph (32 km/h). Never travel at a speed

which does not allow adequate control of steering and

stopping. Reduce speed if towed load is not equipped with

brakes.

▲ Comply with state and local laws.

▲ Do not tow a Disk Harrow unless the towing vehicle is rated

for, and ballasted for, the weight of the Disk Harrow.

▲ Carry reflectors or flags to mark Disk Harrow in case of

breakdown on the road.

▲ Do not fold or unfold the Disk Harrow while the tractor is

moving.

Check for Overhead Lines

The Disk Harrow requires at least 14 feet (4.3 m) for

Models 7329 & 7333 and 15 feet (4.6m) for Models 7336

of vertical clearance in transport. Contacting overhead

electrical lines can introduce lethal voltage levels on Disk

Harrow and tractor frames. A person touching almost any

metal part can complete the circuit to ground, resulting in

serious injury or death. At higher voltages, electrocution

can occur without direct line or body contact.

▲ Avoid overhead lines during folding, unfolding, transport

and parking.

Shutdown and Storage

▲ Lower Disk Harrow, put tractor in park, turn off engine,

and remove the key.

▲ Secure Disk Harrow using blocks and supports provided.

▲ Detach and store Disk Harrow in an area where children

normally do not play.

2014-06-30 Table of Contents Index 556-235M

4 7000 Series II Table of Contents Index Great Plains Manufacturing, Inc.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper tools

and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Lower the Disk Harrow, put tractor in park, turn off engine,

and remove key before performing maintenance.

▲ Make sure all system pressure is relieved.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on Disk

Harrow.

▲ Inspect all parts. Make sure parts are in good condition and

installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from Disk Harrow before

operation.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all Disk Harrow functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave Disk Harrow unattended with tractor engine

running.

▲ Do not dismount a moving tractor. Dismounting a moving

tractor could cause serious injury or death.

▲ Do not stand between the tractor and Disk Harrow during

hitching.

▲ Keep hands, feet and clothing away from moving parts.

▲ Watch out for wires, trees, etc., when folding and raising

Disk Harrow. Make sure all persons are clear of working

area.

556-235M Table of Contents Index 2014-06-30

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

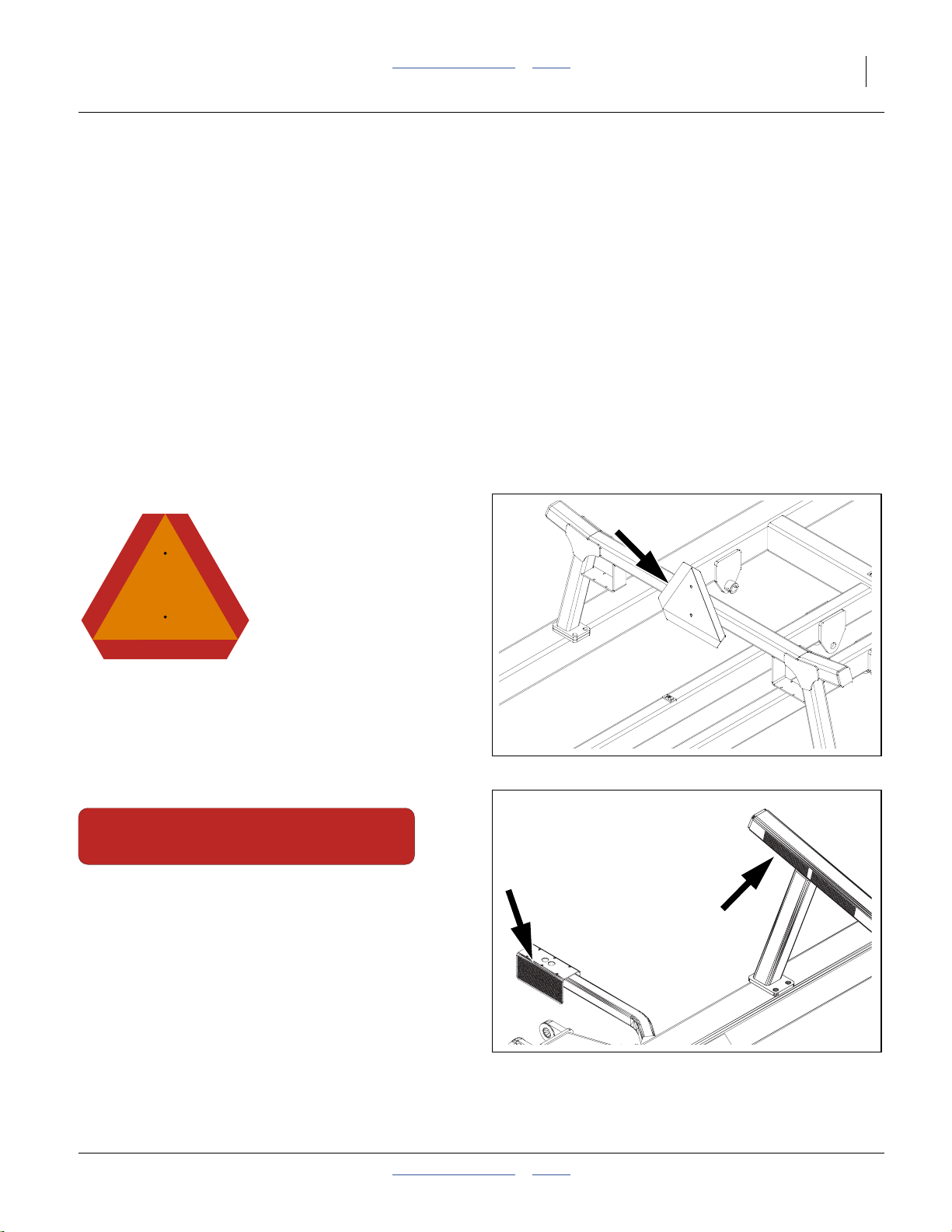

Transport Decals

818-055C

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

Slow Moving Vehicle Reflector

On rear of wing stop;

1 total

838-614C

Red Reflectors

On rear face of light bracket mount tube (top); and Rear

of Wing Stop on Models 7330, 7333, & 7336 (outside)

2 total - Models 7323-7329

4 total - Models 7330-7336

43367

43408

2014-06-30 Table of Contents Index 556-235M

6 7000 Series II Table of Contents Index Great Plains Manufacturing, Inc.

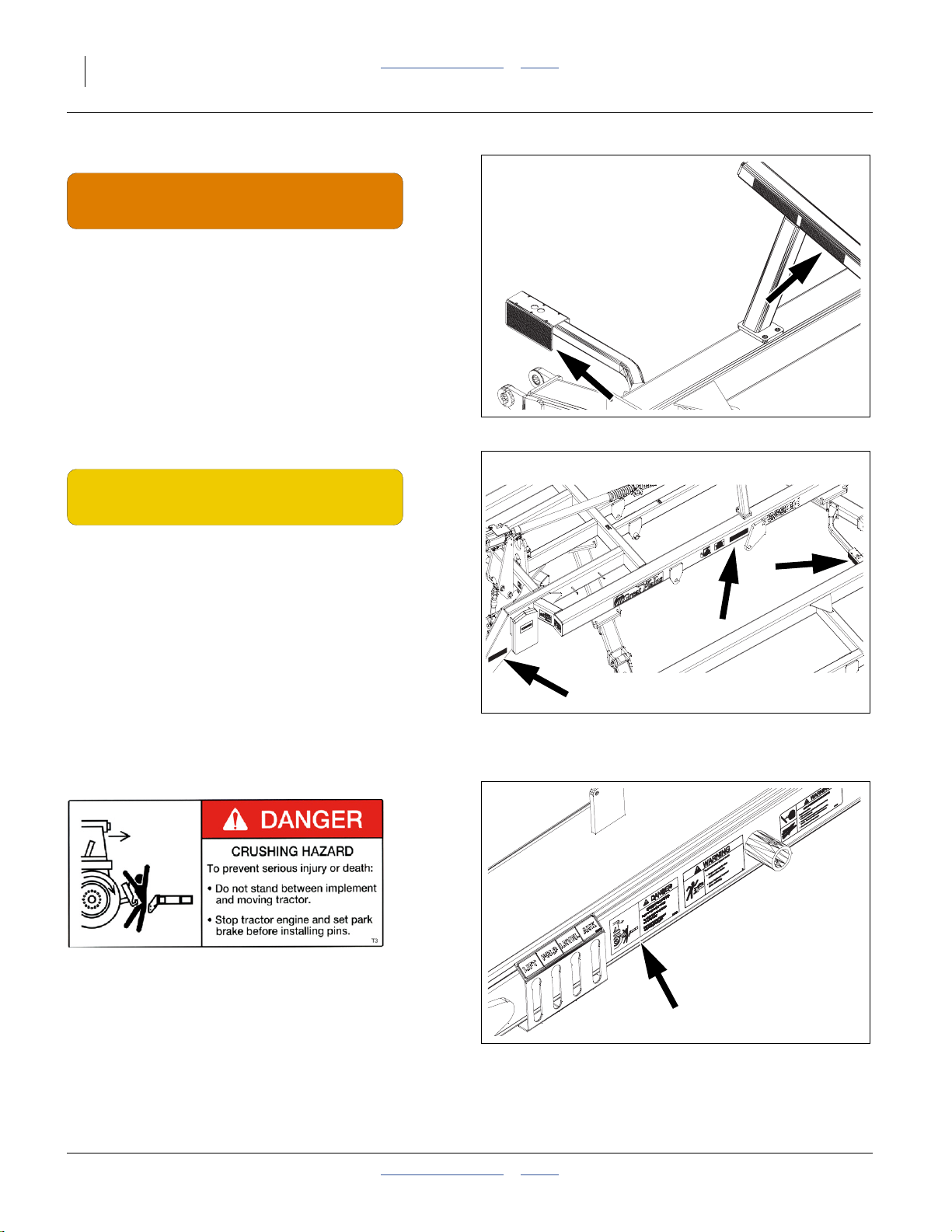

838-603C

Daytime Reflectors

On rear face of light bracket mount tube (bottom); and

Rear of Wing Stop on Models 7330, 7333, & 7336

(inside);

2 total - Models 7323-7329

4 total - Models 7330-7336

43408

838-615C

Amber Reflectors

On front of light brackets. On front, outside of center

frame, on outside, rear of center frame, rear of finishing

attachment (not shown), visible from side while folded for

transport;

8 total

Danger Decals

838-600C

Danger: Crushing Hazard

On front of hitch tube (left, front);

1 total

43423

43424

556-235M Table of Contents Index 2014-06-30

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

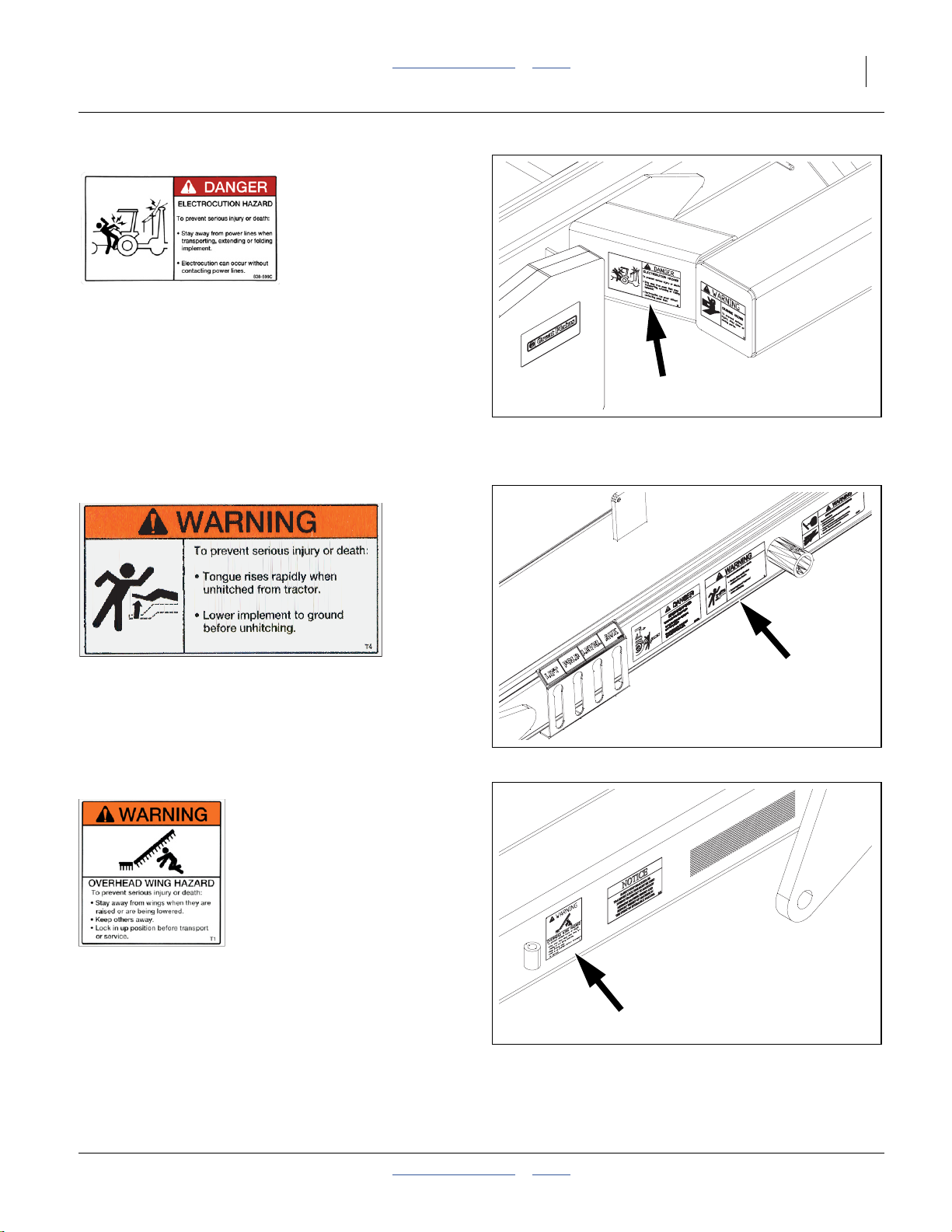

838-599C

Danger: Electrocution

On front side of center frame, (left side);

1 total

43425

Warning Decals

838-606C

Warning: Tongue Rising

Front od hitch (left, front);

1 total

838-602C

Warning: Overhead Wing

Outside, center of center frame and wing frames

(both sides);

4 total

43424

43426

2014-06-30 Table of Contents Index 556-235M

8 7000 Series II Table of Contents Index Great Plains Manufacturing, Inc.

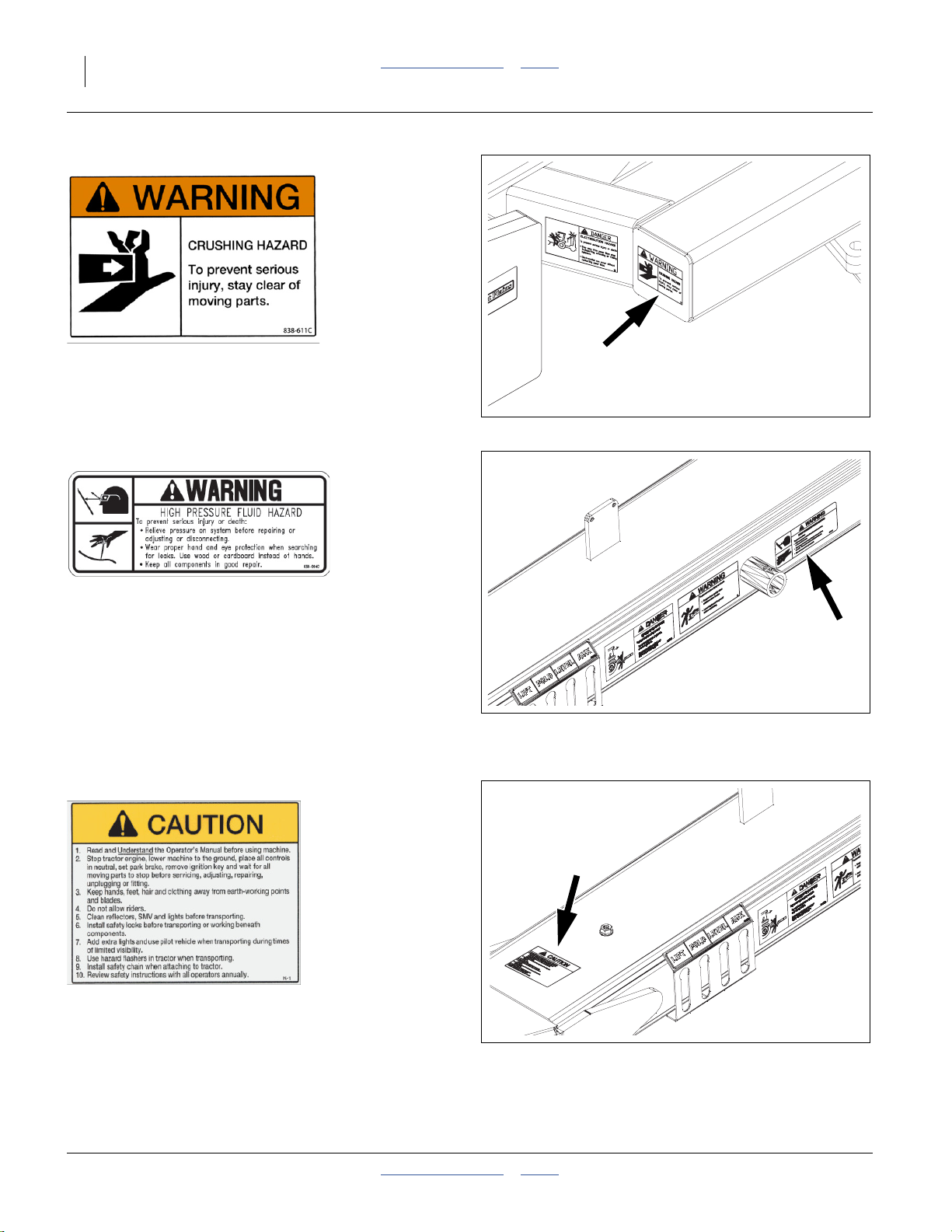

838-611C

Warning: Hand Crushing

On front side of center frame (both sides);

2 total

43425

838-094C

Warning: High Pressure Fluid Hazard

On front of hitch tube, left rear;

1 total

Caution Decals

838-598C

Caution: General Instructions

On front face of hitch tube (top);

1 total

43424

43424

556-235M Table of Contents Index 2014-06-30

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 9

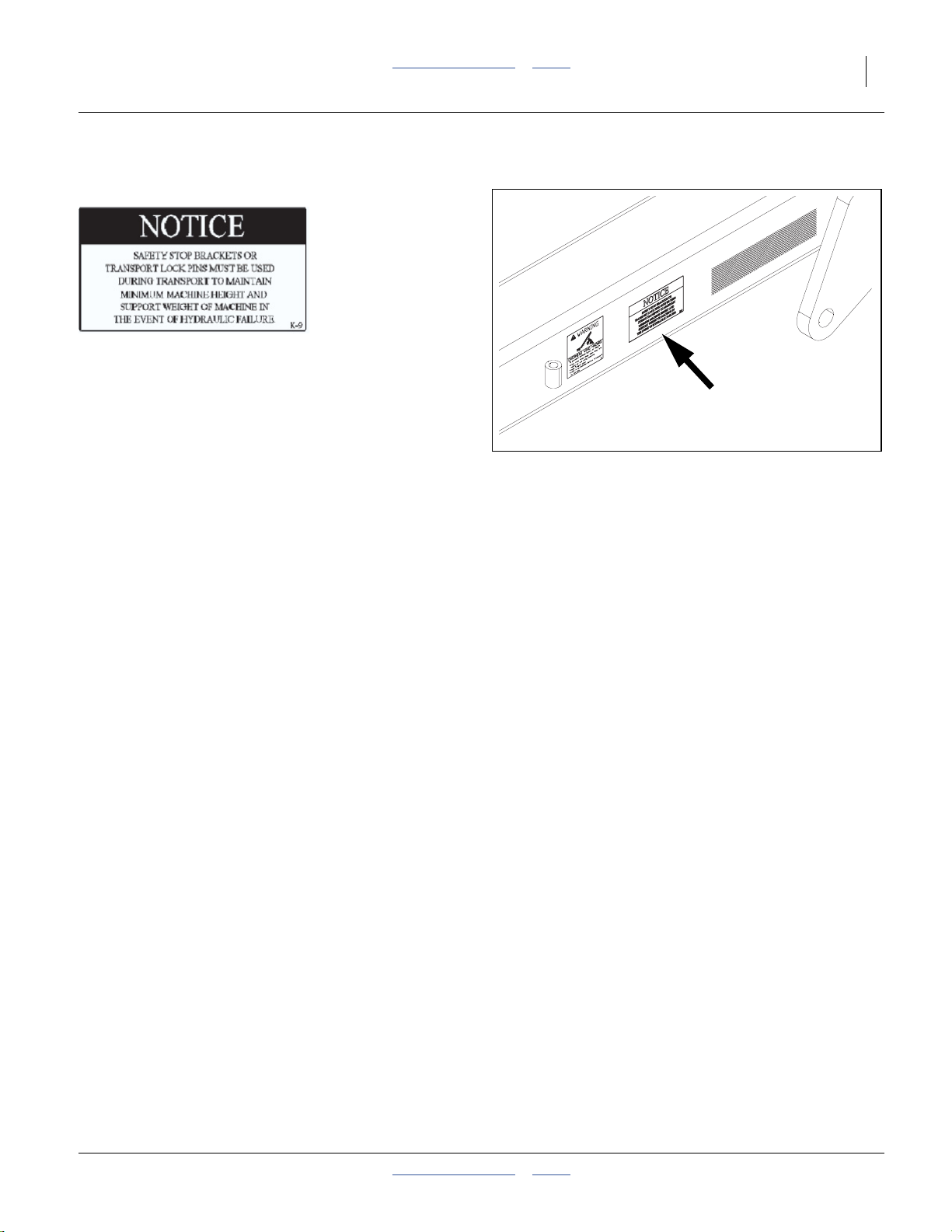

Notice Decals

838-613C

Notice: Transport Lock

Outside of center frame (both sides);

2 total

43426

2014-06-30 Table of Contents Index 556-235M

10 7000 Series II Table of Contents Index Great Plains Manufacturing, Inc.

Introduction

Great Plains welcomes you to its growing family of new

R

F

U

B

L

D

R

L

product owners. The 7000 Series II Disk Harrow 7323 7336DH has been designed with care and built by skilled

workers using quality materials. Proper setup,

maintenance, and safe operating practices will help you

get years of satisfactory use from the machine.

Description of Unit

The 7000 Series II Disk Harrow 7323 - 7336DH is a three

section primary and secondary tillage tool. Working

width ranges from 23 to 36 feet. The implement is

designed to cut out and bury roots and crop residue. Kill

weeds and dry out the soil, level ridges and ruts and for

seedbed preparation. Various finishing attachments are

also available to further smooth, redistribute residue, kill

weeds, and break clods.

Intended Usage

Use the 7000 Series II Disk Harrow for building and

maintaining beds in conventionally tilled ground. Do not

modify the disk harrow for use with attachments other

than Great Plains options and accessories specified for

use7000 Series IIDisk Harrow.

Models Covered

7323DH 23-Foot, 3-Section

7326DH 26-Foot, 3-Section

7329DH 29-Foot, 3-Section

7330DH 30-Foot, 3-Section

7333DH 33-Foot, 3-Section

7336DH 36-Foot, 3 Section

Document Family

556-235Q Pre-Delivery Manual

556-235M Owner’s Manual (this document)

556-235P Parts Manual

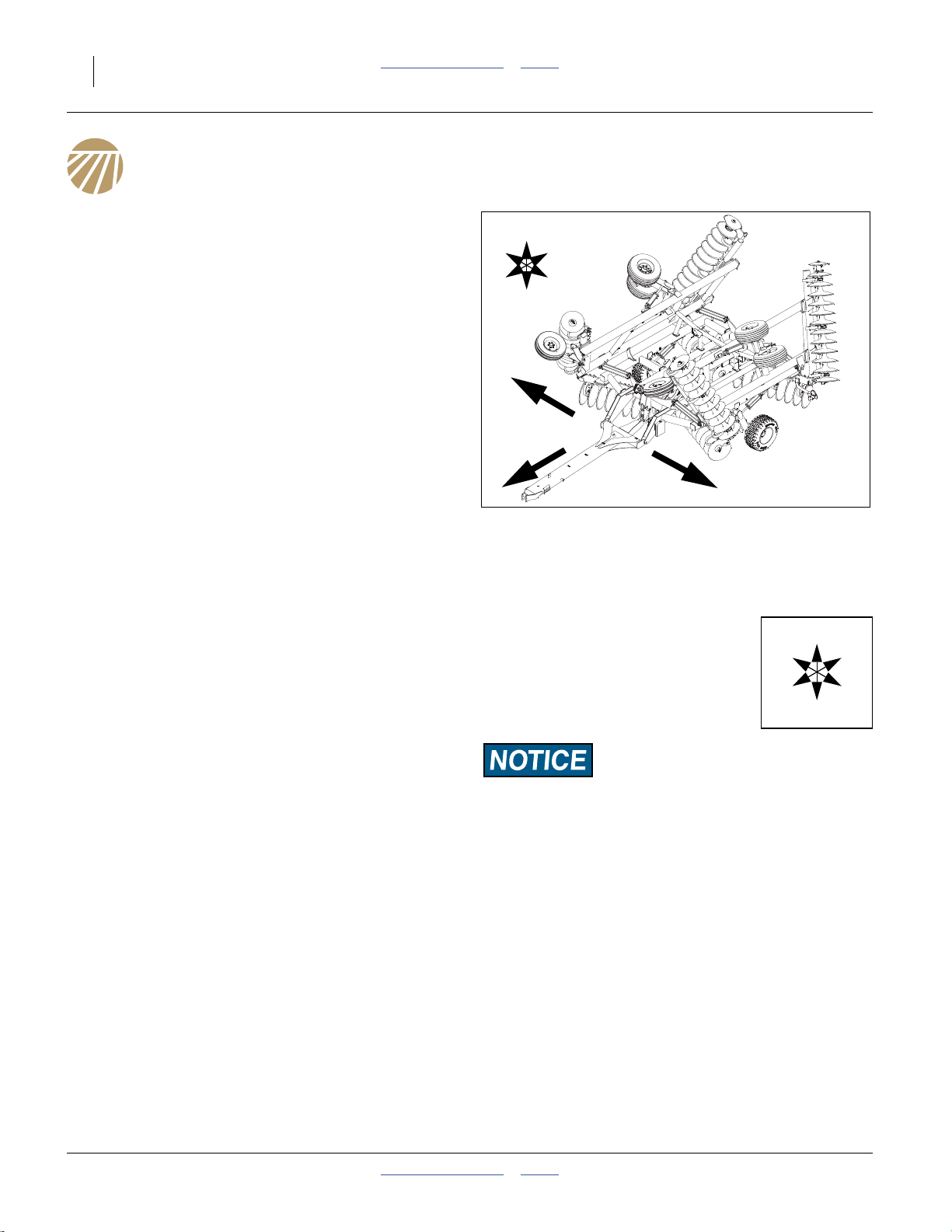

Figure 1

7000 Series II Disk Harrow

43401

Definitions

The following terms are used throughout this manual.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

A crucial point of information related to the current topic. Read

and follow the directions to remain safe, avoid serious damage

to equipment and ensure desired field results.

Note: Useful information related to the preceding topic.

R

F

U

B

L

D

Using This Manual

This manual will familiarize you with safety, assembly,

operation, adjustments, troubleshooting, and

maintenance. Read this manual and follow the

recommendations to help ensure safe and efficient

operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

556-235M Table of Contents Index 2014-06-30

Loading...

Loading...