Great Plains Mfg., Inc.

Installation Instructions

EWNT7 and 705

Harrow Option

Used with:

EWNT7

•

705

•

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

!

the lives of others depend on it!

General Information

These instructions explain how to install the optional spring-tine

harrow. Mounted behind the drill, the harrow evenly distributes

crop residue in no-till conditions.

These instructions apply to:

116-072A EWNT7 & 705 CPH HARROW

Manual Update

Refer to the drill operator’s manual for detailed information on

safely operating, adjusting, troubleshooting and maintaining the

spring-tine harrow. Refer to the parts manual for part identification.

• EWNT7Operator’s Manual . . . . . . 150-082M-A or 150-082M

• EWNT7 Parts Manual . . . . . . . . . . . . . . . . . . . . . . 150-082P

• 705 Operator’s Manual. . . . . . . . . . . . . . . . . . . . . .150-213M

• 705 Parts Manual. . . . . . . . . . . . . . . . . . . . . . . . . . 150-213P

Before You Start

Page 3 is a detailed listing of parts included in the spring-tine harrow package. Use this list to inventory parts received.

Assembly Instructions

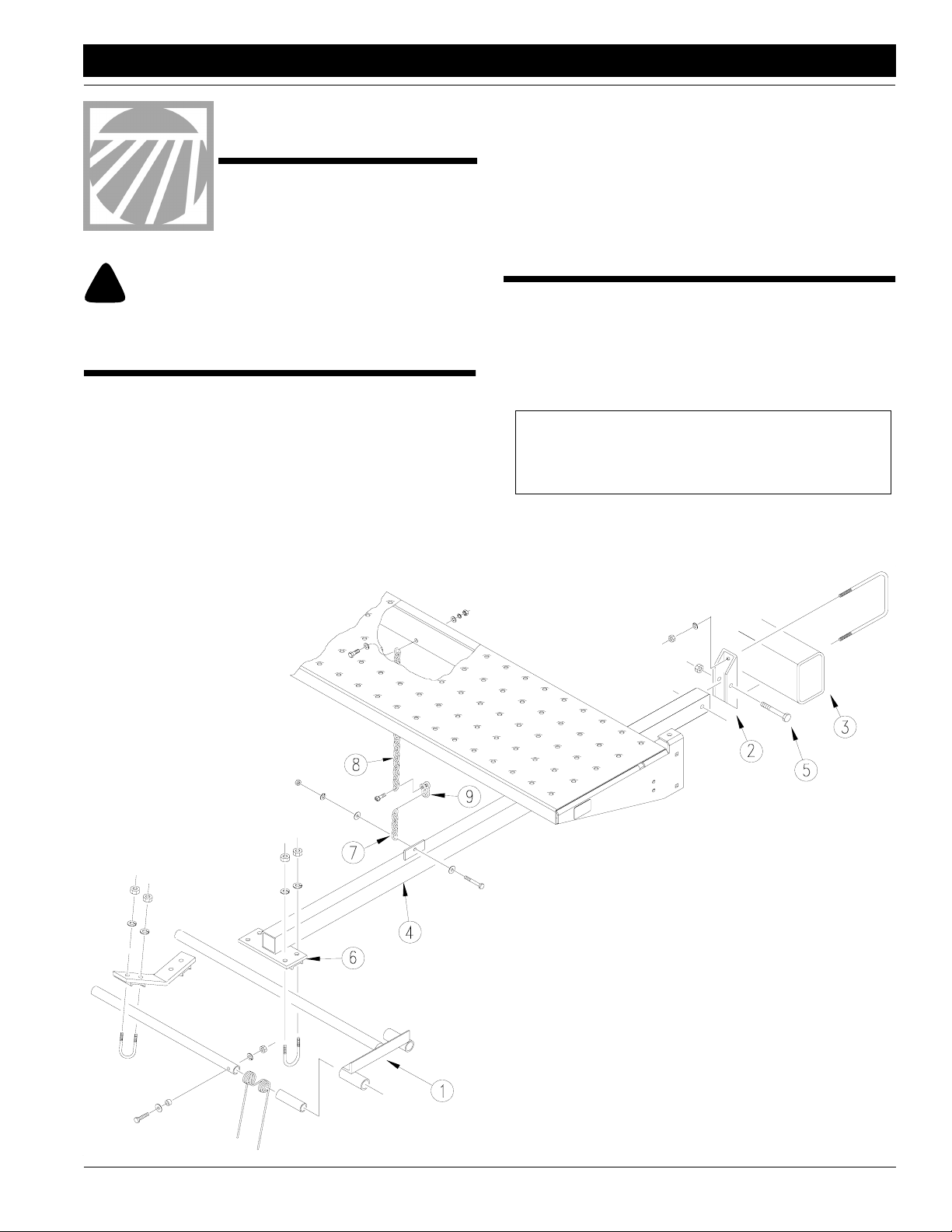

Refer to Figure 1.

1. Lower drill into field position. Place harrow frames (1) behind drill.

2. Mount hinge brackets (2) on 4-by-6-inch frame tube (3) on

drill. Position hinge brackets so harrow arms (4) will be close

to the ends of harrow frames. Center hinge brackets between drill openers.

IMPORTANT: Position hinge brackets so drill openers do

not contact harrow arms during drill operation. Exact location of hinge brackets on frame tube will differ with drill row

spacing.

Attach hinge brackets to frame tube using square u-bolts,

lock washers and nuts as shown.

3. Install harrow arms (4) in hinge brackets so arms pivot on

1/2-inch bolts (5). Secure bolts with nylock nuts.

Harrow Assembly

17868

Figure 1

4. Place harrow frames under channels (6) on harrow arms.

Bolt harrow frames to harrow arms using round u-bolts, lock

washers and nuts. Leave u-bolts loose for harrow adjustment.

5. Bolt short support chain (7) to tab on top of harrow arms with

3/8-inch hex bolts, flat washers, lock washers, and hex nuts.

Bolt long support chain (8) to rib under walkboard using 3/8inch hex bolts, flat washers, lock washers and hex nuts.

6. Connect support chains with chain clevis (9). Adjust chains

so both harrow sections are 152 mm (6 in.) above the

ground.

© Copyright 2000 Printed 4/25/2007

116-109M Rev. A

1

Assembly

Harrow Adjustment

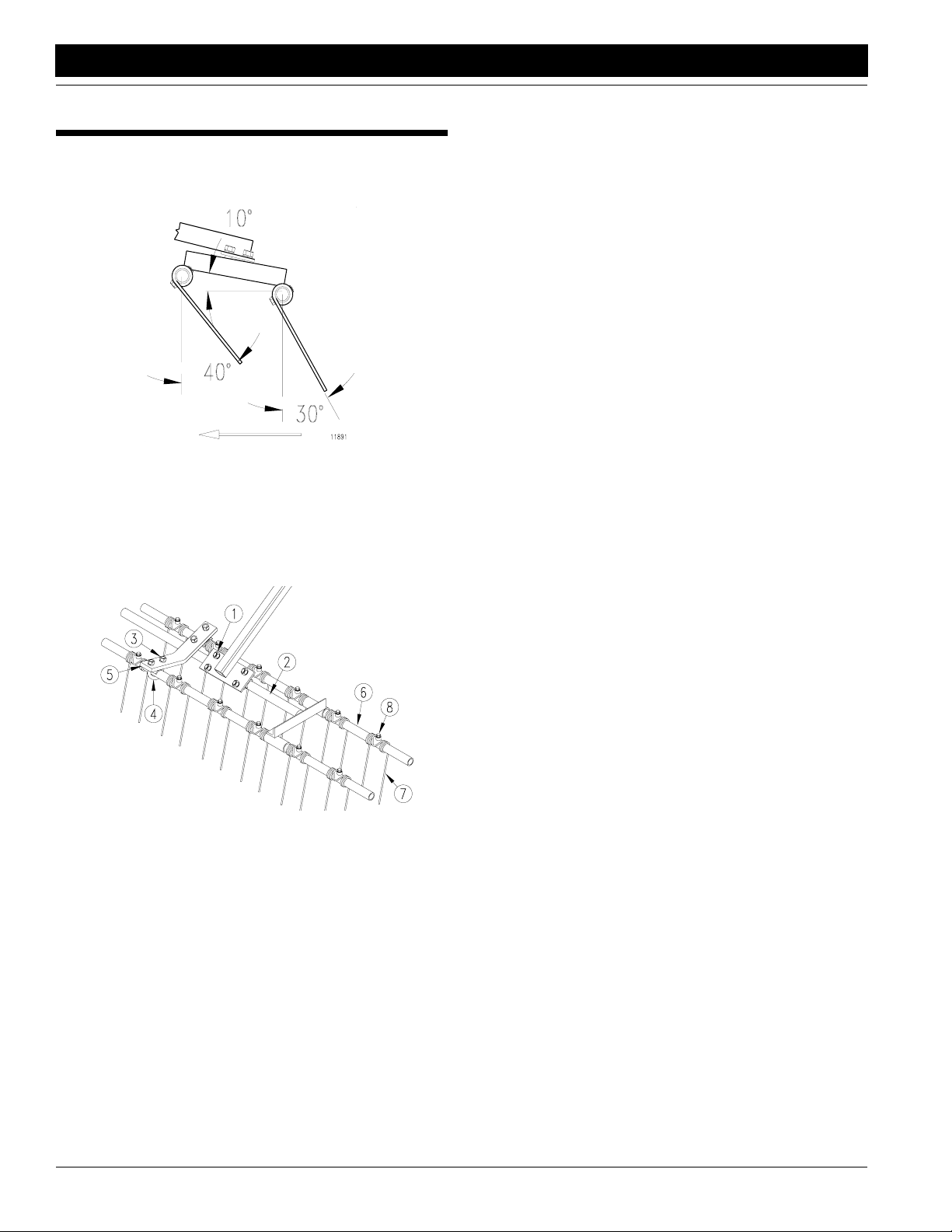

Figure 1 shows one harrow setting that has been successful in

no- and minimum-till conditions. Because of different soil moisture, trash levels and trash types, you may need to reposition the

tube frame or tines.

11891

Figure 1

Harrow Tines

To adjust frame tube, refer to Figure 2. Loosen four hex nuts (1)

on u-bolts and rotate frame tube (2).

To adjust tines, loosen four 1/2-inch hex nuts (3) on 1/2-inch ubolts (4) on support bar (5). Rotate tine tubes (6) so tines (7) are

against stop bushings (8) and are at desired angle. Retighten

hex nuts on u-bolts.

Great Plains Mfg., Inc.

16297

Figure 2

Harrow Adjustment

EWNT7 and 705 Harrow Option 116-109M Rev. A 4/25/2007

2

Great Plains Mfg., Inc.

Listing of Parts

116-072A EWNT7 & 705 HARROW

Your Kit Includes:

Qty. Part No. Part Description

2 116-062H CENTER BRACE WELDMENT

1 116-066H 14’ FRAME WELDMENT

1 116-109M MANUAL 7’ & 10’ EWNT HARROW

2 116-116D 14’ TINE TUBE

2 116-122D HARROW HINGE BRACKET

2 116-124D NO-TILL SUPPORT CHAIN LONG

2 116-125D NO-TILL SUPPORT CHAIN SHOR

2 116-192H NO-TILL HARROW HANGER ARM

4 802-022C HHCS 3/8-16X1 1/2 GR5

22 802-138C HHCS 5/16-18X2 1/4 GR5

2 802-226C HHCS 1/2-13X2 3/4 GR5

8 803-014C NUT HEX 3/8-16 PLT

16 803-020C NUT HEX 1/2-13 PLT

22 803-084C NUT HEX NYLOCK 5/16-18 PLT

2 803-147C NUT HEX NYLOCK 1/2-13

22 804-010C WASHER FLAT 5/16 USS PLT

8 804-012C WASHER FLAT 3/8 SAE PLT

4 804-013C WASHER LOCK SPRING 3/8 PLT

16 804-015C WASHER LOCK SPRING 1/2 PLT

8 806-046C U-BOLT 1/2-13 X 1 3/8X2 3/

2 806-051C U-BOLT 3/8-16 X 6 1/32 X 7

22 807-079C SPRING HARROW DBL TORSION

1 813-010C 7 FT HARROW PALLET

2 890-178C SCREW PIN ANCHOR SHACKLE

22 890-351C BUSHING 5/8 OD X 11/32 ID

4/25/2007

EWNT7 and 705 Harrow Option 116-109M Rev. A

3

Loading...

Loading...