Page 1

Installation Instructions

401-508A and 401-516A

Pressure Relief Kits

for 403-143K, 403-226K

and 403-174K Hoppers

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

27352

Cover illustration shows a 401-508A 82 bu kit installed in a 403-143K hopper.

© Copyright 2007 Printed 12/28/2007 401-514M

Page 2

YP Pressure Relief Kits Great Plains Manufacturing, Inc.

Table of Contents

Important Safety Information.................................... 1

Introduction ................................................................ 3

Description of Unit........................................................ 3

Document Family ......................................................... 3

Kits Covered by this Manual ........................................ 3

Hoppers Which May Be Updated............................. 3

Using This Manual ....................................................... 4

Call-Outs .................................................................. 4

Definitions ................................................................4

Owner Assistance ........................................................ 4

Installation Instructions ............................................ 5

Before You Start .......................................................... 5

Tools Required............................................................. 5

Prepare Hopper ........................................................... 5

Dismount Hopper ......................................................... 6

Remove Old Door Slide ............................................... 7

Install Bottom Weldment .............................................. 7

Install New Door Slide.................................................. 8

Assemble Upper Pipe Support..................................... 9

Attach 150 bu Angle Brackets.................................. 9

Install 82 bu Upper Components ............................... 10

Remove Support for Drilling................................... 10

Mark Holes and Drill............................................... 10

Re-Install Strainer Support..................................... 11

Position Air Pipe..................................................... 11

Install Upper Pipe Support ..................................... 11

Install 150 bu Upper Components ............................. 12

Mark Holes for Drilling............................................ 12

Insert Pipe in Hopper .............................................13

Cap and Position Pipe ........................................... 13

Drill 150 bu Holes................................................... 13

Attach Upper 150 bu Support ................................ 14

Closeout..................................................................... 14

Appendix................................................................... 15

Torque Values............................................................ 15

Parts Lists .................................................................. 16

401-508A 82 bu Pressure Release Kit................... 16

401-508A Part Numbers .................................... 17

401-516A 150 bu Pressure Release Kit................. 18

401-516A Part Numbers .................................... 19

Existing Parts Affected........................................... 19

© Copyright 2007. All rights Reserved.

Great Plains Manufacturing, Inc. provides this publication “as is”without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at

the time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

401-514M 12/28/2007

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Page 3

Great Plains Manufacturing, Inc. 1

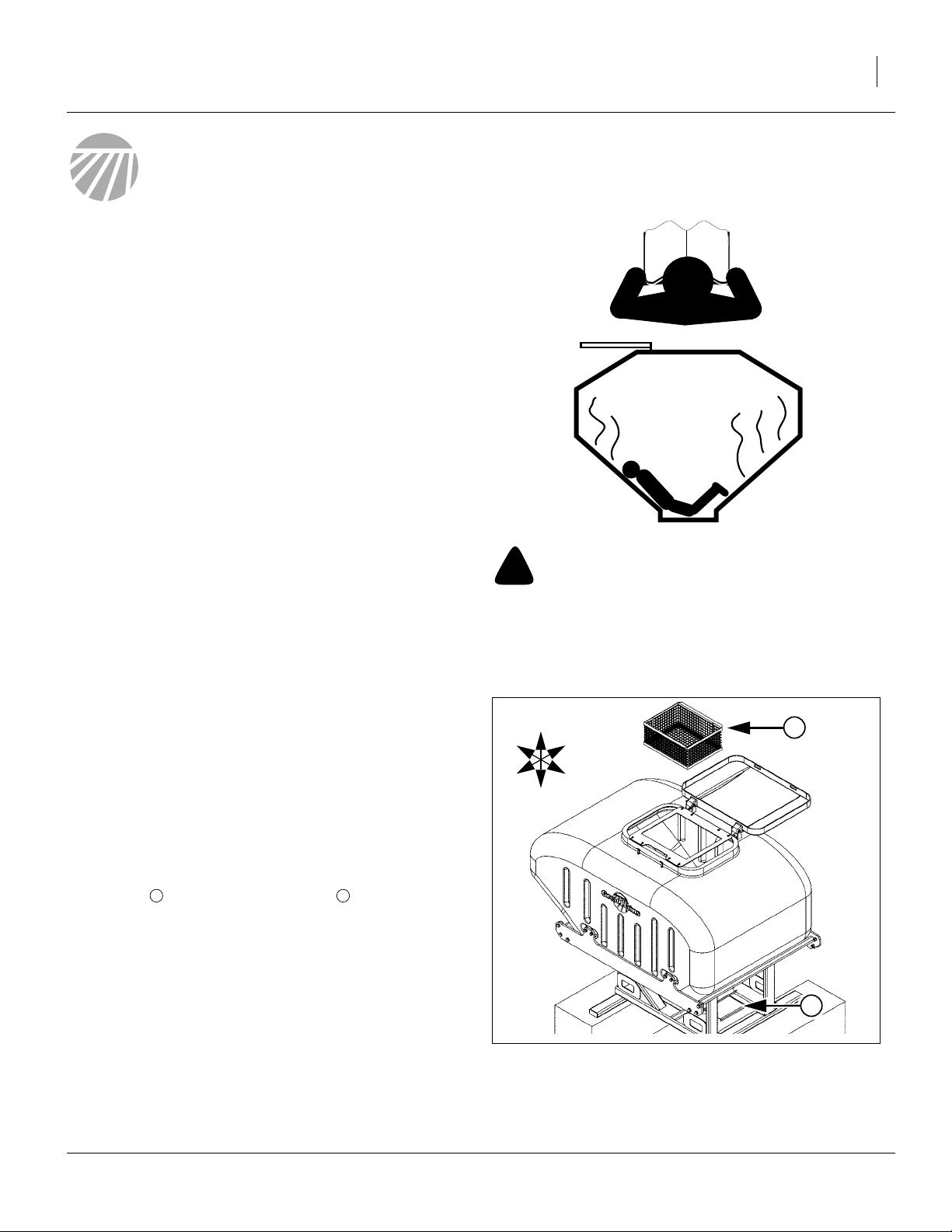

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

!

!

!

!

DANGER

WARNING

CAUTION

Be Familiar with Safety Decals

▲ Read and understand “Safety Reflectors and Decals”in

the Operator Manual.

▲ Read all instructions noted on the decals.

12/28/2007 401-514M

Page 4

2 YP Pressure Relief Kits Great Plains Manufacturing, Inc.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper tools

and equipment. Refer to this manual for additional information.

▲ Work in a clean, dry area.

▲ Wear gloves when handling row cleaner tines.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Inspect all parts. Make sure parts are in good condition and

installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from implement before

operation.

OFF

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Safety At All Times

▲ Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on the

safety decals.

▲ Be familiar with all implement functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave implement unattended with tractor engine

running.

▲ Wear snug-fitting clothing to avoid entanglement with mov-

ing parts.

911

401-514M 12/28/2007

Page 5

Great Plains Manufacturing, Inc. Introduction 3

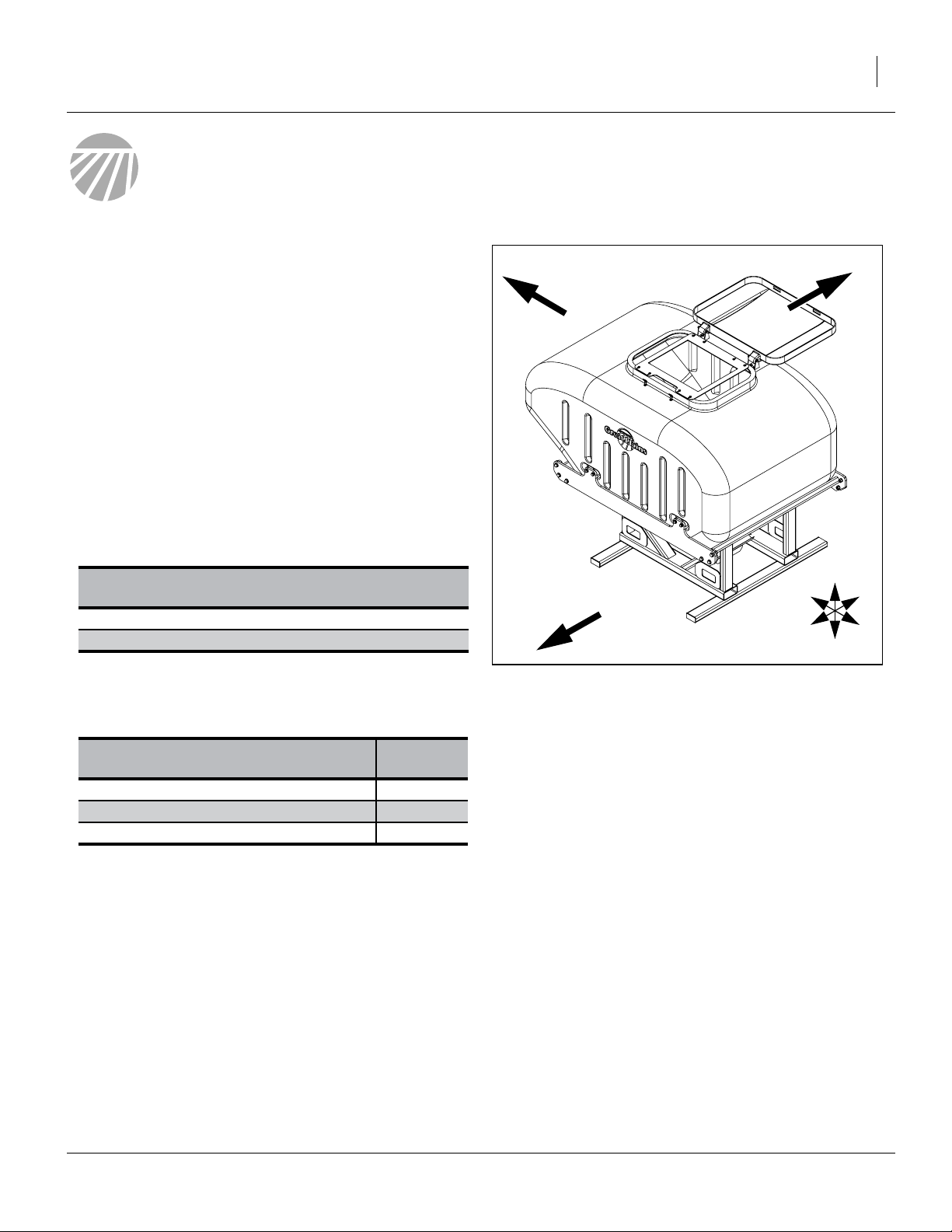

Introduction

Description of Unit

These kits update older hoppers to the current pneumatic configuration, which includes a vertical pipe to

equalize pressure at the top of the hopper and at the

base of the seed mass. This allows the hydraulic fan to

run at higher speeds, and provides more consistent seed

flow at all pressures and seed delivery rates.

Document Family

401-514M Installation Instructions (this document)

Also update your Operator and Parts Manuals for correct

information on fan operations with updated hoppers, and

current replacement part data.

The information in this manual is current at printing.

Some parts may change to assure top performance.

R

Kits Covered by this Manual

Part

Number

401-508A YP 82 BU AIR RELEASE FLD KIT

401-516A YP 150 BU AIR RELEASE FLD KIT

Each kit updates one hopper.

Hoppers Which May Be Updated

Part

Number

403-143K 82 bu, latch on left side 401-508A

403-226K 82 bu, latch on right side 401-508A

403-174K 150 bu, latches to center 401-516A

Inspect the hopper before ordering a kit. Only hoppers

manufactured prior to late 2007 support this update kit.

Hoppers made after that date have the vent tube components as standard equipment.

Description

Description Use Kit

L

Figure 1:

403-143K Hopper

U

F

L

R

B

D

37353

12/28/2007 401-514M

Page 6

4 YP Pressure Relief Kits Great Plains Manufacturing, Inc.

Using This Manual

This manual familiarizes you with safety, assembly, operation, adjustments, troubleshooting, and maintenance.

Read this manual and follow the recommendations to

help ensure safe and efficient operation.

Call-Outs

1

11 34

to

85 89

to

Definitions

The following terms are used throughout this manual.

Note: Paragraphs in this format provide useful informa-

Paragraphs in this format present a crucial point of

information related to the current topic. Read and follow the directions to:

- remain safe,

- avoid serious damage to equipment and

- ensure desired field results.

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts in the range 11-34 reference new parts from the new parts lists

beginning on page 16. The descriptions

match those on the parts, cartons, bags or

item tags, as well as descriptions your

updated Parts Manual.

Two-digit callouts in the range 85-89 reference existing parts removed and reused.

tion related to the current topic.

IMPORTANT !

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts.

Record your pressure relief kit kit model number here for

quick reference:

Model Number:__________________________

Date Purchased: __________________________

Your Great Plains dealer wants you to be satisfied with

your updated machine. If you do not understand any part

of this manual or are not satisfied with the service

received, please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or general manager of the dealership.

For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

Refer to Figure 1 on page 3

Right-hand and left-hand as

used in this manual are determined by facing the direction

the machine will travel while in

use unless otherwise stated.

An orientation rose (shown at

right) depicts Up, Right, Back,

Down, Left and Front.

401-514M 12/28/2007

U

F

L

R

B

D

785-823-3276

Page 7

Great Plains Manufacturing, Inc. Installation Instructions 5

Installation Instructions

Before You Start

Most accidents are the result of negligence and carelessness, usually caused by failure of the operator to follow simple but necessary safety precautions. Allow no

one to install the pressure relief kit before carefully reading this manual.

Some fasteners may be loosely assembled. Remove

them before mounting that component. Due to evolving

manufacturing practices, some assemblies may already

be completely pre-assembled. If so, check that fasteners

are tight, and skip the unneeded assembly steps.

Tools Required

• Basic hand tools, including a center punch and a fine

tip indelible marker

• Portable drill with a

• Twist drill bits of sizes:

Bolt hole: 0.41in,

Pilot hole: approx. 0.13in,

• Measuring square

• Silicone sealant

• Blocks of supports for hopper

• Ladder

Torque values for fasteners are shown on page 15.

1. Read and understand “Important Safety Informa-

tion” starting on page 1.

1

⁄

in (12mm) chuck

2

13

⁄

in, Z, or 10.1mm

32

1

⁄

8

in, #31, or 3.0mm

Prepare Hopper

!

WARNING

Possible Confined Space Hazard. Do not enter hopper.

The instructions in this manual do not require hopper entry.

A hopper that has been used may represent a Confined Space

Hazard, due to low oxygen, high dust and/or chemical fumes.

U

F

L

R

B

D

+

1

Refer to Figure 2

2. Empty the hopper per the clean-out instructions in

your Operator Manual. Remove the strainer basket(s) and leave the slide gate open.

3. From the walkboard (or a lift, if the hopper is dis-

mounted), thoroughly pressure wash the inside of

the hopper.

4. Allow the hopper to drain and dry.

1 2

2

Figure 2:

Prepare Hopper

12/28/2007 401-514M

27354

Page 8

6 YP Pressure Relief Kits Great Plains Manufacturing, Inc.

Dismount Hopper

U

!

CAUTION

You will be handling the bottom components of the hopper, and

any remaining moisture may contain residual seed treatments.

This update cannot be performed with a hopper cradled

on a planter, as the planter airbox obstructs access from

below. Consult the planter Operator manual for hopper

removal instructions.

5. While waiting for the hopper to dry, prepare a suitable work location. Use a level, dry, well-lighted area.

Pick a location with a clear surface beneath, so that

any dropped tools or parts can be easily located.

For work access to the bottom of the hopper, the

assembly needs to raised at least 18in (46cm). One

method, as shown in Figure 3, is to rest it on blocks

or supports under the lateral tubes of the structure.

F

L

R

B

D

!

CAUTION

Use adequate supports.

Make sure each support can safely support at least 150% its

apparent share of the weight. See step 6 for hopper weights.

Do not perform this work in high wind.

!

CAUTION

Anchor the hopper laterally.

Make sure that workers on ladders at later steps cannot push

or tip the hopper off the supports.

6. If the hopper to be updated is presently on a planter,

use a suitably rated forklift or hoist to remove the

hopper.

A 403-143K or 403-226K 82 bu hopper weighs 1200

pounds (544 kg) empty. Allow another 400 pounds

(181 kg) for two workers and tools,

for a total of 1600 pounds (726 kg).

A 403-174K 150 bu hopper weighs 1350 pounds

(612 kg) empty. Allow another 400 pounds (181 kg)

for two workers and tools,

for a total of 1750 pounds (794 kg).

7. Place the hopper in the prepared work location.

Figure 3:

Hopper on Blocks

27354

401-514M 12/28/2007

Page 9

Great Plains Manufacturing, Inc. Installation Instructions 7

Remove Old Door Slide

The single center stop bolt of the existing door slide interferes with the lower weldment installed at step 11. Your

kit includes a new door slide using two corner stop bolts.

Refer to Figure 4,

which depicts the water guard and door slide assembly

2

disassembled from the hopper. It is not necessary to

disassemble these components other than the door slide.

8. Pull the old slide door

82

403-234D BULK HOPPER UNLOAD DOOR (single stop bolt hole) halfway open, to provide access to

the nut and bolt.

9. Remove and save one each:

83

802-004C HHCS 1/4-20X3/4 GR5

87

803-088C NUT HEX LOCK 1/4-20 FLG

1

1

2

87

82

10. Remove the old slide door .

It is not reused.

82

Install Bottom Weldment

Installation of this part is the same for both 82 bu and

150 bu hoppers.

Refer to Figure 5

11. Select one new:

13

403-241H LOWER AIR PIPE SUPPORT 82 YP

Note: This part is not symmetrical, and must be installed

in the correct orientation. Inspect it and note:

The longer end of the large center tube is the top,

and points Up when installed. The holes on the

bracket bar are toward the bottom (Down).

With the top Up, the larger tube tilts Back, and the

longer ends of the bracket bars are Forward.

1

2

U

F

L

R

B

83

D

Figure 4:

Remove Old Door Slide

27376

1

U

13

2

Figure 5:

13

403-241H Lower Weldment

F

L

R

B

D

27356

12/28/2007 401-514M

Page 10

8 YP Pressure Relief Kits Great Plains Manufacturing, Inc.

Refer to Figure 6, which depicts (top to bottom):

13

the new weldment,

3

the water guard,

4

the door slide assembly with

85 89 87

,2x , forward fasteners and

86 89 87

,2x , rear fasteners.

12. Remove and save the side fasteners in the door

guide assembly. This is:

two sets forward:

85

1 802-167C HHCS 1/4-20X1 1/2 GR5

87

1 803-088C NUT HEX LOCK 1/4-20 FLG

89

2 804-007C WASHER FLAT 1/4 SAE PLT

two sets rear:

86

1 802-370C HHCS 1/4-20X1 3/4 GR5

87

1 803-088C NUT HEX LOCK 1/4-20 FLG

89

2 804-007C WASHER FLAT 1/4 SAE PLT

Note: Remove only the side fasteners, and no fasteners

on the front or rear faces of the door slide frame.

13. Orient the lower air pipe weldment as necessary

to pass it up through the door slide frame .

14. Re-orient top-Up/tilt-Back as shown, and align

the holes on the bracket bar with the holes in the

water guard and door slide frame. Hold it temporarily

with the four removed bolts ( and ).

15. Check that the correct bolts are in their proper holes

(longer bolts to Back). Remove each bolt. Place a flat

washer on it.

16. Apply silicone sealant to the washer and underside

of bolt head.

17. Re-insert bolt. Add a second washer inside

frame, and a nut . Tighten.

13

2

89

87

13

4

85 86

89

3

85

13

U

F

L

R

B

D

2

4

87

89

89

86

87

27355

29

12

Figure 6:

Lower Hopper Components

2

Install New Door Slide

Refer to Figure 7.

Note that either bolt may be used in either hole,

and either nut may be used on either bolt.

18. Select one set new:

17

802-004C HHCS 1/4-20X3/4 GR5

29

803-088C NUT HEX LOCK 1/4-20 FLG

Note that these are identical to the saved bolt and

87

nut removed in step 9.

19. Select one new:

12

403-234D BULK HOPPER UNLOAD DOOR

(new, with two stop bolt holes)

20. With the bent lip down, insert the new door slide

into the door frame about halfway.

401-514M 12/28/2007

2

83

21. Insert a

12

22. Pull the door slide fully open so that any debris

29

87

1783 17

Figure 7:

Install New Door Slide

17

83

or HHCS 1/4-20X3/4 GR5 bolt into

each stop bolt hole from below, and secure it with a

29 87

or NUT HEX LOCK 1/4-20 FLG.

12

from later steps can fall out of the hopper.

83

27377

Page 11

Great Plains Manufacturing, Inc. Installation Instructions 9

Assemble Upper Pipe Support

17

20

15

24

18

22

16

23

27357

Assembly of this part, if necessary, is the same for 82 bu

and 150 bu hoppers, up to step 30.

Refer to Figure 8

If this component

14

403-242S UPPER PIPE SUPPORT WELDMENT

appears to be pre-assembled, skip to step 29.

23. Select one each new:

16

403-408D AIR TRANSFER TUBE CAP

24

816-245C RUBBER GUARD REAR CTR.OUTER

and two sets new:

18

802-080C HHCS 7/16-14X1 GR5

20

803-015C NUT HEX 7/16-14 PLT

22

804-014C WASHER LOCK 7/16 PLT

23

804-041C WASHER FLAT 7/16 SAE PLT

24. Place the lock washers on the bolts .

25. Insert the rubber guard in the slot at the top of the

tube cap and capture it with the bolts. Secure the

bolts with flat washers and nuts .

26. Select one new:

15

403-407D BRACKET

and four sets new:

17

802-004C HHCS 1/4-20X3/4 GR5

19

803-006C NUT HEX 1/4-20 PLT

21

804-006C WASHER LOCK SPRING 1/4 PLT

27. Place the lock washers on the bolts .

16

22 18

24

23 20

21 17

19

21

U

F

L

R

B

D

Figure 8:

14

Upper Pipe Support

27

30

28. Position the bracket on the open front end of the

16

cap , with the break on top and facing the cap.

Secure with the four bolts and nuts .

29. If you are updating an 82 bu hopper, the upper support is complete and ready for installation. Skip to

step 39 on page 11.

15

15

19

31

28

Attach 150 bu Angle Brackets

Refer to Figure 9

30. Select two each:

27

802-017C HHCS 3/8-16X1 GR5

28

803-014C NUT HEX 3/8-16 PLT

30

804-013C WASHER LOCK SPRING 3/8 PLT

31

403-409D BRACKET ANGLE WITH HOLES

31. Loosely assemble the angle brackets to the cap

bracket through the center holes of the angle

brackets. Orient the angle bends to the inside.

12/28/2007 401-514M

15

31

U

F

L

R

B

D

Figure 9:

150 bu Angle Brackets

14

27358

Page 12

10 YP Pressure Relief Kits Great Plains Manufacturing, Inc.

Install 82 bu Upper Components

If you are updating a 150 bu hopper, use the instructions

at “Install 150 bu Upper Components” on page 12.

Remove Support for Drilling

Refer to Figure 10

The new upper pipe support for an 82 bu hopper mounts

on the existing strainer basket support , which nor-

mally will not already have holes for this purpose. Follow

step 32 through step 38 to prepare the support.

32. Remove and save eight sets of:

84

802-005C HHCS 1/4-20X1 GR5

89

804-007C WASHER FLAT 1/4 SAE PLT

88

803-230C NUT HEX FLANGE 1/4-20 PLT

33. Remove the:

81

403-332D HOPPER STRAINER BASKET SUP-

PORT

Note: The support has a notch , which must be on

81 1

the latch side of the hopper opening. The latch is:

on the left for a 403-143K 82bu hopper,

on the right for a 403-226K 82 bu hopper, and:

toward the center for a 403-174K 150bu hopper.

81

U

F

L

R

B

84

89

D

81

1

Figure 10:

Remove Strainer Support

88

27382

Mark Holes and Drill

34. Mark holes on the back span of strainer support

at the following dimensions:

Latch-side edge to latch-side hole:

A

8.25in, 8

Latch-side hole to hinge-side hole:

B

9.00in, 22.86cm

Rear edge to hole center-line

C

1.00in, 2.54cm

Hole diameter is:

H

0.41in,

Alternate reference dimensions:

D

17.25in, 17

E

1.81in, 1

F

0.81in,

35. Check hole marking with (not shown):

15

403-407D BRACKET (part of upper support )

36. Drill pilot holes, then final holes.

1

⁄

in, 20.96cm

4

13

⁄

in, 10.4mm

32

1

⁄

in, 43.82cm (L. edge to L. hole)

4

13

⁄

in, 4.60cm (back span width)

16

13

⁄

in, 2.06cm (inside to hole c/l)

16

14

81

F

Latch

Hinge

B

H

F

E

C

A

D

Figure 11:

Strainer Support Holes

B

27381

81

401-514M 12/28/2007

Page 13

Great Plains Manufacturing, Inc. Installation Instructions 11

Re-Install Strainer Support

Refer to Figure 12 (which depicts a 403-143K hopper)

37. Select the eight sets of saved:

84

802-005C HHCS 1/4-20X1 GR5

89

804-007C WASHER FLAT 1/4 SAE PLT

88

803-230C NUT HEX FLANGE 1/4-20 PLT

38. Position the drilled strainer support with the notch

to the hopper latch side and the new holes to the

rear. Place a washer on each bolt . Insert bolt

from above and secure with nut .

89 84

81

88

Position Air Pipe

39. With the upper pipe support at hand,

select one new:

25

403-403D 82 BU AIR PRESSURE PIPE

and two sets of:

27

802-017C HHCS 3/8-16X1 GR5

30

804-013C WASHER LOCK SPRING 3/8 PLT

28

803-014C NUT HEX 3/8-16 PLT

40. Insert the pipe into the hopper and slide it over the

lower pipe support weldment. Temporarily lean it

against the back of the hopper.

14

U

F

L

R

B

81

D

25

13

Figure 12:

Insert 82 bu Pipe

27363

Install Upper Pipe Support

Refer to Figure 13

41. With the bolts at hand,

swing the pipe back into the opening,

place the upper support on the pipe, with the

bracket forward.

42. Swing the pipe and support to the back of the hopper, so that the bracket edge is under the rear span

of strainer support .

43. Align the holes in the two brackets and secure them

with the bolts , washers and nuts .

44. Skip to “Closeout” on page 14.

27

25

14

81

27 30 28

U

F

R

14

L

B

D

27

30

81

28

25

Figure 13:

Install Upper 82 bu Support

12/28/2007 401-514M

27365

Page 14

12 YP Pressure Relief Kits Great Plains Manufacturing, Inc.

Install 150 bu Upper Components

If you are updating an 82bu hopper, use the instructions

at “Install 82 bu Upper Components” on page 10.

Refer to Figure 14

In the 150 bu hopper, the upper tube support mounts to

the stiffener rib molded into the hopper. Four holes, two

each side, need to be drilled.

This work is most easily accomplished from the walkboard, while the hopper is on the planter.

Refer to Figure 15,

which depicts a view fromthe right side above a view from

31

14

Figure 14:

150 bu Hopper Drill Region

27359

the rear. The eventual location of top tube support is

shown in dotted line, and the angle bracket shown in

dashed line.

Hole locations are in the side walls of the center stiffener

rib. Measurements are referenced from:

1

front face, rear lip of tank top openings

2

underside of center stiffener rib

After installation, the bottom edge of the angle bracket

31

is flush with the underside of the center stiffener rib.

Mark Holes for Drilling

45. Holes are above the underside of center stiffener rib:

A

2.28in, 2

46. The rear holes are located forward of the lip at:

B

7.02in, 7

47. The front holes are forward of the rear holes by:

C

5.50in, 5

For reference, the total distance from the lip to the

forward holes is:

E

12.52in, 12

48. Mark the hole centers. Hole diameter is:

H

0.41in,

49. Use a 16in (41cm) straight edge to mark a line

between the hole centers, and about 2in (5cm) on

either side.

Note: Depending on the hopper and part tolerances,

these may not be the final hole positions. The final

holes are marked and drilled beginning at step 53.

9

⁄

in, 5.79cm

32

1

⁄

in, 17.82cm

64

1

⁄

in, 13.97cm

2

33

⁄

64

13

⁄

in, 10.4mm

32

in, 31.79cm

B

U

D

E

F

B

C

1

H

31

A

14

2

Figure 15: Side / Rear View

27360

150 bu Drill Holes

401-514M 12/28/2007

Page 15

Great Plains Manufacturing, Inc. Installation Instructions 13

Insert Pipe in Hopper

Refer to Figure 16

50. Select one new:

32

403-427D 150 BU AIR PRESSURE PIPE

51. Insert the pipe into the hopper and slide it over

the lower pipe support weldment. Have a second

worker hold it, or temporarily lean it against the back

of the hopper.

32

Cap and Position Pipe

52. Select the:

14

403-242S UPPER PIPE SUPPORT WELDMENT

with the angle brackets loosely attached.

Refer to Figure 17

53. Place the cap assembly on top of the pipe and

maneuver it so that the four holes in the angle brack-

31

ets align with the marks for the holes to be drilled.

It may be necessary to temporarily remove one

angle bracket in some cases.

If all four holes cannot be aligned, align to the forward holes. If both left and right side forward holes

cannot be aligned, use the left forward hole.

54. Make sure the angle bracket bolts are finger tight,

and make final marks for drilling. Fore-and-aft location of the holes is not critical, but if a hole needs to

be re-marked, make sure the vertical position is on

the centerline marked at step 49.

31

14 32

U

D

R

B

32

F

L

13

Figure 16:

Insert 150 bu Pipe

27364

Drill 150 bu Holes

These holes need to be drilled from the inside, as the

exterior channel of the stiffener rib is not wide enough for

most portable drills.

55. Swing the pipe assembly clear.

56. Drill pilot holes. Re-check hole placement and drill

final holes.

57. Sweep out any drill swarf that might eventually clog a

seed meter.

IMPORTANT !

If any error is made in hole drilling, close the hole with

5

a

⁄

in or 8mm bolt, washers and nut, coated with

16

silicone sealant. A hole left open adversely affects

seed delivery.

12/28/2007 401-514M

32

Figure 17:

Position 150 bu Pipe

31

14

27366

Page 16

14 YP Pressure Relief Kits Great Plains Manufacturing, Inc.

Attach Upper 150 bu Support

Refer to Figure 18

58. Select four sets of new:

33

802-079C HHCS 3/8-16X1 1/4 GR5

34

803-209C NUT FLANGE LOCK 3/8-16 PLT

31

59. Loosen the bolts holding the angle brackets, and

apply silicone sealant around the holes in the hopper. Re-position the angle brackets at the holes and

loosely re-tighten bolts .

60. Apply silicone sealant to the underside of bolt heads

33

, and insert them. from the inside of the hopper,

through the angle brackets and hopper. Secure with

flange lock nuts .

61. When all four flange lock nuts are tight, tighten

27

bolts .

27

27

34

34

Closeout

62. Re-install strainer(s).

63. Close lid(s).

64. Close door slide.

65. Re-mount hopper on planter (if next use will rely on

hopper rather than bulk seed box).

66. Obtain an updated Operator Manual for your planter.

Review sections on fan and hopper operations, as

recommended fan speeds are higher for updated

hoppers.

27

34

Figure 18:

Attach 150 bu Upper Support

33

27367

401-514M 12/28/2007

Page 17

Great Plains Manufacturing, Inc. Appendix 15

Appendix

Torque Values

Bolt

Size

in-tpi

1

⁄4-20

1

⁄4-28

5

⁄16-18

5

⁄16-24

3

⁄8-16

3

⁄8-24

7

⁄16-14

7

⁄16-20

1

⁄2-13

1

⁄2-20

9

⁄16-12

9

⁄16-18

5

⁄8-11

5

⁄8-18

3

⁄4-10

3

⁄4-16

7

⁄8-9

7

⁄8-14

1-8

1-12

11⁄8-7

11⁄8-12

11⁄4-7

11⁄4-12

13⁄8-6

13⁄8-12

11⁄2-6

11⁄2-12

Bolt Head Identification

Bolt Head Identification

Bolt

Size

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

1

N-m2ft-lb

7.4 5.6 11 8 16 12

8.5 6 13 10 18 14

15 11 24 17 33 25

17 13 26 19 37 27

27 20 42 31 59 44

31 22 47 35 67 49

43 32 67 49 95 70

49 36 75 55 105 78

66 49 105 76 145 105

75 55 115 85 165 120

95 70 150 110 210 155

105 79 165 120 235 170

130 97 205 150 285 210

150 110 230 170 325 240

235 170 360 265 510 375

260 190 405 295 570 420

225 165 585 430 820 605

250 185 640 475 905 670

340 250 875 645 1230 910

370 275 955 705 1350 995

480 355 1080 795 1750 1290

540 395 1210 890 1960 1440

680 500 1520 1120 2460 1820

750 555 1680 1240 2730 2010

890 655 1990 1470 3230 2380

1010 745 2270 1670 3680 2710

1180 870 2640 1950 4290 3160

1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

3

N-m ft-lb N-m ft-lb

mm x pitch

4

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

1. in-tpi = nominal thread diameter in inches-threads per inch

2. N· m = newton-meters

3. ft-lb = foot pounds

4. mm x pitch = nominal thread diameter in millimeters x thread

pitch

5.8 8.8 10.9

N-m ft-lb N-m ft-lb N-m ft-lb

43659 7

7 5 11 8 15 11

17 12 26 19 36 27

18 13 28 21 39 29

33 24 52 39 72 53

39 29 61 45 85 62

58 42 91 67 125 93

60 44 95 70 130 97

90 66 105 77 145 105

92 68 145 105 200 150

99 73 155 115 215 160

145 105 225 165 315 230

155 115 240 180 335 245

195 145 310 230 405 300

220 165 350 260 485 355

280 205 440 325 610 450

310 230 650 480 900 665

480 355 760 560 1050 780

525 390 830 610 1150 845

960 705 1510 1120 2100 1550

1060 785 1680 1240 2320 1710

1730 1270 2650 1950 3660 2700

1880 1380 2960 2190 4100 3220

12/28/2007 401-514M

Page 18

16 YP Pressure Relief Kits Great Plains Manufacturing, Inc.

Parts Lists

401-508A 82 bu Pressure Release Kit

19

27

24

30

14

{

28 18

15

25

21

17

23

22

20

16

13

12

29

401-508A YP 82 BU AIR RELEASE FLD KIT

401-514M 12/28/2007

17

27350

Page 19

Great Plains Manufacturing, Inc. Appendix 17

401-508A Part Numbers

Callout Part Number Quantity Part Description

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

401-514M 1

403-234D 1

403-241H 1

403-242S 1

403-407D 1

403-408D 1

802-004C 4

802-080C 2

803-006C 4

803-015C 2

804-006C 4

804-014C 2

804-041C 2

816-245C 1

403-403D 1

802-004C 1

802-017C 2

803-014C 1

803-088C 1

804-013C 2

MANUAL 82 & 150 BU AIR KIT (This manual. Not shown.)

BULK HOPPER UNLOAD DOOR (new, with two stop bolt holes)

LOWER AIR PIPE SUPPORT 82 YP

UPPER PIPE SUPPORT WELDMENT

BRACKET

AIR TRANSFER TUBE CAP

HHCS 1/4-20X3/4 GR5

HHCS 7/16-14X1 GR5

NUT HEX 1/4-20 PLT

NUT HEX 7/16-14 PLT

WASHER LOCK SPRING 1/4 PLT

WASHER LOCK 7/16 PLT

WASHER FLAT 7/16 SAE PLT

RUBBER GUARD REAR CTR.OUTER

82 BU AIR PRESSURE PIPE

HHCS 1/4-20X3/4 GR5

HHCS 3/8-16X1 GR5

NUT HEX 3/8-16 PLT

NUT HEX LOCK 1/4-20 FLG

WASHER LOCK SPRING 3/8 PLT

12/28/2007 401-514M

Page 20

18 YP Pressure Relief Kits Great Plains Manufacturing, Inc.

401-516A 150 bu Pressure Release Kit

27

34

19

14

15

{

32

21

17

30

33

31

28

24

18

23

22

20

16

13

12

29

401-516A YP 150 BU AIR RELEASE FLD KIT

401-514M 12/28/2007

17

27351

Page 21

Great Plains Manufacturing, Inc. Appendix 19

401-516A Part Numbers

Callout Part Number Quantity Part Description

11

12

13

13

15

16

17

18

19

20

21

22

23

24

17

27

28

29

30

31

32

33

34

401-514M 1

403-234D 1

403-241H 1

403-242S 1

403-407D 1

403-408D 1

802-004C 4

802-080C 2

803-006C 4

803-015C 2

804-006C 4

804-014C 2

804-041C 2

816-245C 1

802-004C 1

802-017C 2

803-014C 2

803-088C 2

804-013C 2

403-409D 2

403-427D 1

802-079C 4

803-209C 4

MANUAL 82 & 150 BU AIR KIT (This manual. Not shown.)

BULK HOPPER UNLOAD DOOR (new, with two stop bolt holes)

LOWER AIR PIPE SUPPORT 82 YP

UPPER PIPE SUPPORT WELDMENT

BRACKET

AIR TRANSFER TUBE CAP

HHCS 1/4-20X3/4 GR5

HHCS 7/16-14X1 GR5

NUT HEX 1/4-20 PLT

NUT HEX 7/16-14 PLT

WASHER LOCK SPRING 1/4 PLT

WASHER LOCK 7/16 PLT

WASHER FLAT 7/16 SAE PLT

RUBBER GUARD REAR CTR.OUTER

HHCS 1/4-20X3/4 GR5

HHCS 3/8-16X1 GR5

NUT HEX 3/8-16 PLT

NUT HEX LOCK 1/4-20 FLG

WASHER LOCK SPRING 3/8 PLT

BRACKET ANGLE WITH HOLES

150 BU AIR PRESSURE PIPE

HHCS 3/8-16X1 1/4 GR5

NUT FLANGE LOCK 3/8-16 PLT

Existing Parts Affected

Callout Part Number Description Disposition

81

82

83

84

85

86

87

88

89

12/28/2007 401-514M

403-332D

403-234D

802-004C

802-005C

802-167C

802-370C

803-088C

803-230C

804-007C

HOPPER STRAINER BASKET SUPPORT Removed, modified and re-installed.

BULK HOPPER UNLOAD DOOR (single

stop bolt hole)

Removed.

Not re-used.

HHCS 1/4-20X3/4 GR5 Removed and re-installed.

HHCS 1/4-20X1 GR5 Removed and re-installed.

HHCS 1/4-20X1 1/2 GR5 Removed and re-installed.

HHCS 1/4-20X1 3/4 GR5 Removed and re-installed.

NUT HEX LOCK 1/4-20 FLG Removed and re-installed.

NUT HEX FLANGE 1/4-20 PLT Removed and re-installed.

WASHER FLAT 1/4 SAE PLT Removed and re-installed.

Page 22

20 YP Pressure Relief Kits

Great Plains Manufacturing, Inc.

Great Plains Manufacturing, Inc.

Corporate Office: P.O. Box 5060

Salina, Kansas 67402-5060 USA

401-514M 12/28/2007

Loading...

Loading...