Page 1

Table of Contents Index

Pre-Delivery Manual

1200TC, 1500TC, 1800TC.

2400TC, 3000TC & 4000TC

Turbo-Chopper

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

Illustrations may show optional equipment not supplied with standard unit.

41378

ORIGINAL INSTRUCTIONS

© Copyright 2013 Printed 2013-07-02 586-239Q

Table of Contents Index

EN

Page 2

1200-4000TC Table of Contents Index

586-239Q Table of Contents Index 2013-07-02

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ...................................... 1

Introduction ..................................................................4

Description of Unit ..........................................................4

Models Covered ............................................................. 4

Document Family ...........................................................4

Tools Required ...............................................................4

Pre-assembly Checklist..................................................4

Using This Manual..........................................................5

Definitions................................................................... 5

Shipping .........................................................................6

Unloading ....................................................................... 6

Unload Smaller Items First .........................................6

Unload Turbo-Chopper............................................... 6

Unpacking Boxes .......................................................6

Assembly and Setup Assistance ................................7

Assembly ......................................................................8

Hitch Assembly........................................................... 8

Wing Assembly........................................................... 8

4000 Outer Wing Assembly........................................ 9

Hitch Hose & Light Harness Assembly....................... 9

3000 Hydraulic Wing Lift Assembly..............................10

4000 Hydraulic Wing Lift & Fold Assembly ..................12

Attach Hose Clamps and Hose wraps...................... 14

Hydraulic Hose Hookup............................................ 14

Hose Handles...........................................................14

Purging Hydraulic System ........................................15

Light Bracket and SMV Assembly ................................16

Rolling Harrow (optional)..........................................18

Reel Following Rolling Harrow (optional) .................19

Detracker Assembly (Optional) ....................................20

Detracker Placement................................................20

Install Rear Hitch (optional) ..........................................21

Extended Rear Hitch ................................................21

A-Frame Hitch ..........................................................21

Rear Stand ...............................................................22

Appendix - Reference Information............................23

Torque Values Chart.................................................... 23

Tire Inflation & Warranty .............................................. 24

Hydraulic Connectors and Torque ............................... 25

1200TC & 1500TC Hydraulic Lift Layout ..................... 27

1800TC Hydraulic Lift Layout....................................... 28

1800TC Hydraulic Fold Layout .................................... 29

2400TC Hydraulic Lift Layout....................................... 30

2400TC Hydraulic Fold Layout .................................... 31

3000TC Hydraulic Lift Layout....................................... 32

3000TC Hydraulic Fold Layout .................................... 33

4000TC Hydraulic Lift Layout....................................... 34

4000TC Hydraulic Fold Layout .................................... 35

1200TC Machine Layout.............................................. 36

1500TC Machine Layout.............................................. 37

1800TC Machine Layout.............................................. 38

2400TC Machine Layout.............................................. 39

3000TC Machine Layout.............................................. 40

4000TC Machine Layout.............................................. 42

4000TC Machine Layout.............................................. 43

1200TC Rolling Harrow Layout.................................... 44

1200TC Heavy Reel Following Rolling Harrow Layout 45

1500TC Rolling Harrow Layout.................................... 46

1500TC Heavy Reel Following Rolling Harrow Layout 47

1800TC Rolling Harrow Layout.................................... 48

1800TC Heavy Reel Following Rolling Harrow Layout 49

2400TC Rolling Harrow Layout.................................... 50

2400TC Heavy Reel Following Rolling Harrow Layout 51

3000TC Rolling Harrow Layout.................................... 52

3000TC Rolling Harrow Layout.................................... 53

3000TC Heavy Reel Following Rolling Harrow Layout 54

3000TC Heavy Reel Following Rolling Harrow Layout 55

4000TC Rolling Harrow Layout.................................... 56

4000TC Rolling Harrow Layout.................................... 57

4000TC Heavy Reel Following Rolling Harrow Layout 58

4000TC Heavy Reel Following Rolling Harrow Layout 59

Index........................................................................... 61

© Copyright 2006, 2007, 2008, 2009, 2010, 2011, 2012, 2013 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

07/02/2013 Cover Index 586-239Q

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Verti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

586-239Q Table of Contents Index 07/02/2013

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

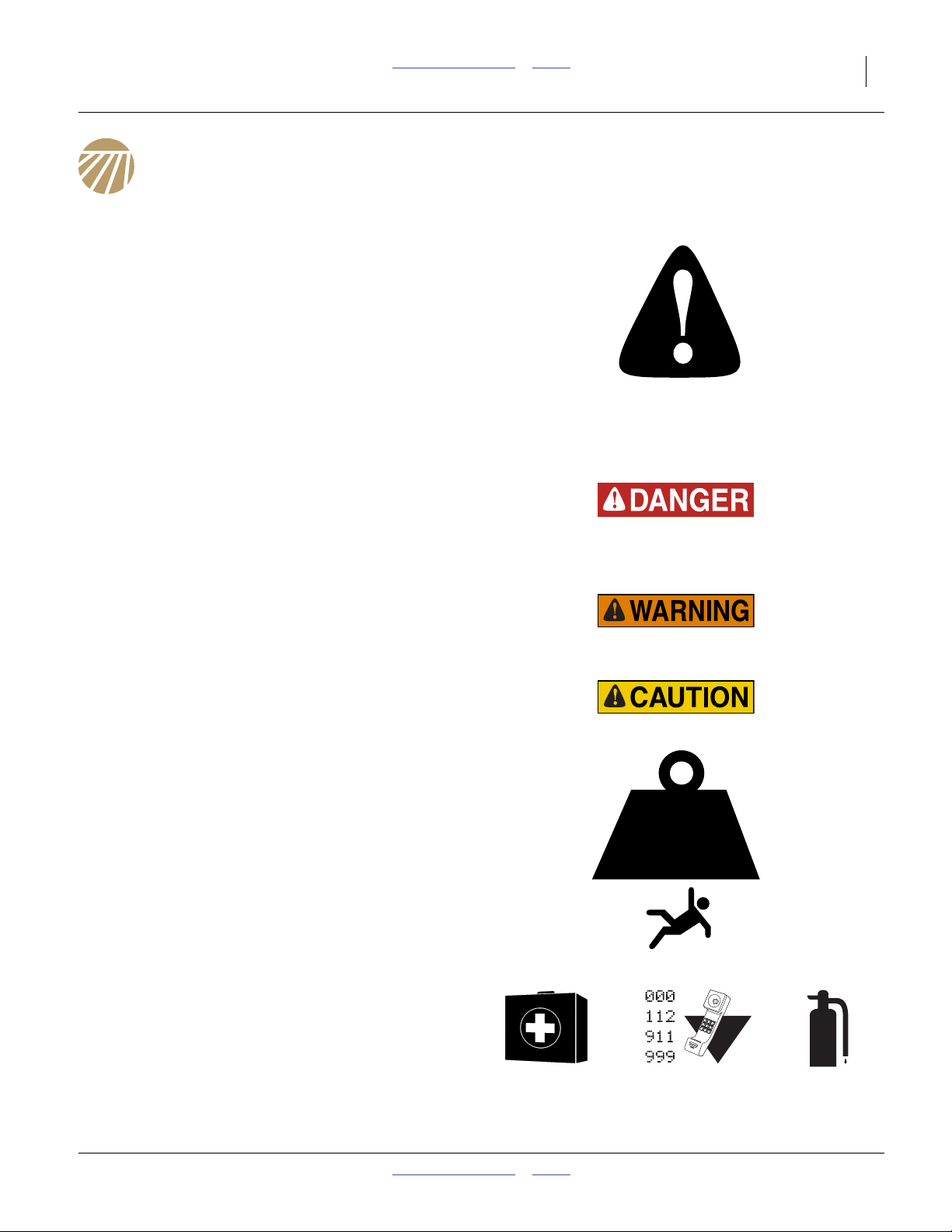

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

Use Adequate Lifting Means

The frame sections and gangs of this machine are

extremely heavy. If using multiple lifters, make sure each

is rated for at least its share of the load.

> 14,000

POUNDS

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

07/02/2013 Table of Contents Index 586-239Q

Page 6

2 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

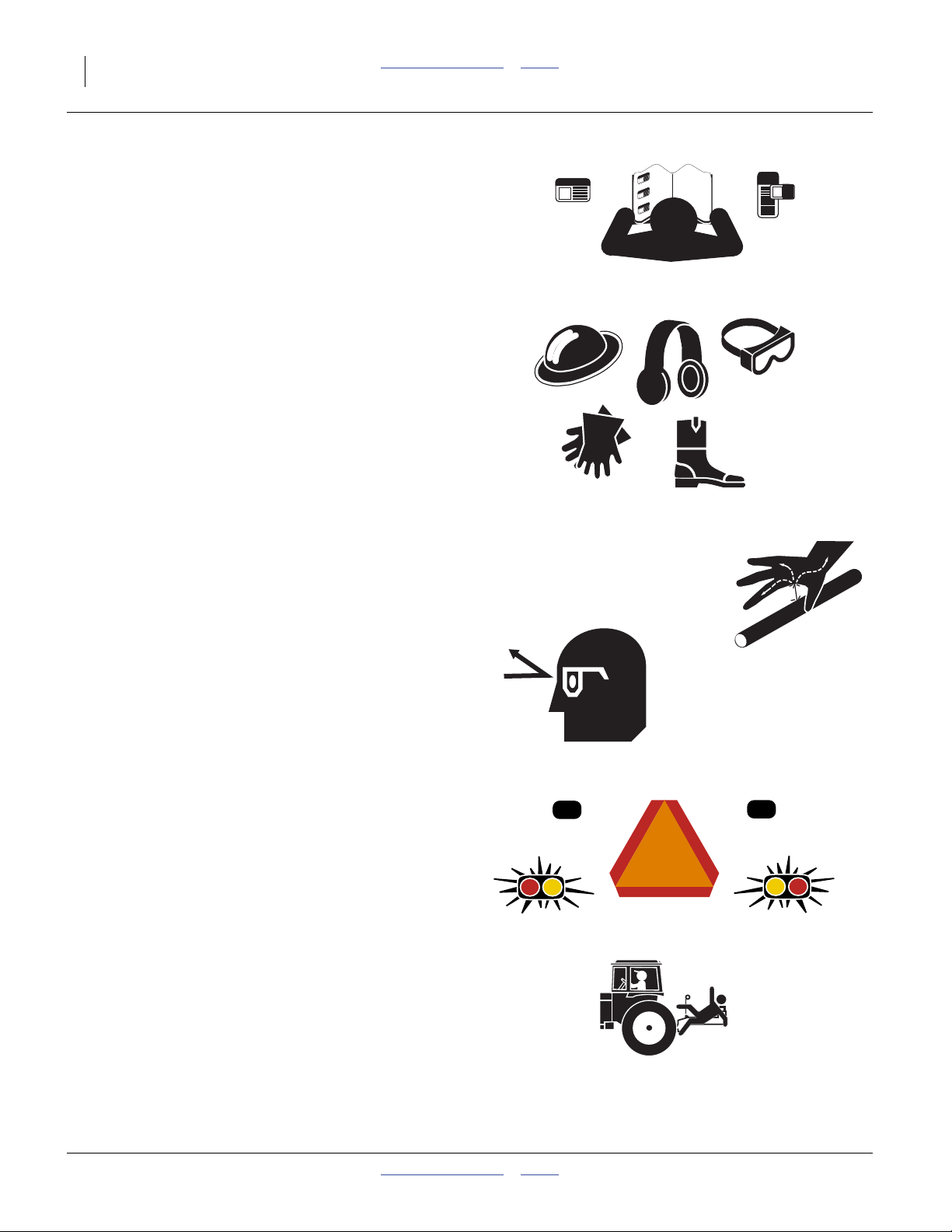

Be Familiar with Safety Decals

▲ Read and understand the “Safety Decals” section of the

Operators Manual.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to loud noise can cause hear-

ing impairment or hearing loss, wear suitable hearing protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever driv-

ing on public roads.

Use lights and devices provided with implement

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

586-239Q Table of Contents Index 07/02/2013

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

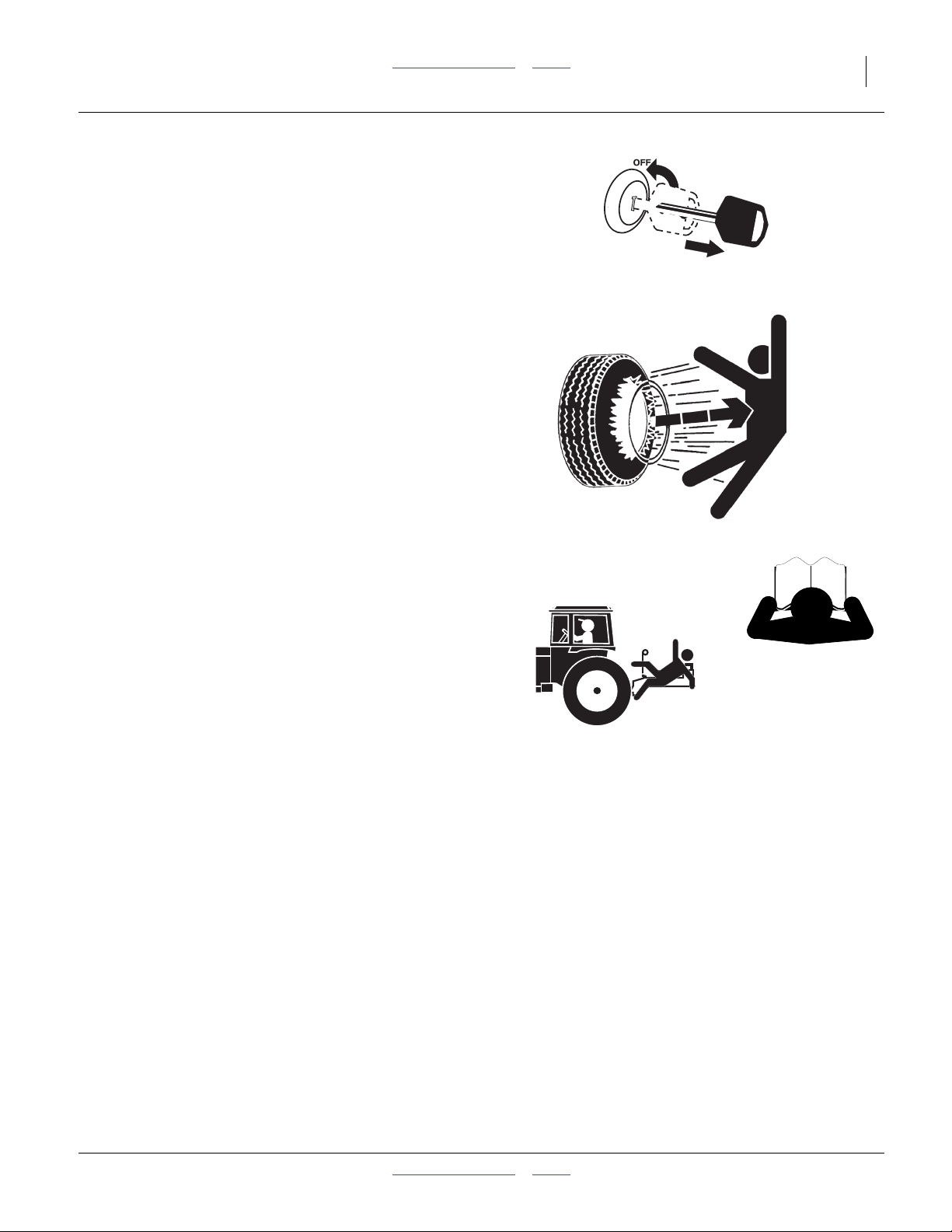

Shutdown and Storage

▲ Lower implement, put tractor in park, turn off engine, and

remove the key.

▲ Secure Turbo-Chopper using blocks and supports provided.

▲ Detach and store Turbo-Chopper in an area where children

normally do not play.

Tire Safety

Tire changing can be dangerous and should be performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all machine functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave machine unattended with tractor engine run-

ning.

▲ Do not stand between the tractor and machine during

hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with mov-

ing parts.

▲ Watch out for wires, trees, etc., when folding and raising

machine. Make sure all persons are clear of working area.

07/02/2013 Table of Contents Index 586-239Q

Page 8

4 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

Introduction

The Turbo-Chopper has been designed with care and

built by skilled workers using quality materials. Proper

setup, maintenance, and safe operating practices will

help the customer get years of satisfactory use from the

machine.

Description of Unit

The 1200-4000TC Turbo-Chopper is a one, three or five

section “vertical” tillage tool. Working width ranges from

12 to 40 feet. The implement is designed to cut and size

residue, till soil for faster seedbed warming, break up soil

crust on hard dried fields while eliminating compaction

layers.Various finishing attachments are also available to

further smooth, redistribute residue, kill weeds, and break

clods

Models Covered

1200TC 12’ (10in) spacing

1500TC 15’ (10in) spacing

1800TC 18’ (10in) spacing

2400TC 24’ (10in) spacing

3000TC 30’ (10in) spacing

4000TC 40’ (10in) spacing

Document Family

586-239Q Pre-Delivery Manual (this document)

586-239M Operator Manual

586-239P Parts Manual

Tools Required

• Basic Hand Tools

• Torque Wrench

• Fork Truck, Overhead Hoist or Loader

Pre-assembly Checklist

1. Before assembling, read and understand “Important

Safety Information” in front part of this manual.

2. Have at least two people on hand while assembling.

3. Make sure area is level and free of obstructions (preferably an open concrete area).

4. Have all major componets

5. Have all fasteners and pins shipped with machine.

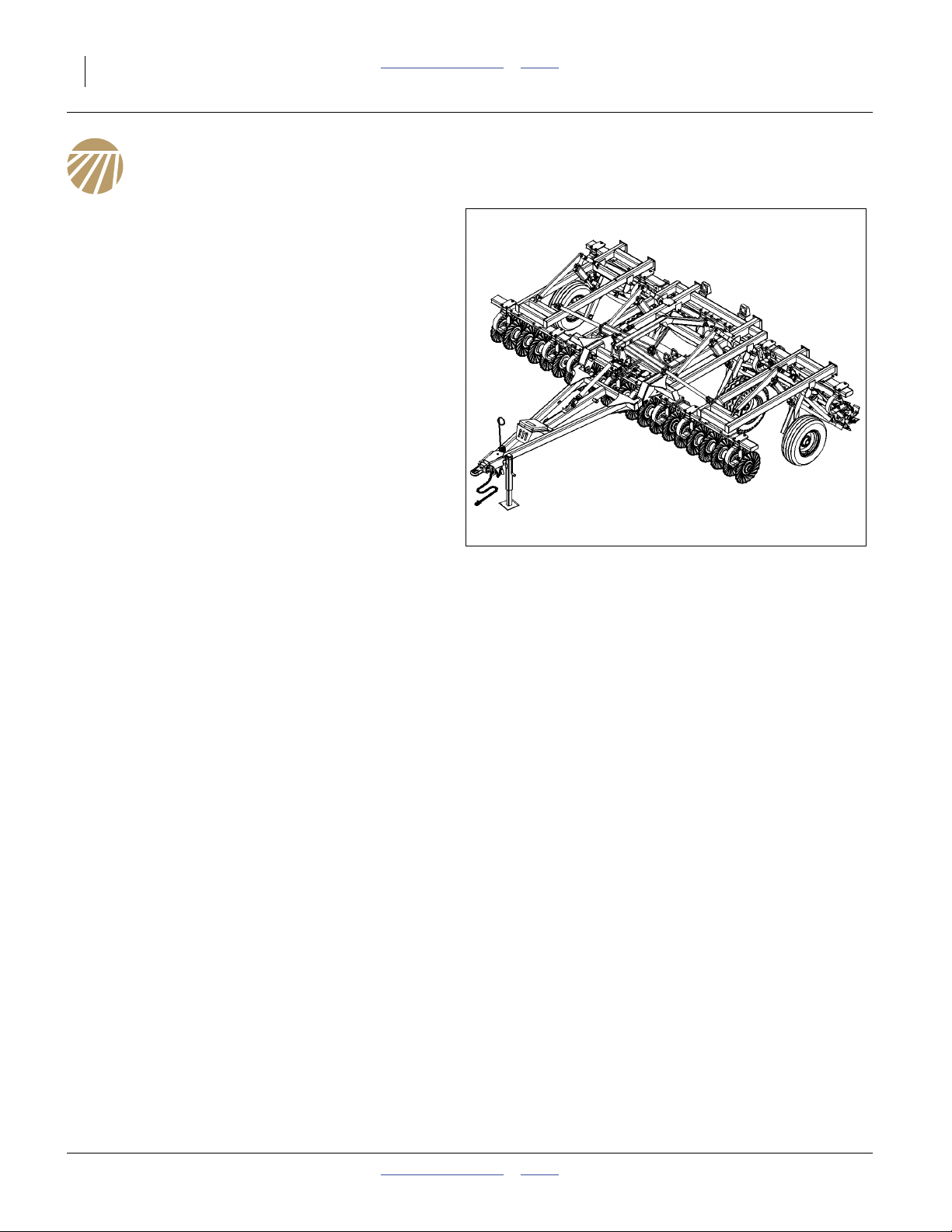

Figure 1

1800 Turbo-Chopper

42096

586-239Q Table of Contents Index 07/02/2013

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 5

Using This Manual

This manual was written to help you assemble and prepare the new machine for the customer. The manual

includes instructions for assembly and setup. Read this

manual and follow the recommendations for safe, efficient

and proper assembly and setup.

An operator’s and parts manual is also provided with the

new machine. Read and understand “Important Safety

Information” and “Operating Instructions” in the operator’s manual before assembling the machine. Refer to the

parts manual for proper part’s identification. As a reference, keep the operator’s and part’s manual on hand while

assembling.

The information in this manual is current at printing. Some

parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

A crucial point of information related to the preceding topic. Read

and follow the directions to remain safe, avoid serious damage to

equipment and ensure desired field results.

Note: Useful information related to the preceding topic.

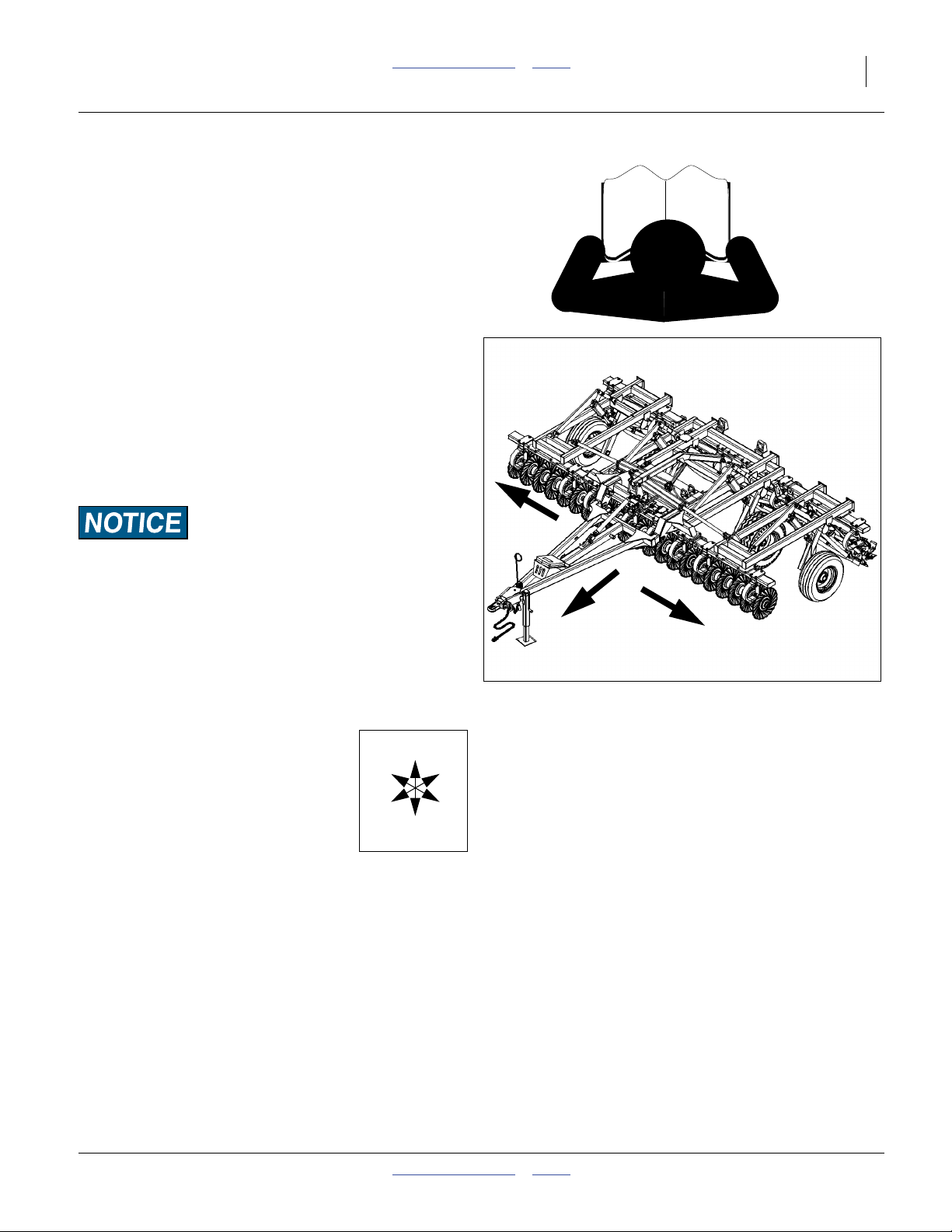

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of: Up,

Back, Left, Down, Front, Right.

R

F

U

B

L

D

R

L

Figure 2

Right / Left

42096

07/02/2013 Table of Contents Index 586-239Q

Page 10

6 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

Shipping

The Turbo-Chopper will be shipped partially pre-assembled.

Refer to Figure 3

• Models 1200-1500 Will be shipped fully assembled,

except for hitch assembly with hydraulic system

charged.

• Models 1800-2400 will be shipped with wings folded

and hydraulic system charged, hitch assembly will

need to be installed.

• Models 3000-4000 will be shipped with center frame

parts installed, wings and attachment frames (if

equipped) will be stacked on stands and banded

together.

• Finishing attachments (if equipped), will be will be

shipped with mounted brackets assembled, reel

assemblies assembled and all bolts will be in a box.

• Remove unit from shipping stands (if equipped), after

machine is lowered to ground and carefully un-band

all componets.

• The shipping stand bolts are not used in the assembly

of unit.

• The shipping stands do not need to be returned to

Great Plains.

1

Figure 3

Turbo-Chopper Shipping

2

42097

Unloading

Be sure the truck is on level ground, preferably concrete.

Centering componets:

Be sure and center fork truck or chains (overhead hoist) on componets

so they won’t slide and cause injury.

Unload Smaller Items First

Unloading the Turbo-Chopper is a potentially dangerous

operation.

Reduce risk and complications by first unloading

1. gangs and finishing attachments

2. misc. boxes

3. Turbo-Chopper

(described in the next section)

Unload Turbo-Chopper

4. Place these components well out of the manoeuvring area needed for unloading the Turbo-Chopper.

5. Double-check that all chains and tie-down straps

have been released and stowed.

6. Set parking brake on trailer tractor.

7. Slowly lift the Turbo-Chopper off trailer bed using two

fork lifts.

8. Stop lifting about 12” above the bed.

9. Have the truck driver slowly pull the trailer straight

out from under the Turbo-Chopper.

10. Making sure to keep level from front to back and side

to side, slowly lower the Turbo-Chopper.

11. Lower theTurbo-Chopper down until the shipping

stands are about 12” off ground.

12. Remove shipping stands.

13. Remove tongue jack from field positions and put in

storage position with foot of jack towards ground.

14. Slowly lower Turbo-Chopper until it resting on the

center transport tires and front tongue jack.

Unpacking Boxes

Note: Position boxes in area that you can maneuver

components up to machine to assembly.

15. Carefully remove banding from boxes.

16. Carefully remove banding from gangs and finishing

reels.

17. Locate and identify all componets before assembling.

586-239Q Table of Contents Index 07/02/2013

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 7

Assembly and Setup Assistance

To order additional copies od pre-delivery instructions or

operator.s and parts manuals, write to the following

address. Include model numbers in all correspondence.

If you do not understand any part of this manual or have

the assembly or setup questions, assistance is available.

Contact:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

(800)255-9215

07/02/2013 Table of Contents Index 586-239Q

Page 12

8 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

Assembly

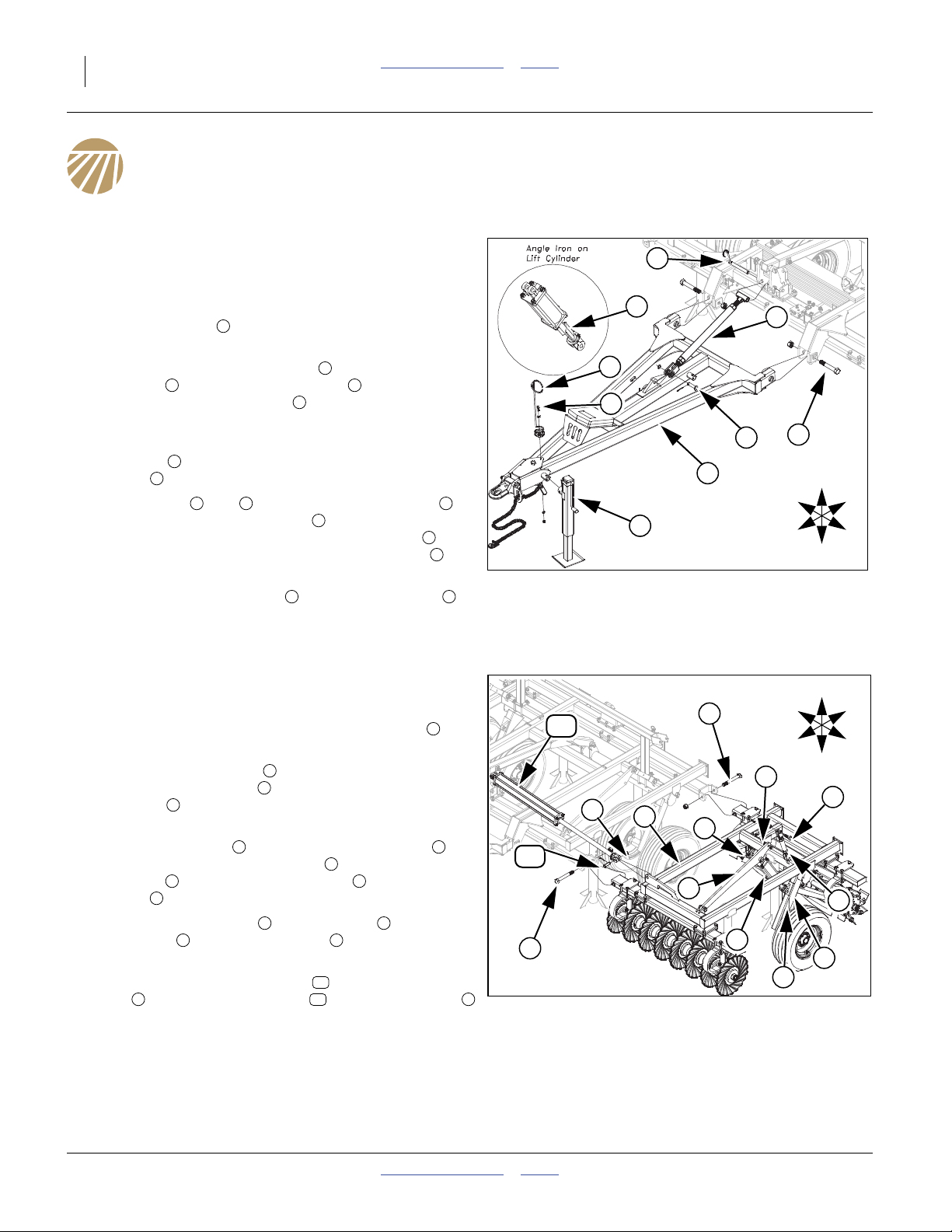

Hitch Assembly

Refer to Figure 4

Note: The center will be shipped pre-assembled.See “Parts

Manual for partnumbers and description ofparts.Place

center frame on stands if available, if not, place turbo

gangs on floor and for ease of attaching wing frames

put a cut angle in center lift cylinders to raise gangs

off floor.

18. Remove the 1 1/4x8Gr.8bolts from the rear of hitch

assembly . Bolt he hitch assembly to center frame

with the 1 1/4 x 8 Gr. 8 bolts and 1 1/4 top lock nuts.

Tighten bolts snug, do not torque, as the hitch must pivot

freely.

19. Instal jack on front outside of hitch to support the front

of hitch .

20. Remove pins and from turnbuckle assembly .

Install the turnbuckle assembly between the level bar

rocker and hitch frame ear with the1x91/2pin ,3/8x

1 3/4 quick pin (rear) and the 1 x 3 3/8 clevis pin ,

machine washer and 3/16 x 2 cotter pin (front).

21. Bolt the spring hose holder with 1/2 x 1 1/2 bolt , 1/

2 flat washer, 1/2 lock washer and 1/2 nut.

3 3

4

3

1

2

2

5 6 7

7

5

6

8 9

8

9

5

1

4

Figure 4

Hitch

7

R

F

2

U

B

L

6

3

D

42072

Wing Assembly

Refer to Figure 5

Note: The wings will come pre-assembled. Models 1800 and

2400 will be shipped with wings attached. On models

3000 and 4000, place wing frame assemblies on

stands next to center frame.

22. Remove 1 1/4 x 10 bolts from center frame hinge. Bolt

wing frame assemblies to center frame with the 1 1/4

x 10 bolts 1 1/4 top lock nuts. Tighten bolts snug, do

not torque, as the wing must pivot freely.

23. Remove 1 x 3 bolts from turnbuckle assembly .

Align holes in cylinder mount bar and turnbuckle

assembly , re-install the 1 x 3 bolts , 1 machine

washer and 1 lock nut.

24. Attach wing lift cylinder to torque tube with 1 x 3 1/

8 pin clevis , 1 machine washer and 3/16 x 2 cotter

pin.

25. Attach rod end of fold cylinders to wing frame assemblies with 1 x 3 1/8clevis pin 1 machine washer

and 3/16 x 2 cotter pin.

26. Do not hook up rod end of fold cylinder until system is

purged of air. See “Purging Hydraulic System” on

page 15.

27. Bolt may be tightened to specs, See “Torque Values

Chart” on page 23

2

4 3

6

8 6

1

2

1

3 4

5

7 9

10

11

1

6

11

2

10

U

2

R

F

B

L

D

6

3

6

1

6

5

4

7

8

9

Figure 5

Wing

41024

586-239Q Table of Contents Index 07/02/2013

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index Assembly 9

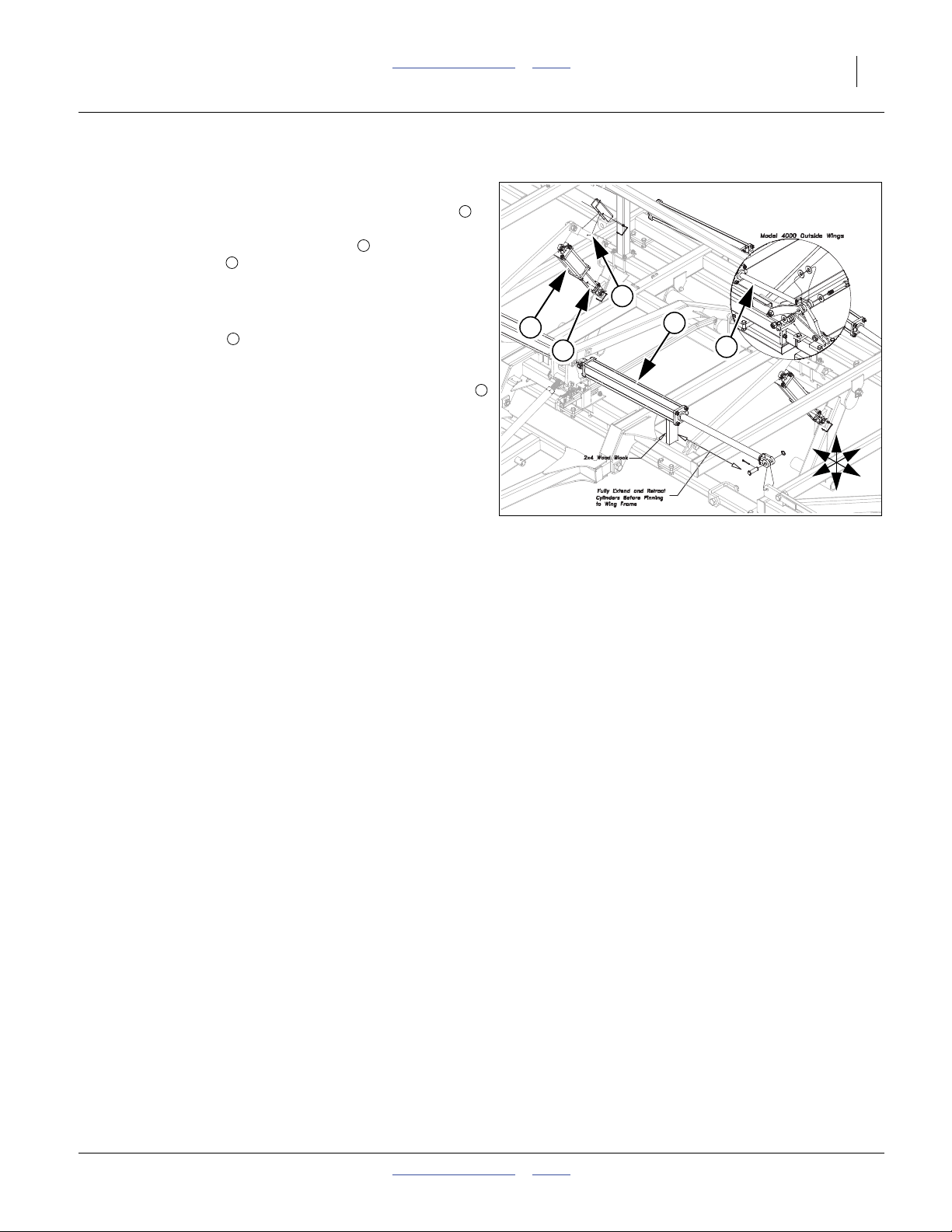

4000 Outer Wing Assembly

Refer to Figure 6

Note: The outer wings will come pre-assembled. Place outer

wing frame assemblies on stands next to center

frame.

28. Remove 1 x 6 bolts Gr. 8 special thread bolts from

center frame hinge. Bolt outer wing frame assemblies

to inner wing frame hinge with the 1 x 6 bolts Gr. 8

special thread bolts and 1 top lock nuts. Tighten bolts

snug, do not torque, as the wing must pivot freely.

29. Bolt the rocker link on outer wing, rod end of fold cylin-

5 6

ders to inside wing fold link with 1 x 7 Gr. 8 special

thread bolts , four, 1 flat washers and 1 top lock nuts.

Tighten bolts snug, do not torque, as the cylinder must

pivot freely.

Note: Do not hook up rod end of fold cylinder until system

purged of air. See “Purging Hydraulic System”on

page 15.

7 8

4

1

2

1

3

2

R

F

5

U

B

L

D

8

6

7

2

3

4

8

1

Hitch Hose & Light Harness Assembly

Refer to Figure 7

Note: The hydraulic hoses and light harness are all attached

to center frame and rolled up for hitch.

30. Un-roll the hoses and route them along right side of hitch

and through spring hose loop as shown. All hoses and

light harness will run through the same double hose

clamps.

31. Fasten hoses to hitch frame with bolts and clamps (provided) on hitch frame.Attach hose wraps on hoses to

prevent hoses from dragging or getting pinched.

32. See “Attach Hose Clamps and Hose wraps” on

page 14 for proper assembly.

R

F

U

D

Figure 6

4000 Outer Wing

B

L

Figure 7

Hitch Hose & Light Harness

41222

41434

07/02/2013 Table of Contents Index 586-239Q

Page 14

10 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

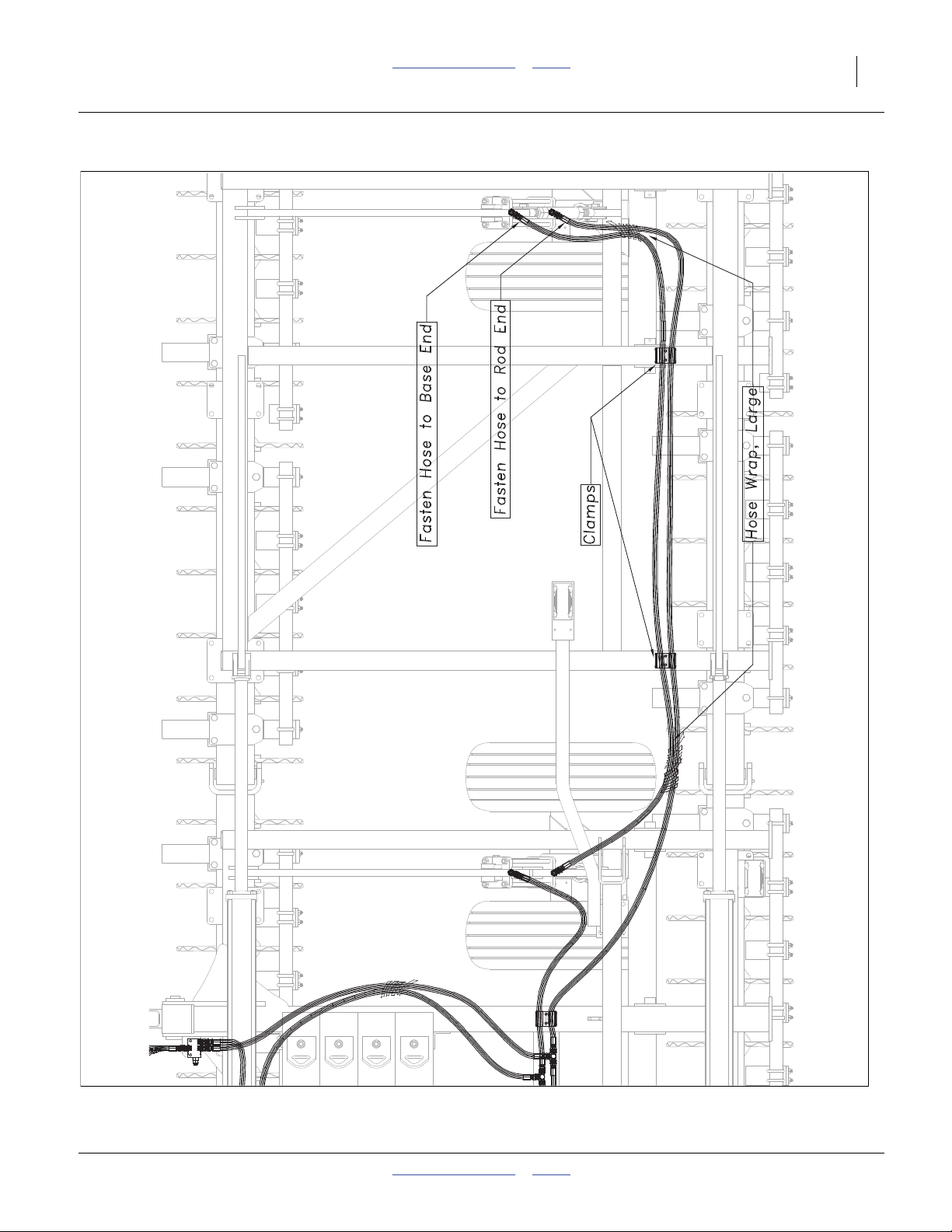

3000 Hydraulic Wing Lift Assembly

Refer to Figure 8

Note: The hydraulic hoses are all attached to center

frame and rolled up for wings.See hydraulic layout

drawings in “Appendix” for complete hose routing.

33. Un-roll the hoses and route them along wing frame

as shown.

34. Hook the hose that is fastened to rod end of cylinder

to base end of wing cylinder.

35. Attach longer hose from tee on center frame to the

rod end of wing cylinder.

36. Fasten hoses to wing frame with bolts and clamps

(provided) on hitch frame.Attach hose wraps on

hoses to prevent hoses from dragging or getting

pinched.

37. See “Attach Hose Clamps and Hose wraps” on

page 14 for proper assembly.

586-239Q Table of Contents Index 07/02/2013

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index Assembly 11

Figure 8

3000 Hydraulic Wing Lift

07/02/2013 Table of Contents Index 586-239Q

41433

Page 16

12 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

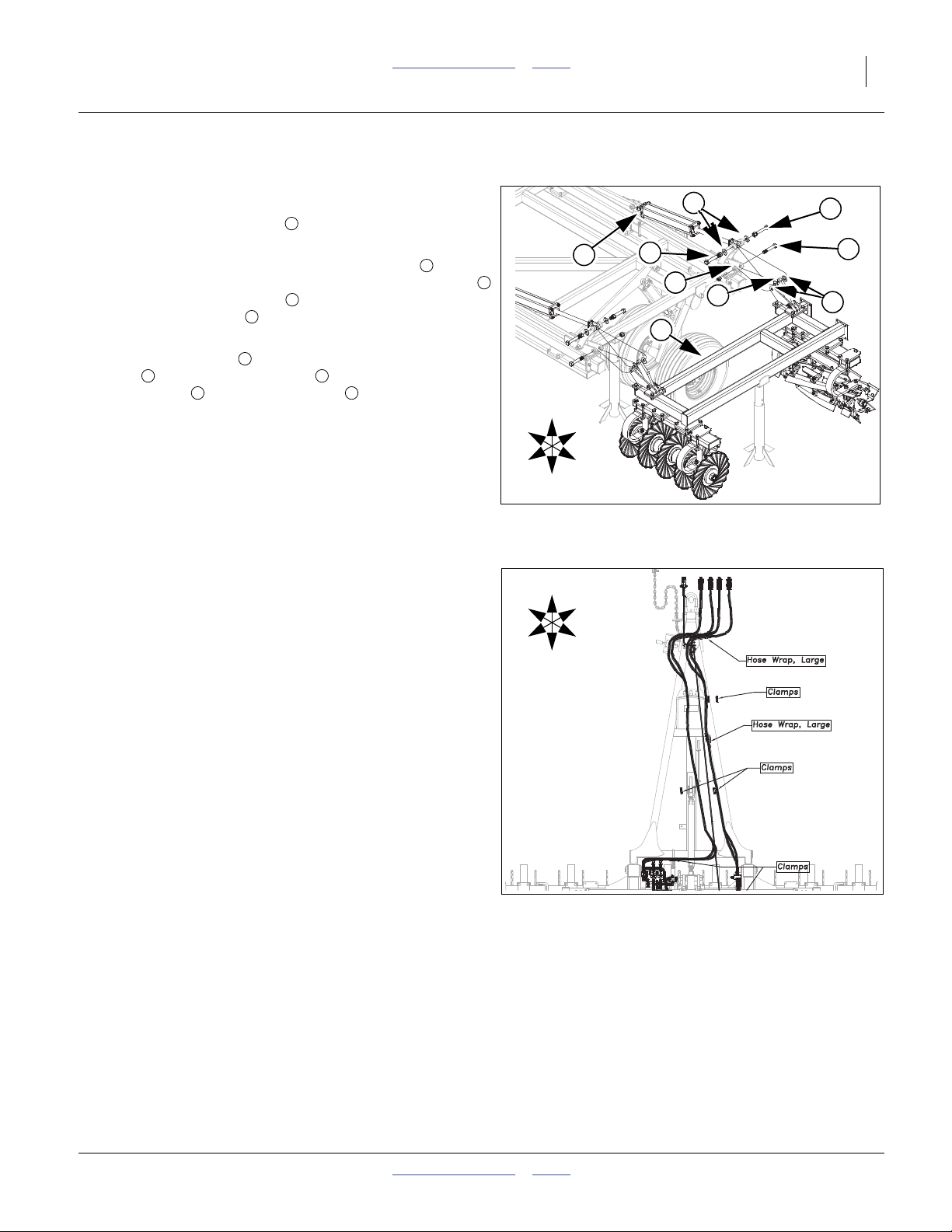

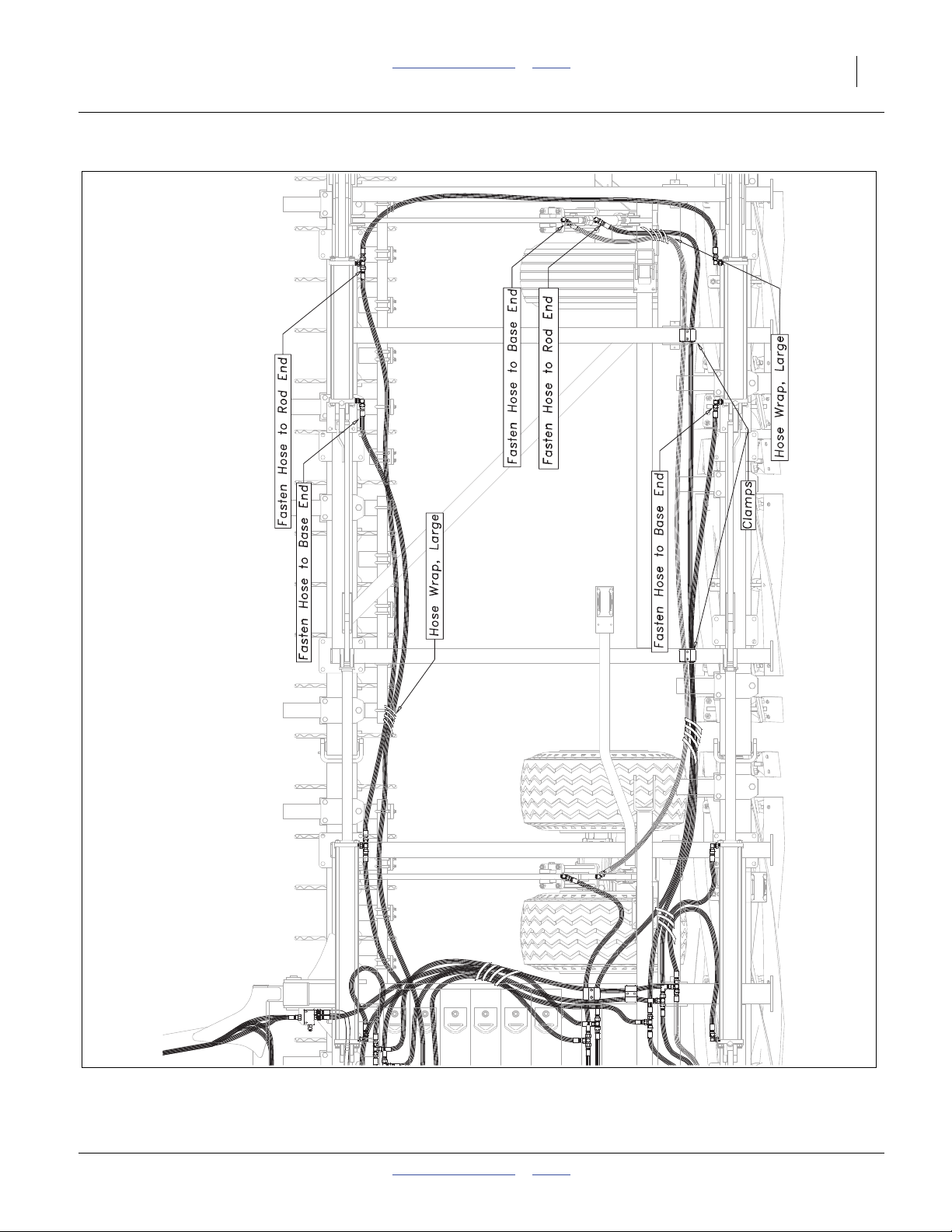

4000 Hydraulic Wing Lift & Fold Assembly

Refer to Figure 9

Note: The hydraulic hoses are all attached to center

frame and rolled up for wings.See hydraulic layout

drawings in “Appendix” for complete hose routing.

38. Un-roll the hoses and route them along wing frame

as shown.

39. Hook the hose that is fastened to rod end of cylinder

to base end of wing cylinder.

40. Attach longer hose from tee on center frame to the

rod end of wing cylinder.

41. Fasten front fold hose from tee to base end of outer

fold cylinder.

42. Attach other front fold hose from rod end of inner fold

cylinder to rod end of outer fold cylinder.

43. Fasten back fold hose from rear tee to base end of

outer fold cylinder.

44. Fasten hoses to wing frame with bolts and clamps

(provided) on hitch frame.Attach hose wraps on

hoses to prevent hoses from dragging or getting

pinched.

45. See “Attach Hose Clamps and Hose wraps” on

page 14 for proper assembly.

586-239Q Table of Contents Index 07/02/2013

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index Assembly 13

Figure 9

4000 Hydraulic Wing Lift & Fold

07/02/2013 Table of Contents Index 586-239Q

41438

Page 18

14 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

u

e

.

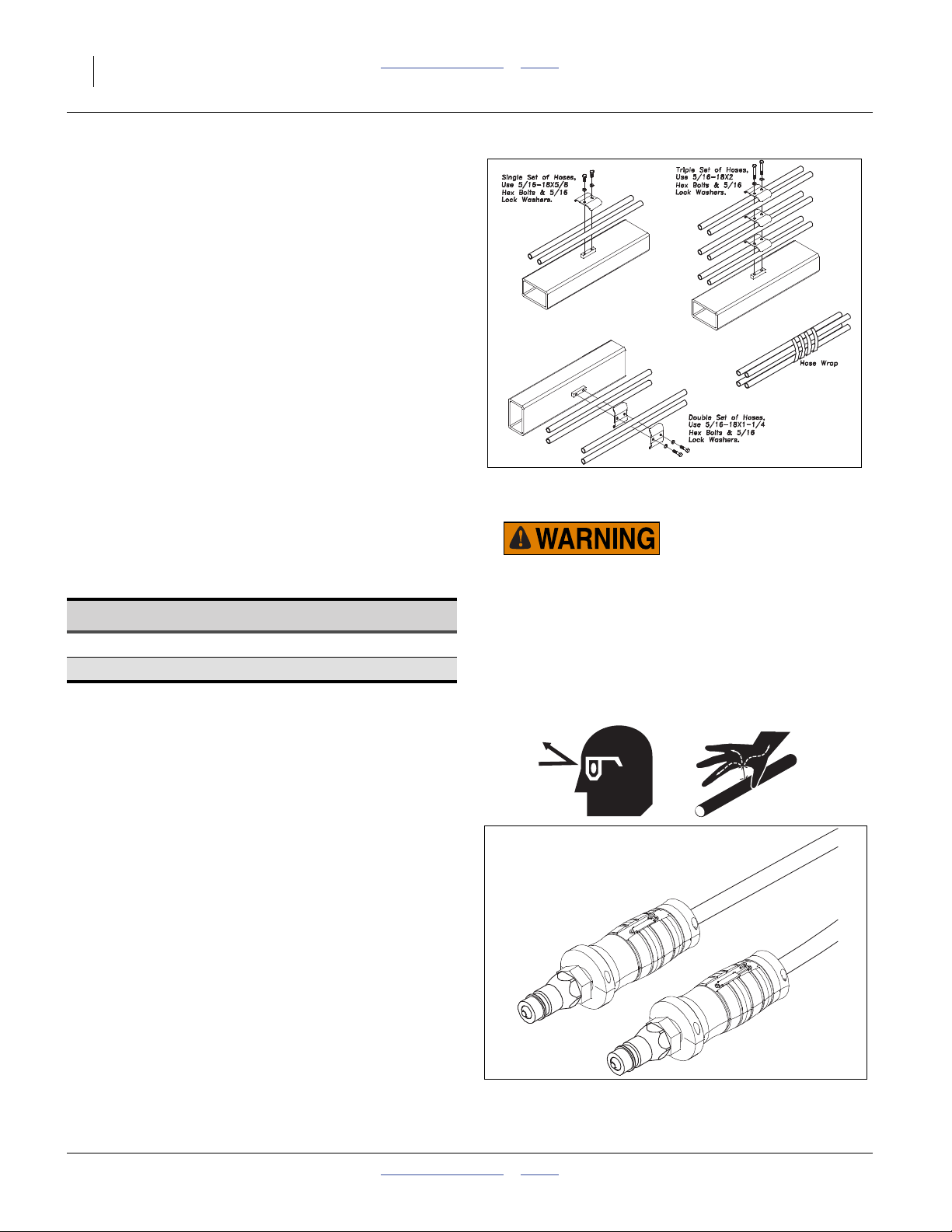

Refer to Figure 10

Attach Hose Clamps and Hose wraps

46. When all the hoses are hooked up and tightened properly, put hose clamps on hoses as shown.

47. Install hose wraps on hoses as needed.

Note: Be sure and get hoses and light wiring harness fas-

tened properly so they do not drag. Check to be sure

there is enough slack in hinge area when folding machine the first time.

Hydraulic Hose Hookup

48. Great Plains hydraulic hoses are color coded to help you

hookup hoses to your tractor outlets. Hoses that go to

the same remote valve are marked with the same color.

Color Hydraulic Function

Black Lift (2 hoses)

Green Fold (2 hoses)

Refer to Figure 11

Hose Handles

49. To distinguish hoses on the same hydraulic circuit, refer

to hose handles. The hose under an extended-cylinder

symbol feeds a cylinder base end. The hose under a

retracted-cylinder symbol feeds a cylinder rod end.

50. Once all hoses are tightened, hook hoses to tractor

Figure 10

Hose Clamp Assembly

High Pressure Fluid Hazard:

Relieve pressure before disconnecting hydraulic lines. Use

paper or cardboard, NOT BODY PARTS, to check for leaks.

Wear protective gloves and safety glasses or goggles when

working with hydraulic systems. Escaping fluid under press

can have sufficient pressure to penetrate the skin causing s

ous injury. If an accident occurs, seek immediate medical

assistance from a physician familiar with this type of injury

Only trained personnel should work on system hydraulics.

41583

586-239Q Table of Contents Index 07/02/2013

Figure 11

Hose Handles

41552

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index Assembly 15

Purging Hydraulic System

Refer to Figure 12

51. Charge the lift system first. Extend the lift cylinders

(black handles) until the center section is fully raise.

Remove the cylinder transport locks and store on lift

mechanism links . Raise and lower the gang system

several times to purge air from system. Watch for leaks

and retighten fittings if necessary.

52. You may now charge the fold system. Before charging

the fold cylinders , make sure the rod end of the cylinders are un-bolted or un-pinned and block is under cylinders as shown, so that when the rod is extended, it will

clear the wing fold brackets. Extend the fold cylinders

(green ends) completely and then close them. Extend

and retract the cylinders several times to purge air from

the system. Now the cylinders may be extended far

enough to be connected to the wing fold brackets.

53. See “Bolt may be tightened to specs, See “Torque

Values Chart” on page 23” on page 8 and See “3000

Hydraulic Wing Lift Assembly” on page 10 for hooking

up rod end of fold cylinders.

3

4

2

1

3

1

2

4

4

4

U

R

F

B

L

D

Figure 12

Purging Hydraulic System

41030

07/02/2013 Table of Contents Index 586-239Q

Page 20

16 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

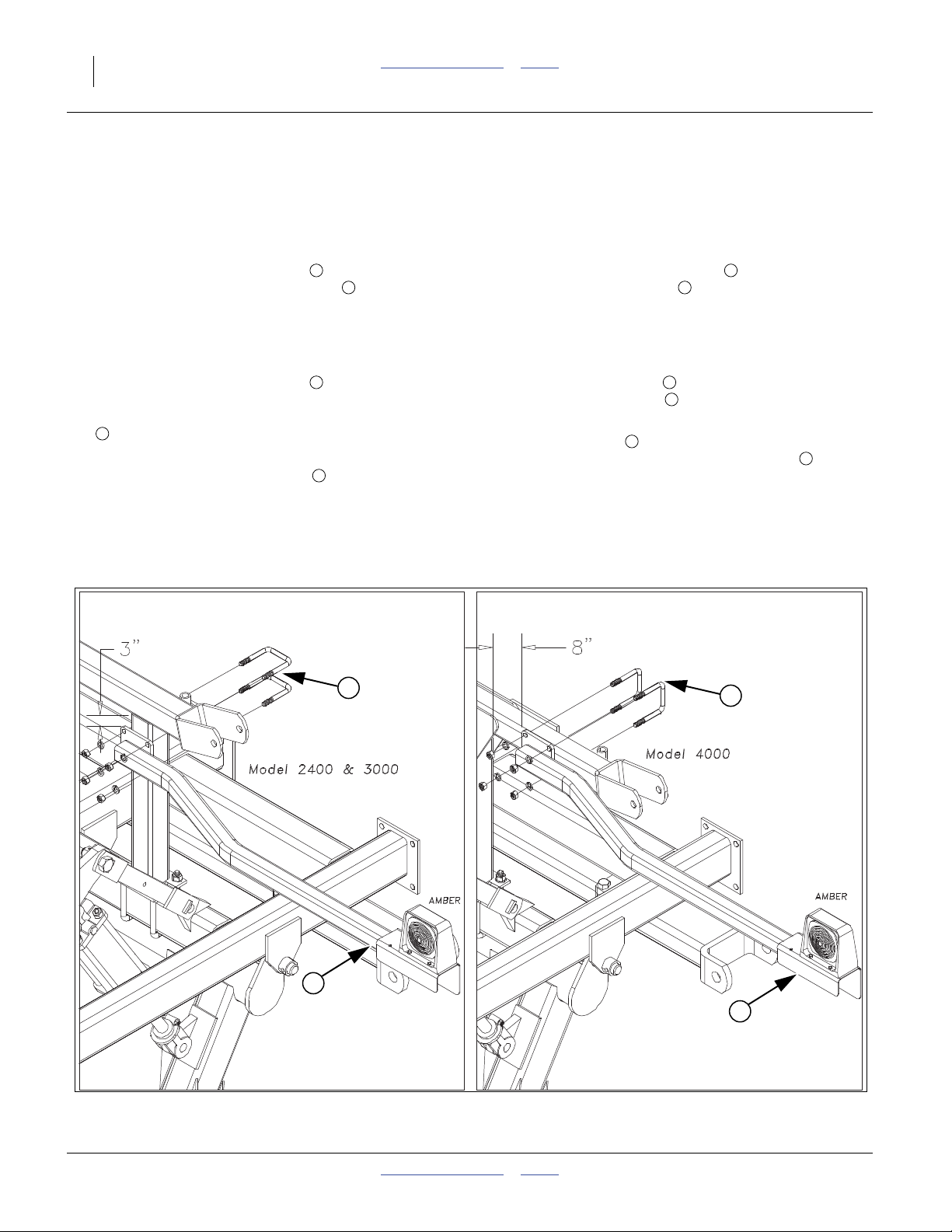

Light Bracket and SMV Assembly

Note: The light brackets will be shipped in right location,

but u-bolts will need to be removed and brackets

will need turned to correct position.

Refer to Figure 13

54. Install light bracket assemblies (models 2400 &

3000) with 1/28 x 3 1/32 x 4 u-bolts , 1/2 lock

1

2

washers and 1/2 nuts, place in proper location, 3”

below bottom of wing stop tube and top edge of plate

of light bracket.

Refer to Figure 14

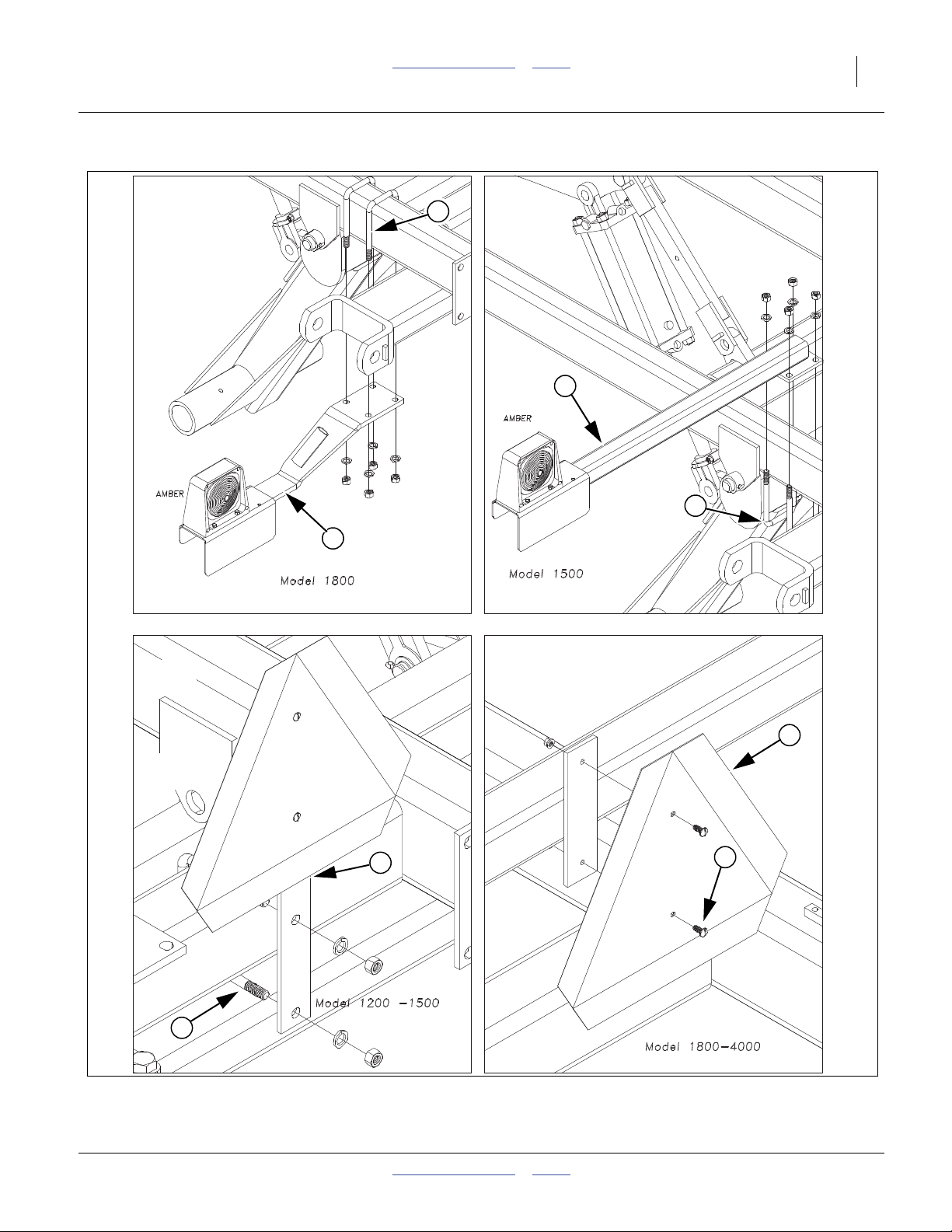

56. Install light bracket assemblies (model 1800) on

3

outside, rear of center frame between gang bar tube

and torque tube bracket with 1/2 x 3 1/32 x 6 u-bolts

, 1/2 lock washers and 1/2 nuts, bottom side of

4

frame tube.

57. Mount light bracket assemblies (model 1500)

5

same way as model 1800, only on top side of frame

tube,

Note: When the lights are mounted, be sure all plugs are

attached on the wiring harness.

55. Install light bracket assemblies (model 4000), with

1/28 x 3 1/32 x 4 u-bolts , 1/2 lock washers and 1/2

1

2

nuts, place in proper location, 8” from outside of vertical tube to inside edge of mounting plate of light

bracket.

58. Attach smv assembly (models 1200 & 1500) with

1/2 x 5 x 5 1/2 u-bolts , 1/2 lock washers and 1/2

6

7

nuts.

59. Mount smv sign (models 1800-4000) to plate on

wing stop with 1/4 x 3/4 pan head screws , lock

8

9

washers and 1/4 nuts.

60. Tighten all bolts to specs, See “Torque Values

Chart” on page 23.

2

2

1

1

Figure 13

Lights

41075

586-239Q Table of Contents Index 07/02/2013

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Assembly 17

4

5

4

3

8

6

9

7

Figure 14

Lights & SMV

07/02/2013 Table of Contents Index 586-239Q

41076

Page 22

18 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

Rolling Harrow (optional)

Note: It is very important to install the rolling harrow

assembly in the order shown below and go to the

rolling harrow placement drawing, see “Layout

Section” of this manual for proper dimensions

where it is marked xxx in drawing below. The rolling harrow bracket dimensions are coming off

3

Refer to Figure 15

61. Start by installing the drag frames with 3/4 x 2 hex

bolts , 3/4 lock washers and 3/4 nuts. Torque bolts

2

1

to 265 ft-lb.

62. Attach rolling harrow brackets in appropriate location with 5/8 x 3 1/32 x 4 1/2 u-bolts , secure with

3

4

5/8 lock washers and 5/8 nuts. Adjust the brackets to

dimensions shown in layout drawings and torque ubolts to 150 ft-lb.

63. Attach ball joint brackets and to rolling spike

tubes with 5/8 x 3 1/32 x 4 1/2 u-bolts , secure

8 4

6 7

with 5/8 lock washers and 5/8 nuts. Place left ball

joint brackets in proper location from layout draw-

6

1

of rear, front tube of drag frame to front of plate

of rolling harrow bracket . The ball joint bracket

is dimensioned off of end of rolling spike tube

6 8

3

to side of plate on ball joint bracket (dimensions

1

6

in layout drawings may come off either end of

tube). For complete parts breakdown see “Attachment Section” of Parts Manual.

ing and torque u-bolts to 150 ft-lb. Leave right ball

joint bracket loose, as it may need move a little to

bolt up to right rolling harrow bracket .

7

3

64. Carefully lower machine down or use fork lift (if available) to raise rolling harrow assemblies to attach

rolling harrow brackets . Align ball joint brackets

and to rolling harrow assemblies , secure with 1

7 9

x 4 hex bolts and 1 nylon lock nut. Torque bolts to

5

3 6

9

645 ft-lb. Also torque the 5/8 x 3 1/32 x 4 1/2 u-bolts

in right ball joint brackets to 150 ft-lb.

4 7

65. Check to see that all bolts have been tightened to

specs, See “Torque Values Chart” on page 23.

2

4

3

4

7

6

8

5

4

Rolling Harrow

Figure 15

42436

586-239Q Table of Contents Index 07/02/2013

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index Assembly 19

Reel Following Rolling Harrow (optional)

Note: It is very important to install the reel assembly in

the order shown below and go to the rolling harrow

placement drawing, see “Layout Section” of this

manual for proper dimensions where it is marked

xxx in drawing below. The reel arm assemblies

dimensions are coming off of rear tube of drag

Refer to Figure 16

66. Install mounting reel arm assemblies in position

shown in reel following rolling harrow placement

drawing with 5/8 x 3 1/32 x 4 1/2 u-bolts , 5/8 lock

washers and 5/8 nuts. Torque u-bolts to 150ft-lb.

67. Attach reel tube assemblies in direction shown in

3

circle and place them in position shown (with arrow

1

2

frame to side of plate of reel arm assemblies .

The reel tube assemblies are dimensioned off

3

of end of reel tube to side of plate on reel arm

assembly (dimensions in layout drawings may

1

come off either end of tube). For complete parts

1

breakdown see “Attachment Section” of Parts

Manual.

towards machine) with 5/8 x 2 17/32 x 3 1/2 u-bolts

, secure with 5/8 lock washers and 5/8 nuts.

4

Torque u-bolts to 150ft-lb.

68. Check to see that all bolts have been tightened to

specs, See “Torque Values Chart” on page 23.

2

1

1

4

3

Figure 16

Reel Following Rolling Harrow

07/02/2013 Table of Contents Index 586-239Q

41429

Page 24

20 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

Detracker Assembly (Optional)

9

Note: See detracker assembly in “Parts Manual” for com-

plete parts breakdown.

Refer to Figure 17

69. Attach detracker mount to center gang hanger with

plate , using 5/8 x 8 hex bolts , 5/8 lock washers

2 3

and 5/8 nuts. See “Detracker Placement” on

page 20, for proper placement. Repeat same procedure for other side.

70. Mount shank assembly to detracker mount by

aligning the holes in the two plates (one on each

side). Align holes in shank clamps on front side of

shank , secure assembly with 1/2 x 5 hex bolts

and 1/2 lock washers . These bolts thread into

shank clamp . See “Detracker Placement” on

page 20, for proper placement and adjustment.

71. Once every thing is adjusted, all bolts may be tight-

ened to specs, See “Torque Values Chart” on

page 23.

4 7

6

1

4 1

5

6

8

6

1

5

8

7

4

2

3

Figure 17

Detracker

42829

Detracker Placement

Refer to Figure 18

72. Adjust detracker frames to approximate location as

shown in Figure 5 to clear other parts on machine.

Adjust coulter assemblies to cover tire tracks.

Note: See detracker height adjustment in “Operator Man-

ual” for detracker adjustments before going to field.

Figure 18

Detracker Placement

41630

586-239Q Table of Contents Index 07/02/2013

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index Assembly 21

Install Rear Hitch (optional)

Note: The rear tow hitch will be shipped with big compo-

nents banded together and bolts will be in a box.

Carefully un-band the components. There are two different types of rear hitches, rear hitch extended or aframe style. See appropriate mounting directions listed below.

Extended Rear Hitch

Refer to Figure 19

73. Attach rear hitch brace brackets to rear of drag

frame with 5/8 x 3 1/32 x 4 1/2 u-bolts , 5/8 lock

washers and 5/8 nuts.

74. Attach middle of rear hitch arms to brace brackets

with 5/8 x 3 1/32 x 5 1/2 u-bolts , 5/8 lock washers

and 5/8 nuts. Attach front plates of rear hitch arms to

rear tube of center frame with 3/4 x 4 1/32 x 1/2 u-bolts

, 3/4 lock washers and 3/4 nuts.

5

75. Attach 46” cross arm to bottom side of rear hitch

arm plates with 5/8 x 3 1/32 x 4 1/2 u-bolts , secure

with 5/8 lock washers and 5/8 nuts.

Note: Do not tighten any bolts until every thing is installed.

76. The bolt on sleeve assembly with rigid or flex slide

may be fastened using 5/8 x 3 1/32 x 4 1/2 u-bolt ,

secure with 5/8 lock washers and 5/8 nuts.

77. Tighten all bolts to specs, See “Torque Values Chart”

on page 23.

6

1

2

3 1

4

3

2

7 8

2

1

5

2

8

Rear Hitch

3

6

Figure 19

4

2

7

42828

A-Frame Hitch

Refer to Figure 20

78. Attach rear mounting bar to rear of center frame with

5/8 x 1 1/2 bolts , 5/8 lock washers and 5/8 nuts.

79. Attach a-frame hitch to rear of center frame with 5/8 x

4 1/32 x 4 1/4 u-bolts , 5/8 lock washers and 5/8 nuts.

80. Hitch will have either the flex slide assembly or the

rigid slide assembly . There will be a 3/4 x 1 1/2 hex

bolt and 3/4 jam nut in front hole of assembly to keep

7

the slide assembly from sliding clear out.

81. If machine is equipped with optional rear hitch accessory

kit may be installed as shown in “Parts Manual”.

82. Tighten all bolts to specs, See “Torque Values Chart”

on page 23.

83. Route hoses and light harness along hitch and frame

with hose clamps and hose wraps, provided.

Note: Be sure hoses and light harness is fastened securely so

they don’t drag or get pinched.

2

1

3

4

5

6

U

1

R

B

4

F

L

D

3

7

2

6

5

Figure 20

A-Frame Hitch

42437

07/02/2013 Table of Contents Index 586-239Q

Page 26

22 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

Rear Stand

R

F

U

D

2

4

1

3

B

L

Figure 21

Rear Stand

42438

Refer to Figure 21

If machine is equipped with a rear attachment, be sure you install

the rear jack stand so machine doesn’t tip backwards when unhooking machine from tractor.

84. Attach the rear stand bracket to the center of, the rear

tube of the drag frame with 5/8x3x41/2u-bolts , 5/8

lock washers and 5/8 nuts.

85. Tightened u-bolts.

86. Slide the rear stand through the rear stand bracket ,

secure with the 3/4 x 4 1/2 pin rear stand bracket and

retainer.

87. Once the options are installed, fold the Turbo-Till to

check for clearance and interferences, also watch that

hoses do not get pinched.

Note: Double check that all bolts are tightened to specs, See

“Torque Values Chart” on page 23.Consult the “Oper-

ator’s Manual”, for the first time field adjustments before

going to the field.

3 1

1

2

4

586-239Q Table of Contents Index 07/02/2013

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index 23

Appendix - Reference Information

Torque Values Chart

Bolt

Size

in-tpi

1

⁄4-20

1

⁄4-28

5

⁄16-18

5

⁄16-24

3

⁄8-16

3

⁄8-24

7

⁄16-14

7

⁄16-20

1

⁄2-13

1

⁄2-20

9

⁄16-12

9

⁄16-18

5

⁄8-11

5

⁄8-18

3

⁄4-10

3

⁄4-16

7

⁄8-9

7

⁄8-14

1-8

1-12

1

1

⁄8-7

1

1

⁄8-12

1

⁄4-7

1

1

⁄4-12

1

3

⁄8-6

1

3

1

⁄8-12

1

1

⁄2-6

1

1

⁄2-12

Bolt Head Identification

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

a

b

d

N-m

ft-lb

7.4 11 16

8.5 13 18

15 24 33

17 26 37

27 42 59

31 47 67

43 67 95

49 75 105

66 105 145

75 115 165

95 150 210

105 165 235

130 205 285

150 230 325

235 360 510

260 405 570

225 585 820

250 640 905

340 875 1230

370 955 1350

480 1080 1750

540 1210 1960

680 1520 2460

750 1680 2730

890 1990 3230

1010 2270 3680

1180 2640 4290

1330 2970 4820

N-m N-m

5.6 8 12

61014 5 811

11 17 25 12 19 27

13 19 27 13 21 29

20 31 44 24 39 53

22 35 49 29 45 62

32 49 70 42 67 93

36 55 78 44 70 97

49 76 105 66 77 105

55 85 120 68 105 150

70 110 155 73 115 160

79 120 170 105 165 230

97 150 210 115 180 245

110 170 240 145 230 300

170 265 375 165 260 355

190 295 420 205 325 450

165 430 605 230 480 665

185 475 670 355 560 780

250 645 910 390 610 845

275 705 995 705 1120 1550

355 795 1290 785 1240 1710

395 890 1440 1270 1950 2700

500 1120 1820 1380 2190 3220

555 1240 2010

655 1470 2380

745 1670 2710

870 1950 3160

980 2190 3560

Bolt Head Identification

Bolt

Size

ft-lb ft-lb ft-lb ft-lb ft-lb

mm x pitch

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

a. in-tpi = nominal thread diameter in inches-threads per inch

b. N· m = newton-meters

c. mm x pitch = nominal thread diameter in mm x thread pitch

d. ft-lb = foot pounds

c

5.8 8.8 10.9

N-m N-m N-m

357

71115

17 26 36

18 28 39

33 52 72

39 61 85

58 91 125

60 95 130

90 105 145

92 145 200

99 155 215

145 225 315

155 240 335

195 310 405

220 350 485

280 440 610

310 650 900

480 760 1050

525 830 1150

960 1510 2100

1060 1680 2320

1730 2650 3660

1880 2960 4100

946

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

25199m

25199

Gang Bolt Torque 1 3/4”-5 850 Foot-pounds (165 lbs on 5’ cheater).

Rolling Harrow Spike Bolt 1 1/2”-6 650-750 Foot-pounds (175 lbs on 4’ cheater).

Wheel Bolt Torque Values 1/2”-20 (75-85 ft-lbs) 9/16”-18 (80-90 ft-lbs) 5/8”-18 (85-100 ft-lbs).

07/02/2013 Table of Contents Index 586-239Q

Page 28

24 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

Tire Inflation & Warranty

Tire Inflation Chart

Wheel Tire Size Inflation

Wing

Wing

Transport

& Wing

Wing

Transport

& Wing

Transport

Transport

Transport 32-1505 x 16.5

Transport 380/55R x 16.5

11L x 15

8-Ply RI

11L x 15

12-Ply RI

11L x 15

F-Ply RI

12L x 15

F-Ply RI

12L x 15

12-Ply RI

12.5L x 16.5

Load G Galaxy

33 x 15.5 x 16.5

14-Ply Skid Steer

Load G Galaxy

Load F RI

36 psi

(248 kPa)

52 psi

(360 kPa)

90 psi

(620 kPa)

90 psi

(620 kPa)

52 psi

(360 kPa

105 psi

(725 kPa

70 psi

(480 kPa)

105 psi

(725 kPa)

73 psi

(503 kPa)

Tire Warranty Information

All tires are warranted by the original manufacturer of the tire.

Tire warranty information is found in the brochures included with

your Operator’s and Parts Manuals or online at the manufacturer’s web sites listed below. For assistance or information, contact your nearest Authorized Farm Tire Retailer.

Manufacturer Web site

Firestone www.firestoneag.com

Gleason www.gleasonwheel.com

Titan www.titan-intl.com

Galaxy www.atgtire.com

BKT www.bkt-tire.com

586-239Q Table of Contents Index 07/02/2013

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 25

Hydraulic Connectors and Torque

Refer to Figure 22 (a hypothetical fitting)

Leave any protective caps in place until immediately prior

to making a connection.

1

NPT - National Pipe Thread

Note tapered threads, no cone/flare, and no O-ring.

Apply liquid pipe sealant for hydraulic applications.

Do not use tape sealant, which can clog a filter and/or

plug an orifice.

2

JIC - Joint Industry Conference (SAE J514)

Note straight threads and the 37° cone on

“M” fittings (or 37° flare on “F” fittings).

Use no sealants (tape or liquid) on JIC fittings.

3

ORB - O-Ring Boss (SAE J514)

Note straight threads and elastomer O-Ring .

Prior to installation, to prevent abrasion during tightening, lubricate O-Ring with clean hydraulic fluid.

Use no sealants (tape or liquid) on ORB fittings.

ORB fittings that need orientation, such as the ell

depicted, also have a washer and jam nut

(“adjustable thread port stud”). Back jam nut away

from washer. Thread fitting into receptacle until

O-Ring contacts seat. Unscrew fitting to desired

orientation. Tighten jam nut to torque specification.

4 5

5 7

8 9

5

Dash

Size

-4

-5

-5

-5

-6

-6

-6

-8

-8

-8

1

9

8

4

2

Figure 22

Hydraulic Connector ID

Fittings Torque Values

Fitting N-m Ft-Lbs

1

⁄4-18 NPT 1.5-3.0 turns past finger

tight

1

⁄2-20 JIC 19-20 14-15

1

⁄2-20 ORB w/jam nut 12-16 9-12

1

⁄2 -20 ORB straight 19-26 14-19

5

⁄16-18 JIC 24-27 18-20

5

⁄16-18 ORB w/jam nut 16-22 12-16

5

⁄16-18 ORB straight 24-33 18-24

3

⁄4 -16 JIC 37-53 27-39

3

⁄4 -16 ORB w/jam nut 27-41 20-30

3

⁄4-16 ORB straight 37-58 27-43

7

5

3

31282

07/02/2013 Table of Contents Index 586-239Q

Page 30

26 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

586-239Q Table of Contents Index 07/02/2013

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 27

1200TC & 1500TC Hydraulic Lift Layout

41223

07/02/2013 Table of Contents Index 586-239Q

Page 32

28 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

1800TC Hydraulic Lift Layout

41224

586-239Q Table of Contents Index 07/02/2013

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 29

1800TC Hydraulic Fold Layout

41225

07/02/2013 Table of Contents Index 586-239Q

Page 34

30 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

2400TC Hydraulic Lift Layout

41226

586-239Q Table of Contents Index 07/02/2013

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 31

2400TC Hydraulic Fold Layout

41227

07/02/2013 Table of Contents Index 586-239Q

Page 36

32 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

3000TC Hydraulic Lift Layout

41228

586-239Q Table of Contents Index 07/02/2013

Page 37

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 33

3000TC Hydraulic Fold Layout

41229

07/02/2013 Table of Contents Index 586-239Q

Page 38

34 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

4000TC Hydraulic Lift Layout

41230

586-239Q Table of Contents Index 07/02/2013

Page 39

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 35

4000TC Hydraulic Fold Layout

41231

07/02/2013 Table of Contents Index 586-239Q

Page 40

36 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

1200TC Machine Layout

41203

586-239Q Table of Contents Index 07/02/2013

Page 41

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 37

1500TC Machine Layout

41204

07/02/2013 Table of Contents Index 586-239Q

Page 42

38 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

1800TC Machine Layout

41205

586-239Q Table of Contents Index 07/02/2013

Page 43

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 39

2400TC Machine Layout

41206

07/02/2013 Table of Contents Index 586-239Q

Page 44

40 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

3000TC Machine Layout

41207

586-239Q Table of Contents Index 07/02/2013

Page 45

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 41

07/02/2013 Table of Contents Index 586-239Q

Page 46

42 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

4000TC Machine Layout

41208

586-239Q Table of Contents Index 07/02/2013

Page 47

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 43

4000TC Machine Layout

41209

07/02/2013 Table of Contents Index 586-239Q

Page 48

44 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

1200TC Rolling Harrow Layout

42372

586-239Q Table of Contents Index 07/02/2013

Page 49

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 45

1200TC Heavy Reel Following Rolling Harrow Layout

42380

07/02/2013 Table of Contents Index 586-239Q

Page 50

46 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

1500TC Rolling Harrow Layout

42373

586-239Q Table of Contents Index 07/02/2013

Page 51

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 47

1500TC Heavy Reel Following Rolling Harrow Layout

42381

07/02/2013 Table of Contents Index 586-239Q

Page 52

48 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

1800TC Rolling Harrow Layout

42374

586-239Q Table of Contents Index 07/02/2013

Page 53

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 49

1800TC Heavy Reel Following Rolling Harrow Layout

42382

07/02/2013 Table of Contents Index 586-239Q

Page 54

50 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

2400TC Rolling Harrow Layout

42375

586-239Q Table of Contents Index 07/02/2013

Page 55

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 51

2400TC Heavy Reel Following Rolling Harrow Layout

42383

07/02/2013 Table of Contents Index 586-239Q

Page 56

52 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

3000TC Rolling Harrow Layout

42376

586-239Q Table of Contents Index 07/02/2013

Page 57

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 53

3000TC Rolling Harrow Layout

42377

07/02/2013 Table of Contents Index 586-239Q

Page 58

54 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

3000TC Heavy Reel Following Rolling Harrow Layout

42384

586-239Q Table of Contents Index 07/02/2013

Page 59

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 55

3000TC Heavy Reel Following Rolling Harrow Layout

42385

07/02/2013 Table of Contents Index 586-239Q

Page 60

56 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

4000TC Rolling Harrow Layout

42378

586-239Q Table of Contents Index 07/02/2013

Page 61

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 57

4000TC Rolling Harrow Layout

42379

07/02/2013 Table of Contents Index 586-239Q

Page 62

58 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

4000TC Heavy Reel Following Rolling Harrow Layout

42386

586-239Q Table of Contents Index 07/02/2013

Page 63

Great Plains Manufacturing, Inc. Table of Contents Index Appendix - Reference Information 59

4000TC Heavy Reel Following Rolling Harrow Layout

42387

07/02/2013 Table of Contents Index 586-239Q

Page 64

60 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

586-239Q Table of Contents Index 07/02/2013

Page 65

Great Plains Manufacturing, Inc. Table of Contents 61

Index

A

address, Great Plains ........................ 7

B

banding .............................................. 6

C

CAUTION, defined ............................. 1

center transport tires .......................... 6

chains and tie-downs ......................... 6

children .............................................. 2

clothing ............................................... 2

color code, hose ............................... 14

componets ......................................... 6

contact Great Plains ........................... 7

covered models .................................. 4

D

DANGER, defined .............................. 1

decals ................................................. 2

definitions ........................................... 5

directions ..................................... 5

, 6

E

electrical hookup ................................ 8

email, Great Plains ............................. 7

F

finishing attachments ......................... 6

fire ...................................................... 1

fork truck ............................................ 6

G

gangs ................................................. 6

H

headphones ....................................... 2

hearing ............................................... 2

high pressure fluids ............................ 2

hose clamps ..................................... 14

hose handles .................................... 14

hydraulic connectors ........................ 25

hydraulic hoses ................................ 14

hydraulic safety .................................. 2

I

IMPORTANT!, defined ........................ 5

inflation ............................................. 24

J

jack ..................................................... 6

JIC .................................................... 25

Joint Industry Conference ................ 25

J514 ................................................. 25

L

layout

1200 machine ............................ 36

1200TC Heavy Reel Following Roll-

ing Harrow ............................. 45

1200TC Rolling Harrow ............. 44

1200-1500 hydraulic lift .............. 27

1500 machine ............................ 37

1500TC Heavy Reel Following Roll-

ing Harrow ............................. 47

1500TC Rolling Harrow ............. 46

1800 hydraulic fold ..................... 29

1800 hydraulic lift ....................... 28

1800 machine ............................ 38

1800TC Heavy Reel Following Roll-

ing Harrow ............................. 49

1800TC Rolling Harrow ............. 48

2400 hydraulic fold ..................... 31

2400 hydraulic lift ....................... 30

2400 machine ............................ 39

2400TC Heavy Reel Following Roll-

ing Harrow ............................. 51

2400TC Rolling Harrow ............. 50

3000 hydraulic fold ..................... 33

3000 hydraulic lift ....................... 32

3000 machine ............................ 40

3000TC Heavy Reel Following Roll-

ing Harrow ............ 54

3000TC Rolling Harrow .. 52

56

4000 hydraulic fold ..................... 35

4000 hydraulic lift ....................... 34

4000 machine ....................42

4000TC Heavy Reel Following Roll-

ing Harrow ............................. 58

4000TC Rolling Harrow ............. 57

leaks .................................................. 2

left-hand, defined ............................... 5

level ................................................... 6

lifters .................................................. 1

lights .................................................. 2

, 55, 59

, 53,

, 43

M

medical assistance ....................2, 14

misc boxes ......................................... 6

N

National Pipe Thread ....................... 25

Note, defined ..................................... 5

NPT ................................................. 25

O

ORB ................................................. 25

orientation rose ........................... 5

O-Ring Boss ..................................... 25

, 6

P

parking brakes ....................................6

protective equipment .......................... 2

purging

fold system ................................. 15

lift system ................................... 15

R

rear tow hitch ....................................21

riders .................................................. 2

right-hand, defined ............................. 5

rolling harrow ....................................19

rose, orientation .......................... 5

, 6

S

SAE J514 ......................................... 25

safety symbol ..................................... 1

shipping stands .................................. 6

shutdown ............................................ 3

storage ............................................... 3

support ............................................... 7

symbol, safety .................................... 1

T

tables

document family ........................... 4

fittings torque ..............................25

hose color code ..........................14

models covered ............................4

tire inflation .................................24

torque values ..............................23

tire inflation ....................................... 24

tires .................................................... 3

torque value chart ............................ 23

trailer bed ........................................... 6

truck driver ......................................... 6

W

WARNING, defined ............................1

warranty 24

.. 52, 53, 54, 55, 57, 58, 59

wings ..................................................6

www ................................................. 24

, 40, 45, 47, 49, 51,

Numerics

12.5Lx15 SL .....................................24

30x8.8x15 .........................................24

586-239M, manual ............................. 4

586-239P, manual ............................... 4

586-239Q, manual ............................. 4

07/02/2013 Table of Contents 586-239Q

Page 66

62 1200-4000TC Table of Contents Index Great Plains Manufacturing, Inc.

586-239Q Table of Contents Index 07/02/2013

Page 67

Table of Contents Index

Table of Contents Index

Page 68

Table of Contents Index

Great Plains Manufacturing, Inc.

Corporate Office: P.O. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...