Great Plains 4000-3S User Manual

Great Plains Mfg., Inc.

Installation Instructions

4000-3S

Marker Option

Used with:

• 4000-3S 40’ 3-Section Drill

General Information

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

!

the lives of others depend on it!

These instructions explain how to install the marker

option. Themarkers foldand unfoldhydraulically for

field operation. The marker disk leaves a line for the

drill operator to follow on thenext field pass. Markers

are mounted on the drill frame and require two hydraulic remote valves on the tractor. A sequence

valve is available so markerscan be operated on one

hydraulic circuit.

These instructions apply to:

113-708A 4000-3S Single Marker Bundle

113-707A 4000-3S Dual Marker Bundle

113-048A 3S-4000 RH Marker Package

Assembly Instructions

NOTE: If installing right hand marker to drill already

equipped with left hand marker, follow instructions

listed under "Dual Marker."

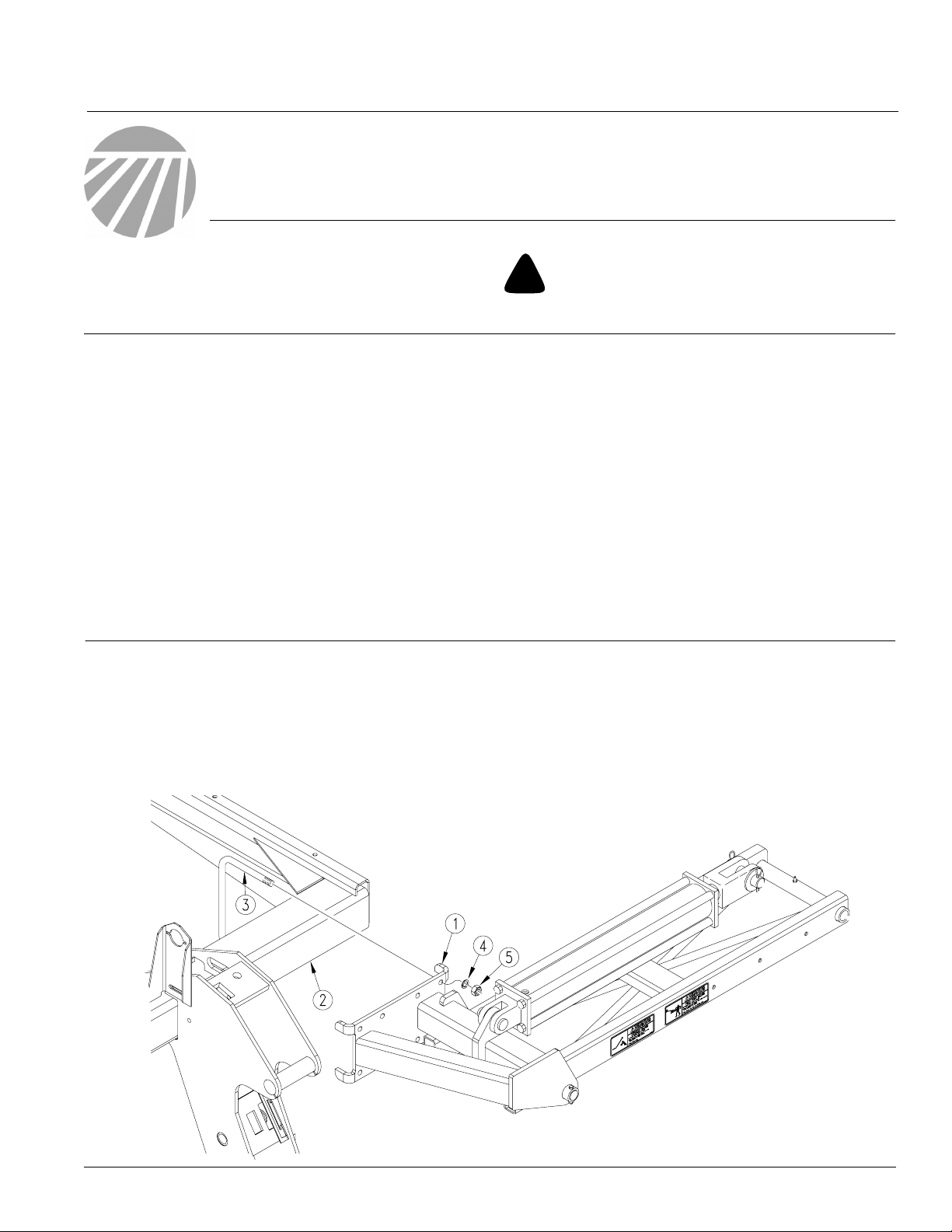

Refer to Figure 1

1. Lower drill into field position. Allow 25 feet on

each end of drill for marker assembly. Always assemble marker in unfolded position.

Manual Information

Refer to the 4000-3S operator’s manual for detailed

information on safely operating, adjusting, troubleshooting and maintaining the marker option. Refer

to the parts manual for part identification.

195-242M 4000-3S Operator’s Manual

195-242P 4000-3S Parts Manual

Before You Start

Beginning on page 12 is a detailed listing of parts included in the marker option package. Use this list to

inventory parts received.

2. Mount firstmarkersection (1)ondrill frame tube

(2) as shown. Secure with four 5/8" x

6" x 7 3/4" U-bolts (3), 5/8" lock washers (4) and

5/8" nuts (5).

NOTE: Mount the marker as far out on the frame as

possible.

© Copyright 2000 Printed

2/28/2006

Figure 1

First Marker Section Assembly

18923

113-728M

Marker Option

2

Great Plains Mfg., Inc.

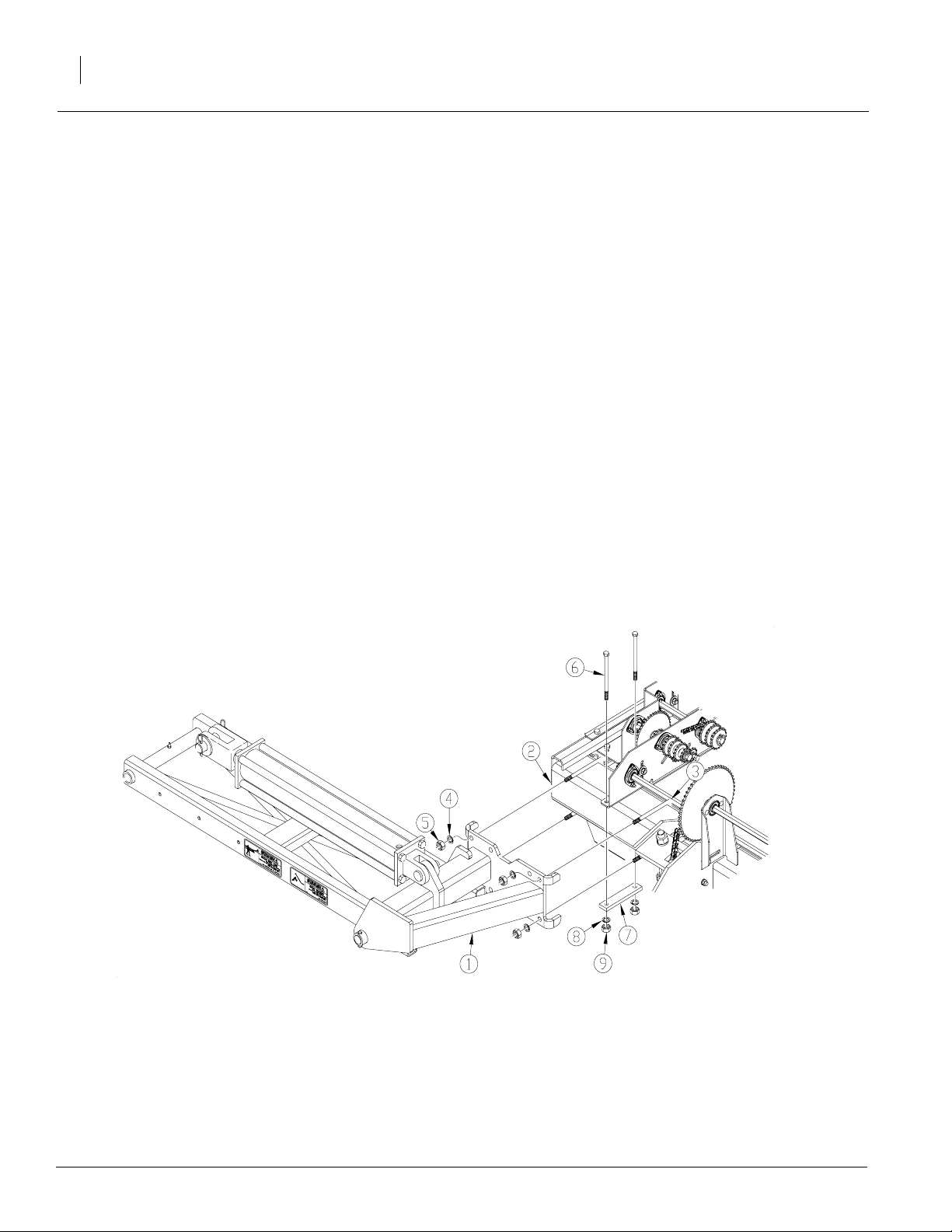

Note: For drills with a fertilizer drive use the following instructions for mounting the first marker section to the right-hand side of the drill.

Refer to Figure 2

3. Remove the 1/2" U-bolt located on the front of

the fertilizer drivemounting plate. Keepthe lock

washers and nuts for later use.

4. Mount firstmarkersection (1)ondrill frame tube

(2) as shown. Secure with four 5/8" x

6" x 7 3/4" U-bolts (3), 5/8" lock washers (4) and

5/8" nuts (5).

NOTE: Mount the marker as far out on the frame

as possible.

5. Insert the two 1/2" x 7 1/2" bolts (6) through the

holes in the fertilizer drive mounting plate

where the U-bolt was removed.

6. Install the clamp bar (7) as shown and secure in

place with1/2" lockwashers (8)and 1/2" nuts (9)

removedinstep3.

21785

Figure 2

Right-hand First Marker Section with Fertilizer Drive

113-728M 2/28/2006

Great Plains Mfg., Inc.

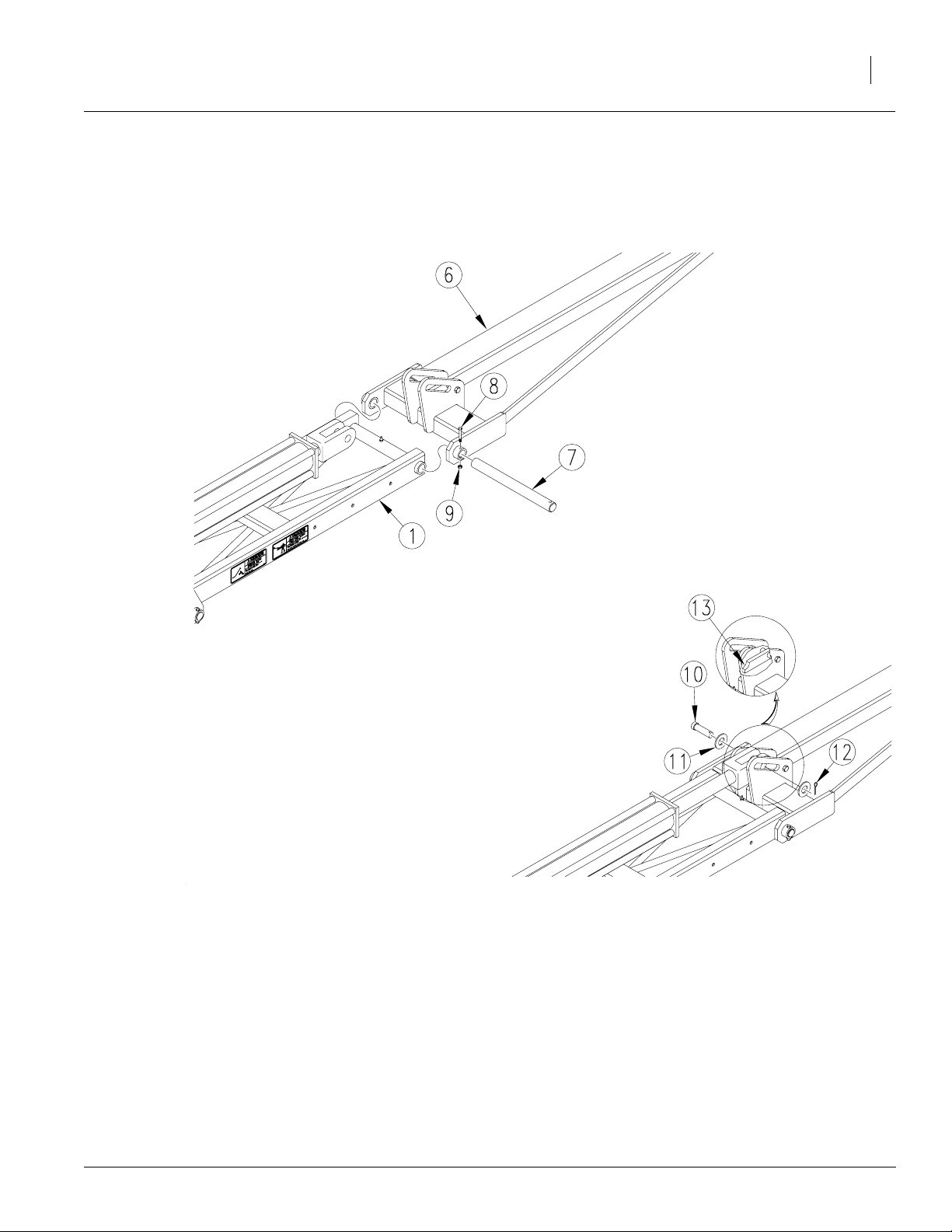

Refer to Figure 3

7. Assemble second marker section (6) to first

marker section (1) with 20 5/8" hinge pin (7). Fasten with5/16" x2 1/4" bolt (8) and 5/16" lock nut

(9).

Installation Instructions

3

Refer to Figure 4

8. Attach cylinder rod end to second marker section with clevis pin (10), flat washers (11) and

cotter pin (12).

NOTE: Make sure cylinder pin lock (13) is positioned

under cylinder clevis pin (10).

Figure 3

Second Marker Section to First Marker Section

18924

Figure 4

Cylinder Rod End to Second Marker Section

2/28/2006

113-728M

Marker Option

4

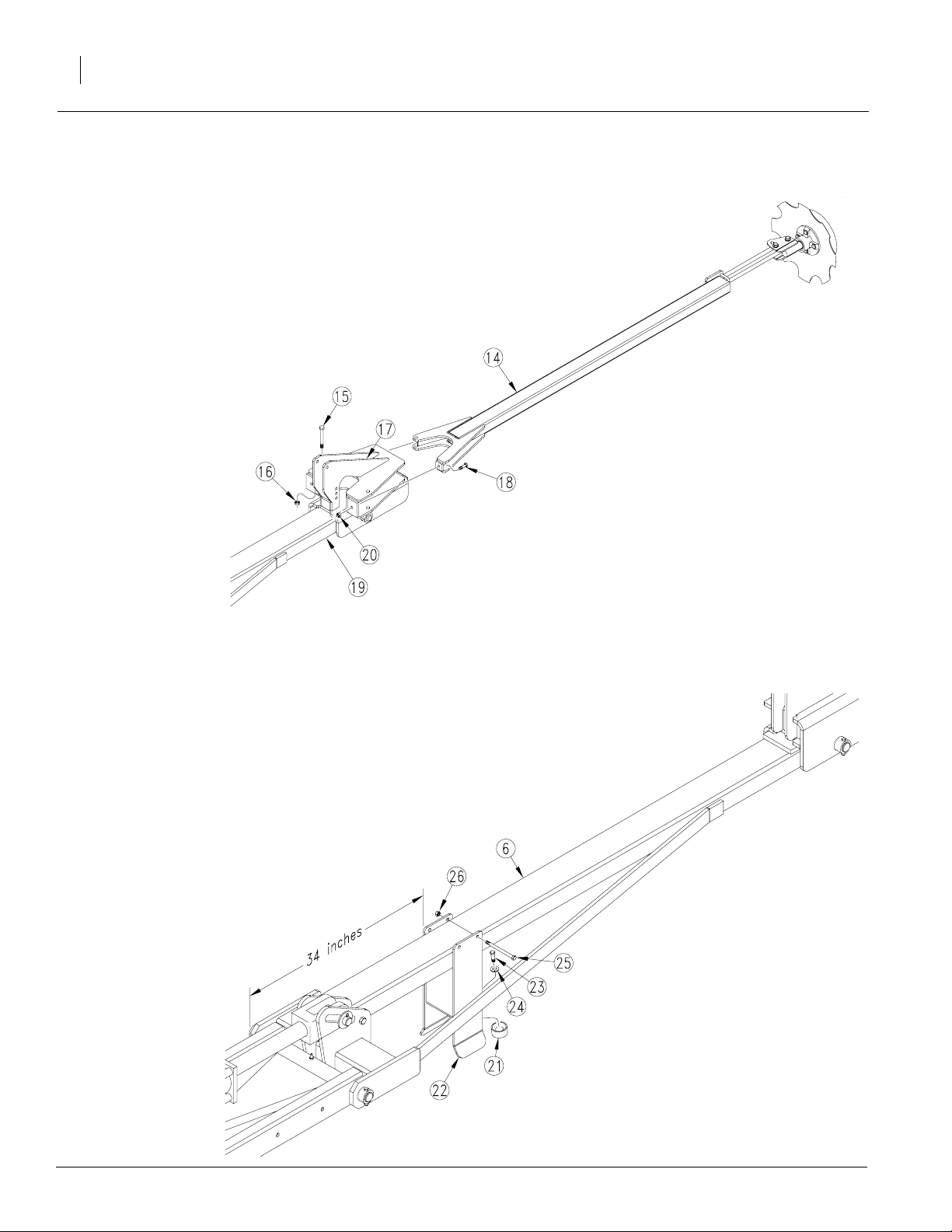

Refer to Figure 5

1. Assemble third marker section (14) to second

marker section (19) with 5/8" x 5" bolt(15) and5/

8" nut lock (16). After hinge bolt is installed, take

as much play out of the assembly by tightening

both hinge bolt (15) and middle clampbolt (17).

Stop tighteningboth boltswhen all the play has

been removed. Do not over tighten. Check to

make sure arm (14) can be rotated by hand. Secure opposite side with 7/16" x 2" bolt (17) and

7/16" nut hex lock (18).

NOTE: The 7/16" bolt (17) is the marker break away

bolt.

Great Plains Mfg., Inc.

Third Marker Section to Second Marker Section

Refer to Figure 6

2. Attach bumper (21) to marker rest bracket (22)

with a 1/2" x 3/4" bolt (23) and 1/2" lock washer

(24).

3. Attach marker rest bracket (22) to second marker section (6) with 3/8" x 6" bolts (25) and 3/8"

lock nuts (26).

NOTE: The 34 inch dimension shown is from the center of the hinge pin to the inner edge of rest bracket.

Figure 5

23204

18926

Figure 6

Marker Rest Bracket to Second Marker Section

113-728M 2/28/2006

Great Plains Mfg., Inc.

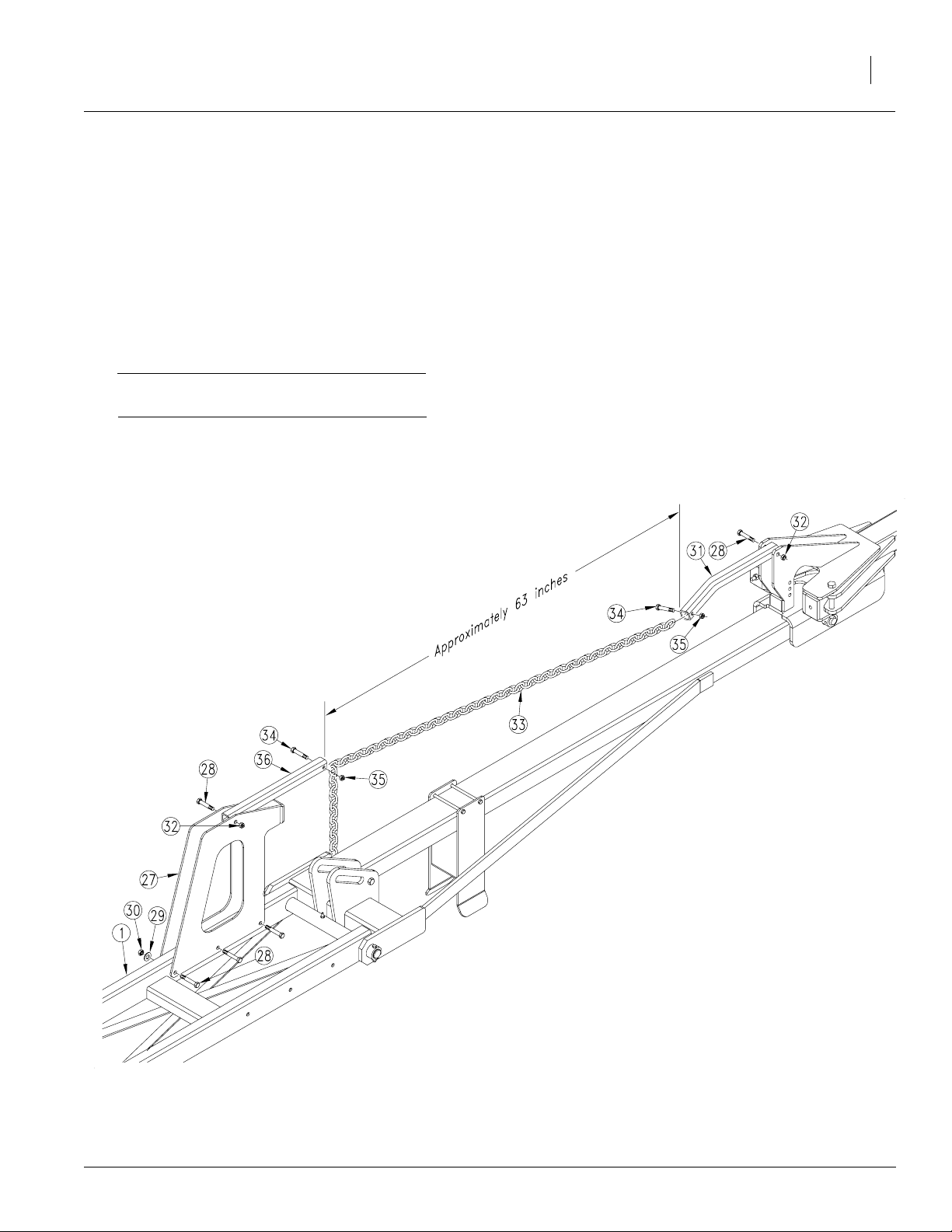

Refer to Figure 7

4. Attach transport brace (27) to first marker section (1) with 1/2" x 3 1/4" bolts (28) 1/2" lock

washers (29) and 1/2" lock nuts (30).

5. Assemble lift arms (31) and (36) to the transport

brace and second marker section as shown. Fasten with 1/2"x3 1/4" bolts(28)and 1/2" lock nuts

(32).

NOTE: Make sure thecurved end of arm (31)is facing

down down as shown.

IMPORTANT: Do not overtighten. The lift arms

must be able to swivel in their mounts.

6. Attach chain (33) to lift arms with 3/8" x 2 1/2"

bolts (34) and 3/8" lock nuts (35) to a length of

approximately 63" as shown.

NOTE: For adjustments for field operation, see drill

operator’s manual.

Installation Instructions

5

2/28/2006

NOTE: Cylinder removed

to show details.

21888

Figure 7

Transport Brace and Marker Chain Assembly

113-728M

Marker Option

6

Marker Carrier Assembly

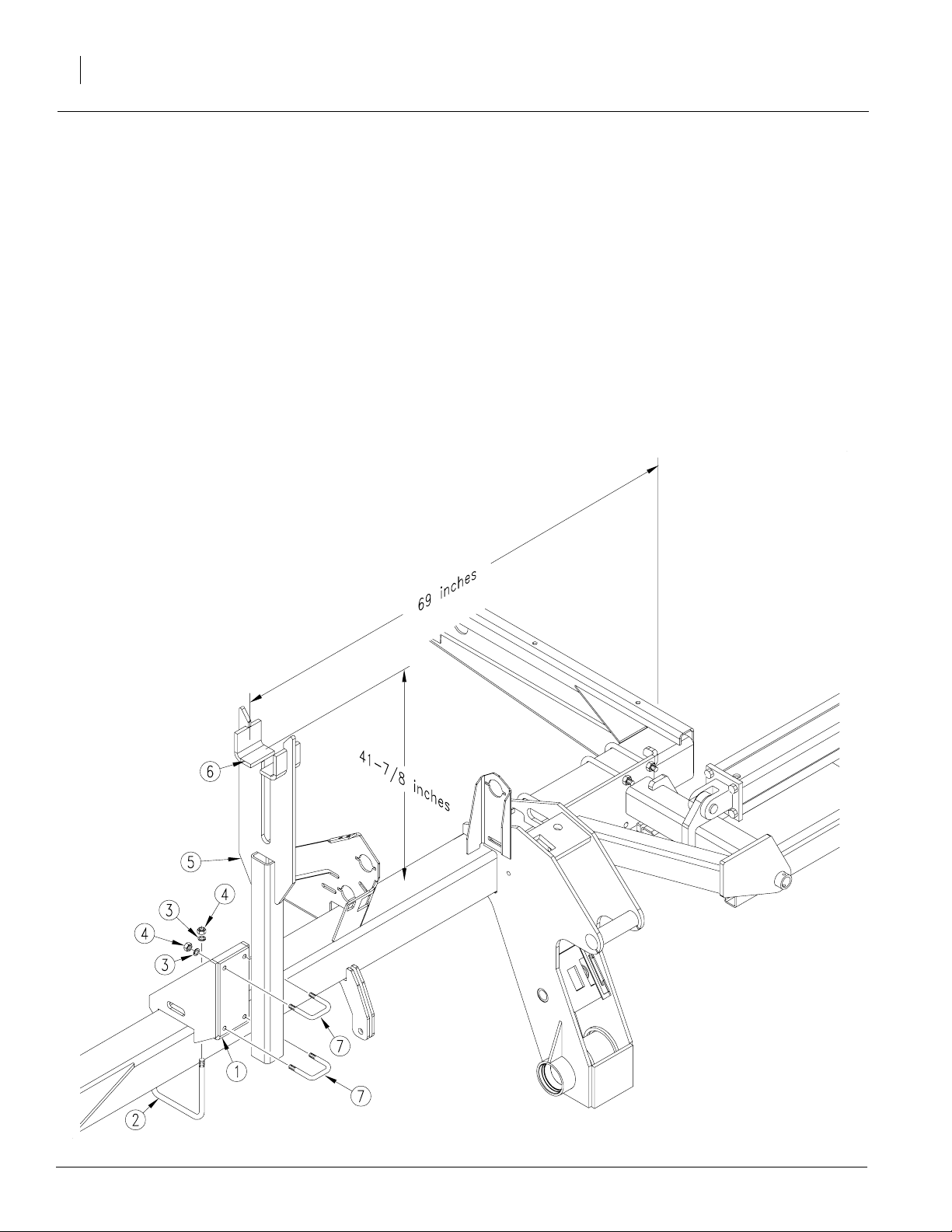

Refer to Figure 8

1. Attach marker carrier mount (1) to drill frame

with 1/2" x 6" x 7 1/4" U-bolts (2), 1/2" lock

washers (3) and 1/2" nuts (4). Center carrier

mount 69" from the outside end of drill frame.

2. U-bolt marker carrier (5) to carrier mount so

top ofsaddle surface (6) isabout 417/8" above

top of drill frame tube. Secure marker carrier

with 1/2" x 3" x 4" U-bolts (7), 1/2" lock washers

(3) and 1/2" nuts (4).

When folded, the second marker section should

rest in marker carrier saddle. After installing and

bleeding thehydraulics, marker carriermay require

further adjustment. Refer to Marker Adjustments in

the drill operator’s manual.

Great Plains Mfg., Inc.

Figure 8

Marker Carrier Installation

113-728M 2/28/2006

18932

Loading...

Loading...