Great Plains 3S-5000HD User Manual

Table of Contents Index

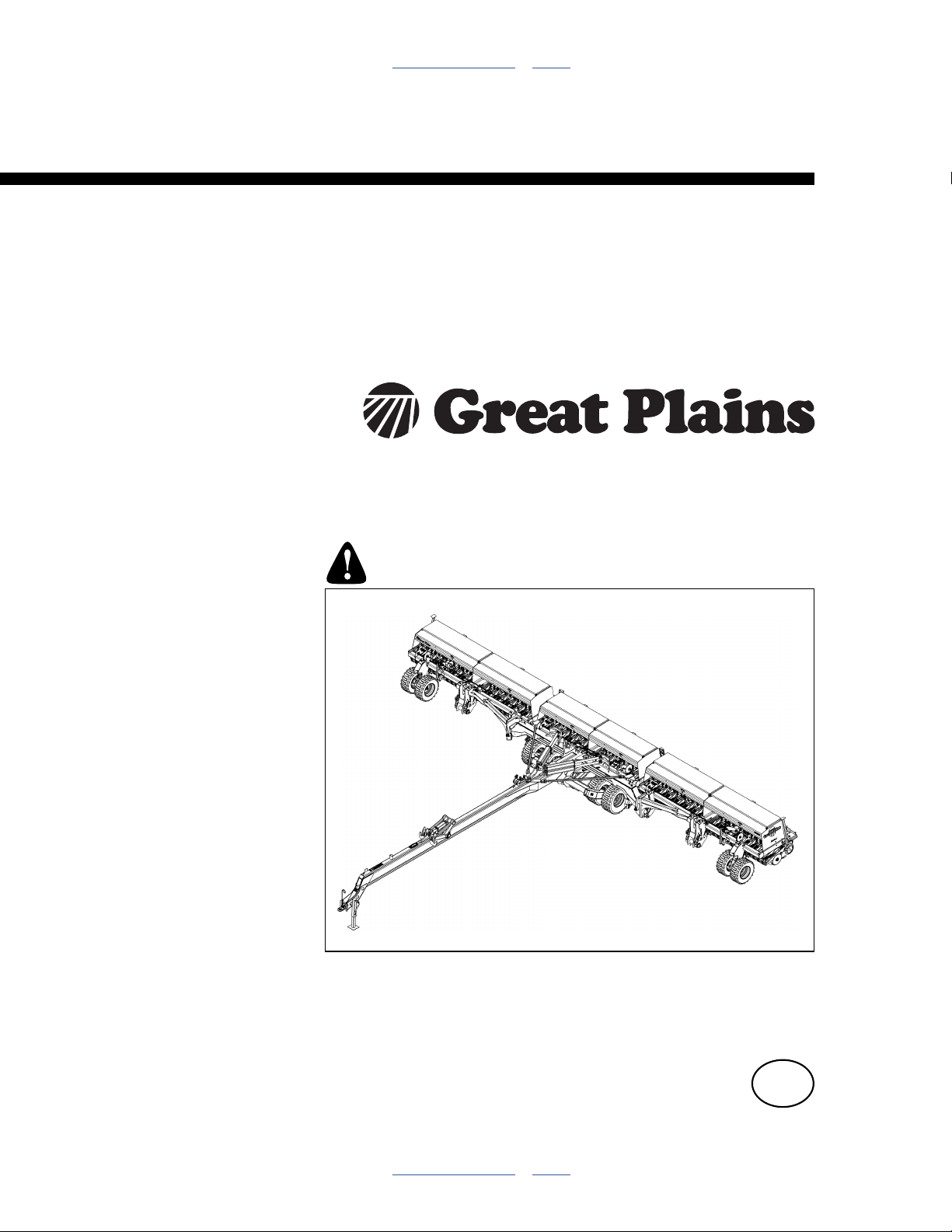

3-Section 50 Foot Folding Drill

Operator Manual

3S-5000/F/HD/HDF

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

34310%

Illustrations may show optional equipment not supplied with standard unit or may

depict similar 2S, 3S-3000, 3S-4000 and HD drills where a topic is identical.

ORIGINAL INSTRUCTIONS

© Copyright 2012 Printed 2012-08-14 195-325M

Table of Contents Index

EN

Table of Contents Index

Table of Contents Index

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ......................................1

Safety Decals .................................................................6

Introduction ................................................................13

Description of Unit ........................................................13

Intended Usage ........................................................13

Models Covered ...........................................................13

Document Family......................................................13

Using This Manual........................................................13

Definitions................................................................. 13

Owner Assistance ........................................................14

Product Support .......................................................14

Preparation and Setup ...............................................15

Post-Delivery/Seasonal Setup......................................15

Pre-Planting Setup .......................................................15

Leveling the Drill...........................................................16

Center Box Frame Leveling...................................... 16

Opener Frames ........................................................16

Wing Box Alignment .................................................17

Tool Bar Height ........................................................17

Align Transfer Drive Shaft ........................................18

Hitching Tractor to Drill.................................................20

Adjusting the Drill Hitch ............................................21

Hydraulic Hose Hookup................................................22

Operating Instructions...............................................23

Pre-Start Checklist .......................................................23

Folding..........................................................................24

Unfolding ......................................................................25

Folding and Unfolding Quick Reference.......................25

Setting the Bypass Valve .............................................26

Opener Operation.........................................................28

Active Hydraulic Systems.........................................29

Priority Flow Hydraulic Systems...............................30

Non-Active Hydraulic System...................................30

Opener Depth...........................................................31

Raising and Lowering Openers ....................................32

Opener Lock Up ..........................................................32

Loading Materials .........................................................33

Fertilizer Box Operation................................................34

Seeding with Both Compartments............................35

Transporting the Drill ....................................................36

Transport Checklist...................................................37

Point Row Operation (Option) ..................................37

Shaft Monitor Operation (Option) .............................38

Acremeter Operation ....................................................38

Normal Operating Sequence.................................... 38

Dormant Display....................................................... 39

Parking......................................................................... 40

Parking with Drill Unfolded ....................................... 40

Parking with Drill Folded .......................................... 40

Storage ........................................................................ 41

Adjustments ............................................................... 42

Main Box Seed Rate Handle........................................ 43

Position Seed Cup Doors............................................. 43

Frame Adjustments...................................................... 44

Tool Bar Height Adjustment ..................................... 44

Opener Frame Adjustment........................................... 45

Opener Frame Clearance ........................................ 46

Hydraulic Down Pressure All Openers......................... 46

00 Row Unit Adjustments............................................. 48

00HD Row Unit Adjustments ....................................... 49

Opener Height.............................................................. 50

Row Unit Down Pressure (Spring) ............................... 50

Disc Blade Adjustments ............................................... 51

Adjusting Disc Contact ............................................. 52

Fertilizer Tube Adjustment ........................................... 52

00 Series Disk Scraper Adjustment ............................. 53

Seed Firmer Adjustments ............................................ 53

Keeton® Seed Firmer Adjustment............................ 53

00 Series Seed-Lok® Lock Up ................................. 53

00 & 00HD Series Opener Depth................................. 54

Press Wheel Adjustment.......................................... 54

Troubleshooting......................................................... 55

Maintenance and Lubrication ................................... 59

Maintenance ................................................................ 59

Bleeding Hydraulics ..................................................... 60

Bleeding Opener Lift Hydraulics............................... 61

Bleeding Fold Hydraulics ......................................... 62

Bleeding Transport Lift Hydraulics ........................... 63

Opener Hydraulic Filters .......................................... 64

Drive System Maintenance .......................................... 65

Seed Flap Replacement .............................................. 66

Materials Clean-Out ..................................................... 66

Main Box Clean-Out.................................................66

Fertilizer Box Clean-Out........................................... 67

Small Seeds Box Clean-Out .................................... 67

Chain Maintenance ...................................................... 67

Chain Slack .............................................................. 67

Lubrication ................................................................... 68

© Copyright 2001, 2002, 2003, 2006, 2007, 2009, 2010, 2012 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2012-08-14 Cover Index 195-325M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

iv 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

Options ....................................................................... 75

Appendix A - Reference Information........................ 79

Specifications and Capacities ...................................... 79

Tire Inflation Chart ....................................................... 79

Dimensions (Transport) 3S-5000/F/HD/HDF .............. 80

Hydraulic Diagrams...................................................... 81

Torque Values Chart ....................................................84

Appendix B - Option Installation...............................85

Carbide Disc Scraper Installation .................................85

Warranty .......................................................................86

Index ............................................................................87

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 1

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

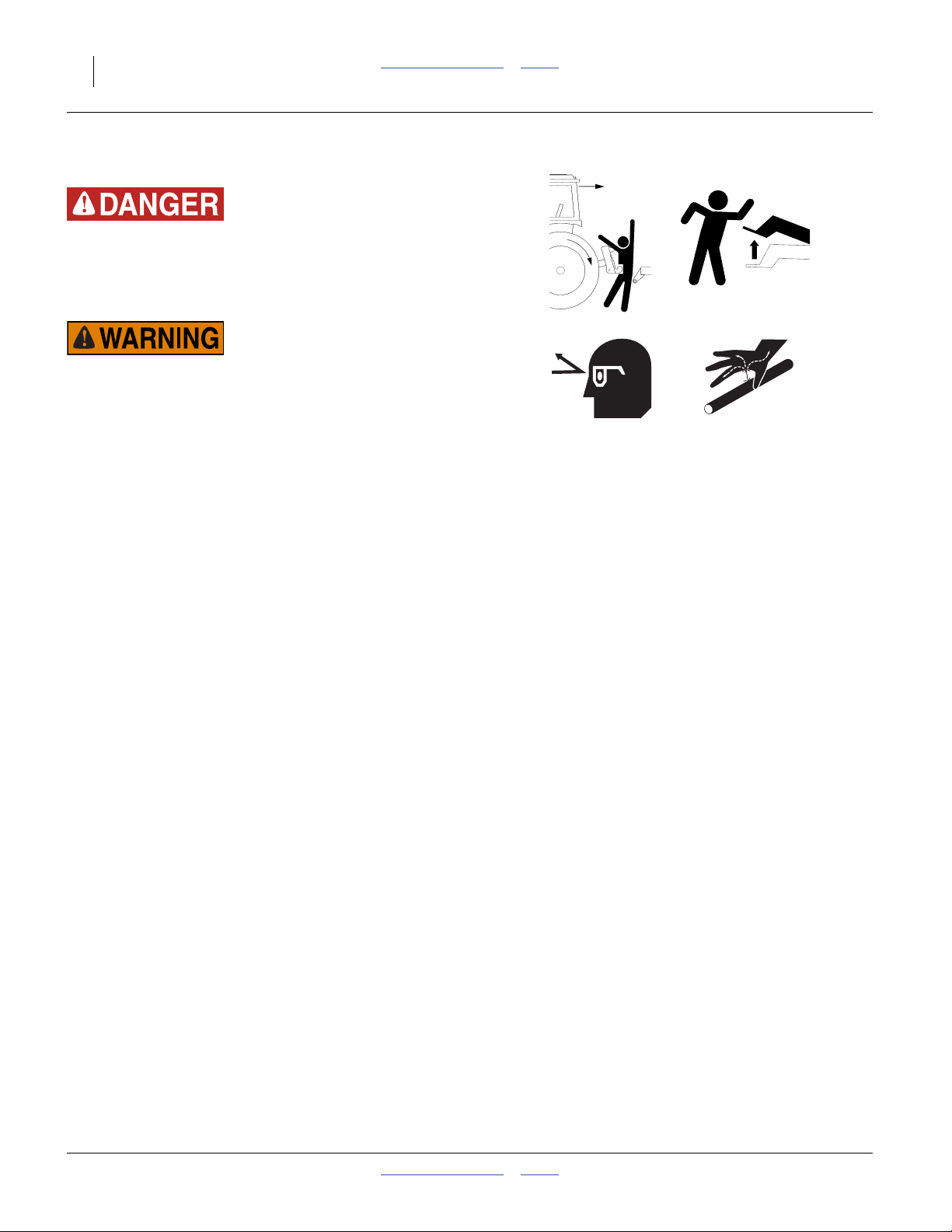

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 6,

thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

2012-08-14 Table of Contents Index 195-325M

2 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

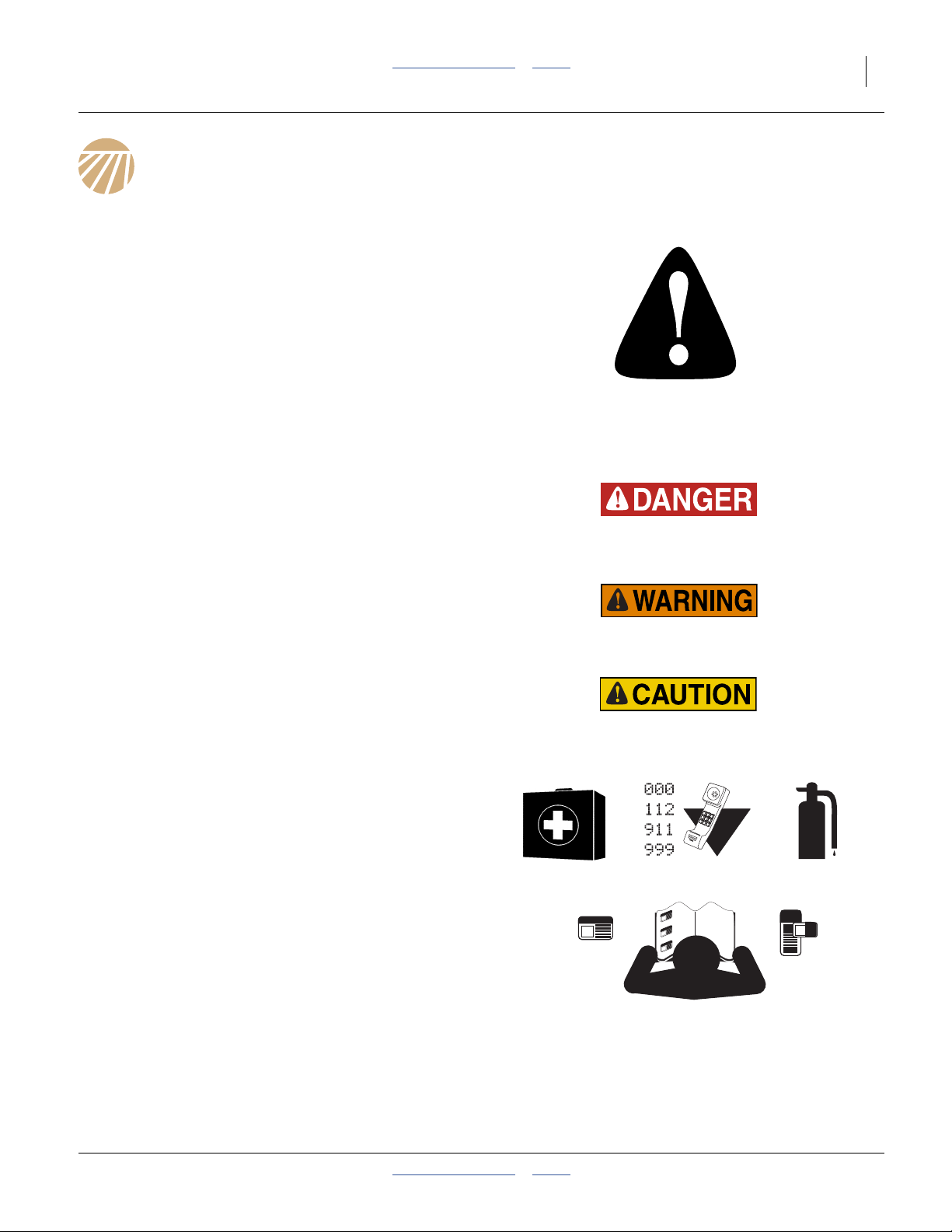

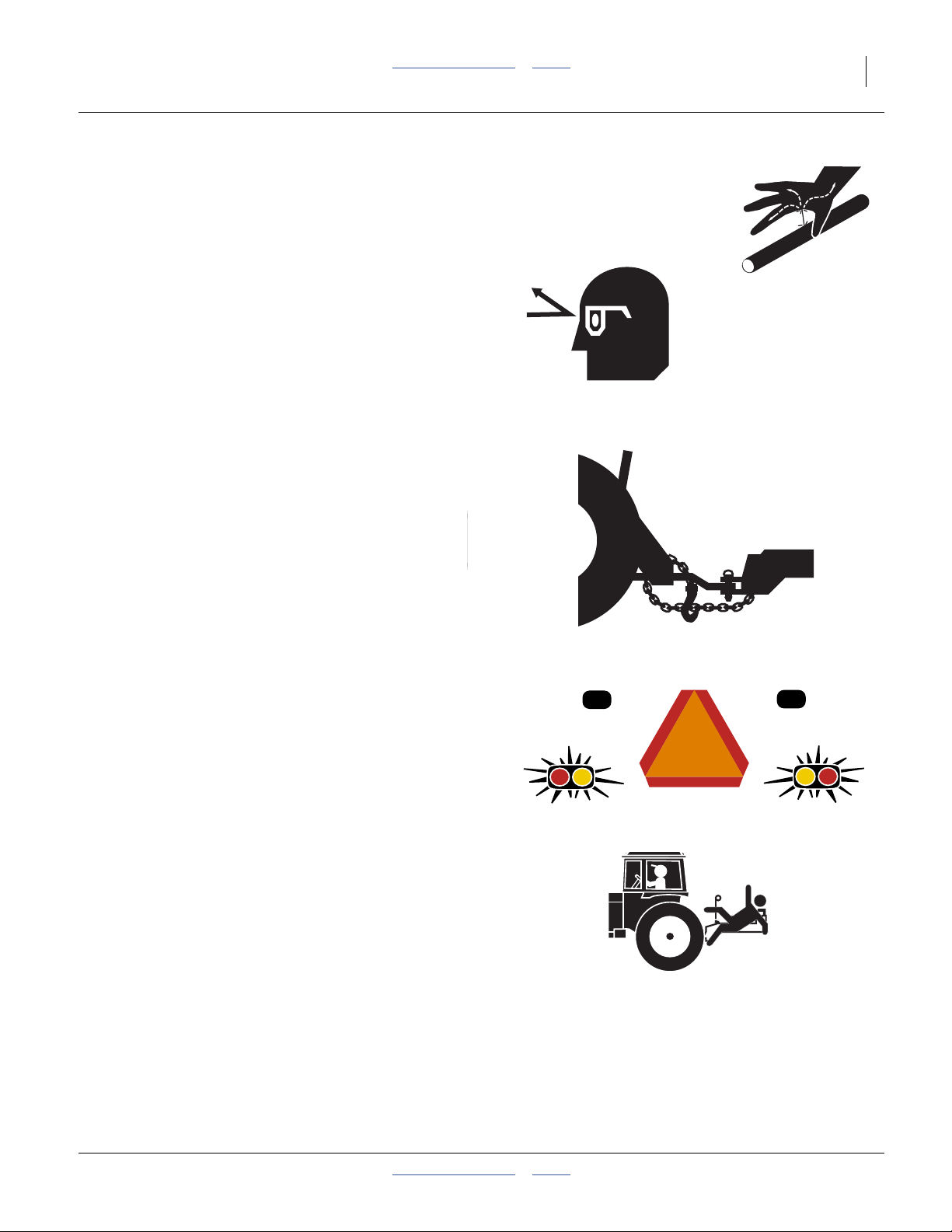

Wear Protective Equipment

Great Plains advises all users of chemical pesticides or

herbicides to use the following personal safety

equipment.

▲ Waterproof, wide-brimmed hat

▲ Waterproof apron.

▲ Face shield, goggles or full face respirator.

▲ Goggles with side shields or a full face respirator is

required if handling or applying dusts, wettable powders, or

granules or if being exposed to spray mist.

▲ Cartridge-type respirator approved for pesticide vapors

unless label specifies another type of respirator.

▲ Waterproof, unlined gloves. Neoprene gloves are

recommended.

▲ Cloth coveralls/outer clothing changed daily; waterproof

items if there is a chance of becoming wet with spray

▲ Waterproof boots or foot coverings

▲ Do not wear contaminated clothing. Wash protective

clothing and equipment with soap and water after each use.

Personal clothing must be laundered separately from

household articles.

▲ Clothing contaminated with certain pesticides must be

destroyed according to state and local regulations. Read

chemical label for specific instructions.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Prolonged exposure to loud noise can cause hearing

impairment or loss. Wear suitable hearing protection such

as earmuffs or earplugs.

▲ Avoid wearing entertainment headphones while operating

machinery. Operating equipment safely requires the full

attention of the operator.

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper use

can seriously injure persons, animals, plants, soil and

property.

▲ Read and follow chemical manufacturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Avoid inhaling smoke from any type of chemical fire.

▲ Store or dispose of unused chemicals as specified by

chemical manufacturer.

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Use A Safety Chain

▲ Use a safety chain to help control drawn machinery should

it separate from tractor draw-bar.

▲ Use a chain with a strength rating equal to or greater than

the gross weight of towed machinery.

▲ Attach chain to tractor draw-bar support or other specified

anchor location. Allow only enough slack in chain to permit

turning.

▲ Replace chain if any links or end fittings are broken,

stretched or damaged.

▲ Do not use safety chain for towing.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever

driving on public roads.

Use lights and devices provided with implement

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

2012-08-14 Table of Contents Index 195-325M

4 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

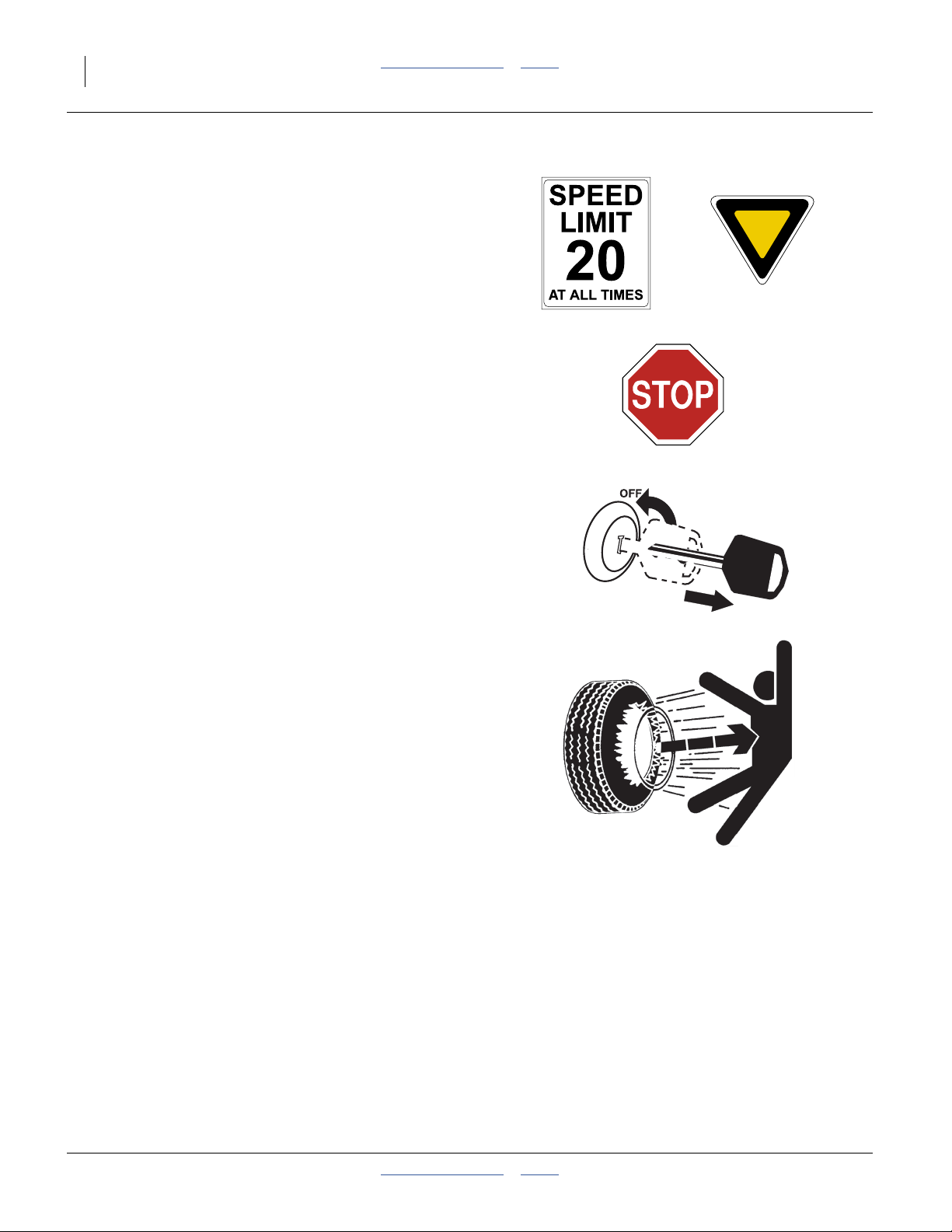

Transport Machinery Safely

Maximum transport speed for implement is 20 mph (32

kph). Some rough terrains require a slower speed.

Sudden braking can cause a towed load to swerve and

upset.

▲ Do not exceed 20 mph. Never travel at a speed which does

not allow adequate control of steering and stopping. Reduce

speed if towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully loaded, weighs

more than 1.5 times the weight of towing vehicle.

▲ Carry reflectors or flags to mark planter in case of

breakdown on the road.

▲ Do not fold or unfold the planter while the tractor is

moving.

Shutdown and Storage

▲ Lower planter, put tractor in park, turn off engine, and

remove the key.

▲ Secure planter using blocks and supports provided.

▲ Detach and store planter in an area where children

normally do not play.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

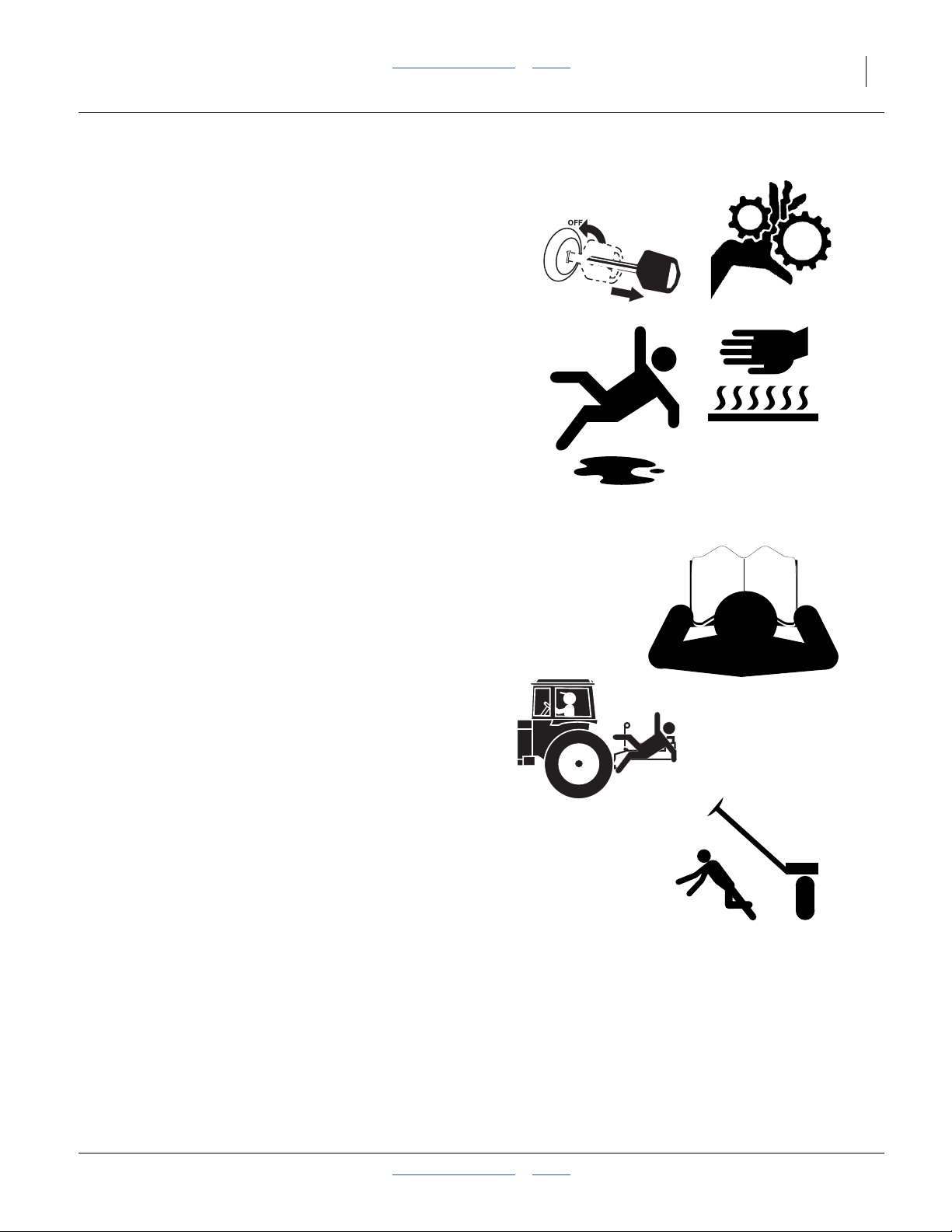

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper tools

and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Lower the planter, put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow planter to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on planter.

▲ Inspect all parts. Make sure parts are in good condition and

installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from planter before

operation.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all planter functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave planter unattended with tractor engine

running.

▲ Do not dismount a moving tractor. Dismounting a moving

tractor could cause serious injury or death.

▲ Do not stand between the tractor and planter during

hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

▲ Watch out for wires, trees, etc., when folding and raising

planter. Make sure all persons are clear of working area.

2012-08-14 Table of Contents Index 195-325M

6 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

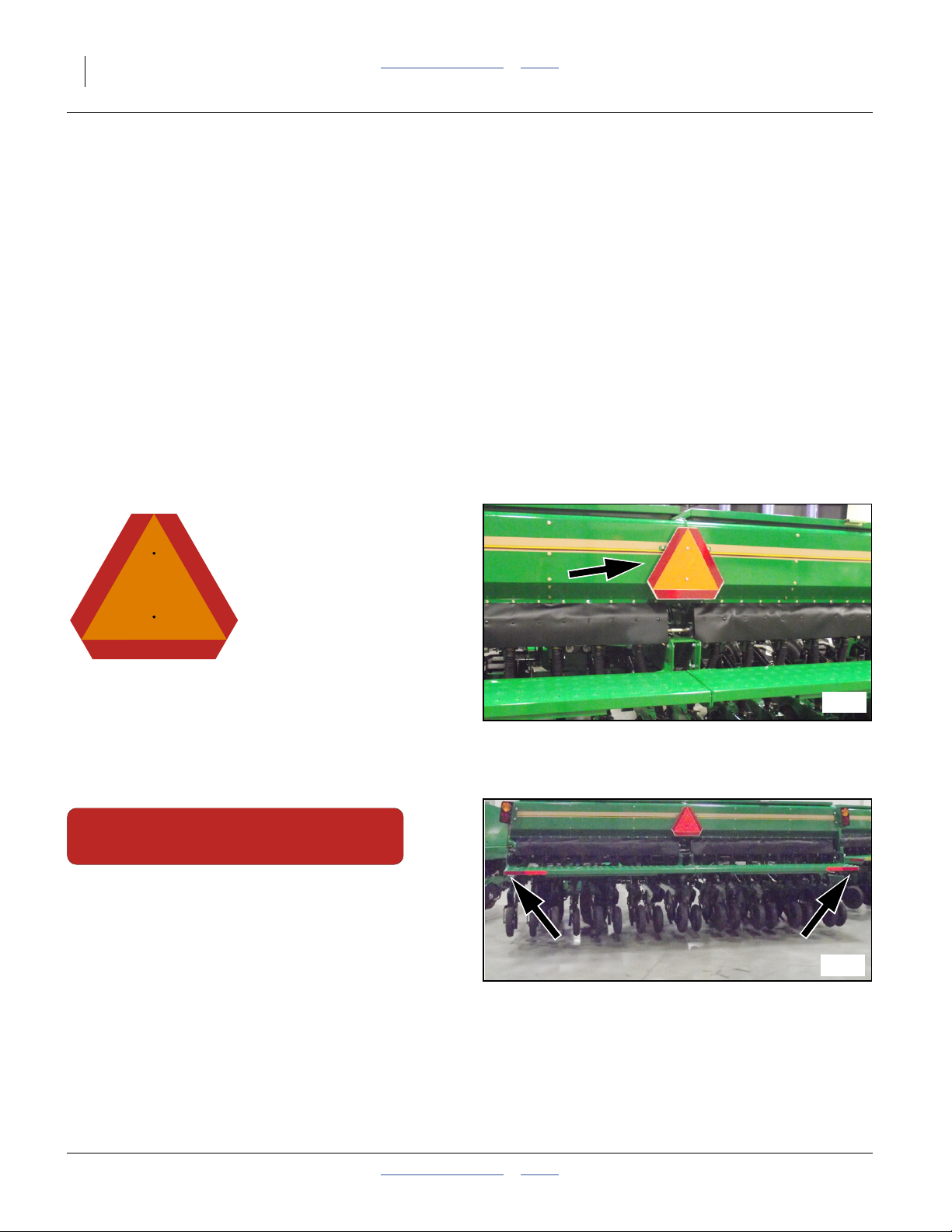

Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

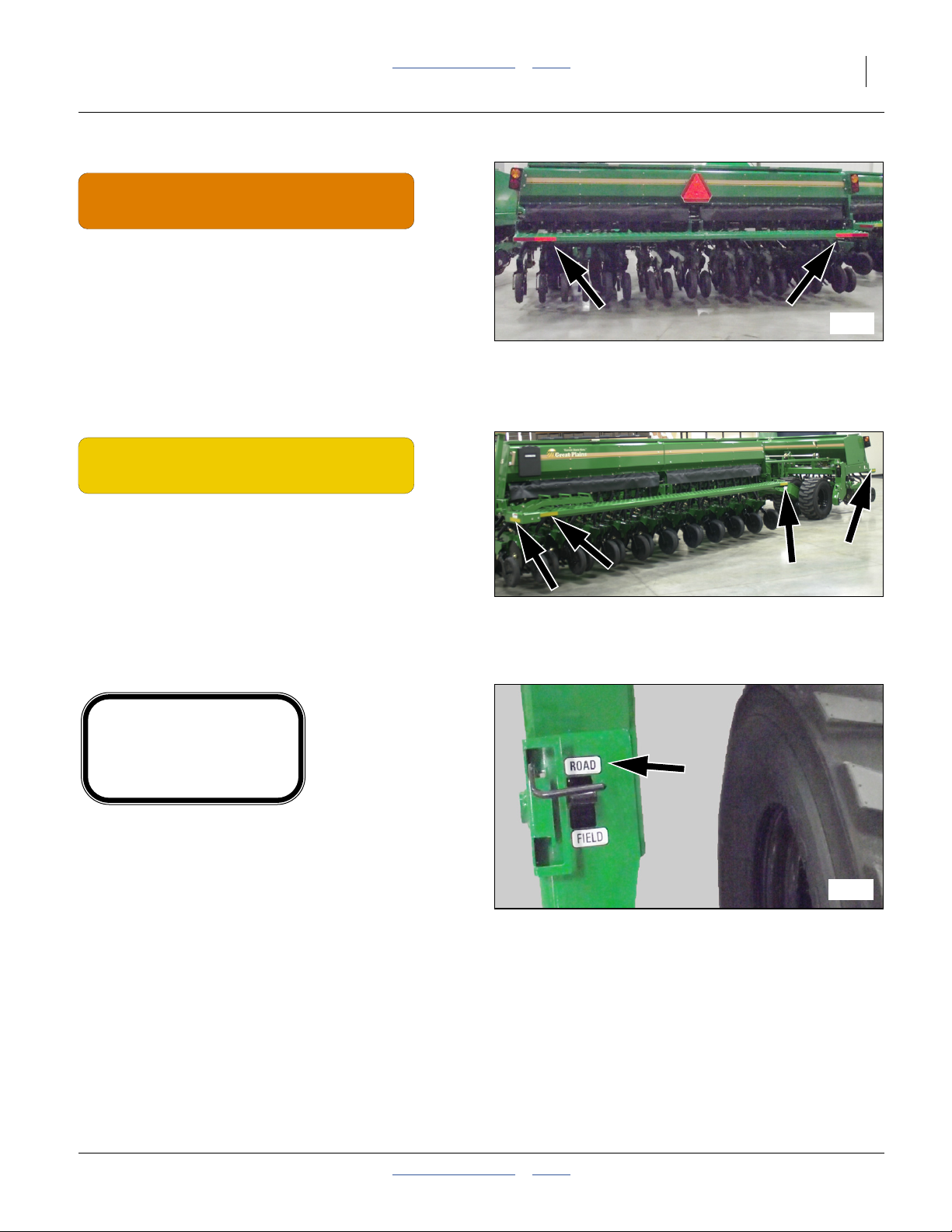

Transport Decals

818-055C

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

Slow Moving Vehicle Reflector

On center section;

one total

838-266C

Red Reflectors

On rear of center section, one each outside corner;

two total

34283

34284

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

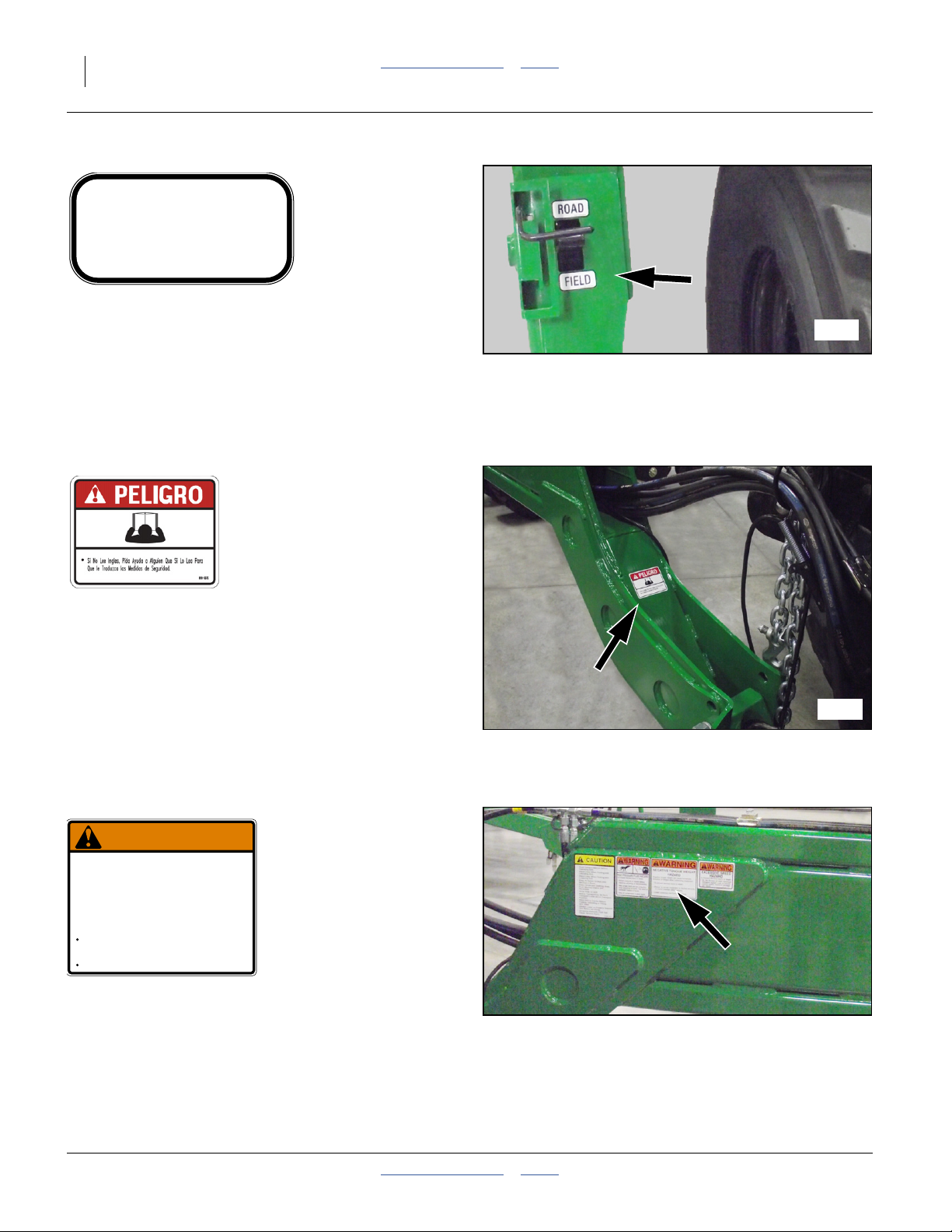

838-267C

Daytime Reflectors

On rear of center section;

two total

34284

838-265C

Amber Reflectors

Three reflectors on each wing section, one reflector

on each end of center section;

eight total

34300

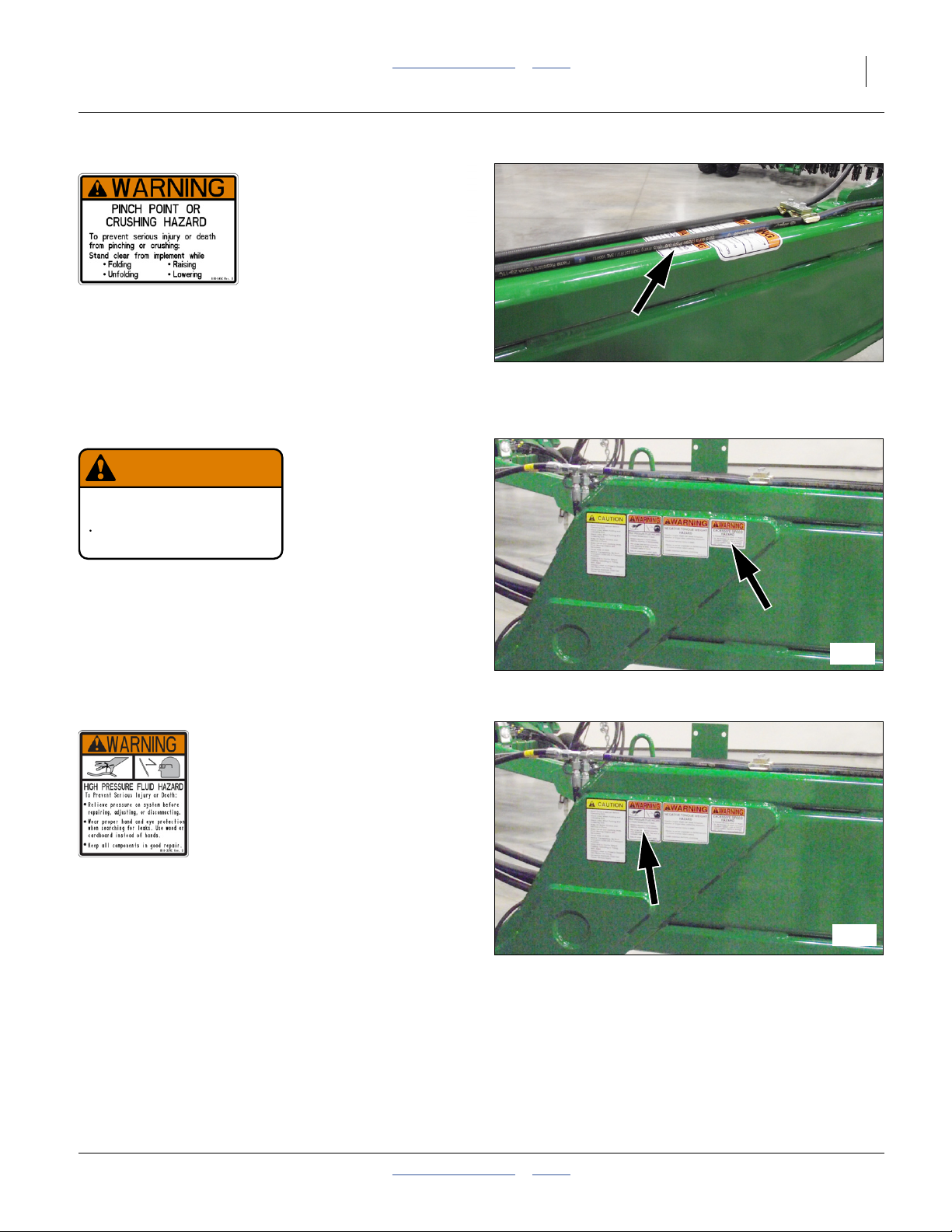

818-257C

ROAD

P.N. 818-257C

Transport Lock Road

Place above lever: two each RH and LH end section,

two on center section;

six total

34285

2012-08-14 Table of Contents Index 195-325M

8 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

818-258C

FIELD

P.N. 818-258C

Transport Lock Field

Place below lever: two each RH and LH end section,

two on center section;

six total

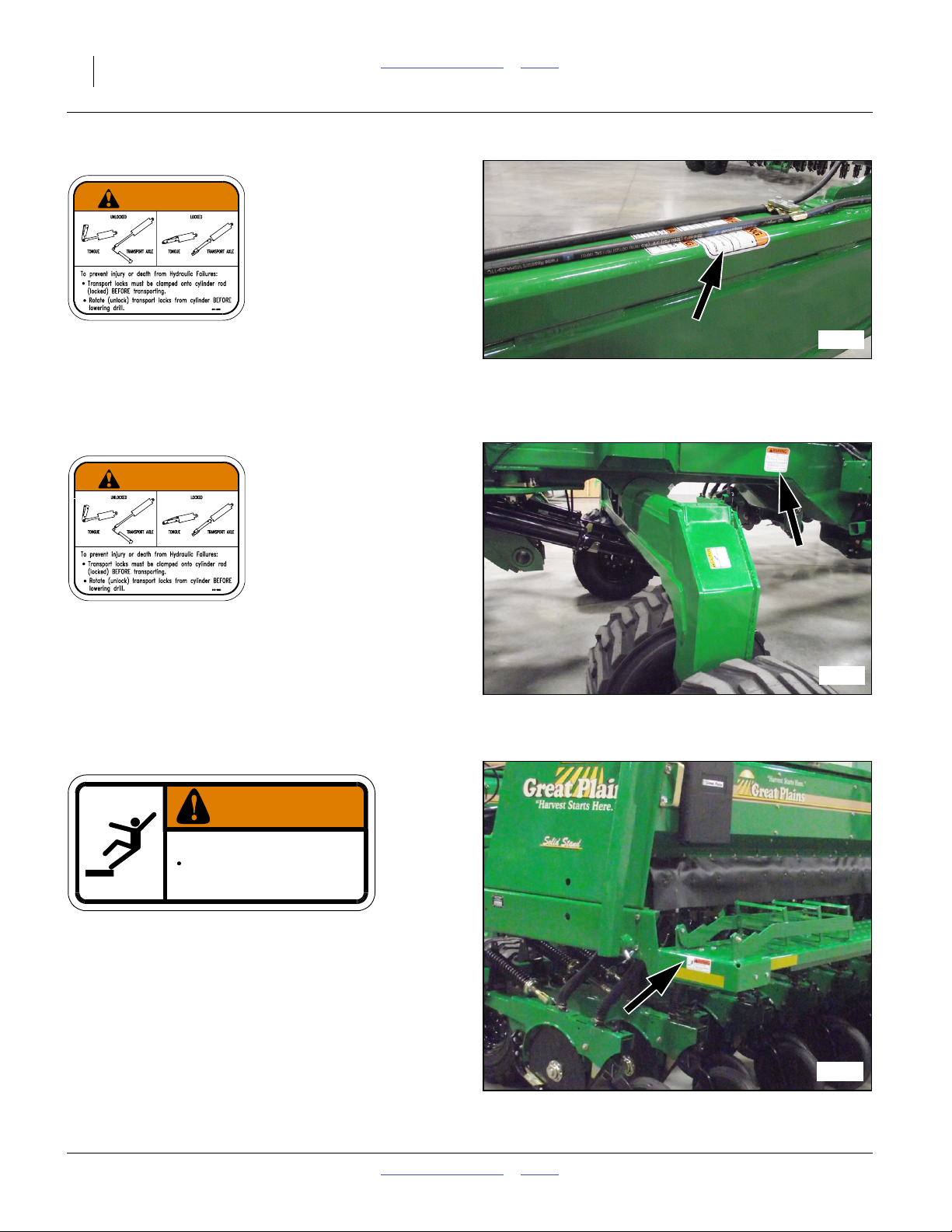

Danger Decals

818-557C

34285

Danger (in Spanish):

Advising non-English readers to seek translation

On tongue, at hitch; one total

Warning Decals

818-019C

WARNING

NEGATIVE TONGUE WEIGHT

Negative tongue weight can cause immediate

elevation of tongue when unhitching implement

To prevent serious injury or death:

Always be certain implement is hitched securely

to tractor drawbar before raising.

Lower implement BEFORE unhitching.

Warning: Negative Tongue Weight Hazard

On the tongue;

one total

HAZARD

818 019C Rev D

34287

34288

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 9

818-045C

Warning: Pinch/Crush

On top of tongue;

one total

34289

818-188C

WARNING

EXCESSIVE SPEED HAZARD

To Prevent Serious Injury or Death:

Do Not exceed 20 mph maximum transport

speed. Loss of vehicle control and/or machine

can result.

Warning: Speed

On left side of tongue, one total

818 188C Rev C

818-339C

Warning: High Pressure Fluid Hazard

On left side of tongue; one total

34288

34288

2012-08-14 Table of Contents Index 195-325M

10 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

818-660C

WARNING

Warning: Transport Lock

On top of tongue;

one total

818-660C

WARNING

Warning: Transport Lock

One on each side of drill frame;

two total

838-102C

34289

34290

WARNING

To avoid serious injury or death:

Watch your step when climbing ladder or

walking on walkboard.

Warning: Falling Hazard

One decal on each end of the drill;

two total

195-325M Table of Contents Index 2012-08-14

838-102C

34291

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 11

Caution Decals

818-078C

CAUTION

34288

Caution: General Instructions

On tongue; one total

818-398C

Caution: Tires Not A Step

One on each transport axle leg;

two total

818-398C

Caution: Tires Not A Step

One on outside face each gauge wheel weldment;

two total

34290

34295

2012-08-14 Table of Contents Index 195-325M

12 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

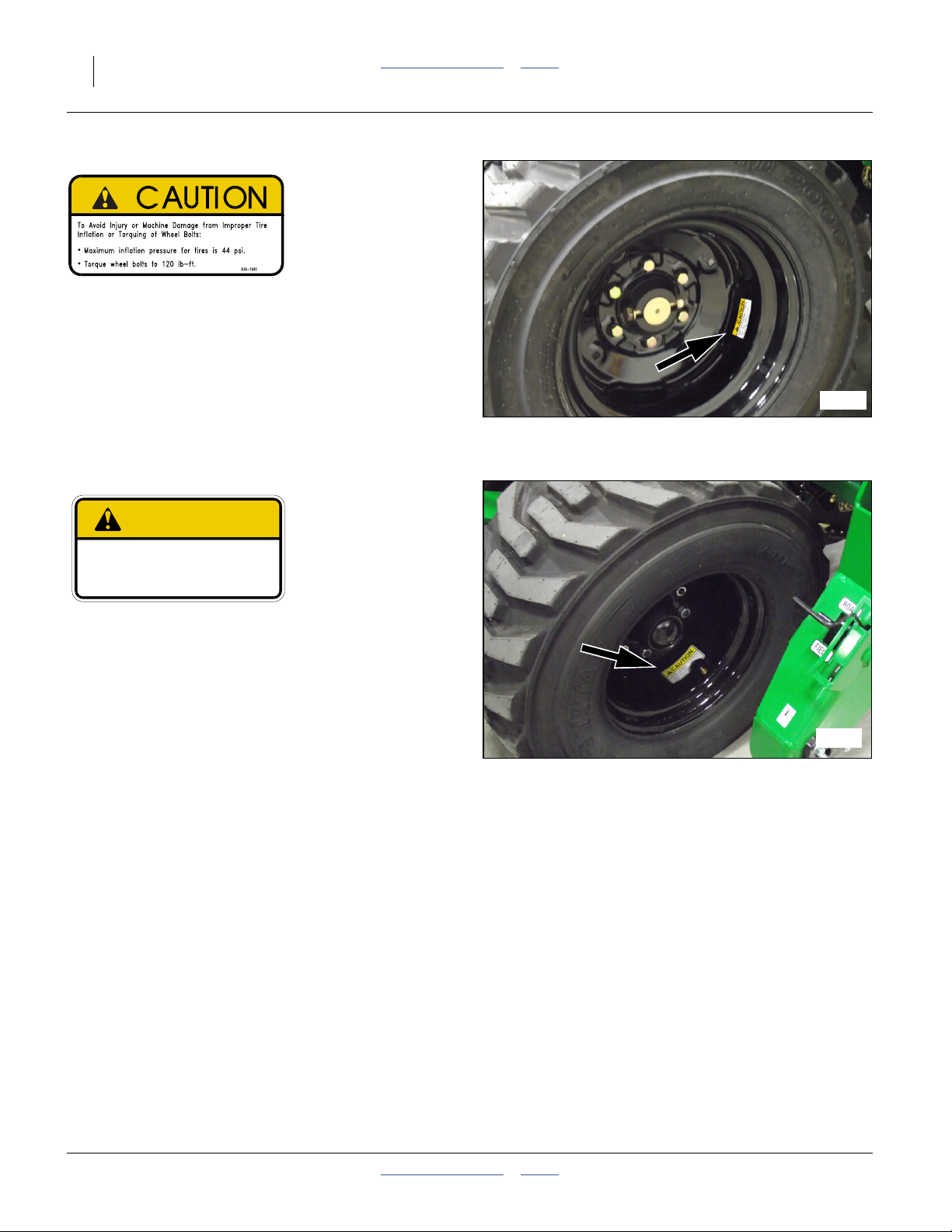

838-258C

Caution: Tire Pressure and Torque

Wing sections: one on each gauge wheel rim;

four or zero total

34298

848-801C

CAUTION

To Avoid Injur y or Machine Damage from Improper Tire

Inflation or Torquing of Wheel Bolts:

Maximum inflation pressure of tires is 80 psi.

Torque wheel bolts to 300 lb-ft.

Caution: Tire Inflation and Torque

Center section: one on each transport wheel rim;

four or zero total

848 801C

34292

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 13

Introduction

Great Plains welcomes you to its growing family of new

product owners. The 3-Section 50 Foot Folding Drill

(3S-5000/F/HD/HDF) has been designed with care and

built by skilled workers using quality materials. Proper

setup, maintenance, and safe operating practices will

help you get years of satisfactory use from the machine.

Description of Unit

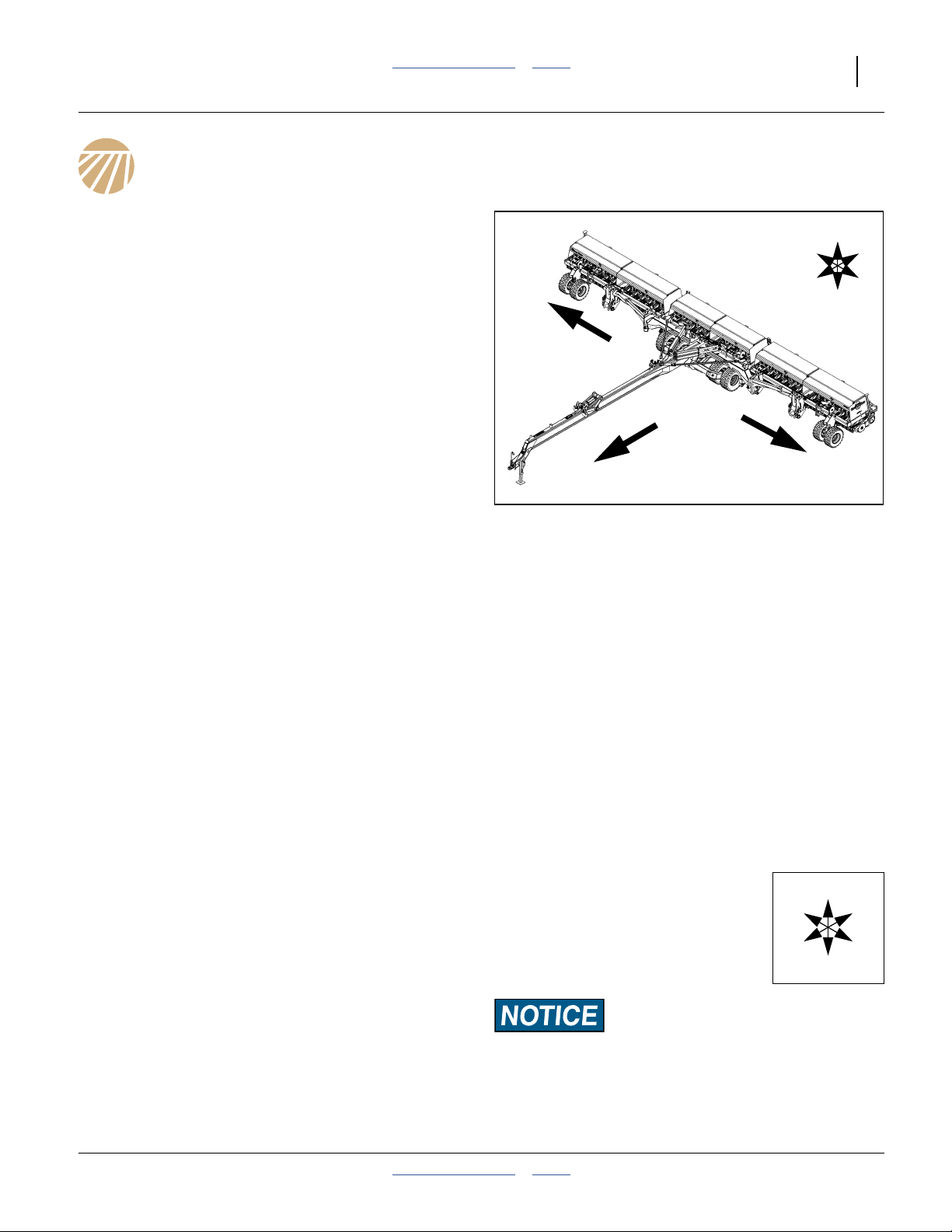

The 3S-5000/F/HD/HDF Drill is a towed seeding

implement for use in conventional or minimum tillage

conditions. This three section drill has a working width of

50 feet (12.2 m). The drill has straight arm, double disk

openers. The opener disks make a seed bed, and seed

tubes mounted between the disks place seed in the

furrow. Press wheels following the opener disks close the

furrow and gauge opener seeding depth. A T-handle on

the opener body is for seeding depth adjustments.

Seeding rates are adjustable with the seed rate

adjustment handle and sprocket changes.

The 3S-5000/F/HD/HDF features active hydraulic down

pressure on the opener frames. When used on a tractor

with closed-center hydraulics, constant down pressure

ensures even opener penetration in uneven ground.

Hydraulic down pressure is adjustable at a single point.

R

Figure 1

3S-5000/F/HD/HDF Drill

R

F

U

B

L

D

L

34310

Intended Usage

Use the 3S-5000/F/HD/HDF Drill to seed

production-agriculture crops only. Do not modify the drill

for use with attachments other than Great Plains options

and accessories specified for use with the 3S-5000 Drill.

Models Covered

3S-5000-6010 60 Row, 10 inch (25.4 cm) Spacing

3S-5000-8075 80 Row, 7.5 inch (19.1 cm) Spacing

3S-5000-1006 100 Row, 6 inch (15.2 cm) Spacing

3S-5000F-6010 60 Row, 10 inch (25.4 cm) Spacing

3S-5000F-8075 80 Row, 7.5 inch (19.1 cm) Spacing

3S-5000F-1006 100 Row, 6 inch (15.2 cm) Spacing

3S-5000HD-4810 60 Row, 10 inch (25.4 cm) Spacing

3S-5000HD-6375 80 Row, 7.5 inch (19.1 cm) Spacing

3S-5000HD-7806 100 Row, 6 inch (15.2 cm) Spacing

3S-5000HDF-4810 60 Row, 10 inch (25.4 cm) Spacing

3S-5000HDF-6375 80 Row, 7.5 inch (19.1 cm) Spacing

3S-5000HDF-7806 100 Row, 6 inch (15.2 cm) Spacing

Document Family

195-325M Owner’s Manual (this document)

195-325B Seed Rate Charts

133-322M Small Seeds Manual

195-325P Parts Manual

Using This Manual

This manual will familiarize you with safety, assembly,

operation, adjustments, troubleshooting, and

maintenance. Read this manual and follow the

recommendations to help ensure safe and efficient

operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

A crucial point of information related to the current topic. Read

and follow the directions to remain safe, avoid serious damage

to equipment and ensure desired field results.

Note: Useful information related to the preceding topic.

R

F

U

B

L

D

2012-08-14 Table of Contents Index 195-325M

14 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Refer to Figure 2

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts. Always

use the serial and model number when ordering parts

from your Great Plains dealer. The serial-number plate is

located on the left end of seed box frame, as shown.

Record your 3S-5000/F/HD/HDF Drill model and serial

number here for quick reference:

Model Number:__________________________

Serial Number: __________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

For further assistance write to:

Figure 2

Serial Number Plate

34299

Product Support

Great Plains Mfg. Inc., Service Department

Salina, KS 67402-5060

PO Box 5060

785-823-3276

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 15

Preparation and Setup

This section helps you prepare your tractor and

3S-5000/F/HD/HDF Drill for use.You must level the drill,

adjust drill tongue height to match your tractor drawbar

height, hook up the drill hydraulics to the tractor, and

check that the hydraulics have been bled.

Post-Delivery/Seasonal Setup

On initial delivery, use with a new tractor, and seasonally,

check and as necessary, complete these items before

continuing to the routine setup items:

• Bleed hydraulic system (page 60).

• Wing leveling and alignment (page 17).

• Marker setup (page 37)

• De-grease exposed cylinder rods if so protected at last

storage.

Pre-Planting Setup

Complete this checklist before routine setup:

❑ Read and understand “Important Safety

Information” on page 1.

❑ Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

❑ Check that all grease fittings are in place and

lubricated. See “Lubrication” on page 68.

❑ Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged.

See “Safety Decals” on page 6.

❑ Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Specifications and

Capacities” on page 79.

2012-08-14 Table of Contents Index 195-325M

16 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

Leveling the Drill

Center Box Frame Leveling

1. Park the drill on a clean level surface.

2. Raise the openers and lock them up.

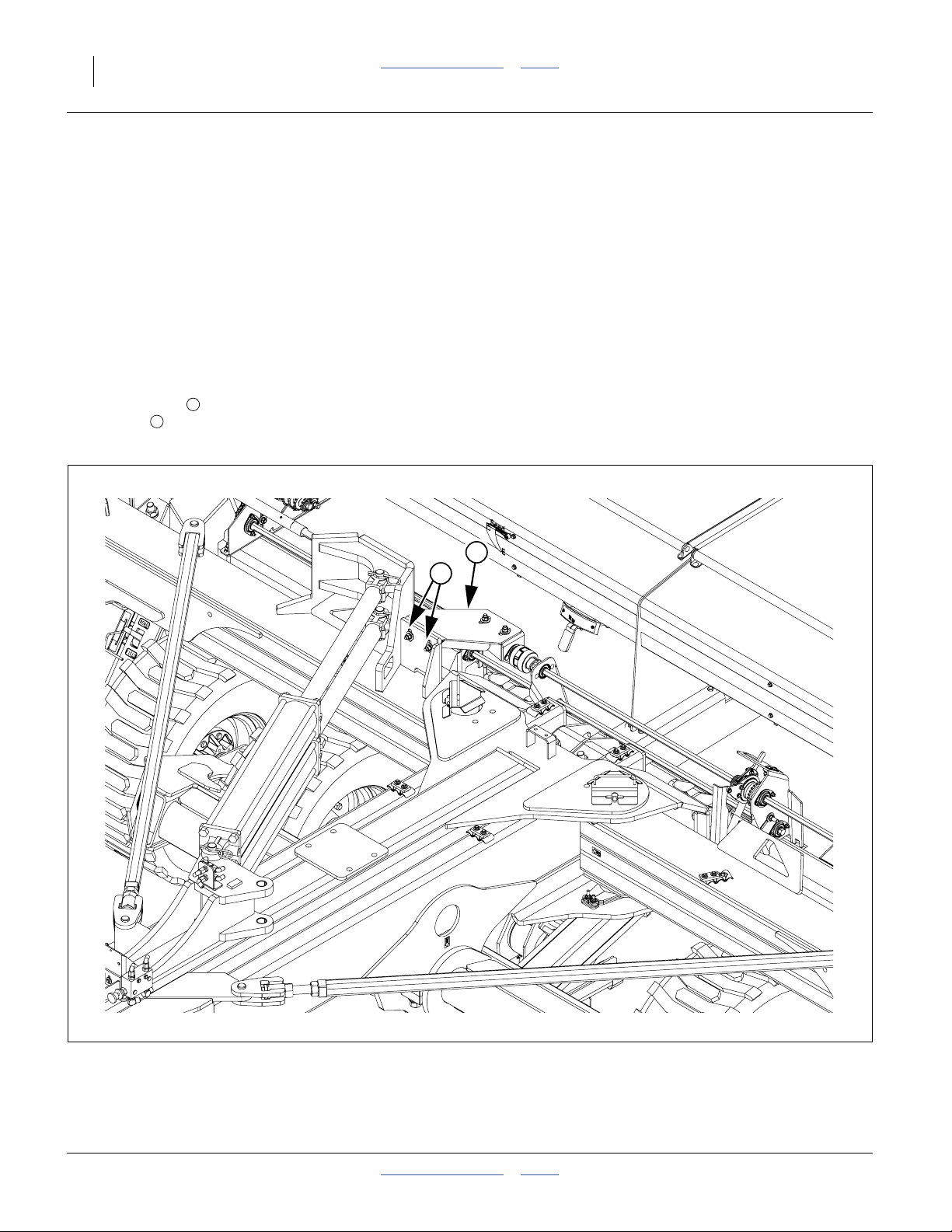

Refer to Figure 3

3. Loosen the eight center box mount bolts , four

bolts on each side of tongue and slide center box

frame sideways until it is centered with mainframe

and transport axle.

Refer to Figure 4

4. Measure the height of center box opener frame

pivots from the level surface and raise low end of

box frame up until both opener frame pivots measure

the same distance from the ground.

5. Torque the7⁄8inch box mount bolts .

2

1

1

1

1

Figure 3

Center Box Mount Bolts

1

1

34319

Opener Frames

Check that opener frames are level across drill. When

fully raised, top of opener mounts should clear bottom of

drill frame tube by at least1⁄2inch (13 mm). See

“Opener Frame Clearance” on page 46, for further

instructions.

2

height

Opener frame

ot

piv

Figure 4

Opener Frame Leveling

34297

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 17

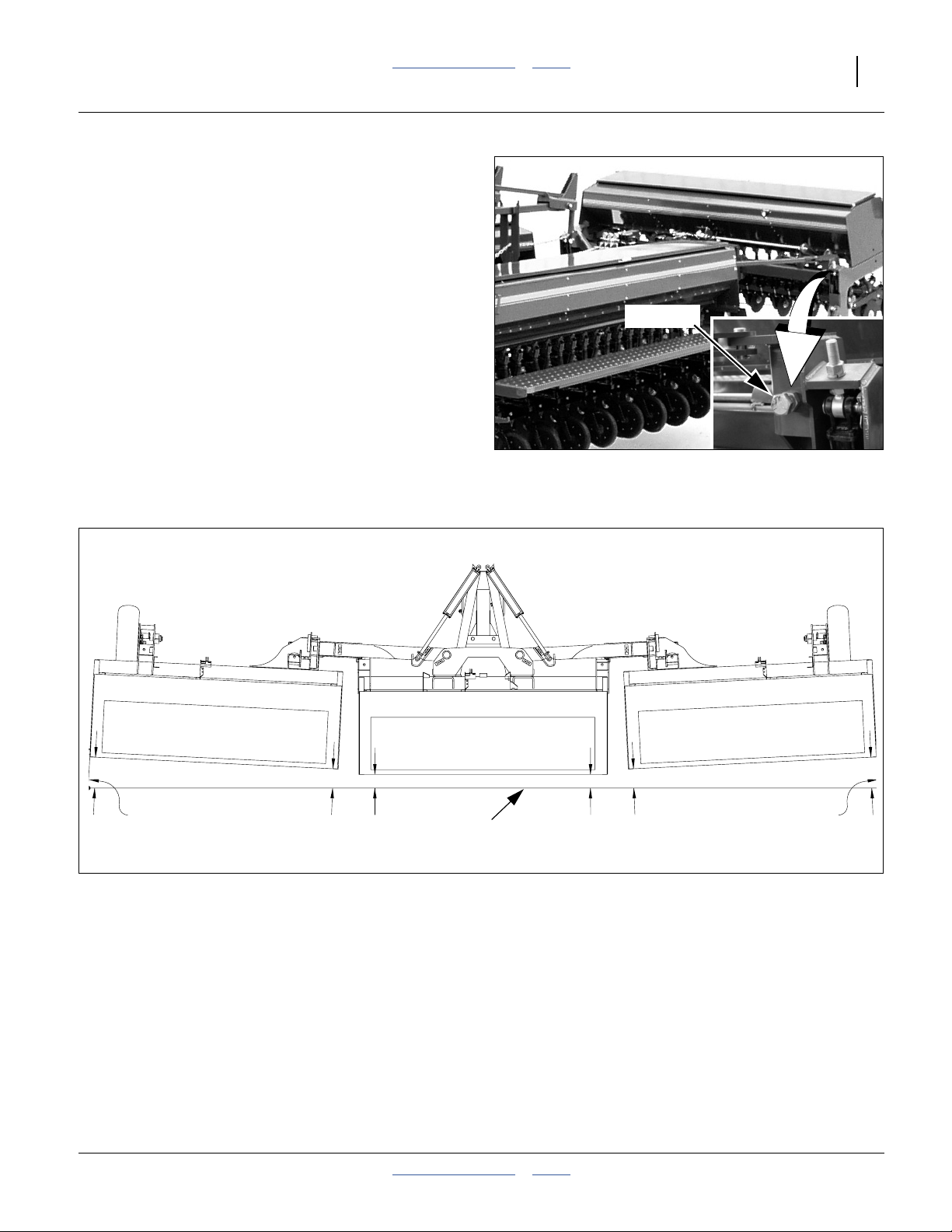

Wing Box Alignment

1. Place a block ahead of the wing gauge wheels.

Refer to Figure 5

2. Pull forward against blocks to rock wing frames back.

Pull forward until stop bolts are firmly against tool

bars.

Refer to Figure 6

3. Check for proper alignment by running a string line

across back of drill toward outer ends of wings. For

proper alignment, outside ends of boxes should be

about 1 inch to 11⁄4inch (25 to 32 mm) ahead of

inside ends.

4. To adjust box alignment, shorten or lengthen stop

bolts to change the contact point with the tool bars.

Adjust stop bolts in or out until outside ends of boxes

are 1 inch to 11⁄4inch (25 to 32 mm) ahead of inside

ends.

Stop Bolt

Figure 5

Stop Bolt Location

18988

C-B=1 to 11⁄4 inch

C

String Line

Support

B

A

String Line

Wing Box Alignment Measurement

Tool Bar Height

Tool bar height is factory set and normally will not require

adjustment. If the tool bar is visibly not level see “Tool

Bar Height Adjustment” on page 44.

Figure 6

String Line

B

A

Support

15654

2012-08-14 Table of Contents Index 195-325M

18 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

Align Transfer Drive Shaft

After wing boxes are properly aligned, the transfer drive

shaft must be aligned so the pair of break-away jaws are

fully engaged and are concentric. The

hex drive shafts holding the clutch jaws should not

contact each other when wing boxes are properly aligned

and back against their stops.

1. Place a 4x4 inch or similar sized block ahead of the

wing gauge wheels and pull forward or push wing

box frames back until the tool bar is firmly against

tool bar stop bolts on the center box frame.

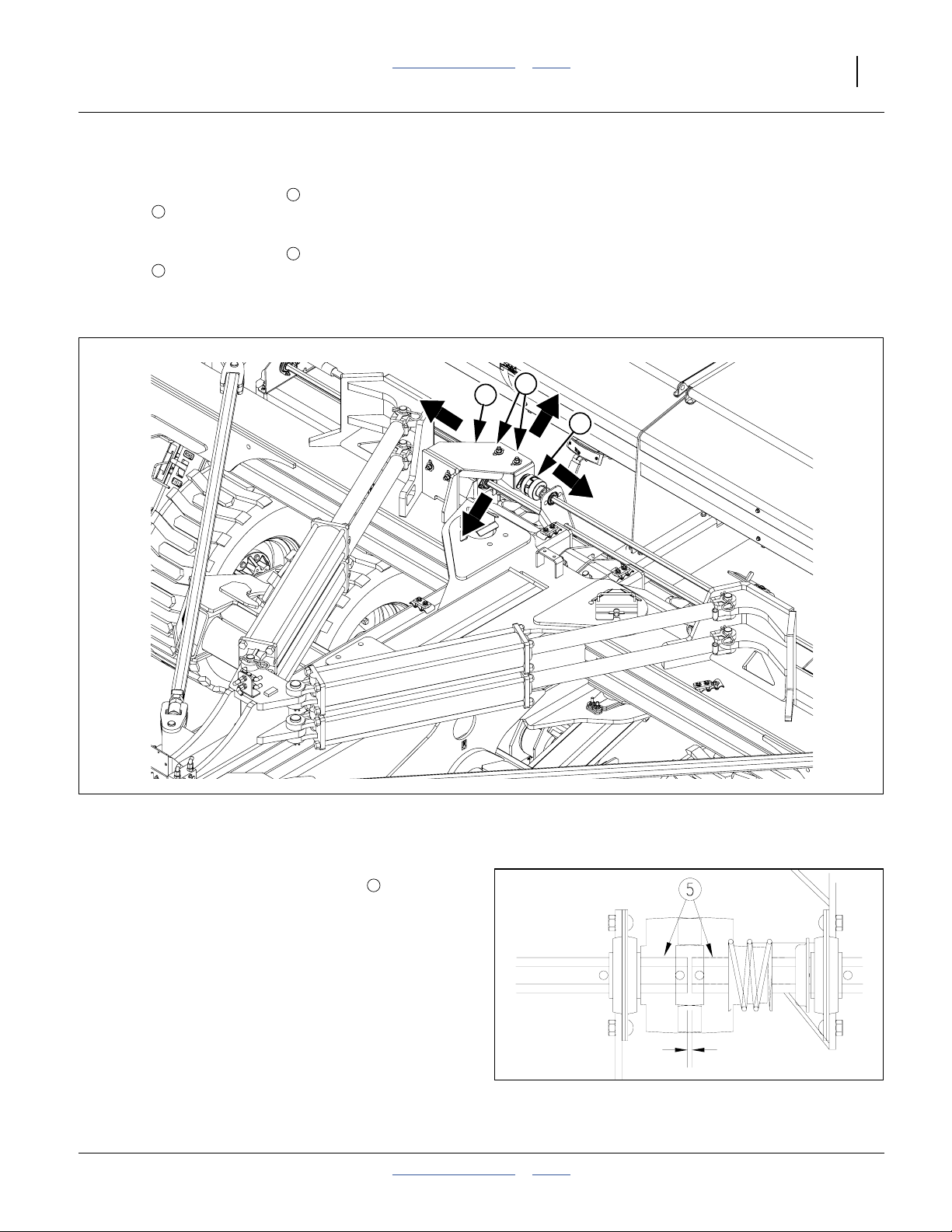

Refer to Figure 8

2. To align the clutch jaws vertically, loosen the two

5

⁄8inch bolts on the backside of the adjustment

bracket . Slide the bracket up or down in the

1

2

desired direction.

7

⁄8inch (19 mm)

2

1

Figure 7

34381

Transfer Drive Shaft Vertical Adjustment

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 19

Refer to Figure 8

3. To align the clutch jaws from front to rear, loosen the

1

⁄2inch carriage bolts and slide breakaway

two

clutch in the desired direction.

4

3

4. To adjust clutch jaws for full jaw contact, loosen the

two1⁄2inch carriage bolts and slide breakaway

clutch until jaws on the fixed half of clutch make

4

3

full contact with jaws on spring loaded half of clutch

without compressing clutch spring.

3

2

4

Figure 8

34381

Transfer Drive Shaft Vertical Adjustment

Refer to Figure 9

Note: The two

1

⁄8inches (3.2 mm) between them when the clutch

7

⁄8inch (19 mm) hex shafts should have

5

jaws have full contact.

1/8in (3.2mm)

Figure 9

18955

Hex Shafts

2012-08-14 Table of Contents Index 195-325M

20 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

Hitching Tractor to Drill

Crushing Hazard:

Do not stand or place any part of your body between planter

and moving tractor. You may be severely injured or killed by

being crushed between the tractor and planter. Stop tractor

engine and set park brake before installing the hitch pin.

Transport Hazard:

This drill can have positive and negative tongue weight, which

can work the hitch pin loose during transport. To avoid serious

injury or death due to a road accident, always use a clevis

hitch or clevis drawbar with a locking-style hitch pin.

1. Choose a drill-hitch option that is compatible with

your tractor drawbar.

The 3S-5000/F/HD/HDF has three hitch options:

• a clevis hitch,

• a small-hole, single-strap hitch or

• a large-hole, single-strap hitch.

Use the clevis hitch with tractors that have

single-tang draw bars. Use the single-strap hitch for

tractors with clevis draw bars. Always use a

locking-style hitch pin sized to match the holes in the

hitch and drawbar.

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 21

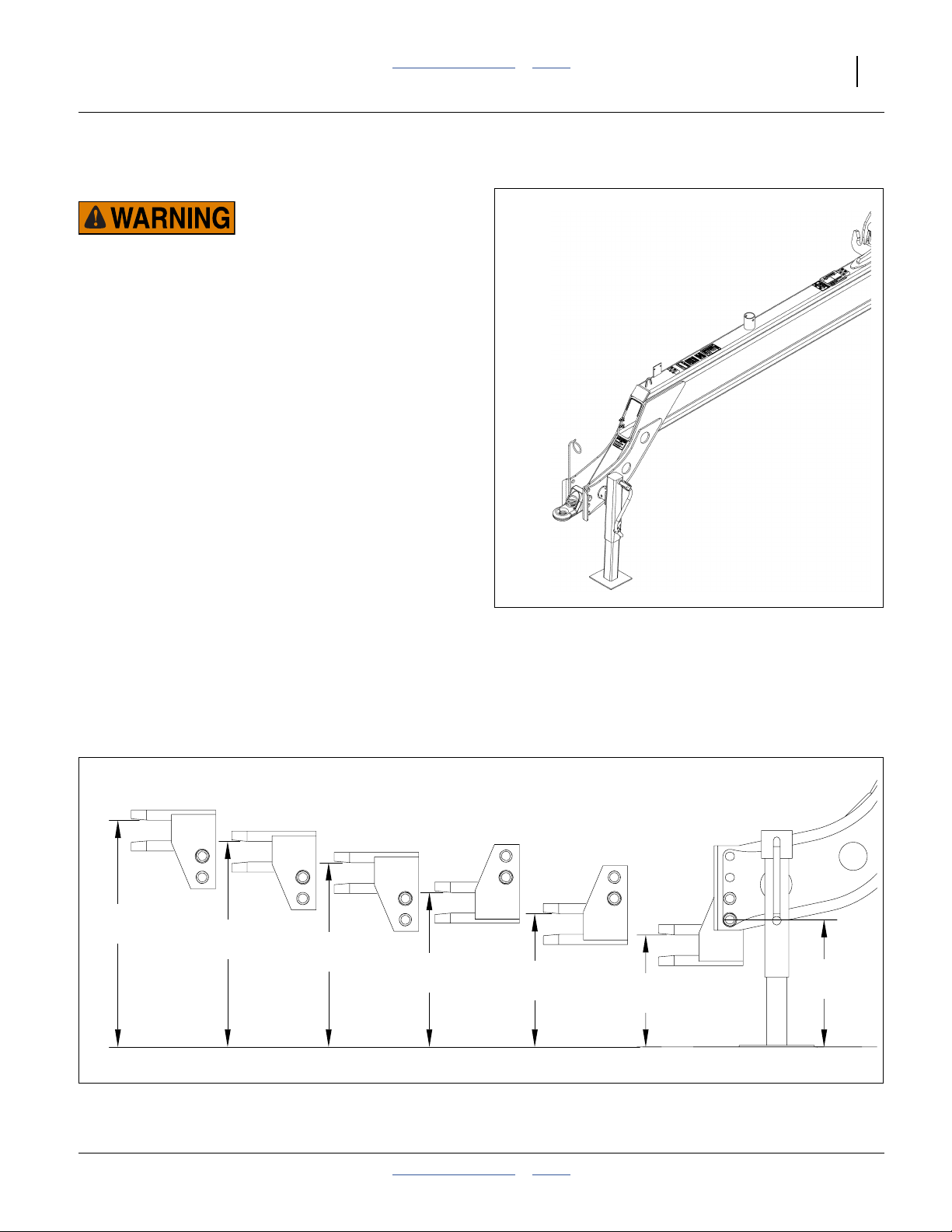

Adjusting the Drill Hitch

Refer to Figure 10 and Figure 11

Crushing Hazard:

You may be severely injured or killed by being crushed

between the tractor and drill. Do not stand or place any part of

your body between machines being hitched. Stop tractor

engine and set parking brake before installing hitch pin.

2. To adjust the drill hitch to match your tractor-drawbar

height, mount tongue jack on side of tongue. Use

jack to raise drill tongue so lowest hitch hole is

18 inches off ground.

Note: When hitching drill to a different tractor, check for a

difference in drawbar heights. If heights are

different, readjust hitch height accordingly.

3. Securely attach safety chain to an anchor on a

tractor capable of pulling the drill.

4. Store jack on top of tongue.

5. Plug drill electrical lead in tractor seven-pin

connector. If your tractor is not equipped with a

seven-pin connector, contact your dealer for

installation.

32.0 inch

(81.3cm)

29.0 inch

(73.7cm)

Figure 10

34349

Jack In Lifting Location

26.0 inch

(66.0cm)

HITCH HEIGHTS AT VARIOUS POSITIONS CORRECT TONGUE HEIGHT

21.5 inch

(54.6cm)

18.5 inch

(47.0cm)

15.5 inch

(39.4cm)

18.0 inch

(45.7cm)

Figure 11

34232

Hitch Heights

2012-08-14 Table of Contents Index 195-325M

22 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

Hydraulic Hose Hookup

High Pressure Fluid Hazard:

Relieve pressure before disconnecting hydraulic lines.

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Use a piece of paper

or cardboard, NOT BODY PARTS, to check for leaks. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. If an accident occurs, seek immediate

medical attention from a physician familiar with this type of

injury.

To run drill on tractors with open center hydraulics or on

tractors with fixed-displacement hydraulic pumps, you must

install a Great Plains kit, part number 194-143A. If you are

not familiar with your tractor hydraulics, consult your tractor

dealer.

Refer to Figure 12

Great Plains hydraulic hoses have color coded handle

grips to help you hookup hoses to your tractor outlets.

Hoses that go to the same remote valve are marked with

the same color.

Current Style Color Coded Hose Handles

Color Hydraulic Function

Red Opener Lift Cylinders

Blue Transport Lift Cylinders

Gray Fold Cylinders

Green Marker Cylinders

To distinguish hoses on the same hydraulic circuit, refer

to the symbol molded into the handle grip. Hoses with an

extended-cylinder symbol feed cylinder base ends.

Hoses with a retracted-cylinder symbol feed cylinder rod

ends.

1. Connect opener-lift hoses to circuit designated for

hydraulic-motor control.

2. Connect transport-lift hoses to tractor remote valve.

3. Connect fold hoses to tractor remote valve.

Note: If your tractor has only two remote valves, you must

install a double-selector valve to combine the

transport-lift and opener-lift circuits. See “Two

Outlet Hydraulic Kit” on page 78.

Figure 12

Color Coded Hose Handles

31733

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 23

Operating Instructions

This section covers general operating procedures.

Experience, machine familiarity, and the following

information will lead to efficient operation and good

working habits. Always operate farm machinery with

safety in mind.

Pre-Start Checklist

Perform the following steps before transporting the

3S-5000/F/HD/HDF Drill to the field.

❑ Carefully read “Important Safety Information” on

page 1.

❑ Lubricate planter as indicated under “Lubrication”

on page 68.

❑ Check all tires for proper inflation. See

“Specifications and Capacities” on page 79.

❑ Check all bolts, pins, and fasteners. Torque as

shown in “Torque Values Chart” on page 84.

❑ Check planter for worn or damaged parts. Repair or

replace parts before going to the field.

❑ Check hydraulic hoses, fittings, and cylinders for

leaks. Repair or replace before going to the field.

❑ Perform all beginning-of-season and daily service

items under “Maintenance” on page 59.

High Pressure Fluid Hazard:

Relieve pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. Escaping fluid under

pressure can have sufficient pressure to penetrate the skin

causing serious injury. If an accident occurs, seek immediate

medical assistance from a physician familiar with this type of

injury.

2012-08-14 Table of Contents Index 195-325M

24 3S-5000/F/HD/HDF Table of Contents Index Great Plains Manufacturing, Inc.

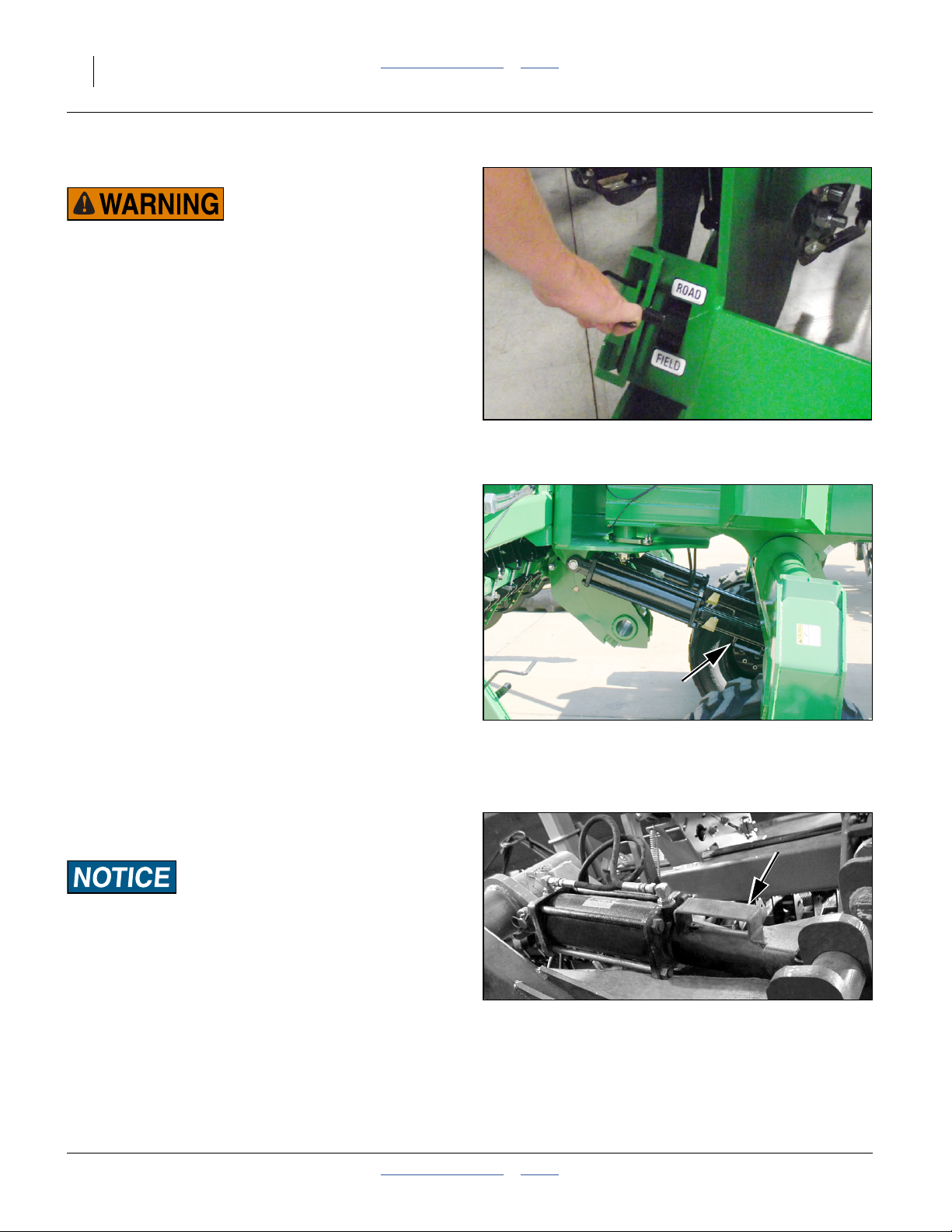

Folding

Crushing Hazard:

Bystanders could be crushed between the folding drill boxes

and the drill tongue. To avoid serious injury or death, keep all

bystanders well away during drill operation.

1. Park tractor and drill on level ground with tractor

transmission in park. Be aware of clearance needed

to fold drill.

2. Fold up markers.

Refer to Figure 13

3. Position opener lock handles in road position and

completely raise openers.

Note: The opener transport lock handles are spring

loaded and can be moved to ROAD position with

openers up or down, but locks will only engage

when openers are completely raised. There are

two locks on each drill section (six total).

4. Make sure transport lift cylinders and front box lift

cylinder are completely retracted.

5. Slowly supply oil to rod end of fold circuit.

Completely fold wing frames until both wing gauge

wheels contact tongue tube.

6. Supply oil to transport lift circuit until transport lift

cylinders and front box lift cylinder are completely

extended and drill is completely raised.

Refer to Figure 14 and Figure 15

7. Rotate cylinder lock channels over rods on the two

transport lift cylinders and the front box lift cylinder.

Figure 13

Opener Lock Up

Figure 14

Transport Lift Cylinder Lock

34294

34321

The channels will remain in position when cylinders settle

against channels.

8. Allow transport lift cylinders to settle back against

lock channels.

9. Before transporting, check that hydraulic cylinders

are holding lock channels securely.

Figure 15

18959

Front Box Lift Cylinder Lock

195-325M Table of Contents Index 2012-08-14

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 25

Unfolding

Crushing Hazard:

Bystanders could be crushed between the folding drill boxes

and the drill tongue. To avoid serious injury or death, keep all

bystanders well away during drill operation.

1. Park tractor and drill on level ground with tractor

transmission in park. Be aware of clearance needed

to unfold drill.

2. Supply oil to transport lift circuit until transport lift

cylinders and front box lift cylinder are completely

extended and drill is raised completely.

Refer to Figure 16 and Figure 17

3. Rotate cylinder lock channels off cylinder rods of

transport lift cylinders and front box lift cylinder.

4. Completely retract transport lift cylinders and front

box lift cylinder.

5. Slowly supply oil to base end of fold circuit. Unfold

wing frames by completely extending fold cylinders.

Refer to Figure 18

6. Position opener transport lock handles in FIELD

position.

7. Completely raise openers to allow opener transport

locks to disengage.

Note: The opener transport lock handles are spring

loaded and can be moved to field position with

openers up or down, but locks will only disengage

when openers are completely raised. There are

two lock handles on each drill section (6 total).

Figure 16

Transport Lift Cylinder Lock

Figure 17

Front Box Lift Cylinder Lock

34321

18959

Folding and Unfolding Quick Reference

To Fold Drill

1. Fold markers.

2. Raise openers.

3. Fold drill.

4. Extend transport and front box lift cylinders.

5. Lock transport and front box lift cylinders.

To Unfold Drill

1. Completely extend transport and front box lift

cylinders.

2. Unlock transport and front box lift cylinders.

3. Retract transport and front box lift cylinders.

4. Unfold drill.

5. Lower openers.

2012-08-14 Table of Contents Index 195-325M

Figure 18

Opener Unlock

34286

Loading...

Loading...