Great Plains 3S-5000HD User Manual

Table of Contents Index

Installation Instructions

133-373A, 133-374A, 133-375A,

133-376A, 133-377A and 133-378A

3S-5000HD and 3S-5000HDF Drills

Small Seeds Options

for 3S-5000, 3S-5000F,

Manufacturing, Inc.

www.greatplainsmfg.com

Read the installation manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without exception.

Your life and the lives of others depend on it!

34583

Cover illustration shows only selected components for one section of one 3S-5000 kit.

Manual illustrations may show similar 3S-2600, 3S-3000 or 3S-4000 models where

installation details are identical for the immediate topic.

ORIGINAL INSTRUCTIONS

© Copyright 2013 Printed 2013-07-30 133-415M

Table of Contents Index

EN

Table of Contents Index

Table of Contents Index

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information......................................1

Introduction ..................................................................3

Description of Unit..........................................................3

Compatible Drills............................................................3

Compatible Kits..............................................................3

Document Family ...........................................................3

Using This Manual..........................................................4

Definitions...................................................................4

Call-Outs ....................................................................4

Owner Assistance ..........................................................4

Installation Instructions...............................................5

Before You Start.............................................................5

Tools Required...............................................................5

Prepare Drill ...................................................................5

Other Options.................................................................5

Remove Corner Hardware .............................................6

Left Section Corner Hardware....................................6

Center Section Corner Hardware...............................6

Right Section Corner Hardware..................................6

Remove Section Centers Fittings...................................7

Center Section: Remove SMV....................................7

Wings: Remove Fasteners.........................................7

Remove Walkboards......................................................8

Install Walkboard Extensions.........................................9

Install LH End Extension ............................................9

Install RH Center Extension .......................................9

Install LH Center Extension........................................9

Install RH End Extension............................................9

Install Mounts & Meter Drives ......................................10

Install Left Mounts ....................................................10

Install Section Center Mounts...................................11

Install Meter Drives...................................................12

Install Forward Components ........................................12

Front Drives without Fertilizer...................................13

Clutch Bearing Plate Components .......................13

Front Drive, Left Section ......................................15

Front Drive, Center and Right Sections ...............16

Align Jackshafts ...................................................17

Front Drives with Fertilizer ....................................... 18

Small Seeds Drive Chains .......................................20

Install Seed Boxes.......................................................22

Identify Box Assemblies...........................................22

Remove Wind Shields..............................................23

Mount Seed Boxes.......................................................23

Mount a RH Box Assembly...................................... 23

Place Coupler...........................................................24

Mount a LH Box Assembly.......................................24

Pin Coupler ..............................................................25

Synchronize Meters .................................................25

Check/Set RH Meters at 50% ..............................25

Adjust LH Shaft to 50%........................................25

Secure Coupler........................................................ 25

Install Guards and Corner Fittings ...........................26

Left Box End Fittings............................................26

Right Box End Fittings.......................................... 27

Install Meter Shaft Chains........................................27

Install Seed Tubes.......................................................28

Delivery Tube - No Fertilizer .................................... 28

Delivery Tube - with Fertilizer...................................28

Install Drop Tubes (all Kits)......................................29

Re-Install Walkboards..................................................30

Re-Install SMV Reflector..............................................30

Re-Install Wind Shields................................................31

Close-Out.....................................................................31

Torque Values..............................................................32

Part Lists......................................................................33

Existing Parts Affected.............................................33

New Parts.................................................................34

Abbreviations...............................................................36

Index............................................................................ 37

© Copyright 2008, 2012, 2013 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication“as is” without warrantyofanykind,eithere xpressedorimplied.Whilee v eryprecaution has been

takeninthe preparation of this manual, Great Plains Manufacturing,Inc. assumes no responsibility forerrors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing,Inc. reserves the rightto revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2013-07-30 Cover Index 133-415M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator,Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel,Turbo-Chopper, TurboMax, Turbo-Till, Ultra-Till, Verti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

iv 3S-5000/F/HD/HDF SGS Table of Contents Index Great Plains Manufacturing, Inc.

133-415M Table of Contents Index 2013-07-30

Great Plains Manufacturing, Inc. Table of Contents Index 1

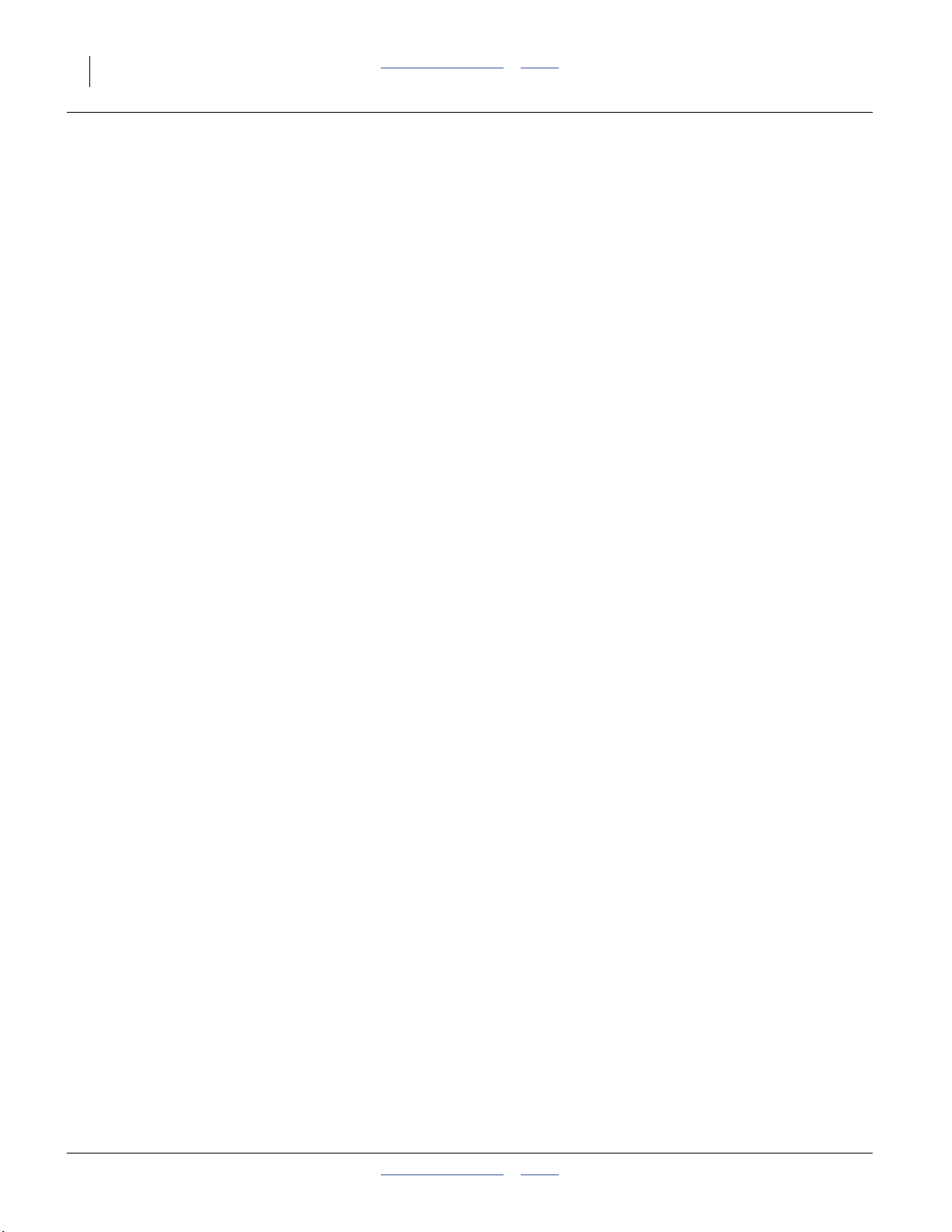

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided,will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Because prolonged exposure to loud noise can cause

hearing impairment or hearing loss, wear suitable hearing

protection such as earmuffs or earplugs.

▲ Because working on equipment safely requires your full

attention, avoid wearing entertainment headphones while

perform the installation.

2013-07-30 Table of Contents Index 133-415M

2 3S-5000/F/HD/HDF SGS Table of Contents Index Great Plains Manufacturing, Inc.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” in the Operator

manual.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

Avoid High Pressure Fluids

Observe normal precautions for hitch hydraulic

connections and disconnections. Escaping fluid under

pressure can penetrate the skin, causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Lower the drill, put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on drill.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from drill before

operation.

Safety At All Times

▲ Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on the

safety decals.

▲ Be familiar with all implement functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave implement unattended with tractor engine

running.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.Introduction

133-415M Table of Contents Index 2013-07-30

Great Plains Manufacturing, Inc. Table of Contents Index 3

Introduction

Description of Unit

These field-installed kits add small seeds planting

capability to the 3S-5000 family of 50-foot 3-section

drills. There are separate kits for drills with and without

fertilizer capability. There are separate kits for each row

spacing.

Compatible Drills

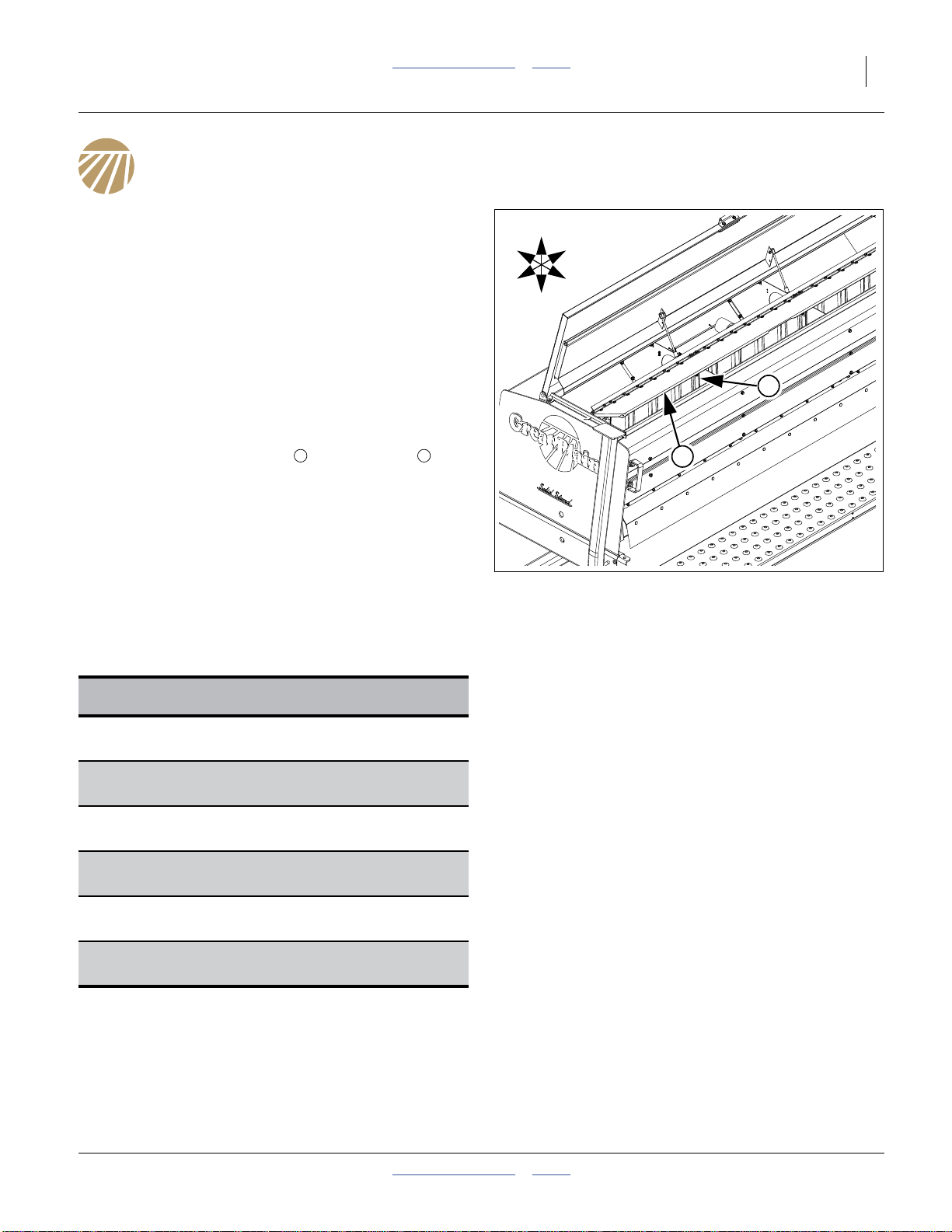

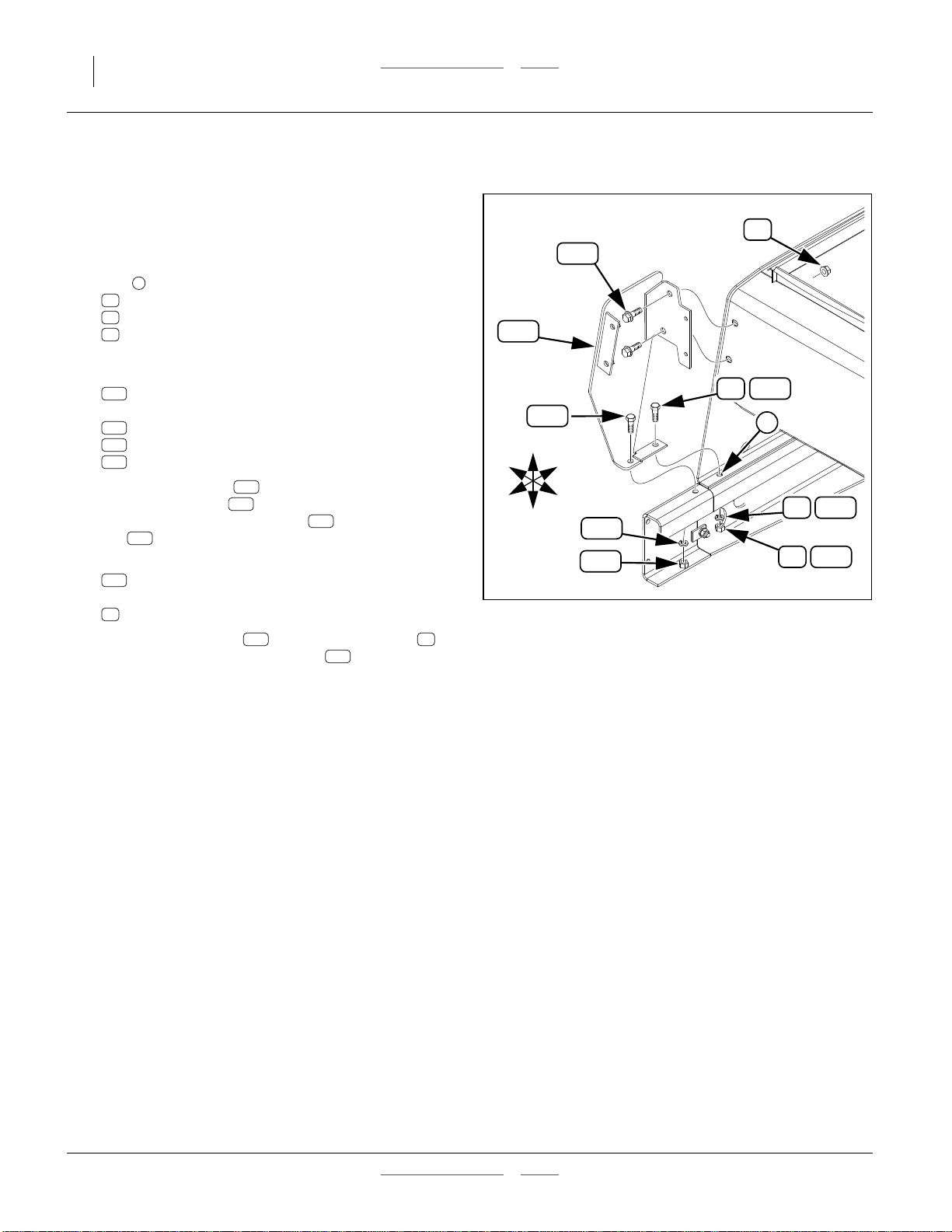

Refer to Figure 1, which depicts the left drill section.

Components on center and right sections are similar.

Before installing any of these kits, inspect a seed box on

any drill section, and the serial number plate.

• If the seed box has a divider and second lid , it is

a Fertilizer model, and must use a “

specifically for a 3S-5000F or 3S-5000HDF model.

These kits rely on drive components present only on

Fertilizer models.

• If the boxes lack dividers and second lids, the drill

must use a standard (“non-fertilizer” “SMALL SEEDS” kit.

1 2

FERT” kit

Compatible Kits

U

F

L

R

B

D

Figure 1:

Fertilizer Drill

Document Family

1

2

34584

Part

Number

133-373A

133-374A

133-375A

133-376A

133-377A

133-378A

Each kit updates one drill.

Description

and Compatible Drill Model

3S-5000 10" SMALL SEEDS BUNDL

for 3S-5000-6010, 3S-5000HD-6010

3S-5000 7.5" SMALL SEEDS BUNDL

for 3S-5000-8075, 3S-5000HD-8075

3S-5000 6" SMALL SEEDS BUNDL

for 3S-5000-1006, 3S-5000HD-1006

3S-5000 6" FERT SM SEEDS BUNDL

for 3S-5000F-1006, 3S5000HDF-1006

3S-5000 7.5" FERT SM SEED BNDL

for 3S-5000F-8075, 3S5000HDF-8075

3S-5000 10" FERT SM SEED BNDL

for 3S-5000F-6010, 3S5000HDF-6010

133-415M Installation, Operation and Maintenance

(this document)

195-325B Multiple Drill Family Seed Rate Manual

195-325M 3S-5000/F/HD/HDF Operator Manual

195-325P 3S-5000/F/HD/HDF Parts Manual

The information in this manual is current at printing.

Some parts may change to assure top performance.

2013-07-30 Table of Contents Index 133-415M

4 3S-5000/F/HD/HDF SGS Table of Contents Index Great Plains Manufacturing, Inc.

Using This Manual

This manual familiarizes you with safety, assembly,

operation, adjustments and maintenance. Follow the

recommendations to help ensure safe and efficient

operation.

Definitions

The following terms are used throughout this manual.

Note: Paragraphs in this format provide useful

information related to the current topic.

Liability, Economic and Results Risks:

Paragraphs in this format present a crucial point of information

related to the curr ent topic. Read and follow the directions to:

remain safe, avoid serious damag e to equipment and ensure

desired field results.

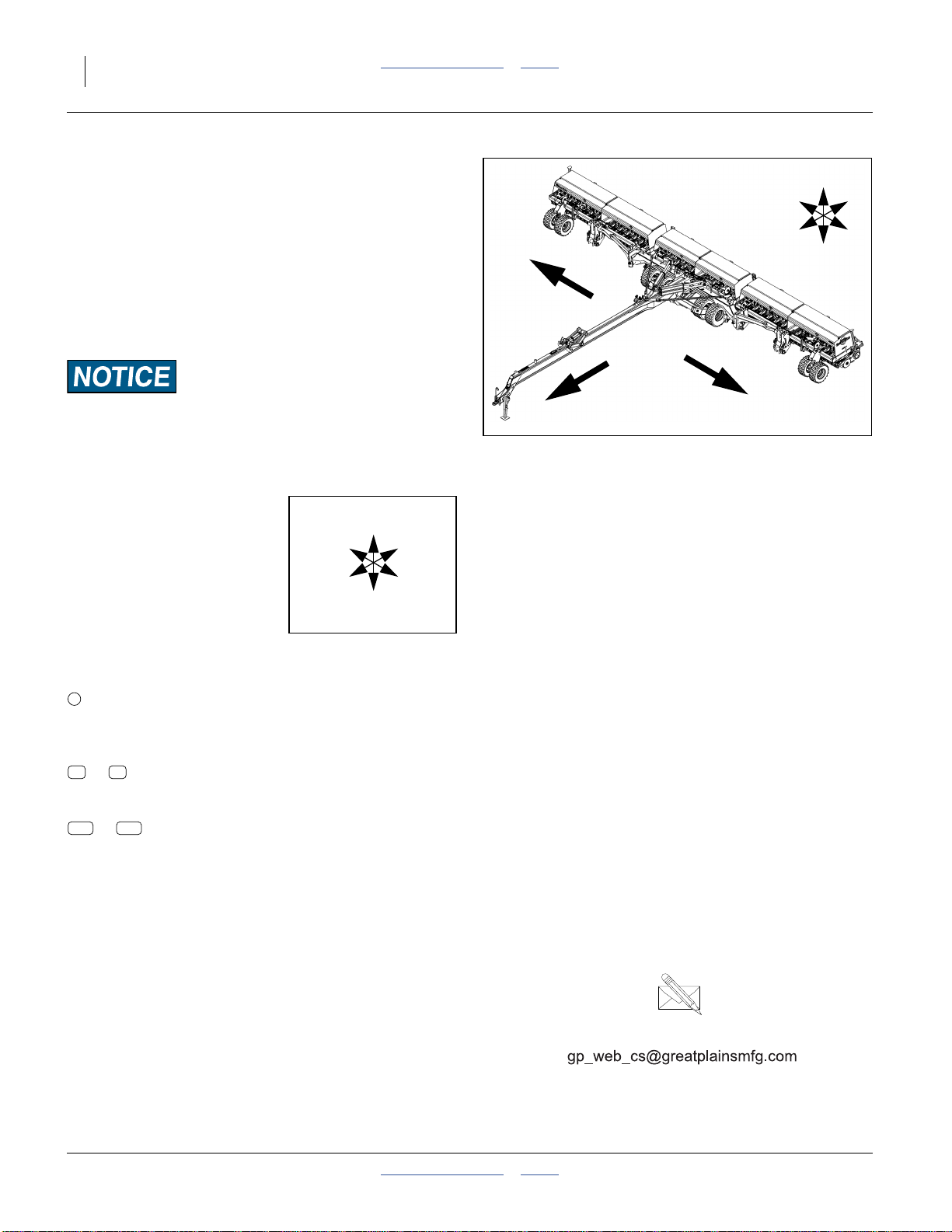

Right-hand and left-hand as

used in this manual are

determined by facing the

direction the machine will

travel while in use unless

otherwise stated.

An orientation rose (shown at

right) depicts Up, Right, Back,

Down, Left and Front.

Call-Outs

1

11

to

101 267

to

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts in the range 11 to 30

30

reference existing parts removed and

reused. They are listed on page 33.

Three-digit callouts in the range 101 to 267

reference new parts from the new parts list

beginning on page 34. The descriptions

match those on the parts, cartons, bags or

item tags, as well as descriptions your

updated Parts Manual.

U

F

L

R

B

D

U

R

F

R

B

L

D

L

Figure 2:

3S-5000 Drill

34310

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products. Your machine’s parts were specially designed

and should only be replaced with Great Plains parts.

Record your small seeds option kit model number here

for quick reference:

Model Number:__________________________

Date Purchased: __________________________

Your Great Plains dealer wants you to be satisfied with

your updated machine. If you do not understand any part

of this manual or are not satisfied with the service

received, please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any

problems so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060 Salina, KS 67402-5060

785-823-3276

133-415M Table of Contents Index 2013-07-30

Great Plains Manufacturing, Inc. Table of Contents Index 5

Installation Instructions

Before You Start

Most accidents are the result of negligence and

carelessness, usually caused by failure of the operator to

follow simple but necessary safety precautions. Allow no

one to install the small seeds option before carefully

reading this manual.

Some fasteners may be loosely assembled. Remove

them before mounting that component. Due to evolving

manufacturing practices, some sub-assemblies may

already be completely pre-assembled. If so, check that

fasteners are tight, and skip the unneeded assembly

steps.

Tools Required

• a lift or hoist with a 150 pound (68 kg) capacity

• basic hand tools, including hose clamp pliers

• scaffold or ladder

Torque values for fasteners are shown on page 32.

1. Read and understand “Important Safety

Information” starting on page 1.

2. Ensure drill is compatible with kit. See page 3.

Prepare Drill

3. Clean-out the Fertilizer box, or Seed box if no

Fertilizer box is present, per the instructions in the

current drill Operator Manual.

4. Positionthe drill in a well lighted location suitable for

the installation. A clear surface beneath makes it

easier to recover any dropped parts.

5. Partially unfold the drill, to allow access to

walkboard mount hardware.

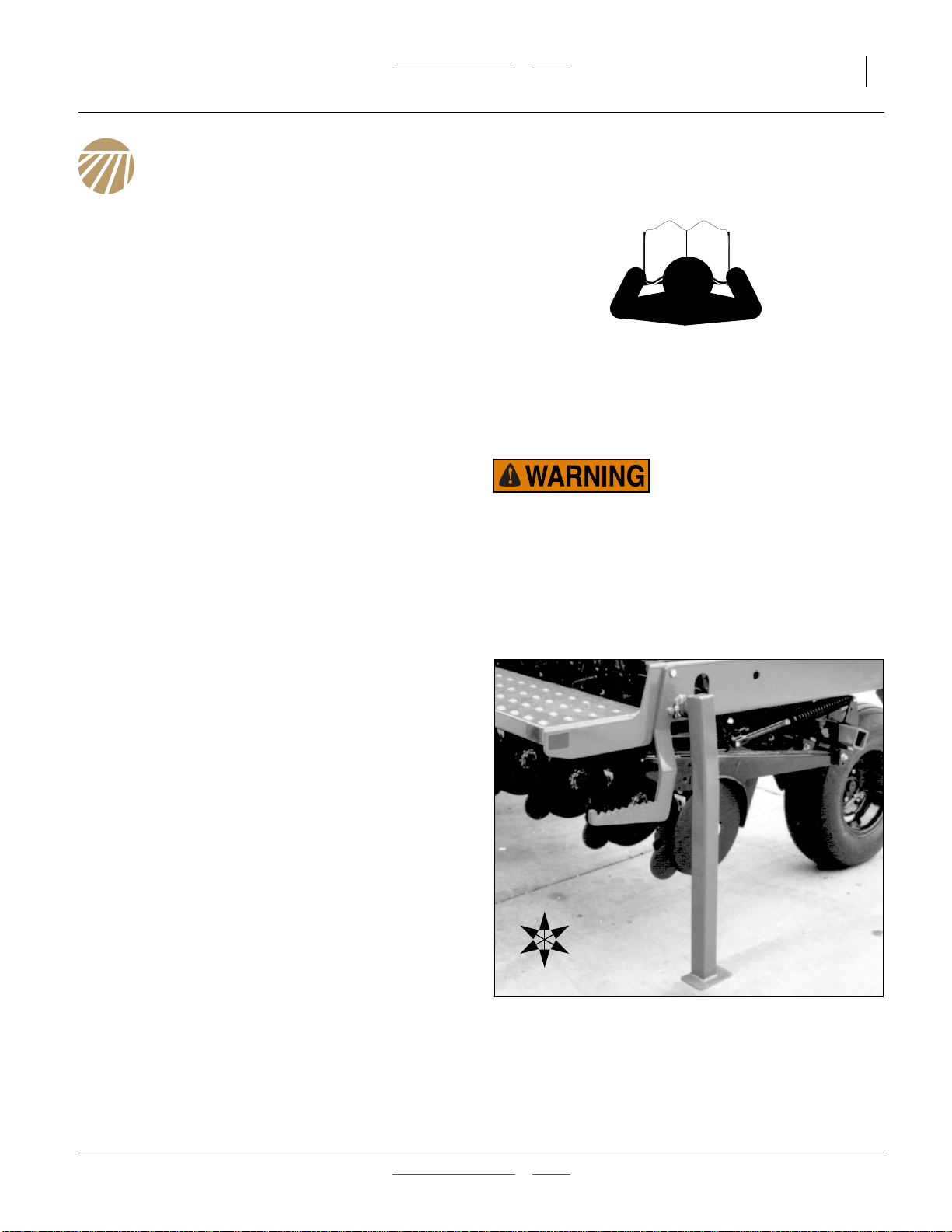

Refer to Figure 3

6. Deploy all parking stands provided with the drill.

7. Lower the drill.

Lower the openers.

Negative Tongue Weight:

Drill must be only partially unfolded, or hitched to a tractor,

or fully lowered, with any parking stands installed, before

commencing work. A fully unfolded raised drill can have a

negative tongue weight of up to 1300 pounds.

U

L

F

Other Options

8. If also installing any main seed box options, install

them before Small Seeds. If this is a new delivery,

defer installation of press wheels and other row unit

options until after installing Small seeds. If also

installing markers, install them after Small Seeds.

9. Swing down the walkboard ladders (if installed).

2013-07-30 Table of Contents Index 133-415M

B

D

R

Figure 3:

Drill Parking Stand

15565

6 3S-5000/F/HD/HDF SGS Table of Contents Index Great Plains Manufacturing, Inc.

Remove Corner Hardware

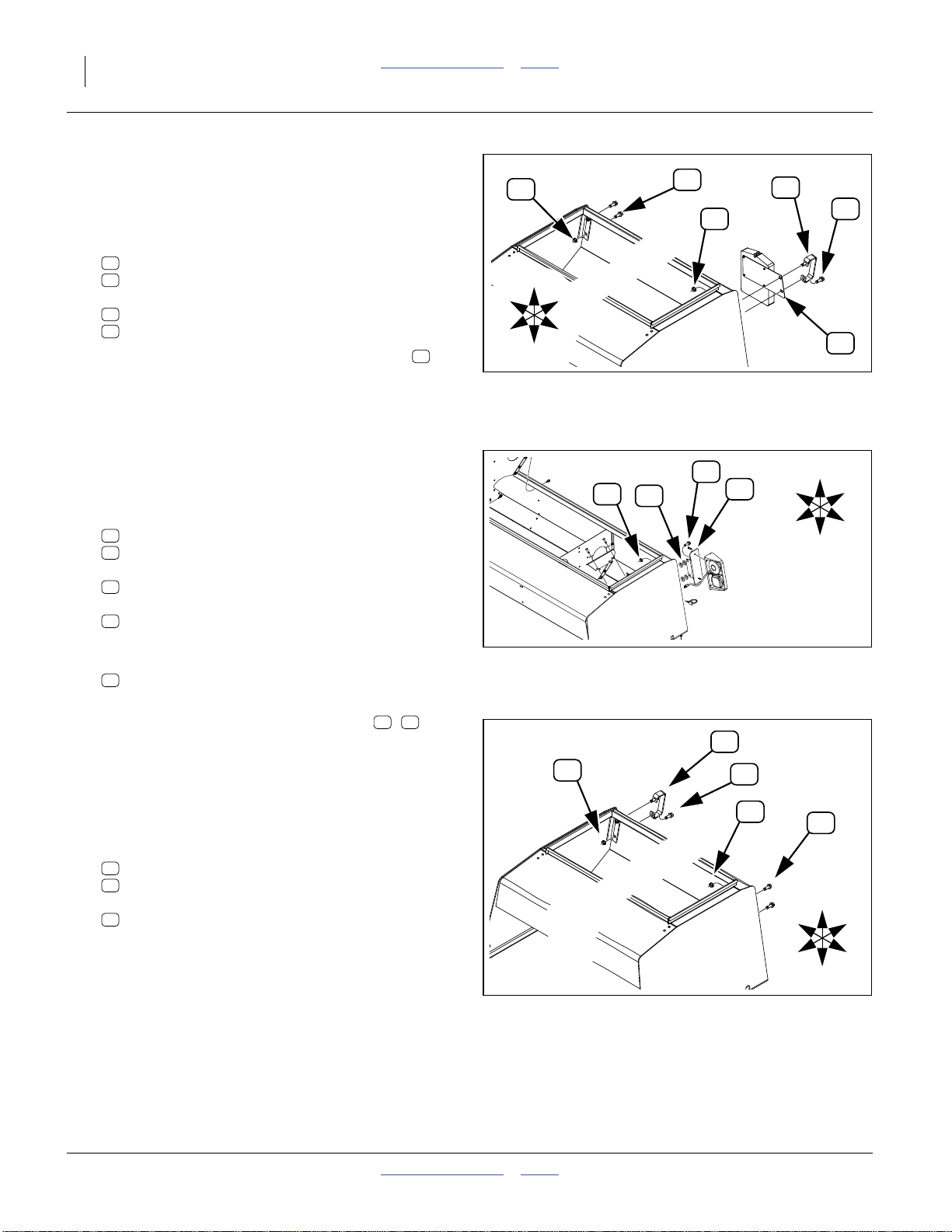

Left Section Corner Hardware

Refer to Figure 4

10. Remove and save two pairs of:

22

803-169C NUT HEX FLG LOCK 1/2-13 PLT

18

802-203C HFSS 1/2-13X1 1/2 GR5

and one each:

11

119-190D HANDLE

15

248-251D MANUAL PAK MOUNTING PLATE

Note: Do not further disassemble the manual pak .

15

R

F

22

18

22

U

B

L

D

11

18

15

Center Section Corner Hardware

Refer to Figure 5 (depicting the LH corner)

11. At the left end of the center section seed box,

remove and save two sets of:

22

803-169C NUT HEX FLG LOCK 1/2-13 PLT

18

802-203C HFSS 1/2-13X1 1/2 GR5

four pairs (8 total):

26

804-016C WASHER FLAT 1/2 SAE PLT

and one:

12

195-417D (LH) 15’3SMT LIGHT BRACKET (LH)

Mark the assembly as “LH” when removed.

12. Repeat step 11 for the right corner and:

13

195-417D (RH) 15’3SMT LIGHT BRACKET (RH)

Mark the assembly as “RH” when removed.

Note: Do not further disassemble the lights ( , ).

Their cables may be left connected if there is

convenient location to position them during the

remainder of the installation.

12 13

Right Section Corner Hardware

Refer to Figure 6

13. Remove and save two pairs of:

22

803-169C NUT HEX FLG LOCK 1/2-13 PLT

18

802-203C HFSS 1/2-13X1 1/2 GR5

and one:

11

119-190D HANDLE

Figure 4:

Left Section Corner Hardware

18

22

26

Figure 5:

Center Section Corner Hardware

12

11

22

18

22

R

F

R

27431

U

B

L

D

34243

18

U

B

F

L

D

Figure 6:

Right Section Corner Hardware

133-415M Table of Contents Index 2013-07-30

27431

Great Plains Manufacturing, Inc. Table of Contents Index Installation Instructions 7

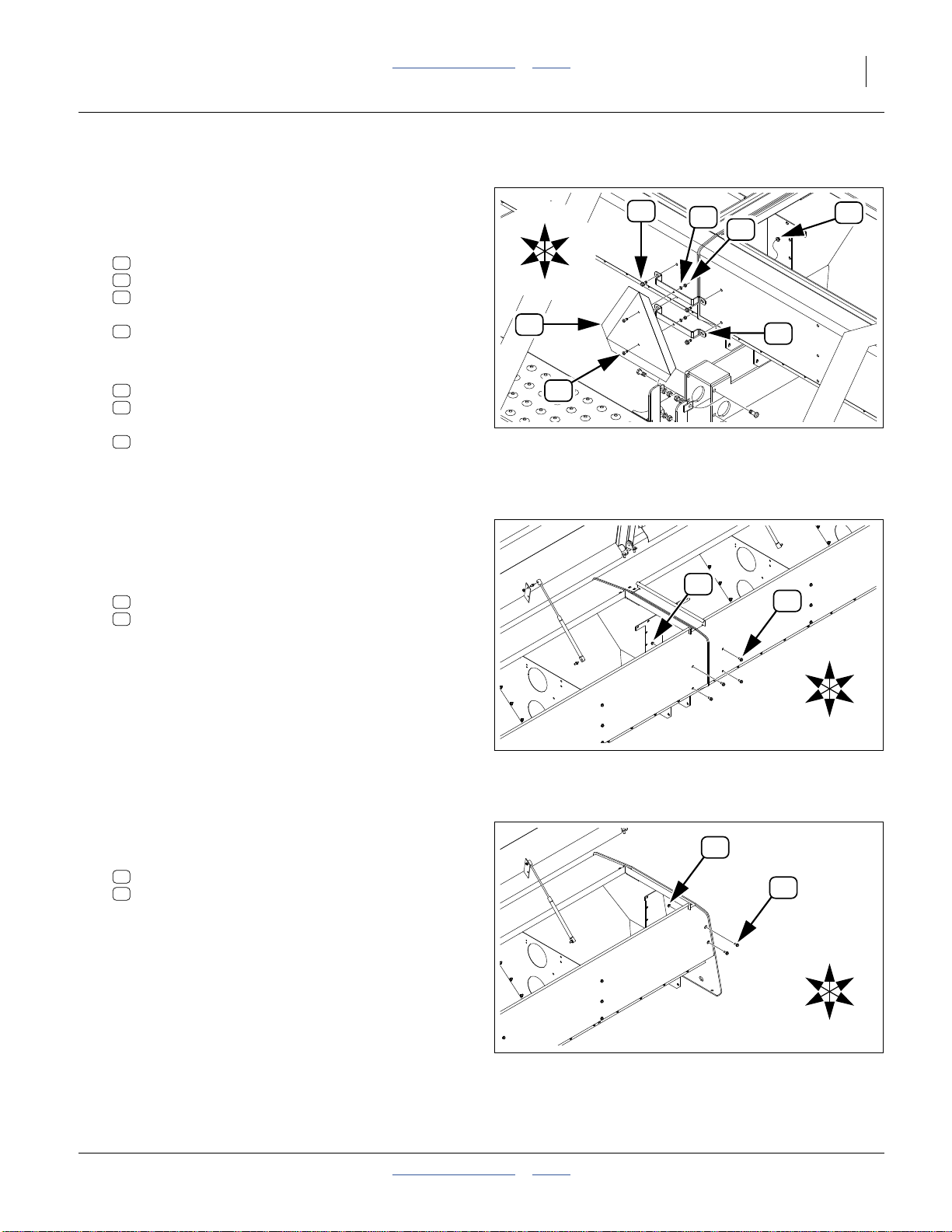

Remove Section Centers Fittings

Center Section: Remove SMV

Refer to Figure 7

14. Remove and save two sets of fasteners:

20

803-006C NUT HEX 1/4-20 PLT

24

804-006C WASHER LOCK SPRING 1/4 PLT

16

802-004C HHCS 1/4-20X3/4 GR5

and one:

30

818-055C DECAL SLOW MOVING-GALV. BACKED

The SMV is re-installed at step 131 on page 30.

15. Remove four sets of fasteners:

23

803-199C NUT HEX FLANGE 5/16-18 PLT

19

802-387C HFS 5/16-18X3/4 GR5

and two:

14

195-420D DECAL BRACKET

The brackets are not re-used. The fasteners are

replaced with identical new parts from the kit.

Wings: Remove Fasteners

Refer to Figure 8

16. At the rear center of each wing box, remove four

sets:

23

803-199C NUT HEX FLANGE 5/16-18 PLT

19

802-387C HFS 5/16-18X3/4 GR5

These fasteners are replaced with identical new

parts from the kit.

L

B

30

U

D

16

F

R

19

Remove SMV

24

Figure 7:

23

20

14

19

23

34306

U

F

R

Refer to Figure 9

17. At the inside end of each wing box, remove and

save two sets:

22

803-169C NUT HEX FLG LOCK 1/2-13 PLT

18

802-203C HFSS 1/2-13X1 1/2 GR5

Figure 8:

Remove Center Fasteners

22

Figure 9:

Remove End Fasteners

18

L

B

D

34585

U

F

L

R

B

D

34585

2013-07-30 Table of Contents Index 133-415M

8 3S-5000/F/HD/HDF SGS Table of Contents Index Great Plains Manufacturing, Inc.

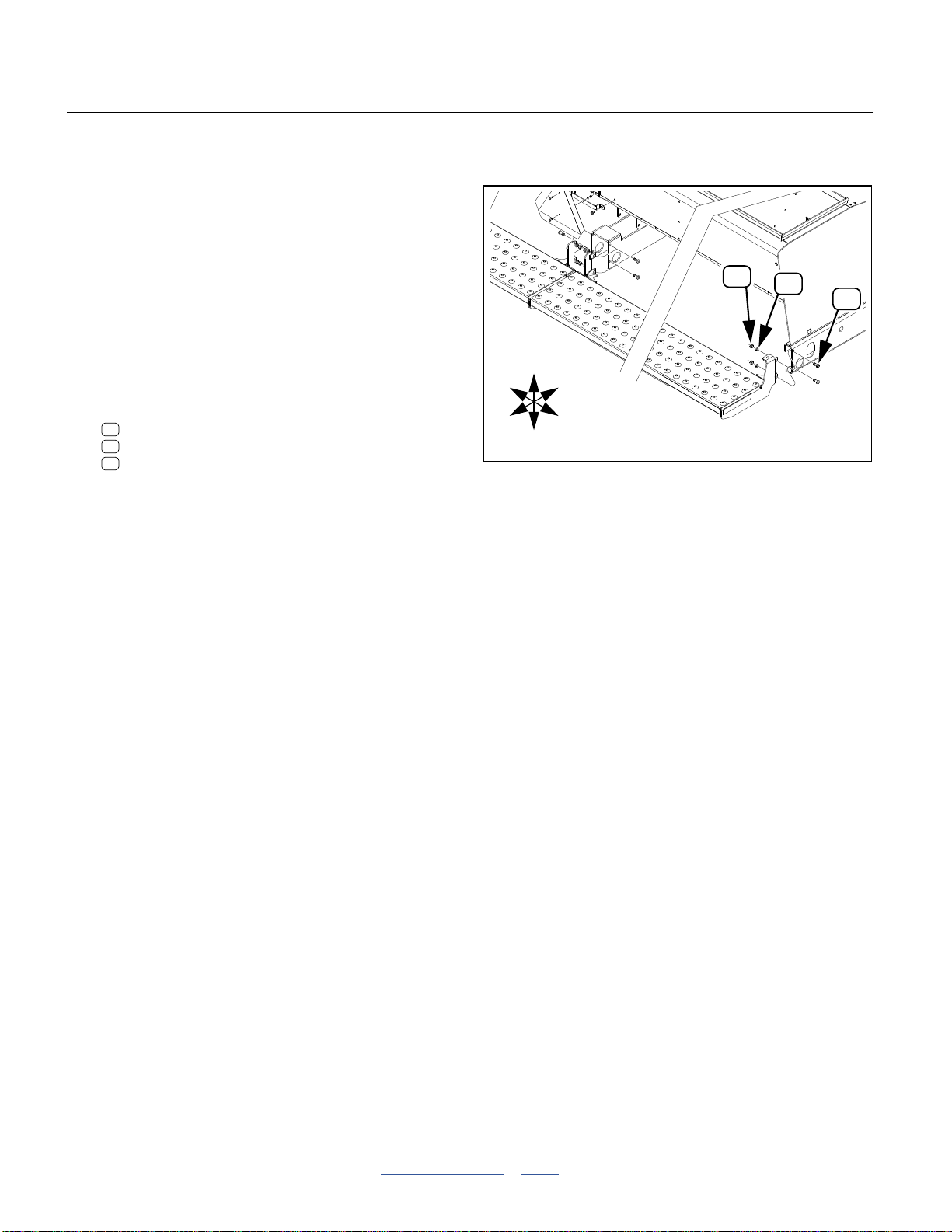

Remove Walkboards

There are two walkboards per section, six total. Due to

length differences, ladders and decals, each is unique to

its section and side of section. Mark each by position to

aid in re-assembly.

Refer to Figure 10

18. Fold ladders (not shown) into storage/transport

position on top of wing walkboards.

Start with the left wing section.

19. Position and attach lift or hoist to support the full

weight of a walkboard.

20. At each end of the walkboard, remove and savetwo

sets:

21

803-020C NUT HEX 1/2-13 PLT

25

804-015C WASHER LOCK SPRING 1/2 PLT

17

802-034C HHCS 1/2-13X1 1/4 GR5

21. Move the walkboard clear of the work area.

Walkboards remain dismounted to ease access to

the rear of the seed boxes. They are re-installed

starting at step 129 on page 30.

L

B

U

F

R

D

Figure 10:

Remove Walkboard

21

25

17

34306

133-415M Table of Contents Index 2013-07-30

Great Plains Manufacturing, Inc. Table of Contents Index Installation Instructions 9

Note:Walkb

)

ith th

Install Walkboard Extensions

These parts move the walkboards back, accounting for

the space consumed by small seeds boxes. Start with

the left section.

Refer to Figure 11

Install LH End Extension

22. Select one new:

181

195-310H WALKBOARD EXTENSION LH

and two sets saved:

17

802-034C HHCS 1/2-13X1 1/4 GR5

25

804-015C WASHER LOCK SPRING 1/2 PLT

21

803-020C NUT HEX 1/2-13 PLT

Align the extension with the box frame channel.

Insert a bolt from the outside, and secure with

lock washer and nut .

17

25 21

Install RH Center Extension

23. Select one new:

182

195-311H WALKBOARD EXTENSION RH

and two sets saved:

17

802-034C HHCS 1/2-13X1 1/4 GR5

25

804-015C WASHER LOCK SPRING 1/2 PLT

21

803-020C NUT HEX 1/2-13 PLT

Align the extension with the tabs to the left of

the center box weldment. Insert a bolt from the

left, and secure with lock washer and nut .

181

182

17

25 21

oard extensions (,

181 182

mount w

double-break (with one hole) side up, and the tabs

forward. The LH version has a tabs to the left,

the RH version has the tabs to the right.

182

181

Install LH Center Extension

24. Select one new:

181

195-310H WALKBOARD EXTENSION LH

and two sets saved:

17

802-034C HHCS 1/2-13X1 1/4 GR5

25

804-015C WASHER LOCK SPRING 1/2 PLT

21

803-020C NUT HEX 1/2-13 PLT

Align the extension with the tabs to the right of

the center box weldment. Insert a bolt from the

right, and secure with lock washer and nut .

181

17

25 21

Install RH End Extension

25. Select one new:

182

195-311H WALKBOARD EXTENSION RH

and two sets saved:

17

802-034C HHCS 1/2-13X1 1/4 GR5

25

804-015C WASHER LOCK SPRING 1/2 PLT

21

803-020C NUT HEX 1/2-13 PLT

Align the extension with the box frame channel.

Insert a bolt from the outside, and secure with

lock washer and nut .

17

25 21

182

e

2013-07-30 Table of Contents Index 133-415M

17

21

25

181

181

Figure 11:

Install Walkboard Extensions (LH Section Shown)

182

182

34587

10 3S-5000/F/HD/HDF SGS Table of Contents Index Great Plains Manufacturing, Inc.

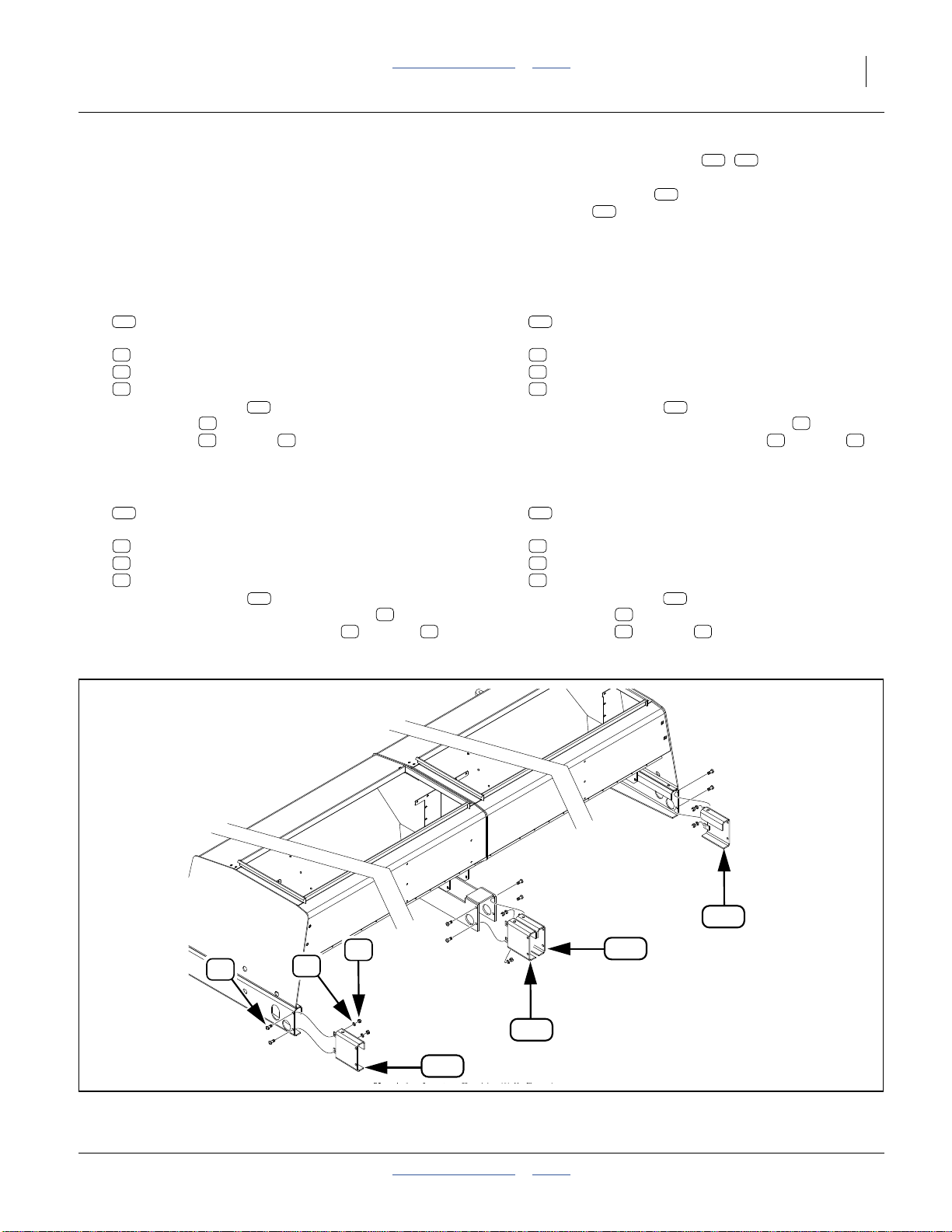

Install Mounts & Meter Drives

Install Left Mounts

Begin with the left drill section.

Refer to Figure 12

26. At the lower rear left corner of the seed box side

27. Select one new:

28. Position the mount over the lower holes and

29. Select two new:

30. Using a flanged bolt and flanged lock nut ,

31. Tighten all fasteners to torque specifications.

Note: The handles, manual pak and lights are not

Repeat step 26 through step 31 for the center and right

drill sections.

1

wall , remove one set:

21

803-020C NUT HEX 1/2-13 PLT

25

804-015C WASHER LOCK SPRING 1/2 PLT

17

802-034C HHCS 1/2-13X1 1/4 GR5

These fasteners are not re-used.

137

133-380H SML SDS LH MOUNT WLDM

and two sets new or saved:

194

802-034C HHCS 1/2-13X1 1/4 GR5

227

804-015C WASHER LOCK SPRING 1/2 PLT

213

803-020C NUT HEX 1/2-13 PLT

137

drop the two bolts in the holes to verify

alignment. Add a lock washer and spin on a

213

nut , finger tight.

202

802-203C HFSS 1/2-13X1 1/2 GR5

and two saved:

22

803-169C NUT HEX FLG LOCK 1/2-13 PLT

secure the top end of the mount to the left rear

corner of the main seed box where the handles,

manual pak or lights were formerly mounted on the

box.

re-installed at this time.

194

204

227

22

137

137

L

B

194

U

D

202

F

R

227

213

Figure 12:

Left Small Seeds Mount

17

22

194

1

25

21

227

213

34588

133-415M Table of Contents Index 2013-07-30

Loading...

Loading...