Page 1

Manufacturing, Inc.

www.greatplainsmfg.com

Seed, Small Seeds and Fertilizer

Rate Charts for the 3S-4010HD

3-Section 40-Foot Heavy Duty Drill

The following pages are to assist in the proper setting of seeding and fertilizer rates for the 3S-4010HD and 3S-4010HDF.

To assure the most accurate seeding rates it is recommended that the drill be calibrated for the desired

seed at the time of planting.

© Copyright 2009 Printed 01/29/2009 196-522B

Page 2

Great Plains Mfg., Inc.

Table of Contents

Introduction ................................................................1

Drill models covered by this manual.............................1

Document Family .........................................................1

Setting Main Box Seed Rate......................................2

Setting Drive Type........................................................3

Changing Drive Type................................................3

Main Box Seed Rate Handle........................................4

Position Seed Cup Doors.............................................4

Main Box Seed Rate Calibration..................................5

Reading a Seed Rate Chart.........................................7

Main Box Seed Rate Charts.........................................8

Alfalfa or Rape.................................................................. 8

Barley (1 of 3) ................................................................... 8

Buckwheat ........................................................................ 8

Buffalograss (1 of 4).......................................................... 9

Flax or Sudan.................................................................... 9

Millet.................................................................................. 9

Milo ................................................................................. 10

Peas................................................................................ 10

Pinto Beans..................................................................... 10

Rice, Short Grain (1 of 2)................................................ 10

Rice, Long Grain (1 of 4)................................................. 11

Rye.................................................................................. 11

Soybeans (1 of 4)............................................................ 12

Sunflower........................................................................ 12

Wheat (1 of 2)................................................................. 13

Wheatgrass..................................................................... 13

Setting Fertilizer Rate ..............................................14

Adjusting for Density ..................................................14

Setting Fertilizer Drive Range ....................................15

Range: Front Sprocket .......................................15

Range: Rear Sprocket........................................15

Changing Range Sprockets....................................15

Setting Fertilizer Transmission...................................16

Fertilizer Rate Calibration...........................................17

Fertilizer Rate Charts, U.S. Customary Units.............19

Fertilizer Rate, 7.5in Row Spacing.........................19

Fertilizer Rate, lbs/ac, 10in Row Spacing...............20

Small Seeds Rate .....................................................21

Small Seeds Rate Calibration ....................................21

Small Seeds Rate Charts, U.S. Customary Units ......23

Alfalfa, Red Alsike, Crimson Clover................................ 23

Kentucky Bluegrass,

Fescue, Annual Rye Grass..........................................23

Bermuda, Red Top, Lespedeza Unhulled,

Sercia, Sand, Weeping Love Grass ............................23

Red & Sweet Clover, Lespedeza Hulled..........................23

Orchard Grass .................................................................23

Millet, Reed Canary .........................................................23

Ladino Clover, Canary Grass,

Timothy, Canola ..........................................................24

Birdsfoot, Trefoil, Sudan ..................................................24

Appendix...................................................................25

Main Seed Box Rate Charts, Metric...........................25

Alfalfa or Rape.................................................................25

Barley (1 of 3) ..................................................................25

Buckwheat .......................................................................25

Buffalograss (1 of 4).........................................................26

Flax or Sudan...................................................................26

Millet.................................................................................26

Milo ..................................................................................27

Peas.................................................................................27

Pinto Beans......................................................................27

Rice, Short Grain (1 of 2).................................................27

Rice, Long Grain (1 of 4)..................................................28

Rye...................................................................................28

Soybeans (1 of 4).............................................................29

Sunflower.........................................................................29

Wheat (1 of 2)..................................................................30

Wheatgrass......................................................................30

Fertilizer Rate Charts, Metric.....................................31

Fertilizer Rate, 19.2cm Row Spacing.....................31

Fertilizer Rate, 25.4cm Row Spacing.....................32

Small Seeds Rate Charts, Metric...............................33

Alfalfa, Red Alsike, Crimson Clover.................................33

Kentucky Bluegrass,

Fescue, Annual Rye Grass..........................................33

Bermuda, Red Top, Lespedeza Unhulled,

Sercia, Sand, Weeping Love Grass ............................33

Red & Sweet Clover, Lespedeza Hulled..........................33

Orchard Grass .................................................................33

Millet, Reed Canary .........................................................34

Ladino Clover, Canary Grass,

Timothy, Canola ..........................................................34

Birdsfoot, Trefoil, Sudan ..................................................34

© Copyright 2000, 2006, 2007, 2008, 2009 All rights Reserved

GreatPlainsManufacturing,Inc. providesthis publication“as is” without warranty ofany kind,either expressedor implied.While ev eryprecaution has been takenin the preparation

of this manual, Great Plains Manufacturing,Inc. assumes noresponsibility for errors or omissions. Neither isany liability assumed for damages resulting from the use of theinformation contained herein. Great Plains Manufacturing, Inc. reserves the right to reviseand improve its products as it sees fit.This publication describes the state of this product at

the timeof its publication,and may notreflect the productin the future.

The followingare trademarks of Great Plains Mfg.,Inc.: Application Systems,Ausherman, Land Pride,Great Plains

All otherbrands and productnames are trademarks or registered trademarks oftheir respective holders.

01/29/2009 196-522B

Great PlainsManufacturing, Incorporated Trademarks

Printed in the United States of America.

Page 3

Great Plains Mfg., Inc.

Introduction

This manual is your guide to planter adjustments for

achieving specific seed population and fertilizer density

targets.

Although some setup/adjustment material herein is

repeated from the drill Operator’s Manual, you need to

be thoroughly familiar with drill operations and adjustments before applying this Seed Rate manual and its

table data.

Drill models covered by this manual

Seed-only models:

3S4010HD-4810 48 row 10in (25cm)

3S4010HD-6475 64 row 7.5in (19cm)

Fertilizer models:

3S4010HDF-4810 48 row 10in (25cm)

3S4010HDF-6475 64 row 7.5in (19cm)

The rate charts are independent of drill width and row

spacing.

1

Document Family

196-522M Owner’s Manual

196-522P Parts Manual

196-522B Seed Rate Manual (this document)

01/29/2009 196-522B

Page 4

3S-4010HD and 3S-4010HDF

2

Setting Main Box Seed Rate

Accurately obtaining the desired seed population

requires four steps:

1. Setting Drive Type sprockets (from chart)

2. Setting initial Seed Rate Handle (from chart)

3. Positioning Seed Cup Door (by seed type)

4. Calibration: checking actual seeding rate

Seed rate charts, and rate setting/calibratinginformation,

is included in both the Operator’s Manual, and this separate Seed Rate Manual. The Seed Rate manual is normally stored in a weatherproof holder on the drill, for field

reference. The charts list proper sprocket pairings and

seed-rate-handle settings for various seeds and seeding

rates.

The seed-rate charts are based on cleaned, untreated

seed of average size and test weight. The charts are

based on 18-22.5 (445/65 D22.5) NHS 16-Ply tires,

inflated to factory specification. Many factors will affect

seeding rates including foreign material, seed treatment,

seed size, seed weight, field conditions, tire pressure

and test weight. Minor adjustments are commonly

required. Set and check the seeding rate using the procedures below, then readjust the rate as necessary.

Great Plains Mfg., Inc.

196-522B 01/29/2009

Page 5

Great Plains Mfg., Inc.

Setting Drive Type

3

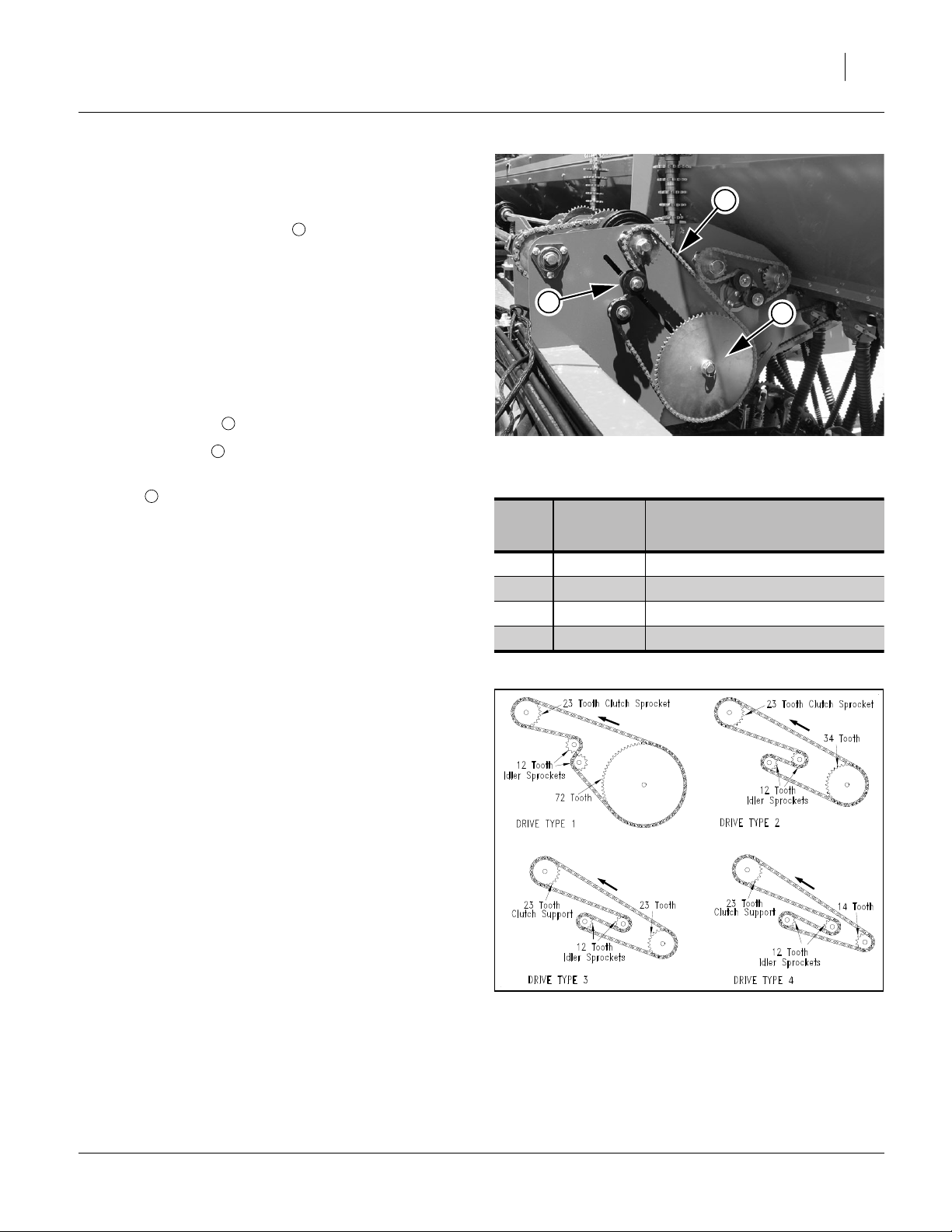

Refer to Figure1

Drive Type is determined by the size (tooth count) of a

sprocket on the seed jackshaft of each drill section. If

1

changed, the sprocket must be set identically on each

drill section (3 locations).

For correct Drive Type, refer to seed-rate charts beginning on page 8. The charts list Drive Types as 1, 2, 3 or

4. Each Drive Type corresponds to a specific sized

sprocket, per the table and Figure 2 at right.

Changing Drive Type

Refer to Figure1

1. Loosen top idler and slide idler up.

2. Lift drive chain off sprocket currently in use.

3. Remove lynch pins and rearrange sprockets on jack-

1

shaft .

Note: Sprockets are stored on both ends of jackshaft (1

alternate sprocket under the Drive Type sprocket,

and 2 alternates (plus Fertilizer alternates) on the

far end of the shaft.

Do not mix Drive Type sprocketswith Fertilizer

sprockets on the vertical storage trees.

2

3

3

2

Figure 1

Drive Type 1 Configured

Drive

Type

Sprocket Relative Speed

1 72 Tooth Slowest

2 34 Tooth 2.12 times faster than Type 1

3 23 Tooth 3.13 times faster than Type 1

4 14 Tooth 5.14 times faster than Type 1

1

28178

4. Sprocketcorresponding to the required Drive Typeis

remounted as the outermost (, with larger side of

raised hub awayfrom pin, keeping teeth aligned with

driving sprocket at top). Make sure all 4 sprockets

are accounted for when remounting them on the

shaft.

5. Remount drive chain on the outermost (Drive Type)

sprocket.

6. Re-engage top idler and secure. Allow

1

⁄

in (1.3cm)

2

slack in longest (top) span of chain.

7. Set the same Drive Type on all three drill sections.

Figure 2

Drive Type Chain Routing

18839

01/29/2009 196-522B

Page 6

3S-4010HD and 3S-4010HDF

4

Main Box Seed Rate Handle

There are main box seed rate handles for each section of

the drill (3 handles total). Generally, all need to be set

identically, and you need to calibrate only one section.

The seed rate handle controls the percent engagement

of the seed sprocket in each seed cup. The initial setting

of the handle is given by the Seed Rate Chart.

Note: Youcantemporarily stop seed flow to a drill section

by setting a handle to zero.

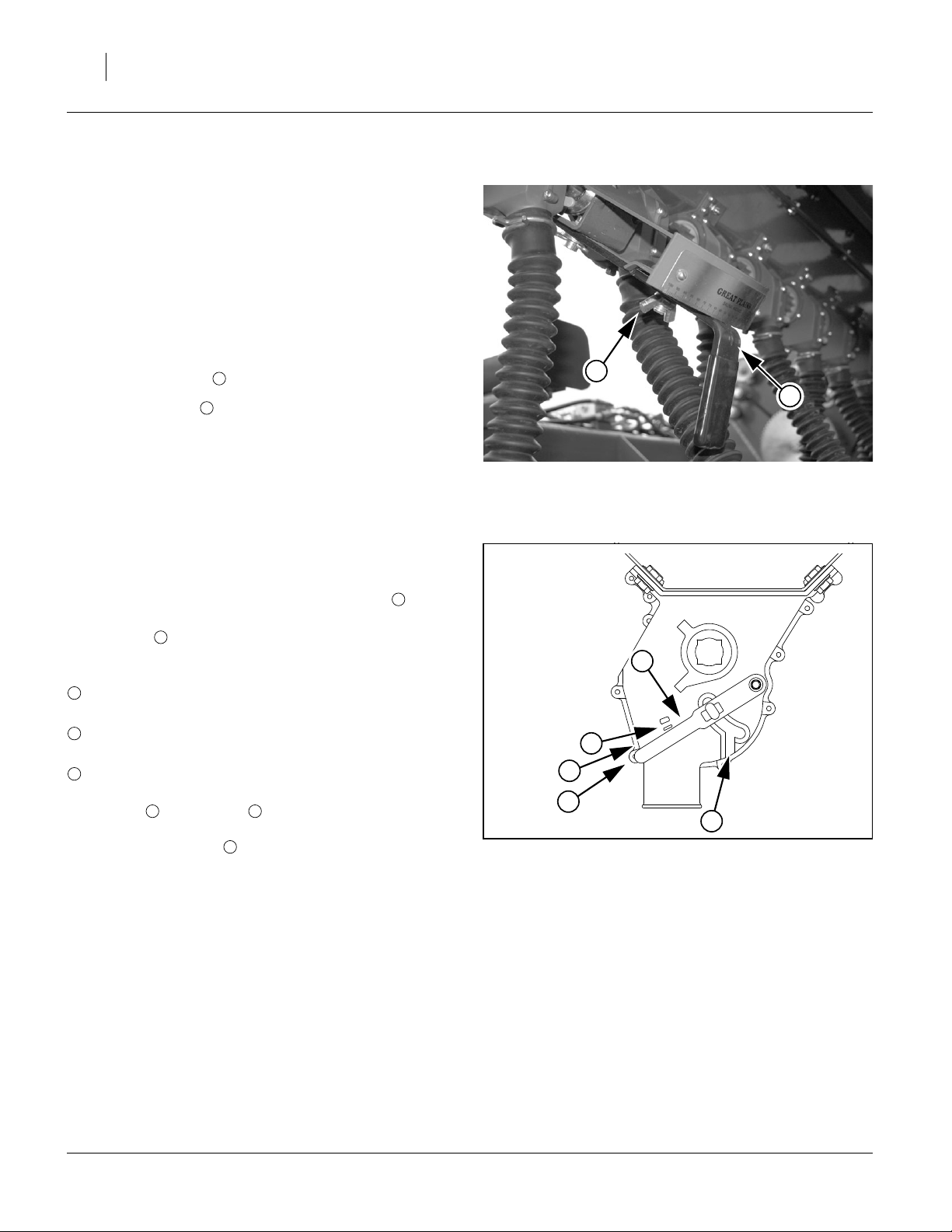

To set a handle:

1. Loosen wing nut under handle.

2. Move indicator to a rate about 10 higher than the

suggested rate from Seed Rate Chart. Then move

handle back to chart rate.

3. Tighten wing nut.

1

1

Fi S

1

Figure 3

Seed Rate Handle

Great Plains Mfg., Inc.

2

28181

Position Seed Cup Doors

Refer to Figure4,

which depicts the seed cup door handle in position .

At each main seed box seed tube, adjust the seed cup

door handle for the seed size.

4

The handle has three normal operating position detents:

(top detent) is for the smallest seeds.

1

Use it for wheat and similar small seeds.

(middle detent) is for larger seeds.

2

Use it for soybeans and similar larger seeds.

(bottom detent) is for oversize or fragile seeds.

3

If you experience excessive cracking with

setting , use setting .

Note: Handle position is used for cleanout, not plant-

2 3

5

ing.Ifset to thispositionwithseedloaded, itmaybe

difficult to reset it to a normal operating position.

3

4

1

2

3

Figure 4

Seed Cup Door Handle

5

26211

196-522B 01/29/2009

Page 7

Great Plains Mfg., Inc.

Main Box Seed Rate Calibration

Differences will exist between the tested seed and field

conditions used to generate the Seed Rate Charts, and

your seed and conditions. To accurately achieve your target population, Great Plains recommends calibrating.

Perform the calibration with the drill unfolded and lowered to field position. Turn off or disconnect power to the

clutches.

Refer to Figure5

1. Lower drill. Set MASTER switch on clutch control

box to OFF position.

2. Remove the calibration crank from its storage location on the right section drive. Store the pin on the

stob.

3. On the right drill section, if fertilizer rate is not also

being calibrated at the same time, and fertilizer is

present, remove the fertilizer drive chain.

Figure 5

Stored Calibration Crank

5

29240

Refer to Figure6

4. Install cr

ank on clutch shaft of right section.

Crank rotation is clockwise, facing to drill left.

5. Use crank to turn clutch shaft and check that the

drives and seed cups are engaged, working properly

and free from foreign material. If not already done,

set the Drive Type, Seed Rate Handle and Seed Cup

Doors across the drill.

ll C

Figure 6

Installed Calibration Crank

For example:

on a drill with a row spacing of:

7.5 inches

and a row count of:

64

you desire to plant barley at:

50 pounds per acre

which, from the Barley Drive Type 2 chart,

is an initial Seed Rate Handle scale setting of:

40

28180

01/29/2009 196-522B

Page 8

3S-4010HD and 3S-4010HDF

6

Great Plains Mfg., Inc.

6. Record the weight of one to three empty containers

collectively large enough to hold seed metered for

6% of one acre or hectare.

7. Place several pounds or kg of seed over three seed

cups on the outside end of the right drill box. Pull

lower end seed hoses off of these drops at the

opener end.

8. Turn the calibration crank several times to fill seed

cups. Turn until seed drops to ground from each

hose.

9. Place empty container(s) under the three hoses to

gather metered seed.

10. Turn crank for one acre (45.1 rotations) or one hectare (111.4 rotations). While turning, check that cups

have ample seed coming into them.

11. Weigh metered seed. Subtract initial weight of container(s).

NetWeight GrossWeight ContainerWeights–=

12. Divide the net seed weight by three. Multiply by number of openers on your drill to determine the total of

pounds-per-acre seeded.

NetWeight

MeasuredRate

------------------------3

OpenerCount×=

For example:

three empty 8 oz. containers weigh a total of:

1.5 lb.

For example: the containers weighed a total of 4.0 lb

after test:

2.7 lb net

2.7 4.2 1.5–=

For example:

on the 64-row 7.5in drill:

57.5 lb/ac

2.7

57.5

-----3

64×=

13. The Seed Rate Handle scale is a percentage of

meter opening, and is quite linear near scale center.

Calculate a new scale setting based on the test.

TargetRate

NewScale

--------------------------------- MeasuredRate

OldScale×=

Note: You may want to repeat calibration procedure if

your results varied greatly from the Seed Rate

Chart, or if you must operate near the ends of the

Seed Rate handle scale (0-20 or 90-100).

14. Set the center and left drill sections to match the

now-calibrated right section.

15. With calibration complete, Reinstall fertilizer chain (if

removed) and reconnect seed hoses.

When drilling, check seeding rate by noting acres drilled,

amount of seed added to drill and seed level in drill box.

If you are seeding more or less than desired, adjust rate

slightly to compensate for field conditions.

For example:

the target rate was 50 lb/ac, and the initial scale 40:

the new scale setting is:

35

50

---------

35

57.5

40×=

196-522B 01/29/2009

Page 9

Great Plains Mfg., Inc.

Reading a Seed Rate Chart

Charts in U.S. customary units begin on page 8.

Metric charts begin on page 25.

1. Find your seed. Charts are in alphabetical order by

seed name. Charts covering more than one seed

may be out of order.

For Rape, see Alfalfa.

For Sudan, see Flax.

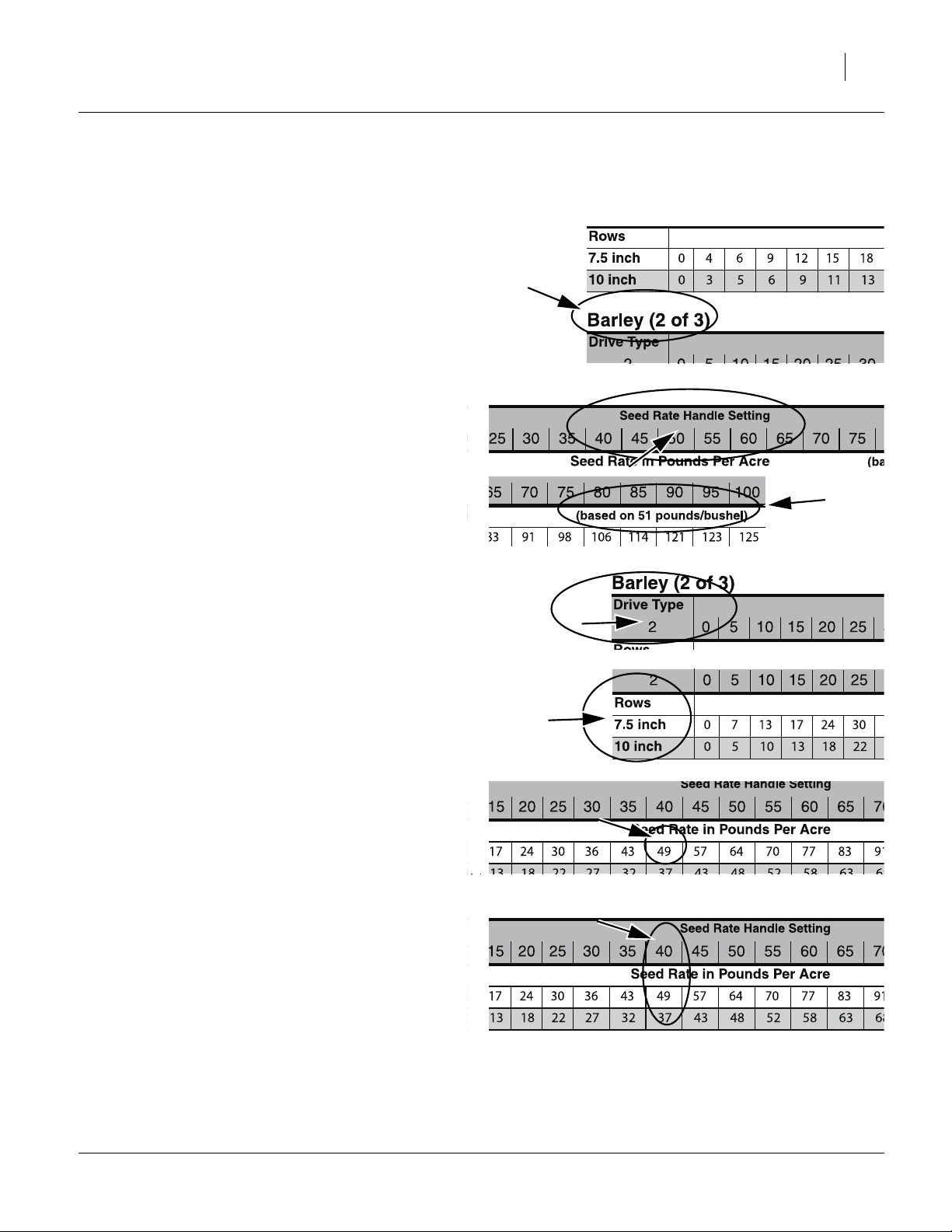

This example presumes we desire to plant Barley at

50 pounds per acre with a 7.5in drill.

There are multiple charts for some seeds, and the

rates may overlap. Use the chart where your desired

rate is closest to 50 on the Seed Rate Handle scale.

In our example, that would be Barley chart 2 of 3.

If your seed is not listed, find one with similar size,

shape and density. Density of the test seed used to

develop the chart appears under the right end of the

handle scale values.

7

2. Note the Drive Type in the upper left corner of the

chart for your seed. This number (1-4) is used to

determine the seed jackshaft sprocket. See page 3.

In our example, this is Drive Type 2 (34T sprocket).

3. Find your row spacing in the far left column.

4. Locate your desired seed rate in the table row for

your row spacing.

In our example, 49 is the closest to 50.

5. Note the Seed Rate Handle setting required, at the

top of the column at that seed rate. This is the initial

value set on the Seed Rate Handle. See page 4.

In our example, we will start with a handle setting of

40, and calibrate. When a target rate falls halfway

between handle settings, you can adjust the handle

slightly to compensate, but calibration is apt to result

in further adjustment anyway.

01/29/2009 196-522B

Page 10

3S-4010HD and 3S-4010HDF

8

Great Plains Mfg., Inc.

Main Box Seed Rate Charts

U.S. Customary Units. Metric charts begin on page 25.

Alfalfa or Rape

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 60 pounds/bushel)

7.5 inch 04 7101215182225293336404347515559636567

10 inch 0 3 5 7 9 12 14 16 19 22 25 27 30 33 35 38 41 44 48 49 50

Barley (1 of 3)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 51 pounds/bushel)

7.5 inch 0 4 6 9 12 15 18 21 24 28 31 35 38 42 46 49 52 55 58 59 59

10 inch 0 3 5 6 9 11 13 16 18 21 23 26 29 32 34 37 39 42 44 44 44

Seed Rate Handle Setting

Seed Rate Handle Setting

Barley (2 of 3)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 51 pounds/bushel)

7.5 inch 071317243036434957647077839198106114121123125

10 inch 0 5 10 13 18 22 27 32 37 43 48 52 58 63 68 74 80 85 91 92 94

Seed Rate Handle Setting

Barley (3 of 3)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 51 pounds/bushel)

7.5 inch 0 17 31 42 58 72 88 105 121 139 155 170 188 204 222 240 260 279 297 301 306

10 inch 0 13 23 32 44 54 66 79 91 104 117 128 141 153 167 180 195 209 222 226 230

Seed Rate Handle Setting

Buckwheat

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 48 pounds/bushel)

7.5 inch 0 9 17 24 34 42 52 62 74 85 99 109 120 132 144 156 167 179 192 194 196

10 inch 0 7 13 18 25 31 39 47 55 64 74 81 90 99 108 117 126 134 144 145 147

Seed Rate Handle Setting

196-522B 01/29/2009

Page 11

Great Plains Mfg., Inc.

9

Seed Rate Charts, Main Box, lbs/ac, continued...

Buffalograss (1 of 4)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 23 pounds/bushel)

7.5 inch 012345 7 8 10111314151718192020202020

10 inch 0 1 2 2 3 4 5 6 7 8 9 11 12 12 13 14 15 15 15 15 15

Buffalograss (2 of 4)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 23 pounds/bushel)

7.5 inch 0 2 4 6 8 11 14 17 20 23 26 29 32 34 36 38 40 41 42 42 41

10 inch 0 2 3 5 6 8 10 13 15 17 19 22 24 26 27 29 30 31 31 31 31

Seed Rate Handle Setting

Seed Rate Handle Setting

Buffalograss (3 of 4)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 23 pounds/bushel)

7.5 inch 0 5 7 9 12 16 20 24 29 34 38 43 47 51 55 58 61 63 64 65 64

10 inch 0 3 5 7 9 12 15 18 22 25 29 32 36 38 41 44 46 47 48 48 48

Seed Rate Handle Setting

Buffalograss (4 of 4)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 23 pounds/bushel)

7.5 inch 0 7 11 15 20 26 33 40 47 55 62 70 77 83 90 95 99 102 104 105 104

10 inch 0 6 8 11 15 20 25 30 35 41 47 52 58 63 67 71 74 77 78 79 78

Seed Rate Handle Setting

Flax or Sudan

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 55 pounds/bushel)

7.5 inch 0 3 7 9 13 16 19 23 26 30 34 37 40 44 47 52 56 61 66 67 68

10 inch 0 2 5 7 10 12 15 17 20 22 25 27 30 33 35 39 42 45 49 50 51

Seed Rate Handle Setting

Millet

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 60 pounds/bushel)

7.5 inch 0 4 7 9 13 16 19 22 25 29 32 35 39 42 46 49 53 57 61 62 63

10 inch 0 3 5 7 9 12 14 16 19 21 24 26 29 32 34 37 40 43 46 46 47

01/29/2009 196-522B

Seed Rate Handle Setting

Page 12

3S-4010HD and 3S-4010HDF

10

Great Plains Mfg., Inc.

Seed Rate Charts, Main Box, lbs/ac, continued...

Milo

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 64 pounds/bushel)

7.5 inch 04 7101418222731364145505560656973788082

10 inch 0 3 5 8 11 14 17 20 23 27 31 34 38 41 45 49 52 55 59 60 61

Oats

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 37 pounds/bushel)

7.5 inch 0 4 10 14 19 25 31 37 44 51 58 64 70 77 84 90 97 104 111 112 112

10 inch 0 3 7 10 14 19 23 28 33 38 43 48 53 58 63 68 73 78 83 84 84

Seed Rate Handle Setting

Seed Rate Handle Setting

Peas

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 61 pounds/bushel)

7.5 inch 0 0 15 27 42 55 67 82 95 110 123 136 149 161 175 188 201 213 225 226 227

10 inch 0 0 11 20 31 41 50 61 71 82 93 102 112 121 131 141 151 160 169 170 171

Seed Rate Handle Setting

Pinto Beans

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 51 pounds/bushel)

7.5 inch 00 7101419242833384247515560656873777777

10 inch 0 0 5 8 10 14 18 21 25 28 32 35 38 41 45 49 51 54 58 58 58

Seed Rate Handle Setting

Rice, Short Grain (1 of 2)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 43 pounds/bushel)

7.5 inch 0 9 14 23 31 37 44 51 59 67 77 85 94 102 111 118 125 132 139 139 139

10 inch 0 7 11 17 23 27 33 38 44 50 57 64 70 77 83 89 94 99 105 105 105

Seed Rate Handle Setting

Rice, Short Grain (2 of 2)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 43 pounds/bushel)

7.5 inch 0 14 24 37 50 60 72 83 96 109 125 139 153 167 181 193 204 215 227 227 227

10 inch 0 11 18 28 38 45 54 62 72 82 94 105 115 125 136 145 153 162 170 170 170

196-522B 01/29/2009

Seed Rate Handle Setting

Page 13

Great Plains Mfg., Inc.

11

Seed Rate Charts, Main Box, lbs/ac, continued...

Rice, Long Grain (1 of 4)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 47 pounds/bushel)

7.5 inch 0 1.1 3.6 5.9 8.3 10.9 13.5 15.9 18.4 20.9 25.3 25.7 28.1 30.5 32.9 35.4 37.5 39.5 41.2 42.3 43.1

10 inch 0 0.8 2.7 4.4 6.2 8.2 10.1 11.9 13.8 15.7 19.0 19.3 21.1 22.9 24.7 26.6 28.1 29.7 30.9 31.7 32.3

Rice, Long Grain (2 of 4)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 47 pounds/bushel)

7.5 inch 02 7121723283338435253586368737781858789

10 inch 0 2 6 9 13 17 21 25 28 32 39 40 43 47 51 55 58 61 64 65 67

Seed Rate Handle Setting

Seed Rate Handle Setting

Rice, Long Grain (3 of 4)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 47 pounds/bushel)

7.5 inch 0 0 11 17 25 34 42 49 57 65 72 79 85 92 100 108 116 123 129 134 138

10 inch 0 0 8 13 19 25 32 37 42 49 54 59 64 69 75 81 87 92 97 100 104

Seed Rate Handle Setting

Rice, Long Grain (4 of 4)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 47 pounds/bushel)

7.5 inch 0 0 17 28 41 55 69 80 92 105 117 128 139 151 163 176 188 200 210 218 226

10 inch 0 0 13 21 31 41 52 60 69 79 88 96 104 113 123 132 141 150 158 164 169

Seed Rate Handle Setting

Rye

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 57 pounds/bushel)

7.5 inch 02 6101519222833384246505559646975818182

10 inch 0 2 5 8 11 14 17 21 24 28 32 35 38 41 44 48 52 56 61 61 61

Seed Rate Handle Setting

01/29/2009 196-522B

Page 14

3S-4010HD and 3S-4010HDF

12

Great Plains Mfg., Inc.

Seed Rate Charts, Main Box, lbs/ac, continued...

Soybeans (1 of 4)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 58 pounds/bushel)

7.5 inch 02 6111519232731364044495357626570747475

10 inch 0 2 5 8 12 14 17 20 24 27 30 33 37 40 43 46 49 52 56 56 56

Soybeans (2 of 4)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 58 pounds/bushel)

7.5 inch 0 5 13 22 32 38 47 55 64 73 81 91 100 109 118 127 134 143 152 153 153

10 inch 0 4 10 16 24 29 35 42 48 55 61 68 75 82 88 95 101 107 115 115 115

Seed Rate Handle Setting

Seed Rate Handle Setting

Soybeans (3 of 4)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 58 pounds/bushel)

7.5 inch 0 9 18 32 48 57 71 81 93 105 119 131 145 157 171 182 199 212 227 227 227

10 inch 0 7 14 24 36 42 53 61 70 79 89 98 108 118 128 137 149 159 170 170 170

Seed Rate Handle Setting

Soybeans (4 of 4)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 58 pounds/bushel)

7.5 inch 0 15 29 53 78 92 116 132 152 171 193 214 236 256 279 297 324 346 370 371 371

10 inch 0 11 22 40 58 69 87 99 114 128 145 160 177 192 209 223 243 260 278 278 278

Seed Rate Handle Setting

Sunflower

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 28 pounds/bushel)

7.5 inch 002357 9 1012141618202224262729313233

10 inch 0 0 1 3 4 5 6 8 9 11 12 14 15 16 18 19 20 22 23 24 24

Seed Rate Handle Setting

196-522B 01/29/2009

Page 15

Great Plains Mfg., Inc.

13

Seed Rate Charts, Main Box, lbs/ac, continued...

Wheat (1 of 2)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 64 pounds/bushel)

7.5 inch 0 10 18 24 32 40 46 56 64 73 84 92 102 112 122 131 142 152 162 164 165

10 inch 0 8 13 18 24 30 34 42 48 55 63 69 76 84 91 99 106 114 122 123 124

Wheat (2 of 2)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 64 pounds/bushel)

7.5 inch 0 13 25 36 48 59 70 83 96 109 123 134 149 162 176 192 205 219 232 237 239

10 inch 0 10 18 27 36 45 53 62 72 82 92 101 111 121 132 144 154 164 174 178 179

Seed Rate Handle Setting

Seed Rate Handle Setting

Wheatgrass

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 23 pounds/bushel)

7.5 inch 012234 5678910111112131415151717

10 inch 0 1 1 2 3 3 4 4 5 6 7 7 8 9 9 10 11 12 11 13 13

Seed Rate Handle Setting

01/29/2009 196-522B

Page 16

3S-4010HD and 3S-4010HDF

14

Setting Fertilizer Rate

The 3S-4010HDF fertilizer meters are driven from the

clutch shaft through a series of sprockets.This system is

independent of the seed meter drive, and is unaffected

by Drive Type. Fertilizer rate is adjusted by changing 1 to

4 sprockets on each drill section (3 or 6 pairs total).

Fertilizer application rates vary with fertilizer type, density and particle size. Relative humidity and field conditions can also affect application rates. The chart on

page 31 is based on fertilizer with average particle size

and a density of 65 pounds per cubic foot. Initially set

rate according to charts, then calibrate the drill to your

material as described on this page.

Perform initial setup and calibration for the right drill box.

Once determined, set the center and left boxes to match.

Accurately obtaining the desired application rate requires

four steps:

1. Adjusting target rate for large differences between

material and chart density.

2. Setting Range sprockets (from chart)

3. Setting initial Transmission (Driver / Driven) sprockets (from chart)

4. Calibration: checking actual application rate

Great Plains Mfg., Inc.

Adjusting for Density

The fertilizer meter rate chart is based on fertilizer with a

density of 65 pounds per cubic foot (1.04 kg/liter). If your

fertilizer density is within a few percent of that, skip step

a through step e and use calibration to determine final

Driver/Driven setup.

For larger variances, particularly with very low densities,

pre-compensating can simplify calibration, bychoosing a

different target chart value for the application rate.

a. Find your actual material density. Normally, this

reported on the container in which it was supplied. If

not, weigh a known volume and calculate it.

b. Find your material Density in the table at right, and

the Conversion Factor below it.

c. Adjust your target application rate prior to consulting

the Fertilizer Rate Chart.

AdjustedRate TargetRate ConversionFactor×=

d. Find the Adjusted rate in the Fertilizer Rate Chart.

e. Calibrate using the Adjusted rate sprocket setup.

Density: lbs/cu-ft

(kg/liter)

Conversion Factor 1.45 1.30 1.20 1.10

Density: lbs/cu-ft

(kg/liter)

Conversion Factor 1.00 0.93 0.87 0.81

Example: 64 row 7.5in drill

Your fertilizer has a density of 60 pounds/cubic-foot,

and you want to apply 140 pounds/acre. First, adjust

the density:

155 140 1.10×=

Example:

The adjusted 155 rate corresponds to either:

LOW Range 24T/12T Transmission, or

HIGH Range, and 12T/21T Transmission.

45.0

(0.72)

65.0

(1.04)

50.0

(0.80)

70.0

(1.12)

55.0

(0.88)

75.0

(1.20)

60.0

(0.96)

80.0

(1.28)

196-522B 01/29/2009

Page 17

Great Plains Mfg., Inc.

Setting Fertilizer Drive Range

Refer to the Fertilizer Rate Chart on page 31 to find the

correct Range sprocket size for your drill’s row spacing

and the target (or adjusted) application rate.

Ranges overlap. Choose a Range so that the Transmission (Driver/Driven)pairing is further from the end of that

Range chart, reducing the chances that a Transmission

adjustment might also require a Range change.

Change fertilizer range requires changing one or two

sprockets per drill section, per the table at right. An idler

1

is loosed and re-engaged for any sprocket change.

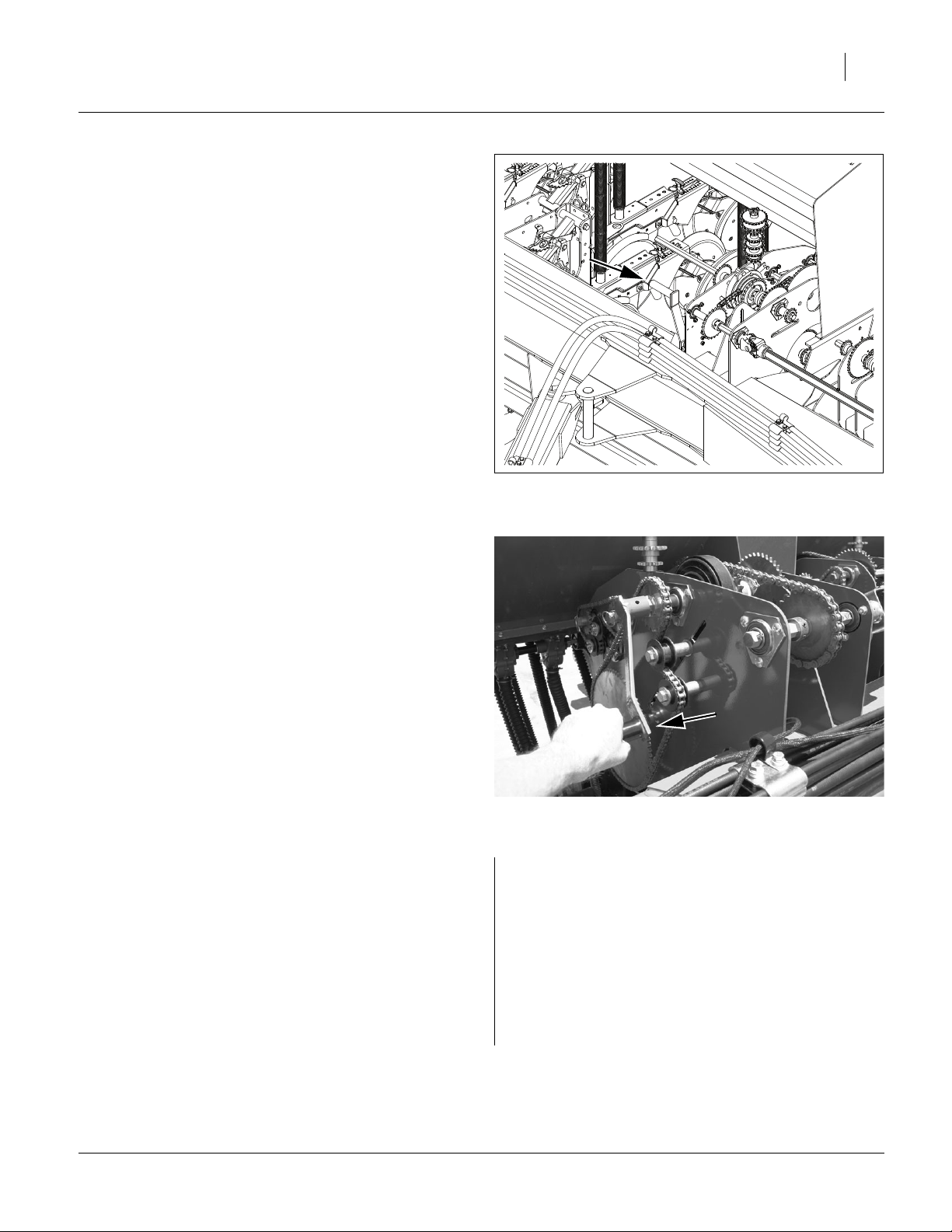

Refer to Figure7

Range: Front Sprocket

15T

The two Front range sprockets ( , ) are permanently installed, and are exchanged by sliding left and

right on the shaft. Remove the spring-clasp polymer

spacer to permit sliding, and re-insert it as instructed

2

below to keep the Front and Rear sprockets aligned.

41T

15

In our example, two settings are near the adjusted rate:

LOW Range 24T/12T Transmission, or

HIGH Range, and 12T/21T Transmission.

Use the HIGH Range setting, as it is further from the

end of the chart, allowing easier adjustment.

Fertilizer Range

Sprockets Low High

Front 15T 41T 41T

Rear 60T 47T 16T

Ultra

High

Range: Rear Sprocket

There are three possible Rear range sprockets ( ,

47T 60T

, ). Remove a lynch pin (not shown) to change

3

16T

this sprocket.

The two rear range sprockets not presently in use are

stored on the Driven Transmission shaft , directly

4

below the Rear range shaft.

There are also main box Drive Type sprockets stored

here, but the tooth counts are unique to each drive.Tooth

counts are stamped into the face of each sprocket.

Changing Range Sprockets

1. Loosen the Range idler.

2. If the Front sprocket needs changing:

remove the polymer spacer ;

slide both sprockets to where spacer was; and,

re-clasp spacer on the other side of sprocket pair.

3. If the Rear sprocket needs changing:

remove the pin from the rear and storage shafts;

remove the current Rear sprocket ;

remove the next sprocket from storage;

place the next sprocket on the Rear shaft and re-pin;

return other sprockets to the lower shaft and re-pin.

4. Re-engage the Range idler for

the top chain span.

5. If this is the final Range setting, after calibration,

repeat step 1 through step 4 for the center and left

drill sections.

2

3

1

⁄

in (6.4mm) slack in

4

4

3

2

41T

4

15T

1

Figure 7

Range Sprockets: Center Section

15T Front Engaged (Low Range)

28179

01/29/2009 196-522B

Page 18

3S-4010HD and 3S-4010HDF

16

Setting Fertilizer Transmission

Refer to Figure8

The fertilizer Transmission is a Driver/Driven pair of

sprockets located above and behind the Drive Type

sprocket.

Refer to the Fertilizer Rate Charts (pages 19, 20, 31 and

32) to find the correct Transmission (Driver/Driven)

sprocket sizes for your drill’s row spacing and target (or

adjusted) application rate.

DRIVEN

Great Plains Mfg., Inc.

4

DRIVER

2

1

Examine the currently installed sprockets ( , ) to con-

1 2

firm that one or both needs to be changed (or moved

between shafts).

To change the transmission setting:

1. Loosen idlers and rotate idlers out of engagement

3

with chain.

2. Remove pin from vertical storage tower , and

4

retrievenewsprocket(s)required.Return other to the

storage tree, but leave pin off.

3. Remove lynch pinsfrom Driver and/or Driven

sprocket shaft to be changed, and remove

sprocket(s).

4. Place correct Driver and Driven sprockets on their

respective shafts.

5. Store removed sprockets on storage tree.

6. Re-install all pins.

7. Reinstall chain and engage idlers, allowing

1

⁄

in

4

(6.4mm) slack in the top chain span.

8. If this is the final setting, after calibration, repeat step

1 through step 7 for the center and left drill sections.

3

Figure 8

Fertilizer Transmission

28178

196-522B 01/29/2009

Page 19

Great Plains Mfg., Inc.

Fertilizer Rate Calibration

Differences will exist between the tested fertilizer and

field conditions used to generate the Rate Chart, and

your fertilizer and conditions. To accurately achieve your

target application, Great Plains recommends calibrating.

Perform the calibration with the drill lowered to field position. Shut off power to the clutches.

If you have previously calibrated your acremeter (see

Operator’s manual), you can use it to tally acres.

Refer to Figure9

1. Lower drill. Set MASTER switch on clutch control

box to OFF position.

2. Remove the calibration crank from its storage location on the right section drive. Remove pin from

crank and return to storage stob.

3. On the right drill section, if seed rate is not also being

calibrated at the same time, and seed is present,

remove the seed box drive chain.

Refer to Figure10

4. Install crank on clutch shaft of right section.

Crank rotation is clockwise, facing to drill left.

5. Use crank to turn clutch shaft and check that the

drives and seed cups are engaged, working properly

and free from foreign material.

Figure 9

Stored Calibration Crank

17

29240

Figure 10

28180

Installed Calibration Crank

6. From the charts, configure the Range and Transmission sprock

ets based on the target or density-

adjusted application rate.

For example:

you desire to apply 60lb/cu-ft material at a rate of:

141 lb/ac

on a 64 row 7.5in drill.

Per the density adjustment on page 14,

the adjusted rate is:

155 pounds/acre

Per the chart, the drive system setup is:

HIGH Range, and

12T/21T Transmission (Driver/Driven)

7. Record the weight of one to three empty containers

collectivelylarge enough to hold fertilizermetered for

6% of one acre or hectare.

01/29/2009 196-522B

For example:

three empty 8 oz. containers weigh: 1.5 lb.

Page 20

3S-4010HD and 3S-4010HDF

18

8. Place several pounds or kilograms of fertilizer over

three fertilizer openings at the outside end of the

right drill box. Pull lower end fertilizer hoses off of

these drops at the opener end.

9. Turn crank several times to fill flute cups. Turn until

fertilizer drops to ground from each hose.

10. Place empty container(s) under the three hoses to

gather metered fertilizer.

11. Turn crank for acre (45.1 rotations) or one hectare

(111.4 rotations). While turning, check that cups

have ample fertilizer coming into them.

12. Weigh metered fertilizer. Subtract initial weight of

container(s).

NetWeight GrossWeight ContainerWeights–=

Great Plains Mfg., Inc.

!

CAUTION

Follow material supplier recommendations for safety precautions in handling fertilizer.

For example:

the three containers weighed a total of 8.9 lb. after test:

7.4 lb. net

7.4 8.9 1.5–=

13. Divide the net fertilizer weight by three. Multiply by

number of openers on your drill to determine the

total of kg or pounds-per-acre applied.

NetWeight

MeasuredRate

14. Subtract to calculate the difference between the

measured rate and the original target (not adjusted)

rate.

Variance TargetRate MeasuredRate–=

15. If a Density Adjustment was made (see page 14),

apply it to the variance.

AdjustedVariance Variance CorrectionFactor×=

16. Consult the chart for the chart rate used for your first

calibration run with this material. If the just-measured

result was low, add the [adjusted] variance to the

previously used chart rate. If the measured result

was high, subtract the [adjusted] variance from the

previous chart rate.

17. Reset the fertilizer Range and Final Drive based on

the settings at the new chart rate.

18. You may want to repeat calibration procedure if your

results varied greatly from the desired target rate.

19. With calibration complete, Reinstall seed chain (if

removed) or reset Seed Rate Handle, reconnect

hoses, and lower gauge wheel to ground.

20. Set the center and left drill sections to match the

now-calibrated right section.

When drilling, check metering rate by noting acres

drilled, amount of fertilizer added to drill and level of

material in drill box. If you are applying more or less fertilizer than desired, adjust metering rate slightly to compensate for field conditions.

------------------------3

RowCount×=

For example:

a 64-row (7.5cm) drill:

158 lb/ac

7.4

157.9

For example: the target rate was 141 lb/ac:

variance=17

17 158 141–=

For example: the density adjustment factor was 1.10:

new variance=19

19 17 1.1×=

For example:

Our measured rate was high, so we

subtract the adjusted variance (19)

from the previous adjusted chart rate (155)

to obtain a new adjusted chart rate (137).

This is close to:

LOW chart rate 137, and

HIGH chart rate 135.

Use either new drive setup:

Rate:

Range:

Driver:

Driven:

-----3

137

LOW

23T

13T

64×=

Rate:

Range:

Driver:

Driven:

135

HIGH

12T

24T

196-522B 01/29/2009

Page 21

Great Plains Mfg., Inc.

Fertilizer Rate Charts, U.S. Customary Units

Fertilizer Rate, 7.5in Row Spacing

Based on 65 pounds per cubic foot

(see page 31 for 19.2cm metric chart))

7.5in Fertilizer Rate 7.5in Fertilizer Rate

Row Spacing Pounds per Acre Row Spacing Pounds per Acre

TRANSMISSION Fertilizer Rates by RANGE TRANSMISSION Fertilizer Rates by RANGE

Sprockets

DRIVER DRIVEN HIGH DRIVER DRIVEN HIGH

12T 24T 39 135 397 18T 17T 82 287 758

12T 23T 40 141 414 13T 12T 84 293 766

13T 24T 42 147 429 23T 21T 85 297 774

12T 21T 44 155 452 20T 18T 86 301 775

12T 20T 47 162 473 18T 16T 87 305 785

13T 21T 48 168 485 23T 20T 89 311 792

13T 20T 50 176 510 21T 18T 91 316 803

12T 18T 52 180 520 20T 17T 91 319 810

16T 23T 54 188 542 24T 20T 93 325 815

12T 17T 55 191 547 16T 13T 95 333 836

17T 23T 57 200 568 21T 17T 96 335 828

18T 24T 58 203 576 20T 16T 97 339 838

16T 21T 59 206 586 23T 18T 99 346 845

18T 23T 61 212 596 21T 16T 102 355 868

16T 20T 62 217 610 24T 18T 103 361 870

17T 21T 63 219 617 23T 17T 105 366 883

20T 24T 65 226 629 18T 13T 107 375 891

17T 20T 66 230 642 24T 17T 110 382 897

18T 21T 67 232 647 17T 12T 110 383 900

20T 23T 67 235 651 23T 16T 112 389 901

18T 20T 70 244 673 18T 12T 116 405 928

21T 23T 71 247 676 20T 13T 119 416 939

12T 13T 72 250 683 21T 13T 125 435 963

17T 18T 73 256 692 20T 12T 129 449 983

20T 21T 74 258 697 21T 12T 136 469 1012

23T 24T 74 259 702 23T 13T 137 475 1015

21T 21T 78 271 724 24T 13T 143 493 1051

24T 23T 81 283 747 23T 12T 149 512 1080

21T 20T 81 284 751 24T 12T 155 531 1121

LOW HIGH

ULTRA Sprockets

ULTRA

LOW HIGH

19

01/29/2009 196-522B

Page 22

3S-4010HD and 3S-4010HDF

20

Great Plains Mfg., Inc.

Fertilizer Rate, lbs/ac, 10in Row Spacing

Based on 65 pounds per cubic foot

(see page 32 for 25.4cm metric chart))

10in Fertilizer Rate 10in Fertilizer Rate

Row Spacing Pounds per Acre Row Spacing Pounds per Acre

TRANSMISSION Fertilizer Rates by RANGE TRANSMISSION Fertilizer Rates by RANGE

Sprockets

DRIVER DRIVEN HIGH DRIVER DRIVEN HIGH

LOW HIGH

12T 24T 29 102 300 18T 17T 62 217 573

12T 23T 31 107 313 13T 12T 64 222 579

13T 24T 32 111 324 23T 21T 64 224 585

12T 21T 34 117 342 20T 18T 65 227 586

12T 20T 35 123 357 18T 16T 66 230 594

13T 21T 36 127 367 23T 20T 67 235 599

13T 20T 38 133 385 21T 18T 68 239 608

12T 18T 39 136 393 20T 17T 69 241 613

16T 23T 41 142 410 24T 20T 70 246 617

12T 17T 41 145 413 16T 13T 72 252 632

17T 23T 43 151 430 21T 17T 72 253 626

18T 24T 44 154 436 20T 16T 73 256 634

16T 21T 45 156 443 23T 18T 75 262 639

18T 23T 46 160 451 21T 16T 77 269 657

16T 20T 47 164 461 24T 18T 78 273 658

17T 21T 47 166 466 23T 17T 79 277 667

20T 24T 49 171 476 18T 13T 81 283 674

17T 20T 50 174 485 24T 17T 83 289 678

18T 21T 50 175 490 17T 12T 83 290 680

20T 23T 51 178 492 23T 16T 84 294 681

18T 20T 53 184 509 18T 12T 88 306 702

21T 23T 54 187 511 20T 13T 90 314 710

12T 13T 54 189 517 21T 13T 95 329 728

17T 18T 55 193 523 20T 12T 98 339 743

20T 21T 56 195 527 21T 12T 103 355 765

23T 24T 56 196 531 23T 13T 104 359 767

21T 21T 59 205 547 24T 13T 108 373 795

24T 23T 61 214 565 23T 12T 112 387 817

21T 20T 62 215 568 24T 12T 117 401 848

ULTRA Sprockets

ULTRA

LOW HIGH

196-522B 01/29/2009

Page 23

Great Plains Mfg., Inc.

Small Seeds Rate

21

Seeding rate from the optional Small Seeds Attachment

is controlled entirely by seed rate handles on each small

seeds box. No sprocket changes are required, and small

seeds rate is unaffected by settings for main seed box.

Refer to Figure11

To set Small Seeds rate, loosen the wing nut at each

handle, and adjust the lever position. Tighten nut.

2

1

Small Seeds Rate Calibration

Differences will exist between the tested seed and field

conditions used to generate the Small Seeds Rate

Charts, and your seed and conditions. To accurately

achieve your target population, Great Plains recommends calibrating.

As small seed rates are typically far lower than main box

seed rates, use a scale that is accurate for small weight

differences, or sample more than the usual three rows.

1. Lower drill. Set MASTER switch on clutch control

box to OFF position.

2. Set the small seed rate handle based on the seed

and rate desired.

Refer to Figure12

3. Remove the calibration crank from its storage location on the right section drive. Remove pin from

crank and return to storage stob.

4. On the right drill section, if fertilizer rate is not also

being calibrated at the same time, and fertilizer is

present, remove a fertilizer box drive chain on the

right drill section.

2

1

Figure 11

Small Seeds Rate Handle

For example: using a row spacing of:

7.5in

and a row count of:

64

you desire to plant alfalfa at:

8 lbs/ac;

this corresponds to an initial Seed Rate Handle of:

40

18511

Figure 12

Stored Calibration Crank

Refer to Figure13

5. Install crank on clutch shaft of right section.

Crank rotation is clockwise, facing to drill left.

6. Use crank to turn clutch shaft and check that the

drives and seed cups are engaged, working properly

and free from foreign material. If not already done,

set the Small Seeds Rate Handle.

Figure 13

Installed Calibration Crank

01/29/2009 196-522B

29240

28180

Page 24

3S-4010HD and 3S-4010HDF

22

7. Check that your gauge-wheel tires are 18-22.5 (445/

65 D22.5) NHS 16-Ply and properly inflated. See

“Tire Inflation Chart” in Operator’s manual.

Great Plains Mfg., Inc.

8. Record the weight of one to three empty containers

collectively large enough to hold seed metered for

6% of one acre.

9. Place several pounds or kilograms of seed over

three seed cups on the outside end of the right drill

box. Pull lower end seed hoses off of these drops at

the opener end.

10. Turn crank several times to fill seed cups. Turn until

seed drops to ground from each hose.

11. Place empty container(s) under the three hoses to

gather metered seed.

12. Turn crank for one acre (45.1 rotations) or one hectare (111.4 rotations). While turning, check that cups

have ample seed coming into them.

13. Weigh metered seed. Subtract initial weight of container(s).

NetWeight GrossWeight ContainerWeights–=

14. Divide the net seed weight by the number of rows

sampled (3 in our example). Multiply by number of

openers on your drill to determine the total of

pounds-per-acre seeded.

NetWeight

MeasuredRate

------------------------3

RowCount×=

For example:

three 8 oz. containers weigh at total of:

1.5 lb

For example:

the three containers weighed a total 1.82 lb. after test:

0.32 lb. net

0.32 1.82 1.5–=

For example:

a 7.5in drill has 64 rows:

6.7 lbs/ac

0.32

---------

6.7

64×=

3

15. The Seed Rate Handle scale is a percentage of

meter opening, and is quite linear near scale center.

Calculate a new scale setting based on the test.

TargetRate

NewScale

--------------------------------MeasuredRate

OldScale×=

Note: You may want to repeat calibration procedure if

your results varied greatly from the Seed Rate

Chart, or if you must operate near the ends of the

Seed Rate handle scale (0-20 or 90-100).

16. Set the center and left drill sections to match the

now-calibrated right section.

17. With calibration complete, Reinstall fertilizer chain (if

removed), and reconnect seed hoses.

When drilling, check seeding rate by noting acres drilled,

amount of seed added to drill and seed level in drill box.

If you are seeding more or less than desired, adjust rate

slightly to compensate for field conditions.

For example:

new scale:

48

8

------

48

6.7

40×=

196-522B 01/29/2009

Page 25

Great Plains Mfg., Inc.

Small Seeds Rate Charts, U.S. Customary Units

See page 21 for instructions. Metric charts begin on page 33.

Alfalfa, Red Alsike, Crimson Clover

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 1.8 2.8 3.9 4.8 6.0 7.0 7.9 9.0 10.0 11.1 12.1 13.2 14.0 15.3 16.2 17.2 18.3 19.3 20.3

10 inch 0 0.0 1.3 2.1 2.8 3.5 4.4 5.1 5.8 6.6 7.4 8.1 8.9 9.7 10.3 11.2 11.9 12.6 13.4 14.2 14.9

Kentucky Bluegrass, Fescue, Annual Rye Grass

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 0.2 .9 1.5 2.2 2.7 3.3 3.7 4.2 4.6 5.1 5.5 5.9 6.3 6.7 7.0 7.4 7.7 8.1 8.4

10 inch 0 0.0 0.1 0.7 1.1 1.6 2.0 2.4 2.7 3.1 3.4 3.7 4.0 4.3 4.6 4.9 5.2 5.4 5.7 5.9 6.2

23

Bermuda, Red Top, Lespedeza Unhulled, Sercia, Sand, Weeping Love Grass

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 0.5 0.9 1.4 2.1 2.6 3.3 4.0 4.7 5.3 5.8 6.3 6.7 7.2 7.6 8.2 8.8 9.3 9.8 10.4

10 inch 0 0.0 0.4 0.6 1.0 1.5 1.9 2.4 3.0 3.5 3.9 4.2 4.6 4.9 5.3 5.6 6.0 6.4 6.8 7.2 7.6

Red & Sweet Clover, Lespedeza Hulled

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 1.2 2.7 4.2 5.7 7.2 9.1 10.6 12.3 13.7 15.3 16.7 18.1 19.7 21.2 22.7 24.2 25.8 27.2 28.6

10 inch 0 0.0 0.9 2.0 3.1 4.2 5.3 6.7 7.8 9.0 10.0 11.2 12.2 13.3 14.4 15.6 16.6 17.8 18.9 19.9 20.9

Orchard Grass

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 0.0 0.2 0.5 0.7 1.1 1.2 1.6 1.9 2.3 2.6 2.8 3.2 3.5 3.9 4.0 4.4 4.6 4.9 5.1

10 inch 0 0.0 0.0 0.1 0.4 0.5 .8 0.9 1.2 1.4 1.7 1.9 2.1 2.3 2.6 2.8 3.0 3.2 3.3 3.6 3.7

Millet, Reed Canary

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.3 1.2 2.0 2.8 3.6 4.4 5.2 6.0 6.8 7.6 8.4 9.3 10.1 10.9 11.7 12.5 13.3 14.1 14.9 15.1

10 inch 0 0.3 0.8 1.4 2.0 2.6 3.2 3.8 4.4 5.0 5.6 6.2 6.8 7.4 8.0 8.6 9.2 9.8 10.4 10.9 11.5

01/29/2009 196-522B

Page 26

3S-4010HD and 3S-4010HDF

24

Great Plains Mfg., Inc.

Small Seeds Rates, lbs/ac, continued...

Ladino Clover, Canary Grass, Timothy, Canola

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 0.9 1.6 2.6 3.9 4.9 6.1 7.4 8.6 9.8 11.1 12.5 13.7 14.9 16.3 17.6 18.8 20.4 21.9 23.5

10 inch 0 0.0 0.6 1.5 1.9 2.5 3.6 4.5 5.4 6.3 7.2 8.1 9.1 10.0 10.9 12.0 12.9 13.8 14.9 16.1 17.2

Birdsfoot, Trefoil, Sudan

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 1.4 2.6 4.2 5.4 7.0 8.6 10.2 11.9 13.5 15.4 17.0 18.8 20.5 22.5 24.0 25.8 27.6 29.1 30.9

10 inch 0 0.0 1.0 1.9 3.1 4.0 5.1 6.3 7.5 8.6 9.9 11.3 12.5 13.8 15.1 16.5 17.6 18.9 20.2 21.4 22.7

196-522B 01/29/2009

Page 27

Great Plains Mfg., Inc.

Appendix

Main Seed Box Rate Charts, Metric

See page 2 for instructions. Charts in U.S. customary units begin on page 8.

Alfalfa or Rape

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.77 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 4.9 7.5 10.8 13.8 17.2 20.5 24.4 28.3 33.0 36.8 40.3 44.6 48.7 53.0 56.8 61.7 66.4 71.2 73.3 75.4

0 3.7 5.6 8.1 10.3 12.9 15.4 18.3 21.2 24.7 27.6 30.2 33.5 36.5 39.7 42.6 46.3 49.7 53.4 55.0 56.6

Barley (1 of 3)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.66 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 4.0 6.8 9.5 12.9 16.3 20.0 23.5 27.1 31.0 34.9 38.8 43.0 47.4 51.3 55.5 58.8 62.1 65.2 65.7 68.2

0 3.0 5.1 7.2 9.7 12.1 14.9 17.6 20.3 23.2 26.2 29.2 32.2 35.6 38.5 41.5 44.1 46.6 48.8 49.3 49.6

Seed Rate Handle Setting

Seed Rate Handle Setting

25

Barley (2 of 3)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.66 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 7.7 14.3 19.3 26.7 33.2 40.5 48.3 55.5 63.8 71.3 78.1 86.1 93.5 101.9 110.1 119.2 127.9 136.1 138.2 140.4

0 5.8 10.7 14.5 20.1 24.9 30.4 36.2 41.7 47.8 53.4 58.6 64.6 70.2 76.5 82.6 89.5 95.9 100.1 103.7 105.3

Seed Rate Handle Setting

Barley (3 of 3)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.66 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 19.0 34.8 47.4 65.5 81.2 99.1 118.0 135.7 155.9 174.4 191.1 210.5 228.7 249.5 269.4 291.7 312.8 332.9 338.2 343.4

0 14.3 26.2 35.5 49.1 60.9 74.3 88.5 101.8 117.0 130.8 143.3 157.9 171.5 187.0 202.1 218.8 234.6 249.7 253.6 257.7

Seed Rate Handle Setting

Buckwheat

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.62 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 10.1 18.9 26.5 37.6 46.9 58.4 70.1 83.0 95.9 110.6 121.8 135.1 148.5 161.2 175.6 187.9 201.2 214.4 214.6 218.9

0 7.6 14.1 19.9 28.2 35.1 43.8 52.5 62.2 72.0 83.0 91.4 101.3 111.4 120.9 131.7 141.0 150.9 160.8 164.7 170.1

Seed Rate Handle Setting

01/29/2009 196-522B

Page 28

3S-4010HD and 3S-4010HDF

26

Great Plains Mfg., Inc.

Main Box Rates, Metric, continued...

Buffalograss (1 of 4)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.30 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 1.1 2.3 3.4 4.5 5.6 7.9 9.0 11.3 12.4 14.6 15.8 16.9 19.2 20.3 21.4 22.5 22.5 22.5 22.5 22.5

0 1.1 2.3 2.3 3.4 4.5 5.6 6.8 7.9 9.0 10.1 12.4 13.5 13.5 14.6 15.8 16.9 1ˇˇˇ 16.9 16.9 16.9

Seed Rate Handle Setting

Buffalograss (2 of 4)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.30 kg per liter)

15.2cm (6in)

19.2cm (7.5in)

25.4cm (10in)

0 3.4 5.6 9.0 12.4 15.8 19.2 23.7 28.2 32.7 36.1 40.6 43.9 48.5 51.8 54.1 56.3 57.5 58.6 58.6 58.6

0 2.3 4.5 6.8 9.0 12.4 15.8 19.2 22.5 25.9 29.3 32.7 36.1 38.3 40.6 42.8 45.1 46.2 47.3 47.3 46.2

0 2.3 3.4 5.6 6.8 9.0 11.3 14.6 16.9 19.2 21.4 24.8 27.0 29.3 30.4 32.7 33.8 34.9 34.9 34.9 34.9

Seed Rate Handle Setting

Buffalograss (3 of 4)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.30 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 5.6 7.9 10.1 13.5 18.0 22.5 27.0 32.7 38.3 42.8 48.5 53.0 57.5 62.0 65.4 68.7 71.0 72.1 73.2 72.1

0 3.4 5.6 7.9 10.1 13.5 16.9 20.3 24.8 28.2 32.7 36.1 40.6 42.8 46.2 49.6 51.8 53.0 54.1 54.1 54.1

Seed Rate Handle Setting

Buffalograss (4 of 4)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.30 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 7.9 12.4 16.9 22.5 29.3 37.2 45.1 53.0 62.0 69.9 78.9 86.8 93.5 101.4 107.0 111.6 114.9 117.2 118.3 117.2

0 6.5 9.0 12.4 16.9 22.5 28.2 33.8 39.4 46.2 53.0 58.6 65.4 71.0 75.5 80.0 83.4 86.8 87.9 89.0 87.9

Seed Rate Handle Setting

Flax or Sudan

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.71 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 3.4 7.4 10.6 14.5 18.1 21.7 25.4 29.4 33.2 37.6 41.1 44.8 48.8 53.1 58.0 62.6 68.0 73.5 74.8 76.2

0 2.5 5.5 7.9 10.9 13.6 16.3 19.1 22.1 24.9 28.2 30.8 33.6 36.6 39.7 43.6 47.0 51.0 55.2 56.0 57.1

Seed Rate Handle Setting

Millet

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.77 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

196-522B 01/29/2009

0 4.2 7.4 10.6 14.0 17.5 21.0 24.5 28.3 32.0 35.7 39.5 43.6 47.0 51.2 55.5 59.3 63.5 68.0 69.2 70.2

0 3.1 5.5 7.9 10.6 13.1 15.7 18.3 21.2 24.0 26.8 29.6 32.7 35.4 38.4 41.5 44.5 47.7 51.1 51.9 52.7

Seed Rate Handle Setting

Page 29

Great Plains Mfg., Inc.

Main Box Rates, Metric, continued...

Milo

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.82 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 4.2 7.9 11.7 15.9 20.2 24.9 30.1 35.0 40.3 46.3 51.0 56.5 61.9 67.1 72.5 77.8 82.3 87.7 90.0 91.6

0 3.1 6.0 8.8 11.9 15.2 18.7 22.6 26.3 30.2 34.7 38.2 42.3 46.4 50.3 54.5 58.4 61.7 65.8 67.6 68.7

Seed Rate Handle Setting

Oats

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.48 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 4.7 10.9 15.6 21.5 28.3 34.7 42.0 49.3 56.8 64.8 71.5 79.0 86.3 93.9 101.4 108.9 116.4 124.4 124.5 127.5

0 3.5 8.2 11.7 16.2 21.2 26.0 31.5 36.9 42.6 48.6 53.7 59.3 64.8 70.4 76.0 81.6 87.3 93.3 93.4 95.6

Seed Rate Handle Setting

27

Peas

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.79 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 8.4 17.1 30.5 46.6 61.7 75.3 91.5 106.8 123.4 138.5 152.2 167.2 181.0 196.0 211.5 225.3 239.0 252.8 254.1 255.2

0 6.4 12.8 22.9 34.9 46.3 56.5 68.6 80.2 92.5 104.0 114.2 125.4 135.7 147.0 158.6 169.0 179.3 189.6 190.5 191.4

Seed Rate Handle Setting

Pinto Beans

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.66 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 0.0 7.6 11.6 15.8 21.2 28.5 31.7 37.0 42.3 47.8 52.3 57.1 61.9 66.8 72.3 76.7 81.5 86.1 87.9 88.3

0 0.0 5.7 8.8 11.7 15.9 19.9 23.8 27.7 31.8 35.7 39.2 42.9 46.4 50.2 54.5 57.5 61.1 64.6 64.8 64.8

Seed Rate Handle Setting

Rice, Short Grain (1 of 2)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.55 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 9.9 16.2 25.4 34.5 41.0 49.8 57.0 65.9 75.2 85.9 95.9 105.3 114.9 124.4 132.9 140.6 148.3 156.4 158.9 159.4

0 7.4 12.1 19.1 25.8 30.8 37.4 42.8 49.4 56.4 64.4 72.0 78.9 86.1 93.3 99.7 105.4 111.3 117.3 119.8 120.7

Seed Rate Handle Setting

Rice, Short Grain (2 of 2)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.55 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

01/29/2009 196-522B

0 16.1 26.4 41.4 56.1 66.8 81.3 93.0 107.3 122.6 140.0 158.4 171.7 187.3 202.9 216.7 229.1 241.8 255.0 262.3 268.2

0 12.0 19.9 31.1 42.1 50.1 61.0 69.7 80.5 91.9 105.0 117.3 128.8 140.4 152.2 162.5 171.9 181.3 191.2 196.6 199.8

Seed Rate Handle Setting

Page 30

3S-4010HD and 3S-4010HDF

28

Great Plains Mfg., Inc.

Main Box Rates, Metric, continued...

Rice, Long Grain (1 of 4)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.60 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

01 5 7 912161820242829323537394345464748

0 1 3 5 7 9 11 14 16 18 21 21 24 26 28 30 32 34 35 36 36

Seed Rate Handle Setting

Rice, Long Grain (2 of 4)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.60 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

02 81419263237434859606571778287919698100

0 2 7 10 15 19 24 28 32 36 37 45 48 53 57 62 65 69 72 73 75

Seed Rate Handle Setting

Rice, Long Grain (3 of 4)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.60 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 0.0 11.8 19.4 28.4 37.6 47.4 55.0 63.5 72.6 80.6 88.1 95.7 103.7 112.5 121.0 129.7 137.6 144.6 150.1 155.3

0 0.0 8.9 14.6 21.2 28.2 35.5 41.2 47.6 54.5 60.5 66.1 71.7 77.8 84.4 90.7 97.2 103.3 108.5 112.6 116.4

Seed Rate Handle Setting

Rice, Long Grain (4 of 4)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.60 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 0.0 19.3 31.7 46.3 61.3 77.2 89.6 103.6 118.3 131.5 143.7 155.9 169.1 183.4 197.3 211.4 224.4 235.8 244.7 253.2

0 0.0 14.5 23.8 34.7 45.9 57.9 67.2 77.7 88.8 98.6 107.8 117.0 126.9 137.6 148.0 158.5 168.4 176.8 183.6 189.8

Seed Rate Handle Setting

Rye

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.73 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 2.5 7.1 11.3 16.6 21.6 25.1 31.1 36.6 42.2 47.6 52.1 56.5 61.4 66.2 72.3 77.7 84.0 90.7 91.3 91.6

0 1.9 5.3 8.5 12.5 16.2 18.9 23.4 27.4 31.7 35.7 39.1 42.4 46.0 49.7 54.2 58.3 63.0 68.0 68.5 68.7

Seed Rate Handle Setting

196-522B 01/29/2009

Page 31

Great Plains Mfg., Inc.

Main Box Rates, Metric, continued...

Soybeans (1 of 4)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.75 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 2.5 7.0 11.8 17.3 20.8 25.7 30.3 35.1 40.1 44.3 49.7 54.8 59.5 64.2 69.2 73.2 78.0 83.1 83.5 83.8

0 1.9 5.3 8.9 13.0 15.6 19.3 22.7 26.4 30.1 33.3 37.4 41.1 44.6 48.2 51.9 54.9 58.5 62.3 62.8 62.9

Seed Rate Handle Setting

Soybeans (2 of 4)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.75 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 5.2 14.4 24.3 35.6 42.7 52.9 62.2 72.3 82.4 91.3 102.3 112.5 122.1 131.9 142.1 150.3 160.4 170.8 171.7 172.1

0 3.9 10.8 18.2 26.7 32.0 39.6 46.7 54.2 61.9 68.5 76.8 84.4 91.6 98.9 106.5 112.8 120.4 127.6 128.8 129.1

Seed Rate Handle Setting

29

Soybeans (3 of 4)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.75 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 10.3 20.2 36.3 53.4 63.5 79.8 90.7 104.5 118.0 133.0 147.3 162.3 176.3 191.9 204.3 223.0 238.2 253.9 254.1 254.5

0 7.7 15.2 27.2 40.1 47.6 59.8 68.0 78.4 88.5 99.7 110.5 121.7 132.3 143.9 153.2 167.2 178.7 190.5 190.8 190.8

Seed Rate Handle Setting

Soybeans (4 of 4)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.75 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 17 33 60 88 104 131 149 171 193 217 241 266 288 314 335 365 390 417 418 418

0 12 25 45 65 78 98 112 128 144 163 163 199 216 236 251 274 293 313 313 313

Seed Rate Handle Setting

Sunflower

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.36 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 0.0 1.8 3.8 5.5 7.5 9.5 11.6 13.8 15.9 18.2 20.2 22.3 24.6 26.6 28.6 30.6 32.3 34.5 35.4 36.5

0 0.0 1.3 2.8 4.2 5.6 7.2 8.8 10.3 12.0 13.6 15.2 16.7 18.4 20.0 21.4 22.9 24.3 25.8 26.6 27.4

Seed Rate Handle Setting

01/29/2009 196-522B

Page 32

3S-4010HD and 3S-4010HDF

30

Great Plains Mfg., Inc.

Main Box Rates, Metric, continued...

Wheat (1 of 2)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.82 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 11.2 19.8 27.3 35.5 44.6 51.5 62.8 72.3 82.1 94.1 103.4 114.4 126.0 136.7 147.4 159.0 170.7 182.3 184.8 184.9

0 8.4 14.8 20.4 26.6 33.5 38.6 47.0 54.2 61.5 70.5 77.6 85.8 94.5 102.5 110.6 119.2 128.0 136.7 138.5 138.8

Seed Rate Handle Setting

Wheat (2 of 2)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.82 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 14.3 27.5 40.2 53.4 66.6 78.6 93.1 107.9 122.6 137.6 150.9 166.7 181.8 197.8 215.4 229.7 245.8 260.4 266.5 268.3

0 10.7 20.7 30.1 40.1 50.0 58.9 69.5 80.8 91.9 103.3 113.2 125.1 138.3 148.3 161.6 172.3 184.3 195.2 199.8 201.3

Seed Rate Handle Setting

Wheatgrass

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare (based on 0.30 kg per liter)

19.2cm (7.5in)

25.4cm (10in)

0 0.0 0.8 1.9 2.7 3.8 4.6 5.4 6.6 7.5 8.6 9.7 10.7 11.8 12.8 13.9 15.0 16.1 16.3 16.6 18.6

0 0.0 0.7 1.5 2.0 2.8 3.5 4.0 4.9 5.7 6.5 7.3 8.0 8.9 9.5 10.4 11.3 12.0 12.2 12.5 14.0

Seed Rate Handle Setting

196-522B 01/29/2009

Page 33

Great Plains Mfg., Inc.

Fertilizer Rate Charts, Metric

Fertilizer Rate, 19.2cm Row Spacing

Based on 1.04 kg per cubic liter

(see page 19 for 7.5in chart in U.S. customary units))

19.2cm Fertilizer Rate 19.2cm Fertilizer Rate

Row Spacing Kilograms per Hectare Row Spacing Kilograms per Hectare

TRANSMISSION Fertilizer Rates by RANGE TRANSMISSION Fertilizer Rates by RANGE

Sprockets

DRIVER DRIVEN HIGH DRIVER DRIVEN HIGH

12T 24T 43 152 445 18T 17T 92 321 849

12T 23T 45 158 464 13T 12T 94 329 858

13T 24T 47 164 480 23T 21T 95 332 867

12T 21T 50 173 507 20T 18T 97 337 869

12T 20T 52 182 530 18T 16T 98 341 880

13T 21T 54 188 544 23T 20T 100 349 888

13T 20T 57 197 571 21T 18T 101 354 901

12T 18T 58 202 582 20T 17T 102 357 908

16T 23T 60 211 608 24T 20T 104 364 914

12T 17T 61 214 613 16T 13T 107 374 937

17T 23T 64 224 637 21T 17T 107 375 928

18T 24T 65 228 646 20T 16T 109 379 939

16T 21T 66 231 656 23T 18T 111 388 947

18T 23T 68 237 668 21T 16T 114 398 973

16T 20T 70 243 683 24T 18T 116 404 975

17T 21T 70 246 691 23T 17T 118 410 989

20T 24T 72 253 705 18T 13T 120 420 999

17T 20T 74 258 720 24T 17T 123 428 1005

18T 21T 75 260 726 17T 12T 123 430 1008

20T 23T 76 264 729 23T 16T 125 436 1009

18T 20T 78 273 755 18T 12T 130 454 1040

21T 23T 79 277 758 20T 13T 134 466 1053

12T 13T 80 280 766 21T 13T 140 488 1079

17T 18T 82 287 775 20T 12T 145 503 1102

20T 21T 83 289 782 21T 12T 152 526 1134

23T 24T 83 291 787 23T 13T 154 532 1137

21T 21T 87 303 812 24T 13T 161 552 1178

24T 23T 91 317 837 23T 12T 167 573 1211

21T 20T 91 319 842 24T 12T 174 595 1257

LOW HIGH

ULTRA Sprockets

ULTRA

LOW HIGH

31

01/29/2009 196-522B

Page 34

3S-4010HD and 3S-4010HDF

32

Great Plains Mfg., Inc.

Fertilizer Rate, 25.4cm Row Spacing

Based on 1.04 kg per cubic liter

(see page 20 for 10in chart in U.S. customary units))

25.4cm Fertilizer Rate 25.4cm Fertilizer Rate

Row Spacing Kilograms per Hectare Row Spacing Kilograms per Hectare

TRANSMISSION Fertilizer Rates by RANGE TRANSMISSION Fertilizer Rates by RANGE

Sprockets

DRIVER DRIVEN HIGH DRIVER DRIVEN HIGH

LOW HIGH

12T 24T 33 115 336 18T 17T 70 243 642

12T 23T 34 120 351 13T 12T 71 249 649

13T 24T 36 124 363 23T 21T 72 251 656

12T 21T 38 131 383 20T 18T 73 255 657

12T 20T 39 138 401 18T 16T 74 258 665

13T 21T 41 142 411 23T 20T 76 264 671

13T 20T 43 149 432 21T 18T 77 268 681

12T 18T 44 153 440 20T 17T 77 270 687

16T 23T 46 160 460 24T 20T 79 275 691

12T 17T 46 162 463 16T 13T 81 283 709

17T 23T 49 170 481 21T 17T 81 284 702

18T 24T 49 172 488 20T 16T 82 287 710

16T 21T 50 175 496 23T 18T 84 293 716

18T 23T 51 180 505 21T 16T 86 301 736

16T 20T 53 184 517 24T 18T 88 306 737

17T 21T 53 186 523 23T 17T 89 310 748

20T 24T 55 191 533 18T 13T 91 318 755

17T 20T 56 195 544 24T 17T 93 324 760

18T 21T 56 197 549 17T 12T 93 325 762

20T 23T 57 200 551 23T 16T 95 330 763

18T 20T 59 207 571 18T 12T 99 343 786

21T 23T 60 210 573 20T 13T 101 352 796

12T 13T 61 212 579 21T 13T 106 369 816

17T 18T 62 217 586 20T 12T 110 380 833

20T 21T 63 219 591 21T 12T 115 398 858

23T 24T 63 220 595 23T 13T 116 402 860

21T 21T 66 229 614 24T 13T 121 418 891

24T 23T 69 239 633 23T 12T 126 434 915

21T 20T 69 241 637 24T 12T 132 450 950

ULTRA Sprockets

ULTRA

LOW HIGH

196-522B 01/29/2009

Page 35

Great Plains Mfg., Inc.

Small Seeds Rate Charts, Metric

Charts in U.S. customary units begin on page 23.

Alfalfa, Red Alsike, Crimson Clover

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

19.2cm (7.5in) 0 0.0 2.0 3.2 4.4 5.4 6.8 7.9 8.9 10.1 11.3 12.5 13.6 14.9 15.8 17.2 18.3 19.4 20.6 21.7 22.9

25.4cm (10in) 0 0.0 1.5 2.4 3.2 3.9 5.0 5.7 6.5 7.4 8.3 9.1 10.0 10.9 11.6 12.6 13.4 14.2 15.1 15.1 15.1

Kentucky Bluegrass, Fescue, Annual Rye Grass

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

19.2cm (7.5in) 0 0.0 0.2 1.0 1.7 2.5 3.0 3.7 4.2 4.7 5.2 5.7 6.2 6.6 7.1 7.5 7.9 8.3 8.3 9.1 9.5

25.4cm (10in) 0 0.0 0.1 0.8 0.8 1.8 2.3 2.3 2.3 3.5 3.5 4.2 4.5 4.8 5.2 5.5 5.5 6.1 6.1 6.6 7.0

Small Seeds Cup Lever Setting

Small Seeds Cup Lever Setting

33

Bermuda, Red Top, Lespedeza Unhulled, Sercia, Sand, Weeping Love Grass

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

19.2cm (7.5in) 0 0.0 0.6 1.0 1.6 2.4 2.9 3.7 4.5 5.3 6.0 6.5 7.1 7.5 8.1 8.6 9.2 9.9 10.5 11.0 11.7

25.4cm (10in) 0 0.0 0.5 0.7 1.1 1.7 2.1 2.7 3.4 3.9 4.4 4.7 5.2 5.2 6.0 6.3 6.8 7.2 7.7 8.1 8.1

Small Seeds Cup Lever Setting

Red & Sweet Clover, Lespedeza Hulled

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

19.2cm (7.5in) 0 0.0 1.4 3.0 4.7 6.4 8.1 10.3 11.9 13.9 15.4 17.2 18.8 20.4 22.2 23.9 25.6 27.3 29.1 30.6 32.2

25.4cm (10in) 0 0.0 1.0 2.3 3.5 4.7 6.0 7.5 8.8 10.1 11.3 12.6 13.7 15.0 16.2 17.6 18.7 20.1 21.3 21.3 23.6

Small Seeds Cup Lever Setting

Orchard Grass

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

19.2cm (7.5in) 0 0.0 0.0 0.2 0.6 0.8 0.8 1.4 1.4 1.4 1.4 1.4 3.2 3.6 3.9 4.4 4.5 5.0 5.2 5.5 5.5

25.4cm (10in) 0 0.0 0.0 0.1 0.5 0.6 0.9 1.0 1.4 1.6 1.9 2.1 2.4 2.6 2.9 3.2 3.4 3.6 3.7 4.1 4.2

Small Seeds Cup Lever Setting

01/29/2009 196-522B

Page 36

Great Plains Mfg., Inc.

Metric Rate Charts, Small Seeds Box, continued...

Millet, Reed Canary

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare