Great Plains 3S-3000HD User Manual

Great Plains Mfg., Inc.

Installation Instructions 1

Main Seed Box Agitator Kit

30-Foot 3-Section 00 Series Drills

Used with:

• 3S-3000

• 3S-3000HD

General Information

These instructions explain how to install a Main Seed

Box Agitator Kit on a drill having only a main seed box.

The agitator stirs seed in the main box directly above the

meter cups. This helps prevent bridging of light fluffy

seeds and helps separate seeds sticky with innoculant.

These instructions apply to an installation of:

Kit Kit Description

118-252A

One kit updates one drill (3 sections). Drills manufactured in 1996 or later (including all 3S-3000HD models)

may be compatible with this kit. Drills manufactured earlier do not have mounts for key components.

Drill Model Kit Compatibility

3000-3S 1996+, serial number S1563 or higher

3S-3000 1996+, serial number S1563 or higher

3S-3000F * Not compatible

3S-3000HD All drills

3S-3000HDF * Not compatible

3S-3000 AGITATOR PKG W/ DRIVE

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

R

F

U

B

L

D

(*) The components in this kit are incompatible with an

installation of Fertilizer and/or Small Seeds.

The kit presumes 6in row spacing, and may include more

components than are required for your drill.

Related Documents

Have the Operator Manual at hand for drill movements.

195-110M-A Operator, 3S-3000

195-068M Operator, 3S-3000HD

Have the current Parts Manual at hand for parts ID.

195-110P Parts, 3S-3000

195-068P Parts, 3S-3000HD

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

©Copyright 2009 Printed 03/24/2009 118-253M

U

F

L

R

B

D

Call-Outs

1 9

to

11 59

to

71 93

to

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts in the range 11 to 59 reference new parts from the new parts lists

beginning on page 19.

Two-digit callouts in the range 71 to 93 reference affected existing parts from the table on

page 21. The descriptions match those in

your Parts Manual. The narrative and table

indicate any re-use of the parts.

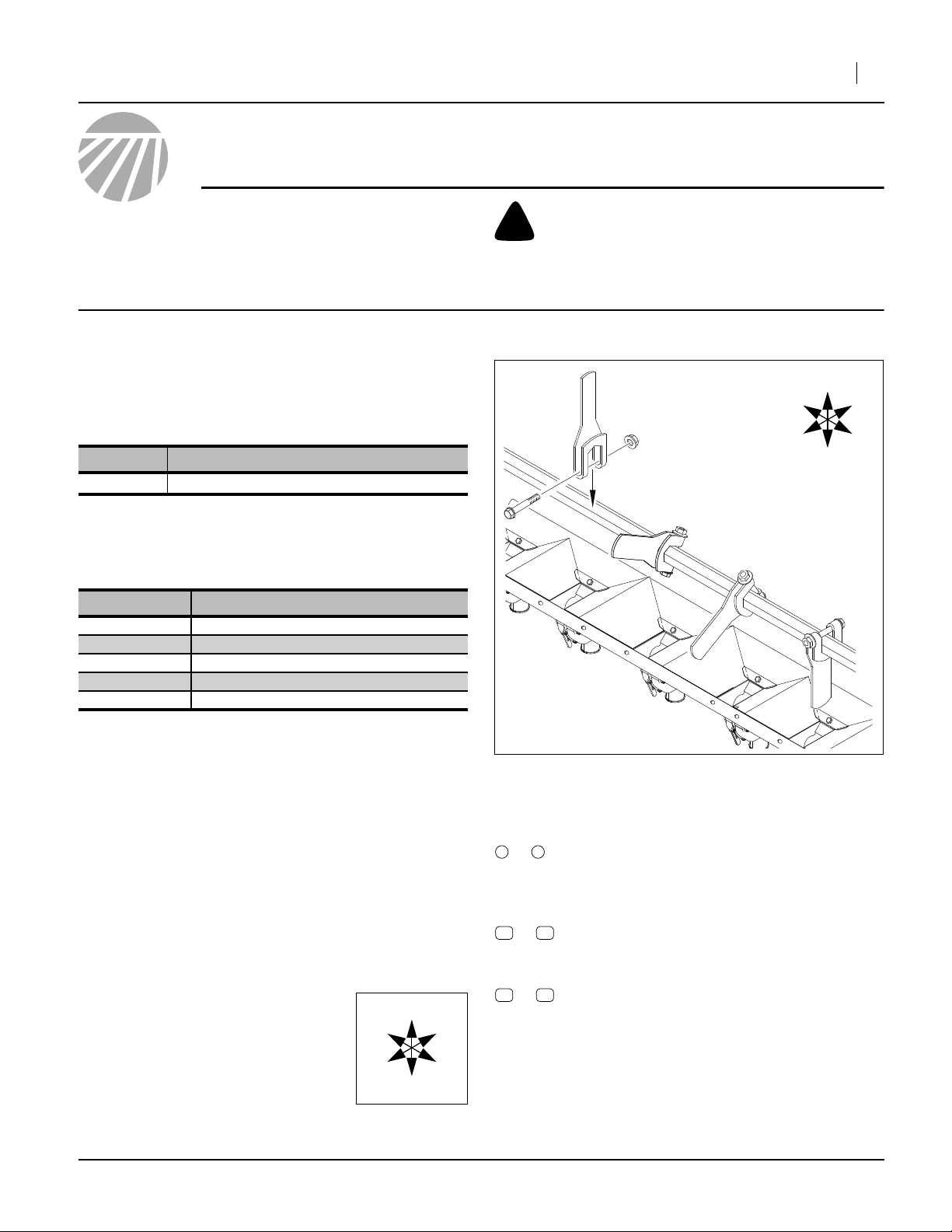

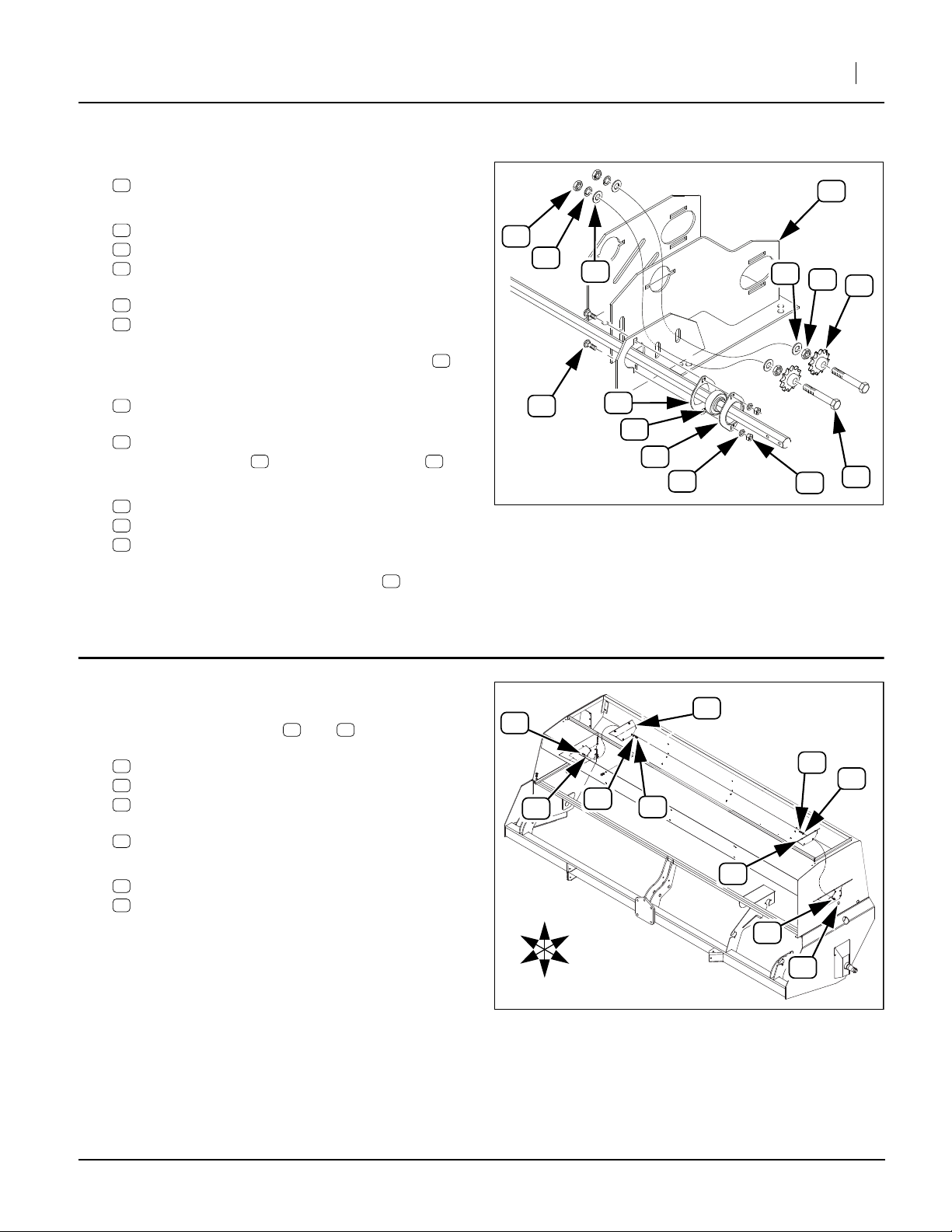

Figure 1

Agitators Above Cups

29355

2 Main Seed Box Agitator Kit

Before You Start

Compatibility

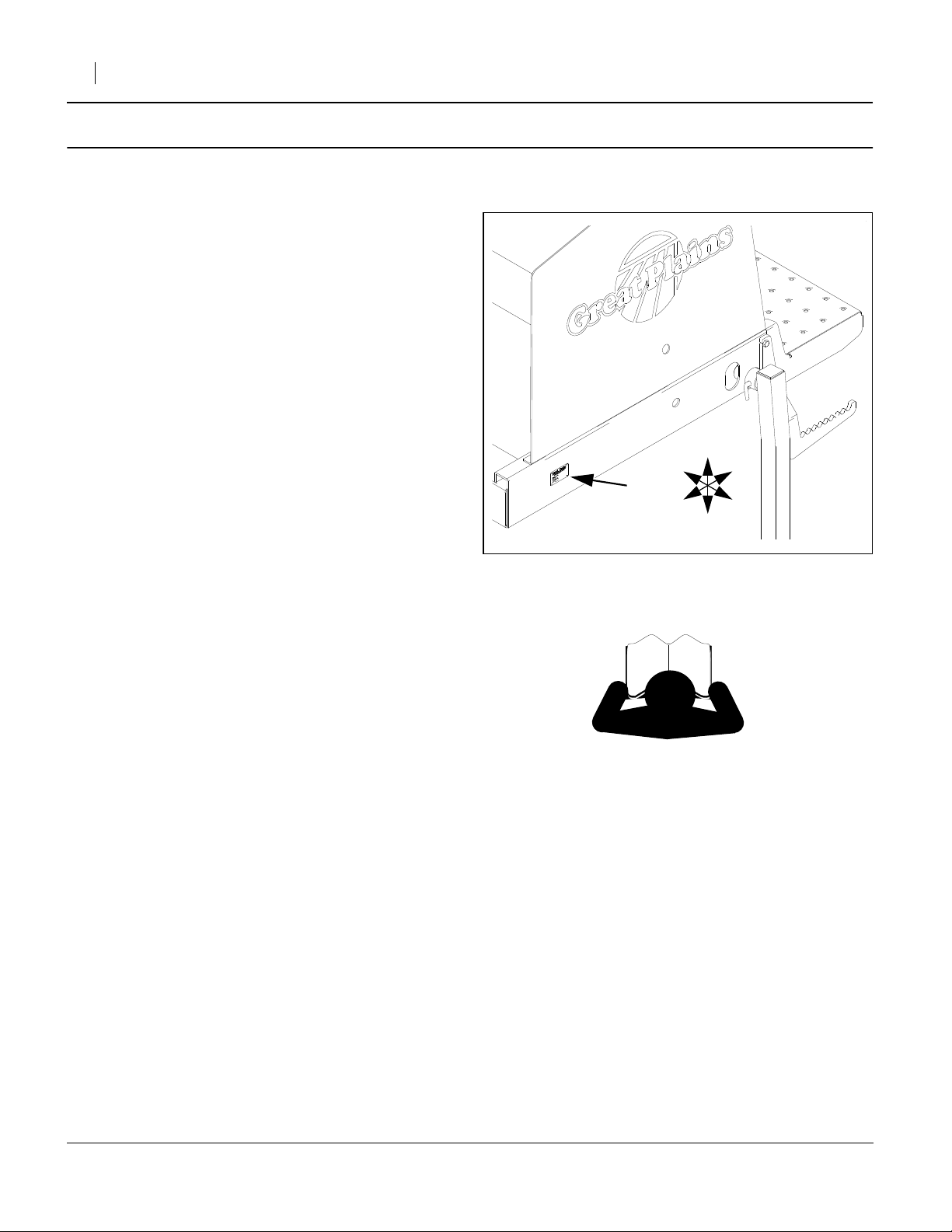

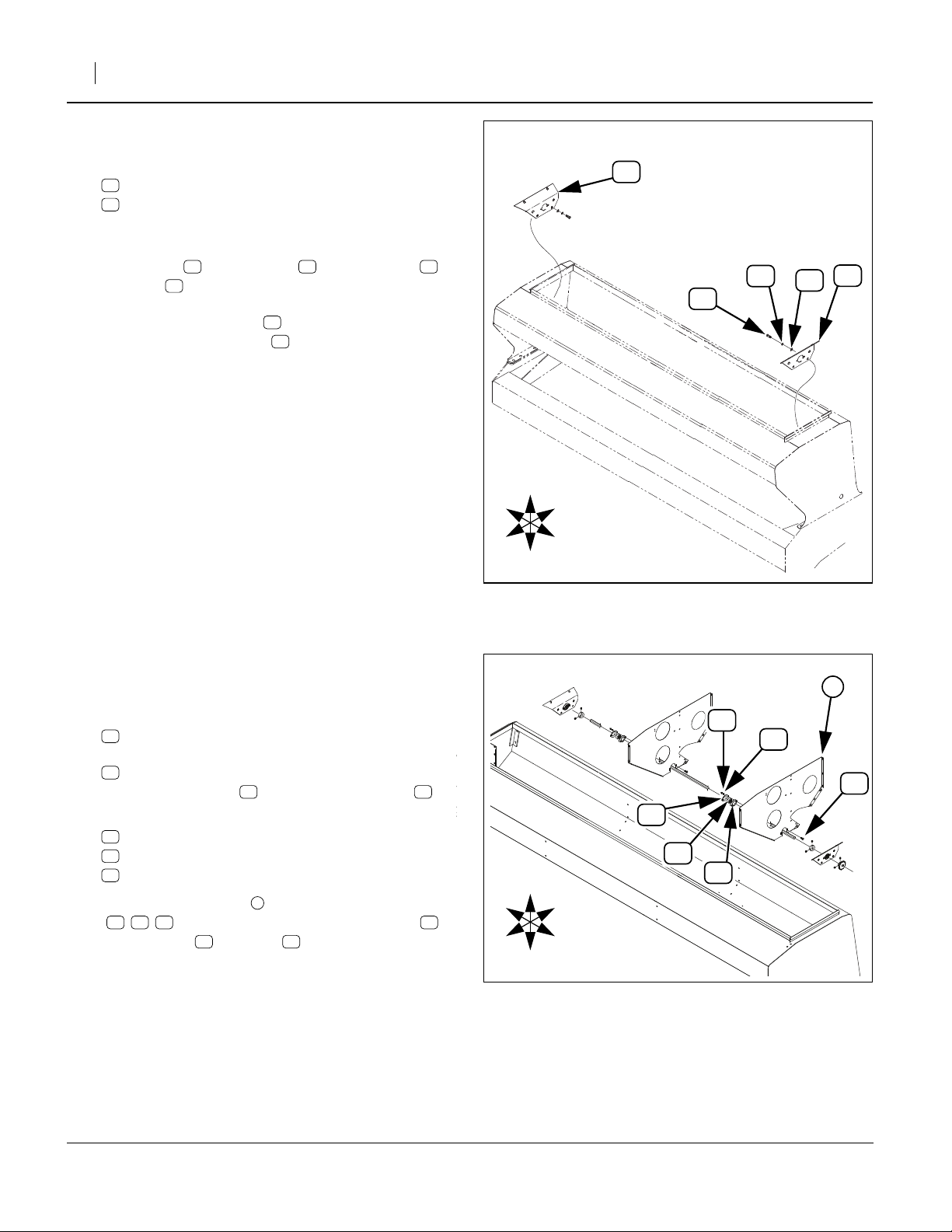

Refer to Figure 2

1. Check the serial number plate against the table on

page 1. Verify from the serial number or date of

manufacture that the drill is compatible with this kit.

2. Check for an installation of Fertilizer (“HDF” model,

or divided main box, and a transmission at front left

of each section). If the drill has Fertilizer, do not

install this kit.

3. Check for an installation of Small Seeds (small seed

box at upper rear of main box). If the drill has Small

Seeds options installed, do not install this kit.

4. Check for an installation of Point Row option (solenoid valve block behind pressure adjustment valves,

mechanical clutch in center section). If the drill has

Point Row installed, do not install this kit.

Note: This kit is compatible with the electric clutch

option.

Inventory

5. Make sure all parts are present.

Comprehension

6. Review these instructions. Make sure the installers

understand where each part or assembly is

installed, and what tools are required for the task.

Note: Some sequences in these instructions have you

update one box at a time. Parts are removed and

re-installed. Parts can vary between boxes, with

some risk of part mix-up if all disassembly is done

at once.

Note: Illustrations in this manual, based on the parts

manuals for this family of drills, may show

exploded views that are fully disassembled. Rely

on the instructions for required disassembly and

reassembly steps.

U

R

F

D

Figure 2

Serial Number Plate

Great Plains Mfg., Inc.

B

L

15614

118-253M 03/24/2009

Great Plains Mfg., Inc.

Pre-Assembly Preparation

Tools Required

• updated drill Parts Manual (see page 1)

• suitable tractor for raising and folding implement

• basic hand tools,

including punch for removing

• two people suggested for shaft installations

Work Location

7. Clean out the main seed boxes. See Operator Man-

ual for instructions.

If treated seed has been used,

open seed cup doors to clean-out position,

wash out the boxes,

thoroughly rinse the boxes, and

allow them to dry.

1

⁄

in roll pins

4

Installation Instructions 3

!

CAUTION

Chemical Hazard

This installation requires contact with interior components of

the main seed box. If treated seed has ever been used in the

box, follow chemical supplier instructions for protective equipment and cleaning residue from the seed box.

Do this in a suitable location other than where the

installation work is to be performed.

8. Move the implement to a location with:

• room to unfold it,

• access to tractor or hydraulic power,

• adequate illumination, and;

• clear surface beneath

for recovery of any falling or dropped parts - if the

surface is not clear, have a tarp or drop cloth

available.

Prepare Implement

9. Partially unfold implement. Stop the unfold about

halfway, both to provide access to the front and

ends of all boxes, and to allow removal of the center

drive shaft.

10. Lower the drill.

11. Shut off tractor or hydraulic source. Put tractor in

Park.

!

WARNING

Negative tongue weight hazard

3S-3000 drills can have significant negative tongue weight

when fully unfolded. The tongue can fly up during transport or

opener lift, if using stationary hydraulic power to operate

implement.

03/24/2009 118-253M

4 Main Seed Box Agitator Kit

Pre-Assemble Components

Great Plains Mfg., Inc.

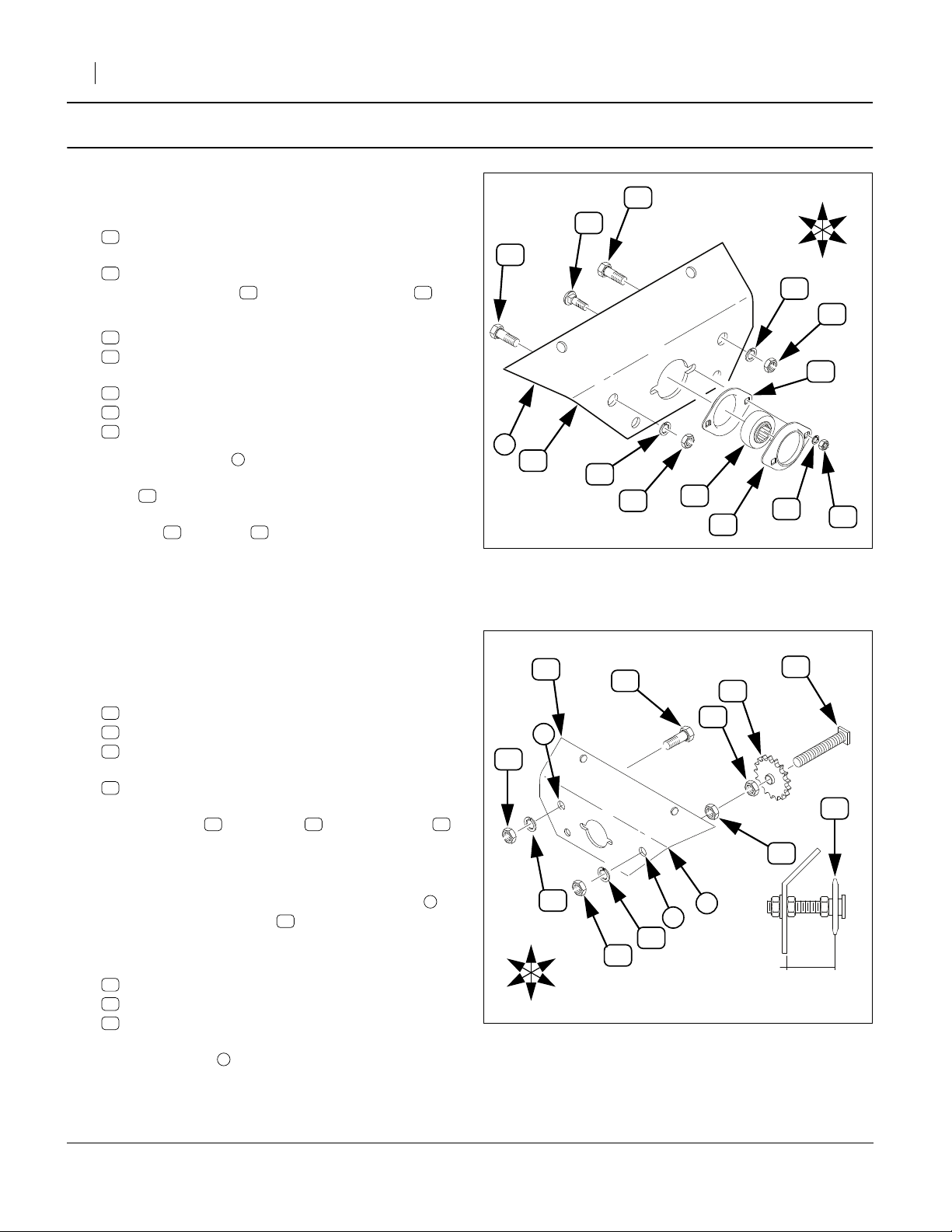

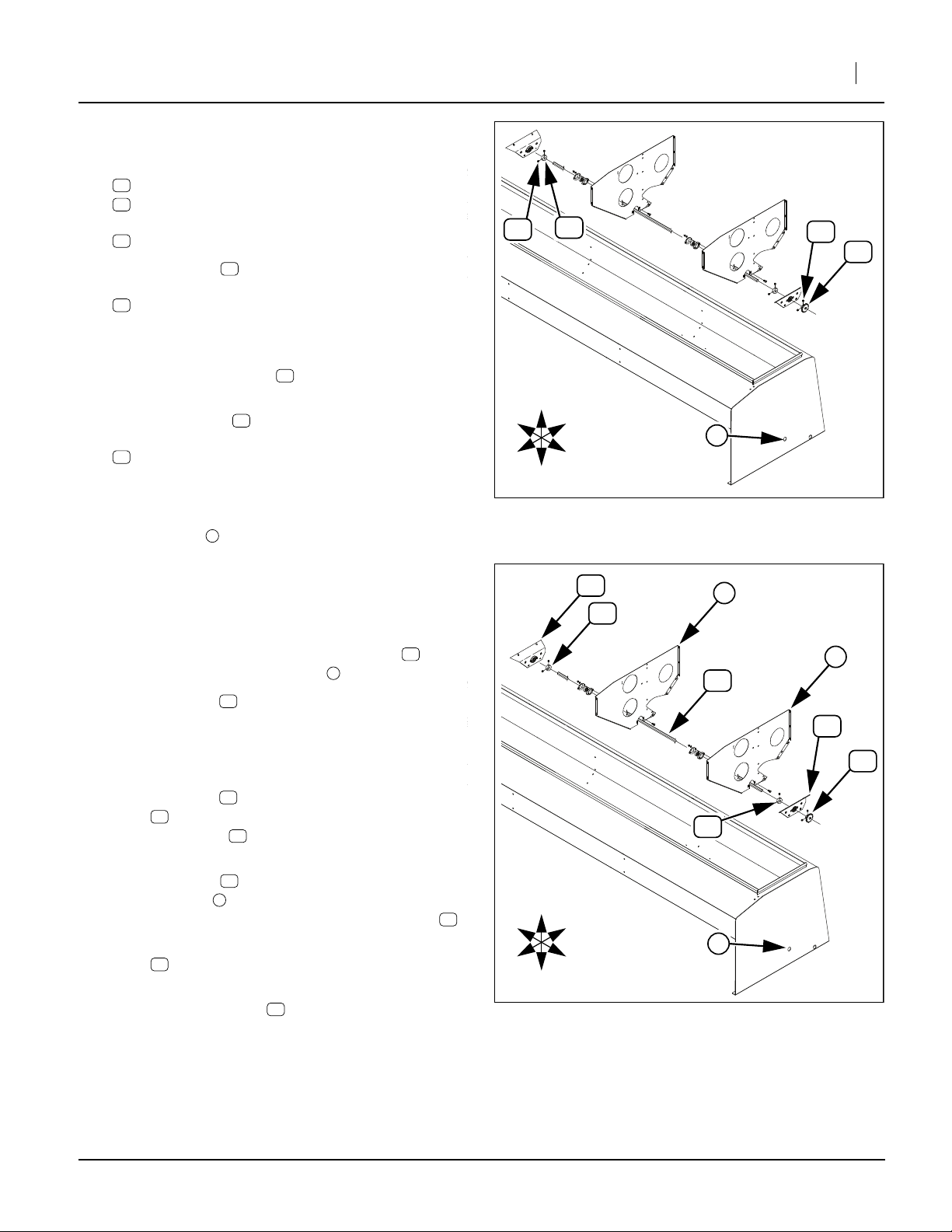

Mount End Plate Bearings

Refer to Figure 3 and Figure 4

12. Select six (6) new:

59

822-128C BRG INS 3/4HEXX1.85OD SPH

and twelve (12) new:

57

822-041C FLANGETTE 47 MST

Insert each bearing in between flangettes .

13. Select three (3) each new:

19

175-339D 1300 AGITATOR BRG PLT RH

20

175-340D 1300 AGITATOR BRG PLT LH

and twelve (12) sets new:

29

802-009C RHSNB 5/16-18X1 1/4 GR5

45

804-009C WASHER LOCK SPRING 5/16 PLT

38

803-008C NUT HEX 5/16-18 PLT

14. With the top break up and away from you, mount

a bearing assembly on the side facing you, with the

29

bolts inserted from behind the plate (under the

break). Secure bolts only to finger-tight with lock

washers and nuts (final tightening is at step

42).

45 38

59 57

1

31

1

19

31

29

47

41

Figure 3

Right Bearing Plate

59

57

R

F

47

45

U

B

L

D

41

57

38

29357

Mount End Plate Idler(s)

Refer to Figure 4

15. Select the left bearing plates and three (3) each

new:

12

118-439H AGITATOR IDLER BOLT 5/8-11

47

804-022C WASHER LOCK SPRING 5/8 PLT

51

808-046C SPKT 40A17 IDLER

and nine (9):

41

803-023C NUT HEX JAM 5/8-11 PLT

Place the idler on the bolt . Add a jam nut

and torque to 100 ft-lbs. Add another jam nut, and

spin on to the position show in Figure 4 - until the

plate face will be 2

line when the bolt is placed in the forward hole .

Secure with third jam nut , torqued to 100 ft-lbs.

Refer to Figure 3 and Figure 4

16. Select nine (9) sets new:

31

802-050C HHCS 5/8-11X1 1/4 GR5

47

804-022C WASHER LOCK SPRING 5/8 PLT

41

803-023C NUT HEX JAM 5/8-11 PLT

Use these bolts, washers and jam nuts to block the

rear middle hole of the left bearing plates, and

both middle holes of the right bearing plates.

51 12 41

1

9

⁄

to 2

⁄

2

3

in from the idler center-

16

41

20

31

51

12

41

3

41

51

41

2

47

1

2

B

R

U

L

F

41

47

2

1

⁄

2

in to 2

9

⁄

in

16

D

Figure 4

Left Bearing Plate

17041

118-253M 03/24/2009

Great Plains Mfg., Inc.

Pre-Assemble Weldments

Refer to Figure 24

17. Select three (3) new:

22

195-145H FERTILIZER DRIVE WELDMENT LH

18. Select six (6) sets new:

33

802-099C HHCS 1/2-13X3 1/4 GR5

54

817-025C NO. 40 12T IDLER SPKT.

46

804-015C WASHER LOCK SPRING 1/2 PLT

and twelve (12) new:

42

803-036C NUT HEX JAM 1/2-13 PLT

48

804-113C WASHER FLAT 1/2 USS HARD PLT

Assemble and install idlers in the idler slots of left

side of the left-most vertical plate of weldment .

19. Select three (3) new:

58

822-119C BRG 7/8HEXX2.05OD SPH

and six (6) new:

56

822-032C FLANGETTE 52 MST

Insert each bearing in between flangettes .

20. Select six (6) sets new:

35

802-282C RHSNB 5/16-18X1 GR5

45

804-009C WASHER LOCK SPRING 5/16 PLT

38

803-008C NUT HEX 5/16-18 PLT

Mount each bearing assembly on the left side of the

left-most vertical plate of the weldment . Thread

nuts on only to finger tight.

58 56

22

22

42

46

35

Installation Instructions 5

48

56

58

56

45

Figure 5

Pre-Assemble a Weldment

48

38

22

42

54

33

29361

Install Shafts and Paddles

Remove End Panel Covers

Refer to Figure 6

21. At all end panel covers ( and ), remove and

save four (4)sets (24 sets total):

85

803-014C NUT HEX 3/8-16 PLT

88

804-011C WASHER FLAT 3/8 USS PLT

83

802-079C HHCS 3/8-16X1 1/4 GR5

which may include 24 or 48:

89

804-013C WASHER LOCK SPRING 3/8 PLT

22. Remove one each:

74

195-101D INTERIOR ENDPANEL COVER LH

75

195-102D INTERIOR ENDPANEL COVER RH

These panels are not re-used.

74 75

85

R

F

89

U

D

75

88

83

B

L

Figure 6

Existing End Panel Covers

83

88

74

89

85

17039

03/24/2009 118-253M

6 Main Seed Box Agitator Kit

Install Bearing Plates

Refer to Figure 7

23. Select the six (6) bearing plate assemblies:

19

Right end, bearing only

20

Left end, bearing and sprocket(s)

24. Install the bearing plates where the end panel covers were removed, using for each plate, four sets of

saved bolts , flat washers , lock washers

and nuts (not shown).

If only one lock washer is available per saved

bolt, place it under a nut .

83 88 89

85

89

85

R

U

B

19

83

Great Plains Mfg., Inc.

89

88

20

Install Divider Bearings

Refer to Figure 8 (which depicts components outside the seed

box for clarity - do not remove dividers)

25. Select six (6) new:

59

822-128C BRG INS 3/4HEXX1.85OD SPH

and twelve (12) new:

57

822-041C FLANGETTE 47 MST

Insert each bearing in between flangettes .

26. Select twelve (12) sets new:

29

802-009C RHSNB 5/16-18X1 1/4 GR5

45

804-009C WASHER LOCK SPRING 5/16 PLT

38

803-008C NUT HEX 5/16-18 PLT

27. At each divider panel , install a bearing assembly

57 59 57 29

( - - ) with two sets of square neck bolts ,

lock washers and nuts .

Mount assembly on whichever side of the divider

places the bearing further from seed cup centerlines. Spin on nuts only to finger-tight.

59 57

4

45 38

F

R

F

L

D

Figure 7

New End Panel Bearing Plates

57

59

U

57

B

L

D

Figure 8

Divider Bearing Component Order

17042

4

38

45

29

29356

118-253M 03/24/2009

Great Plains Mfg., Inc.

Prepare Agitator Shaft Components

Refer to Figure 9

28. Select three (3) each new:

15

118-592H

16

118-647D 1006 AGITATOR SHAFT

and six (6) new:

14

118-494D LOCK COLLAR 3/4 HEX BORE

29. If the sprockets do not have set screws installed,

select six (6) new:

28

801-035C SCREW SET 5/16-18 SKT KP X 3/8

Screw the set screws into the sprockets, stopping

just before the tips intrude into the hex bore.

SPKT 40B17X3/4 HEXBR&LCK COLLR

15

28

14

Installation Instructions 7

28

15

Note that the sprockets have a raised hub on

one side. When installed, this hub is to drill right.

30. If the lock collars do not have set screws

installed, select twelve (12) new:

28

801-035C SCREW SET 5/16-18 SKT KP X 3/8

Screw the set screws into the collars, stopping just

before the tips intrude into the hex bore.

31. At the left end of each box, note the location of the

external hole for the agitator shaft.

5

15

14

Prepare Agitator Shaft Components

Two people are recommended for this sequence.

At each box.

Refer to Figure 10

32. Insert an inch (2-3cm) of an agitator shaft

through the external shaft hole .

33. Add a sprocket to the end of the shaft just inside

the left end wall. Orient the sprocket with the flat

toothed side to the left (onto the shaft first), and the

raised hub (with set screws) to the right. Do not

tighten the set screws at this time.

34. Insert the shaft through the left end bearing/idler

20

plate . When the shaft appears inside the box,

add a lock collar . Do not tighten the set screws

at this time.

15

16

14

5

16

R

F

U

D

B

L

19

Divider Bearings

14

Figure 9

14

5

29356

4

4

16

20

15

35. Insert the shaft through the bearings of both

divider panels . When the shaft appears to the

right of the right divider, add another lock collar .

36. Insert the shaft through the right end bearing

19

plate . Stop insertion when the shaft ends are

about equal distances from both outside end walls.

37. Slide both lock collars to the outside. Secure

their set screws.

03/24/2009 118-253M

16

4

14

R

U

B

5

F

L

D

14

Figure 10

Divider Bearing Component Order

29356

Loading...

Loading...