Page 1

Operator’ s Manual

SN S1399+

3S-3000

Three-Section Folding Drill

Manufacturing, Inc.

www .g reatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious -follow without exception. Your life and thelivesof

others depend on it!

© Copyright 2001 Printed

11/9/2007

15485

Cover illustration may show optional equipment not supplied with standard unit.

195-110M-A

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Description of Unit . . . . . . . . . . . . . . . . . . 10

Intended Usage . . . . . . . . . . . . . . . . . . . . 10

Using This Manual. . . . . . . . . . . . . . . . . . 10

Owner Assistance . . . . . . . . . . . . . . . . . . 10

Section 1 Drill Preparation and Setup . . . . 12

Leveling the Drill. . . . . . . . . . . . . . . . . . . . 12

Tractor Drawbar Hookup . . . . . . . . . . . . . 17

Tractor Hydraulic Hookup. . . . . . . . . . . . . 18

Safety Lights . . . . . . . . . . . . . . . . . . . . . . 18

Acre Meter . . . . . . . . . . . . . . . . . . . . . . . . 18

Bleeding the Hydraulic Systems . . . . . . . 19

Section 2 Operating Instructions . . . . . . . . 22

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Folding. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unfolding . . . . . . . . . . . . . . . . . . . . . . . . . 23

Transporting . . . . . . . . . . . . . . . . . . . . . . . 24

Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Setting the Bypass Valve . . . . . . . . . . . . . 26

Field Operation . . . . . . . . . . . . . . . . . . . . 27

Fertilizer Box Operation. . . . . . . . . . . . . . 30

Marker Operation. . . . . . . . . . . . . . . . . . . 31

Double Selector Valves . . . . . . . . . . . . . . 31

Shaft Monitor Operation. . . . . . . . . . . . . . 31

Point-Row Operation . . . . . . . . . . . . . . . . 31

Section 3 Adjustments. . . . . . . . . . . . . . . . . 32

Seeding Adjustment. . . . . . . . . . . . . . . . . 32

Seed Rate Calibration . . . . . . . . . . . . . . . 33

Seed Rate Charts (pounds per acre). . . . 34

Fertilizer Adjustment . . . . . . . . . . . . . . . . 38

Fertilizer Rate Calibration. . . . . . . . . . . . . 38

Fertilizer Meter Rate Charts. . . . . . . . . . . 39

Seeding Depth. . . . . . . . . . . . . . . . . . . . . 40

00 Series Opener Down Pressure . . . . . . 40

00 Series Opener Adjustments . . . . . . . . 42

00 Series Opener Frame Adjustments. . . 43

00 Series Disk Scraper Adjustment . . . . . 43

00 Series Seed-Lok® Lock Up. . . . . . . . . 43

Bleeding Marker Hydraulic System. . . . . 44

Dual Markers Speed Adjustment . . . . . . 44

Single Marker Speed Adjustment . . . . . . 45

Transport Carrier. . . . . . . . . . . . . . . . . . . 45

Marker Chain . . . . . . . . . . . . . . . . . . . . . 46

Disk Adjustment . . . . . . . . . . . . . . . . . . . 46

Breakaway Protection. . . . . . . . . . . . . . . 47

Seed and Fertilizer Capacity. . . . . . . . . . 48

Section 4 Troubleshooting . . . . . . . . . . . . . 49

Section 5 Maintenance and Lubrication . . 51

Maintenance . . . . . . . . . . . . . . . . . . . . . . 51

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Lubrication . . . . . . . . . . . . . . . . . . . . . . . 53

Section 6 Options . . . . . . . . . . . . . . . . . . . . 59

3S-3000 Flat Folding Marker . . . . . . . . . 59

00 Series Seed Lok Firming Wheel . . . . 59

3S-3000 Feed Cup Plugs . . . . . . . . . . . . 60

3S-3000 Shaft Monitors . . . . . . . . . . . . . 60

Two Outlet Tractor Hydraulic Kit . . . . . . . 61

3S-3000 Dual Gauge Wheels. . . . . . . . . 61

3S-3000F Offset Box Divider . . . . . . . . . 62

Point-Row Clutches. . . . . . . . . . . . . . . . . 62

Section 7 Specifications and Capacities. . 63

Section 8 Appendix. . . . . . . . . . . . . . . . . . . 64

Tire Inflation Chart . . . . . . . . . . . . . . . . . 64

Torque Values Chart. . . . . . . . . . . . . . . . . 64

Chain Routings . . . . . . . . . . . . . . . . . . . . 65

Hydraulic Schematics . . . . . . . . . . . . . . . 66

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . 70

© Copyright 2001 All rights Reserved

Great Plains Manufacturing,Inc. provides this publication “as is” without warranty of any kind, either expressedor implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing,Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication,and maynot reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Page 3

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

Be Aware of Signal Words

The word that designates a degree

or level of hazard seriousness. The

signal words are:

!

DANGER!

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for functional purposes, cannot be guarded.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

!

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

!

Keep Riders

Off Machinery

▲ Riders obstruct the operator’s

view they could be struck by foreign objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

For Your Protection

▲ Thoroughly read and understand

the “Safety Label” section, read all

instructions noted on them.

OFF

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine,

and remove the key.

▲ Detach and store implements in a

area where children normally do

not play. Secure implement by

using blocks and supports.

Handle

Chemicals Properly

▲ Protective clothing should be

worn.

▲ Handle all chemicals with care.

▲ Follow instructions on container

label.

▲ Agricultural chemicals can be

dangerous. Improper use can

seriously injure persons, animals,

plants, soil, and property.

▲ Inhaling smoke from any type of

chemical fire is a serious health

hazard.

▲ Store or dispose of unused chem-

icals as specified by the chemical

manufacturer.

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

1

Page 4

Important Safety Information

Great Plains Mfg., Inc.

Use Safety

Lights and Devices

▲ Slow moving tractors, self-pro-

pelled equipment, and towed

implements can create a hazard

when driven on public roads. They

are difficult to see, especially at

night.

▲ Flashing warning lights and turn

signals are recommended whenever driving on public roads. Use

lights and devices provided with

implement.

Transport

Machinery Safely

▲ Comply with state and local laws.

▲ Maximum transport speed for

implement is 20 mph. DO NOT

EXCEED. Never travel at a speed

which does not allow adequate

control of steering and stopping.

Some rough terrains require a

slower speed.

▲ Sudden breaking can cause a

towed load to swerve and upset.

Reduce speed if towed load is not

equipped with breaks.

▲ Use the following maximum

speed - tow load weight ratios as

a guideline:

20 mph when weight is less

than or equal to the weight of

tractor.

10 mph when weight is double

the weight of tractor.

IMPORTANT: Do not tow a load that

is more than double the weight of

tractor.

Use A Safety Chain

▲ A safety chain will help control

drawn machinery should it separate from the tractor drawbar.

▲ Use a chain with the strength

rating equal to or greater than

the gross weight of the towed

machinery.

▲ Attach the chain to the tractor

drawbar support or other specified anchor location. Allow only

enough slack in the chain to permit turning.

▲ Do not use safety chain for tow-

ing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment, refer to Operator’s

Manual for additional information.

▲ Work in a clean dry area.

▲ Lower the implement to the

ground, put tractor in park, turn off

engine, and remove key before

preforming maintenance.

▲ Allow implement to cool completely.

▲ Install all transport locks on raised

drill before working underneath, refer

to the Operator’s Manual for quantity

and location of transport locks.

▲ Do not grease or oil implement

while it is in operation.

▲ Move the opener handle to the

“ROAD” position and complete

raising the openers to lock them

up before working underneath

them.

▲ Disk edges are sharp. Be careful

when working in this area.

▲ Disconnect battery ground cable

(-) before servicing or adjusting

electrical systems or before welding on implement.

▲ Inspect all parts. Make sure parts

are in good condition & installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused pars

from implement before operation.

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

2

Page 5

Great Plains Mfg., Inc.

Important Safety Information

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extin-

guisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Protective clothing and equipment

should be worn.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose fitting clothing.

▲ Prolonged exposure to loud noise

can cause hearing impairment or

hearing loss. Wear suitable hearing protection such as earmuffs or

earplugs.

▲ Operating equipment safely

requires the full attention of the

operator. Avoid wearing radio

headphones while operating

machinery.

Avoid High

Pressure Fluids Hazard

▲ Escaping fluid under pressure can

penetrate the skin causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or card-

board, NOT BODY PARTS, to

check for suspected leaks.

Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a doc-

tor immediately. Any fluid injected

into the skin must be surgically

removed within a few hours or

gangrene may result.

Safety at All Times

Thoroughly read and understand the

instructions given in this manual

before operation. Refer to the “Safety

Label” section, read all instructions

noted on them.

▲ Operator should be familiar with

all functions of the unit.

▲ Operate implement from the

driver’s seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Dismounting from a moving tractor

could cause serious injury or death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet, and clothing

away from power-driven parts.

▲ Wear snug fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when folding and raising implement. Make sure all persons are

clear of working area.

▲ Turning tractor too tight may

cause implement to ride up on

wheels. This could result in injury

or equipment damage.

Tire Safety

▲ Tire changing can be dangerous

and should be preformed by

trained personnel using the correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side and NOT in front of or

over the tire assembly. Use a

safety cage if available.

▲ When removing and installing

wheels, use wheel handling

equipment adequate for the

weight involved.

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

3

Page 6

Important Safety Information

Great Plains Mfg., Inc.

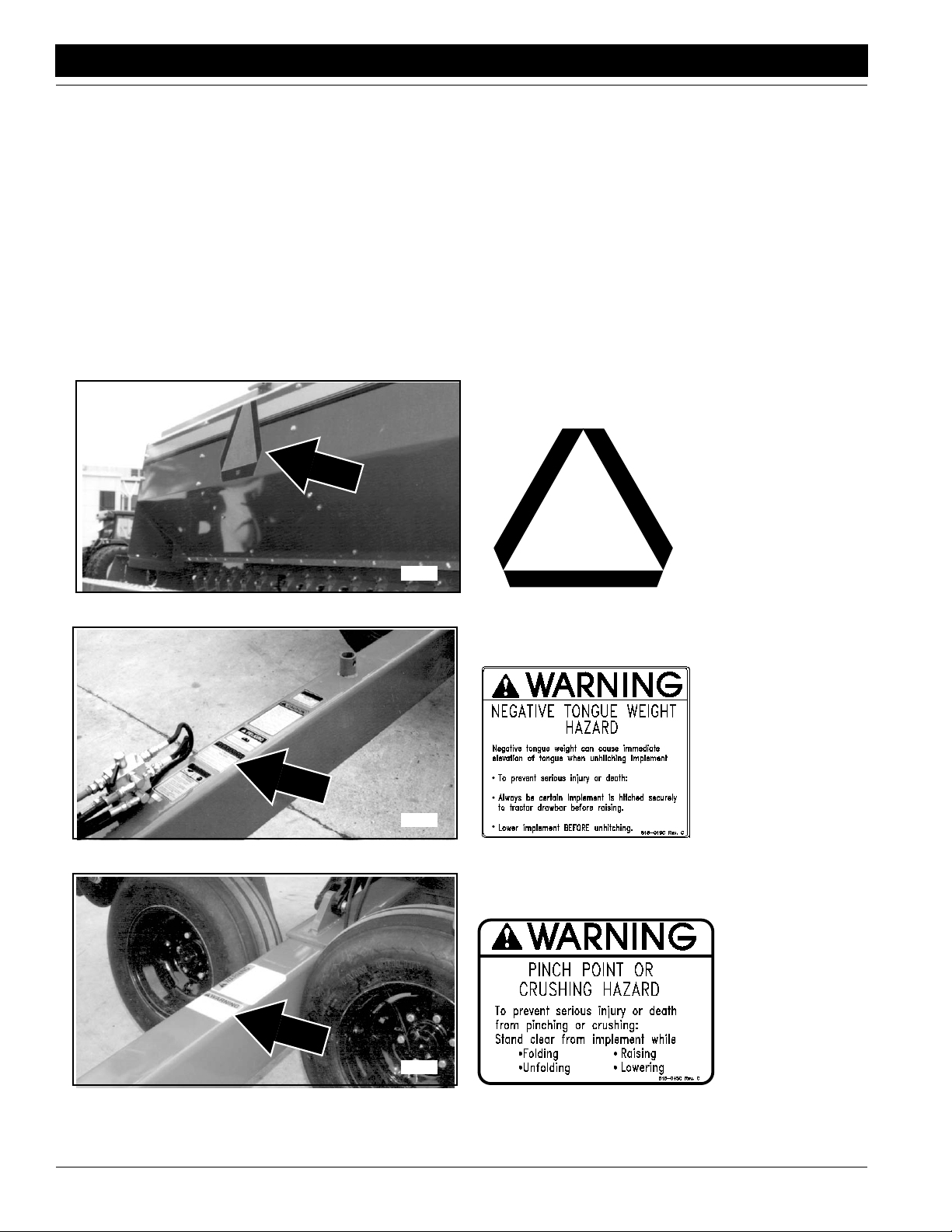

Safety Labels

Your implement comes equipped with all safety labels in place.

They were designed to help you safely operate your implement.

1. Read and follow label directions.

2. Keep all safety labels clean and legible.

3. Replace all damaged or missing labels.

4. Some new equipment installed during repair require safety

labels to be affixed to the replaced component as specified

by the manufacturer. When ordering new components make

15568

sure the correct safety labels are included in the request. To

order new labels go to your Great Plains dealer.

5. Refer to this section for proper label placement.

To install new labels:

a. Clean the area the label is to be placed.

b. Peel backing from label. Press firmly on surface

being careful not to cause air bubbles under label.

818-003C

Slow Moving VehicleLabel

15532

Negative Tongue Weight

818-045C

818-019C

15531

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

4

Pinch PointCrushing

Page 7

Great Plains Mfg., Inc.

Important Safety Information

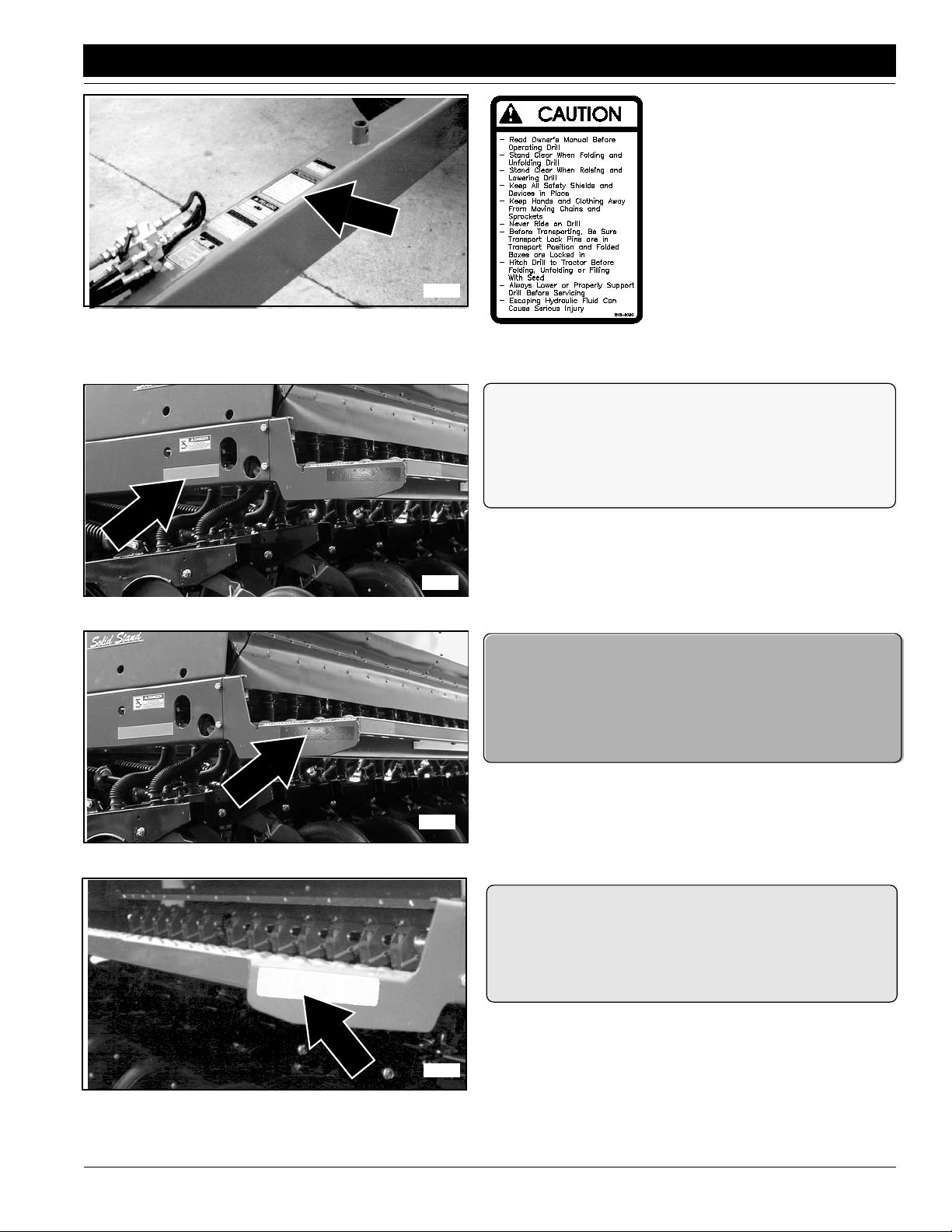

15532

15528

818-078C

General Instructions

838-267C

Daytime Reflector

Wing Walkboards

inside ends

11/9/07

15528

15527

838-266C

Red Reflector

Wing Walkboards

inside ends

838-265C

Amber Reflector

Center Walkboard

both ends

3S-3000 Three-Section Folding Drill 195-110M-A

5

Page 8

Important Safety Information

15528

Great Plains Mfg., Inc.

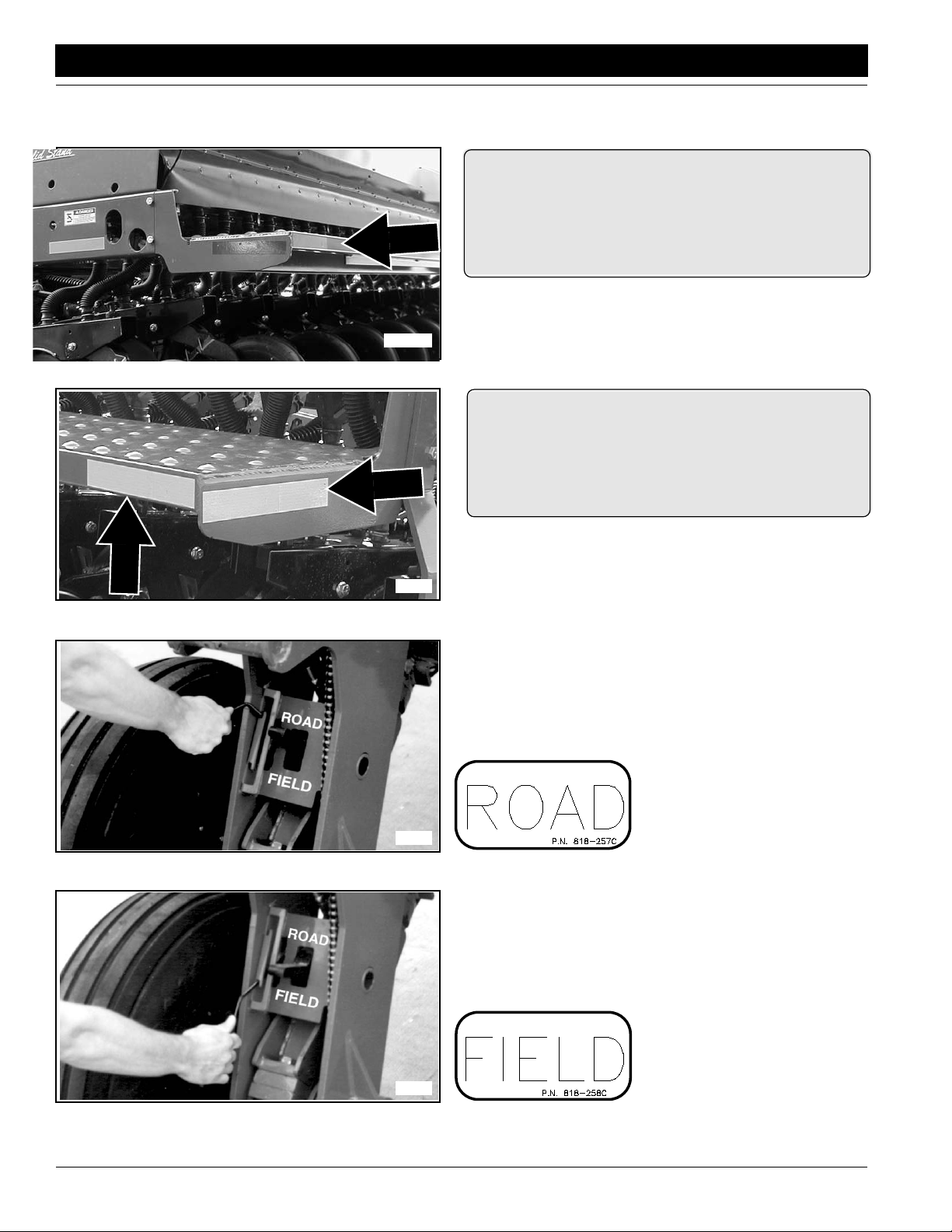

838-265C

Amber Reflector

Wing Walkboards

Backside of both ends

15566

15549

838-265C

Amber Reflector

Wing Walkboards

outside end

818-257C

ROAD Position

15548

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

6

FIELD Position

818-258C

Page 9

Great Plains Mfg., Inc.

Important Safety Information

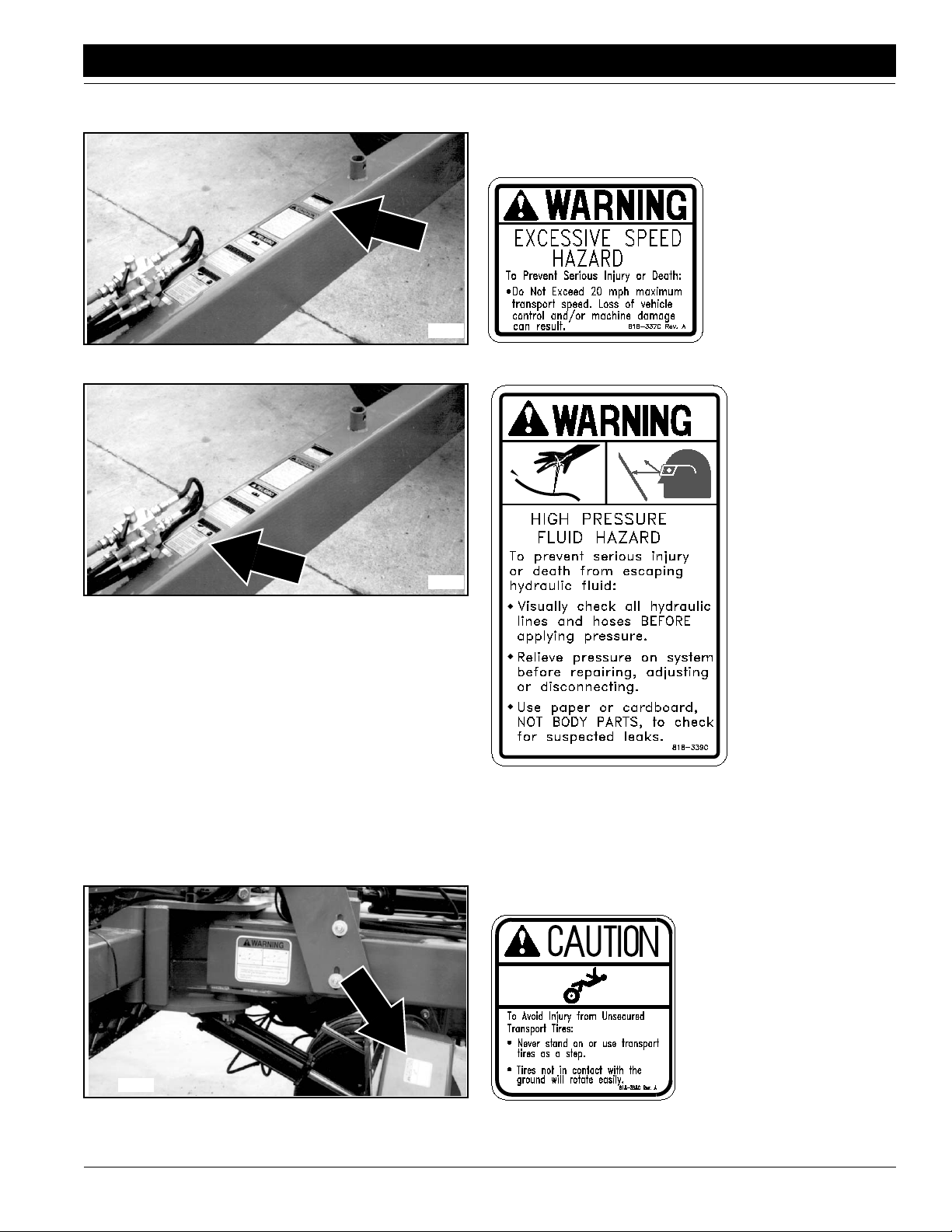

15532

818-337C

Excessive Speed

15532

818-339C

High Pressure Fluid

11/9/07

15526

818-398C

Tire is Not a Step

3S-3000 Three-Section Folding Drill 195-110M-A

7

Page 10

Important Safety Information

Great Plains Mfg., Inc.

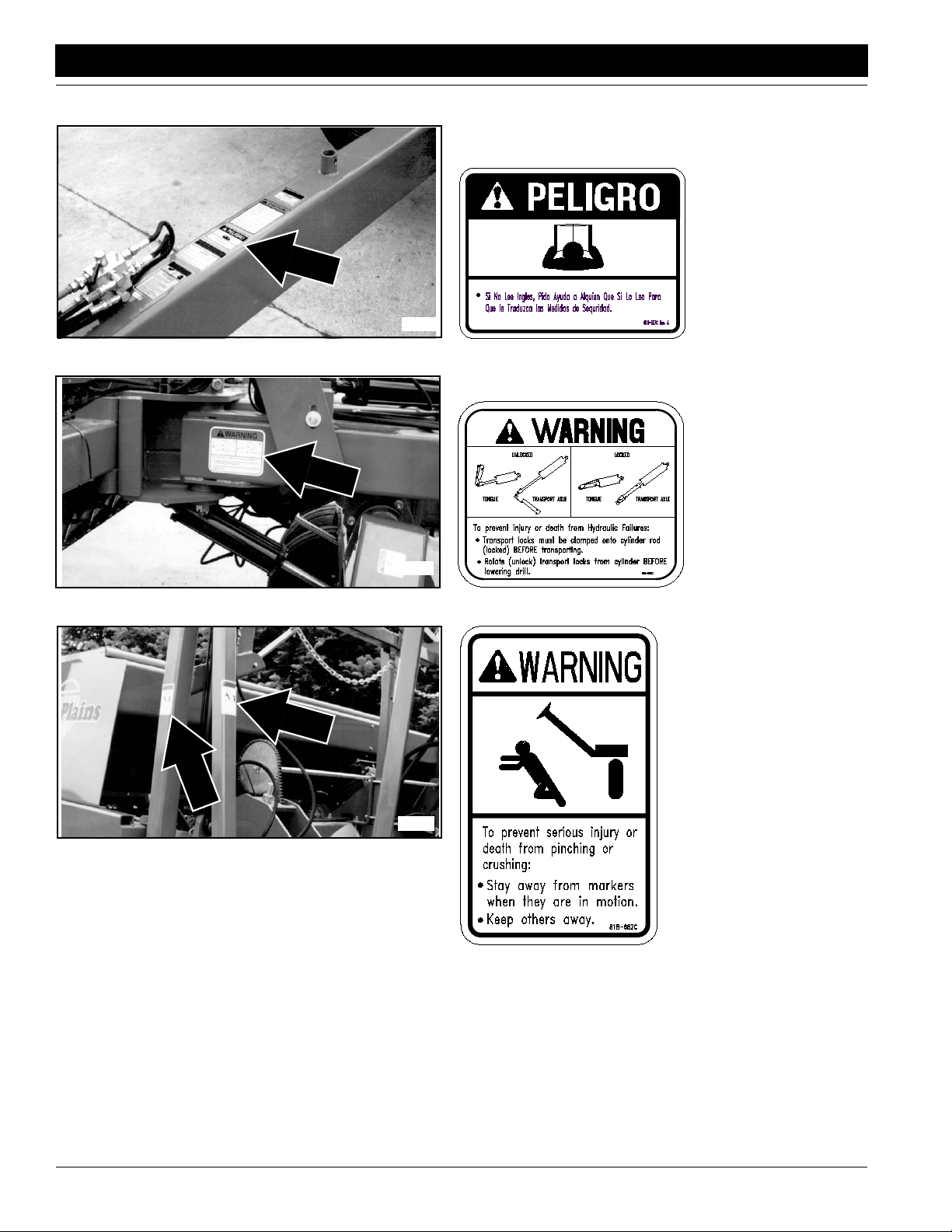

15532

15526

818-557C

Can Not Read English

818-660C

Transport Locks

818-682C

15670

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

8

Marker Pinch Point Crushing

Page 11

Great Plains Mfg., Inc.

Important Safety Information

15676

15677

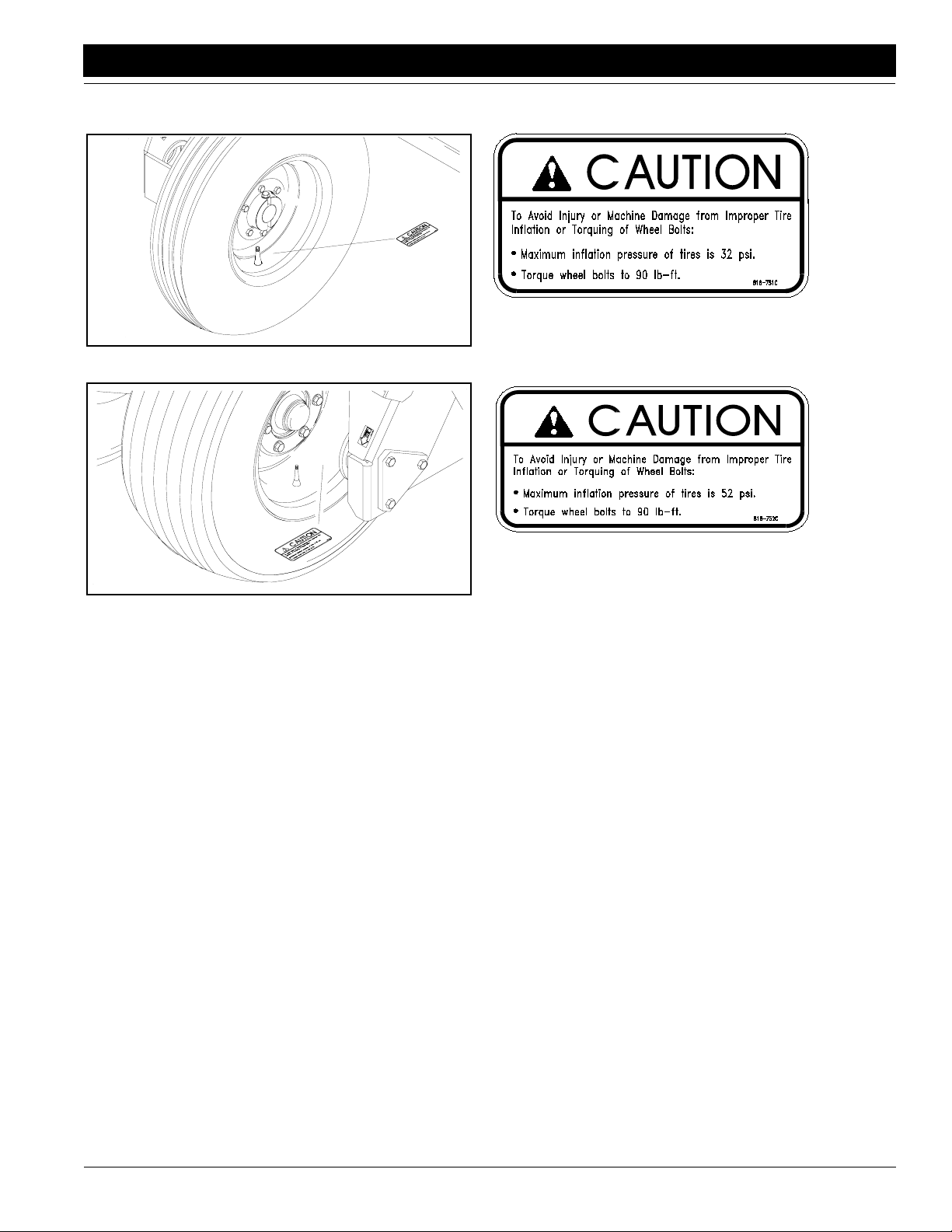

818-751C

Improper Tire Inflation - Wing Gauge Wheel Tires

818-752C

Improper Tire Inflation - Transport Tires

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

9

Page 12

Introduction

Introduction

Great Plains Mfg., Inc.

Great Plains welcomes you to the growing family of new

product owners.

This implement has been designed with care and built by

skilled workers using quality materials. Proper assembly,

maintenance, and safe operating practices will help you

get years of satisfactory use from the machine.

Description of Unit

The 3S-3000 Drillis a 30 ft. 3 section grain drill which couples our solid stand double disk openers with live closedcentertractorhydraulicsto achieveconstant opener down

pressure through a wide range of opener movement. Hydraulic down pressure provides easy single point opener

pressure adjustment while providing accurate depth controland seed placementoveruneventerrain.TheT handle

adjustment on the depth controlling press wheels provide

easy seed depth adjustment for each individual row unit.

The3S-3000Fallowsyouto plant seed andapplyfertilizer

inthe same fieldpass.Dividers partitionthedrillboxesinto

seed and fertilizer compartments. The openers apply dry

fertilizerto the seed trench beforethe furrow isclosed.You

can use both compartments for seed.

Features include:

• Single tang or Clevis style hitches

• 15 degree wing box down flex and 20 degree wing box

up flex

• Floating opener frames for increased flexibility over un-

even terrain

• Multiple opener pressure valves to vary the opener

pressure from wings to center

• 4 speed drive system for a wide range of seeding rates

• Solid Stand openers

• 3.2 bushel-per-foot seed box

• Seed level gauges.

• V-bottom boxes for complete cleanout

• Internal drive gauge wheels that ride on tapered roller

bearings

• Safety lights which couple with tractor lighting system

Plains. Keep your copy in the manual for use when corresponding with the dealer.

To order a newOperator or Parts Manual contact your authorized dealer or write to the address listed below in the

Owner Assistance paragraph.Include the model and serial numbers of your unit.

The information in this manual was current at printing.

Some parts may change to assure top performance.

Definitions:

"Right " or "Left" as used in this manual is determined by

facingthe direction the machine will travelwhile in use unless otherwise stated.

NOTE: A special point of information related to it’s

preceding topic. The author’s intention is that you

read and note this information before continuing.

IMPORTANT:Aspecialpoint ofinformationthat the author

feels you must be aware of before continuing with the instructions that follow.

Owner Assistance

If customer service or repair parts are required contact

your local Great Plains dealer. He has trained personnel,

repair parts, and the equipment needed to service your

implement. These parts have been specially designed

and should only be replaced with genuine Great Plains

parts.

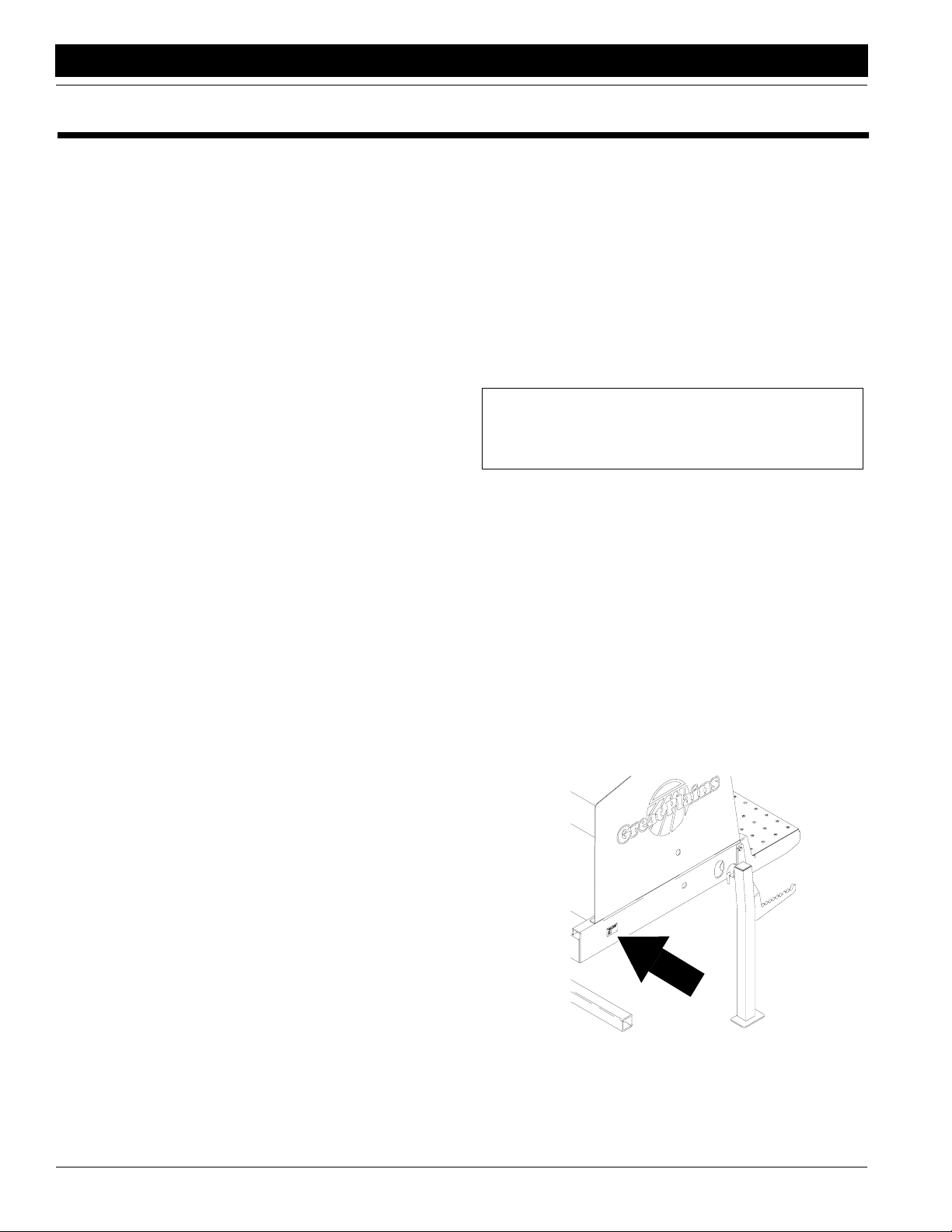

Serial Number Plate

Referto the Figure 1forthe location of yourserial number

plate.

Intended Usage

This machine is intended to be used primarily for conventional tillage applications. It has capability of some minimum or light no-till drilling.

Using This Manual

ThisOperator’sSection is designed to help familiarizeyou

with safety, operation, adjustments, troubleshooting, and

maintenance.Read this manual and followtherecommendations to help ensure safe and efficient operation.

The warranty sheet should be filled out by the owner and

dealer at the time of purchase. After completion give the

dealer the white copy and send the pink copy to Great

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

10

Serial Number Plate Location

Figure 1

15614

Page 13

Great Plains Mfg., Inc.

Introduction

Forpromptservicealwaysusethe serial numberand model

numberwhenordering parts from yourGreat Plains dealer.

Be sure to include your serial and model numbers in correspondence also.

Your dealer wants you to be satisfied with your new machine. If forany reason you do not understand any partof

this manual or are not satisfied with the service received,

the followingactions are suggested:

1. Discuss the matter with your dealership Service Manager make sure he is aware of any problems you may

haveand that he has had the opportunity to assist you.

2. If you are still not satisfied, seek out the Owner or

General Manager of the dealership, explain the problem and request assistance.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

P.O. Box 5060

Salina, KS 67402-5060

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

11

Page 14

Section 1 Drill Preparation and Setup

Section 1 Drill Preparation and Setup

Leveling the Drill

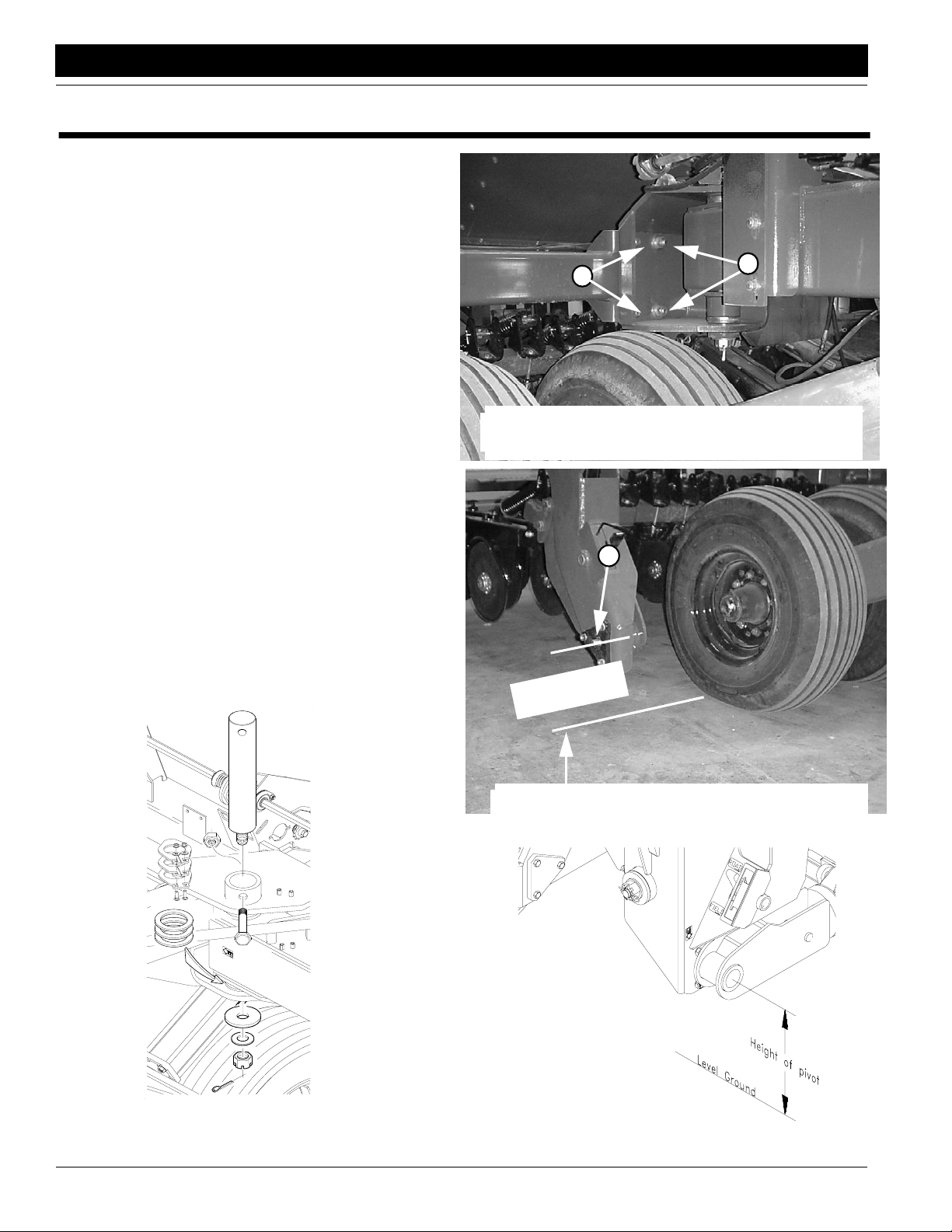

Center Box Frame Leveling

1. Park the drill on a clean level surface.

2. Raise the openers and lock them up.

3. Loosen the eight center box mount bolts (1), four bolts

on each side of tongue, see Figure 1-1, and slide center box frame sidewaysuntil it is centered with mainframe and transport axle.

4. See Figure 1-2. Measure the height of center box

opener frame pivots (2) from the level surface and

raise low end of box frame up until both opener frame

pivots measure the same distance from the ground.

5. Torque the 7/8 inch box mount bolts (1), Figure 1-1.

Adjust Toolbar Height

The height of the Toolbars are set at the factory fora level

drill and should not require adjustment. Three spacer

washersaboveand below the toolbars at their vertical pivot pins allow for a small amount of toolbar height adjustment.Measurefrom the levelsurface to theinnerwingbox

opener frame pivots. See Figure 1-3. If the opener frame

pivotsvary more than 1/4"raise the lower toolbar upbyremoving spacer washers from the top side of the toolbar

and placing them on the bottom side of the toolbar as

shown in Figure 1-4.

It is best to lower the openers and apply enough hydraulic

pressure to them to help balance the wing frame when removing the vertical pivot pin to adjust toolbar height.

Opener

pivot

1

Center Box Mount Bolts

Figure 1-1

2

frame

height

Great Plains Mfg., Inc.

1

18873

Opener Frame Leveling

Figure 1-2

15617

Toolbar Height Adjustment

Figure 1-4

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

12

15616

Toolbar Height Leveling Dimension

Figure 1-3

18874

Page 15

Great Plains Mfg., Inc.

Section 1 Drill Preparation and Setup

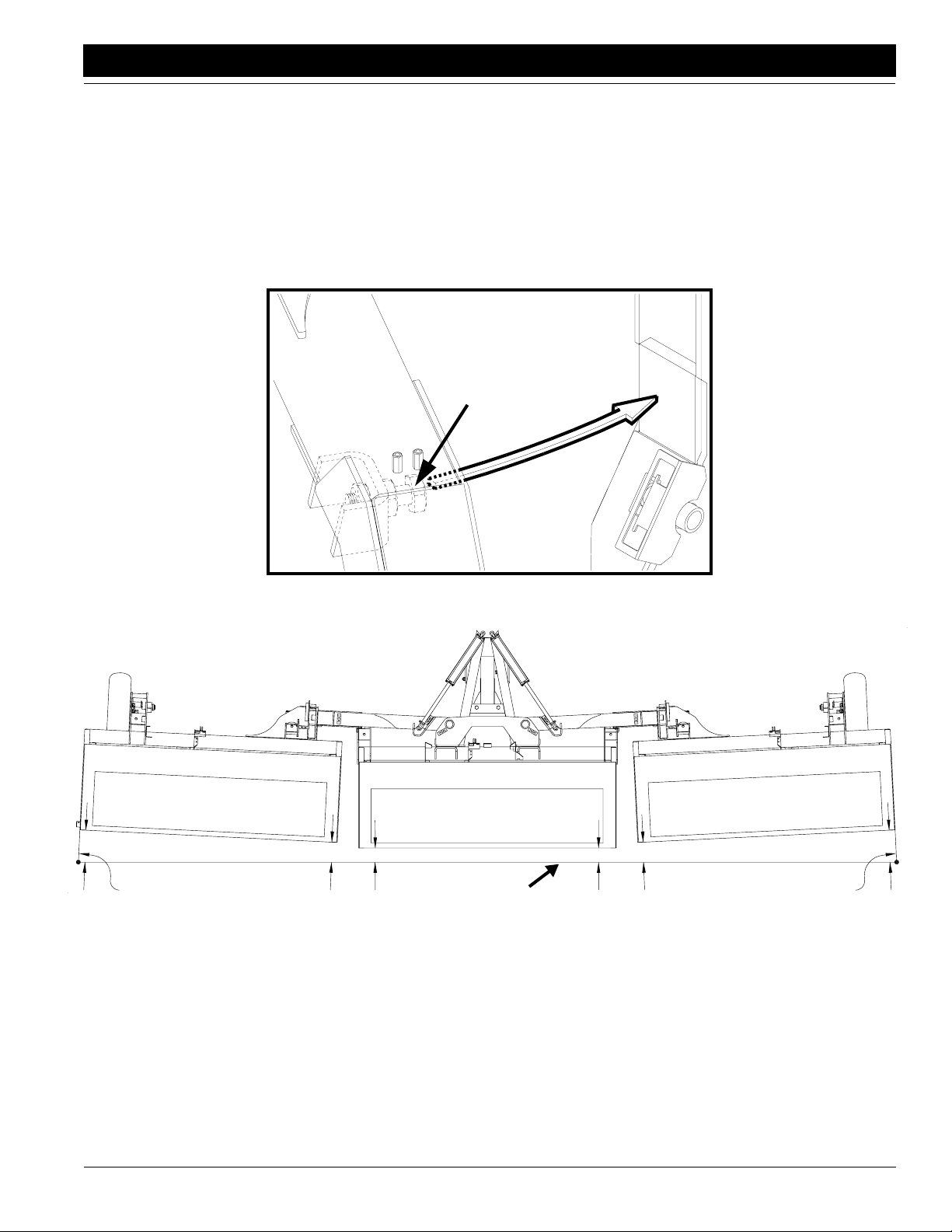

1. Adjust The Wing Box Alignment

Refer to Figure 1-5, place a 4x4 or similar sized block

ahead of the wing gauge wheels. Pull forward or rock the

wing frames back until the toolbar stop bolt is firmly

againstthestop plate on the center boxframe.The toolbar

stop bolt runs through a formed channel on the bottom

side of the toolbar. Run a string line across the back of the

Stop Bolt

center box and out toward the outer ends of the wings.

The outboard ends of the wing boxesshould be toed forwardabout1" ahead of the inboard ends.Adjust thewing

boxalignment by controlling when the 1 1/4" toolbar stop

bolt contacts the stop plate on the center box frame. Adjust the 1 1/4" toolbar stop bolts in or out until the outer

end of the wing boxes are toed forward about 1".

C

15654

String Line

Support

C-B=1"

15655

C

B

A

Wing Box Alignment Measurement

String Line

Figure 1-5

B

A

C-B=1"

String Line

Support

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

13

Page 16

Section 1 Drill Preparation and Setup

Great Plains Mfg., Inc.

2. Align Transfer Drive Shaft

After the wing boxes are properly aligned, the transfer

driveshaft must be aligned so the pair of break-awayjaws

have full engagement and are concentric.The 7/8" hex

drive shafts holding the clutch jaws should not contact

each other when the wing boxesare properly aligned and

back against their stop. Place a 4x4 or similar sized block

ahead of the wing gauge wheels and pull forward or push

the wing box frames backuntil the toolbar stop bolt is firmly against the stop plate on the center box frame.

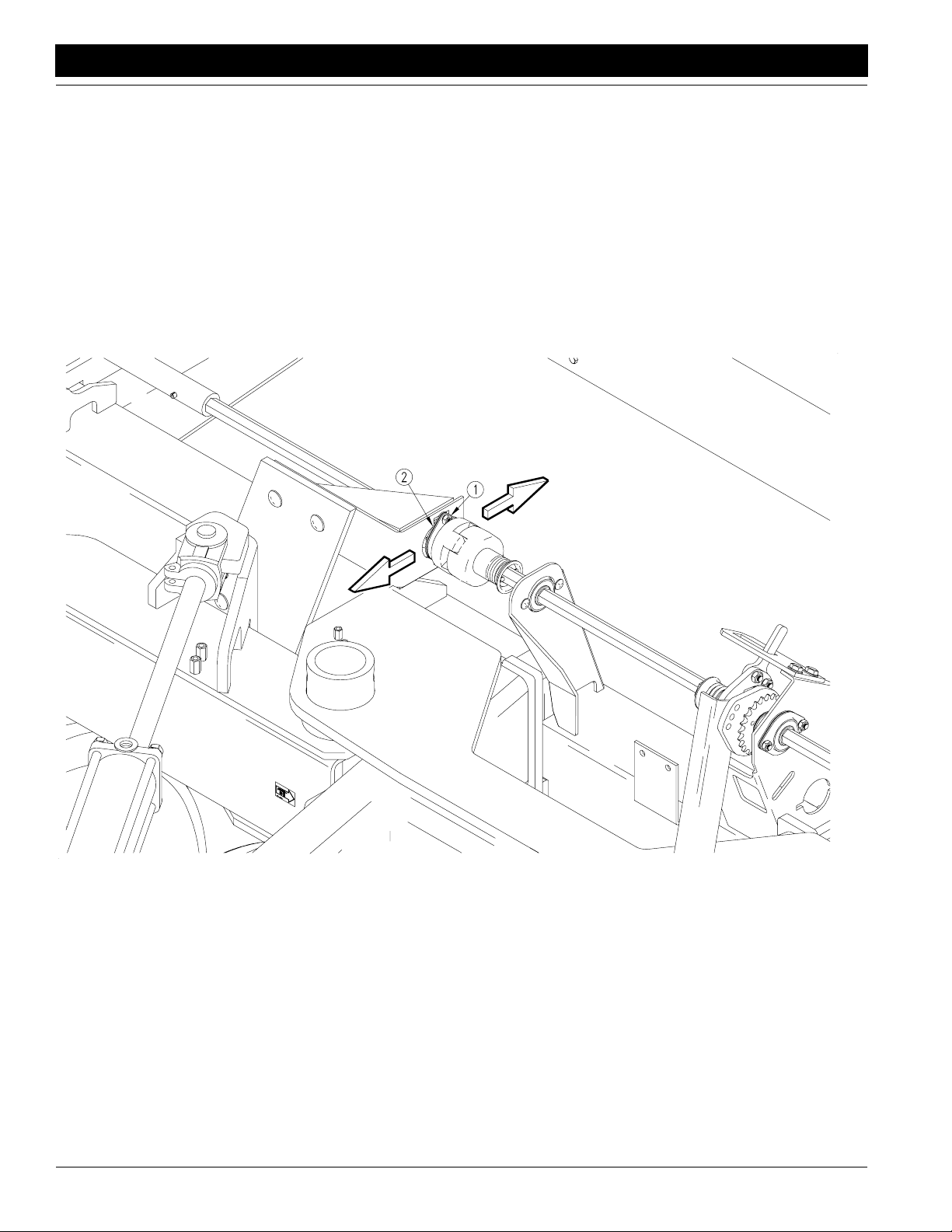

Toaligntheclutch jaws in thefronttoreardirection,loosen

the two 5/16" (#1) bolts which hold the 7/8" hex bearing

flangettes (#2) and slide the bearing assembly in the desired direction, as shown in Figure 1-6.

Transfer Drive Shaft Front to Rear Adjustment

Figure 1-6

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

14

15620

Page 17

Great Plains Mfg., Inc.

Section 1 Drill Preparation and Setup

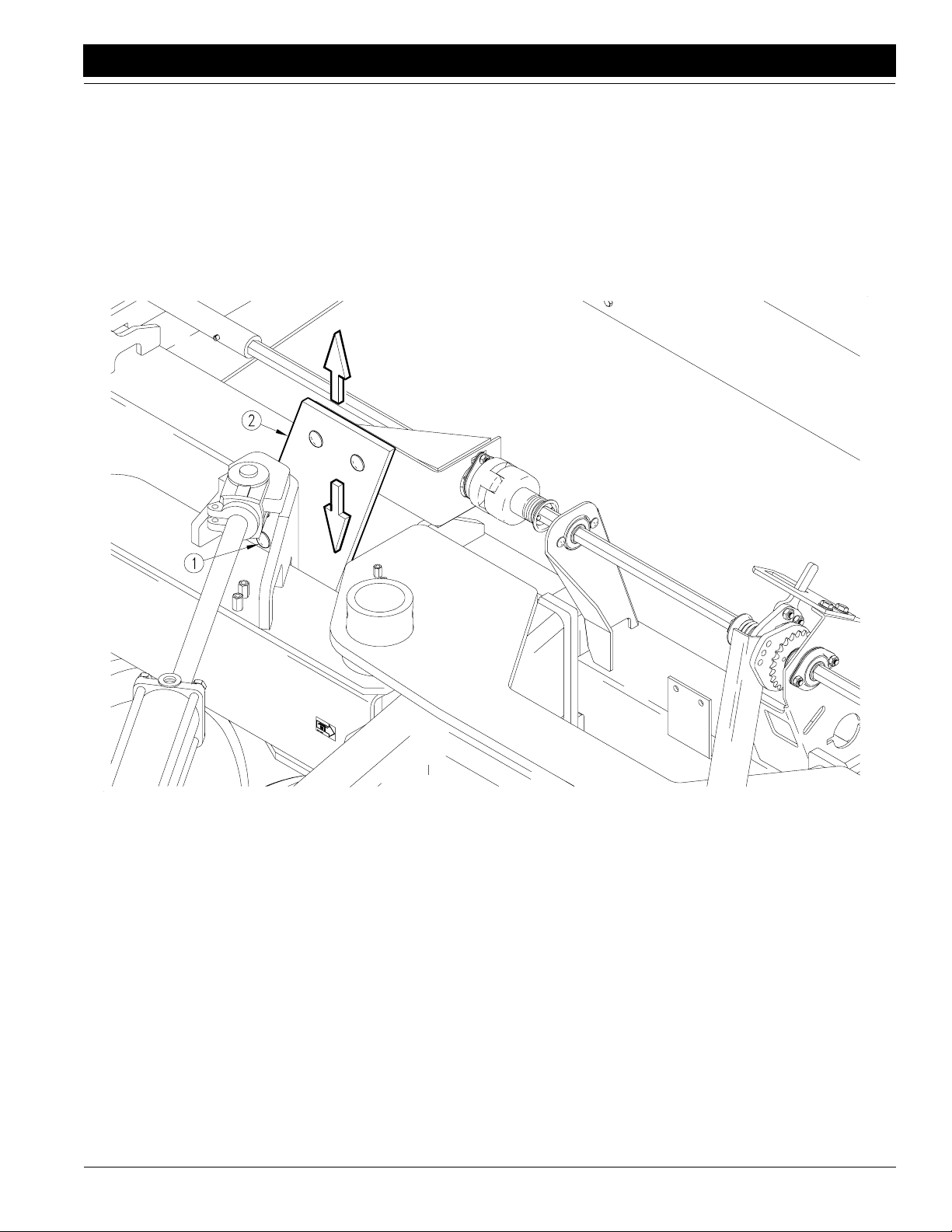

To align the clutch jaws in thevertical direction, loosen the

two 5/8" bolts (#1) on the break-awayadjustment plate at

thebacksideof the toolbar and slide the 1/2"(#2)plate up

or down in the desired direction, as shown in Figure 1-7.

11/9/07

Transfer Drive Shaft Vertical Adjustment

Figure 1-7

3S-3000 Three-Section Folding Drill 195-110M-A

15621

15

Page 18

Section 1 Drill Preparation and Setup

Great Plains Mfg., Inc.

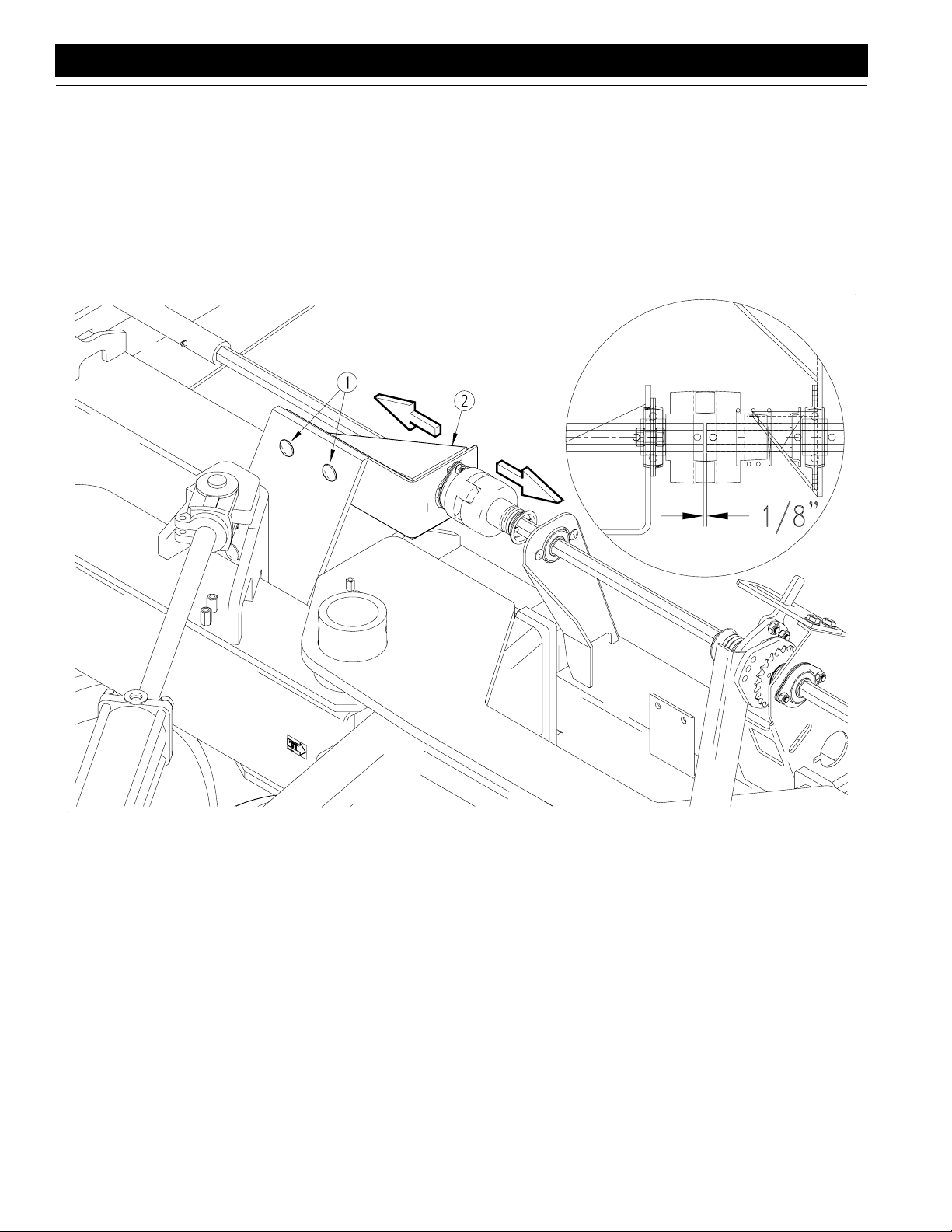

Toadjustthe clutch jawsforfull jawcontact,loosen the two

1/2" (#1) bolts which fasten the bearing bracket(#2) to the

1/2" adjustment plate and slide the bearing bracket until

the jaws on the fixed half of the clutch make full contact

withthe jaws onthespringloadedhalfofthe clutch without

compressing the clutch spring, as shown in Figure 1-8.

The two 7/8" hex shafts should have 1/8" between them

when the clutch jaws have full contact.

Top View

Transfer Drive Shaft Clutch Jaw Adjustment

Figure 1-8

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

16

15622

Page 19

Great Plains Mfg., Inc.

Section 1 Drill Preparation and Setup

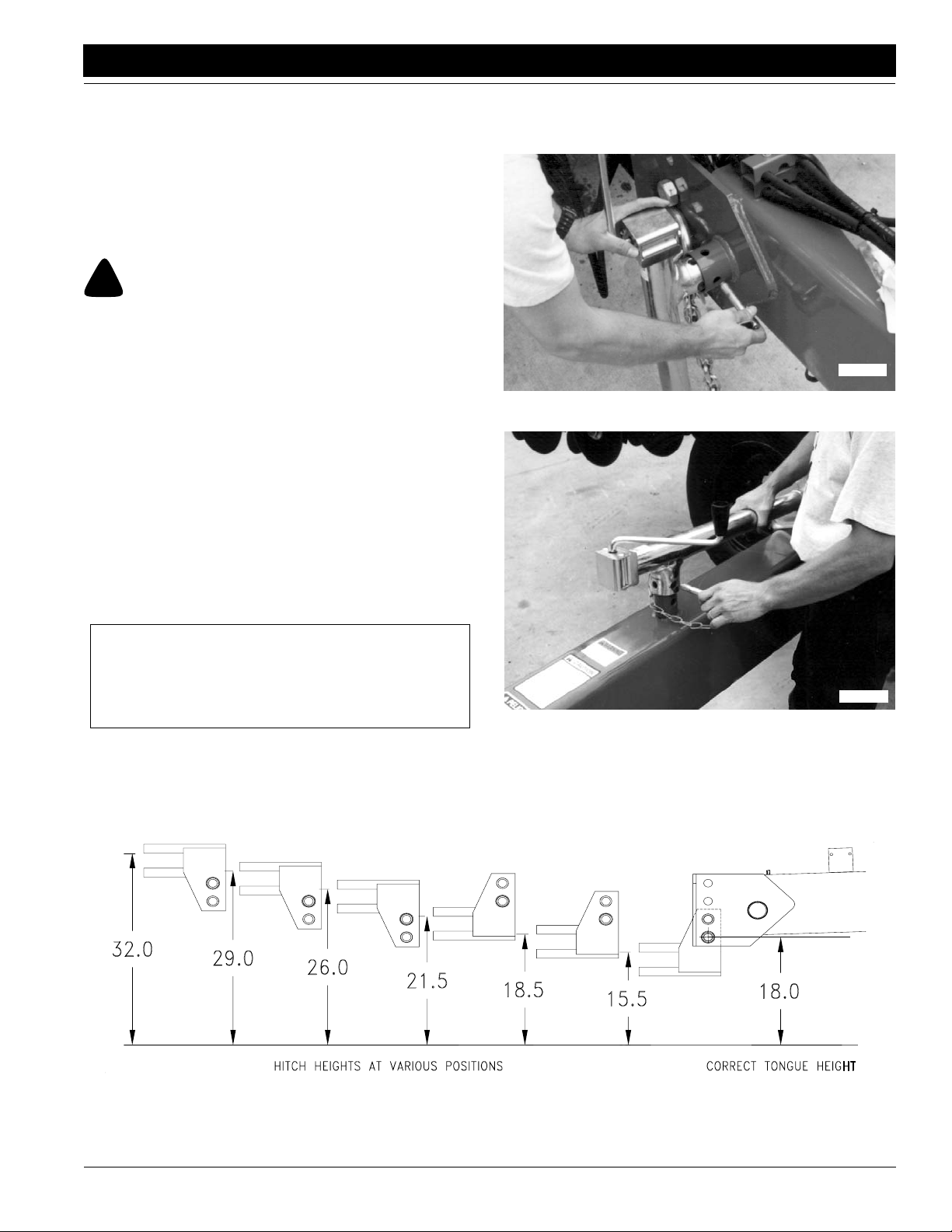

Tractor Drawbar Hookup

The Great Plains 30 ft 3 section drill has three hitch options: a clevis hitch, a small hole single strap hitch, and a

large hole single strap hitch. Use the single strap hitch for

tractors with clevis drawbars, and use the clevis hitch with

tractors which have single tang drawbars. In either case

alwaysuse a locking style drawbar pin sized to match the

holes in the hitch and drawbar.

!

WARNING!

Since this drill can have both positive and negative hitch forces

always use a clevis hitch or clevis drawbar with a locking style

hitch pin through the clevis.

TheGreatPlains 30 ft 3 section drill is designed to operate

with the lowest hitch hole in the tongue measuring about

18" off the ground when in FIELD (lowered) position. The

mounting holes in the hitch have been offset so the hitch

can be turned overand bolted onin three positions, giving

you six hitching positions. Use the screw jack to raise the

front of the drill tongue so the lowest hitch hole in the

tongue measures 18" off the ground. Adjust the drillhitch

to match your tractor drawbar. See Figure 1-9. The drill

hitch can accommodate tractor drawbars ranging from

15.5 to 32 inches high.

Your drill is equipped with a hitch safety chain. The safety

chainshouldbe securely attached to the drill hitch andthe

tractor whenever towing or planting.

Use the jack to raise and lower the front of the drill when

hitching to the tractor, and store it in the storage tube on

the top of the tongue as shown in Figure 1-11.

15564

Jack Lifting Position

Figure 1-10

NOTE: When hitching the drill to a different tractor,

check for a difference in drawbar heights. If the

heights are different, the hitch height must be readjusted accordingly.

Hitch Height Adjustment

15563

Storing Tongue Jack

Figure 1-11

15623

Figure 1-9

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

17

Page 20

Section 1 Drill Preparation and Setup

Great Plains Mfg., Inc.

Tractor Hydraulic Hookup

!

WARNING!

Escaping fluid under pressure can penetrate the skin causing

serious injury. Avoid the hazard by relieving pressure before

disconnecting hydraulic lines. Use a piece of paper or cardboard, NOT BODY PARTS, to check for suspected leaks. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. If an accident occurs, see a doctor immediately.Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result.

NOTE: To run drill on tractors with open-center hydraulics or on tractors with fixed-displacement hydraulic pumps, you must install a Great Plains kit, part

number 194-143A. If you are not familiar with your

tractor hydraulics, consult your tractor dealer.

Great Plains hydraulic hoses are color coded to help you

hook up hoses to yourtractor outlets. Hoses that go to the

same remote valve are marked with the same color.

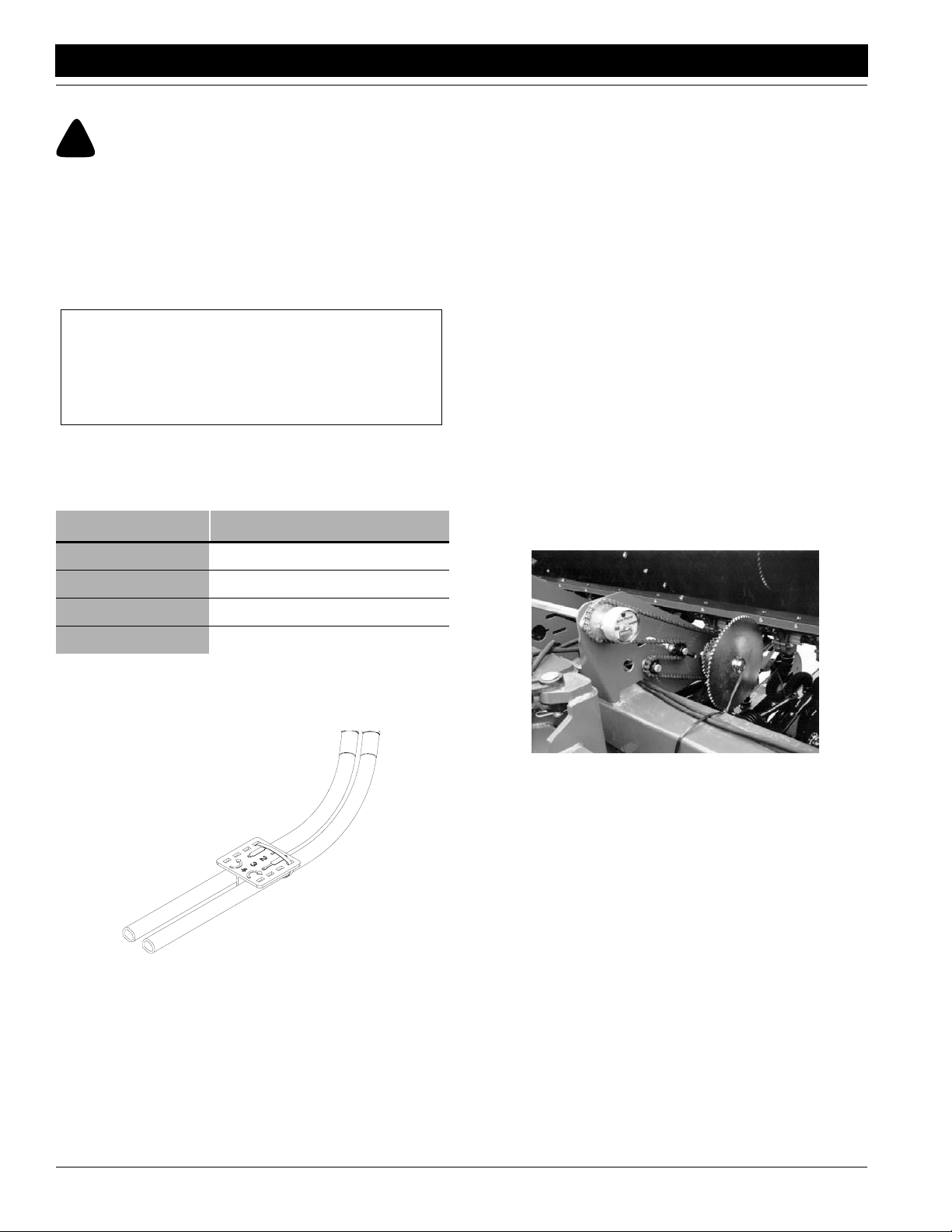

Color Hydraulic Function

Red Opener Lift

1. Connect opener-lift hoses to circuit designated for hydraulic-motor control.

2. Connect transport-lift hoses to tractor remote valve.

3. Connect fold hoses to tractor remote valve.

IMPORTANT: If your tractor has only two remote valves,

you must install a double-selector valve to combine the

transport-lift and opener-lift circuits. Refer to 3S-3000

Two-Outlet TractorHydraulic Kit,“Options,” page 61.

Safety Lights

The light package that yourdrill is equippedwith, requires

that your tractor have the correct electrical connections.

Your tractor should be wired fora standard 7-pin electrical

connector which works with the tractor'sflashers and turn

signals. All that should be necessary to hook up the lights

is to plug them into the tractor's 7-pin connector.

If your tractor is not equipped with a 7-pin connector,

please contact your local dealer for installation to your

tractor manufacturers specifications.

Acre Meter

Assemblethe acre meter to the end of the main drive shaft

onthe center section as shownin Figure1-13. Record the

acres before you begin planting and subtract that number

from the final reading to get acres planted.

Blue T ransport Lift

White Fold

Orange Marker

Todistinguishhoses on the same hydraulic circuit, refer to

plastic hose holders. See Figure 1-12. Hoses under extended-cylinder symbol feed cylinder base ends. Hoses

under retracted-cylinder symbol feed cylinder rod ends.

17641

Hydraulic Hose Label

Figure 1-12

Acre Meter Location

Figure 1-13

15660

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

18

Page 21

Great Plains Mfg., Inc.

Section 1 Drill Preparation and Setup

Bleeding the Hydraulic Systems

NOTE:Check hydraulic fluid levelin tractor reservoir

and fill it to proper level before starting this procedure. Add fluid to system as needed. A low reservoir

levelmay drawair back into the system causing jerky

or uneven cylinder movements. System capacity for

entire drill is approximately 4 1/2 gallons.

!

CAUTION!

This drill has a negative tongue weight when unfolded and the

openers raised. Be certain that the drill is hitched securely to

your tractor drawbar and be certain the safety chain is securely

attachedto the tractor before raising the openers and unfolding

the drill.

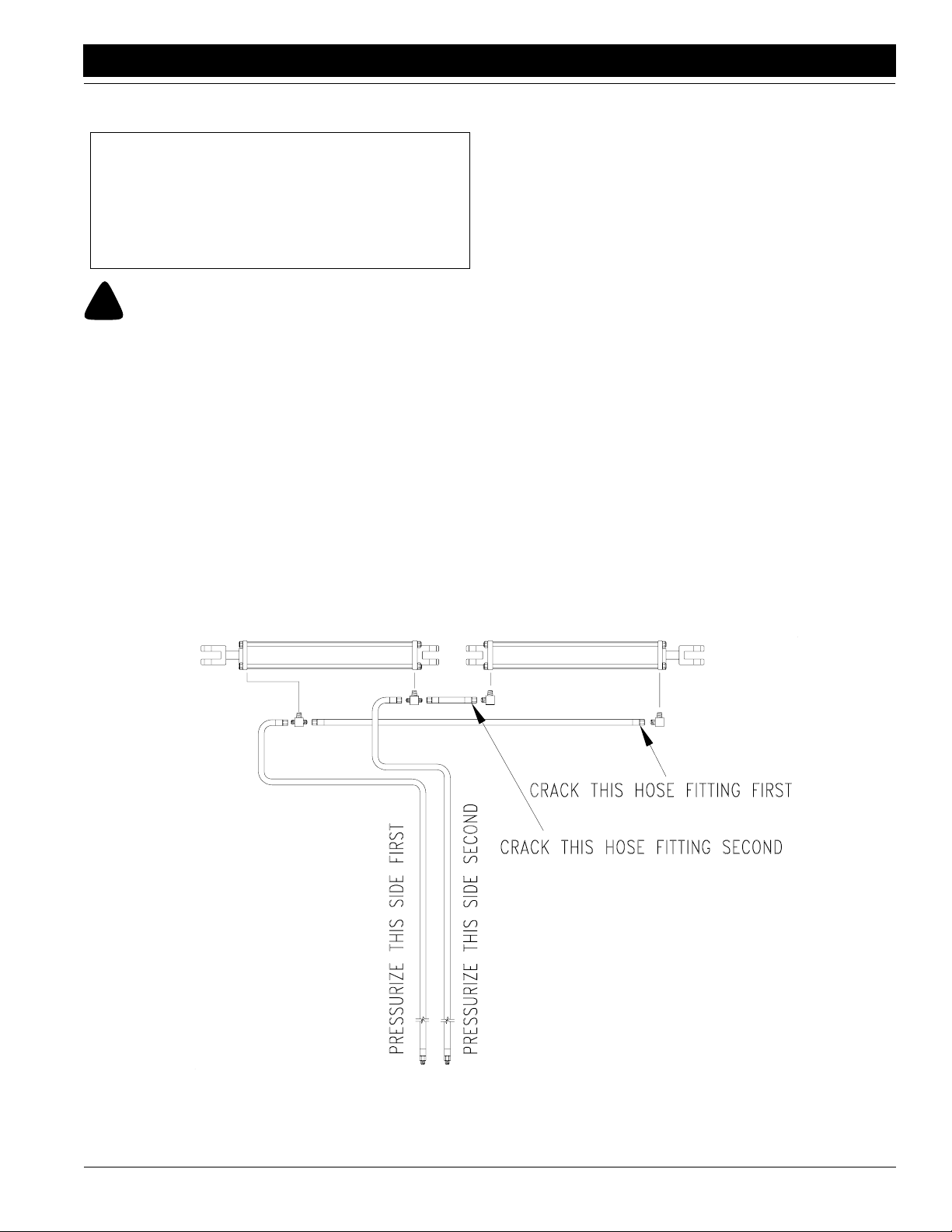

Bleeding the Fold Hydraulics

Refer to Figure 1-14:

1. With the drill unfolded (the fold cylinders completely

extended),disconnect the rod end pins and swingthe

cylinders so they will not catch or contact anything

during the bleeding process.

2. Loosen the rod end hose fitting at the elbowon the left

fold cylinder.

3. Slowly supply oil to the rod end of the fold cylinders

until oil appears at the loosened hose fitting. Tighten

therod end hose fitting and completelyretractthe fold

cylinders.

4. With the cylinders completely retracted, loosen the

base end hose fitting at the elbow on the left fold cylinder.

5. Slowly supply oil to the base end of the fold cylinders

until oil appears at the loosened hose fitting. Tighten

thebase end hosefittingandcycle the foldcylinders in

and out several times.

6. Repin the cylinder rod clevis.

11/9/07

Bleeding the Fold Hydraulics

Figure 1-14

3S-3000 Three-Section Folding Drill 195-110M-A

15644

19

Page 22

Section 1 Drill Preparation and Setup

Great Plains Mfg., Inc.

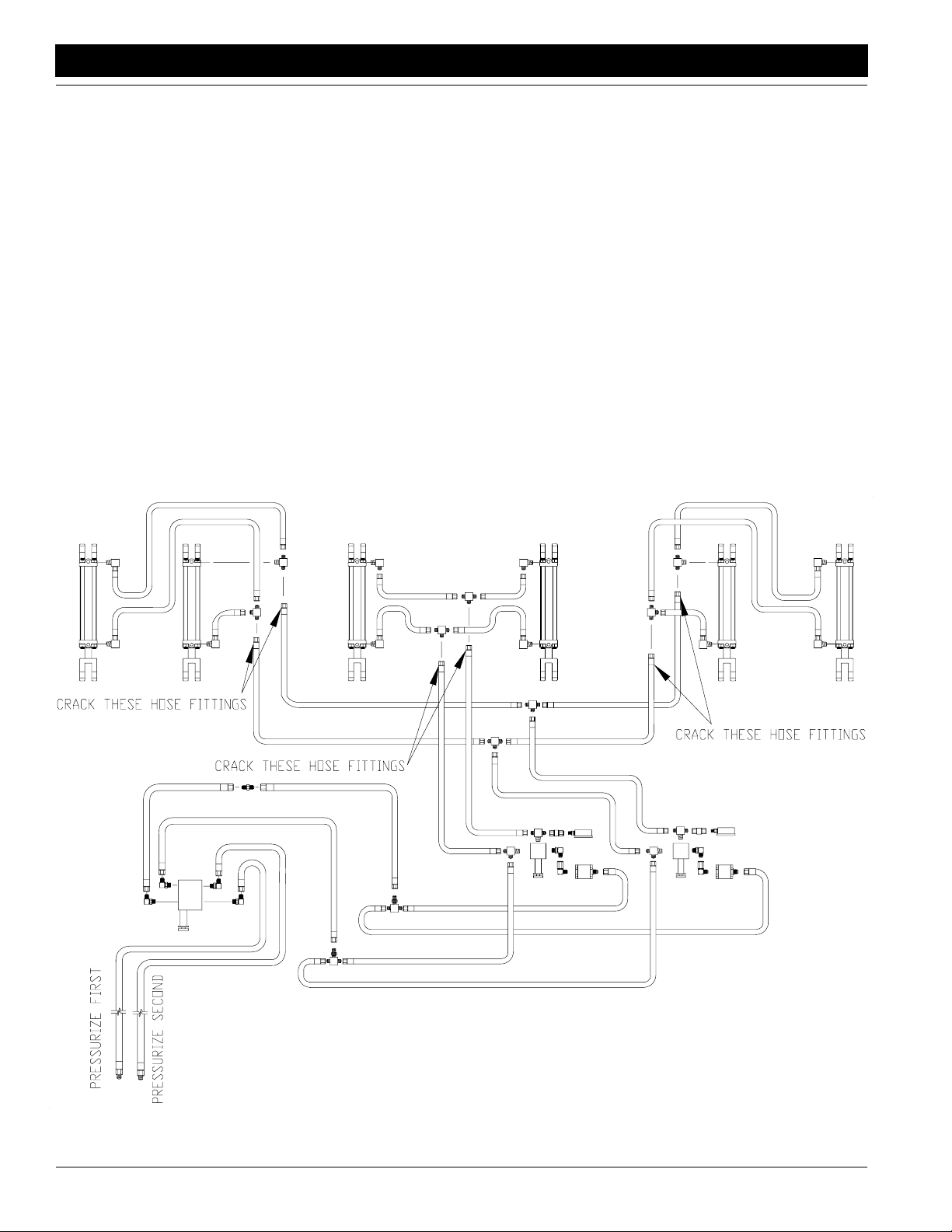

Bleeding the Opener Lift Hydraulic System

Refer to Figure 1-15:

1. Check that opener frames are locked in ROAD position.

2. Turn knobs on pressure-control valves completely

counterclockwise, then turn knobs clockwise three

turns.

3. Turn knob on bypass valve completely clockwise for

no oil flow.

4. Loosen six hose-end fittings at three locations on

opener-lift circuit:

• both JIC fittings on thetwo 3/8" opener lift hoses ex-

tending from the end of each wing toolbar,

• the JIC fittings on the two 3/8" opener lift hoses

feeding the center opener lift cylinders, and

• the end where these center two hoses tee at the

middle of the center box frame.

5. Slowly supply oil to top side of pressure-control

valves.As oil begins to appear at a fitting, tighten that

fitting. Continue supplying oil until one of the two fittings is tightened at each of the three locations.

6. Slowly supply oil to bottom side of pressure-control

valves.As oil begins to appear at a fitting, tighten that

fittinguntil all hosefittingsare tight. Continuetosupply

oil to bottom side of pressure-control valves until

openers are raised completely.

7. Move opener transport hooks to FIELD position and

cycleopeners up and downabouttentimes. Each time

you pressure openers down, hold tractor remote lever

until opener circuit builds up to pressure you have set

at control valves. Turn knobs on pressure-control

valvesclockwise far enough to build up at least 1000

psi on pressure gauges when cycling openers.

8. Onceopeners havebeencycled,return transport hooks

to ROAD position and lock openers up.

20009

Bleeding the Opener Lift Hydraulics

Figure 1-15

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

20

Page 23

Great Plains Mfg., Inc.

Section 1 Drill Preparation and Setup

Bleeding the Transport Lift Hydraulics

Refer to Figure 1-16:

1. Start with the transport axle in the lowered (field) position, and the box lift cylinder (at the middle of the

tongue) completely retracted. Loosen the base end

hose fitting at the elbow on the left transport lift cylinder and the base end hose fitting on the box lift cylinder at the middle of the tongue.

2. Slowly supply oil to the base end of the transport lift

cylinders until oil appears at the loosened hose fittings. Oil may not appear at both location at same

time.As oil begins to appearat a fitting, tighten thatfitting and proceed until both fittings have been tightened. Completely extend the transport lift cylinders

andIMMEDIATELY lock the cylindersupbyflipping up

the cylinder lock channels on both transport lift cylinders and the box lift cylinder at the middle of the

tongue.

!

WARNING!

NEVER CRAWL UNDER THE DRILL IN THE RAISED POSITON WITHOUT THE CYLINDER LOCK CHANNELS IN

PLACE.

3. When the cylinder lock channels are in place, loosen

the rod end hose fitting at the elbow on the left transport lift cylinder and the rod end hose fitting on the box

lift cylinder at the middle of the tongue.

4. Slowly supply oil to the rod end of the transport lift cylinders until oil appears at the loosened hose fittings.

As oil begins to appear at a fitting, tighten that fitting

and proceed until both fittings have been tightened.

5. Extend the transport lift cylinders, and removethe cylinderlockchannels. Completelycyclethetransport lift

hydraulics several times.

11/9/07

Bleeding the Transport Lift Hydraulics

Figure 1-16

3S-3000 Three-Section Folding Drill 195-110M-A

15645

21

Page 24

Section 2 Operating Instructions

Section 2 Operating Instructions

Lifting

The openers are raised and lowered on their own hydrauliccircuit. To operatethemwith livehydraulicpoweralways

connect the opener lift circuit to the #1 remote hydraulic

circuit or the circuit designed for HYDRAULIC MOTOR

control. On many CLOSED CENTER or PRESSURE/

FLOWCOMPENSATEDtractorsthe #1circuitisthe circuit

designed to supply live hydraulic power to remote locations.

The openers can be locked up for transportingor for working under the drill. To lock the openers up, position the

opener transport lock handles in the ROAD position Figure 2-1 and completely raise the openers.

Great Plains Mfg., Inc.

15548

15549

Opener Frames Locked Up (Handles in ROAD Position)

Figure 2-1

To unlock the openers, position the opener transport lock

handles in the FIELD position Figure 2-2 and completely

raise the openers to allow the opener transport locks to

disengage. There are two lock handles on each drill section.

Opener Frames Unlocked (Handle in FIELD Position)

Figure 2-2

Folding

1. Folding is best achievedon level ground with the tractor transmission in neutral. Be aware of the clearance

required to fold the drill.

!

CAUTION!

NEVER allow anyone near the drill during folding operations.

2. Position the opener transport lock handles in the

ROAD position Figure 2-1 and completely raise the

openers. The opener transport lock handles are

springloadedand can bemovedtotheROADposition

withthe openers up or down, but the locks will only engage when the openers are completely raised. There

are two lock handles on each drill section.

3. Make sure the transport lift cylinders and front box lift

cylinder are completely retracted.

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

22

Page 25

Great Plains Mfg., Inc.

Section 2 Operating Instructions

4. Slowly supply oil to the rod end of the foldcircuit.Completely fold the wing frames until both wing gauge

wheels contact the tongue tube.

5. Supply oil to the transport lift circuit until the transport

lift cylinders and front box lift cylinder are completely

extended and the drill is completely raised.

6. Rotate the cylinderlockchannels overtherods on the

twotransportliftcylinders and front-box,lift cylinderas

shown in Figure 2-3.

NOTE: Make sure the u-shaped clips in the lock

channels clasp the cylinder rods securely. The clips

must hold the channels in position until the cylinders

settle against the channels. You may need to adjust a

clip by turning the bolt inside the channel.

7. Allow the transport-lift cylinders to settle back against

the lock channels.

8. Beforetransporting, checkthatthehydrauliccylinders

havesettledagainstthe lockchannelsand are holding

the channels securely.

Unfolding

1. Supplyoil to the transportlift circuit until the transport lift

cylinders and front box lift cylinder are completely extended(thedrilliscompletelyraised).Rotatethecylinder

lock channels off the rods of the transport lift cylinders

and front box lift cylinder,as shown in Figure 2-4.

15551

Transport Lift Cylinder

Cylinder Lock Channels Inserted for Transporting

Front Box Lift Cylinder

Cylinder Lock Channel Inserted for Transporting

Figure 2-3

11/9/07

15552

15631

15553

Transport Cylinder Lock Channels Removed

for Field Use

Figure 2-4

2. Completely retract the transportlift cylinders and front

box lift cylinder.

3. Slowly supply oil to the baseendof the foldcircuit. Unfold the wing frames by completely extending the fold

cylinders.

4. Position the opener transport lock handles in the

FIELDposition, as shown back in Figure 2-2 and com-

3S-3000 Three-Section Folding Drill 195-110M-A

23

Page 26

Section 2 Operating Instructions

pletelyraisetheopenerstoallowthe opener transport

lockstodisengage.Theopener transport lock handles

are springloaded and can be moved to the FIELD position with the openers up or down, but the locks will

only disengage when the openers are completely

raised.There are two lockhandlesoneachdrillsection.

Transporting

!

CAUTION!

This drill should never be pulled faster than 20 miles per hour!

Before transportingthe drill check the following items.

1. Transport only with a tractor of proper size. See Trac-

tor Requirements in the “Drill Preparation and Set-

up” section on page 17.

2. The drill must be hitched securely to tractor. Always

use a locking style drawbar pin sized to match the

holes in the hitch and drawbar (minimum of 1" diameter).

3. The safety chain should be securely attached to the

drill hitch and the tractor.

4. The Safety Lights must be plugged in with tractor

lights using the standard 7-pin terminal.

5. Make sure the drill is properly folded. Refer to Folding

on page 22.

6. The opener transport lock handles should be in the

ROADposition and the openers completely raised for

the opener locks to engage and lock the openers up.

There are two lock handles on each drill section.

7. The cylinder lock channels must be on the rods of the

twotransportlift cylindersandfront boxliftcylinder.As

shown back in Figure 2-3, allow the transport lift cylinders to settle back against the lock channels.

Marker Transportation

Always transport the marker with it folded in the flat position. Make sure the second marker section rests securely

on the transport carrier.

Great Plains Mfg., Inc.

Jack Lifting Position

Jack Storage Location

Using and Storing the Front Tongue Jack

Figure 2-5

15564

15563

Parking

Unhitching with the drill unfolded.

!

CAUTION!

This drill has a negative tongue weight when unfolded and the

openers raised. Do not unhitch the drill in the unfolded position

without first lowering the parking stand and pressurizing the

openers down. Unhitching in the unfolded position with the

openers raised could result in sudden elevation of the tongue

causing injury or death.

1. Removethejack from itsstoragelocationon top of the

tongue and pin it in the post located on the left side of

the tongue, refer to Figure 2-5. Extend the jack until

weight of the tongue is on the jack.

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

24

2. Lower the parking stands located at the outer end of

each wing box by unpinning the keeper pin and rotating the stand down. See Figure 2-6. Place a block under the foot of the stand if it does not contact the

ground.

Page 27

Great Plains Mfg., Inc.

Section 2 Operating Instructions

15565

Parking Stand Positioned for Unhitching

Using and Storing the Parking Stands

Figure 2-6

3. Lower the openers and pressure them down.

4. Unplug the drills’ hydraulic lines and electrical lines

from the tractor.

5. Removethehitchpinandsafetychain from the tractor

drawbar. Use caution when removing the hitch pin because a slight tongue elevation might still occur.

NOTE:After the drill has been unhitched fora time in

the unfolded position the tongue may rise above the

tractor drawbar height. Lower the tongue back down

by connecting the opener lift circuit and pressuring

the openers back down.

15566

Parking Stand Storage Position

Unhitching with the drill folded.

1. Fold, raise, and lock the drill in the transport position.

2. Park the drill on a level, solid area.

3. Removethejack from itsstoragelocationon top of the

tongue and pin it in the post located on the left side of

the tongue, refer back to Figure 2-5. Extend the jack

until weight of the tongue is on the jack. If the ground

is soft, place a board or plate under the jack to widen

the ground contact area.

4. Unplug the drills’ hydraulic lines and electrical lines

from the tractor.

5. Removethehitchpinandsafetychain from the tractor

drawbar.

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

25

Page 28

Section 2 Operating Instructions

Great Plains Mfg., Inc.

Setting the Bypass Valve

A bypass valveis plumbed into the opener downpressure

circuit. See . Tractors with load-sensing, closed-center hydraulics require this bypass valveto protect the tractor hydraulic system.

If you are unsure what type of hydraulicsystem is on your

tractor,contact your tractor manufacturer.

19045

Bypass Valve

Figure 2-7

downpressure so gauges are at 1800 psi. See Figure

2-6.

15557

Opener Down Pressure Control Valves

Figure 2-8

Tractors with Open Center Hydraulics

Closebypassvalvefor no oil flow by turningknob on valve

clockwise completely. Always operate the drillwith the bypass valveclosed.

Tractors with Pressure Compensating Closed Center

Hydraulics (PC Closed)

Closebypassvalvefor no oil flow by turningknob on valve

clockwise completely. Always operate the drillwith the bypass valveclosed.

Tractors with Load Sensing Closed Center Hydraulics

(LS Closed) or Pressure Flow Compensating (PFC)

Systems

IMPORTANT: Failure to use the bypass valve on loadsensing tractors may cause major tractor damage.

1. Close bypass valvefor no oil flow by turning knob on

valve clockwise completely.

2. With tractorathalf throttle, adjustflow-controlvalveon

tractor so openers raise and lower at a reasonable

speed. Keeptractor at one-half throttle for remaining

steps.

NOTE:The fasteropenersraise and lower,the greater potential for oil heating, premature wear or tractor damage.

5. While watching gauges on drill, slowly turn knob on

bypass valve counterclockwise. Adjust bypass valve

justuntil needles on gauges begin to move down from

1800 psi. Lock bypass valve at this setting. (See also

note below.)

6. Adjust pressure-control valves on drill to desired

opener down pressure as explained under Opener

Down Pressure, beginning on page 40.

NOTE: The higher the bypass pressure, the greater the

potential for oil heating and premature tractor damage. At

the same time, for proper opener operation the bypass

valvemust be set at least 300 psi above the opener downpressure setting when the tractor is at one-half throttle.

Therefore,you should set the bypassvalveas low as possiblewhilestayingat least300 psi abovetheopener down

pressure setting.

While 1800 psi is a good starting point for setting the bypass valve, if you consistently operate the drill with low

opener down pressure you can set the bypass valve below 1800 psi. If you consistently operate the drill with very

highopener down pressure,youmayneedabypass-valve

setting above 1800 psi.

3. Engage tractor hydraulics and lower openers. Lock

hydraulic lever on tractor for continuous operation.

4. Adjust pressure-control valves on drill for opener

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

26

Page 29

Great Plains Mfg., Inc.

Section 2 Operating Instructions

Field Operation

The openers are mounted on floating opener frames

which followthe contour of the ground while maintaining

constant opener down pressure. To achievethe designed

opener flotation the opener hydraulic circuit must be powered by an active hydraulic system. An active hydraulic

system requires a tractor with closed-center hydraulicsor

pressure/flowcompensatedhydraulicswhichare powered

by a variable-displacement hydraulic pump.

To run the drill on tractors with open-center hydraulics or

on tractors with fixed-displacement hydraulic pumps requiresakit (Great Plains partnumber 194-143A). Referto

Non-ActiveHydraulicson page 28 foradjusting a drill with

Non-Active Hydraulics.

IMPORTANT: Tractors with load-sensing hydraulics

must use the bypass valve to operate the 3S-3000.

Failureto use the bypass valve can cause major tractor damage. Before adjusting opener down pressure,

set bypass valve as explained under Setting the By-

pass Valve, page 26.

Active Hydraulic System

(Tractors with closed-center hydraulic systems and

variable-displacement hydraulic pumps)

1. Lower the opener frames by pushing FORWARD on

the tractor remote hydraulic lever. The remote lever

must be LOCKED OPEN in this position to provide

constant pressure/flow to the openers.

John Deere tractors with Sound-Gard ® Body: Use

leverlock clip, John Deere part number R52667, to

lock lever forward. See your tractor dealer for clip purchase and installation.

John Deere 7000 Series tractors: Rotate valve

detent selector to motor position to lock lever in forward position.

John Deere 8000 Series tractors: Set timer to con-

tinuous. Push lever forward until detent clicks.

Case-IH Magnum tractors: Lock lever forward in

detent position. You may need to turn up detent pressure to its maximum setting. Do not tie hydrauliclever

past detent position with a strap. See your tractor

dealer for hydraulic-system details.

Other tractors: Lock leverforward in detent position.

You mayneedto turn updetent pressure to maximum

or use a mechanical detent holder to hold lever forward.See your tractor dealerforproper means of providing constant flow to openers.

2. With thetractorhydraulicleverlockedforward,turnthe

knob on the pressure control valves as shown in Figure 2-9. Watch the pressure gauge and dial in the desired pressure on the openers. Clockwise increases

the pressure and counterclockwise decreases pressure. Once the pressure is set, lock each knob with

the lock disk. There is one pressure control valve for

the center section, and one for the wing sections. In

some typical applications, the pressure on the center

sectionis set slightly higher thanthe wings to account

for additional compaction from the drill transport tires

and tractor tires. The recommended pressure range

fordrilling isbetween200 psi and1200psi. Setting the

opener down pressure above 1600 psi. will raise the

drivewheelsoffthegroundwhentheseedboxis empty causing skips and poor seed metering. See Plant-

ing Adjustments in the “Adjustments” section

starting on page 38 to convert hydraulic pressure at

the gauge to opener down force.

Pressure Control Valves

Figure 2-9

15639

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

27

Page 30

Section 2 Operating Instructions

Great Plains Mfg., Inc.

3. After the opener pressure is set, opener depth is controlledbythepress wheel adjustment. Attached to the

rear of each opener is one of several optional press

wheels.The press wheels close thefurrowand gently

press soil over the seed while also providing depth

control for the opener. To adjust the position of the

press wheel, which automatically changes the seeding depth of the opener, lift the "T" handle located on

top of the opener and slide it forward or rearwarduntil

the seeding depth is correct, as shown in Figure 2-10.

Moving the handle forward plants shallower while

moving the handle rearward plants deeper.A spring

loaded pin holds the "T" handle at the setting to maintaintheproperdepth.Lifttheopenerframesslightly to

take the pressure off the "T" handles when adjusting

the press wheel depth.

15659

Press Wheel Adjustment

Figure 2-10

NOTE:The opener pressure setting controls the soil

firming pressure on the press wheel as well as the

disk penetrating force. DO NOT use more opener

down pressure than necessary to obtain the desired

opener penetration and to maintain the proper firming action over the seed. Set the planting depth with

the depth controlling press wheel and only use

enough opener pressure to cut the proper seed

groove and maintain the desired soil firming action.

Excessive opener force will lead to excessive wear

and damage of the opener components.

To operate markers and constant opener down pressure

atthesame time, connect theopenerstocircuit#2 and the

markers to circuit #3.

Non-Active Hydraulic System

(Tractors with open-center hydraulic systems or

fixed-displacement hydraulic pumps)

To run the drill on tractors with open-center hydraulics or

on fixed-displacement hydraulic pumps requires a kit

(Great Plains part number 194-143A). This kit utilizes a

non-active hydraulic system which allows you to pressurize your openers down and lock in that pressure on level

ground by holding the opener frames in a fixed position.

1. Lower the opener frames by pushing FORWARD on

the tractor remote hydraulic lever. The remote lever

must be TEMPORARILY LOCKED OPEN in this position while the pressure adjustment is being made to

provide constant pressure and flow to the openers.

2. With thetractorhydraulicleverlockedforward,turnthe

knob on the pressure control valves as shown in Figure 2-9. Watch the pressure gauge and dial in the desired pressure on the openers. Clockwise increases

the pressure, and counterclockwise decreases pressure. Once the pressure is set, lock each knob with

the lock disk. There is one pressure control valve for

the center section and one for the wing sections. In

some typical applications, the pressure on the center

sectionis set slightly higher thanthe wings to account

for additional compaction from the drill and tractor

tires. The recommended pressure range for drillingis

between 200 psi and 1200 psi. Setting the opener

down pressure above 1600 psi. will raise the drive

wheels off the ground when the seed box is empty

causing skips and poor seed metering. See “Fertiliz-

erAdjustment”onpage 38toconverthydraulicpressure at the gauge to opener down force.

3. After the opener pressure is set, RETURN THE

TRACTOR REMOTE HYDRAULICLEVER TO ITS

NEUTRAL POSITION. This "locks in" the previously

selected pressure and the opener frames remain in a

fixed position.

NOTE: Open center tractors and tractors with fixed

displacement pumps are not designed to provide a

continuous supply of pressurized oil to remote locations. Attempting to continuously supply oil to the

pressure control valves will cause your tractor hydraulic pump to bypass a large volume of pressurized oil. This will result in overheating of the tractor

hydraulicoil supply and WILL RESULTIN TRACTOR

DAMAGE.

Priority Flow Hydraulic Systems

On some tractors with load-sensing hydraulics, the circuit

#1 is capable of taking nearly 100 percent of available hydraulic flow. Operating the openers or markers on circuit

#1 will starvethe other circuit, making one function inoperable.

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

28

Page 31

Great Plains Mfg., Inc.

Section 2 Operating Instructions

NOTE: On some tractors with very positive remote

hydraulic checks, a slight increase in the reading on

the pressure gauges may occur after the tractor remote lever is returned to neutral. This is caused by

backpressure on the opener cylindersandshouldbe

ignored. The NET OPERATING PRESSURE on the

opener cylinders is maintained at the pressure you

selected while the tractor remote lever was held forward–notatthe "apparently increased" pressure. Reactivating the tractor lever forward will confirm this.

4. Each time the openers are lowered, hold the tractor

remote hydraulicleverforwardfora fewsecondsto recharge the circuit, then return it to its neutral position.

The tractor and drill should be on levelground when

you return the tractor lever to neutral.

5. The open center hydraulic kit allows the tractor operator to momentarilyoperate the opener down pressure

circuit as an active circuit. When approaching a

mound or valley where active hydraulics is desirable,

the tractor operator can MOMENTARILY PUSH THE

TRACTOR REMOTE HYDRAULICLEVER FORWARDwhichwillallowthe opener frames to followthe

uneventerrain with constant opener down pressure.

As soon as the drill returns to level ground RETURN

THE TRACTOR REMOTE HYDRAULIC LEVER TO

ITS NEUTRAL POSITION to "lockin" the preset pressure once again. DO NOT activate the tractor remote

hydraulic lever for more than 20 seconds at a time,

onceevery2 minutes.Alwayswaituntilthetractor and

drill are on levelground before returning the tractor remote hydraulicleverto its neutralposition. The tractor

remote hydrauliclever can be momentarily bumped

forwardany time on level ground to assure the preset

pressureis correctly lockedin and to reset the system

if it has not been operated for a long period of time.

6. After the opener pressure is set, opener depth is controlledbythe press-wheel adjustment. Attached tothe

rear of each opener is one of several optional press

wheels.The press wheels close thefurrowand gently

press soil over the seed while also providing depth

control for the opener. To adjust the position of the

press wheel, which automatically changes the seeding depth of the opener, lift the "T" handle located on

top of the opener at the rear and slide it forward or

rearwarduntil theseedingdepth iscorrectas shownin

Figure 2-10, page 28. Moving the handle forward

plants shallower while moving the handle rearward

plants deeper.A spring loaded pin holds the "T" handle at the setting to maintain the proper depth. Lift the

opener frames slightly to take the pressure off the "T"

handles when adjusting the press wheel depth.

NOTE:The opener pressure setting controls the soil

firming pressure on the press wheel as well as the

disk penetrating force. DO NOT use more opener

down pressure than necessary to obtain the desired

opener penetration and to maintain the proper firming action over the seed. Set the planting depth with

the depth controlling press wheel and only use

enough opener pressure to cut the proper seed

groove and maintain the desired soil firming action.

Excessive opener force will lead to excessive wear

and damage of the opener components.

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

29

Page 32

Section 2 Operating Instructions

Great Plains Mfg., Inc.

Fertilizer Box Operation

The 3S-3000F is equipped with a fertilizer compartment

so you can plant seed and apply fertilizer in the same field

pass. Use dry,granular fertilizer and follow the procedure

below.

1. Clean any seed or debris from the fertilizer compartment.

2. Adjust theseedand fertilizercompartments todesired

capacity. The 3S-3000F is equipped with standard dividers that partition the drill boxes into 60 percent

seed and 40 percent fertilizer. If your drill is outfitted

withoptional offset dividers, the seed-to-fertilizer ratio

can be changed. Refer to Seed and Fertilizer Capaci-

ty,“Adjustments,” on page 48.

3. Calibrate the fertilizer application rate as explained

under Fertilizer Rate Adjustment and Fertilizer Rate

Calibration,“Adjustments,” on page 38.

4. Check that the divider door is closed so seed and fertilizer cannot pass between compartments. See Figure 2-13.

5. Check that the fertilizercleanout door is latched securely as shown in Figure2-11. Close all door latches

before loading the fertilizer compartment.

Seeding with Both Compartments

1. Clean out the boxesas explainedunderMaintenance,

“Maintenance and Lubrication,” on page 51.

2. Open the divider door between the seed and fertilizer

compartments. To open the door, loosen the black

knobs shown in Figure 2-13. Loosen each knob until

thebentclipcanbe turnedoff the door,then retighten.

When all bent clips have been turned, swivel the door

back against the fertilizer tray opening.

16383

Divider Door

Figure 2-13

3. Use the vinyl washout cover to hold the divider door

open as shown in Figure 2-14.

Clamp Latched Securely

16377

Cleanout Door Latched

Figure 2-11

6. Open thelidoverthe fertilizercompartment andswivel

back until it rests against the open drill box lid. See

Figure 2-12. The fertilizerlid servesas a spill guard to

keep fertilizer out of the seed compartment.

16375

Spill Lid

Figure 2-12

7. Fill fertilizer compartment.

16380

Divider Door Secured

Figure 2-14

4. To avoid unnecessary wear, on each box remove the

chain from the clutch shaft to the fertilizer drive shaft.

Refer to Figure 2-15.

16384

Remove Chain

Figure 2-15

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

30

Page 33

Great Plains Mfg., Inc.

Section 2 Operating Instructions

Marker Operation

Themarkeroptionassembliesare equipped with adouble

selector valveto combine the transport fold hydraulic circuit with the marker hydraulic circuit.

Afterthe drill is unfoldedforfieldoperation,shift thedouble

selectorvalveto the marker circuit as showninFigure2-16.

Before operating the markers, make sure they are properlybledas described in Bleeding theMarkerHydraulicSys-

tem in the “Adjustments” section on page 43.

Double Selector Valves

Drillsequippedwithmarkersuseadoubleselector to combine the transport foldhydrauliccircuit with the markerhydraulic circuit. Tractors with only two sets of remote

hydraulicoutlets must use a second doubleselector valve

TwoOutletTractor Hydraulic Kit Great Plains Part No.194122A.Thiscombinesthe transport lift hydraulic circuit and

opener lift hydrauliccircuit. To operate thedoubleselector

valves,turn the handle on top of the valve toward the hydraulic hoses of the circuit which you wish to operate.

Shaft Monitor Operation

To operate the shaft monitor,turn system on by activating

on-offswitchon monitor head. If the drill’s feedercupshaft

is turning, both of the lights will be on, and the alarm will

not sound.

If any of the feeder cup shafts stop for a period of 30 seconds,the alarm will sound and the light on the monitorwill

flash designating the failed shaft.

The 30 second delay is to preventnuisance alarmswhen

turning at the end of the field.

If a failure does occur and the alarm sounds, remember

you have traveledfor 30 seconds without planting. Figuring the distance traveled in 30 seconds will allow you to

determine where the failure occurred.

Shifting the Double Selector Valve

15550

Figure 2-16

To operate a single marker,activate the tractor remote hydraulic lever to move the marker in the desired direction.

Singlemarkersareequipped with aneedlevalvetocontrol

the marker lifting speed. Excessive folding speed could

damage the markers, so adjust theneedle valveto set the

markersto a safeefficient operating speedasdescribedin

Single Marker Speed Adjustment in the “Adjustments”

section on page 44.

Dual markers are equipped with a sequence valve to controlmarkerlift sequence.Starting with bothmarkerup,the

sequence is:

1. Activate the remote hydraulic lever; right marker lowers while left marker stays up.

2. Reverse the remote hydraulic lever; right marker raises while left marker stays up.

3. Activate the remote hydraulic lever again; left marker

lowers while right marker stays up.

4. Reversethe remote hydraulic lever; left marker raises

while right marker stays up.

5. The sequence repeats this same pattern.

Dual marker’s raise and lower speeds are adjusted with

hexadjustment screwsonthe body of the sequencevalve.

Excessive folding speed could damage the markers, so

adjust the hex screws to set the markers to a safeefficient

operating speed as described in Dual Markers with Se-

quence Valve Marker Speed Adjustment in the “Adjust-

ments” section on page 44.

Point-Ro w Operation

The point-row option allows you to raise and lower individual drillsections. Toraise and lower all sections together,

flipthepowerswitch (1) so the master lift control light (2) is

lit. Raise or lower all openers by moving the switch under

the light.

To raise and lower individual sections, flip the power

switchso the sectioncontrollight (3) is lit. Raise and lower

theopenersonindividual sections bymovingtheswitches

under the light.

17060

Point-Row Control Monitor

Figure 2-17

NOTE:Be sure to turn the point-row powerswitch off

when the tractor is off.

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

31

Page 34

Section 3 Adjustments

Section 3 Adjustments

Great Plains Mfg., Inc.

Seeding Adjustment

Seed Rate Sprocket Changes

The feeder cup drivesystem on your drill provides four different drive speeds and adjustable fluted feed cups to allows you to plant a wide variety of seeds and easily vary

the seeding rate. All the seed rate charts for this drill are

based on first selecting one of four available drive sprocketswhich are referred to as DRIVE TYPES. These sprockets, shown in Figure 3-1, are located on a 7/8 hex transfer

shaft behind the drive clutch on each box section. The

Drive Type Sprocket Location

Figure 3-1

drive types are easily changed by loosening the 12 tooth

idlersprocketsonthedrivechain, removing the keeperpin

on the hex shaft, and repositioning the sprockets so the

desired drive type sprocket lines up with theclutch sprocket. Reroute the drive chain as shown in Figure 3-2 and on

thedrive type decallocatedon thedrivesupportplate near

the idler sprockets. Set the same drive type on all three

drill sections.

15559

NOTE:Be sure chain is installed with the chain connector

link retainer towards the centerline and the clip opening

(split end) faces the opposite wayof the chain travel.

Drive Type Sprocket Ratio

1 72 T ooth Slowest drive type

2 34 T ooth 2.12 faster than drive type 1

3 23 T ooth 3.13 faster than drive type 1

4 14 T ooth 5.14 faster than drive type 1

Seed Rate Adjustment Handle

Once the correct drive type is chosen according to the

Seed Rate Chart, starting on page 34, position the seed

rateadjustment handle for the desired rate in the chart. To

adjustthe seed rate handleasshownin Figure 3-3, loosen

thewingnuton the bottom side of the handle and slide the

handle until the indicator mark lines up with the desired

cup setting. Retighten the wing nut to hold the lever in

place.There is aseedrateadjustment handleforeach drill

section.

Seed Rate Adjustment Handle

Figure 3-3

Feeder Cup Setting

The drill is equipped with a four-position feed cup door on

each feedercup,asshown in Figure 3-4. Thehighest handle position is for wheat and other small grain seeds. The

second handle position down is for soybeans and other

large grain seeds. Should excessivecracking occur to

Drive Type Sprockets and Chain Routing

Figure 3-2

large seeds, drop the handle to the third position down.

The wide open position will allow complete clean-out of

the feed cup.MAKE SURE all handles are in thesame position before drilling.

3S-3000 Three-Section Folding Drill 195-110M-A 11/9/07

32

15561

Page 35

Great Plains Mfg., Inc.

Section 3 Adjustments

NOTE: Do not open the cup door to the wide open

position with seed in the box unless complete

cleanoutisdesired. The door maybedifficult to close

off once it is opened.

Feed Cup Door Adjustment

Figure 3-4

15555

Seed Rate Calibration

NOTE: Seeding rates will v ary greatly with v ariations

in sizes of the seeds. The seeding rates listed in this

manual are based on average seed size. We recommend that you test and adjust your drill using the procedurebelowto help ensure an accurate seeding rate.

1. Jackup the wing gauge wheelsandrotatethem to see

thatthe feedcupsand drivesareworkingproperlyand

are free from foreign matter. The right wing gauge

wheeldrivesthecenter section, butthe drive does not

engage unless the drill is completely unfolded.

2. Set the desired DRIVE TYPE from the rate chart by

choosing the correct drive type sprocketfrom the four

available7/8" hex bore quick-change sprockets.

Routethechainaccordingtothe decal and tighten the

chain by sliding the 12 tooth idler sprockets in the

slots. Make sure the DRIVE TYPE SPROCKET lines

up with the CLUTCH SPROCKET so the drives run

free and true.The wing sections require a blank

sprocket between the shaft bearing and the DRIVE

TYPE SPROCKET for the chain to align properly.

3. Set the seed rate adjustment handle to the desired

chart setting. Make sure all the feed cup doors are in

the desired position.

4. There aremanyfactorswhichwill affectseeding rates:

seed treatment, weight of seed, size of seed, surface

condition of seed, tire configuration, tire pressure and

tire slippage. Minor adjustments will probably be

needed to compensate for these factors.

5. The pounds-per-acre in the seed rate charts are

based on the drill having 9.5L-15 6 PLY ribbed implement tires inflated to 32 psi and 265/70B16 skid steer

tires inflated to 70 psi on the wing gauge wheels.

Check your tires for proper inflation pressure.

6. The large differences in seed size and treatment can

cause a wide variation in actual seeding rates. The

seed rate charts on the followingpages are based on

averagesize seed. This may differ from the seed you

areusing.Use the seed rate charts as a guide.Setthe

pounds per acre desired for your row spacing and

complete the following procedure to calibrate the drill

for your specific seed.

a. Place several pounds of seed over three of the

feed cups at the outboard drive end of the drill

box.

b. Disconnect the seed tubes from these three disk

openers.

c. Lowerthe opener frames to planting position in or-

der to activate the clutch and raise the proper

drive tire off the ground with a jack so it can be rotated by hand.

d. Place a container under the three seed tubes to

gather the seed as it is metered.

e. Rotate the drive wheel until oneacrehasbeental-

liedon the acremeter.This willbe175rotations on

the 30' drill. Be sure to check the three cups to

make sure each cup has plenty of seed coming

into it.

f. Weigh the seed which has been metered. Divide

by three to get the ounces/pounds metered by

each feed cup. Multiply by the number of openers

on your drill to arrive at the total pounds-per-acre

your drill would meter at that setting. If this figure

is different than desired, set your feed cup adjustment handle accordingly.

g. You maywant to repeat the calibration procedure

if the results of your calibration vary greatly from

the suggested settings contained in this manual.

REMEMBER: Tire size, tire air pressure, and field conditions also affect seeding rates. When drilling, check the

amount of seed you are using by noting acres drilled,

amount of seed added to the drill, and level of seed in

each drill box. If you suspect that you are drilling more or

less than desired, you may need to adjust the seeding

rates slightly to compensate for your field conditions.

11/9/07

3S-3000 Three-Section Folding Drill 195-110M-A

33

Page 36

Section 3 Adjustments

Seed Rate Charts (pounds per acre)

Great Plains Mfg., Inc.

Setting number

Alfalfa

Drive Type 1

(Based on

60#/bu)

Barley

Drive Type 1

(Based on

51#/bu)

Barley

Drive Type 2

(Based on

51#/bu)

Barley

Drive Type 4

(Based on

51#/bu)

Buck Wheat

Drive Type 3

(Based on

48#/bu)

Canola or

Rape

Drive Type 1

(Based on

51#/bu)

Flax or

Sudan

Drive Type 1

(Based on

55#/bu)

6" 2 6 8 12 15 19 23 27 32 37 41 45 50 54 59 63 69 74 79 82 84

7.5" 2 4 7 10 12 15 18 22 25 29 33 36 40 43 47 51 55 59 63 65 67

Spacing

10" 1 3 5 7 9 12 14 16 19 22 25 27 30 33 35 38 41 44 48 49 50

6" 2 5 8 11 14 18 22 26 30 35 39 43 48 53 57 62 66 69 73 73 74

7.5" 24691215182124283135384246495255585959

Spacing

10" 1 3 5 6 9 11 13 16 18 21 23 26 29 32 34 37 39 42 44 44 44

6" 4 9 16 22 30 37 45 54 62 71 76 87 96 104 114 123 133 142 152 154 156

7.5" 3 7 13 17 24 30 36 43 49 57 64 70 77 83 91 98 106 114 121 123 125

Spacing

10" 2 5 10 13 18 22 27 32 37 43 48 52 58 63 68 74 80 85 91 92 94

6" 9 21 39 53 73 90 110 131 151 174 194 213 234 255 278 300 325 348 371 377 382

7.5" 7 17 31 42 58 72 88 105 121 139 155 170 188 204 222 240 260 279 297 301 306

Spacing

10" 5 13 23 32 44 54 66 79 91 104 117 128 141 153 167 180 195 209 222 226 230

6" 0 11 21 29 42 52 65 78 92 107 123 136 150 165 180 195 209 224 240 242 245

7.5" 0 9 17 24 34 42 52 62 74 85 99 109 120 132 144 156 167 179 192 194 196

Spacing

10" 0 7 13 18 25 31 39 47 55 64 74 81 90 99 108 117 126 134 144 145 147

6" 0 4 8 11 14 18 21 25 29 32 36 39 43 47 51 54 59 63 68 69 71

7.5" 03691114172023262932343740434750545557

Spacing

10" 0 2 5 6 9 11 13 15 17 19 22 24 26 28 30 33 35 38 41 42 43

6" 0 4 8 12 16 20 24 28 33 37 42 46 50 54 59 65 70 76 82 83 85

7.5" 03791316192326303437404447525661666768

Spacing

10” 0 2 5 7 10 12 15 17 20 22 25 27 30 33 35 39 42 45 49 50 51

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Millet

Drive Type 1

(Based on

60#/bu)

Milo

Drive Type 1

(Based on

60#/bu)

Oats

Drive Type 3

(Based on

37#/bu)

Peas

Drive Type 3

(Based on

61#/bu)

Pinto Bean

Drive Type 1

(Based on

61#/bu)

6" 1 5 8 12 16 20 23 27 32 36 40 44 49 52 57 62 66 71 76 77 78

7.5" 14791316192225293235394246495357616263

Spacing

10" 1 3 5 7 9 12 14 16 19 21 24 26 29 32 34 37 40 43 46 46 47

6" 0 5 9 13 18 23 28 34 39 45 52 57 63 69 75 81 87 92 98 100 102

7.5” 0 4 7 10 14 18 22 27 31 36 41 45 50 55 60 65 69 73 78 80 82

Spacing

10" 0 3 5 8 11 14 17 20 23 27 31 34 38 41 45 49 52 55 59 60 61