Page 1

Table of Contents Index

3-Point 40-Foot Yield-Pro® Planter

Pre-Delivery

3PYPA

with Air-Pro

Manufacturing, Inc.

www.greatplainsmfg.com

®

Seed Meters

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

29852

Illustrations may show optional equipment not supplied with standard unit,

or may show similar 3PYP models and their options.

ORIGINAL INSTRUCTIONS

© Copyright 2012 Printed 2012-08-08 401-647Q

Table of Contents Index

EN

Page 2

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ...................................... 1

Introduction ..................................................................5

Models Covered ............................................................. 5

Description of Unit ..........................................................5

Compatible Tractors ...................................................5

Using This Manual..........................................................6

What’s On The Truck .....................................................6

Shipment Inventory ........................................................7

Assembly and Setup Assistance ....................................8

Plan The Mainframe Unload ........................................ 9

Use a Hoist or One to Four Lifters.............................. 9

Location Requirements ..................................................9

Wings: No Lift - No Hoist ..............................................10

Hoist Lifting...................................................................10

Three Hoist Points....................................................10

Four Hoist Points......................................................11

Fork Lifting....................................................................11

Single-Lift Points ......................................................11

Two Lift Points..........................................................12

Three Lift Points .......................................................13

Four Lift Points .........................................................14

Unloading....................................................................15

Unload Smaller Items First ...........................................15

Unload the Seed Frame ...........................................15

Unload The Mainframe.................................................16

Planter Assembly ....................................................... 20

Press Wheel Shipping ..................................................20

Shipping Stands ........................................................... 20

Prepare Parallel Arms .................................................. 21

Mount Seed Box Frame ...............................................22

Seed Cart Self-Lift ....................................................23

Remove Cart Shipping Stands .................................23

Install Casters...............................................................23

Caster Arms..............................................................23

Install Left and Right Caster Arms............................ 24

Install Caster Wheels................................................24

Adjust Steering Tie Rod............................................25

Lower Seed Box Structure........................................26

Remove Hopper (Option) .........................................26

Connect Steering Hoses ..............................................27

Route Steering Sensor Lead ........................................27

Route Lighting/Seed Box Leads...................................28

Adjust Air Box Pads......................................................28

Connect Seed Hose Rack ............................................29

Seed Hose Routing...................................................... 31

Port Identification: “12 Port” ..................................... 31

Port Assignments: 12, 23 and 24-Row..................... 31

Port Identification: “16 Port” ..................................... 32

Port Assignments: 16, 31 and 32-Row..................... 32

Connect Seed Hoses ................................................... 33

Connect Hoses at Air Box Manifold ......................... 33

Connect Hoses at Wing Tubes ................................ 33

Connect Air Box Inlet Hose ...................................... 34

Install Lower Walkboard Step ...................................... 35

Install Press Wheel Assemblies................................... 36

Install Row Unit Side Wheels....................................... 37

Hopper Installation ....................................................... 37

Hopper Level Sensor Installation ............................. 38

Row Unit Options ......................................................... 38

Planter Closeout .......................................................... 39

Emergency Moves Without Steering........................39

Force Caster Float ............................................... 39

Console Installation................................................... 40

Seed Monitor Console Installation ............................... 40

Tractor Steering ......................................................... 41

Install Switchbox .......................................................... 41

Install GP Linear Sensor .............................................. 42

Assemble Tractor Sensor......................................... 43

Install Tractor Steering Sensor................................. 43

Case IH® MX/Magnum™ Installation....................... 44

John Deere® 8000 (RFS) Installation....................... 46

John Deere® 8000 ILS Installation........................... 48

Install Harness for Linear Sensor.............................50

Install Electronic Module .............................................. 51

Install Gray Module Harness........................................ 52

ISObus Compatible Connection................................... 53

John Deere® R-Series ISObus ................................ 53

John Deere® 8000 Series ISObus ........................... 53

Install Harness for Native Steering Sensor .................. 54

Case or New Holland Native Sensor Harness ......... 55

John Deere® Tracked Native Sensor Harness ........ 56

John Deere® Wheeled Native Sensor Harness ....... 57

Install Module Output Harness..................................... 58

Steering Calibration ..................................................... 59

Steering System Hydraulic Bleeding........................59

Calibration ................................................................ 59

Steering Configuration Switch..................................59

Wheel Sensor Calibration ........................................ 60

Wheel Tractors and Alternate Method for Tracked

© Copyright 2006, 2007, 2008, 2009, 2010, 2011, 2012 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2012-08-08 Cover Index 195-325M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Tractors ............................................................ 60

Steering Troubleshooting............................................. 61

Steering Flash Error Codes ..................................... 63

Appendix A - Reference Information........................ 64

Specifications and Capacities, 1 of 2 ........................... 64

Tire Inflation Chart ....................................................... 65

Torque Values Chart ....................................................66

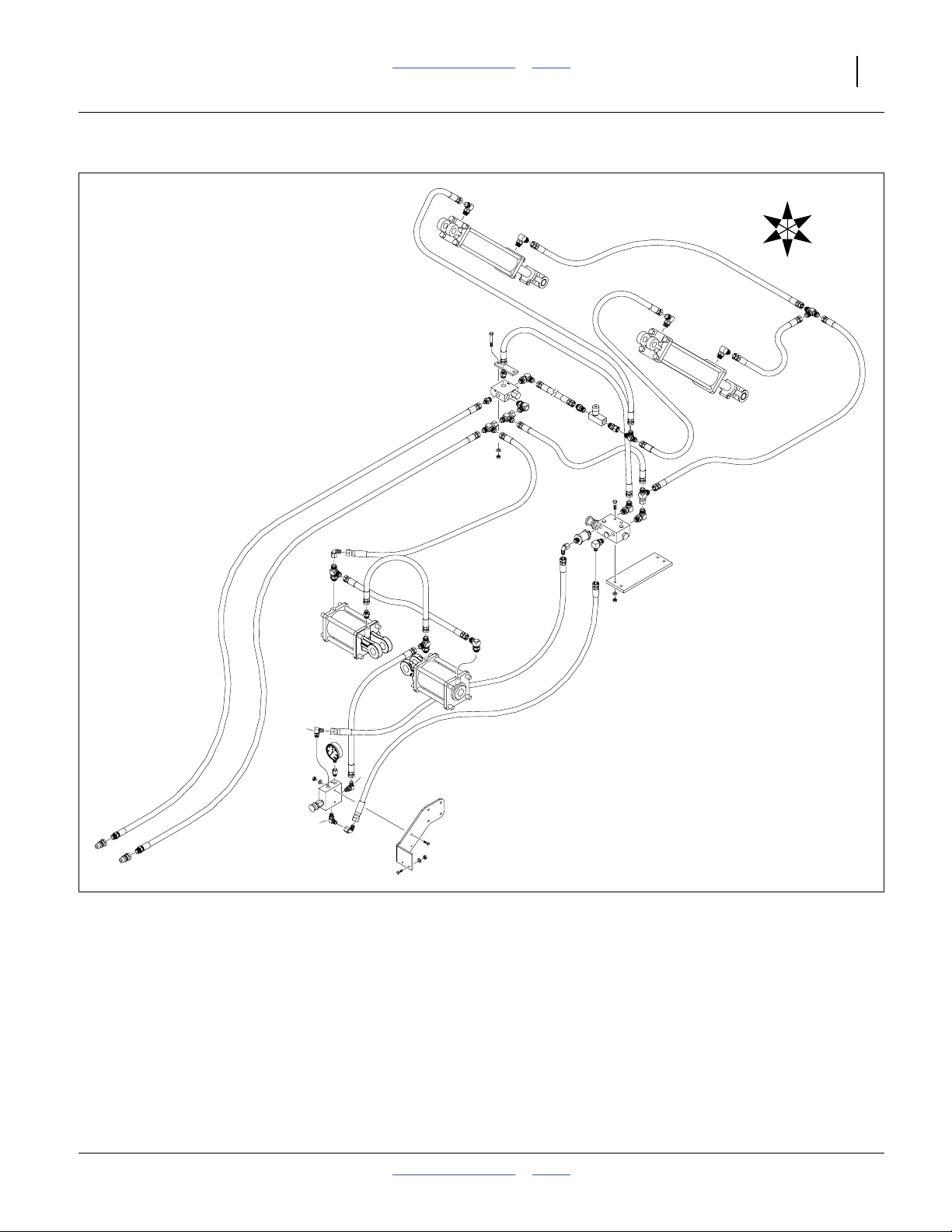

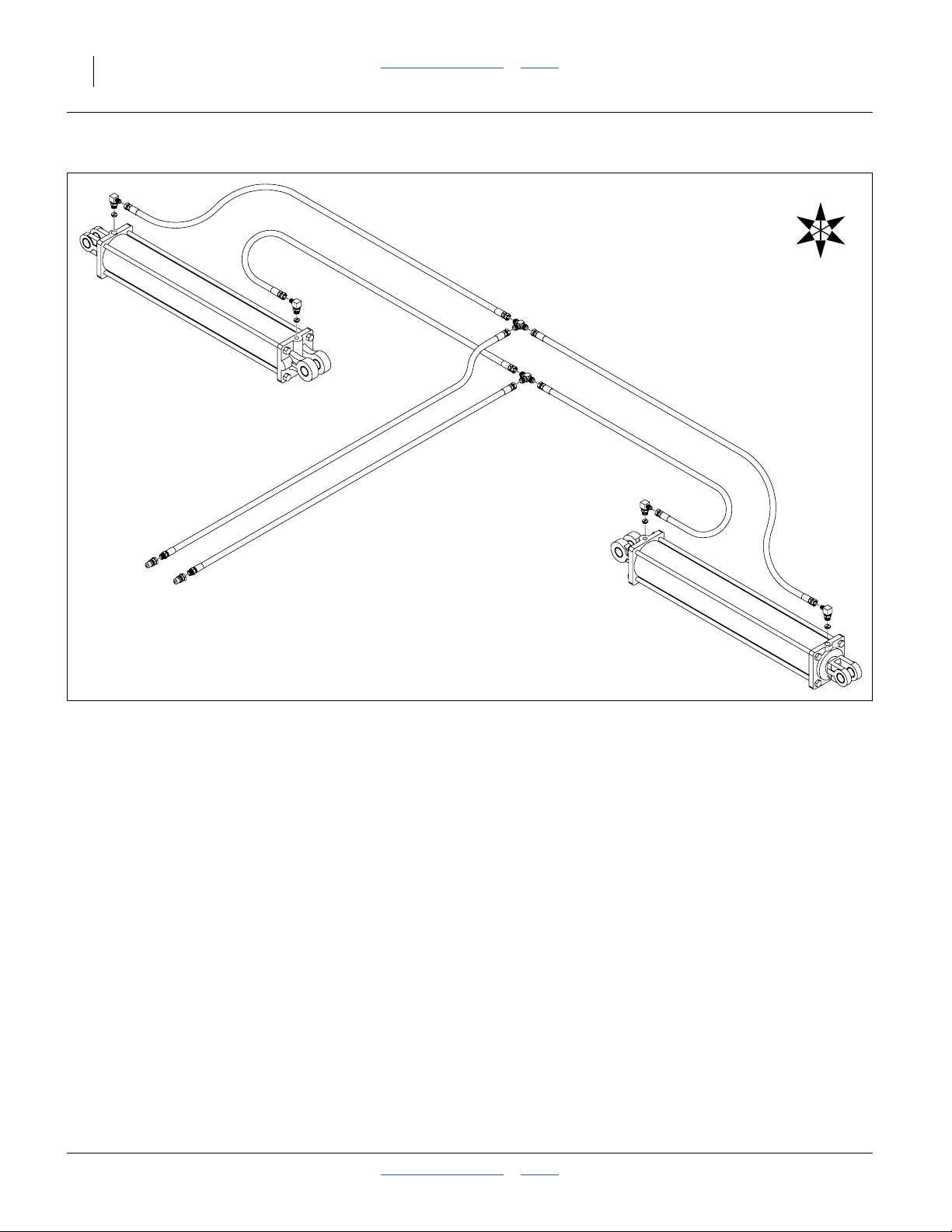

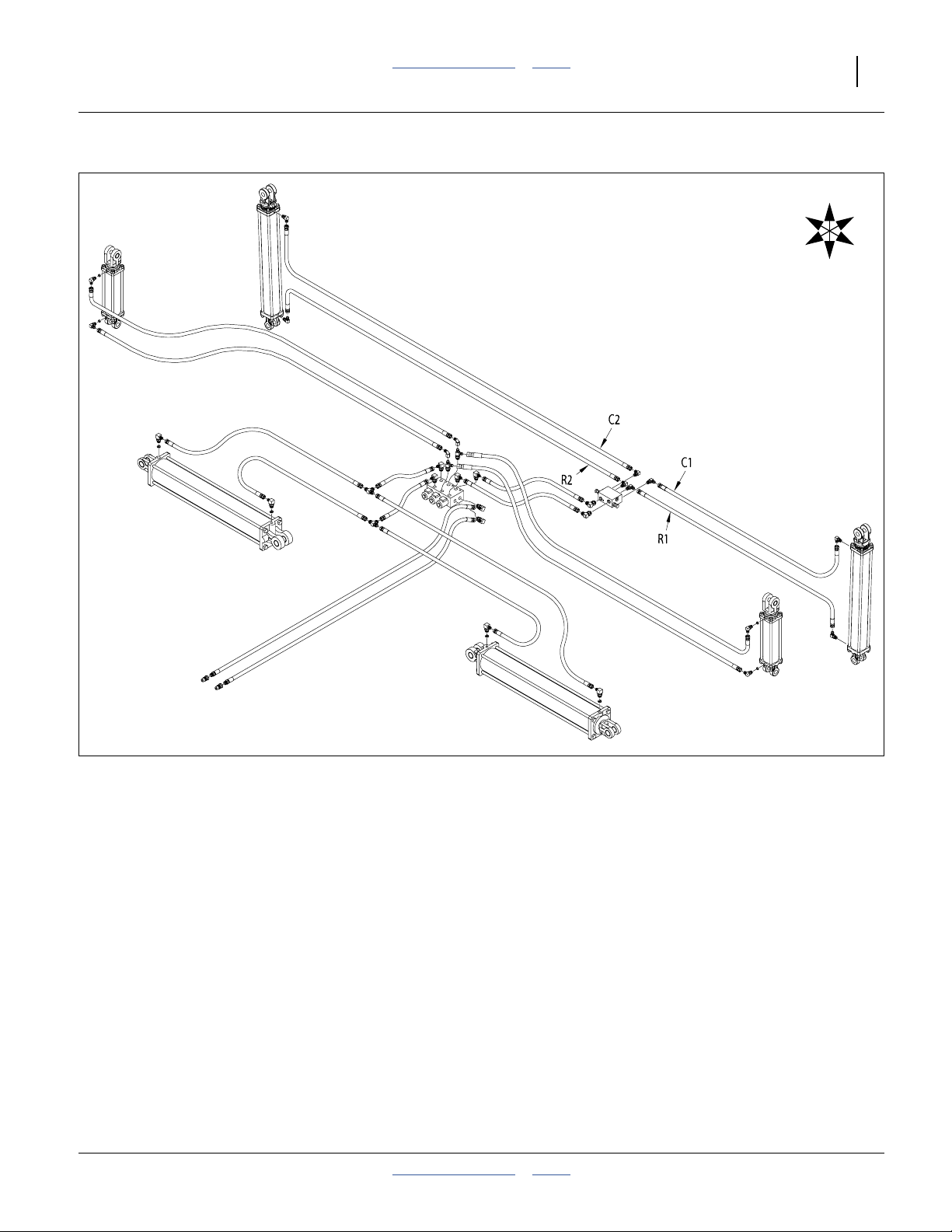

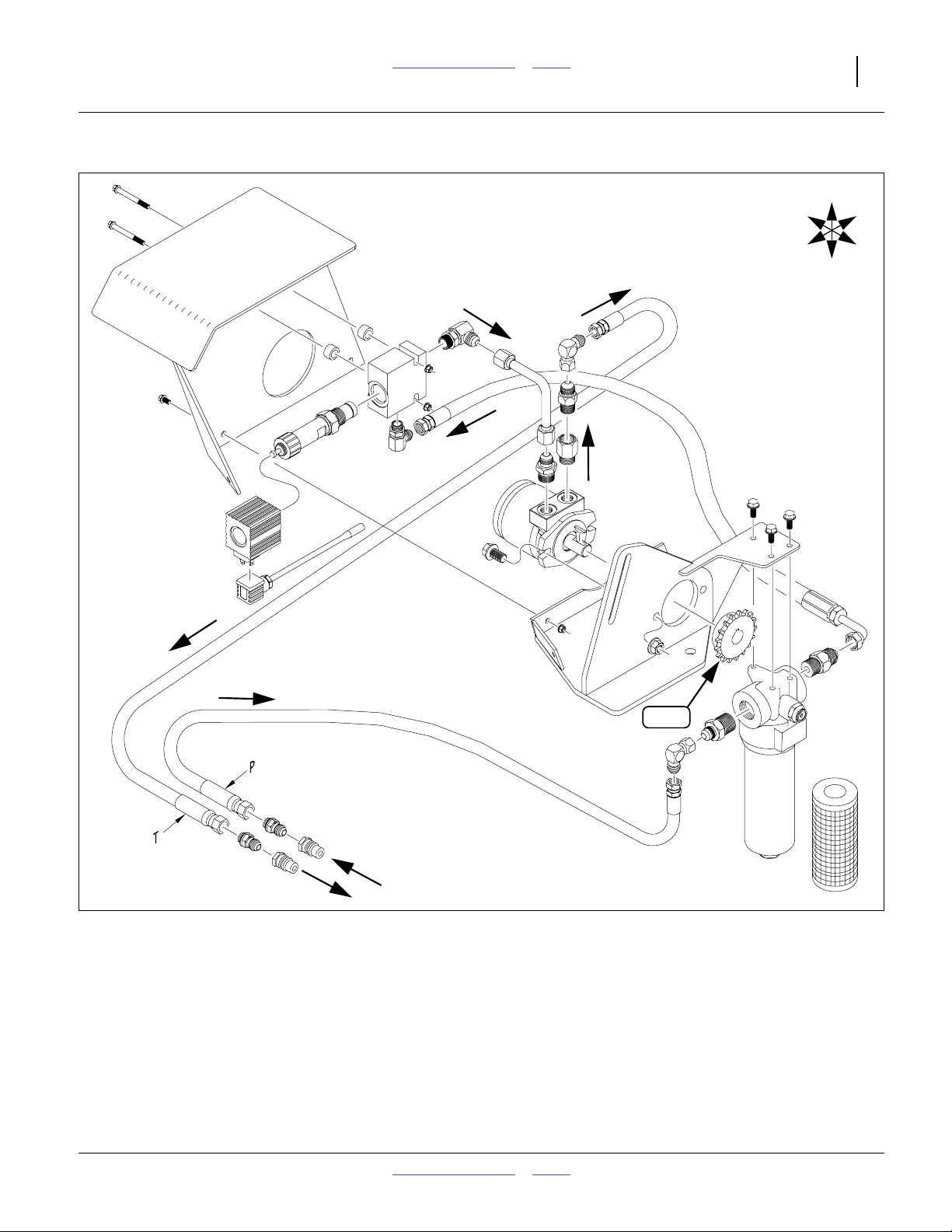

Hydraulic Diagrams ......................................................67

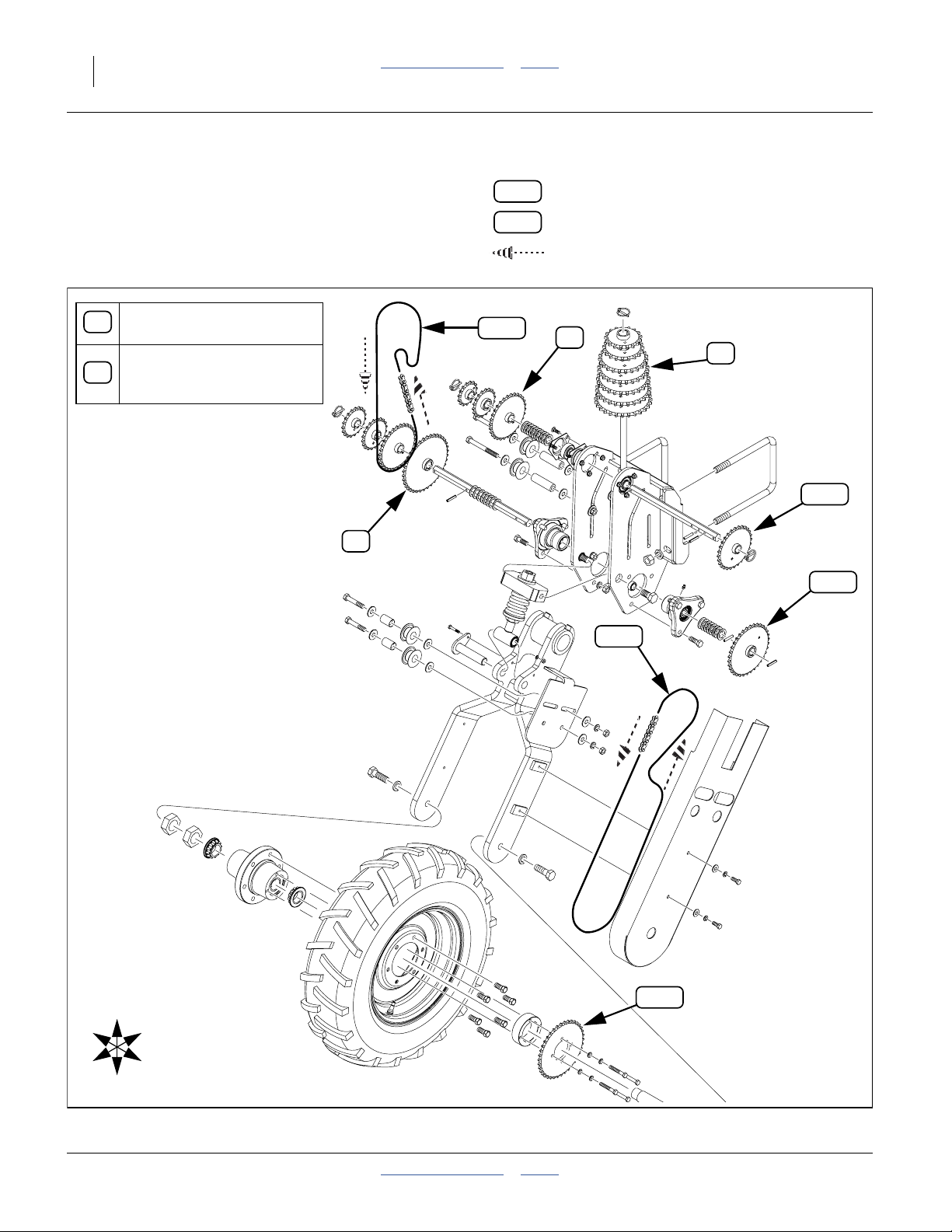

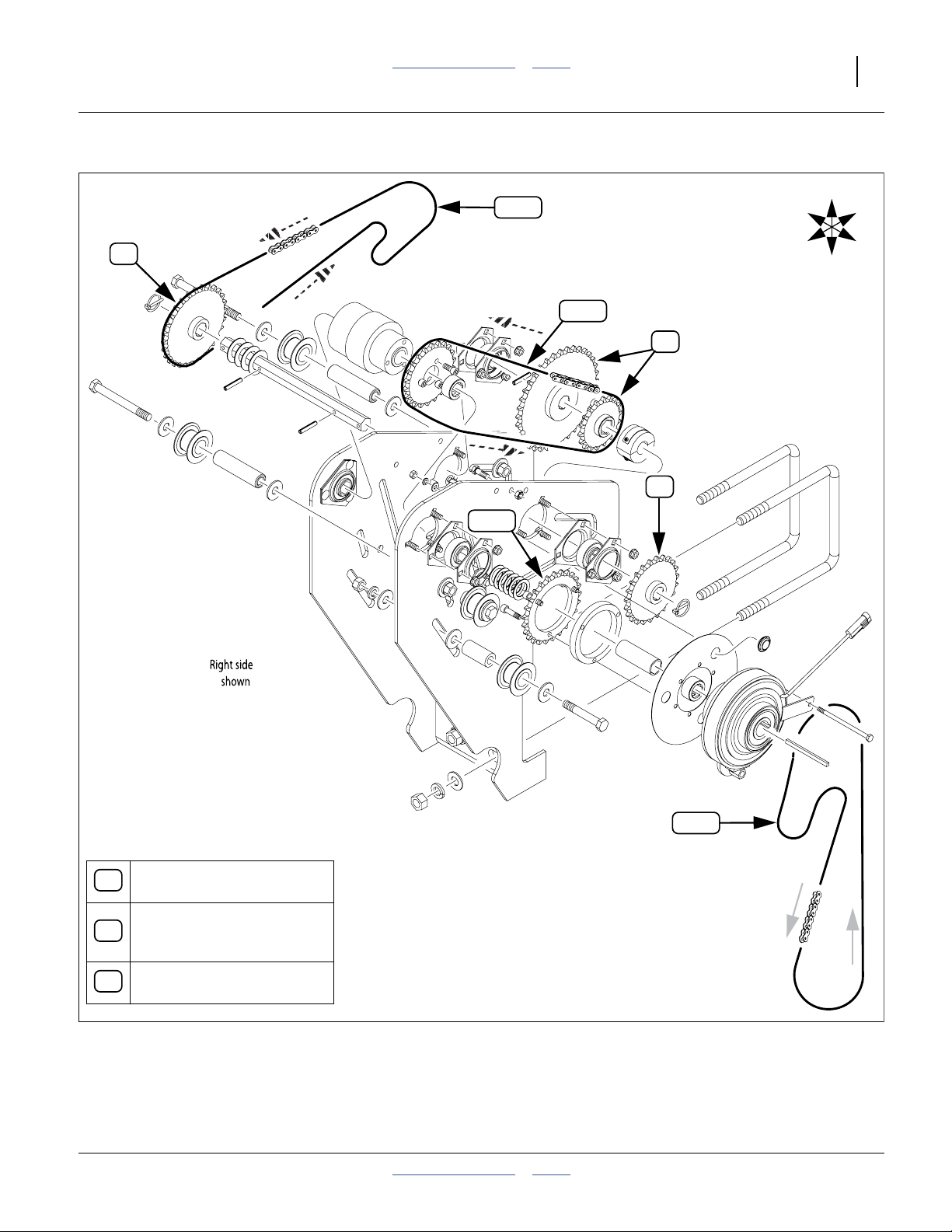

Chain Routing...............................................................74

Index ............................................................................79

195-325M Table of Contents Index 2012-08-08

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Use Adequate Lifting Means

The main section of this planter is extremely heavy. If

using multiple lifters, make sure each is rated for at least

its share of the load.

Unless using a crane, do not lift and move the planter.

Lift it off the delivery truck, pull the truck away, and lower

the planter to the ground.

> 14,000

POUNDS

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

2012-08-08 Table of Contents Index 401-647Q

Page 6

2 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

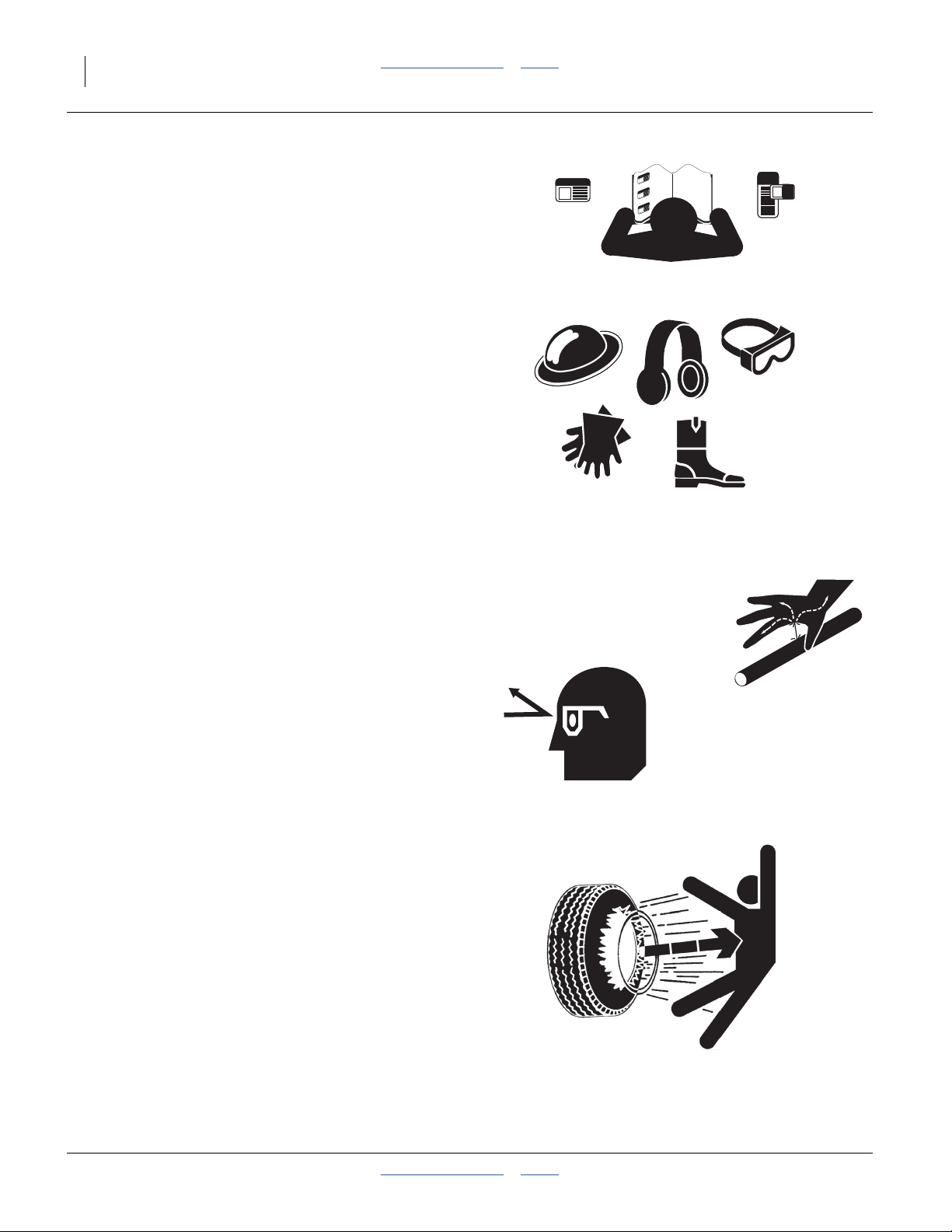

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” in the Operator

manual.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to loud noise can cause

hearing impairment or hearing loss, wear suitable hearing

protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

assembling or operating machinery.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury. This planter requires a

Power-Beyond port, which is always under pressure

when the tractor is running.

▲ Avoid the hazard by relieving pressure at other remotes, and

shutting down tractor before connecting, disconnecting or

inspecting hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

401-647Q Table of Contents Index 2012-08-08

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

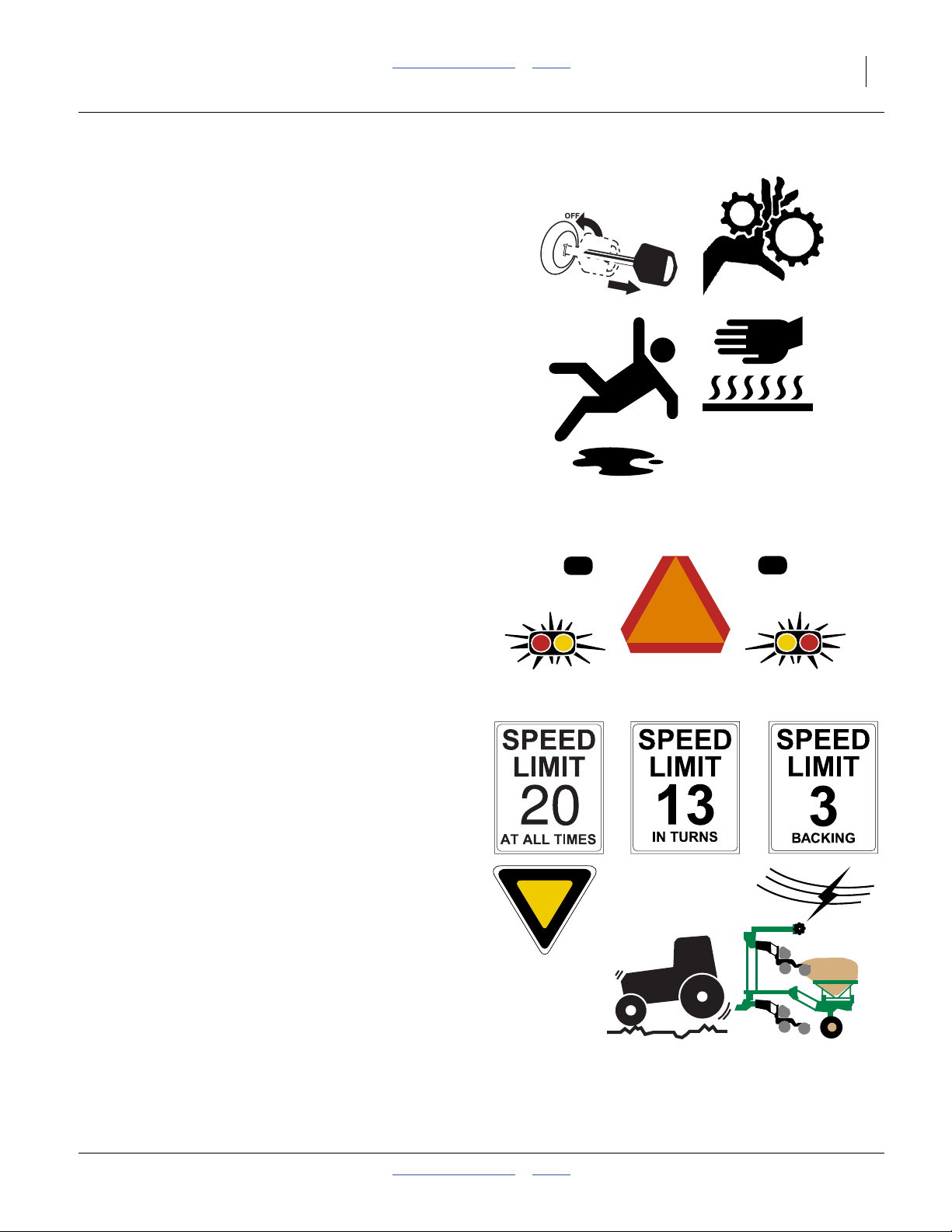

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Lower the planter, put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow planter to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on planter.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from planter before

operation.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever

driving on public roads.

▲ Use lights and devices provided with implement.

Transport Machinery Safely

Maximum transport speed for implement is 20 mph

(32 km/h), 13 mph (22 km/h) in turns. Some rough

terrains require a slower speed. Sudden braking can

cause a towed load to swerve and upset.

▲ Do not exceed 20 mph. Never travel at a speed which does

not allow adequate control of steering and stopping. Reduce

speed if towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully loaded, weighs

more than 1.5 times the weight of towing vehicle.

▲ Carry reflectors or flags to mark planter in case of

breakdown on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions in

Appendix, starting on page 64.

▲ Do not fold or unfold the planter while the tractor is

moving.

2012-08-08 Table of Contents Index 401-647Q

Page 8

4 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

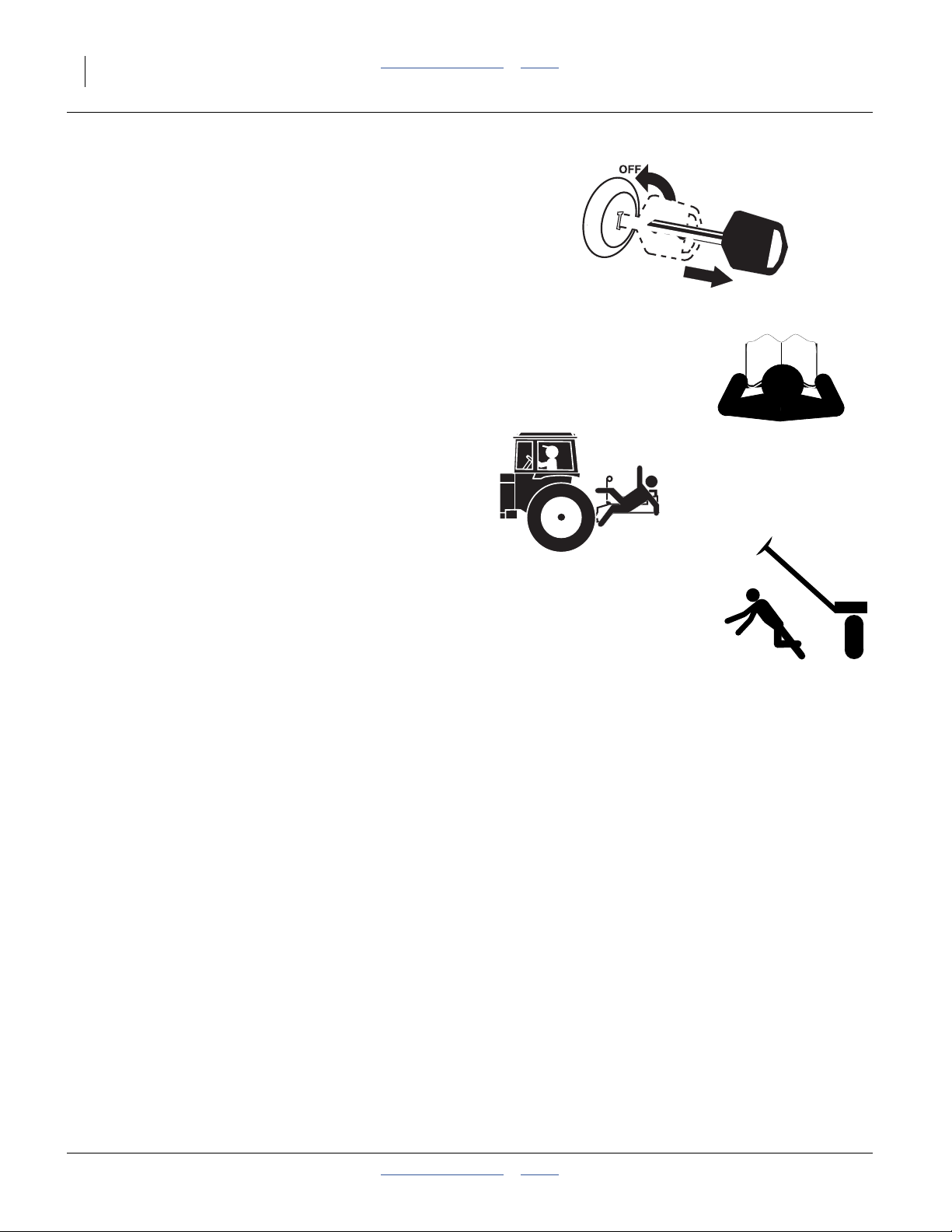

Shutdown and Storage

▲ Lower planter, put tractor in park, turn off engine, and

remove the key.

▲ Secure planter using blocks and supports provided.

▲ Detach and store planter in an area where children

normally do not play.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all planter functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave planter unattended with tractor engine

running.

▲ Do not stand between the tractor and planter during

hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

▲ Watch out for wires, trees, etc., when folding and raising

planter. Make sure all persons are clear of working area.

401-647Q Table of Contents Index 2012-08-08

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index 5

Introduction

The 3-Point 40-Foot Yield-Pro® Planter (3PYPA) has

been designed with care and built by skilled workers

using quality materials. Proper setup, maintenance, and

safe operating practices will help the customer get years

of satisfactory use from the machine.

Models Covered

3PYPA-1236 12-Row, 36 inch Spacing

3PYPA-1238 12-Row, 38 inch Spacing

3PYPA-1240 12-Row, 40 inch Spacing

3PYPA-1630 16-Row, 30 inch Spacing

3PYPA-24TR36 24-Row (12 Twin), 36 inch Spacing

3PYPA-24TR38 24-Row (12 Twin), 38 inch Spacing

3PYPA-24TR40 24-Row (12 Twin), 40 inch Spacing

3PYPA-3115 31-Row, 15 inch Spacing

3PYPA-32TR30 32-Row (16 Twin), 30 inch Spacing

Description of Unit

The 3PYPA planter is a semi-mounted implement for use

in conventional till, minimum-till, or light no-till conditions.

The 3PYPA accepts optional unit mounted coulters. The

unit mounted coulters make it suitable for light to

moderate no-till conditions only. The 3PYPA includes

25 Series openers with Air-Pro® meters supporting a

wide choice of seed disks. The planter stack-folds for

transport.

Intended Usage

Use the 3PYPA planter to seed production-agriculture

crops only. It is suitable for conventional till, min-till and

moderate no-till conditions. Do not modify the planter for

use with attachments other than Great Plains options

and accessories specified for use with the 3PYPA.

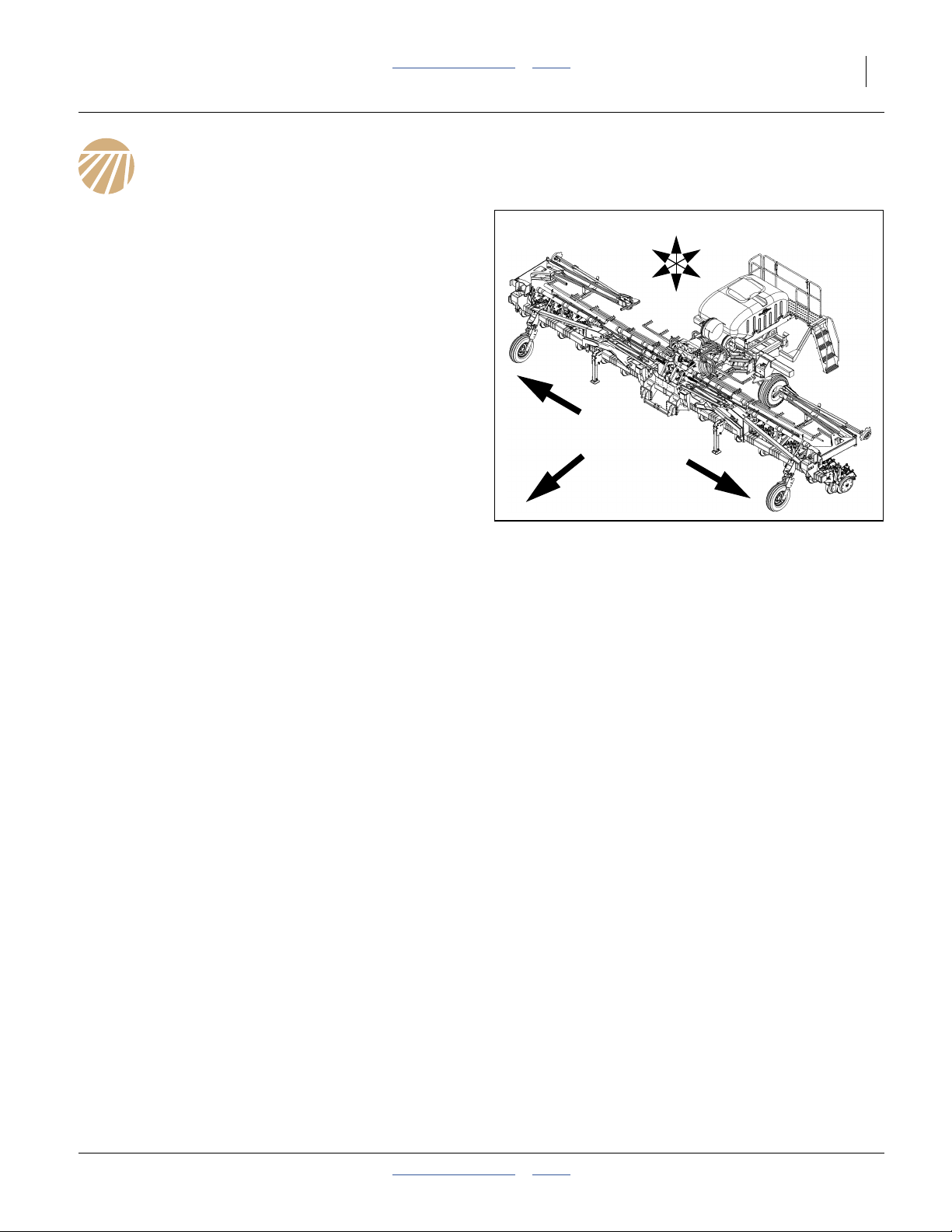

U

R

F

B

L

D

R

L

Figure 1

3PYPA Planter

Compatible Tractors

3PYPA planters include hydraulic steering, which

requires mounting a sensor in the tractor steering gear.

Brackets and instructions are included for the following

tractor brands and models.

Case IH

John Deere

John Deere

John Deere

The tractor must otherwise also meet the requirements

listed under Specifications and Capacities in Appendix A

of the Operator Manual (401-647M).

If the customer does not have one of the brands and

models listed above, contact the factory.

At time of publication, this 3PYPA steering system was

not compatible with articulated tractors.

®

®

®

®

MX or Magnum™ Series

225 through 385

8000 and 8000R Series with

rigid front suspension

8000 Series ILS

(Independent Live Suspension)

8000RT Series tracked

29852

2012-08-08 Table of Contents Index 401-647Q

Page 10

6 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Using This Manual

This manual will familiarize you with planning, unloading,

assembly, and some calibration of the planter. Most

operating information is contained in the Operator

manual (401-647M). It is essential that the Operator

manual be available during assembly and checkout.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

A crucial point of information related to the preceding topic.

Read and follow the directions to remain safe, avoid serious

damage to equipment and ensure desired field results.

Note: Useful information related to the preceding topic.

U

R

F

D

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

B

while in use unless otherwise stated.

An orientation rose in some line art

L

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

Document Family

401-647M Owner’s Manual (this document)

401-647B Seed Rate Charts

401-647P Parts

401-647Q Pre-Delivery manual

DICKEY-john®IntelliAg® manuals:

110011508 Planter/Drill Control, User Level 1

110011501 Planter/Drill Control, User Level 2&3

110011531 3PYPA-1236 Quick-Start Guide

110011531 3PYPA-1238 Quick-Start Guide

110011531 3PYPA-1240 Quick-Start Guide

110011530 3PYPA-1630 Quick-Start Guide

110011528 3PYPA-24TR36 Quick-Start Guide

110011528 3PYPA-24TR38 Quick-Start Guide

110011528 3PYPA-24TR40 Quick-Start Guide

110011529 3PYPA-3115 Quick-Start Guide

110011529 3PYPA-32TR30 Quick-Start Guide

110011126 DICKEY-john® hopper level sensor install

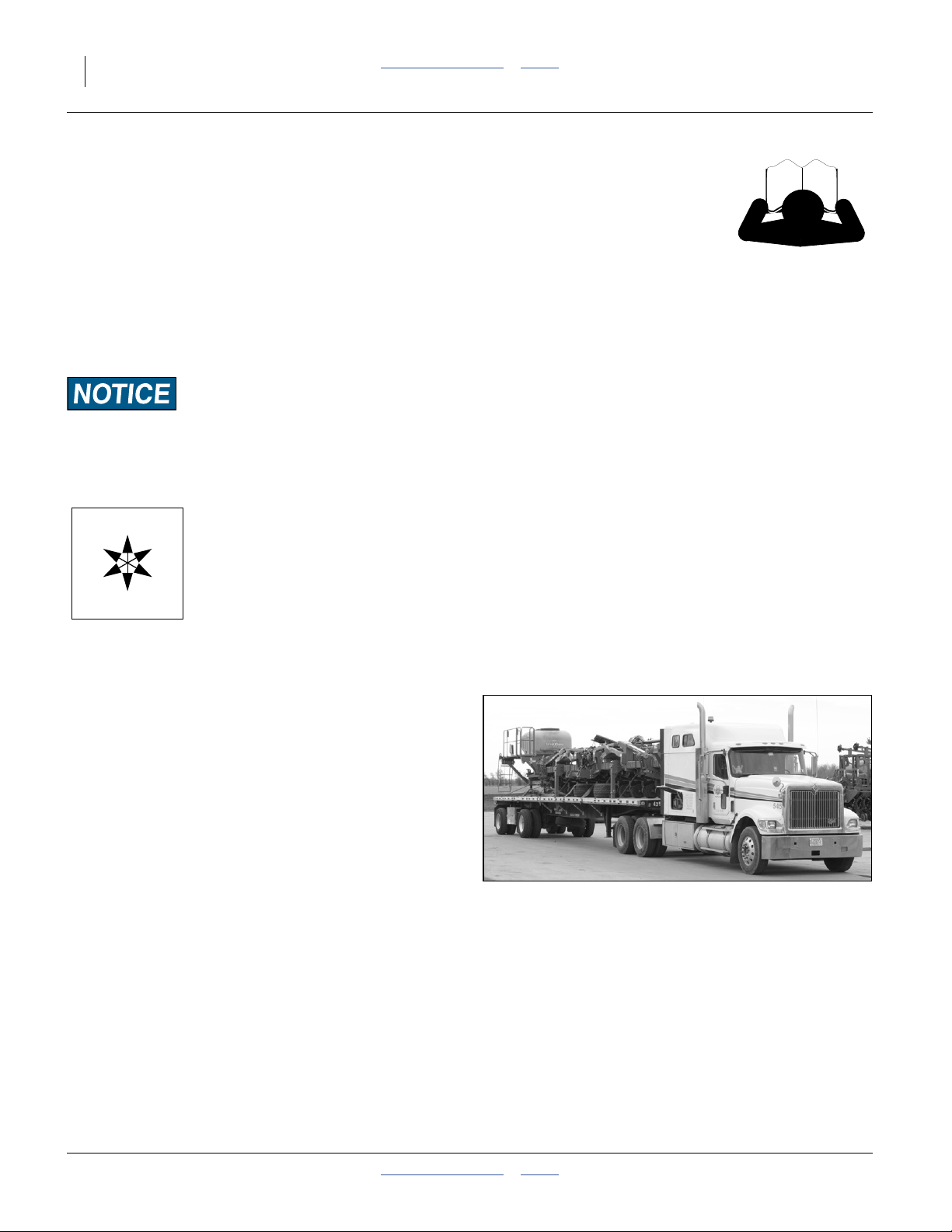

What’s On The Truck

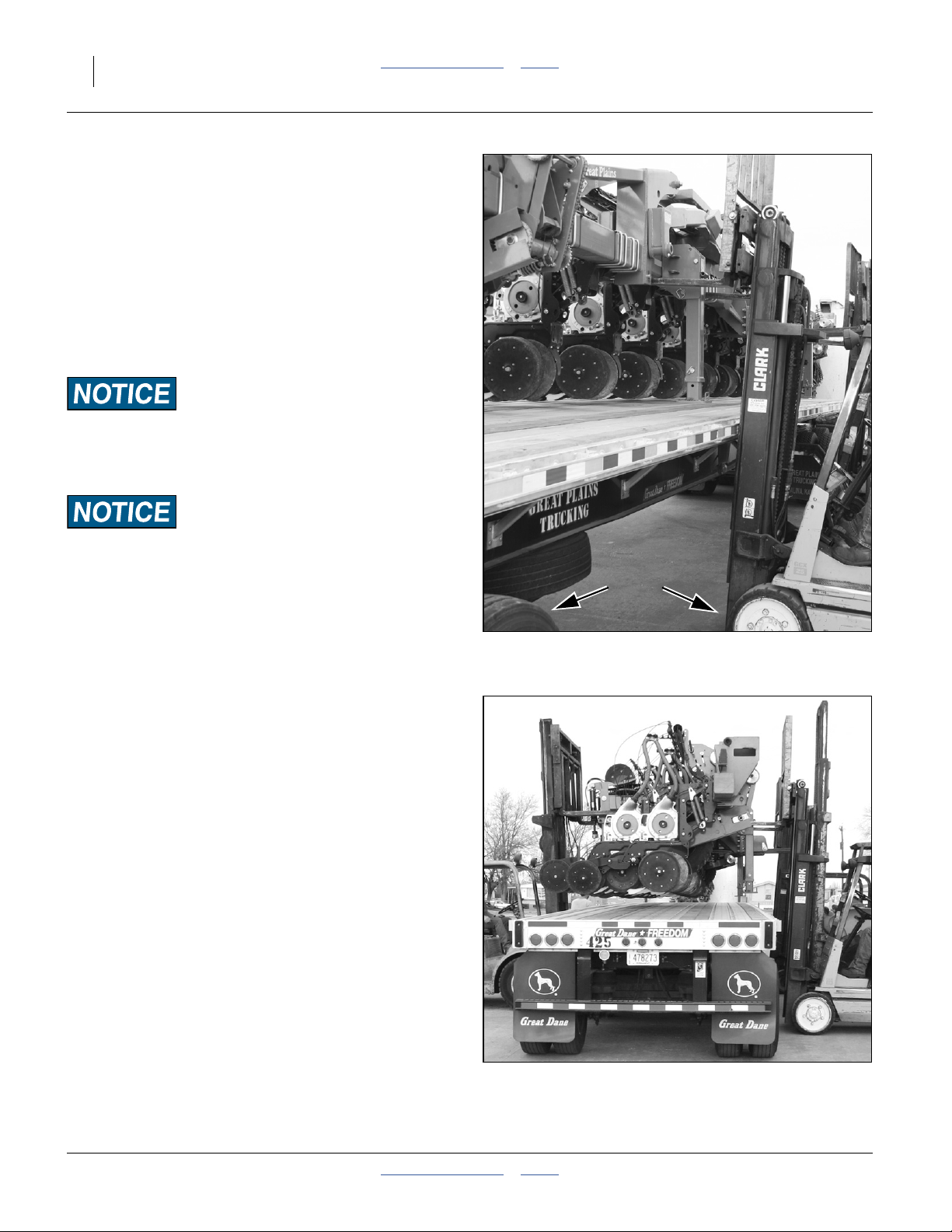

Refer to Figure 2

The 3PYPA planter is delivered from the factory on a

flatbed semi-trailer. It needs to be unloaded from the

truck at the spot where final assembly takes place.

It is expected that final delivery to the customer will be

done using the planter’s own transport wheels, after final

assembly.

Figure 2

Planter Arriving on Truck

25344

401-647Q Table of Contents Index 2012-08-08

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 7

Shipment Inventory

The planter is shipped as the following 5 subassemblies

or kits:

Refer to Figure 3

1. Main frame consisting of:

the complete tool bar with all the row units,

press wheels (two center units strapped on top),

air delivery system,

markers (if ordered),

parallel arms, and

gauge wheels (except on planters with 15 inch row

spacing).

Refer to Figure 4 (which depicts an optional seed hopper on

the seed structure)

2. Rear Seed support structure consisting of

the frame, with

hydraulic steering components,

air distribution box,

caster mounts,

walkboard, and;

82 bushel hopper (if ordered).

Note: The optional hopper is mounted on the frame at

90 degrees from its operating orientation.

Figure 3

Main Frame

29142

Figure 4

31695

Rear Support Structure

Refer to Figure 5

3. Right and left caster assemblies including the

wheel hub and spindle assemblies. See “Caster

Arms” on page 23.

4. Rear lift assist wheels and tires (not shown).

Figure 5

31688

Caster Arms

2012-08-08 Table of Contents Index 401-647Q

Page 12

8 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

5. A crate containing the hardware to final assemble

the planter, seed monitor console, tractor-side

steering equipment, and seed disks (if ordered).

Assembly and Setup Assistance

To order additional copies of pre-delivery instructions or

operator’s and parts manuals, write to the following

address. Include model numbers in all correspondence.

If you do not understand any part of this manual or have

other assembly or setup questions, assistance is

available. Contact:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

Figure 6

Miscellaneous Crate

29938

785-823-3276

401-647Q Table of Contents Index 2012-08-08

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index 9

Plan The Mainframe Unload

Unloading the main frame can be a safe, smooth

operation if it is properly planned in advance.

▲ Scope the lift equipment and team size required.

▲ Review the steps with all lift team members.

▲ For multiple lifters, gather lifters and practice simultaneous

lift. Learn control operations for equal lift rates.

▲ Designate an observer to be lift leader.

▲ Have an agreed signalling or command for simultaneous

halting of the lift if any team member detects a problem.

▲ Move the trailer, not the planter.

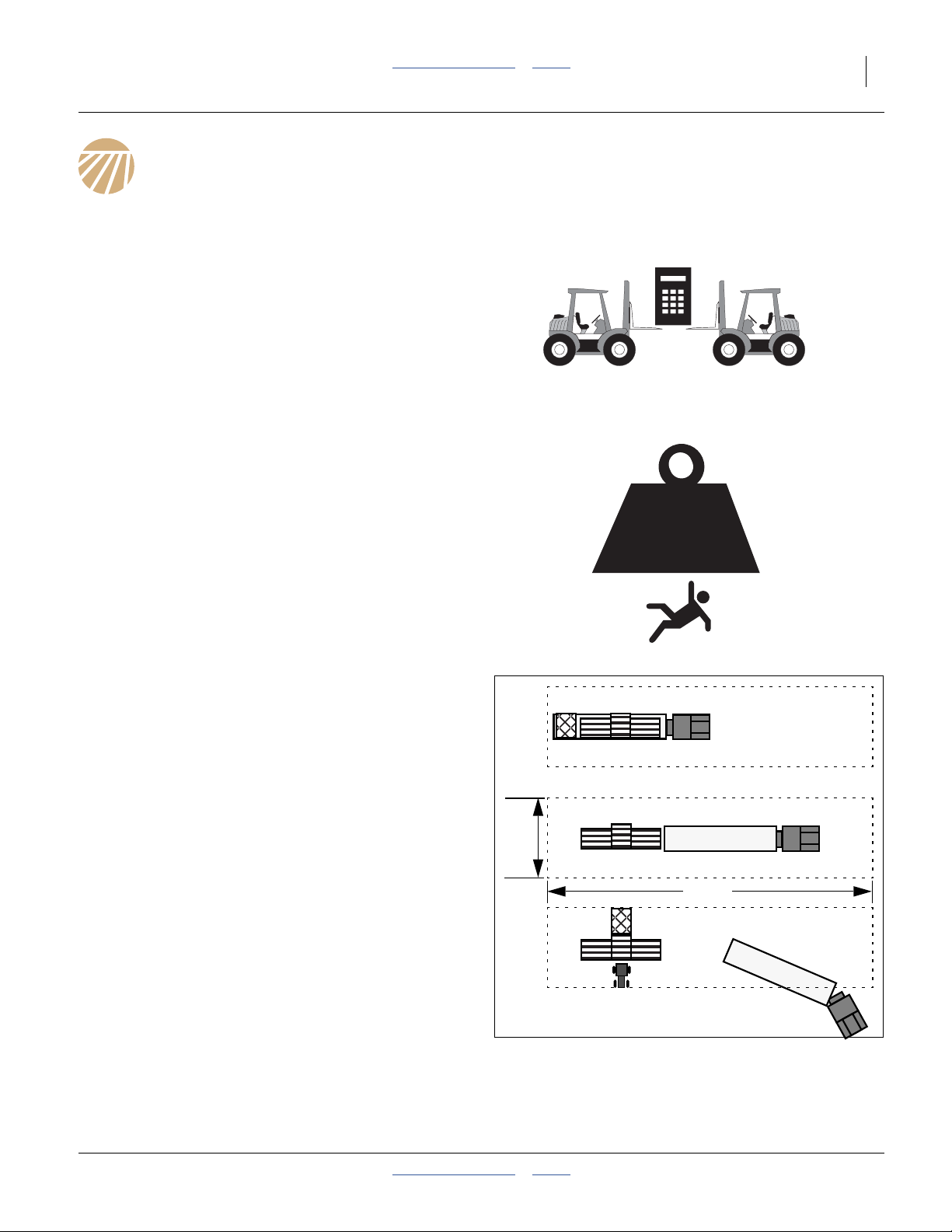

Use a Hoist or One to Four Lifters

Use lifter(s) with a combined capacity greater than the

weight of the planter main frame.

Do not use more than 4 lifters. There are no safe rear lift

points for more than one lifter.

When using N (2 to 4) lifters, do not assume that each is

getting1⁄Nth of the load. Plan excess capacity. Monitor

load indicators and overload indications or alarms.

> 14,000

POUNDS

Location Requirements

Until assembled, the planter mainframe is impractical to

move. It needs to be unloaded directly above the spot

where final assembly takes place.

This location needs to be:

• firm level ground or pavement the parking stand loads can approach 100 psi

• there must be adequate space to pull the trailer out

from under the lifted mainframe, without turns,

• there must be adequate open space behind the

mainframe to attach the seed substructure,

• there must be adequate space all around to easily

maneuver fork lifts on both sides, and later behind the

seed frame, and

• there must be adequate space in front of the planter to

attach a tractor and move forward for delivery.

Mark the parking location with traffic cones or pavement

markers.

Note: Unless it is certain that the assembled planter will

only be moved with the tractor on which the

steering sensor is installed, allow ample room in

front of the planter, so that non-sensor tractors

need only make forward moves.

40ft

150ft

Figure 7

Suggested Unload Clearances

2012-08-08 Table of Contents Index 401-647Q

Page 14

10 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

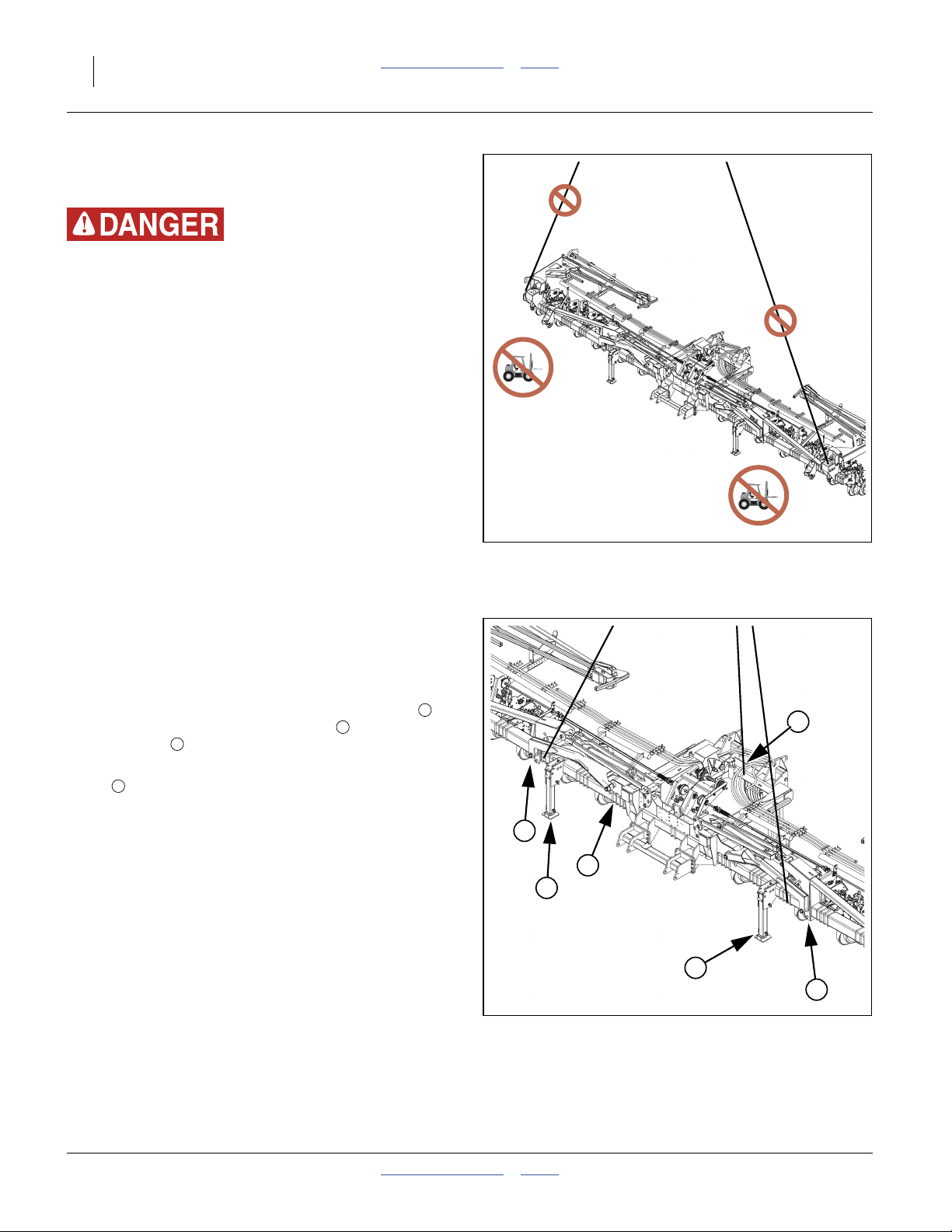

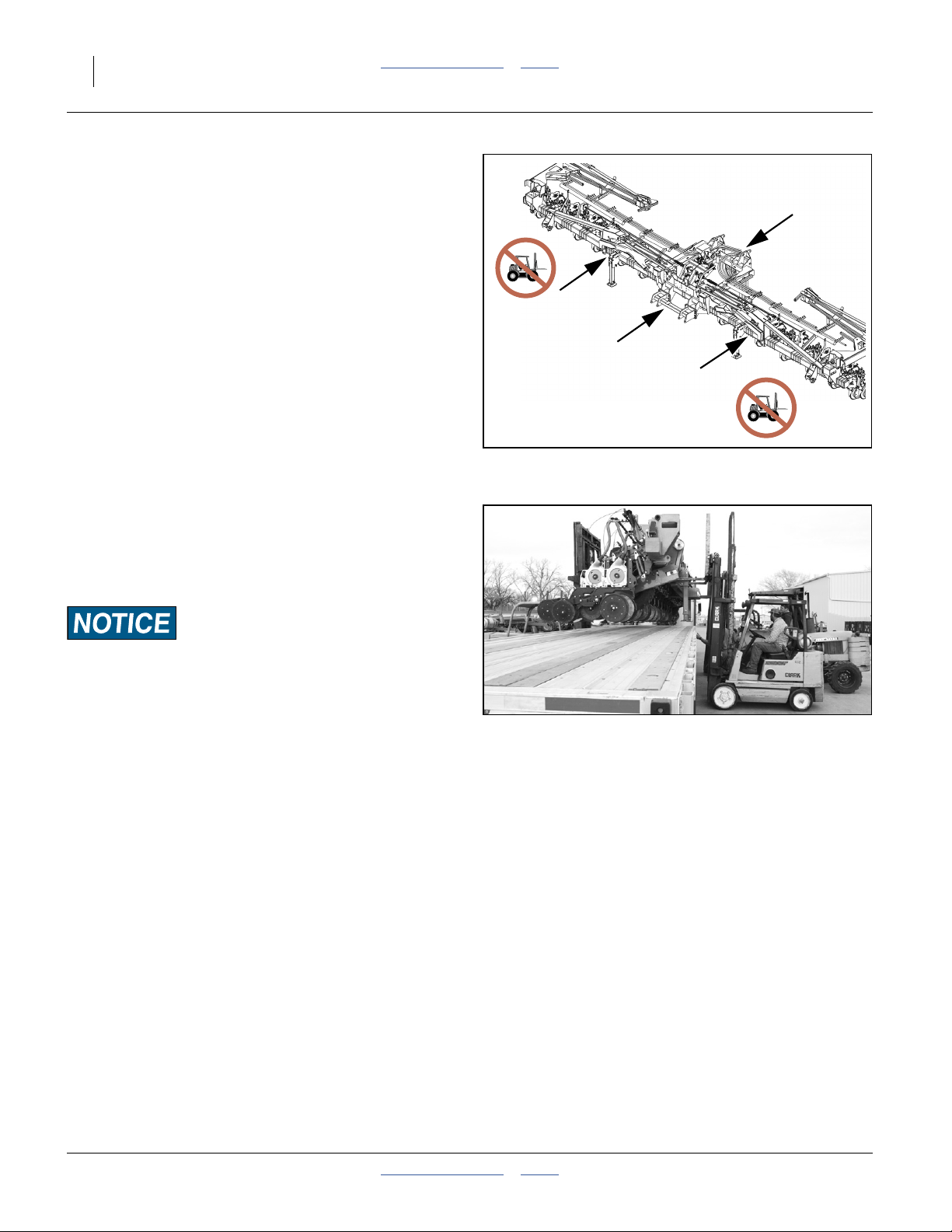

Wings: No Lift - No Hoist

Refer to Figure 8

Lift Failure Hazard:

Do no lifting on the wings beyond the lock-down pins. There is

significant risk of hinge failure and lift collapse, with possible

serious injury or death, and major damage to both planter and

lift equipment.

The folding/stacking wings of the 3PYPA planter must not

be used for lifting. Although they are shipped in the

pinned-down configuration, the hinge/arm system is

designed only to carry the weight of the wings, and not

the center section.

Lift only by the center section.

{

{

Hoist Lifting

Three Hoist Points

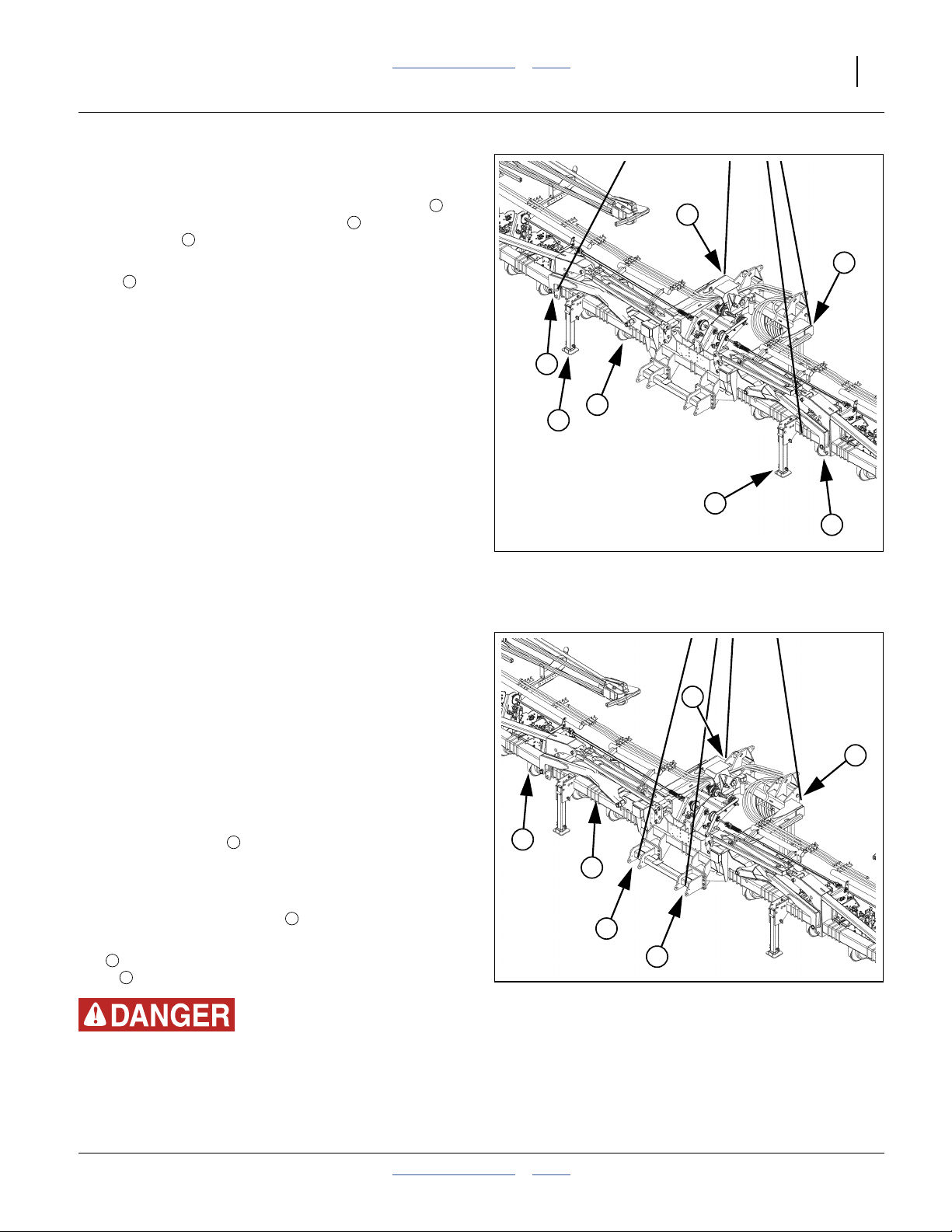

Refer to Figure 9

Attach two hoist lines to the center section tool bar ,

outboard of the forward parking stands , but inboard of

the wing joints .

Attach the third hoist line to the center of the rear box

frame and secure that line against side-slip.

4

3

2

1

Figure 8

No-Lift/No-Hoist Regions

25348

4

3

1

2

2

3

Figure 9

3-Hoist Points

401-647Q Table of Contents Index 2012-08-08

25348

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index Plan The Mainframe Unload 11

Four Hoist Points

Refer to Figure 10

Attach two hoist lines to the center section tool bar ,

outboard of the forward parking stands , but inboard of

the wing joints .

Attach two hoist lines to the rear corners of the rear box

frame .

8

7

6

5

8

8

7

5

6

6

7

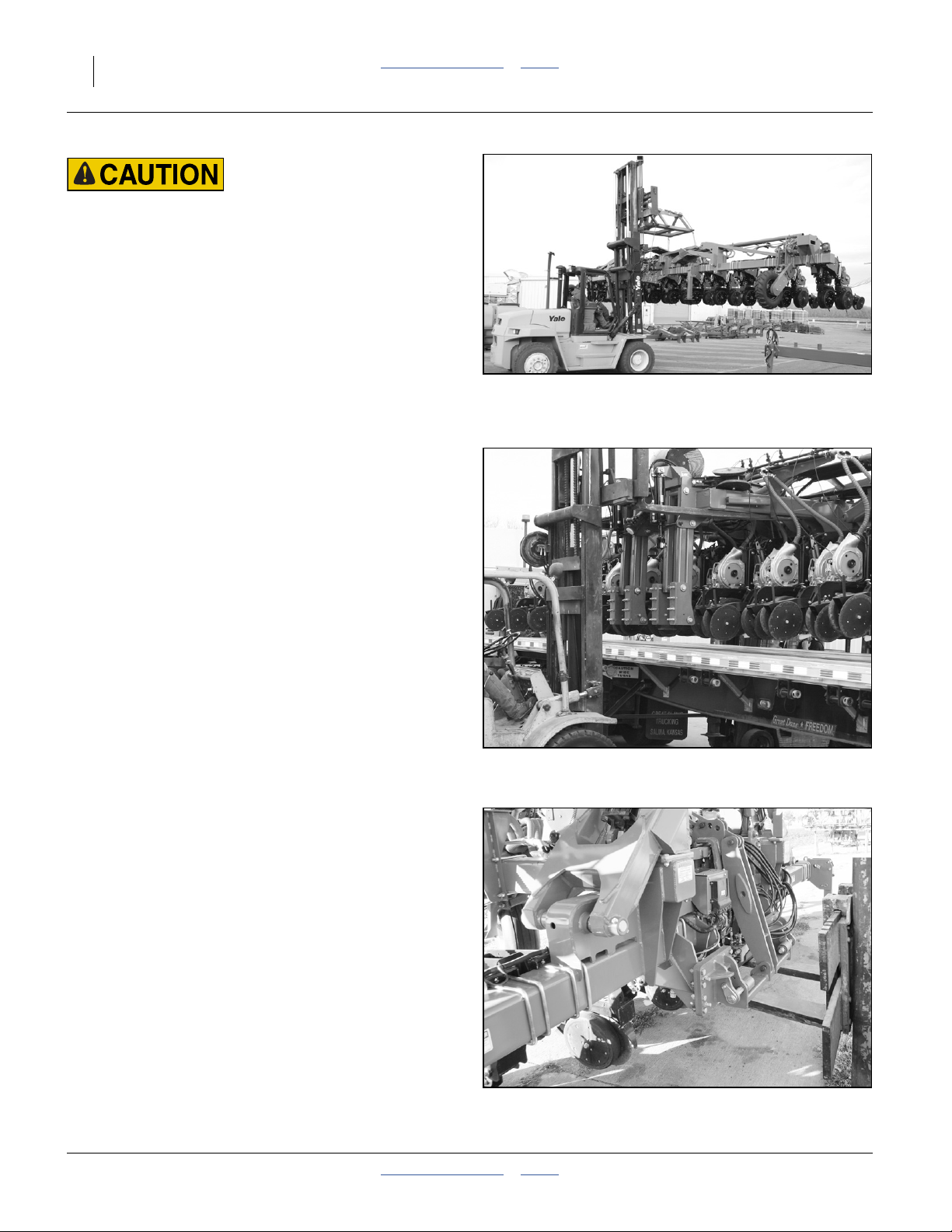

Fork Lifting

Single-Lift Points

Refer to Figure 11 and Figure 12

If a fork lift is available rated for 14,000 pounds or higher,

the planter may be lifted from the front using 4 chains or

straps.

Note: The center of gravity is generally within 12 inches

ahead or behind the row unit springs.

If using 4 hoist lines, attach two lines to the rear corners

of the rear box frame . If using 3 lines, attach one to

the center of the rear tool bar, and secure it so that it

cannot slide side-to-side.

If using 4 lines, you may attach the front lines to the lower

two points of the 3-point hitch .

If using 3 lines, attach the front lines to the front tool

3

bar outboard of the hitch, but inboard of the wing

7

joints .

1

2

Figure 10

4-Hoist Points

25348

1

1

4

3

2

2

Figure 11

Single Lift Hoist Points

25348

Unstable Load Hazard:

Do not attach to the hitch using 3 lines.

2012-08-08 Table of Contents Index 401-647Q

Page 16

12 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Tipping Hazard:

Do not attempt single-lift from planter rear. The center of

gravity is too far forward for safety.

Two Lift Points

Refer to Figure 13 and Figure 14

Using two lifters, position the lifter with the lowest

capacity at center frame rear, and lift via center frame

side tubes, as for single-lift.

Position the lifter with the highest capacity at the hitch,

and lift via the cross-tube of the hitch.

Note: The observer/lift leader needs to pay close

attention to planter front-to-back level, and signal

each lift operator how to compensate if imbalance

is detected.

Figure 12

Single Fork Lift

Figure 13

Rear Lift point

25349

25350

Figure 14

25351

Two/Four Front Lift Point

401-647Q Table of Contents Index 2012-08-08

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index Plan The Mainframe Unload 13

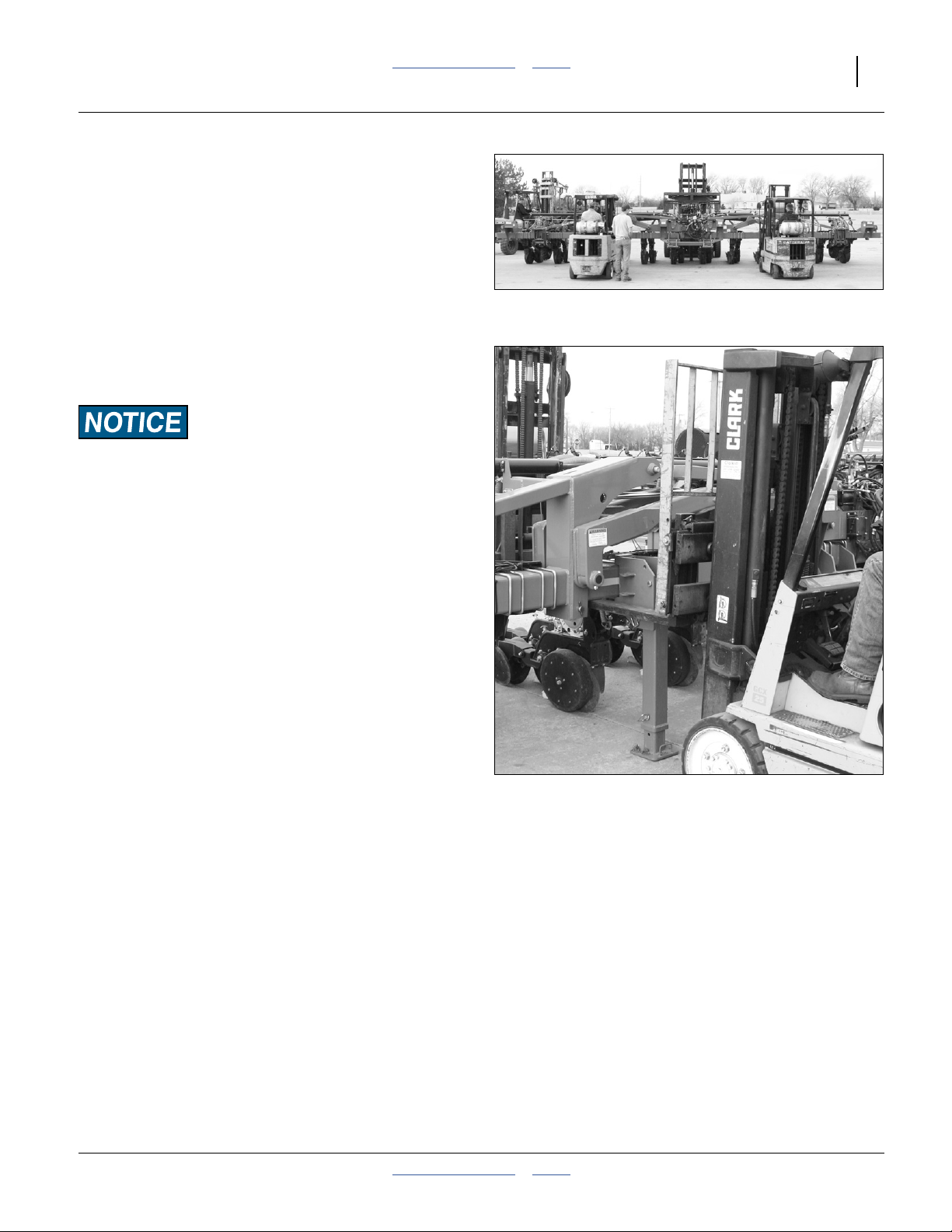

Three Lift Points

Refer to Figure 13, Figure 15 and Figure 16

Using three lifters, position one (with the highest

capacity) at center frame rear, and lift via center frame

side tubes, as for single-lift (ref).

Position the other two lifters near, but not beyond, the

center-to-wing connection. Make sure both forks are

inboard, and lifting only the center section.

Unbalanced Load Risk:

Two observers are needed, one for front-back level, and the

other for side-to-side.

The observers need to pay close attention to planter level, and

signal each lift operator how to compensate if imbalance is

detected.

Figure 15

Three-lift points

25352

Figure 16

25353

Front Side Lift Point

2012-08-08 Table of Contents Index 401-647Q

Page 18

14 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Four Lift Points

Refer to Figure 13, Figure 15, Figure 16 and Figure 18

Using four lifters, position one (with the highest capacity)

at center frame rear, and lift via center frame side tubes,

as for single-lift.

{

{

Position one lifter at the hitch, and lift via the cross-tube

of the hitch, as for 2-lift.

Position the other two lifters near, but not beyond, the

center-to-wing connection, as for 3-lift. Make sure both

forks are inboard, and lifting only the center section.

Unbalanced Load Risk:

Two observers are needed, one for front-back level, and the

other for side-to-side.

The observers need to pay close attention to planter level, and

signal each lift operator how to compensate if imbalance is

detected.

Figure 17

4-Lift Regions

Figure 18

Four-lift in Progress

25348

25354

401-647Q Table of Contents Index 2012-08-08

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index 15

Unloading

Have the driver spot the truck as marked during

See “Plan The Mainframe Unload” on page 9.

Unload Smaller Items First

Unloading the mainframe is a potentially dangerous

operation.

Reduce risk and complication by first unloading

1. the caster components,

2. the miscellaneous crate and

3. the seed frame

(described below)

Place these components well out of the maneuvering

area needed for unloading the mainframe.

Figure 19

Trailer w/Main & Seed Frames

25355

Unload the Seed Frame

Although relatively light compared to the main frame, the

seed frame is tall and an awkward shape for fork-lifting.

It is easiest to approach it from what will later be the

front. If you fork-lift from its back (not recommended),

first swing open and secure the walkboard.

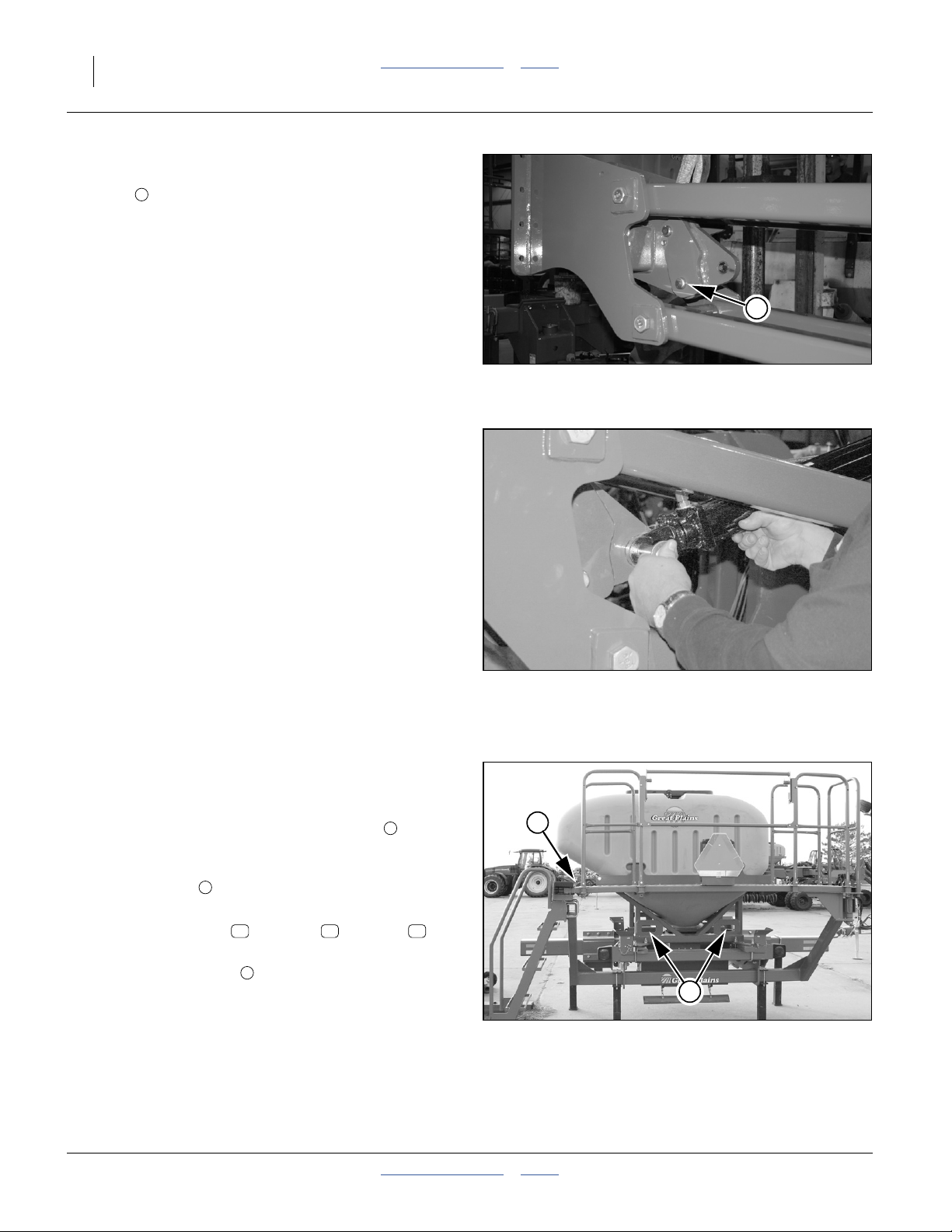

Refer to Figure 20 (which depicts an earlier revision frame)

If the planter was delivered with a hopper, lift via the side

fork lift holes on the diagonal braces.

If the planter did not include a hopper, use chains, and

be sure to check load balance.

4. Remove the seed structure from the trailer.

Figure 20

Approaching Seed frame

25356

2012-08-08 Table of Contents Index 401-647Q

Page 20

16 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Unload The Mainframe

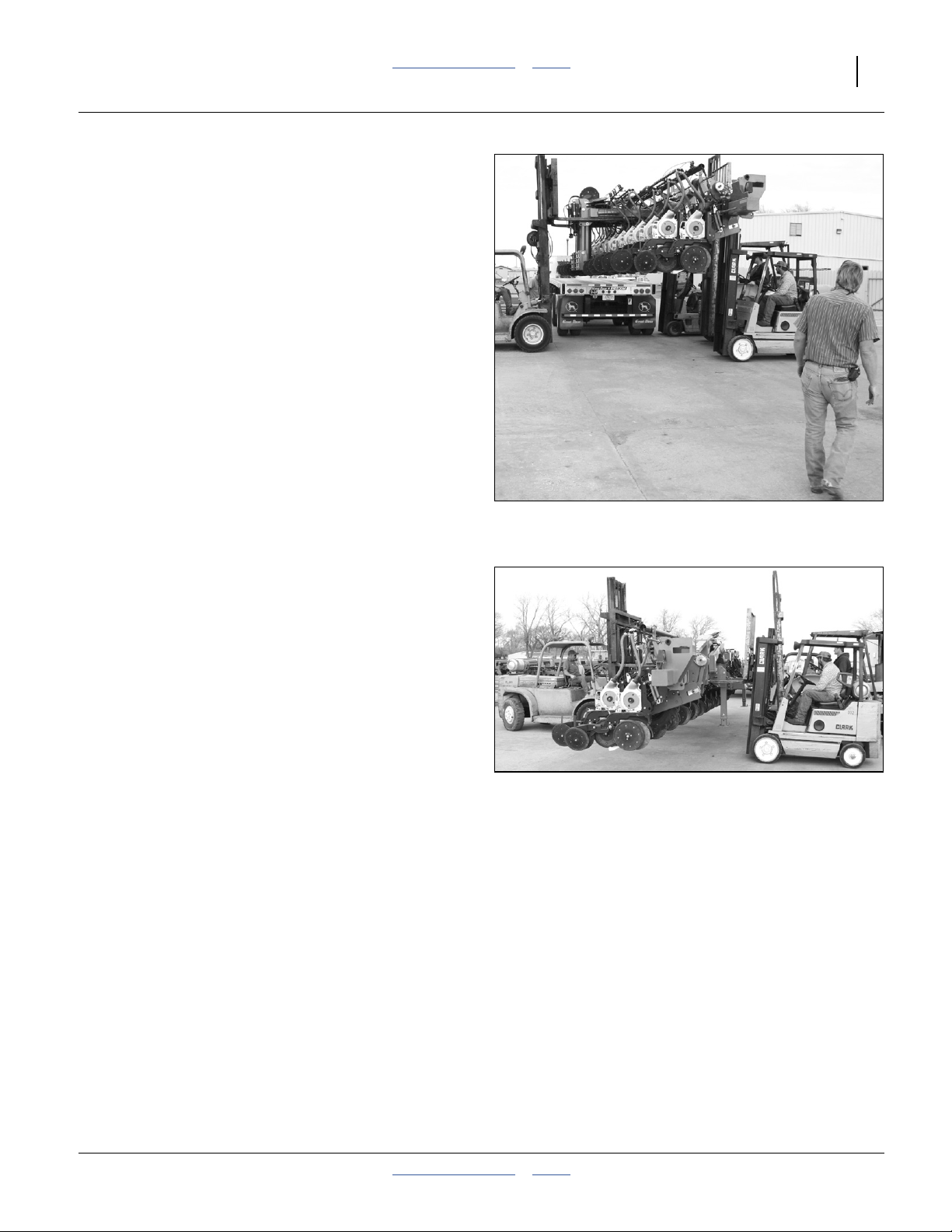

Refer to Figure 21 and Figure 22

(which depict a three fork lift)

5. Double-check that all chains and tie-down straps

have been released and stowed.

6. Make sure that all team members are fully briefed

and ready.

7. Set parking brake on trailer tractor.

8. Attach crane hoist lines at planned points or move

fork lifts into planned positions.

Lifter-Trailer Contact Risk:

Do not move lifters or crane so far in that trailer wheels will

not be able to clear them when pulling trailer out from under

planter.

Load “Wedging” Risk:

If using multiple lifters, do not drive the lifts fully forward into

the planter, unless the lifts are known to have precisely vertical

motion. If the load moves forward while lowering, the planter

will tend to push the lifters backward.

Refer to Figure 22 (which depicts a three fork lift)

9. Slowly lift the planter off the trailer bed.

10. Stop lifting about 12in above the bed.

Figure 21

Position Lifters

25357

Figure 22

25358

planter Lifted

401-647Q Table of Contents Index 2012-08-08

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Unloading 17

Refer to Figure 23 (which depicts a three fork lift)

11. Have the truck driver slowly pull the trailer straight

out from under the planter.

Refer to Figure 24 (which depicts a three fork lift)

12. Making sure to keep level from front to back and

side to side, slowly lower the planter.

13. If the planter has the gauge wheels swung back

under for shipment, stop lowering about 18 inches

above the ground.

If the planter does not have the gauge wheels

mounted, skip to step 20.

Figure 23

Truck Pulling Away

Figure 24

Planter Lowering

25359

25360

2012-08-08 Table of Contents Index 401-647Q

Page 22

18 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Refer to Figure 25

14. Swing the gauge wheels most of the way out in front

of the planter.

Refer to Figure 26

15. Remove and save one set (not all shown):

43

803-006C NUT HEX 1/4-20 PLT

52

804-006C WASHER LOCK SPRING 1/4 PLT

87

802-167C HHCS 1/4-20X1 1/2 GR5

and remove the pin:

24

402-209H PIN 1 X 4 5/8 NONROTATE

16. Orient the cross-tube of the adjustment rod

weldment so that the grease zerk is facing

1

forward.

17. Continue swinging wheel forward until cross-tube

aligns with pin hole.

18. Re-insert pin. Secure with saved bolt ,

washer and nut .

52 43

87

19. Repeat this for the other gauge wheel assembly.

Figure 25

Swing Gauge Wheels Forward

1

24

25361

87

Figure 26

29186

Secure Gauge Wheel with Pin

401-647Q Table of Contents Index 2012-08-08

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index Unloading 19

Refer to Figure 27

20. Making sure to keep level from front to back and

side to side, slowly complete lowering the planter to

the ground.

21. Uncouple hoist lines, or lower forks and withdraw

lifters.

Figure 27

Planter Lowered to Ground

25360

2012-08-08 Table of Contents Index 401-647Q

Page 24

20 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

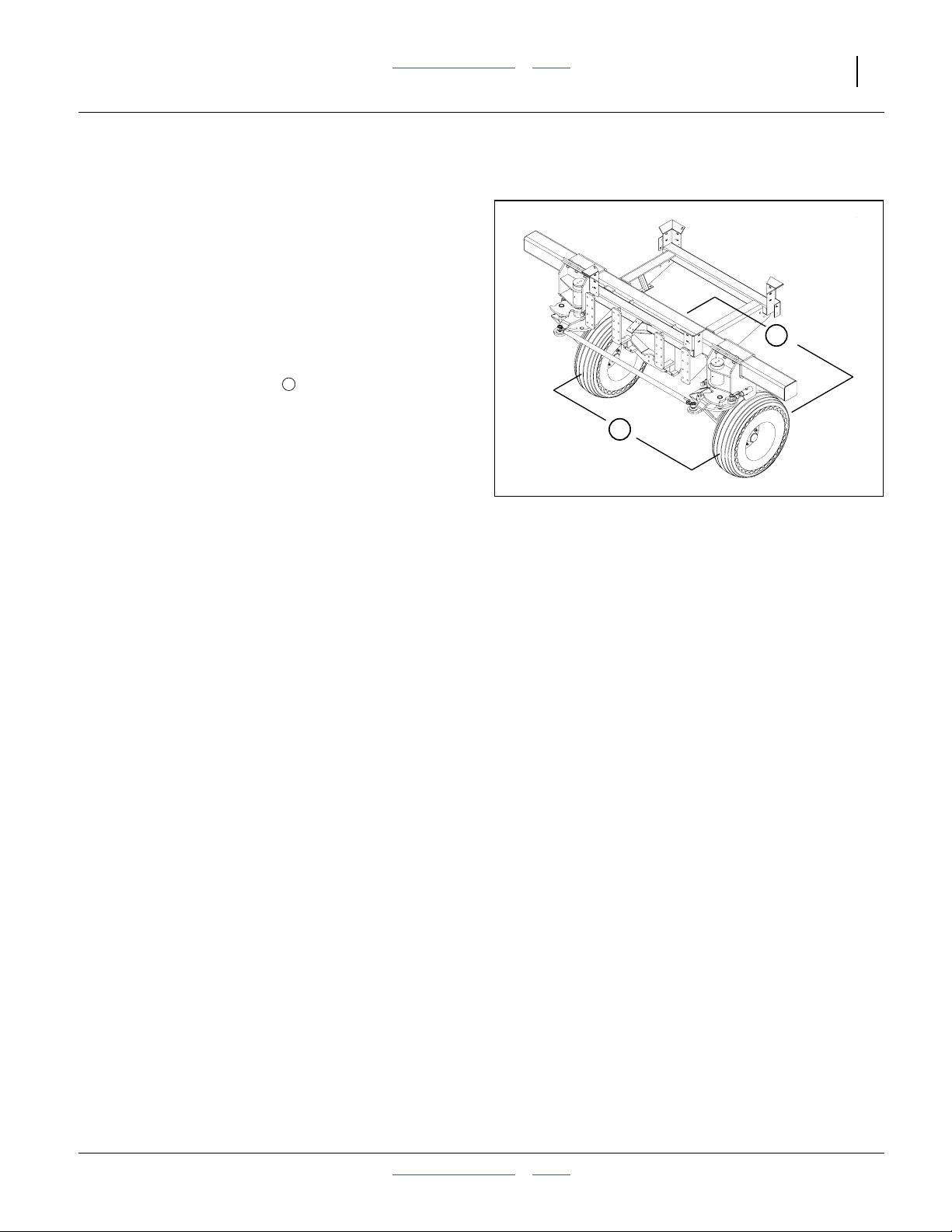

Planter Assembly

Press Wheel Shipping

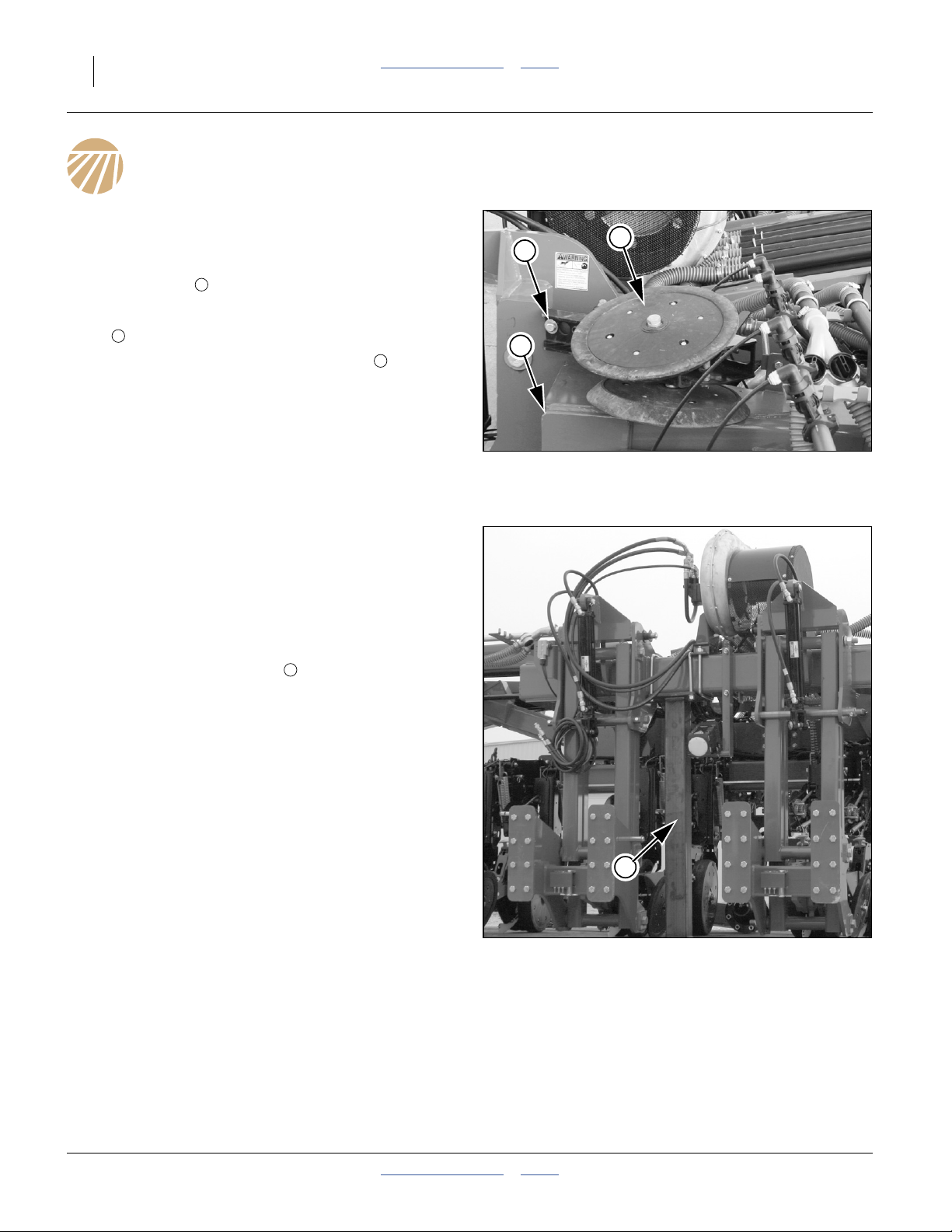

Refer to Figure 28

Depending on machine configuration, two or more press

wheel assemblies may have been shipped

dismounted. If only two were dismounted, they will have

been shipped bolted to the rear corners of the main

frame . If none or all were dismounted, skip to step 24.

22. Remove the bolt, nut, and any washers that

23. Set the press wheel assemblies aside. They are

2

secure the press wheel assemblies to the main

frame. These fasteners are not reused.

installed at step 102. Leaving them off now eases

access to this part of the planter.

1

3

3

2

1

Figure 28

Press Wheel Shipping

25365

Shipping Stands

As delivered from the factory, the planter includes:

• 2 parking stands intended to remain on the planter

(front tool bar just inboard of wing joints)

Refer to Figure 29 (which depicts an earlier 3PYP parallel

arm configuration - the shipping stand has not changed)

• 1 main frame shipping stand that is removed after

assembly, but needs to remain with the customer, as it

eases changing caster tires

• 4 seed frame shipping stands that are not needed

after final assembly.

• Do not remove any of these stands until instructed.

During assembly, let the planter main frame rest on the

two parking stands on front of the tool bar and the

shipping stand under the rear tube of the frame. Do not

let any of the supports sink into the ground.

1

1

Figure 29

Main Frame Shipping Stand

29209

401-647Q Table of Contents Index 2012-08-08

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index Planter Assembly 21

Prepare Parallel Arms

The seed frame is attached to the main frame’s parallel

arms, after releasing the arms from their shipping

configuration.

Refer to Figure 30

24. Remove and save the 32 sets of:

47

803-021C NUT HEX 5/8-11 PLT

58

804-022C WASHER LOCK SPRING 5/8 PLT

36

802-057C HHCS 5/8-11X2 1/4 GR5

25. Remove and save the extra pin and cotter pin

stored near the spare shear bolts.

Refer to Figure 32

The parallel arms are shipped mounted to the rear of the

main frame and each is held in the vertical down position

by a 11⁄4inch diameter pin .

26. Remove both arm locking pins . These pins are

not re-used.

27. Remove and save the cotter pins, washers and

cross-pins in the free ends of the lift-assist

cylinder clevises.

5

4

4

3

36

3

47

58

Figure 30

Parallel Arm Flange Bolts

4

29147

Refer to Figure 32 (which depicts elevating with a strap and

forklift, and depicts the clevis attached [step 31])

28. Using a hoist, elevate each parallel arm until

roughly horizontal. Parallel arms can be supported

by re-inserting pins from step 27.

4

5

Figure 31

Parallel Arm Shipping Pin

4

Figure 32

Elevate and Support Parallel Arm

29145

29146

2012-08-08 Table of Contents Index 401-647Q

Page 26

22 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Refer to Figure 33

29. Insert the pin saved at step 25 into the lower lug

6

hole .

6

Refer to Figure 34

30. Use the hoist to adjust the height of the parallel

arms until the lift-assist cylinder rod clevis can be

aligned with forward hole of the lug.

31. Secure with pin & hardware removed and saved at

step 27.

32. Carefully lower the hoist. The lift-assist cylinders

may or may not fully extend, depending on how

much air is in the hoses and cylinders.

Mount Seed Box Frame

Refer to Figure 35

Note: If no hopper is included, leave walkboard closed,

and lift structure using 3 adequately sized chains

so it lifts evenly side-to-side and front-to-back.

33. Open the walkboard by removing the pin ,

swinging it open to the right. Secure with keeper.

34. Lift the seed support structure from the rear using

the fork holes in the hopper support.

5

Refer to Figure 36

Have the Grade 5 bolts , washers and nuts

47 58 36

saved in step 24 at hand.

35. Position the flanges on the front of the structure

6

to mate up with the corresponding flanges on the

rear of one of the two parallel arms. Secure with 16

bolts, washers and nuts.

36. Use the lift or hoist to align the flanges on the other

side. Secure with 16 bolts, washers and nuts.

4

Figure 33

29148

Lower Lug Pin

Figure 34

29149

Pin Lift-Assist Cylinder

4

5

Figure 35

Seed Box Frame w/Hopper

25368

401-647Q Table of Contents Index 2012-08-08

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index Planter Assembly 23

Seed Cart Self-Lift

If only one hoist or fork lift is available (the one presently

supporting the seed cart structure), it will be needed for

hoisting casters. The lift-assist cylinders are capable of

supporting the entire weight of the seed structure if the

mainframe is hitched to a 3-point tractor, and the lift

hoses (blue) are connected to a tractor remote.

If you need to free the hoist/lift:

37. Lower the seed structure onto its shipping stands.

38. Hitch a 3-point tractor and connect the lift-assist

circuit.

39. Raise the seed structure until the parallel arms are

slightly above level at the rear.

40. Put blocks or jack stands under the rear shipping

strands of the seed structure.

47 58 36

Align Seed Box with Arms

6

Figure 36

7

7

29151

Remove Cart Shipping Stands

41. Remove the four shipping stands from the seed

structure. These are not re-used.

7

Install Casters

Determine how to lift move and align the caster arms

with the available lifting equipment.

Note: Recommend securing caster arm by clamping to

fork of lift.

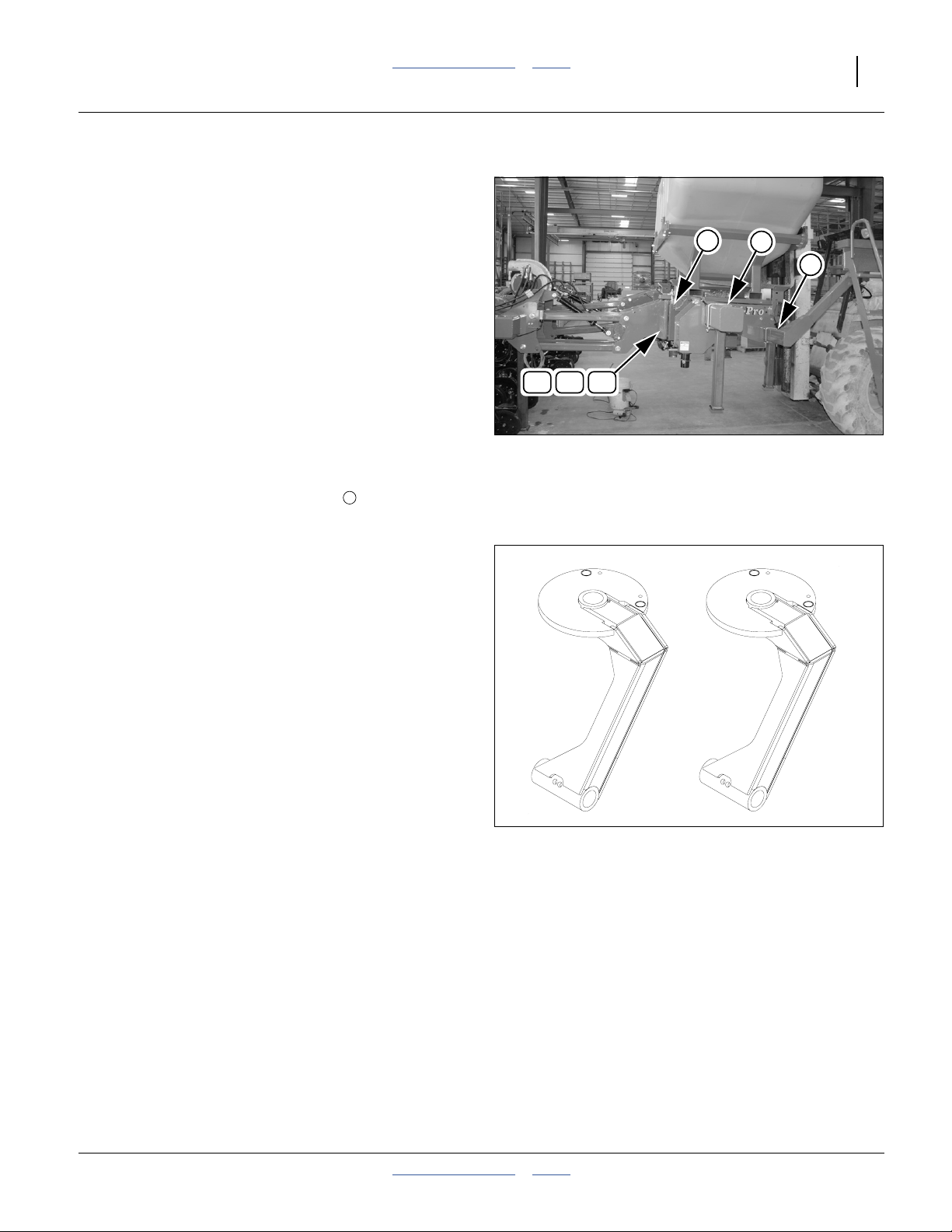

Caster Arms

Refer to Figure 37

42. The left and right caster arms are identical.

Figure 37

LH/RH Caster Arms are Identical

31678

2012-08-08 Table of Contents Index 401-647Q

Page 28

24 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Install Left and Right Caster Arms

Refer to Figure 38 and Figure 39

43. Carefully secure one caster arm to a lift or hoist

capable of holding the arm with the pivot hole

vertical, and remaining clear of the seed structure

while positioning the arm.

44. At the cart, remove and save one set of:

48

803-026C NUT LOCK 3/4-10 PLT (not shown)

40

802-360C HHCS 3/4-10X6 1/2 GR5

61

804-102C PIVOT THRUST WASHER

Coat the spindle with anti-seize compound.

45. Align the arm under the spindle. Place the thrust

washer on the spindle before the spindle

contacts the arm.

46. Fully raise the arm on the spindle. If the spindle

rises, tap it down with a rubber mallet.

47. Align the holes in the arm and the spindle, and

secure the arm to the spindle with the cross-bolt

and nut .

48. Repeat steps to install other caster arm.

61

48

40

Figure 38

Move Caster Arm to Spindle

31693

Install Caster Wheels

Refer to Figure 40 (tie rods not installed)

49. Remove and save the lug nuts (not shown)

51

803-219C NUT LUG 5/8-18 X 90 DEG PLT

from the right caster hub.

50. Roll one of the wheel assemblies (they are identical)

up to the caster arm. Orient the side with the valve

stem away from the hub (toward seed structure

center).

51. Adjust the elevation of the seed structure so that the

wheel just fits over the threaded studs on the hub.

This eases the assembly.

52. Seat the wheel on the hub and secure with saved

lug nuts .

53. Rotate caster until the 11⁄4inch diameter alignment

pin holes in the caster top plate and the steering

arm align. Install the alignment from the bottom and

lock in place with1⁄2inch bolt and nut supplied.

51

40

Figure 39

Cross Bolt and Thrust Washer

Figure 40

Install Caster Wheels

61

31694

31691

401-647Q Table of Contents Index 2012-08-08

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Planter Assembly 25

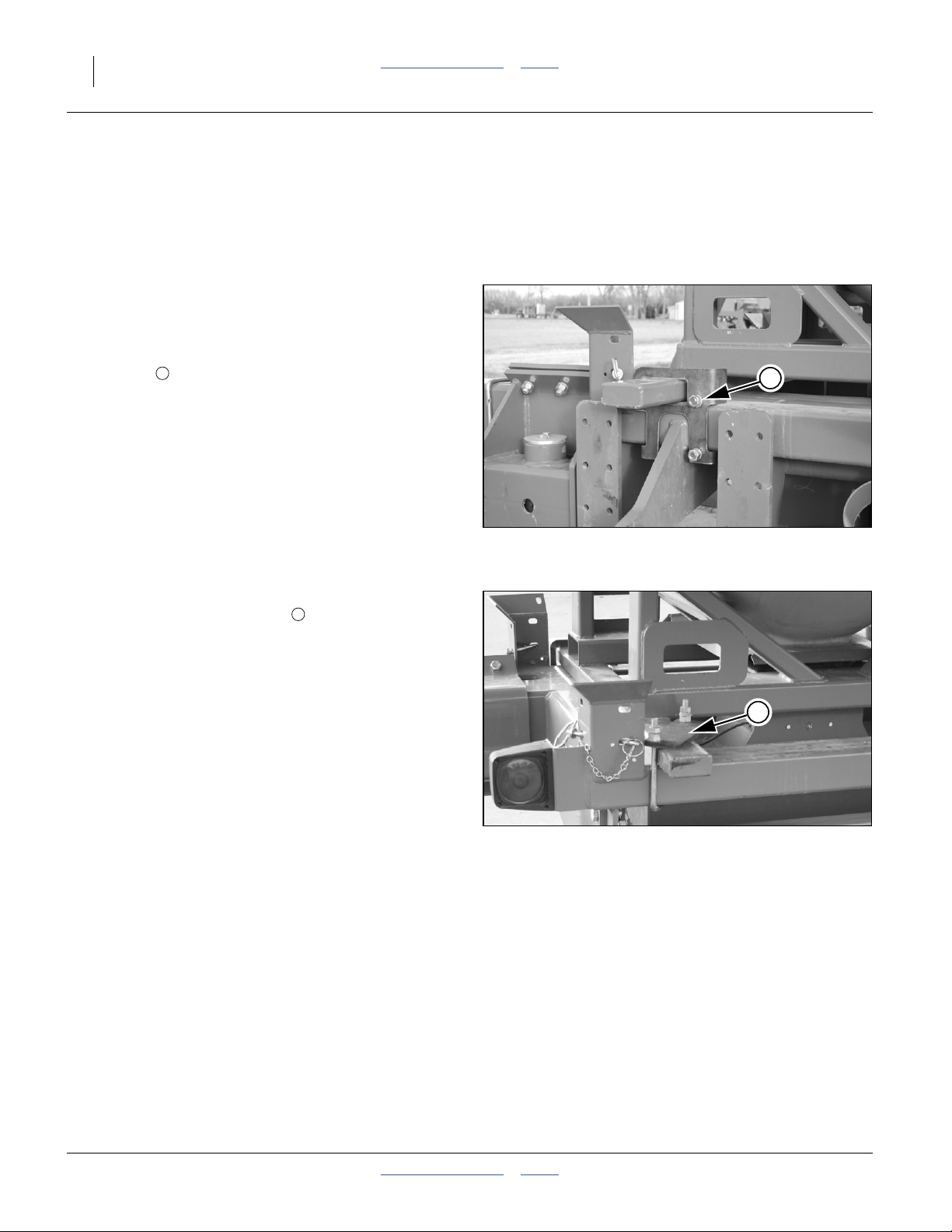

Adjust Steering Tie Rod

Refer to Figure 41

54. Adjust tie rod to these objectives:

• The rod is installed at the factory but tire

alignment needs to be checked and adjusted

once final field assembly is complete.

• Pivot both casters until the tires are close to full

trailing (straight running) orientation. All

measurements must be made with the tires in a

position to have the planter traveling straight

forward.

• Measure the distance from the center of one

D

tire to the center of the other tire both in front of

the tires as well as behind the tires.

• The measurements are to be equal. If the

measurement across the front of the tires is less

than the measurement across the back of the

tires then the tie rod needs to be lengthened. If

the measurement across the front is more than

the measurement across the back then the tie rod

needs to be shortened.

• Make the appropriate adjustment then re-center

the tires and take another set of dimensions.

• Repeat as necessary until the dimensions are

equal.

• Do NOT have any toe in or toe out.

• Tighten the lock nuts on the ends of the tie rod.

(Right side has right-hand thread and left side

has left-hand thread.)

D

Figure 41

Tie Rod Adjustment

D

31679

2012-08-08 Table of Contents Index 401-647Q

Page 30

26 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Lower Seed Box Structure

55. Check tire pressure. See “Tire Inflation Chart” on

page 65.

56. Depending on how the structure is being supported,

use the lift-assist cylinders, hoist or lift to lower the

seed box structure onto the tires.

Remove Hopper (Option)

If no seed hopper was included, skip to step 60.

Refer to Figure 42

57. Remove the bolts holding the hopper shipping

bracket . The bracket and bolts are not reused.

1

1

Refer to Figure 43

58. Remove the U-bolt and bar restraining the

hopper on the opposite side. The bar and fasteners

are not reused.

59. Use a fork lift to remove the hopper and set it out of

the way temporarily.

Note: For shipping, the hopper was installed sideways on

the seed support structure. It must be removed and

correctly remounted before use. Remount is done

at step 110.

2

Figure 42

Hopper Shipping Bracket

Figure 43

Hopper Shipping U-Bolt

25369

2

25370

401-647Q Table of Contents Index 2012-08-08

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Planter Assembly 27

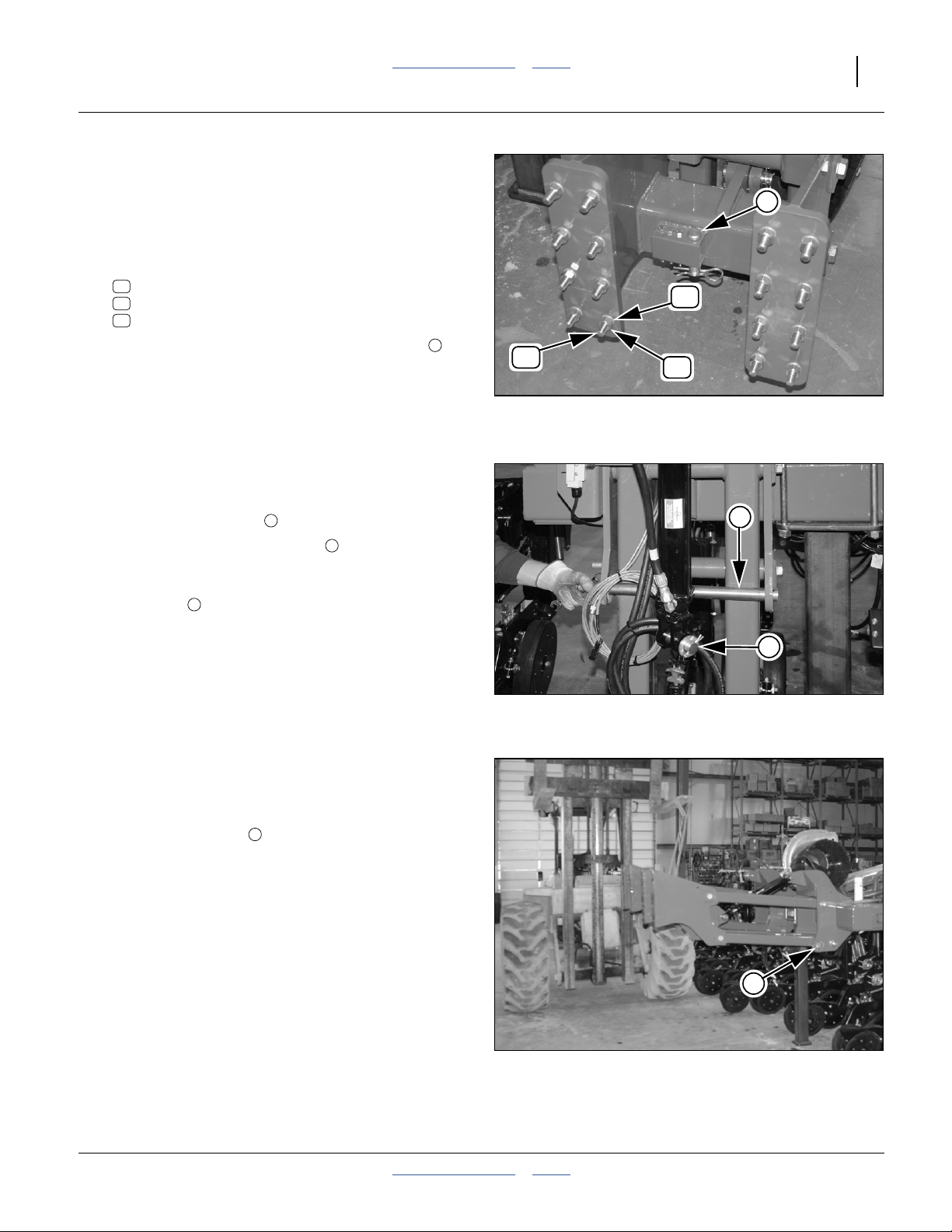

Connect Steering Hoses

Note: Hose and harness installation consumes cable ties

provided in the parts crate. Use the shortest tie

length at each point.

ST2

ST2

ST1

ST1

60. Locate the two steering hoses coiled up at the rear

left end of the center frame. Cut the tie holding the

coil.

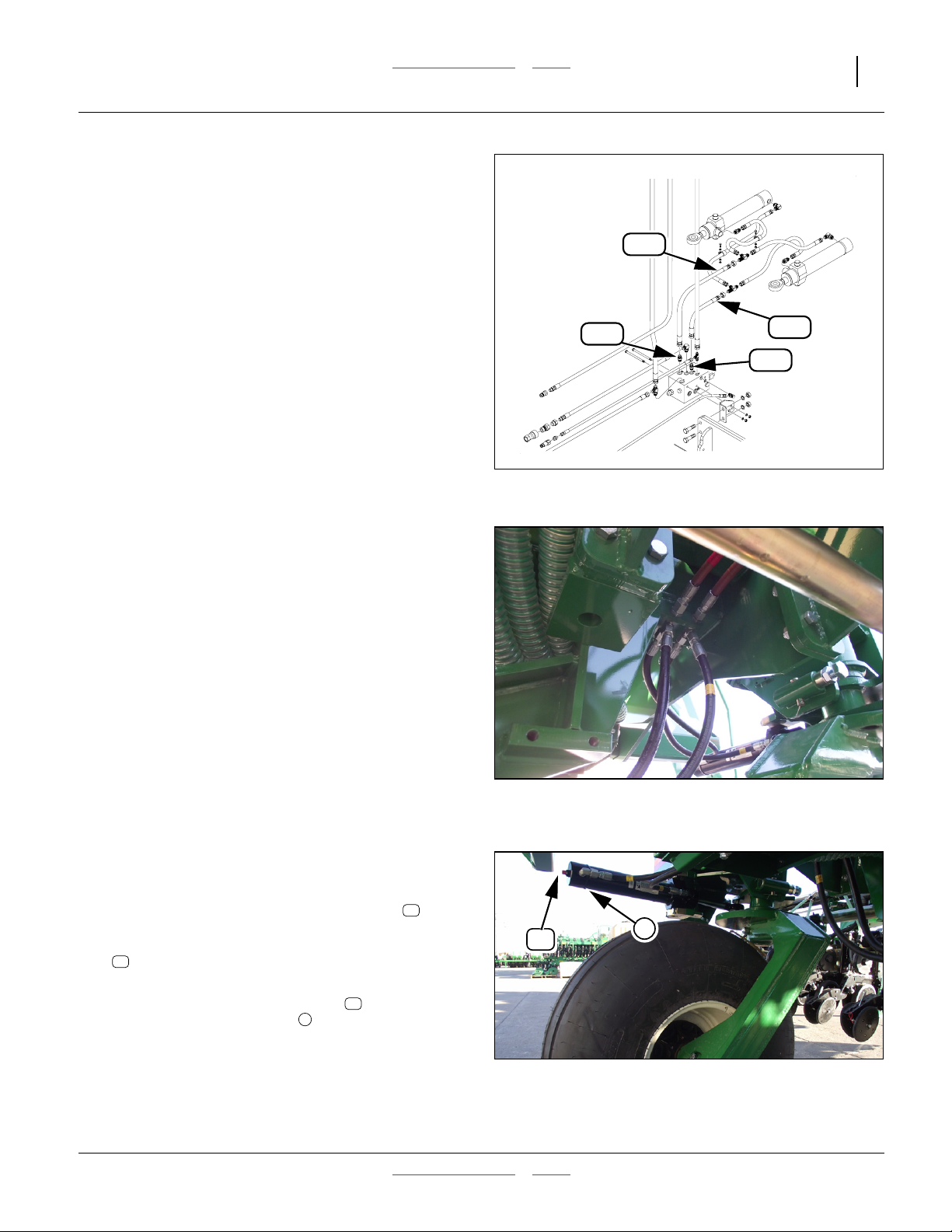

Refer to Figure 44 and Figure 45

61. Route the hoses:

under the upper cross tube at the mainframe

parallel arm pivot weldment,

over the upper forward arm pivot tube,

along the inside of the lower left parallel arm,

over the lower rear arm pivot tube,

beneath the steering tie rods,

down to the rod end of the left steering cylinder.

62. To help in the connecting of the steering hoses, the

two hoses have different size connector fittings.

Connect each hose to its mating fitting attached to

the seed carrier structure just to the inside of the left

parallel arm bracket (see photo).

63. Check that all steering hose and fitting connections

are tight.

64. Secure the hoses with ties.

Route Steering Sensor Lead

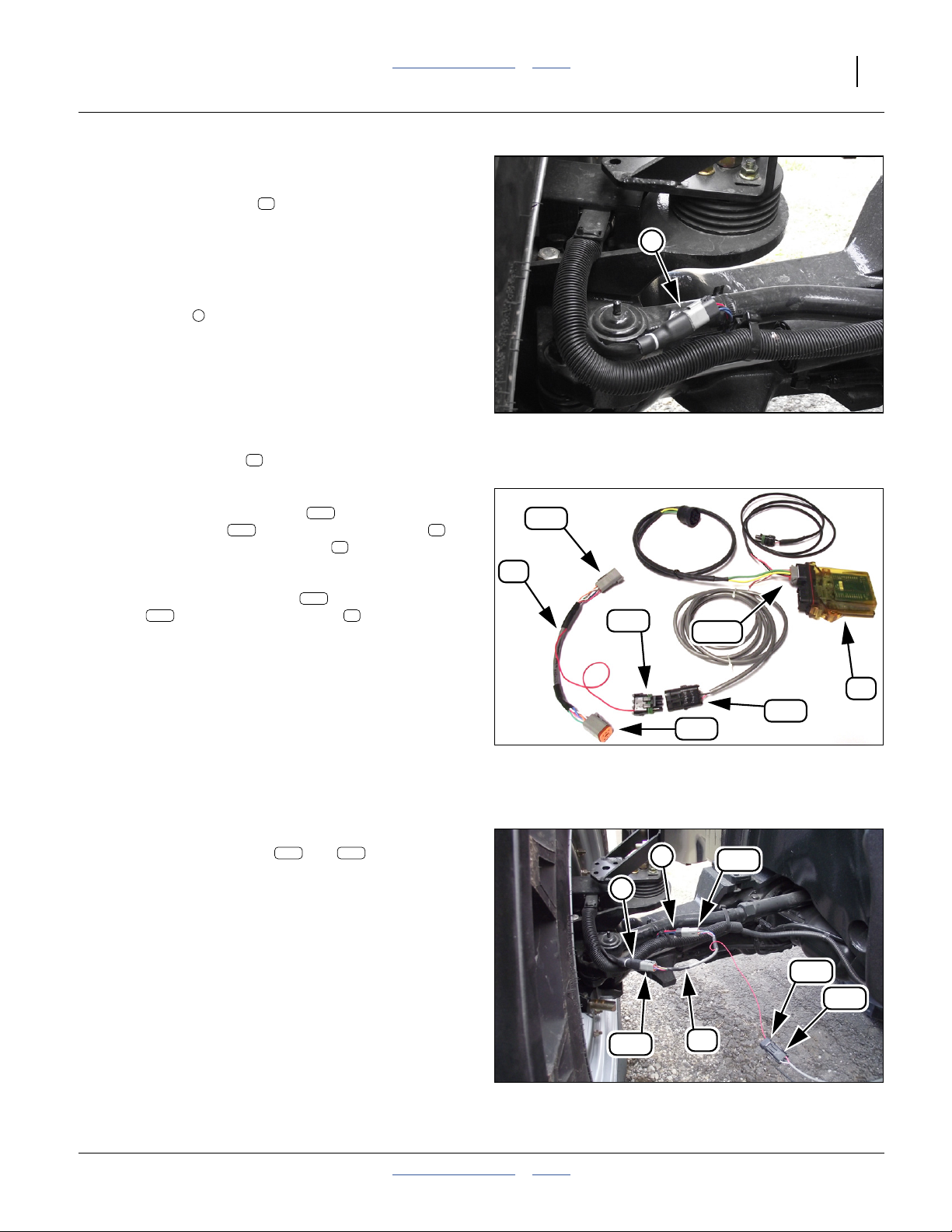

Refer to Figure 46

65. Identify the seed cart steering sensor lead . It is a

4-pin circular connector that is part of the harness

Find:

315-032 HARNESS IMPLEMENT F/FWD STEER

14

Route this lead along the ST1 and ST2 hoses.

66. Connect the steering sensor lead to the left end

of the left steering cylinder

14

1

14

14

Figure 44

Identify Steering Hoses

Figure 45

Steering Hose Routing

1

31680

31696

Figure 46

Steering Sensor Routing

2012-08-08 Table of Contents Index 401-647Q

31697

Page 32

28 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Route Lighting/Seed Box Leads

Refer to Figure 47

67. Uncoil the lighting and seed box sensor harnesses.

Route them along the steering hoses, and under the

main cart cross tube.

Note: There are two cable clamps attached to the

inside of the cart side frames, near the main cross

tube, shown as gray “J” shapes in Figure 47.

68. Using a cable tie, loosely secure the harness bundle

to the left cable clamp.

69. Identify the Right light harness . Route it along the

back side of the main cross tube, to the right side

cable clamp . Using a cable tie, loosely secure the

C

harness at that side.

Refer to Figure 48

70. At each tail light assembly, route the lead through

the nearby hole in the cart side frame.

H

71. Route the Right light harness along the inside of

the right side frame and connect it to the right tail

light lead.

72. Route the Left light harness along the inside of

the left side frame and connect it to the left tail light

lead.

73. Route the seed box sensor harness along the left

light harness, and then to the seed box sensor lead.

Use a cable tie to secure the sensor harness to the

light harness. Plug sensor harness and cable

together.

74. Check that steering hoses, and all cables have

adequate slack for parallel arm movement (at both

ends or arms). Tighten the other cable ties.

C

R

R

L

S

S

R

C

Figure 47

Lighting and Seed Box Harnesses

H

Figure 48

Tail Light Lead

L

C

25371

29169

Adjust Air Box Pads

Refer to Figure 49

If the planter was delivered without a hopper, verify pad

positions.

If the planter was ordered with a seed hopper, two corner

1

pads will have been lowered to allow transport

mounting of the hopper.

75. Loosen two bolts on each corner pad bracket.

2

76. Raise the pads until their top surfaces are 1 inch

higher than the perimeter pad .

3

77. Tighten the bolts.

401-647Q Table of Contents Index 2012-08-08

1

3

2

Figure 49

Air Box Pads

25371

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Planter Assembly 29

Connect Seed Hose Rack

Refer to Figure 51

For shipping, the seed tube hoses and rack ( or )

that interconnect the air box and mainframe are strapped

to the walkboard. The seed tubes/rack need to be

dismounted and connected between the air box manifold

and the inner ends of the wing tubes.

Refer to Figure 50

78. Dismount the rack assembly from walkboard. It may

have a tag with the part number of the tube rack:

401-367K SEED TUBE RACK ASSY REAR 16

15

401-368K SEED TUBE RACK ASSY REAR 12

16

79. Identify rack orientation:

Ends: The hose lengths and mounting hardware are

different for each end of the rack. The end with the

longer hoses connects to the wing tubes. The end

with the shorter hoses connects to the air box. The

air box end also has pivot holes in the frame.

1

15 16

Wings

2

1

15

16

Figure 50

Seed Tube Rack, Dismounted

Air Box

29944

Bottom: At the front (wing) end of the rack, the

bottom side frame has a short rail on each side.

Refer to Figure 51

80. Note the idler spools on each side of the inner

rear portion of the parallel arm brackets. The

forward end of the rack rests on these and is free to

slide during vertical movement of planter

components.

Refer to Figure 52

The rear ends of the outside tubes of the seed tube rack

have large holes to accept a pivot sleeve for mounting.

1

3

2

2

3

Figure 51

Seed Tube Rack, Below Forward

1

Figure 52

Rear Rack Pivot Hole

2

3

29170

25379

2012-08-08 Table of Contents Index 401-647Q

Page 34

30 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Refer to Figure 53 and Figure 54

The hardware for this mount is normally pre-installed on

the rear parallel arm flange weldments, but may be in the

miscellaneous crate.

81. Select or remove two sets of:

46

803-020C NUT HEX 1/2-13 PLT

56

804-015C WASHER LOCK SPRING 1/2 PLT

11

120-306D TUBE RND 1 OD X 7/32W X 2.13

58

802-042C HHCS 1/2-13X3 3/4 GR5

and two (four total):

62

804-113C WASHER FLAT 1/2 USS HARD PLT

Place the lock washer on the bolt.

82. Place a flat washer , than a spacer tube , on

each bolt .

83. From the inside of the rack, pass each bolt

assembly through the hole at the lower/rear pivot

end of the rack. Add another flat washer .

84. Align the rack holes with the weldment holes .

Pass the bolt thread through the weldment holes.

Secure each bolt with a lock washer and nut .

The next activities (connecting seed hoses to the air box

manifold and wing tubes) require the port mapping tables

on the following two pages. Installation steps resume on

page 33.

58

62 11

1

62

1 3

56 46

58

3

56

46

Rack Pivot Hardware

62

Figure 53

1

11

62

29839

58

Figure 54

Rack Pivot Installed

58

29173

401-647Q Table of Contents Index 2012-08-08

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index Planter Assembly 31

Seed Hose Routing

Port Identification: “12 Port”

Air Box Ports (P) Splitter

LR

L

P01

P06

P11

“12 Port” Seed Hose Connection Stations (Facing Forward)

R

P16

Figure 55

T07 T12

T01 T06

Hose Rack Tubes (T)

Y

()

No

Splitter

(|)

29174

Port Assignments: 12, 23 and 24-Row

3PYP-1236: 12-Row, 36in 3PYP-1238: 12-Row, 38in 3PYP-1240: 12-Row, 40in

Left Wing Center Section Right Wing

Box Port P04 P05 P06 P01 P02 P03 P16 P15 P14 P13 P12 P11

Rack Tube T07 T08 T09 T01 T02 T03 T06 T05 T04 T12 T11 T10

Splitter

Row Unit R01 R02 R03 R04 R05 R06 R07 R08 R09 R10 R11 R12

|||||||||||

|

3PYP-2320: 23-Row 20in

Left Wing Center Section Right Wing

Box Port P04 P05 P06 P01 P02 P03 P16 P15 P14 P13 P12 P11

Rack Tube T07 T08 T09 T01 T02 T03 T06 T05 T04 T12 T11 T10

Splitter

Row Unit 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23

3PYP-24TR36: 24-Row (12 Twin), 36in 3PYP-24TR38: 24-Row (12 Twin), 38in 3PYP-24TR40: 24-Row (12 Twin), 40in

YYYYYY

|

YYYYY

Left Wing Center Section Right Wing

Box Port P04 P05 P06 P01 P02 P03 P16 P15 P14 P13 P12 P11

Rack Tube T07 T08 T09 T01 T02 T03 T06 T05 T04 T12 T11 T10

Splitter

Row Unit 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

YYYYYYYYYYYY

2012-08-08 Table of Contents Index 401-647Q

Page 36

32 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Port Identification: “16 Port”

Air Box Ports (P) Splitter

L

P01

R

P16

Figure 56

“16 Port” Seed Hose Connection Stations (Facing Forward)

Hose Rack Tubes (T)

T09 T16

L

T01 T08

R

Y

()

No

Splitter

(|)

29174

Port Assignments: 16, 31 and 32-Row

3PYP-1630: 16-Row, 30in

Left Wing Center Section Right Wing

Box Port P05 P06 P07 P08 P01 P02 P03 P04 P16 P15 P14 P13 P12 P11 P10 P09

Rack Tube T09 T10 T11 T12 T01 T02 T03 T04 T08 T07 T06 T05 T16 T15 T14 T13

Splitter

Row Unit R01 R02 R03 R04 R05 R06 R07 R08 R09 R10 R11 R12 R13 R14 R15 R16

3PYP-3115: 31-Row 15in

Box Port P05 P06 P07 P08 P01 P02 P03 P04 P16 P15 P14 P13 P12 P11 P10 P09

Rack Tube T09 T10 T11 T12 T01 T02 T03 T04 T08 T07 T06 T05 T16 T15 T14 T13

Splitter

Row Unit 010203040506070809101112131

||||||||||||||||

Left Wing Center Section Right Wing

YYYYYYY|YYYYYYYY

1617181920212223242526272829303

15

4

1

3PYP-32TR30: 32-Row (16 Twin), 30in

Left Wing Center Section Right Wing

Box Port P05 P06 P07 P08 P01 P02 P03 P04 P16 P15 P14 P13 P12 P11 P10 P09

Rack Tube T09 T10 T11 T12 T01 T02 T03 T04 T08 T07 T06 T05 T16 T15 T14 T13

Splitter

Row Unit 010203040506070809101112131415161718192021222324252627282930313

401-647Q Table of Contents Index 2012-08-08

YYYYYYYYYYYYYYYY

2

Page 37

Great Plains Manufacturing, Inc. Table of Contents Index Planter Assembly 33

Connect Seed Hoses

Connect Hoses at Air Box Manifold

Refer to tables on page 31 or page 32

85. To ease the connection process, mark the free end

of each hose with its rack Tube number and Port or

Row assignment. Check that each hose has a

clamp.

P16

T06

Rack Tubes are numbered from T01 (bottom row,

planter left) to T12 or T16 (top row, planter right).

Air box manifold ports are numbered from P01

(planter left) to P16 (planter right).

Obtain the Tube-to-Port assignment from the tables

on page 31 (12 port) or page 32 (16_port).

86. Remove any slip-on shipping caps on the manifold

ports. On a 12 port planter, ports P07-P10 are

unused, and have caps secured with clamps. Leave

these caps in place.

Refer to Figure 57

The free ends of the flexible seed hoses are guided

under the frame tube but above the steering gear.

It is generally easier to start at the center manifold ports

(P08 and P09), and work outwards.

87. Slide each hose fully onto its assigned manifold

port.

88. Slide the clamp toward the end of the hose and

secure it at3⁄4inch (1.9 cm) from the face of the air

box.

89. Repeat step 87 and step 88 for all hoses.

P11

P06

P01

Figure 57

Rack to Air Box Seed Hoses

T01

29952

Connect Hoses at Wing Tubes

Refer to Figure 58 (which depicts wings folded for routing

clarity - make these connections prior to first wing fold)

90. Route hoses from lower rack tubes to center section

tubes and rows. In general, the outermost rack tube

is connected to the rear-most section tube. The

center rack tubes connect directly to Y-tube or rows.

Secure with clamps.

91. Route hoses from upper rack tubes to wing tubes.

The outermost rack tube is connected to the rear-most wing tube. Secure with clamps.

2012-08-08 Table of Contents Index 401-647Q

Rack to Wing Tube Hoses

Figure 58

29945

Page 38

34 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Connect Air Box Inlet Hose

Install Hose Routing Clamp

Refer to Figure 59, Figure 60 and Figure 61

92. Select two (2) each:

25

403-579D CLAMP, HOSE ROUTE 6 INCH

64

806-192C U-BOLT 5/16-18X1 1/2X2 1/2 RND

and four (4) sets:

59

804-036C WASHER FLAT 5/16 SAE PLT

49

803-084C NUT HEX NYLOCK 5/16-18 PLT

93. Loosely assemble the clamps to the top side of the

top level rack tube that is just right of center. Slide

the clamp down the tube, to a position

7 inches (18 cm) from the rear end of the tubes

(measured from rear edge of clamps to just beyond

hose clamps on tubes).

94. Route the large hose from the lower outlet of the fan

manifold, through the fan frame cradles and the

routing clamp .

95. Locate one (not shown):

31

800-151C CLAMP WRM DRV #96SS (4.75-6.5)

This may be on the hose or in a crate.

96. Add the clamp to the hose. Slide the hose end

onto the air box inlet. Secure with hose clamp.

97. Adjust the routing clamps so that they just keep

the hose from sliding in the clamps. Tighten the lock

49

nuts just enough to keep the clamps from sliding

on the tube. Do not over-tighten the nuts, or the rack

tube may be damaged.

25

31

25

1

49

59

64

Figure 59

Air Box Inlet Hose Clamp

2

1

1

25

25

25

29839

Figure 60

Fan Outlet Hose Route

25

2

25

29949

7 in.

Figure 61

Fan Outlet Hose

401-647Q Table of Contents Index 2012-08-08

29946

Page 39

Great Plains Manufacturing, Inc. Table of Contents Index Planter Assembly 35

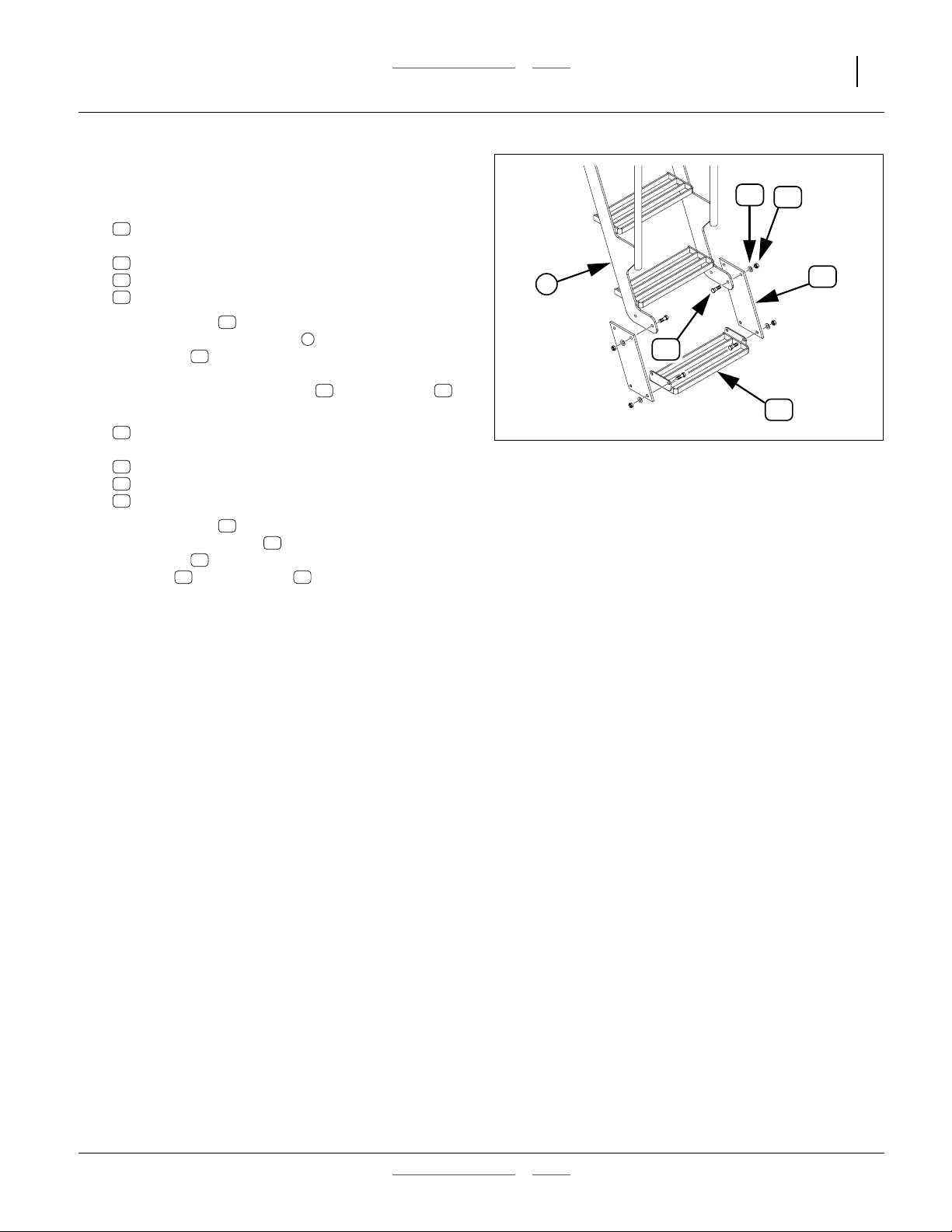

Install Lower Walkboard Step

Refer to Figure 62

98. Select two:

67

816-634C STEP EXTENSION RUBBER

and four (4) sets:

38

802-091C HHCS 1/2-13X1 1/2 GR5

57

804-016C WASHER FLAT 1/2 SAE PLT

45

803-019C NUT LOCK 1/2-13 PLT

99. Insert the bolts from the inside of the bottom four

holes of the existing ladder . Align the rubber

extensions to cant out (following the angle of the

38

3

67

ladder) and place them over the bolt threads.

Loosely secure with washers and lock nuts .

57 45

100. Select one:

18

401-591H STEP SINGLE BOLT-ON

and four (4) sets:

38

802-091C HHCS 1/2-13X1 1/2 GR5

57

804-016C WASHER FLAT 1/2 SAE PLT

45

803-019C NUT LOCK 1/2-13 PLT

101. Insert the bolts from the inside of the bottom four

holes of the new step . Align the rubber

extensions over the bolt threads. Add

washers and lock nuts . Secure all nuts

38

18

67

57 45

(tighten to Grade 2 torque specification).

57

45

3

67

38

18

Figure 62

Step Installation

29104

2012-08-08 Table of Contents Index 401-647Q

Page 40

36 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Install Press Wheel Assemblies

Refer to Figure 63 and Figure 64

If any press wheel assemblies were shipped

separately, or removed at step 22, install them now.

Note: With twin row planters, long and short press wheel

arm mount boxes are alternated every other row.

The long box is identified by the notches on its side

plate. The long box belongs on the right hand row

of a set of twins.

102. Remove and save the

and washer at the back of one of the center row

6

units .

Avoid Alignment Disturbance:

There are four bolts at this location. Remove only the hex head

bolts. Do not loosen or remove the square head bolts forward.

103. Remove and save the1⁄2-13 × 11⁄2inch hex head

7

bolt , washer, and eccentric adjuster nut.

104. Align the1⁄2in holes in the press wheel assembly

with the1⁄2-13 tapped holes in the row unit, loosely

assemble with the1⁄2-13 × 1 inch hex head bolt and

washer .

105. Loosely screw in the1⁄2-13 × 11⁄2inch hex head

7

bolt , washer, and eccentric adjuster nut. Rotate

the adjuster to visually align the press wheel

assembly with the row unit, and tight the adjust and

both bolts.

5

5

4

8

1

⁄2-13 × 1 inch hex head bolt

6

7

Figure 63

Press Wheel Installation

8

Figure 64

Notches Identify Long Press

Wheel Box

4

8

5

25383

32191

401-647Q Table of Contents Index 2012-08-08

Page 41

Great Plains Manufacturing, Inc. Table of Contents Index Planter Assembly 37

Install Row Unit Side Wheels

This applies to Model 3PYPA-3115 only. For all other

models, skip to step 110.

On 3PYPA planters with 15-inch single row spacings, the

side depth gauge wheels are left uninstalled on four

rows, to permit the wing gauge wheel to fold under the

wing for shipment.

Refer to Figure 65

106. Select one of the side depth gauge wheels, which

may be one of:

69

814-173C 4 X 16 GAUGE TIRE ASSY-PLASTIC

69

814-257C 2.5X16 SIDE DEPTH WHEEL ASSY

69

814-260C 3X16 SIDE DEPTH WHEEL ASSY

107. Select one each:

42

802-646C HHCS 5/8-11 X 3 GR8

58

804-022C WASHER LOCK SPRING 5/8 PLT

63

804-195C WASHER FLAT 1.31ODX.65IDX.188T

and six (6) each:

60

804-040C WASHER MACH 1.19 X .63 X 18GA

108. Place the lock washer and three (3) of the

machine washers on the bolt . Insert the bolt

assembly through the outside face of the wheel .

109. Add the flat washer and the remaining machine

washers to the bolt. Secure the wheel assembly

to the arm .

60

26

58

60 42

69

63

69

63

58

42

{

60

Figure 65

Side Gauge Wheel Installation

26

{

60

29954

Hopper Installation

Refer to Figure 66

110. If the 82 bushel hopper is included, set it on the

support structure with the slide gate facing to the

rear. Secure it in place with the pins. See Operator

Manual for mounting instructions.

111. If the standard 833-253C level sensor is installed on

the hopper, and a 466820710S3 extension cable is

available, route the extension cable along the

steering hose/cable bundle to the mainframe.

Connect the forward end to the mainframe harness

lead “HOPPER 2”. Secure extension cable to

existing bundle with tie wraps.

112. Close and secure the walkboard.

3

Figure 66

Hopper Sensor Lead

25382

2012-08-08 Table of Contents Index 401-647Q

Page 42

38 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Hopper Level Sensor Installation

Regardless of hopper/seed box used, the 3PYPA planter

includes a factory-installed seed level sensor in the

airbox.

If a 403-143K 82 bushel hopper was ordered with the

planter, it includes an 833-235C hopper level sensor

which is not factory-installed. This sensor can provide a

second, earlier, low seed level alarm.

An optional 466820710S3 extension cable is required to

connect the hopper level sensor to the 3PYPA seed

monitor harness.

Use of the hopper level sensor is optional, and level

placement is at your discretion. To install:

113. Perform the installation before first use of the

hopper. The sensor body is mounted inside the

hopper. It can be dangerous to enter a hopper if it

contains any seed, or has ever been used with

treated seed.

114. Refer to Figure 68 for placement elevations based

on remaining hopper capacity. Great Plains

suggests mounting the sensor on the lower front

wall of the hopper.

115. Follow the steps in DICKEY-john®instruction sheet

110011126 to install the sensor.

116. Use silicone to seal the cable at the grommet, and

around the grommet, to prevent air leaks which can

interfere with consistent seed delivery.

117. Connect the sensor lead to the harness installed at

step 111 on page 37.

Figure 67

833-235C Hopper Level Sensor

Approximate capacity of bulk seed hopper,

in bushels, at 10 inch increments

29328

Figure 68

Hopper Capacity (bushels)

29869

Row Unit Options

Optional row unit capabilities that are not

factory-installed include their own installation

instructions, or rely on instructions in the planter

Operator manual.

401-647Q Table of Contents Index 2012-08-08

Page 43

Great Plains Manufacturing, Inc. Table of Contents Index Planter Assembly 39

Planter Closeout

118. Using the lift assist cylinders, lift the planter and

remove the rear main frame shipping stand. Save it

for customer use.

Emergency Moves Without Steering

To move the planter with a tractor lacking 3PYPA planter

steering components, or to move a planter with a

steering system malfunction, the casters must be in

Float. Steps below describe methods for several

situations.

Force Caster Float

Any of these configurations will float the casters.

1. Normal Caster Float

(for forward travel only - do not back up)

a. Shut off tractor. Power-Beyond cannot be

connected with tractor running.

b. Make all normal hydraulic and electrical

connections, including steering. Start tractor.

c. Set “STEER” switch on steering switch box OFF.

d. If casters do not float, try step 2.

Steering Not Yet Set Up:

The planter is now safe to move, forward only, or hitch to any

3-point tractor of sufficient capability. Make no reverse moves

until hitched to the tractor on which the steering sensor is

installed.

Equipment Damage Risk:

Make only careful forward moves with casters in Float. With

options 1- 3, do not make reverse moves. The casters

immediately swivel to a hard turn state, usually opposite to

any tractor turn. Damage to planter and tractor is likely.

2. ECU-Disconnected Caster Float

(for forward travel only - do not back up)

a. Shut off tractor. Power-Beyond cannot be

connected with tractor running.

b. Make all normal hydraulic connections, including

steering. Start tractor.

c. Make all normal electrical connections, EXCEPT

steering.

3. Mechanical Float

(for forward travel and for backing up)

a. Remove 11⁄4inch pin locking the caster

weldment and steering arm weldment together.

b. Make all normal hydraulic and electrical

connections EXCEPT power beyond pressure

line.

2012-08-08 Table of Contents Index 401-647Q

Page 44

40 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Console Installation

If the tractor to be used with this planter is not available

prior to customer delivery, provide this manual to the

customer for installation of the console.

Seed Monitor Console Installation

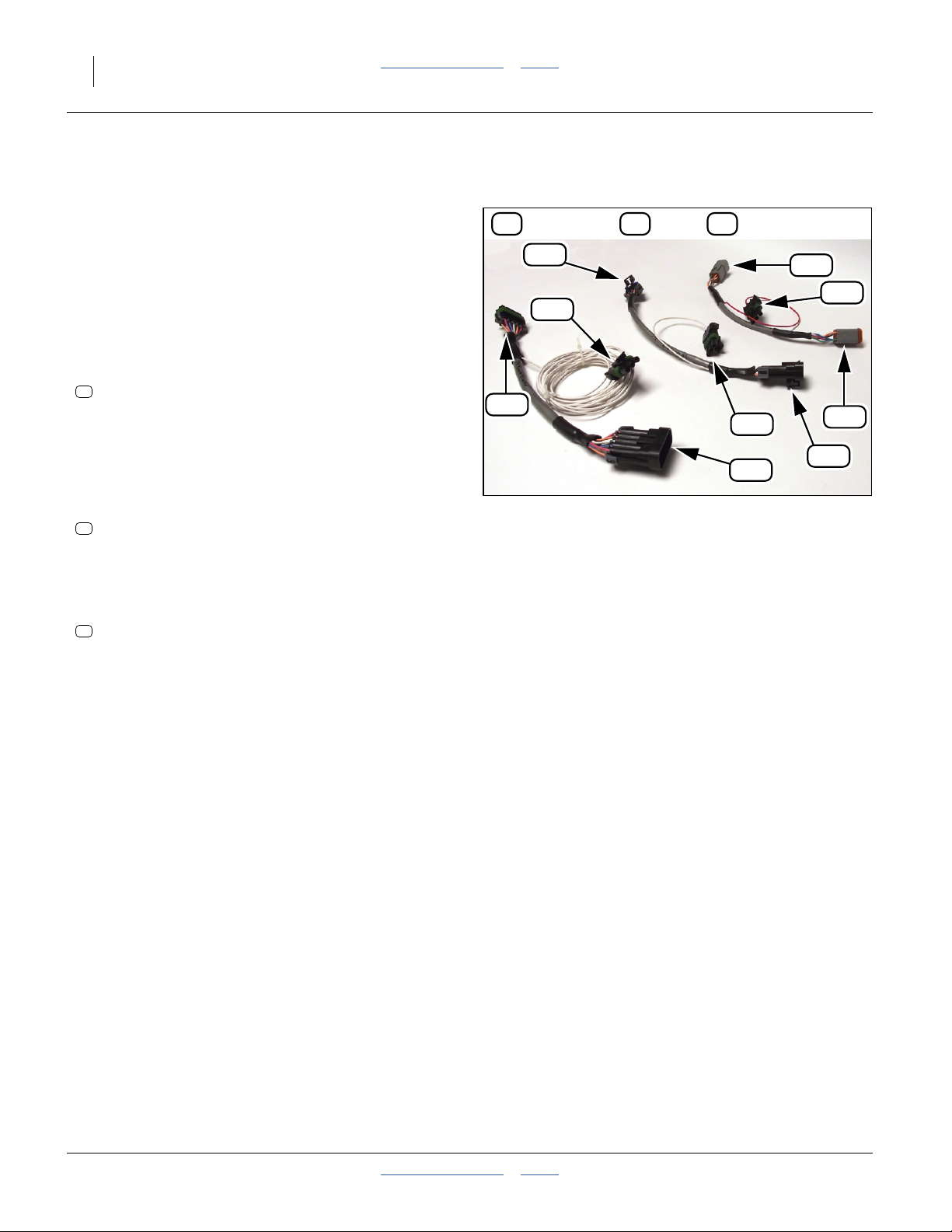

The planter’s standard seed monitor system includes a

virtual terminal and switch panel that must be mounted in

the tractor cab. As supplied by DICKEY-john®, the kit

includes a flat bracket for the modules, and a ball swivel

for mounting the bracket in the tractor.

Transport and Field Safety Risk:

Mount the modules so that they are easy to monitor during

planting, but do not interfere with safe operation of the tractor

in the field or on public roads.

The ball swivel includes four 10-32 screws. You or your

dealer must provide the mounting holes for the screws.

Your dealer may have alternate suction cup or clamping

brackets available if you prefer to avoid drilling holes.

Refer to the included DICKEY-john®manual for harness

connections.

Figure 69

Terminal and Switch Panel

26303

401-647Q Table of Contents Index 2012-08-08

Page 45

Great Plains Manufacturing, Inc. Table of Contents Index 41

p74p

Tractor Steering

Integration of tractor steering and planter steering is

required. The tractor must be a model listed under

“Compatible Tractors” on page 5, and must meet the

requirements listed under Specifications and Capacities,

“Appendix A - Reference Information” on page 64.

Seed cart steering is hydraulically controlled to match

steering of the tractor based on data from a steering

sensor.

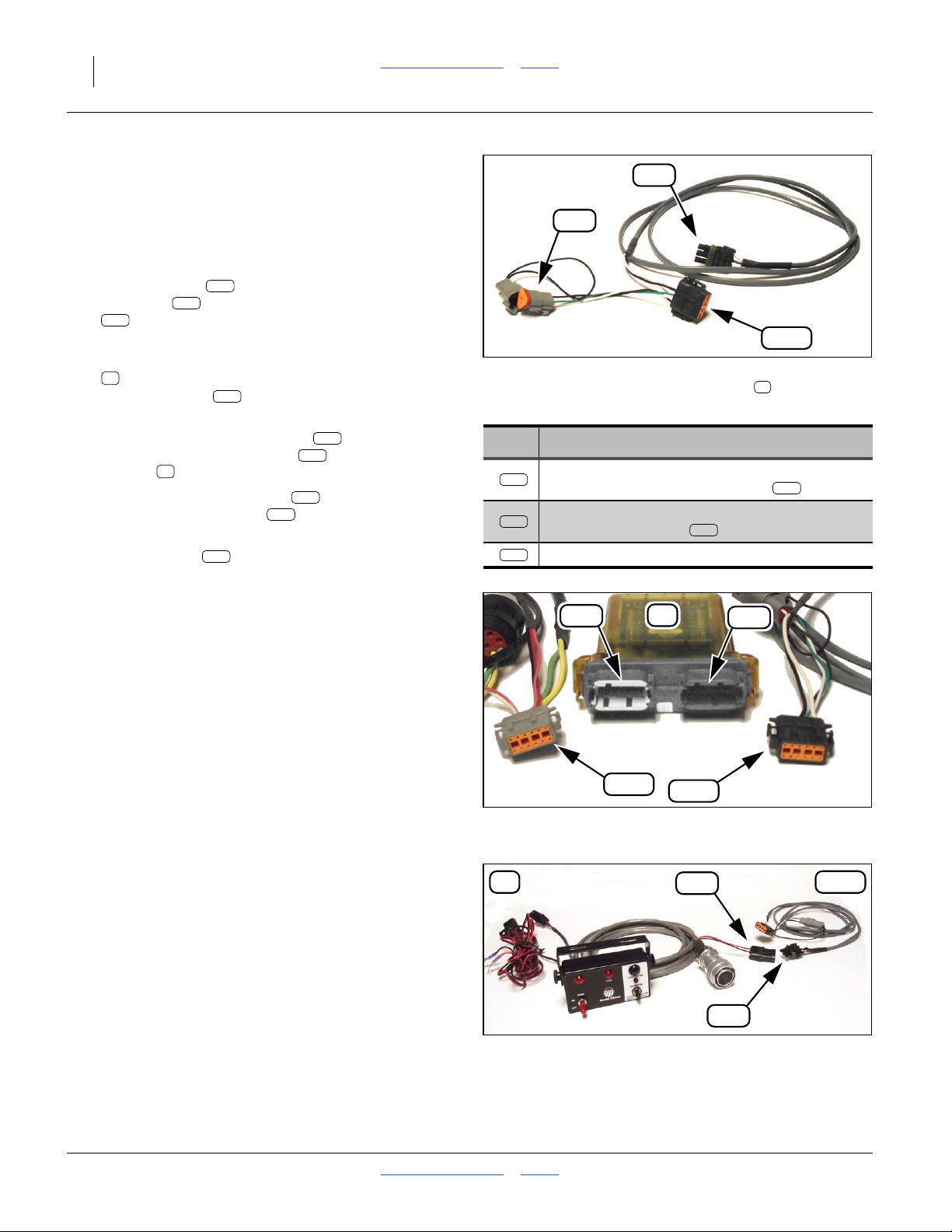

There are five sensor data configurations. All require

some optional hardware. See table below.

If the tractor is not have one of the brands and models

listed, consult your Great Plains dealer. At time of

publication, this 3PYPA planter steering system is not

compatible with articulated tractors.

Steering Signal Source Requires Description

Great Plains linear sensor

a

Tractor ISObus data

Case IH® tractor steering sensor

John Deere® tracked tractor steering sensor

John Deere® wheeled tractor steering sensor

a. Additional tractor-specific mounting hardware is included with the standard planter.

401-748A

401-747A

401-747A

833-544C

401-747A

833-546C

401-747A

833-548C

LINEAR STEERING SENSOR OPT

HARNESS ASY STEER SNSR ADAPTOR

HARNESS ASY STEER SNSR ADAPTOR

HARNESS CNH WHEEL ANGLE SENSOR WHEEL TYPE

HARNESS ASY STEER SNSR ADAPTOR

HARNESS JD WHEEL ANGLE SENSOR TRACK TYPE

HARNESS ASY STEER SNSR ADAPTOR

HARNESS JD WHEEL ANGLE SENSOR WHEEL TYPE

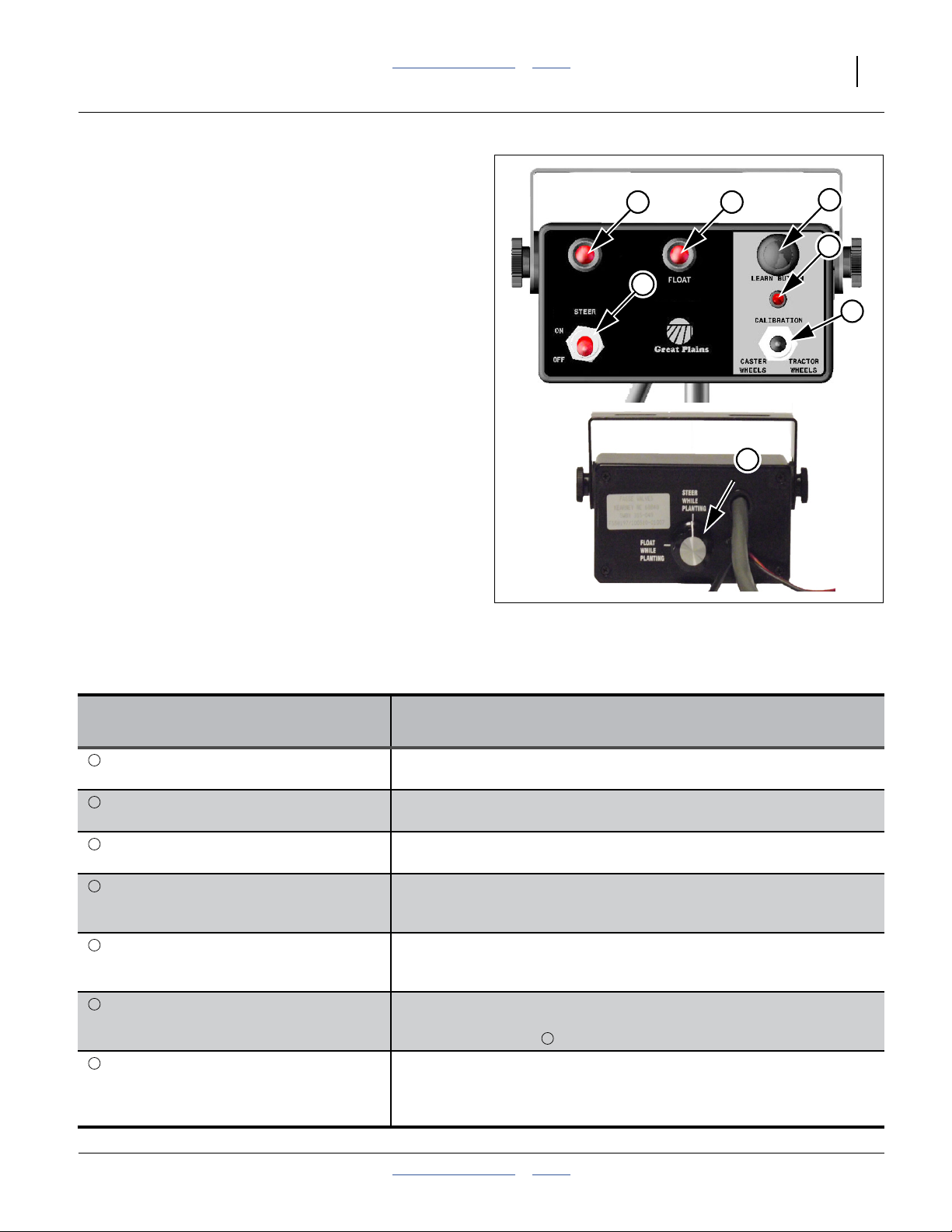

Install Switchbox

70p

Refer to Figure 70

The switchbox is used in all sensor configurations.

4. Select one:

70

833-437C SWITCH CAB

70

70s

Mount the switchbox in any convenient location

70

that allows easy access to switches in the field,

observation of fault indications, and does not

obstruct safe operation of the tractor. Set the

STEER switch to Off.

5. Connect the battery power leads to an

70b

unswitched 12Vdc source. Red+, Black-.

6. Route the main harness to the hitch, where it

70h

mates with the Steering ECU harness from the

planter.

The next step depends on the tractor steering signal

70b

70

Figure 70 833-437C

Steering Switch Box & Harness

Lead Function

70h

31783

source:

Ring tongue terminals: 12Vdc Battery Power in

• For a Great Plains linear sensor, continue at “Install

GP Linear Sensor” on page 42.

• For a tractor ISObus signal source, or native tractor

steering sensor, continue at “Install Electronic

Module” on page 51.

2012-08-08 Table of Contents Index 401-647Q

70b

10-pin: Steering Harness to Hitch

70h

3-pin: normalized PWM steering sensor input

70s

(from linear sensor or electronic module)

3-pin (2 used): Power out to harness

70

Page 46

42 3PYPA Table of Contents Index Great Plains Manufacturing, Inc.

Install GP Linear Sensor

The linear sensor is installed when not using native

tractor steering sensor or CANbus steering data.

Major subassemblies to install are:

• tractor steering sensor , with brand-model-specific

brackets, which detects tractor wheel pointing; and

• the cab steering switch console which controls

operation and calibration of the steering system.