Great Plains 3PNG15 User Manual

Manufacturing, Inc.

www.greatplainsmfg.com

Seed, Small Seeds, and Native Grass Rate Charts for 2007+ 3PNG12 and 3PNG15 Native Grass Drills

The following pages are to assist in the proper setting of seeding and fertilizer application rates for the 12ft and 15ft Native Grass 3-Point drills. The

rates indicated in the charts are approximate values. To assure the most

accurate seeding rate it is recommended that the drill be calibrated for the

desired seed at the time of planting.

© Copyright 2007 Printed 12/01/2010 202-579B

3PNG12 & 3PNG15 Great Plains Manufacturing, Inc.

Table of Contents

Introduction ................................................................ 1

Products Covered ........................................................ 1

Document Family ......................................................... 1

Setting Planting Rate ................................................... 1

Main Seed Box Planting ............................................ 2

Main Seed Box Rate .................................................... 2

Setting Drive Type ................................................... 2

Changing Double Sprocket .................................. 3

Changing Jackshaft Sprocket .............................. 3

Main Seed Box Rate Handle.................................... 4

Position Seed Cup Doors......................................... 4

Checking Main Seed Box Rate .................................... 5

Rate Charts, Main Seed Box ....................................... 6

Alfalfa or Rape ..................................................... 6

Barley ................................................................... 6

Buckwheat............................................................ 6

Buffalograss (1 of 4)............................................. 6

Flax or Sudan....................................................... 7

Millet..................................................................... 7

Milo....................................................................... 7

Oats or Safflower ................................................. 7

Peas ..................................................................... 7

Pinto Beans.......................................................... 7

Rice, Short Grain (1 of 2) ..................................... 8

Rice, Long Grain (1 of 2)...................................... 8

Rye....................................................................... 8

Soybeans (1 of 3)................................................. 8

Sunflower ............................................................. 9

Wheat (1 of 2) ...................................................... 9

Wheatgrass .......................................................... 9

Smalls Seeds Box Planting .................................... 10

Small Seeds Box Rate............................................... 10

Small Seeds Drive Type ........................................ 10

Changing Double Sprocket................................ 11

Changing Jackshaft Sprocket ............................ 11

Checking Small Seeds Box Rate............................... 12

Rate Charts, Small Seeds Box .................................. 13

Alfalfa, Red Alsike, Crimson Clover................... 13

Kentucky Bluegrass,

Fescue, Annual Rye Grass ............................ 13

Bermuda, Red Top, Lespedeza Unhulled,

Sercia, Sand, Weeping Love Grass............... 14

Red & Sweet Clover, Lespedeza Hulled............ 14

Orchard Grass ................................................... 14

Millet, Reed Canary ........................................... 14

Ladino Clover, Canary Grass,

Timothy, Canola............................................. 14

Birdsfoot, Trefoil, Sudan .................................... 14

Native Grass Planting ............................................. 15

Series II Native Grass Calibration ............................. 15

Native Grass Calibration Formulas/Example......... 18

Native Grass Box Cup Rates..................................... 19

Model 3PNG12 (12-foot)........................................ 19

Model 3PNG15 (15-foot)........................................ 19

Great Plains Graphite Lubricant: ....................... 19

Seeding Brome Grass

with Native Grass Box ........................................... 20

Brome Native Grass Rates .................................... 22

7.5in Spacing: Model 3PNG12 or 3PNG15 ....... 22

10in Spacing: Model 3PNG15 or 3PNG15 ........ 22

© Copyright 2004, 2006, 2007. All rights Reserved.

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at

the time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

202-579B 12/01/2010

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Great Plains Manufacturing, Inc. Introduction 1

Introduction

This manual is your guide to drill adjustments for achieving specific seed population targets. Although some

setup/adjustment material herein is repeated from the

Operator’s Manual, you need to be thoroughly familiar

with drill operations and adjustments before applying this

Seed Rate manual and its table data.

Products Covered

3PNG12 12ft 3-Point Native Grass Drill, 2007+

3PNG15 15ft 3-Point Native Grass Drill, 2007+

Document Family

202-553M Operator’s Manual

202-553P Parts Manual

202-579B Seed Rate Charts (this manual)

This manual relies on information found only in your

Operator’s Manual. Have both available when preparing

to plant.

Setting Planting Rate

There are four steps to obtaining the desired number of

seeds per acre:

1. Know the characteristics of the seed.

Consult your seed supplier’s reference documents.

2. Find your settings in the charts:

• Main Seed Box, page 6.

• Small Seeds Box, page 13.

• Native Grass Seeds Box, page 15 (Native Grass

mixes other than Brome require calibration).

3. Set the rate for the seed box in use:

• Main Seed Box, page 2.

• Small Seeds Box, page 10.

• Native Grass Seeds Box, page 15.

4. Check planting rate:

• Main Seed Box, page 5.

• Small Seeds Box, page 12.

• Native Grass Seeds Box, page 15.

The charts are based on original factory tires, and

cleaned, untreated seed of average size and test weight.

Many factors affect field results, including field conditions, foreign material, seed size, seed treatment and tire

pressure. Minor adjustments are likely to be needed.

26253

12/01/2010 202-579B

2 3PNG12 & 3PNG15 Great Plains Manufacturing, Inc.

Main Seed Box Planting

Main Seed Box Rate

Initial seeding rate from the main box is controlled by:

• Drive Type on the ground drive,

• Main box Seed Rate Handle, and

• Seed Cup Door setting

Note: The main seed box rate is unaffected by the Small

Seed Rate Handle and Small Seed/Native Grass

sprocket settings.

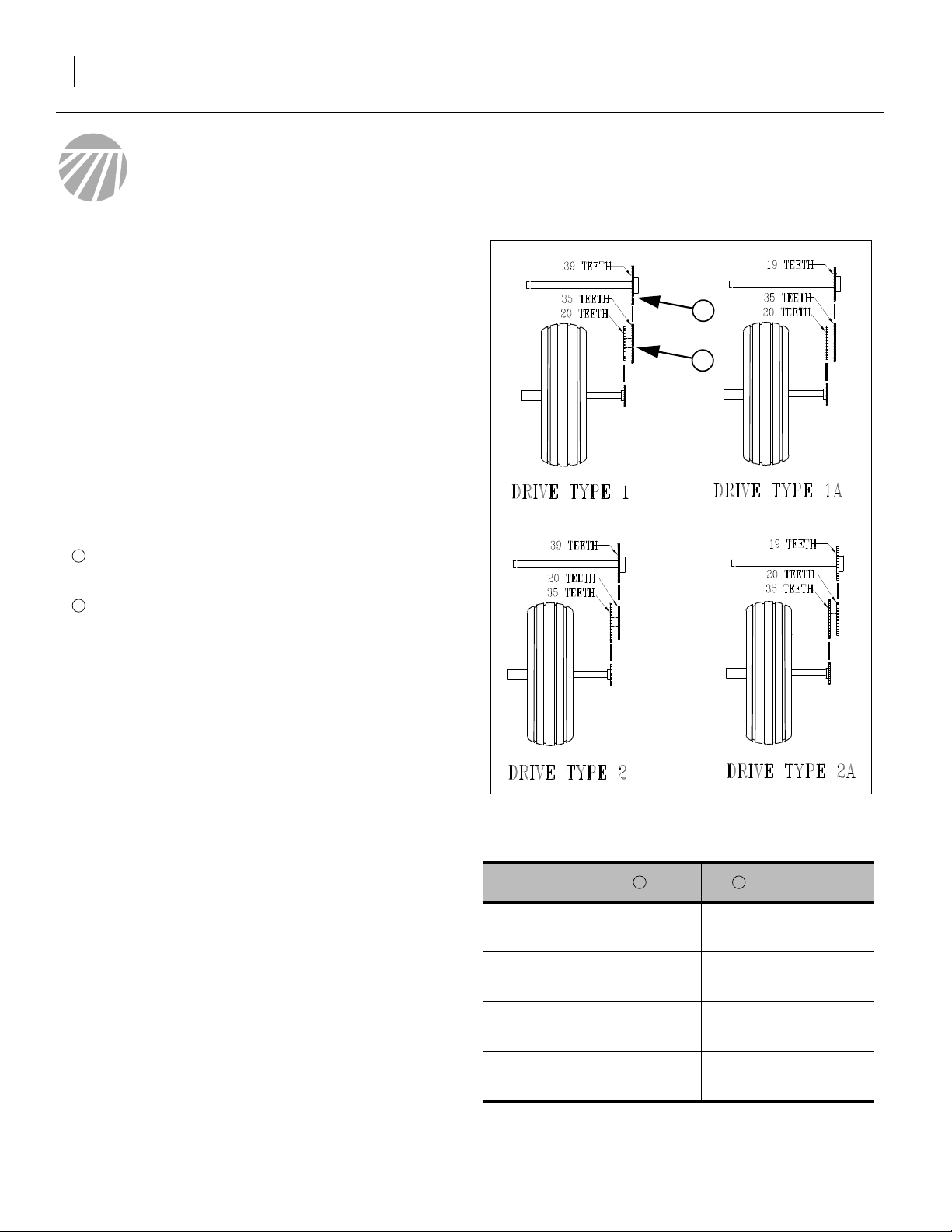

Setting Drive Type

Main seed box Drive Type is a ground drive sprocket

combination. There are no sprocket changes at the main

seed box itself.

All necessary sprockets are already on the shafts, and

need only be inverted and/or shifted into place.

2

1

Lower double 20T+35T sprocket.

1

Invert on shaft to change.

Upper single jackshaft sprockets (19T or 39T).

2

Slide aside to change.

Before setting the drive type, rotate the gauge wheels.

Check that seed cups, seed tubes and drives are working properly and free from foreign material.

Select the drive type from the seed rate charts. The drive

type varies by seed type and intended population.

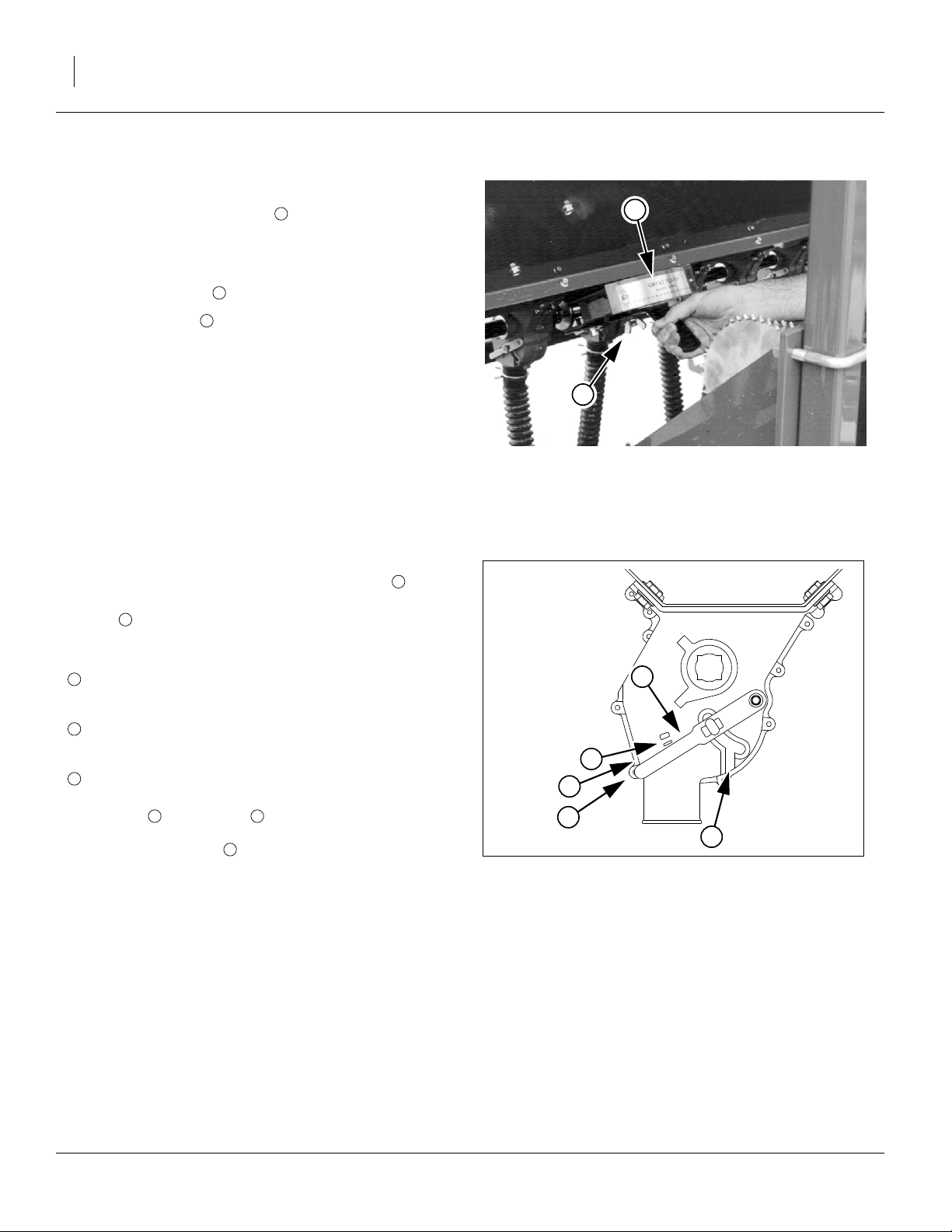

Refer to Figure 1

1. Find your drive type in the seed rate charts of this

manual.

2. Find the drive type sprocket set required in Figure 1

or the table at right.

Note: Whether sprockets are changed or not, verify

chain slack, and check that clip openings on

removable links are facing away from the direction

of chain travel.

3. If the double sprocket is already configured as

needed, skip to step 12.

Figure 1

Drive Type Sprockets

Type Speed

Type 1 20T Driven

Type 1A 20T Driven

1 2

35T Driving

35T Driving

39T -

19T 2x Type 1

16400

Type 2 35T Driven

20T Driving

Type 2A 35T Driven

20T Driving

202-579B 12/01/2010

39T

19T

1

⁄

Type 1

3

2

⁄

Type 1

3

Great Plains Manufacturing, Inc. Main Seed Box Planting 3

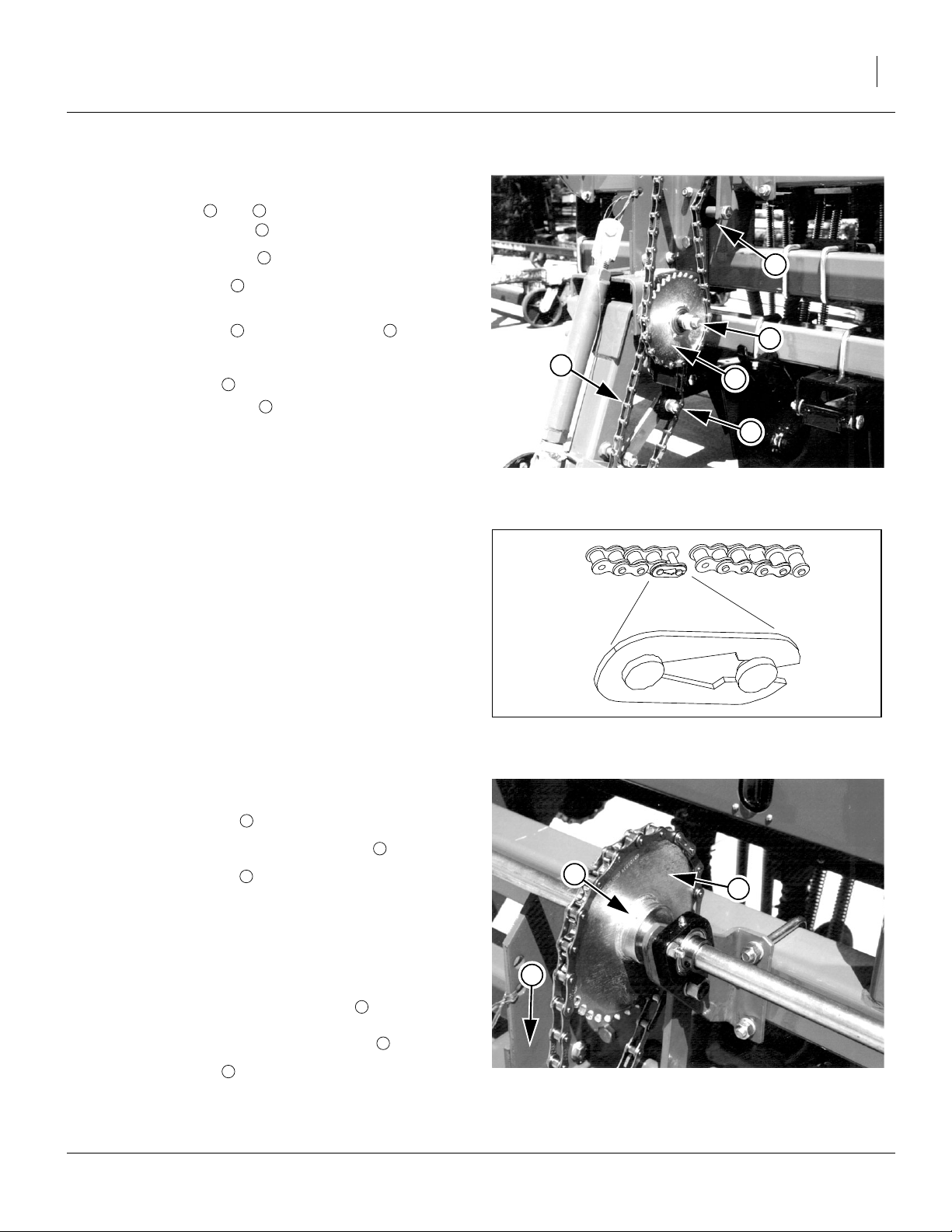

Changing Double Sprocket

Refer to Figure 2

4. Loosen idlers and , and remove both chains

from double sprocket .

3 4

1

5. Remove retaining pin from shaft.

6. Remove sprocket from shaft, and reverse orienta-

5

1

tion of which disk is in/out.

7. Replace sprocket on shaft and re-pin .

1 5

8. Place chains back on sprockets.

9. Re-engage idler and tighten, leaving

forward span of chain .

3

6

3

⁄

in slack in

4

10. If jackshaft sprocket does not need to be changed,

skip to step 17.

Changing Jackshaft Sprocket

It may be necessary to shorten or lengthen the upper

chain. It has removable links for this purpose.

Refer to Figure 3

When re-assembling a chain, make sure the open end of

the clip faces away from the direction of chain travel, to

reduce chain fouling from debris caught in the clip.

3

5

6

1

4

Figure 2

Double Sprocket

16409

Figure 3

26482

Chain Link and Clip

CRefer to Figure 4

11. If the double sprocket did not need to be changed,

loosen upper idler ( in Figure 2).

12. Remove chain from jackshaft sprocket .

13. Loosen set screws on both upper sprockets (only

one of two shown in figure).

3

2

7

7

2

14. Slide current sprocket aside. Position it so that it

does not rub on any fixed machine parts. Re-tighten

the set screw.

15. Slide new sprocket into approximate position.

16. Re-mount chain, and align sprocket so that chain

2

8

is perpendicular to the jackshaft (parallel to the

ground drive frame). Tighten set screw .

17. Re-engage idler and tighten it until there is

3

slack in the forward span.

12/01/2010 202-579B

7

1

⁄

in

2

Figure 4

16412

Jackshaft Sprockets

4 3PNG12 & 3PNG15 Great Plains Manufacturing, Inc.

Main Seed Box Rate Handle

Refer to Figure 5

There is one seed rate handle for the entire main seed

box, located on the left front of the drill above the ground

drive. The seed rate handle controls the percent engagement of the seed sprocket in each seed cup.

1

1

1. Loosen wing nut under handle.

2. Move indicator to about 10 past desired value

from calibration or seed rate chart, then return handle to desired value.

3. Tighten wing nut.

Note: Setting the handle to zero (0) stops all seed flow.

This is useful for making certain row unit adjustments without planting seed.

2

1

Position Seed Cup Doors

Refer to Figure 6,

which depicts the seed cup door handle in position .

At each seed box seed tube, adjust the seed cup door

handle for the seed size.

The handle has three normal operating position detents:

1

2

3

Note: Handle position is used for cleanout, not plant-

4

(top detent) is for the smallest seeds.

Use it for wheat and similar small seeds.

(middle detent) is for larger seeds.

Use it for soybeans and similar larger seeds.

(bottom detent) is for oversize or fragile seeds.

If you experience excessive cracking with

setting , use setting .

2 3

5

ing. If set to this positionwith seed loaded, it may be

difficult to reset it to a normal operating position.

3

2

Figure 5

Main Seed Box Rate Handle

4

1

2

3

5

Figure 6

Seed Cup Door Handle

17618

26211

202-579B 12/01/2010

Great Plains Manufacturing, Inc. Main Seed Box Planting 5

p

c

Checking Main Seed Box Rate

1. Set the Drive Type and Seed Rate Handle to the

table value (or leave them at your adjusted value).

2. Record the weight of an empty container large

enough to hold seed metered from the seed box.

3. Raise drill to get drive wheel off the ground. To calibrate using calibration crank, attach crank to upper

jackshaft.

4. Fill three or more compartments at least

seed in the main seed box. Pull seed hoses off open-

ers under the compartments.

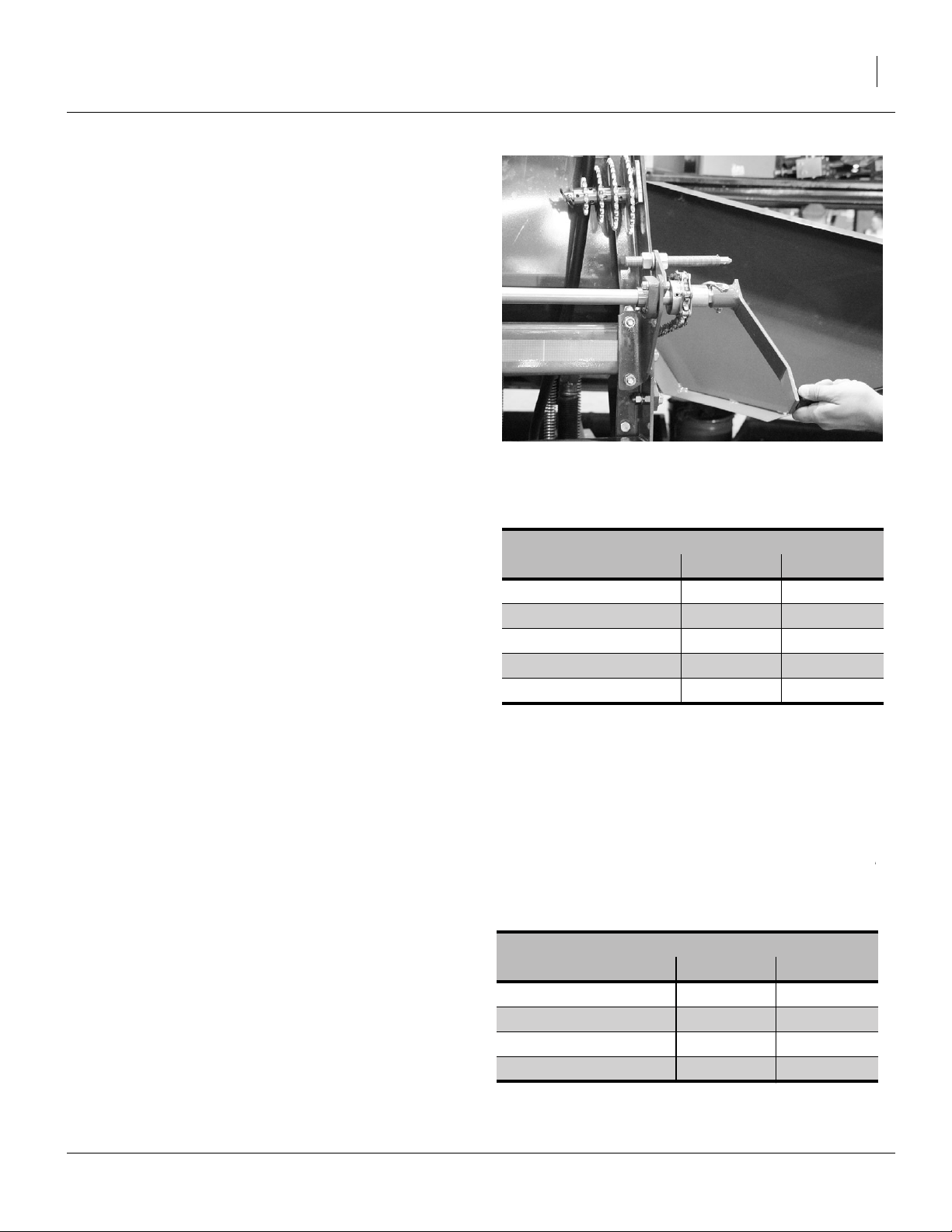

Refer to Figure 7

5. To calibrate using calibration crank, disengage

gauge wheel lockout, and attach calibration crank to

coupler on left-hand side of gauge wheel jackshaft

using retaining pin.

1

/

2

full of

Figure 7

3PNG Calibration Crank

and Native Grass Sprockets

23467

6. Turn gauge wheel or crank several times to fill seed

cups with seed. Continue to turn gauge wheel or

crank until seed falls to the ground from each cup.

7. Place the empty container under three seed hoses to

gather the seed as it is metered.

8. Rotate gauge wheel or calibration crank one acre, as

tallied on Acremeter, or as counted based on values

from table at right.

Note: These settings are based on 9.5L-15 tires inflated

to factory specifications.

Note: You can also rotate the gauge wheel jackshaft by

means of a wrench or socket. If rotating gauge

wheel jackshaft, disengage the lockout on the drive

wheel and use same number of rotations as for rotating drive wheel.

9. Check that the three seed cups have plenty of seed

coming into them.

10. Weight metered seed. Subtract initial weight of container. Divide by three.

11. Multiply by the number of openers on the drill to

determine total pounds seeded per acre. If this figure

is different than desired, change your rate handle

and drive type accordingly.

Note: You may want to repeat the calibration proce-

dure if your results vary greatly from seed rate

chart.

Revolutions for One Acre

3PNG12 3PNG15

Crank: Drive Type 1 302 245

Crank: Drive Type 1A 621 502

Crank: Drive Type 2 99 80

Crank: Drive Type 2A 203 164

Gauge Wheel 450 364

easuredSeed EmptyContainer–

----------------------------------------------------------------------------------------- -

undsPerSeedCup NumberOfOpeners× PoundsPerA

Total Row Units

Model Spacing Rows

3PNG12-1410 10 inch 14

3PNG12-1975 7.5 inch 19

3PNG15-1810 10 inch 18

3PNG15-2475 7.5 inch 24

3

PoundsPerSeedCu

=

=

12/01/2010 202-579B

6 3PNG12 & 3PNG15 Great Plains Manufacturing, Inc.

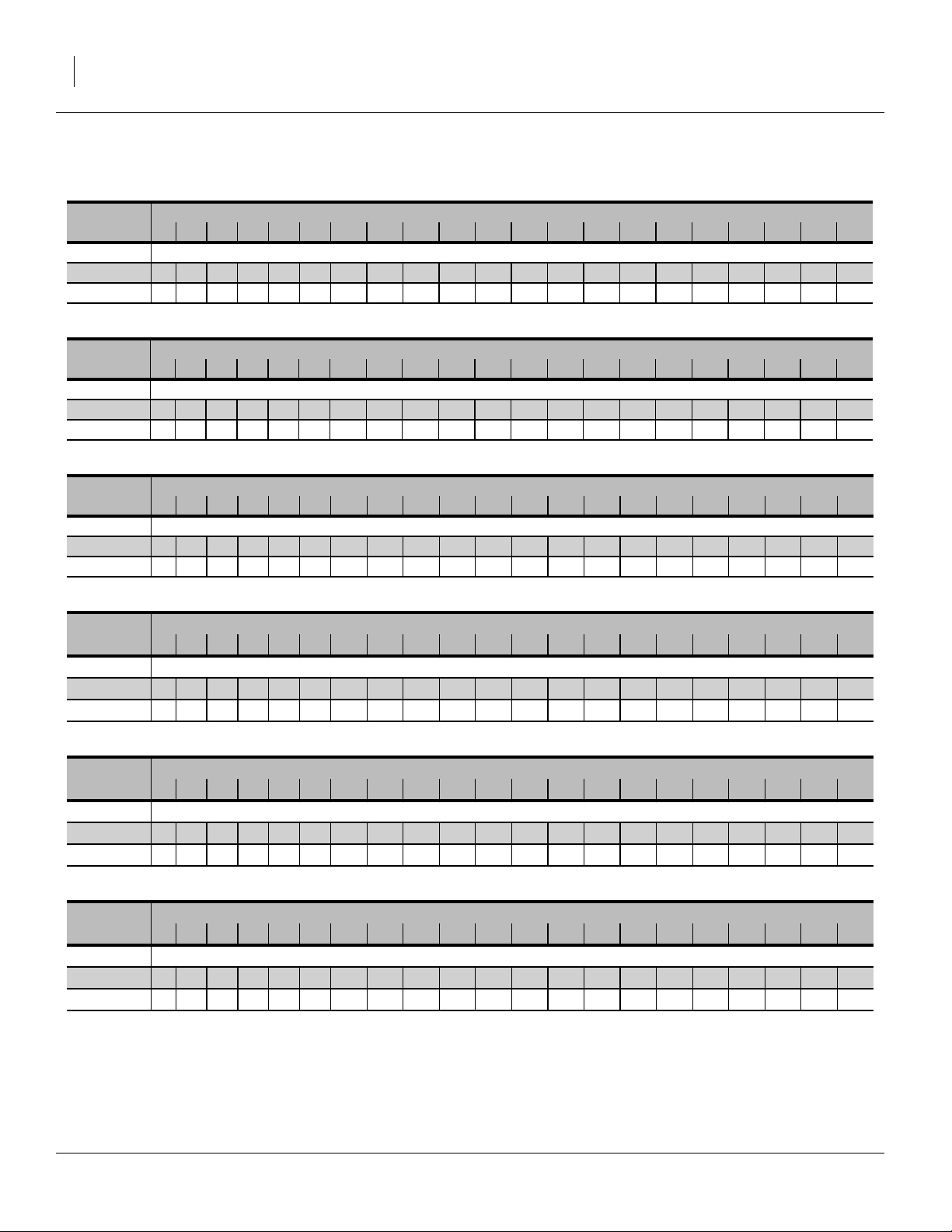

Rate Charts, Main Seed Box

Alfalfa or Rape

Drive Type Seed Rate Handle Setting

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 60 pound

7.5 inch 0 3 5 7 9 12 14 16 18 21 23 26 28 30 32 34 36 38 40 41 43

10 inch 0 2 3 5 7 9 10 12 14 16 18 19 21 22 24 25 27 28 30 31 32

Barley

Drive Type Seed Rate Handle Setting

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre (based on 46.4 pounds/bushel)

7.5 inch 0 0 6 11 16 21 26 31 36 40 44 50 55 60 66 70 75 79 81 84 86

10 inch 0 0 4 8 12 16 20 23 27 30 33 37 41 45 49 53 56 59 61 63 64

Buckwheat

Drive Type Seed Rate Handle Setting

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7.5 inch 0 6 11 16 21 26 32 37 44 50 56 62 68 75 82 89 94 99 102 107 111

10 inch 05 8121520242833374246515661677174778083

s/bushel)

Buffalograss (1 of 4)

Drive Type Seed Rate Handle Setting

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7.5 inch 0 0.1 0.5 1.0 1.6 2.4 3.2 4.1 5.1 6.1 7.1 8.1 9.1 10.1 11.0 11.9 12.7 13.4 13.9 14.4 14.7

10 inch 0 0.0 0.3 0.7 1.2 1.8 3.1 3.8 4.6 5.3 6.1 6.9 7.6 8.3 8.9 8.9 9.5 10.0 10.5 10.8 11.0

(based on 23 pounds/bushel)

Buffalograss (2 of 4)

Drive Type Seed Rate Handle Setting

2A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7.5 inch 0 0.1 0.9 2.0 3.3 4.9 6.6 8.5 10.5 12.5 14.6 16.7 18.7 20.7 22.6 24.4 26.0 27.4 28.6 29.5 30.1

10 inch 0 0.1 0.7 1.5 2.5 3.7 5.0 6.4 7.8 9.4 10.9 12.5 14.1 15.6 17.0 18.3 19.5 20.6 21.4 22.1 22.6

(based on 23 pounds/bushel)

Buffalograss (3 of 4)

Drive Type Seed Rate Handle Setting

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7.5 inch 0 0.0 1.4 3.0 5.0 7.3 9.9 12.6 15.6 18.6 21.7 24.9 27.9 30.9 33.8 36.4 38.8 40.9 42.6 44.0 44.8

10 inch 0 0.0 1.0 2.3 3.7 5.5 7.4 9.5 11.7 14.0 16.3 18.6 21.0 23.2 25.3 27.3 29.1 30.7 32.0 33.0 33.6

(based on 23 pounds/bushel)

202-579B 12/01/2010

Loading...

Loading...