Page 1

Great Plains Mfg., Inc.

Installation Instructions

Three-Point Drill

Flat-Fold Markers

Used with:

3PD27 and 3PD30

•

3PD15 and 3PD20 (Old-Style Drill)

•

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

!

the lives of others depend on it!

General Information

These instructions explain how to install the flat-fold markers.

These instructions apply to:

113-211A 15-Foot Left-Hand Marker

113-212A 15-Foot Dual Markers

113-208A 20-Foot Left-Hand Marker

113-209A 20-Foot Dual Markers

113-199A 27-Foot Dual Markers

113-195A 30-Foot Dual Markers

Manual Update

Refer to the drill operator’ s manual for detailed information on

safely operating, adjusting, troubleshooting and maintaining the

flat-fold markers. Refer to the parts manual for part identification.

• 3PD27 and 3PD30 Operator’s Manual. . . . . . . . 118-365M-A

• 3PD27 and 3PD30 Parts Manual. . . . . . . . . . . . . . 118-365P

• 3PD15 and 3PD20 Operator’s Manual. . . . . . . . . . 118-262D

• 3PD15 and 3PD20 Parts Manual. . . . . . . . . . . . . . 118-365P

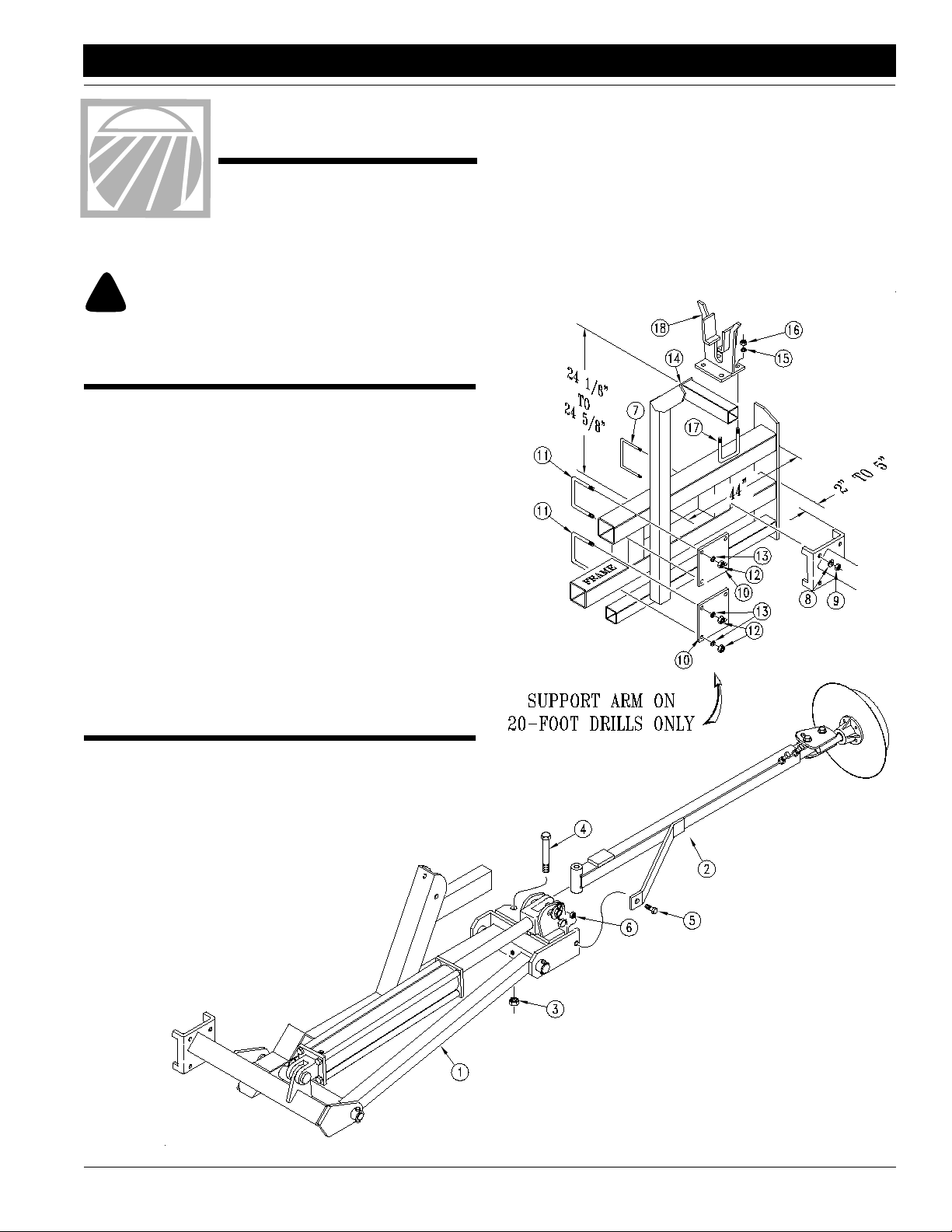

5. On 20-foot drills, mount support arm (14) at dimension

shown using clamp plates (10),1/2-inch u-bolts (11), hex

nuts (12) and lock washers (13).

6. Mount support-arm saddle (18) to support arm with 1/2-inch

u-bolts (17), lock washers (15) and hex n uts (16). T o prev ent

wear when folded, center saddle under the square tube of

second section.

7. Adjust support arm and saddle so second section is parallel

with seed-box lid when marker is folded.

Marker Assembly

15- or 20-Foot Markers

1. Lower drill into field position. From end of each drill box, allow 9 feet of clearance on a 15-f oot drill or 11 f eet of clearance on a 20-foot drill for marker assembly.

2. Mount first marker section (1) on lower 3 1/2-inch frame

tube. Mount marker as close to end of frame as

possible. Mount with 5/8-inch u-bolts (7), hex

nuts (9) and lock washers (8).

3. Remove port plugs from cylinder so you can

extend fold cylinder . Unf old first section and

lift hinge.

4. Align holes in second section (2) with

holes in lift hinge. Bolt sections together

with 5/8-inch bolt (5), lock nut (6), 3/8-inch

shear bolt (4) and lock nut (3). Assemble

sections so stop block on second section

faces up.

11010

8. If necessary, repeat steps

After assembling markers, proceed

to Hydraulic Setup,

to mount other marker.

page 3.

© Copyright 1998 Printed 4/9/04

113-380M

1

Page 2

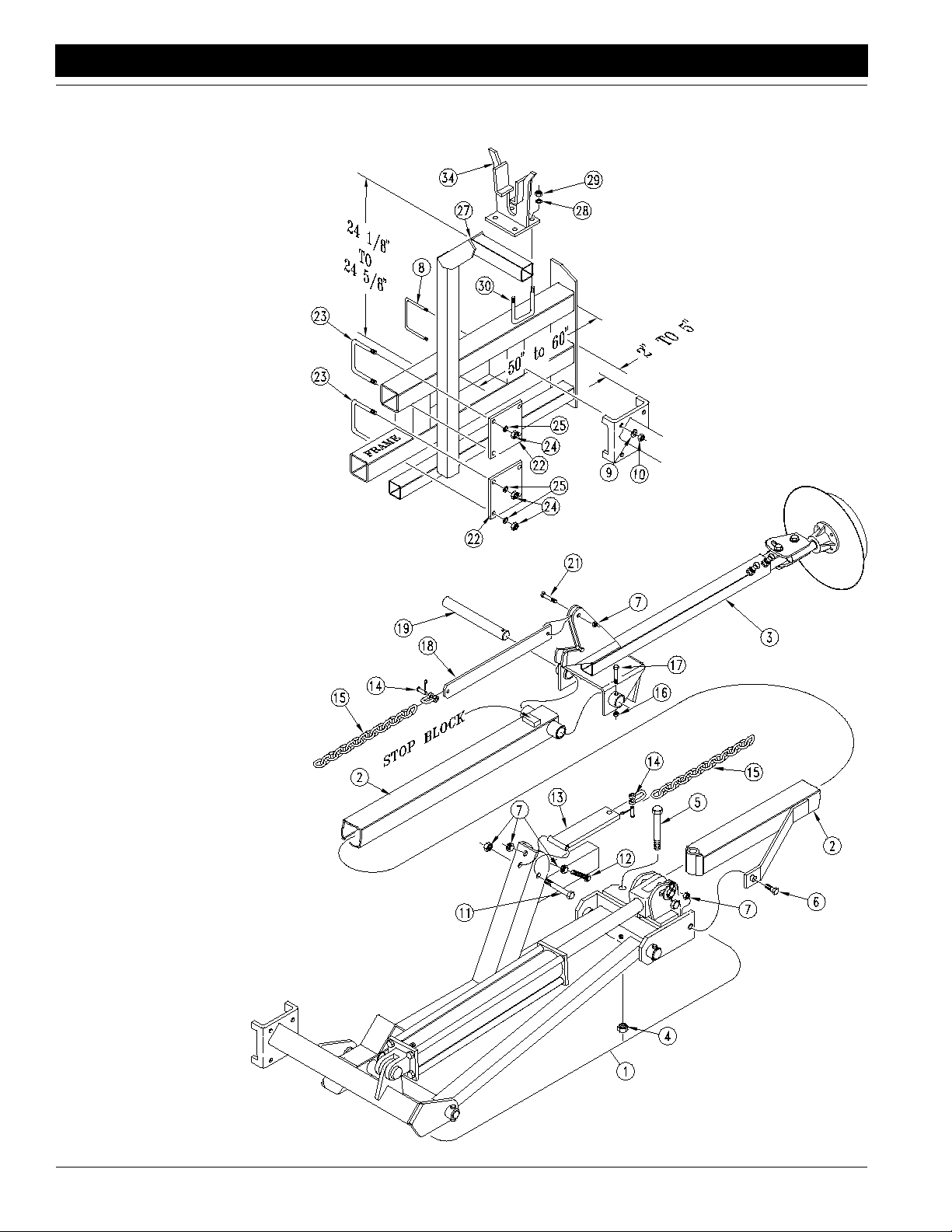

Assembly

27- or 30-Foot Markers

1. Lower drill into field position. From end of each drill box, allow 14 feet of clearance on a 27-f oot drill or 16 feet of

clearance on a 30-foot drill for marker as

sembly.

2. Mount first marker section (1) on lower

3 1/2-inch frame tube. Mount with 5/8inch u-bolts (8), lock washers (9) and hex

nuts (10).

3. Remove port plugs from hydraulic cylinder so you can extend f old cylinder. Unfold first section and lift lug.

4. With stop block positioned on top of

second section (2), align holes in

second section with holes in first

section. Bolt sections together with

5/8-inch bolt (6), lock nut (7), 3/8-by-2inch shear bolt (5) and lock nut (4).

5. Place third section (3) over end of

second section and insert hinge pin

(19) through pivot. Secure hinge pin

with 1/4-inch bolt (17) and lock nut (16).

6. Bolt chain-bar weldment (13) to first section with 3/8-by-3 1/4-inch bolt (11) and

lock nut (7). Bolt chain-bar weldment so it

pivots freely.

7. Bolt chain bar (18) to third section with

3/8-by-1 1/2-inch bolt (21) and lock nut (7).

Bolt chain bar so it pivots freely.

8. Connect marker chain (15) to chain bar and chain-bar weldment with 5/16-inch utility clevis (14).

9. With marker disk adjusted for seeding width and disk touching the ground, adjust chain length to remove chain slack.

Make chain-length adjustments at the utility clevis on the

chain-bar weldment.

10. Install 3/8-by-2 1/2-inch stop bolt (12) and lock

nuts (7) so stop bolt extends as little as possible .

Fold marker and adjust stop bolt to tighten chain.

NOTE: Stop bolt must hold tension on marker chain only when the marker is folded.

Stop-bolt should not affect chain tension

when marker is unfolded.

11. Mount support arm (27) to drill frame at

dimension shown. Secure arm to

drill frame with clamp plates (22),

1/2-by-3 1/2-by-6 1/2-inch u-bolts

(23), lock washers (25) and hex

nuts (24). Set support-arm height at

about 24 1/8 inches above drill frame.

12. Mount support-arm saddle (34) to support arm with 1/2-by-2-by-3-inch u-bolts

(30), lock washers (28) and hex n uts

(29). To prevent w ear when folded, cen

ter saddle under marker chain and

square tube of second section.

13. Adjust height of support arm so second section is parallel

with seed-box lid when marker is folded.

14. Fold marker into transport position. With marker chain in slot

of the support-arm saddle, take up chain slack by threading

3/8-inch stop bolt out against the chain-bar weldment. Lock

stop bolt in place with hex nuts.

15. Repeat steps to mount other

marker. After assemb ling

markers, proceed to Hy

draulic Setup, page 3.

-

-

-

Great Plains Mfg., Inc.

Three-Point Drill Flat-Fold Markers 113-380M 4/9/04

2

11008

Page 3

Great Plains Mfg., Inc.

Assembly

Hydraulic Setup

!

CAUTION!

Folding the markers with air in the system

will cause erratic, jerky movement. With

air in the system, the markers may crash,

causing injury to bystanders. Always bleed

the marker cylinders before folding.

1. Attach adaptor (1) and elbow fit-

ting (2) to needle valve (3). Attach

elbow fittings (2 and 4) to cylinder

ports. Attach hoses (5 and 6) to

needle valve and elbow fitting.

Route hoses down to and along

drill frame to center of drill. Use ca

ble ties (7) to keep hoses in place.

2. Bleed air out of the hydraulic sys-

tem.

a. Unpin rod end of cylinder.

Support cylinder with a block

under cylinder body on the

first marker section.

b. Extend and retract the cylin-

der rod several times to w ork

air out of the system.

c. Repin cylinder with clevis pin,

cotter pin and flat washers.

3. Using needle valve, adjust marker

folding speed to a slow setting.

4. Fold marker up and down a f e w

times and check for pinching and

kinking of hoses. Reposition hos

es if necessary.

-

-

4/9/04

Three-Point Drill Flat-Fold Markers 113-380M

17276

3

Loading...

Loading...