Page 1

Table of Contents Main Box Rates

Manufacturing, Inc.

www.greatplainsmfg.com

Seed, Native Grass, Small Seeds and Fertilizer Rate Charts

for the 3P806NT 3-Point 8-Foot No-Till Drill

The following pages are to assist in the proper setting of seeding

rates for the 8-foot (2.5 m) no-till drill. The rates indicated in the

charts are approximate. To assure the most accurate seeding, it is

recommended that the drill be calibrated for the desired seed at

the time of planting.

ORIGINAL INSTRUCTIONS

© Copyright 2011 Printed 2011-10-21 151-143B

EN

Page 2

Great Plains Manufacturing, Inc. Cover Main Box Rates ii

Table of Contents

Introduction ..................................................................1

Models Covered .............................................................1

Document Family ...........................................................1

Material Rates Overview ................................................1

Calibration Overview ......................................................2

Calibration Crank Storage .......................................... 2

Using Calibration Crank..............................................2

Main and Dual Box Seed Rate.....................................3

Setting Drive Type......................................................3

Main and Dual Box Seed Rate Handle....................... 4

Position Seed Cup Doors ........................................... 4

Main/Dual Seed Row Shutoff .....................................4

Reading a Seed Rate Chart .......................................5

Main/Dual Box Seed Rate Calibration........................6

Rate Charts, Main Seed Box..........................................8

Alfalfa (Medicago sativa) ............................................ 8

Bahia Grass (Paspalum notatum) ..............................8

Barley (Hordeum vulgare) ..........................................8

Buckwheat (Fagopyrum esculentum).........................9

Buffalograss (Buchloe dactyloides) ............................ 9

Bermuda Grass (Cynodon dactylon) .......................... 9

K-31 Fescue (Festuca).............................................10

Flax (Linum usitatissimum) or Sudan

(Sorghum bicolor subsp. drummondii)..................10

Eastern Gamma Grass - Pete

(Tripsacum dactyloides) .......................................10

Kentucky Blue Grass (Poa pratensis).......................11

Millet (Pennisetum glaucum, Setaria italica,

Panicum miliaceum, Eleusine coracana)..............11

Milo (Sorghum).........................................................11

Oats (Avena sativa)..................................................12

Orchard Grass Potomac (Dactylis glomerata).......... 12

Peas (Pisum sativum)...............................................12

Pinto Beans (Phaseolus vulgaris).............................13

Rape (Brassica napus).............................................13

Rice, Long Grain (Oryza sativa indica)..................... 13

Rice, Short Grain (Oryza sativa japonica,

Oryza sativa sinica) ..............................................14

Rye (Secale cereale)................................................14

Perennial Rye Grass - Palmer

(Lolium perenne, Lolium multiflorum) ...................14

Soybeans (Glycine max) ..........................................15

Sunflower (Helianthus annuus) ................................15

Tiffany Teff, Coated (Erogrostis tef) .........................15

Wheat (Triticum)....................................................... 16

Wheatgrass (Pascopyrum smithii,

Agropyron elongatum).......................................... 16

Native Grass Rate ...................................................... 17

Setting Native Grass Seed Rate .................................. 17

Native Grass Rate Calibration ..................................... 17

Native Grass Meter Shaft Rates .................................. 20

Standard Shaft Rates...............................................20

Shaft Rates with Seed Rate Reduction.................... 20

Seed Lubricant ..................................................... 20

Brome Grass Seeding.................................................. 21

Brome Rate Charts .................................................. 23

Small Seeds Rate ....................................................... 24

Small Seeds Rate Calibration ...................................... 24

Small Seeds Row Shut-Off .................................. 26

Small Seeds Rate Charts............................................. 27

Alfalfa, Red Alsike, Crimson Clover ..............................27

Kentucky Bluegrass,

Fescue, Annual Rye Grass.......................................27

Bermuda, Red Top, Lespedeza Unhulled,

Sercia, Sand, Weeping Love Grass.......................... 27

Red & Sweet Clover, Lespedeza Hulled....................... 27

Orchard Grass ..............................................................27

Millet, Reed Canary ......................................................28

Ladino Clover, Canary Grass,

Timothy, Canola........................................................ 28

Birdsfoot, Trefoil, Sudan ...............................................28

Fertilizer Rate ............................................................. 29

Setting Fertilizer Rate .................................................. 29

Fertilizer Rate Chart..................................................... 29

Fertilizer Rates in Pounds per Acre .............................. 29

Metric Fertilizer Rate Chart ...........................................29

Adjusting for Density .................................................... 30

Density Conversion Charts ...................................... 30

U.S. Customary Units ...................................................30

Metric ............................................................................ 30

Fertilizer Rate Calibration......................................... 31

Appendix..................................................................... 33

Metric Rate Charts, Main Seed Box............................. 33

Metric Rate Charts, Small Seeds Box.......................... 42

Metric Native Grass Rates ........................................... 44

Metric Native Grass Shaft Rates.................................. 45

Brome Seed Rates, Metric ....................................... 46

© Copyright 2003, 2004, 2006, 2008, 2011 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2011-10-21 Cover Main Box Rates 151-143B

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 3

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates 1

Introduction

This manual is your guide to drill adjustments for

achieving specific seed populations.

Although some setup, operation and adjustment material

herein is repeated from the drill Operator Manual, you

need to be thoroughly familiar with drill operations and

adjustments before applying this Seed Rate Manual and

its table data.

Models Covered

This rate manual applies to drill models:

3P806NT-1375 13-row 7.5-inch (19.1 cm)

Document Family

151-143M Operator Manual

151-143P Parts Manual

151-143B Seed Rate Manual (this document)

Figure 1

3P806NT No-Till Drill

28357

Material Rates Overview

Details of seed and fertilizer rate setting are found in the

Adjustments section of the Operator Manual, and rely

on data from this Seed Rate Manual.

Rate setting controls are different for each box. Some

boxes have more than one control.

Main Box

Dual Seed

(page 3)

Rate Range

Fine Rate Rate Handle Driver/Driven

Cup Adjustment Door Handle

Small Seeds

(page 24)

Rate Handle

All chart rates, for all boxes, are approximate.

Great Plains strongly recommends calibration of each

box to the material to be applied.

Native Grass

(page 17)

Seed Rate Reduction

Fertilizer

(page 29)

Rate KnobCoarse Rate Drive Type Drive Type

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 4

2 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Calibration Overview

Detailed calibration steps vary with each box, see:

“Main/Dual Box Seed Rate Calibration” on page 6,

“Fertilizer Rate Calibration” on page 31,

“Native Grass Rate Calibration” on page 17, and

“Small Seeds Rate Calibration” on page 24,

Some general information applies to all boxes, and is not

repeated in those pages referenced above.

Calibrate with Drill Raised

Perform the calibration with the drill hitched and raised.

Install lift-assist cylinder lock(s). Calibration with the drill

lowered is not recommended, as the drive tires in ground

contact prevent drive operation.

2

1

Calibrate for1⁄

The number of revolutions per area is:

revolutions for

Full Acre 656 1170

1/10th Acre

Full Hectare 1622 2890

1/10th Hectare

Crank counts below 10 are not recommended. Sample

sizes may be too low, and fractional crank turns

introduce more error.

th

Acre or Hectare

10

Crank Tire

65.6 117

162 289

32341

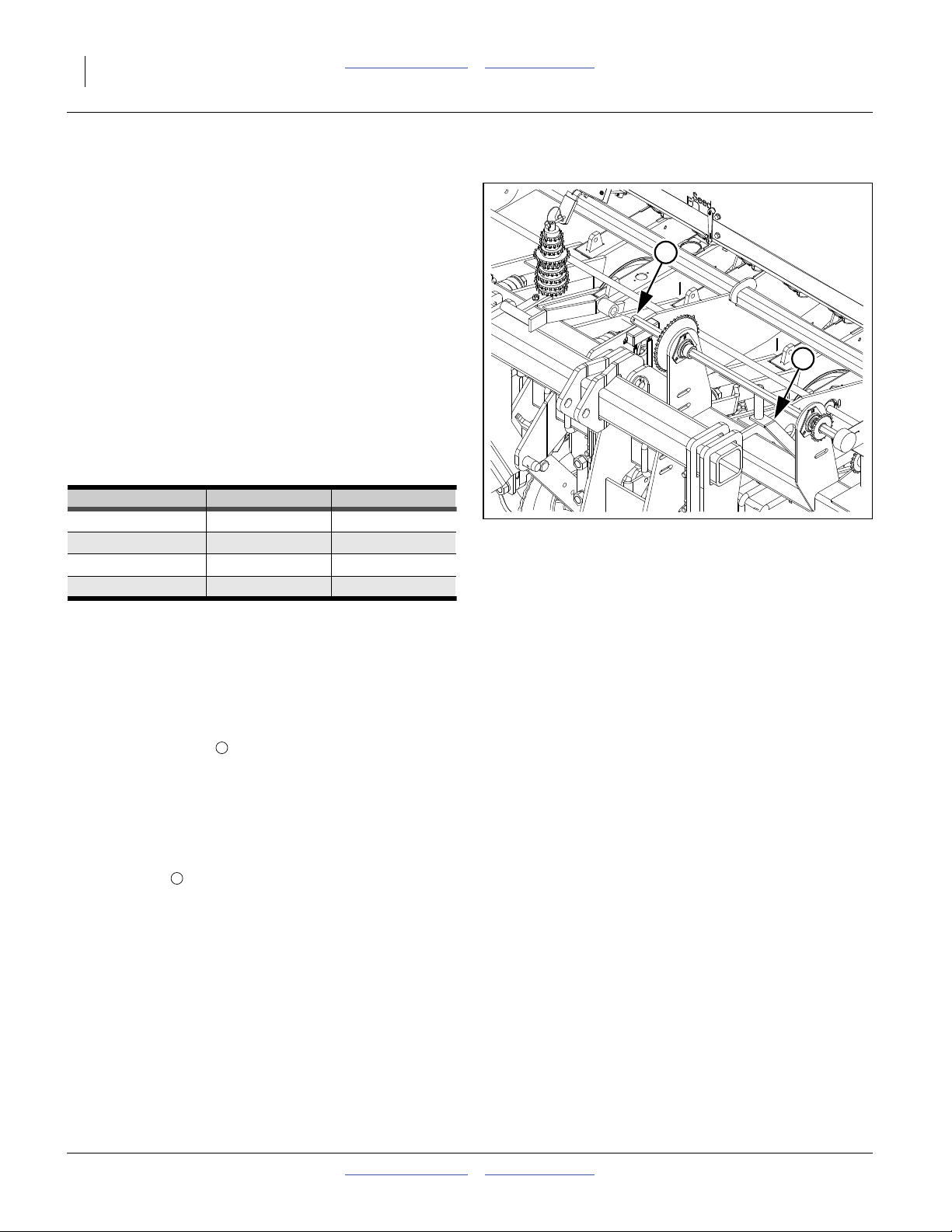

Calibration Crank Storage

Refer to Figure 2

The calibration crank is found at the top front frame,

left of center, pinned to a stob on a 3-point weldment.

Note: The retaining pin at the stob can also secure the

crank to the jackshaft.

1

Using Calibration Crank

Place the hex socket of the crank on the right end of the

main jackshaft .

Operate the crank clockwise

A wide range of cranking speeds produce accurate

calibrations. For reference, at 6 mph (10 kph) field speed,

jackshaft rpm is 65 (about 1 revolution per second).

2

Figure 2

Calibration Crank

28410

Check Affected Boxes

Empty any boxes not being calibrated or remove a drive

chain to prevent undesired meter operation. Alternatively,

set rate handles to zero.

151-143B Table of Contents Main Box Rates 2011-10-21

Page 5

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates 3

83P806NT

2011 09 23

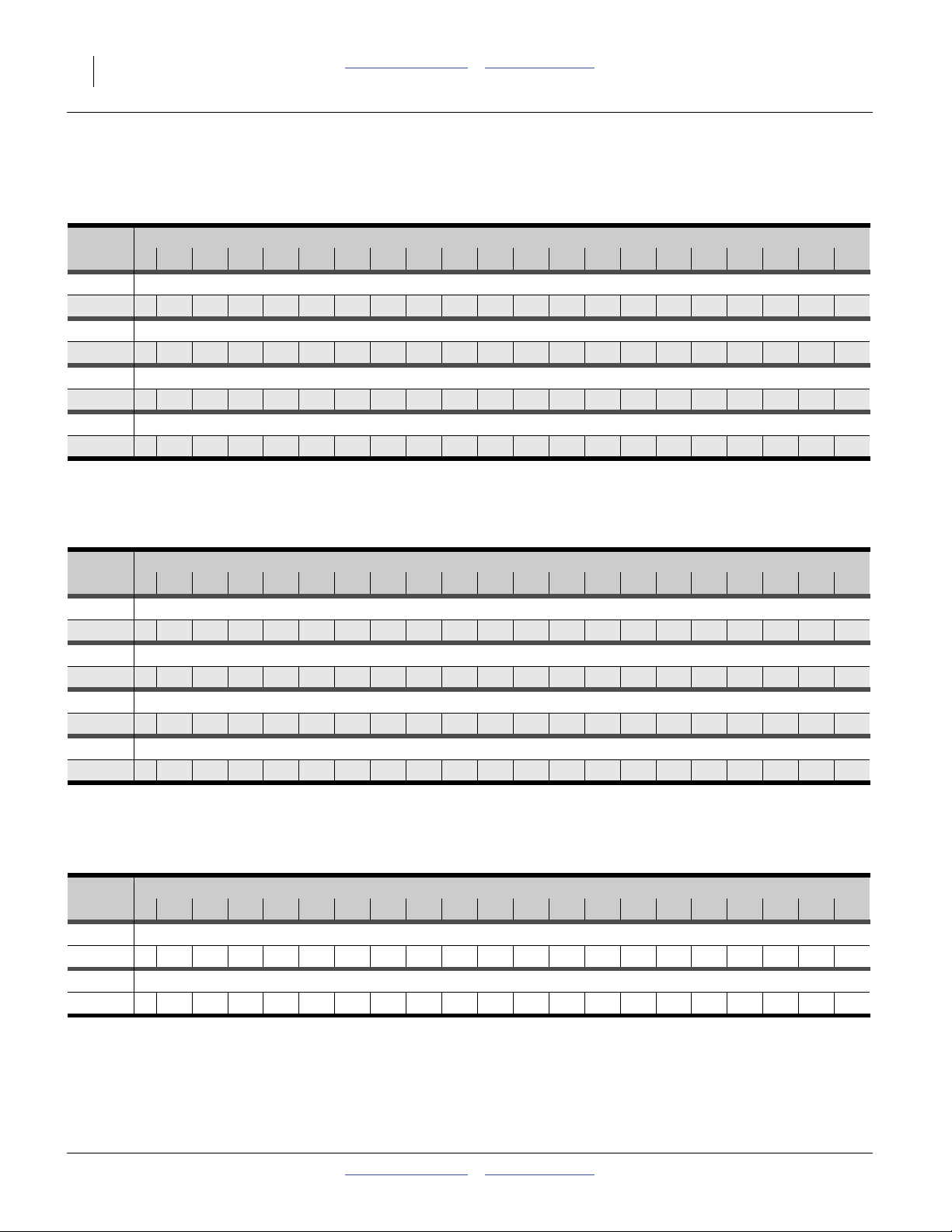

Rate Charts, Main Seed Box

Charts n U S customary units

Metric charts begin on page 33

Alfalfa (Medicago sativa)

Bahia Grass (Paspalum notatum)

Barley (Hordeum vulgare)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

(based on 60 pounds/bushel)

7 5 in

04667911215182125283236394347505457616466

Drive Type: 2 Seed Rate n Pounds Per Acre

7 5 in

0 9 5 14 19 24 30 37 44 51 58 66 73 81 89 96 104 111 118 125 131 136

Dr ve Type: 3 Seed Rate in Pounds Per Acre

7 5 n

0 15 22 29 37 46 55 65 75 86 97 108 119 130 141 151 162 171 180 189 196

Drive Type: 4 Seed Rate in Pounds Per Acre

7 5 in

0 25 35 47 60 75 90 106 123 140 158 176 194 212 230 247 264 279 294 308 320

32291C

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

(based on 40 pounds bushe )

7 5 in

0 2 2 31 4 5 6 3 8 5 11 14 17 20 23 27 30 33 37 40 43 46 48 50 52

Drive Type: 2 Seed Rate in Pounds Per Acre

7 5 in

0 4 4 64 9 3 13 18 23 28 35 41 48 55 62 69 76 82 88 94 99 104 107

Drive Type: 3 Seed Rate n Pounds Per Acre

7 5 in

0 6 6 10 14 20 26 34 43 52 62 72 82 93 103 113 123 132 141 149 156 161

Drive Type: 4 Seed Rate in Pounds Per Acre

7 5 n

0 11 16 23 32 43 56 70 85 101 117 134 151 168 185 201 216 230 243 254 263

32292C

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

(based on 51 pounds/bushel)

7 5 in

04763841114172024273135394245495154565758

Drive Type: 2 Seed Rate in Pounds Per Acre

7 5 in

01013172228354249566472798693100105110115118120

Drive Type: 3 Seed Rate in Pounds Per Acre

7 5 in

0 14 19 26 34 43 52 62 72 83 94 105 116 126 137 147 156 165 173 180 186

Drive Type: 4 Seed Rate in Pounds Per Acre

7 5 in

0 22 32 43 56 70 85 101 118 135 153 171 189 206 223 239 255 269 282 293 303

32293C

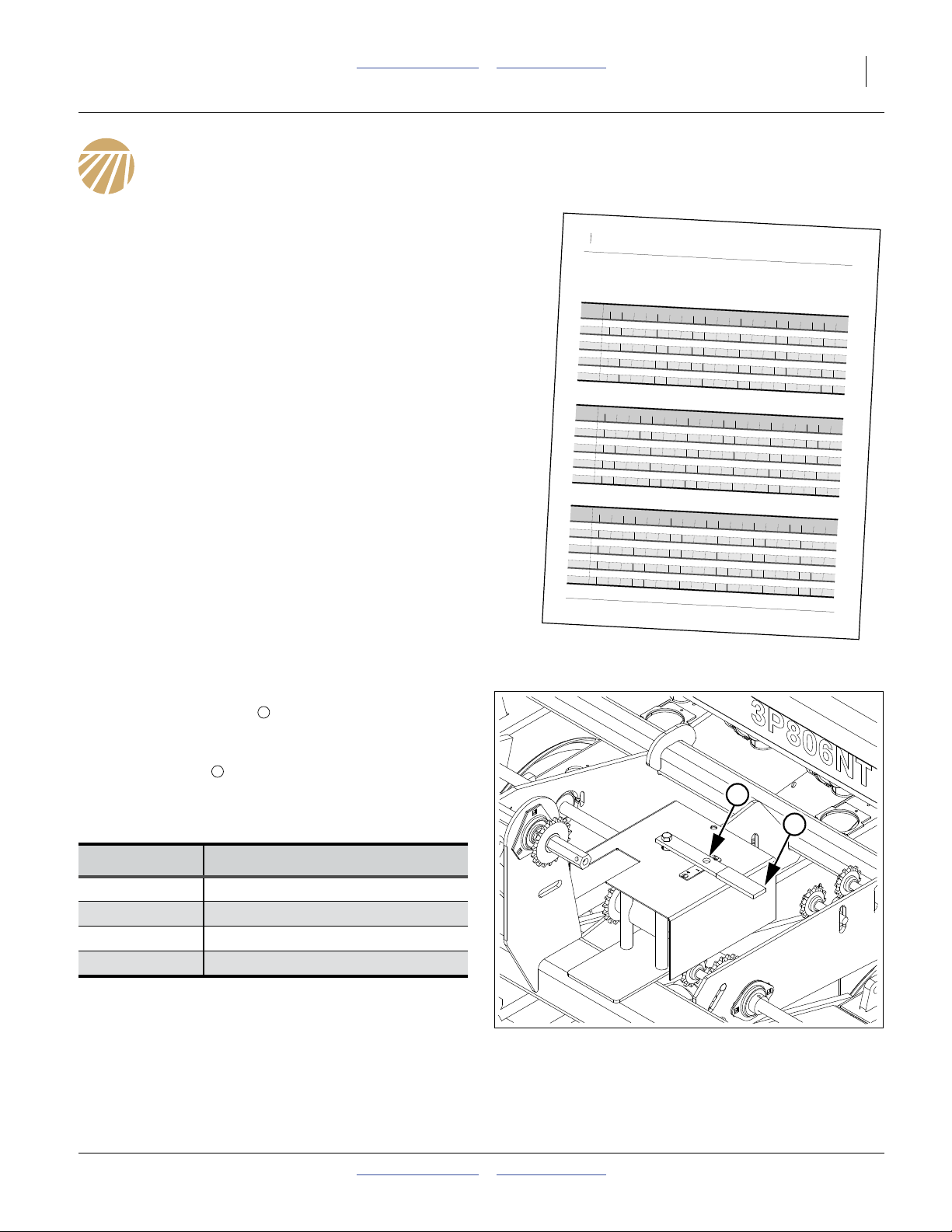

Main and Dual Box Seed Rate

Accurately obtaining the desired seed population

requires four steps:

1. Setting Drive Type gearbox (from chart)

2. Setting initial Seed Rate Handle (from chart)

3. Positioning Seed Cup Door (by seed type)

4. Calibration: checking predicted seeding rate

Seed rate charts begin on page 8. The charts list proper

Drive Type and seed rate handle settings for various

seeds and seeding rates.

The seed rate charts are based on cleaned, untreated

seed of average size and test weight. The charts are

based on factory-supplied 5.70-8 8-Ply tires inflated to

factory specification. Many factors affect seeding rates

including foreign material, seed treatment, seed size,

seed weight, field conditions, tire pressure and test

weight.

Use the charts only as a starting point. Minor

adjustments are commonly required. Set and check the

seeding rate using the procedures beginning on page 6,

then readjust the rate as necessary.

32342

Setting Drive Type

Refer to Figure 3

The charts list Drive Types as 1, 2, 3 or 4. Drive Type is

determined by the handle on the gearbox cover, at left

front of drill.

Move the handle until the Drive Type number appears in

the handle window .

For correct Drive Type, refer to the charts in the Seed

Rate manual. Each Drive Type corresponds to a specific

gear ratio.

Drive Type Relative Speed

1 Slowest

Note: The gear box is shared between Main Seed Box

2011-10-21 Table of Contents Main Box Rates 151-143B

2 2.06 times faster than Type 1

3 3.08 times faster than Type 1

4 5.02 times faster than Type 1

and the optional Dual Seed and Native Grass

boxes. It is possible to plant from both boxes at the

same time only if their settings use the same Drive

Type.

2

1

2

1

32790

Figure 3

Gearbox Handle Adjustment

28414

Page 6

4 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Main and Dual Box Seed Rate Handle

Refer to Figure 4

There is a single rate handle for the entire box. There are

separate handles for the standard main seed box and the

optional dual seed box.

The seed rate handle controls the percent engagement

of the seed sprocket in each seed cup. The initial setting

of the handle is given by the Seed Rate Chart.

Note: You can temporarily stop main seed flow (such as

for adjusting level/depth) with handle set to zero.

To set the handle:

1. Loosen wing nut under handle.

2. Move indicator from current setting to about 10

higher than the new desired value from calibration or

the Seed Rate Chart, then back to the desired value.

3. Tighten wing nut.

6

7

7

Figure 4

Main/Dual Box Seed Rate Handle

6

32772

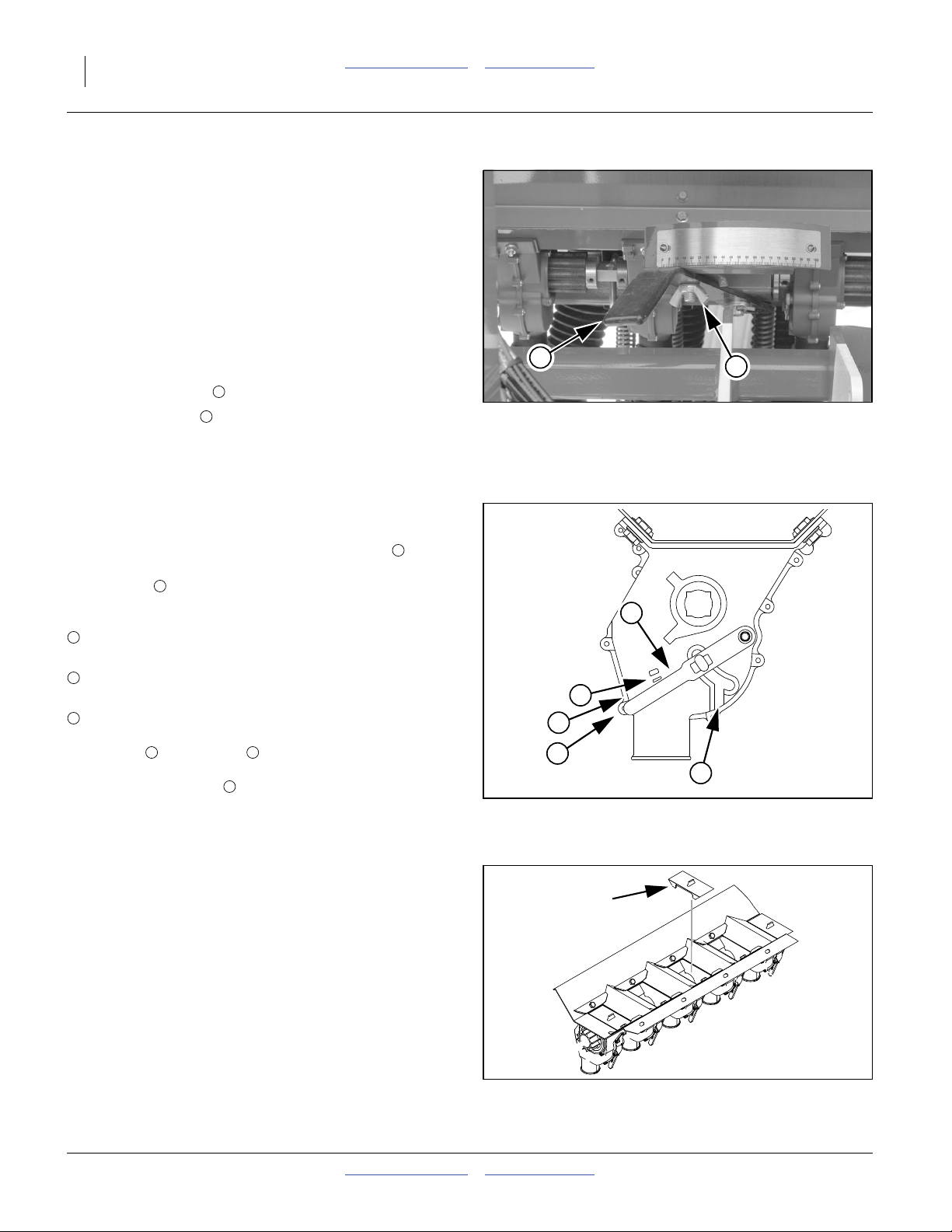

Position Seed Cup Doors

Refer to Figure 5,

which depicts the seed cup door handle in position .

At each main seed box seed tube, adjust the seed cup

door handle for the seed size.

The handle has three normal operating position detents:

1

(top detent) is for the smallest seeds.

Use it for wheat and similar small seeds.

2

(middle detent) is for larger seeds.

Use it for soybeans and similar larger seeds.

3

(bottom detent) is for oversize or fragile seeds.

If you experience excessive cracking with

setting , use setting .

Note: Handle position is used for clean-out, not

4

2 3

5

planting. If set to this position with seed loaded,

it may be difficult to reset it to a normal operating

position.

3

4

1

2

3

5

Figure 5

Seed Cup Door Handle

26211

Main/Dual Seed Row Shutoff

If alternate row spacings are desired, the unused rows

can be shut off with optional plugs.

1. Clean-out seed. The seed box must be empty prior

to inserting plugs. See “Main Box Clean-Out” in

Operator manual.

Refer to Figure 6

2. Insert one plug at each row to shut off. Verify the

seed hose path before inserting the plug, as some

hoses do not make a strictly vertical drop to their row

units.

3. Review seed rate settings prior to planting. Perform

calibration calculations with the actual active row

count.

151-143B Table of Contents Main Box Rates 2011-10-21

Figure 6

Seed Cup Plug

26279

Page 7

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Main and Dual Box Seed Rate 5

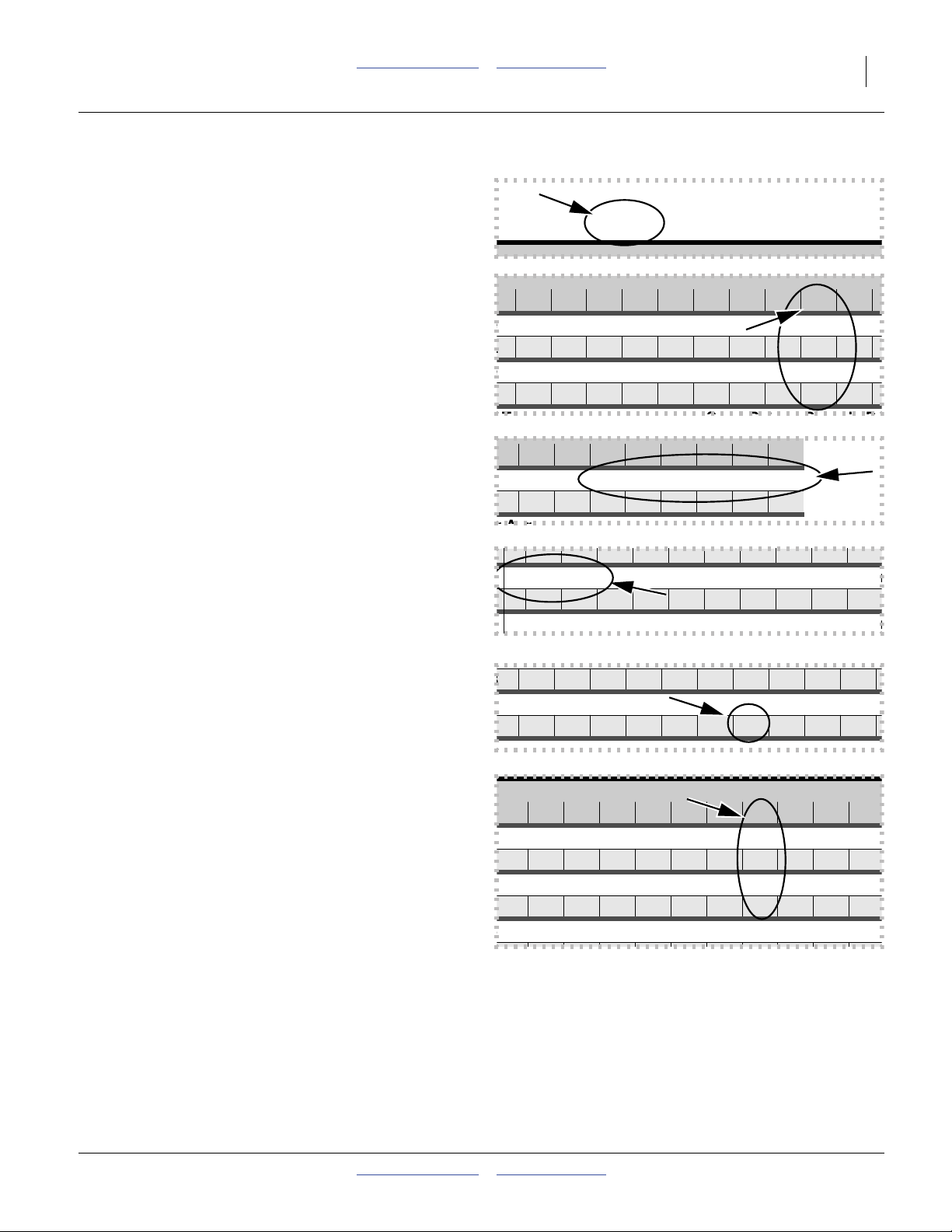

Seed Rate Handle Se

e

e

04.76.38.411141720242731

n

n

Reading a Seed Rate Chart

1. Find your seed. Charts are in alphabetical order by

common North American seed name. Scientific

names are provided. Charts covering more than one

seed may be out of order.

For Sudan, see Flax.

The example presumes Barley at 60 pounds/acre.

There are multiple chart sections for some seeds,

and the rates may overlap. Use the chart where your

desired rate is closest to 50 on the Seed Rate Handle scale.

In the example, this would be Drive Type 2.

If your seed is not listed, find one with similar size,

shape and density. Density of the test seed used to

develop the chart appears under the right end of the

handle scale values.

Barley (Hordeum vulgare)

10 15 20 25 30 35 40 45 50 55

Type: 1 Seed Rate in Pounds P

32342

76.38.41114172024273135

Type: 2 Seed Rate in Pounds P

013172228354249566472

065707580859095100

Acre

94245495154565758

(based on 51 pounds/bushel)

32342

32342

2. Note the Drive Type for the chart rate row chosen (at

left above rates). This number (1-4) is used to

determine the gearbox handle setting. See page 3.

In the example, this is

Drive Type 2

3. Locate your desired seed rate in the table row for

your row spacing.

In the example the rate closest to 60 is:

64

4. Note the Seed Rate Handle setting required, at the

top of the column at that seed rate. This is the initial

value set on the Seed Rate Handle. See page 4.

In the example, start with a handle setting of:

50 (or interpolate to 48),

and calibrate. When a target rate falls halfway

between handle settings, you can adjust the handle

slightly to compensate, as in the example, but

calibration is apt to result in further adjustment

anyway.

Drive Type: 2 Seed Rate in Pou

32342

010131722283542495664

Drive Type: 3 Seed Rate in Pou

.4 11 14 17 20 24 27 31 35 39 42

32342

Seed Rate in Pounds Per Acre

722283542495664727986

Seed Rate Handle Setting

15 20 25 30 35 40 5 50 55 60 65

Seed Rate in Pounds Per Acre

8.411141720242731353942

32342

Seed Rate in Pounds Per Acre

17 22 28 35 42 49 56 64 72 79 86

Seed Rate in Pounds Per Acre

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 8

6 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Main/Dual Box Seed Rate Calibration

Differences will exist between the tested seed and field

conditions used to generate the Seed Rate Charts, and

your seed and conditions. To accurately achieve your

target population, Great Plains recommends calibrating.

Due to the large number of crank revolutions per acre

(310 or 569) and per hectare (766 or 1405), a practical

calibration is a simulation of1⁄

th

acre or1⁄

10

th

hectare.

10

1. Estimate the sample sizes.

TargetRate

RateSample

SamplePerRow

ExpectedSample SamplePerRow SampledRows×=

-----------------------------

=

=

10

RateSample

-----------------------------------

RowCount

Example: You want to apply barley at a TargetRate of

60 pounds per acre. RateSample is:

60

------

6.0

=

10

Example: the drill has 13 rows. SamplePerRow is:

6.0

0.46

------- -

=

13

Example: 3 rows are to be used in the sampling.

ExpectedSample is:

1.38 0.46 3×=

The expected sample net weight is 1.2 lb.

2. To perform this calibration, you need a scale that is

accurate at the aggregate sample size, and three (3)

light containers, each capable of holding the

expected SamplePerRow. Record the empty

container weights.

3. Raise the drill so the gauge wheel is out of ground

contact.

4. Remove the calibration crank from its storage stob.

Store the retaining pin on the stob.

5. Place the hex socket of the crank on the end of the

gearbox input jackshaft (see page 2).

6. Pull the seed hoses off the top of three opener seed

tubes, at the top of the openers. Place the hoses into

each sample container.

7. If not already done, set the Drive Type, Seed Rate

Handle and Seed Cup Doors across the drill. If any

optional seed boxes are loaded, disconnect their

drive or set their rate to zero (unless you are

simultaneously calibrating multiple boxes).

8. Load seed above the rows to be sampled. Load well

more than the expected sample size.

9. Rotate the crank or tire several turns to ensure that

the drives and seed cups are engaged, working

properly, free from foreign material, and that seed is

flowing steadily from the meters. Stop.

10. Note the current reading of the acremeter, unless

you do not plan to rely on it for the calibration.

11. Empty the sample containers back into the seed box,

and place them back under the three hoses to gather

metered seed.

Example: 3 containers, each weighing 0.5lb:

ContainerWeight = 1.5 lb

Crushing Hazard:

Install lift cylinder lock(s) on a raised drill.

Note: You can also rotate the tire, the gauge wheel

jackshaft or the gear box jackshaft. If using a

non-standard rotating/cranking point, rely on the

acremeter to determine the area simulated.

Example: you desire to plant barley at:

60 pounds per acre

which is between

45 and 50

on the Drive Type 2 chart.

Use an initial Seed Rate Handle (InitialHandle) scale

setting of:

48

151-143B Table of Contents Main Box Rates 2011-10-21

Page 9

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Main and Dual Box Seed Rate 7

12. Turn crank at a steady rate for the number of turns

specified on page 2, or until one tenth acre or

hectare is tallied on acremeter. While turning, check

that cups have ample seed coming into them.

13. Weigh metered seed. Subtract initial weight of

container(s).

NetWeight GrossWeight ContainerWeight–=

14. Divide the net seed weight by three. Multiply by

number of openers on your drill, and then by ten, to

determine the total of pounds per acre seeded.

NetWeight

MeasuredRate

--------------------------------------

SampledRows

OpenerCount× 10×=

15. The Seed Rate Handle scale is a percentage of

meter opening, and its effect is linear near scale

center. Calculate a new scale setting based on the

test.

Set the Seed Rate Handle to the new scale setting.

16. You may want to repeat calibration procedure at the

new setting if your results varied greatly from the

Seed Rate Chart, or if you must operate near the

ends of the Seed Rate handle scale (0-20 or

90-100).

TargetRate

NewScale

-------------------------------------- -

MeasuredRate

PreviousScale×=

3P806NT crank rotations for1⁄

10

th

acre:

31

Example: the containers weighed a total of

2.98 pounds after test. NetWeight is:

1.48 lbs net

1.48 2.98 1.5–=

Example: MeasuredRate is:

64 lbs/ac

1.48

64.3

-----------

3

13 10××=

For example:

the target rate was 60 lbs/ac, and the initial scale 48:

the NewScale setting is:

45

60

44.8

------

64

48×=

17. With calibration complete, store calibration crank,

reinstall any removed chains or sprockets and

reconnect seed hoses.

18. Check that your tire(s) is(are) properly inflated. See

“Tire Inflation Chart” in Operator manual.

When drilling, check seeding rate by noting acres drilled,

amount of seed added to drill and seed level in drill box.

If you are seeding more or less than desired, adjust rate

slightly to compensate for field conditions.

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 10

8 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Rate Charts, Main Seed Box

Charts in U.S. customary units.

Metric charts begin on page 33.

Alfalfa (Medicago sativa)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 4.6 6.7 9.1 12 15 18 21 25 28 32 36 39 43 47 50 54 57 61 64 66

Drive Type: 2 Seed Rate in Pounds Per Acre

0 9.5 14 19 24 30 37 44 51 58 66 73 81 89 96 104 111 118 125 131 136

Drive Type: 3 Seed Rate in Pounds Per Acre

015222937465565758697108119130141151162171180189196

Drive Type: 4 Seed Rate in Pounds Per Acre

0 25 35 47 60 75 90 106 123 140 158 176 194 212 230 247 264 279 294 308 320

(based on 60 pounds/bushel)

32291C

Bahia Grass (Paspalum notatum)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 2.2 3.1 4.5 6.3 8.5 11 14 17 20 23 27 30 33 37 40 43 46 48 50 52

Drive Type: 2 Seed Rate in Pounds Per Acre

0 4.4 6.4 9.3 13 18 23 28 35 41 48 55 62 69 76 82 88 94 99 104 107

Drive Type: 3 Seed Rate in Pounds Per Acre

0 6.6 10 14 20 26 34 43 52 62 72 82 93 103 113 123 132 141 149 156 161

Drive Type: 4 Seed Rate in Pounds Per Acre

01116233243567085101117134151168185201216230243254263

Barley (Hordeum vulgare)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 4.7 6.3 8.4 11 14 17 20 24 27 31 35 39 42 45 49 51 54 56 57 58

Drive Type: 2 Seed Rate in Pounds Per Acre

01013172228354249566472798693100105110115118120

Drive Type: 3 Seed Rate in Pounds Per Acre

014192634435262728394105116126137147156165173180186

Drive Type: 4 Seed Rate in Pounds Per Acre

0 22 32 43 56 70 85 101 118 135 153 171 189 206 223 239 255 269 282 293 303

(based on 40 pounds/bushel)

32292C

(based on 51 pounds/bushel)

32293C

151-143B Table of Contents Main Box Rates 2011-10-21

Page 11

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Main and Dual Box Seed Rate 9

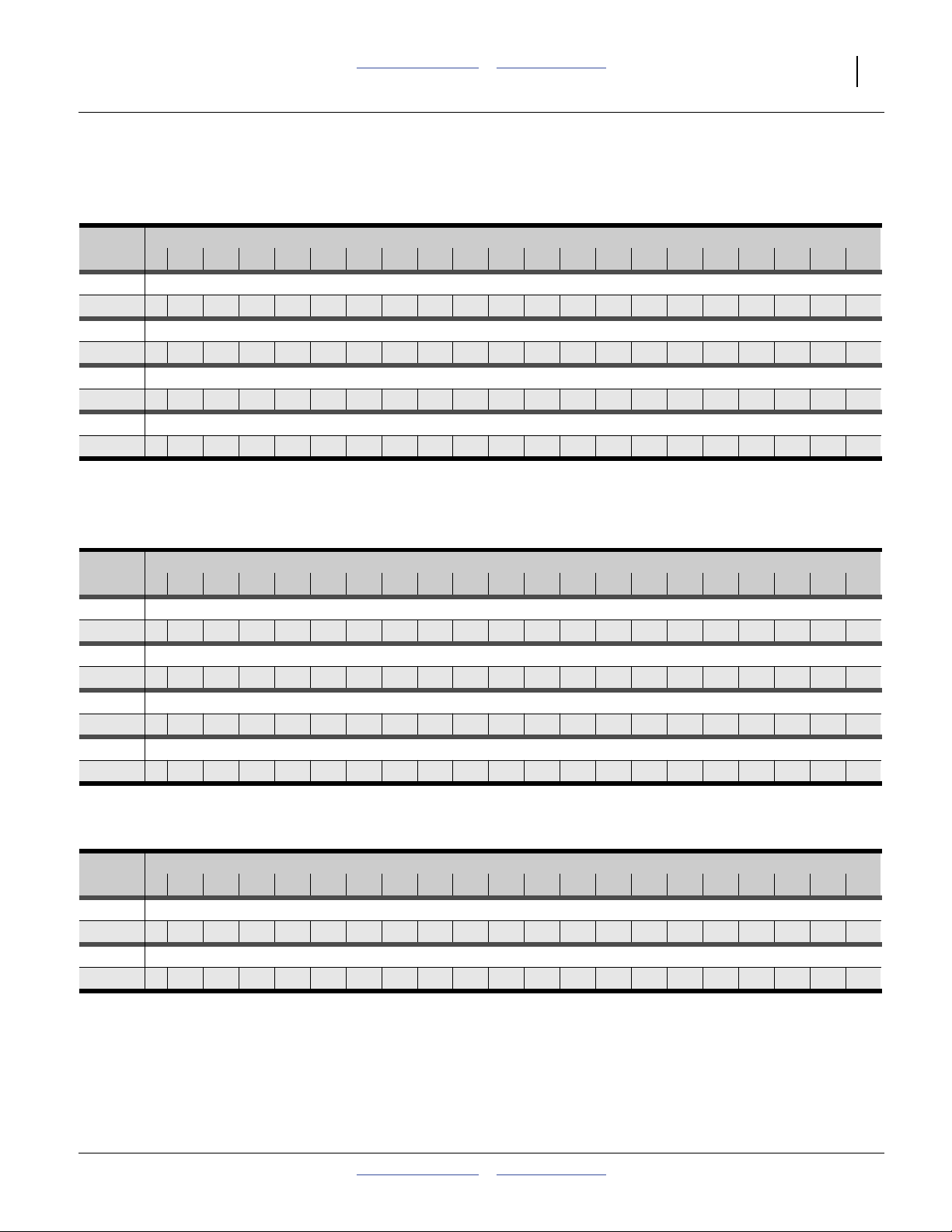

Rate Charts, Main Seed Box, continued...

Buckwheat (Fagopyrum esculentum)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 3.9 5.7 7.9 10 13 16 20 23 27 30 34 37 41 44 47 50 52 54 55 57

Drive Type: 2 Seed Rate in Pounds Per Acre

0 8.0 12 16 22 27 34 41 48 55 62 70 77 84 90 96 102 107 111 114 116

Drive Type: 3 Seed Rate in Pounds Per Acre

015182431394960728597110123136148159170179187192197

Drive Type: 4 Seed Rate in Pounds Per Acre

0 24 30 39 50 64 80 98 118 138 159 180 201 222 241 260 277 292 304 314 320

Buffalograss (Buchloe dactyloides)

(based on 48 pounds/bushel)

32295C

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

01.21.92.94.05.36.68.09.4111214151617181920202020

Drive Type: 2 Seed Rate in Pounds Per Acre

02.44.06.08.311141619222528313336383940414141

Drive Type: 3 Seed Rate in Pounds Per Acre

0 4.4 6.4 8.9 12 16 20 24 28 33 37 42 46 50 54 57 60 62 63 63 63

Drive Type: 4 Seed Rate in Pounds Per Acre

0 7.2 10 15 20 26 32 39 46 54 61 68 75 82 88 93 97 101 103 103 103

Bermuda Grass (Cynodon dactylon)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 1.8 3.5 5.3 7.2 9.1 11 13 15 17 19 21 23 25 27 29 31 33 35 36 38

Drive Type: 2 Seed Rate in Pounds Per Acre

03.67.2111519232731353943475155596367717578

Drive Type: 3 Seed Rate in Pounds Per Acre

0 5.7 11 17 22 28 34 40 46 52 58 64 70 76 81 87 92 97 102 107 112

Drive Type: 4 Seed Rate in Pounds Per Acre

0 9.3 18 27 36 46 55 65 75 85 94 104 114 123 132 141 150 159 167 175 182

(based on 23 pounds/bushel)

32296C

(based on 60 pounds/bushel)

32294C

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 12

10 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Rate Charts, Main Seed Box, continued...

K-31 Fescue (Festuca)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 1.9 2.9 4.0 5.2 6.4 7.7 9.0 10 12 13 14 16 17 18 19 20 21 21 22 23

Drive Type: 2 Seed Rate in Pounds Per Acre

0 3.9 5.9 8.2 11 13 16 18 21 24 27 29 32 34 37 39 41 43 44 45 46

Drive Type: 3 Seed Rate in Pounds Per Acre

06.69.3121619232731353943475155586164676970

Drive Type: 4 Seed Rate in Pounds Per Acre

0111520253137445057647077838995100105109112115

Flax (Linum usitatissimum) or Sudan

(Sorghum bicolor subsp. drummondii)

(based on 21 pounds/bushel)

32297C

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 4.6 6.8 9.3 12 15 19 22 26 29 33 37 41 44 48 52 55 59 62 65 67

Drive Type: 2 Seed Rate in Pounds Per Acre

0 9.4 14 19 25 31 38 45 53 60 68 76 84 91 99 107 114 121 127 133 139

Drive Type: 3 Seed Rate in Pounds Per Acre

014212937465666768697108118129140150160169179187195

Drive Type: 4 Seed Rate in Pounds Per Acre

0 23 35 47 61 75 91 107 124 141 158 175 193 210 228 244 261 276 291 305 318

Eastern Gamma Grass - Pete

(Tripsacum dactyloides)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

03.85.37.09.011141619212426293134363840414243

Drive Type: 2 Seed Rate in Pounds Per Acre

0 7.9 11 14 18 23 28 33 38 44 49 54 60 65 69 74 78 81 84 86 88

(based on 55 pounds/bushel)

32298C

32299C

151-143B Table of Contents Main Box Rates 2011-10-21

Page 13

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Main and Dual Box Seed Rate 11

Rate Charts, Main Seed Box, continued...

Kentucky Blue Grass (Poa pratensis)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 1.5 2.1 2.9 3.7 4.6 5.6 6.7 7.7 8.8 10 11 12 13 14 15 16 17 17 18 18

Drive Type: 2 Seed Rate in Pounds Per Acre

03.04.45.97.710121416182023252729313334353737

Drive Type: 3 Seed Rate in Pounds Per Acre

04.87.2101215182124273033363942444749515355

Drive Type: 4 Seed Rate in Pounds Per Acre

0 7.9 12 16 20 25 29 34 39 44 49 54 59 63 68 72 76 80 83 87 89

Millet (Pennisetum glaucum, Setaria italica,

Panicum miliaceum, Eleusine coracana)

(based on 23 pounds/bushel)

32300C

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 4.8 6.8 9.2 12 15 18 21 25 28 32 35 39 42 46 49 52 55 58 60 62

Drive Type: 2 Seed Rate in Pounds Per Acre

01014192430374351586573808794101107113118123127

Drive Type: 3 Seed Rate in Pounds Per Acre

014202836455565768798109120131141151161170178185191

Drive Type: 4 Seed Rate in Pounds Per Acre

0 22 33 45 59 74 90 107 124 142 160 178 196 213 230 247 262 277 290 301 311

Milo (Sorghum)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

04.67.1101417222631364045505560646872757880

Drive Type: 2 Seed Rate in Pounds Per Acre

0 9.4 15 21 28 36 44 54 63 73 83 93 103 113 122 131 140 148 154 160 165

(based on 60 pounds/bushel)

32301C

(based on 60 pounds/bushel)

32302C

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 14

12 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Rate Charts, Main Seed Box, continued...

Oats (Avena sativa)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 1.8 3.1 4.5 6.1 7.8 10 12 14 16 18 20 22 24 26 28 30 32 33 35 36

Drive Type: 2 Seed Rate in Pounds Per Acre

0 3.7 6.3 9.2 13 16 20 24 28 32 37 41 46 50 54 58 62 65 69 71 74

Drive Type: 3 Seed Rate in Pounds Per Acre

0 6.8 10 14 18 24 30 36 43 50 57 64 71 78 84 90 96 101 105 109 111

Drive Type: 4 Seed Rate in Pounds Per Acre

011162230394859708193104115127137147156164171177181

Orchard Grass Potomac (Dactylis glomerata)

(based on 37 pounds/bushel)

32303C

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 1.1 1.5 2.0 2.7 3.3 4.1 4.9 5.8 6.7 7.6 8.5 9.4 10 11 12 13 13 14 14 15

Drive Type: 2 Seed Rate in Pounds Per Acre

02.33.14.25.56.98.51012141618192123252627282930

Drive Type: 3 Seed Rate in Pounds Per Acre

03.34.66.17.910121417202225273032353739414344

Drive Type: 4 Seed Rate in Pounds Per Acre

05.47.4101316202428323640454953576164677072

Peas (Pisum sativum)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 2.1 5.2 8.7 13 17 21 26 30 35 40 44 49 53 57 61 64 67 70 72 73

Drive Type: 2 Seed Rate in Pounds Per Acre

0 4.4 11 18 26 34 43 53 62 72 81 91 100 109 117 125 132 138 143 147 150

Drive Type: 3 Seed Rate in Pounds Per Acre

0 3.2 12 22 33 45 58 71 84 98 112 125 138 151 163 174 184 192 199 205 209

Drive Type: 4 Seed Rate in Pounds Per Acre

0 5.2 20 36 54 74 94 116 138 160 182 204 225 246 265 283 299 313 325 334 341

(based on 18 pounds/bushel)

32304C

(based on 61 pounds/bushel)

32305C

151-143B Table of Contents Main Box Rates 2011-10-21

Page 15

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Main and Dual Box Seed Rate 13

Rate Charts, Main Seed Box, continued...

Pinto Beans (Phaseolus vulgaris)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

04.16.8101418222732374247525660646871737576

Drive Type: 2 Seed Rate in Pounds Per Acre

0 8.5 14 21 28 37 46 56 65 76 86 96 106 115 124 132 140 146 151 155 157

Drive Type: 3 Seed Rate in Pounds Per Acre

01422314254678195109124139153167180192203213221227231

Drive Type: 4 Seed Rate in Pounds Per Acre

0 23 35 51 68 88 109 131 155 178 203 226 250 272 294 313 331 347 360 369 376

Rape (Brassica napus)

(based on 61 pounds/bushel)

32306C

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 4.2 6.2 8.5 11 14 16 19 22 25 28 31 34 37 40 43 46 49 52 54 56

Drive Type: 2 Seed Rate in Pounds Per Acre

0 8.6 13 18 23 28 34 39 45 52 58 64 70 77 83 89 95 101 106 111 116

Drive Type: 3 Seed Rate in Pounds Per Acre

01318253139475665758494104113122131139147154161166

Drive Type: 4 Seed Rate in Pounds Per Acre

0 22 30 40 51 64 77 91 106 122 137 153 169 184 199 214 227 240 252 262 271

Rice, Long Grain (Oryza sativa indica)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

00.93.35.88.311141619212426293133353739404142

Drive Type: 2 Seed Rate in Pounds Per Acre

01.86.7121722283339444954596468727679828587

Drive Type: 3 Seed Rate in Pounds Per Acre

0 3.0 10 18 25 33 40 48 56 63 71 78 85 92 99 106 113 119 125 130 136

Drive Type: 4 Seed Rate in Pounds Per Acre

0 4.9 17 29 41 53 66 78 91 103 115 127 139 151 162 173 183 194 203 213 221

(based on 51 pounds/bushel)

32307C

(based on 47 pounds/bushel)

32308C

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 16

14 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Rate Charts, Main Seed Box, continued...

Rice, Short Grain (Oryza sativa japonica,

Oryza sativa sinica)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

02.54.66.99.312141720232528313336384042444647

Drive Type: 2 Seed Rate in Pounds Per Acre

05.29.5141924303541475258636974798387919497

Drive Type: 3 Seed Rate in Pounds Per Acre

0111621283543515968778594102110117123128133136138

Drive Type: 4 Seed Rate in Pounds Per Acre

01826354557708397111125139153166179190200209217222225

(based on 43 pounds/bushel)

32309C

Rye (Secale cereale)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

03.86.6101418222731364146515661656973767981

Drive Type: 2 Seed Rate in Pounds Per Acre

0 7.8 14 20 28 36 45 55 65 75 85 95 105 115 124 133 142 149 156 162 167

Drive Type: 3 Seed Rate in Pounds Per Acre

01321314254678196111126142157173188202216228240250259

Drive Type: 4 Seed Rate in Pounds Per Acre

0 22 35 50 68 88 109 132 156 181 206 231 257 282 306 329 352 372 391 407 422

Perennial Rye Grass - Palmer

(Lolium perenne, Lolium multiflorum)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 2.4 3.6 4.9 6.3 7.9 10 11 13 15 17 19 21 22 24 26 27 29 30 31 31

Drive Type: 2 Seed Rate in Pounds Per Acre

04.97.3101316202327313539424650535659616365

Drive Type: 3 Seed Rate in Pounds Per Acre

010121519242935414754616773798590949799101

Drive Type: 4 Seed Rate in Pounds Per Acre

01619243138475767778899109120129138146153158162164

(based on 57 pounds/bushel)

32310C

(based on 36 pounds/bushel)

32311C

151-143B Table of Contents Main Box Rates 2011-10-21

Page 17

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Main and Dual Box Seed Rate 15

Rate Charts, Main Seed Box, continued...

Soybeans (Glycine max)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

04.06.9101418222631354044495357616467707274

Drive Type: 2 Seed Rate in Pounds Per Acre

0 8.3 14 21 29 37 45 54 63 73 82 91 100 109 117 125 132 139 144 149 152

Drive Type: 3 Seed Rate in Pounds Per Acre

01121314355678093106120133146158170182193203212220228

Drive Type: 4 Seed Rate in Pounds Per Acre

0 18 34 51 70 89 110 131 152 173 195 216 237 258 278 297 314 331 346 359 371

Sunflower (Helianthus annuus)

(based on 58 pounds/bushel)

32312C

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

00.31.73.24.86.58.31012141618202223252728303132

Drive Type: 2 Seed Rate in Pounds Per Acre

0 0.6 3.4 6.5 10 13 17 21 25 29 33 37 41 44 48 52 55 58 61 64 66

Drive Type: 3 Seed Rate in Pounds Per Acre

0 2.5 5.4 9.0 13 17 22 27 33 38 44 50 55 61 66 71 76 80 84 88 90

Drive Type: 4 Seed Rate in Pounds Per Acre

04.18.91521283645546372819099108116124131137143147

Tiffany Teff, Coated (Erogrostis tef)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 4.0 6.3 8.8 12 14 18 21 24 28 31 35 39 43 47 51 54 58 62 65 69

Drive Type: 2 Seed Rate in Pounds Per Acre

0 8.3 13 18 24 30 36 43 50 57 65 72 80 88 96 104 112 119 127 134 142

Drive Type: 3 Seed Rate in Pounds Per Acre

012192736455464758697109120132144156167179190202212

Drive Type: 4 Seed Rate in Pounds Per Acre

0 20 32 44 58 73 88 105 122 140 158 177 196 215 235 254 273 292 311 329 346

(based on 28 pounds/bushel)

32313C

(based on 65 pounds/bushel)

32314C

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 18

16 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Rate Charts, Main Seed Box, continued...

Wheat (Triticum)

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

07.18.9111418222630354045505559646872757880

Drive Type: 2 Seed Rate in Pounds Per Acre

01518232937455363728293103113122131140147154159164

Drive Type: 3 Seed Rate in Pounds Per Acre

01826344455688094108122136150164177190201212222230236

Drive Type: 4 Seed Rate in Pounds Per Acre

0 30 42 56 72 90 110 131 153 176 199 222 245 267 289 309 329 346 362 375 385

Wheatgrass (Pascopyrum smithii,

Agropyron elongatum)

(based on 64 pounds/bushel)

32315C

Seed Rate Handle Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Drive Type: 1 Seed Rate in Pounds Per Acre

7.5 in

7.5 in

7.5 in

7.5 in

0 0.9 1.7 2.4 3.2 4.0 4.9 5.8 6.6 7.5 8.4 9.3 10 11 12 13 14 14 15 16 16

Drive Type: 2 Seed Rate in Pounds Per Acre

0 1.9 3.4 4.9 6.6 8.3 10 12 14 15 17 19 21 23 25 26 28 29 31 32 33

Drive Type: 3 Seed Rate in Pounds Per Acre

0 3.5 5.3 7.4 10 12 15 17 20 23 25 28 31 33 36 39 41 43 45 47 49

Drive Type: 4 Seed Rate in Pounds Per Acre

05.78.7121620242832374146505559636770747779

(based on 23 pounds/bushel)

32316C

151-143B Table of Contents Main Box Rates 2011-10-21

Page 19

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates 17

Native Grass Rate

Setting Native Grass Seed Rate

The Series II Native Grass Box is for seeding fluffy,

native grass blends like Big Blue Stem, Indian Grass,

and Side Oats Grama.

Refer to Figure 7

Native Grass mixes are too variable for seed rate tables

to be useful. Seeding rate for Native Grass is determined

by calibration, and set by:

• Drive Type handle at the ground drive gearbox ,

• Driven sprocket at the Native Grass box, using a

sprocket from the storage tree , and;

• Rate Reduction kit (See manual 202-583M), using

an alternate set of ground drive gearbox output and

Native Grass jackshaft input sprockets.

Great Plains recommends that you calibrate and adjust

your drill to help insure an accurate seeding rate. Fine

rate adjustment is done with the Driven sprocket.

1 a

2

b

3

Native Grass Rate Calibration

Before completing these steps, review “Calibration

Overview” on page 2.

This Native Grass calibration works on any type of native

grass no matter what seed type, weight, or density. It

also does not require any particular initial drive setup.

The drill’s revolutions-per-acre at the native grass cup

allows you to calibrate the output in pounds by cup

sprocket revolution per acre.

The pounds per acre in the seed charts are based on

drills with 5.70-8 8-Ply ground drive tires. Be certain that

your tires are properly inflated (see Operator Manual).

To calibrate seed mix:

1. Know your intended field seeding rate in pounds per

acre.

2. Raise drill and install lift-assist lock(s).

3. Rotate the right ground drive wheel to see that feed

cups and drive are working properly and are free

from foreign matter.

4. Record the weight of one or more empty containers

large enough to hold seed metered from three rows

of the native grass box.

Refer to Figure 2 on page 2

5. Remove the calibration crank from its storage stob

on the left top side of the main toolbar.

2

b

1

3

a

Figure 7

Native Grass Rate Control

Seeding Rate Risk:

Calibrate. All native grass mixes vary in weight, seed type, and

density. You must calibrate each mix.

Factors that affect seeding rates are: weight of seed, size of

seed, relative humidity and moisture content of the seed, ratio

of inert material to seed, different proportions of seed types

affecting density, tire configuration, tire pressure, and tire

slippage. The charts in this manual are based on factory tires

at recommended inflation.

For example:

You desire to plant at a TargetRate of:

32

pounds per acre

For example:

3 containers each weigh:

1.5 lb

or a total of:

4.5 lb.

28378

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 20

18 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Refer to Figure 2 on page 2

6. At the right main (Native Grass) gearbox input

jackshaft, place the hex socket of the crank on

whichever end allows most convenient full crank

rotations.

7. Fill three or more Native Grass compartments at

least1⁄2 full of seed. Pull seed hoses off openers

under those compartments.

8. Turn gauge wheel or crank several times to fill seed

cups with seed. Turn wheel or crank until seed falls

to the ground from each cup.

9. Place empty container(s) under the seed tubes to

gather the seed as it is metered.

1

Refer to Figure 8 and Figure 9

10. Note the Drive Type and Native Grass driven

sprocket . Also establish whether or not optional

2

1

Native Grass Rate Reduction is installed. This

information is needed for step 12 and for the

calculations later.

Note: If you are planting a mix similar to mixes planted in

the past with this drill, set the Drive Type and final

sprocket for the previous mix.

11. Note the current reading of the acremeter, unless

you do not plan to rely on it for the calibration.

12. Rotate crank or ground drive tire for one acre or

hectare (see chart on page 2).

13. Check that the three seed cups have plenty of seed

coming into them.

Figure 8

Native Grass Drive Type 2

For example, the drill is presently configured for:

Drive Type: 2

Driven Sprocket: 20T

Standard Range: (no Rate Reduction)

2

Figure 9

Native Grass Driven Sprocket 20T

28374

28379

151-143B Table of Contents Main Box Rates 2011-10-21

Page 21

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Native Grass Rate 19

14. Calculate the area rate at current drill settings.

Weigh metered seed, and subtract the initial weight

of the container. Divide this number by SampleRows

(the number of cups measured, typically 3). Multiply

by the number of openers (which is less than 13 if

using alternate spacing)

NetWeight GrossWeight EmptyContainer s()–=

PoundsPerSeedCup

PoundsPerAcre PoundsPerSeedCup 13×=

NetWeight

----------------------------------

=

SampleRows

15. If the measured rate is within 3% of your desired field

rate, no further adjustment is necessary. Skip to

step 21.

The rate just measured is used to locate a new setting in

the Native Grass Cup Rate tables on page 20.

16. Calculate the revolutions needed for the target field

rate. Multiply the calibration revolution rate by the

ratio of desired to measured seeding rate. Divide the

rate just measured by the cup revolution rate (from

the tables) at the current drill settings.

TargetRate

FinalRevs RevolutionsPerAcre

-------------------------------------------

×=

PoundsPerAcre

For example, GrossWeight of containers & sample is:

13 pounds

The NetWeight (pounds) is:

8.5 = 13 - 4.5

The PoundsPerSeedCup per acre is:

2.83 = 8.5 ÷ 3

The PoundsPerAcre is:

36.8 = 2.83 x 13

In our example, the 36.8 lbs/ac rate is 115% of the

desired 32 lbs/ac rate, or 15% high. An adjustment is

indicated.

For example:

Drive Type 2, 20T Driven, and no Rate Reduction is a

cup shaft rate of:

139 RevolutionsPerAcre

The FinalRevs shaft rate needed for the target rate is

120.8 = 139 x 32 ÷ 36.8

17. Find this number (or the closest number to this) in

the drive setting chart. This gives Drive Type and

Native Grass sprocket sizes. If the setting needed is

below 50 revs/ac, the Rate Reduction kit is required.

18. Set the new Drive Type at the gearbox lever.

19. Remove the access panel at the right end of the

Native Grass box, and exchange the current Driven

sprocket for the new one (from the storage tree at

drill front).

20. As necessary, exchange installed sprockets at

gearbox with those from the Rate Reduction kit (see

instructions in kit).

You may want to repeat the calibration procedure if your

results vary greatly from the seed rate chart.

21. Remove the crank from the jackshaft and store it on

the stob.

22. When drilling, check the amount of seed you are

using by noting the acres drilled, amount of seed

added to drill, and the level of seed in the box. If you

suspect you are drilling more or less seed than

desired, and you have accurately calibrated the drill

to you seed, you may need to change your sprocket

arrangement to compensate for your field conditions.

Note: On older model drills, if all sprocket combinations

result in rates higher than desired, a Seed Rate

Reduction kit (202-580A) is available.

For example:

The closest setting to 120.8 revs/ac is:

120 (found in the Standard rate table)

which is a configuration of:

Drive Type: 2

Driven Sprocket: 23T

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 22

20 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Native Grass Meter Shaft Rates

These charts are used during calibration. They provide

rotations of the meter shaft per acre, and are not seed

rate charts. For metric charts, see page 45.

Once the pounds per shaft revolution is known for your

seed mix, the charts provide the Transmission, Drive

Type, and Final Sprocket required.

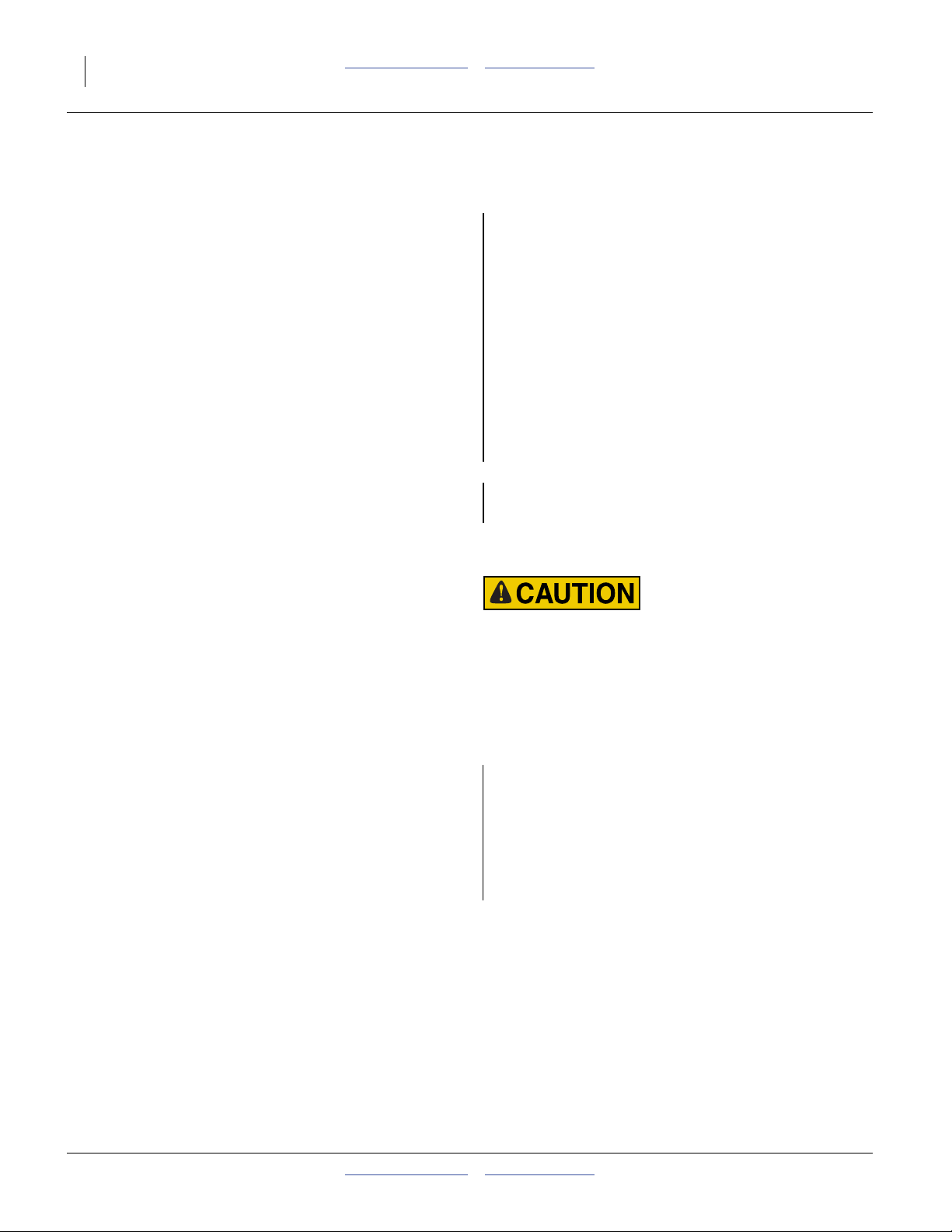

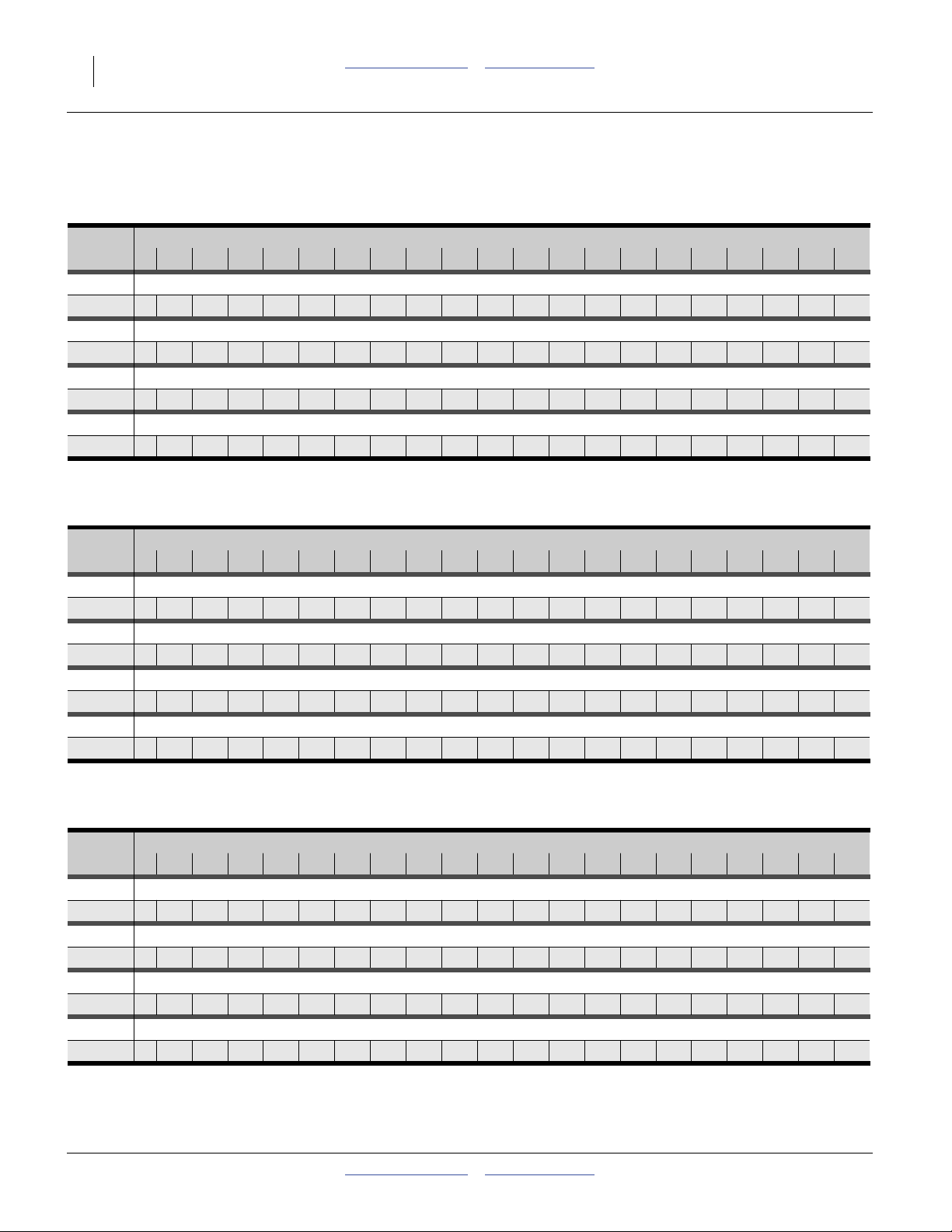

Standard Shaft Rates

Native Grass Driven Sprocket (Standard Rate)

Drive

Type

196.389.984.279.374.970.967.464.261.358.6

2 198 185 173 163 154 146 139 132 126 120

3 297 277 260 244 231 219 208 198 189 181

4 484 452 424 399 377 357 339 323 308 295

14T 15T 16T 17T 18T 19T 20T 21T 22T 23T

Native Grass Cup Revolutions Per Acre

32343A

Shaft Rates with Seed Rate Reduction

Native Grass Driven Sprocket (with Rate Reduction Kit)

Drive

Type

154.450.847.644.842.340.138.136.334.633.1

2 112 104 97.9 92.1 87.0 82.4 78.3 74.6 71.2 68.1

3 168 157 147 138 130 124 117 112 107 102

4 274 255 239 225 213 202 192 182 174 167

The Native Grass attachment includes, as standard

equipment, an agitator.

14T 15T 16T 17T 18T 19T 20T 21T 22T 23T

Native Grass Cup Revolutions Per Acre

32343B

Equipment Damage Risk:

Do not transport with seed loaded in the Native Grass box.

Load seed at field. Transport with seed loaded compacts the

seed at the meter inlets and can easily clog agitators and

meters. Drive system operation in the field can then damage

the agitator and drive components.

Seed Lubricant

Add graphite seed lubricant after loading seed in the

Native Grass box. For humid planting environments,

double or triple graphite as needed. Use1⁄3cup (80 mL)

across the top of the seed mix. Graphite part numbers:

821-042C 1 pound (0.45 kg) bottle

821-060C 5 pound (2.3 kg) jug

Native Grass Agitator Series II

When drilling, check the amount of seed you are using

by noting the acres drilled, amount of seed added to drill,

and the level of seed in the box. If you suspect you are

drilling more or less seed than desired, and you have

accurately calibrated the drill to your seed, change your

sprocket arrangement to compensate for your field

conditions.

151-143B Table of Contents Main Box Rates 2011-10-21

Figure 10

25041

Page 23

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Native Grass Rate 21

Brome Grass Seeding

When the seeding material is strictly brome grass, you

can set an initial rate based on the tables following, and

then calibrate. You can also use the procedure for mixes

(page 17), but what follows is usually easier.

Refer to Figure 11

1. Find the desired pounds per acre on the Brome

Grass Rate Charts on page 23. Determine which

Drive Type and Final Drive sprocket are required,

and for low rates, if Seed Rate Reduction is needed.

2. Set the Drive Type with the gearbox handle (see

“Setting Drive Type” on page 3).

3. Install the sprocket from storage on the right-hand

side of the Native Grass box. To change sprockets,

loosen the chain idlers and remove chain. Replace

with desired sprocket.

4. Fill three or more compartments at least half full of

seed at the outboard end of the box. Pull seed tubes

off the openers at rows to be sampled. This example

assumes three rows are used.

5. To perform this calibration, you need a scale that is

accurate at the aggregate sample size, and three (3)

light containers, each capable of holding the

expected SamplePerRow. Record the empty

container weights. The total is ContainerWeight.

6. Estimate the sample sizes. This example simulates a

full acre.

TargetRate

SamplePerRow

ExpectedSample SamplePerRow SampledRows×=

------------------------------

=

RowCount

7. Raise the drill so the gauge wheel is out of ground

contact.

8. Remove the calibration crank from its storage stob.

Store the retaining pin on the stob.

9. Place the hex socket of the crank on the gearbox

input jackshaft (see page 2).

10. If the Main Box or optional Small Seeds box are

loaded, disconnect their drive or set their rates to

zero (unless you are simultaneously calibrating

multiple boxes).

11. Rotate the crank several turns to ensure that the

drives and seed cups are engaged, working properly,

free from foreign material, and that seed is flowing

steadily from the meters. Stop.

12. Note the current reading of the acremeter, unless

you do not plan to rely on it for the calibration.

13. Empty the sample containers back into the seed box,

and place them back under the three hoses to gather

metered seed.

Figure 11

Native Grass Final Drive Sprocket

Example: You want to apply brome at a TargetRate of

121⁄4 pounds per acre. The nearest chart rate is:

12.0

Standard Transmission,

Drive Type: 2

Final Drive: 22T

Example: 3 containers, each weighing 8 oz. (1⁄2 lb.).

ContainerWeight is 1.5 lb:

1.5 = 3 x 0.5

SamplePerRow is 0.92 pounds:

12.25

=

--------------

13

0.94

ExpectedSample is 2.8 pounds:

2.8 0.92 3×=

Crushing Hazard:

Install lift cylinder lock(s) on a raised drill.

18670

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 24

22 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

14. Turn crank at a steady rate for the number of turns

specified on page 2, or until one acre or hectare is

tallied on acremeter. While turning, check that cups

have ample seed coming into them.

15. Weigh metered seed. Subtract initial weight of

container(s).

NetWeight GrossWeight ContainerWeight–=

16. Divide the sample NetWeight by SampleRows (the

number of row sampled, typically 3). Multiply by

number of openers on your drill to determine the

total of pounds per acre seeded.

NetWeight

MeasuredRate

--------------------------------------

SampleRows

OpenerCount×=

17. If the calibration sample is more than a few percent

different than the desired FieldRate, pick a new chart

rate based on the difference factor.

TargetRate

NewChart

-------------------------------------- -

MeasuredRate

PreviousChart×=

18. Find the chart rate closest to NewChart. Change the

Final Drive sprocket and Drive Type as needed. If the

correction went off the Standard chart to the low

side, consider installing the Rate Reduction kit.

19. You may want to repeat calibration procedure at the

new setting if your results varied greatly from the

Seed Rate Chart.

When drilling, check the amount of seed you are using

by noting the acres drilled, amount of seed added to drill,

and the level of seed in the box. If you suspect you are

drilling more or less seed than desired, and you have

accurately calibrated the drill to your seed, you may need

to change your sprocket arrangement to compensate for

your field conditions.

3P806NT crank rotations for 1 acre:

656

Example: the containers weighed a total of 7.66

pounds after test. NetWeight is 3.16 pounds.

3.16 7.66 4.5–=

Example: MeasuredRate is:

13.7 lbs/ac

3.16

13.7

-----------

3

13×=

Example:

TargetRate = 12.25

PreviousChart = 12.0

MeasuredRate = 13.7

The new chart rate is:

NewChart = 10.7 pounds per acre

12.25

10.7

--------------

13.7

12.0×=

The nearest Standard chart rate to 10.7 is 11.0, or

Drive Type: 2

Final Sprocket: 24T

Alternatively, you could use the Reduced Rate chart,

which has a 10.5 rate setting at Drive Type 3, 22T.

151-143B Table of Contents Main Box Rates 2011-10-21

Page 25

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Native Grass Rate 23

Brome Rate Charts

Factors which will affect seeding rates are: weight of

seed, size of seed, relative humidity and moisture

content of seed, ratio of inert material to seed, different

proportions of seed types affecting density, tire

configuration, tire pressure, and tire slippage. Seed

mixes vary.

Field Results Risk:

The charts are to be used as a reference to your own brome

grass mix. All brome grass mixes vary so this is why you must

calibrate each mix using the chart only as a starting point.

The rates are based on a 5.70-8 8-Ply tire inflated to

factory specification (see Operator Manual).

For metric charts, see page 46.

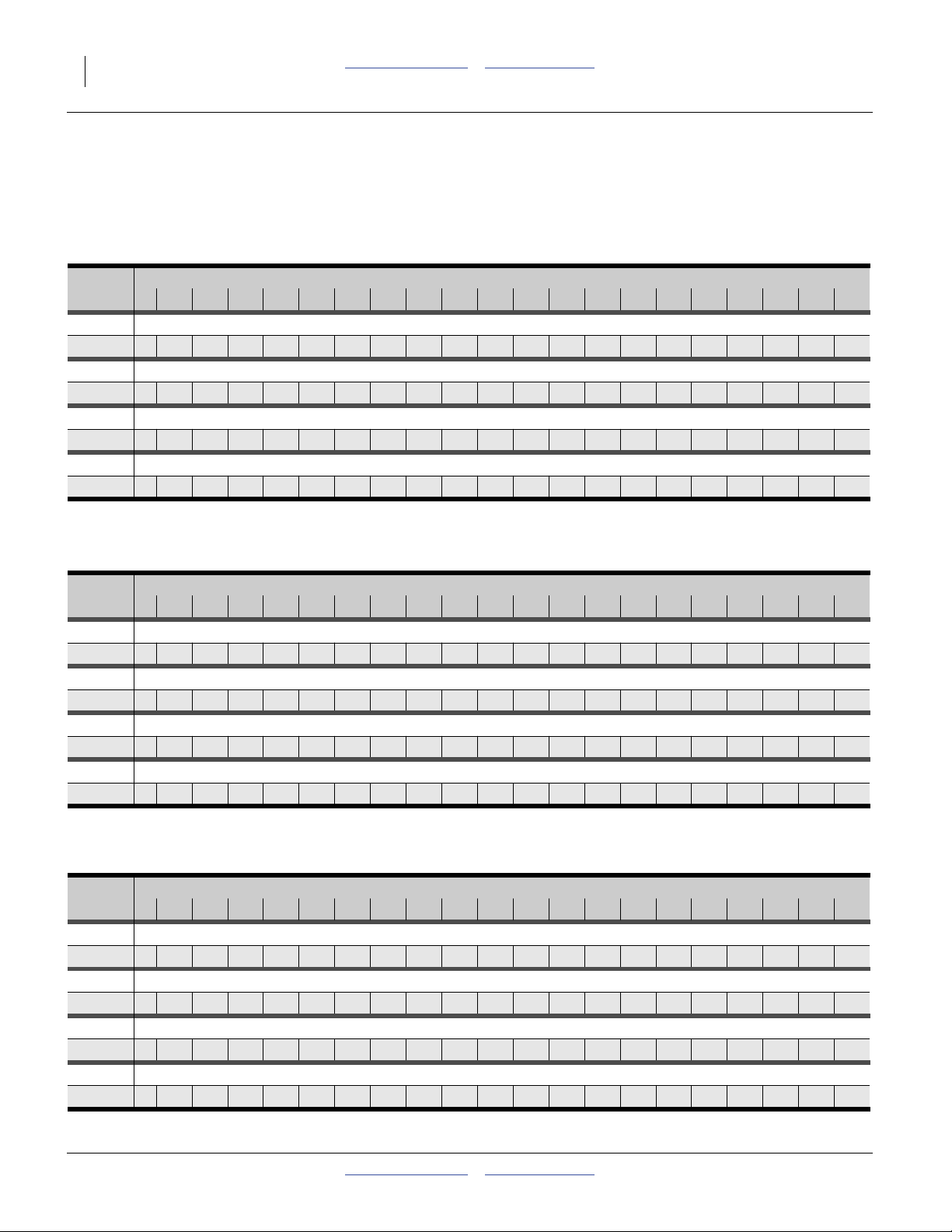

Standard Brome Rates

Native Grass Driven Sprocket (Standard Rate)

Drive

Type

1 8.6 8.1 7.6 7.2 6.8 6.4 6.1 5.9 5.6 5.4

217.716.515.614.713.913.212.612.011.511.0

326.524.823.422.120.919.918.918.117.316.5

443.240.538.136.034.132.430.829.428.227.0

15 16 17 18 19 20 21 22 23 24

Brome Grass Seeding Rate in Pounds per Acre

32336A

Reduced Brome Rates

Native Grass Driven Sprocket (with Rate Reduction Kit)

Drive

Type

1 5.0 4.7 4.4 4.2 3.9 3.7 3.5 3.4 3.2 3.1

2 10.3 9.6 9.0 8.5 8.1 7.7 7.3 7.0 6.7 6.4

315.414.413.612.812.111.511.010.510.0 9.6

425.023.522.120.919.818.817.917.016.315.6

15 16 17 18 19 20 21 22 23 24

Brome Grass Seeding Rate in Pounds per Acre

32336B

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 26

24 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Small Seeds Rate

Seeding rate from the optional Small Seeds Attachment

is controlled entirely by the seed rate handle on the small

seeds box. No sprocket changes are required, and small

seeds rate is unaffected by settings for the main seed

box or other optional boxes.

Refer to Figure 12

To set Small Seeds rate, loosen the wing nut at the

handle. Move the lever until the indicator is about 10

2

higher than the intended setting, then return it to that

setting. Tighten nut.

Set the initial rate based on the charts on page 27 and

page 28.

Small Seeds Rate Calibration

Differences will exist between the tested seed and field

conditions used to generate the Small Seeds Rate

Charts, and your seed and conditions. To accurately

achieve your target population, Great Plains

recommends calibrating.

Due to the large number of crank revolutions per acre

(310 or 569) and per hectare (766 or 1405), a practical

calibration is a simulation of1⁄

1. Estimate the sample sizes.

TargetRate

RateSample

SamplePerRow

-----------------------------

=

=

10

RateSample

----------------------------------- -

RowCount

th

acre or1⁄

10

1

th

hectare.

10

2

1

Figure 12

Small Seeds Rate Handle

Example: You want to apply alfalfa at 12 pounds per

acre. RateSample is:

12

------

1.2

=

10

Example: SamplePerRow is

0.09 pounds:

1.2

0.092

-------

=

13

Example: 3 rows are to be used in the sampling.

ExpectedSample is:

0.28 pounds

32634

ExpectedSample SamplePerRow SampledRows×=

2. To perform this calibration, you need a scale that is

accurate near the aggregate sample size, and

0.277 0.092 3×=

Example: 3 containers each weighing 0.20 lb or:

0.60 lb total

three (3) light weight containers, each capable of

holding a row’s sample.

3. Raise the drill so the gauge wheel is out of ground

contact. If the gauge wheel is in ground contact,

cranking is difficult or impossible.

4. Remove the calibration crank from its storage stob.

Crushing Hazard:

Install lift cylinder lock(s) on a raised drill.

Store the retaining pin on the stob.

5. Rotate the crank or tire several turns to ensure that

the drives and seed cups are engaged, working

properly, free from foreign material, and that seed is

flowing steadily from the meters. Stop.

6. Pull the small seed hoses off the top of three opener

seed tubes, at the top of the openers. Place the

hoses into each sample container.

151-143B Table of Contents Main Box Rates 2011-10-21

Page 27

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Small Seeds Rate 25

7. If not already done, set the Small Seeds Rate

Handle.

8. Load seed above the rows to be sampled. Load well

more than the expected sample size.

9. Rotate the crank several turns to ensure that the

drives and seed cups are engaged, working properly,

free from foreign material, and that seed is flowing

steadily from the meters. Stop.

10. Note the current reading of the acremeter, unless

you do not plan to rely on it for the calibration.

11. Empty the sample containers back into the seed box,

and place them back under the three hoses to gather

metered seed.

12. Turn crank at a steady rate for the number of turns

specified on page 2, or until one tenth acre or

hectare is tallied on acremeter. While turning, check

that cups have ample seed coming into them.

13. Weigh metered material. Subtract initial weight of

container(s).

NetWeight GrossWeight ContainerWeights–=

14. Divide the net material weight by three. Multiply by

number of openers on your drill, and then by ten, to

determine the total of pounds per acre applied.

NetWeight

MeasuredRate

--------------------------------------

SampleRows

RowCount× 10×=

Example: planting alfalfa at 12 pounds/ac has an initial

small seeds rate handle setting of:

60

Crank rotations for one tenth acre is:

65.6

Example: the three containers weighed a total of

0.85 pounds after test, NetWeight is:

0.25 pounds

0.25 0.85 0.60–=

Example: MeasuredRate is:

10.8 lbs/ac, lower than the target rate of 12.

0.25

10.8

-----------

3

13× 10×=

15. Divide the desired original field rate by the measured

rate to calculate a scale adjustment factor.

FieldRate

CorrectionFactor

--------------------------------------

=

MeasuredRate

16. Multiply the scale setting just used times correction

factor to obtain the next scale setting to use.

NextScale PreviousS cale CorrectionFactor×=

17. Set the Small Seeds Rate Handle to the new scale

setting.

18. You may want to repeat calibration procedure at the

new setting if your results varied greatly from the

Seed Rate Chart, or if you must operate near the

ends of the Seed Rate handle scale (0-20 or

90-100).

19. Check that your tire(s) is (are) properly inflated. See

“Tire Inflation Chart” in the Operator manual.

20. With calibration complete, store calibration crank,

reinstall any removed chains or sprockets and

reconnect seed hoses.

For example: the target rate was 12 lbs/ac:

the CorrectionFactor is:

1.11

12

˙

1.11

-----------

=

10.8

For example: the previous scale setting was 60,

the NextScale setting is:

66.5

66.5 60 1.11×=

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 28

26 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

When drilling, check seeding rate by noting acres drilled,

amount of seed added to drill and seed level in drill box.

If you are seeding more or less than desired, adjust rate

slightly to compensate for field conditions.

Small Seeds Row Shut-Off

If alternate row spacing is required for small seeds,

optional plugs are available to block flow inside the seed

box tray.

1. Clean-out seed. The seed box must be empty prior

to inserting plugs. See “Small Seeds Box

Clean-Out” in Operator manual.

2. Before installing plugs, inspect the seed boxes for

existing factory-installed plugs. These are blocking

extra unused seed ports. You may want to identify

these plugs with an indelible marker.

3. Insert one plug at each row to shut off. Verify the

seed hose path before inserting the plug, as some

hoses do not make a strictly vertical drop to their row

units.

4. Review seed rate settings prior to planting. Perform

calibration calculations with the actual active row

count.

When removing plugs to restore rows to operation, be

sure to not disturb a factory-installed plug.

Figure 13

27407

Small Seeds Tube Plug

151-143B Table of Contents Main Box Rates 2011-10-21

Page 29

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates Small Seeds Rate 27

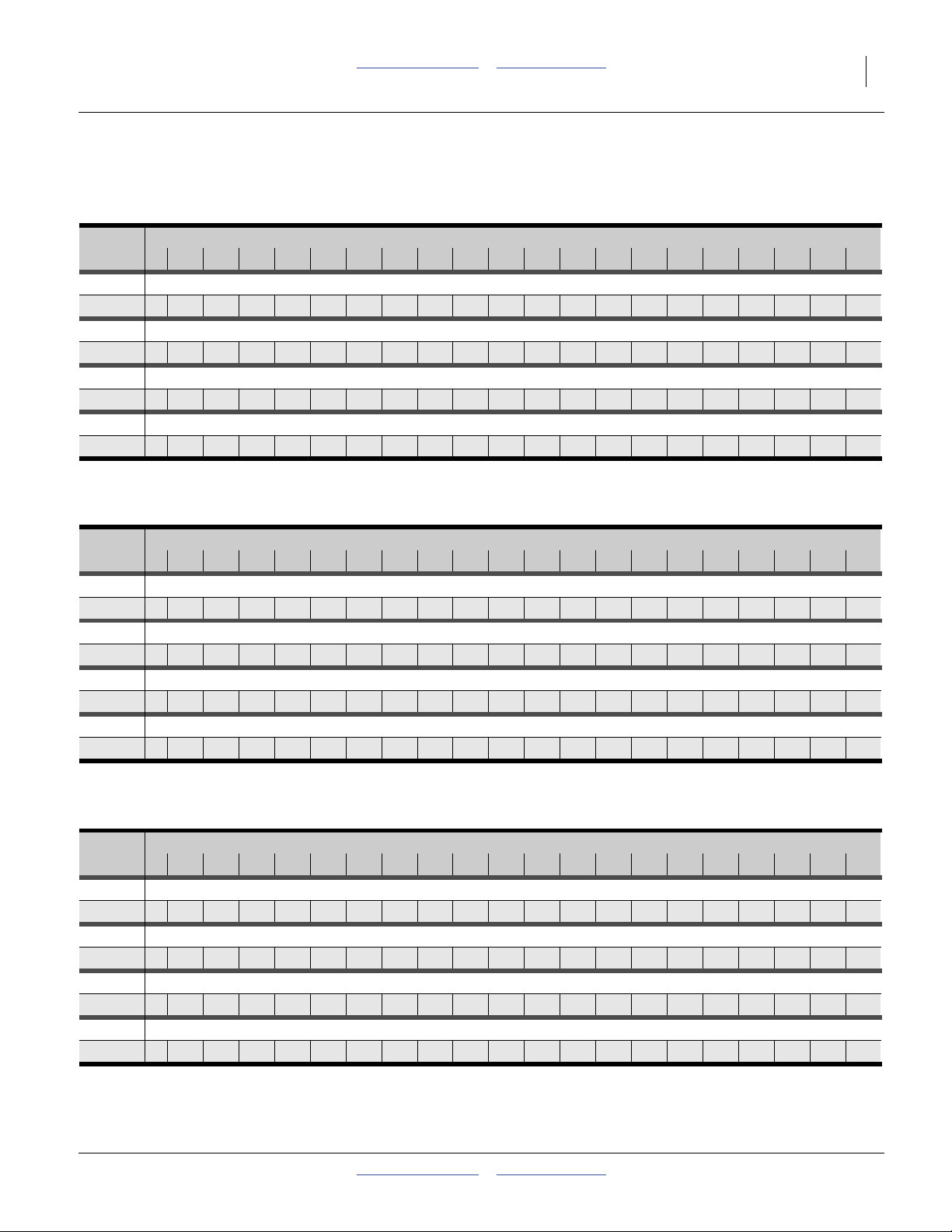

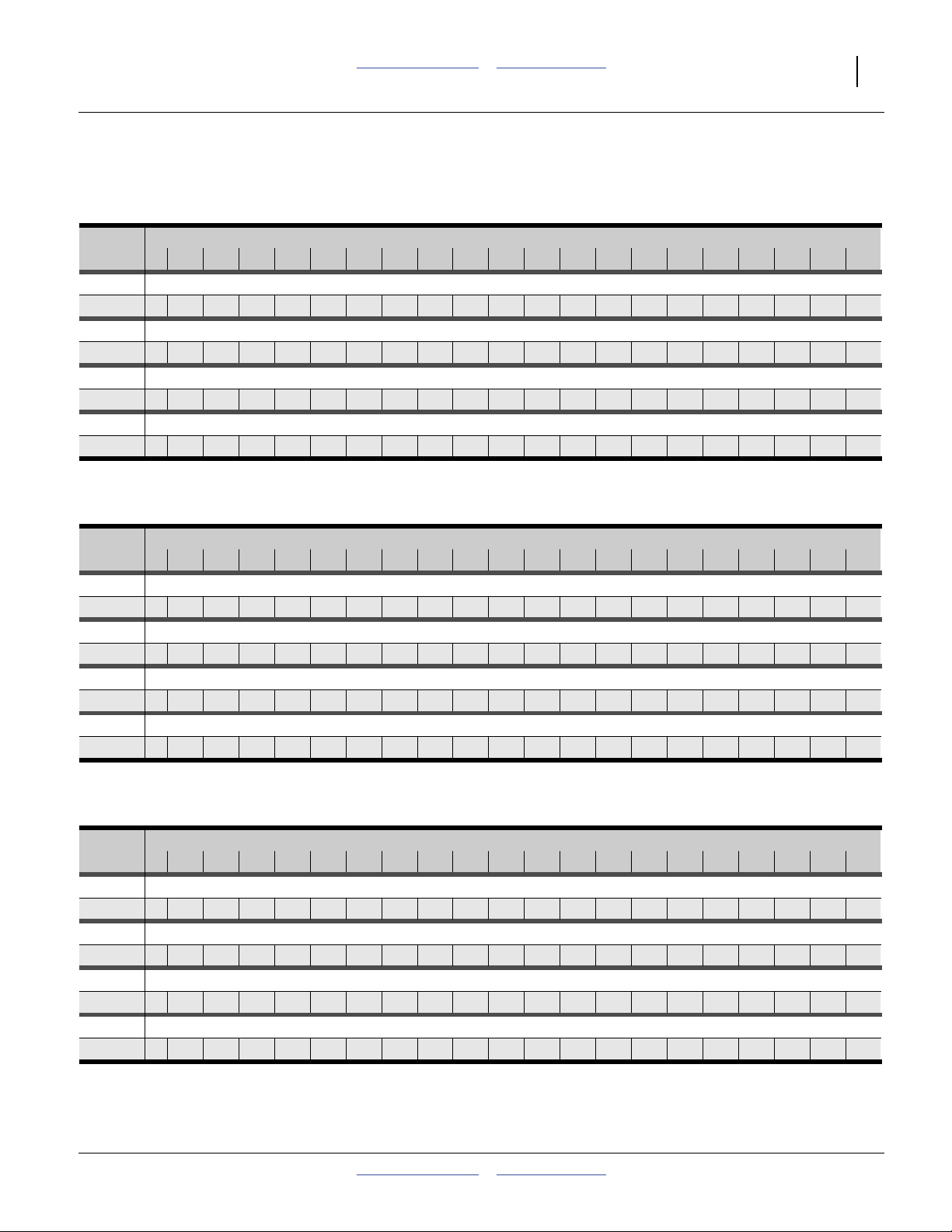

Small Seeds Rate Charts

U.S customary units. Metric charts begin on page 42.

Alfalfa, Red Alsike, Crimson Clover

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 1.8 2.8 3.9 4.8 6.0 7.0 7.9 9.0 10.0 11.1 12.1 13.2 14.0 15.3 16.2 17.2 18.3 19.3 20.3

Kentucky Bluegrass, Fescue, Annual Rye Grass

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 0.2 .9 1.5 2.2 2.7 3.3 3.7 4.2 4.6 5.1 5.5 5.9 6.3 6.7 7.0 7.4 7.7 8.1 8.4

Bermuda, Red Top, Lespedeza Unhulled, Sercia, Sand, Weeping Love Grass

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 0.5 0.9 1.4 2.1 2.6 3.3 4.0 4.7 5.3 5.8 6.3 6.7 7.2 7.6 8.2 8.8 9.3 9.8 10.4

Red & Sweet Clover, Lespedeza Hulled

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 1.2 2.7 4.2 5.7 7.2 9.1 10.6 12.3 13.7 15.3 16.7 18.1 19.7 21.2 22.7 24.2 25.8 27.2 28.6

Orchard Grass

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 0.0 0.2 0.5 0.7 1.1 1.2 1.6 1.9 2.3 2.6 2.8 3.2 3.5 3.9 4.0 4.4 4.6 4.9 5.1

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 30

28 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Rate Charts, Small Seeds Box, continued...

Millet, Reed Canary

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.3 1.2 2.0 2.8 3.6 4.4 5.2 6.0 6.8 7.6 8.4 9.3 10.1 10.9 11.7 12.5 13.3 14.1 14.9 15.1

Ladino Clover, Canary Grass, Timothy, Canola

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 0.9 1.6 2.6 3.9 4.9 6.1 7.4 8.6 9.8 11.1 12.5 13.7 14.9 16.3 17.6 18.8 20.4 21.9 23.5

Birdsfoot, Trefoil, Sudan

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7.5 inch 0 0.0 1.4 2.6 4.2 5.4 7.0 8.6 10.2 11.9 13.5 15.4 17.0 18.8 20.5 22.5 24.0 25.8 27.6 29.1 30.9

151-143B Table of Contents Main Box Rates 2011-10-21

Page 31

Great Plains Manufacturing, Inc. Table of Contents Main Box Rates 29

Fertilizer Rate

Setting Fertilizer Rate

The fertilizer meters are driven by a chain system

independent of the seed meter drives, and are

unaffected by Drive Type. Fertilizer rate is adjusted with

the Rate Adjuster at the fertilizer box.

Fertilizer application rates vary with fertilizer type,

density and particle size. Relative humidity and field

conditions can also affect application rates. The chart is

based on fertilizer with average particle size and a

density of 65 pounds per cubic foot. Initially set rate

according to charts, then calibrate the drill to your

material as described on this page.

Accurately obtaining the desired application rate requires

three steps:

1. Adjusting target rate for large differences between

material and chart density.

2. setting the Rate Adjuster to the scale value from

the chart, and;

3. calibration: checking predicted application rate, and

resetting rate adjuster as needed.

1 2

Figure 14

Fertilizer Rate Adjuster

1

2

32673

Fertilizer Rate Chart

Fertilizer Rates in Pounds per Acre

Setting Number

15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Application Rate - Pounds per Acre (based on 65 lbs/cu.ft)

7.5 inch 11 20 38 54 72 89 105 123 138 157 174 187 209 223 234 242 245 247

Metric Fertilizer Rate Chart

Setting Number

10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Application Rate - Kilograms per Hectare (based on 1.04 kg/liter)

19.1cm (7.5in) 13 20 27 42 57 76 98 112 126 150 175 189 202 222 243 265 287 310 331

2011-10-21 Table of Contents Main Box Rates 151-143B

Page 32

30 3P806NT Table of Contents Main Box Rates Great Plains Manufacturing, Inc.

Adjusting for Density

The fertilizer meter rate charts are based on fertilizer with

a density of 65 pounds per cubic foot (1.04 kg/liter). If

your fertilizer density is within a few percent of that, you

can skip this step and rely on calibration to determine

final Rate Adjuster setup.

For larger variances, particularly with very low densities,

pre-compensating can simplify calibration, by choosing a

different target chart value for the application rate.

Density Conversion Charts

U.S. Customary Units

Density, lb/ft

Conversion Factor

3

Metric

Density, kg/liter 725 800 875 950 1041 1125 1200 1275

Conversion Factor

45.0 50.0 55.0 60.0 65.0 70.0 75.0 80.0

1.45 1.30 1.20 1.10 1.00 0.93 0.87 0.81

1.44 1.30 1.19 1.10 1.00 0.93 0.87 0.82