Page 1

Great Plains Mfg., Inc.

s

Installation Instructions 1

Small Seeds Option

5- and 6-Foot Drills

Used with:

• 3P500, 3P600

• 605NT, 606NT

• 3P605NT, 3P606NT

General Information

These instructions explain how to install a Small Grass

Seeds (SGS) assembly on a compatible drill.

The Small Seeds option adds the capability to meter the

smallest of seeds at rates more precise than using the

main seed box for those seeds.

These instructions apply to an installation of:

Kit Kit Description

133-124A 605NT 7 1/2" SGS ASSEMBLY

133-131A 3P605NT 7 1/2" SGS ASSEMBLY

133-133A 6’ 6" SGS

133-134A 6’ 7 1/2" SGS

133-150A 5’ 6" SGS

133-151A 5’ 7 1/2" SGS

133-369A 3P605NT FIELD SGS ON NG

133-370A 605NT FIELD SGS ON NG

When you see this symbol, the subsequent instruction

and warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

One kit updates one drill.

Drill Model Uses Kit

3P500-0775 (7.5 in) 133-151A

3P500-0906 (6 in) 133-150A

3P500V (any spacing) (SGS not available)

3P600-0975 (7.5 in) 133-134A

3P600-1106 (6 in) 133-133A

3P605NT-0975 (7.5 in) 133-131A or 133-369A

3P606NT-0975 (7.5 in) 133-131A or 133-369A

605NT-0975 (7.5 in) 133-124A or 133-370A

606NT-0975 (7.5 in) 133-124A or 133-370A

Related Documents

Have the Operator Manual at hand for drill movements.

118-794M 3P500-3P600 OPERATORS MANUAL

151-061M MANUAL 605NT OPERATOR

Have the current Parts Manual at hand for parts ID.

118-794P 3P500-3P600 PARTS MANUAL

151-061P MANUAL 605NT PARTS

Figure 1

Small Seeds Box and Hoses

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

Call-Outs

1 9

to

11 45

to

and

61 67

to

81 96

to

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts in the ranges:

11 to 45 reference kit parts, and

61 to 67 reference optional parts from the

new parts lists beginning on page 18.

Two-digit callouts in the range 81 to 96 reference affected existing parts from the table on

page 20. The descriptions match those in

your Parts Manual. The narrative and table

indicate any re-use of the parts.

18484

U

F

L

R

B

D

©Copyright 2000, 2006, 2009 Printed 04/02/2009 133-140M

Page 2

2 Small Seeds Option

Before You Start

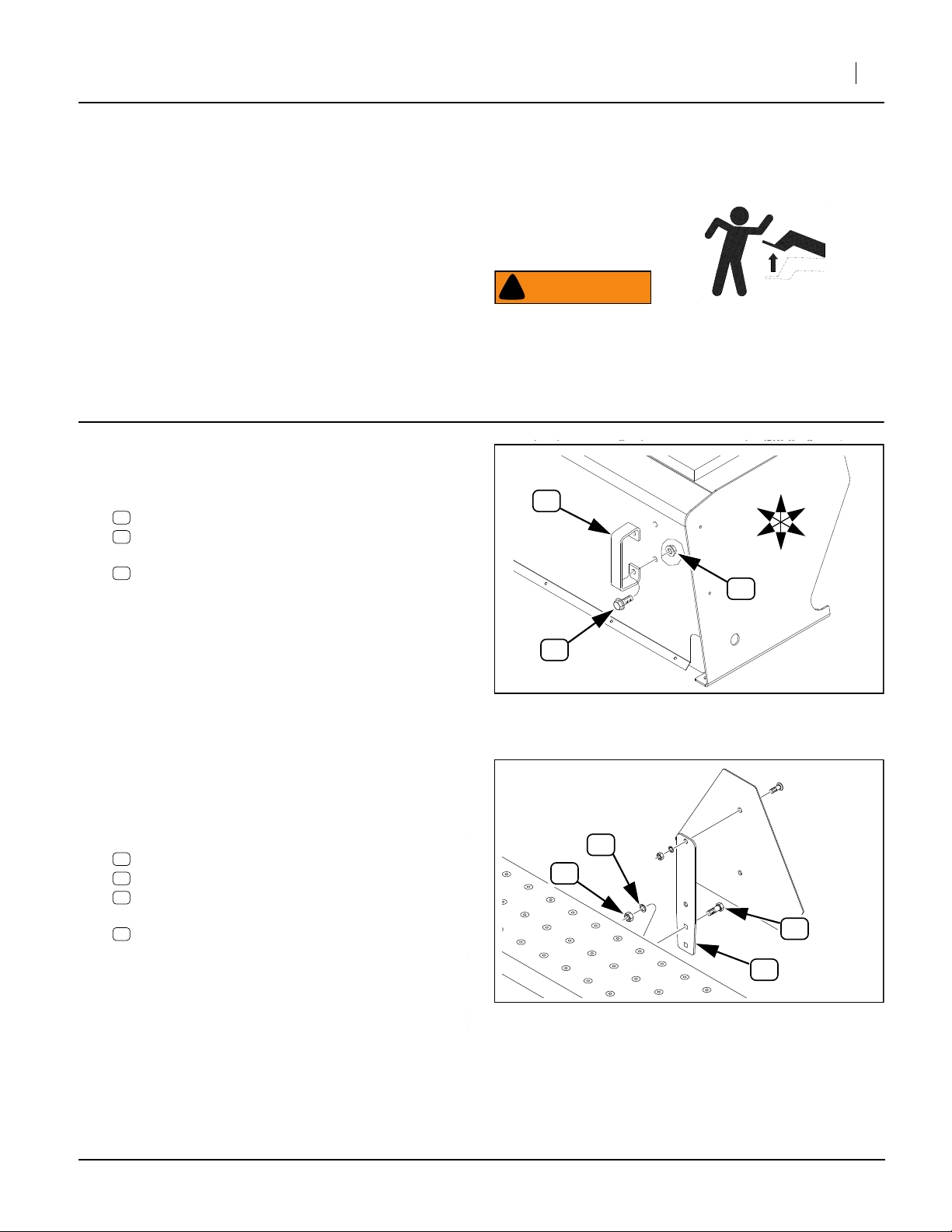

Compatibility

Refer to Figure 2

1. Make sure that the drill is a compatible model for the

kit. See table on page 1. The full model number for

the drill is found on the serial number plate.

2. If the drill is a model 605NT or 606NT, you may want

to replace the ‘606 decal in the kit with the correct

decal for your drill. It is not necessary to have these

decals on hand during the kit installation.

Order one of:

67

838-207C DECAL 605NT

838-203C DECAL 3P605NT

Inventory

3. Make sure all parts are present. Remove all parts

and any packing material from inside the new Small

Seeds box.

Great Plains Mfg., Inc.

Comprehension

4. Review these instructions. Make sure the installers

understand where each part or assembly is

installed, and what tools are required for the task.

Note: Illustrations in this manual, based on the parts

manuals for this family of drills, may show

exploded views that are fully disassembled. Rely

on the instructions for required disassembly and reassembly steps.

Pre-Assembly Preparation

Tools Required

• updated drill Parts Manual (see page 1)

• suitable tractor for positioning and lowering drill

• blocks for securing transport tires if drill will be

unhitched for the work

• two people or a hoist - several longs parts are suitable

for unassisted single-person removal/installation

• chain lube

• basic hand tools, including:

snap ring pliers

Figure 2

Serial Number Plate

18515

133-140M 04/02/2009

Page 3

Great Plains Mfg., Inc.

Work Location

5. Move the drill to a location with:

• room to maneuver large parts around it,

• access to tractor or hydraulic power,

• adequate illumination, and;

• clear surface beneath for recovery of any falling

or dropped parts - if the surface is not clear, have

a tarp or drop cloth available.

6. Park the drill per the instructions in the Operator

Manual.

7. Lower the drill and the openers

8. Shut off tractor if left hitched.

Remove Existing Parts

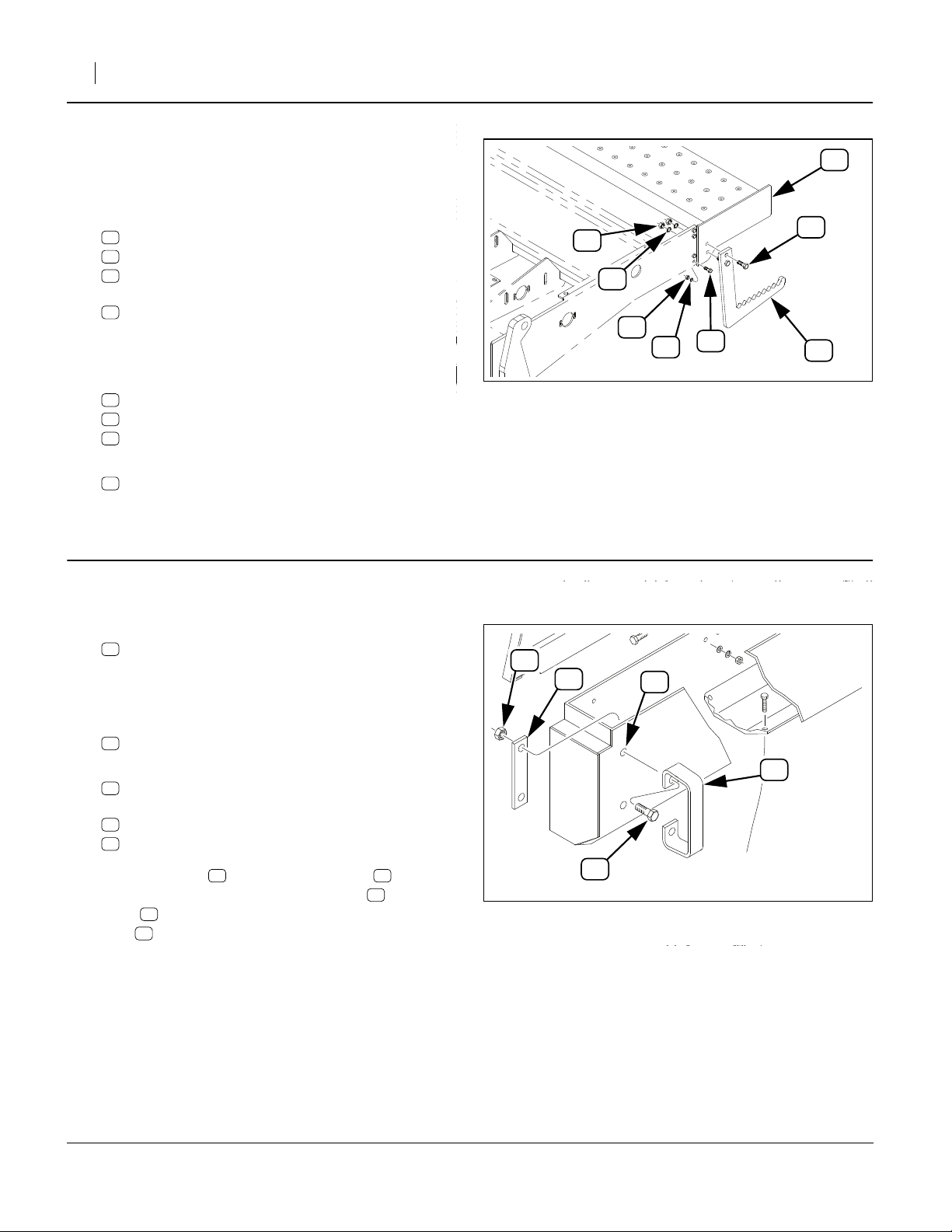

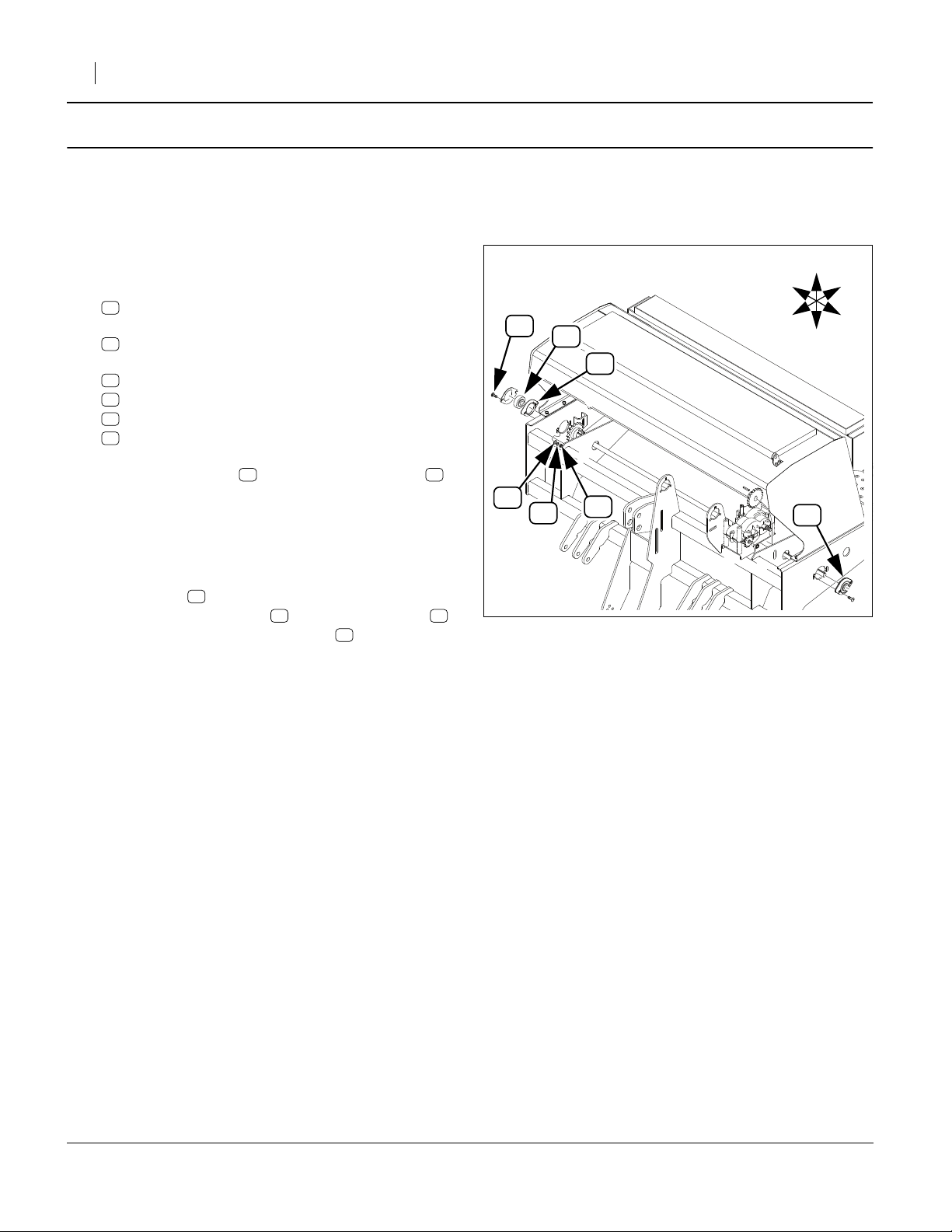

Refer to Figure 3

9. At each grab handle on the back corners of the rearmost seed box, remove and save two sets (four sets

total) of:

88

802-203C HFSS 1/2-13X1 1/2 GR5

92

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

and two:

81

119-190D HANDLE

These are re-mounted on the new SGS box at

step 15 on page 4.

Note: Existing hardware may vary slightly from parts

called out in these instructions. For example,

instead of flange nuts, there may be separate

washers and there may be a 133-045D strap. Note

such changes, so that parts are correctly reinstalled.

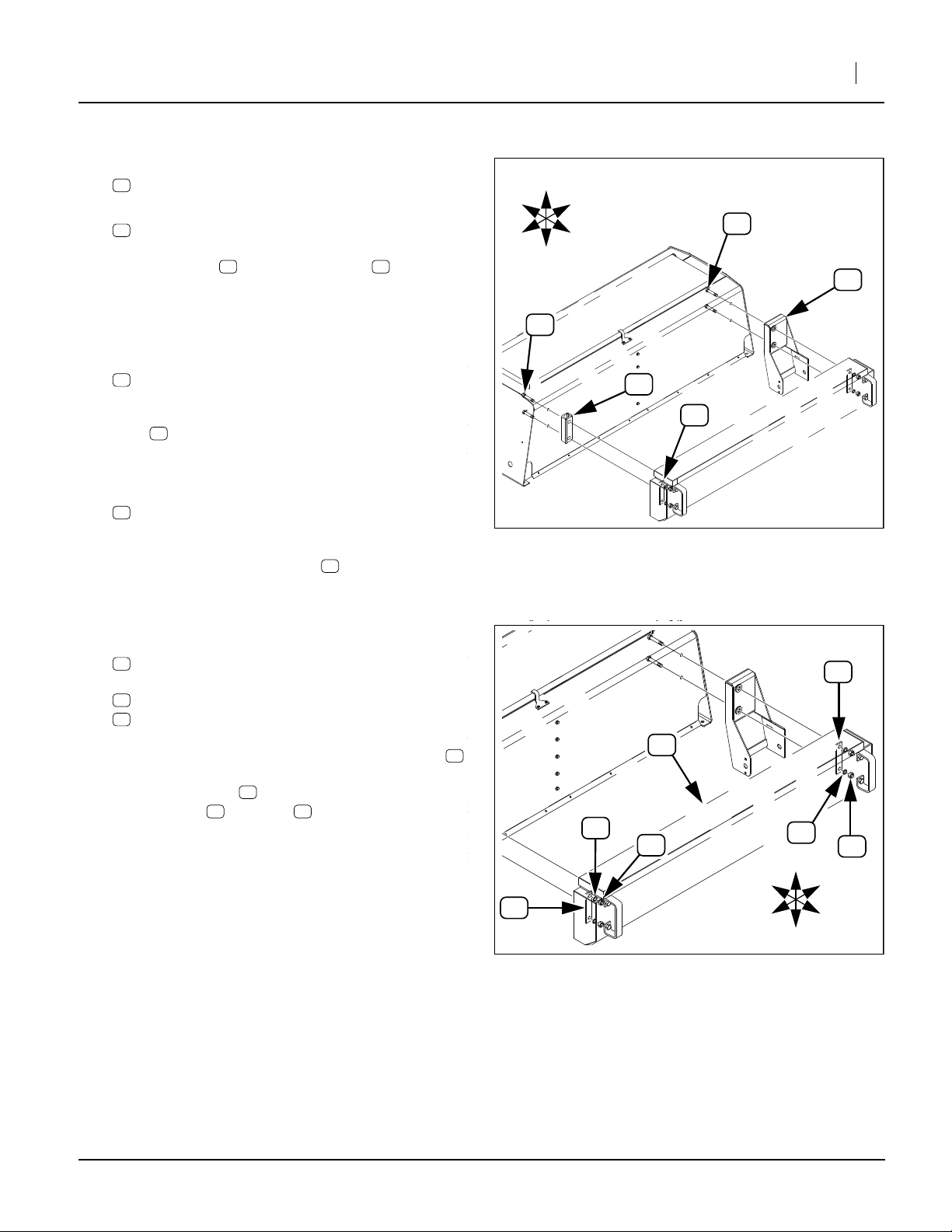

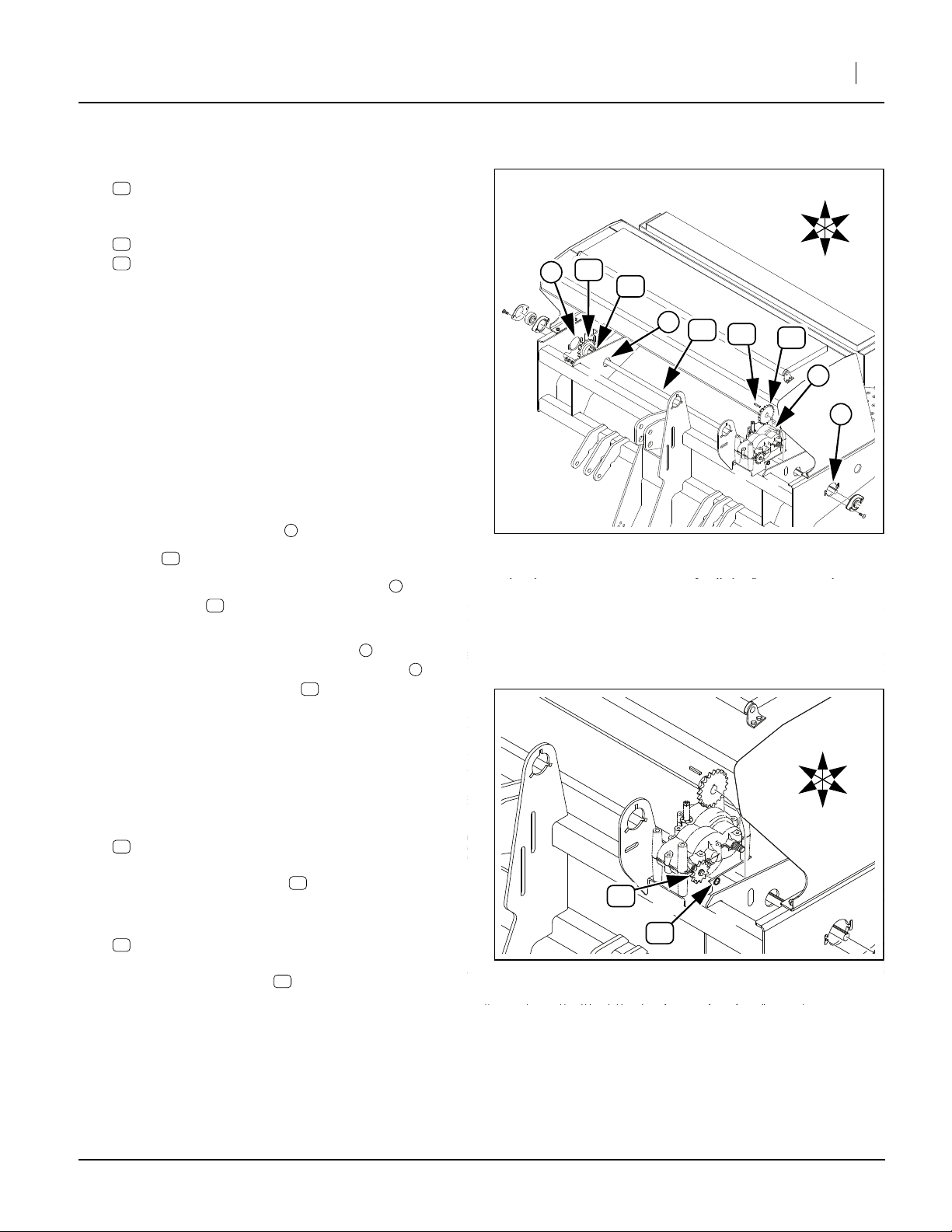

Refer to Figure 4

Step 10 is required only for drills with existing Native

Grass boxes, but is recommended for all drills, to clear

access for mounting the SGS box.

10. At the SMV placard remove and save two sets:

85

802-007C HHCS 5/16-18X3/4 GR5

93

804-009C WASHER LOCK SPRING 5/16 PLT

89

803-008C NUT HEX 5/16-18 PLT

and then remove the still-assembled SMV

96

890-153C SMV MOUNTING BLADE

Installation Instructions 3

WARNING

!

Negative tongue weight hazard:

Lower the openers on pull-type drills. The weight of a person

on raised openers can cause an unhitched tongue to fly up,

causing a fall and possible serious injury.

U

81

L

B

F

R

D

92

88

Figure 3

Dismount Grab Handle

18651

93

89

85

96

Figure 4

Dismount SMV

04/02/2009 133-140M

18565

Page 4

4 Small Seeds Option

Refer to Figure 5

Step 11 through step 13 are performed only if the drill

has a Native Grass seed box installed. For Main-box-only

drills, skip to step 16 on page 5.

11. At each end of the walkboard, remove and save two

sets (four sets total):

87

802-091C HHCS 1/2-13X1 1/2 GR5

95

804-015C WASHER LOCK SPRING 1/2 PLT

91

803-020C NUT HEX 1/2-13 PLT

then remove and save two steps:

82

119-192D STEP

Note: Two people or a hoist are required for this step.

12. At each end of the walkboard, remove and save four

sets (eight sets total):

86

802-079C HHCS 3/8-16X1 1/4 GR5

89

804-013C WASHER LOCK SPRING 3/8 PLT

90

803-014C NUT HEX 3/8-16 PLT

13. Remove the walkboard:

83

119-272H SEED & SGS WALKBOARD WELDMENT

The walkboard is not re-used.

Great Plains Mfg., Inc.

91

95

90

86

89

Figure 5

Dismount Walkboard (NG only)

83

87

82

18565

Attach SGS box & Final Drive

Re-Install Grab Handles

Refer to Figure 6

14. Select the SGS box from your kit, one of:

16

133-129L 6’ 7 1/2" SGS BOX ASSY

133-135L 6’ 6" SGS BOX ASSEMBLY

133-148L 5’ 6" SGS BOX ASSEMBLY

133-149L 5’ 7 1/2" SGS BOX ASSEMBLY

and two new:

15

133-045D SGS BOX SUPPORT STRAP

15. Select two saved:

81

119-190D HANDLE

and four sets saved hardware, typically:

88

802-203C HFSS 1/2-13X1 1/2 GR5

92

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

Insert the bolts through the handles , then

through the rear holes of the SGS box . Add a

15

strap to each handle assembly, and secure with

92

nuts (and any washers removed at step 9).

88 81

16

92

15

16

88

Figure 6

Re-install grab Handles

81

18568

133-140M 04/02/2009

Page 5

Great Plains Mfg., Inc.

Attach SGS Box

Refer to Figure 7

16. If removed at step 9, select two saved:

84

133-045D SGS BOX SUPPORT STRAP

17. Select four new:

28

802-041C HHCS 1/2-13X3 1/2 GR5

Insert the bolts through the straps (if present

- newer drills have internal stiffener plates and do

not require straps). From the inside of the box,

insert the bolts, or bolt/strap assemblies, through

the holes previously used for the grab handles.

18. Select one new:

24

202-186D NG/SGS BOX SPACER

28 84

Installation Instructions 5

U

F

R

28

L

B

D

17

28

24

Place this spacer over the threaded ends of the

28

bolts at the left end of the existing seed box. If it

tends to fall off, use saved 1/2-13 nuts to temporarily

hold it.

19. Select one new:

17

133-130K 6’ SGS DRIVER ASSY

With the sprocket drive end down, place this over

the threaded ends of the bolts at the right end of

the existing seed box. If it tends to fall off, use saved

1/2-13 nuts to temporarily hold it.

Refer to Figure 8

20. Select two new

15

133-045D SGS BOX SUPPORT STRAP

and four sets new:

35

804-015C WASHER LOCK SPRING 1/2 PLT

31

803-020C NUT HEX 1/2-13 PLT

Remove any temporary nuts. Place the SGS box

over the bolts inserted at step 17. Inside the SGS

box, place a strap over the same bolts. Secure

with washers and nuts .

15

35 31

28

16

15

84

Figure 7

Prepare for SGS Box Install

16

35

31

Figure 8

Install SGS Box

18566

15

35

31

U

F

L

R

B

D

18566

04/02/2009 133-140M

Page 6

6 Small Seeds Option

Install SGS Drive

Install 3P500/3P600 Drive Components

Install 3P500/3P600 Shaft Bearings

For 3P605NT, 3P606NT, 605NT or 606NT, skip to

“Install 3P/605/606NT Drive Components” on page 10.

Refer to Figure 9

21. Select two (2) new:

43

822-040C BRG INS .75IDX1.85OD SPH LCK

four new:

44

822-041C FLANGETTE 47 MST

and four sets new:

29

802-282C RHSNB 5/16-18X1 GR5

37

804-036C WASHER FLAT 5/16 SAE PLT

34

804-009C WASHER LOCK SPRING 5/16 PLT

30

803-008C NUT HEX 5/16-18 PLT

29

43

44

Great Plains Mfg., Inc.

U

R

F

B

L

D

Place each bearing between two flangettes .

As necessary, back out set screws in lock collars so

that bearings can slide freely on shaft. Bearing lock

collars (not shown) are oriented to drill center

(inside). Mount each flangette on the forward bearing opening on the outside of the end panels.

Insert a bolt through the flangettes and the

panel. Add a flat washer , then a lock washer ,

and secure to finger-tight with nut .

29

43 44

37 34

30

37

34

30

Figure 9

Install 3P500/600 Bearings

44

18655

133-140M 04/02/2009

Page 7

Great Plains Mfg., Inc.

Install 3P500/3P600 Shaft and Sprockets

Refer to Figure 10

22. Select the shaft in your kit, one of:

14

133-037D SGS/AUXILLARY DRIVE SHAFT

133-052D 5’ SGS DRIVE SHAFT

and one each new:

40

808-170C SPKT 40B17 X 3/4BORE W/KW&SS

38

808-100C SPKT 40B22 3/4B W/K.W. &SS

As necessary, back out the set screws in the

sprockets so that the sprockets can slide freely on

the shaft.

Note: The shaft has keyways of different lengths on each

end. The end with the shorter keyway is the right

end. The end with the longer keyway is the left

(gearbox) end. The shaft may be inserted in the

drill from either side, as long as the sprockets are

correctly oriented. These steps use the left side.

Note: The sprockets are not symmetrical. For ease of

future maintenance, the set-screw side is oriented

to drill center.

23. Insert the right (short keyway) end of the shaft

through the new bearing .

Note: Keys are installed at step 31 and step 35.

24. As the shaft passes behind the gearbox , add the

22T sprocket , with the set screw side facing

right.

23

38

1

2

Installation Instructions 7

U

R

F

40

4

B

L

D

23

3

14

23

38

2

1

Figure 10

Install 3P500/600 Shaft

18655

25. As the shaft nears the right bearing (and after

passing through the right-most brace-plate , if

any), add the 17T sprocket , with the set screw

side facing left.

26. Adjust lateral shaft position so that about equal

lengths of shaft end are exposed at the end panels.

Rotate shaft to ensure it spins freely. Secure both

bearing lock collars.

Refer to Figure 11

27. Select one each new:

39

808-160C SPKT 40B12 X 36T SPLINE BORE

Place the spline sprocket , raised hub side first,

onto the left front gearbox shaft.

28. Select one each new:

25

800-141C SNAP RING EXT F/PEERLESS G.B.

Secure spline sprocket to gearbox shaft with

snap ring.

40

39

39

4

3

39

25

Figure 11

3P500/600 Gearbox Sprocket

R

F

U

B

L

D

18655

04/02/2009 133-140M

Page 8

8 Small Seeds Option

Install 3P500/3P600 Drive Idlers

3P500/3P600 Right Idler

Refer to Figure 12

29. Select one set new:

28

802-041C HHCS 1/2-13X3 1/2 GR5

42

817-025C NO. 40 12T IDLER SPKT.

32

803-036C NUT HEX JAM 1/2-13 PLT

36

804-017C WASHER FLAT 1/2 USS PLT

33

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

Place the idler on the bolt . Thread the jam

32

nut all the way on, then back off one turn. Add

the flat washer .

30. Using the flange lock nut , loosely secure the

idler assembly to the idler weldment at drill right

(near the new 17T sprocket ).

31. Select one new:

23

168-127D 3/16 X 1 KEY (not shown)

42 28

36

33

5

40

33

40

Great Plains Mfg., Inc.

U

R

B

5

36

32

F

L

D

42

28

28

42

32

36

Adjust the position of the 17T sprocket until the

teeth are in the same rotational plane as those of

the new idler . Insert the key in the 17T

sprocket. Secure the set screw in that sprocket.

42 23

40

3P500/3P600 Left (Gearbox) Idler

32. Locate the idler slot to use. Align the new 22T

sprocket with the new spline sprocket on the

gearbox. Locate the nearest

ward of the 22T sprocket and on an adjacent brace

plate.

33. Select one set new:

28

42

32

36

33

Place the idler on the bolt . Thread the jam

nut all the way on, then back off one turn. Add

the flat washer ,

34. Using the flange lock nut , loosely secure the

idler assembly at the slot identified in step 32.

35. Select one new:

23

38 39

1

⁄

in slot that is for-

2

802-041C HHCS 1/2-13X3 1/2 GR5

817-025C NO. 40 12T IDLER SPKT.

803-036C NUT HEX JAM 1/2-13 PLT

804-017C WASHER FLAT 1/2 USS PLT

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

42 28

32

36

33

6

168-127D 3/16 X 1 KEY (not shown)

6

39

Figure 12

3P500/600 Idlers

38

6

33

18719

Adjust the position of the 22T sprocket until the

teeth are in the same rotational plane as those of

the new left idler and the new gearbox sprocket .

Insert the key in the 22T sprocket. Secure the

set screw in that sprocket.

133-140M 04/02/2009

23

38

39

Page 9

Great Plains Mfg., Inc.

Install 3P500/3P600 Chains

Three new chains are installed to connect the gearbox to

the Small Seeds meter shaft.

36. Review “Chain Installation” on page 17 before

mounting chains.

Refer to Figure 13

3P500/600 Gearbox to SGS Chain

37. Select the gearbox chain from your kit, one of:

21

136-104D CHAIN RL #40 62 PITCHES

136-172D CHAIN RL #40 63 PITCHES

Route the chain around the new 12T gearbox

sprocket , the new accessory shaft input

sprocket , and above the new left idler .

Adjust left idler for

chain .

3P500/600 SGS Transmission Chain

39

38 42

1

42

21

⁄

in slack in the top span of

2

39

21

F gur S

LEFT

Installation Instructions 9

U

F

B

FINAL

3

D

18

4

20

2

38. Select one new:

20

136-063D CHAIN RL #40 94 PITCHES

Route the chain around the new accessory shaft

output sprocket , around the final drive jackshaft

input sprocket , and above the new right idler .

Adjust right idler for

20

chain .

40

142

3

42

⁄

in slack in the top span of

4

3P500/600 SGS Final Drive Chain

39. Select one new:

18

136-017D CHAIN RL #40 49 PITCHES

Route the chain around the final drive jackshaft output sprocket , around the final drive meter shaft

input sprocket , and behind the final drive idler .

Adjust final drive idler for

span of chain .

40. Continue at “Install Seed Delivery Hardware” on

page 14.

2

3 4

1

4

⁄

in slack in the rear

4

18

42

RIGHT

38

42

40

Figure 13

3P500/3P600 New Chain Routing

1

18656

04/02/2009 133-140M

Page 10

10 Small Seeds Option

Install 3P/605/606NT Drive Components

For 3P500 or 3P600, return to “Install 3P500/3P600

Drive Components” on page 6.

Install 3P/605/606NT Shaft Bearings

Refer to Figure 14

41. Select one new:

43

822-040C BRG INS .75IDX1.85OD SPH LCK

two new:

44

822-041C FLANGETTE 47 MST

and two sets new:

29

802-282C RHSNB 5/16-18X1 GR5

37

804-036C WASHER FLAT 5/16 SAE PLT

34

804-009C WASHER LOCK SPRING 5/16 PLT

30

803-008C NUT HEX 5/16-18 PLT

Place the bearing between two flangettes . As

necessary, back out set screws in lock collars so

that bearing can slide freely on shaft.

Mount the first flangette assembly on the forward

bearing opening on the outside of the right end

panel. Orient the bearing lock collar (not shown) to

the left/inside.

Insert a bolt through the flangettes and the

panel. Add a flat washer , then a lock washer ,

and secure to finger-tight with nut .

Refer to Figure 15

42. Select one new:

43

822-040C BRG INS .75IDX1.85OD SPH LCK

two new:

44

822-041C FLANGETTE 47 MST

and two sets new:

29

802-282C RHSNB 5/16-18X1 GR5

37

804-036C WASHER FLAT 5/16 SAE PLT

34

804-009C WASHER LOCK SPRING 5/16 PLT

30

803-008C NUT HEX 5/16-18 PLT

43 44

29

37 34

30

R

F

29

43

U

37

B

L

34

D

Figure 14

Install 3P/605/606NT Bearing (R)

29

44

Great Plains Mfg., Inc.

44

30

44

43

44

1

18649

Place the bearing between two flangettes . As

necessary, back out set screws in lock collars so

that bearing can slide freely on shaft.

Mount this flangette assembly on the right side of

the forward bearing opening on the brace plate to

the right of the gearbox. Orient the bearing lock collar (not shown) to the right (toward drill center).

Insert a bolt through the flangettes and the

panel. Add a flat washer , then a lock washer ,

and secure to finger-tight with nut .

133-140M 04/02/2009

43 44

29

37 34

30

R

F

U

37

B

L

D

Figure 15

Install 3P/605/606NT Bearing (L)

34

30

18649

Page 11

Great Plains Mfg., Inc.

Install 3P/605/606NT Shaft and Sprockets

Refer to Figure 16

43. Select one new:

14

133-052D 5’ SGS DRIVE SHAFT

and one each new:

40

808-170C SPKT 40B17 X 3/4BORE W/KW&SS

38

808-100C SPKT 40B22 3/4B W/K.W. &SS

As necessary, back out the set screws in the

sprockets so that the sprockets can slide freely on

the shaft.

Note: The shaft has keyways of different lengths on each

end. The end with the shorter keyway is the right

end. The end with the longer keyway is the left

(gearbox) end.

Note: The sprockets are not symmetrical. For ease of

future maintenance, the set-screw side is oriented

to drill center.

44. Insert the left (long keyway) end of the shaft

through the new right bearing .

2

14

Installation Instructions 11

U

2

23

40

R

F

14

23

B

L

D

38

3

45. Add the 17T sprocket , with the set screw side

facing left.

46. Pass the left end of the shaft through the new

left bearing at the gearbox.

47. Add the 22T sprocket , with the set screw side

facing right.

Note: Keys are installed at step 54 and step 58.

Refer to Figure 17

48. Select one each new:

39

808-160C SPKT 40B12 X 36T SPLINE BORE

Place the spline sprocket , raised hub side first,

onto the right front gearbox shaft.

49. Select one each new:

25

800-141C SNAP RING EXT F/PEERLESS G.B.

Secure spline sprocket to gearbox shaft with

snap ring .

Refer to Figure 16 and Figure 17

50. Adjust the position of the new 22T shaft input (left

end) sprocket to be in the same plane as the

new 12T gearbox sprocket .

51. While keeping sprocket in plane, adjust lateral

shaft position so that about equal lengths of shaft

end are exposed beyond the new right bearing

and the new left sprocket . Rotate shaft to ensure

it spins freely. Secure both bearing lock collars.

3

23

25

38

40

14

38

39

39

39

38

38

18649

25

Figure 16

Install 3P/605/606NT Shaft

39

U

R

F

B

L

D

Figure 17

3P/605/606NT Gearbox Sprocket

2

18650

04/02/2009 133-140M

Page 12

12 Small Seeds Option

Install 3P/605/606NT Drive Idlers

3P/605/606NT Right Idler

Refer to Figure 18

52. Select two sets new:

28

802-041C HHCS 1/2-13X3 1/2 GR5

42

817-025C NO. 40 12T IDLER SPKT.

32

803-036C NUT HEX JAM 1/2-13 PLT

36

804-017C WASHER FLAT 1/2 USS PLT

33

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

Place the idlers on the bolt . Thread the jam

32

nuts all the way on, then back off one turn. Add

the flat washer .

42 28

36

33

Great Plains Mfg., Inc.

4

42

36

42

53. Using the flange lock nut , loosely secure each

idler assembly to the idler weldment at drill right

(near the new 17T sprocket ).

54. Select one new:

23

168-127D 3/16 X 1 KEY (not shown)

Adjust the position of the 17T sprocket until the

teeth are in the same rotational plane as those of

the new idler . Insert the key in the 17T

sprocket. Secure the set screw in that sprocket.

42 23

33

4

40

40

3P/605/606NT Left (Gearbox) Idler

55. Select the remaining 1/2IN bolt, one of:

28

802-041C HHCS 1/2-13X3 1/2 GR5

802-045C HHCS 1/2-13X5 GR5

56. Select one set new:

42

817-025C NO. 40 12T IDLER SPKT.

32

803-036C NUT HEX JAM 1/2-13 PLT

36

804-017C WASHER FLAT 1/2 USS PLT

33

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

Place the idler on the bolt . Thread the jam

32

nut all the way on, then back off one turn. Add

the flat washer .

42 28

36

R

F

40

U

D

32

B

L

3P/605/606NT Idlers

28

33

5

36

Figure 18

32

39

42

28

18650

57. Using the flange lock nut , loosely secure the

idler assembly at the right side of the angled slot

forward of the new shaft input sprocket (not

shown in Figure 18).

Refer to Figure 16 on page 11

58. Select one new:

23

168-127D 3/16 X 1 KEY

Adjust the position of the 22T sprocket until the

teeth are in the same rotational plane as those of

the new left idler and the new gearbox sprocket .

Insert the key in the 22T sprocket. Secure the

set screw in that sprocket.

133-140M 04/02/2009

23

33

5

38

38

39

Page 13

Great Plains Mfg., Inc.

Install 3P/605/606NT Chains

Three new chains are installed to connect the gearbox to

the Small Seeds meter shaft.

59. Review “Chain Installation” on page 17 before

mounting chains.

Refer to Figure 19

3P/605/606NT Gearbox to SGS Chain

60. Select the new gearbox chain, one of:

19

136-057D CHAIN RL #40 42 PITCHES

136-170D CHAIN RL #40 40 PITCHES

Route the chain around the new 12T gearbox

sprocket , the new accessory shaft input

sprocket , and above the new left idler .

Adjust left idler for

span of chain .

3P/605/606NT SGS Transmission Chain

39

38 42

1

42

21

⁄

in (12mm) slack in the top

2

39

LEFT

19

Installation Instructions 13

U

F

B

FINAL

D

18

22

9

7

38

RIGHT

8

61. Select the new transmission chain, one of:

22

136-115D CHAIN RL #40 142 PITCHES

136-163D CHAIN RL #40 217 PITCHES

Route the chain around the new accessory shaft

output sprocket , around the final drive jackshaft

input sprocket , above the new right rear idler

and below the new right front idler .

Adjust right idlers for 1in (2.5cm) slack in the top

span of chain .

40

642

42

42

22

3P/605/606NT SGS Final Drive Chain

62. Select one new:

18

136-017D CHAIN RL #40 49 PITCHES

Route the chain around the final drive jackshaft output sprocket , around the final drive meter shaft

input sprocket , and behind the final drive idler .

Adjust final drive idler for

rear span of chain .

7

8 9

1

9

⁄

in (6mm) slack in the

4

18

42

40

3P/605/606NT New Chain Routing

42

42

Figure 19

6

18653

04/02/2009 133-140M

Page 14

14 Small Seeds Option

Install Seed Delivery Hardware

Refer to Figure 20

63. Select one new per row:

13

123-939H SMALL SEEDS TUBE WELDMENT

and two per row:

27

801-002C SCREW HEX SLT10-16X1/2P.THD CT

Insert a seed tube in the open hole directly ahead of

the T-handle adjustment slot , in each opener

frame. The seed tube may be pointed forward or

back. Great Plains recommends angling the bent

lower tube to face to the rear.

Secure each seed tube to each opener with the selftapping screws.

Seed Hose Installation

1

Great Plains Mfg., Inc.

27

13

1

Refer to Figure 21

64. Start with row 1 (left-most row), and work to the

right, one row at a time, to assure correctly connecting each meter to its assigned row (row units are not

necessarily directly below their meters).

65. Select one per row:

41

816-513C SGS HOSE 85 RIBS

and two per row:

26

800-321C HOSE CLAMP NO.12 3/4 ID

Slide one clamp onto each end of the hose, about

2in (5cm) from the end of the hose.

Slide one end of the hose fully onto the meter

2

outlet . The end of the hose should touch the conical section of the meter.

Squeeze the clamp to release it, and slide the

clamp to about

(or about the same distance above the end of the

outlet). Release the clamp.

Slide the lower end of the hose fully over the

exposed top of the small seeds delivery tube .

Squeeze the clamp to release it, and slide the

clamp to about

hose (halfway between the bump and the flange).

Release the clamp.

66. If the drill is not equipped with Native Grass, continue at step 69 on page 15.

1

⁄

in (6mm) from the end of the hose

4

1

⁄

in (13mm) from the end of the

2

41

13

Figure 20

Seed Tube Installation

26

26

Figure 21

Seed Hose Installation

18721

2

41

13

18721

133-140M 04/02/2009

Page 15

Great Plains Mfg., Inc.

Install Walkboard (NG only)

Refer to Figure 22

67. Select one new:

12

119-274H

and eight sets saved:

86

802-079C HHCS 3/8-16X1 1/4 GR5

89

804-013C WASHER LOCK SPRING 3/8 PLT

90

803-014C NUT HEX 3/8-16 PLT

Attach the new walkboard to the rear of the drill end

panels. Insert bolts from outside.

68. Select two saved:

82

119-192D STEP

and four sets saved:

87

802-091C HHCS 1/2-13X1 1/2 GR5

95

804-015C WASHER LOCK SPRING 1/2 PLT

91

803-020C NUT HEX 1/2-13 PLT

SEED,SGS,&NG WALKBOARD WELD

90

89

Installation Instructions 15

91

95

87

12

86

82

Attach the steps near the front of the new walkboards. Insert bolts from outside.

Close-Out

Refer to Figure 23

69. Select the decal from your kit, one of:

45

838-253C DECAL 3P500

838-202C DECAL 3P600

848-094C DECAL 606NT

848-093C DECAL 3P606NT

or one of these separately-ordered optional decals:

67

838-207C DECAL 605NT

838-203C DECAL 3P605NT

Clean and dry the right rear face of the SGS box.

Determine the location for the decal, typically with:

lower edge aligned with top of the yellow stripe ,

and right edge at the same distance from the

right end of the box as the left edge of the Great

Plains log is from the left end of the box.

Remove the release paper from the decal. Carefully

apply the decal on the box. Smooth out any air bubbles, from center to edge of decal.

4

5

Figure 22

Install NG Walkboard

18717

5

3

3

Figure 23

Model Decal

4

29465

04/02/2009 133-140M

Page 16

16 Small Seeds Option

Refer to Figure 24

70. If this is a Native Grass drill, locate the center of the

new walkboard. Otherwise, use the same walkboard

hole from which the SMV was removed at step 10.

71. Select one saved:

96

890-153C SMV MOUNTING BLADE

and two sets saved set:

85

802-007C HHCS 5/16-18X3/4 GR5

93

804-009C WASHER LOCK SPRING 5/16 PLT

89

803-008C NUT HEX 5/16-18 PLT

Great Plains Mfg., Inc.

93

89

85

Re-install the still-assembled SMV at walkboard

center.

Check System Function

72. Lubricate new chains.

73. Hitch tractor.

74. Raise and lower drill, checking for excess tension or

slack in new seed hoses.

75. Raise drill. Exercise the calibration procedure for

the drill, checking for correct operation of all new

sprockets and chains.

Small Seeds Operation

Make sure you have the latest Operator and Seed Rate

manuals for your drill. Details of Small Seeds box adjustment and calibration are covered in the Seed Rate manual.

Small Seeds rate is set entirely by the rate handle on the

new SGS box and is unaffected by the Drive Type setting

used for the Main seed box.

Unless also metering from the Main box and/or Native

Grass box at the same time, prevent wear by disconnecting chains, or reduce Main box wear by setting the Drive

Type to 1.

Figure 24

Re-mount SMV

96

18565

133-140M 04/02/2009

Page 17

Great Plains Mfg., Inc.

Small Seeds Maintenance

Chain Installation

Whenever mounting a chain, make sure the clip at the

removable link is oriented to minimize snags.

Refer to Figure 25 (arrow shows chain direction)

Install clip with open end facing away from direction of

chain travel (striped arrows in routing diagrams).

Chain Slack

Check slack within the first 8 hours of operation and

tighten idlers as necessary.

Refer to Figure 26, which, for clarity, greatly exaggerates slack, and omits the idlers.

1. Measure the span for allowable slack:

Locate the longest span of each chain (usually the

span which does not run through the idlers).

2. Determine the ideal slack:

Long chains (over 36in/91cm):

Vertical short chains:

Horizontal short chains:

3. Measure the slack by acting at a right angle to the

chain span at the center of the span, and deflecting

in both directions. The slack is the distance of the

movement.

4. Adjust the idlers for ideal slack.

1

1

⁄

in per foot

1

⁄

in per foot (2.1cm/m)

4

1

⁄

2

4

in per foot (4.2cm/m).

2

Installation Instructions 17

Figure 25

Chain Clip Orientation

1

2

Figure 26

Measuring Chain Slack

26482

27264

Small Seeds Drive Sprocket Hanger Bearing

15

Type of Lubrication: Grease

Quantity = Until grease emerges

Drive Chains

As

Required

This installation adds three (3) chains.

Type of Lubrication: Chain Lube

Quantity = Coat thoroughly.

12225

12227

04/02/2009 133-140M

Page 18

18 Small Seeds Option

Appendix

New Parts

This manual covers the installation of several kits. Not all

parts are in all kits.

Quantities are units (“ea”).

Kit Contents

Great Plains Mfg., Inc.

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Quantity in Kit 133-

Call

124A 131A 133A 134A 150A 151A 369A 370A

-out

11

12

13

14

14

15

16

16

16

16

17

18

19

19

20

21

21

22

22

23

24

25

26

27

28

28

29

30

31

32

33

34

35

36

37

11111111133-140M

991199799123-939H

1 1 133-037D

11 1111133-052D

2 2 2 2 2 2 2 2 133-045D

1 1 1 1 1 133-129L

1 133-135L

1 133-148L

1 133-149L

11111111133-130K

1 1 1 1 1 1 1 1 136-017D

1 1 136-057D

1 1 136-170D

1111 136-063D

1 1 136-104D

1 1 136-172D

1 1 136-115D

2 2 2 2 2 2 2 2 168-127D

11111111202-186D

1 1 1 1 1 1 1 1 800-141C

18 18 22 18 18 14 18 18 800-321C

18 18 22 18 18 14 18 18 801-002C

67666676802-041C

1 1 802-045C

44444444802-282C

4 4 4 4 4 4 4 4 803-008C

44444444803-020C

3 3 2 2 2 2 3 3 803-036C

33222233803-169C

4 4 4 4 4 4 4 4 804-009C

44444444804-015C

3 3 2 2 2 2 3 3 804-017C

44444444804-036C

Part

Number

1 1 119-274H

1 1 136-163D

Part Description

MANUAL 6’ SMALL SEED INSTALL

SEED,SGS,&NG WALKBOARD WELD

SMALL SEEDS TUBE WELDMENT

SGS/AUXILLARY DRIVE SHAFT

5’ SGS DRIVE SHAFT

SGS BOX SUPPORT STRAP

6’ 7 1/2" SGS BOX ASSY

6’ 6" SGS BOX ASSEMBLY

5’ 6" SGS BOX ASSEMBLY

5’ 7 1/2" SGS BOX ASSEMBLY

6’ SGS DRIVER ASSY

CHAIN RL #40 49 PITCHES

CHAIN RL #40 42 PITCHES

CHAIN RL #40 40 PITCHES

CHAIN RL #40 94 PITCHES

CHAIN RL #40 62 PITCHES

CHAIN RL #40 63 PITCHES

CHAIN RL #40 142 PITCHES

CHAIN RL #40 217 PITCHES

3/16 X 1 KEY

NG/SGS BOX SPACER

SNAP RING EXT F/PEERLESS G.B.

HOSE CLAMP NO.12 3/4 ID

SCREW HEX SLT10-16X1/2P.THD CT

HHCS 1/2-13X3 1/2 GR5

HHCS 1/2-13X5 GR5

RHSNB 5/16-18X1 GR5

NUT HEX 5/16-18 PLT

NUT HEX 1/2-13 PLT

NUT HEX JAM 1/2-13 PLT

NUT HEX FLG. LOCK 1/2-13 PLT.

WASHER LOCK SPRING 5/16 PLT

WASHER LOCK SPRING 1/2 PLT

WASHER FLAT 1/2 USS PLT

WASHER FLAT 5/16 SAE PLT

133-140M 04/02/2009

Page 19

Great Plains Mfg., Inc.

Installation Instructions 19

Quantity in Kit 133-

Call

124A 131A 133A 134A 150A 151A 369A 370A

-out

38

39

40

41

42

43

44

45

45

45

45

1 1 1 1 1 1 1 1 808-100C

11111111808-160C

1 1 1 1 1 1 1 1 808-170C

991199799816-513C

3 3 2 2 2 2 3 3 817-025C

22222222822-040C

4 4 4 4 4 4 4 4 822-041C

1 1 838-202C

1 1 838-253C

1 1 848-093C

1 1 848-094C

Number

Optional Items

These items are not included in the kits above, and may

be order from your Great Plains dealer or directly from

Great Plains.

Manuals are available in Adobe Portable Document Format (PDF) on the Great Plains web site:

www.greatplainsmfg.com

Callout Part No. Optional Part Description

61

62

63

64

65

66

67

67

118-794B

118-794M

118-794P

151-061B

151-061M

151-061P

838-203C

838-207C

3P500 & 3P600 SEEDRATE BOOK

3P500-3P600 OPERATORS MANUAL

3P500-3P600 PARTS MANUAL

6’ NO-TILL SEEDRATE BOOK

MANUAL 605NT OPERATOR

MANUAL 605NT PARTS

DECAL 3P605NT

DECAL 605NT

Part

Part Description

SPKT 40B22 3/4B W/K.W. &SS

SPKT 40B12 X 36T SPLINE BORE

SPKT 40B17 X 3/4BORE W/KW&SS

SGS HOSE 85 RIBS

NO. 40 12T IDLER SPKT.

BRG INS .75IDX1.85OD SPH LCK

FLANGETTE 47 MST

DECAL 3P600

DECAL 3P500

DECAL 3P606NT

DECAL 606NT

04/02/2009 133-140M

Page 20

20 Small Seeds Option

Existing Parts Affected

The following existing parts are involved in the kit installation. The Disposition column indicates whether the part

is left in place, moved or not re-used.

The part call-out numbers in the list matches all Figures

in the installation instructions. The general descriptions

match those in your drill Parts manual.

Great Plains Mfg., Inc.

The part numbers are representative of parts found on

older drills, but may not exactly match those on your drill.

This is not a concern for undamaged parts re-installed or

not re-used at all. If you need to replace any parts not in

the kit, older the current part number called for in the latest Parts manual.

Callout

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

Typical

Part No.

119-190D

119-192D

119-272H

133-045D

802-007C

802-079C

802-091C

802-203C

803-008C

803-014C

803-020C

803-169C

804-009C

804-013C

804-015C

890-153C

Abbreviations

##T

3P

ASSY

BRG

F/

FLG

G.B.

GR5

HEX

HHCS

ID

INS

K.W.

LCK

MST

Tooth count

Three Point (hitch)

Assembly

Bearing

Fits

Flanged

Gear Box

Grade 5

Hexagonal

Hex Head Cap Screw (Bolt)

Inside Diameter

Inside

Keyway

Lock (collar)

Metric Spherical Two-hole

Typical Part Description Part Disposition

HANDLE Removed and re-installed.

STEP Re-installed if removed.

SEED & SGS WALKBOARD WELDMENT Not re-used if removed.

SGS BOX SUPPORT STRAP Re-installed if removed.

HHCS 5/16-18X3/4 GR5 Removed and re-installed.

HHCS 3/8-16X1 1/4 GR5 Re-installed if removed.

HHCS 1/2-13X1 1/2 GR5 Re-installed if removed.

HFSS 1/2-13X1 1/2 GR5 Removed and re-installed.

NUT HEX 5/16-18 PLT Removed and re-installed.

NUT HEX 3/8-16 PLT Re-installed if removed.

NUT HEX 1/2-13 PLT Re-installed if removed.

NUT HEX FLG. LOCK 1/2-13 PLT. Removed and re-installed.

WASHER LOCK SPRING 5/16 PLT Removed and re-installed.

WASHER LOCK SPRING 3/8 PLT Re-installed if removed.

WASHER LOCK SPRING 1/2 PLT Re-installed if removed.

SMV MOUNTING BLADE Removed and re-installed.

NG

NO.

NT

OD

PLT

RHSNB

SAE

SGS

SLT

SPH

SPKT

SS

THD CT

USS

W/

X

Native Grass

Number

No Till

Outside Diameter

Plated

Round Head Shank Neck Bolt

Society of Automotive Engineers (std.)

Small Grass Seeds

Slotted

Spherical

Sprocket

Set Screw

Thread Cutting (self-tapping)

United States Standard (HD std.)

with

by

133-140M 04/02/2009

Page 21

Great Plains Mfg., Inc.

Torque Values

Installation Instructions 21

Bolt

Size

in-tpi

1

⁄4-20

1

⁄4-28

5

⁄16-18

5

⁄16-24

3

⁄8-16

3

⁄8-24

7

⁄16-14

7

⁄16-20

1

⁄2-13

1

⁄2-20

9

⁄16-12

9

⁄16-18

5

⁄8-11

5

⁄8-18

3

⁄4-10

3

⁄4-16

7

⁄8-9

7

⁄8-14

1-8

1-12

11⁄8-7

11⁄8-12

11⁄4-7

11⁄4-12

13⁄8-6

13⁄8-12

11⁄2-6

11⁄2-12

Bolt Head Identification

Bolt Head Identification

Bolt

Size

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

1

N-m2ft-lb

7.4 5.6 11 8 16 12

8.5 6 13 10 18 14

15 11 24 17 33 25

17 13 26 19 37 27

27 20 42 31 59 44

31 22 47 35 67 49

43 32 67 49 95 70

49 36 75 55 105 78

66 49 105 76 145 105

75 55 115 85 165 120

95 70 150 110 210 155

105 79 165 120 235 170

130 97 205 150 285 210

150 110 230 170 325 240

235 170 360 265 510 375

260 190 405 295 570 420

225 165 585 430 820 605

250 185 640 475 905 670

340 250 875 645 1230 910

370 275 955 705 1350 995

480 355 1080 795 1750 1290

540 395 1210 890 1960 1440

680 500 1520 1120 2460 1820

750 555 1680 1240 2730 2010

890 655 1990 1470 3230 2380

1010 745 2270 1670 3680 2710

1180 870 2640 1950 4290 3160

1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

3

N-m ft-lb N-m ft-lb

mm x pitch

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

1. in-tpi = nominal thread diameter in inches-threads per inch

2. N· m = newton-meters

3. ft-lb = foot pounds

4. mm x pitch = nominal thread diameter in millimeters x thread

pitch

4

5.8 8.8 10.9

N-m ft-lb N-m ft-lb N-m ft-lb

43659 7

7 5 11 8 15 11

17 12 26 19 36 27

18 13 28 21 39 29

33 24 52 39 72 53

39 29 61 45 85 62

58 42 91 67 125 93

60 44 95 70 130 97

90 66 105 77 145 105

92 68 145 105 200 150

99 73 155 115 215 160

145 105 225 165 315 230

155 115 240 180 335 245

195 145 310 230 405 300

220 165 350 260 485 355

280 205 440 325 610 450

310 230 650 480 900 665

480 355 760 560 1050 780

525 390 830 610 1150 845

960 705 1510 1120 2100 1550

1060 785 1680 1240 2320 1710

1730 1270 2650 1950 3660 2700

1880 1380 2960 2190 4100 3220

04/02/2009 133-140M

Page 22

22 Small Seeds Option

Great Plains Mfg., Inc.

EOD

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

133-140M 04/02/2009

Loading...

Loading...