Great Plains 3P600 Operator Manual

Table of Contents Index

3-Point 5-Foot and 6-Foot Drills

Operator Manual

3P500, 3P500V and 3P600

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operation manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

18556

Illustrations may show optional equipment not supplied with standard unit, and may

show 3P500, 3P500V or 3P600 models.

ORIGINAL INSTRUCTIONS

© Copyright 2011 Printed 2011-10-21 118-794M

Table of Contents Index

EN

Rev. B

Table of Contents Index

Table of Contents Index

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ......................................1

Safety Decals .................................................................5

Introduction ..................................................................9

Description of Unit ..........................................................9

Intended Usage ..........................................................9

Models Covered .........................................................9

Document Family........................................................9

Using This Manual........................................................10

Owner Assistance ........................................................10

Preparation and Setup ...............................................11

Pre-Setup Checklist......................................................11

Hitching Tractor to Drill.................................................11

Electrical Connection (Option)......................................12

Height and Leveling the Drill ........................................12

Operation Instructions...............................................13

Pre-Start Checklist .......................................................13

Transporting .................................................................14

Use an Adequate Tractor (3-Point)...........................14

3P500 Example Weights .......................................... 14

3P500V Example Weights........................................ 14

3P600 Example Weights .......................................... 14

Loading Seed ............................................................... 15

Main Seed Box Loading ...........................................15

Loading Small Seeds Box ........................................15

Acremeter Operation ....................................................16

Normal Operating Sequence....................................16

Dormant Display.......................................................16

Field Operation.............................................................17

Parking .........................................................................17

Storage.........................................................................17

Adjustments................................................................18

Adjusting 3-Point Height...............................................19

00 Series Row Unit Adjustments..................................20

Opener Springs ........................................................21

Disc Blade Adjustments ........................................... 22

Disc Scraper Adjustment.......................................... 23

Seed Firmer Adjustments......................................... 23

Seed-Lok® Lock-Up (Option) ............................... 23

Keeton® Seed Firmer Adjustment (Option) .......... 24

Small Seeds Tube Adjustment (Option)................... 24

Opener Depth (Press Wheel Height) ....................... 25

Troubleshooting......................................................... 26

Maintenance and Lubrication ................................... 28

Maintenance ................................................................ 28

Seed Clean-Out ....................................................... 29

Main Box Clean-Out............................................. 29

Small Seeds Box Clean-Out ................................ 29

Seed Flap Replacement........................................... 30

Current Drill Model Flap .......................................30

Older Drill Model Flap .......................................... 30

Chain Maintenance .................................................. 31

Chain Slack .......................................................... 31

Gearbox Maintenance..............................................31

Lubrication and Scheduled Maintenance..................... 32

Options ....................................................................... 34

Seed-Lok® Seed Firmer........................................... 37

Appendix A - Reference Information........................ 39

Specifications and Capacities: 3P500 and 3P600 ....... 39

Specifications and Capacities: 3P500V ....................... 40

Tire Pressures.............................................................. 40

Torque Values Chart.................................................... 41

Drive System Diagrams ............................................... 42

Appendix B - Pre-Delivery......................................... 44

Appendix C - Accessory Installation........................ 46

Carbide Disc Scraper Installation................................. 46

Warranty ..................................................................... 51

Index............................................................................ 53

© Copyright 2000, 2002, 2008, 2011 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2011-10-21 Cover Index 118-794M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

iv 3P500, 3P500V & 3P600 Table of Contents Index Great Plains Manufacturing, Inc.

118-794M Table of Contents Index 2011-10-21

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER, and the color Safety Red, indicate an

imminent hazard which, if not avoided, will result in death

or serious injury. This signal word is limited to the most

extreme situations, typically for machine components

that, for functional purposes, cannot be guarded.

WARNING, and the color Safety Orange, indicate a

potential hazard which, if not avoided, could result in

death or serious injury, and includes hazards that are

exposed when guards are removed. It may also be used

to alert against unsafe practices.

CAUTION, and the color Safety Yellow, indicate a

potential hazard which, if not avoided, may result in

minor or moderate injury. It may also be used to alert

against unsafe practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 5,

thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

2011-10-21 Table of Contents Index

2 3P500, 3P500V & 3P600 Table of Contents Index Great Plains Manufacturing, Inc.

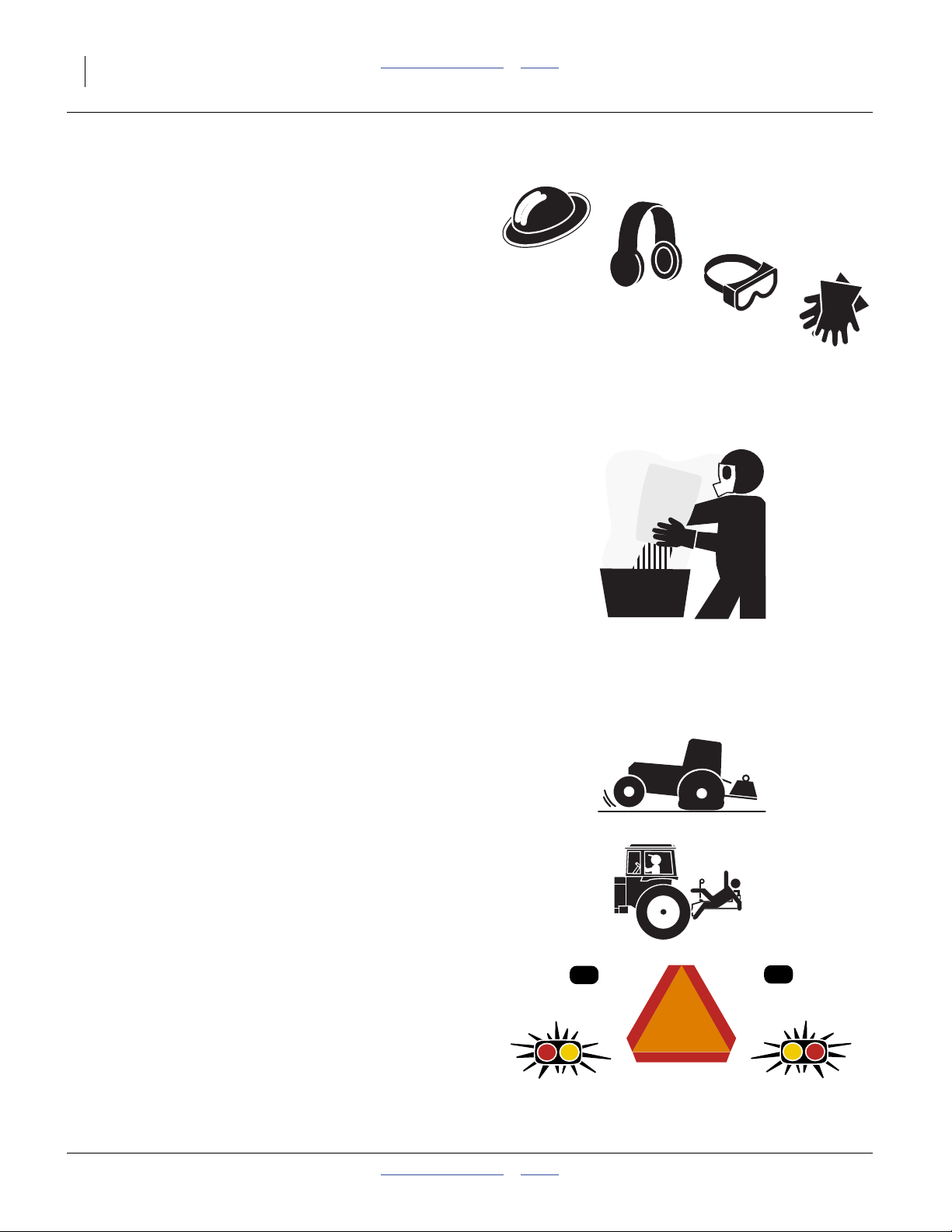

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to loud noise can cause

hearing impairment or hearing loss, wear suitable hearing

protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper use

can seriously injure persons, animals, plants, soil and

property.

▲ Do not use liquid seed treatments with the drill.

▲ Read and follow chemical manufacturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Avoid inhaling smoke from any type of chemical fire.

▲ Never drain, rinse or wash dispensers within 100 feet

(30 m) of a freshwater source, nor at a car wash.

▲ Store or dispose of unused chemicals as specified by

chemical manufacturer.

▲ Dispose of empty chemical containers properly. Laws

generally require power rinsing or rinsing three times,

followed by perforation of the container to prevent re-use.

Use an Adequate Tractor

▲ Ensure that the tractor is rated for, and correctly ballasted

for the drill’s 3-point loading. Check that drill plus ballast

does not exceed the tractor’s capability.

▲ Avoid transport with material loaded in boxes.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever

driving on public roads.

▲ Use lights and devices if provided with implement.

Table of Contents Index 2011-10-21

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

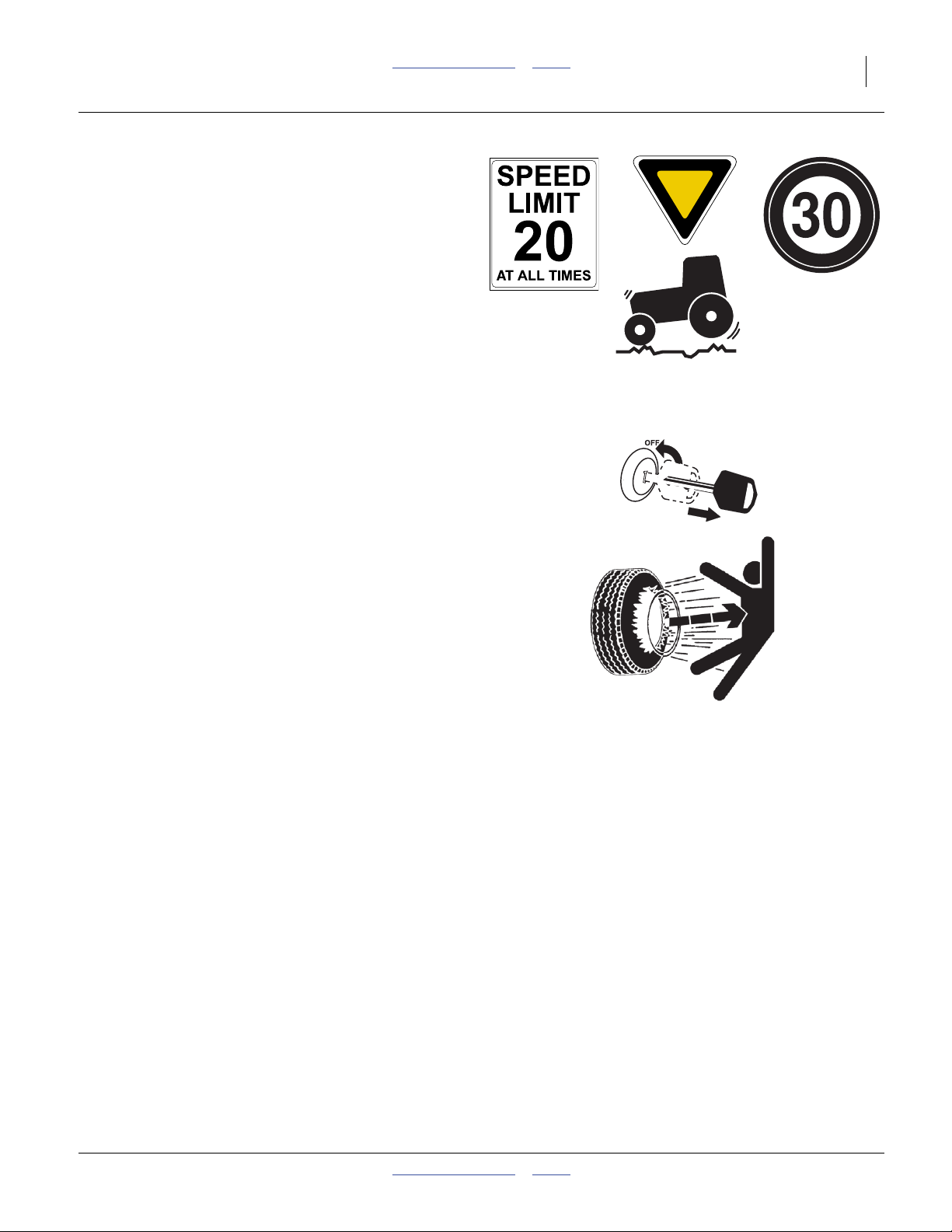

Transport Machinery Safely

Maximum transport speed for the implement on its own

tires is 20 mph (30 kph). Rough terrain may require a

slower speed. Sudden braking can cause a towed load to

swerve and upset.

▲ Do not exceed 20 mph (30 kph). Travel only at a speed

which allows adequate control of steering and stopping.

▲ Comply with state and local laws.

▲ Carry reflectors or flags to mark drill in case of breakdown

on the road.

▲ 3-point implements reduce weight on steering tires. Verify

that tractor is correctly ballasted. Watch for signs of poor

steering traction.

Shutdown and Storage

▲ Park on level ground.

▲ Unhitch and store the drill in an area where children

normally do not play.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

2011-10-21 Table of Contents Index

4 3P500, 3P500V & 3P600 Table of Contents Index Great Plains Manufacturing, Inc.

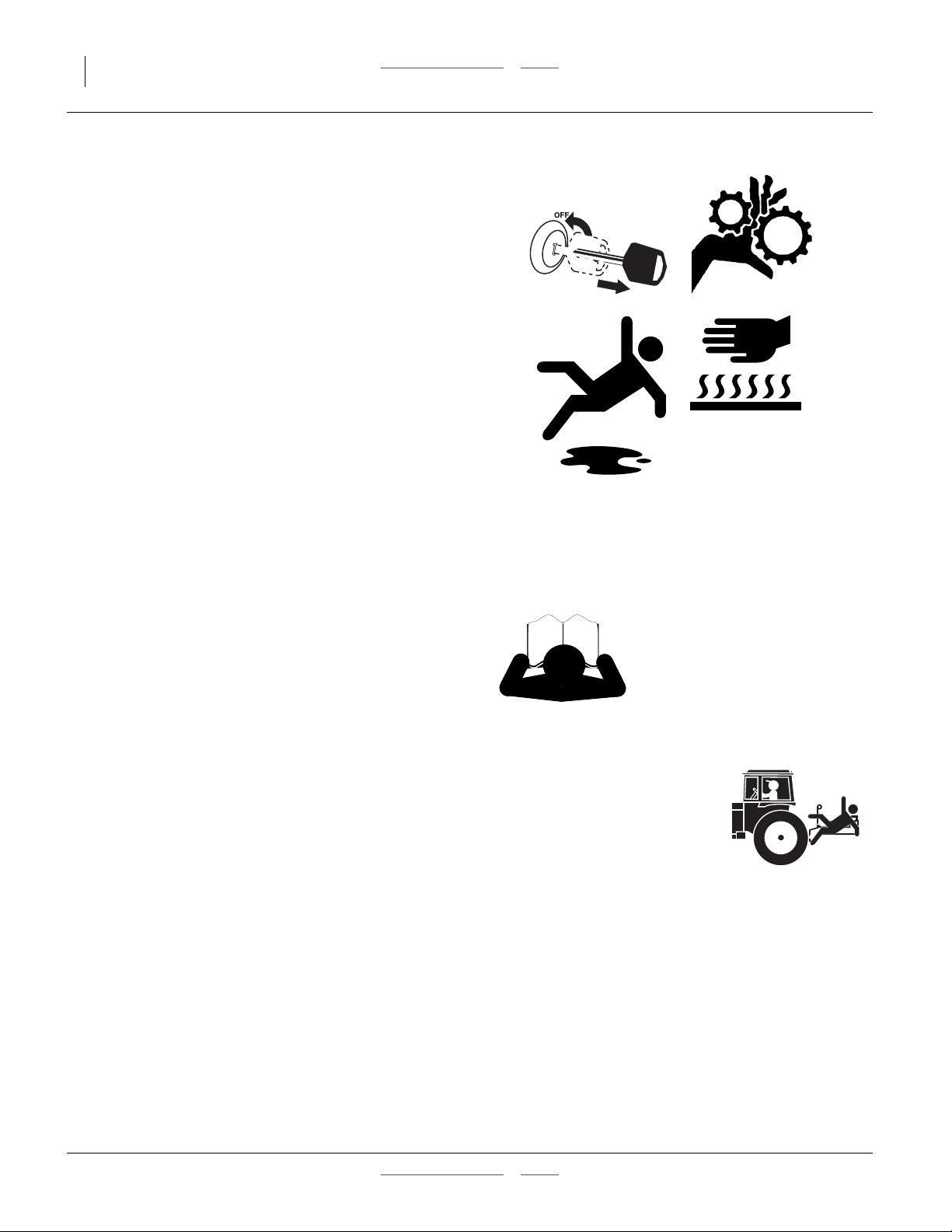

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual.

▲ Work in a clean, dry area.

▲ Lower the drill, put tractor in park, turn off engine, and

remove key before performing maintenance. If work must

be performed with implement raised, use blocks or

jackstands rated for the drill weight.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow drill to cool completely.

▲ Disconnect lighting connector before servicing or

adjusting electrical systems.

▲ Welding: Disconnect battery ground. Avoid fumes from

heated paint.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from drill before

operation.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all drill functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave drill unattended with tractor engine running.

▲ Do not stand between the moving tractor and drill during

hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

▲ Make sure all persons are clear of working area.

Table of Contents Index 2011-10-21

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

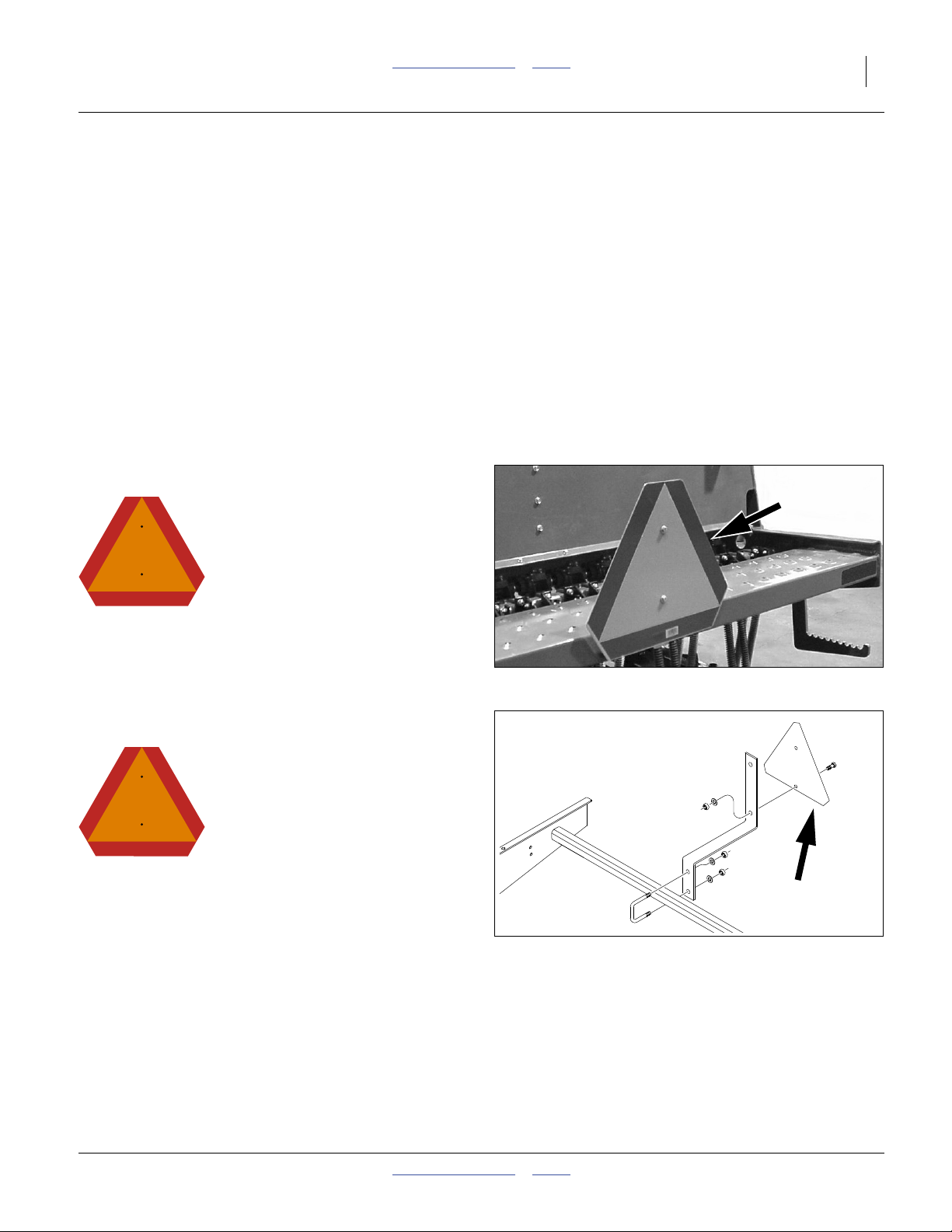

Reflector: Slow Moving Vehicle (SMV)

818-055C

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

18490

Models 3P500 and 3P600

At center of walkboard;

1 total

See transport topic on page 14.

Reflector: Slow Moving Vehicle (SMV)

818-055C

Model 3P500V

At center of walkboard;

1 total

See transport topic on page 14.

32717

2011-10-21 Table of Contents Index

6 3P500, 3P500V & 3P600 Table of Contents Index Great Plains Manufacturing, Inc.

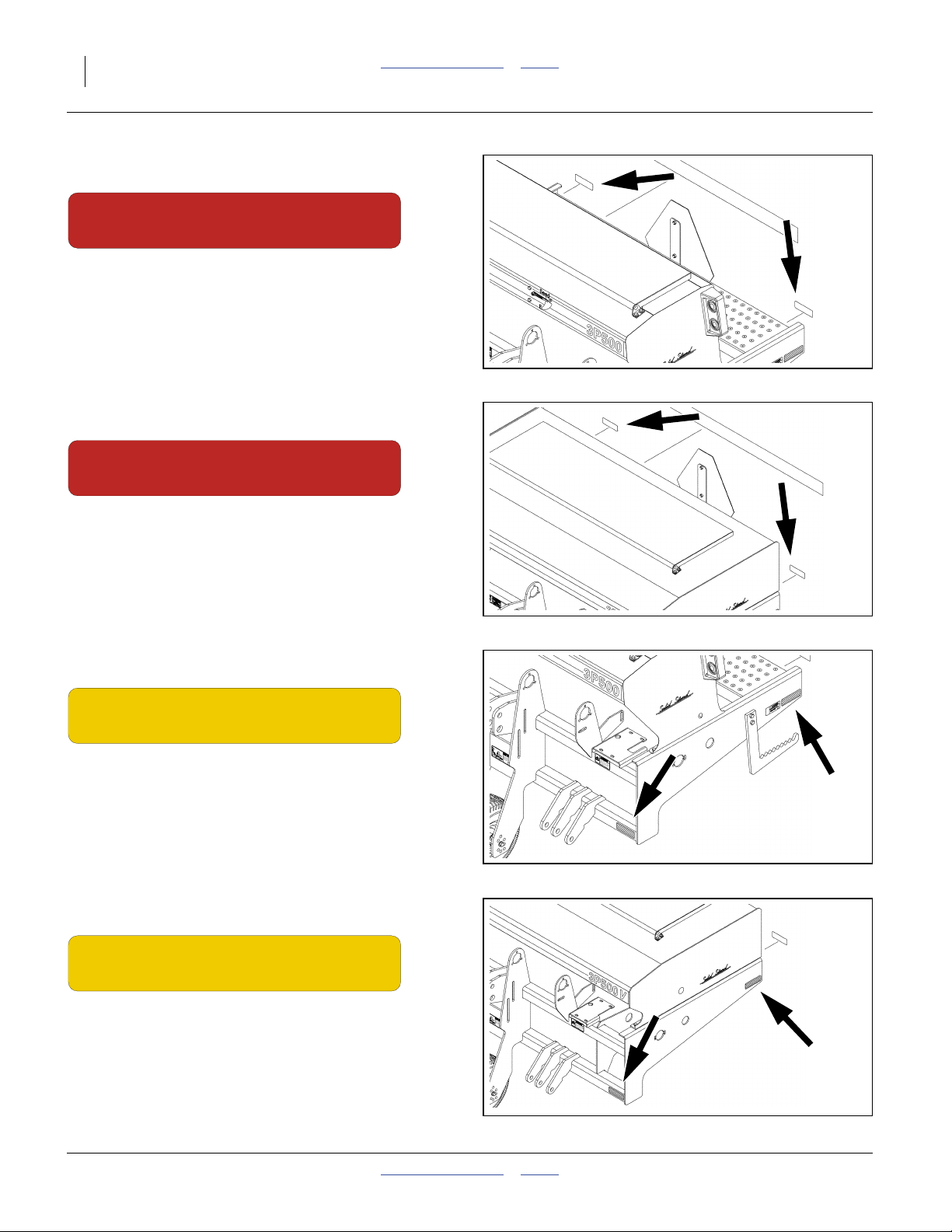

Reflectors: Red

838-266C

Models 3P500 and 3P600 (standard) Model 3P500V (Option)

On rear face of walkboard, left and right ends;

2 total

See transport topic on page 14.

Reflectors: Red

838-266C

Model 3P500V (Standard)

On rear face of seed box, left and right ends;

2 total

See transport topic on page 14.

32713

32727

Reflectors: Amber

838-265C

Models 3P500 and 3P600

On outside face of side frames, at rear below walkboard

face of walkboard, and on front face of lower front tool

bar, at ends;

4 total

See transport topic on page 14.

Reflectors: Amber

838-265C

Model 3P500V

On outside face of side frames, at rear, and

on front face of lower front tool bar, at ends;

4 total

See transport topic on page 14.

32713

32727

Table of Contents Index 2011-10-21

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

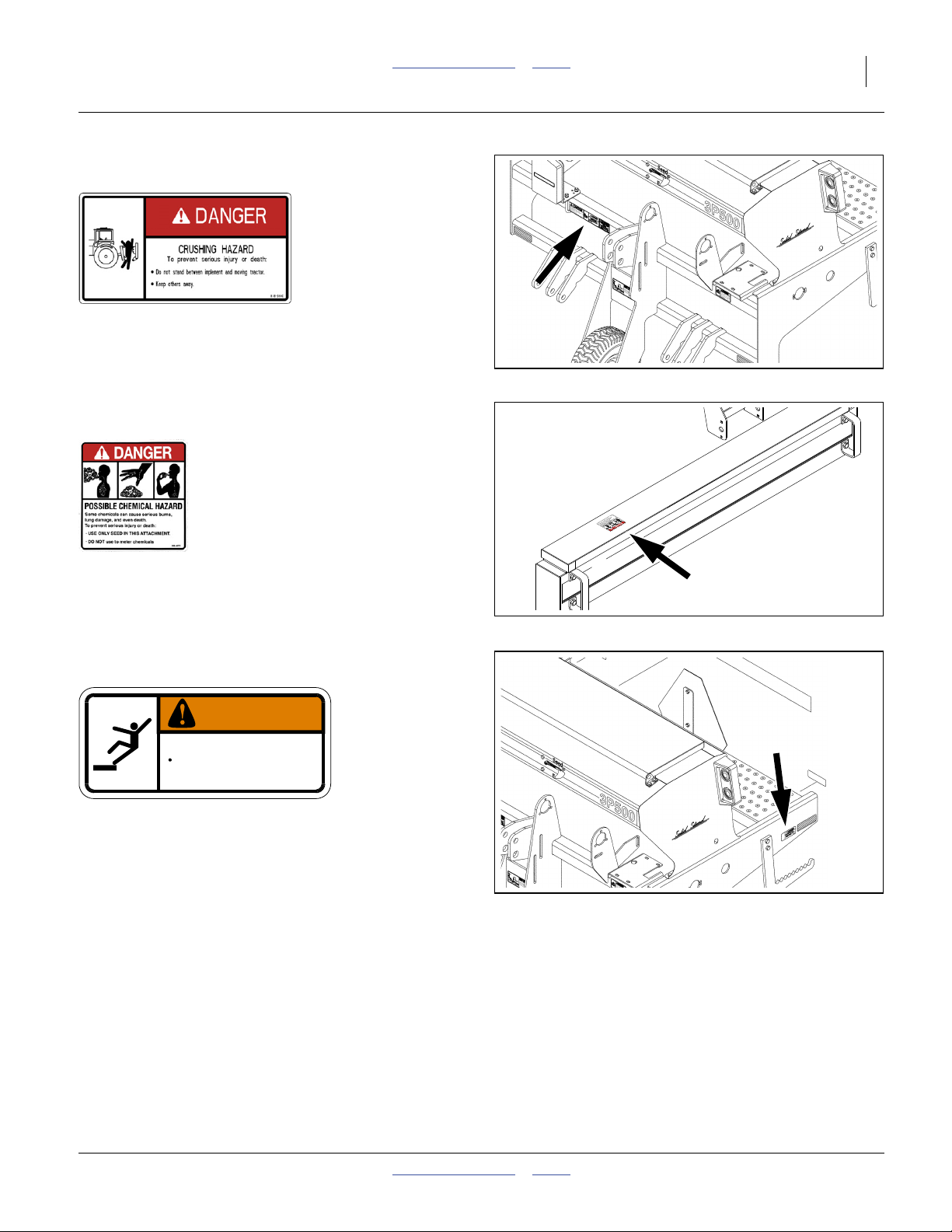

Danger: Hitch Crush

818-590C

All Models

Front face, top front tool bar, right of center;

32713

2 total

Danger: Possible Chemical Hazard (Option)

838-467C

(with Small Seeds Option only)

Under lid;

1 total

Warning: Falling Hazard

838-102C

WARNING

To avoid serious injury or death:

Watch your step when climbing ladder or

walking on walkboard.

Models 3P500 and 3P600 (standard) Model 3P500V (Option)

On side frames at walkboard ends;

2 total

See “Loading Seed” on page 15.

838-102C

32696

32713

2011-10-21 Table of Contents Index

8 3P500, 3P500V & 3P600 Table of Contents Index Great Plains Manufacturing, Inc.

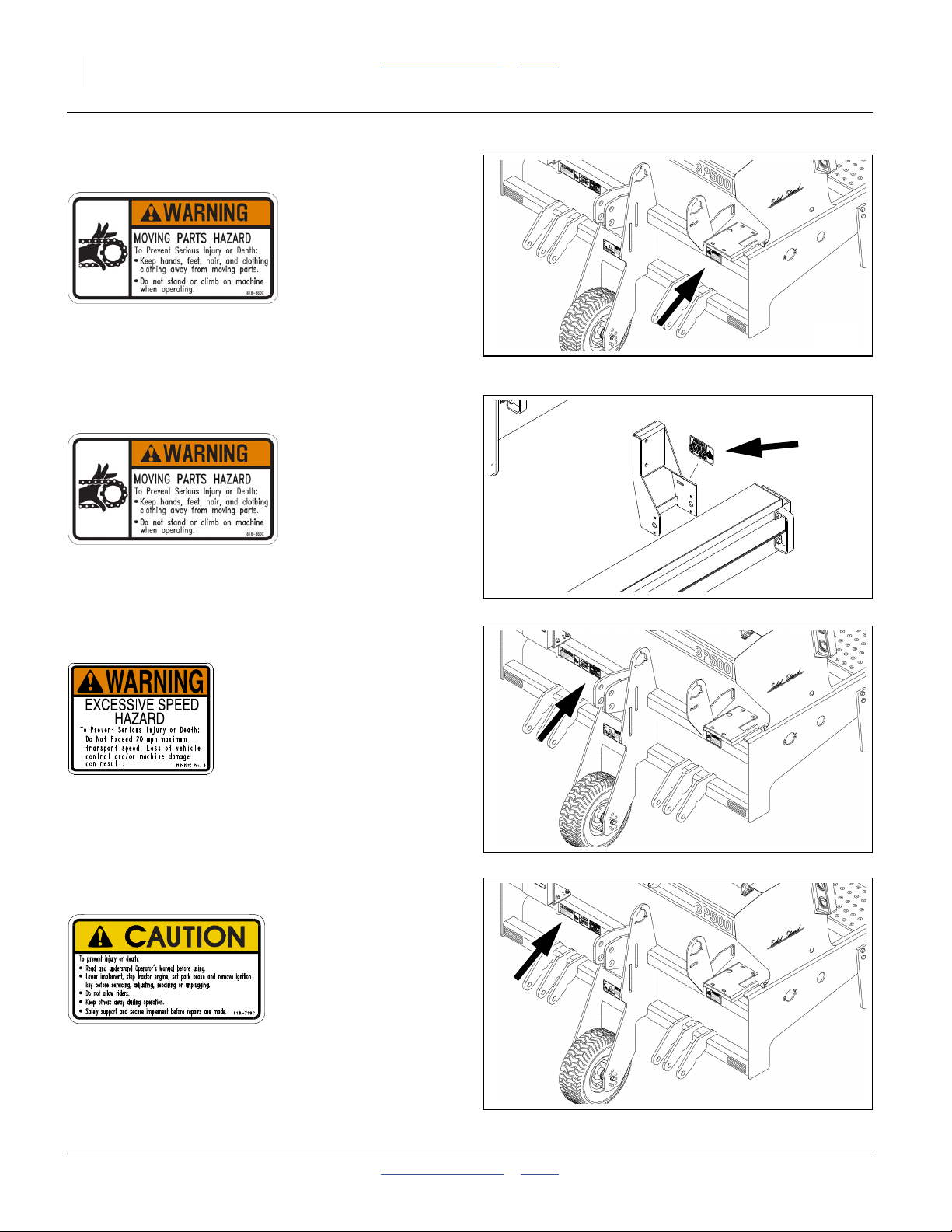

Warning: Moving Parts (standard)

818-860C

All Models

On front face, upper front frame tube, below gearbox;

1 total

32713

Warning: Moving Parts (Option)

818-860C

(with Small Seeds Option only)

On front face, upper front frame tube, below gearbox;

1 total

Warning: Speed

818-337C

All Models

On front face, upper front frame tube, right of center;

1 total

See transport topic on page 14.

Caution: General

818-719C

32696

32713

All Models

On front face, upper front frame tube, right of center;

1 total

See “Important Safety Information” on page 1.

Table of Contents Index 2011-10-21

32713

Great Plains Manufacturing, Inc. Table of Contents Index 9

Introduction

Great Plains welcomes you to its growing family of new

product owners. Your no-till drill has been designed with

care and built by skilled workers using quality materials.

Proper setup, maintenance, and safe operating practices

will help you get years of satisfactory use from the

machine.

Description of Unit

The 3P500, 3P500V and 3P600 are 3-point seeding

implements. The drill has straight arm, double disc

00 Series openers. The opener discs make a seed bed,

and seed tubes mounted between the discs place seed

in the furrow. Press wheels following the opener discs

close the furrow and gauge opener seeding depth.

A T-handle on the opener body makes seeding depth

adjustments.

The metering system is driven from the gauge wheel.

Seeding rates are set by rate adjustment handles and a

Drive Type gearbox for the main seed box.

Intended Usage

Use this implement to seed production-agriculture crops

in conventional or minimum tillage applications.

Models Covered

This manual applies to Great Plains drill models:

3P500-0775 7-Row 7.5 in. (19.1 cm)

3P500-0906 9-Row 6 in. (15.2 cm)

3P500V-0775 7-Row 7.5 in. (19.1 cm)

3P500V-0872 8-Row 7.25 in. (18.4 cm)

3P500V-0906 9-Row 6 in. (15.2 cm)

3P600-0975 9-Row 7.5 in. (19.1 cm)

3P600-1106 11-Row 6 in. (15.2 cm)

Standard drills have a Main Seed box. Small Seeds

capability may be added to Models 3P500 or 3P600.

The Model 3P500V (Vineyard) is a low-profile version of

the 3P500.

Document Family

118-794M Operator Manual (this document)

118-794P Parts Manual

118-794B Seed Rate Manual

152-314M Electronic Acremeter Manual

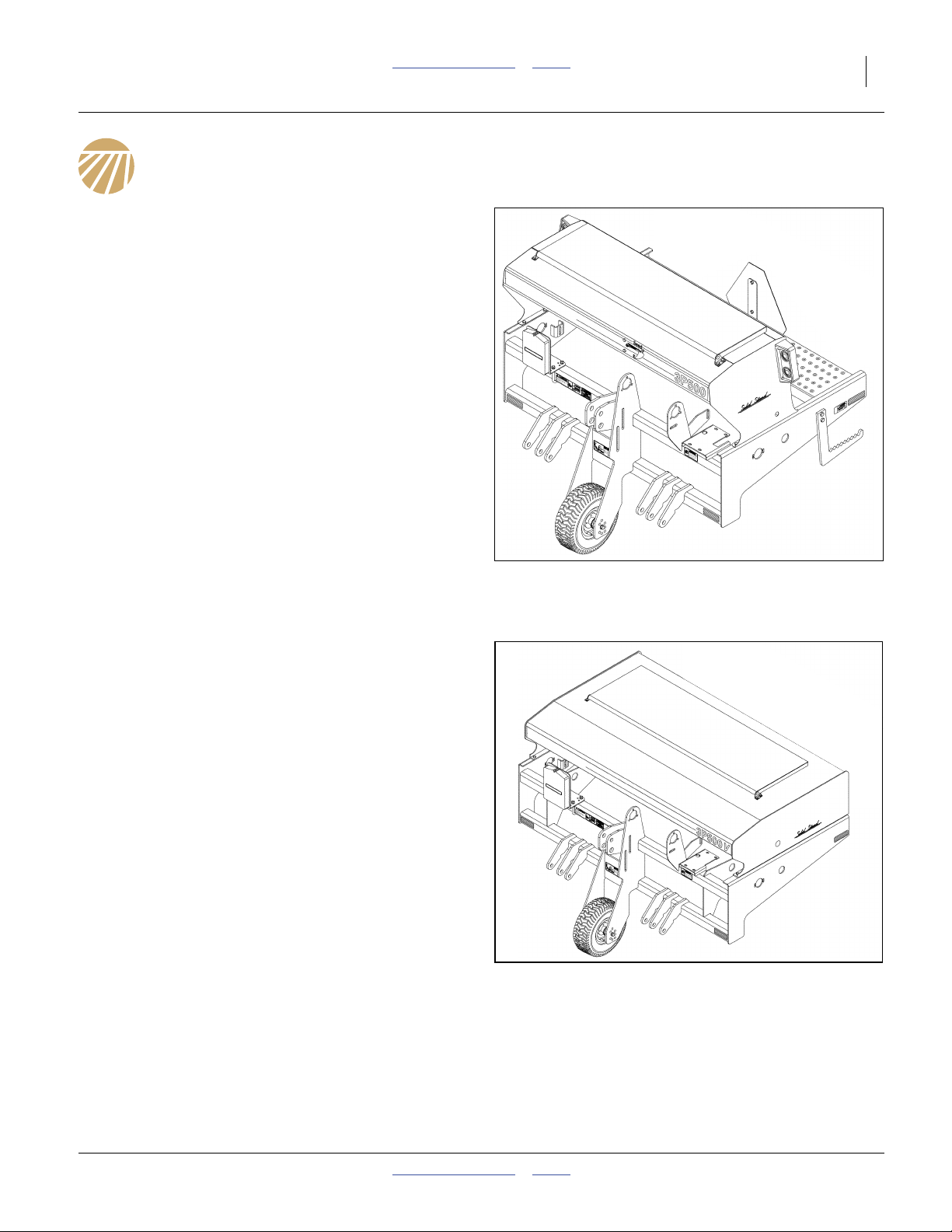

Figure 1

3P500 No-Till Drill

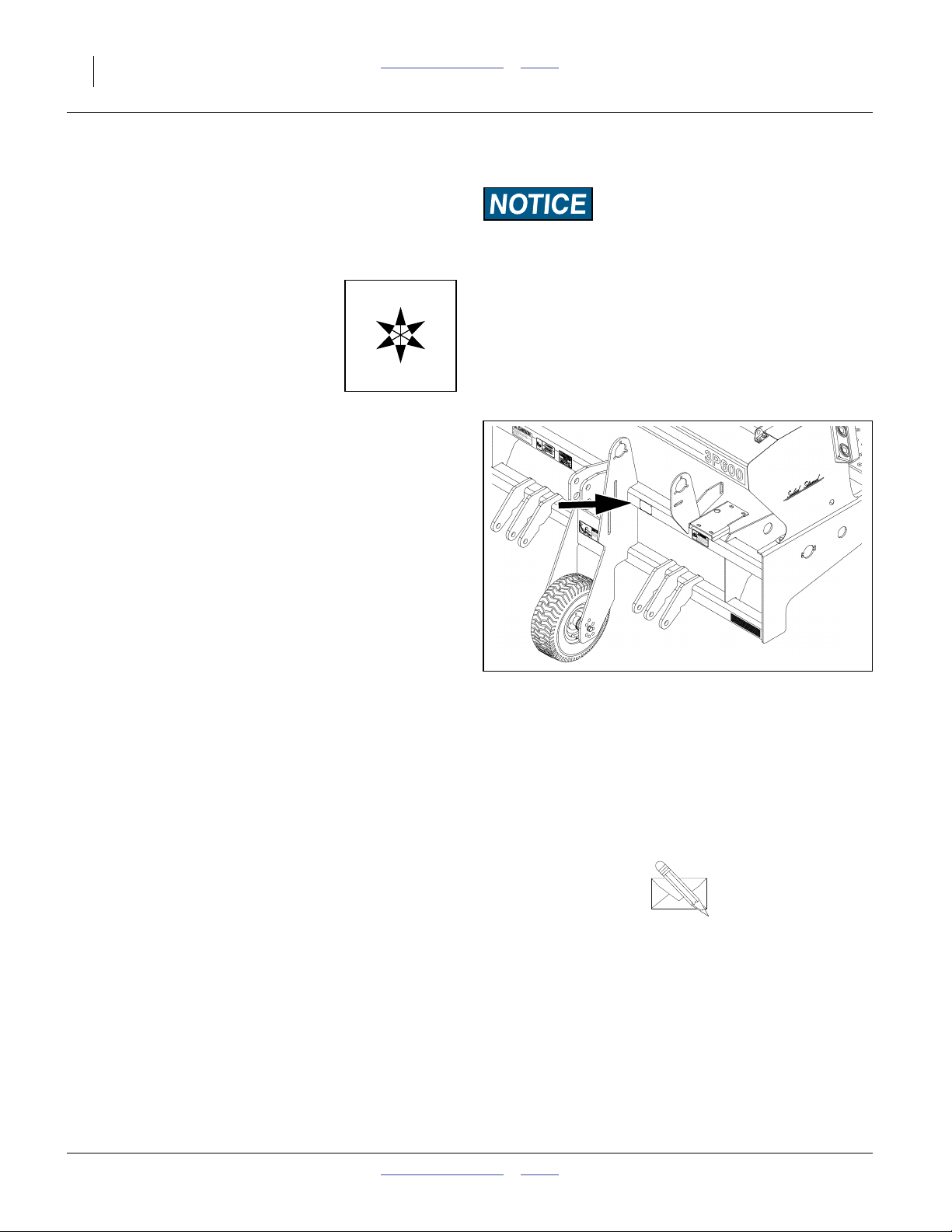

Figure 2

3P500V No-Till Drill

32713

32727

2011-10-21 Table of Contents Index

10 3P500, 3P500V & 3P600 Table of Contents Index Great Plains Manufacturing, Inc.

Using This Manual

This manual familiarizes you with safety, assembly,

operation, adjustments, troubleshooting, and

maintenance. Read this manual and follow the

recommendations to help ensure safe and efficient

operation.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

U

R

F

D

B

L

Identifies an Economic (not a Safety) Risk:

NOTICE provides a crucial point of information related to the

current topic. Read and follow the instructions to avoid damage

to equipment and ensure desired field results.

Note: This form sets off useful information related to the

current topic, or forestalls possible

misunderstanding.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

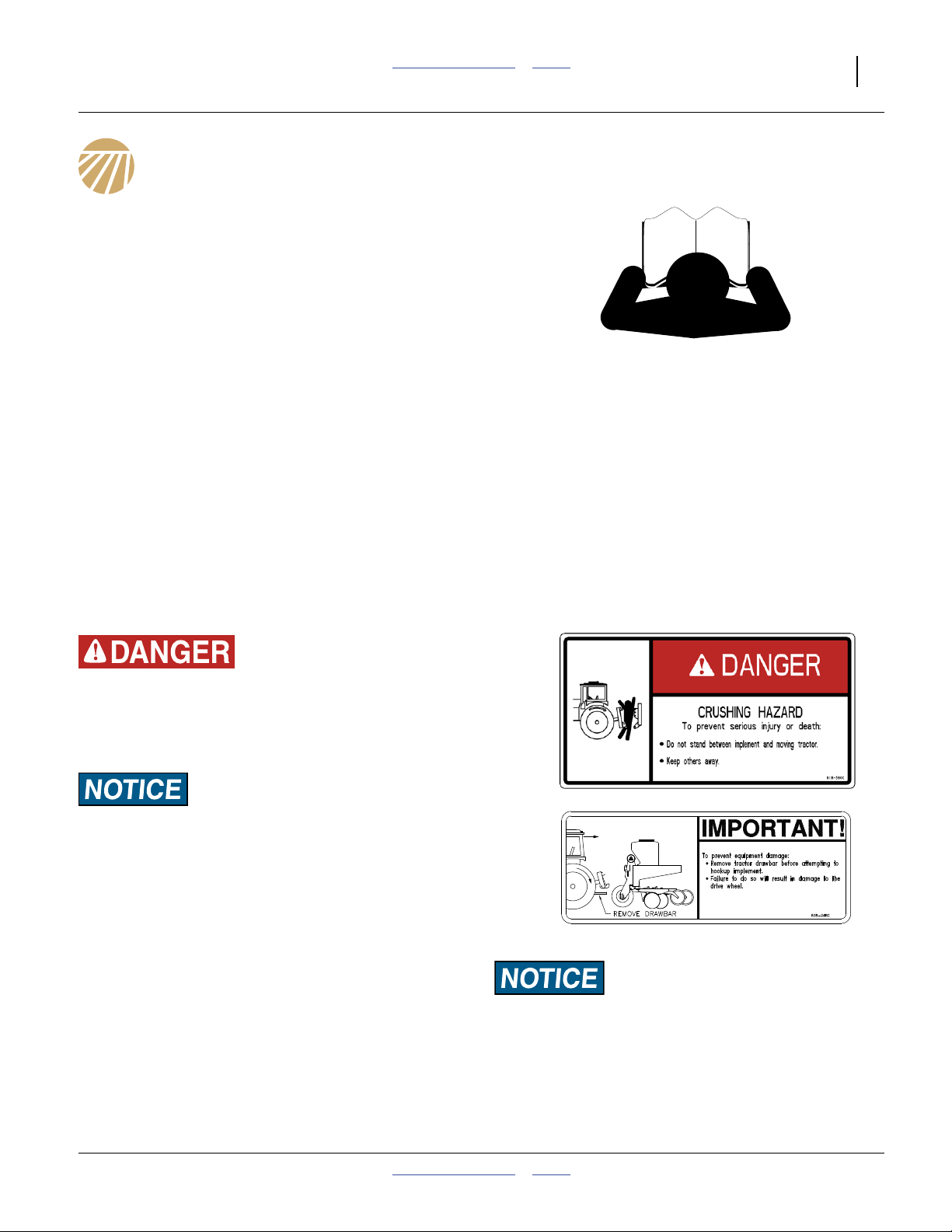

Refer to Figure 3

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts. Always

use the serial and model number when ordering parts

from your Great Plains dealer. The serial-number plate is

located on the upper front frame tube, left of center.

Record your drill model and serial number here for quick

reference:

Model Number:__________________________

Serial Number: __________________________

Figure 3

Serial Number Location

18709

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

Table of Contents Index 2011-10-21

For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

gp_web_cs@greatplainsmfg.com

785-823-3276

Great Plains Manufacturing, Inc. Table of Contents Index 11

Preparation and Setup

This section helps you prepare your tractor and drill for

use. Before using the drill in the field, you must hitch the

drill to a suitable tractor and also setup the drill.

Pre-Setup Checklist

1. Verify that dealer pre-delivery is complete (page 44)

and optional accessories are installed (page 46).

2. Read and understand “Important Safety

Information” on page 1.

3. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

4. Check that all grease fittings are in place and

lubricated. See “Lubrication and Scheduled

Maintenance” on page 32.

5. Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged.

See “Safety Decals” on page 5.

6. Inflate tires and tighten wheel bolts as at “Tire

Pressures” on page 40.

Hitching Tractor to Drill

Crushing Hazard:

You may be severely injured or killed by being crushed

between the tractor and drill. Do not stand or place any part of

your body between drill and moving tractor. Stop tractor

engine and set park brake before installing the hitch pin.

Certain Machine Damage:

Remove tractor draw bar before hitching. The drill drive wheel

will be damaged if drawbar is not removed.

1. Raise or lower tractor 3-point arms as needed and

pin lower arms to drill.

2. Pin upper arm to drill.

3. Slowly raise drill. Watch for cab interference.

4. Adjust top 3-point link so the top edge of drill box is

parallel with the ground when drilling.

Note: Do not use link to adjust opener depth. For opener

adjustments, refer to “Opener Depth (Press

Wheel Height)” on page 25. Set your tractor

3-point draft control to Float position for planting.

Equipment Damage Risk:

Due to interference with the gauge wheel assembly, drill

models 3P500, 3P500V and 3P600 are not compatible with

Great Plains accessory hitches CPH, PFH and SSH, nor with

the Great Plains hitch set-back kit.

2011-10-21 Table of Contents Index

12 3P500, 3P500V & 3P600 Table of Contents Index Great Plains Manufacturing, Inc.

Electrical Connection (Option)

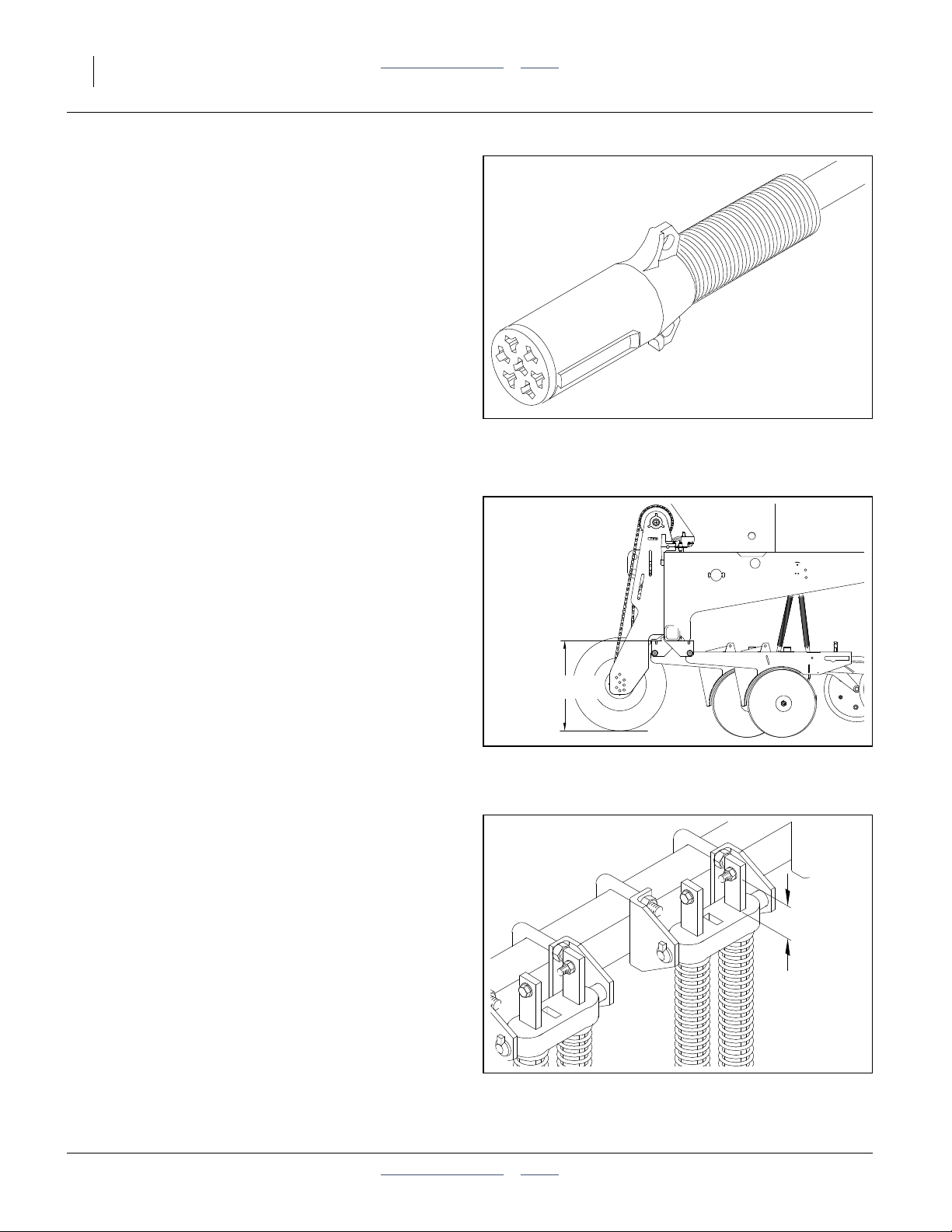

Refer to Figure 4

5. Plug drill electrical lead into tractor seven-pin

connector. If your tractor is not equipped with an

SAE-J560B seven-pin connector, contact your dealer

for installation.

Height and Leveling the Drill

Refer to Figure 5 and Figure 9 on page 19

1. Initially adjust drill so opener tool bar runs

18 in. (45.7 cm) above ground when drill is lowered

in the field.

2. The drive wheel should be in the fourth mounting

hole from the top (factory setting).

Note: The drive may need to be adjusted due to ground

conditions.

3. Level the drill frame with the top 3-point link.

Refer to Figure 6

4. When drill is level, the gap between the spring-rod

casting and the cross bolt will be about 2 inches.

This is a general dimension that will vary with the

amount of down pressure required for your planting

conditions.

18 in. (45.7 cm)

Figure 4

Lighting Connector

Figure 5

Initial Field Height

26467

18545

2.0 in.

5.1 cm

Figure 6

Initial Spring Rod Reveal

Table of Contents Index 2011-10-21

10548

Great Plains Manufacturing, Inc. Table of Contents Index 13

Operation Instructions

This section covers general operating procedures.

Experience, machine familiarity and the following

information will lead to efficient operation and good

working habits. Always operate farm machinery with

safety in mind.

Pre-Start Checklist

1. Carefully read “Important Safety Information”

starting on page 1.

2. Lubricate drill per “Lubrication and Scheduled

Maintenance” starting on page 32.

3. Check all tires for proper inflation. See “Tire

Pressures” on page 40.

4. Check all bolts, pins and fasteners. See “Torque

Values Chart” on page 41.

5. Check drill for worn or damaged parts. Repair or

replace faulty parts before going to the field.

6. Rotate both drive wheel to verify that the drive and

meters are working properly and free from foreign

material.

Falling Hazard:

Watch your step when walking on drill steps and walkboard.

Falling from drill could cause severe injury or death.

WARNING

To avoid serious injury or death:

Watch your step when climbing ladder or

walking on walkboard.

838-102C

2011-10-21 Table of Contents Index

14 3P500, 3P500V & 3P600 Table of Contents Index Great Plains Manufacturing, Inc.

Transporting

Use an Adequate Tractor (3-Point)

Loss of Control Hazard:

Insufficient weight on tractor steering tires can dangerously

reduce steering authority, particularly during acceleration and

ascending hills. You can lose directional control entirely,

which could result in a major accident, serious injury, or

death. Adding too much ballast could lead to brake or other

mechanical failures, tire failures and loss of control.

▲ Ensure that the tractor is rated for, and correctly ballasted

for the drill’s 3-point loading. Check that drill plus ballast

does not exceed the tractor’s capability.

▲ Avoid transport with material loaded in boxes.

The total drill weight and center of gravity vary with drill

configuration and material load. See tables below.

3P500 Example Weights

Standard Drill (Main Seed Only), Empty

Standard Drill with Main Seed Loaded

Drill with Small Seeds option, Empty

Drill with Main and Small Seeds Loaded

3P500V Example Weights

Standard Drill (Main Seed Only), Empty

Standard Drill with Main Seed Loaded

3P600 Example Weights

Standard Drill (Main Seed Only), Empty

Standard Drill with Main Seed Loaded

Drill with Small Seeds option, Empty

Drill with Main and Small Seeds Loaded

3P500 Configuration

7-Row 7.5 inch (19.1 cm)

1100 lbs. (500 kg) 1300 lbs. (590 kg)

1700 lbs. (770 kg) 1900 lbs. (860 kg)

1170 lbs. (530 kg) 1370 lbs. (620 kg)

1840 lbs. (840 kg) 2040 lbs. (930 kg)

3P500V Configuration

7-Row 7½ in. 8-Row 7¼ in.

(19.1 cm) (18.4 cm) (15.2 cm)

1100 lbs. (500 kg) 1200 lbs. (540 kg) 1300 lbs. (590 kg)

1700 lbs. (270 kg) 1800 lbs. (270 kg) 1900 lbs. (270 kg)

3P600 Configuration

9-Row 7.5 inch (19.1 cm)

1380 lbs. (630 kg) 1500 lbs. (680 kg)

2100 lbs. (950 kg) 2220 lbs. (1010 kg)

1470 lbs. (670 kg) 1590 lbs. (720 kg)

2270 lbs. (1030 kg) 2390 lbs. (1090 kg)

9-Row 6 inch (15.2 cm)

32807D

9-Row 6 in.

32807E

11-Row 6 inch (15.2 cm)

32807G

Table of Contents Index 2011-10-21

Loading...

Loading...