Page 1

Part Lists Great Plains Manufacturing, Inc. 1

Caster Wheel Update Kit

3P806NT and 3P1006NT Drills

Used with:

• 3P806NT (S/N A1034V-)

• 3P1006NT (S/N A1047-)

General Information

These instructions explain how to install a Caster Wheel

Update Kit. One kit updates an entire drill:

Kit Kit Description

124-047A Caster Wheel Update Kit

Related Documents

Have the Operator and Parts Manuals at hand.

151-143M Operator, 3P806NT

151-143P Parts, 3P806NT

151-144M Operator, 3P1006NT

151-144P Parts, 3P1006NT

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

Your life and the lives of others depend on it!

Tools Required

• basic hand tools

• grease and grease gun

Work Location

1. Move the implement to a location with:

• flat, smooth surface

• adequate illumination

Prepare Drill

2. Block the tires and install the parking jack.

3. Disconnect all hydraulic and electrical conections at

the hitch. Secure hoses and cables to prevent

ground contact.

Notations and Conventions

U

F

L

D

“Left” and “Right” are facing in the

direction of machine travel. An orienta-

R

tion rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

B

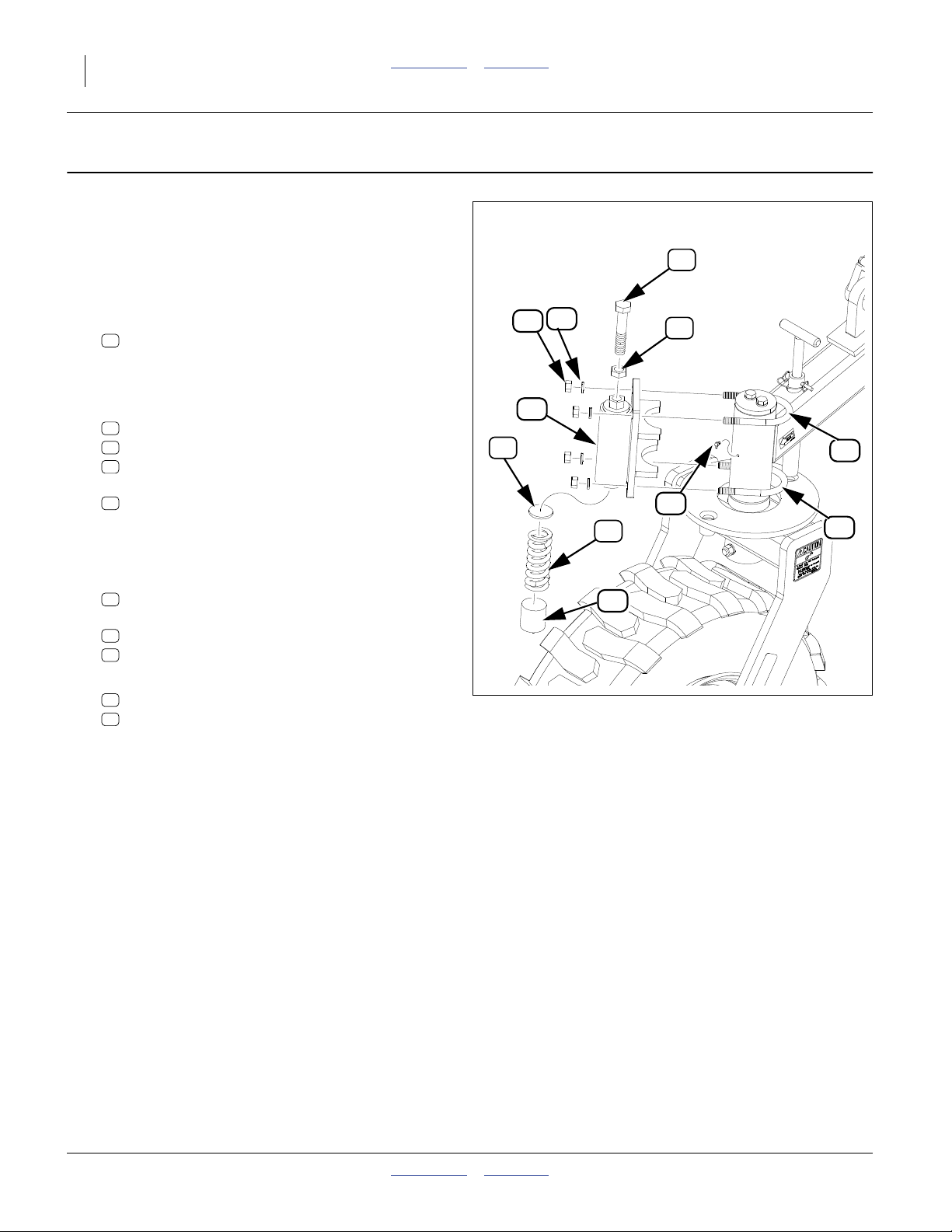

Figure 1

Caster Wheel Update Kit

High Pressure Fluid Hazard:

Releive pressure from all lines before

working on hydraulic connections. Wear

eye protection and gloves when opening hydraulic

connections. Open connections slowly. Use a piece of

paper or cardboard, NOT BODY PARTS, to check for leaks. Escaping

fluid under pressure can have sufficient pressure to penetrate the skin

causing serious injury. If an accident occurs, seek immediate medical

assistance from a physician familiar with this type of injury.

29969

Call-Outs

1 9

to

11

to

51

Single-digit callouts identify components in

the currently referenced Figure. These numbers may be reused for different items from

page to page.

21

Two-digit callouts in the range 11 to 21 reference new parts from the list on page 4.

This callout references an existing part from

page 4.

© Copyright 2009 Printed 12/22/2009 Part Lists 124-049M

Page 2

2 Great Plains Manufacturing, Inc. Front Page Part Lists Caster Wheel Update

Caster Wheel Update

Installation

Refer to Figure 2

These instructions are for both caster wheels.

1. Remove existing straight grease zerk from lift assist

arm.

2. Replace with 90 degree zerk from kit:

15

800-073C GREASE ZERK 1/4-28 X90-DEG

3. Using grease gun apply one or two shots of grease

to zerk.

4. Select one each:

13

266-012D PLATE RND 3/16" THK 1 7/8"

21

807-143C SPRING COMP 1.88OD X .362W

14

266-020D UHMW RND 2.0 DIA X 2.0 LONG

Install in bottom of caster disk weldmount

12

124-048H CASTER DISC MOUNT.

5. Leaving room for grease zerk maintenance, rotate

assembly to the left and install on lift assist arm.

13

17

12

19

21

16

18

20

15

20

Select two:

20

806-217C U-BOLT ROUND 1/2-13 X 3 9/3

Select four washers and nuts:

19

804-015C WASHER LOCK SPRING 1/2 PLT

17

803-020C NUT HEX 1/2-13 PLT

6. Select one bolt and nut:

18

803-048C NUT HEX JAM 3/4-10 PLT

16

802-067C HHCS 3/4-10X4 GR5 FTHD

Install in top of caster disk mount.

7. Repeat steps 1 through 7 for opposite caster wheel.

14

Figure 2

Caster Disk Mount

29968

124-049M Front Page Part Lists 12/22/2009

Page 3

Caster Wheel Update Front Page Part Lists Great Plains Manufacturing, Inc. 3

Final Adjustments

The function of this new drill feature is to dampen caster

motion. This avoids oscillation in transport and possible

furrow damage in the field.

Refer to Figure 3

Initial Adjustment

1

⁄

The initial adjustment should be about 1

inches from

2

the bracket base to bolt head top.

Field and Road Adjustments

Check castering in both field and road transport. Adjust

as needed.

The caster brake may need to be adjusted as field and

road conditions vary. Factors affecting the caster brake

adjustment include: field residue, no-till or min-till conditions and moisture.

Check Adjustments

It may also be necessary to adjust when switching from

field to road transport or vice versa.

1.5 in.

Figure 3

29967

Final Caster Brake Adjustments

12/22/2009 Front Page Part Lists 124-049M

Page 4

4 Front Page Part Lists

Appendix

Part Lists

New Parts

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Quantities are units (“ea”).

Kit Contents

124-047A Caster Wheel Update Kit

Callout Quantity Part Number Part Description

11 1 124-049M MANUAL CASTER DISC MOUNT

12 2 124-048H CASTER DISC MOUNT

13 2 266-012D PLATE RND 3/16" THK 1 7/8"

14 2 266-020D UHMW RND 2.0 DIA X 2.0 LONG

15 2 800-073C GREASE ZERK 1/4-28 X 90-DEG

16 2 802-067C HHCS 3/4-10X4 GR5 FTHD

17 8 803-020C NUT HEX 1/2-13 PLT

18 2 803-048C NUT HEX JAM 3/4-10 PLT

19 8 804-015C WASHER LOCK SPRING 1/2 PLT

20 4 806-217C U-BOLT ROUND 1/2-13 X 3 9/3

21 2 807-143C SPRING COMP 1.88OD X .362W

Existing Parts Affected

The following existing parts are involved in the kit installation. The Disposition column indicates whether the part

is left in place, moved or not re-used.

The part call-out numbers in the list matches all Figures

in the installation instructions. The descriptions match

those in your implement Parts manual.

Callout Part No. Part Description Part Disposition

51 800-001C GREASE ZERK STRAIGHT 1/4-28 Removed. Not reused.

Abbreviations

3P, 3-PT Three Point (hitch) NT No-Till

DEG Degree OD Outside Diameter

DIA Diameter PLT Plated

F/ For RND Round

FTHD Full Thread THK Thick

GR5 Grade 5 UHMW Ultra High Molecular Weight

HEX Hexagonal (6-sided) W Wide/Width

HH Hydraulic Hose W/ With

HHCS Hex Head Cap Screw (Bolt) X by

JIC Joint Industry Conference (Fitting)

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

124-049M Front Page Part Lists 12/22/2009

Loading...

Loading...