Page 1

Table of Contents Index

3N-4010F, 3N-4010HDF and 3N-4020F

3-Section 40-Foot No-Till Drills

Operator Manual

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

20476

Illustrations may show optional equipment not supplied with standard unit or may

depict similar models where a topic is identical.

ORIGINAL INSTRUCTIONS

© Copyright 2013 Printed 2013-10-29 196-359M

Table of Contents Index

EN

Page 2

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ...................................... 1

Safety Decals ................................................................. 5

Introduction ................................................................11

Document Family .........................................................11

Description of Unit ........................................................11

Models Covered by this Manual ...............................11

Intended Usage ........................................................11

Definitions................................................................. 11

Using This Manual........................................................12

Owner Assistance ........................................................12

Preparation and Setup ...............................................13

Pre-Setup Checklist......................................................13

Hitching ........................................................................13

Make Electrical Connections ....................................13

Make Hydraulic Connections.................................... 14

Hydraulic Circuit Connections ..................................14

Initial Setup...................................................................16

Initial Tractor Setup ..................................................16

Veris Controller.....................................................16

Point Row Switch Module.....................................17

Drill Setup Checks....................................................17

Hydraulic Bleed ....................................................17

Drill Level..............................................................17

Drill Option Setup .....................................................17

Scrapers (Option) ................................................. 17

Marker Setup (Option) ..........................................18

Shaft Monitor (Option) .......................................... 18

Install Weight Brackets (Option)...............................19

Install Outer Brackets ........................................... 19

Install Mid-Wing Brackets .....................................20

Operating Instructions...............................................21

Pre-Start Checklist .......................................................21

Lift / Lower....................................................................22

Opener Operation Lowered......................................22

Rephasing Lift System..............................................22

Folding the Drill ............................................................23

Unfolding the Drill .........................................................24

Transport ......................................................................26

Pre-Transport Checklist............................................ 27

Loading Seed ............................................................... 28

No Seed Lubricants..................................................28

Planting ........................................................................29

Seed Rate ................................................................29

Set Seed Rate Handle..........................................29

Set Seed Cup Door ..............................................29

About Hydraulic Drive Rate.................................. 30

Seeding Depth ......................................................... 30

Point Row Switches ..................................................... 31

Point Row CAL Mode...............................................31

Field Operations........................................................... 32

Final Field Checklist ................................................. 32

Planting Sequence ................................................... 32

Marker Operation (Option) ........................................... 33

Shaft Monitor Operation (Option) ............................. 33

Parking......................................................................... 34

Storage ........................................................................ 34

Hydraulic Drive Operation......................................... 35

Drive Operational Requirements.................................. 35

Hydraulic System: .................................................... 35

Electrical System:..................................................... 35

Tractor Hookup ............................................................ 35

Hydraulics: ............................................................... 35

Electrical:.................................................................. 35

Controller Menu ........................................................... 36

Console Functions ....................................................... 37

Basic Operation ........................................................... 37

Power Up ................................................................. 37

Seed Rate ................................................................ 37

Power Off ................................................................. 37

Hydraulic Drive Field Operations ................................. 38

Seed Rate Calibration.................................................. 39

Seed Rate Calibration Steps....................................39

Hydraulic Drive Calibration....................................... 40

Prime Seed Meters .............................................. 44

Full Calibration .....................................................47

Speed Calibration ........................................................ 51

Varying Rates with Pre-set Function............................ 54

GPS-Based Planting .................................................... 55

FarmWorks SiteMate ............................................... 55

GP Precision Population Settings ............................ 56

Ag Leader PF3000 ................................................... 57

Precision Population Settings .............................. 58

Adjustments ............................................................... 59

Planting Depth ............................................................. 59

Frame Level ................................................................. 60

Frame Height ............................................................... 60

Frame Height without Frame-Mounted Coulters.......... 61

Frame-Mounted Coulters ............................................. 63

Frame Height - Frame Mounted Coulters ................ 63

© Copyright 2003, 2005, 2010, 2012, 2013 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2013-10-29 Cover Index 196-359M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Verti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Individual Frame-Mounted Coulter Depth ................ 65

Frame-Mounted Coulter Force................................. 66

Row Unit Shut-Off ........................................................ 66

Implement Lift Switch Adjustment................................ 67

Frame Weight .............................................................. 68

Available Down Force .............................................. 68

Marker Adjustments ..................................................... 69

Marker Disk Adjustment........................................... 69

Adjusting Mark Width ........................................... 69

10 Series Row Unit Adjustments ................................. 70

10 Series Row Unit Down Pressure......................... 71

10 Series Disk Blade Adjustments........................... 72

10 Series Seed Firmer Adjustments ........................ 73

10 Series Opener Depth .......................................... 74

10HD Series Row Unit Adjustments ............................ 75

Unit-Mounted Coulter Adjustments .......................... 76

10HD Row Unit Down Pressure............................... 78

Row Unit Down Pressure......................................... 79

10HDP Series Down-Pressure............................. 79

10HD Row Unit Lock-Up ...................................... 80

10HD Disk Blade Adjustments................................. 80

10HD Seed Firmer Adjustments .............................. 81

10HD Press Wheel Adjustments.............................. 82

Opener Depth (Press Wheel Height) ................... 82

10HD Press Wheel Spacing................................. 83

20 Series Row-Unit Adjustments ................................. 84

20 Series Row-Unit Down Pressure......................... 85

20 Series Row-Unit Planting Depth.......................... 85

20 Series Disk Adjustments ..................................... 86

Side Gauge Wheel Adjustments .............................. 86

20 Series Seed Firmer Adjustments ........................ 88

20 Series Press Wheels........................................... 89

Troubleshooting......................................................... 90

General Drill Troubleshooting ...................................... 90

Point Row Troubleshooting.......................................... 92

Hydraulic Drive Troubleshooting.................................. 92

Calibration Troubleshooting: .................................... 95

Hydraulic Drive Troubleshooting Flow Chart ............... 96

Hydraulic Drive Electronics Troubleshooting ............... 97

GPS Troubleshooting................................................... 98

Troubleshooting GPS with SiteMate ........................ 98

Troubleshooting GPS with PF3000.......................... 99

Maintenance and Lubrication ................................. 100

Welding ...................................................................... 100

Seed Cleanout ........................................................... 101

Frame Alignment and Level ....................................... 101

Adjusting Fold Cylinders ........................................ 101

Level Frame Side to Side....................................... 102

Level Frame Front to Rear..................................... 102

Box Alignment........................................................ 103

Tongue Spacer Block .................................................104

Bleeding Hydraulics....................................................105

Bleeding Lift Hydraulics ..........................................105

Bleeding Fold Hydraulics ........................................106

Lock Cylinders ....................................................106

Fold Cylinders.....................................................106

Marker Maintenance...................................................107

Bleeding Markers....................................................107

Marker Speed .........................................................107

Single Marker/Needle Valve Speed....................107

Dual-Marker/Sequence Valve Speed .................108

Marker Shear Bolt Replacement.............................108

Marker Chain Length ..............................................109

Electric Clutch Lockup ................................................109

Hydraulic Drive Maintenance......................................110

To change the element: ..........................................110

Row Unit Maintenance ...............................................111

Seed Flap Replacement (s/n 1066TT-) ..................111

Seed Flap Replacement (s/n 1067TT+) .................111

10HD Opener Maintenance ....................................112

20 Series Opener Maintenance ..............................112

Lubrication ..................................................................114

Options ......................................................................119

Hitch Options ..............................................................119

Flat Fold Markers........................................................119

Dual Weight Kit...........................................................120

Frame-Mounted Coulters........................................120

Coulter Tines ..............................................................121

Shaft Monitor ..............................................................121

Row Unit Options........................................................121

Seed Tube Plug ......................................................121

10HD Unit-Mounted Coulters..................................122

15in Coulter Blades ............................................122

10HD Lock-Up Pin ..................................................122

Inside Carbide Scrapers .........................................123

20 Series Depth Wheel Scraper .............................123

Seed Firmers ..............................................................124

Seed-Lok® Seed Firmer.........................................124

Keeton Seed Firmer................................................124

Press Wheels .............................................................124

Appendix ...................................................................125

Specifications and Capacities.....................................125

Tire Inflation Chart ......................................................125

Torque Values Chart ..................................................126

Row Spacing Data......................................................127

Hydraulic Diagram ......................................................130

Warranty .....................................................................131

Index ..........................................................................133

196-359M Table of Contents Index 2013-10-29

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

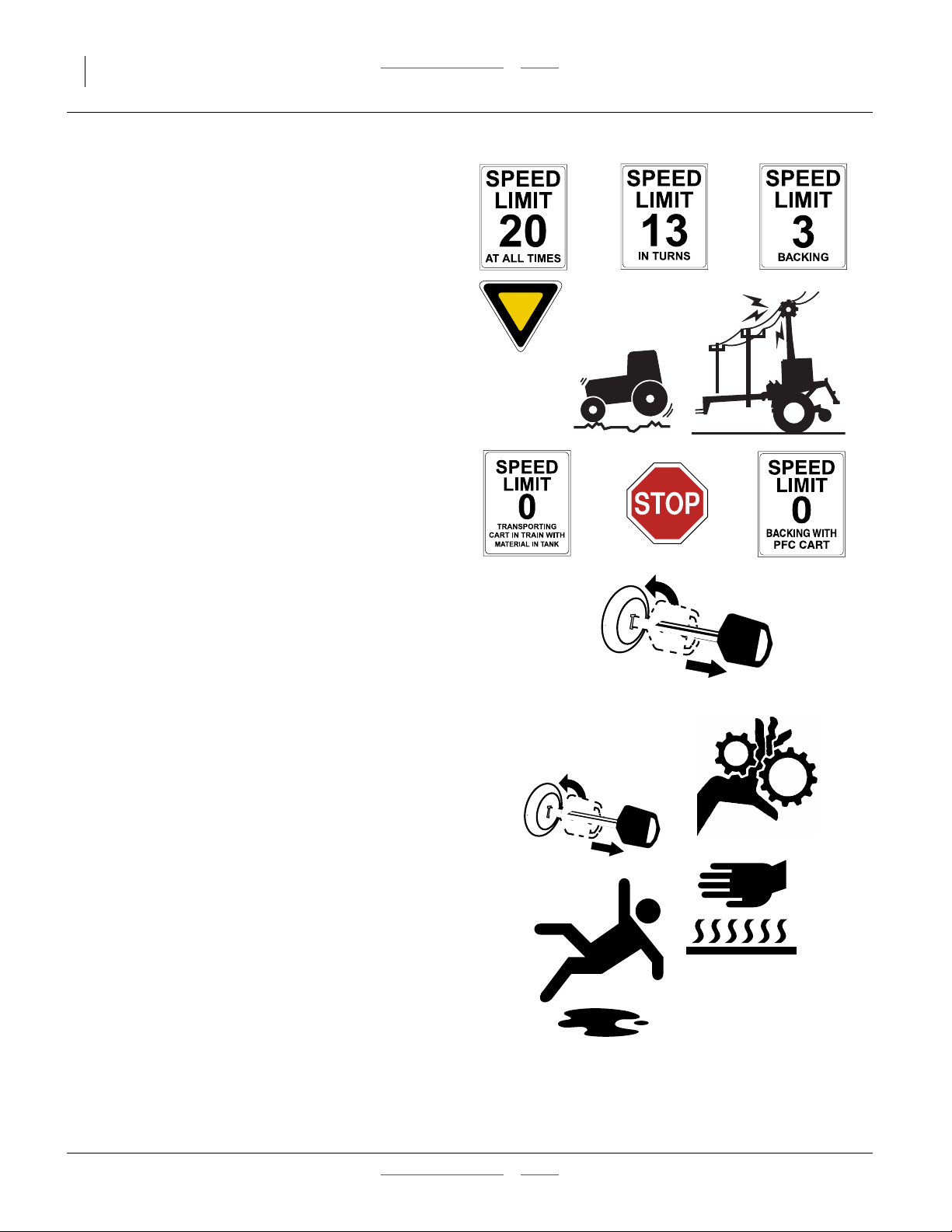

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

000

112

911

999

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 5, thor-

oughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

2013-10-29 Table of Contents Index 196-359M

Page 6

2 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

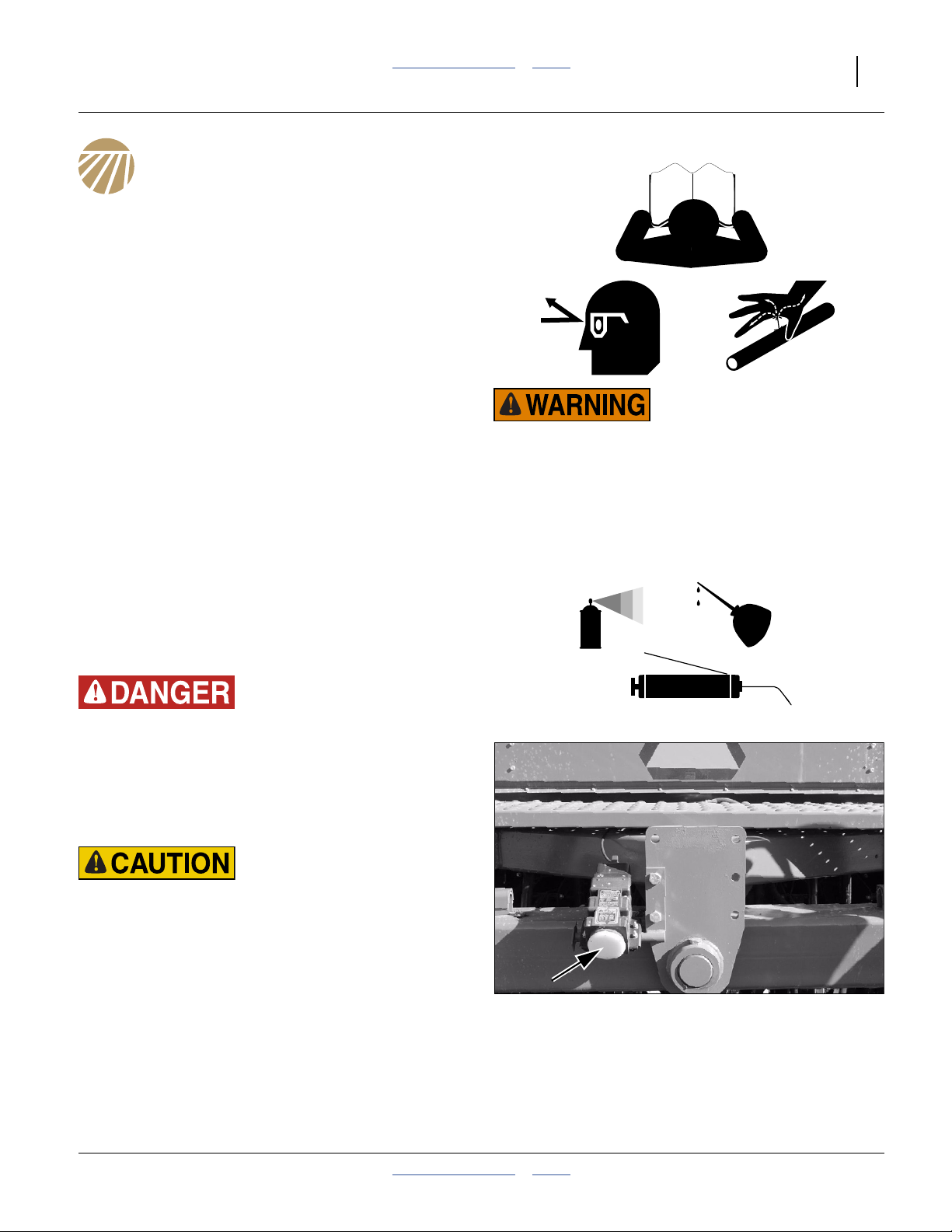

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to loud noise can cause hear-

ing impairment or hearing loss, wear suitable hearing protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper use

can seriously injure persons, animals, plants, soil and

property.

▲ Do not use liquid treatments with drill.

▲ Read and follow chemical manufacturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Avoid inhaling smoke from any type of chemical fire.

▲ Never drain, rinse or wash dispensers within 100 feet (30m)

of a freshwater source, nor at a car wash.

▲ Store or dispose of unused chemicals as specified by chemi-

cal manufacturer.

▲ Dispose of empty chemical containers properly. Laws gener-

ally require power rinsing or rinsing three times, followed by

perforation of the container to prevent re-use.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical attention

from a physician familiar with this type of injury.

196-359M Table of Contents Index 2013-10-29

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

Use A Safety Chain

▲ Use a safety chain to help control drawn machinery should

it separate from tractor drawbar.

▲ Use a chain with a strength rating equal to or greater than

the gross weight of towed machinery.

▲ Attach chain to tractor drawbar support or other specified

anchor location. Allow only enough slack in chain to permit

turning.

▲ Replace chain if any links or end fittings are broken,

stretched or damaged.

▲ Do not use safety chain for towing.

Check for Overhead Lines

Drill markers contacting overhead electrical lines can

introduce lethal voltage levels on drill and tractor frames.

A person touching almost any metal part can complete

the circuit to ground, resulting in serious injury or death.

At higher voltages, electrocution can occur without direct

contact.

▲ Avoid overhead lines during seed loading and marker oper-

ations.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine when fold-

ing/unfolding, raising/lowering markers, raising/lowering

openers, and transporting.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever driv-

ing on public roads.

▲ Use lights and devices provided with drill.

2013-10-29 Table of Contents Index 196-359M

Page 8

4 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Transport Machinery Safely

Maximum transport speed for drill is 20 mph (32 kph).

Some rough terrains require a slower speed. Sudden

braking can cause a towed load to swerve and upset.

▲ Drill must be raised, locked-up, folded and locked for trans-

port.

▲ Do not exceed 20 mph (32 kph). Never travel at a speed

which does not allow adequate control of steering and stopping. Reduce speed if towed load is not equipped with

brakes.

▲ Comply with national, regional and local laws.

▲ Do not tow a load that weighs more than 1.5x the weight of

the tractor. See page 26 for details.

▲ Carry reflectors or flags to mark drill in case of breakdown

on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions under

“Specifications and Capacities” on page 125.

Shutdown and Storage

▲ Clean out and safely store or dispose of residual chemicals.

▲ Secure drill using blocks and transport locks. Lower open-

ers if not locked up.

▲ Store in an area where children normally do not play.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper tools

and equipment. Refer to this manual on the Parts manual

for additional information.

▲ Work in a clean, dry area.

▲ Put tractor in park, turn off engine, and remove key before

performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on drill.

▲ Inspect all parts. Make sure parts are in good condition and

installed properly.

▲ Remove buildup of grease, oil or debris.

OFF

OFF

▲ Remove all tools and unused parts from drill before opera-

tion.

196-359M Table of Contents Index 2013-10-29

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

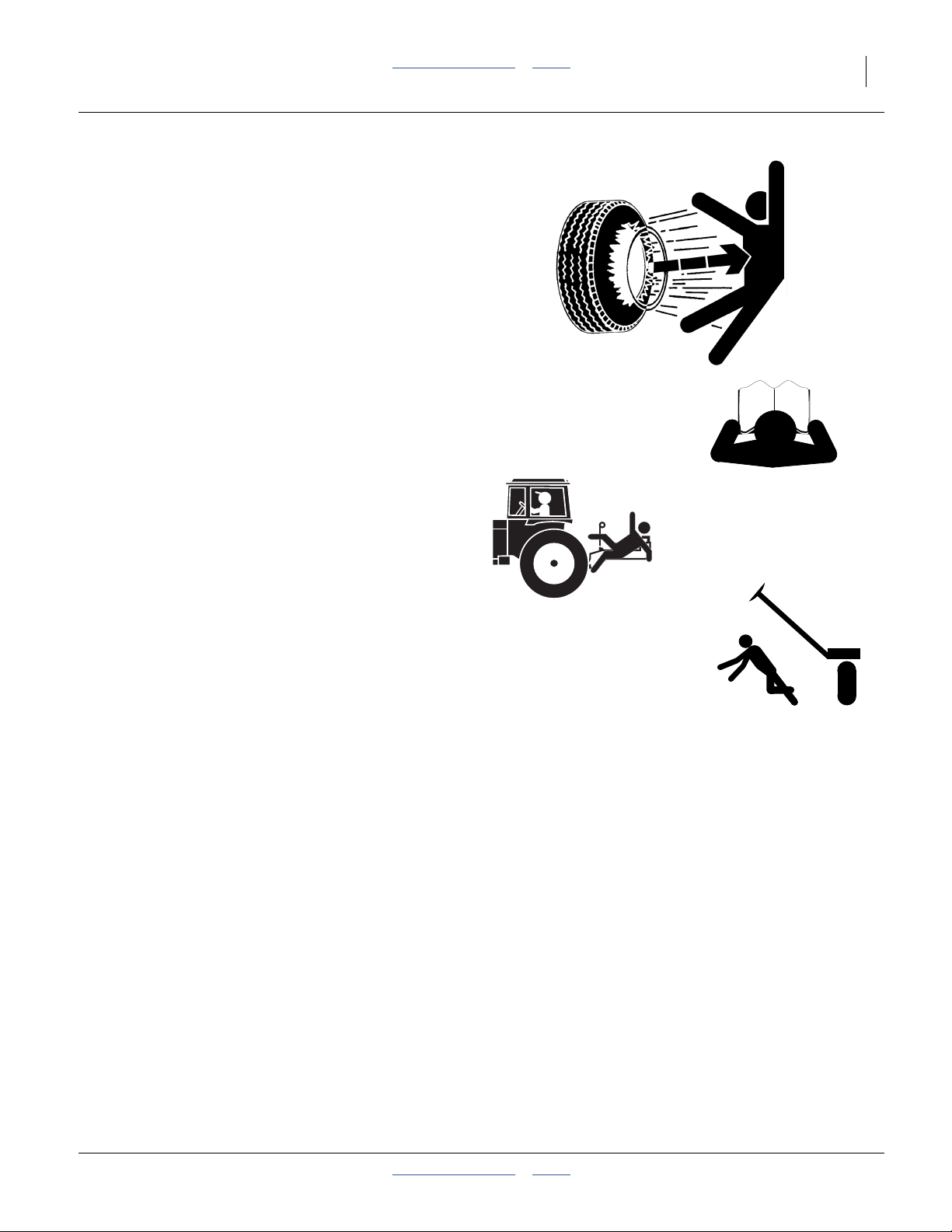

Tire Safety

Tire changing can be dangerous and should be performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all drill functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave drill unattended with tractor engine running.

▲ Do not dismount a moving tractor. Dismounting a moving

tractor could cause serious injury or death.

▲ Do not stand between the tractor and drill during hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with mov-

ing parts.

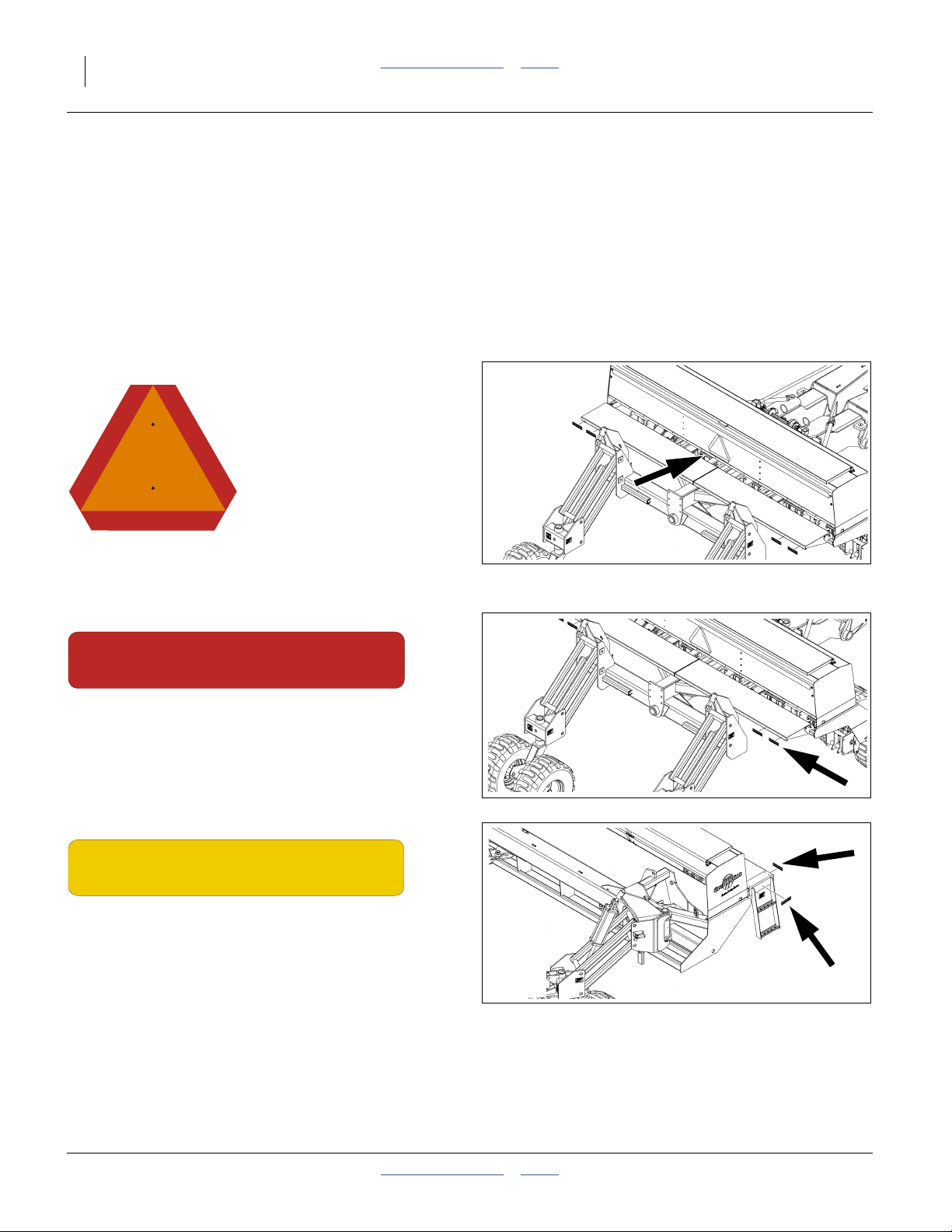

Safety Decals

Safety Reflectors and Decals

Your drill comes equipped with all lights, safety reflectors

and decals in place. They were designed to help you

safely operate your drill.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request cor-

responding safety decals.

To install new decals:

2013-10-29 Table of Contents Index 196-359M

Page 10

6 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

818-055C

Slow Moving Vehicle Reflector

Center rear of center box;

1 total

838-266C

Red Reflectors

On the outside edge of center walkboard each end;

4 total

838-265C

Amber Reflectors

On the ends and back edges of walkboards on both

wings;

2 total

196-359M Table of Contents Index 2013-10-29

Page 11

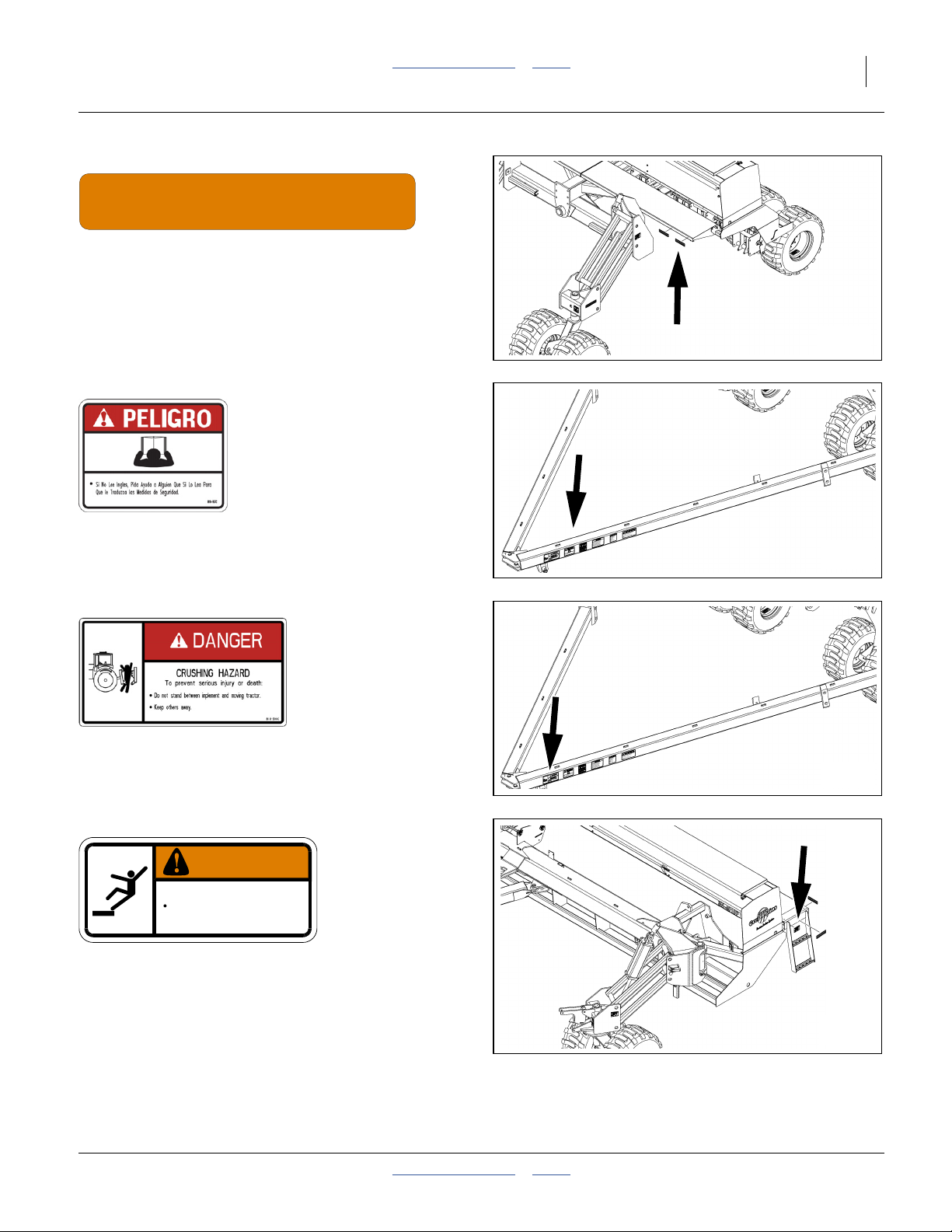

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

838-267C

Daytime Reflectors

On the outside edge of center walkboard each end;

2 total

20301

818-557C

Danger: Cannot Read English

On tongue near hitch;

1 total

818-590C

Danger: Crushing Hazard

On tongue near hitch;

1 total

838-102C

WARNING

To avoid serious injury or death:

Watch your step when climbing ladder or

walking on walkboard.

Danger: Falling Hazard

Outside edge of wing walkboards;

2 total

838-102C

20301

20301

20301

2013-10-29 Table of Contents Index 196-359M

Page 12

8 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

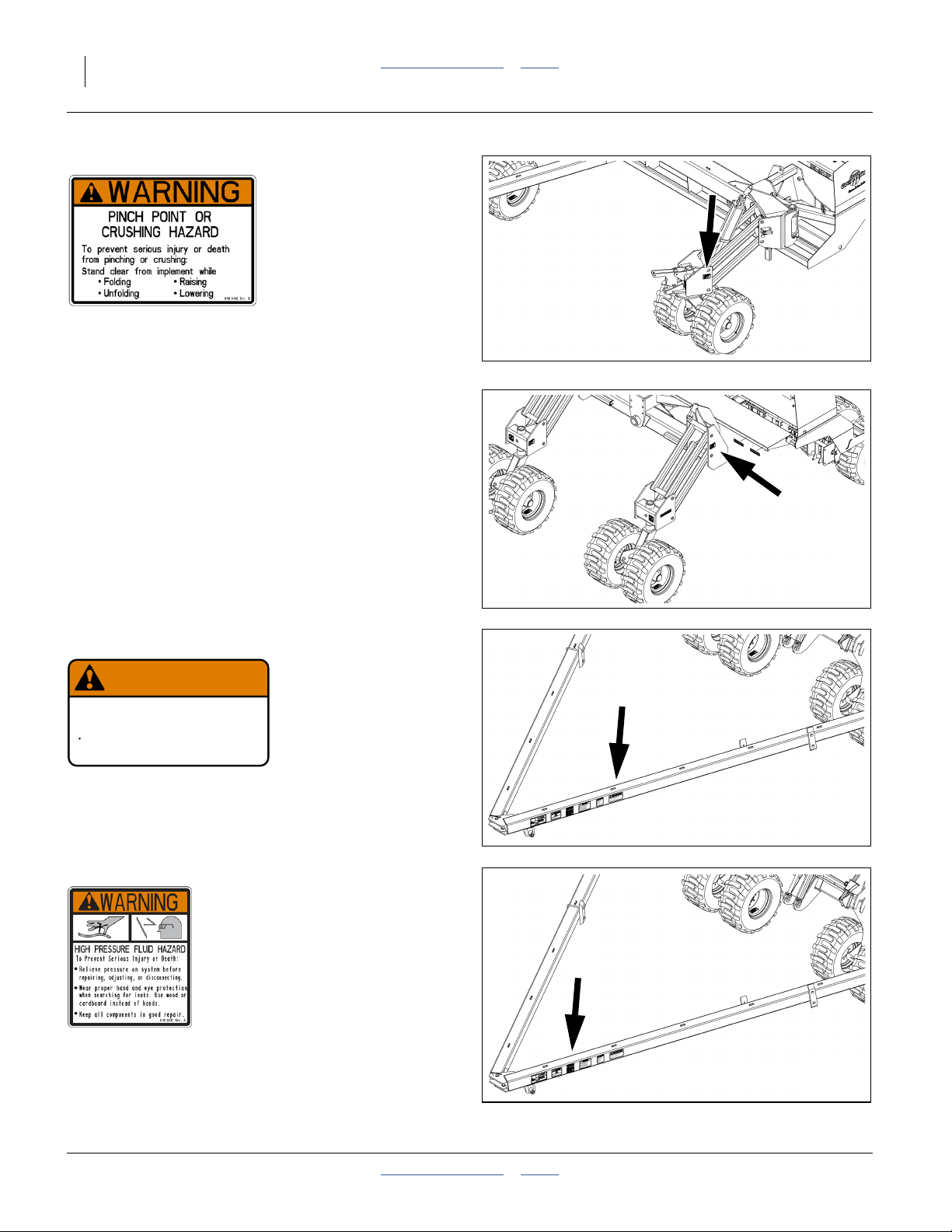

818-045C

Warning: Pinch/Crush

On transport wheel assembly;

4 total

20301

818-188C

WARNING

EXCESSIVE SPEED HAZARD

To Prevent Serious Injury or Death:

Do Not exceed 20 mph maximum transport

speed. Loss of vehicle control and/or machine

can result.

Warning: Speed Hazard

On tongue near hitch;

1 total

818-339C

818-188C Rev. C

20301

20301

Warning: High Pressure Fluid Hazard

On tongue near hitch;

1 total

196-359M Table of Contents Index 2013-10-29

20301

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 9

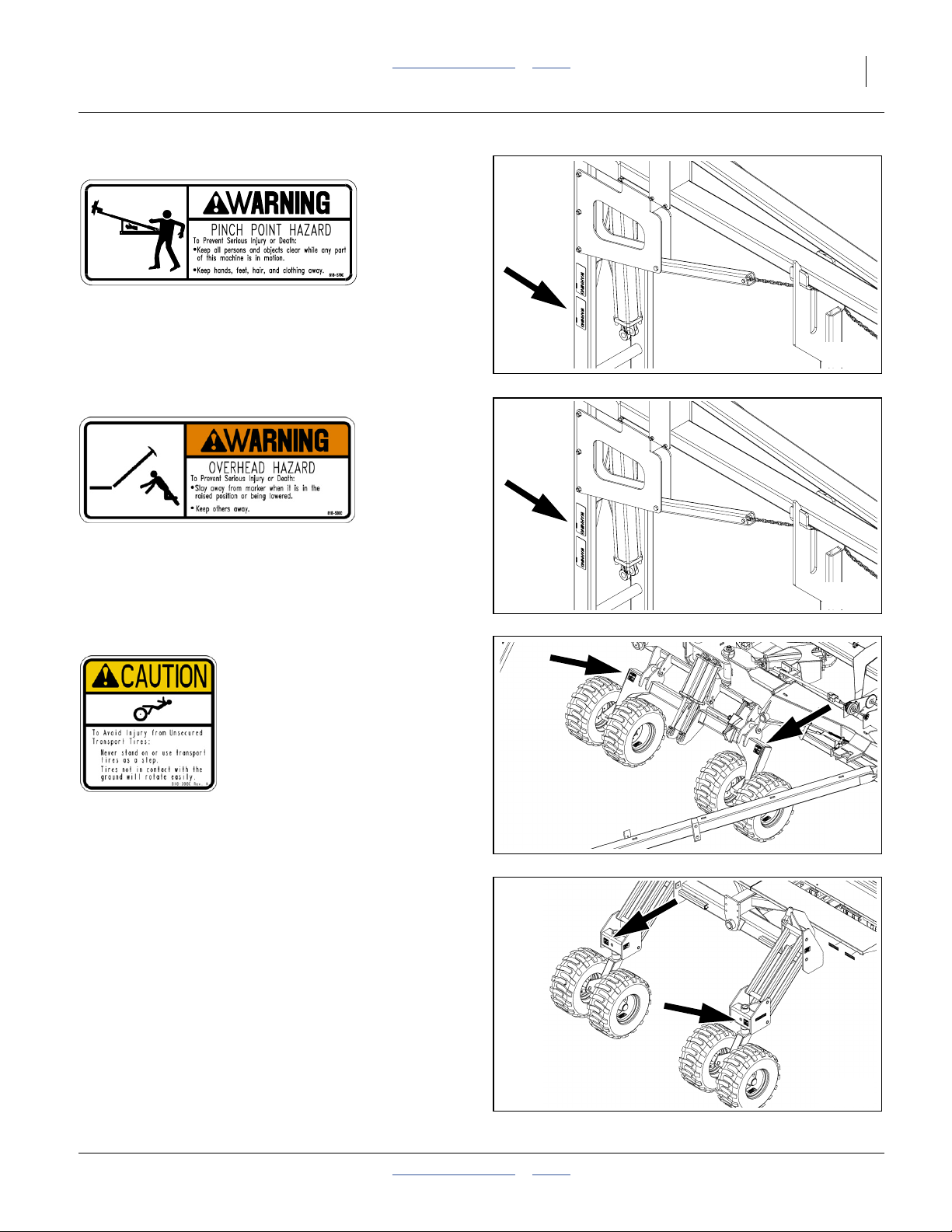

818-579C (Option)

Warning: Pinch Point

On marker, two with single, four with dual marker option;

2 or 4 total

20306l

818-580C (Option)

Warning: Overhead Hazard

On marker, two with single, four with dual marker option;

2 or 4 total

818-398C

Caution: Tires Not A Step

Above all sets of tires;

6 total

20306

20301

20301

2013-10-29 Table of Contents Index 196-359M

Page 14

10 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

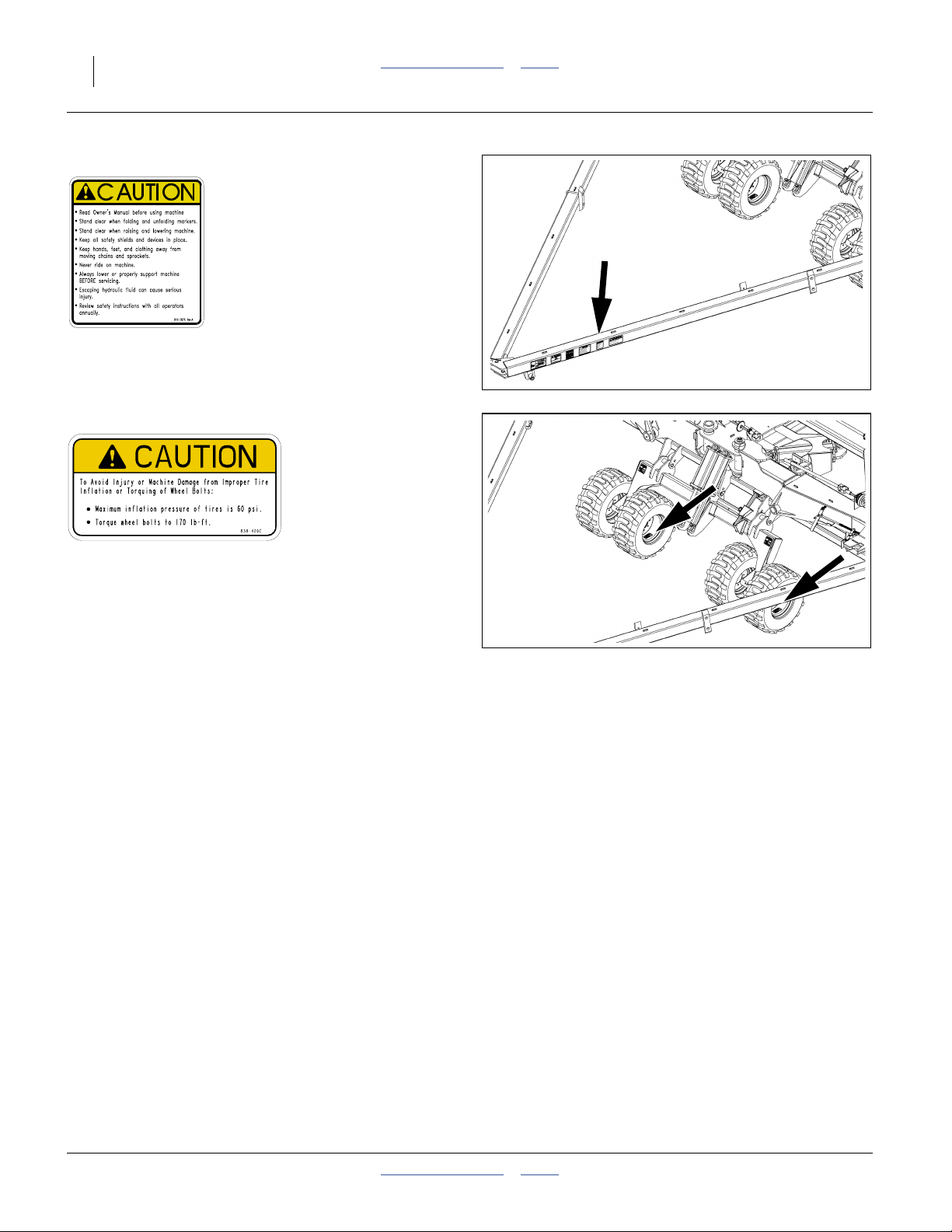

818-587C

Caution: General

On tongue near hitch;

1 total

20301

838-426C

Caution: Pressure/Torque

On the rim of each tire;

12 total

20301

196-359M Table of Contents Index 2013-10-29

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index 11

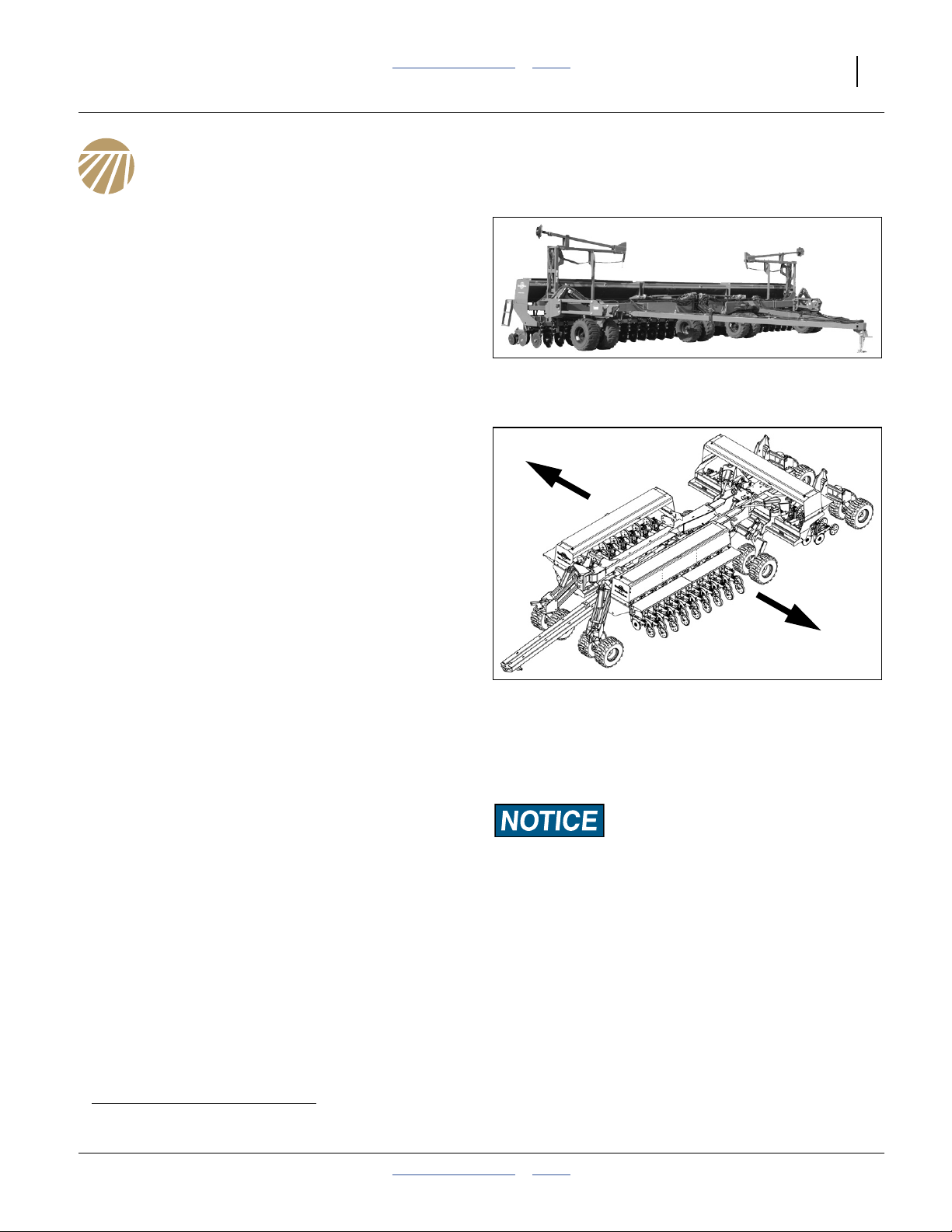

Introduction

Great Plains welcomes you to its growing family of new

product owners. Your 3-Section 40-Foot No-Till Drill has

been designed with care and built by skilled workers

using quality materials. Proper setup, maintenance, and

safe operating practices will help you get years of satisfactory use.

Document Family

196-359M Operator Manuala (this document)

196-359P Parts Manual

Description of Unit

The 3N-4010F, 3N-4010HDF and 3N-4020F are pull-type

seeding implements outfitted with hydraulic drive metering and no-till coulters for use in no-till or minimum-till

conditions.

The 3N-4010F has 10 Series, parallel-arm openers.

The 3N-4010HDF has 10HD (Heavy Duty) openers.

The 3N-4020F has 20 Series, side-depth-control openers. All models fold for transport.

Models Covered by this Manual

10 Series Openers:

3N-4010F-4810 48 Rows, 10 inch/25cm

3N-4010F-6475 64 Rows, 7.5 inch/19cm

10HD (Heavy Duty) Series Openers:

3N4010HDF-481048 Rows, 10 inch/25cm

3N4010HDF-647564 Rows, 10 inch/19cm

20 Series Openers:

3N-4020F-4810 48 Rows, 10 inch/25cm

3N-4020F-6475 64 Rows, 7.5 inch/19cm

Intended Usage

Use the drill to seed production-agriculture crops only.

Do not modify the drill for use with attachments other

than Great Plains options and accessories specified or

recommended for use with the drill.

Definitions

The following terms are used throughout this manual.

Right-hand and left-hand as used in this manual are

determined by facing the direction the machine will travel

while in use unless otherwise stated.

Figure 1

3N-40 Drill

28229

R

L

Figure 2

Left/Right Notation

Paragraphs in this format present a crucial point of information

related to the current topic.

Read and follow the directions to:

- remain safe,

- avoid serious damage to equipment and

- ensure desired field results.

Note: Paragraphs in this format provide useful informa-

tion related to the current topic.

20476

a. This manual also covers seeding rate. There is no separate Seed Rate manual.

2013-10-29 Table of Contents Index 196-359M

Page 16

12 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Using This Manual

This manual will familiarize you with safety, assembly,

operation, adjustments, troubleshooting, and maintenance. Read this manual and follow the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Refer to Figure 3

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts. Always

use the serial and model number when ordering parts

from your Great Plains dealer. The serial number plate is

located on the front of the left hand side of the center

section as shown.

Record your drill model and serial number here for quick

reference:

Model Number:__________________________

Serial Number: __________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or general manager of the dealership.

For further assistance write to:

Figure 3

Serial Number Plate

20270

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

785-823-3276

196-359M Table of Contents Index 2013-10-29

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index 13

Preparation and Setup

This section will help you prepare your tractor and drill for

use. Before using the drill in the field, you must hitch the

drill to a suitable tractor and level the drill.

Pre-Setup Checklist

1. Read and understand “Important Safety Information” on page 1.

2. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and lubricated. See “Lubrication” on page 114.

4. Check that all safety decals and reflectors are correctly located and legible. Replace if damaged. See

“Safety Decals” on page 5.

5. Inflate tires to pressure recommended and tighten

wheel bolts as specified. “Appendix” on page 125.

Hitching

There are three hitch options (see page 119). Check that

the tractor and drill are compatible before hitching.

Crushing Hazard: You may be severely injured or killed by

being crushed between the tractor and drill. Do not stand or

place any part of your body between machines being hitched.

Stop tractor engine and set park brake before installing hitch

pins.

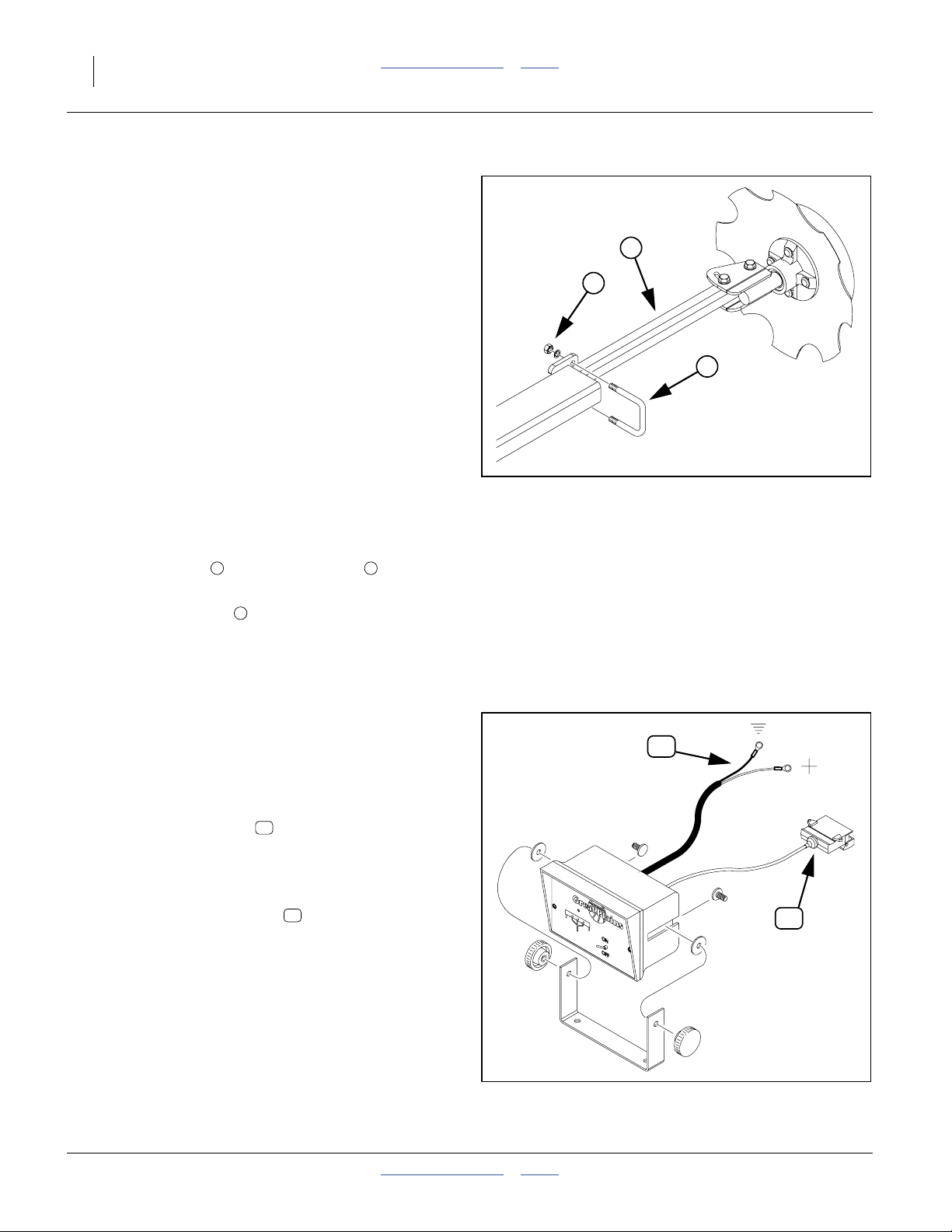

Refer to Figure 4

1. Use drill parking jack to raise or lower tongue as

needed. Hitch drill to tractor using a hitch pin of ade-

quate strength - minimum diameter 11⁄2in (38mm).

2. Install a retaining clip on the hitch pin to prevent it

from working up.

3. Securely attach drill safety chain to tractor drawbar.

4. Lower tongue onto tractor drawbar with jack.

Remove jack and store on tongue.

Make Electrical Connections

Make sure tractor is shut down with accessory power off

before making connections. Connections include:

5. Lighting

6. Veris controller harness

7. Electric Clutch (Point Row) harness (2 connectors)

8. Shaft monitor (option)

Figure 4

Hitching Tractor to Drill

20273

2013-10-29 Table of Contents Index 196-359M

Page 18

14 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Make Hydraulic Connections

High Pressure Fluid Hazard:

Only trained personnel should work on system hydraulics!

Escaping fluid under pressure can penetrate skin, causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic lines. Use a piece of paper or cardboard,

NOT BODY PARTS, to check for leaks. Wear protective gloves

and safety glasses or goggles when working with hydraulic

systems. If an accident occurs, seek immediate medical attention from a physician familiar with this type of injury.

The drive is compatible only with closed center, PC (pressure

compensated) closed or LS (load sensing) hydraulic systems.

Do not use an open center system.

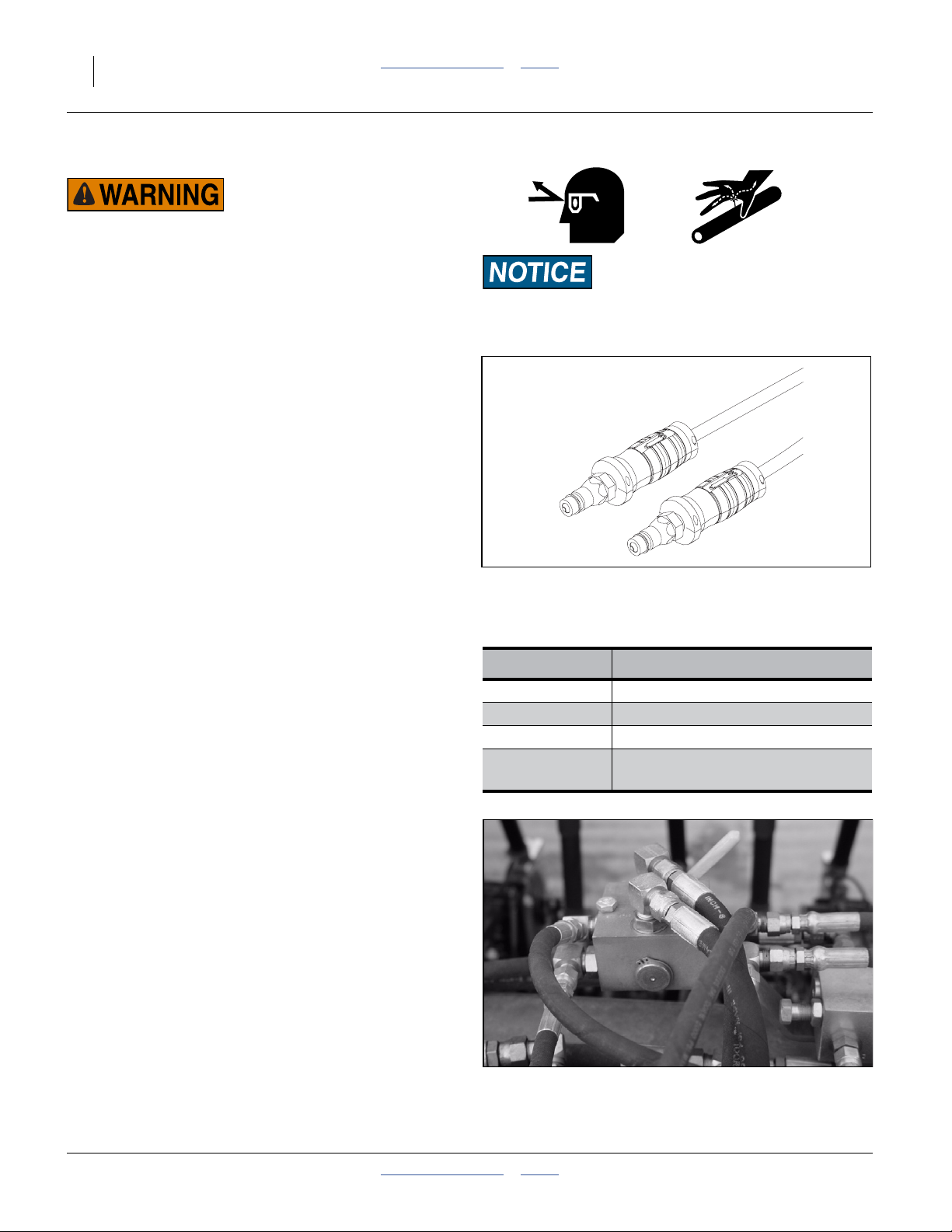

Hydraulic Circuit Connections

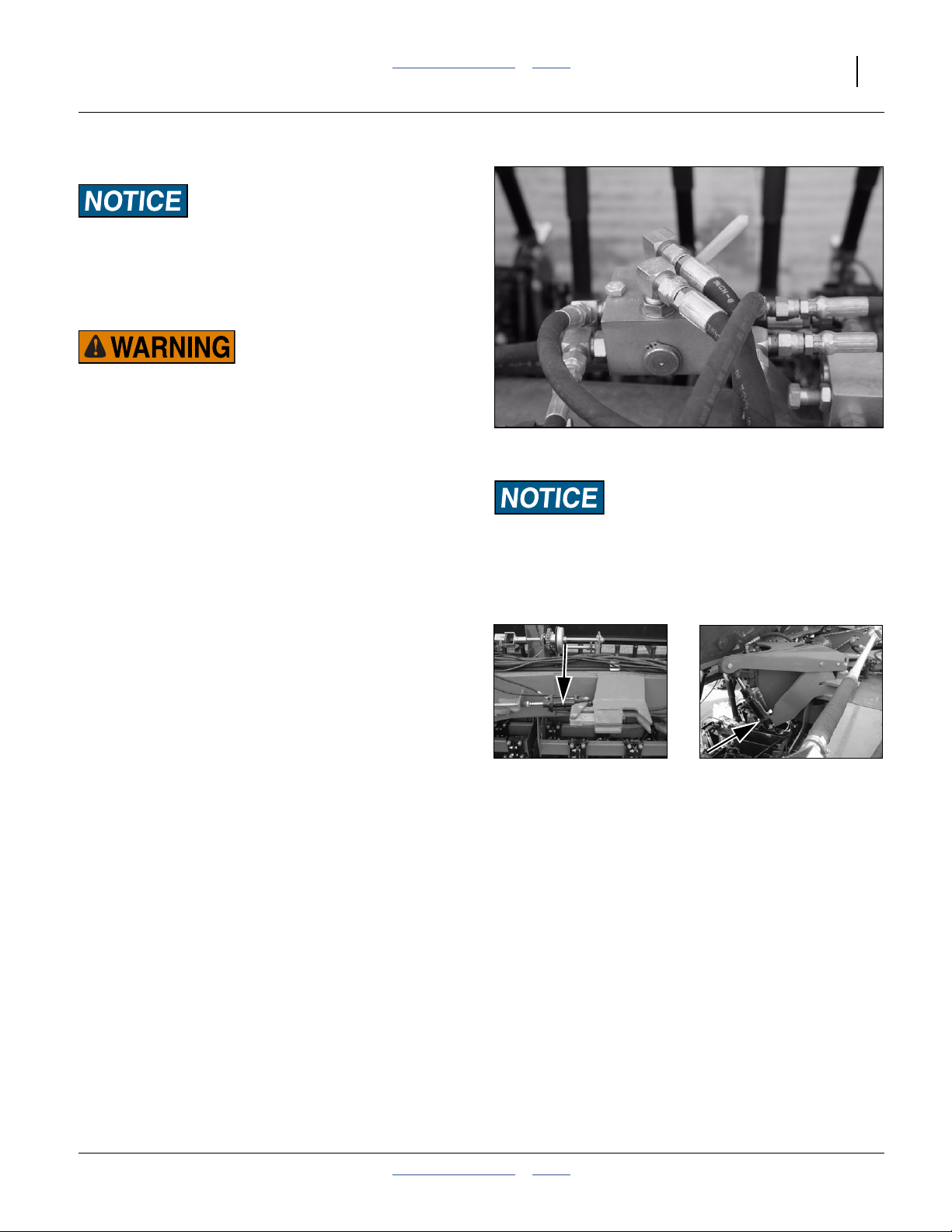

Refer to Figure 5

Great Plains hydraulic hoses are color coded handle

grips to help you hookup hoses to your tractor outlets.

Hoses that go to the same remote valve are marked with

the same color.

To distinguish hoses on the same hydraulic circuit, refer

to the symbol molded into the handle grip. Hoses with an

extended-cylinder symbol feed cylinder base ends.

Hoses with a retracted-cylinder symbol feed cylinder rod

ends.

The drill has three or four hydraulic circuits. The standard

circuits power drive/locks, lift, and fold. If markers are

present, they require a fourth circuit (or an additional

selector valve sharing the fold circuit).

If the tractor has only one circuit rated for continuous

flow, reserve it for the hydraulic drive.

1. Shut down tractor hydraulics.

2. Connect the hydraulic drive circuit.

3. Connect remaining circuits.

4. Check hose routing to ensure adequate slack for link

arm movement, and clearance from pinching or

abrading drill components.

Refer to Figure 6

Figure 5

Color Coded Hose Handles

Current Style Color Coded Hose Handles

Hose Color Hydraulic Function

Gray Fold

Blue Lift

Green Marker Cylinders (Option)

Yellow

Hydraulic Drive and

Wing and Swivel Locks

31733

5. If the drill is to be unfolded, set the selector valve to

Locks (handle to drill center). Valve is located near

rear end of left tongue tube.

Figure 6

Hitching: Drive/Lock Selector Valve

196-359M Table of Contents Index 2013-10-29

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 15

Older Style Hoses with Color Ties

Refer to Figure 7

To distinguish hoses on the same hydraulic circuit, refer

to plastic hose label. The hose under an extended-cylinder symbol feeds a cylinder base end. The hose under a

retracted-cylinder symbol feeds a cylinder rod end.

.

The drive is compatible only with closed center, PC (pressure

compensated) closed or LS (load sensing) hydraulic systems.

Do not use an open center system.

Hose Color Hydraulic Function

White Fold

Blue Lift

Orange Marker Cylinders (Option)

Yellow

Hydraulic Drive and

Wing and Swivel Locks

Figure 7

Plastic Hose Label

817-348c

17641

2013-10-29 Table of Contents Index 196-359M

Page 20

16 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Initial Setup

The following items need to be done for first use, and

some need to be re-done if the tractor changes.

Initial Tractor Setup

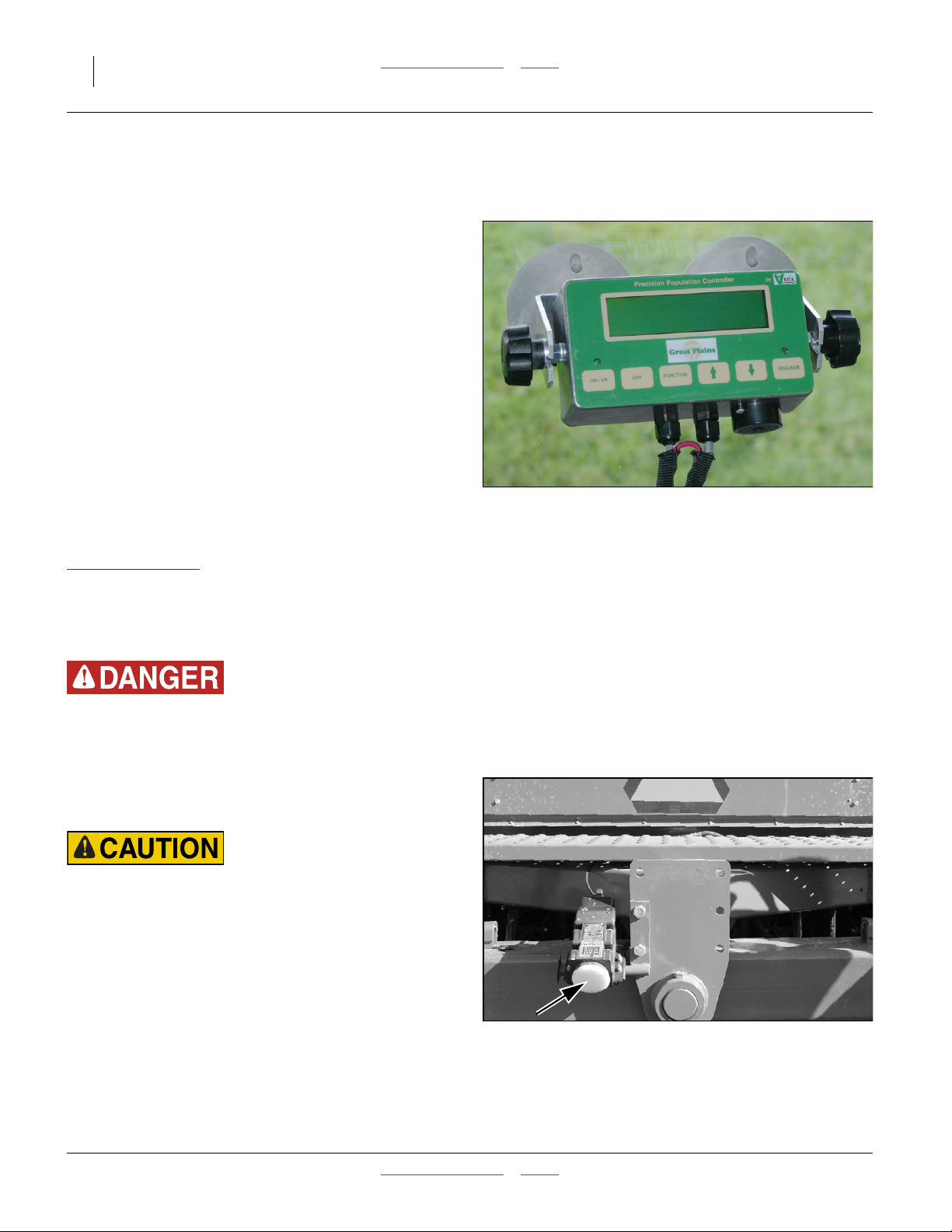

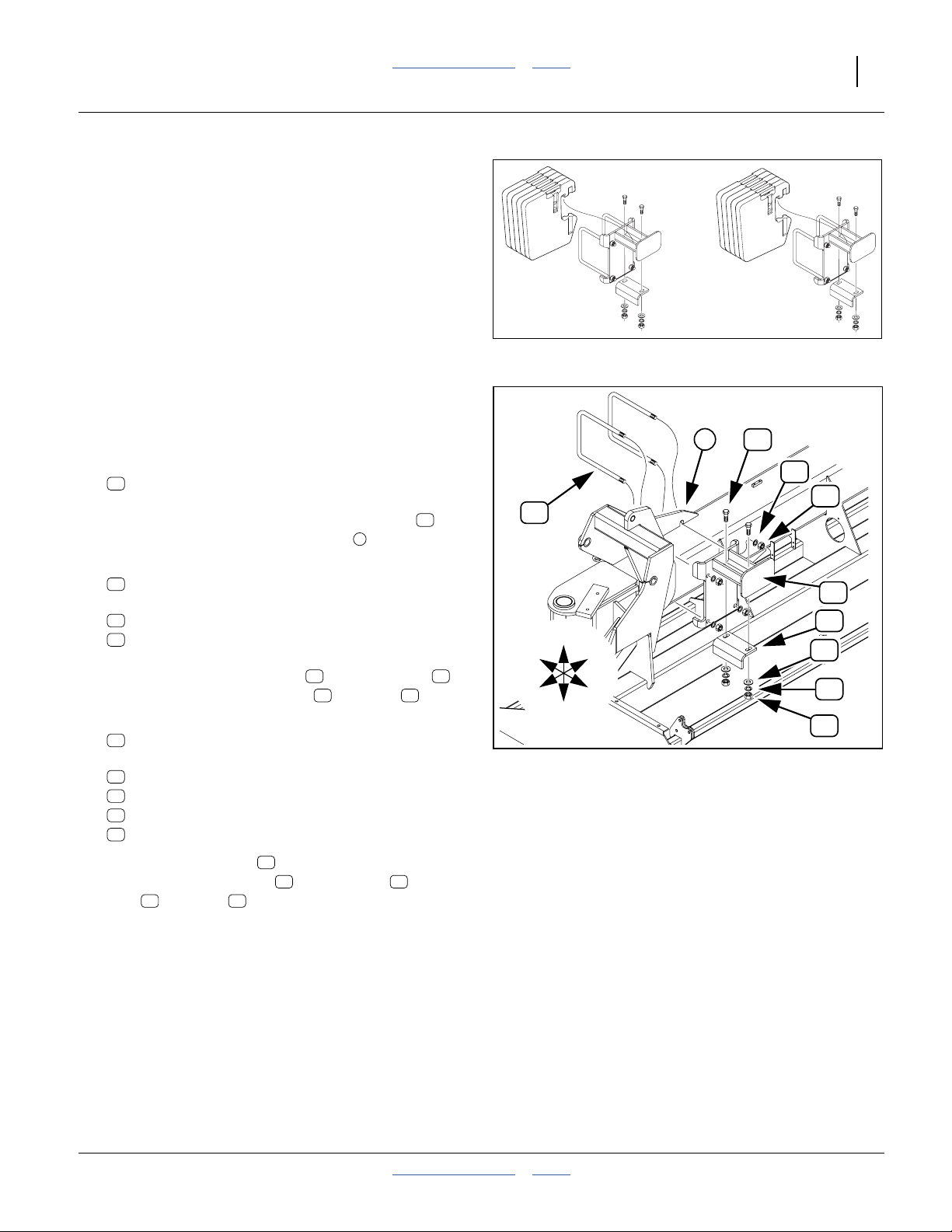

Veris Controller

The standard Veris hydraulic drive, controller module and

DICKEY-john radar are factory-installed on the drill. The

Veris console needs to be installed in the tractor prior to

first use. It includes suction cup feet that can support the

console on glazing for extended periods.

Route the power lead to a +12Vdc source. Route the

harness to the hitch, allowing enough slack for hitch

movement and any tractor articulation.

Refer to Figure 8

Mount the console where the display is visible during

planting, but does not obstruct vision of tractor or drill

systems, and does not impair safe highway transport.

Installation instructions are found in an included Veris

manual. Additional copies are available at:

www.veristech.com

Expanded operating information from that manual is found in this manual, starting on page 35.

Once the console is installed, you can enter the initial

setup data by stepping through the calibration sequence

but not actually operating the motor. See page 39.

Figure 8

Veris Controller

28326

Moving Chain Hazard

Pinch/Crush Hazard

Shaft Entanglement Hazard:

Be careful when working around drill while tractor is running.

Any movement detected by the radar gun (Figure 9) can activate the Veris hydraulic drive causing motion of chains,

sprockets, shafts and seed meters.

Vision Hazard:

The DICKEY-john RVS II radar speed sensor is an intentional

radiator of RF energy. Although its radiated energy level is far

below the limits set by EN 61010-1: 1993\A2: 1995 - Chapter

12.4, it is advisable not to look directly into the face of the unit.

The radar must radiate toward the ground and at least 20 cm

(8 inches) away from a human during use to comply with the

RF human exposure limits per FCC 47 CFR Sec. 2.1091.

DO NOT mount or use the radar in a manner inconsistent with

its defined use.

Figure 9

DICKEY-john Radar

20310

196-359M Table of Contents Index 2013-10-29

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 17

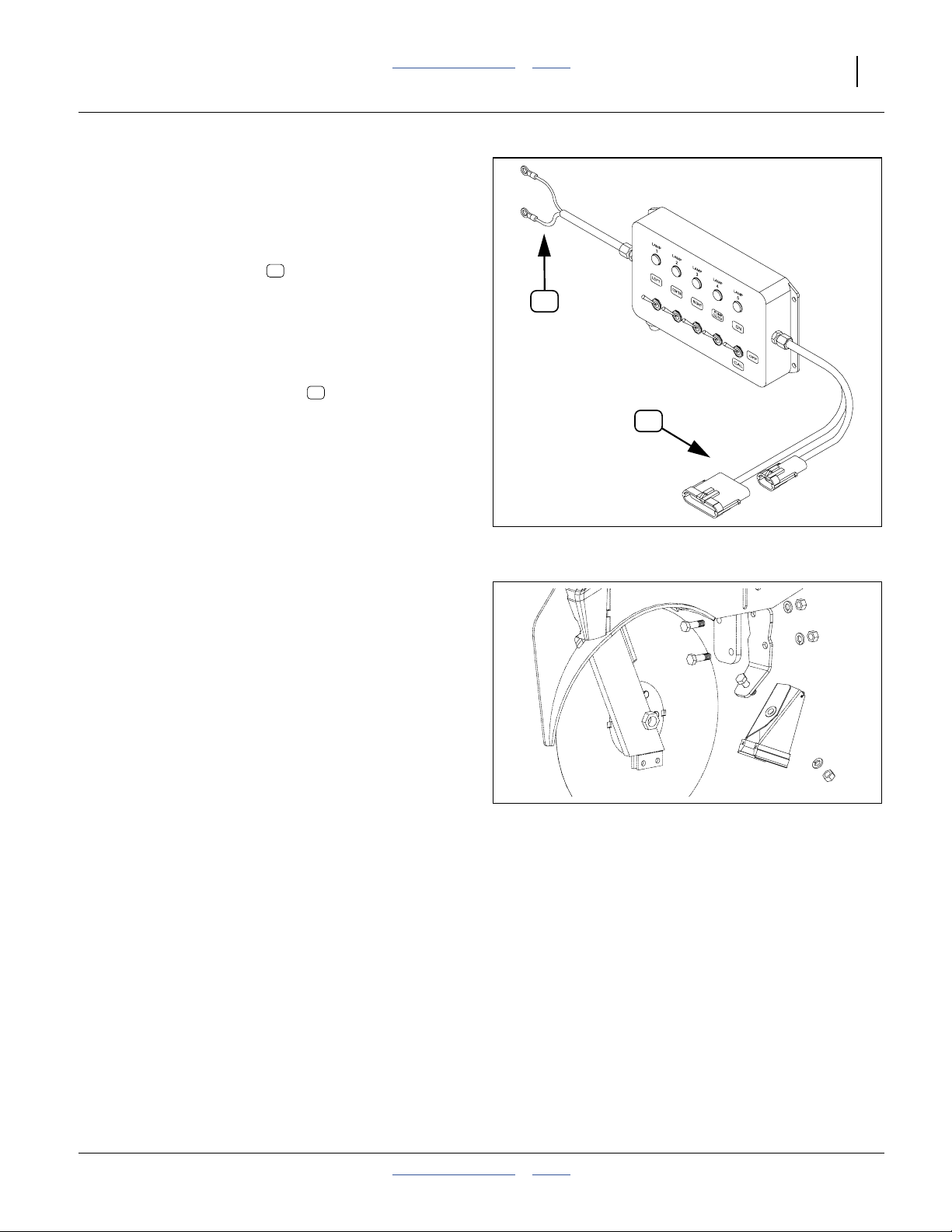

Point Row Switch Module

Refer to Figure 10

6. Choose a tractor cab location where the module

does not obstruct vision, and the switches can be

safely operated during planting passes.

7. Route the power leads to a source of +12 Vdc

power capable of supplying 12.6A.

Color code is red+, black-.

Direct battery connection is acceptable; the controller module has its own master switch and fuse.

8. Use a tie to secure the power lead.

9. Route the controller harness to the tractor hitch.

Use ties to secure the hitch lead.

P

H

Drill Setup Checks

Hydraulic Bleed

Bleeding the hydraulic system is not a routine daily setup

item. If the system has not been charged since delivery,

or any hydraulic work has been done (such as installing

markers), see “Bleeding Hydraulics” on page 105.

Drill Level

Drill sections are aligned and leveled at the factory, and

re-checked during dealer pre-delivery. Level normally

does not require routine adjustment before use. Great

Plains does recommend checking it once prior to first

field use. See “Level Frame Side to Side” on page 102.

Drill Option Setup

Even if factory- or dealer-installed, some optional items

may need checking or adjustment prior to first field use.

Install any that were not pre-installed.

Scrapers (Option)

If scrapers were ordered, and not dealer-installed, install

them now per the instructions in one of the following

manuals, which are available on the Great Plains website

if not ordered or included:

Kit: Manual

122-259K 122-262M (ordered separately)

198-960A 198-961M (included in kit)

P

H

Figure 10: 833-294C

Point Row Switch Module

Figure 11: 122-259K

10 & 20 Series Inside Scraper

28240

20162

2013-10-29 Table of Contents Index 196-359M

Page 22

18 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Marker Setup (Option)

If markers are not installed, install them now per the

instructions included with the markers.

Once installed, verify that they have been correctly bled

(See “Bleeding Markers” on page 107).

Set initial marker extension - the distance to the mark on

each side from the outside row unit on that side.

1. Move the hitched drill to a typical flat field.

2. Extend a marker on one side (see page 33). Pull forward a few feet or a meter or so to leave a mark.

3. Measure from the centerline of the outside row unit

(whether that row unit is to be used or not) to the

mark, along a line parallel to the wing.

Refer to Figure 175 through Figure 180 on pages 127 and 129

4. Check the measurement against the value recommended by Great Plains.

Refer to Figure 12

3

1

2

Figure 12

Adjusting Marker Extension

18878

If the marker extensions need adjustment:

5. Loosen the nuts securing the U-bolt at the

outer marker section.

6. Slide the inner tube in or out, and re-secure nuts.

See page 69 for further marker adjustments. Re-check

marker extension when changing disk angle, or when

inverting the disk, as both adjustments change the position of the centerline of the mark.

Shaft Monitor (Option)

1. Choose a tractor cab location where the module

does not obstruct vision, and the shaft indicators can

be easily seen if an alert sounds.

Refer to Figure 13

2. Route the power leads to a source of +12 Vdc

power.

Color code is red+, black-.

3. Use a tie to secure the power lead.

4. Route the monitor harness to the tractor hitch.

Use ties to secure the hitch lead.

For operation, see:

“Shaft Monitor Operation (Option)” on page 33.

For ordering information, see:

“Shaft Monitor” on page 121.

1 2

3

P

H

P

H

Figure 13: 823-060C

Shaft Monitor

196-359M Table of Contents Index 2013-10-29

28241

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 19

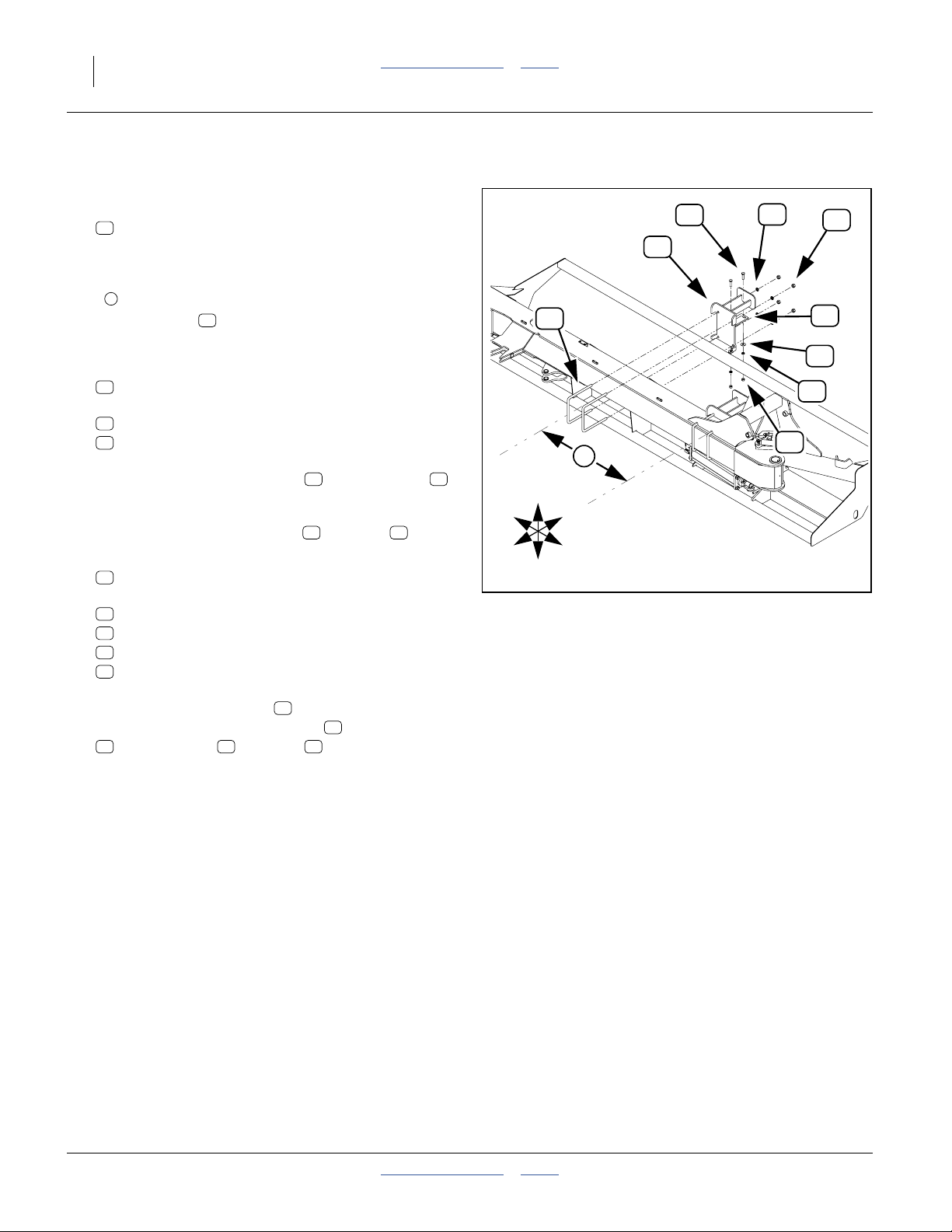

Install Weight Brackets (Option)

If weight brackets were ordered, and were not

dealer-installed, install them now. Two kits (4 brackets)

are supported, accepting five standard 100 pound (45

kg) “suitcase” tractor weights each, for a maximum additional weight of 2000 pounds (907 kg). Weights are not

included with kits.

If only one weight kit is to be installed, use the “Outer”

position.

Once the brackets are installed, see “Frame Weight”on

page 68 for operating information.

Install Outer Brackets

Start with the left wing.

Refer to Figure 15

1. Select two:

19

806-172C U-BOLT 3/4-10 X 10 1/32X11 1/2

Figure 14:

Weight Bracket Kit and Weights

1

13

18

27068

15

From the front of the wing, insert the U-Bolts

through the holes in the outside lug .

2. Select one:

11

196-291H 40P WEIGHT BRACKET WLDMNT

and four sets:

18

804-023C WASHER LOCK SPRING 3/4 PLT

15

803-027C NUT HEX 3/4-10 PLT

Mount the bracket weldment on the U-Bolts ,

and secure with lock washers and nuts .

3. Select one:

12

197-062D WEIGHT BRACKET ADJ LEG

and two sets:

13

802-057C HHCS 5/8-11X2 1/4 GR5

16

804-019C WASHER FLAT 5/8 USS PLT

17

804-022C WASHER LOCK SPRING 5/8 PLT

14

803-021C NUT HEX 5/8-11 PLT

11 19

1

18 15

19

19

F

L

U

D

R

B

Figure 15

Weight Bracket, Outer

11

12

16

17

14

20323

Orient the adjustment leg toward the outside (end of

wing), and secure with bolts , flat washers , lock

washers and nuts .

4. Repeat step 1 through step 3 for the right wing.

2013-10-29 Table of Contents Index 196-359M

17 14

12

13 16

Page 24

20 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Install Mid-Wing Brackets

Refer to Figure 16

5. Select two:

19

806-172C U-BOLT 3/4-10 X 10 1/32X11 1/2

From the centerline of the inside U-Bolt installed at

step 1, measure toward drill center, approximately:

1

2

35

⁄

in (90cm)

2

Insert a U-bolt from drill front, under the hoses.

Insert the second U-Bolt 7

6. Select one:

11

196-291H 40P WEIGHT BRACKET WLDMNT

and four sets:

18

804-023C WASHER LOCK SPRING 3/4 PLT

15

803-027C NUT HEX 3/4-10 PLT

Position the bracket weldment on the U-Bolts ,

and adjust the placement as necessary to clear tube

weldments, web plates, grease banks, marker parts

and secure with lock washers and nuts .

7. Select one:

12

197-062D WEIGHT BRACKET ADJ LEG

and two sets:

13

802-057C HHCS 5/8-11X2 1/4 GR5

16

804-019C WASHER FLAT 5/8 USS PLT

17

804-022C WASHER LOCK SPRING 5/8 PLT

14

803-021C NUT HEX 5/8-11 PLT

19

1

⁄

in (19cm) further in.

2

11 19

18 15

R

F

U

D

19

13

11

2

B

L

Figure 16

Weight Bracket, Mid-Wing

18

15

12

16

17

14

28243

Orient the adjustment leg toward the inside (center of drill), and secure with bolts , flat washers

16 17 14

, lock washers and nuts .

8. Repeat step 5 through step 7 for the right wing.

12

13

196-359M Table of Contents Index 2013-10-29

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index 21

Operating Instructions

This section covers general operating procedures. It

assumes that setup items have been completed.

Experience, machine familiarity and this information

leads to efficient operation and good working habits.

Always operate farm machinery with safety in mind.

Pre-Start Checklist

❑ Review “Important Safety Information” on page 1.

❑ Lubricate the drill as indicated under Lubrication,

“Maintenance and Lubrication” on page 100.

❑ Check the tires for proper inflation according to “Tire

Inflation Chart” on page 125.

❑ Check for worn or damaged parts and repair or

replace before going to the field.

❑ Check all nuts, bolts and screws. Tighten bolts as

specified on “Torque Values Chart” on page 126

❑ Check hydraulic hoses, fittings and cylinders for

leaks. Tighten, repair or replace before planting.

High Pressure Fluid Hazard: Escaping fluid under pressure

can penetrate skin, causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs,

seek immediate medical attention from a physician familiar

with this type of injury.

Moving Chain Hazard

Pinch/Crush Hazard

Shaft Entanglement Hazard:

Be careful when working around drill while tractor is running.

Any movement detected by the radar gun (Figure 17) can activate the Veris hydraulic drive causing motion of chains,

sprockets, shafts and seed meters.

Vision Hazard:

The DICKEY-john RVS II radar speed sensor is an intentional

radiator of RF energy. Although its radiated energy level is far

below the limits set by EN 61010-1: 1993\A2: 1995 - Chapter

12.4, it is advisable not to look directly into the face of the unit.

The radar must radiate toward the ground and at least 20 cm

(8 inches) away from a human during use to comply with the

RF human exposure limits per FCC 47 CFR Sec. 2.1091.

DO NOT mount or use the radar in a manner inconsistent with

its defined use.

2013-10-29 Table of Contents Index 196-359M

Figure 17

DICKEY-john Radar

20310

Page 26

22 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Lift / Lower

Machine Damage Risk:

Lower only when the drill is unfolded. The drill must be raised

and locked up for folding and unfolding.

The drill has six rephasing lift cylinders that raise and

lower the opener frame.

Six (6) transport locks are provided, two for the rockshaft

(center forward) cylinders, and one each for the rear and

wing caster cylinders. These assure that the drill stays

raised during folding/unfolding, transport, storage, lubrication, maintenance and some setup/adjustment tasks.

Opener Operation Lowered

The “lowered” position of the opener frame is regulated

by an adjustable valve, factory set for 2in coulter depth.

See “Frame Height” on page 60 for adjustment.

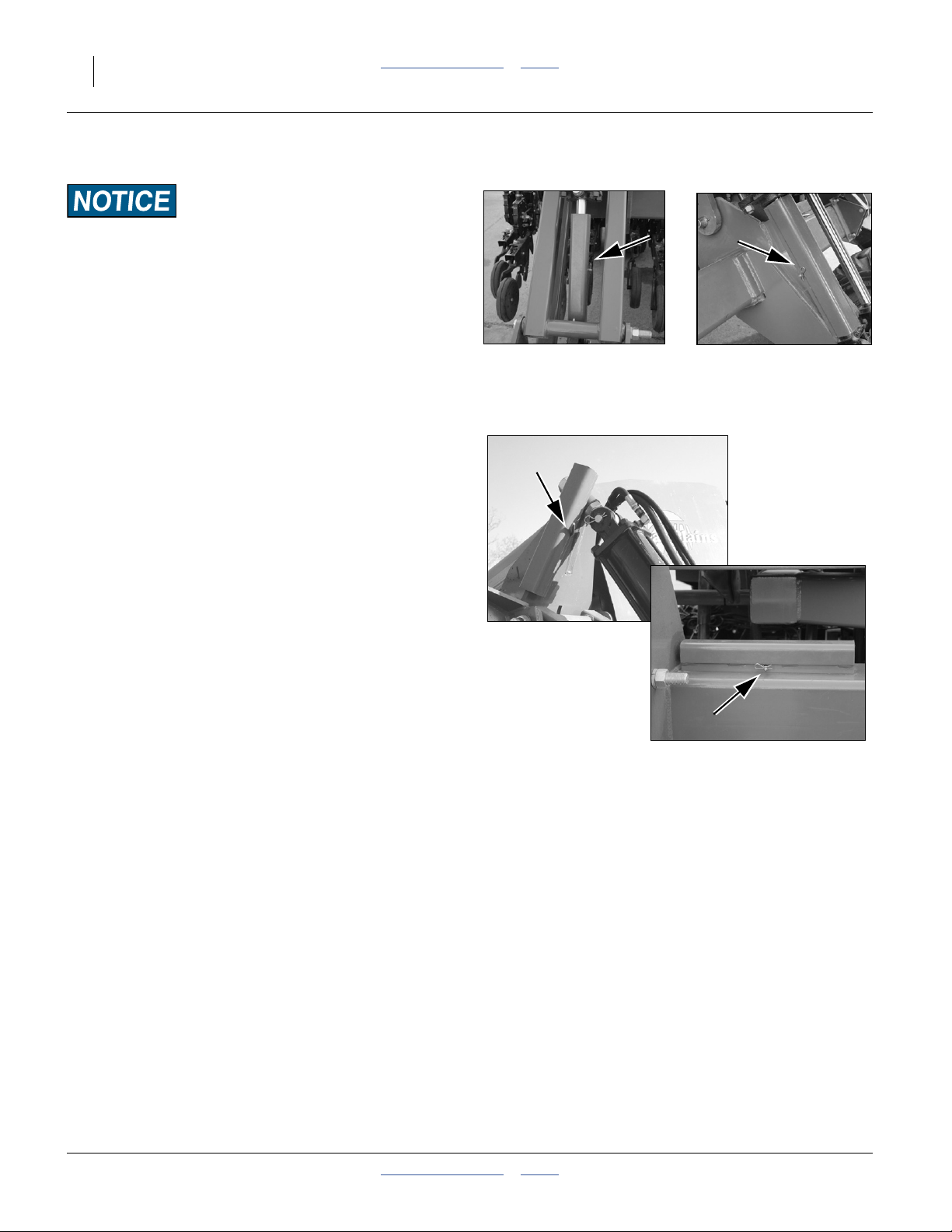

Figure 18

Transport Locks Installed

20264

20266

Rephasing Lift System

Over a period of normal use the cylinders may get out of

phase. This causes some implement sections to run

higher than others when lowered. To minimize this, or

rephase the cylinders, make the following steps your normal raise sequence:

9. Raise drill completely and hold the hydraulic remote

lever on for several seconds until all cylinders are

fully extended. Do this every 3rd or 4th time you

raise the drill out of the ground.

10. When all cylinders are fully extended, momentarily

reverse the hydraulic remote lever to retract the sys-

1

tem

⁄

inch (13mm) to maintain levelness.

2

If implement is still not level after re-phasing, see “Bleed-

ing Lift Hydraulics” on page 105 and “Level Frame

Side to Side” on page 102.

Figure 19

Lock Channel Storage

20268

20269

196-359M Table of Contents Index 2013-10-29

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 23

Folding the Drill

Machine Damage Risk:

Fold only when the drill is raised and locked up.

Fold the drill on level ground with the tractor in neutral.

If your drill has markers, be certain they are folded and

their control switches are off before folding.

Pinch Point and Crushing Hazard.

To prevent serious injury or death:

▲ Always use transport lift locks when drill is folded.

▲ Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

▲ Stay away from frame sections when they are being raised

or lowered.

▲ Keep away and keep others away when folding drill.

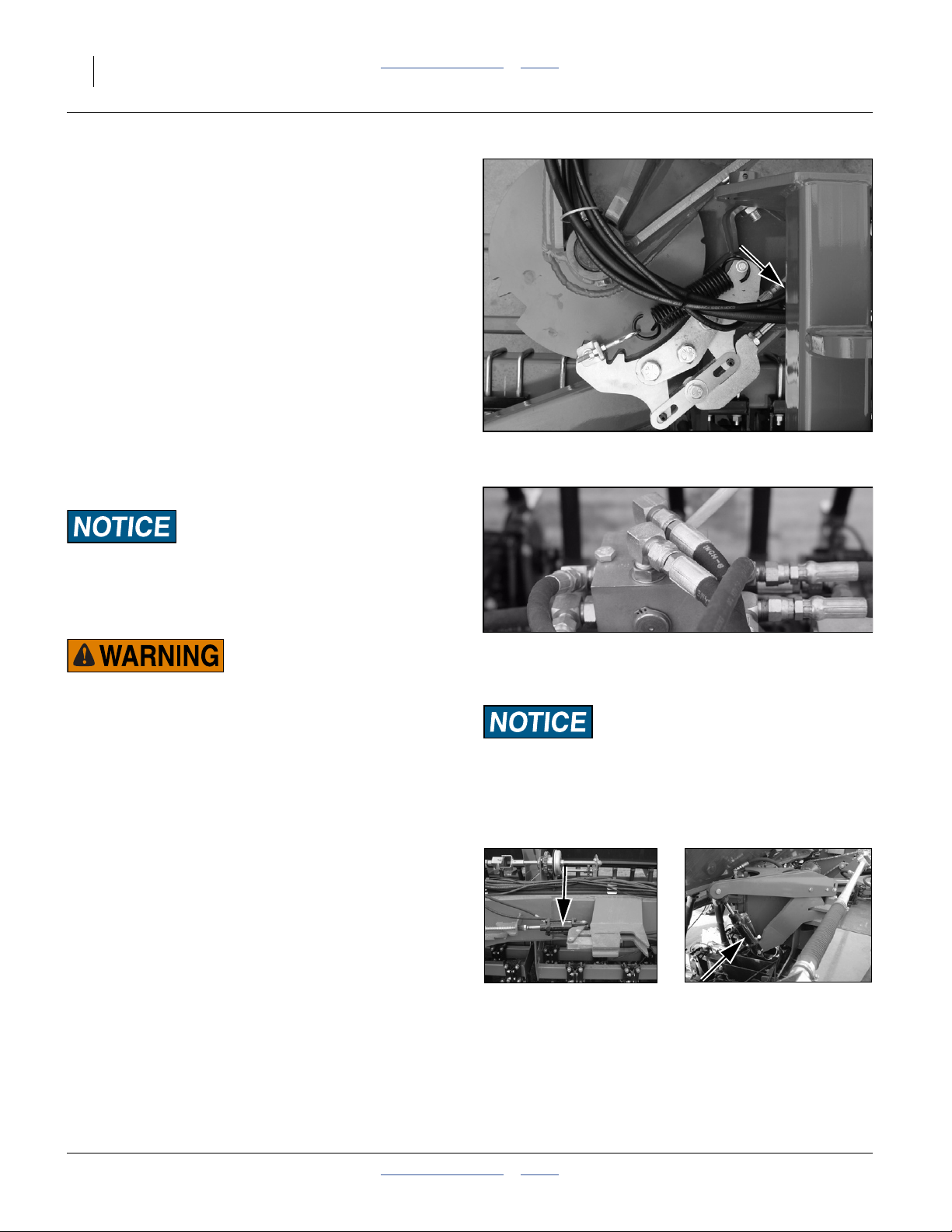

Refer to Figure 20

Figure 20

Fold: Drive/Lock Selector Valve

Pinch/Crush Risk: Drill Center section moves back while

folding. Tractor may move forward. Allow at least 10ft (3m)

clearance behind drill and ahead of tractor when folding.

21844

1. Set Drive/Lock selector valve to Lock.

2. Fold markers (Option). See page 33.

3. Raise drill with lift cylinders until cylinders are fully

extended. Install lock channels over extended

wheel-cylinder rods. Six cylinder rods total. See

page 22.

4. Retract the Lock cylinder circuit lever to:

• disengage the tool bar locks (2),

• disengage swivel locks (2),

• disengage caster locks (2), and

• enable the self-latching transport lock (1).

Set circuit to Neutral. Do not Extend.

Figure 21

Transport/Tool Bar Lock Cylinders

21841

21845

2013-10-29 Table of Contents Index 196-359M

Page 28

24 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Note: There are two key points to remember when oper-

ating the lock cylinders.

a. All seven lock cylinders are plumbed together,

and all move at the same time.

b. Operate the lock circuit lever (Retract/Neutral)

only once to fold. As the cylinders move, they

unlock 6 points then stop in a “ready to fold

position.” When the drill is folded, the 7th lock,

spring loaded, snaps shut, locking the drill.

5. Extend the Fold cylinder circuit lever to slowly fold

wings forward. The transport lock automatically captures the right wing tool bar for transport.

Note: It may be necessary to ease forward slightly with

the tractor to assist wings in folding completely.

Unfolding the Drill

Machine Damage Risk:

Unfold only when the drill is raised and locked up.

Unfold the drill on level ground with the tractor transmission in neutral.

Crushing, Pinch-Point and Overhead Hazards:

To prevent serious injury or death:

▲ Always use transport locks when drill is folded.

▲ Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

▲ Stay away from frame sections when they are being raised

or lowered.

▲ Keep away and keep others away when unfolding drill.

Note: When unfolding, operate the lock circuit exactly in

reverse of folding. Operate the circuit once (Extend/Neutral). Remember that when the cylinders

move, they release one lock, and enable six others,

stopping in a “ready to unfold” position. As the drill

is unfolded, the six spring loaded locks snap shut,

locking the drill.

Refer to Figure 23

1. Check selector valve set to Locks.

Figure 22

27183

Swivel Lock Cylinder

Figure 23

21844

Unfold: Drive/Lock Selector Valve

Pinch/Crush Risk:

Center section of drill moves forward while unfolding.

Tractor may move backward. Keep all personnel clear of drill

and tractor wheels.

Figure 24

Transport/Tool Bar Lock Cylinders

21841

21845

196-359M Table of Contents Index 2013-10-29

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 25

2. Extend the Lock cylinder circuit lever to:

• disengage the self-latching transport lock,

• enable two tool bar locks,

• enable two swivel locks, and

• enable two caster locks.

Set circuit to Neutral. Do not Retract.

Refer to Figure 18 and 19 on page 22

3. Raise the drill. Remove lock channels from all six

wheel cylinders. Store lock channels.

4. Activate fold hydraulics and slowly unfold the drill

until wings are fully unfolded and all spring loaded

locks have snapped into position.

Figure 25

Caster Lock Cylinder

21842

5. Lower drill.

Refer to Figure 23

6. Move selector valve handle from Locks to Drive.

2013-10-29 Table of Contents Index 196-359M

Page 30

26 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

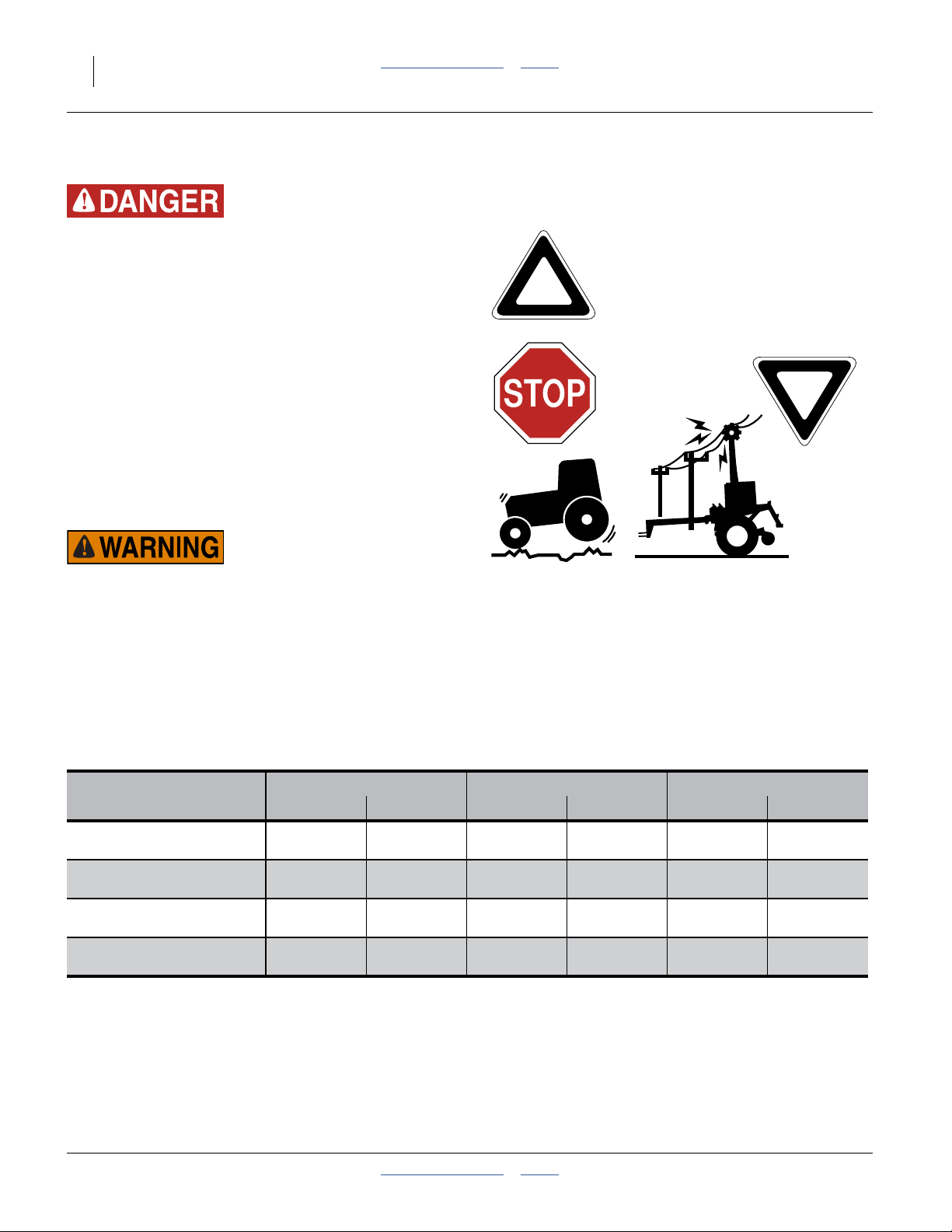

Transport

Electrocution Hazard:

To prevent serious injury or death from electric shock, keep

clear of overhead power lines when transporting, folding,

unfolding or operating drill components. Machine is not

grounded. At higher voltages, electrocution can occur without

direct contact.

Great Plains recommends transporting the drill without

seed loaded. Although designed for highway movement

with full seed boxes, the additional weight of seed may

cause the drill to exceed the rated towing and stopping

ability of the tractor, makes the drill more difficult to control and stop, and increases wear on tires and wheel

bearings.

Make sure the tractor weighs at least

drill, including any material load. Check the table at the

bottom of this page for weights of various configurations.

2

⁄

(67%) of the

3

Loss of Control Hazard:

Towing the drill at high speeds or with a vehicle that is not

heavy enough can lead to loss of vehicle control. Loss of vehicle control can lead to serious road accidents, injury and

death. To reduce the hazard:

▲ Do not exceed 20 mph (32 kph).

▲ Do not tow a drill that weighs more than 1.5 times the

weight of the towing vehicle.

Typicala Transport Weights

3N-4010F 3N-4010HDF 3N-4020F

Rows 7.5in 10in 7.5in 10in 7.5in 10in

Empty,

no markers, no weights

Empty,

w/markers and weights

Full Seed Load,

no markers, no weights

Full Seed Load,

w/markers and weights

a. Weights do not include row unit accessories or other options. If table weight is near recommended limit for the tractor,

obtain a precise weight for the empty drill at a scale.

28260 lbs

12819 kg

32142 lbs

14579 kg

34404 lbs

15605 kg

38286 lbs

17366 kg

26660 lbs

12093 kg

30542 lbs

13854 kg

32804 lbs

14880 kg

36686 lbs

16640 kg

29540 lbs

13399 kg

33422 lbs

15160 kg

35684 lbs

15605 kg

39566 lbs

17366 kg

27620 lbs

12528 kg

31502 lbs

14289 kg

33764 lbs

15315 kg

37646 lbs

17076 kg

31652 lbs

14357 kg

35534 lbs

16118 kg

37796 lbs

17144 kg

41678 lbs

18905 kg

29204 lbs

13247 kg

33086 lbs

15008 kg

35348 lbs

16034 kg

39230 lbs

17794 kg

196-359M Table of Contents Index 2013-10-29

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 27

Pre-Transport Checklist

Before transporting the drill, check and observe the following items.

❑ Make sure the weight of the tractor equals or exceeds

the value specified for your drill configuration.

❑ Marker Checklist Complete

Markers must be folded.

❑ Master Switches Off

Check that the Veris and point row (if any) master

switches are off while transporting.

❑ Drill Raised and Locked

Lift transport locks installed.

Wings folded and locked, with circuit lever in neutral.

❑ Tires

Check that all tires are properly inflated as listed on

“Tire Inflation Chart” on page 125.

❑ Bystanders

Check that no one is in the way before moving. Do not

allow any one to ride on the drill.

❑ Warning Lights

Always use tractor and drill warning lights when transporting the drill.

❑ Clearance

Know the maximum dimensions of the tractor and drill

in transport position and follow a route that provides

adequate clearance from all obstructions, including

overhead lines.

See “Specifications and Capacities” on page 125.

❑ Stopping Distance

Allow sufficient stopping distance and reduce speed

prior to any turns or maneuvers. If the drill is transported full, allow extra stopping distance.

❑ Road Rules

Comply with all national, regional and local laws when

transporting on public roads.

❑ Watch Traffic

The drill boxes obstruct a portion of your rear view. Be

prepared for sudden maneuvers from following vehicles.

Figure 26

Marker in Transport Cradle

18857

2013-10-29 Table of Contents Index 196-359M

Page 32

28 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Loading Seed

To unload seed, see “Seed Cleanout” on page 101.

Misstep Hazard:

Watch your step when walking on drill ladder and walkboard.

Falling from drill could cause severe injury or death.

Great Plains recommends loading materials after the drill

has been transported to the planting ground.

Seed is heavy. A full load of dense seed adds over 6000

pounds (2780 kg) to the drill. Pre-loading substantially

increases transport hazards:

• Stopping distance increases.

• Turns are more difficult to initiate and more difficult to

stop, due to the inertia of the load.

To load materials:

1. Load only in dry conditions.

2. If the seed is treated, wear protective equipment rec-

ommended for the hazards.

3. Lower the drill.

4. Open the lids for the boxes.

5. Remove any debris or obstructions from the boxes. If

other seed needs to be first removed, see “Seed

Cleanout” on page 101.

6. If not planting all rows, shut off unused rows. See

page 66.

7. Load seed. Load or spread materials evenly across

all partitions. Use a tool or gloved hand.

8. Make a note of the quantity loaded, for later confir-

mation of population or application density desired.

9. Close and secure the box lids.

WARNING

To avoid serious injury or death:

Watch your step when climbing ladder or

walking on walkboard.

838-102C

No Seed Lubricants

Fluted-feed materials do not require lubricants.

838-102C

818-323C

25477

196-359M Table of Contents Index 2013-10-29

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 29

Planting

Seed Rate

Seed rate on this family of drills is controlled by:

• Seed rate handles.

• Seed cup door handles.

• Rate set by the hydraulic drive console.

Set Seed Rate Handle

Refer to Figure 27

There are main box seed rate handles for each section of

the drill (3 handles total). All must be set identically.

The seed rate handle controls the percent engagement

of the seed sprocket in the seed cups. The setting of the

handle is given by the chart on page 40. These settings

have been chosen based on the seed size, and a coarse

rate that allows the hydraulic drive to provide optimal fine

rate control. Once set, the handles are not adjusted.

To set a handle:

6

1. Loosen wing nut under handle.

2. Consult the chart on page 40 for your seed and rate

range. Note the Rate Handle setting provided.

6

7

3. Move indicator to a scale value about 10 higher

than the setting from the chart. Then move handle

back to the chart setting.

4. Tighten wing nut.

Set Seed Cup Door

Refer to Figure 28,

which depicts the seed cup door handle in position .

At each seed tube, adjust the seed cup door handle

for the seed size.

The handle has three normal operating position detents:

(top detent) is for the smallest seeds.

1

Use it for wheat and similar small seeds.

(middle detent) is for larger seeds.

2

Use it for soybeans and similar larger seeds.

(bottom detent) is for oversize or fragile seeds.

3

If you experience excessive cracking with

setting , use setting .

Note: Handle position is used for clean-out (page 101),

2 3

not planting. If set to this position with seed loaded,

it may be difficult to reset it to a normal operating

position.

7

3

5

4

Figure 27

Seed Rate Handle

5

1

2

3

Figure 28

Seed Cup Door Handle

28181

4

26211

2013-10-29 Table of Contents Index 196-359M

Page 34

30 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

About Hydraulic Drive Rate

Before it can control seed rate, the console must be:

• configured with information about your drill and

intended planting speed,

• configured with a calibration number for the seed and

rate range, and;

• calibrated to fine-tune the calibration number and

speed.

This process is described starting on page 39.

Refer to Figure 29

With those steps completed, field seeding rate is controlled manually by adjusting the target “set=” rate

using the ⇑/⇓ arrow buttons. Field rate can also be controlled by a pre-loaded “recipe” or an external GPS controller.

In field operation, the hydraulic drive console displays:

set= the currently active desired seeding rate

out= the current system seeding rate

spd= (over number), the current speed

Seeding Depth

Refer to Figure 29

Seeding depth is controlled by coulter depth in

front, and press-wheel height in back. Seed cannot be

placed any deeper than coulter depth. Before adjusting

row units, make sure coulters are performing as desired.

See “Level Frame Side to Side” on page 102.

See “Level Frame Front to Rear” on page 102.

See “Frame-Mounted Coulters” on page 63.

See “10 Series Opener Depth” on page 74.

Consistent seeding depth relies on appropriate

down-pressure for conditions.

See “Frame Weight” on page 68.

See “10 Series Row Unit Down Pressure” on page 71.

For information on opener adjustments, see one of:

“10 Series Row Unit Adjustments” on page 70

“10HD Series Row Unit Adjustments” on page 75

“20 Series Row-Unit Adjustments” on page 84

For information on troubleshooting opener problems, see

“Troubleshooting” on page 90.

1 2

3

Figure 29

Console Planting Display

2 1

Figure 30

Seeding Depth

28325

3

27070

196-359M Table of Contents Index 2013-10-29

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 31

Point Row Switches

The hydraulic drive motor operates whenever the speed

radar detects motion. The Point Row system determines

whether or not that motion is coupled to the meter drives,

by controlling the electric clutches. The implement lift

switch is part of the Point Row system.

A Point Row troubleshooting chart is found on page 92.

Refer to Figure 31

Note: The Pump switch has no function on 3N-40

drills configured byGreat Plains. Unless connected

to field-installed equipment, leave it off.

P

When Not Planting or Calibrating

Set the Master switch OFF when you do not intend to

meter seed.

Entanglement Hazard:

If the hydraulic drive system is on, and the drill is lowered (or

the Master switch is in CAL), unexpected motion of chains,

sprockets, shafts and seed meters can occur if the speed radar

detects motion, such as someone moving near the radar.

M

Normal Full Pass

1. Set Master switch ON (up)

Set all sections ON (up).

Check that corresponding lamps are on.

2. Height switch automatically energizes clutches when

row units are lowered.

M

L C R

Point Row in Pass

3. Turn desired sections off as non-planting regions are

reached.

4. Turn the sections back on before commencing next

full-width pass.

Point Row CAL Mode

When the drill is raised, the lift switch normally causes

the Point Row Monitor to disengage the clutches for each

drill section. To keep one or more clutches engaged during hydraulic drive calibration, set the Master switch to

CAL.

For a typical 3-row calibration, set the Left section switch

L C R

on, and the center and right section switches /

off during calibration.

{

S

L

F

Cab Switch Box

RC

CAL

Figure 31

P

Switch

or

Function

Indicator

MASTER

M

Switch

MASTER

m

S

C

R

P

CAL

Lamp

Section

Lamps

L

LEFT

CENTER

RIGHT

PUMP

F

Fuse

CAL Lamp

a. However, the section’s meters may still be coupled to the

drive system, if lock-up bolts are installed in the clutch.

See page 109.

m M

b. If lamp fails to illuminate with set ON, check the

F

fuse . If open, check for damaged cable / failed clutch.

Up: ON: System enabled

Center: OFF System inactive

Down: CAL: Lift switch bypassed on

On: System enabled

Off: System OFF

On: Clutch enabled for that section.

Off: Clutch not energized

Up: section enabled

Down: section disabled

May control customer-provisioned

equipment.

Protects switch box, clutches and

b

battery.

On: Lift switch overridden

Off: Lift switch active (or system off)

a

M

28246

2013-10-29 Table of Contents Index 196-359M

Page 36

32 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

d

r

r

Field Operations

This section presumes that all pre-operation checks have

been made on drill, and drill is hitched and loaded with

seed.

Final Field Checklist

❑ Drill unfolded and raised.

❑ Selector valve set to hydraulic drive.

❑ Hydraulic drive console set per seed rate calibration.

❑ Check all seed hoses secure.

❑ Check all row configurations identical (except where

compensating for tire tracks, etc.).

If you desire to verify that all meters and seed tubes are

working, you can run a Veris calibration for 4 seconds

(the minimum time) and “KEEP OLD” when it presents a

proposed new calibration number. See page 39.

Planting Sequence

1. All Clutch/Point Row switches up (except Pump).

Check lamps illuminated.

2. Press Veris “ON/VR” button once.

Check LED above button illuminated.

3. Pull forward to field.

4. Lower drill to field position.

5. Move lever for hydraulic drive circuit forward and lock

it open.

6. Option: Extend marker side desired.

7. Option: Shaft Monitor ON

8. Press Veris “ENGAGE” button once.

Check LED above button illuminated.

9. Accelerate to planting speed.

10. Raise drill for turns (drive stops automatically).

11. Option: Retract and extend markers at turns.

Stop early in the first pass to verify:

• Openers are at correct depth.

• Seed is flowing to furrows.

• Press wheels are covering furrows as desired.

Monitor the seed level indicators on the seed box. After a

third or more of the first seed load has been planted, stop

and check the seed boxes from above. Look for evidence

of unexpected unevenness in the seed level. There may

be mounds at any blocked rows.

Seed consumption is uneven, and end rows run out

before mid-section rows. Re-load seed when the level

indicators near Empty.

Figure 32

DICKEY-john Radar

Moving Chain Hazard

Pinch/Crush Hazard

Shaft Entanglement Hazard:

Be careful when working around drill while tractor is running.

Any movement detected by the radar gun can activate the Veris

hydraulic drive causing motion of chains, sprockets, shafts an

seed meters.

Vision Hazard:

The DICKEY-john RVS II radar speed sensor is an intentional

radiator of RF energy. Although its radiated energy level is fa

below the limits set by EN 61010-1: 1993\A2: 1995 - Chapte

12.4, it is advisable not to look directly into the face of the unit.

The radar must radiate toward the ground and at least 20 cm

(8 inches) away from a human during use to comply with the

RF human exposure limits per FCC 47 CFR Sec. 2.1091.

DO NOT mount or use the radar in a manner inconsistent with

its defined use.

Certain Machine Damage: Do not back up with openers in the

ground. To do so will cause severe damage and opener plugging.

20310

196-359M Table of Contents Index 2013-10-29

Page 37

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 33

Marker Operation (Option)

Markers are on a separate hydraulic circuit on the drill.

Before operating markers, make sure they are properly

bled as described in “Bleeding Markers” on page 107.

Dual markers are equipped with a sequence valve to

control lift sequence. Starting with both markers up, the

sequence is:

1. Activate tractor hydraulic lever; right marker lowers

while left marker stays up.

2. Reverse hydraulic lever; right marker raises while left

marker stays up.

3. Activate hydraulic lever; left marker lowers while right

marker stays up.

4. Reverse hydraulic lever; left marker raises while right

marker stays up.

5. Pattern repeats.

Folding speed of dual markers is adjusted with adjustment screws on sequence valve body. Because exces-

sive folding speed may damage markers, adjust markers

to a safe folding speed according to “Marker Speed” on

page 107.

Note: To get both markers in the lowered position at the

same time, activate hydraulic lever to lower one

marker. After marker is lowered, move lever to

opposite position then quickly reverse lever and

hold until other marker is lowered.

Shaft Monitor Operation (Option)

Refer to Figure 33

To operate the optional shaft monitor, turn the system on

via the ON-OFF switch.

During normal movement, the indicator lamps for each

section are on steady, indicating that shaft rotation is

detected.

If the seed-cup shaft stops for 30 seconds or more, an

alarm sounds and the lamp for the affected section

flashes.

The 30-second delay is to prevent nuisance alarms when

turning at the end of passes.

If a shaft failure does occur, remember that you have

traveled for 30 seconds without planting under the

affected section.

For installation, see:

“Shaft Monitor (Option)” on page 18.

For ordering information, see:

“Shaft Monitor” on page 121.

3

1

2

3

2

Figure 33

Shaft Monitor Console

1

18943

2013-10-29 Table of Contents Index 196-359M

Page 38

34 3N-4010F/3N-4010HDF/3N-4020F Table of Contents Index Great Plains Manufacturing, Inc.

Parking

Following these steps when parking the drill for periods

of less than 36 hours. For longer periods, see Storage,

the next topic.

1. Spot the drill on firm, level ground.