Page 1

Great Plains Mfg., Inc.

Installation Instructions

3-Section Folding No-Till Precision Seeding System

Monitor Systems Option

Used with:

• 3N - 3010P & 3020P

General Information

When you see this symbol, the subsequent instructions and

warnings areserious- follow without exception. Your life and

!

!

the lives of others depend on it!

These instructions explainhow to installthe monitor system option(s).

These instructions apply to:

833-232C 30P-48 Row 7.5" Row Spacing

833-233C 30P-36Row 10" Row Spacing

833-234C 30P-24 Row 15" Row Spacing

and TwinRow only Machines

Referto pages 9and 10 for templatesif thereare

no predrilled holes.

Definitions

Right-hand and left-hand as used in this manual

are determined by facing the direction thedrill will

travelwhile inuse.

Refer to thedrill operator’s manual for detailed information on safely operating, adjusting,

troubleshootingand maintaining the drill. Refer to

the parts manual for part identification.

Manual Part Numbers

196-248M 3N-3010Pand3020P Operator’s

Manual

196-248P 3N-3010P and 3020P Parts

Manual

DJ Manual-Supplied in Option Bundles

Refertothismanual forinstructions regarding the

console assembly, speed sensor, and other schematic illustrations.

NOTE: Be sure you have the correct instructions for the monitor system you are

using.

833-232C 30P-48 Row 7.5" Row Spacing Begin on page 2

833-233C 30P-36 Row 10" Row Spacing Begin on page 4

833-234C 30P-24 Row 15" Row Spacing Begin on page 6

and TwinRow only Machines

© Copyright 2000 Printed

6/4/2002

196-264m

Page 2

Monitor Systems Option

2

Assembly Instructions f or 833-232C 7 1/2 Ro w Spacing

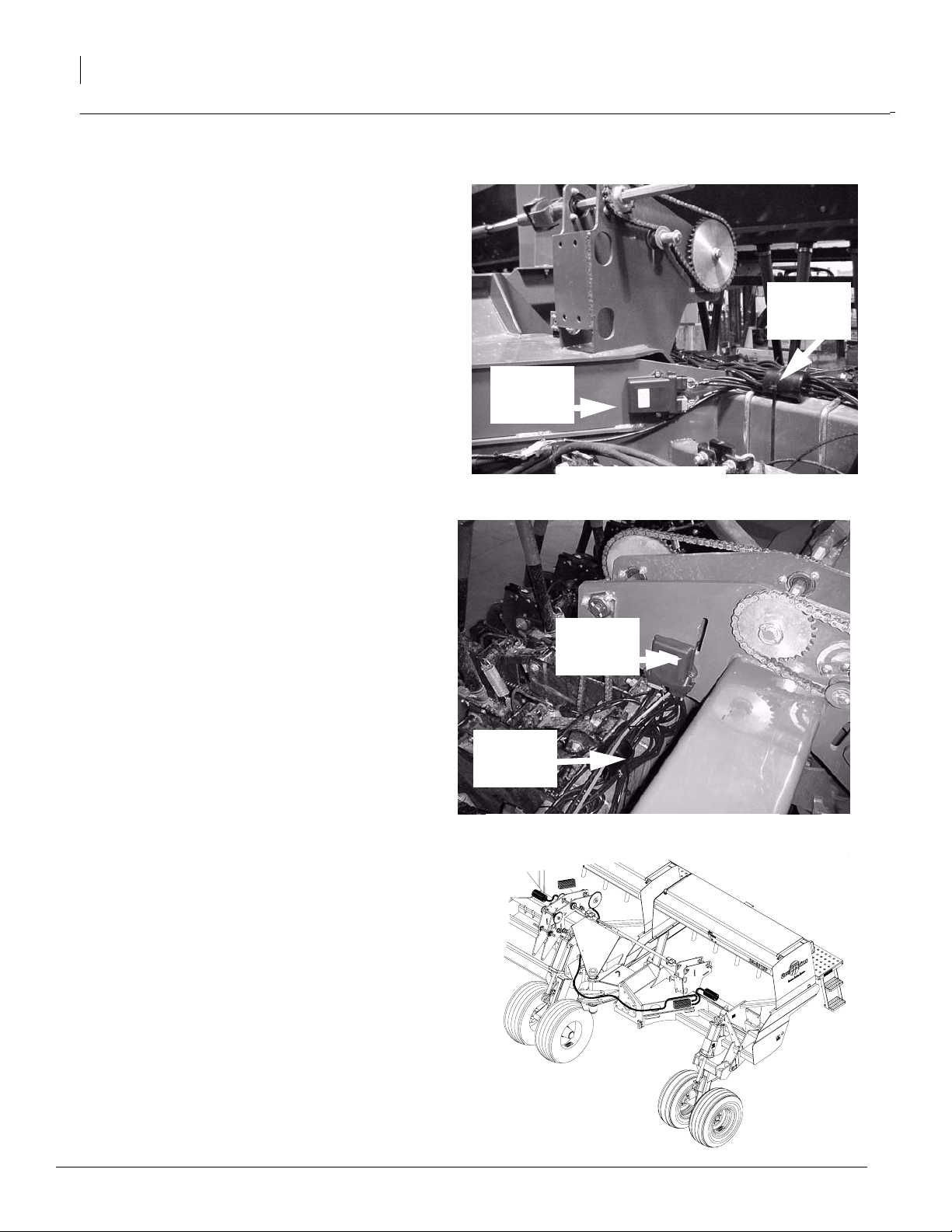

Refer to Figures 1 and 2

1. Mount one each ofthe materialflowmodules to

the wing frame asshownin figure 1.Mount one

each of the material flow modules to the drive

system frame as shown in figure 2.

NOTE:If there areno predrilled holes in theframeuse the

templates provided, mark and drill 5/16” holes for mounting modules. (Pages 9 & 10

2. Place the harness wire bundle onthe frame by

the material flow module.Connect the wire extensions to the openers starting at the left side

of the drill in numerical order. Wire extension

number 1 with first openeron the left. Continue

in the same manner until allwire extensionsare

connected.Fastentheharnesstotheframewith

cable ties as shown in figures 1 and 2.

)

Material

Flow

Module

Great Plains Mfg., Inc.

Harness

Harness

Wire

Wire

Bundle

Bundle

3. Connect black and gray colored leads into the

material flowmodules. Inlets are color coded.

Black to blackand gray to gray.

4. Referto Figure 3.Attach sensor lead marked IN

from the wing frame harness to the 15’ smart

sensor extension wire.Route the 15’ extension

using the same path as the openerlift hoses allowing the same slack at the drill toolbar pivots

as the other hoses. Connect this extension to

the center frame harness lead marked OUT.

Usecabletiesto secure the wires in place.Mark

these extensions P-1 and P-2 for further reference.

5. Assemble two of the 20’seed smart extensions

together then attach them to the center frame

harness sensor lead marked IN. Route the 20’

extensions through the tongue tube up to the

tractor.The left extensions will connect to Port 1

and the right extensions will connect to port 2.

NOTE: Left-hand side of drill is shown in figures. Lefthand and Right-hand sides on the Drill are done in the

same manner. The left side will go to port 1 and the right

side to port 2.

Figure 1 Wing Frame

Material

Flow

Module

Harness

Wire

Bundle

Figure 2 Center- Drive System Frame

19217

19218

6. Referto page3 for a detailed listing of partsand

schematics for this particular monitor system.

7. For console assembly, speed sensor and other

schematics illustrations refer to the DJ manual

found in the monitor system package.

8. Refer to page 8 for speed sensor instructions if

sensor is being used.

NOTE: J1 accessory harness and two 20’ extensions are not used if speed sensor on drills is not

Routing for wire Harness

used.

196-264m 4/8/2004

Figure 3

19255

Page 3

Great Plains Mfg., Inc.

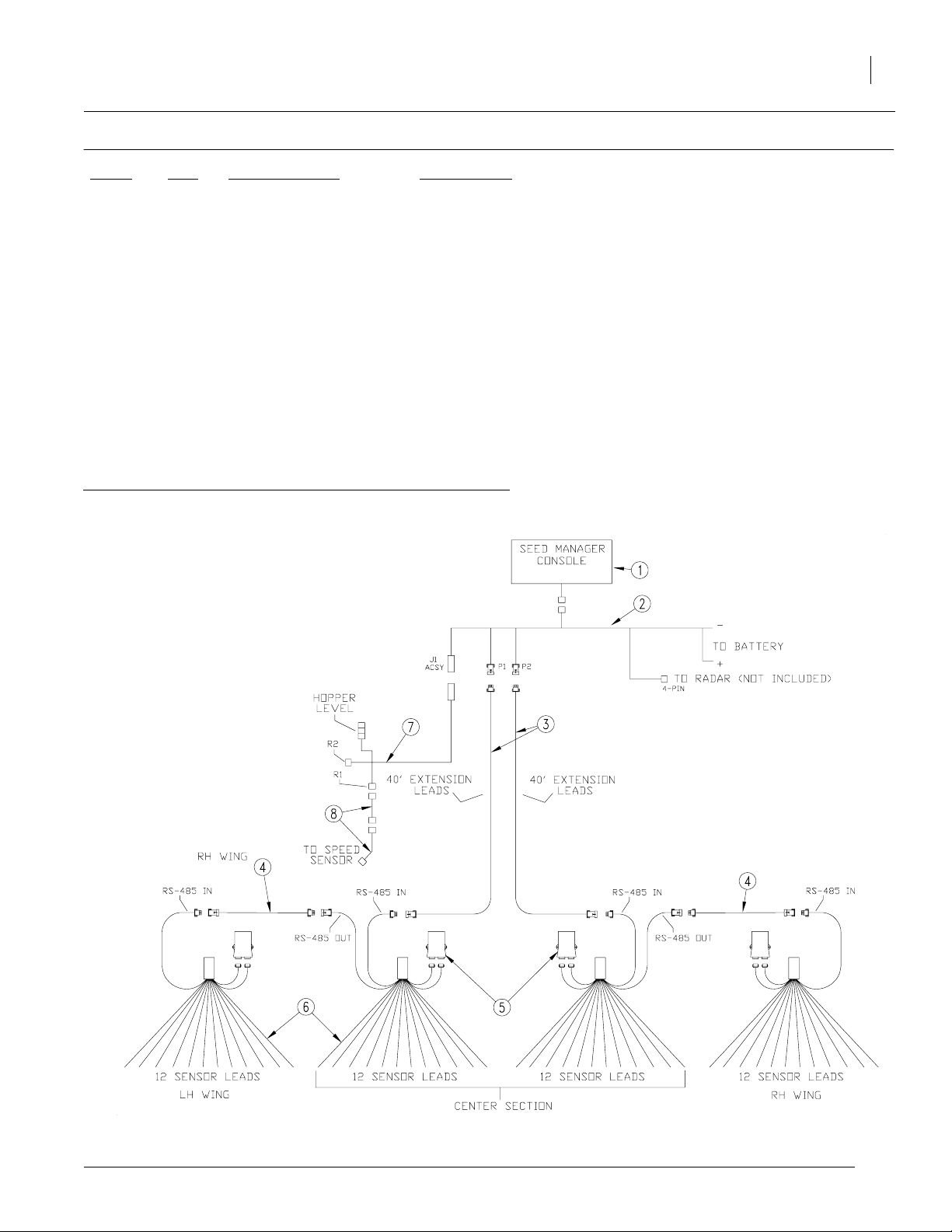

833-232C cont.

Ref # Qty Part Number Description

1. 1 466820010S3 Seed Manager Console*

2. 1 466820131S1 J1 Harness 1-36 Rows (485B)

3. 2 466820517S3 40’ SeedSmart Sensor Ext.

4. 2 466820513S3 15’ SeedSmart Sensor Ext.

5. 4 467751020S1 Material FlowModule

6. 4 467751041S1 Material FlowModule Harness 12

7. 1 466820640S1 J1 Accessory Harness

8. 2 466820833S1 20’ ReedSW/RLCTNC SensorExt

*NOTE: Refer to DJ manual for Console installation.

30P 48 Row 7.5" Spacing Monitor System Schematics

Installation Instructions

3

Note: For further schematic illustration, refer to the DJ manual supplied in the Monitor System Package.

4/8/2004

19228

196-264m

Page 4

Monitor Systems Option

4

Assembly Instructions f or 833-233C 10 inc h Ro w Spacing

Great Plains Mfg., Inc.

Refer to Figure 4

1. Mount the end of the 16 row harness to the lefthand wing frame as shown in figure 4. Route the

wire extension acrossthe frame. Usethe cable ties

provided to fasten the harness to the frame.

2. Mount the end of the 20 row harness to the righthand wing frame. Route usingthe samepath asthe

opener lift hosesallowing thesame slack at thedrill

toolbar pivots as the other hoses.

3. Connect the wire extensions to the openersstarting

atthe left side of the drillin numericalorder. Wire extension number 1 with first opener. Continue inthe

same manner until all wire extensions are connected. Fasten the wires downwith cable ties.

4. Attachsensorleadfromharness(Left-hand 348") to

the J1 Harness. Attachsensor leadfrom harness

(Right-hand 348") to the J2 Harness.These leads

willthenconnecttotheconsole.Referto DJ manual.

NOTE:Left-hand side ofdrillareshownin figures.

Left-hand and Right-hand sides on the Drill are

done in the samemanner. The left side will go to

J1 and the right side to J 2.

5. Refer to page 5 fora detailedlisting ofparts and

schematics for this particular monitor system.

6. For console assembly, speedsensor, and other

schematicsillustrations referto theDJmanualfound

in the monitor system package.

7. Refer to page 8 for speed sensorinstructions if sensor is being used

Figure 4

Routing

196-264m 4/8/2004

19257

Page 5

Great Plains Mfg., Inc.

Installation Instructions

833-233C cont.

Ref # Qty Part Number Description

1. 1 466820010S1 Seed ManagerConsole*

2. 1 466820121S1 J1 Harness

3. 1 466820141S1 J2 Harness.

4. 1 458411340 16 Row Harness

5. 1 4584113411 20 Row Harness

6. 1 110001103 Manual (included in 466820010S1)

7. 1 110011161 Ver. 5.0 Addendum (included in 466820010S1)

8. 1 110011178 Ver 6.0 Addendum (included in 466820010S1)

*NOTE: Refer to DJ manual for Console installation.

5

30P 46 Row 10" Spacing Monitor System Schematics

Note: For further schematic illustration, refer to the DJ manual supplied in the Monitor System Package.

4/8/2004

19229

196-264m

Page 6

Great Plains Mfg., Inc.

Monitor Systems Option

6

Assembly Instructions for 833-234C Harness f or 15 inch Row Spacing,

Twin Row only Machines and 833-169C Console.

Refer to Figure 5

1. Mount one end of the harness to the frame as

shown in figure 5. Route the wire extension using

the same path as theopener lift hoses allowing the

same slack at the drill toolbar pivots as the other

hoses.Use the cable ties provided to fasten the harness to the frame.

2. Mount the center module to the frame. Route the

wire extensionthrough the tongue tube as shown in

figure 2.

3. Connectthe wire extensionstotheopeners starting

attheleftsideof the drill in numerical order.Wireextension number 1 with first opener on the left. Continue in the same manner until all wire extensions

are connected. Fasten the wires down with cable

ties.

4. Attach sensor lead(380) from thecenter module to

the console in your tractor.

5. Refer to page 7 fora detailedlisting ofparts and

schematics for this particular monitor system.

6. For console assembly, speedsensor andother

schematics illustrations refer to the DJ manual

found in the monitor system package.

7. Referto page 8for speed sensorinstructions if sensor is being used

19257

196-264m 4/8/2004

Figure 5

Page 7

Great Plains Mfg., Inc.

Installation Instructions

833-234C cont.

Ref# Qty Part Number Description

1. 1 45814-1360S1 30P 24 Row 15/TR Monitor Harness

2. 1 833-169C DJ-45841-0720 PM3000 Seed Monitor Console

30P 24 Row 15/TR Monitor Harness Schematics

7

ote: For further schematic illustration, refer to the DJ manual supplied in the Monitor System Package.

4/8/2004

19230

196-264m

Page 8

Monitor Systems Option

8

Refer to Figure 1

1. Assemble mounting bracket (1)and sensor

bracket(2) together using hardwaresupplied

in kit. Assemble mounting bracket tothe inside of the plate on the left gauge wheel. Install the Dickey-john magnetic pickup sensor

(3) to the sensor mounting bracket.

2. Loosen fasteners at bearings (4) on either

side of the contact wheel pivot shaft (5). Slide

pickupdisk (6)ontoshaft usinglockcollars(7)

on either side to hold in place.

Refer to Figure 2

3. Tighten bearings back down. Alignsensor

and pickup disk with centerline. Be sure to

tighten set screws after alignment is done.

4. Connect sensor to wire harness sensor extension.

Great Plains Mfg., Inc.

Templates for 833-232C 7 1/2 Row Spacing Material Flow Module

5. Set initial distance between sensor and pickupdisk at 0.040 inch. This may need to be adjusted up or down as necessary.

6. Figure 3 shows routing for wire harness.

Refer to the DICKEY-john Installation and

Operating Manual for further instructions.

Centerline

Figure 1

19286

Figure 2

Routing of Wire Harness

196-264m 4/8/2004

19284Figure 3

Page 9

Great Plains Mfg., Inc.

Templates for 833-232C 7 1/2 Row Spacing Material Flow Module

Installation Instructions

19288

9

4/8/2004

196-264m

Page 10

Monitor Systems Option

10

Great Plains Mfg., Inc.

Templates for 833-232C 7 1/2 Row Spacing Material Flow Module

19289

196-264m 4/8/2004

Loading...

Loading...