Page 1

Great Plains Mfg., Inc.

Manufacturing, Inc.

Seed Rate and Microband

Application Charts for 30 ft

Precision Seeding System

The following pages are to assist in the proper setting of seeding and

fertilizer application rates for the 30’ precision seeding system. The

rates indicated in the charts are approximate values. To assure the

most accurate seeding rate it is recommended that the drill be calibrated for the desired seed at the time of planting.

© Copyright 2009 Printed

12/01/2009

196-248B

Page 2

2

Table of Contents

Talc Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Graphite Lubricant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Sprockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Drive Speed Range Sprockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Transmission Sprockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Checking Seeding Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Checking Volumetric Seeding Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Checking Singulated Seeding Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Seed Rate Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Barley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Corn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cotton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Milo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Oats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Rice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Rye . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Soybeans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Wheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Small Seeds Attachment Seed Rate Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Microband . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Microband without Veris Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Microband with Veris Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Great Plains Mfg., Inc.

Singulator Plus Meters (all seeds)

Ezee Glide Plus Talc-Graphite Mix

821-069C bucket, 5 gallon (19 liter

Ezee Glide Plus Lubricant

To maximize performance of Great Plains metering systems,

it is imperative to use only “Ezee Glide Plus” lubricant. “Ezee

Glide Plus” Talc-Graphite lubricant is mandatory for all seeds,

especially treated or inoculated seed. Thorough mixing of

seed and added lubricant is required.

Recommended usage:

For clean seeds other than milo and cotton sprinkle

one cup of Ezee Glide Plus Talc per 4 bushels or units

(170 ml per 100 liters) of seed.

For milo and cotton double the application to

one cup (or more) per 2 bu or units (335 ml per 100 liters) of

seed.

Adjust this rate as necessary so all seeds become coated

while avoiding an accumulation of lubricant in the bottom of

the hopper.

For seed with excessive treatment, or for humid planting environments, increase the rate as needed for smooth meter

operation.

Irritation and Chronic Exposure Hazard:

Wear gloves. DO NOT use hands or any part of your body to mix

seed lubricant. Wear a respirator when transferring and mixing.

Avoid breathing lubricant dust. Not an acute hazard. May cause mechanical eye or skin irritation in high concentrations. As with all

mineral spills, minimize dusting during clean-up. Prolonged inhalation may cause lung injury. Product can become slippery when wet.

)

Finger Pickup Meters

EZ-Slide Graphite Powder

821-042C bottle, 1 pound (450 grams)

821-060C jug, 5 pound (2.3 kg)

For Finger Pick Up Meters Only

Use only approved Graphite Powder available from Great

Plains Mfg. Inc. or Precision Planting to ensure proper lubrication of finger pickup corn seed meters.

Recommended usage:

For finger pickup meters, add one tablespoon (15 ml) of

graphite for each unit of seed corn (80,000 kernels).

In high humidity conditions, or seeds with heavy seed treatments, increase the application to two tbsp (30ml).

If delivery of seed from the hopper to the finger meter is an issue, add “Ezee Glide Plus” talc and graphite blend at a rate of

one cup (237ml) per 4 units of seed. Adjust until issue is

resolved.

Irritation and Chronic Exposure Hazard:

Wear gloves. DO NOT use hands or any part of your body to mix

seed lubricant. Wear a respirator when transferring and mixing.

Avoid breathing lubricant dust. Not an acute hazard. May cause mechanical eye or skin irritation in high concentrations. As with all

mineral spills, minimize dusting during clean-up. Prolonged inhalation may cause lung injury.

196-248B 12/1/2009

Page 3

Great Plains Mfg., Inc.

Sprockets

3

Adjusting the seeding rate requires the following:

• adjusting drive speed range sprockets,

• adjusting transmission sprockets,

• preparing seed meters, and

• checking seeding rate.

Before setting the seeding rate, rotate the gauge

wheels. Check that seed meters, seed tubes and

drives are working properly and free from foreign

material.

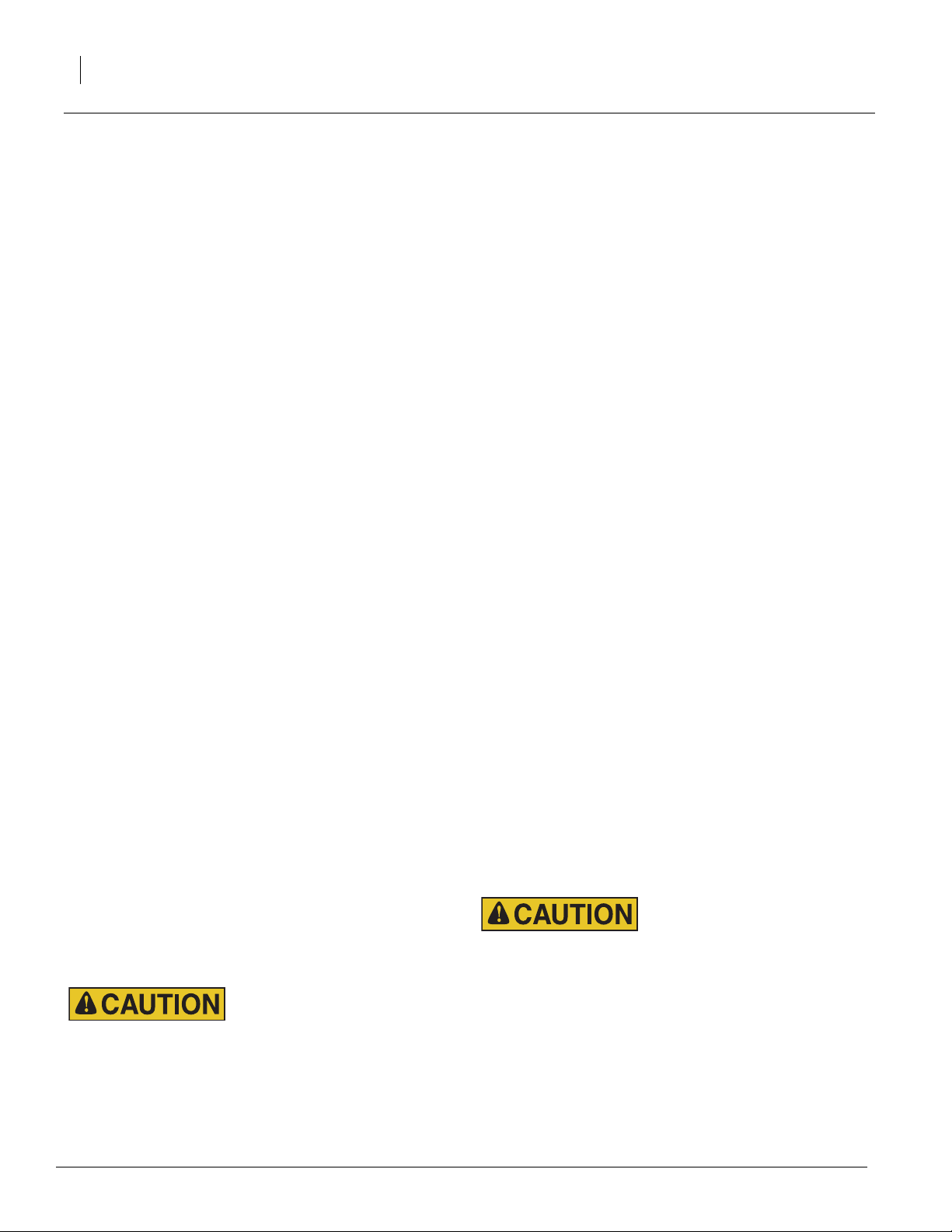

Drive Speed Range Sprockets

Select the correct drive speed range sprockets for

your seed by referring to Seed Rate Charts, beginning on 6.

Refer to Figure 1

Loosen idler plate (1) and remove chain. Remove

retaining pins from shafts and install speed range

sprockets as necessary.

NOTE: Make sure the correct sprockets have

been installed in the DRIVER and DRIVEN locations as shown.

Reroute chain over sprockets and idlers as

shown. Move idler into chain so chain has 1/4inch to 1/2-inch slack in its longest span. Tighten

idler and install retaining pins.

Driver

19113

Driven

1

Figure 1

Drive speed range sprockets

Set the same drive range sprocket combination

on both sides of drill.

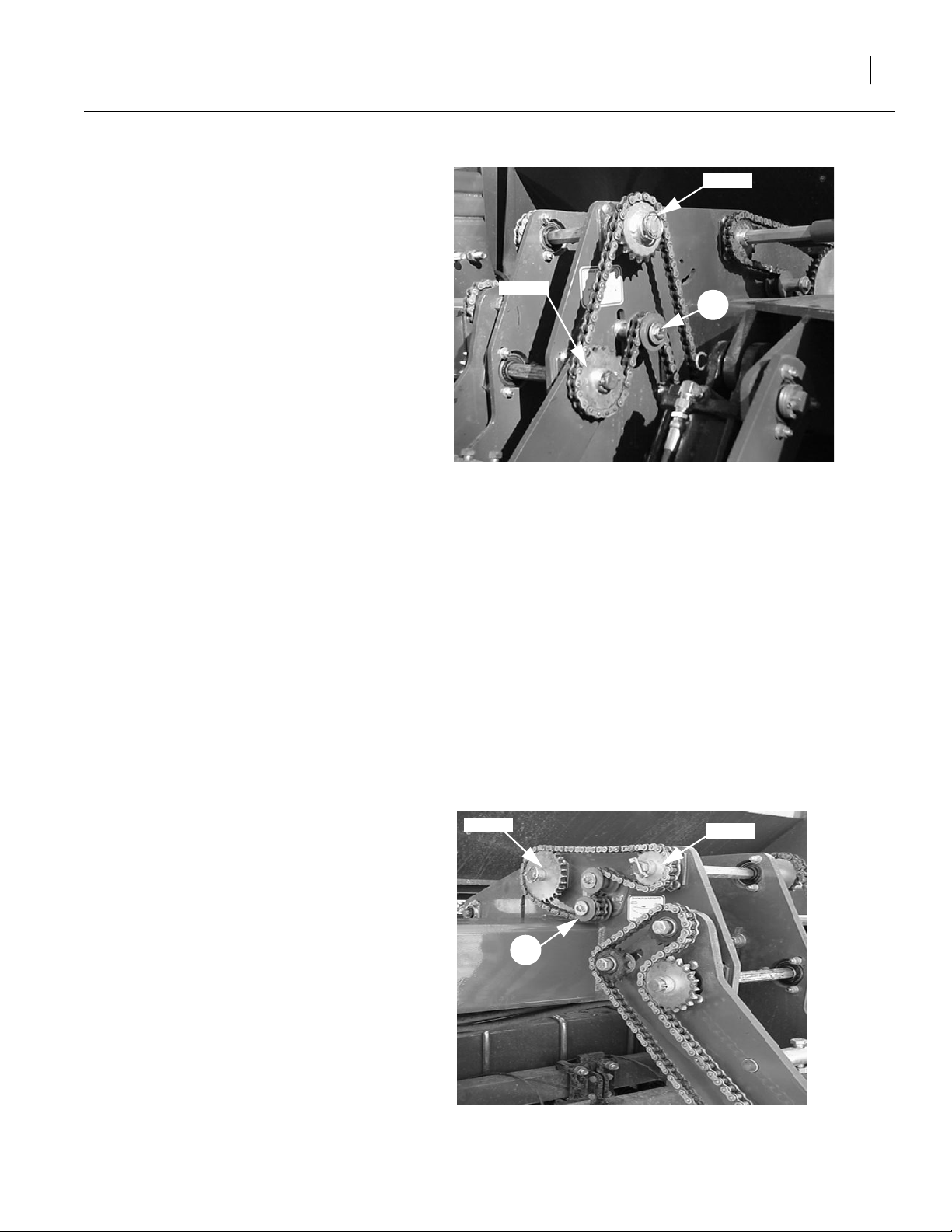

Transmission Sprockets

To change the seeding rate, change the transmission sprocket combination. Refer to Seed Rate

Charts, beginning on 6.

Refer to Figure 2

Loosen idler (1) and remove drive chain. Remove

lynch pins from shafts and rearrange driver and

driven sprockets as necessary.

Reroute drive chain over sprockets and idlers as

shown. Move idlers into chain so chain has #-inch

slack in its longest span. Tighten idlers and install

lynch pins.

Set the same transmission sprocket combination

on both sides of drill.

12/1/2009

Driven

1

19106

Driver

Figure 2

Transmission sprockets

196-248B

Page 4

4

Checking Seeding Rate

Checking Volumetric Seeding Rate

The seed charts are based on cleaned seed and

12.5 x 15, rib implement transport tires and 13 x

5.00 - 6 contact drive wheel tires. Factors including foreign material, seed treatment, seed size,

seed weight, field conditions and tire pressure will

affect seeding rate. Set and check the seeding

rate, then readjust the rate as necessary.

1. Record the weight of an empty container

large enough to hold seed metered from three

meters for one acre.

2. Place several pounds of seed over three seed

meters on an outside end of the drill box.

NOTE: If drill box is full, shut off sliding seed tubes

to all but three meters on an outside end.

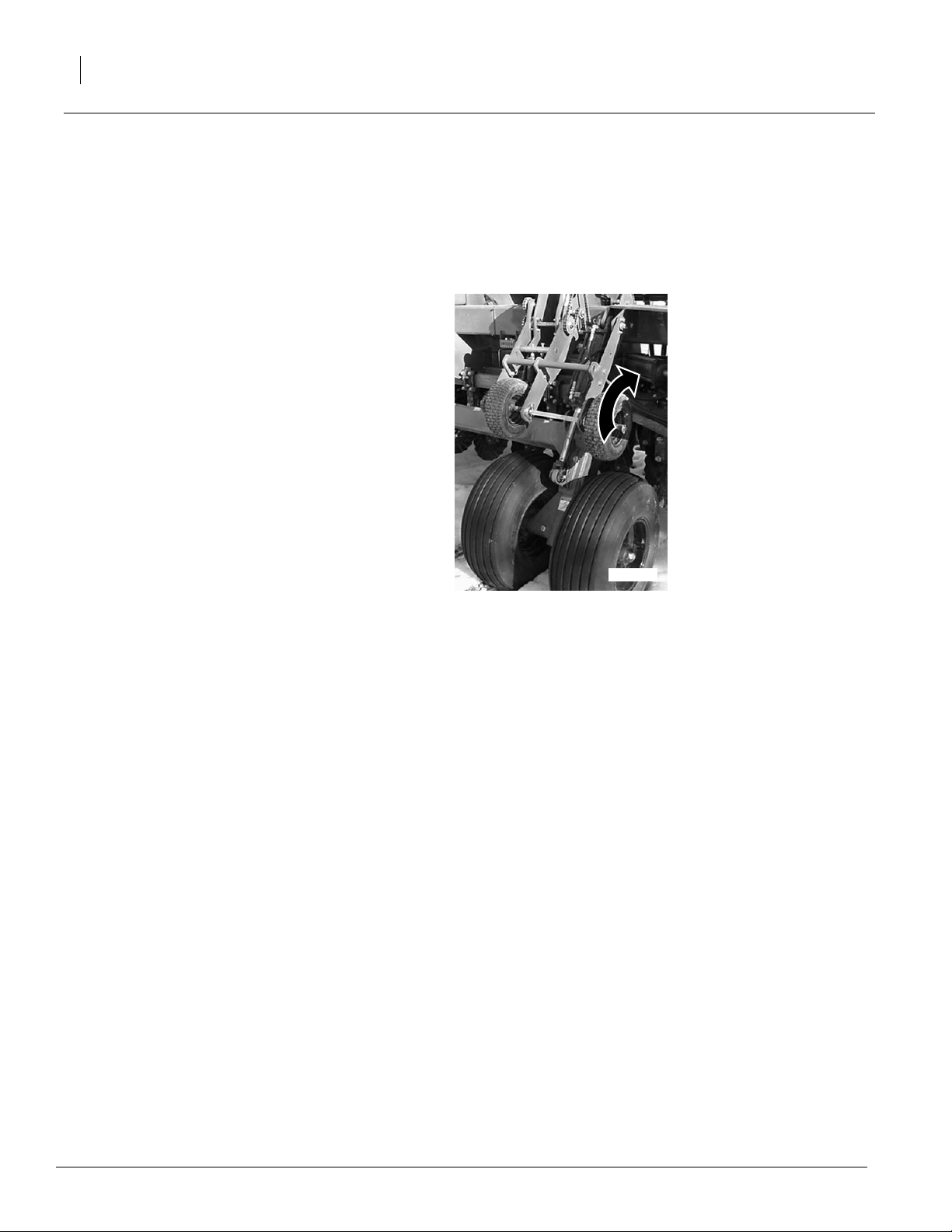

Refer to Figure 3

Great Plains Mfg., Inc.

3. Turn contact drive wheel clockwise a few

turns to fill meters with seed and until seed

drops to ground from all three openers.

4. Place a container under the three openers to

gather seed as it is metered.

5. Turn contact drive wheel clockwise 420 revolutions. Check to make sure seed tubes have

plenty of seed covering them.

6. Weigh measured seed. Subtract initial weight

of empty container. Divide by three for the

amount metered by each meter, then multiply

by the number of drill openers for the poundsper-acre seeding rate.

7. If seeding rate is different than desired:

• Double check transmission sprocket and

drive range sprocket combinations.

• Check for meter malfunction.

• Check for correct seed meter wheel.

• Check that all three rows are getting seed.

• Refer to the troubleshooting guide in the

operator’s manual.

19114

Figure 3

Equations for calibrating volumetric seeding rate:

measured seed empty container–

----------------------------------------------------------------------------------------- pounds per meter=

3 (number of meters measured)

pounds per meter number of openers× pounds per acre=

8. Readjust transmission and/or range sprockets and repeat test.

196-248B 12/1/2009

Page 5

Great Plains Mfg., Inc.

5

Checking Singulated Seeding Rate

The seed charts are based on cleaned and sized seed.

Extreme seed size variations, foreign material and tire

pressure will affect the seeding rate. Check the seed

population rate as described below.

1. Adjust the planting depth to a shallow setting.

2. Plant at the desired planting speed for a short distance.

3. Using the table, determine how many rows need to

be counted.

4. Measure a distance, according to the table, for the

row spacing in the planted area.

5. Count the number of seeds, in the appropriate number of rows, over the distance measured.

6. Multiply the number of seeds counted by 200 if

measuring for 1/200 acre or by 1,000 if measuring

for 1/1,000 acre. This is the plant population in

seeds per acre.

Example 1:

If you have a 10" row spacing drill, three rows must be

counted. Measure 17’ 5” and count the number of seeds

in three rows. If the number is, for example, 180, multiply 180 by 1,000.

180 x 1,000 = 180,000 seeds per acre.

Example 2:

If you have a Twin Row 30" row spacing drill two rows

must be counted. Measure 87’ 1” and count the number

of seeds in two rows. If the number is, for example, 170,

multiply 170 by 200.

170 x 200 = 34,000 seeds per acre.

7. If the planting population issignificantly different than

desired, make the following checks:

• Double check the transmission and range sprocket

combinations. Refer to the seed population chart for

the seed being planted.

• Check the air pressure in the gauge wheel tires. Refer to “Tire Inflation Chart” in the operator’s manual.

• Refer to the troubleshooting guide in the operator’s

manual.

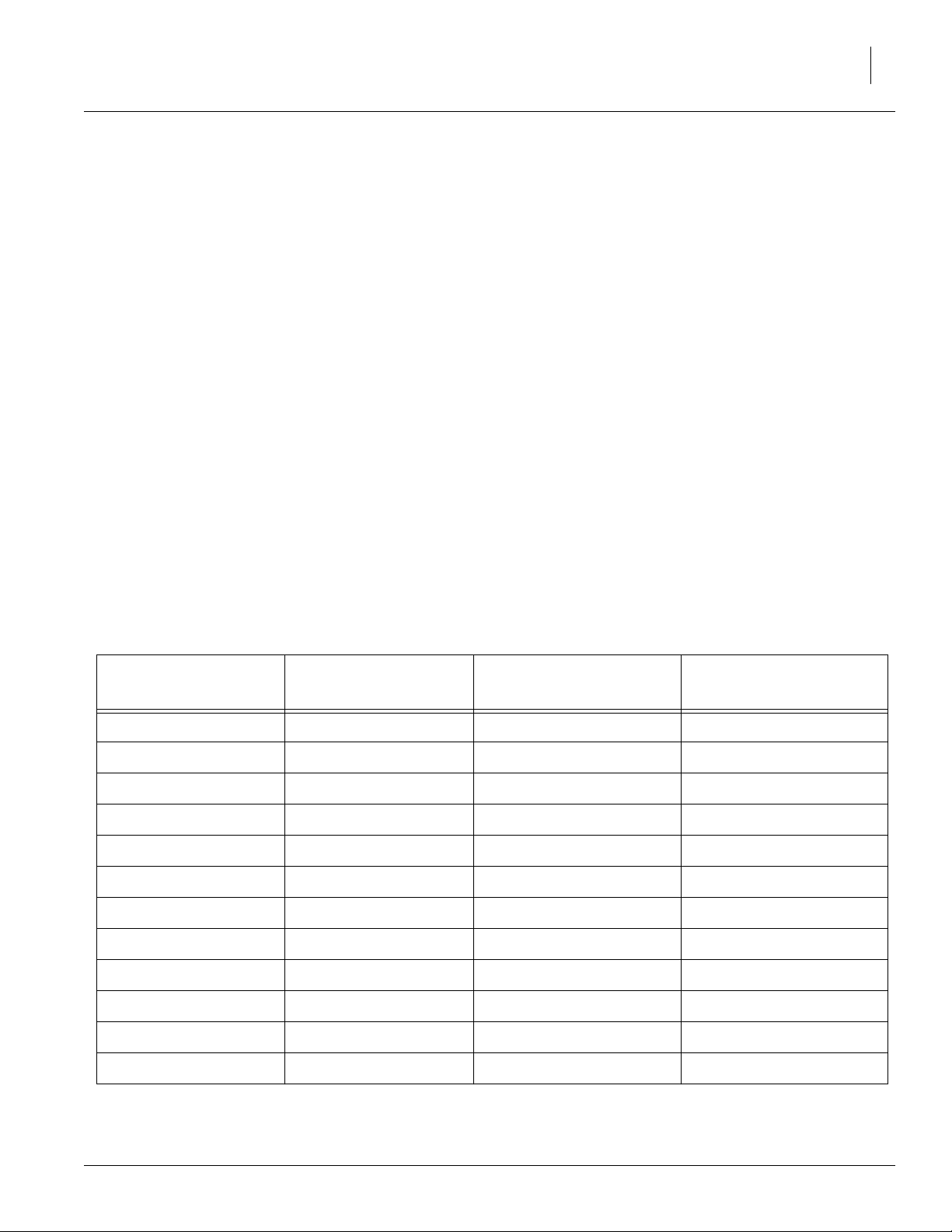

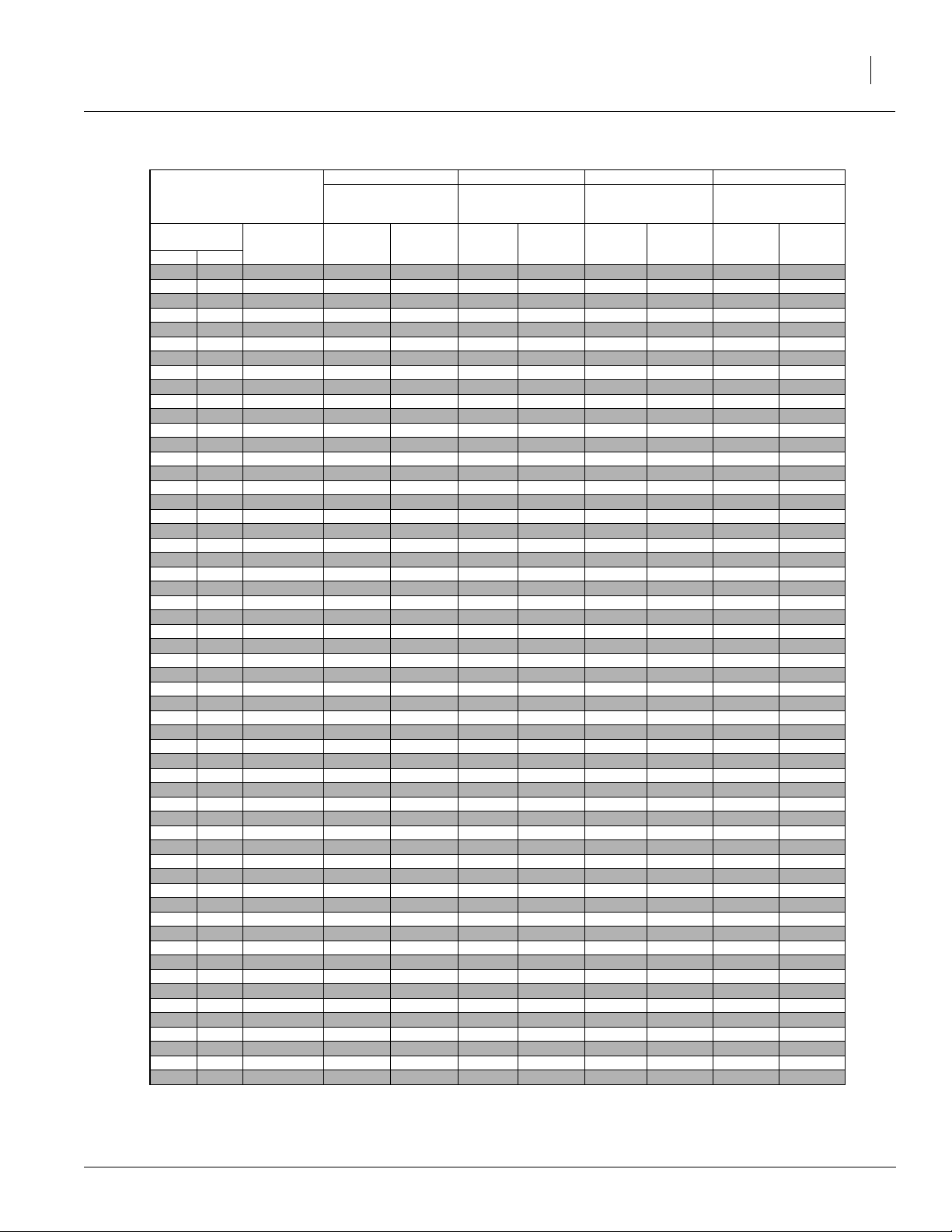

Seed Rate Charts

Seed rate charts begin on page 6. The charts give transmission sprocket combinations and drive range sprocket

combinations used to achieve desired population or

pounds per acre for each row spacing. The charts also

give seed spacing for singulated and volumetric seeds.

Planted Row Spacing

(Inches)

Number of Rows to

Count

Length of Row to Measure

for 1/1,000 acre

Length of Row to Measure

for 1/200 acre

7 1/2 4 17’5"

9 1/2 3 18’4"

10 3 17’5"

15 2 17’5" 87’1"

19 2 13’9" 68’9"

20 1 26’2" 130’8"

Twin Row 30 or 30 1** 17’5" 87’1"

Twin Row 36 or 36 1** 14’6" 72’7"

Twin Row 38 or 38 1** 13’9" 68’9"

Twin Row 40 or 40 1** 13’1" 65’4"

15 Skip Row or 17 1/7 2 15’3" 76’3"

**Count Twin Row as one row.

NOTE: Use 1/200 acre for populations less than 100,000 seeds/acre. Use 1/1,000 acre for populations above

100,000 seeds/acre.

196-248B12/1/2009

Page 6

6

Great Plains Mfg., Inc.

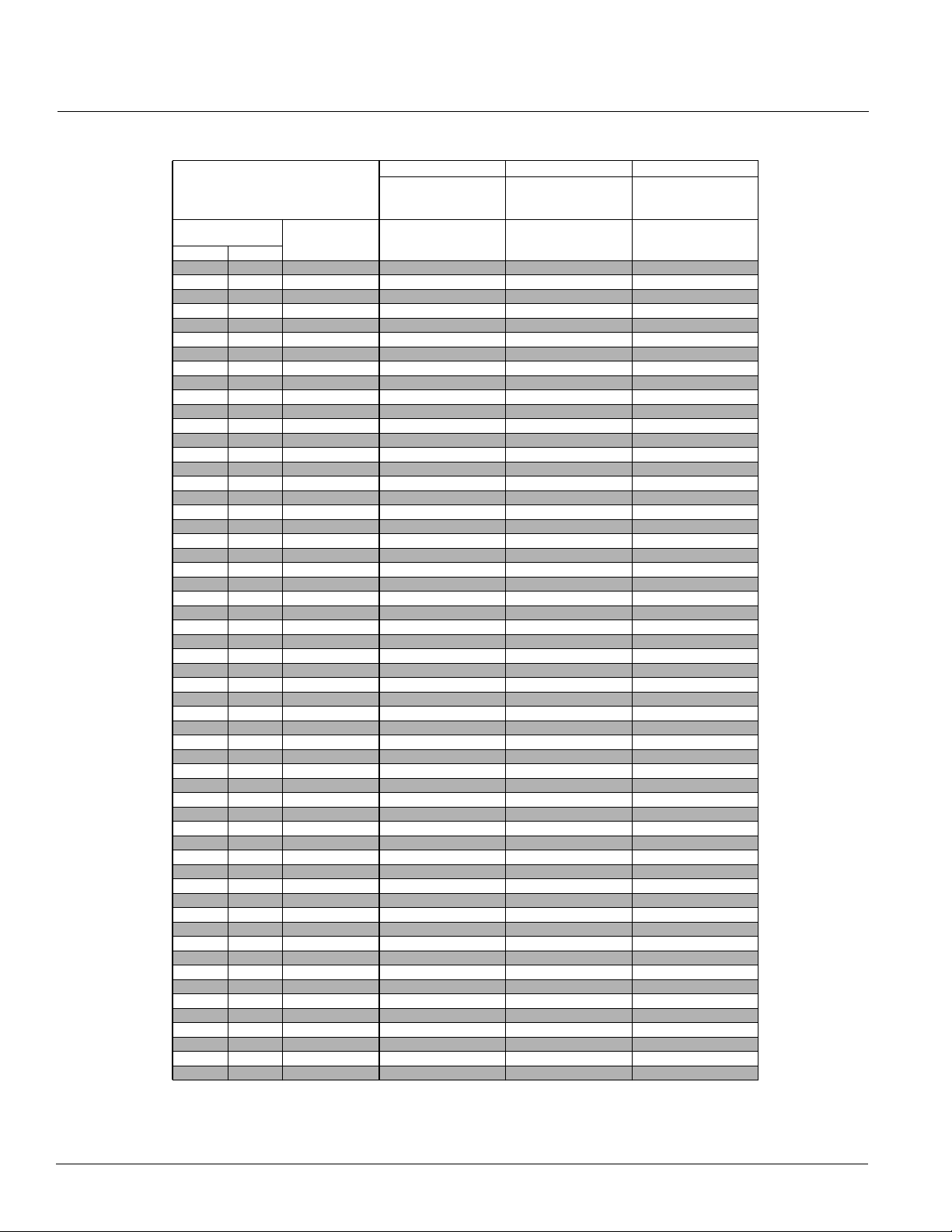

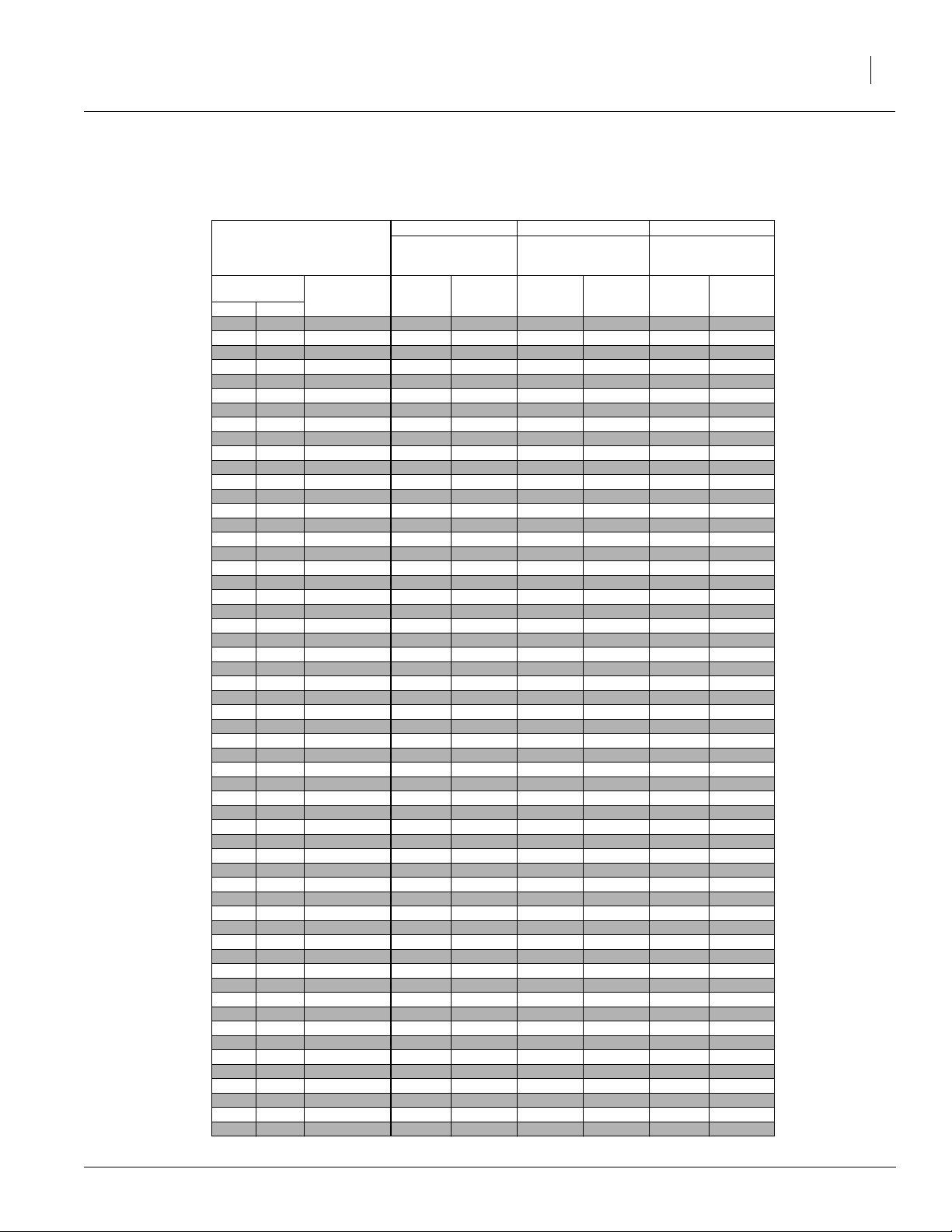

Barley (Volumetric)

Seed Rate Charts

52 lb. bu.

No Seed Treatment

with Talc Driver = 20

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 23.6 8 8 8

17 27 24.5 8 8 8

17 26 25.4 8 8 8

19 28 26.4 8 8 8

17 25 26.5 8 8 8

19 27 27.4 8 8 8

17 24 27.6 8 8 8

19 26 28.4 8 8 8

17 23 28.8 8 8 8

19 25 29.6 8 8 8

19 24 30.8 8 8 8

23 28 32.0 8 8 8

19 23 32.1 8 8 8

23 27 33.1 8 8 8

24 28 33.3 8 8 8

23 26 34.4 8 8 8

24 27 34.6 8 8 8

25 28 34.7 8 8 8

17 19 34.8 8 8 8

23 25 35.8 8 8 8

24 26 35.9 8 8 8

25 27 36.0 8 8 8

26 28 36.1 8 8 8

23 24 37.3 8 8 8

24 25 37.4 8 8 8

25 26 37.4 8 8 8

26 27 37.5 8 8 8

27 28 37.5 8 8 8

23 23 38.9 8 8 8

28 27 40.3 8 8 8

27 26 40.4 8 8 8

26 25 40.5 8 8 8

25 24 40.5 8 8 8

24 23 40.6 8 8 8

28 26 41.9 8 8 8

27 25 42.0 8 8 8

26 24 42.2 8 8 8

25 23 42.3 8 8 8

19 17 43.5 8 8 7

28 25 43.6 8 8 7

27 24 43.8 8 8 7

26 23 44.0 8 8 7

28 24 45.4 8 8 7

27 23 45.7 8 8 7

23 19 47.1 8 8 7

28 23 47.4 8 8 7

24 19 49.1 8 8 7

25 19 51.2 8 8 6

23 17 52.6 8 8 6

26 19 53.2 8 8 6

24 17 54.9 8 8 6

27 19 55.3 8 8 6

25 17 57.2 8 8 6

28 19 57.3 8 8 6

26 17 59.5 8 8 5

27 17 61.8 8 8 5

28 17 64.1 8 8 5

Wheel P/N 403-060D Wheat

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Seed

Rate

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

12/1/2009

196-248B

Page 7

Great Plains Mfg., Inc.

7

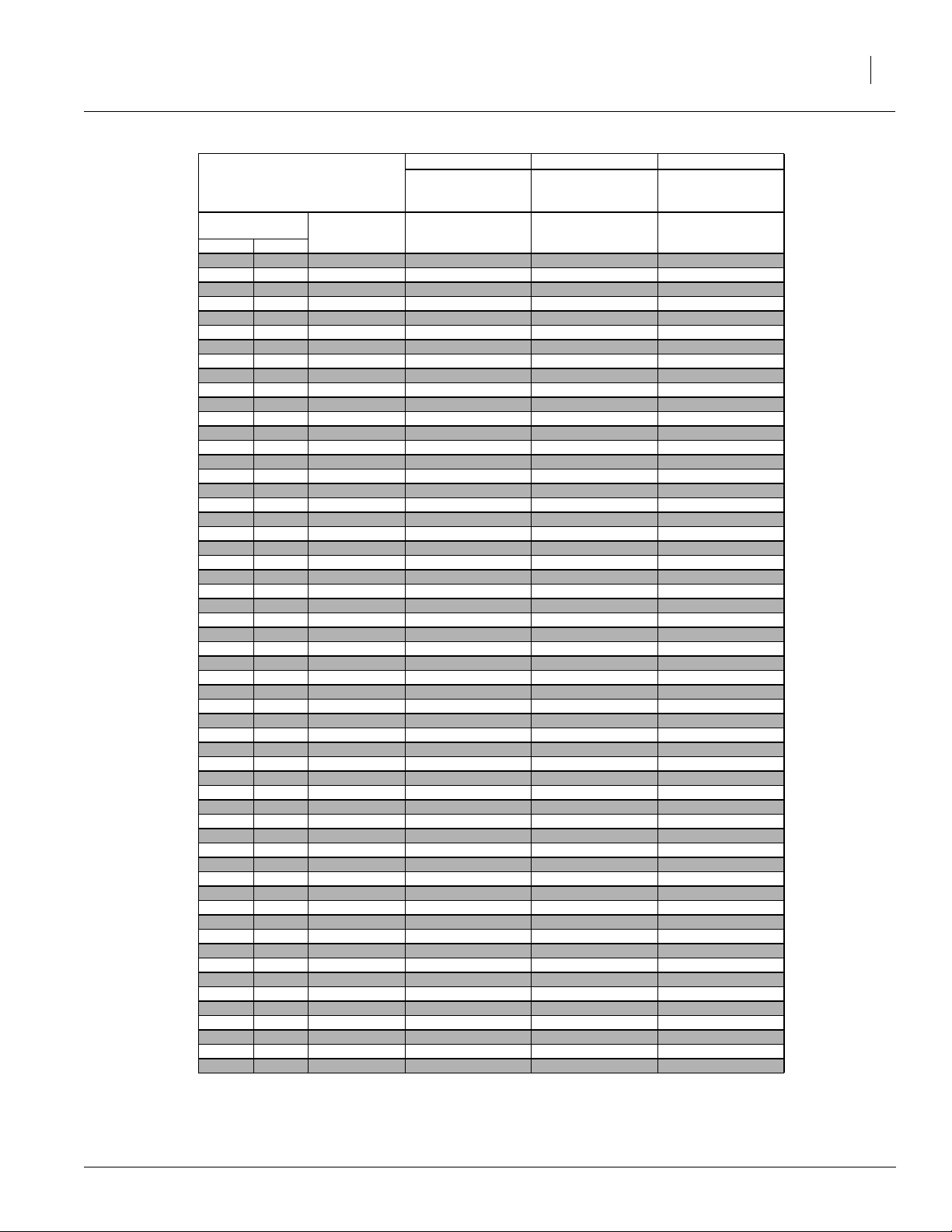

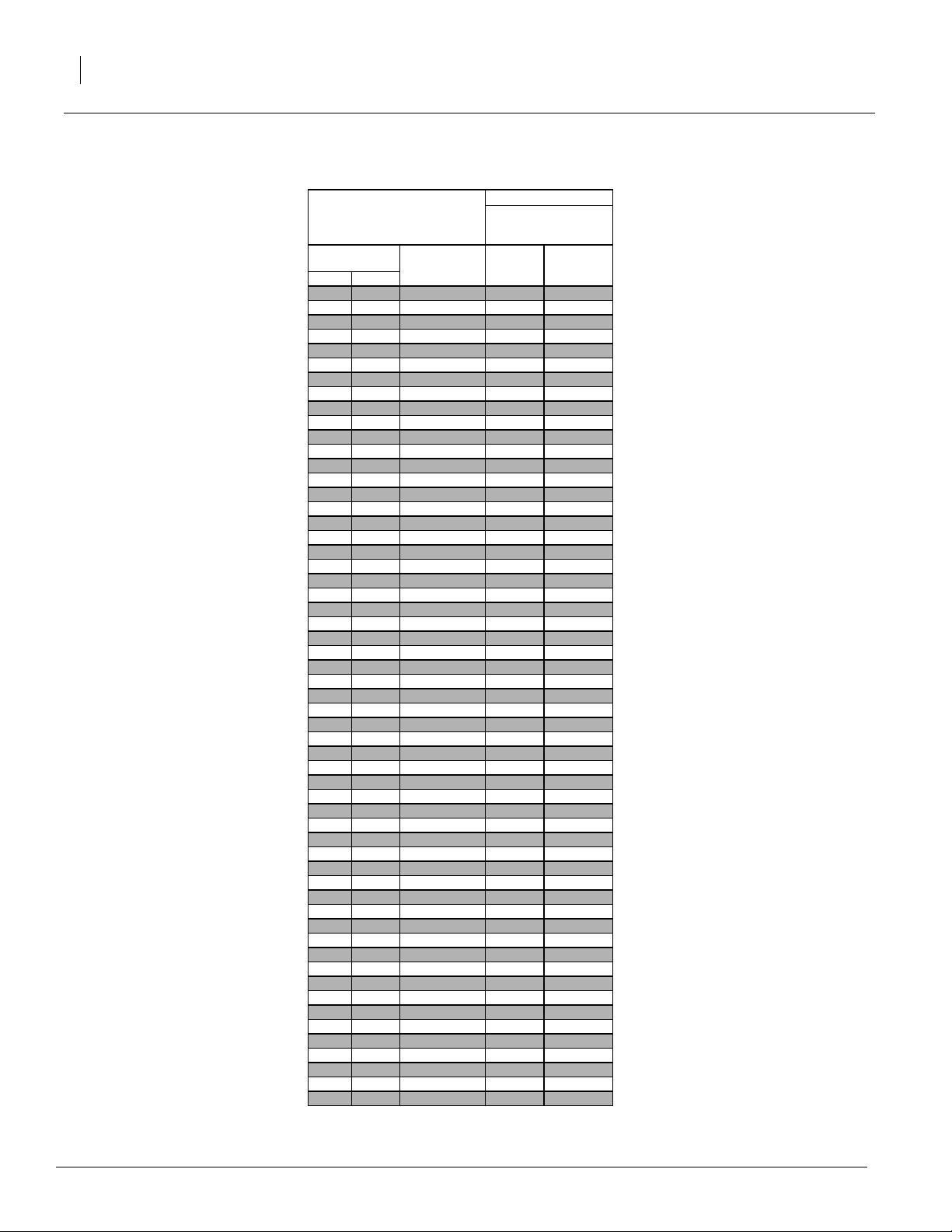

Barley (Volumetric)

Wheel P/N 403-085D Wheat Wide

52 lb. bu.

No Seed Treatment

with Talc Driver = 20

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 51.8 8 8 8

17 27 53.7 8 8 8

17 26 55.8 8 8 8

19 28 57.9 8 8 8

17 25 58.0 8 8 8

19 27 60.0 8 8 8

17 24 60.4 8 8 8

19 26 62.3 8 8 8

17 23 63.0 8 8 8

19 25 64.8 8 8 8

19 24 67.5 8 8 8

23 28 70.0 8 8 8

19 23 70.4 8 8 8

23 27 72.6 8 8 8

24 28 73.1 8 8 8

23 26 75.4 8 8 8

24 27 75.8 8 8 8

25 28 76.1 8 8 8

17 19 76.3 8 8 8

23 25 78.5 8 8 7

24 26 78.7 8 8 7

25 27 79.0 8 8 7

26 28 79.2 8 8 7

23 24 81.7 8 8 7

24 25 81.9 8 8 7

25 26 82.0 8 8 7

26 27 82.1 8 8 7

27 28 82.2 8 8 7

23 23 85.3 8 8 7

28 27 88.4 8 8 6

27 26 88.6 8 8 6

26 25 88.7 8 8 6

25 24 88.8 8 8 6

24 23 89.0 8 8 6

28 26 91.8 8 8 6

27 25 92.1 8 8 6

26 24 92.4 8 8 6

25 23 92.7 8 8 6

19 17 95.3 8 8 6

28 25 95.5 8 8 6

27 24 95.9 8 8 6

26 23 96.4 8 8 6

28 24 99.5 8 8 6

27 23 100.1 8 8 6

23 19 103.2 8 8 5

28 23 103.8 8 8 5

24 19 107.7 8 8 5

25 19 112.2 8 8 5

23 17 115.4 8 8 5

26 19 116.7 8 7 5

24 17 120.4 8 7 5

27 19 121.2 8 7 5

25 17 125.4 8 7 4

28 19 125.7 8 7 4

26 17 130.4 8 7 4

27 17 135.4 8 6 4

28 17 140.4 8 6 4

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

12/1/2009

196-248B

Page 8

8

Great Plains Mfg., Inc.

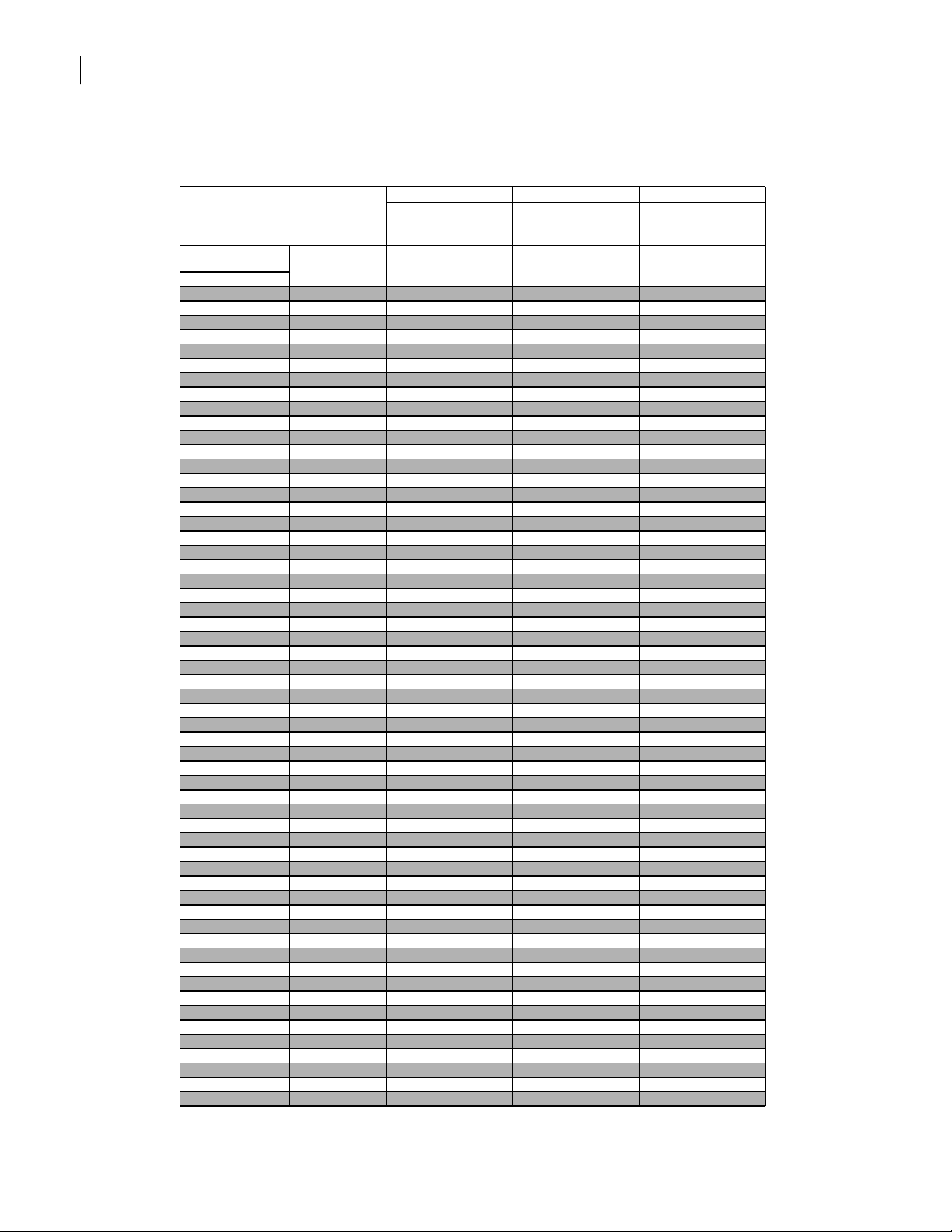

Barley (Volumetric)

Wheel P/N 403-094D V-3

48 lb. bu.

No Seed Treatment

with Talc Driver = 20

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 64.5 8 8 8

17 27 66.9 8 8 8

17 26 69.4 8 8 8

19 28 72.1 8 8 8

17 25 72.2 8 8 8

19 27 74.7 8 8 8

17 24 75.2 8 8 8

19 26 77.6 8 8 8

17 23 78.5 8 8 8

19 25 80.7 8 8 8

19 24 84.1 8 8 8

23 28 87.2 8 8 8

19 23 87.7 8 8 8

23 27 90.5 8 8 8

24 28 91.0 8 8 8

23 26 93.9 8 8 8

24 27 94.4 8 8 8

25 28 94.8 8 8 8

17 19 95.0 8 8 8

23 25 97.7 8 8 7

24 26 98.0 8 8 7

25 27 98.3 8 8 7

26 28 98.6 8 8 7

23 24 101.8 8 8 7

24 25 101.9 8 8 7

25 26 102.1 8 8 7

26 27 102.3 8 8 7

27 28 102.4 8 8 7

23 23 106.2 8 8 7

28 27 110.1 8 8 6

27 26 110.3 8 8 6

26 25 110.4 8 8 6

25 24 110.6 8 8 6

24 23 110.8 8 8 6

28 26 114.4 8 8 6

27 25 114.7 8 8 6

26 24 115.0 8 8 6

25 23 115.4 8 8 6

19 17 118.7 8 8 6

28 25 118.9 8 8 6

27 24 119.5 8 8 6

26 23 120.0 8 8 6

28 24 123.9 8 8 6

27 23 124.7 8 8 6

23 19 128.5 8 8 5

28 23 129.3 8 8 5

24 19 134.1 8 8 5

25 19 139.7 8 8 5

23 17 143.7 8 8 5

26 19 145.3 8 7 5

24 17 149.9 8 7 5

27 19 150.9 8 7 5

25 17 156.2 8 7 4

28 19 156.5 8 7 4

26 17 162.4 8 7 4

27 17 168.6 8 6 4

28 17 174.9 8 6 4

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

196-248B 12/1/2009

Page 9

Great Plains Mfg., Inc.

9

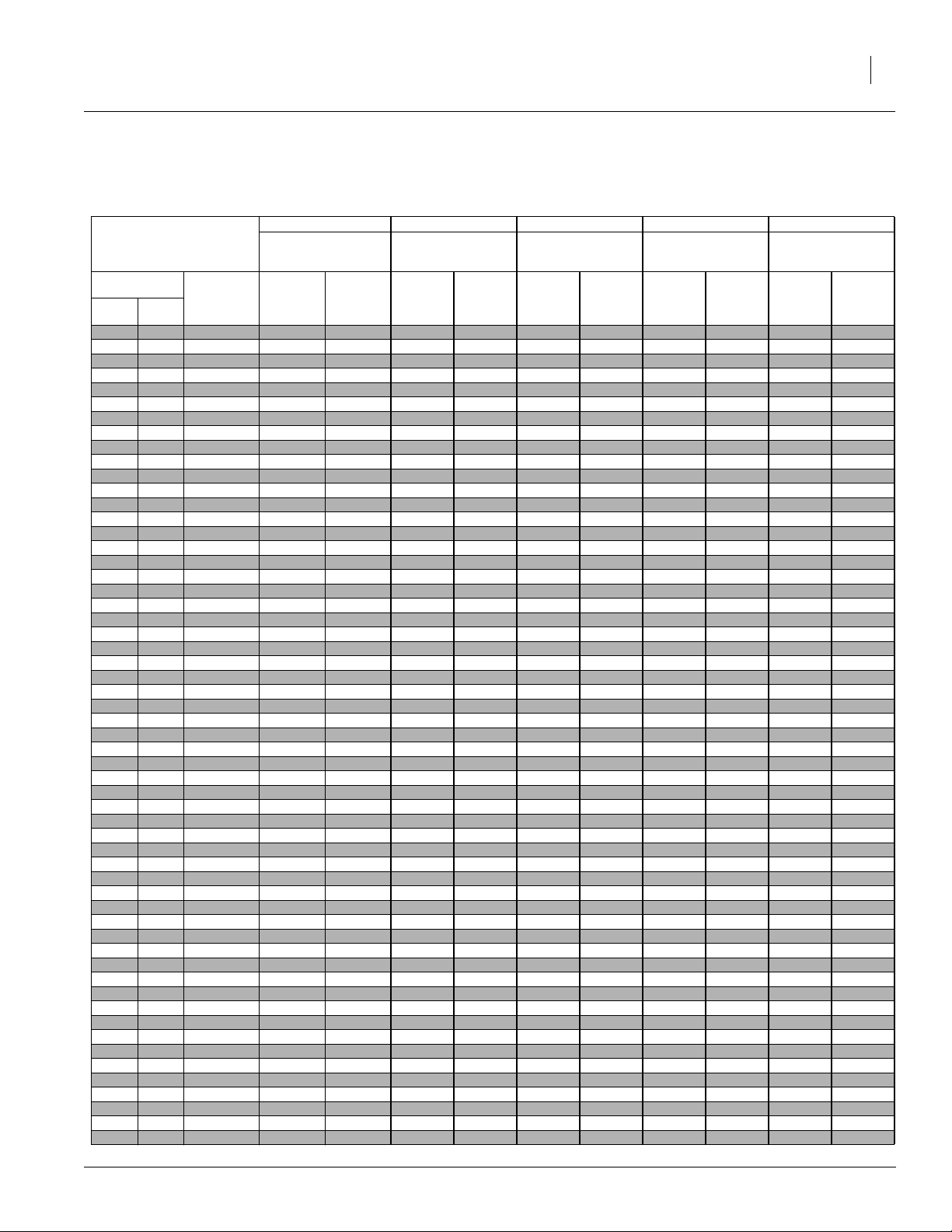

Corn 28 Cell Wheel (Singulating)

Wheel P/N’s

403-083D (round corn 1400-1900 krl/lb)

403-096D (round corn 1700-2200 krl/lb)

Rd corn 1400-2200 krl/lb.

Flat corn 1500-1800 krl/lb.

Talc Required

Transmission

Sprockets

Driver Driven (inches) (mph)

17 28 13,780 30.0 8 30.0 8 22.5 8

17 27 14,290 28.9 8 28.9 8 21.7 8

17 26 14,840 27.9 8 27.9 8 20.9 8

19 28 15,401 26.9 8 26.9 8 20.1 8

17 25 15,433 26.8 8 26.8 8 20.1 8

19 27 15,971 25.9 8 25.9 8 19.4 8

17 24 16,076 25.7 8 25.7 8 19.3 8

19 26 16,586 24.9 8 24.9 8 18.7 8

17 23 16,775 24.7 8 24.7 8 18.5 8

19 25 17,249 24.0 8 24.0 8 18.0 8

19 24 17,968 23.0 8 23.0 8 17.3 8

23 28 18,643 22.2 8 22.2 8 16.6 8

19 23 18,749 22.1 8 22.1 8 16.5 8

23 27 19,334 21.4 8 21.4 8 16.0 8

24 28 19,454 21.3 8 21.3 8 15.9 8

23 26 20,077 20.6 8 20.6 8 15.4 8

24 27 20,174 20.5 8 20.5 8 15.4 8

25 28 20,264 20.4 8 20.4 8 15.3 8

17 19 20,307 20.4 8 20.4 8 15.3 8

23 25 20,881 19.8 8 19.8 8 14.9 7

24 26 20,950 19.7 8 19.7 8 14.8 7

25 27 21,015 19.7 8 19.7 8 14.8 7

26 28 21,075 19.6 8 19.6 8 14.7 7

23 24 21,751 19.0 8 19.0 8 14.3 7

24 25 21,788 19.0 8 19.0 8 14.2 7

25 26 21,823 19.0 8 19.0 8 14.2 7

26 27 21,856 18.9 8 18.9 8 14.2 7

27 28 21,886 18.9 8 18.9 8 14.2 7

23 23 22,696 18.2 8 18.2 8 13.7 7

28 27 23,537 17.6 8 17.6 8 13.2 6

27 26 23,569 17.5 8 17.5 8 13.2 6

26 25 23,604 17.5 8 17.5 8 13.1 6

25 24 23,642 17.5 8 17.5 8 13.1 6

24 23 23,683 17.5 8 17.5 8 13.1 6

28 26 24,442 16.9 8 16.9 8 12.7 6

27 25 24,512 16.9 8 16.9 8 12.7 6

26 24 24,588 16.8 8 16.8 8 12.6 6

25 23 24,670 16.8 8 16.8 8 12.6 6

19 17 25,366 16.3 8 16.3 8 12.2 6

28 25 25,420 16.3 8 16.3 8 12.2 6

27 24 25,533 16.2 8 16.2 8 12.1 6

26 23 25,657 16.1 8 16.1 8 12.1 6

28 24 26,479 15.6 8 15.6 8 11.7 6

27 23 26,643 15.5 8 15.5 8 11.6 6

23 19 27,474 15.1 7 15.1 7 11.3 5

28 23 27,630 15.0 7 15.0 7 11.2 5

24 19 28,669 14.4 7 14.4 7 10.8 5

25 19 29,863 13.8 7 13.8 7 10.4 5

23 17 30,707 13.5 7 13.5 7 10.1 5

26 19 31,058 13.3 7 13.3 7 10.0 5

24 17 32,042 12.9 6 12.9 6 9.7 5

27 19 32,253 12.8 6 12.8 6 9.6 5

25 17 33,377 12.4 6 12.4 6 9.3 4

28 19 33,447 12.4 6 12.4 6 9.3 4

26 17 34,712 11.9 6 11.9 6 8.9 4

27 17 36,047 11.5 6 11.5 6 8.6 4

28 17 37,382 11.1 5 11.1 5 8.3 4

Seed

Population

(seeds/acre)

15" Row Spacing 30" Twin Row 20" Row Spacing

Range Sprockets

Driver= 15

Driven = 30

Seed

Spacing

(inches)

Max Plant

Speed

(mph)

403-086D (flat corn 1500-1675 krl/lb)

403-088D (flat corn 1625-1800 krl/lb)

Range Sprockets

Driver= 15

Driven = 30

Seed

Spacing

Max Plant

Speed

Range Sprockets

Driver=20

Driven=30

Seed

Spacing

(inches)

Max Plant

Speed

(mph)

12/1/2009

196-248B

Page 10

10

Great Plains Mfg., Inc.

Corn 42 Cell Wheel (Singulating)

Wheel P/N’s

403-097D (1400-1700 seeds/lb)

Rd corn 1400-2000 krl/lb

Talc Required Range Sprockets

Transmission

Sprockets

Driver Driven

17 28 13,780 15.0 8

17 27 14,290 14.5 8

17 26 14,840 13.9 8

19 28 15,401 13.4 8

17 25 15,433 13.4 8

19 27 15,971 12.9 8

17 24 16,076 12.9 8

19 26 16,586 12.5 8

17 23 16,775 12.3 8

19 25 17,249 12.0 8

19 24 17,968 11.5 8

23 28 18,643 11.1 8

19 23 18,749 11.0 8

23 27 19,334 10.7 8

24 28 19,454 10.6 8

23 26 20,077 10.3 8

24 27 20,174 10.3 8

25 28 20,264 10.2 8

17 19 20,307 10.2 8

23 25 20,881 9.9 7

24 26 20,950 9.9 7

25 27 21,015 9.8 7

26 28 21,075 9.8 7

23 24 21,751 9.5 7

24 25 21,788 9.5 7

25 26 21,823 9.5 7

26 27 21,856 9.5 7

27 28 21,886 9.4 7

23 23 22,696 9.1 7

28 27 23,537 8.8 6

27 26 23,569 8.8 6

26 25 23,604 8.8 6

25 24 23,642 8.7 6

24 23 23,683 8.7 6

28 26 24,442 8.5 6

27 25 24,512 8.4 6

26 24 24,588 8.4 6

25 23 24,670 8.4 6

19 17 25,366 8.2 6

28 25 25,420 8.1 6

27 24 25,533 8.1 6

26 23 25,657 8.1 6

28 24 26,479 7.8 6

27 23 26,643 7.8 6

23 19 27,474 7.5 5

28 23 27,630 7.5 5

24 19 28,669 7.2 5

25 19 29,863 6.9 5

23 17 30,707 6.7 5

26 19 31,058 6.7 5

24 17 32,042 6.5 5

27 19 32,253 6.4 5

25 17 33,377 6.2 4

28 19 33,447 6.2 4

26 17 34,712 6.0 4

27 17 36,047 5.7 4

28 17 37,382 5.5 4

Seed

Population

(seeds/acre)

403-098D (1700-2000 seeds/lb)

30" Row Spacing

Driver=20

Driven=30

Seed

Spacing

(inches)

Max Plant

Speed

(mph)

196-248B 12/1/2009

Page 11

Great Plains Mfg., Inc.

11

Cotton 120 Cell Wheel (Singulating)

Wheel P/N’s

403-078D (4000-4600 seeds/lb)

403-076D (5200-6000 seeds/lb)

403-077D (4600-5200 seeds/lb)

4000-6000 seeds/pound

Talc Required Range Sprockets

Transmission

Sprockets

Driver Driven (seeds/

17 28 59,056 14.0 8 10.5 8 7.0 8 5.3 8 3.5 8

17 27 61,244 13.5 8 10.1 8 6.8 8 5.1 8 3.4 8

17 26 63,599 13.0 8 9.8 8 6.5 8 4.9 8 3.3 8

19 28 66,004 12.5 8 9.4 8 6.3 8 4.7 8 3.1 7

17 25 66,143 12.5 8 9.4 8 6.3 8 4.7 8 3.1 7

19 27 68,449 12.1 8 9.1 8 6.0 8 4.5 8 3.0 7

17 24 68,899 12.0 8 9.0 8 6.0 8 4.5 8 3.0 7

19 26 71,082 11.6 8 8.7 8 5.8 8 4.4 8 2.9 7

17 23 71,895 11.5 8 8.6 8 5.8 8 4.3 8 2.9 7

19 25 73,925 11.2 8 8.4 8 5.6 8 4.2 8 2.8 6

19 24 77,005 10.7 8 8.1 8 5.4 8 4.0 8 2.7 6

23 28 79,900 10.4 8 7.8 8 5.2 8 3.9 8 2.6 6

19 23 80,353 10.3 8 7.7 8 5.1 8 3.9 8 2.6 6

23 27 82,859 10.0 8 7.5 8 5.0 8 3.7 8 2.5 6

24 28 83,374 9.9 8 7.4 8 5.0 8 3.7 8 2.5 6

23 26 86,046 9.6 8 7.2 8 4.8 8 3.6 8 2.4 6

24 27 86,462 9.6 8 7.2 8 4.8 8 3.6 8 2.4 5

25 28 86,848 9.5 8 7.1 8 4.8 8 3.6 8 2.4 5

17 19 87,031 9.5 8 7.1 8 4.8 8 3.6 8 2.4 5

23 25 89,488 9.2 8 6.9 8 4.6 8 3.5 8 2.3 5

24 26 89,787 9.2 8 6.9 8 4.6 8 3.5 8 2.3 5

25 27 90,064 9.2 8 6.9 8 4.6 8 3.4 8 2.3 5

26 28 90,322 9.2 8 6.9 8 4.6 8 3.4 8 2.3 5

23 24 93,217 8.9 8 6.7 8 4.4 8 3.3 8 2.2 5

24 25 93,379 8.9 8 6.6 8 4.4 8 3.3 8 2.2 5

25 26 93,528 8.8 8 6.6 8 4.4 8 3.3 8 2.2 5

26 27 93,667 8.8 8 6.6 8 4.4 8 3.3 8 2.2 5

27 28 93,796 8.8 8 6.6 8 4.4 8 3.3 8 2.2 5

23 23 97,269 8.5 8 6.4 8 4.3 8 3.2 7 2.1 5

28 27 100,872 8.2 8 6.2 8 4.1 8 3.1 7 2.1 5

27 26 101,011 8.2 8 6.1 8 4.1 8 3.1 7 2.0 5

26 25 101,160 8.2 8 6.1 8 4.1 8 3.1 7 2.0 5

25 24 101,322 8.2 8 6.1 8 4.1 8 3.1 7 2.0 5

24 23 101,499 8.1 8 6.1 8 4.1 8 3.1 7 2.0 5

28 26 104,752 7.9 8 5.9 8 3.9 8 3.0 7 2.0 4

27 25 105,051 7.9 8 5.9 8 3.9 8 3.0 7 2.0 4

26 24 105,375 7.8 8 5.9 8 3.9 8 2.9 7 2.0 4

25 23 105,728 7.8 8 5.9 8 3.9 8 2.9 7 2.0 4

19 17 108,713 7.6 8 5.7 8 3.8 8 2.9 7 1.9 4

28 25 108,942 7.6 8 5.7 8 3.8 8 2.8 7 1.9 4

27 24 109,428 7.6 8 5.7 8 3.8 8 2.8 7 1.9 4

26 23 109,957 7.5 8 5.6 8 3.8 8 2.8 7 1.9 4

28 24 113,481 7.3 8 5.5 8 3.6 8 2.7 6 1.8 4

27 23 114,186 7.2 8 5.4 8 3.6 8 2.7 6 1.8 4

23 19 117,747 7.0 8 5.3 8 3.5 8 2.6 6 1.8 4

28 23 118,415 7.0 8 5.2 8 3.5 8 2.6 6 1.7 4

24 19 122,867 6.7 8 5.0 8 3.4 8 2.5 6 1.7 4

25 19 127,986 6.5 8 4.8 8 3.2 8 2.4 6 1.6 4

23 17 131,600 6.3 8 4.7 5 3.1 7 2.4 5 1.6 3

26 19 133,106 6.2 8 4.7 8 3.1 7 2.3 8 1.6 3

24 17 137,322 6.0 8 4.5 8 3.0 7 2.3 5 1.5 3

27 19 138,225 6.0 8 4.5 8 3.0 7 2.2 5 1.5 3

25 17 143,043 5.8 8 4.3 8 2.9 7 2.2 5 1.4 3

28 19 143,344 5.8 8 4.3 8 2.9 7 2.2 5 1.4 3

26 17 148,765 5.6 8 4.2 8 2.8 6 2.1 5 1.4 3

27 17 154,487 5.4 8 4.0 8 2.7 6 2.0 5 1.3 3

28 17 160,209 5.2 8 3.9 8 2.6 6 1.9 4 1.3 3

Seed

Population

acre)

7 1/2" Row Spacing 10" Row Spacing 15" Row Spacing 20" Row Spacing 30" Row Spacing

Driver=15

Driven=60

Seed

Spacing

(inches)

Max Plant

Speed

(mph)

Range Sprockets

Driver=20

Driven=60

Seed

Spacing

(inches)

Max

Plant

Speed

(mph)

Range Sprockets

Driver=15

Driven=30

Seed

Spacing

(inches)

Max

Plant

Speed

(mph)

Range Sprockets

Driver=20

Driven=30

Seed

Spacing

(inches)

Max

Plant

Speed

(mph)

Range Sprockets

Driver=30

Driven=30

Seed

Spacing

(inches)

Max

Plant

Speed

(mph)

12/1/2009

196-248B

Page 12

12

Great Plains Mfg., Inc.

High Rate Cotton 120 Cell Wheel (Singulating)

Wheel P/N’s

403-078D (4000-4600 seeds/lb)

403-077D (4600-5200 seeds/lb)

4000-6000 seeds/pound

Talc Required Range Sprockets

Transmission

Sprockets

Driver Driven (seeds/acre)

17 28 118,113 7.0 8 5.3 8 3.5 8

17 27 122,487 6.8 8 5.1 8 3.4 8

17 26 127,199 6.5 8 4.9 8 3.3 8

19 28 132,009 6.3 8 4.7 8 3.1 7

17 25 132,286 6.3 8 4.7 8 3.1 7

19 27 136,898 6.0 8 4.5 8 3.0 7

17 24 137,798 6.0 8 4.5 8 3.0 7

19 26 142,163 5.8 8 4.4 8 2.9 7

17 23 143,790 5.8 8 4.3 8 2.9 7

19 25 147,850 5.6 8 4.2 8 2.8 6

19 24 154,010 5.4 8 4.0 8 2.7 6

23 28 159,800 5.2 8 3.9 8 2.6 6

19 23 160,706 5.1 8 3.9 8 2.6 6

23 27 165,718 5.0 8 3.7 8 2.5 6

24 28 166,748 5.0 8 3.7 8 2.5 6

23 26 172,092 4.8 8 3.6 8 2.4 6

24 27 172,924 4.8 8 3.6 8 2.4 5

25 28 173,965 4.8 8 3.6 8 2.4 5

17 19 174,061 4.8 8 3.6 8 2.4 5

23 25 178,976 4.6 8 3.5 8 2.3 5

24 26 179,574 4.6 8 3.5 8 2.3 5

25 27 180,129 4.6 8 3.4 8 2.3 5

26 28 180,643 4.6 8 3.4 8 2.3 5

23 24 186,433 4.4 8 3.3 8 2.2 5

24 25 186,757 4.4 8 3.3 8 2.2 5

25 26 187,057 4.4 8 3.3 8 2.2 5

26 27 187,334 4.4 8 3.3 8 2.2 5

27 28 187,591 4.4 8 3.3 8 2.2 5

26 26 194,539 4.3 8 3.2 7 2.1 5

28 27 201,744 4.1 8 3.1 7 2.1 5

27 26 202,021 4.1 8 3.1 7 2.0 5

26 25 202,321 4.1 8 3.1 7 2.0 5

25 24 202,645 4.1 8 3.1 7 2.0 5

24 23 202,997 4.1 8 3.1 7 2.0 5

28 26 209,503 3.9 8 3.0 7 2.0 4

27 25 210,102 3.9 8 3.0 7 2.0 4

26 24 210,751 3.9 8 2.9 7 2.0 4

25 23 211,455 3.9 8 2.9 7 2.0 4

19 17 217,426 3.8 8 2.9 7 1.9 4

28 25 217,884 3.8 8 2.8 7 1.9 4

27 24 218,856 3.8 8 2.8 7 1.9 4

26 23 219,914 3.8 8 2.8 7 1.9 4

28 24 226,962 3.6 8 2.7 6 1.8 4

27 23 228,372 3.6 8 2.7 6 1.8 4

23 19 235,495 3.5 8 2.6 6 1.8 4

28 23 236,830 3.5 8 2.6 6 1.7 4

24 19 245,733 3.4 8 2.5 6 1.7 4

25 19 255,972 3.2 8 2.4 6 1.6 4

23 17 263,200 3.1 7 2.4 5 1.6 3

26 19 266,211 3.1 7 2.3 5 1.6 3

24 17 274,643 3.0 7 2.3 5 1.5 3

27 19 276,450 3.0 7 2.2 5 1.5 3

25 17 286,087 2.9 7 2.2 5 1.4 3

28 19 286,689 2.9 7 2.2 5 1.4 3

26 17 297,530 2.8 6 2.1 5 1.4 3

27 17 308,974 2.7 6 2.0 5 1.3 3

28 17 320,417 2.6 6 1.9 4 1.3 3

Seed

Population

403-076D (5200-6000 seeds/lb)

7 1/2" Row Spacing 10" Row Spacing 15" Row Spacing

Driver=15

Driven=30

Seed

Spacing

(inches)

Max Plant

Speed

(mph)

Range Sprockets

Driver=20

Driven=30

Seed

Spacing

(inches)

Max

Plant

Speed

(mph)

Range Sprockets

Driver=30

Driven=30

Seed

Spacing

(inches)

Max

Plant

Speed

(mph)

196-248B 12/1/2009

Page 13

Great Plains Mfg., Inc.

Solid Milo Low Rate 51 Cell Wheel (Singulating)

403-079D (12000-18000 seeds/lb)

10500-18000 seeds/pound

Talc and Graphite

Required

Transmission

Sprockets

Driver Driven (seeds/acre) (inches) (mph) (inches) (mph) (inches) (mph) (inches) (mph)

17 28 25,099 33.0 8 24.7 8 16.5 8 16.5 8

17 27 26,029 31.8 8 23.8 8 15.9 8 15.9 8

17 26 27,030 30.6 8 23.0 8 15.3 8 15.3 8

19 28 28,052 29.5 8 22.1 8 14.7 8 14.7 8

17 25 28,111 29.4 8 22.1 8 14.7 8 14.7 8

19 27 29,091 28.4 8 21.3 8 14.2 8 14.2 8

17 24 29,282 28.2 8 21.2 8 14.1 8 14.1 8

19 26 30,210 27.4 8 20.5 8 13.7 8 13.7 8

17 23 30,555 27.1 8 20.3 8 13.5 8 13.5 8

19 25 31,418 26.3 8 19.7 8 13.2 8 13.2 8

19 24 32,727 25.3 8 19.0 8 12.6 8 12.6 8

23 28 33,957 24.4 8 18.3 8 12.2 8 12.2 8

19 23 34,150 24.2 8 18.2 8 12.1 8 12.1 8

23 27 35,215 23.5 8 17.6 8 11.7 8 11.7 8

24 28 35,434 23.3 8 17.5 8 11.7 8 11.7 8

23 26 36,570 22.6 8 17.0 8 11.3 8 11.3 8

24 27 36,746 22.5 8 16.9 8 11.5 8 11.5 8

25 28 36,910 22.4 8 16.8 8 11.2 8 11.2 8

17 19 36,988 22.4 8 16.8 8 11.2 8 11.2 8

23 25 38,032 21.7 8 16.3 8 10.9 8 10.9 8

24 26 38,160 21.7 8 16.3 8 10.8 8 10.8 8

25 27 38,277 21.6 8 16.2 8 10.8 8 10.8 8

26 28 38,387 21.5 8 16.2 8 10.8 8 10.8 8

23 24 39,617 20.9 8 15.7 8 10.4 8 10.4 8

24 25 39,686 20.8 8 15.6 8 10.4 8 10.4 8

25 26 39,750 20.8 8 15.6 8 10.4 8 10.4 8

26 27 39,808 20.8 8 15.6 8 10.4 8 10.4 8

27 28 39,863 20.8 8 15.6 8 10.4 8 10.4 8

23 23 41,340 20.0 8 15.0 8 10.0 8 10.0 8

28 27 42,871 19.3 8 14.5 8 9.6 8 9.6 8

27 26 42,930 19.3 8 14.5 8 9.6 8 9.6 8

26 25 42,993 19.2 8 14.4 8 9.6 8 9.6 8

25 24 43,062 19.2 8 14.4 8 9.6 8 9.6 8

24 23 43,137 19.2 8 14.4 8 9.6 8 9.6 8

28 26 44,519 18.6 8 13.9 8 9.3 8 9.3 8

27 25 44,647 18.5 8 13.9 8 9.3 8 9.3 8

26 24 44,784 18.5 8 13.9 8 9.2 8 9.2 8

25 23 44,934 18.4 8 13.8 8 9.2 8 9.2 8

19 17 46,203 17.9 8 13.4 8 9.0 8 9.0 8

28 25 46,300 17.9 8 13.4 8 8.9 8 8.9 8

27 24 46,507 17.8 8 13.3 8 8.9 8 8.9 8

26 23 46,732 17.7 8 13.3 8 8.9 8 8.9 8

28 24 48,229 17.2 8 12.9 8 8.6 8 8.6 8

27 23 48,529 17.0 8 12.8 8 8.5 8 8.5 8

23 19 50,043 16.5 8 12.4 8 8.3 7 8.3 7

28 23 50,326 16.4 8 12.3 8 8.2 7 8.2 7

24 19 52,218 15.8 8 11.9 8 7.9 7 7.9 7

25 19 54,394 15.2 8 11.4 8 7.6 7 7.6 7

23 17 55,930 14.8 8 11.1 8 7.4 7 7.4 7

26 19 56,570 14.6 8 11.0 8 7.3 7 7.3 7

24 17 58,362 14.2 8 10.6 8 7.1 6 7.1 6

27 19 58,746 14.1 8 10.6 8 7.0 6 7.0 6

25 17 60,793 13.6 8 10.2 8 6.8 6 6.8 6

28 19 60,921 13.6 8 10.2 8 6.8 6 6.8 6

26 17 63,225 13.1 8 9.8 8 6.5 6 6.5 6

27 17 65,657 12.6 8 9.4 8 6.3 6 6.3 6

28 17 68,089 12.1 8 9.1 8 6.1 5 6.1 5

Seed

Population

7 1/2" Row Spacing 10" Row Spacing 15" Row Spacing 30" Twin Row

Range Sprockets

Driver=15

Driven=60

Seed

Spacing

Max Plant

Wheel P/N’s

Range Sprockets

Speed

Seed

Spacing

Driver=20

Driven=60

Max Plant

Speed

13

403-092D (10500-18000 seeds/lb)

Range Sprockets

Driver=15

Driven=30

Seed

Spacing

Max Plant

Speed

Range Sprockets

Driver=15

Driven=30

Seed

Spacing

Max Plant

Speed

12/1/2009

Note: For 20 and 30 inch row spacings refer to Row Milo Low Rate Chart for use

with 102 cell wheel.

196-248B

Page 14

14

Row Milo Low Rate 102 Cell Wheel (Singulating)

403-080D (12000-18000 seeds/lb)

Great Plains Mfg., Inc.

Wheel P/N’s

403-093D (10500-18000 seeds/lb)

10500-18000 seeds/pound

Talc and Graphite

Required

Transmission

Sprockets

Driver Driven (seeds/acre) (inches) (mph) (inches) (mph) (inches) (mph) (inches) (mph)

17 28 25,099 16.5 8 16.5 8 12.4 8 8.2 8

17 27 26,029 15.9 8 15.9 8 11.9 8 7.9 8

17 26 27,030 15.3 8 15.3 8 11.5 8 7.7 8

19 28 28,052 14.7 8 14.7 8 11.1 8 7.4 8

17 25 28,111 14.7 8 14.7 8 11.0 8 7.4 8

19 27 29,091 14.2 8 14.2 8 10.7 8 7.1 8

17 24 29,282 14.1 8 14.1 8 10.6 8 7.1 8

19 26 30,210 13.7 8 13.7 8 10.3 8 6.8 8

17 23 30,555 13.5 8 13.5 8 10.2 8 6.8 8

19 25 31,418 13.2 8 13.2 8 9.9 8 6.6 8

19 24 32,727 12.6 8 12.6 8 9.5 8 6.3 8

23 28 33,957 12.2 8 12.2 8 9.1 8 6.1 8

19 23 34,150 12.1 8 12.1 8 9.1 8 6.1 8

23 27 35,215 11.7 8 11.7 8 8.8 8 5.9 8

24 28 35,434 11.7 8 11.7 8 8.8 8 5.8 8

23 26 36,570 11.3 8 11.3 8 8.5 8 5.7 8

24 27 36,746 11.3 8 11.3 8 8.4 8 5.6 8

25 28 36,910 11.2 8 11.2 8 8.4 8 5.6 8

17 19 36,988 11.2 8 11.2 8 8.4 8 5.6 8

23 25 38,032 10.9 8 10.9 8 8.2 8 5.4 8

24 26 38,160 10.8 8 10.8 8 8.1 8 5.4 8

25 27 38,277 10.8 8 10.8 8 8.1 8 5.4 8

26 28 38,387 10.8 8 10.8 8 8.1 8 5.4 8

23 24 39,617 10.4 8 10.4 8 7.8 8 5.2 8

24 25 39,686 10.4 8 10.4 8 7.8 8 5.2 8

25 26 39,750 10.4 8 10.4 8 7.8 8 5.2 8

26 27 39,808 10.4 8 10.4 8 7.8 8 5.2 8

27 28 39,863 10.4 8 10.4 8 7.8 8 5.2 8

23 23 41,340 10.0 8 10.0 8 7.5 8 5.0 8

28 27 42,871 9.6 8 9.6 8 7.2 8 4.8 8

27 26 42,930 9.6 8 9.6 8 7.2 8 4.8 8

26 25 42,993 9.6 8 9.6 8 7.2 8 4.8 8

25 24 43,062 9.6 8 9.6 8 7.2 8 4.8 8

24 23 43,137 9.6 8 9.6 8 7.2 8 4.8 8

28 26 44,519 9.3 8 9.3 8 7.0 8 4.6 8

27 25 44,647 9.3 8 9.3 8 6.9 8 4.6 8

26 24 44,784 9.2 8 9.2 8 6.9 8 4.6 8

25 23 44,934 9.2 8 9.2 8 6.9 8 4.6 8

19 17 46,203 9.0 8 9.0 8 6.7 8 4.5 8

28 25 46,300 8.9 8 8.9 8 6.7 8 4.5 8

27 24 46,507 8.9 8 8.9 8 6.7 8 4.4 8

26 23 46,732 8.9 8 8.9 8 6.6 8 4.4 8

28 24 48,229 8.6 8 8.6 8 6.4 8 4.3 8

27 23 48,529 8.5 8 8.5 8 6.4 8 4.3 8

23 19 50,043 8.3 8 8.3 8 6.2 8 4.1 8

28 23 50,326 8.2 8 8.2 8 6.2 8 4.1 7

24 19 52,218 7.9 8 7.9 8 5.9 8 4.0 7

25 19 54,394 7.6 8 7.6 8 5.7 8 3.8 7

23 17 55,930 7.4 8 7.4 8 5.5 8 3.7 7

26 19 56,570 7.3 8 7.3 8 5.5 8 3.7 7

24 17 58,362 7.1 8 7.1 8 5.3 8 3.5 7

27 19 58,746 7.0 8 7.0 8 5.3 8 3.5 6

25 17 60,793 6.8 8 6.8 8 5.1 8 3.4 6

28 19 60,921 6.8 8 6.8 8 5.1 8 3.4 6

26 17 63,225 6.5 8 6.5 8 4.9 8 3.3 6

27 17 65,657 6.3 8 6.3 8 4.7 8 3.1 6

28 17 68,089 6.1 8 6.1 8 4.6 8 3.0 5

Seed

Population

15" Row Spacing 30" Twin Row 20" Row Spacing 30" Row Spacing

Range Sprockets

Driver=15

Driven=60

Seed

Spacing

Max

Plant

Speed

Range Sprockets

Driver=15

Driven=60

Seed

Spacing

Max

Plant

Speed

Range Sprockets

Driver=20

Driven=60

Seed

Spacing

Max Plant

Speed

Range Sprockets

Driver=15

Driven=30

Seed

Spacing

Max

Plant

Speed

Note: For 7 1/2 and 10 inch row spacings refer to Solid Milo Low Rate Chart for use

with 51 cell wheel.

196-248B 12/1/2009

Page 15

Great Plains Mfg., Inc.

Solid Milo High Rate 135 Cell Wheel (Singulating)

403-081D (12000-18000 seeds/lb)

15

Wheel P/N’s

403-090D (10500-14000 seeds/lb)

10500-18000 seeds/pound

Talc and Graphite

Required

Transmission

Sprockets

Driver Driven (seeds/acre) (inches) (mph)

17 28 66,439 12.5 8 9.3 8 6.2 8 6.2 8

17 27 68,899 12.0 8 9.0 8 6.0 8 6.0 8

17 26 71,549 11.6 8 8.7 8 5.8 8 5.8 8

19 28 74,255 11.1 8 8.4 8 5.6 8 5.6 8

17 25 74,411 11.1 8 8.3 8 5.6 8 5.6 8

19 27 77,005 10.7 8 8.1 8 5.4 8 5.4 8

17 24 77,512 10.7 8 8.0 8 5.3 8 5.3 8

19 26 79,967 10.3 8 7.8 8 5.2 8 5.2 8

17 23 80,882 10.2 8 7.7 8 5.1 8 5.1 8

19 25 83,165 9.9 8 7.5 8 5.0 8 5.0 8

19 24 86,631 9.5 8 7.2 8 4.8 8 4.8 8

23 28 89,887 9.2 8 6.9 8 4.8 8 4.8 8

19 23 90,397 9.2 8 6.9 8 4.6 8 4.6 8

23 27 93,217 8.9 8 6.7 8 4.4 8 4.4 8

24 28 93,796 8.8 8 6.6 8 4.4 8 4.4 8

23 26 96,802 8.5 8 6.4 8 4.3 8 4.3 8

24 27 97,269 8.5 8 6.4 8 4.3 8 4.3 8

25 28 97,704 8.5 8 6.3 8 4.2 8 4.2 8

17 19 97,909 8.4 8 6.3 8 4.2 8 4.2 8

23 25 100,674 8.2 8 6.2 8 4.1 8 4.1 8

24 26 101,011 8.2 8 6.1 8 4.1 8 4.1 8

25 27 101,322 8.2 8 6.1 8 4.1 8 4.1 8

26 28 101,612 8.1 8 6.1 8 4.1 8 4.1 8

23 24 104,869 7.9 8 5.9 8 3.9 8 3.9 8

24 25 105,051 7.9 8 5.9 8 3.9 8 3.9 8

25 26 105,219 7.9 8 5.9 8 3.9 8 3.9 8

26 27 105,375 7.8 8 5.9 8 3.9 8 3.9 8

27 28 105,520 7.8 8 5.9 8 3.9 8 3.9 8

23 23 109,428 7.6 8 5.7 8 3.8 8 3.8 8

28 27 113,481 7.3 8 5.5 8 3.6 8 3.6 8

27 26 113,637 7.3 8 5.5 8 3.6 8 3.6 8

26 25 113,805 7.3 8 5.5 8 3.6 8 3.6 8

25 24 113,988 7.3 8 5.4 8 3.6 8 3.6 8

24 23 114,186 7.2 8 5.4 8 3.6 8 3.6 8

28 26 117,846 7.0 8 5.3 8 3.5 8 3.5 8

27 25 118,182 7.0 8 5.2 8 3.5 8 3.5 8

26 24 118,547 7.0 8 5.2 8 3.5 8 3.5 8

25 23 118,944 7.0 8 5.2 8 3.5 8 3.5 8

19 17 122,302 6.8 8 5.1 8 3.4 8 3.4 8

28 25 122,560 6.7 8 5.1 8 3.4 8 3.4 8

27 24 123,107 6.7 8 5.0 8 3.4 8 3.4 8

26 23 123,701 6.7 8 5.0 8 3.3 8 3.3 8

28 24 127,666 6.5 8 4.9 8 3.2 8 3.2 8

27 23 128,459 6.4 8 4.8 8 3.2 8 3.2 8

23 19 132,466 6.2 8 4.7 8 3.1 7 3.1 7

28 23 133,217 6.2 8 4.7 8 3.1 7 3.1 7

24 19 138,225 6.0 8 4.5 8 3.0 7 3.0 7

25 19 143,984 5.7 8 4.3 8 2.9 7 2.9 7

23 17 148,050 5.6 8 4.2 8 2.8 7 2.8 7

26 19 149,744 5.5 8 4.1 8 2.8 7 2.8 7

24 17 154,487 5.4 8 4.0 9 2.7 6 2.7 6

27 19 155,503 5.3 8 4.0 8 2.7 6 2.7 6

25 17 160,924 5.1 8 3.9 8 2.6 6 2.6 6

28 19 161,263 5.1 8 3.8 8 2.6 6 2.6 6

26 17 167,361 4.9 8 3.7 8 2.5 6 2.5 6

27 17 173,798 4.8 8 3.6 8 2.4 6 2.4 6

28 17 180,235 4.6 8 3.4 8 2.3 5 2.3 5

Seed

Population

7 1/2" Row Spacing 10" Row Spacing 15" Row Spacing 30" Twin Row

Range Sprockets

Driver=15

Driven=60

Seed

Spacing

(inches)

Max Plant

Speed

(mph)

Range Sprockets

Driver=20

Driven=60

Seed

Spacing

(inches)

Max

Plant

Speed

(mph)

Range Sprockets

Driver=15

Driven=30

Seed

Spacing

(inches)

Max

Plant

Speed

(mph)

Range Sprockets

Driver=15

Driven=30

Seed

Spacing

Max

Plant

Speed

12/1/2009

Note: For 20 and 30 inch row spacings refer to Row Milo High Rate Chart for use

with 270 cell wheel.

196-248B

Page 16

16

Great Plains Mfg., Inc.

Row Milo High Rate 270 Cell Wheel (Singulating)

Wheel P/N’s

403-082D (12000-18000 seeds/lb)

10500-18000 seeds/pound

Talc and Graphite

Required

Transmission

Sprockets

Driver Driven (seeds/acre) (inches) (mph) (inches) (mph) (inches) (mph) (inches) (mph)

17 28 66,439 6.2 8 6.2 8 4.7 8 3.1 8

17 27 68,899 6.0 8 6.0 8 4.5 8 3.0 8

17 26 71,549 5.8 8 5.8 8 4.3 8 2.9 8

19 28 74,255 5.6 8 5.6 8 4.2 8 2.8 8

17 25 74,411 5.6 8 5.6 8 4.2 8 2.8 8

19 27 77,005 5.4 8 5.4 8 4.0 8 2.7 8

17 24 77,512 5.3 8 5.3 8 4.0 8 2.7 8

19 26 79,967 5.2 8 5.2 8 3.9 8 2.6 8

17 23 80,882 5.1 8 5.1 8 3.8 8 2.6 8

19 25 83,165 5.0 8 5.0 8 3.7 8 2.5 8

19 24 86,631 4.8 8 4.8 8 3.6 8 2.4 8

23 28 89,887 4.6 8 4.6 8 3.5 8 2.3 8

19 23 90,397 4.6 8 4.6 8 3.4 8 2.3 8

23 27 93,217 4.4 8 4.4 8 3.3 8 2.2 8

24 28 93,796 4.4 8 4.4 8 3.3 8 2.2 8

23 26 96,802 4.3 8 4.3 8 3.2 8 2.1 8

24 27 97,269 4.3 8 4.3 8 3.2 8 2.1 8

25 28 97,704 4.2 8 4.2 8 3.2 8 2.1 8

17 19 97,909 4.2 8 4.2 8 3.2 8 2.1 8

23 25 100,674 4.1 8 4.1 8 3.1 8 2.1 8

24 26 101,011 4.1 8 4.1 8 3.1 8 2.0 8

25 27 101,322 4.1 8 4.1 8 3.1 8 2.0 8

26 28 101,612 4.1 8 4.1 8 3.1 8 2.0 8

23 24 104,869 3.9 8 3.9 8 3.0 8 2.0 8

24 25 105,051 3.9 8 3.9 8 3.0 8 2.0 8

25 26 105,219 3.9 8 3.9 8 2.9 8 2.0 8

26 27 105,375 3.9 8 3.9 8 2.9 8 2.0 8

27 28 105,520 3.9 8 3.9 8 2.9 8 2.0 8

23 23 109,428 3.8 8 3.8 8 2.8 8 1.9 8

28 27 113,481 3.6 8 3.6 8 2.7 8 1.8 8

27 26 113,637 3.6 8 3.6 8 2.7 8 1.8 8

26 25 113,805 3.6 8 3.6 8 2.7 8 1.8 8

25 24 113,988 3.6 8 3.6 8 2.7 8 1.8 8

24 23 114,186 3.6 8 3.6 8 2.7 8 1.8 8

28 26 117,846 3.5 8 3.5 8 2.6 8 1.8 8

27 25 118,182 3.5 8 3.5 8 2.6 8 1.7 8

26 24 118,547 3.5 8 3.5 8 2.6 8 1.7 8

25 23 118,944 3.5 8 3.5 8 2.6 8 1.7 8

19 17 122,302 3.4 8 3.4 8 2.5 8 1.7 8

28 25 122,560 3.4 8 3.4 8 2.5 8 1.7 8

27 24 123,107 3.4 8 3.4 8 2.5 8 1.7 8

26 23 123,701 3.3 8 3.3 8 2.5 8 1.7 8

28 24 127,666 3.2 8 3.2 8 2.4 8 1.6 8

27 23 128,459 3.2 8 3.2 8 2.4 8 1.6 8

23 19 132,466 3.1 8 3.1 8 2.3 8 1.6 7

28 23 133,217 3.1 8 3.1 8 2.3 8 1.6 7

24 19 138,225 3.0 8 3.0 8 2.2 8 1.5 7

25 19 143,984 2.9 8 2.9 8 2.2 8 1.4 7

23 17 148,050 2.8 8 2.8 8 2.1 8 1.4 7

26 19 149,744 2.8 8 2.8 8 2.1 8 1.4 7

24 17 154,487 2.7 8 2.7 8 2.0 8 1.3 6

27 19 155,503 2.7 8 2.7 8 2.0 8 1.3 6

25 17 160,924 2.6 8 2.6 8 1.9 8 1.3 6

28 19 161,263 2.6 8 2.6 8 1.9 8 1.3 6

26 17 167,361 2.5 8 2.5 8 1.9 8 1.2 6

27 17 173,798 2.4 8 2.4 8 1.8 8 1.2 6

28 17 180,235 2.3 8 2.3 8 1.7 8 1.1 5

Seed

Population

Note: For 7 1/2 and 10 inch row spacings refer to Solid Milo High Rate Chart for use

with 135 cell wheel.

15" Row Spacing 30" Twin Row 20" Row Spacing 30" Row Spacing

Range Sprockets

Driver=15

Driven=60

Seed

Spacing

Max

Plant

Speed

Range Sprockets

Driver=15

Driven=60

Seed

Spacing

Max

Plant

Speed

403-091D (10500-14000 seeds/lb)

Range Sprockets

Driver=20

Driven=60

Seed

Spacing

Max

Plant

Speed)

Range Sprockets

Driver=15

Driven=30

Seed

Spacing

Max

Plant

Speed

196-248B 12/1/2009

Page 17

Great Plains Mfg., Inc.

17

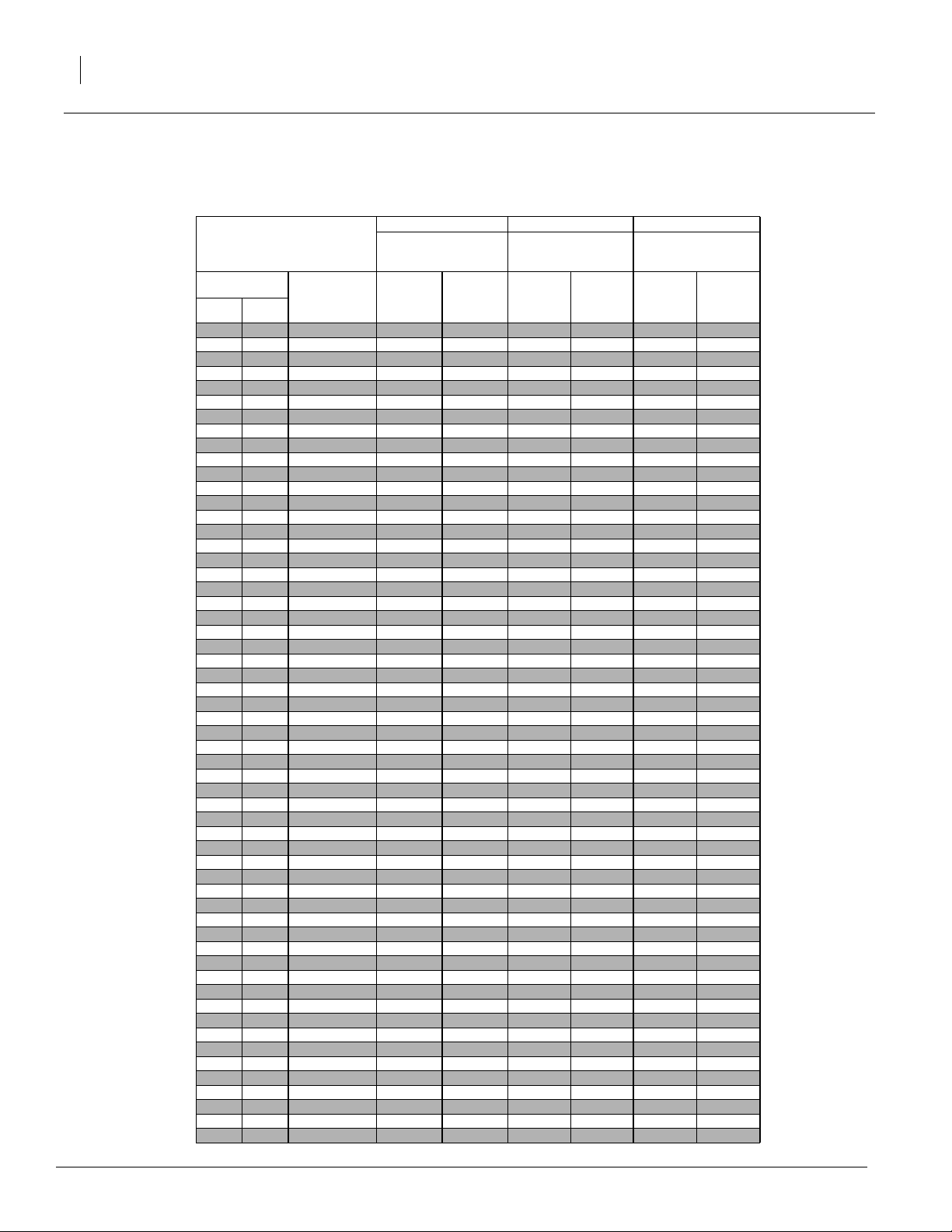

Oats (Volumetric)

Wheel P/N 403-060D Wheat

41 lb. bu.

No Seed Treatment

with Talc Driver = 20

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 15.7 8 8 8

17 27 16.3 8 8 8

17 26 17.0 8 8 8

19 28 17.6 8 8 8

17 25 17.6 8 8 8

19 27 18.3 8 8 8

17 24 18.4 8 8 8

19 26 19.0 8 8 8

17 23 19.2 8 8 8

19 25 19.7 8 8 8

19 24 20.5 8 8 8

23 28 21.3 8 8 8

19 23 21.4 8 8 8

23 27 22.1 8 8 8

24 28 22.2 8 8 8

23 26 22.9 8 8 8

24 27 23.1 8 8 8

25 28 23.2 8 8 8

17 19 23.2 8 8 8

23 25 23.9 8 8 8

24 26 23.9 8 8 8

25 27 24.0 8 8 8

26 28 24.1 8 8 8

23 24 24.9 8 8 8

24 25 24.9 8 8 8

25 26 24.9 8 8 8

26 27 25.0 8 8 8

27 28 25.0 8 8 8

23 23 25.9 8 8 8

28 27 26.9 8 8 8

27 26 26.9 8 8 8

26 25 27.0 8 8 8

25 24 27.0 8 8 8

24 23 27.1 8 8 8

28 26 27.9 8 8 8

27 25 28.0 8 8 8

26 24 28.1 8 8 8

25 23 28.2 8 8 8

19 17 29.0 8 8 7

28 25 29.1 8 8 7

27 24 29.2 8 8 7

26 23 29.3 8 8 7

28 24 30.3 8 8 7

27 23 30.4 8 8 7

23 19 31.4 8 8 7

28 23 31.6 8 8 7

24 19 32.8 8 8 7

25 19 34.1 8 8 6

23 17 35.1 8 8 6

26 19 35.5 8 8 6

24 17 36.6 8 8 6

27 19 36.9 8 8 6

25 17 38.1 8 8 6

28 19 38.2 8 8 6

26 17 39.7 8 8 5

27 17 41.2 8 8 5

28 17 42.7 8 8 5

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

12/1/2009

196-248B

Page 18

18

Great Plains Mfg., Inc.

Oats (Volumetric)

Wheel P/N 403-085D Wheat Wide

41 lb. bu.

No Seed Treatment

with Talc Driver = 20

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 38.0 8 8 8

17 27 39.4 8 8 8

17 26 40.9 8 8 8

19 28 42.5 8 8 8

17 25 42.6 8 8 8

19 27 44.0 8 8 8

17 24 44.3 8 8 8

19 26 45.7 8 8 8

17 23 46.3 8 8 8

19 25 47.6 8 8 8

19 24 49.5 8 8 8

23 28 51.4 8 8 8

19 23 51.7 8 8 8

23 27 53.3 8 8 8

24 28 53.6 8 8 8

23 26 55.4 8 8 8

24 27 55.6 8 8 8

25 28 55.9 8 8 8

17 19 56.0 8 8 8

23 25 57.6 8 8 7

24 26 57.8 8 8 7

25 27 57.9 8 8 7

26 28 58.1 8 8 7

23 24 60.0 8 8 7

24 25 60.1 8 8 7

25 26 60.2 8 8 7

26 27 60.3 8 8 7

27 28 60.3 8 8 7

23 23 62.6 8 8 7

28 27 64.9 8 8 6

27 26 65.0 8 8 6

26 25 65.1 8 8 6

25 24 65.2 8 8 6

24 23 65.3 8 8 6

28 26 67.4 8 8 6

27 25 67.6 8 8 6

26 24 67.8 8 8 6

25 23 68.0 8 8 6

19 17 69.9 8 8 6

28 25 70.1 8 8 6

27 24 70.4 8 8 6

26 23 70.7 8 8 6

28 24 73.0 8 8 6

27 23 73.5 8 8 6

23 19 75.8 8 8 5

28 23 76.2 8 8 5

24 19 79.0 8 8 5

25 19 82.3 8 8 5

23 17 84.7 8 8 5

26 19 85.6 8 7 5

24 17 88.3 8 7 5

27 19 88.9 8 7 5

25 17 92.0 8 7 4

28 19 92.2 8 7 4

26 17 95.7 8 7 4

27 17 99.4 8 6 4

28 17 103.1 8 6 4

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

196-248B 12/1/2009

Page 19

Great Plains Mfg., Inc.

19

Oats (Volumetric)

Wheel P/N 403-094D V-3

38.5 lb. bu.

No Seed Treatment

with Talc Driver = 20

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 51.7 8 8 8

17 27 53.6 8 8 8

17 26 55.6 8 8 8

19 28 57.8 8 8 8

17 25 57.9 8 8 8

19 27 59.9 8 8 8

17 24 60.3 8 8 8

19 26 62.2 8 8 8

17 23 62.9 8 8 8

19 25 64.7 8 8 8

19 24 67.4 8 8 8

23 28 69.9 8 8 8

19 23 70.3 8 8 8

23 27 72.5 8 8 8

24 28 73.0 8 8 8

23 26 75.3 8 8 8

24 27 75.7 8 8 8

25 28 76.0 8 8 8

17 19 76.2 8 8 8

23 25 78.3 8 8 7

24 26 78.6 8 8 7

25 27 78.6 8 8 7

26 28 79.0 8 8 7

23 24 81.6 8 8 7

24 25 81.7 8 8 7

25 26 81.8 8 8 7

26 27 82.0 8 8 7

27 28 82.1 8 8 7

23 23 85.1 8 8 7

28 27 88.3 8 8 6

27 26 88.4 8 8 6

26 25 88.5 8 8 6

25 24 88.7 8 8 6

24 23 88.8 8 8 6

28 26 91.7 8 8 6

27 25 91.9 8 8 6

26 24 92.2 8 8 6

25 23 92.5 8 8 6

19 17 95.1 8 8 6

28 25 95.3 8 8 6

27 24 95.7 8 8 6

26 23 96.2 8 8 6

28 24 99.3 8 8 6

27 23 99.9 8 8 6

23 19 103.0 8 8 5

28 23 103.6 8 8 5

24 19 107.5 8 8 5

25 19 112.0 8 8 5

23 17 115.1 8 8 5

26 19 116.5 8 7 5

24 17 120.2 8 7 5

27 19 120.9 8 7 5

25 17 125.2 8 7 4

28 19 125.4 8 7 4

26 17 130.2 8 7 4

27 17 135.2 8 6 4

28 17 140.2 8 6 4

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driven = 30

Max Plant

speed

(mph)

Driven = 30

Driver = 30

Max Plant

speed

(mph)

12/1/2009

196-248B

Page 20

20

Great Plains Mfg., Inc.

Rice (Volumetric)

Wheel P/N 403-095D High Rate

(Requires P/N 817-529C Flow Gate)

45 lb. bu. CYPRESS Rice

No Seed Treatment

with Talc Driver = 20

Transmission

Sprockets

Driver Driven (pounds/acre)

23 25 65.6 8 8 7

24 26 65.8 8 8 7

25 27 66.0 8 8 7

26 28 66.2 8 8 7

23 24 68.4 8 8 7

24 25 68.5 8 8 7

25 26 68.6 8 8 7

26 27 68.7 8 8 7

27 28 68.8 8 8 7

23 23 71.3 8 8 7

28 27 74.0 8 8 7

27 26 74.1 8 8 7

26 25 74.2 8 8 7

25 24 74.3 8 8 6

24 23 74.4 8 8 6

28 26 76.8 8 8 6

27 25 77.0 8 8 6

26 24 77.3 8 8 6

25 23 77.5 8 8 6

19 17 79.7 8 8 6

28 25 79.9 8 8 6

27 24 80.2 8 8 6

26 23 80.6 8 8 6

28 24 83.2 8 8 6

27 23 83.7 8 8 6

23 19 86.3 8 8 6

28 23 86.8 8 8 5

24 19 90.1 8 8 5

25 19 93.9 8 8 5

23 17 96.5 8 8 5

26 19 97.6 8 7 5

24 17 100.7 8 7 5

27 19 101.4 8 7 5

25 17 104.9 8 7 4

28 19 105.1 8 7 4

26 17 109.1 8 7 4

27 17 113.3 8 6 4

28 17 117.5 8 6 4

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

196-248B 12/1/2009

Page 21

Great Plains Mfg., Inc.

21

Medium Rice (Volumetric)

Wheel P/N 403-142D Med. Rate

(Requires P/N 817-529C Flow Gate)

Chart established with

Clearfield 161

20900 seeds/pound

Transmission

Sprockets

Driver Driven (pounds/acre)

24 23 44.0 8 8 6

28 26 45.4 8 8 6

27 25 45.5 8 8 6

26 24 45.7 8 8 6

25 23 45.8 8 8 6

19 17 47.1 8 8 6

28 25 47.2 8 8 6

27 24 47.4 8 8 6

26 23 47.6 8 8 6

28 24 49.2 8 8 6

27 23 49.5 8 8 6

23 19 51.0 8 8 5

28 23 51.3 8 8 5

24 19 53.2 8 8 5

25 19 55.5 8 8 5

23 17 57.0 8 8 5

26 19 57.7 8 7 5

24 17 59.5 8 7 5

27 19 59.9 8 7 5

25 17 62.0 8 7 4

28 19 62.1 8 7 4

26 17 64.5 8 7 4

27 17 66.9 8 6 4

28 17 69.4 8 6 4

with Talc

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driver = 20

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

12/1/2009

196-248B

Page 22

22

Great Plains Mfg., Inc.

Rye (Volumetric)

Wheel P/N 403-060D Wheat

58 lb. bu.

No Seed Treatment

with Talc Driver = 20

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 27.6 8 8 8

17 27 28.6 8 8 8

17 26 29.7 8 8 8

19 28 30.8 8 8 8

17 25 30.9 8 8 8

19 27 31.9 8 8 8

17 24 32.2 8 8 8

19 26 33.2 8 8 8

17 23 33.6 8 8 8

19 25 34.5 8 8 8

19 24 35.9 8 8 8

23 28 37.3 8 8 8

19 23 37.5 8 8 8

23 27 38.7 8 8 8

24 28 38.9 8 8 8

23 26 40.2 8 8 8

24 27 40.3 8 8 8

25 28 40.5 8 8 8

17 19 40.6 8 8 8

23 25 41.8 8 8 8

24 26 41.9 8 8 8

25 27 42.0 8 8 8

26 28 42.2 8 8 8

23 24 43.5 8 8 8

24 25 43.6 8 8 8

25 26 43.6 8 8 8

26 27 43.7 8 8 8

27 28 43.8 8 8 8

23 23 45.4 8 8 8

28 27 47.1 8 8 8

27 26 47.1 8 8 8

26 25 47.2 8 8 8

25 24 47.3 8 8 8

24 23 47.4 8 8 8

28 26 48.9 8 8 8

27 25 49.0 8 8 8

26 24 49.2 8 8 8

25 23 49.3 8 8 8

19 17 50.7 8 8 7

28 25 50.8 8 8 7

27 24 51.1 8 8 7

26 23 51.3 8 8 7

28 24 53.0 8 8 7

27 23 53.3 8 8 7

23 19 54.9 8 8 7

28 23 55.3 8 8 7

24 19 57.3 8 8 7

25 19 59.7 8 8 6

23 17 61.4 8 8 6

26 19 62.1 8 8 6

24 17 64.1 8 8 6

27 19 64.5 8 8 6

25 17 66.8 8 8 6

28 19 66.9 8 8 6

26 17 69.4 8 8 5

27 17 72.1 8 8 5

28 17 74.8 8 8 5

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

196-248B 12/1/2009

Page 23

Great Plains Mfg., Inc.

23

Rye (Volumetric)

Wheel P/N 403-085D Wheat Wide

58 lb. bu.

No Seed Treatment

with Talc Driver = 20

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 61.0 8 8 8

17 27 63.3 8 8 8

17 26 65.7 8 8 8

19 28 68.2 8 8 8

17 25 68.3 8 8 8

19 27 70.7 8 8 8

17 24 71.2 8 8 8

19 26 73.5 8 8 8

17 23 74.3 8 8 8

19 25 76.4 8 8 8

19 24 79.6 8 8 8

23 28 82.6 8 8 8

19 23 83.0 8 8 8

23 27 85.6 8 8 8

24 28 86.2 8 8 8

23 26 88.9 8 8 8

24 27 89.3 8 8 8

25 28 89.7 8 8 8

17 19 89.9 8 8 8

23 25 92.5 8 8 7

24 26 92.8 8 8 7

25 27 93.1 8 8 7

26 28 93.3 8 8 7

23 24 96.3 8 8 7

24 25 96.5 8 8 7

25 26 96.6 8 8 7

26 27 96.8 8 8 7

27 28 96.9 8 8 7

23 23 100.5 8 8 7

28 27 104.2 8 8 6

27 26 104.4 8 8 6

26 25 104.5 8 8 6

25 24 104.7 8 8 6

24 23 104.9 8 8 6

28 26 108.2 8 8 6

27 25 108.6 8 8 6

26 24 108.9 8 8 6

25 23 109.3 8 8 6

19 17 112.3 8 8 6

28 25 112.6 8 8 6

27 24 113.1 8 8 6

26 23 113.6 8 8 6

28 24 117.3 8 8 6

27 23 118.0 8 8 6

23 19 121.7 8 8 5

28 23 122.4 8 8 5

24 19 127.0 8 8 5

25 19 132.3 8 8 5

23 17 136.0 8 8 5

26 19 137.5 8 7 5

24 17 141.9 8 7 5

27 19 142.8 8 7 5

25 17 147.8 8 7 4

28 19 148.1 8 7 4

26 17 153.7 8 7 4

27 17 159.6 8 6 4

28 17 165.5 8 6 4

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driven = 30

Max Plant

speed

(mph)

Driven = 30

Driver = 30

Max Plant

speed

(mph)

12/1/2009

196-248B

Page 24

24

Great Plains Mfg., Inc.

Soybeans 100 Cell Wheel (Singulating)

Wheel P/N 403-071D (1700-2200 seeds/lb)

1700-2200 seeds/pound

Talc Required Range Sprockets

Transmission

Sprockets

Driver Driven (seeds/acre) (inches) (mph) (inches) (mph) (inches) (mph)

17 28 98,427 8.4 8 6.3 8 4.2 8

17 27 102,073 8.1 8 6.1 8 4.1 8

17 26 105,999 7.8 8 5.9 8 3.9 8

19 28 110,007 7.5 8 5.6 8 3.8 8

17 25 110,239 7.5 8 5.6 8 3.8 8

19 27 114,081 7.3 8 5.4 8 3.6 8

17 24 114,832 7.2 8 5.4 8 3.6 8

19 26 118,469 7.0 8 5.2 8 3.5 8

17 23 119,825 6.9 8 5.2 8 3.5 8

19 25 123,208 6.7 8 5.0 8 3.4 8

19 24 128,342 6.4 8 4.8 8 3.2 8

23 28 133,167 6.2 8 4.7 8 3.1 8

19 23 133,922 6.2 8 4.6 8 3.1 8

23 27 138,099 6.0 8 4.5 8 3.0 8

24 28 138,956 6.0 8 4.5 8 3.0 8

23 26 143,410 5.8 8 4.3 8 2.9 8

24 27 144,103 5.7 8 4.3 8 2.9 8

25 28 144,746 5.7 8 4.3 8 2.9 8

17 19 145,051 5.7 8 4.3 8 2.9 8

23 25 149,147 5.5 8 4.2 8 2.8 8

24 26 149,645 5.5 8 4.1 8 2.8 8

25 27 150,107 5.5 8 4.1 8 2.8 8

26 28 150,536 5.5 8 4.1 8 2.7 8

23 24 155,361 5.3 8 4.0 8 2.7 8

24 25 155,631 5.3 8 4.0 8 2.7 8

25 26 155,881 5.3 8 4.0 8 2.7 8

26 27 156,112 5.3 8 4.0 8 2.6 8

27 28 156,326 5.3 8 4.0 8 2.6 8

23 23 162,116 5.1 8 3.8 8 2.6 7

28 27 168,120 4.9 8 3.7 8 2.5 7

27 26 168,351 4.9 8 3.7 8 2.5 7

26 25 168,600 4.9 8 3.7 8 2.5 7

25 24 168,871 4.9 8 3.7 8 2.4 7

24 23 169,164 4.9 8 3.7 8 2.4 7

28 26 174,586 4.7 8 3.6 8 2.4 7

27 25 175,085 4.7 8 3.5 8 2.4 7

26 24 175,625 4.7 8 3.5 8 2.4 7

25 23 176,213 4.7 8 3.5 8 2.3 7

19 17 181,188 4.6 8 3.4 8 2.3 7

28 25 181,570 4.6 8 3.4 8 2.3 7

27 24 182,380 4.5 8 3.4 8 2.3 7

26 23 183,261 4.5 8 3.4 8 2.3 7

28 24 189,135 4.4 8 3.3 8 2.2 6

27 23 190,310 4.3 8 3.3 8 2.2 6

23 19 196,245 4.2 8 3.2 8 2.1 6

28 23 197,358 4.2 8 3.1 8 2.1 6

24 19 204,778 4.0 8 3.0 8 2.0 6

25 19 213,310 3.9 8 2.9 8 1.9 6

23 17 219,333 3.8 8 2.8 8 1.9 5

26 19 221,843 3.7 8 2.8 8 1.9 5

24 17 228,869 3.6 8 2.7 8 1.8 5

27 19 230,375 3.6 8 2.7 8 1.8 5

25 17 238,406 3.5 8 2.6 8 1.7 5

28 19 238,907 3.5 8 2.6 8 1.7 5

26 17 247,942 3.3 8 2.5 7 1.7 5

27 17 257,478 3.2 8 2.4 7 1.6 4

28 17 267,014 3.1 8 2.3 7 1.5 4

Seed

Population

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Driver = 15

Driven = 30

Seed

Spacing

Max

Plant

speed

Range Sprockets Range Sprockets

Driver = 20

Driven = 30

Seed

Spacing

Max

Plant

speed

Driver = 30

Driven = 30

Seed

Spacing

Max Plant

speed

196-248B 12/1/2009

Page 25

Great Plains Mfg., Inc.

25

Soybeans 100 Cell Wheel (Singulating) (Continued)

Wheel P/N 403-071D (1700-2200 seeds/lb)

1700-2200 seeds/pound

Talc Required Range Sprockets

Transmission

Sprockets

Driver Driven (seeds/acre) (inches) (mph) (inches) (mph) (inches) (mph)

17 28 98,427 4.2 8 3.2 8 2.1 6

17 27 102,073 4.1 8 3.0 8 2.0 6

17 26 105,999 3.9 8 2.9 8 2.0 6

19 28 110,007 3.8 8 2.8 8 1.9 5

17 25 110,239 3.8 8 2.8 8 1.9 5

19 27 114,081 3.6 8 2.7 8 1.8 5

17 24 114,832 3.6 8 2.7 8 1.8 5

19 26 118,469 3.5 8 2.6 8 1.7 5

17 23 119,825 3.5 8 2.6 8 1.7 5

19 25 123,208 3.4 8 2.5 7 1.7 5

19 24 128,342 3.2 8 2.4 7 1.6 5

23 28 133,167 3.1 8 2.3 7 1.6 4

19 23 133,922 3.1 8 2.3 7 1.5 4

23 27 138,099 3.0 8 2.2 7 1.5 4

24 28 138,956 3.0 8 2.2 6 1.5 4

23 26 143,410 2.9 8 2.2 6 1.4 4

24 27 144,103 2.9 8 2.2 6 1.4 4

25 28 144,746 2.9 8 2.1 6 1.4 4

17 19 145,051 2.9 8 2.1 6 1.4 4

23 25 149,147 2.8 8 2.1 6 1.4 4

24 26 149,645 2.8 8 2.1 6 1.4 4

25 27 150,107 2.8 8 2.1 6 1.4 4

26 28 150,536 2.7 8 2.1 6 1.4 4

23 24 155,361 2.7 8 2.0 6 1.3 4

24 25 155,631 2.7 8 2.0 6 1.3 4

25 26 155,881 2.7 8 2.0 6 1.3 4

26 27 156,112 2.6 8 2.0 6 1.3 4

27 28 156,326 2.6 8 2.0 6 1.3 4

23 23 162,116 2.6 7 1.9 5 1.3 3

28 27 168,120 2.5 7 1.8 5 1.2 3

27 26 168,351 2.5 7 1.8 5 1.2 3

26 25 168,600 2.5 7 1.8 5 1.2 3

25 24 168,871 2.4 7 1.8 5 1.2 3

24 23 169,164 2.4 7 1.8 5 1.2 3

28 26 174,586 2.4 7 1.8 5 1.2 3

27 25 175,085 2.4 7 1.8 5 1.2 3

26 24 175,625 2.4 7 1.8 5 1.2 3

25 23 176,213 2.3 7 1.8 5 1.2 3

19 17 181,188 2.3 7 1.7 5 1.1 3

28 25 181,570 2.3 7 1.7 5 1.1 3

27 24 182,380 2.3 7 1.7 5 1.1 3

26 23 183,261 2.3 7 1.7 5 1.1 3

28 24 189,135 2.2 6 1.6 5 1.1 3

27 23 190,310 2.2 6 1.6 5 1.1 3

23 19 196,245 2.1 6 1.6 4 1.1 3

28 23 197,358 2.1 6 1.6 4 1.0 3

24 19 204,778 2.0 6 1.5 4 1.0 3

25 19 213,310 1.9 6 1.5 4 1.0 3

23 17 219,333 1.9 5 1.4 4 0.9 2

26 19 221,843 1.9 5 1.4 4 0.9 2

24 17 228,869 1.8 5 1.4 4 0.9 2

27 19 230,375 1.8 5 1.3 4 0.9 2

25 17 238,406 1.7 5 1.3 4 0.9 2

28 19 238,907 1.7 5 1.3 4 0.9 2

26 17 247,942 1.7 5 1.3 3 0.8 2

27 17 257,478 1.6 4 1.2 3 0.8 2

28 17 267,014 1.5 4 1.2 3 0.8 2

Seed

Population

30” Twin Row 20” Row Spacing 30” Row Spacing

Driver = 30

Driven = 30

Seed

Spacing

Max

Plant

speed

Range Sprockets Range Sprockets

Driver = 20

Driven = 15

Seed

Spacing

Max

Plant

speed

Driver = 30

Driven = 15

Seed

Spacing

Max Plant

speed

12/1/2009

196-248B

Page 26

26

Soybeans 110 Cell Wheel (Singulating)

403-070D (2200-2700 seeds/lb)

403-061D (2700-3200 seeds/lb)

Great Plains Mfg., Inc.

Wheel P/N’s

403-066D (3100-3800 seeds/lb)

403-068D (3600-4000 seeds/lb)

2200-4000 seeds/pound

Talc Required Range Sprockets

Transmission

Sprockets

Driver Driven (seeds/acre) (inches) (mph) (inches) (mph) (inches) (mph)

17 28 108,270 7.6 8 5.7 8 3.8 8

17 27 112,280 7.4 8 5.5 8 3.7 8

17 26 116,599 7.1 8 5.3 8 3.5 8

19 28 121,263 6.8 8 5.1 8 3.4 8

17 25 121,879 6.9 8 5.1 8 3.4 8

19 27 125,490 6.6 8 4.9 8 3.3 8

17 24 126,315 6.5 8 4.9 8 3.3 8

19 26 130,316 6.3 8 4.8 8 3.2 8

17 23 131,807 6.3 8 4.7 8 3.1 8

19 25 135,529 6.1 8 4.6 8 3.1 8

19 24 141,176 5.9 8 4.4 8 2.9 8

23 28 146,483 5.6 8 4.2 8 2.8 8

19 23 147,314 5.6 8 4.2 8 2.8 8

23 27 151,909 5.4 8 4.1 8 2.7 8

24 28 152,852 5.4 8 4.1 8 2.7 8

23 26 157,751 5.2 8 3.9 8 2.6 8

24 27 158,513 5.2 8 3.9 8 2.6 8

25 28 159,221 5.2 8 3.9 8 2.6 8

17 19 159,556 5.2 8 3.9 8 2.6 8

23 25 164,061 5.0 8 3.8 8 2.5 8

24 26 164,610 5.0 8 3.8 8 2.5 8

25 27 165,118 5.0 8 3.8 8 2.5 8

26 28 165,590 5.0 8 3.7 8 2.5 8

23 24 170,897 4.8 8 3.6 8 2.4 8

24 25 171,194 4.8 8 3.6 8 2.4 8

25 26 171,469 4.8 8 3.6 8 2.4 8

26 27 171,723 4.8 8 3.6 8 2.4 8

27 28 171,959 4.8 8 3.6 8 2.4 8

23 23 178,327 4.6 8 3.5 8 2.3 8

28 27 184,932 4.5 8 3.4 8 2.2 8

27 26 185,186 4.5 8 3.3 8 2.2 8

26 25 185,460 4.5 8 3.3 8 2.2 8

25 24 185,758 4.5 8 3.3 8 2.2 8

24 23 186,081 4.4 8 3.3 8 2.2 8

28 26 192,045 4.3 8 3.2 8 2.2 8

27 25 192,594 4.3 8 3.2 8 2.1 8

26 24 193,188 4.3 8 3.2 8 2.1 8

25 23 193,834 4.3 8 3.2 8 2.1 8

19 17 199,307 4.2 8 3.1 8 2.1 7

28 25 199,727 4.1 8 3.1 8 2.1 7

27 24 200,618 4.1 8 3.1 8 2.1 7

26 23 201,587 4.1 8 3.1 8 2.1 7

28 24 208,049 4.0 8 3.0 8 2.0 7

27 23 209,341 4.0 8 3.0 8 2.0 7

23 19 215,870 3.8 8 2.9 8 1.9 7

28 23 217,094 3.8 8 2.9 8 1.9 7

24 19 225,256 3.7 8 2.8 8 1.8 7

25 19 234,641 3.5 8 2.6 8 1.8 6

23 17 241,266 3.4 8 2.6 8 1.7 6

26 19 244,027 3.4 8 2.5 8 1.7 6

24 17 251,756 3.3 8 2.5 8 1.6 6

27 19 253,413 3.3 8 2.4 8 1.6 6

25 17 262,246 3.2 8 2.4 8 1.6 6

28 19 262,798 3.1 8 2.4 8 1.6 6

26 17 272,736 3.0 8 2.3 8 1.5 5

27 17 283,226 2.9 8 2.2 8 1.5 5

28 17 293,716 2.8 8 2.1 8 1.4 5

Seed

Population

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Driver = 15

Driven = 30

Seed

Spacing

Max

Plant

speed

Range Sprockets Range Sprockets

Driver = 20

Driven = 30

Seed

Spacing

Max

Plant

speed

Driver = 30

Driven = 30

Seed

Spacing

Max Plant

speed

196-248B 12/1/2009

Page 27

Great Plains Mfg., Inc.

Soybeans 110 Cell Wheel (Singulating) (Continued)

403-070D (2200-2700 seeds/lb)

403-061D (2700-3200 seeds/lb)

27

Wheel P/N’s

403-066D (3100-3800 seeds/lb)

403-068D (3600-4000 seeds/lb)

2200-4000 seeds/pound

Talc Required Range Sprockets

Transmission

Sprockets

Driver Driven (seeds/acre) (inches) (mph) (inches) (mph) (inches) (mph)

17 28 108,270 3.8 8 2.9 8 1.9 7

17 27 112,280 3.7 8 2.8 8 1.8 7

17 26 116,599 3.5 8 2.7 8 1.8 6

19 28 121,008 3.4 8 2.6 8 1.7 6

17 25 121,263 3.4 8 2.6 8 1.7 6

19 27 125,490 3.3 8 2.5 8 1.6 6

17 24 126,315 3.3 8 2.5 8 1.6 6

19 26 130,316 3.2 8 2.4 8 1.6 6

17 23 131,807 3.1 8 2.4 8 1.6 6

19 25 135,529 3.1 8 2.3 8 1.5 5

19 24 141,176 2.9 8 2.2 8 1.5 5

23 28 146,483 2.8 8 2.1 8 1.4 5

19 23 147,314 2.8 8 2.1 8 1.4 5

23 27 151,909 2.7 8 2.0 7 1.4 5

24 28 152,852 2.7 8 2.0 7 1.4 5

23 26 157,751 2.6 8 2.0 7 1.3 5

24 27 158,513 2.6 8 2.0 7 1.3 4

25 28 159,221 2.6 8 1.9 7 1.3 4

17 19 159,556 2.6 8 1.9 7 1.3 4

23 25 164,061 2.5 8 1.9 7 1.3 4

24 26 164,610 2.5 8 1.9 7 1.3 4

25 27 165,118 2.5 8 1.9 7 1.3 4

26 28 165,590 2.5 8 1.9 7 1.2 4

23 24 170,897 2.4 8 1.8 6 1.2 4

24 25 171,194 2.4 8 1.8 6 1.2 4

25 26 171,469 2.4 8 1.8 6 1.2 4

26 27 171,723 2.4 8 1.8 6 1.2 4

27 28 171,959 2.4 8 1.8 6 1.2 4

23 23 178,327 2.3 8 1.7 6 1.2 4

28 27 184,932 2.2 8 1.7 6 1.1 4

27 26 185,186 2.2 8 1.7 6 1.1 4

26 25 185,460 2.2 8 1.7 6 1.1 4

25 24 185,758 2.2 8 1.7 6 1.1 4

24 23 186,081 2.2 8 1.7 6 1.1 4

28 26 192,045 2.2 8 1.6 6 1.1 4

27 25 192,594 2.1 8 1.6 6 1.1 4

26 24 193,188 2.1 8 1.6 6 1.1 4

25 23 193,834 2.1 8 1.6 6 1.1 4

19 17 199,307 2.1 7 1.6 5 1.0 3

28 25 199,727 2.1 7 1.6 5 1.0 3

27 24 200,618 2.1 7 1.5 5 1.0 3

26 23 201,587 2.1 7 1.5 5 1.0 3

28 24 208,049 2.0 7 1.5 5 1.0 3

27 23 209,341 2.0 7 1.5 5 1.0 3

23 19 215,870 1.9 7 1.4 5 1.0 3

28 23 217,094 1.9 7 1.4 5 1.0 3

24 19 225,256 1.8 7 1.4 5 0.9 3

25 19 234,641 1.8 6 1.3 5 0.9 3

23 17 241,266 1.7 6 1.3 4 0.9 3

26 19 244,027 1.7 6 1.3 4 0.8 3

24 17 251,756 1.6 6 1.2 4 0.8 3

27 19 253,413 1.6 6 1.2 4 0.8 3

25 17 262,246 1.6 6 1.2 4 0.8 3

28 19 262,798 1.6 6 1.2 4 0.8 3

26 17 272,736 1.5 5 1.1 4 0.8 2

27 17 283,226 1.5 5 1.1 4 0.7 2

28 17 293,716 1.4 5 1.1 4 0.7 2

Seed

Population

30” Twin Row 20” Row Spacing 30” Row Spacing

Driver = 30

Driven = 30

Seed

Spacing

Max

Plant

speed

Range Sprockets Range Sprockets

Driver = 20

Driven = 15

Seed

Spacing

Max

Plant

speed

Driver = 30

Driven = 15

Seed

Spacing

Max Plant

speed

12/1/2009

196-248B

Page 28

28

Great Plains Mfg., Inc.

Wheat (Volumetric)

Wheel P/N 403-060D Wheat

64 lb. bu.

Hard Red Winter Wheat

No Seed Treatment

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 33.5 8 8 8

17 27 34.7 8 8 8

17 26 36.0 8 8 8

19 28 37.4 8 8 8

17 25 37.5 8 8 8

19 27 38.8 8 8 8

17 24 39.0 8 8 8

19 26 40.3 8 8 8

17 23 40.7 8 8 8

19 25 41.9 8 8 8

19 24 43.6 8 8 8

23 28 45.3 8 8 8

19 23 45.5 8 8 8

23 27 47.0 8 8 8

24 28 47.2 8 8 8

23 26 48.8 8 8 8

24 27 49.0 8 8 8

25 28 49.2 8 8 8

17 19 49.3 8 8 8

23 25 50.7 8 8 8

24 26 50.9 8 8 8

25 27 51.0 8 8 8

26 28 51.2 8 8 8

23 24 52.8 8 8 8

24 25 52.9 8 8 8

25 26 53.0 8 8 8

26 27 53.1 8 8 8

27 28 53.2 8 8 8

23 23 55.1 8 8 8

28 27 57.2 8 8 8

27 26 57.2 8 8 8

26 25 57.3 8 8 8

25 24 57.4 8 8 8

24 23 57.5 8 8 8

28 26 59.4 8 8 8

27 25 59.5 8 8 8

26 24 59.7 8 8 8

25 23 59.9 8 8 8

19 17 61.6 8 8 7

28 25 61.7 8 8 7

27 24 62.0 8 8 7

26 23 62.3 8 8 7

28 24 64.3 8 8 7

27 23 64.7 8 8 7

23 19 66.7 8 8 7

28 23 67.1 8 8 7

24 19 69.6 8 8 7

25 19 72.5 8 8 6

23 17 74.6 8 8 6

26 19 75.4 8 8 6

24 17 77.8 8 8 6

27 19 78.3 8 8 6

25 17 81.1 8 8 6

28 19 81.2 8 8 6

26 17 84.3 8 8 5

27 17 87.5 8 8 5

28 17 90.8 8 8 5

with Talc

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driver = 20

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

196-248B 12/1/2009

Page 29

Great Plains Mfg., Inc.

29

Wheat (Volumetric)

Wheel P/N 403-085D Wheat Wide

64 lb. bu.

Hard Red Winter Wheat

No Seed Treatment

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 76.8 8 8 8

17 27 79.6 8 8 8

17 26 82.7 8 8 8

19 28 85.8 8 8 8

17 25 86.0 8 8 8

19 27 89.0 8 8 8

17 24 89.6 8 8 8

19 26 92.4 8 8 8

17 23 93.5 8 8 8

19 25 96.1 8 8 8

19 24 100.1 8 8 8

23 28 103.9 8 8 8

19 23 104.5 8 8 8

23 27 107.7 8 8 8

24 28 108.4 8 8 8

23 26 111.9 8 8 8

24 27 112.4 8 8 8

25 28 112.9 8 8 8

17 19 113.1 8 8 8

23 25 116.3 8 8 8

24 26 116.7 8 8 8

25 27 117.1 8 8 8

26 28 117.4 8 8 8

23 24 121.2 8 8 8

24 25 121.4 8 8 8

25 26 121.6 8 8 8

26 27 121.8 8 8 8

27 28 121.9 8 8 8

23 23 126.5 8 8 8

28 27 131.1 8 8 8

27 26 131.3 8 8 8

26 25 131.5 8 8 8

25 24 131.7 8 8 8

24 23 131.9 8 8 8

28 26 136.2 8 8 8

27 25 136.6 8 8 8

26 24 137.0 8 8 8

25 23 137.4 8 8 8

19 17 141.3 8 8 7

28 25 141.6 8 8 7

27 24 142.3 8 8 7

26 23 142.9 8 8 7

28 24 147.5 8 8 7

27 23 148.4 8 8 7

23 19 153.1 8 8 7

28 23 153.9 8 8 7

24 19 159.7 8 8 7

25 19 166.4 8 8 6

23 17 171.1 8 8 6

26 19 173.0 8 8 6

24 17 178.5 8 8 6

27 19 179.7 8 8 6

25 17 186.0 8 8 6

28 19 186.3 8 8 6

26 17 193.4 8 8 5

27 17 200.8 8 8 5

28 17 208.3 8 8 5

with Talc

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driver = 20

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

12/1/2009

196-248B

Page 30

30

Great Plains Mfg., Inc.

Wheat (Volumetric)

Wheel P/N 403-085D Wheat Wide

62 lb. bu.

Soft Red Winter Wheat

with Seed Treatment

with Talc

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 66.9 8 8 8

17 27 69.4 8 8 8

17 26 72.1 8 8 8

19 28 74.8 8 8 8

17 25 75.0 8 8 8

19 27 77.6 8 8 8

17 24 78.1 8 8 8

19 26 80.6 8 8 8

17 23 81.5 8 8 8

19 25 83.6 8 8 8

19 24 87.3 8 8 8

23 28 90.6 8 8 8

19 23 91.1 8 8 8

23 27 93.6 8 8 8

24 28 94.5 8 8 8

23 26 97.5 8 8 8

24 27 98.0 8 8 8

25 28 98.4 8 8 8

17 19 98.6 8 8 8

23 25 101.4 8 8 8

24 26 101.8 8 8 8

25 27 102.1 8 8 8

26 28 102.4 8 8 8

23 24 105.6 8 8 8

24 25 105.8 8 8 8

25 26 106.0 8 8 8

26 27 106.2 8 8 8

27 28 106.3 8 8 8

23 23 110.2 8 8 8

28 27 114.3 8 8 8

27 26 114.5 8 8 8

26 25 114.6 8 8 8

25 24 114.8 8 8 8

24 23 115.0 8 8 8

28 26 118.7 8 8 8

27 25 119.1 8 8 8

26 24 119.4 8 8 8

25 23 119.8 8 8 8

19 17 123.2 8 8 7

28 25 123.5 8 8 7

27 24 124.0 8 8 7

26 23 124.6 8 8 7

28 24 128.6 8 8 7

27 23 129.4 8 8 7

23 19 133.4 8 8 7

28 23 134.2 8 8 7

24 19 139.2 8 8 7

25 19 145.1 8 8 6

23 17 149.1 8 8 6

26 19 150.9 8 8 6

24 17 155.6 8 8 6

27 19 156.7 8 8 6

25 17 162.1 8 8 6

28 19 162.5 8 8 6

26 17 168.6 8 8 5

27 17 175.1 8 8 5

28 17 181.6 8 8 5

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driver = 20

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

196-248B 12/1/2009

Page 31

Great Plains Mfg., Inc.

31

Wheat (Volumetric)

Wheel P/N 403-094D V-3

62 lb. bu.

Soft Red Winter Wheat

with Seed Treatment

Transmission

Sprockets

Driver Driven (pounds/acre)

17 28 89.2 8 8 8

17 27 92.5 8 8 8

17 26 96.0 8 8 8

19 28 99.7 8 8 8

17 25 99.9 8 8 8

19 27 103.4 8 8 8

17 24 104.0 8 8 8

19 26 107.3 8 8 8

17 23 108.6 8 8 8

19 25 111.6 8 8 8

19 24 116.3 8 8 8

23 28 120.6 8 8 8

19 23 121.3 8 8 8

23 27 125.1 8 8 8

24 28 125.9 8 8 8

23 26 129.9 8 8 8

24 27 130.6 8 8 8

25 28 131.1 8 8 8

17 19 131.4 8 8 8

23 25 135.1 8 8 7

24 26 135.6 8 8 7

25 27 136.0 8 8 7

26 28 136.4 8 8 7

23 24 140.8 8 8 7

24 25 141.0 8 8 7

25 26 141.2 8 8 7

26 27 141.4 8 8 7

27 28 141.6 8 8 7

23 23 146.9 8 8 7

28 27 152.3 8 8 6

27 26 152.5 8 8 6

26 25 152.8 8 8 6

25 24 153.0 8 8 6

24 23 153.3 8 8 6

28 26 158.2 8 8 6

27 25 158.6 8 8 6

26 24 159.1 8 8 6

25 23 159.6 8 8 6

19 17 164.2 8 8 6

28 25 164.5 8 8 6

27 24 165.2 8 8 6

26 23 166.0 8 8 6

28 24 171.4 8 8 6

27 23 172.4 8 8 6

23 19 177.8 8 8 5

28 23 178.8 8 8 5

24 19 185.5 8 8 5

25 19 193.3 8 8 5

23 17 198.7 8 8 5

26 19 201.0 8 7 5

24 17 207.4 8 7 5

27 19 208.7 8 7 5

25 17 216.0 8 7 4

28 19 216.5 8 7 4

26 17 224.6 8 7 4

27 17 233.3 8 6 4

28 17 241.9 8 6 4

with Talc

Seed

Rate

7 1/2” Row Spacing 10” Row Spacing 15” Row Spacing

Range Sprockets

Driver = 15

Driven = 30

Max Plant

speed

(mph)

Range Sprockets Range Sprockets

Driver = 20

Driven = 30

Max Plant

speed

(mph)

Driver = 30

Driven = 30

Max Plant

speed

(mph)

12/1/2009

196-248B

Page 32

32

Great Plains Mfg., Inc.