Page 1

Great Plains Mfg., Inc.

Installation Instructions

No-Till and

No-Till Precision Seeding System

Veris Drive Option

Used with:

• 3N-3010P and 3N-3020P

• 3N-3010 and 3N-3020

General Information

When you see this symbol, the subsequent instructions and

warnings areserious- follow without exception. Your life and

!

!

the lives of others depend on it!

These instructions explain how to install theVeris

Drive Option. TheVeris Drive isa precision popu-

lation controller which uses a hydraulic drive to

accurately drive the metering system or the feeder cups.

These instructions apply to:

120-298A Veris Drive Option

Manual Update

Refer to the 30 No-Till or the 30P No-Till operator’s manual for detailedinformation on safely

operating, adjusting, troubleshooting and maintaining the Veris Drive. Refer to the parts manual

for part identification.

196-248M Operator’sManual

196-248P Parts Manual

196-366M Operator’sManual

196-366P Parts Manual

Before You Start

Page9is a detailed listing ofpartsincluded in the

Veris DriveOption package. Usethis list to inventory parts received.

Tools Required

• Basic Hand Tools

Definitions

Right-hand and left-hand as used in this manual

are determined by facing the direction the

machine will travel while in use unless otherwise

stated.

© Copyright 2002 Printed

3/26/2003

120-301M

Page 2

Veris Drive Option

2

Assembly Instructions

!

Before installing the Precision Population Controller

on the seeding system, besure that the unit isproperly

supported to avoid injury during installation.

CAUTION!

Great Plains Mfg., Inc.

Refer to Figure 1

1. Remove contact wheel drive chains on both

sides of the unit.

Refer to Figure 2

2. Remove range drivechains onboth sidesof

the unit.

Contact Drive Wheel

Chain Removed

Drive Chain Removed

Range Chain

Figure 1

20033

Figure 2

Range Drive Chain

Refer to Figure 3

3. Driveout roll pins from drivecouplers on both

ends of the pivot shaft. Slide shaft couplers

toward the center and slide shaft through

tongue away from the left-hand drive.

Figure 3

Pivot Shaft and Coupler

120-301M 4/8/2004

Shaft Coupler

Pivot Shaft

20034

20035

Page 3

Great Plains Mfg., Inc.

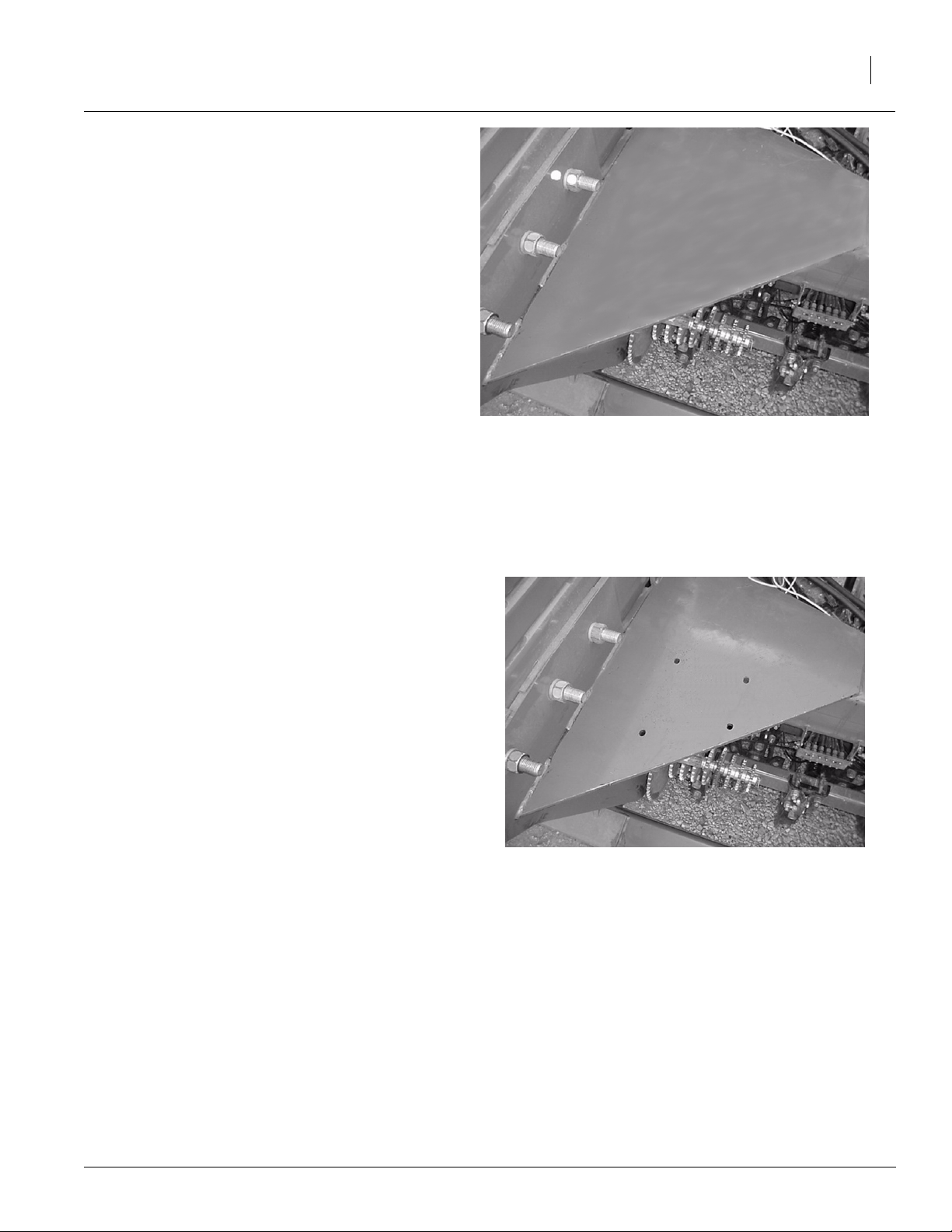

Refer to Figure 4

4. To mark and drill mounting holes for the controller/motor kit, usethe dimensionssupplied

on page 8. Mark the holes on the left-hand

tonguegusset onthemainframe andcarefully

drill all four holes.

Note: It is important that you carefully mark and

drill these mounting holes.The lower portion of

the drive mount houses the carrierbearingfor the

pivot shaft. Misalignment will cause operational

problems.

Installation Instructions

Place Template

Here

Figure 4

Hole Chart

3

20198

Refer to Figure 5

5. Drillholeswitheithera17/32”or 9/16” drillbit.

17/32”

Holes

Figure 5

Left-hand Gusset

20036

4/8/2004

120-301M

Page 4

Veris Drive Option

4

Great Plains Mfg., Inc.

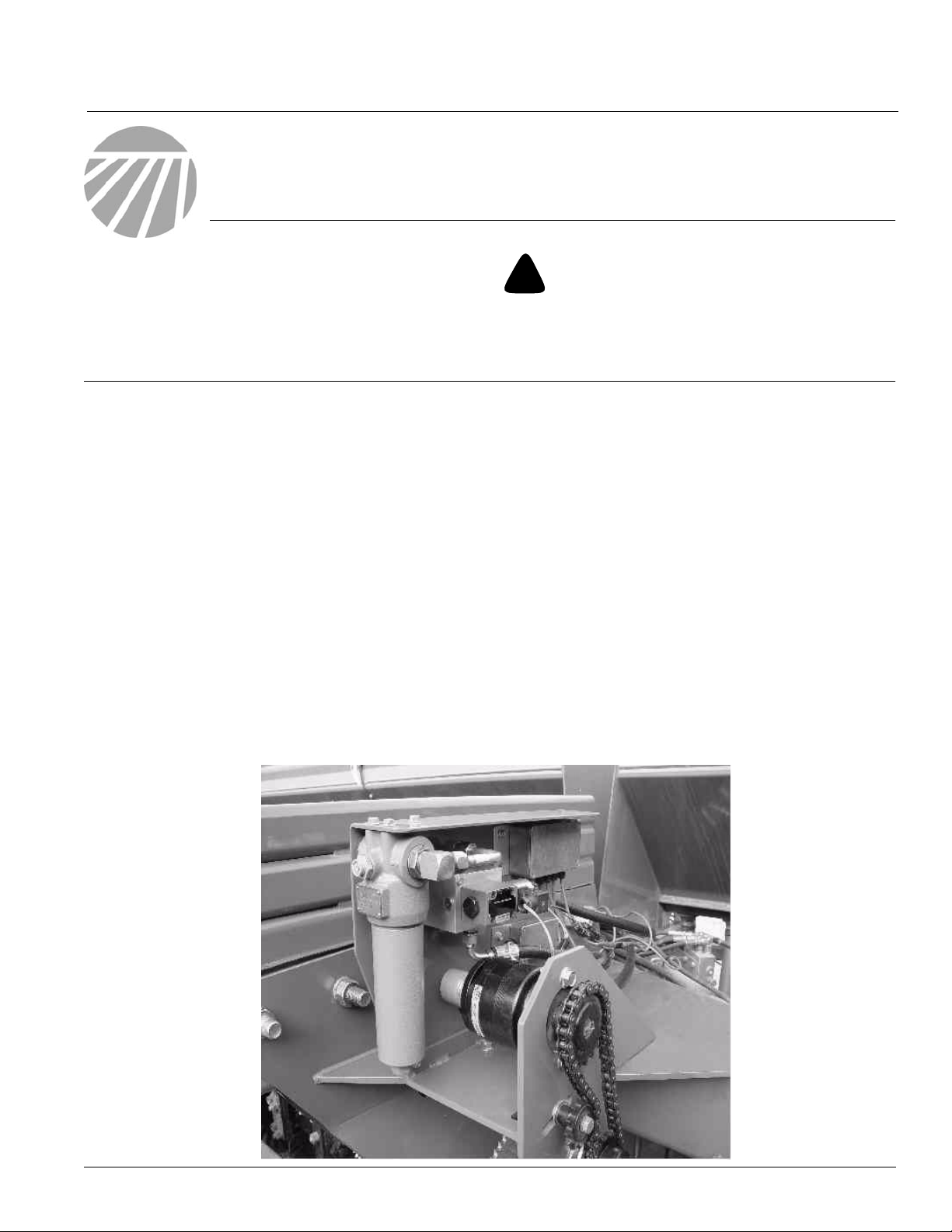

Refer to Figure 6

6. Mount controller/motor kit to the gusset with

four flanged 1/2” x 1 1/4” bolts and 1/2”

flanged lock nuts, do not tighten at this time.

Leavehydraulichosesandharness coiled until later in the assembly.

Refer to Figure 7

Mounting

Bolts

Controller/Motor Kit

Figure 6

Controller/Motor

Pivot Shaft

20037

7. Slide the pivot shaft towardsthe installed

drivemountuntilshaftisafewinches through

the bearing hanger. Slide on one lock collar,

bearing and bearing flangettes. Installthe 19

tooth sprocket and second lockcollar. Slide

shaft back into position, then slide couplers

backinto position. Check to see if shaft is centered in the bearinghanger opening. Loosely

attach bearings flangettes, then tighten the

four mounting bolts on the controller/motor.

Tighten bearing flangettes.

Note:Shaft should nowturnfreely byhand with no

bindingat the shaftcouplers.If thisisnotthe case,

the drivemount isnot properly positioned on the

gusset. Tocorrect this, enlarge the mounting

holes to allow the mount to be moved forward or

backwardto properly alignthe mountwith the pivot shaft.

Once the mountis properlyaligned with the pivot

shaft,reinstall the shaft couplers with 1/4” x1 3/4”

bolts and 1/4” lock nuts.

Bearing

Figure 7

Pivot Shaft

Sprocket

Lock Collar

20038

120-301M 4/8/2004

Page 5

Great Plains Mfg., Inc.

Refer to Figure 8

8. Slide the firstlock collar installed on the pivot

shaft against the bearing and tighten. Slide

the 19 tooth sprocket installed on the pivot

shaft against the bearing. Slide the second

lock collar installedon the pivotshaft against

the sprocket and tighten.

9. Install chain idler and chain.

Note: In orderfor themotor tohavethe correct ratio to the seed metersyou must set therange and

the transmission sprockets.

Installation Instructions

Idler

Figure 8

Chain and Chain Idler

5

20039

Refer to Figure 9

10. For Precision drill:

Set the range sprockets with a 30 tooth

sprocketfor the driver, and a30 tooth sprocket for the driven, on bothsides of the unit.Reinstall chains and tighten the idlers.

11. For Feeder Cupdrill:

Set the range sprockets to drive type4 on

both sides of the unit. Reinstall chains and

tighten the idlers.

Refer to Figure 10

12. Setthe transmissionsprocketswitha28 tooth

sprocketfor the driver, and a25 tooth sprocket for the driven, on both sides of the unit.

Note: Be sure to set both the left-hand and righthand range and transmission sprockets. Once

they are set they will not need to be changed.

Note: For FeederCup drill there is no transmission sprocket change.

Figure 9

Range Sprockets

20040

4/8/2004

Figure 10

Transmission Sprockets

20041

120-301M

Page 6

Veris Drive Option

6

Refer to Figure 11

13. Removetheleft wheel from theleft-hand contactwheelshaftandslide the shaft to the right

allowing clearance forthe speedsensor disc

andsensorbracket.Install the sensor bracket

with one bearing onto the shaft. Install the

speed sensor disc with one lock collar on

each side. Do not tighten lock collars.

14. Remove the forward boltfrom theoutside

bearingandreplace it witha5/16" x 13/4"bolt

and 5/16" nut and tighten. Place the spacer

on the bolt then mount the sensor bracket on

the bolt. Secure bracket with a 5/16" nut.

15. Screw the sensor into thesensor mount until

there is a .030 clearance. Lock sensor in

place with the jam nut. Move the sensor disc

so it aligns with the sensor and secure it in

place with the lock collars. Route the cable

along the contact wheel arm and up to the

controller/motor mount. Repeat steps 13

through 15 to install the Verissensor and sensor bracket on the right-hand drive.

Lock Collars

Figure 11

Speed Sensor and Bracket

Left-Hand Side

Great Plains Mfg., Inc.

Seed Sensor

Speed Sensor

Sensor Disc

20042

16. Relocate the seed monitor speed sensor to

the bracket installed on the left-hand drive.

Properly adjustclearance. Tie bothcables to

the contact wheel arm, and make sure they

are routed to prevent pinching.

Note: You can not leave the seed monitor speed

sensor on the pivot shaft or the sensor will be

reading motor drivespeed instead offield speed.

It is not necessaryto movethe sensor disc for the

seedmonitor.Theseed monitorcanusethe same

sensor disc as the Veris sensor.

Note: After relocatingthe seed monitor speed

sensor it will be necessary to calibrate the

monitor. Refer to the DICKEY-john® manual

for monitor distance calibration instructions.

120-301M 4/8/2004

Page 7

Great Plains Mfg., Inc.

Refer to Figure 12

17. Connect sensor cable to short leads on sen-

sor module. Either cable can be connected to

either lead.

18. Uncoilhydraulichosesandmainharnessand

tie ends together. Feed a fish tape or a wire

fromthefront of thetongueandpullthe hoses

and cable through the maintongueand route

through the hose carrier on front of the

tongue.

19. Install the plastic hose label, P/N 817-348C,

to hose with “extension” symbol on the hose

runningtofilter (markedP)oncontrol module.

Use the yellow cable tieto identifythis asa

motor hose. Attach motor return hose

(marked T) on the side showing the “retract”

symbol.Run tie strapthroughnumber thatwill

correspond to the valve 2 through 4 that the

drive will be connected to.

Installation Instructions

Console

Sensor Module

Figure 12

Sensor Module

7

20043

Refer to Figure 13

20. Installthe console in a convenientlocation on

a side window glass. Make sure the glass is

clean.Moisten cups and press firmly ontothe

glass. To remove, pull tab on suction cup.

21. Connect power port adaptor cable to the ter-

minal on the console.

22. Route the power and communication cables

through the cab access hole and connect to

the appropriate terminals on the console.

Power Port

Adapter

Serial Cable

(for recipe input)

Figure 13

Control Console

Communication

Cable

19977

4/8/2004

120-301M

Page 8

Veris Drive Option

8

Great Plains Mfg., Inc.

120-301M 4/8/2004

Page 9

Great Plains Mfg., Inc.

120-298A PPC-30 Veris Vari-Rate Drive

Your kit includes:

Qty. Part No. Part Description

1 120-301M MANUAL INSTALL VERIS 30P

2 120-309D SENSOR DISC, 42T 5.3 DIA P

2 120-311D SENSOR U-MOUNT BRACKET

1 136-182D CHAIN RL #50 50 PITCHES

1 198-029D PARALLEL ARM PIVOT TUBE

6 402-025S LOCK COLLAR, 7/8 HEX W/ SET SCREWS

1 802-039C HHCS 1/2-13X3 GR5

3 802-159C HHCS 5/16-18X1 GR5

2 802-572C RHSNB 5/16-18X1 3/4 GR5

4 802-705C HHCS 5/16-18X5/8

4 803-011C NUT LOCK 5/16-18 PLT

1 803-069C NUT HEX SLOTTED 7/16-14 PLT

3 803-177C NUT HEX LOCK 5/16-18 FLG.

3 804-017C WASHER FLAT 1/2 USS PLT

4 804-036C WASHER FLAT 5/16 SAE PLT

1 808-006C SPKT 50B19 X 1 BORE

1 808-304C SPKT 50C19 X 7/8 HEX BORE

1 808-341C SPKT 50B13 IDLER

4 822-032C FLANGETTE 52 MST

2 822-119C BRG.7/8HEX BR 52MM SPHRICAL

2 822-175C FLANGETTE 52 3-BOLT PLT

1 822-195C BRG.7/8HEX 52MM SPHR OD PE

1 833-250C VERIS PPC-30 CONTROLLER

Installation Instructions

9

120-301M4/8/2004

Loading...

Loading...