Great Plains 3N-3010P User Manual

Great Plains Mfg., Inc.

Assembly Instructions

3N-3010P, No-Till

Flat Fold Marker Option

Used with:

3N-3010P Drills

•

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception. Your

!

!

life and the lives of others depend on it!

General Information

These instructions explain how to assemble,installandsetupthe

optional hydraulic markers for your three-section, folding no-till

drill. The units are operated hydraulically and have a cast hub, tapered roller bearings and a bolt-on notched blade to cut though

heavy residue, leaving a line to follow on the next field pass.

Markers are sold as single or dual units. Dual markers are

equipped with a sequence valve for easy operation.

These instructions apply to:

113-735A 30P-Left-Hand Flat-Fold Marker

113-736A 30P-Dual Flat-Fold Markers

Manual Update

Refer to the drill operator’s manual for detailed information on

safely operating, adjusting, troubleshooting and maintaining the

markers. Refer to the drill parts manual for part identification.

• 3N-3010P and 3N-3020P Operator’s Manual . . . .196-248M

• 3N-3010P and 3N-3020P Parts Manual . . . . . . . . 196-248P

Definitions

Right and left as used in this manual are determined by facing

the direction the machine will travel while in use unless otherwise

stated.

IMPORTANT: A crucial point of information related to the

preceding topic. For safe and correct operation, read and

follow the directions provided before continuing.

NOTE: Useful information related to the preceding topic.

Before You Start

Pages 8 through 9 are detailed listings of parts included in the

marker kit. Use these lists to inventory parts received.

Assembly and Setup Instructions

Marker Assembly

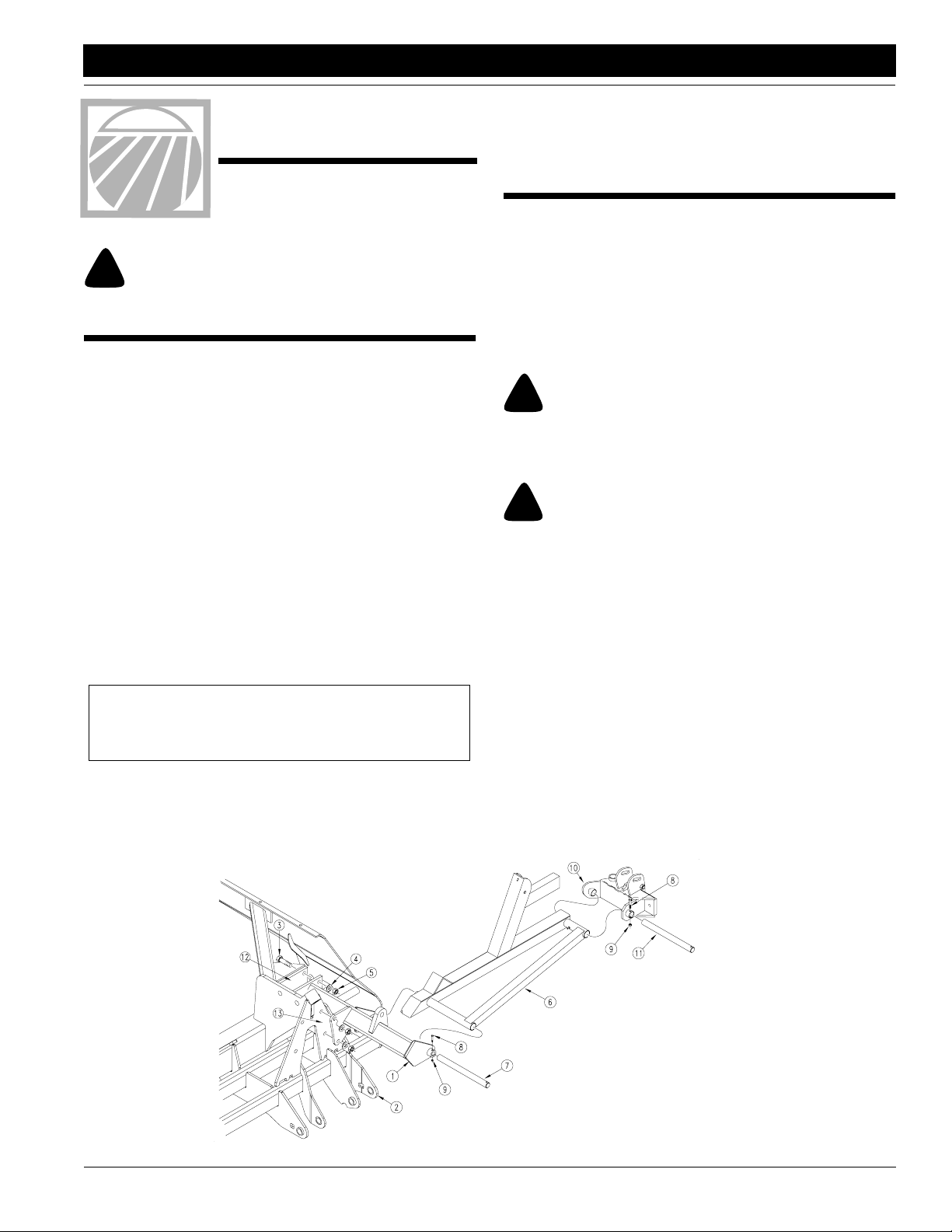

Refer to Figure 1.

1. Park the drill in an area large enough for folding and unfolding the assembled markers. A single marker will increase

the width of the drill by 15 feet.

2. Unfold and lower the drill. Park and shut off the tractor.

3. The marker sections are pre-assembled and banded together for shipment. Unpack the shipment and group the assemblies according to right-hand or left-hand.

!

Do not lift the assemblies unassisted. Lifting the assemblies without

mechanical aid could cause severe injury. Use a forklift or hoist to

move the assemblies during installation, or disassemble the assemblies

into smaller pieces before installation.

You could be severely injured by a failing assembly. Obey all safety instructions from lifting-equipment manufacturer. Do not walk or place

any body part under the raised sections. Be sure lifting equipment has

enough capacity.

NOTE: These instructions explain how to assemble the marker

if the sections are completely disassembled. If you do not have

adequate lifting equipment, disassemble the sections before

proceeding. If you do have a forklift or hoist large enough to lift

the pre-assembled sections, you can skip many of the following

steps.

4. Install the left-hand marker mount (1) on the left wing (2) of

CAUTION!

!

WARNING!

the drill. Install the mount on the marker mount pads at the

end of the wing frame. Fasten the marker mount to the

mount pad (12) and the "A" cylinder gusset (13) with 3/4" x

2 1/4" bolts (3), lock washers (4), andnuts (5). Install the first

section of the marker (6) on the mount (1) by pushing the

pivot shaft (7) through the pivot holes on the mount and the

first section. Use the bolt (8) and lock nut (9) to secure the

shaft.

Mount the left-hand breakaway hinge (10) onto the first section (6) by pushing the pivot shaft (11) through the pivot

holes in each part. Use

the bolt (8) and lock nut

(9) to secure the shaft.

© Copyright 1997 Printed 3/21/2001

Figure 1

Marker Assembly

■

19171

113-739M

1

Assembly Instructions

Great Plains Mfg., Inc.

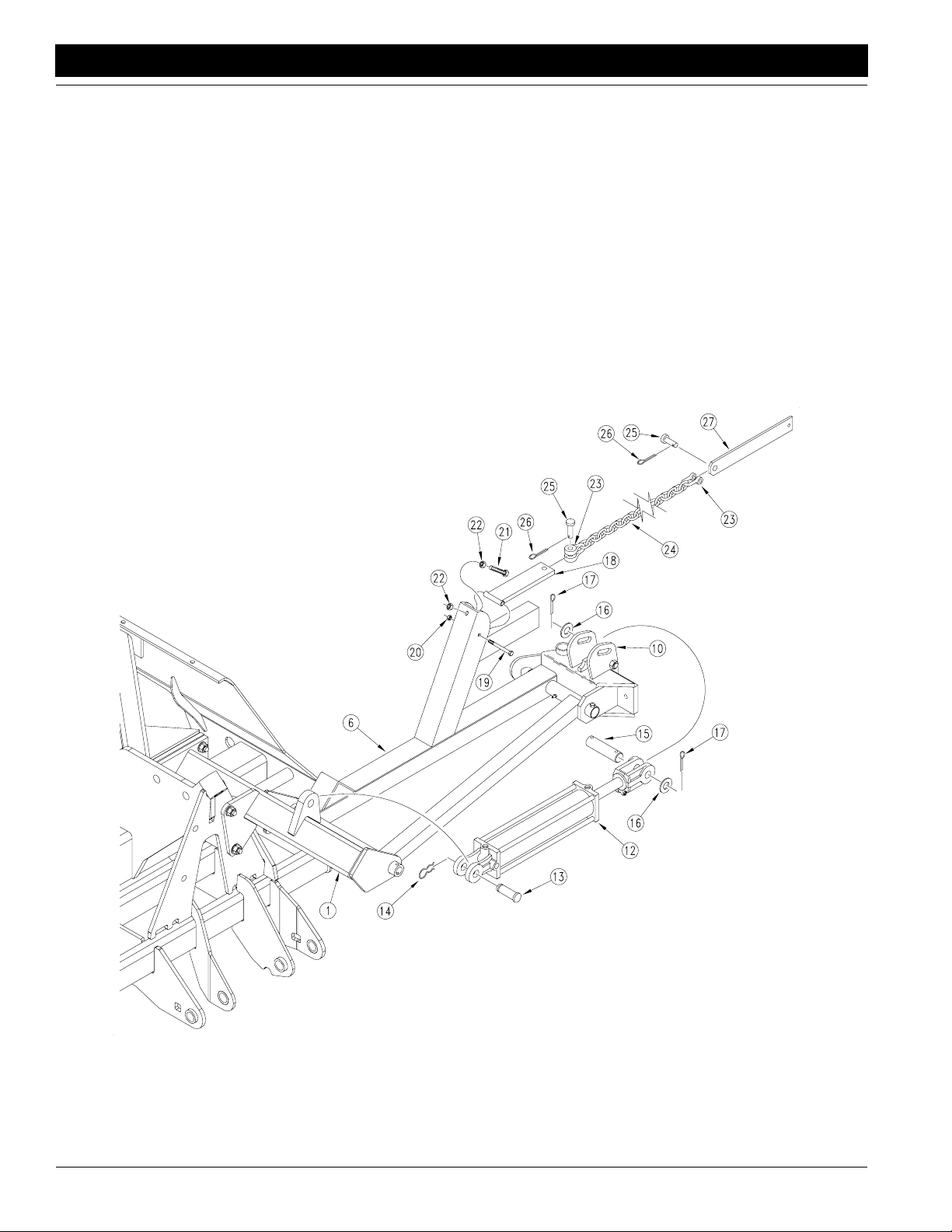

Refer to Figure 2.

5. Pin the base end of the hydraulic cylinder (12) to the marker

mount (1) using the pin and clip (13 and 14). Remove the

plastic plugs from the cylinder ports. Pull the rod end of the

cylinder out to its maximum length. Pin the rod end of the

cylinder to the breakaway hinge using the cylinder pin (15),

flat washers (16) and cotter pins (17) provided.

6. Install the chain bar (18) on the first section (6) with the bolt

(19) and lock nut (20). The chain bar should pivot freely

around the bolt (19).

7. Install the full-threaded adjustment bolt (21) in the hole directly above the pivot bolt (19). To install, first thread one

lock nut (22) up the entire length of the adjustment bolt.

Next, push the bolt with nut through the hole. Complete the

assembly by threading a second lock nut (22) up the entire

remaining length of the adjustment bolt.

After marker assembly, use the adjustment bolt to control

folding slack. For now, turn the adjustment bolt so its head

extends as little as possible to prevent damage the first time

the marker is folded.

8. Thread a utility clevis (23) through one end of the chain (24).

Pin this clevis to the chain bar (18) using the pin and cotter

pin (25 and 26) provided. Do not fully bend the cotter pin at

this time. Thread a second utility clevis (23) through the last

link at the opposite end of the chain (24). Pin this clevis to

the rounded end of the chain bar (27) using the pin and cotter pin (25 and 26) provided.

19171

Figure 2

Marker Assembly

3N-3010P, No-Till Flat Fold Marker Option 113-739M 5/5/06

2

■

Great Plains Mfg., Inc.

Assembly Instructions

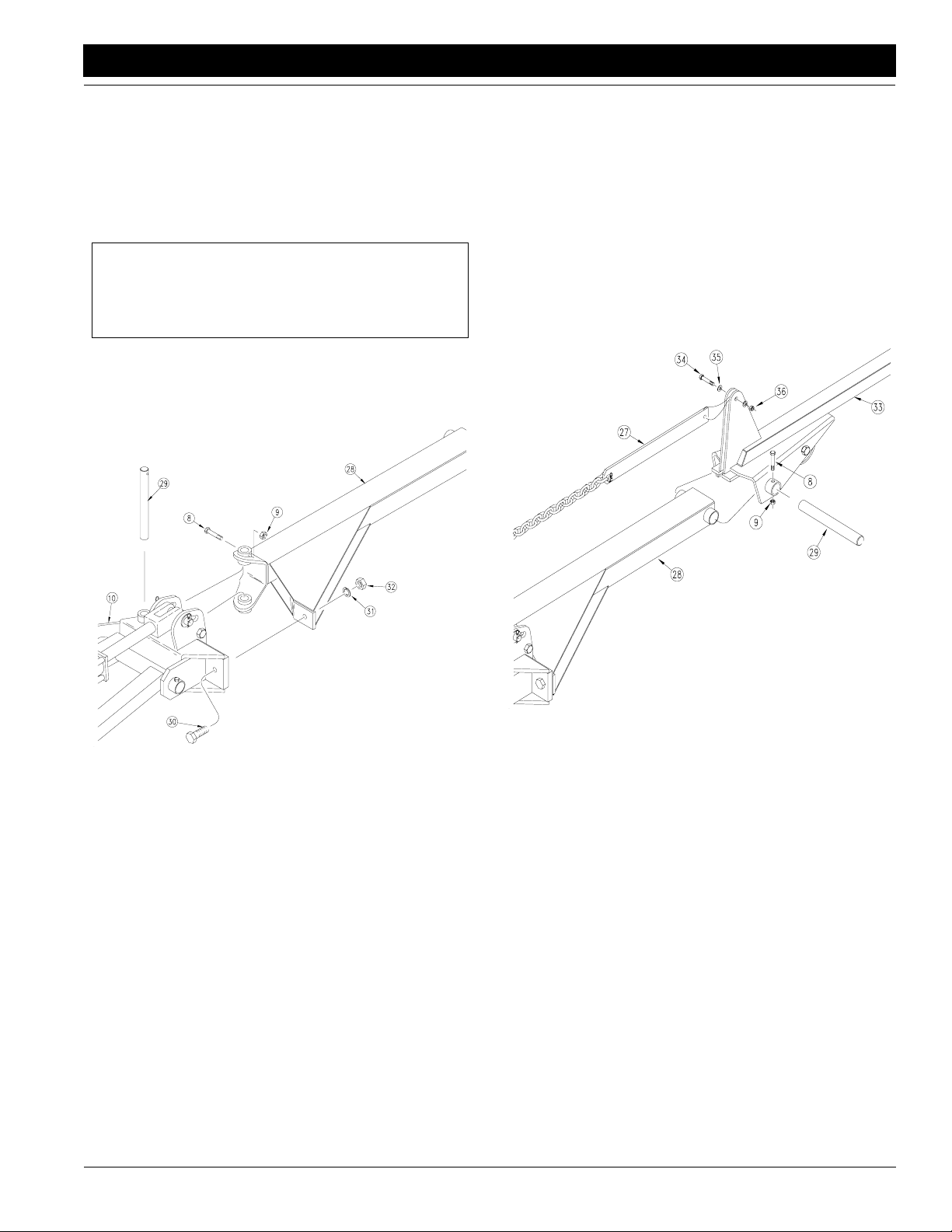

Refer to Figure 3.

9. Attach the second section (28) to the breakaway hinge (10)

with the pivot pin (29). Secure the pivot pin (29) with the bolt

and lock nut (8 and 9). Complete this joint by passing the

grade 5 breakaway bolt (30) through the holes in the hinge

and second section. Install the lock washer (31) and nut (32)

on the breakaway bolt.

IMPORTANT: The breakaway bolt (30) is a 7/16 x

2 1/4-inch, grade 5 (G.P. # 802-234C). It is identified as a

grade 5 by having three marks on the head. If it breaks, replace it with an equivalent grade 5 bolt to prevent marker

damage.

Refer to Figure 4.

10. Attach the third section (33) to the second section (28) by using the pivot pin (29). Secure the pivot pin with the bolt (8) and

lock nut (9).

Fasten the loose end of chain bar (27) to the ears on the

third section (33) by using the bolt (34) flat washers (35) and

lock nut (36). Do not over tighten this pivot, which would

cause the ears to bend in. The chain bar must pivot freely

around the bolt.

Figure 3

Attaching Second Section

11102

11101

Figure 4

Attaching Third Section

5/5/06

■

3N-3010P, No-Till Flat Fold Marker Option 113-739M

3

Loading...

Loading...